Page 1

Preface

Thank you for choosing DELTA’s high-performance VFD-S Series. The VFD-S Series is

manufactured with high-quality components and materials and incorporates the latest microprocessor

technology available.

Getting Started

This quick start will be helpful in the installation and parameter setting of the AC motor drives. To

guarantee safe operation of the equipment, read the following safety guidelines before

connecting power to the AC motor drives. For detail information, refer to the VFD-S User Manual

on the CD supplied with the drive.

DANGER!

1. AC input power must be disconnected before any wiring to the AC motor drive is made.

2. A charge may still remain in the DC-link capacitors with hazardous voltages, even if the power

has been turned off. To prevent personal injury, please ensure that power has turned off before

opening the AC motor drive and wait ten minutes for the capacitors to discharge to safe voltage

levels.

3. Never reassemble internal components or wiring.

4. The AC motor drive may be destroyed beyond repair if incorrect cables are connected to the

input/output terminals. Never connect the AC motor drive output terminals U/T1, V/T2, and

W/T3 directly to the AC mains circuit power supply.

5. Ground the VFD-S using the ground terminal. The grounding method must comply with the laws

of the country where the AC motor drive is to be installed. Refer to the Basic Wiring Diagram.

6. VFD-S series is used only to control variable speed of 3-phase induction motors, NOT for 1-

phase motors or other purpose.

7. VFD-S series shall NOT be used for life support equipment or any life safety situation.

WAR NI NG!

1. DO NOT use Hi-pot test for internal components. The semi-conductor used in AC motor drive

easily damage by high-pressure.

2. There are highly sensitive MOS components on the printed circuit boards. These components

are especially sensitive to static electricity. To prevent damage to these components, do not

touch these components or the circuit boards with metal objects or your bare hands.

3. Only quality person is allowed to install, wire and maintain AC motor drive.

CAUTION!

1. Some parameters settings can cause the motor to run immediately after applying power.

2. DO NOT install the AC motor drive in a place subjected to high temperature, direct sunlight,

high humidity, excessive vibration, corrosive gases or liquids, or airborne dust or metallic

particles.

3. Only use AC motor drives within specification. Failure to comply may result in fire, explosion or

electric shock.

4. To prevent personal injury, please keep children and unqualified people away from the

equipment.

5. When the motor cable between AC motor drive and motor is too long, the layer insulation of the

motor may be damaged. Please use a frequency inverter duty motor or add an AC output

reactor to prevent damage to the motor. Refer to appendix B Reactor for details.

6. The rated voltage for AC motor drive must be ≤240V (≤480V for 460V models) and the mains

supply current capacity must be ≤5000A RMS (≤10000A RMS for the ≥40hp (30kW) models).

English- 1

Page 2

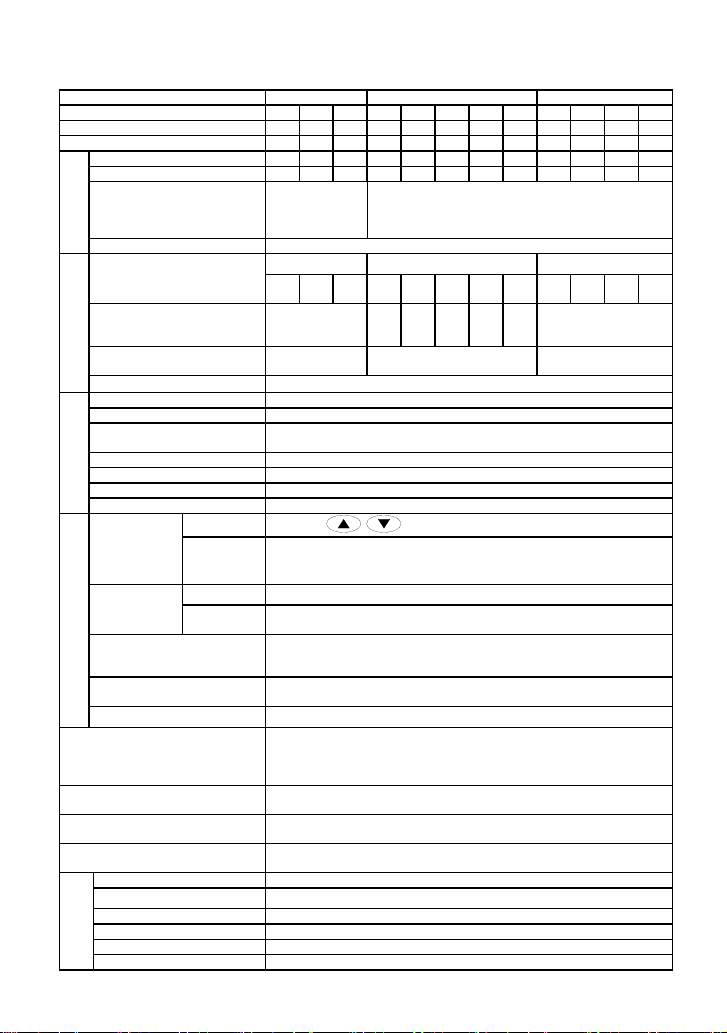

Specifications

Model Number VFD-XXXS 002 004 007 002 004 007 015 022 004 007 015 022

Max. Applicable Motor Output (kW) 0.2 0.4 0.75 0.2 0.4 0.75 1.5 2.2 0.4 0.75 1.5 2.2

Max. Applicable Motor Output (HP) 0.25 0.5 1.0 0.25 0.5 1.0 2.0 3.0 0.5 1.0 2.0 3.0

Voltage Class 115V Class 230V Class 460V Class

Rated Output Capacity (KVA) 0.6 1.0 1.6 0.6 1.0 1.6 2.9 4.2 1.2 2.0 3.3 4.4

Rated Output Current (A) 1.6 2.5 4.2 1.6 2.5 4.2 7.5 11.0 1.5 2.5 4.2 5.5

Maximum Output Voltage (V)

Output Rating

Rated Frequency (Hz) 1.0 to 400 Hz

Rated Input Current (A)

Input Current for 1-phase model

drive to be used as 3-phase

model drive

Input Rating

Rated Voltage/Frequency

Voltage/Freq. Tolerance

Control System SPWM (Sinusoidal Pulse Width Modulation, carrier frequency 3k-10kHz)

Output Frequency Resolution 0.1Hz

Torque Characteristics

Overload Endurance 150% of rated current for 1 minute

Control

Accel/Decel Time 0.1to 600 second (2 Independent settings for Accel/Decel Time)

Characteristics

V/F Pattern V/F pattern adjustable

Stall Prevention Level 20 to 250%, Setting of Rated Current

Keypad

Frequency

Setting

Operation

Setting Signal

External

Signal

Keypad Setting by RUN, STOP

External

Signal

Multi-Function Input Signal

Operating Characteristics

Multi-Function Output Indication

3-phase

Proportional to

Twice the Input

Voltage

3-phase Proportional to Input Voltage

Single phase Single/3-phase model drive 3-phase

4.9/

6.5/

9.7/

15.7/

6918

1.9

2.7

5.1

9.0

24/

1.7 2.9 5.1 6.9

15

-- -- 1.6 3.0 5.1 8.4 -- -- --

100/110/120 VAC

50/60 Hz

Voltage: ±10%, Frequency: ±5%

Including the auto-torque, auto-slip compensation; starting torque can be

150% at 5Hz

200/208/220/240 VAC

50/60Hz

380/400/415/480 VAC

50/60Hz

Setting by or Potentiometer

Potentiometer-5KΩ/0.5W, DC 0 to +10V or 0 to +5V (Input impedance

47KΩ), RS-485 interface, 4 to 20mA (Input impedance 250Ω); MultiFunction Inputs 1 to 5 (7 steps, Jog, up/down)

M0 to M5 can be combined to offer various modes of operation, RS-485

serial interface (MODBUS).

Multi-step selection 0 to7, Jog, accel/decel inhibit, first/second accel/decel

switch, counter, 8-step PLC operation, external Base Block (NC, NO),

increase/decrease Master Frequency

AC Drive Operating, Frequency Attained, Non-zero, Base Block, Fault

Indication, Local/Remote indication, PLC Operation indication.

Analog Output Signal Analog frequency/current signal output.

AVR, S-Curve, Over-Voltage/Over-Current Stall Prevention, Fault Records,

Other Function

Built-in EMI Filter

Protection

Cooling

Installation Location Altitude 1,000 m or below, keep from corrosive gasses, liquid and dust

Adjustable Carrier Frequency, DC Braking, Start Frequency for DC Braking,

Momentary Power Loss restart, Frequency Limits, Parameter Lock/Reset,

PID Feedback Control, Reverse Inhibition, etc.

VFD002S21E, VFD004S21E, VFD004S43E, VFD007S21E, VFD007S43E,

VFD015S21E, VFD015S43E, VFD022S21E, VFD022S43E

Self-testing, Over Voltage, Over Current, Under Voltage, Overload,

Overheating, External Fault, Electronic thermal, Ground Fault.

Forced air-cooling (ONLY FOR 022S2XA/B; XXXS43A/B/E 1HP~3HP;

XXXSXXD; XXXS21E 400W~3HP). Others are Natural air-cooling.

Pollution Degree 2

Ambient Temperature -10°C to 40°C (Non-Condensing and not frozen)

Storage Temperature -20°C to 60°C

Ambient Humidity Below 90% RH (non-condensing)

Enviroment

Vibration 9.80665m/s2 (1G) less than 20Hz, 5.88m/s2 (0.6G) at 20 to 50Hz

English- 2

Page 3

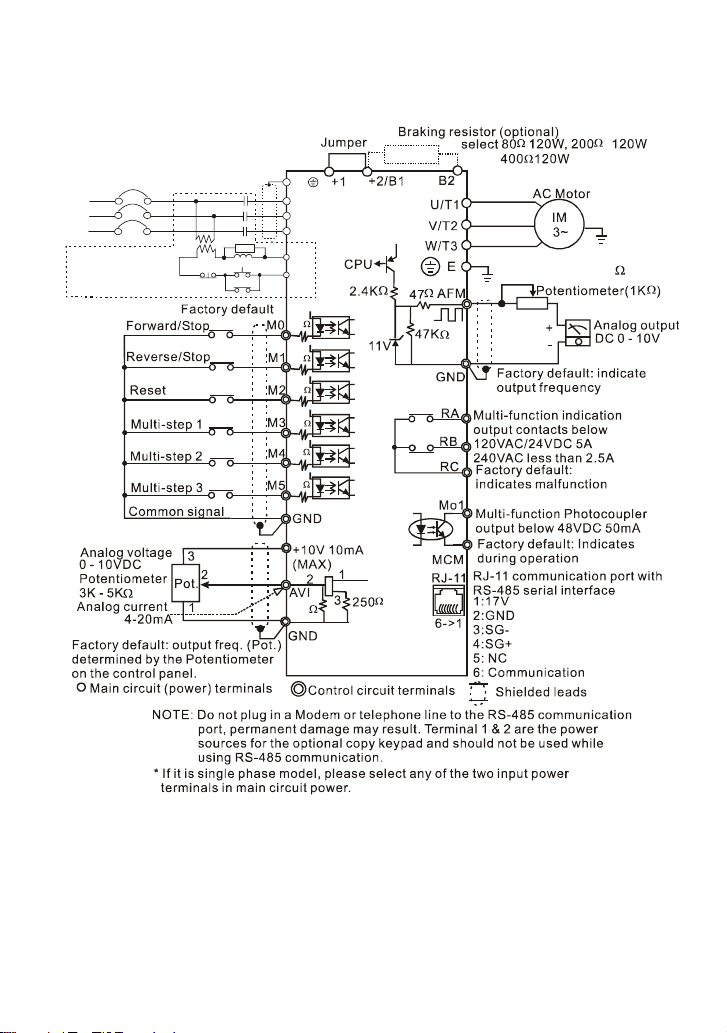

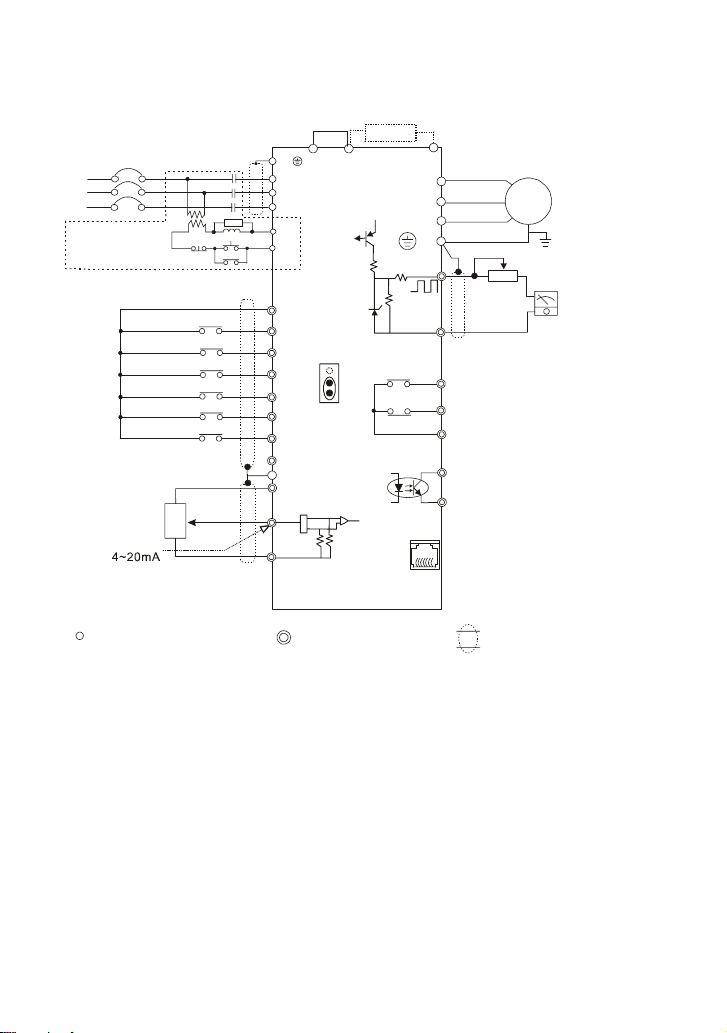

Basic Wiring Diagram

Users must connect wiring according to the following circuit diagram shown below.

For VFDXXXSXXA/B/D/U

Main Circuit Powe r

NFB

R/L1

S/L2

T/L3

Recommended Circuit

when power supply

is tu rned O FF by a

fault output

OFF

E

R/L1

S/L2

T/L3

SA

RB

MC

RC

ON

MC

17V

4.7k

17V

4.7k

17V

4.7k

17V

4.7k

17V

4.7k

17V

4.7k

47K

17V

Grounding resistan ce

less than 100

English- 3

Page 4

For VFDXXXSXXE

A

NPN (sink mode)

Main Circuit Power

NFB

R/L1

S/L2

T/L3

Recommended Circuit

when power supply

is turned OFF by a

fault output

Analog voltage

010VDC

Potenti ometer

3K 5K~~Ω

Analog current

Factory default: output freq. (Pot.)

determined by the Potentiometer

on the control panel.

Main circuit (power ) terminals

OFF

Factory default

Forward/Stop

Reverse/St op

Reset

Multi-step 1

Multi- step 2

Multi-step 3

Comm. signal (sink)

3

2

Pot.

1

NOTE: Do not plug in a Modem or telephone line to the RS-485 communication

port, permanent damage may result. Terminal 1 & 2 are the power

sources for the optional copy keypad and should not be used while

using RS -485 communi cati on.

* If it is single phase model, please s elect any of the two input power

terminal s in main circuit power.

Jumper

+1

E

R/L1

S/L2

T/L3

SA

RB

MC

RC

ON

MC

17V

M0

M1

M2

M3

M4

M5

GND

E

+10V 10mA

(MAX)

1

2

AVI

3

250

Ω

GND

Control circuit terminals

Braking resistor (optional)

+2/B1

+17V

CPU

Ω

2.4

47

47K

11V

NPN

PNP

J2

47K

Ω

ΩΩ

120W, 200 120W

400 120W

Ω

AC Motor

3~

Potentiom eter(1K )

+

-

Factory default: indicate

output frequency

Multi-function indication

output contacts below

120VAC/24VDC 5A

Factory default:

indicates malfunction

Multi-function Photocoupler

output below 48VDC 50mA

Factory default: Indicates

during operation

RJ-11 communication port with

RS-485 serial interface

1:17

V

2:GND

3:SG4:SG+

Shielded leads

B2

U/T1

V/T2

W/T3

Ω

Ω

GND

RA

RB

RC

Mo1

MCM

RJ-11

61

select 80

E

FM

←

IM

Grounding resist ance

less than 100

Analog output

DC 0 10V

~

Ω

Ω

English- 4

Page 5

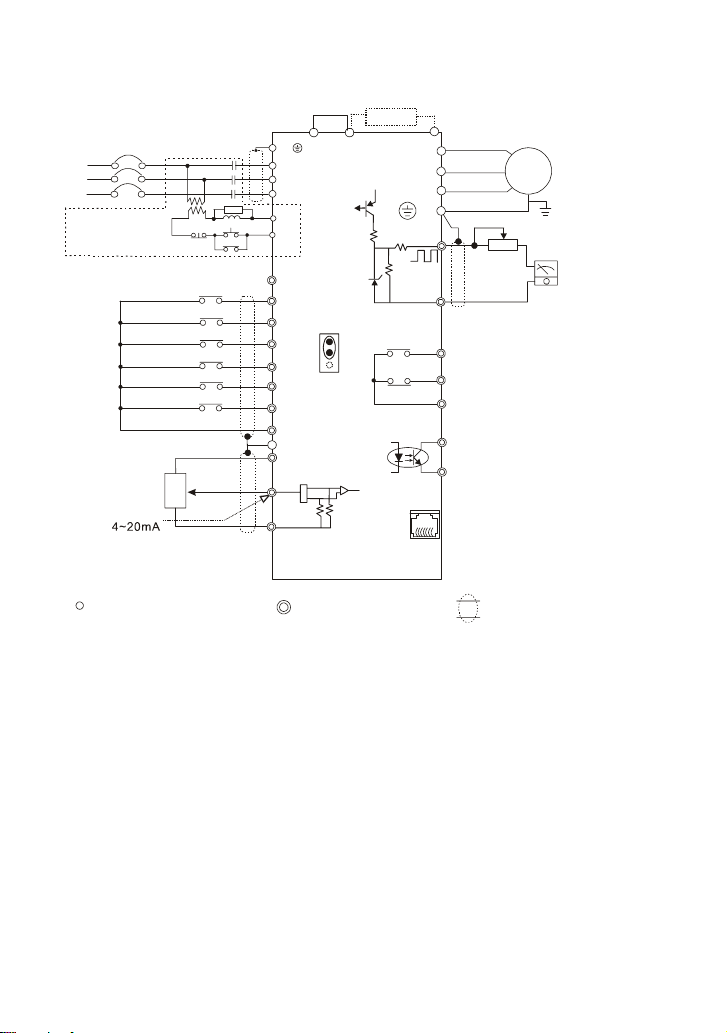

For VFDXXXSXXE

A

PNP (source mode)

Main Circuit Power

NFB

R/L1

S/L2

T/L3

Recommended Circuit

when power supply

is turned OFF by a

fault output

Analog voltage

010VDC

~

Potenti ometer

3K 5K

Analog current

Factory default: output freq. (Pot.)

determined by the Potentiometer

on the control panel.

Main circuit (power ) terminals

OFF

Common signal (source)

Forward/Stop

Reverse/St op

Reset

Multi-step 1

Multi- step 2

Multi-step 3

3

2

Pot.

~Ω

1

NOTE: Do not plug in a Modem or telephone line to the RS-485 communication

port, permanent damage may result. Terminal 1 & 2 are the power

sources for the optional copy keypad and should not be used while

using RS -485 communi cati on.

* If it is single phase model, please s elect any of the two input power

terminal s in main circuit power.

Jumper

+1

E

R/L1

S/L2

T/L3

SA

RB

MC

RC

ON

MC

17V

M0

M1

M2

M3

M4

M5

GND

E

+10V 10mA

(MAX)

1

2

AVI

3

Ω

250

GND

Control circuit terminals

Braking resistor (optional)

+2/B1

+17V

CPU

2.4

Ω

47

47K

11V

NPN

PNP

J2

47K

Ω

ΩΩ

120W, 200 120W

400 120W

Ω

AC Motor

3~

Potentiom eter(1K )

+

-

Factory default: indicate

output frequency

Multi-function indication

output contacts below

120VAC/24VDC 5A

Factory default:

indicates malfunction

Multi-function Photocoupler

output below 48VDC 50mA

Factory default: Indicates

during operation

RJ-11 communication port with

RS-485 serial interface

V

1:17

2:GND

3:SG4:SG+

Shielded leads

B2

U/T1

V/T2

W/T3

Ω

Ω

GND

RA

RB

RC

Mo1

MCM

RJ-11

61

select 80

E

FM

←

IM

Grounding resist ance

less than 100

Analog output

DC 0 10V

~

Ω

Ω

English- 5

Page 6

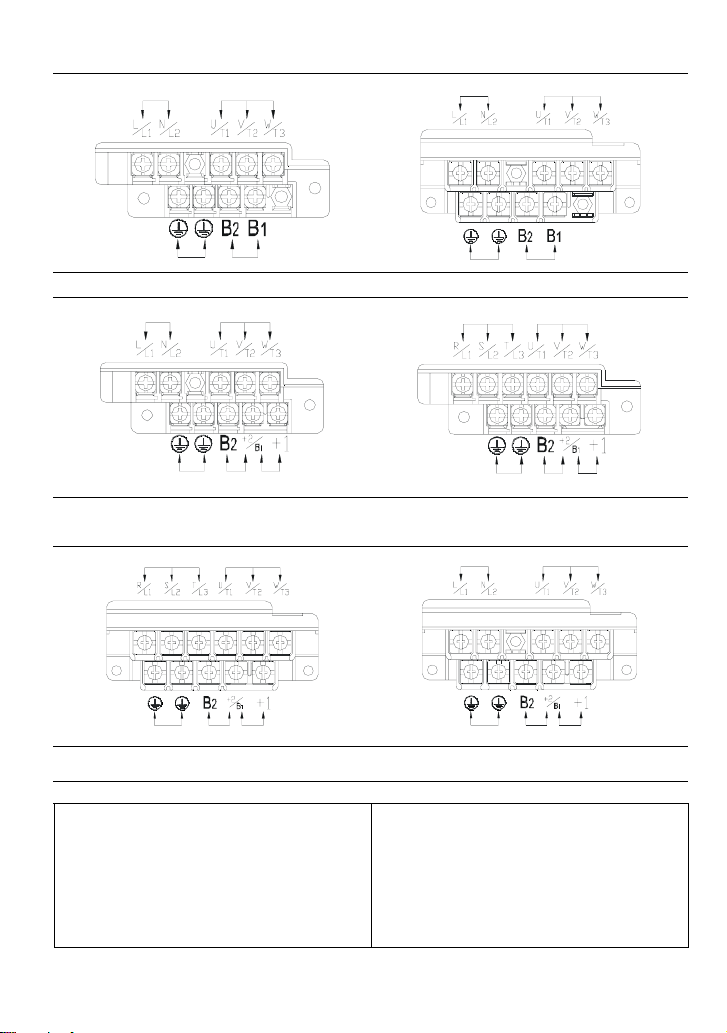

Power Terminals

A

AC Input Line

Ter min al

Motor

Connection

AC Input Line

Terminal

Mo tor

Connection

Groun d Brak ing Resist or

Figure 1: VFD002S11A/11B, VFD004S11A/11B Figure 2: VFD007S11A/B

AC Input Line

Ter min al

Groun d

Motor

Connection

Brak ing

Resistor

DC Reactor

Figure 3: VFD002S21A/E, VFD004S21A/E,

VFD007S21A/E

C Input Line

Te rm in al

Ground

Braking

Resistor

Mo tor

Connection

DC Reactor

Figure 5: VFD015S21U/43D/43E/43U,

Figure 4: VFD002S21B/23A,

VFD004S21B/23A/43A/43B/43E,

VFD007S21B/23A/43A/43B/43E, VFD015S23D

AC Input Line

Te r mi na l

Figure 6: VFD015S21D/E, VFD022S21D/E

Braking ResistorGround

AC Input Line

Terminal

Motor

Connection

Brak ing

Ground DC Reactor

Resistor

Connection

Brakin g

Resistor

Motor

DC ReactorGround

VFD022S21U/23D/43D/43E/43U

Figure 1/figure3/figure 4:

Wire Gauge: 14-20 AWG (2.1-0.5mm

Wire Type: copper wire only, 75°C

Torque: 12 kgf-cm (10 in-lbf)

2

)

English- 6

Figure 2/figure5/figure 6:

Wire Gauge: 10-18 AWG (5.3-0.8mm2)

Wire Type: stranded copper wire only, 75°C

Torque: 20 kgf-cm (17.4 in-lbf)

Page 7

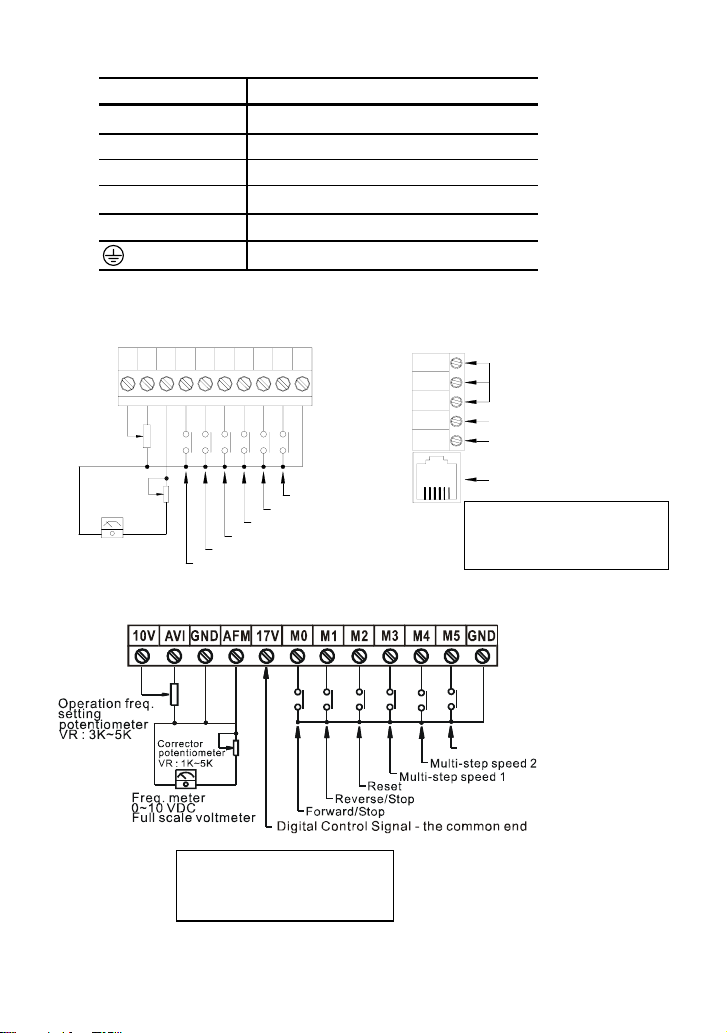

Terminal Explanations

*

*

Terminal Symbol Explanation of Terminal Function

R/L1, S/L2, T/L3 AC line input terminals (three phase)

L/L1, N/L2 AC line input terminals (single phase)

U/T1, V/T2, W/T3 Motor connections

+2/B2 – B1 Connections for Braking Resistor (optional)

+2/+1 – B1 Connections for DC Link Reactor (optional)

Earth Ground

Control Terminal Wiring (Factory Setting)

A. XXXSXXA/B/D/U

Operation freq.

setting

potentiometer

VR : 3K~5K

Corrector

potentiometer

VR : 1K~5K

Freq. meter

0~10 VDC

Full scale voltmeter

M1AVI10V+AFM M0 M4M2 M3 M5

Reverse/Stop

Forward/Stop

GND

Multi-step speed 3

Multi-step speed 2

Multi-step speed 1

Reset

B. XXXSXXE

RA

RB

RC

MO1

MCM

RJ11

6 ~ 1

Relay contactor output

Factory setting : Fault indication

Photo coupler output

Factory setting : in work

RS485 Communication port

Wire Gauge: 24-12 AWG

Wire Type: Copper Only

Torque: 4 kgf-cm (3.5 in-lbf)

Multi -step spee d 3

Wire Gauge: 24-16 AWG

Wire Type: Copper Only

Torque: 2 kgf-cm (1.7 in-lbf)

English- 7

Page 8

Terminal Explanations

Terminal

symbols

RA-RC

RB-RC

Multi-Function Indication Output

Contact

Multi-Function Indication Output

Contact

Terminal name Remarks

Refer to Pr.3-06 Relay output contact

RA-RC (N.O. Contact)

RB-RC (N.C. Contact)

MO1-MCM Multi-function PHC output Refer to Pr.3-05

RJ-11 Serial communication port RS-485 serial communication interface

+10V-GND Power for speed setting Power Supply (+10 V/10mA)

AVI-GND

Analog voltage/current freq.

command

0 to +10 V (Max. Output Frequency) Input or

4 to 20mA (Max. Output Frequency) Input

AFM-GND Analog frequency/current meter 0 to +10 V (Max. output Frequency) Output

17V DC Voltage Source (17V/20mA), used for source mode.

M0 Multi-function auxiliary input

M1 Multi-function input 1

M2 Multi-function input 2

M3 Multi-function input 3

Refer to Pr.4-04 to Pr.4-08

M4 Multi-function input 4

Multi-function input 5

M5

GND Digital Signal Common

Note: Use twisted-shielded, twisted-pair or shielded-lead wires for the control signal wiring. It is

recommended to run all signal wiring in a separate steel conduit. The shield wire should only be

connected at the drive. Do not connect shield wire on both ends.

Description of Digital Keypad

This digital keypad includes two parts: Display panel and keypad. Display panel provides the

parameter display and shows operation status of the AC drive. Keypad provides programming

interface between users and AC drives.

LED indication

Light during RUN,

STOP, FWD and

REV operation.

Potentiometer for

frequency setting.

Could be the Master

Frequency input

by setting Pr.2-00.

Mode Key

Change between

different display

modes.

RUN

FWD

REV

MIN. MAX.

MODE

RUN

STOP

STOP/RESET

PROG

DATA

LED Displa y

Indicate frequency, motor

parameter setting value

and alarm content s.

RUN Key

Start inverter drive operation.

STOP/RESET Key

Stop inverter drive operation

and reset the inverter after

faults occurred.

PROG/DATA Key

Set the different parameters

and enter info rmation .

UP and DOWN Key

Sets the pa rameter number

or changes the numerical

data such as the freq.

reference.

English- 8

Page 9

Operation steps of the Digital Keypad

MODE

Set frequency

Set frequency

Change display mode

Set frequency

Change disp lay item

Set

Freq.

MODE

MODE

Change disp lay

mode

Display freq. Command

Communication

error, only appears

when communication

error happens.

MODE

Change display

mode

MODE

Change display

mode

MODE

Display

parameter

number

Display

parameter

number

PROG

DATA

PROG

DATA

MODE

Display the

data of

parameter

Parameter is locked or data is out of range, or

data can't be entered during RUN mode.

Set parameter group

Set parameter

number

PROG

DATA

Set parameter

data

Change

operation

direct ion

REV state can't

attain if reverse

is inhibited.

Store data

Data is stored

English- 9

Page 10

Summary of Parameter Settings

a: The parameter can be set during operation.

Group 0 User Parameters

Pr. Explanation Settings

0-00 Identity Code of the AC Motor Drive Read-only d #

0-01 Rated Current Display of the AC

Read-only d##.#

Motor Drive

0-02 Parameter Reset d09: All parameters are reset to

factory settings

d0: Display the frequency command

value (LED F)

d1: Display the actual output

frequency (LED H)

a0-03 Start-up Display Selection

d2: Multifunction display, see Pr.00-

04

d3: Display output current (LED A)

d4: Display forward/reverse

command (Frd/rEv)

d0: Display User-Defined Unit (u)

d1: Display Counter Value (C)

d2: Display Process Operation (1.tt)

a0-04 Content of Multi-Function Display

d3: Display DC-BUS Voltage (

d4: Display output voltage (E)

d5: Display frequency commands of

PID (P)

d6: Display analog feedback signal

value (b) (%)

a0-05 User-Defined Coefficient K d0.1 to d160 d1.0

0-06 Software Version Read-only d#.#

0-07 Password Input d0 to d999 d0

0-08 Password Set d0 to d999 d0

a0-09 Memory Mode Selections d0 to d63 d8

Group 1 Basic Parameters

Pr. Explanation Settings

1-00 Maximum Output Frequency (Fmax) d50.0 to d400 Hz d60.0

1-01 Maximum Voltage Frequency (Fbase) d10.0 to d400 Hz d60.0

1-02 Maximum Output Voltage (Vmax)

230V series: d2.0V to d255V d220

460V series: d4.0V to d510V d440

1-03 Mid-Point Frequency (Fmid) d1.0 to d400 Hz d1.0

Mid-Point Voltage (Vmid)

1-04

230V series: d2.0V to d255V d12

460V series: d4.0V to d510V d24

1-05 Minimum Output Frequency (Fmin) d1.0 to d60.0 Hz d1.0

Minimum Output Voltage (Vmin)

1-06

230V series: d2.0V to d255V d12.0

460V series: d4.0V to d510V d24.0

1-07 Output Frequency Upper Limit d1 to d110% d100

1-08 Output Frequency Lower Limit d0 to d100% d0

a1-09 Accel Time 1 d0.1 to d600 Sec d10.0

a1-10 Decel Time 1 d0.1 to d600 Sec d10.0

a1-11 Accel Time 2 d0.1 to d600 Sec d10.0

a1-12 Decel Time 2 d0.1 to d600 Sec d10.0

English- 10

u

)

Factory

Setting

d0

d0

d0

Factory

Setting

NOTE

NOTE

Page 11

Pr. Explanation Settings

Factory

Setting

a1-13 Jog Acceleration / Deceleration Time d0.1 to d600 Sec d10.0

a1-14 Jog Frequency d1.0 Hz to d400 Hz d6.0

d0: Linear Accel/Decel

d1: Auto Accel, Linear Decel

d2: Linear Accel, Auto Decel

Auto acceleration / deceleration (refer

1-15

to Accel/Decel time setting)

d3: Auto Accel/Decel (Set by load)

d4: Linear Accel; Auto Decel, Stall

Prevention during Decel

d0

d5: Auto Accel/Decel, Stall

Prevention during Decel

1-16 Acceleration S-Curve d0 to d7 d0

1-17 Deceleration S-Curve d0 to d7 d0

d0.0 Jog Decelerating Time

1-18 Jog Decelerating Time

Determined by Pr.1-13

d0.0

d0.1 to d600

Group 2 Operation Method Parameters

Pr. Explanation Settings

Factory

Setting

d0: Master Frequency input

determined by digital keypad.

(record the frequency of power

loss and it can do analog

overlap plus)

d1: Master Frequency determined

by analog signal DC 0V-10V

(external terminal AVI). (won’t

record the frequency of power

loss and it can’t do analog

overlap plus)

d2: Master Frequency determined

by analog signal DC 4mA -

Source of Master Frequency

2-00

Command

20mA (external terminal AVI).

(won’t record the frequency of

power loss and it can’t do

d0

analog overlap plus)

d3: Master Frequency determined

by Potentiometer on the digital

keypad. (won’t record the

frequency of power loss and it

can do analog overlap plus)

d4: Master Frequency operated by

RS-485 serial communication

interface and record frequency

of power loss. (record the

frequency of power loss and it

can do analog overlap plus)

NOTE

NOTE

English- 11

Page 12

Pr. Explanation Settings

Factory

Setting

d5: Master Frequency operated by

RS-485 serial communication

Source of Master Frequency

2-00

Command

interface and won’t record

frequency before power loss.

(won’t record the frequency of

d0

power loss and it can do analog

overlap plus)

d0: Digital Keypad

d1: External terminals. Keypad

STOP/RESET enabled.

d2: External terminals. Keypad

Source of Operation

2-01

Command

STOP/RESET disabled.

d3: RS-485 serial communication

(RJ-11) .Keypad STOP/RESET

d0

enabled.

d4: RS-485 serial communication

(RJ-11). Keypad STOP/RESET

disabled.

d0: STOP: ramp to stop; E.F.: coast

2-02 Stop Method

to stop

d1: STOP: coast to stop; E.F.: coast

d0

to stop

2-03 PWM Carrier Frequency Selections

d3: 3KHz

d4: 4KHz

d5: 5KHz

d6: 6KHz

d7: 7KHz

d8: 8KHz

d9: 9KHz

d10: 10KHz

d10

d0: Enable forward/reverse

2-04 Motor Direction Control

operation

d0

d1: Disable reverse operation

d0: Decelerate to 0 Hz

2-05 Loss of ACI Signal

d1: Coast to stop and display “EF”

d2: Continue operation by last

d0

frequency command

d0: Disable

2-06 Analog Auxiliary Frequency Operation

d1: Enable + AVI

d2: Enable + ACI

d0

Group 3 Output Function Parameters

Pr. Explanation Settings

3-00 Analog Output Signal

d0: analog frequency meter

d1: analog current meter

Factory

Setting

d0

a3-01 Analog Output Gain d1 to d200% d100

3-02 Desired Frequency Attained d1.0 to d400 Hz d1.0

NOTE

NOTE

3-03 Terminal Count Value d0 to d999 d0

3-04 Preliminary Count Value d0 to d999 d0

Multi-Function Output Terminal 1

3-05

(Photocoupler Output)

d0: No Function d1

English- 12

Page 13

Pr. Explanation Settings

Factory

Setting

d1: AC Drive Operational

d2: Master Frequency Attained

d3: Zero Speed

d4: Over Torque Detection

d5: Base-Block (B.B.) Indication

d6: Low-Voltage Indication

d7: Operation Mode Indication

d8: Fault Indication

d9: Desired Frequency Attained

Multi-Function Output Terminal 2

3-06

(Relay Output)

d10: PLC Program Running

d11: PLC Program Step Completed

d8

d12: PLC Program Completed

d13: PLC Program Operation

Paused

d14: Terminal Count Value Attained

d15: Preliminary Count Value

Attained

d16: AC Motor Drive Ready

d17: FWD command Indication

d18: REV command Indication

Group 4 Input Function Parameters

Pr. Explanation Settings

Factory

Setting

a4-00 Potentiometer Bias Frequency d 0.0 to d 100.0% d0.0

Potentiometer Bias

a4-01

Polarity

Potentiometer

a4-02

Frequency Gain

Potentiometer Reverse

4-03

Motion Enable

d0: Positive Bias

d1: Negative Bias

d0

d1 to d200 % d100

d0: Forward Motion Only

d1: Reverse Motion enabled

d0

d0: No Function

Multi-Function Input Terminal 1 (M0,

4-04

M1)

d1: FWD/STOP, REV/STOP

d2: FWD/REV, RUN/STOP

d3: 3-wire Operation Control Mode

d1

d4: E.F. External Fault Input (N.O.)

Multi-Function Input Terminal 2 (M2) d5: E.F. External Fault Input (N.C.)

d6: Reset

d7: Multi-Step Speed Command 1

4-05

d8: Multi-Step Speed Command 2

d6

d9: Multi-Step Speed Command 3

d10: Jog Operation

d11: Accel/decel Inhibit

Multi-Function Input Terminal 3 (M3) d12: First or Second

Acceleration/deceleration Time

4-06

Selection

d7

d13: External base block (N.O.)

d14: External base block (N.C.)

Multi-Function Input Terminal 4 (M4) d15: Up: Increment master

frequency

4-07

d16: Down: Decrement master

frequency

d8

d17: Run PLC Program

NOTE

NOTE

English- 13

Page 14

Pr. Explanation Settings

Factory

Setting

d18: Pause PLC Program

d19: Counter Trigger Signal

d20: Counter Reset

d21: Select ACI / Deselect AVI

d22: PID Function Disabled

d23: JOG FWD

d24: JOG REV

d25: The source of master

4-08 Multi-Function Input Terminal 5(M5)

frequency is AVI.

d26: The source of master

d9

frequency is ACI.

d27: Press UP/DOWN key to switch

forward/reverse (N.O.) motion

d28: Press UP/DOWN key to switch

forward/reverse (N.C.) motion

d29: M0: 0: RUN 1: STOP, M1: no

function, Direction is controlled

by keypad

4-09 Line Start Lockout

d0: Disable

d1: Enable

d0

d0: Based on accel/decel time

d1: Up frequency according to

constant speed, down frequency

4-10 Up/Down Mode

according to deceleration time

d2: Up frequency according to

d3

acceleration time, down

frequenc according to constant

speed

d3: Constant speed

Accel/Decel Rate of Change of

4-11

UP/DOWN Operation with Constant

0~1000, unit: 5 Hz/sec d1

Speed

Group 5 Multi-Step Speed and PLC Parameters

Pr. Explanation Settings

Factory

Setting

5-00 1st Step Speed Freq. d0.0 to d400 Hz d0.0

5-01 2nd Step Speed Freq. d0.0 to d400 Hz d0.0

5-02 3rd Step Speed Freq. d0.0 to d400 Hz d0.0

5-03 4th Step Speed Freq. d0.0 to d400 Hz d0.0

5-04 5th Step Speed Freq. d0.0 to d400 Hz d0.0

5-05 6th Step Speed Freq. d0.0 to d400 Hz d0.0

5-06 7th Step Speed Freq. d0.0 to d400 Hz d0.0

d0: Disable PLC Operation

d1: Execute one program cycle

d2: Continuously execute program

5-07 PLC Mode

cycles

d3: Execute one program cycle step

d0

by step

d4: Continuously execute one

program cycle step by step

NOTE

NOTE

English- 14

Page 15

Pr. Explanation Settings

Factory

Setting

d5: Disable PLC operation, but can

PLC Forward/ Reverse

5-08

Motion

set direction of 1st speed to 7th

speed

d0 to d255 (0: FWD 1: REV) d0

5-09 Time Duration of Zero Step Speed d0 to d65500 Sec d0

5-10 Time Duration of 1st Step Speed d0 to d65500 Sec d0

5-11 Time Duration of 2nd Step Speed d0 to d65500 Sec d0

5-12 Time Duration of 3rd Step Speed d0 to d65500 Sec d0

5-13 Time Duration of 4th Step Speed d0 to d65500 Sec d0

5-14 Time Duration of 5th Step Speed d0 to d65500 Sec d0

5-15 Time Duration of 6th Step Speed d0 to d65500 Sec d0

5-16 Time Duration of 7th Step Speed d0 to d65500 Sec d0

Group 6 Protection Parameters

Pr. Explanation Settings

6-00 Over-Voltage Stall Prevention

Over-Voltage Stall Prevention Level

6-01

d0: Disable

d1: Enable

115V/230V series: d350 to d410V d390

460V series: d700 to d820V d780

Factory

Setting

d1

6-02 Over-Current Stall Prevention Level d20 to d150% d130

d0: Disabled

d1: Enabled during constant speed

operation. After the over-torque

is detected, keep running until

OL1 or OL occurs.

d2: Enabled during constant speed

6-03 Over-Torque Detection Mode

operation. After the over-torque

is detected, stop running.

d0

d3: Enabled during running and

continues before Continuous

Output Time Limit (Pr.6-05) is

reached

d4: Enabled during running. After

the over-torque is detected, stop

running.

6-04 Over-Torque Detection Level d30 to d200% d150

6-05 Over-Torque Detection Time d0.1 to d10.0 Sec d0.1

Electronic Thermal Overload Relay

6-06

Selection

Electronic Thermal

a6-07

Characteristic

6-08

Present Fault Record

d0 to d2 d2

d30 to d600 Sec d60

d0: No fault

d0

d1: Over current (oc)

d2: Over voltage (ov)

d3: Over heat (oH)

d4: Over load (oL)

d5: Over load (oL1)

d6: External fault (EF)

d7: Reserved

NOTE

NOTE

English- 15

Page 16

Pr. Explanation Settings

6-09 Second Most Recent Fault Record

d8: Reserved

d9: Excess current during

acceleration (ocA)

Factory

NOTE

Setting

d10: Excess current during

deceleration (ocd)

d11: Excess current during steady

6-10 Third Most Recent Fault Record

state (ocn)

d12: Ground fault (GF)

d13: Reserved

d14: Low voltage (Lv)

d15: CPU failure 1 (cF1)

d16: CPU failure 2 (cF2)

d17: Base block (b.b.)

d18: Overload (oL2)

d19: Auto acceleration/deceleration

failure (cFA)

d20: Software protection enable

(codE)

d21: Reserved

d22: CPU failure (cF3.1)

d23: CPU failure (cF3.2)

d24: CPU failure (cF3.3)

d25: CPU failure (cF3.4)

d26: CPU failure (cF3.5)

d27: CPU failure (cF3.6)

d28: CPU failure (cF3.7)

d29: Hardware protection failure

(HPF.1)

d30: Hardware protection failure

(HPF.2)

d31: Hardware protection failure

(HPF.3)

d32: Communication time-out

(CE10)

d33: Reserved

d34: Software error (SErr)

d0

d35: Reserved

d36: PID error (Pld)

d37: Reserved

d38: Phase loss (PHL)

Group 7 Motor Parameters

Factory

Pr. Explanation Settings

Setting

NOTE

a7-00 Motor Rated Current d30 to d120% d85

Motor No-Load Current

a7-01

Torque Compensation

a7-02

d0 to d90% d50

d0 to d10 d1

a7-03 Slip Compensation d0.0 to d10.0 d0.0

Group 8 Special Parameters

Pr. Explanation Settings

Factory

Setting

NOTE

8-00 DC Braking Voltage Level d0 to d30% d0

English- 16

Page 17

Pr. Explanation Settings

Factory

Setting

8-01 DC Braking Time during Start-Up d0.0 to d60.0 Sec d0.0

8-02 DC Braking time during Stopping d0.0 to d60.0 Sec d0.0

8-03 Start-Point for DC Braking d0.0 to d400 Hz d0.0

d0: Operation stops after

Momentary Power Loss

d1: Operation continues after

momentary power loss, speed

Momentary Power Loss Operation

8-04

Selection

search starts with the Master

Frequency reference value

d2: Operation continues after

d0

momentary power loss, speed

search starts with the minimum

frequency

Maximum Allowable Power Loss

8-05

Time

d0.3 to d5.0 Sec d2.0

8-06 B.B. Time for Speed Search d0.3 to d5.0 Sec d0.5

8-07 Current Limit for Speed Search d30 to d200% d150

8-08 Skip Frequency 1 Upper Limit d0.0 to d400 Hz d0.0

8-09 Skip Frequency 1 Lower Limit d0.0 to d400 Hz d0.0

8-10 Skip Frequency 2 Upper Limit d0.0 to d400 Hz d0.0

8-11 Skip Frequency 2 Lower Limit d0.0 to d400 Hz d0.0

8-12 Skip Frequency 3 Upper Limit d0.0 to d400 Hz d0.0

8-13 Skip Frequency 3 Lower Limit d0.0 to d400 Hz d0.0

8-14 Auto Restart After Fault d0 to d10 d0

d0: Enable

8-15 AVR Function

d1: Disable

d2

d2: Disable when deceleration

Software Braking Level

8-16

115V/230V series: d350 to d450V d380

460V series: d700 to d900V d760

8-17 DC Braking Lower Bound Limit d0.0 to d400 Hz d0.0

Group 9 Communication Parameters

Pr. Explanation Settings

Communication

a9-00

Address

a9-01 Transmission Speed

a9-01 Transmission Speed

d1 to d254 d1

d0: Baud Rate 4800 bps

d1: Baud Rate 9600 bps

d2: Baud Rate 19200 bps

d3: Baud Rate 38400 bps

Factory

Setting

d1

d1

d0: Warn and Keep Operating

a9-02

Transmission Fault

Treatment

d1: Warn and Ramp to Stop

d2: Warn and Coast to Stop

d0

d3: Keep Operating without Warning

d0: Disable

a9-03 Time-out Detection

d1 to d20: time setting (1 sec

d0

increment)

a9-04 Communication

Protocol

d0: 7,N,2 (Modbus, ASCII)

d1: 7,E,1 (Modbus, ASCII)

d0

d2: 7,O,1 (Modbus, ASCII)

d3: 8,N,2 (Modbus, ASCII)

NOTE

NOTE

English- 17

Page 18

Pr. Explanation Settings

Group A PID Parameters

Pr. Explanation Settings

A-00 Input terminal for PID Feedback

A-01 Gain over PID Detection value d0 to d999 d100

A-02 Proportional Gain (P) d0 to d999 d100

A-03 Integral Time (I) d0 to d999 d100

A-04 Derivative Control (D) d0 to d100 d0

A-05 Upper Bound for Integral Control d0 to d100% d100

A-06 Primary Delay Filter Time d0 to d999 d0

A-07 PID Output Freq. Limit d0 to d110% d100

A-08 Feedback Signal Detection Time d0.0 to d650 seconds d0.0

A-09

A-10 Sleep Frequency d0.0 to d400Hz d0.0

A-11 Wakeup Frequency d0.0 to d400Hz d0.0

A-12 Sleep Period d0.0 to d650 seconds d0.0

A-13 PID User Defined d0.0 to d400 d0.0

Treatment of the Erroneous

Feedback Signals

d4: 8,E,1 (Modbus, ASCII)

d5: 8,O,1 (Modbus, ASCII)

d6: 8,N,2 (Modbus, RTU)

d7: 8,E,1 (Modbus, RTU)

d8: 8,O,1 (Modbus, RTU)

d0: Disable PID function

d1: Negative PID feedback from

external terminal (AVI) 0 to

+10V

d2: Negative PID feedback from

external terminal (ACI) 4 to

20mA

d3: Positive PID feedback from

external terminal (AVI) 0 to

+10V

d4: Positive PID feedback from

external terminal (ACI) 4 to

20mA

d0: warn and RAMP to stop

d1: warn and COAST to stop

Fault Codes

Fault

Name

Fault Descriptions Corrective Actions

1. Check if motor power corresponds with the AC

motor drive output power.

Over current

Abnormal increase in current.

2. Check the wiring connections to U/T1, V/T2,

W/T3 for possible short circuits.

3. Check the wiring connections between the AC

motor drive and motor for possible short

circuits, also to ground.

Factory

NOTE

Setting

Factory

NOTE

Setting

d0

d0

English- 18

Page 19

Fault

Name

Fault Descriptions Corrective Actions

Over current

Abnormal increase in current.

Over voltage

The DC bus voltage has

exceeded its maximum

allowable value.

Overheating

Heat sink temperature too high

Low voltage

The AC motor drive detects

that the DC bus voltage has

fallen below its minimum

value.

Overload

The AC motor drive detects

excessive drive output current.

NOTE: The AC motor drive

can withstand up to 150% of

the rated current for a

maximum of 60 seconds.

Overload 1

Internal electronic overload trip

Overload 2

Motor overload.

Over-current during

acceleration

4. Check for loose contacts between AC motor

drive and motor.

5. Increase the Acceleration Time.

6. Check for possible excessive loading

conditions at the motor.

7. If there are still any abnormal conditions when

operating the AC motor drive after a shortcircuit is removed and the other points above

are checked, it should be sent back to

manufacturer.

1. Check if the input voltage falls within the rated

AC motor drive input voltage range.

2. Check for possible voltage transients.

3. DC-bus over-voltage may also be caused by

motor regeneration. Either increase the Decel.

Time or add an optional brake resistor.

4. Check whether the required braking power is

within the specified limits.

1. Ensure that the ambient temperature falls within

the specified temperature range.

2. Make sure that the ventilation holes are not

obstructed.

3. Remove any foreign objects from the heatsinks

and check for possible dirty heat sink fins.

4. Check the fan and clean it.

5. Provide enough spacing for adequate

ventilation.

1. Check whether the input voltage falls within the

AC motor drive rated input voltage range.

2. Check whether the motor has sudden load.

3. Check for correct wiring of input power to R-S-T

(for 3-phase models) without phase loss.

1. Check whether the motor is overloaded.

2. Reduce torque compensation setting in Pr.7-

02

3. Take the next higher power AC motor drive

model.

1. Check for possible motor overload.

2. Check electronic thermal overload setting.

3. Use a higher power motor.

4. Reduce the current level so that the drive

output current does not exceed the value set

by the Motor Rated Current Pr.7-00.

1. Reduce the motor load.

2. Adjust the over-torque detection setting to an

appropriate setting (Pr.6-03 to Pr.6-05).

1. Short-circuit at motor output: Check for

possible poor insulation at the output lines.

2. Torque boost too high: Decrease the torque

compensation setting in Pr.7-02

English- 19

Page 20

Fault

Name

Fault Descriptions Corrective Actions

3. Acceleration Time too short: Increase the

Over-current during

acceleration

Over-current during

deceleration

Over-current during steady

state operation

External Fault

Internal EEPROM can not be

programmed.

Internal EEPROM can not be

programmed.

Drive’s internal circuitry

abnormal.

Hardware protection failure. Return to the factory.

Software protection failure

Auto accel/decel failure

Ground fault

4. AC motor drive output power is too small:

1. Short-circuit at motor output: Check for

2. Deceleration Time too short: Increase the

3. AC motor drive output power is too small:

1. Short-circuit at motor output: Check for

2. Sudden increase in motor loading: Check for

3. AC motor drive output power is too small:

1. When multi-function input terminals (MI1-MI6)

2. Give RESET command after fault has been

Return to the factory.

Return to the factory.

1. Switch off power supply.

2. Check whether the input voltage falls within

Return to the factory.

1. Check if the motor is suitable for operation by

2. Check if the regenerative energy is too large.

3. Load may have changed suddenly.

When (one of) the output terminal(s) is grounded,

short circuit current is more than 50% of AC motor

drive rated current, the AC motor drive power

module may be damaged.

NOTE: The short circuit protection is provided

for AC motor drive protection, not for

protection of the user.

1. Check whether the IGBT power module is

2. Check for possible poor insulation at the

Acceleration Time.

Replace the AC motor drive with the next

higher power model.

possible poor insulation at the output line.

Deceleration Time.

Replace the AC motor drive with the next

higher power model.

possible poor insulation at the output line.

possible motor stall.

Replace the AC motor drive with the next

higher power model.

are set to external fault, the AC motor drive

stops output U, V and W.

cleared.

the rated AC drive input voltage. Switch on the

AC drive.

AC motor drive.

damaged.

output line.

English- 20

Page 21

Fault

Name

Fault Descriptions Corrective Actions

Communication Error

External Base Block.

(Refer to Pr. 8-06)

Dimensions are in mm [inch]

A

D

1. Check the RS485 connection between the AC

motor drive and RS485 master for loose wires

and wiring to correct pins.

2. Check if the communication protocol, address,

transmission speed, etc. are properly set.

1. When the external input terminal (B.B) is

active, the AC motor drive output will be

turned off.

2. Deactivate the external input terminal (B.B) to

operate the AC motor drive again.

F

B

E

C

5.0 [0.20]

Model Name A B C D E F G H I

002S11A/21A/23A

004S11A/21A/23A

004S43A/43E,

007S21A/23A

007S43A/43E

002S21E, 004S21E,

007S21E, 015S23D

002S11B/21B/23B

004S11B/21B/23B

004S43B,

007S21B/23B

85.0

[3.35]

85.0

[3.35]

85.0

[3.35]

85.0

[3.35]

85.0

[3.35]

85.0

[3.35]

85.0

[3.35]

85.0

[3.35]

148.0

[5.83]

148.0

[5.83]

148.0

[5.83]

148.0

[5.83]

148.0

[5.83]

148.0

[5.83]

148.0

[5.83]

148.0

[5.83]

H

88.0

[3.47]

102.0

[4.02]

124.0

[4.89]

126.0

[4.96]

127.0

[5.00]

88.0

[3.47]

102.0

[4.02]

124.0

[4.89]

English- 21

74.0

[2.92]

74.0

[2.92]

74.0

[2.92]

74.0

[2.92]

74.0

[2.92]

74.0

[2.92]

74.0

[2.92]

74.0

[2.92]

IG

132.2

[5.21]

132.2

[5.21]

132.2

[5.21]

132.2

[5.21]

133.7

[5.27]

132.2

[5.21]

132.2

[5.21]

132.2

[5.21]

5.8

[0.23]

5.8

[0.23]

5.8

[0.23]

5.8

[0.23]

5.8

[0.23]

5.8

[0.23]

5.8

[0.23]

5.8

[0.23]

- - -

- - -

- - -

- - -

- - -

73.0

[2.88]

[0.63]

73.0

[2.88]

[0.63]

73.0

[2.88]

[0.63]

16.0

16.0

16.0

67.8

[2.67]

67.8

[2.67]

67.8

[2.67]

Page 22

Model Name A B C D E F G H I

85.0

148.0

126.0

74.0

132.2

5.8

007S43B

[3.35]

[5.83]

[4.96]

[2.92]

[5.21]

[0.23]

73.0

[2.88]

Dimensions are in mm [inch]

16.0

[0.63]

67.8

[2.67]

A

D

G I

5.5 [0.22]

F

B

E

H

C

Model Name A B C D E F G H I

100.0

186.0

143.0

86.5

015S21A/23A

015S21D/21E,

022S21D/21E/23D

007S11A,

015S43A/43E,

022S23A/43A/43E

022S21A

007S11B,

015S21B/23B/43B,

022S23B/43B

022S21B

015S21U/43U

022S21U/43U

[3.94]

100.0

[3.94]

100.0

[3.94]

118.0

[4.65]

100.0

[3.94]

118.0

[4.65]

100.0

[3.94]

[7.33]

186.0

[7.33]

186.0

[7.33]

220.0

[8.67]

186.0

[7.33]

220.0

[8.67]

186.0

[7.33]

[5.63]

129.3

[5.09]

129.0

[5.08]

130.9

[5.16]

129.0

[5.08]

130.9

[5.16]

129.3

[5.09]

[3.41]

86.5

[3.41]

86.5

[3.41]

105.5

[4.16]

86.5

[3.41]

105.5

[4.16]

86.5

[3.41]

173.0

173.0

173.0

207.0

173.0

207.0

173.0

[6.82]

[6.82]

[6.82]

[8.16]

[6.82]

[8.16]

[6.82]

5.4

[0.21]

5.4

[0.21]

5.4

[0.21]

4.4

[0.17]

5.4

[0.21]

4.4

[0.17]

5.4

[0.21]

- - -

- - -

- - -

- - -

73.0

16.0

[2.88]

[2.67]

[2.67]

73.0

16.0

[2.88]

[2.67]

[2.67]

73.0

16.0

[2.88]

[2.67]

[2.67]

67.8

67.8

67.8

English- 22

Loading...

Loading...