Page 1

Page 2

5011200503

200305-22

AE02

Page 3

Page 4

TABLE OF CONTENTS

Chapter 1 Introduction

Getting Started .............................................................................................. 1

Receiving Storage and Transportation .......................................................... 2

Nameplate Information .................................................................................. 2

Identification of components and accessories ............................................... 3

Chapter 2 Installation and Wiring

Installation Requirements .............................................................................. 5

Main Circuit Wiring ........................................................................................ 6

Control Circuit Wiring..................................................................................... 9

Basic Wiring Diagram ...................................................................................10

Chapter 3 Digital Keypad Operation

Description of the Digital Keypad..................................................................11

Explanation of Displayed Messages .............................................................12

Chapter 4 Start Up .......................................................................................................16

Chapter 5 Parameter Settings.....................................................................................19

Chapter 6 Summary of Parameter Settings ...............................................................52

Chapter 7 Troubleshooting and Fault information ....................................................57

Appendix A Standard Specifications.............................................................................61

Appendix B Serial Communications..............................................................................64

Appendix C Dimensions .................................................................................................70

Appendix D Accessories List .........................................................................................77

Appendix E EMI Filters ...................................................................................................78

Appendix F EC Declaration of Conformity....................................................................79

Appendix G NFB (No-Fuse Breaker) Specification .......................................................81

Page 5

1

Introduction

Congratulations on your purchase of the DELTA VFD-A series AC motor drive. The VFD series is a

high-performance / low noise general-purpose AC motor drive, manufactured using high-quality

components and incorporating the latest micro-processor technology available.

The purpose of this chapter is to provide specific, yet simple information to unpack, install, and

operate the AC drive. This chapter contains information on the following:

Getting Started

Receiving, Transportation, and Storage

Nameplate Information

Identification of Components and Accessories

Getting Started

This manual will help in the installation, parameter setting, troubleshooting, and maintenance of

the AC drive. To guarantee safe operation of the equipment, read the following safety guidelines

before connecting the drive to the AC power line. Keep this manual in a place where it is available

to all users for their reference.

!

Warning! To avoid personal injury, do not remove the cover of the AC motor drive until all of the

digital keypad “DISPLAY LED” lamps are off. The DC-link capacitor remains charged with a

hazardous voltage even after input power is removed.

!

Warning! Do not connect or disconnect wires and connectors while power is applied to the circuit.

All connections should be performed by qualified personnel.

Attention: Grounding the VFD-A drive is done by connecting the Earth Ground to the drive

!

ground terminal.

Attention: The final enclosure for operating the AC Motor Drive must comply with the

!

requirements of EN 50178. ( Live parts shall be arranged in enclosures or located behind barriers

that meet at least the requirements of the Protective Type IP20; Top surfaces of enclosures or

barriers that are easily accessible shall meet at least the requirements of the Protective Type IP40

)

Caution: There are highly sensitive components on the printed circuit boards. These components

!

are especially sensitive to ESD (electrostatic discharge). To avoid damage to the drive, do not

touch components or the circuit boards until all static control precautions have been taken.

!

Caution: Never connect the main circuit output terminals U, V, and W directly to the AC main

circuit power supply as this will damage the drive.

!

Caution: Do not apply the antirust to screws for fastening drives; Please clean the drives and

screws with dry cloth or alcohol, not with synthetic cleaner. Fasten the screws with washers and

rated torque lest the enclosure corners of drives be distorted.

This manual is for DELTA AC Motor Drive VFD-A and VFD-H Series. For the frequency in Pr.03,

Pr.04, Pr.06, Pr.16, Pr.17, Pr.18, Pr.19, Pr.20, Pr.21, Pr.22, Pr.23, Pr.36, Pr.37, Pr.47, Pr.67, Pr.68

and Pr.69, VFD-A Series can be regulated up to 400Hz and VFD-H Series up to 1500Hz.

1

Page 6

Receiving, Storage and Transportation

The AC motor drive has gone through rigorous quality control tests at the factory before shipment.

After receiving the AC drive, check for the following.

Receiving

Check to make sure that the package includes an AC drive, the User Manual, dust covers

and rubber bushings.

Inspect the unit to insure it was not damaged during shipment.

Make sure that the part number indicated on the nameplate corresponds with the part

number of your order.

Storage

The AC Drive should be kept in the shipping carton before installation. In order to retain the

warranty coverage, the AC drive should be stored properly when it is not to be used for an

extended period of time. Some storage suggestions are:

Store in a clean, dry location.

Store within an ambient temperature range of -20°C to +60°C.

If possible, store in an air-conditioned environment where the relative humidity is less

than 95%, non-condensing.

Do not store the AC drive in places where it could be exposed to corrosive gases.

Do not store the AC drive on a shelf or on an unstable surface.

Transportation

Temperature: -25°C to +70°C; R.H.: 0% to 95%; Air Pressure: 70kPa to 106kPa.

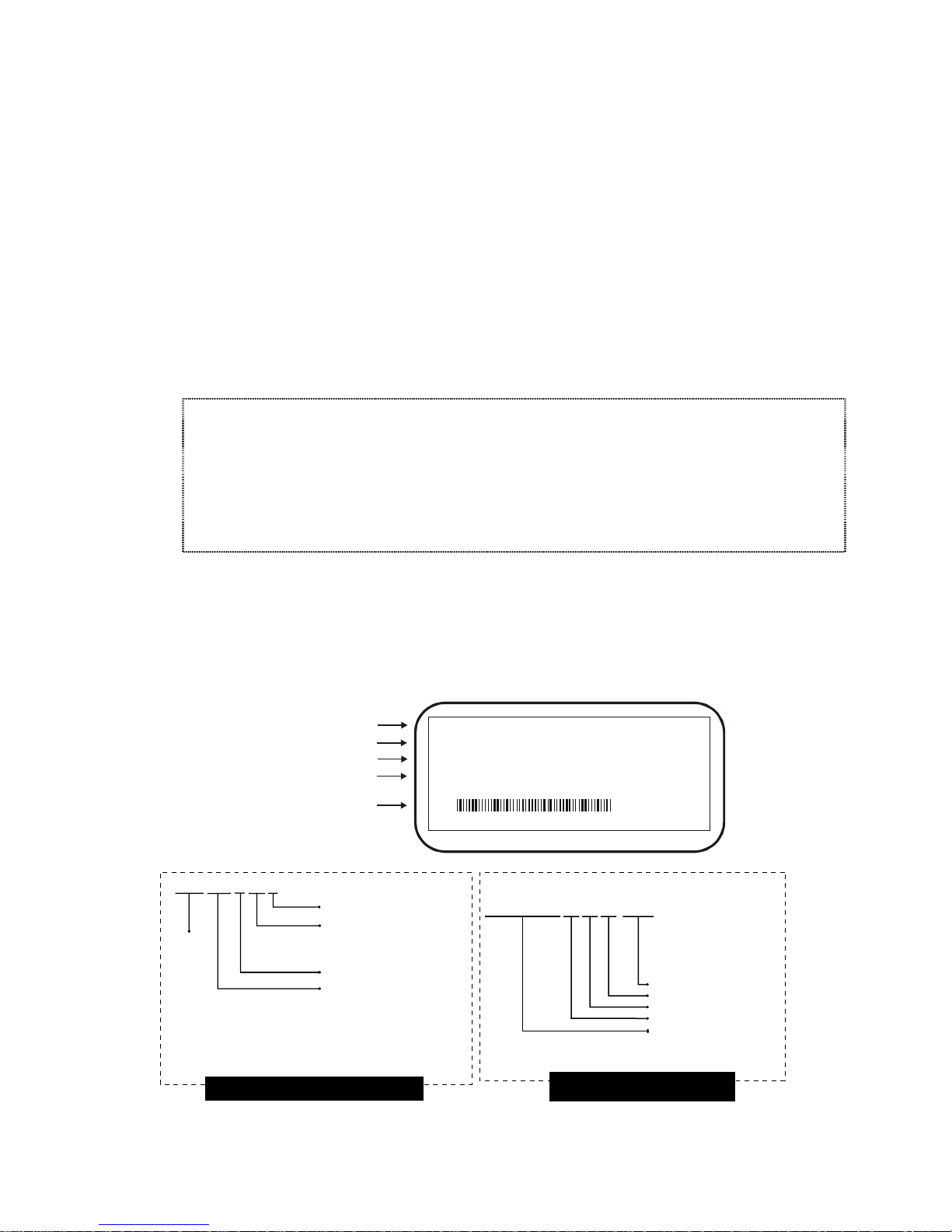

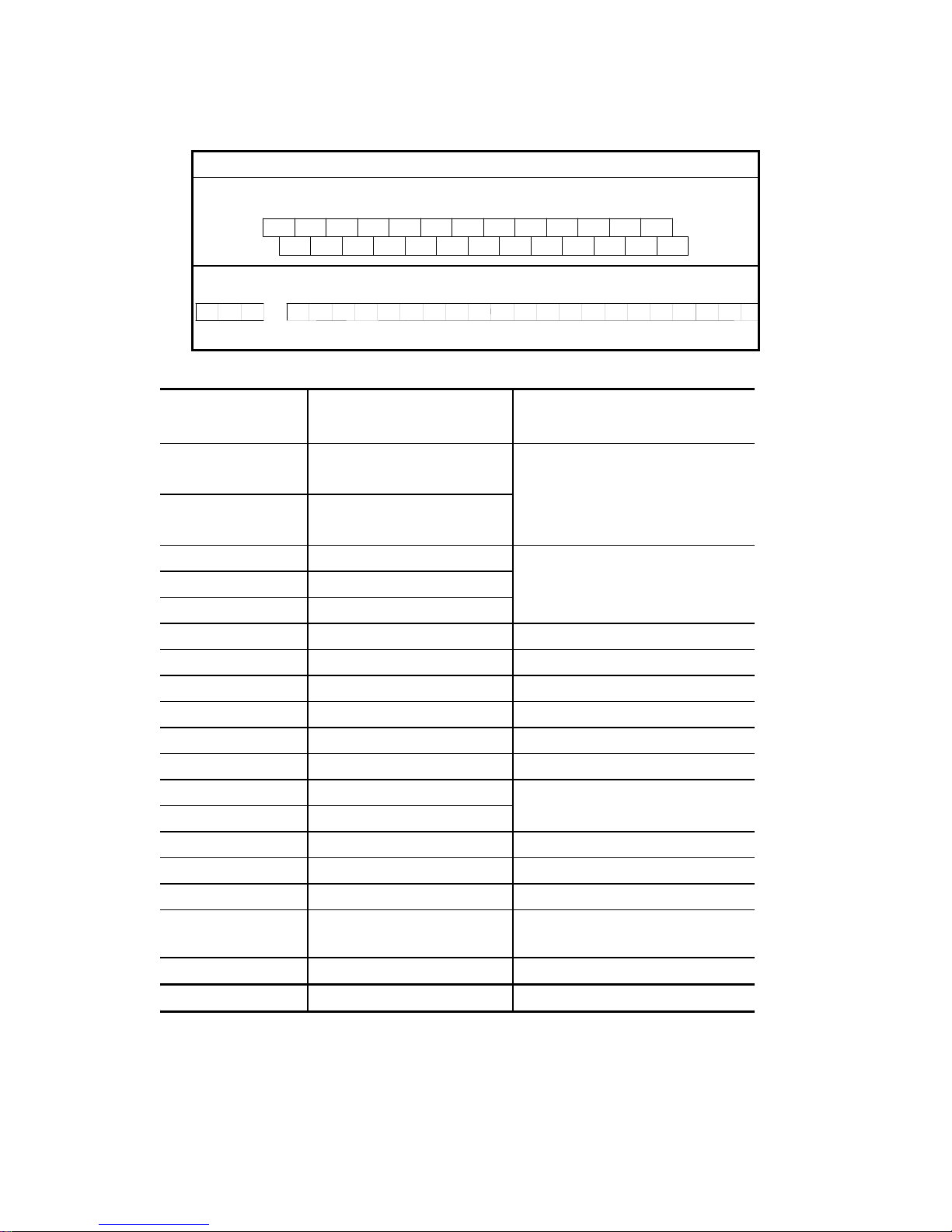

Nameplate Information

3HP, 440V AC Drive example

Output Frequency Range

Serial Number & Bar Code

VFD 022 A 43 A

Series name

AC Drive Model

Input Spec.

Output Spec.

Version type

Input voltage

21 : Single phase 220V class

23 : Three phase 220V class

43 : Three phase 440V class

A Series

Applicable motor capacity

007 : 0.75 kW

015 : 1.5 kW

022 : 2.2 kW

037 : 3.7 kW

055 : 5.5 kW

075 : 7.5 kW

MODEL : VFD022A43A

INPUT : 3PH 380-480V 50/60Hz 7.2A

OUTPUT : 3PH 0-480V 5.5A 4.2KVA 3HP

Frequenc y Range : 0.1-400Hz

022A43AT7010001

DELTA ELECTRONICS INC.

022A43A T 8 01 0001

110 : 11.0 kW

150 : 15.0 kW

185 : 18.5 kW

220 : 22.0 kW

MADE IN XXXXX

Production number

Production week

Production year

Factory control code

Model Name

Description of AC Motor Drive Model

Description of Serial Number

2

Page 7

Identification of components and accessories

1

2

7

3

4

1. Mounting screw holes

2. Heat sink

3. Digital keypad

4. Ventilation hole and blind plate

installation position

5. Nameplate label

6. Terminal cover

7. Input / output rating

8. Cooling fan

9. External braking resistor (optional)

5

6

9

8

Removing and Installing the Front Cover

Refer to the figure shown below to remove the front cover. To re-install the front cover,

simply reverse the indicated procedures.

♦0.75 - 1.5 KW (1-2HP) ♦2.2 - 3.7 KW (3-5HP)

The front cover snaps on. Pull as The front terminal block cover snaps

shown to remove the front cover. on. Pull as shown to release cover.

♦5.5 - 22.0 KW (7.5-30HP) ♦5.5 - 22.0 KW (7.5-30HP)

3

Page 8

Removing the Digital Keypad

The digital keypad can be easily removed from the AC motor drive unit as shown

below.

♦0.75 - 1.5 KW (1-2HP) ♦2.2 - 3.7 KW (3-5HP)

♦5.5 KW - 22.0 KW The 7.5 thru 30 HP units have screws holding the digital

keypads in place. To remove the keypad, first remove the screws and then lift the

keypad out of the AC drive.

♦5.5 – 7.5 KW (7.5-10HP) ♦11.0 – 22.0 KW (15-30HP)

♦Installing the Optional Remote Control Unit (RC-01)

4

Page 9

2

Installation and Wiring

Chapter 2 provides the information needed to properly install and wire the AC drive. Make sure that

the AC drive is wired according to the instructions contained in this chapter. The instructions should be

read and understood before the actual installation begins.

Installation Requirements

Wiring

Basic Wiring Diagram

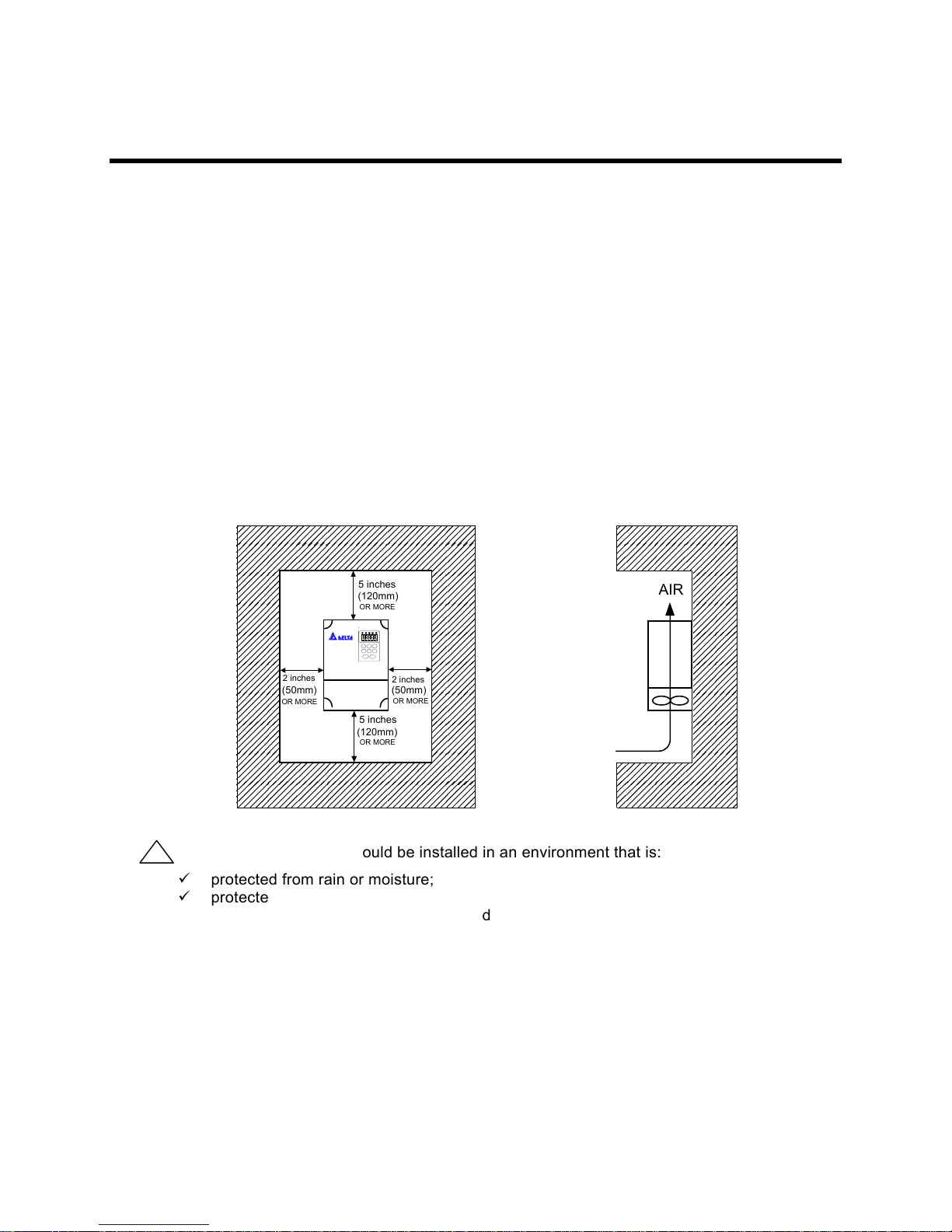

Installation Requirements

Install the AC drive vertically to provide proper ventilation. Adequate space is required between

the drive and a wall or other equipment. The figure below shows the minimum space needed. All

enclosures must provide adequate ventilation and the internal ambient temperature must be kept

C or below.

°

at 40

2 inches

(50mm)

OR MORE

Caution: The AC drive should be installed in an environment that is:

!

5 inches

(120mm)

OR MORE

5 inches

(120mm)

OR MORE

2 inches

(50mm)

OR MORE

AIR

protected from rain or moisture;

protected from direct sunlight;

protected from corrosive gases or liquids;

free from airborne dust or metallic particles;

free from vibration;

free from magnetic noise

temperature: -10°C to +40°C; R.H.: 0% to 90%; air pressure: 86kPa to 106 kPa

Violating the conditions listed above may void the warranty!

5

Page 10

Wiring

Main Circuit Wiring

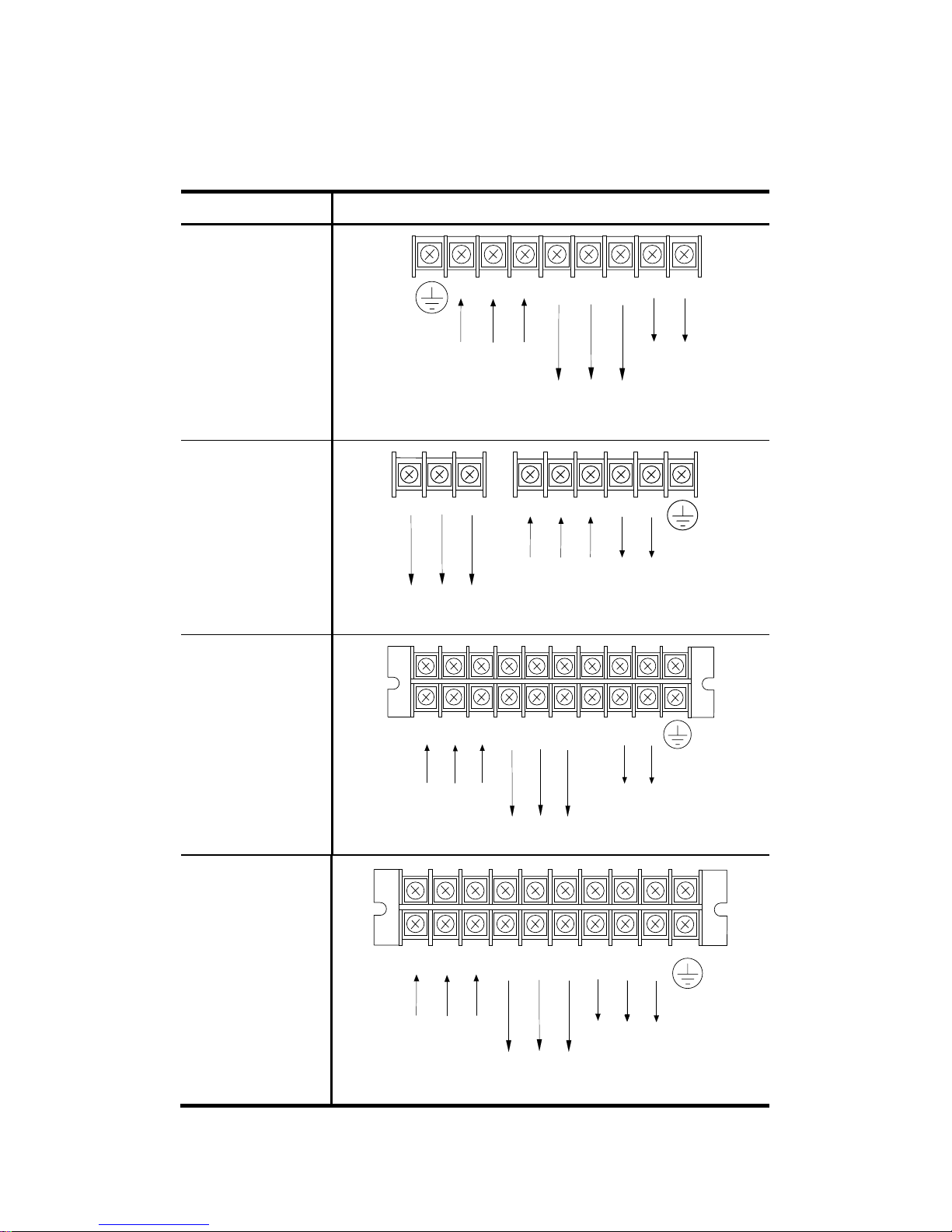

(1) Power terminal block designations

Power input and output may be connected via a nine or ten position terminal block. The

pin assignments are as follows:

Model Power terminal pin assignments

VFD007A21A

VFD007A23A

VFD015A21A

VFD015A23A

VFD007A43A

VFD015A43B

AWG: 22-16

Torque: 10kgf-cm

Earth

Ground

VFD022A21A

VFD022A23A

VFD037A23A

VFD022A43A

VFD037A43A

AWG:18-10

Torque: 16kgf-cm

RST UVWB1

AC Input Line

Terminals

UVW RST B1

Motor

Connection

Motor

Connection

AC Input Line

Terminals

Braking

Resistor

B2

Braking

Resistor

B2

Earth

Ground

VFD055A23B

VFD075A23B

VFD055A43B

VFD075A43B

AWG: 14-8

Torque: 20kgf-cm

VFD110A23A

VFD150A23A

VFD185A23A

VFD220A23A

VFD110A43A

VFD150A43A

VFD185A43A

VFD220A43A

AWG:10-2

Torque: 52kgf-cm

R

S

AC Input Line

Terminals

R/L1

AC Input Line

Terminals

S/L2

T/L3 +1

T U W N P/B1 B2V

Motor

Connection

Braking

6

Unit

Earth

Ground

Braking

Resistor

+2

N(-)

V/T2

U/T1

Motor

Connection

W/T3

Earth

Ground

Page 11

For VFD-A Series 15-30HP (VFD110A23A/43A, VFD150A23A/43A, VFD185A23A/43A,

VFD220A23A/43A), the ring terminals below are suggested to be used when proceeding

with main circuit wiring:

Vendor AWG Vendor Part NO.

Moles 2 (Red) G-975-14

4 (Yellow) F-966-14

6 (Blue) E-957-14

8 (Red) D-950-14

AMP : ECBT 2 320383

4 33469

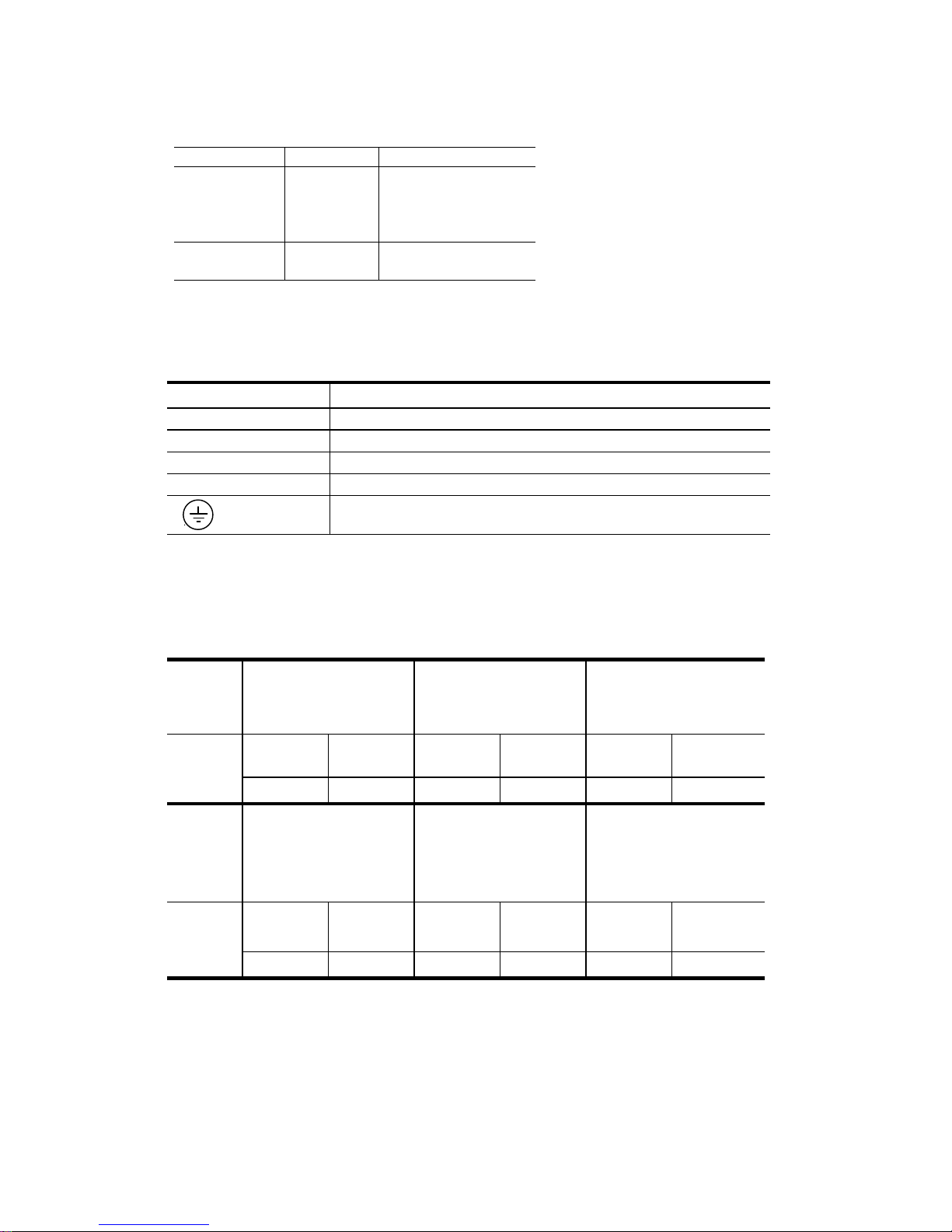

(2) Power block terminal designations

Terminals Description

R, S, T AC input line terminals

U, V, W Motor connection

P/B1, B2 Connection for the regenerative resistor (option)

P/B1, N Connection for the braking unit

Ground (connect appropriate ground wire to avoid electrical shock

and noise interference)

(3) Terminal dimensions

Model

Terminal

Spec.

Model

Terminal

Spec.

VFD007A21A⋅VFD007A23A VFD022A21A⋅VFD022A23A VFD055A23B⋅VFD075A23B

VFD037A23A

VFD015A21A⋅VFD015A23A

VFD007A43A⋅VFD015A43B VFD022A43A⋅VFD037A43A

Terminal

diameter

Terminal

width

Terminal

diameter

Terminal

width

VFD055A43B⋅VFD075A43B

Terminal

diameter

Terminal

width

M3 7 mm M3.5 8 mm M4 10 mm

VFD110A23A⋅VFD110A43A

VFD150A23A⋅VFD150A43A

VFD185A23A⋅VFD185A43A

VFD220A23A⋅VFD220A43A

Terminal

diameter

Terminal

width

M6 18.5mm

7

Page 12

(4) Attention:

!

The user must provide a circuit breaker or disconnect switch and fuses in accordance

with all applicable electrical codes.

Make sure that the leads are connected correctly and the AC drive is properly

grounded. (Ground leads should be at least the same size wire as the input leads R, S,

and T.)

Use ground leads that comply with AWG standards. Make the length of these ground

leads as short as possible.

Should several AC drive units be installed side by side, all the units should be

grounded directly to the ground poles. Do not form a loop with the ground leads.

Make sure that the power source supplies the correct voltage and is capable of

supplying the required current to the AC drive. Refer to specification for “Rated AC

Input Power.” Motor Voltage should match the line voltage.

When power is applied to the AC drive, the DC bus charge indicator LED will be on.

For single phase applications, the AC input line can be connected to any two of the

three input terminals R, S, T. A single phase VFD-A drive can be powered from three

phase as well as single phase.

Note: This drive is not intended for use with single-phase motors.

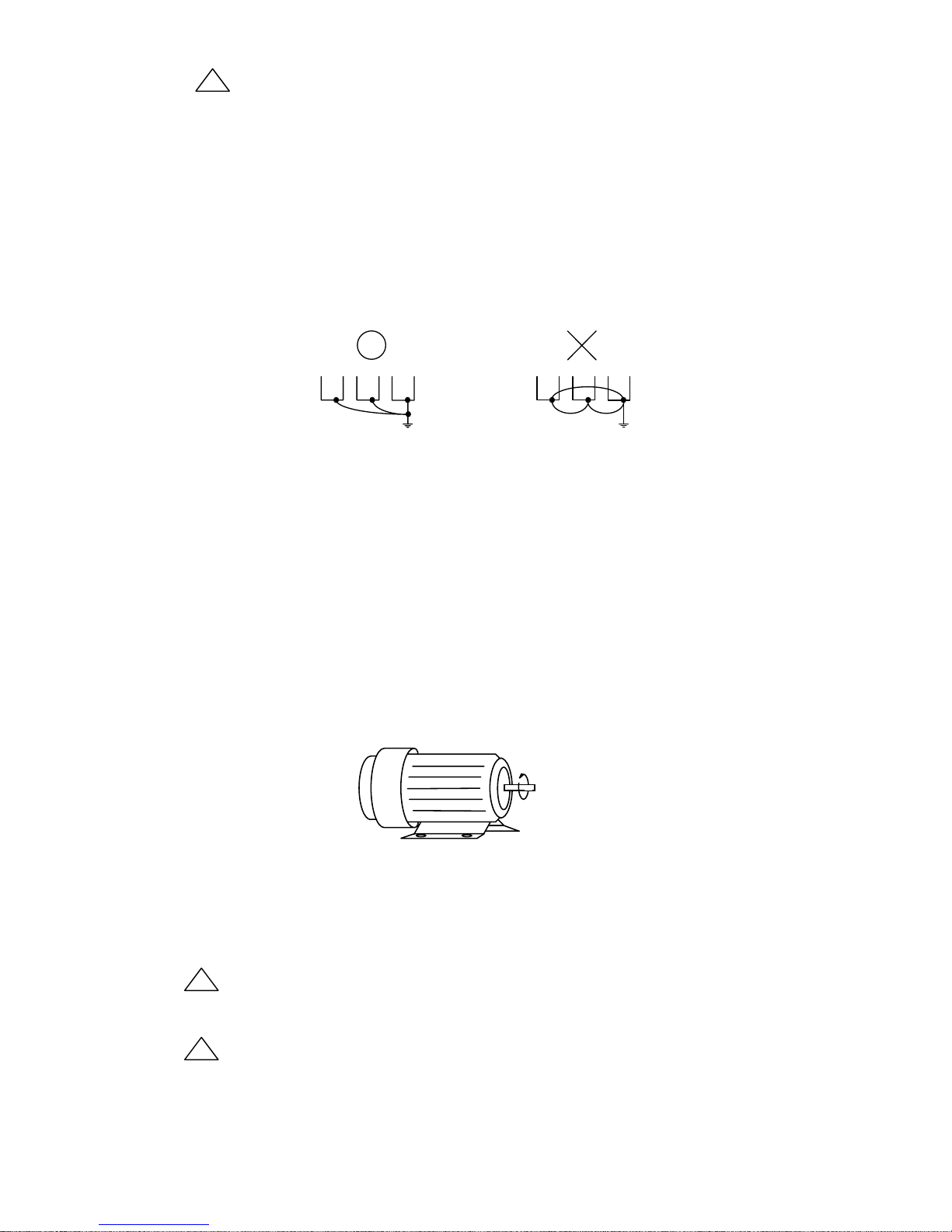

When the AC drive output terminals U, V, and W are connected to the motor terminals

U, V, and W, respectively, the motor will rotate counter-clockwise (viewed from the

shaft of the motor as shown below) if a forward operation command is entered (FWD

lamp is ON).

Forward

running

To reverse the direction of rotation, interchange any two connections of the three

motor leads.

The control lines and power lines (R,S,T;U,V,W;P,N,B1,B2) should be separated and

avoid parallel wiring lest it should generate noise and cause mis-operation.

Caution: Do not attach or remove wiring or connectors when power is applied to the

!

AC drive. Do not monitor the signals at any point on the circuit board while the AC

drive is in operation.

Caution: Do not connect the AC input to any of the U, V, W terminals, as this will

!

damage the AC drive.

8

Page 13

Control Circuit Wiring

G

(1) Control terminal block designations

The control leads must be routed separately from the power supply and motor leads.

They must not be fed through the same cable conduit.

220V/440V Class 1∼5HP (AWG: 28 – 14; Torque:4 kgf-cm)

RA

MI1

RB RC

MI2

+10V

MI3 DCM

Terminal Symbol

ACI

AVI

RST

REVFWD

ACMAFM

TRGEF SG-SG+DFM

MO1

+EV

MCMMO2

DCM

220V/440V Class 7.5∼30HP (AWG: 24 – 12; Torque:4 kgf-cm)

RA

MI1

MI2 MI3

REV

FWD

RST

MO1 ACM

MO2

DCMTRGEF S

MCM

+10VRB RC

AFM

XX

ACIAVI

(2) Control terminal block descriptions

Close Contacts

between Terminals

RA - RC Multi-function indication output

contact

RB - RC Multi-function indication output

contact

MI1 - DCM Multi-function input 1

MI2 - DCM Multi-function input 2 Refer to Chapter 5, Pr.39, 40, 41

MI3 - DCM Multi-function input 3

REV - DCM Reverse / Stop “Open”→stop, “Close” → Reverse

FWD - DCM Forward / Stop “Open”→stop, “Close” → Forward

RST - DCM Reset “Close” → Reset

EF - DCM External fault “Close” → External fault

DFM - DCM Digital frequency meter Digital frequency output (0, +10 V)

TRG - DCM Counter trigger input “Open”→“Close”:(counter value)+1

MO1 - MCM Multi-function PHC output 1 Refer to Pr.45, 46

MO2 - MCM Multi-function PHC output 2 (open collector output)

+10V - ACM Power supply for speed setting +10 V (20 mA max. output current)

AVI - ACM Analog voltage input 0 ∼10 V (Max. output freq.) input

ACI - ACM Analog current input 4 ∼20 mA (Max. output freq.) input

AFM - ACM

Analog frequency/current

meter

SG+ - SG- Serial communication interface RS-485 serial port

Terminals Use Function

Refer to Chapter 5, Pr.57

0 ∼10 V (Max. output freq.) output

SG+DFM

+EV - DCM Auxiliary control power source DC 20V ~ 24V (50mA Max.)

Note: Use twisted-shielded or twisted-pair shielded-lead wires for the control signal. It is

recommended to run signal wiring in a separate steel conduit. The shield wire should only be

connected at the drive.

9

Page 14

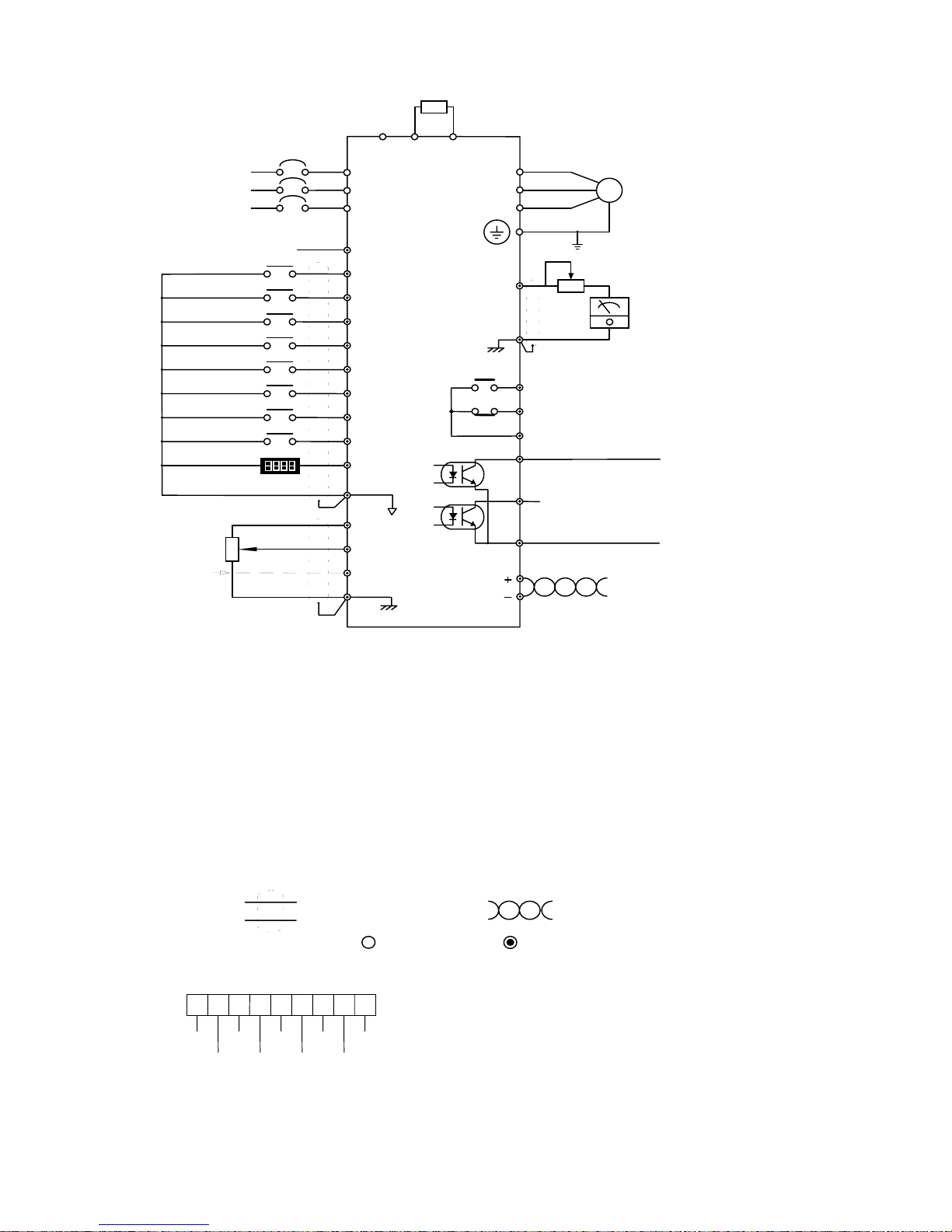

Basic Wiring Diagram

>

Braking resistior(option)

Power source 3 phase

200-240V or

380-480V

50/60Hz

DC 20V ~ 24V ( 50mA Max. )

Multi-function input 1

Multi-function input 2

Multi-function input 3

REV/STOP(REV/STOP)

FWD/STOP(RUN/STOP)

Reset

External fault

Counter trigger input

Digital frequency meter

Digital signal common

Frequency setting

0- +10V

1K

- 5K

Current input

4 - 20ma

5

Analog signal common

R

S

T

1

1

1

2

2

3

4

3

2

1

Use a disconnect

and fuse

R

S

T

+EV

MI1

MI2

MI3

REV

FWD

RST

EF

TRG

DFM

DCM

+10V

AVI

ACI

ACM

0V

P/B1

VFD-A

B2N

U

V

W

AFM

ACM

RA

RB

RC

MO1

MO2

MCM

SG

SG

Multi-function indication

output contact

}

RS-485 Serial interface

Motor

IM

Grounding

Analog frequency/current meter

7

AC 250V 2A below

DC 30V 2A below

Multi-function PHC output 2

48V 50mA below

Signal +

Signal -

8

}

PC

9

6

Multi-function PHC output 1

48V 50mA below

8

Notes A:

AC Motor Drive

1

Refer to Pr.39, 40, 41 on page 35.

2

Refer to Pr.38 on page 34.

3

Refer to Pr.45, 46 on page 38 and Pr.63, 64, 66 on pages 45 and 46.

4

Refer to Pr.43 on page 36.

5

Refer to Pr.00 on page 21, Pr.48, 49 on page 39.

6

Refer to Pr.42, 44 on pages 36 and 37.

7

Refer to Pr.57 on page 42.

8

Refer to Pr.45, 46 on page 38.

9

Refer to Pr.00, 01 on page 21 and Pr.77, 78 on page 50.

Notes B:

1.

2.

Terminal symbols :

indicates shielded leads and twisted-pair shielded leads.

shows main circuit; shows control circuit;

Wiring diagram and programming for the RC-01 external control.

AVI

+10V

16

151413 11

DCM

RST

FWD

REV

MI1

or

MI2

or

MI3

Program Parameters

Pr. 00 =d0001 Pr. 01 = d0001 or d0002

Pr. 38 = d0001 Pr. 39, Pr. 40 or Pr. 41 =d0003

Note: Pr. 41

Pr. 40 > Pr. 39

8654

AFM

ACM

10

Page 15

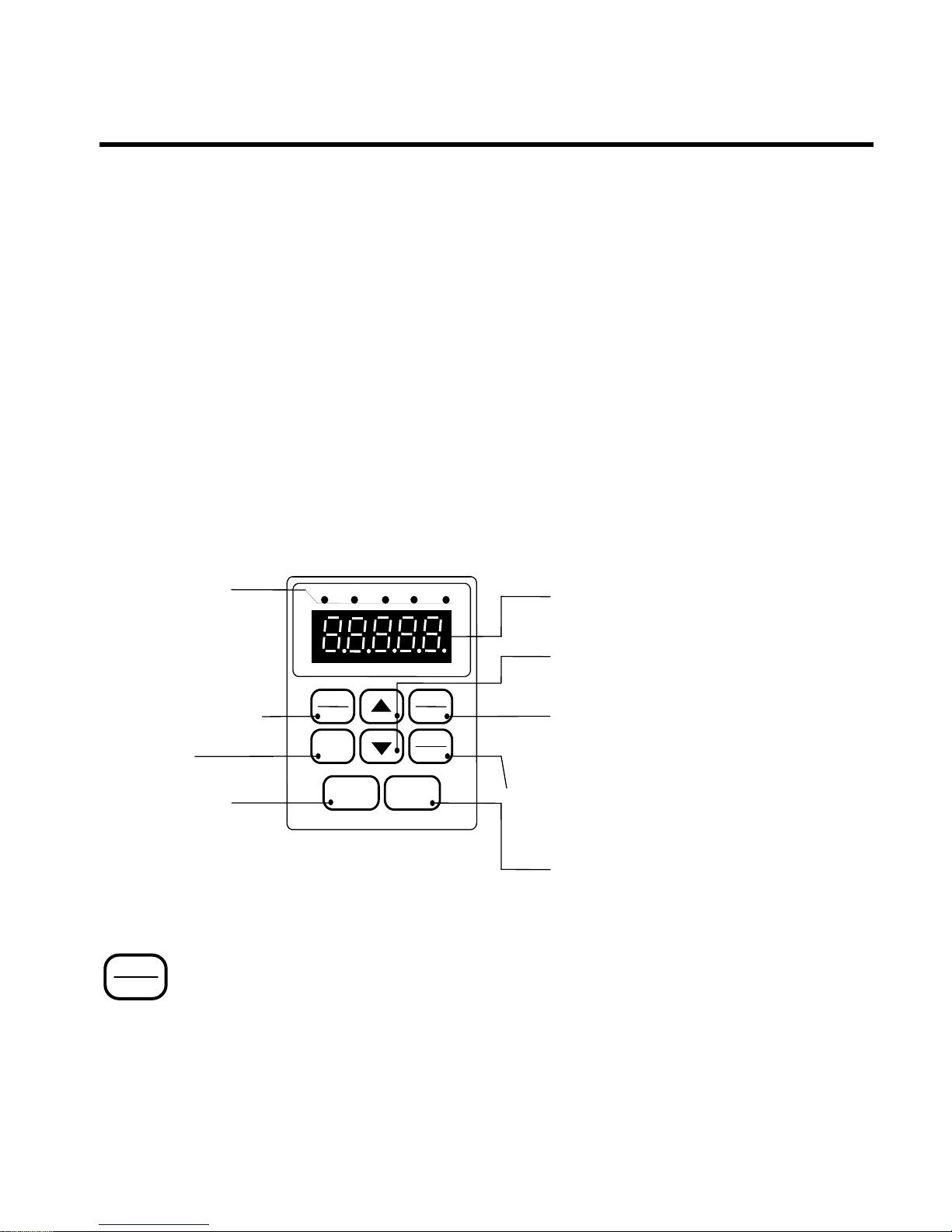

Digital Keypad Operation

,

Chapter 3 describes the various controls and indicators found on the digital keypad of the VFD-A

AC drive. The information in this chapter should be read and understood before performing the

start-up procedures described in Chapter 4.

Description of the Digital Keypad

Explanation of Screen Display

Digital Keypad Operating Modes & Programming steps

Description of the Digital Keypad

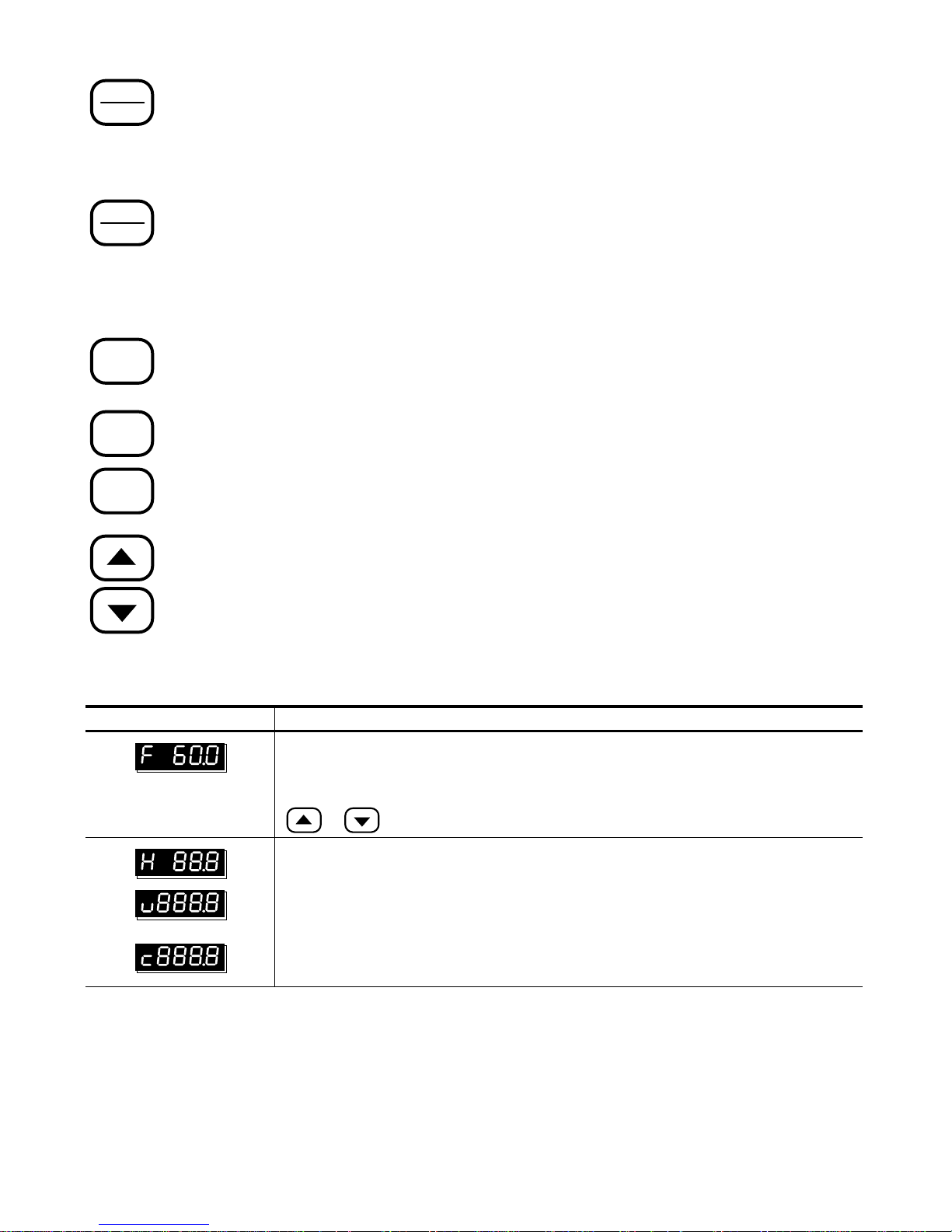

Digital Keypad Parts and Functions

This digital keypad module includes two parts: display panel and a keypad. The display panel

allows the user to program the AC drive, as well as view the different operating parameters. The

keypad is the user interface to the AC motor drive. Refer to the following figure for a description of

the different parts.

3

LED indication

Red lamp lights during RUN,

STOP, JOG, FWD, or

REV operation.

Forward / Reverse key

Selects FWD or REV operation.

Jog key

While pressing this key, jog

speed is available.

Run key

Starts inverter drive

operation.

PRGM

RESET

Program / Reset

Used to select the Normal mode of operation or to program the AC drive when either the

drive is running or has stopped. Switch to the PRGM mode to select a parameter or change

the setting of a parameter. If the AC drive has stopped due to a fault, press this button to

reset the drive.

RUN STOP JOG FWD REV

FWD

REV

JOG

RUN STOP

PRGM

RESET

FUNC

DATA

LED display

Indicates frequency, motor current

and alarm contents.

Up and down keys

Sets the parameter number or changes

the numerical data such as the

frequency reference.

Program / Reset key

Selects normal mode / program mode.

Displays the motor drive status, such

as output freq., selects the

parameters, FWD/REV or output

etc.

current

Function / Data key

Displays the motor drive status, such as frequency

program mode.

reference, output fr equency or output current under

the normal mode; or sets parameters under the

Stop key

Stops AC Motor Drive operation.

11

Page 16

FUNC

DATA

Function / Data

Displays information on the AC drive status such as the reference frequency, output frequency, or

output current in the normal mode.

While the drive is in the Program Mode, press this key once to display the current parameters.

After changing the parameters, press this key again to store the new parameters.

FWD

REV

JOG

RUN

STOP

Forward / Reverse

Used to toggle between forward and reverse operation.

Pressing this key will cause the motor to ramp down to 0 Hz and then ramp up to the preset

speed in the opposite direction. By default, the digital keypad controls the AC drive

forward/reverse operation. To control the forward/reverse operation via the control terminal block,

change the Pr.01 parameter to “d0001” or “d0002”.

Jog

Used to start the AC drive, then run at the jog frequency as set by the parameter specified under

Pr.23 [Jog Frequency].

Run

Used to start the AC drive operation. This key has no effect when the drive is set to terminal run.

Stop

Used to stop the AC drive operation.

Up / Down

Press the “Up” or “Down” button to change parameter settings. These keys may also be used to

scroll through different operating values or parameters.

Note: Pressing the “Up” or “Down” button momentarily changes the parameter settings in

increments. Press and hold down either of these keys to rapidly run through the possible

settings.

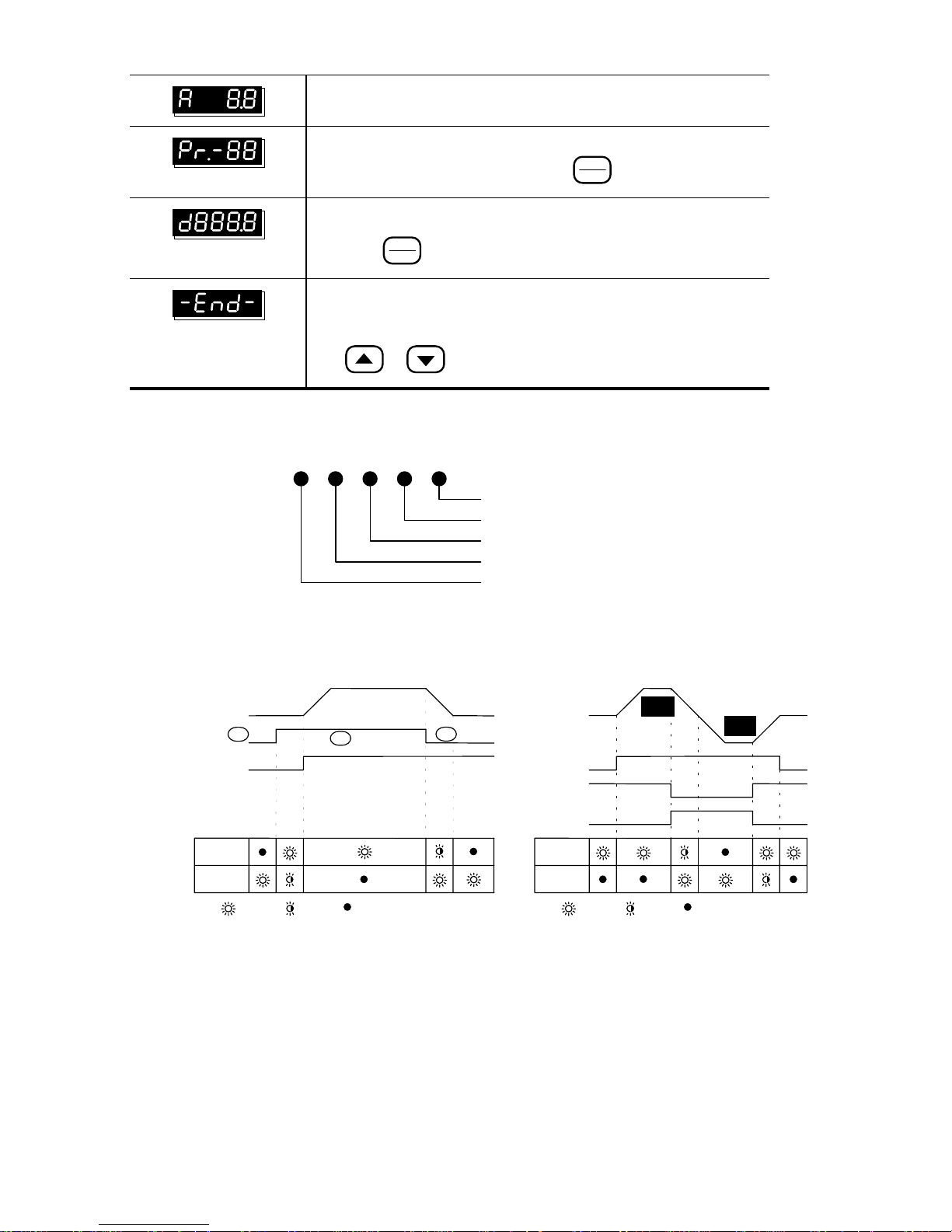

Explanation of Displayed Messages

Displayed Message Description

Displays the AC drive output frequency controlled by the Maximum Output Frequency

(Pr. 03), Jog Frequency (Pr. 16), or by the Multi-Function Input Terminals (Pr. 39-41).

If the frequency source originates from the Digital keypad, the user can use either the

or key to set the frequency.

Displays the output frequency present at terminals U, V, and W.

Displays the custom unit (v), where v = H x Pr.65.

Displays the internal counter value (C).

Note: Refer to Chapter 5, Pr.45, 46, 64 - 66 for a detailed description of the above.

12

Page 17

Displays the output current present at terminals U, V, and W

Displays the specified parameter number. The actual parameter

value may be displayed by pressing the

Displays actual value stored within the specified parameter.

Press the

The display will read “end” (as shown) for approximately 1 second if

Explanation of the LED Indicators

the input has been accepted. After a parameter value has been set,

the new value is automatically stored in memory. To modify an entry,

use

STOPRUN

FUNC

DATA

or key.

FWD

JOG

FUNC

DATA

key.

key to store the value of the specified parameter.

REV

Red lamp lights during REV operation.

Red lamp lights during FWD operation.

Red lamp lights during JOG.

Red lamp lights by pressing STOP.

Red lamp lights by pressing RUN.

RUN or STOP lamp indication is

defined by the following operation

Inverter output frequency

STOP

key

Frequency command

RUN

LAMP

STOP

LAMP

LIGHT

BLINK

RUN

key

LIGHT OFF

STOP

key

FWD or REV lamp changes indication is

defined by the following operation

OUTPUT

FREQ.

RUN

FWD

REV

FWD

LAMP

REV

LAMP

LIGHT

FWD

BLINK

LIGHT OFF

REV

13

Page 18

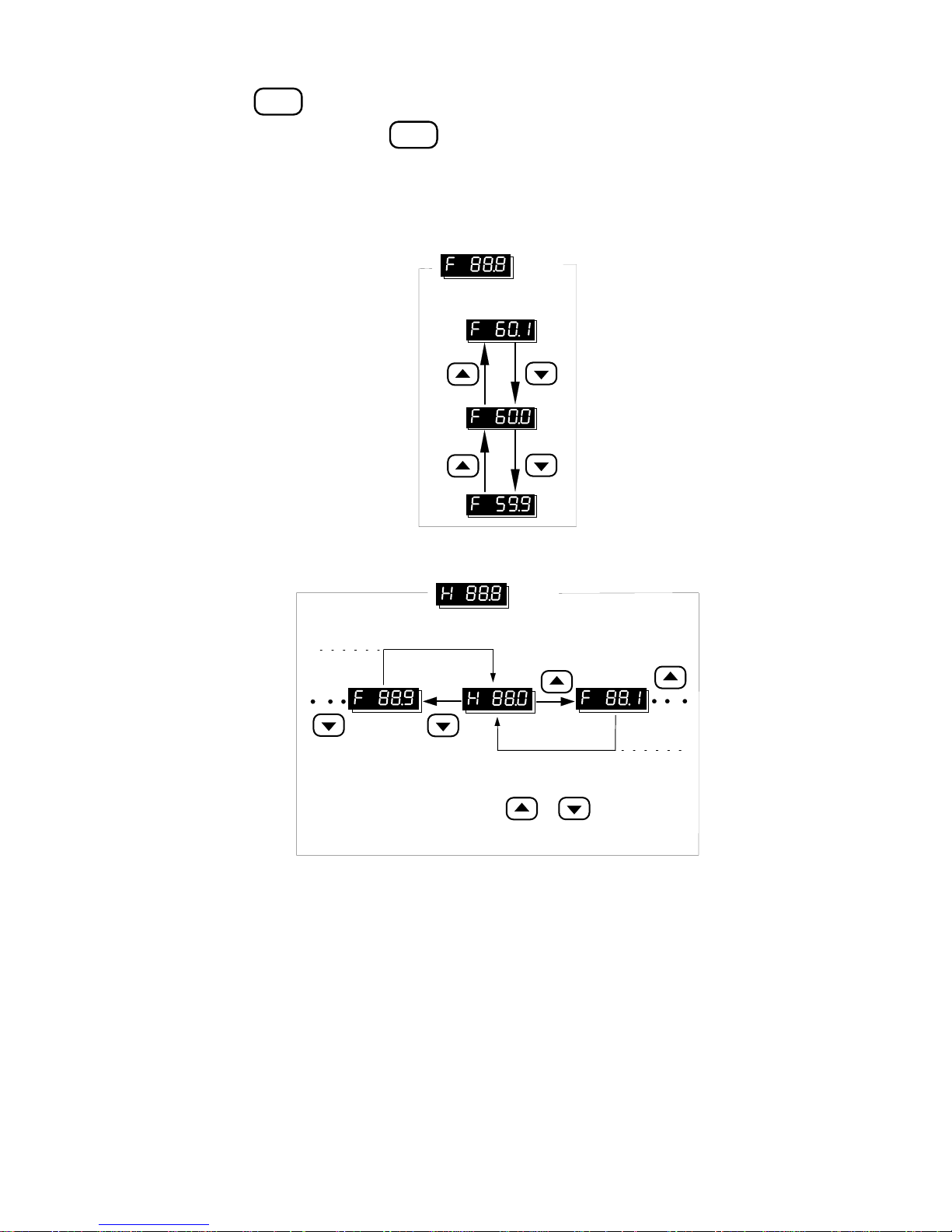

Digital Keypad Operating Modes & Programming steps

RUN

Pressing the

factory default setting. Use the

key after power on will cause the AC drive to operate at 60 Hz, which is the

STOP

key to halt operation. Refer to the Basic Wiring Diagram in

Chapter 2 for information on the wiring connection.

To change the operating frequency, proceed as follows:

The operating frequency may be changed in either the “STOP” or “RUN” mode.

MODE

MODE

Increase the frequency

Decrease the frequency

NOTES:

Display changes every time key is pressed.

or

14

Page 19

Setting parameters:

To operate the AC drive under optimum conditions, some parameter values may be modified

as required. During the “Run” mode, the following set of parameters may be modified: 10-14,

16-23, 44, 48-50, 52-55, 65. It is also possible to check all the parameter settings during

operation.

Indication after

power on.

Frequency command

PRGM

RESET

Press PRGM key

FUNC

DATA

Press FUNC key

Press PRGM key

PRGM

RESET

Press PRGM key, return to

the normal operation mode.

Output frequency

monitor

PRGM

RESET

FUNC

DATA

Press FUNC key

PRGM

RESET

Press PRGM key

Press up / down key to set

the parameter setting number.

FUNC

DATA

Press DATA key to display

parameter data.

Output current

monitor

FUNC

DATA

Press FUNC key

PRGM

RESET

Press PRGM key, return to

the normal operation mode.

(Data entered will not be stored.)

Press up / down key to set

the parameter data.

FUNC

DATA

Press DATA key to

store the data.

15

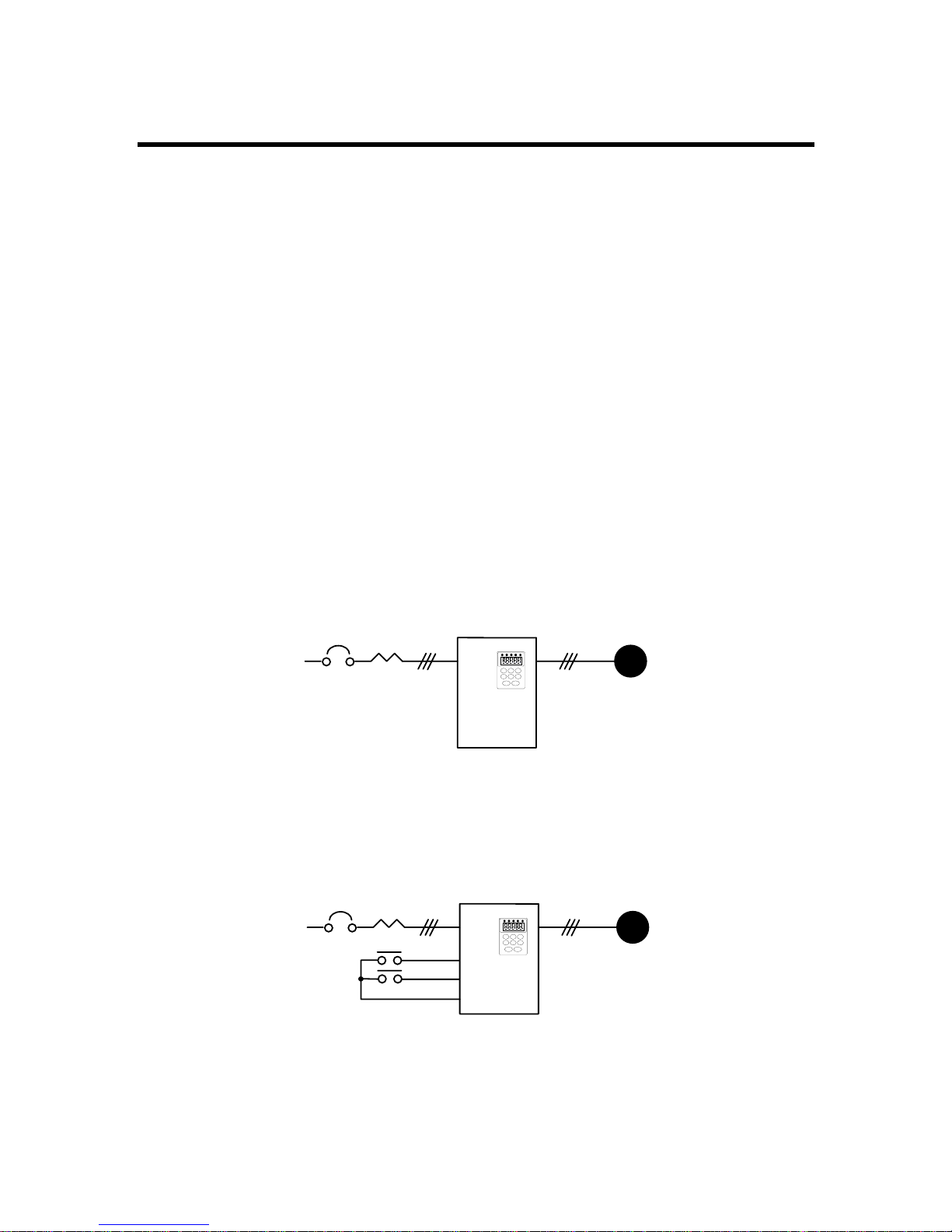

Page 20

4

Start-up

Initial Operation - Motor Disconnected

Verify that the AC power line, at the disconnect device, is within the rated power

of the AC drive.

Disconnect and lockout all incoming power to the drive.

Connect the AC drive to the power line.

Reconnect the incoming power to the drive.

Proceed as follows to select a mode of operation.

This chapter describes the steps needed to start the AC drive and typical adjustment

and verification procedures to ensure a simple and efficient start-up. The following

start-up procedures describe the most common parameter settings and system

configurations.

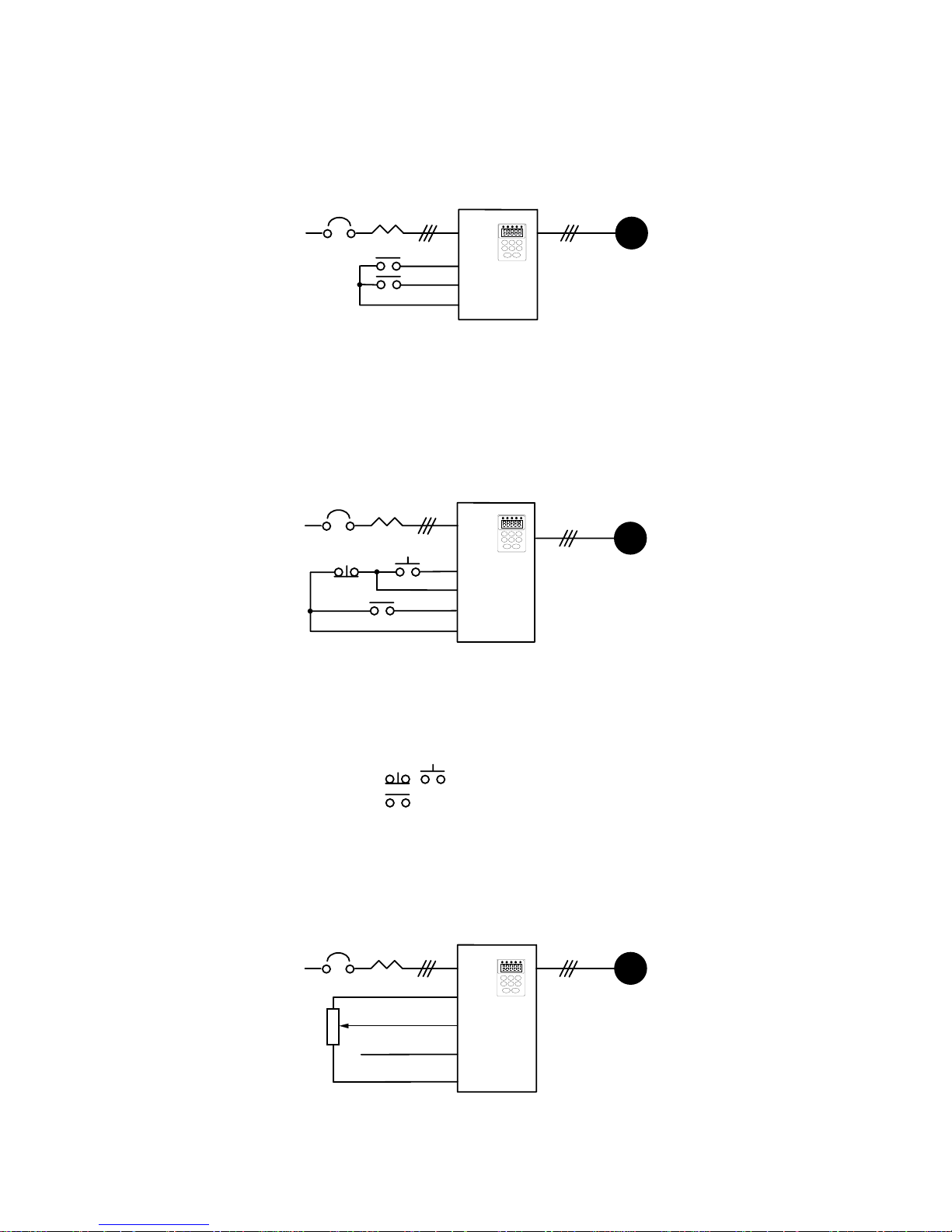

1. Operating frequency determined by the digital keypad,

Digital keypad enabled to control AC drive operation.

(Pr.00 = d0000, Pr.01 = d0000) (Factory default setting)

IM

2. Operating frequency determined by the digital keypad,

Control terminals enabled to control AC drive operation; ”Stop” key on digital

keypad is enabled.

Two wire “REV/STOP” and “FWD/STOP” remote control enabled.

(Pr.00 = d0000, Pr.01 = d0001, Pr.38 = d0000)

IM

REV/STOP

FWD/STOP

REV

FWD

DCM

16

Page 21

3. Operating frequency determined by the digital keypad;

Control terminals enabled to control AC Drive operation; ”Stop” key on digital

keypad is enabled.

Two wire “REV/FWD and “RUN/STOP” remote control enabled.

(Pr.00 = d0000, Pr.01 = d0001, Pr.38 = d0001)

IM

RUN/STOP

REV/FWD

FWD

REV

DCM

4. Operating frequency determined by the digital keypad;

Control terminals enabled to control AC Drive operation; ”Stop” key on digital

keypad is enabled.

Three wire sequence remote control is enabled.

(Pr.00 = d0000, Pr.01 = d0001, Pr.38 = d0002)

IM

STOP

REV/FWD

RUN

FWD

EF

REV

DCM

Note: Descriptions of the close / open function are as follows:

Example: To select Rev and Stop operations:

Rev / Fwd Contact “close” = reverse operation

Stop Contact “open” = stop

Momentary input

Maintained input

5. Operating frequency determined by analog input;

(DC 0 to +10 V) + (DC 4 to 20 mA)

Digital keypad enabled to control AC Drive operation.

(Pr.00 = d0001, Pr.01 = d0000)

3

2

0-10V Analog input

4-20mA Analog input

1

+10V

AVI

ACI

ACM

17

IM

Page 22

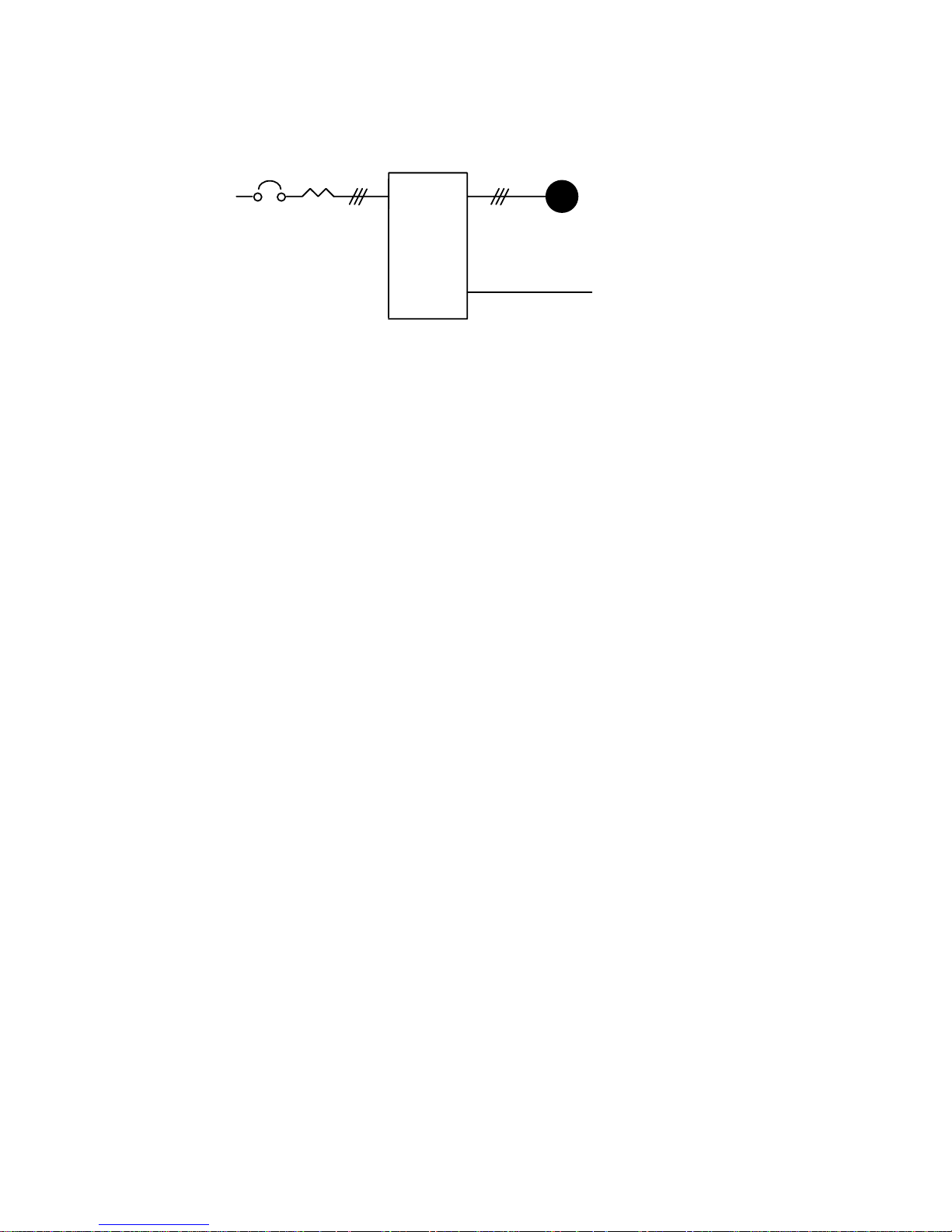

6. Operating frequency determined by remote control via the RS-485 serial interface;

RS-485 interface enabled to control AC Drive operation. “Stop” key on digital

keypad is enabled.

(Pr.00 = d0002, Pr.01 = d0003)

INVERTER

SG+,SG-

This completes the operation mode selection. Verify your operation mode works correctly,

then proceed to the next section for motor connection and initial operation.

Initial Operation – Setting Parameters and connecting the Motor.

1) Verify Minimum and Maximum Output Frequency Settings (Pr. 08 and 03) are

correct for your application.

2) Verify the Motor Stop Method (Pr.02) is correct for your application. If set to

“Ramp to Stop”, then verify the Accel/Decel Time Settings (Pr.10 and 11) are

correct for your application.

3) Disconnect and lock out all incoming power to the AC drive. A DC bus voltage

may be present at the terminal block for up to 1 minute after the power has been

removed from the drive.

IM

PC

4) Connect the motor to the terminals U, V, and W

5) Connect all applicable control wiring. Refer to the Control Circuit Wiring diagram

in Chapter 2.

6) Reconnect the incoming power to the AC drive.

7) Check for correct motor shaft rotation (counter clockwise when viewed from the

shaft).

8) Verify the Stop command is functioning by pressing the Stop Key on the Digital

Keypad or using your Control Terminal Stop method.

This completes the basic start-up. Depending on the application, some parameter values

may need to be modified. Refer to Chapter 5 for parameter settings.

18

Page 23

5

Parameter Settings

Chapter 5 describes all VFD-A drive parameters. These parameters are divided into

groups to simplify “start-up” programming procedures and minimize tuning.

AC Drive parameters and functions:

Operation Modes ....................................................................................21

V / F Data Settings ..................................................................................22

Accel. / Decel. Time Setting....................................................................25

Frequency Reference Setting ................................................................27

Operating and Protective Functions Setting ........................................28

External Control Terminal .....................................................................34

Torque and Slip Compensation ............................................................41

Overload Detection ................................................................................43

Display Functions ..................................................................................46

System Functions ..................................................................................47

19

Page 24

Operation Modes

Pr.00

Pr.01

Operating Frequency Source Select

Parameter # 00

Parameter Name

Factory Setting

Settings

d0001

d0002 Master Frequency determined by the RS-485 Interface.

This parameter is used to determine the AC drive command frequency source.

However, the actual AC drive command frequency may also be determined by [Jog

frequency], [Multi-step speed 1-7] or [Up / Down frequency], using the Multi-function

inputs 1, 2, and 3. Refer to Pr.39, 40, 41.

Operation Command Source Select

Parameter Name

Factory Setting

Settings

d0001 Operating instructions determined by the external terminal

d0002 Operating instructions determined by the external terminal

d0003 Operating instructions determined by the RS-485 interface,

d0004 Operating instructions determined by the RS-485 interface,

d0000 Master Frequency determined by the digital keypad

Parameter # 01

d0000 Operating instructions determined by the digital keypad

Master Frequency source select

d0000

Master Frequency determined by the analog input signal

(DC 0 to +10V) + (DC 4 to 20 mA)

Operation instructions source select

d0000

connections, Keypad STOP key is enabled

connections, Keypad STOP key is not enabled

Keypad STOP key is enabled

Keypad STOP key is not enabled

This parameter is used to determine the source of the AC Drive operating

instructions.

Pr.02

Motor Stop Method Select

Parameter # 02

Parameter Name

Factory Setting

Settings

d0001 Coast to stop

This parameter determines how the motor is stopped when the AC Drive receives a

valid stop command.

d0000 Ramp stop

Motor stop method

d0000

20

Page 25

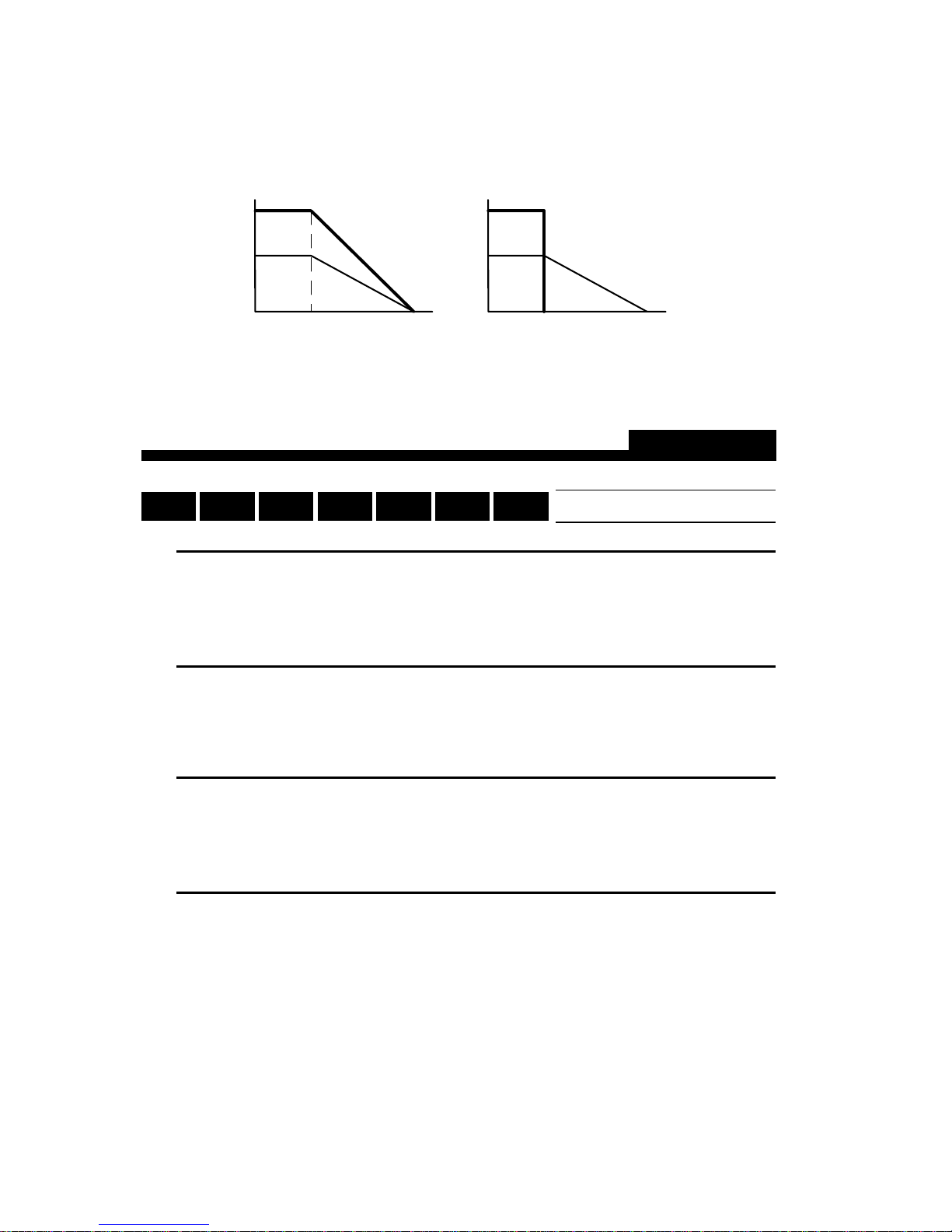

Ramp The AC drive output frequency decelerates in the time specified by Pr.11

or Pr.13, down to the frequency specified by Pr.08, and then the drive output

turns off.

Coast The AC drive is turned off immediately while the motor free runs until it

comes to a complete stop.

Hz

Frequency command

Speed

Stop command

Ramp

Setting value

sec

Frequency command

Hz

Stop command

Speed(Free running to stop)

?

Coast

sec

V / F Data Setting

Pr.09Pr.03 Pr.04 Pr.05 Pr.06 Pr.07 Pr.08

V / F Curve

Parameter # 03

Parameter Name

Factory Setting

Units

Parameter value

Maximum output frequency

d060.0 Hz

0.1 Hz

d050.0 - d400.0 Hz

This parameter determines the AC drive’s maximum output frequency. All the AC

drive analog inputs (0 - 10V, 4 - 20mA) are scaled to correspond to the output

frequency range. (See graph on Page 24)

Parameter # 04

Parameter Name

Factory Setting

Units

Parameter value

Maximum voltage frequency (Base frequency)

d060.0 Hz

0.1 Hz

d010.0 -d400.0 Hz

This value should be set according to rated frequency of the motor as indicated on

the motor nameplate (See graph on Page 24). Maximum voltage frequency

determines the volts per hertz ratio. For example, if the drive is rated for 460 VAC

output and the maximum voltage frequency is set to 60Hz, the drive will maintain a

constant ratio of 7.66 v/Hz.

21

Page 26

Parameter # 05

Parameter Name

Factory Setting

Units

Parameter value

Maximum output voltage

d220.0 V ; d440.0 for 440 V class.

0.1 V

d002.0 - d255.0 V ; d004.0 – d510.0 for 440 V class.

This parameter determines the Maximum Output Voltage of the AC drive. The

maximum output voltage setting must be smaller than or equal to the rated voltage

of the motor as indicated on the motor nameplate. (See graph on Page 24)

Parameter # 06

Parameter Name

Factory Setting

Units

Parameter value

Mid-point frequency

d001.5 Hz

0.1 Hz

d000.1 - d400.0 Hz

This parameter sets the Mid-point frequency on the V/F curve. It may be used to

determine the V/F ratio between the Minimum frequency and the Mid-point

frequency. (See graph on Page 24)

Parameter # 07

Parameter Name

Factory Setting

Units

Parameter value

Mid-point voltage

d010.0 V ; d020.0 for 440 V class.

0.1 V

d002.0 - d255.0 V ; d004.0 – d510.0 for 440 V class.

This parameter sets the Mid-point voltage on the V/F curve. It may be used to

determine the V/F ratio between the Minimum frequency and the Mid-point

frequency. (See graph on Page 24)

Parameter # 08

Parameter Name

Factory Setting

Units

Parameter value

Minimum output frequency

d001.5 Hz

0.1 Hz

d000.1 - d020.0 Hz

This parameter sets the minimum output frequency of the AC Drive. (See graph on

Page 24)

Parameter # 09

Parameter Name

Factory Setting

Units

Parameter value

Minimum output voltage

d010.0 V ; d020.0 for 440 V class.

0.1 V

d002.0 - d050.0 V ; d004.0 – d100.0 for 440 V class.

This parameter sets the minimum output voltage of the AC Drive.

22

Page 27

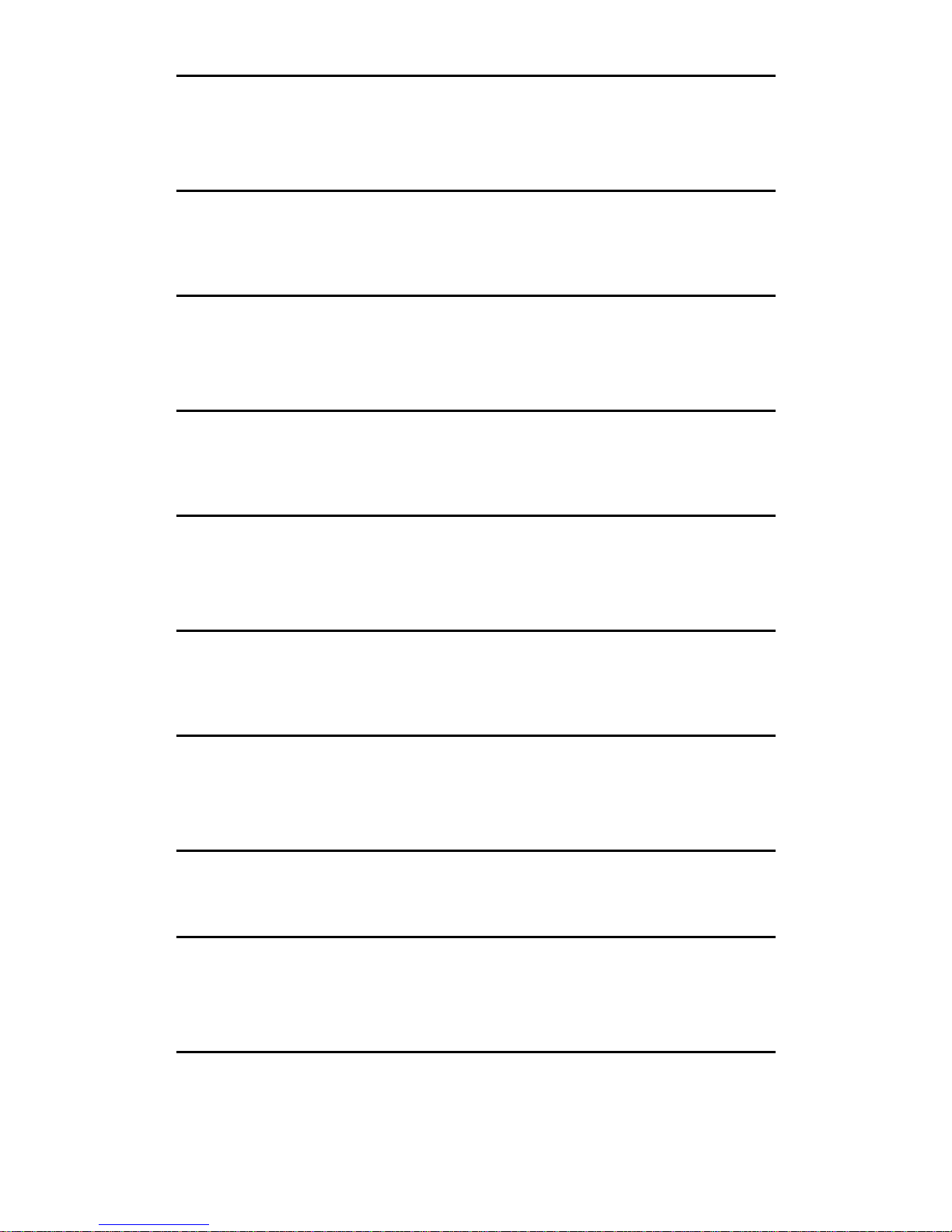

Voltage

Pr.05

Pr.09Pr.07

0

Voltage

Pr.05

Pr.07

Pr.09

Pr.06

Pr.08

Pr.08

Pr.03

Pr.04

Standard V/F Curve

Pr.06

Pr.04 Pr.03

Custom V/F Curve

Frequency

Frequency

Voltage

Pr.05

Pr.07

Pr.09

Pr.08 Pr.06 Pr.04 Pr.03

Fan/Pump V/F Curve

23

Frequency

Page 28

Commonly Used V / F Pattern Settings

(1) General

Factory Settings

Motor Spec. 60Hz

No.

Set value

Motor Spec. 50Hz

No.

Set value

V

220

10

1.5

60.0

(2) Fans and Pumps

Motor Spec. 60Hz

V

220

50

10

1.5

30

60.0

Pr.03

Pr.04

Pr.05

Pr.06

Pr.07

Pr.08

Pr.09

f

No.

Pr.03

Pr.04

Pr.05

Pr.06

Pr.07

Pr.08

Pr.09

f

60.0

60.0

220.0

1.5

10.0

1.5

10.0

Set value

60.0

60.0

220.0

30

50.0

1.5

10.0

V

220

10

1.5

Motor Spec. 50Hz

V

220

50

10

1.3

25

50.0

50.0

Pr.03

Pr.04

Pr.05

Pr.06

Pr.07

Pr.08

Pr.09

50.0

50.0

220.0

1.3

12.0

1.3

12.0

f

Set value

No.

Pr.03

Pr.04

Pr.05

Pr.06

Pr.07

Pr.08

Pr.09

50.0

50.0

220.0

25

50.0

1.3

10.0

f

(3) High Starting Torque

Motor Spec. 60Hz

V

220

23

18

1.5

3

60.0

f

No.

Pr.03

Pr.04

Pr.05

Pr.06

Pr.07

Pr.08

Pr.09

Set value

60.0

60.0

220.0

3.0

23

1.5

18.0

24

Motor Spec. 50Hz

V

220

23

14

2.2

1.3

50.0

Set value

No.

Pr.03

Pr.04

Pr.05

Pr.06

Pr.07

Pr.08

Pr.09

50.0

50.0

220.0

2.2

23.0

1.3

14

f

Page 29

Accel / Decel Time Setting

Pr.10 Pr.11 Pr.12 Pr.13

Accel / Decel Time Setting

Parameter # 10

Parameter Name

Factory Setting

Units

Parameter value

Acceleration Time 1

d010.0 Sec

0.1 Sec

d000.1 - d600.0 Sec

This parameter can be programmed while the drive is running.

This parameter is used to determine the time required for the AC drive to ramp from

0 Hz to its Maximum operating frequency (Pr.03). The rate is linear unless S Curve

is “Enabled.”

Parameter # 11

Parameter Name

Factory Setting

Units

Parameter value

Deceleration Time 1

d010.0 Sec

0.1 Sec

d000.1 - d600.0 Sec

This parameter can be programmed while the drive is running.

This parameter is used to determine the time required for the AC drive to decelerate

from the Maximum operating frequency (Pr.03) down to 0 Hz. The rate is linear

unless S Curve is “Enabled.”

Speed

Command frequency

Accel

Time

Pr.10

Decel

Time

or

Pr.11Pr.12

Time

or

Pr.13

25

Page 30

Parameter # 12

Parameter Name

Factory Setting

Units

Parameter value

This parameter can be programmed while the drive is running.

This parameter determines the time required for the AC drive to ramp from 0 Hz to

the Maximum operating frequency (Pr.03). The rate is linear unless S Curve is

“Enabled.” Acceleration time 1 is the default. A Multi-Function Input Terminal can

be programmed to select Acceleration time 1 or Acceleration time 2. See

parameters 39, 40, and 41.

Parameter # 13

Parameter Name

Factory Setting

Units

Parameter value

Acceleration time 2

d010.0 Sec

0.1 Sec

d000.1 - d600.0 Sec

Deceleration time 2

d010.0 Sec

0.1 Sec

d000.1 - d600.0 Sec

This parameter can be programmed while the drive is running.

This parameter determines the time for the AC drive to decelerate from the

Maximum operating frequency (Pr.03) down to 0 Hz. The rate is linear unless S

Curve is “Enabled.” Deceleration time 1 is the default. A Multi-Function Input

Terminal can be programmed to select Deceleration time 1 or Deceleration time 2.

See parameters 39, 40, and 41.

Pr.14

Jog Accel / Decel Time

Parameter # 14

Parameter Name

Factory Setting

Units

Parameter value

Jog Accel / Decel time select

d010.0 Sec

0.1 Sec

d000.1 - d600.0 Sec

This parameter can be programmed while the drive is running.

This parameter determines the time required for the AC Drive to ramp from 0 Hz to the

Jog frequency and the time required to ramp from the Jog frequency to 0 Hz.

This parameter must accompany with parameter P111 deceleration S curve. In order to

get the different results of S curves, just setting the parameter P111 to meet the

requirement.

26

Page 31

Pr.15

S-curve

Parameter # 15

Parameter Name

Factory Setting

Parameter value

S-curve setting

d0000 (Disabled)

d0000 - d0007

This parameter should be set during start-up. It is used to provide smooth

acceleration and deceleration. The S-curve may be set from 1 to 7.

Frequency

Pr.15 > d0001

"S curve Enabled"

S-curve characteristics Time S-curve characteristics Time

Accel Time

1 or 2

Decel Time

1 or 2

Time

Pr.15 = d0000

"S curve Disabled"

Time

Frequency Reference Setting

Pr.22Pr.16 Pr.17 Pr.18 Pr.19 Pr.20 Pr.21

Multi-speed Operation

Parameter # 16, 17, 18, 19, 20, 21, 22

Parameter Name

Factory Setting

Units

Parameter value

Multi-step speed setting 1, 2, 3, 4, 5, 6, 7

d000.0 Hz

0.1 Hz

d000.1 - d400.0 Hz

These parameters can be programmed while the drive is running.

The multi-function input terminals (refer to parameters 39, 40, and 41) are used to

select one of eight AC drive Multi-Speed output frequencies. The frequency is

determined by Pr.16 to 22.

27

Page 32

Pr.23

Jog Frequency

Parameter # 23

Parameter Name

Factory Setting

Units

Parameter value

This parameter can be programmed while the drive is running.

Jog frequency select

d006.0 Hz

0.1 Hz

d000.1 - d400.0 Hz

This parameter is used to set the AC drive jog frequency. Upon receipt of a jog

command the drive will ramp to the jog frequency.

Speed

JOG frequency

Pr.23

Time

JOG command

Accel

Time

Pr.14

ON

Decel

Time

Pr.14

Operating and Protective Functions Setting

Pr.24

REV Run Setting

Parameter # 24

Parameter Name

Factory Setting

Settings

d0000 REV run enabled

d0001 REV run disabled

REV run

d0000

This parameter determines whether the AC Drive can operate in the reverse

direction.

28

Page 33

Pr.25

Over-voltage Stall Prevention

Parameter # 25

Parameter Name

Factory Setting

Settings

d0000 Disable over-voltage stall prevention

Over-voltage stall prevention during deceleration

d0001

d0001 Enable over-voltage stall prevention

During deceleration, the motor DC bus voltage may exceed its maximum allowable

value due to motor regeneration. When Pr.25 is enabled and an over-voltage is

detected, the AC drive will cease to decelerate and will then maintain a constant

output frequency. The drive will only resume deceleration when the DC bus voltage

drops below the preset value.

DC bus

voltage

Over voltage

detection

level

Time

Time

Pr.26 Pr.27

Output

frequency

Over voltage stall prevention

Over-current Stall Prevention

Parameter # 26

Parameter Name

Factory Setting

Units

Parameter value

Over-current stall prevention during acceleration

d0170 %

1%

d0050 - d0200 %

During periods of rapid acceleration or excessive load on the motor, the AC drive

output current may increase abruptly and exceed the value specified by Pr.26.

When over-current occurs, the AC drive will cease to accelerate and will maintain a

constant output frequency until the current falls below the preset value. (The drive

will only resume acceleration when the current drops below the preset value.)

29

Page 34

Output

current

Pr.26

Overcurrent

detection

level

Output

frequency

Stall prevention during acceleration

Time

Time

Parameter # 27

Parameter Name

Factory Setting

Units

Parameter value

Over-current stall prevention during steady-state operation

d0170%

1%

d0050 - d0200%

During steady-state operation with the motor load rapidly increasing, the AC drive

output current may exceed the limit specified in Pr.27. When this occurs, the output

frequency will decrease to maintain a constant motor speed. The drive will

accelerate to the steady-state operating frequency only when the output current

drops below the level specified by Pr.27. A setting of 100% is equal to the rated

current of the drive.

Output

current %

Pr.27

Over current

detection

level

Output

frequency

Over-current stall prevention during steady-state operation

30

Time

Time

.

Page 35

Pr.28 Pr.29 Pr.30 Pr.31

Parameter # 28

Parameter Name

Factory Setting

Units

Parameter value

This parameter determines the DC current that will be applied to the motor during

braking when the Motor Stop Method is set to “RAMP stop” (refer to Pr.02). DC

braking current is set in increments of 1%. A setting of 100% is equal to the rated

current of drive.

Note: When setting this parameter, begin at a lower current level then increase the

value until sufficient holding torque is achieved. The rated motor current cannot be

exceeded.

Parameter # 29

Parameter Name

Factory Setting

Units

Parameter value

DC Braking Current (DC Injection Current)

DC braking current

d0000%

1%

d0000 - d0100%

DC braking time during start-up

d000.0 Sec

0.1 Sec

d000.0 - d005.0 Sec

This parameter determines the time duration that DC braking current will be applied

to the motor during the AC drive start-up.

Parameter # 30

Parameter Name

Factory Setting

Units

Parameter value

This parameter determines the time duration that DC braking current will be applied

to the motor when the Motor Stop Method is set to “Ramp Stop”.

Parameter # 31

Parameter Name

Factory Setting

Units

Parameter value

This parameter determines the frequency at which DC breaking will start during AC

drive deceleration. The frequency may be set in 0.1 Hz increments.

When the preset value is less than that specified by Pr.08 (Minimum output

frequency), the starting frequency for DC braking will be the Pr.08 frequency.

DC braking time during stopping

d000.0 Sec

0.1 Sec

d000.0 - d025.0 Sec

DC braking starting frequency

d000.0 Hz

0.1 Hz

d000.0 - d060.0 Hz

31

Page 36

Pr.08

Minimum output

frequency

DC brake starting frequency

Pr.31

Pr.29

DC braking current %

Pr.28

Pr.30

Pr.32 Pr.33 Pr.34 Pr.35

Momentary Power Loss Protection

Parameter # 32

Parameter Name

Factory Setting

Settings

d0000 Operation stops after momentary power loss

d0001

Momentary power failure operation mode

d0000

Operation continues after momentary power loss.

Speed search starts with the frequency reference value

d0002

Operation continues after momentary power loss.

Speed search starts with the Minimum output frequency, Pr.08

Note Multi-function Indication and Photocoupler outputs that are

programmed for “fault indication” will not be energized during

restart after a momentary power failure. (refer to Pr. 45 and 57)

This parameter determines the AC drive mode of operation after recovery from a

momentary power failure.

Parameter # 33

Parameter Name

Factory Setting

Units

Parameter value

Maximum allowable power loss time

d002.0 Sec

0.1 Sec

d000.3 - d005.0 Sec

If during a power failure the power loss is less than the time defined by Pr.33, then

the AC drive will resume operation (set by Pr.32). If the maximum allowable power

loss time is exceeded, the AC drive output power will remain off and must be reset

to resume operation (the fault indication will be set).

Parameter # 34

Parameter Name

Factory Setting

Units

Parameter value

Minimum base block time

d000.5 Sec

0.1 Sec

d000.3 - d005.0 Sec

When a momentary power loss is detected and the power failure is less than the

time set by Pr.33, the AC drive output will resume operation after the specified

period of time determined by Pr.34. This parameter should be set to a value where

the residual output voltage is nearly zero.

32

Page 37

Parameter # 35

Parameter Name

Speed Search Current Limit

Factory Setting

Units

Parameter value

d0150%

1%

d0030 - d0200%

Following a power failure, the AC drive will start its speed search operation, only if

the output current is greater than the value determined by Pr.35.

When the output current is less than that of Pr.35, the AC drive output frequency is

at a “speed synchronization point”. The drive will start to accelerate or decelerate

back to the operating frequency at which it was running prior to the power failure.

Speed search time increases as the current limit setting is reduced.

INPUT

POWER

OUTPUT

FREQUENCY

OUTPUT

VOLTAGE

Allowable maximum

power loss time

Pr.33

Pr.32

Speed search starts with

the frequency reference value

Min. baseblock time

= d0001

Pr.34

Speed synchronization

detection

Speed search

operation

INPUT

POWER

OUTPUT

FREQUENCY

OUTPUT

VOLTAGE

Allowable maximum

power loss time

Pr.33

Pr.32

Speed search starts with

minimum starting frequency

Min. baseblock time

= d0002

Pr.34

Pr.36 Pr.37

Reference Frequency Upper / Lower Limit

Parameter # 36

Parameter Name

Factory Setting

Units

Parameter value

Reference frequency upper limit setting

d400.0 Hz

0.1 Hz

d000.1 - d400.0 Hz

Determines the upper limit of the reference frequency in 0.1 Hz increments.

Parameter # 37

Parameter Name

Factory Setting

Units

Parameter value

Reference frequency lower limit setting

d000.0 Hz

0.1 Hz

d000.0 - d400.0 Hz

Determines the lower limit of the reference frequency in 0.1 Hz increments.

33

Page 38

Output frequency

Pr.36

Pr.37

Input frequency

External Control Terminal

Pr.38

External Control Terminal Configuration

Parameter # 38

Parameter Name

Factory Setting

Settings

d0000 FWD / STOP, REV / STOP

2-wire / 3-wire operation control selection

d0000

d0001 FWD / REV, RUN / STOP

d0002 3-WIRE operation control mode

This parameter determines the control functions and operating modes available

through the external control terminals. The following configurations are available:

Pr.38 Control terminal wiring diagram

d0000

Two wire

FWD/STOP

REV/STOP

FWD

"Open" : Stop; "Close" : FWD Run

REV

"Open" : Stop; "Close" : REV Run

FWD / STOP

REV / STOP

DCM

VFD-A

d0001

FWD

Two wire

REV / FWD

RUN / STOP

d0002

Three wire

RUN/STOP

REV/FWD

STOP

RUN

REV/FWD

"Open" : Stop; "Close" : Run

REV

"Open" : FWD; "Close" : REV

DCM

FWD

(Run command, Runs when "Close)

EF

(Stop command, stops when "Open")

REV ( REV/FWD Run select

"Open" : FWD Run

"Close" : REV Run)

DCM

VFD-A

VFD-A

34

Page 39

Pr.39 Pr.40 Pr.41

Multi-function Input Terminals

Parameter # 39 (MI1), 40 (MI2), 41 (MI3)

Parameter Name

Factory Setting

Settings

d0000 Multi-step speed command 1

Multi-function input terminals 1, 2, 3

d0000, d0001, d0002

d0001 Multi-step speed command 2

d0002 Multi-step speed command 3

d0003 Jog frequency reference select

d0004 Accel/decel speed inhibit command

d0005 First and second accel/decel time select

d0006 External baseblock (NO-contact input)

d0007 External baseblock (NC-contact input)

d0008 Up command

d0009 Down command

Parameter setting value limit Pr.41> Pr.40> Pr.39.

Description

d0000∼d0002: The multi-step speed commands 1 to 3 are used to determine a

command frequency via the multi-step speed settings (Pr.16 to Pr.22).

Pr.-16

Pr.-17

Pr.-18

Pr.-19

Pr.-20

Pr.-21

Pr.-22

step 1

step 2

step 3

step 4

step 5

step 6

step 7

Master frequency

reference

MI1-DCM

MI2-DCM

MI3-DCM

Hz

step 1

ON

ON

step 2

ON

ON

step 3

step 4

ON ON

step 5

ON

step 6

ON

ON

ON

ON

ON

step 7

Time

d0003: When “Closed,” the jog reference frequency is selected.

d0004: When “Closed,” the output frequency remains constant.

d0005: When “Open,” the AC drive accelerates / decelerates according to the

values set by ACCEL time 1 and DECEL time 1 (Pr.10,11).

When “Closed,” the AC drive accelerates / decelerates according to the values set

by in ACCEL time 2 and DECEL time 2 (Pr.12, 13).

d0006: When “Closed,” the AC drive output is turned off. (The reference frequency

is held constant.)

d0007: When “Open,” the AC Drive output is turned off. (The reference frequency

is held constant)

35

Page 40

d0008: When “Closed,” the AC Drive output frequency is increased.

d0009: When “Closed,” the AC Drive output frequency is decreased.

FWD RUN COMMAND

UP COMMAND

DOWN COMMAND

MAX. OUTPUT FREQUENCY

MIN. OUTPUT FREQUENCY

UP TO FREQUENCY SETTING SIGNAL

Note: When both the Up and Down command terminals are “closed”, the AC

drive neither accelerates or decelerates. The output frequency is also held

constant.

Pr.42

Analog Meter Output Select

Parameter # 42

Parameter Name

Factory Setting

Settings

d0000 Analog frequency meter ( 0 to [Maximum Frequency])

d0001

Analog meter output select

d0000

Analog current meter (0 to 250% of the rated drive output

current)

This parameter selects the analog Meter output for either output frequency or output

current (refer to Control Terminals AFM, ACM).

Pr.43

Digital Output Frequency Multiplier Factor

Parameter # 43

Parameter Name

Factory Setting

Units

Parameter value

This parameter determines the multiplying factor for the AC drive digital output

frequency (+10V pulse, 50% duty cycle) at the digital output terminals (DFM, DCM).

The number of output pulses per second on DFM is equal to the AC drive output

frequency multiplied by Pr.43. The maximum output frequency is 1.2 KHz or less.

Digital output frequency multiplier factor

d0001

1

d0001 - d0020

36

Page 41

Pr.44

Analog Output Gain Setting

Parameter # 44

Parameter Name

Factory Setting

Units

Parameter value

Analog output gain setting

d0100%

1%

d0001 - d0200%

This parameter can be programmed while the drive is running.

This function regulates the voltage level of the analog signal output (frequency or

current) at the AFM output terminal, which is then fed to the meter.

AFM ACM

Analog frequency meter

AFM ACM

Analog current meter

The analog voltage output is proportional to the

AC drive output frequency. The AC drive

maximum operating frequency (Pr.03) is

equivalent to 10 VDC. If necessary, adjust the

output level using Pr.44 Analog Output Gain.

The analog voltage output is proportional to the

AC drive output current. 10 VDC of analog voltage

is equivalent to 2.5 times the AC drive rated

output current. If necessary, adjust the output

level using Pr.44 Analog Output Gain.

DFM DCM

DC10V

Digital frequency meter

T1

T2

T1 / T2 (duty cycle) = 50%

The number of output pulses per second is equal

to the output frequency multiplied by [Pr.43].

Note: The digital frequency output should be less

than 1.2 KHz.

37

Page 42

Pr.45 Pr.46

Parameter Name

Factory Setting

Settings

d0001 Pre-set frequency attained

d0002 Desired frequency attained

d0003 Count down complete

d0004 Non-zero speed

Control terminals MO1 and MO2 are open collector outputs. Terminal MCM is

signal return (refer to Control Terminal Block description).

Multi-function Output Terminal Setting

Parameter # 45 (MO1), 46(MO2)

Multi-function photocoupled output terminals: MO1, MO2

d0000, d0001

Units

d0000 AC drive operational

d0005 Over-torque detection

d0006 Baseblock indicator

d0007 Low-voltage detect indicator

d0008 AC drive operation mode

d0009 Fault indicator

None

Please see

descriptions below.

Description

AC drive operational: This terminal will be “closed” when there is output from the

AC drive or when the FWD or REV run command is input.

Pre-set frequency attained: This terminal will be “closed” once the AC drive

attained the specified operating frequency.

Desired frequency attained: This terminal will be “closed” once the AC drive

attained the desired operating frequency.

Count down complete: This terminal will be “closed” when the AC drive’s internal

counter, triggered by the external input TRG, starts countdown and reaches d0001.

Set the count down value using Pr.63 and Pr.66.

Non-zero speed: This terminal will be “closed” when the AC drive output frequency

is greater than the minimum output frequency.

Over-torque detection: This terminal will remain “closed” as long as over-torque is

detected. Set the over-torque detection level using Pr.61 and the over-torque

detection time using Pr.62.

Baseblock indicator: This terminal will always be “closed” as long as the AC drive

output is turned off.

Low-voltage detect indicator: This terminal will be “closed” when the AC drive

detects a low voltage state.

AC drive operation mode: This terminal will be “closed” when the AC drive is

operated by commands via the RS-485 serial interface or control terminals.

Fault indicator: This terminal will be “closed” when a major fault is detected.

38

Page 43

Pr.47

Pr.48 Pr.49

Desired Frequency Attained Setting

Parameter # 47

Parameter Name

Factory Setting

Units

Parameter value

Used to select a specified frequency, set in increments of 0.1 Hz. ( See Pr.45, 46 )

Analog Input Setting for Output Frequency Range

Parameter # 48

Parameter Name

Factory Setting

Units

Parameter value

Desired frequency attained setting

d000.0 Hz

0.1 Hz

d000.0 - d400.0 Hz

Maximum output frequency voltage setting

d010.0 V

0.1 V

d000.0 - d010.0 V

This parameter can be programmed while the drive is running.

Sets the input signal voltage level (0 – 10V) that corresponds to the maximum

output frequency (Pr.03). Used in conjunction with Pr.49, this parameter may be

used to set the analog input for frequency command curve setting. (See graph on

next page)

Parameter # 49

Parameter Name

Factory Setting

Units

Parameter value

Minimum output frequency voltage setting

d000.3 V

0.1 V

d000.0 - d010.0 V

This parameter can be programmed while the drive is running.

Sets the input signal voltage level (0 – 10V) that corresponds to the minimum

output frequency (Pr.08). (See graph on next page)

Note: The absolute value of the difference between the settings of Pr.48 and Pr.49

should be greater than or equal to 3.

39

Page 44

Output frequency Output frequency

Pr.03

Pr.03

Pr.08

Pr.49 Pr.48

0V

10V

Pr.08

0V

Pr.49Pr.48

10V

Analog input signal levelAnalog input signal level

The analog input signal level is the combined input signals from the analog voltage input

(AVI) (0 - 10 V) and analog current input (ACI) (4 - 20 mA). The voltage corresponding to

the analog current input (4 - 20 mA) and analog input signal level is defined as follows:

Voltage corresponding to the

analog input signal level

10 V

5 V

0 V

4 mA

Analog current frequency command

12 mA

20 mA

An example of such application may be illustrated as follows:

Output frequency Output frequency

Pr.03

= 60.0 Hz

Pr.08

= 1.5 Hz

Pr.48 = 5.0 V

Pr.49

= 0 V

Pr.50

Pr.51

60 Hz

1.5 Hz

Reserved

Reserved

0V

5V

Analog input signal level

10V

Pr.03

Pr.08

Pr.48 = 5.0 V

Pr.49

40

= 60.0 Hz

= 1.5 Hz

= 1 V

60 Hz

1.5 Hz

0 V

5 V1 V

Analog input signal level

10 V

Page 45

Torque and Slip Compensation

Pr.52 Pr.53

Parameter Name

Factory Setting

Parameter value

Motor Current Setting

Parameter # 52

Motor rated current

d0100%

Units

1%

d0030 - d0120%

This parameter can be programmed while the drive is running.

This parameter must be set according to the motor specification found on its

nameplate. This setting will limit the AC drive output current in order to prevent the

motor from overheating. When the motor current exceeds this value, the output

frequency will be reduced until the current drops below this limit.

Parameter # 53

Parameter Name

Factory Setting

Units

Parameter value

Motor no-load current

d0040

1%

d0000 - d0099%

This parameter can be programmed while the drive is running.

This parameter sets the motor no-load current in 1% increments.

Pr.54

Torque Compensation Setting

Parameter # 54

Parameter Name

Factory Setting

Units

Parameter value

Auto torque-compensation

d0000

1%

d0000 - d0010%

This parameter can be programmed while the drive is running.

This parameter may be set so that the AC drive will increase the voltage output

during startup to obtain a higher initial starting torque. This additional torque will be

present until the master operating frequency is attained.

Be careful while setting the value for Pr.54. If the value is too high, the motor might

!

overheat or be damaged.

41

Page 46

Pr.55

Slip Compensation

Parameter # 55

Parameter Name

Factory Setting

Units

Parameter value

Slip compensation

d000.0

0.1%

d000.0 - d010.0%

This parameter can be programmed while the drive is running.

This parameter is used to compensate for the nominal slip within a range of 0.0 -

10.0%. When the output current of the AC drive is greater than the motor no-load

current (Pr.53), the AC drive will adjust its output frequency according to Pr.55.

Example: If Pr. 04 is set at 60Hz and Pr. 55 is set at 10%, the drive will increase the

output frequency up to 6% under full load conditions to compensate for slip.

Pr.56

Pr.57

Reserved

Multi-function Indication Output Contact

Parameter # 57

Parameter Name

Factory Setting

Settings

d0001 AC drive operational

d0002 Pre-set frequency attained

d0003 Desired frequency attained

d0004 Non-zero speed

d0005 Over-torque detection

d0006 Baseblock indicator

This parameter sets the multi-function programmable relay contact outputs. The

contact ratings are 250Vac @ 2A, 30Vdc @ 2A. Set parameter Pr.57 according to

the table listed above.

d0000 Fault indicator

Multi-function indication output contact

d0000

RA-RC(NO), RB-RC(NC)

42

Page 47

Overload Detection Setting

Pr.58 Pr.59

Parameter Name

Factory Setting

Settings

d0001 Active with special motor

d0002 Inactive

To prevent self-cooling motors from over-heating while running at low speeds, this

parameter may be set to limit the AC drive output power.

Electronic Thermal Overload Relay

Parameter # 58

Motor derating curve during temperature change

d0002

Units

None

d0000 Active with standard motor

d0000:

The electronic thermal characteristics behave in accordance with a

reduced torque motor (standard motor).

d0001:

The electronic thermal characteristics behave in accordance with a

constant torque motor (special motor).

Parameter # 59

Parameter Name

Factory Setting

Units

Parameter value

Electronic thermal characteristics selection

d0060

1 Sec

d0030 - d0300 Sec.

This parameter determines the time required to activate the I

protection function. The activation time may be defined according to short, standard

and long time ratings.

Operation

time (min)

5

4

3

60Hz or more

50Hz

10Hz

5Hz

2

t electronic thermal

2

1

0 80 120 140 20020 40 60 100

43

160 180

Load

factor (%)

Page 48

Pr.60 Pr.61 Pr.62

Parameter # 60

Parameter Name

Factory Setting

Settings

d0001

d0002

d0003

d0004

This parameter determines the AC drive operation after an over-torque is detected.

Over-torque detection is based on the following: When the output current exceeds

the over-torque detection level (Pr.61, factory preset value = 150%) and the overtorque detection time (Pr.62, factory preset value = 0.1 second, hysteresis fixed at

10%). The Multi-function PHC output 1 and 2 may be set to indicate an over-torque

condition. Refer to Pr.45, 46. The Multi-function Indication Output (Pr. 57) may also

be set to indicate an over-torque condition.

Over-torque Detection Setting

Over-torque detection mode select

d0000

d0000 Over-torque detection not enabled

Over-torque detection during constant speed operation,

operation halted after over-torque detection

Over-torque detection during constant speed operation,

operation continues after over-torque detection

Over-torque detection during operation, operation halted

after over-torque detection

Over-torque detection during operation, operation continues

after over-torque detection

Parameter # 61

Parameter Name

Factory Setting

Units

Parameter value

This parameter sets the over-torque detection level at 1% increments. The AC

drive rated current is regarded as 100%.

Parameter # 62

Parameter Name

Factory Setting

Units

Parameter value

This parameter sets the over-torque detection time in units of 0.1 second.

Over-torque detection level

d0150

1%

d0030 - d0200%

Over-torque detection time

d000.1 Sec

0.1 Sec

d000.1 - d010.0 Sec

44

Page 49

Pr.63

Pre-set Count Down Value Attained Setting

Parameter # 63

Parameter Name

Factory Setting

Parameter value

Pre-set count down value attained

d0001

d0001 - d9999

When the VFD-A internal counter, triggered by the external input TRG, counts down

and reaches this specified value, the specified output terminal (MO1) will be closed

(assuming that Pr.45 is set to d0003). The output terminal (MO1) will be opened

when the internal counter reaches the value specified in Pr.66. (See chart below)

Pr.66

Count Down Value Setting

Parameter # 66

Parameter Name

Factory Setting

Units

Parameter value

Count down value setting

d0001

1

d0001 - d9999

This parameter determines the value of the VFD-A internal counter. The internal

counter may be triggered by an external signal via the external input TRG terminal.

Upon completion of the countdown, the specified output terminal (MO2) will be

closed (assuming that Pr.46 is set to d0003). (See chart below)

The timing chart is illustrated as follows:

Application example:

Control

terminal

Control

terminal

Control

terminal

Pr.45 = d0003

Pr.46 = d0003

c 10 c 09

TRG

MO1

MO2

Pr.63 = d0005

Pr.66 = d0010

c 08

2

T

1

T

c 07 c 06 c 05 c 04 c 03 c 02 c 01 c 10

"CLOSED"

"CLOSED"

c 09 c 08

Note: The minimum On time for T2 is 2 msec or more.

The minimum cycle time for T1 is 6 msec. or more.

45

Page 50

Display Functions

Pr.64

Function Display Setting

Parameter # 64

Parameter Name

Factory Setting

Settings

d0001 Displays the user-defined setting (v)

d0002 Displays the value of the internal counter (c)

Displays the contents of the monitored item as follows:

H: Displays the actual operation frequency

v: Displays the user-defined setting ( where v = H x Pr.65 )

c: Displays the value of the internal counter. This counter is triggered by an

external signal provided via the external input TRG. When the counter reaches

d0000 during count down, the multi-function output terminal MO1 or MO2 will be

“closed” (Refer to Pr.45, 46). The counter will use the value contained in Pr.66 as

its starting point when another count down is to be executed.

d0000 Displays the actual operating frequency (H)

Displays the contents of the monitored item

d0000

Pr.65

Coefficient K Setting

Parameter # 65

Parameter Name

Factory Setting

Units

Parameter value

Coefficient of line speed

d001.0

0.1

d000.1 - d200.0

This parameter can be programmed while the drive is running.

Coefficient K determines the multiplying factor for the user-defined setting (v).

The value of the user-defined setting (v) is calculated and displayed as follows:

Display value of v = output frequency x K. The maximum value that can be

displayed is

the display value multiplied by 10.

. If the value of v exceeds 9999, the actual value is equal to

46

Page 51

System Functions

Pr.67 Pr.68 Pr.

69

Pr.70

Parameter # 67, 68, 69

Parameter Name

Factory Setting

Units

Parameter value

Skip frequency 1, 2, 3

d000.0 Hz

0.1 Hz

d000.1 - d400.0 Hz

This parameter determines the three skip frequencies, which in conjunction with

Pr.70 [Skip Frequency Band] will cause the AC drive to skip operation at these

frequency ranges. (See graph below)

Parameter # 70

Parameter Name

Factory Setting

Units

Parameter value

Skip frequency band

d000.1

0.1 Hz

d000.1 - d020.0 Hz

Skip Frequencies 1 to 3 Setting

This parameter determines the frequency band of a given [Skip frequency]. The

actual band is 2 x Skip frequency band, half of which is above and the other half is

below the [Skip frequency] setting. Setting this parameter to 0.1 to disable all skip

frequencies. (See graph below)

Output frequency

Pr.67

Skip frequency

set point

Pr.68

Pr.69

0

Decelerating

Accelerating

Adjustable range

Command

Pr.70

Frequency to

be jumped

Pr.70

frequency

47

Page 52

Pr.71

PWM Frequency Setting

Parameter # 71

Parameter Name

Factory Setting

Settings

d0001 fc = 3 KHz

PWM frequency setting

d0005

d0002 fc = 6 KHz

d0003 fc = 9 KHz

d0004 fc = 12 KHz

d0005 fc = 15 KHz