Page 1

Automation for a Changing World

Delta Sensorless Vector Control

Compact Drive

VFD-E Series

www.deltaww.com

Page 2

Features

Modular Design

Modular structure and extension with

optional cards

Standard MODBUS Protocol

Standard MODBUS protocol via RS-485

Built-in EMC Filter

(230V single-phase and 460V 3-phase)

Efciently reduces electromagnetic

interference

Compact Design

Space saving and easy DIN rail mounting

with optional DIN rail adapter

Optional Fieldbus Modules

Provide connection to a variety of networks,

including PROFIBUS, DeviceNet and CANopen

RFI Switch for IT Mains

Removable "Y"

capacitor to use with

IT mains supplies

Easy DC Bus Sharing

Multiple VFD-E units can be connected in

parallel to share regenerative braking energy.

It prevents over-voltage and stabilizes the

DC bus voltage

Complete Protection Functions

High precision current detection, full overload

protection (oL, oL1 and oL2), overvoltage/

overcurrent stall prevention, short circuit

protection, reset after fault, speed search

function and motor overheat protection by

PTC

Flexible Extension

Via optional cards, such

as I/O card, Relay card,

PG (Encoder) card and

USB card, to meet your

application requirements

Removable Keypad

The standard keypad

acts as a status monitor.

More functions, including

parameter modication,

RUN/STOP, speed

change, and status

display, are available via

an optional keypad

1

Page 3

Built-in PLC Function

Side-by-side Installation (40 oC)

PLC programming and editing capability

without the need of an actual PLC

Power Range

Single-phase115 V series: 0.2 ~ 0.75 kW (0.25 ~ 1 hp)

Single-phase 230 V series: 0.2 ~ 2.2 kW (0.25 ~ 3 hp)

3-phase 230 V series: 0.2 ~ 15 kW (0.25 ~ 20 hp)

3-phase 460 V series: 0.4 ~ 22 kW (0.50 ~ 30 hp)

High-efciency cooling and exible spacing

Easy Maintenance

Removable cooling fan for easy maintenance

Applications

Vacuum compressor

Outstanding overload capability of VFD-E

reduces the impact of sudden load increase

to the vacuum compressor

Escalator

Built-in PLC function and

multi-step speed control

provide energy saving

escalator performance

and save the cost of

purchasing a host

controller

2

Page 4

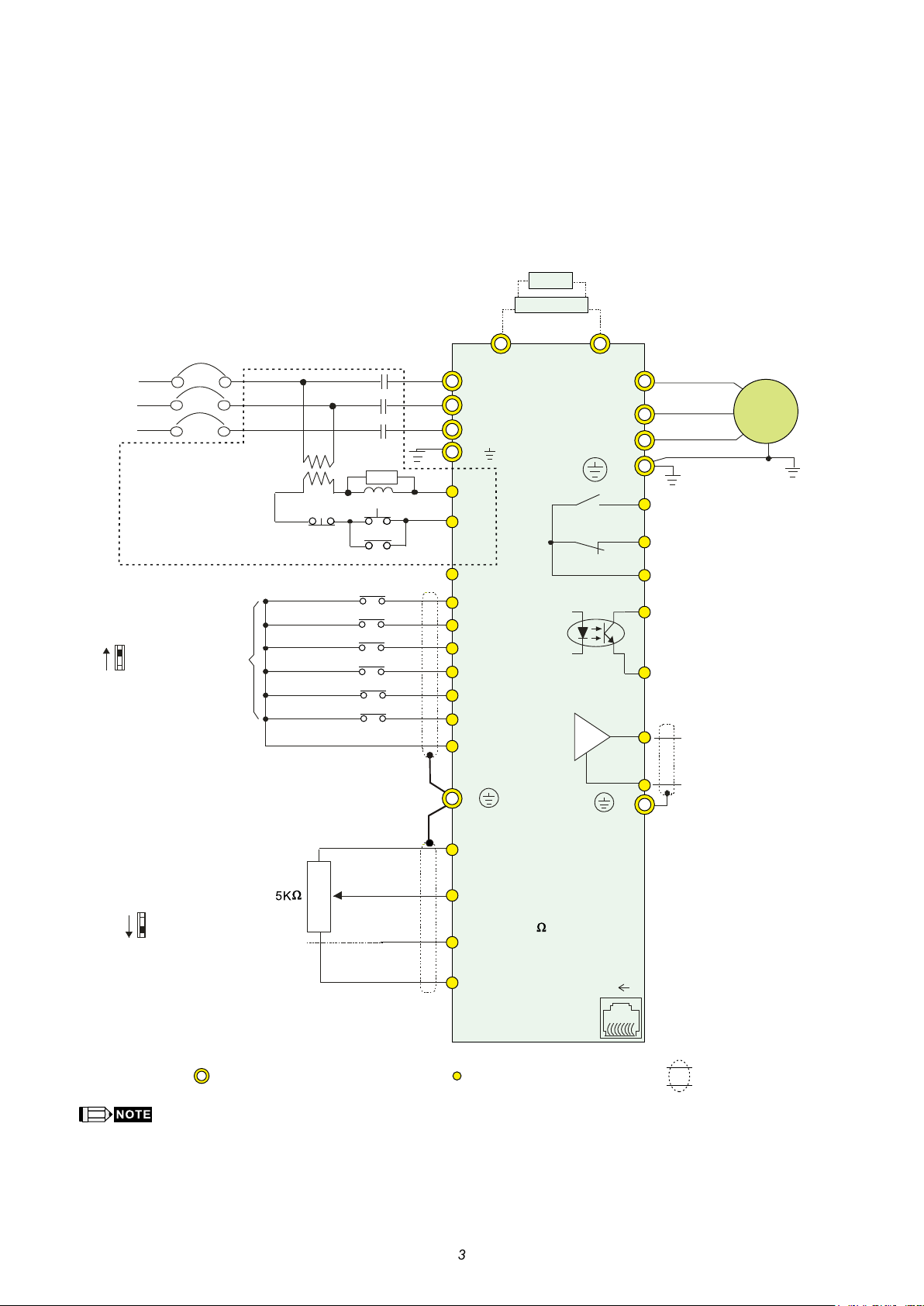

Standard Wiring Diagram

Fus e /N F B (No Fuse B reake r)

R(L1)

S( L2)

T( L3)

Reco mmended Circu i t

when power s uppl y

is turned O FF b y a

fault out put

If th e f ault occ urs, t h e

cont a ct w ill be O N to

turn off th e pow e r a nd

protect t he power sys tem .

Fact or y set ti n g:

NPN M o de

NPN

Sw1

PNP

Pl ease refer to F ig ur e 7

fo r w i r in g of N PN

mod e a n d PNP

mod e .

F act or y s et ting:

ACI Mod e

AVI

Sw2

ACI

ACI/AVI s w itch

Wh en swi tc h ing to AVI,

it in dicates AVI2

Fac to r y

se ttin g

OF F

FWD/St o p

REV/St o p

Mu lti-s tep 1

Mu l ti-s tep 2

Mu lti-s tep 3

Mu lti-s tep 4

Dig ital Si gnal Common

3

2

1

SA

MC

ON

MC

BR

BUE

brake unit

( optional)

+

R(L1)

S( L2)

T( L3)

E

RB

RC

+2 4V

MI1

MI2

MI3

MI4

MI5

MI6

DCM

E

+1 0V

Po w e r supply

+10V 20m A

AVI

Ma ster Fr equency

0 to 10 V 47K

ACI /AVI2

4-20mA/ 0 -10V

ACM

brake re si stor

(opti o na l)

-

U(T 1)

V( T2)

W(T3)

E

RA

RB

RC

MO1

MCM

AFM

ACM

E

F ac to r y se tt ing: output frequency

RS-485 se rial interface

(N O T for VFD *E* C m odels)

1: R eserv ed

2: EV

3: G ND

4: S G -

5: S G +

6: R eserv ed

7: R eserv ed

1

8

8: EV

Mo t o r

IM

3~

Mu lti-funct ion contac t output

Refer to c hapter 2.4 fo r det a ils .

Fac to r y se tt ing is

ma lfunct ion indica t ion

F ac to r y se tt ing:

Driv e is in operatio n

48V50m A Max.

Mu l ti-funct ion

Photocoupler Ou tput

Analog Mu lti- fun c tion Ou t put

Ter minal

factory setti ng : Analo g fr eq.

/ c ur rent me t e r

Analog S ignal co mmo n

For VFD*E* C m o dels,

please ref er to fi gu re 8 .

0~1 0VDC/2 mA

Ma in c irc ui t (pow e r) t e rm inals Contr ol c ircu it ter minal s

Sh ielded l eads & Cable

It is recommended to install a circuit breaker at the control terminal to protect the circuit from an operation

abnormality or sudden power outage.

The protection circuit uses the multi-function output terminal of the AC motor drive for connection. When an

abnormal condition (closed contact) occurs, the external power supply is disconnected to protect the power

system of the AC motor drive.

3

Page 5

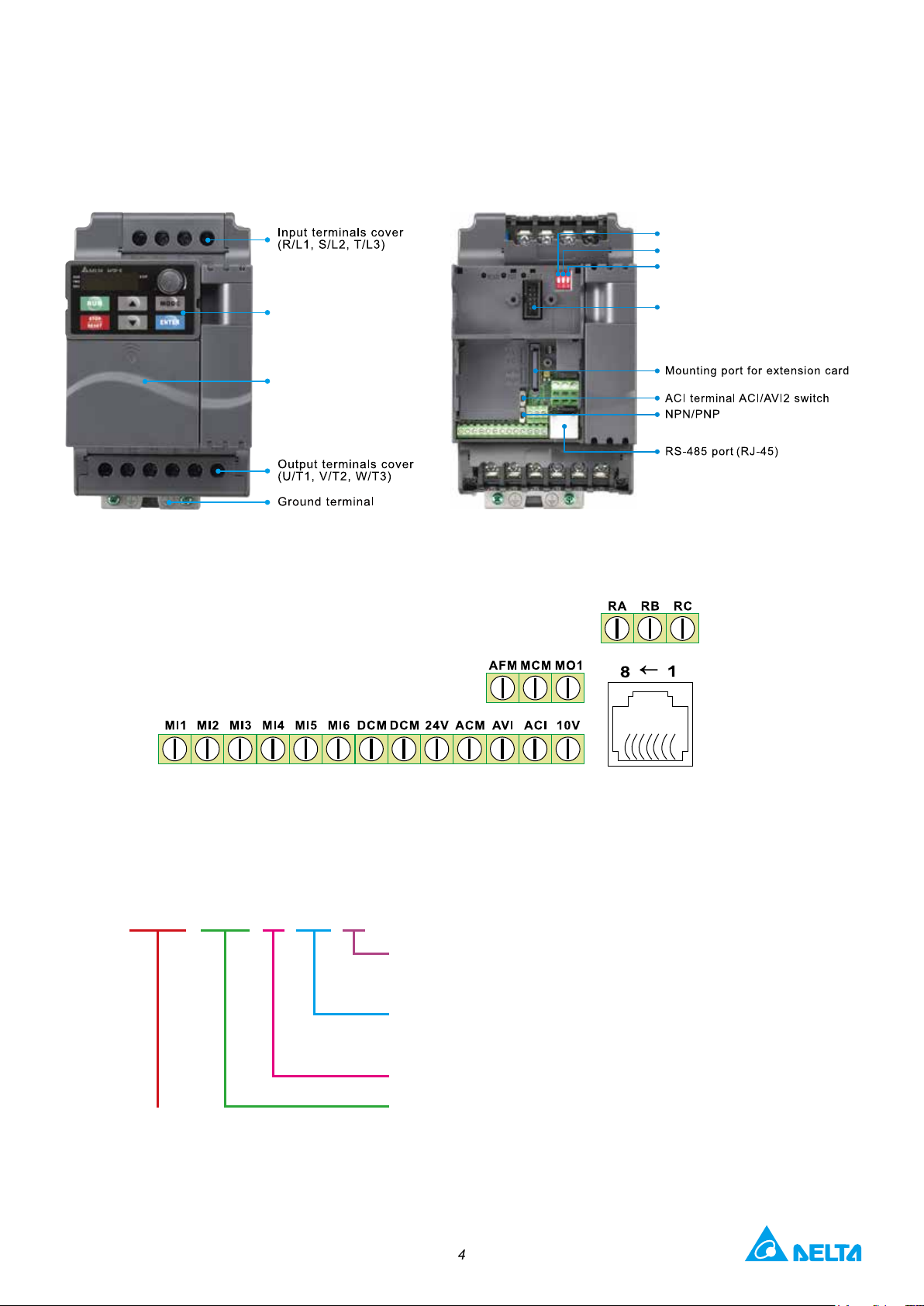

External Parts

Base frequency switch

Motor stopping method switch

Frequency source switch

Digital keypad (optional)

Control board cover

Control Terminals

Mounting port for keypad

Model Explanation

VFD 007 E 23 A

Product

(Variable Frequency Drive)

Version Type

A: Standard drive

C: CANopen

P: Cold plate drive (frame A only)

T: Frame A, built-in brake chopper

Input Voltage

11: 115V Single-phase

21: 230V Single-phase

23: 230V 3-phase

43: 460V 3-phase

E Series

Applicable Motor Capacity

002: 0.25 HP(0.2 kW)

004: 0.5 HP(0.4 kW)

007: 1 HP(0.75 kW)

015: 2 HP(1.5 kW)

022: 3 HP(2.2 kW)

037: 5 HP(3.7 kW)

055: 7.5 HP(5.5 kW)

075: 10 HP(7.5 kW)

RS-485

110: 15 HP(11 kW)

150: 20 HP(15 kW)

185: 25 HP(18.5 kW)

220: 30 HP(22 kW)

4

Page 6

Application Fields

Conveyor and Transportation Machinery

● Conveyor belt

● Automatic door

● Roller door

● Small elevator

● Escalator

● X-Y axis traveling crane

Fan/Pump Equipment

● Building air conditioning system

● Wastewater processing system

● Constant pressure water treatment system

● Water treatment pump

● Agricultural pump

● Temperature control of mid and larger oven

● Air compressor

● Heat exchange fan

● Building water dispenser system

● Dryer's windmill

Paper/Textile Machinery

● Round weaver

● Cross weaver

● Ribbon weaver

● Printing press

● Industrial sewing machine

● Knitting machine

5

Page 7

Food Processing

Wood Working Machinery

● Dumpling making machine

● Food mixer

● Noodle making machine

● 4 side planer

● Wood carving machine

● Woodworking machine

● Simple cutting machine for wood working

● Spraying machine

Machine Tool/Metal Processing Machinery

● Grinding machine

● Drilling machine

● Small lathe

● Milling machine

● Injection molding (clamp)

Others

● Ironing machine

● Pulverizer

● Treadmill

● Feeder

● Industrial washing machine

● Car washing machine

● Packing machine

● Centrifuge

● Liquid mixing machine

6

Page 8

Specications

Voltage Class

115V

Model Number VFD-___ E

Max. Applicable Motor Output (kW)

Max. Applicable Motor Output (hp)

Rated Output Capacity (kVA)

Rated Output Current (A)

Maximum Output Voltage (V)

Output Frequency (Hz)

Output RatingOutput RatingOutput Rating

Carrier Frequency (kHz)

Rated Input Current (A)

Rated Voltage/Frequency

Voltage Tolerance

Input Rating

Frequency Tolerance

Cooling Method

Weight (kg)

Voltage Class

230V

Model Number VFD-___ E

Max. Applicable Motor Output (kW)

Max. Applicable Motor Output (hp)

Rated Output Capacity (kVA)

Rated Output Current (A)

Maximum Output Voltage (V)

Output Frequency (Hz)

Carrier Frequency (kHz)

Rated Input Current (A)

Rated Voltage/Frequency

Voltage Tolerance

Input Rating

Frequency Tolerance

Cooling Method

Weight (kg)

115 V

002 004 007

0.2 0.4 0.75

0.25 0.5 1.0

0.6 1.0 1.6

1.6 2.5 4.2

3-phase proportional to twice the input voltage

0.1 ~ 599 Hz

1 - 15

Single-phase

6 9 18

Single-phase 100-120 V, 50 / 60 Hz

±10% (90 - 132 V)

±5% (47 - 63 Hz)

Natural cooling Fan cooling

1.2 1.2 1.2

230 V

002 004 007 015 022 037 055 075 110 150

0.2 0.4 0.75 1.5 2.2 3.7 5.5 7.5 11 15

0.25 0.5 1.0 2.0 3.0 5.0 7.5 10 15 20

0.6 1.0 1.6 2.9 4.2 6.5 9.5 12.5 17.1 25

1.6 2.5 4.2 7.5 11 17 25 33 45 65

3-phase proportional to twice the input voltage

0.1 ~ 599 Hz

1 - 15

Single / 3-phase 3-phase

4.9 / 1.9 6.5 / 2.7 9.7 / 5.1 15.7 / 9 24 / 15 20.6 26 34 48 70

Single / 3-phase, 200 - 240 V, 50 / 60 Hz 3-phase, 200 - 240 V, 50 / 60 Hz

±10% (180 - 264 V)

±5% (47 - 63 Hz)

Natural cooling Fan cooling

1.1 1.1 1.1 1.9 1.9 1.9 3.5 3.5 3.57 6.6

Voltage Class

460V

Model Number VFD-___ E

Max. Applicable Motor Output (kW)

Max. Applicable Motor Output (hp)

Rated Output Capacity (kVA)

Rated Output Current (A)

Maximum Output Voltage (V)

Output Frequency (Hz)

Carrier Frequency (kHz)

Rated Input Current (A)

Rated Voltage/Frequency

Voltage Tolerance

Input Rating

Frequency Tolerance

Cooling Method

Weight (kg)

460 V

004 007 015 022 037 055 075 110 150 185 220

0.4 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22

0.5 1.0 2.0 3.0 5.0 7.5 10 15 20 25 30

1.2 2.0 3.3 4.4 6.8 9.9 13.7 18.3 24 29 34

1.5 2.5 4.2 5.5 8.5 13 18 24 32 38 45

3-phase proportional to input voltage

0.1 ~ 599 Hz

1 - 15

3-phase

1.9 3.2 4.3 7.1 11.2 14 19 26 35 41 49

3-phase, 380 - 480 V, 50 / 60 Hz

±10% (342 - 528 V)

±5% (47 - 63 Hz)

Natural cooling Fan cooling

1.2 1.2 1.2 1.9 1.9 4.2 4.2 4.2 7.47 7.47 7.47

7

Page 9

Control System

Frequency Setting Resolution

Output Frequency Resolution

Torque Characteristics

Overload Endurance

Skip Frequency

Accel/Decel Time

Stall Prevention Level

DC Braking

Control CharacteristicsOperating CharacteristicsEnvironmental Conditions

Regenerated Braking Torque

V/F Pattem

Frequency

Setting

Operation

Setting

Signal

Keypad

External Signal

Keypad

External Signal

Multi-function Input Signal

Multi-function Output Indication

Analog Output Signal

Alarm Output Contact

Operation Functions

Protection Functions

Display Keypad

Built-in EMC Filter

Enclosure Rating

Pollution Degree

Installation Location

Ambient Temperature

Storage/Transportation

Temperature

Ambient Humidity

Vibration

SPWM (Sinusoidal Pulse Width Modulation) Control (V/F or sensorless vector control)

0.01 Hz

0.01 Hz

Including the auto-torque/auto-slip compensation; starting torque can be 150% at 3.0 Hz

150% of rated current for 1 minute

Three zones, setting range 0.1 ~ 599 Hz

0.1 to 600 seconds (2 Independent setting of Accel/Decel time)

Setting 20 to 250% of rated current

Operation frequency 0.1 ~ 599.0 Hz, output 0~100% rated current

Start time 0~60 seconds, stop time 0~60 seconds

Approx. 20% (up to 125% possible with optional brake resistor or externally mounted brake

unit, 1-15hp models (built-in brake chopper))

Adjustable V/F pattern

Setting by ▲▼

Potentiometer 5 kΩ / 0.5 W, 0 to +10 V

, 4 to 20 mA,RS-485 interface;

DC

Multi-function Inputs 3 to 9 (15 steps, Jog, up/down)

Set by RUN and STOP

2 wires / 3 wires (MI1, MI2, MI3), JOG operation, RS-485 serial interface (MODBUS),

programmable logic controller

Multi-step selection 0 to 15, Jog, accel/decel inhibit, 2 accel/decel switches, counter, external

Base Block (NC, NO), auxiliary motor control is invalid, ACI / AVI / AUI selections, driver reset,

UP/DOWN key settings, sink/source (=NPN / PNP) selection

AC drive operating, frequency attained, non-zero frequency, Base Block, fault indication,

local/remote indication, auxiliary motor output, drive is ready, overheat alarm,

emergency stop and status selections of input terminals (NC / NO)

Output frequency/current

Contact will be On when drive malfunctions

(1 Form C/change-over contact or 1 open collector output)

Built-in PLC, AVR, accel / decel S-Curve, over-voltage / over-current stall prevention, 5 fault

records, reverse inhibition, momentary power loss restart, DC braking, auto torque/slip

compensation, auto tuning, adjustable carrier frequency, output frequency limits, parameter

lock/reset, vector control, PID control, external counter, MODBUS communication,

abnormal reset, abnormal re-start, power-saving, sleep/wake function, fan control,

1st / 2nd frequency source selections, 1st / 2nd frequency source combination,

NPN / PNP selection

Over voltage, over current, under voltage, under current, external fault, overload,

ground fault, overheating, electronic thermal, IGBT short circuit, PTC, instantly stop and then

reboot (up to 20 sec by setting parameter)

6-key, 7-segment LED with 4-digit, 5 status LED, master frequency, output

frequency, output current, custom units, parameter values for setup and lock,

faults, RUN, STOP, RESET, FWD / REV

For 230 V 1-phase and 460 V 3-phase models

IP20

2

Altitude 1,000 m or lower, keep from corrosive gasses, liquid and dust

-10 ºC to + 50 ºC (40 ºC for side-by-side mounting) Non-Condensing and not frozen

-20 ºC to 60 ºC

Below 90% RH (non-condensing)

10 Hz≤ f≤ 57 Hz Fix Amplitude: 0.075 mm, 57 Hz≤ f≤ 150 Hz Fix Acceleration: 1 G

(According to IEC 60068-2-6)

Certifications

8

Page 10

Dimensions

D

Frame A1

MODEL

VFD002E11A/11C/11T

VFD002E21A/21C/21T

VFD002E23A/23C/23T

VFD004E11A/11C/11T

VFD004E21A/21C/21T

VFD004E23A/23C/23T

VFD004E43A/43C/43T

VFD007E23A/23C/23T

VFD007E43A/43C/43T

Frame W W1 H H1 D D1 D2 S1 S2

A1

mm 72.0 60.0 142.0 120.0 152.0 50.0 4.5 5.2 5.2

inch 2.83 2.36 5.59 4.72 5.98 1.97 0.18 0.20 0.20

Unit: mm[inch]

Frame A2

W

W1

H1

H

D1

D2

S2S1

MODEL

VFD015E23A/23C/23T

VFD015E43A/43C/43T

Frame W W1 H H1 D D1 D2 S1 S2

A2

mm 72.0 60.0 142.0 120.0 152.0 50.0 4.5 5.2 5.2

inch 2.83 2.36 5.59 4.72 5.98 1.97 0.18 0.20 0.20

Unit: mm[inch]

9

Page 11

Frame A3

W

W1

H1

H

D

D1

MODEL

VFD002E11P/21P/23P

VFD004E11P/21P/23P/43P

VFD007E21P/23P/43P

VFD015E23P/43P

Frame W W1 H H1 D D1 S1

A3

mm 72.0 56.0 155.0 143.0 111 . 5 9.5 5.3

inch 2.83 2.20 6.10 5.63 4.39 0.37 0.21

S1

Unit: mm[inch]

Frame B

MODEL

VFD007E11A/11C

VFD015E21A/21C

VFD022E21A/21C

VFD022E23A/23C

VFD022E43A/43C

VFD037E23A/23C

VFD037E43A/43C

Frame W H D W1 H1 D1 D2 S1 S2

mm 100.0 174.0 152.0 89.0 162.0 50.0 4.0 5.5 5.5

B

inch 3.94 6.86 5.98 3.50 6.86 1.97 0.16 0.22 0.22

Unit: mm[inch]

10

Page 12

Frame C

MODEL

VFD055E23A/23C

VFD055E43A/43C

VDF075E23A/23C

VDF075E43A/43C

VFD110E23A/23C

VFD110E43A/43C

Frame W H D W1 H1 D1 D2 S1 S2

mm 130.0 260.0 169.2 116.0 246.5 78.5 8.0 6.5 5.5

C

inch 5.12 10.24 6.66 4.57 9.70 3.09 0.31 0.26 0.22

Unit: mm[inch]

Frame D

MODEL

VFD150E23A/23C

VFD150E43A/43C

VFD185E43A/43C

VFD220E43A/43C

Frame W H D W1 H1 D1 D2 S1 S2

mm 200.0 310.0 190.0 180.0 290.0 92.0 10.0 10.0 9.0

D

inch 7.87 12.20 7.48 7.09 11.42 3.62 0.39 0.39 0.35

Unit: mm[inch]

11

Page 13

Accessories

Option Cards

▪ EME-R3AA

Relay card

(3 form A/ NO contacts)

▪ EME-A22A

Anglog I/O Card (12 bits)

▪ EME-R2CA

Relay card

(2 form C/Change-over contacts)

▪ EME-PG01

PG card

▪ EME-A1D3A

Anglog I/O Card (12 bits)

▪ CME-USB01

Second communication card

(USB1.1)

▪ EME-D33A

I/O card

(photocoupler 3in + 3out)

▪ EME-D611A

Multi-function Input

Terminal MI1~MI6-COM Card

(For Internal Installation)

12

▪ EME-D611B

Multi-function Input Terminal

MI1~MI6-COM Card

(For External Installation)

Page 14

Accessories

Fieldbus Modules

Others

▪ Brake Unit

BUE-20015 BUE-40015

BUE-20037 BUE-40037

▪ DeviceNet

CME-DN01

▪ PROFIBUS

CME-PD01

▪ Keypad for Communication

VFD-PU06 / KPC-CC01

▪ CANopen

CME-COP01

▪ DIN Rail (Width 35mm)

MKE-DRA MKE-DRB

▪ Brake Resistor

▪ Digital

Keypad

▪ Zero Phase Reactor

RF220X00A

13

▪ Grounding Plate

MKE-EP

Page 15

Ordering Information

VFD-E Series

Frame

A1~A3

Frame B

Frame Size

Power Range Models

Frame A1:

VFD002E11A/11C/11T

VFD002E21A/21C/21T

VFD002E23A/23C/23T

VFD004E11A/11C/11T

VFD004E21A/21C/21T

115 V: 0.2 kW ~ 0.4 kW

230 V: 0.2 kW ~ 1.5 kW

460 V: 0.4 kW ~ 1.5 kW

115 V: 0.75 kW

230 V: 1.5 kW ~ 3.7 kW

460 V: 2.2 kW ~ 3.7 kW

Frame A2:

VFD015E23A/23C/23T

VFD015E43A/43C/43T

Frame A3:

VFD002E11P/21P/23P

VFD004E11P/21P/23P/43P

VFD007E11A/11C

VFD015E21A/21C

VFD022E21A/21C

VFD022E23A/23C

VFD022E43A/43C

VFD037E23A/23C

VFD037E43A/43C

VFD004E23A/23C/23T

VFD004E43A/43C/43T

VFD007E23A/23C/23T

VFD007E43A/43C/43T

VFD007E21P/23P/43P

VFD015E23P/43P

Frame C

Frame D

230 V: 5.5 kW ~ 11 kW

460 V: 5.5 kW ~ 11 kW

230 V: 15 kW

460 V: 15 kW ~ 22 kW

VFD055E23A/23C

VFD055E43A/43C

VDF075E23A/23C

VDF075E43A/43C

VFD110E23A/23C

VFD110E43A/43C

VFD150E23A/23C

VFD150E43A/43C

VFD185E43A/43C

VFD220E43A/43C

14

Page 16

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan District,

Taoyuan City 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Shanghai) Co., Ltd.

No.182 Minyu Rd., Pudong Shanghai, P.R.C.

Post code : 201209

TEL: 86-21-6872-3988 / FAX: 86-21-6872-3996

Customer Service: 400-820-9595

Delta Electronics (Japan), Inc.

Tokyo Ofce

Industrial Automation Sales Department

2-1-14 Shibadaimon, Minato-ku

Tokyo, Japan 105-0012

TEL: 81-3-5733-1155 / FAX: 81-3-5733-1255

Delta Electronics (Korea), Inc.

Seoul Ofce

1511, 219, Gasan Digital 1-Ro., Geumcheon-gu,

Seoul, 08501 South Korea

TEL: 82-2-515-5305 / FAX: 82-2-515-5302

Delta Energy Systems (Singapore) Pte Ltd.

4 Kaki Bukit Avenue 1, #05-04, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No.43, Sector 35, HSIIDC Gurgaon,

PIN 122001, Haryana, India

TEL: 91-124-4874900 / FAX : 91-124-4874945

Delta Electronics (Thailand) PCL.

909 Soi 9, Moo 4, Bangpoo Industrial Estate (E.P.Z),

Pattana 1 Rd., T.Phraksa, A.Muang,

Samutprakarn 10280, Thailand

TEL: 66-2709-2800 / FAX : 662-709-2827

Delta Electronics (Australia) Pty Ltd.

Unit 20-21/45 Normanby Rd., Notting Hill Vic 3168, Australia

TEL: 61-3-9543-3720

Americas

Delta Electronics (Americas) Ltd.

Raleigh Ofce

P.O. Box 12173, 5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3813 / FAX: 1-919-767-3969

Delta Electronics Brazil

São Paulo Sales Ofce

Rua Itapeva, 26 - 3°, andar Edicio Itapeva,

One - Bela Vista 01332-000 - São Paulo - SP - Brazil

TEL: 55-12-3932-2300 / FAX: 55-12-3932-237

Delta Electronics International Mexico S.A. de C.V.

Mexico Ofce

Gustavo Baz No. 309 Edicio E PB 103

Colonia La Loma, CP 54060

Tlalnepantla, Estado de México

TEL: 52-55-3603-9200

EMEA

Headquarters: Delta Electronics (Netherlands) B.V.

Sales: Sales.IA.EMEA@deltaww.com

Marketing: Marketing.IA.EMEA@deltaww.com

Technical Support: iatechnicalsupport@deltaww.com

Customer Support: Customer-Support@deltaww.com

Service: Service.IA.emea@deltaww.com

TEL: +31(0)40 800 3900

BENELUX: Delta Electronics (Netherlands) B.V.

De Witbogt 20, 5652 AG Eindhoven, The Netherlands

Mail: Sales.IA.Benelux@deltaww.com

TEL: +31(0)40 800 3900

DACH: Delta Electronics (Netherlands) B.V.

Coesterweg 45, D-59494 Soest, Germany

Mail: Sales.IA.DACH@deltaww.com

TEL: +49(0)2921 987 0

France: Delta Electronics (France) S.A.

ZI du bois Challand 2, 15 rue des Pyrénées,

Lisses, 91090 Evry Cedex, France

Mail: Sales.IA.FR@deltaww.com

TEL: +33(0)1 69 77 82 60

Iberia: Delta Electronics Solutions (Spain) S.L.U

Ctra. De Villaverde a Vallecas, 265 1º Dcha Ed.

Hormigueras – P.I. de Vallecas 28031 Madrid

TEL: +34(0)91 223 74 20

Carrer Llacuna 166, 08018 Barcelona, Spain

Mail: Sales.IA.Iberia@deltaww.com

Italy: Delta Electronics (Italy) S.r.l.

Via Meda 2–22060 Novedrate(CO)

Piazza Grazioli 18 00186 Roma Italy

Mail: Sales.IA.Italy@deltaww.com

TEL: +39 039 8900365

Russia: Delta Energy System LLC

Vereyskaya Plaza II, ofce 112 Vereyskaya str.

17 121357 Moscow Russia

Mail: Sales.IA.RU@deltaww.com

TEL: +7 495 644 3240

Turkey: Delta Greentech Elektronik San. Ltd. Sti. (Turkey)

Şerifali Mah. Hendem Cad. Kule Sok. No:16-A

34775 Ümraniye – İstanbul

Mail: Sales.IA.Turkey@deltaww.com

TEL: + 90 216 499 9910

GCC: Delta Energy Systems AG (Dubai BR)

P.O. Box 185668, Gate 7, 3rd Floor, Hamarain Centre

Dubai, United Arab Emirates

Mail: Sales.IA.MEA@deltaww.com

TEL: +971(0)4 2690148

Egypt + North Africa: Delta Electronics

Unit 318, 3rd Floor, Trivium Business Complex, North 90 street,

New Cairo, Cairo, Egypt

Mail: Sales.IA.MEA@deltaww.com

*We reserve the right to change the information in this catalogue without prior notice.

DELTA_IA-MDS_VFD-E_C_EN_20200818

Loading...

Loading...