Page 1

INSTRUCTION MANUAL

Unifence

TM

Saw Guide

30 " C a p acity

(Model 36-905)

REVISED: 10-27-98 PA RT NO. 422-27-655-0053

'Delta International Machinery Corp. 1998

Page 2

2

TABLE OF CONTENTS

INTRODUCTION...............................................................................................................................................................2

UNPACKING.....................................................................................................................................................................3

CONSTRUCTING UNIFENCE TABLE.............................................................................................................................3

ASSEMBLING LEGS AND FRONT TABLE SUPPORT..................................................................................................4

ASSEMBLING TABLE ADAPTER PLATE TO SAW TABLE..........................................................................................5

ASSEMBLING UNIFENCE TABLE TO SAW ..................................................................................................................6

ASSEMBLING UNIFENCE GUIDE RAIL TO TABLE......................................................................................................7

ASSEMBLING REAR EXTENSION WING SUPPORT BAR .........................................................................................12

ASSEMBLING CURSOR TO UNIFENCE BODY ..........................................................................................................13

ASSEMBLING UNIFENCE BODY TO GUIDE RAIL .....................................................................................................13

ASSEMBLING FENCE TO UNIFENCE BODY..............................................................................................................14

FENCE OPERATION......................................................................................................................................................15

RIPPING WITH THE UNIFENCE ...................................................................................................................................16

ADJUSTING FENCE PARALLEL TO MITER GAGE SLOTS .......................................................................................17

ADJUSTING FENCE 90 DEGREES TO TABLE...........................................................................................................17

ADJUSTING CLAMPING ACTION OF FENCE LOCKING HANDLE...........................................................................17

RIPPING ON LEFT SIDE OF SAW BLADE ..................................................................................................................18

USING THE FENCE AS A C U T-OFF GAGE .................................................................................................................18

USING AUXILIARY WOOD FACING ON THE UNIFENCE...........................................................................................19

CONSTRUCTING A PUSH STICK.................................................................................................................................19

PARTS, SERVICE OR WARRANTYASSISTANCE......................................................................................................20

W ARRANTY...................................................................................................................................................................20

INTRODUCTION

The model 36-905, 30 cap acity UnifenceTMSaw Guide can be assembled to the Delt a 10 Contractor s

Saw; 10 Tilting Arbor Saw and 10 Unisaw in addition to other makes of t able saws. The 36-905

UnifenceTMSaw Guide includes the fence, carriage assembly, front guide rail, t able frame, legs and shelf

support. The accessory 34-914 table is not included with the 36-905 UnifenceTM Saw Guide and must be

ordered separately or a similar t able must be constructed by following the instructions in this manual.

Page 3

3

UNPACKING

Carefully unp ack the Unifence and all loose items from the shipping cartons. NOTE: Do not discard the card board template shipped with the Unifence as it will be used in the assembly.

If you purchased the 36-905 Unifence without the acces sory 34-914 t able, a similar t able must be constructed,

preferably of p article board.

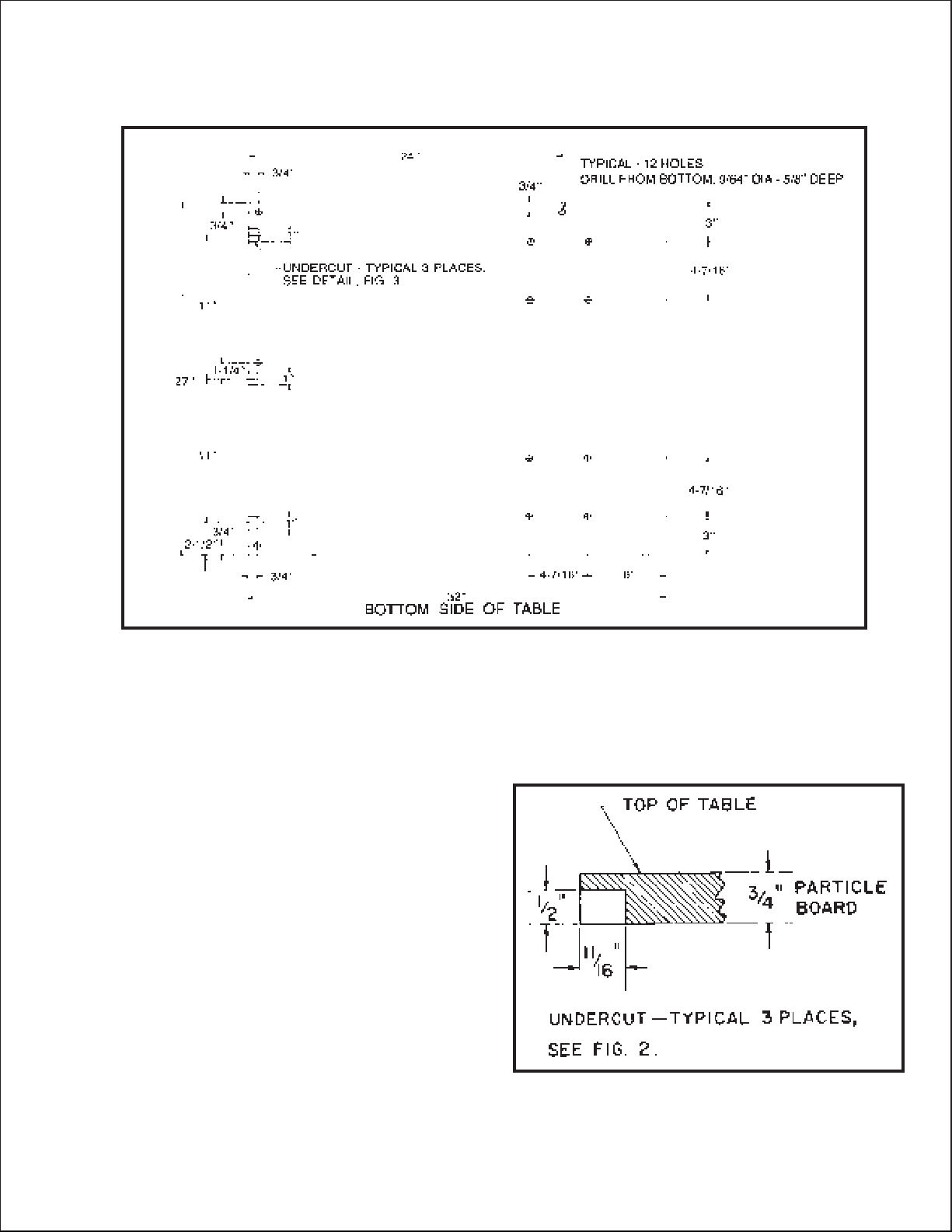

1. A 32 long by 27 wide t able should be constructed

using 3/4 inch material by following the dimensions

shown in Fig. 2.

2. T welve 9/64 inch diameter holes must be drilled

5/8 inch deep in the bottom side of the t able. These

twelve hole locations are shown in Fig. 2.

3. Three undercuts must also be made on the bottom

lef t side of the t able. The location of these undercut s are

shown in Fig. 2. The size of the undercuts are shown in

det ail in Fig. 3. NOTE: On saws other than Delt a, it may

be necessary to change the location of the three under cut s in the t able depending on the position of the table

adapter plate mounting screws. Refer to section

ASSEMBLING TABLE ADAPTER PLATE TO SAW

TABLE.

4. IMPORTANT: For maximum operational ease when

sliding the fence across the t able, the top of the t able

should be covered with a veneer.

Fig. 2

CONSTRUCTING UNIFENCE TABLE

Fig. 3

Page 4

4

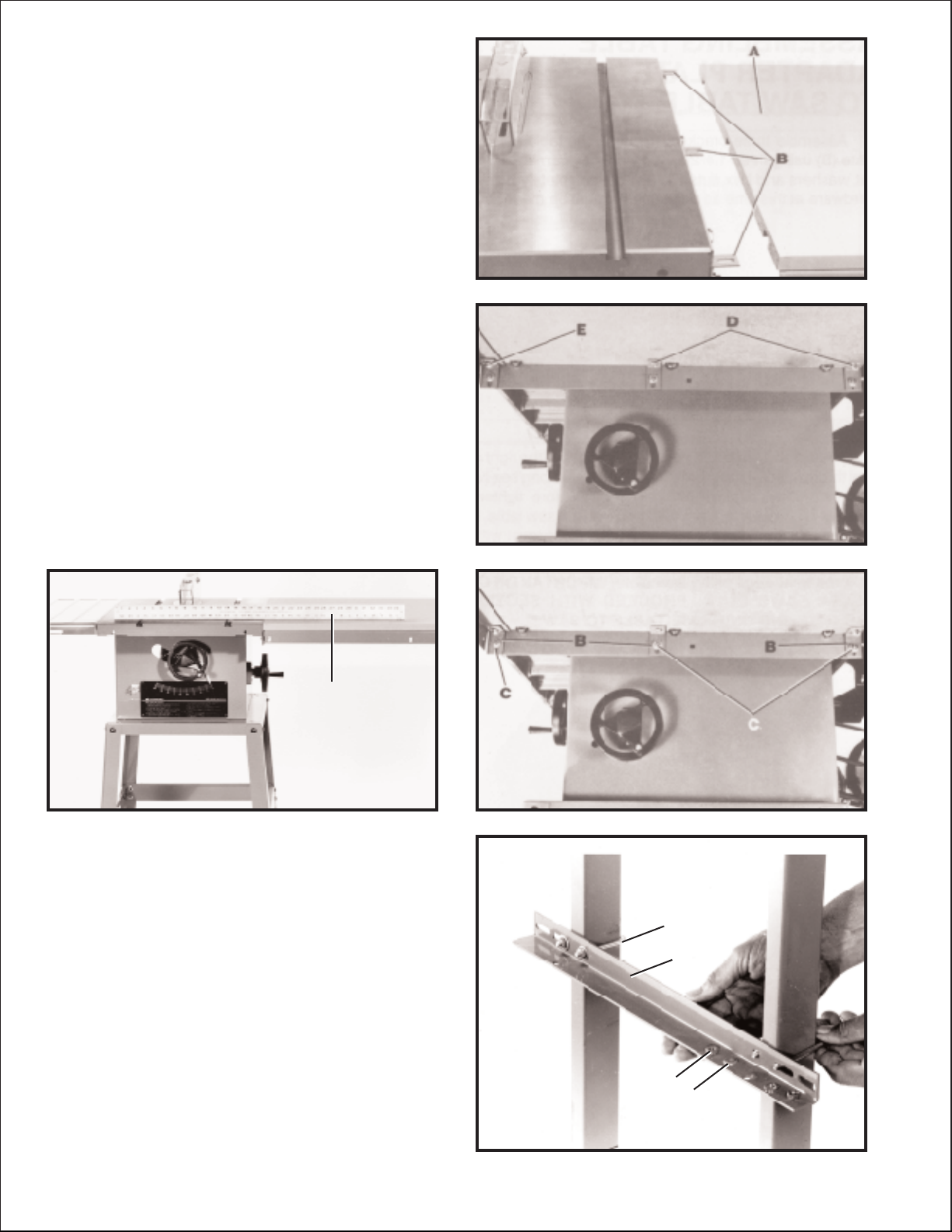

Fig. 4

ASSEMBLING LEGS AND FRONT TABLE SUPPORT

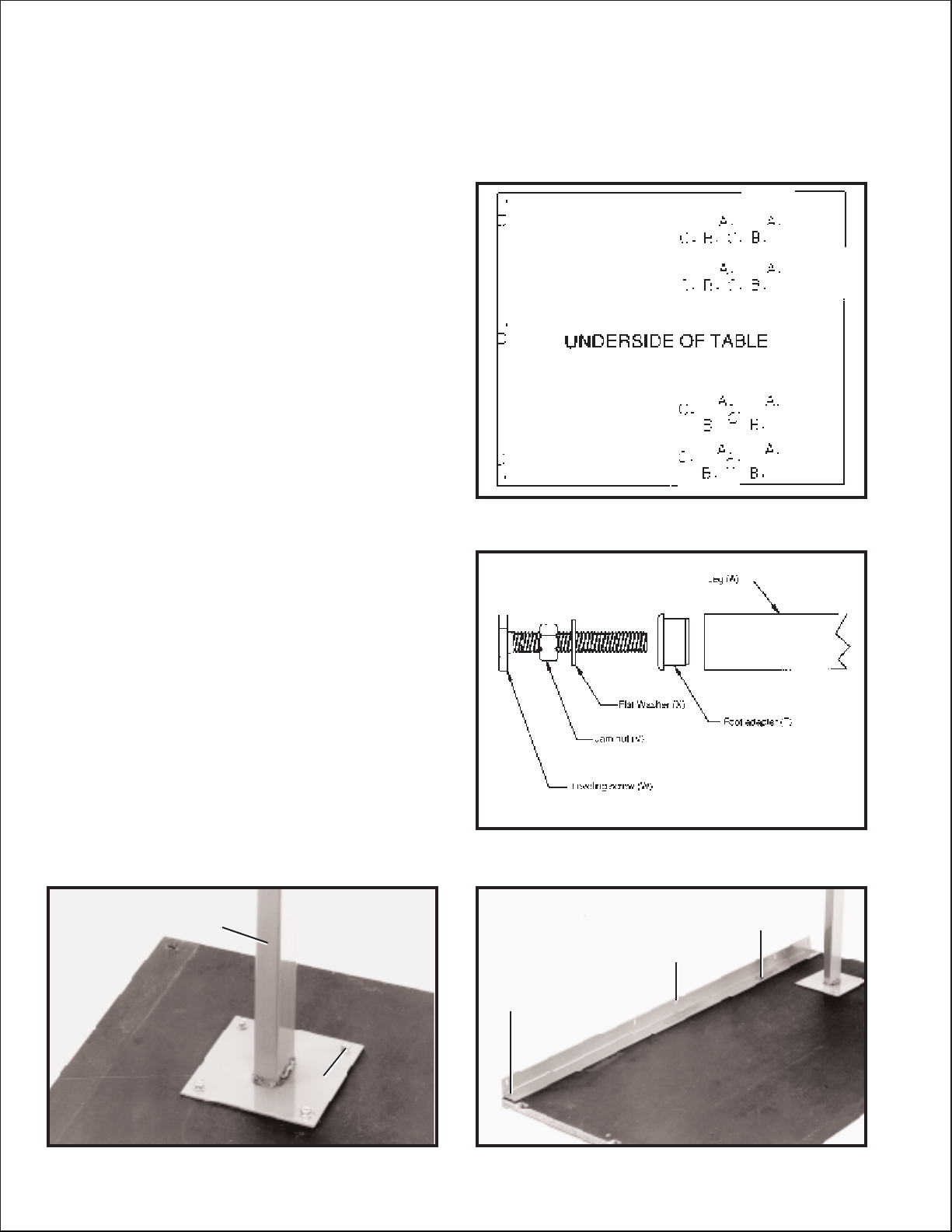

1. Lay the t able up side down on the floor or bench.

2. If you purchased the 36-905 Unifence with the accessory 34-914 t able, three set s of holes have been

predrilled in the underside of the t able to assemble the t able legs. NOTE: These hole patterns will allow the

table legs to be set correctly if you are using Delt a Mobile Bases and Mobile Base Table Extensions.

A. Eight holes indicated as (A) Fig. 4, beginning 6

inward from the end of the t able, are used to

mount the legs when assembling the t able to a

Delt a 10 Contractor s S aw.

B. Eight holes indicated as (B) Fig. 4, beginning

7-3/8 inward from the end of the t able, are used

to mount the legs when assembling the t able to

Delt a Unisaw.

C. Eight holes indicated as (C) Fig. 4, beginning

9-5/8 inward from the end of the t able, are used

to mount the legs when assembling the t able to a

Delt a 10 T ilting Arbor Saw.

Fig. 5

Fig. 7Fig. 6

3. Before assembling the legs to the t able, insert the

foot adapter (T) Fig. 5, into the bottom of each leg (A).

Assemble the 3/8-16 jam nut (V) approximately 3/4 of the

way onto leveling screw (W) and place a flat washer (X)

over the jam nut (V) as shown in Fig. 5. Thread the leve ing screw (W) into foot adapter (T); height adjustment s

can be made later.

4. Assemble leg (A) Fig. 6, to the bottom of the t able

using four #14 x 3/4 inch-long screws (B) as shown.

Assemble the remaining leg to the t able in the same

manner.

5. Fasten the front t able support (D) Fig. 7, to the bot tom of the t able as shown, using two #14 x 3/4 inch-long

screws (E) and (F) supplied. NOTE: The slots closer to

the bend in the support should be against the t able. Do

not completely tighten the two screws at this time.

IMPORTANT: SCREW (E) MUST BE REMOVED A N D

REINSTALLED WHEN ASSEMBLING UNIFENCE

TABLE TO SAW (REFER TO PAGE 6).

A

B

E

D

F

Page 5

5

Fig. 8

Fig. 9

ASSEMBLING TABLE ADAPTER PLATE

TO SAW TABLE

Fig. 10

1. Assemble three bracket s (A) Fig. 8, to t able adapter

plate (B) using three 1/4-20 x 3/4 inch-long carriage

bolt s, flat washers and hex nut s (C). Do not completely

tighten hardware at this time as adjustment s must be

made.

FOR DELTA TABLE SAWS ONLY

2. Assemble t able adapter plate (B) Fig. 9, to the right

side of the saw t able using three 7/16-20 x 1 inch-long

hex head screws (D) and lockwashers. NOTE: Before

tightening screws (D), place a straight edge (E) on the

saw t able, and make cert ain the top of adapter plate (B)

is level with or slightly below the surface of the saw

table. Also, make certain the front of adapter plate (B)

does not extend out p ast the front edge of the saw t able.

IMPORTANT: FOR DELTA S AW S O N LY, PROCEED

WITH SECTION ASSEMBLING UNIFENCE TABLE

TO SAW .

FOR TABLE SAWS OTHER THAN DELTA

3. Assemble t able adapter plate (B) Fig. 10, to the right

side of the saw t able as shown using three 3/4 inch

screws, lockwashers and hex nut s (D), (not supplied).

IMPORTANT: If the pre-drilled holes in adapter plate (B)

do not line up with the holes in the saw t able, new holes

must be drilled in adapter plate (B) and/or saw t able.

NOTE: Do not drill any hole to fasten adapter plate (B)

Fig. 10, to the saw t able that will be located less than two

inches from either end of the adapter plate.

4. Before tightening three screws (D) Fig. 10, place a

straight edge on the saw t able and make cert ain the top

of adapter plate is level with or slightly below the surface

of the saw t able, refer to Fig. 9. Also, make cert ain front

of adapter plate (B) Fig. 10, does not extend out p ast the

front edge of the saw t able.

Page 6

6

Fig. 1 1

Fig. 12

Fig. 14Fig. 13

Fig. 15

F

K

H

M

L

ASSEMBLING

UNIFENCE TABLE

TO SAW

1. Remove #14 x 3/4 inch-long screw (E) Fig. 12, which

was inst alled in STEP 5, p age 4.

2. Assemble Unifence t able (A) Fig. 1 1, to bracket s (B)

using two #14 x 3/4 inch-long screws (D) and screw (E)

which was removed in STEP 1, Fig. 12. NOTE: The two

screws (D) Fig. 12, can be tightened; screw (E) should

be lef t slightly loose at this time. CAUTION: Overtightening screws in p article board may cause them to strip.

3. Using a straight edge (F) Fig. 13, make cert ain the

Unifence t able surface is level with the saw t able by

adjusting two leveling screws on bottom of t able legs and

adjusting bracket s (B) Fig. 14. Then tighten three nut s

(C) Fig. 14. IMPORTAN T: Front edge of Unifence table

must be flush with or slightly behind front edge of saw

table.

4. Place the shelf support (H) Fig. 15, against t able legs

and fasten with U-bolt s (K), flat washers (L), and hex

nuts (M) as shown.

Page 7

7

Fig. 16

5. Fig. 16, illustrates the shelf support (H) assembled to

the t able legs. NOTE: Shelf support (H) can be rot ated or

adjusted to fit any type of shelf.

6.After the t able and legs are assembled to the saw ,

check if the Unifence t able is level with the saw t able. If

an adjustment is necessary, loosen jam nut (P) Fig. 16,

and rot ate leveling screw (R) as necessary. T ighten jam

nut (P) against bottom of each t able leg.

ASSEMBLING UNIFENCE GUIDE RAIL TO TABLE

1. MAKE CERTAIN THE TABLE SAW IS DISCONNECTED FROM THE POWER SOURCE.

2. Remove the fence, guide rails, right hand extension wing and blade guard assembly from the t able saw.

IMPORTANT: THE BLADE GUARD ASSEMBLY MUST BE RE-ASSEMBLED TO YOUR TABLE SAW

AFTER THE UNIFENCE ASSEMBLY IS COMPLETED. NOTE: If you are assembling the Unifence to a Delt a

10 Contractors S a w, assemble the extension wing support bar supplied with the Unifence, to the rear of the

lef t extension wing and saw t able. (Refer to p age 12 of this manual).

3. Raise the saw blade to it s maximum height and make sure the blade is 90 degrees to the t able. NOTE:

If you are assembling the Unifence to a Delt a Table Saw, proceed to STEP 13.

Fig. 19

Fig. 18

FOR TABLE SAWS OTHER THAN DELTA

4. Locate p aper template (A) Fig. 17, included with the

instructional literature and identified as p art no. 422-27655-0009.

5. Fold p aper template (A) along the line marked t able

top and place it on the saw t able with the fold along the

top front edge of the t able, as shown in Fig. 18.

6. Position a straight edge (B) Fig. 19, along the right

side of the saw blade with one end of the straight edge

extending out to the front of the saw t able over the tem plate (A) as shown.

H

P

R

P

R

Fig. 17

A

A

A

B

Page 8

8

Fig. 20

Fig. 21

Fig. 22

Fig. 23

7. Slide template (A) Fig. 20, lef t or right, along the t able

until the line (C) on the template marked lineup with right

side of blade is aligned with the lef t edge of the straight

edge (B). Make sure the fold in the template is along the

top front edge of the t able and t ape the template to the

table.

8. Check to see if the two holes (D) Fig. 21, illustrated

on the template match the holes on the front edge of your

saw t able.

A. If the location of the holes in your saw t able

match the holes (D) Fig. 21, illustrated on the tem plate and are 7/16 in diameter , remove the template

and proceed to STEP 13. IMPORTANT: IF HOLES

IN FRONT OF SAW ARE THREADED, THEY MUST

BE DRILLED OUT.

B. If the location of the holes in your saw t able

match the holes (D) Fig. 21, illustrated on the

template but are not 7/16 in diameter, remove the

template and enlarge the holes in the t able by drilling

them out. Then proceed to STEP 13.

C. If the location of the holes in your saw t able do

not match holes (D) Fig. 21, illustrated on the tem plate, it will be necessary to drill two new 7/16 diam eter holes in the saw t able at locations indicated at

(D), on the template, providing structural ribs or

existing holes in the t able do not interfere with the

two new holes. Center punch to locate the two new

holes to be drilled and remove the template. Drill the

two new 7/16 diameter holes in the table and pro ceed to STEP 13.

D. If structural ribs or existing holes in the saw t able

prevent drilling holes at the locations shown on tem plate at (D) Fig. 22, it will be necessary to move one

or both of the holes, making sure the new holes are

on the same center line as holes (D). Mark the loca tion of new hole(s) (E) on the template, as shown in

Fig. 22. Center punch the location of the new hole(s),

remove the template, drill the new hole(s) in the t able

and proceed to STEP 9.

9. Cut the template along the line marked 0 (zero on

guide rail scale), as shown in Fig. 23.

C

B

A

D

D

D

E

Page 9

9

Fig. 24

Fig. 25

Fig. 26

Fig. 27 Fig. 28

10. Fold the top portion of the template toward you in the

line marked top of guide rail (F), as shown in Fig. 24.

11. Position the template on the guide rail, as shown in

Fig. 25, with the printed side of the template against the

guide rail and the fold in the template along the top of the

rail. Position the template so that edge (G) which was cut

in STEP 9 is aligned with the 0 mark on the scale, as

shown. Tape the template in place on the guide rail. Hole

(H) Fig. 25, indicates the hole that was drilled in the t able

in STEP 8D and is the location of the new hole to be

drilled in the guide rail.

12. Center punch the location of the new hole(s) (H)

Fig. 26, to be drilled in the guide rail, as shown. Remove

the template and drill the new 7/16 diameter hole(s) in

the back of the guide rail.

FOR ALL TABLE SAW S

IMPORTANT: If the mounting holes in the front of the

table saw are threaded, the threads must be drilled out to

7/16 inch thru holes.

13. The guide rail (N) Fig. 27, has end cap s, one of

which is shown at (W), inserted into each end of the rail.

Remove the lef t end cap (W) Fig. 28, by inserting a flat

headed screwdriver (X) into the channel in front of the

guide rail and press outward against the inside of the end

cap (W) as shown. The end cap (W) will pop out. NOTE:

DO NOT ATTEMPT TO REMOVE THE END CAP B Y

FORCING THE SCREWDRIVER BETWEEN THE END

C A P AND THE END OF THE RAIL. THIS WILL D A MAGE BOTH THE CAP AND THE RAIL.

F

H

G

H

A

B

A

Page 10

10

Fig. 29

Fig. 30

Fig. 31

Fig. 32

14. Locate the cardboard template (K) Fig. 29, from the

packing material of the Unifence.

15. Place the two 3/8 - 24 hex nut s, one of which is

shown at (J) Fig. 29, in position on the two t abs on the

cardboard template (K).

16. Insert cardboard template (K) into channel in end of

guide rail, as shown in Fig. 29, until the hex nut s, one of

which is shown at (J), line up with the mounting holes in

the rail.

17. Locate the two double threaded studs (L) Fig. 30,

packed with the Unifence and thread the short fine

threads of the studs (L), into the two hex nut s inside the

channel of the guide rail, as shown.

18. Assemble the guide rail to the saw t able by inserting

two studs (L) Fig. 31, into the two matching holes in the

front edge of the t able and fasten using two flat washers

and hex nut s (M). Only snug up two hex nut s (M), at this

time.

19. Adjust the guide rail (N) Fig. 32, p arallel with the saw

table surface by placing a square (O), on the saw t able

at both the lef t and right front end of the t able, with rule

of square against flat surface on top of guide rail, as

shown. The guide rail (N) can be moved up or down at

either end. Af ter you are cert ain the flat surface of the

guide rail is p arallel with the t able surface, firmly tighten

the two hex nut s that fasten the guide rail to the t able.

NOTE: For all saws other than Delt a Series 2000

Contractor s Saws, continue with STEP 23.

K

J

L

L

L

M

M

L

O

N

V

Page 11

11

SWITCH MOUNTING FOR DELTA SERIES 2000

10 CONTRACTOR S SAW S EQUIPPED WITH

MODEL NO. 36-905 30 C A PACITY UNIFENCE

Fig. 33

Fig. 34 Fig. 35

20. The ON/OFF switch (X) Fig. 33, for the Delt a Series

2000 10 Contractor s Saw is mounted to the lef t exten sion wing (V) as shown.

21. Fasten the ON/OFF switch (X) Figs. 33 and 34, to

guide rail (N) using 1/4-20 x 1 long screw and flat wash er (S). Do not completely tighten screw at this time.

22. Using a square (O) Fig. 35, adjust the extension

win g (V) p arallel to saw t able (Y), then tighten screw (S)

Fig. 34.

V

X

N

X

N

S

Y

V

O

Fig. 36

FOR ALL TABLE S AW S

23. Fasten the guide rail (N) Fig. 36, to extension wing

(V) by threading 1/4-20 x 5/8 inch-long screw (S) Fig. 36,

with flat washer through slotted hole in the front of exten sion wing (V), and into threaded hole in guide rail (N) as

shown.

S

V

N

Page 12

12

F OR ALL DELTA S AW S EQUIPPED WITH

STAMPED STEEL EXTENSION WINGS

ASSEMBLING

REAR EXTENSION WING

SUPPORT BAR

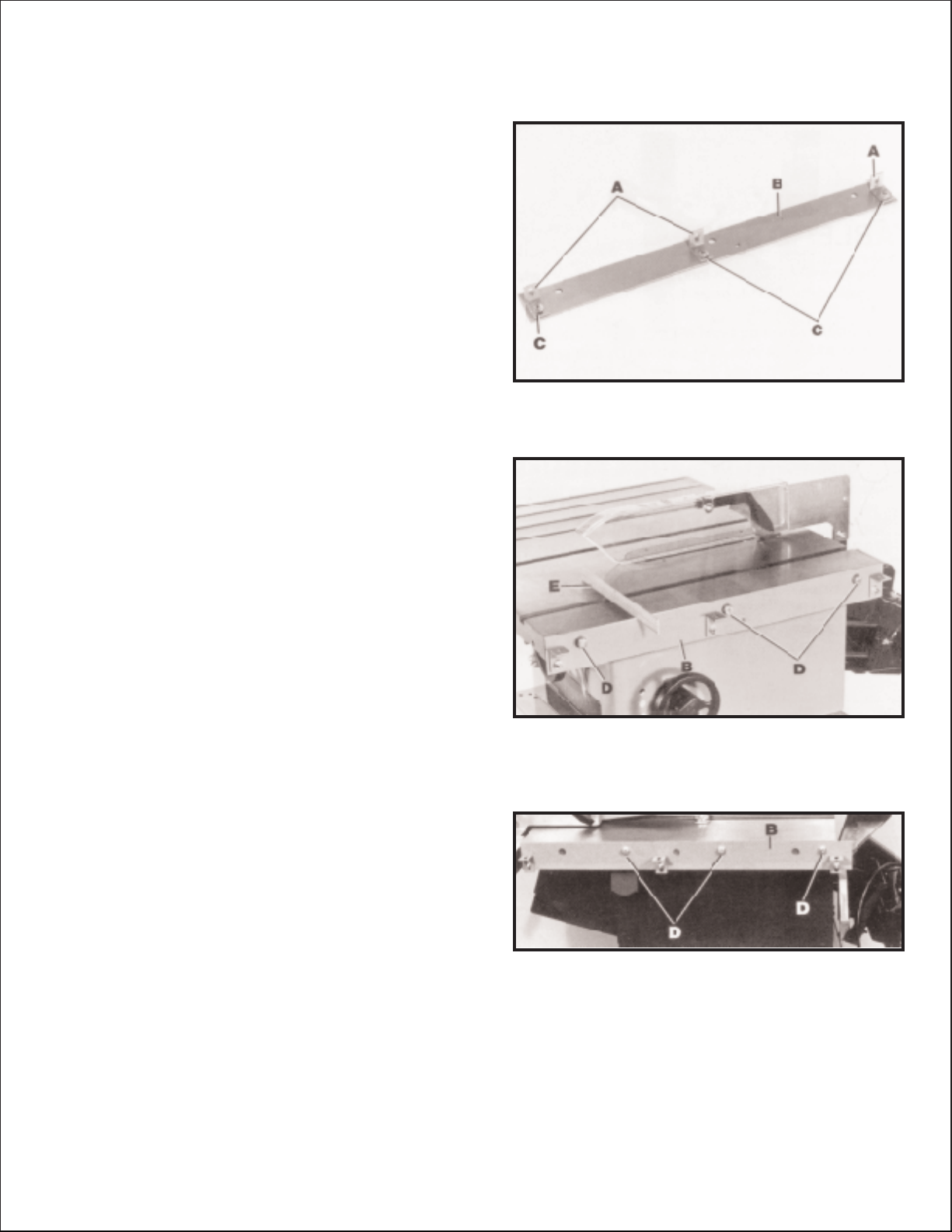

1. Assemble rear extension wing support bar (A)

Fig. 40, to the saw t able and extension wing, using three

3/8-16 x 1 long hex head screws, flat washers, and hex

nut s (B ).

BB

A

Fig. 37

Fig. 38

Fig. 39

Fig. 40

24. Move front t able support (R) Fig. 37, until it cont act s

the back of guide rail (N) and fasten with 1/4-20 x 5/8

inch-long screw and flat washer (S).

25. T ighten two screws (T) Fig. 38, that fasten t able to

front t able support (R).

26. Replace end cap (W) Fig. 39, that was removed in

STEP 13.

S

N

R

T

R

T

Page 13

13

Fig. 41

Fig. 42

Fig. 43

Fig. 45Fig. 44

FOR ALL TABLE S AW S

ASSEMBLING CURSOR

TO UNIFENCE BODY

1. Remove two screws and flat washers (A) Fig. 41,

and assemble the cursor (B) to the Unifence body (C).

Replace the two screws and flat washers (A).

2. Fig. 42, illustrates the cursor (B) assembled to the

Unifence body. Adjustment to the cursor (B) will be made

later.

ASSEMBLING UNIFENCE

BODY TO GUIDE RAIL

1. T urn fence body (A) Fig. 43, up side down and lay it

on a table or bench. Push handle (B) in against fence

body. Make cert ain the surface (C) of clamp bracket is

p arallel to the face (D) of the fence body , and that

the inside edge (E) of the clamp bracket is p arallel to

surface (F) of the fence body. T urn handle (B) Fig. 43, if

necessary.

2. Place fence body (A) Fig. 44, onto the guide rail as

shown, making sure clamp bracket is inserted into chan nel (G) on rail. Notice that the clamp handle (B) is turned

to the lef t indent position.

3. T urn handle (B) Fig. 45, to the right indent position as

shown. This will prevent fence clamp from sliding out of

the channel (G).

B

C

A

B

D

A

B

C

E

F

A

B

G

B

G

Page 14

14

Fig. 46

Fig. 47

Fig. 48

Fig. 49

4. Lock fence body (A) to the guide rail by pushing

down on handle (B) as shown in Fig. 46.

ASSEMBLING FENCE

TO UNIFENCE BODY

1. The fence (A) can be assembled to clamp plate (B)

in either the horizont al position as shown in Fig. 47, or

the vertical position as shown in Fig. 48. Make cert ain the

two lock knobs (C), are loose and slide fence (A) onto

clamp plate (B) as shown. Then tighten the two lock

knobs (C).

2. For most normal ripping operations, the bottom of

the fence should be positioned slightly above the t able

surface. Loosen two lock knobs (C) Fig. 49, and place a

thin object such as a ruler (D) between the t able and

fence, as shown. Then tighten two lock knobs (C).

A

B

A

B

C

C

D

Page 15

15

Fig. 50

Fig. 51

Fig. 52

Fig. 54Fig. 53

FENCE OPERATION

1. Before operating fence, make sure the fence is

adjusted p arallel to miter gage slot, as explained later on

in this manual.

2. For most normal ripping operations of st andard size

lumber the fence is used in the vertical position, as

shown in Fig. 50.

3. When ripping thin stock, it is sometimes more con venient to use the fence in the horizont al position, as

shown in Fig. 51.

4. To move the fence along the guide rail, simply lif t up

clamp lever (A), as shown in Fig. 52, slide fence to

desired position on the rail, and push down on clamp

lever (A) to lock fence in place.

5. The dist ance the fence is positioned away from the

blade is indicated by the two witness lines (B) and (C)

Fig. 53, located on the cursor (D). The witness lines (B)

and (C) easily indicate the dist ance the fence is posi tioned away from the saw blade. W itness line (B) indi cates the dist ance the fence is away from the blade when

the fence is in the horizont al position, and witness line

(C) indicates the dist ance the fence is away from the

blade when the fence is in the vertical position. If it is

necessary to adjust cursor (D), make a test cut with the

fence in either the vertical or horizont al position, measure the dist ance of the finished cut and move the cursor

(D) by loosening the two screws (E) Fig. 53. Af ter adjust ment is completed tighten the two screws (E).

6. To remove the fence and fence body assembly (F)

Fig. 54, from the guide rail, lif t up on fence clamping lever

(A) and turn lever (A) to the lef t indent position. The fence

assembly (F) can then be pulled straight of f the guide rail

and removed, as shown in Fig. 54.

A

F

A

E

D

E

C

B

Page 16

16

Fig. 55

Fig. 56

Fig. 57

Fig. 58

RIPPING WITH

THE UNIFENCE

Ripping is the operation of making a lengthwise cut

through a board, as shown in Fig. 55, and the rip fence

(A) is used to position and guide the work. One edge of

the work rides against the rip fence while the flat side of

the board rest s on the t able. Since the work is pushed

along the fence, it must have a straight edge and make

solid cont act with the t able. The saw blade guard must be

used. On Delt a saws, the guard has anti-kickback

fingers to prevent kickback and a splitter to prevent the

saw kerf from closing and binding the blade.

Never st and in the line of the saw cut when ripping. Hold

the work with both hands and push it along the fence and

into the saw blade as shown in Fig. 55. The work can

then be fed through the saw blade with one or two hands.

After the work is beyond the saw blade and anti-kickback

fingers, the hand is removed from the work. When this is

done the work will either st ay on the t able, tilt up slightly

and be caught by the end of the rear guard or slide of f the

table to the floor . Alternately , the feed can continue to the

end of the t able, af ter which the work is lif ted and brought

along the out side edge of the fence. The cut-of f stock

remains on the t able and is not touched with the hands

until the saw blade is stopped, unless it is a large piece

allowing safe removal. When ripping boards longer than

three feet, it is recommended that a work support be

used at the rear of the saw to keep the workpiece from

falling of f the saw t able.

If the ripped work is less than 4 inches wide, a push stick

should always be used to complete the feed, as shown

in Fig. 56. The push stick can easily be made from scrap

material as explained in the section CONSTRUCTING

PUSH STICK. When ripping stock 2 inches or narrower,

assemble an auxiliary wood facing to the fence, as

explained in the section USING AUXILIARY WOOD

FACING ON THE UNIFENCE and use a push stick.

When ripping material with a veneer facing that extends

over the material, the fence (A) should be in the horizon tal position with the veneer (B) extending over the lip of

the fence, as shown in Fig. 57.

When ripping material with a veneer facing and the

material is not thick enough for the veneer to extend over

the lip of the fence or if the veneer facing (B) is on both

sides of the material, as shown in Fig. 58, the fence can

be positioned slightly above the surface of the t able. T h e

veneer can be placed between the fence and the t able

or the veneer can straddle the fence with the material

solidly against the fence, as shown.

A

B

A

B

Page 17

17

Fig. 59

Fig. 60

Fig. 61

Fig. 62

ADJUSTING FENCE

PARALLEL TO

MITER GAGE SLOTS

The fence (A) Fig. 59, should be adjusted so it is p arallel

to miter gage slot s (B). To check and adjust, move the

fence (A) until the bottom front edge of the fence is in line

with the edge of the miter gage slot as shown, and push

down on fence clamping lever (C). Check to see if the

fence is p arallel to the miter gage slot the entire length of

the t able. If the rear of the fence must be moved, slightly

tighten or loosen one of the adjustment plugs (D) or (E)

Fig. 59, using the arbor wrench or 7/8 wrench, until the

fence is p arallel with the miter gage slot. IMPORTA NT:

DO NOT OVERTIGHTEN ADJUSTMENT PLUGS (D)

AND (E) FIG. 59. VERY LITTLE MOVEMENT OF THESE

ADJUSTMENT PLUGS IS NECESSARY WHEN ADJUSTING THE FENCE PARALLEL WITH THE MITER

GAGE SLOT.

ADJUSTING FENCE

90 DEGREES TO TABLE

The fence must be adjusted so that the face of fence (A)

Fig. 60, is 90 degrees to the t able. To check if the fence

is 90 degrees to the t able, place a square (B) on the t able

with one end of the square against the fence, as shown.

If an adjustment is necessary, tighten or loosen one of

two screws (C) or (D) using the wrench supplied, until the

fence is 90 degrees to the t able. IMPORTANT: VERY

LITTLE MOVEMENT OF THESE SCREWS (C) AND (D)

IS NECESSARY TO MAKE THIS ADJUSTMENT.

ADJUSTING CLAMPING

ACTION OF FENCE

LOCKING HANDLE

When the fence locking handle (A) is pushed to the down

position, as shown in Fig. 61, the fence body (B) should

be completely clamped to the guide rail. If the fence body

(B) is not completey clamped to the guide rail when the

handle (A) is in the position shown in Fig. 61, lif t up on

locking handle (A) Fig. 62, and slightly tighten two adjust ment plugs (C) using arbor wrench or 7/8 wrench.

Adjustment plugs (C) should be tightened an equal

amount. Check to see if the fence body (B) is completely

fastened to the rail by pushing down on locking lever (A).

Adjust further if necessary. IMPORTAN T: AFTER ADJUSTING THE CLAMPING ACTION OF THE FENCE

LOCKING HANDLE, CHECK TO SEE IF THE FENCE

IS PARALLEL TO THE MITER GAGE SLOT A N D

ADJUST IF NECESSARY.

A

B

D

C

E

B

A

A

C

B

C

Page 18

18

Fig. 66 Fig. 67

Fig. 65

Fig. 64

Fig. 63

USING THE FENCE A S A CUT-OFF GAGE

RIPPING ON LEFT SIDE

OF SAW BLADE

In some cases it may be desirable to use the fence on

the lef t side of the saw blade. This is easily accomplished

by repositioning the fence (A) Figures 63 and 64, fence

clamp bar (B) and lock knobs (C) so that the fence (A)

will be att ached to the right side of the fence body , as

shown in Fig. 64. The complete fence assembly (D)

Fig. 64, can easily be moved to the lef t side of the saw

table.

The fence can be used as a cut-of f gage when cross

cutting a number of pieces to the same length. IMPORTA N T: When using the fence as a cut-of f gage, it is very

import ant that the rear end of the fence be positioned in

front of the saw blade. When using the fence as a cut-of f

gage, simply position the fence (A) to the front as shown

in Fig. 65, or purchase the accessory 34-878, 12 long

fence (B), as shown in Fig. 66. Fig. 67, illustrates a

typical operation using the accessory 34-878 12 long

fence (B) as a cut-of f gage.

C

A

B

A

D

C

A

B

B

Page 19

19

Fig. 68

CONSTRUCTING A PUSH STICK

When ripping work less than 4 inches wide, a push stick should be used to complete the feed and could easily

be made from scrap material by following the p attern shown in Fig. 69 (not shown to scale).

Fig. 69

PUSH STICK

MAKE FROM 1/2 OR 3/4

WOODORTHICKNESS

LESS THAN WIDTH OF

MATL. TO BE CUT

CUT OFF HERE TO

PUSH 1/4 WOOD

CUT OFF HERE TO

PUSH 1/2 WOOD

1/2 SQUARES

NOTCH TO HELP

PREVENT HAND

FROMSLIPPING

USING AUXILIARY WOOD

FACING ON THE UNIFENCE

It is necessary when performing special operations such

as when using the moulding cutterhead to add wood fac ing (A) Fig. 68, to one side of the rip fence as shown. T h e

wood facing is att ached to the fence with wood screws

through holes drilled in the fence. 3/4 inch stock is suit able for most work although an occasional job may

require one inch facing.

A

Page 20

20

Delt a will rep air or replace, at it s expense and at its option, any Delt a machine, machine p art, or machine

accessory which in normal use has proven to be defective in workmanship or material, provided that the

customer returns the product prepaid to a Delt a factory service center or authorized service st ation with

proof of purchase of the product within two years and provides Delta with reasonable opportunity to verify the alleged defect by inspection. Delt a may require that electric motors be returned prep aid to a motor

manufacturer s authorized station for inspection and repair or replacement. Delt a will not be responsible

for any asserted defect which has resulted from normal wear, misuse, abuse or rep air or alteration made

or specifically authorized by anyone other than an authorized Delta Service facility or representative.

Under no circumstances will Delt a be liable for incident al or consequential damages resulting from defective products. This warranty is Delta s sole warranty and sets forth the customer s exclusive remedy, with

respect to defective products; all other warranties, express or implied, whether of merchantability , fitness

for purpose, or otherwise, are expressly disclaimed by Delt a.

Two Year Limited Warranty

Delt a Machinery

Printed in U.S.A.

PARTS, SERVICE O R W ARRANTY ASSISTANCE

All Delt a Machines and accessories are manufactured to

high quality st andards and are serviced by a network of

factory service centers and authorized service st ations

listed in your owner s manual. To obtain additional infor -

mation regarding your Delt a quality product or to obt ain

part s, service or warranty assist ance, please call or fax

Delt a s toll-free hotline number.

Delt a maint ains a modern,

ef ficient Part s Distribution

Center, maint aining an

inventory of over 15,000

parts located in Memphis,

Tennessee.

Highly qualified and experienced Customer Service

Representatives are st anding

by to assist you on weekdays

from 7:00 A.M. to 6:00 P.M.

Memphis time.

Memphis, TN 38118

4290 Raines Road

Phone: (901) 363-8800

800-223-PA R T

FAX: 800-535-6488

Loading...

Loading...