Page 1

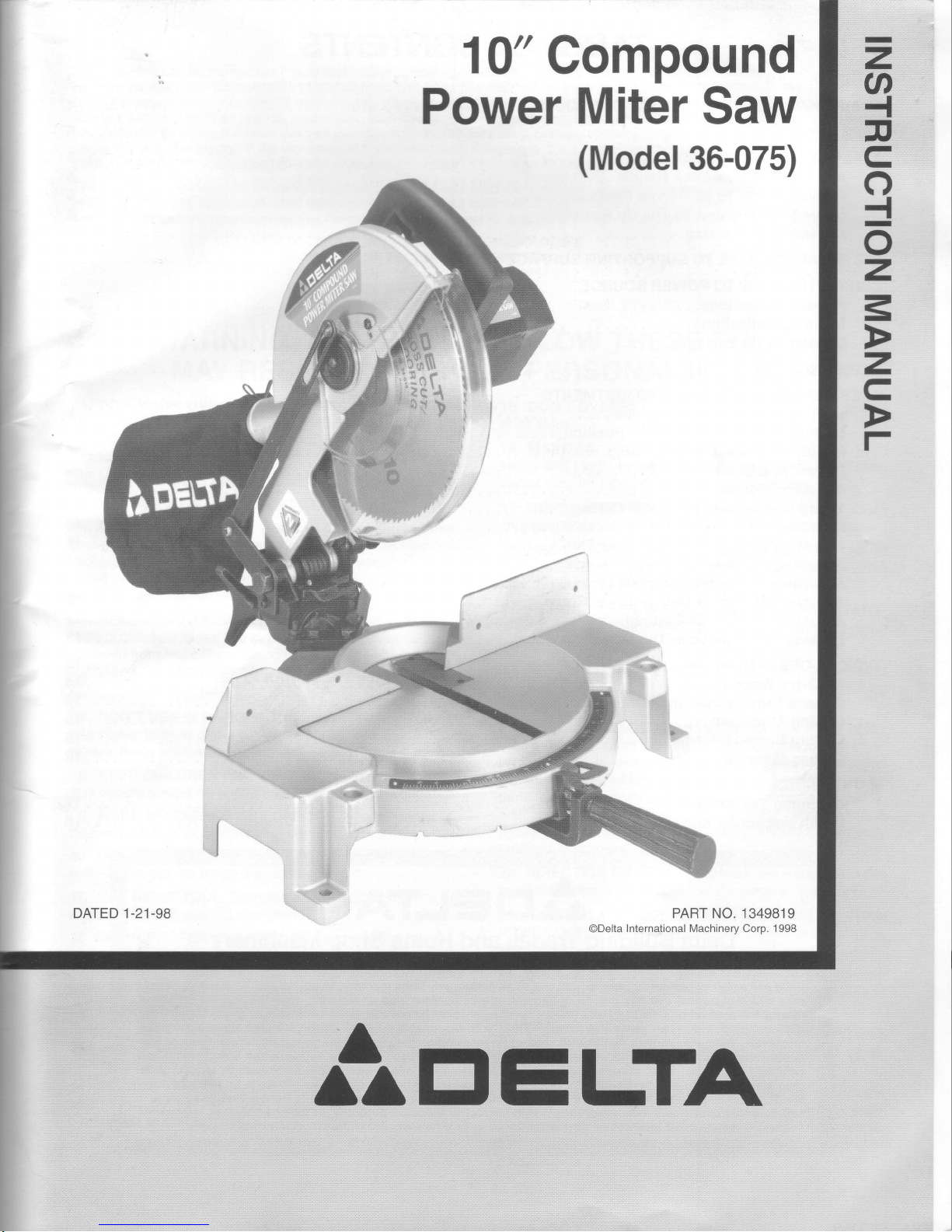

l0"

Compound

Power

Miter

Saw

(Model

36-075)

2

a

{

F

C

o

{

o

z

=

z

c

r

t,'t

PART NO. 1349819

ODelta

International l\,4achinery Corp. 1998

A

AA

trIELTA

Page 2

TABLE OF CONTENTS

SAFETY

RULES.

ADDITIONALSAFETYRULES

FORCOMPOUND

MITERSAWS.

........4

UNPACKING

ASSEMBLYINSTRUCTIONS.

.....5

AssemblingTable

LockHandle

.....5

RotatingTableTogO

Degree

Position

......5

Moving Cuttinghead

To The Up

Position

. . . . 6

Assembling

Dust

Bag

.......6

FASTENING

MACHINETOSUPPORTING

SURFACE

.....6

CONNECTING

SAW

TO POWER SOURCE

PowerConnections.....

-...7

MotorSpecifications...

- ----7

Grounding

Instructions

- - - - -.7

EXTENSTONCORDS

......8

OPERATING

CONTROLS

AND

ADJUSTMENTS

StartingAnd

Stopping

Machine

. -...8

Locking Switch

ln

The "OFF"

Position

. . . . .8

RotatingTableForMiterGutting....

"""9

PointerAndScale

....9

AdjustingPointer

....9

Tilting Cuttinghead

ForBevelCutting

.....10

RearSupporVCarrying

Handle

.....10

Adjusting

Blade Parallel

To Table Slot.

.

. . . 11

Adjusting

Fence 90

Degrees

To Blade

. . . . . 11

Adiusting

DownwardTravel

OlSaw

Blade.

.......11

Adjusting

90And

45 Degree

Bevel Stops

....

- - -.12

AdjustingTension

Of Cuttinghead

Return Spring

'..

-.. -.12

Locking Cuttinghead

lnTheDown

Position

......13

TYPICALOPERATIONSAND

HELPFULHINTS.

........13

AuxiliaryWood

Fence.

. - -. -14

General Cutting

Operations

.......14

CuttingAluminum

...15

Cutting

Bowed Material

....15

Gutting

Crown

Moulding.

...16

MAINTENANCE

ChangingThe

Blade

.

- - - - - -17

Brush InspectionAnd

Replacement.

- '....18

rArtrlELTA

Delta

Building

Trades and

Home Shop

Machinery

Two

Year Limited

Warranty

Delta will repair or

replace, at

its expense and

at its option,

any

Delta machine,

machine

part,

or machine

acces-

sory

which in normai

use has

proven

to be delective

in workmanship

or

material,

provided

that

the

customer

returns the

product prepaid

to a Delta

factory service center

or authorized

service

station

with

proof

of

purchase

ol

the

product

withih two

years

and

provides

Delta

with reasonable

opportunity

to verify

the alleged

defect by

inspeciion.

Delta may

require that electric

motors be

returned

prepaid

to a motor

manufacturer's

authorized

sta-

tion

for inspeclion and

repair or

replacement.

Delta will not be

responsible

for any asserted

defect

which has

resulted

from normal

wear, misuse,

abuse or

repair or alteration

made

or specifically

authorized

by anyone other

than an authorized

Delta Service

facility or

representative. Under

no circumstances

will

Delta be

liable for

inci-

dental or

consequential

damages

resulling from defective

products,

This warranty

is

Delta's sole

warranty and

sets

forth the customer's

exclusive

remedy,

with respect to defective

products;

all other

warranties,

express

or

implied,

whether of

merchantability,

fitness

for

purpose,

or otherwise,

are expressly

disclaimed

by

Delta.

Page 3

SAFETY RULES

Woodworking

can

be dangerous if

safe and

proper

operating

procedures

are not followed.

As with

all

machinery

there

are certain

hazards

invOlved

with the

operation

of

the

product.

Using the machine with

respect and caution will

considerably lessen

the

possi-

bility of

personal

injury. However,

if normal

safety

precautions

are overlooked or ignored,

personal

injury to the

operator may

result.

Safety equipment

such

as

guards, push

sticks, hold-downs,

featherboards,

goggles,

dust

masks

and hearing

protection

can reduce

your

potential

for

injury. But

even the

best

guard

won't

make

up

for

poor

judgment,

carelessness or inattention.

Always

use common

sense

and exercise

caution in the workshop.

lf

a

procedure

feels

dangerous,

don't try

it.

Figure out an

alternative

procedure

that feels

safer. REMEMBER:

Your

personal

safety is

your

responsibility.

This machine

was

designed for

certain applications

only. Delta Machinery

strongly recommends

that this machine

not

be modified

and/oj

yse!

]or

any

application

other than that for

which it

was designed. lf

you

have any

questions

relative

to

a

particular

applica-

tion, DO NOT

use the machine

until

you

have first

contacted

Delta to determine if it

can or should be

performed

on the

product.

DELTA

INTERNATIONAL

MACHINERY

CORP.

MANAGER

OF TECHNICAL

SERVICES

246 ALPHA

DRIVE

PITTSBURGH,

PENNSYLVANIA

1

5238

(lN

CANADA:

644 IMPERIAL

ROAD,

GUELPH, ONTARIO N1H 6M7)

WARNING:

FAILURE

TO

FOLLOW

THESE

RULES

MAY

RESULT

IN

SERIOUS PERSONAL

INJURY

1. FOR

YOUR

OWN SAFETY,

READ INSTRUCTION

MANUAL

BEFORE

OPERATING THE

TOOL.

Learn

the

tool's

application

and limitations

as well

as the

specific

hazards

peculiar

to it.

2. KEEP

GUARDS lN

PLACE

and in working

order.

3, ALWAYS

WEAR EYE PROTECTION.

4.

GROUND ALL

TOOLS.

lf tool is

equipped

with three-

prong plug,

it

should

be

plugged

into

a three-hole

electrical

receptacle.

lf

an adapter is

used to

accommodate

a two-

prong

receptacle,

the

adapter lug

must

be attached

to a

known

ground.

Never

remove

the third

prong.

5. REMOVE

ADJUSTING

KEYS

AND WRENCHES,

Form

habit

of checking to

see that keys

and

adjusting wrenches

are

removed

from

tool

before turning it

"on."

6. KEEP WORK

AREA

CLEAN.

Cluttered

areas

and

benches invite

accidents.

7.

DON'T

USE ILLDANGEROUS

ENVIRONMENT.

Don't

use

power

tools

in

damp or wet locations,

or expose

them

to rain.

Keep work

area well-lighted.

8. KEEP

CHILDREN

AND VISITORS

AWAY.

Att

chitdren

and visitors

should

be kept

a safe distance from

work

area.

9.

MAKE

WORKSHOP

CHILDPROOF

-

with

padtocks,

master

switches,

or

by

removing

starter keys.

10.

DON'T FORCE

TOOL.

lt will

do the

job

better and

be

safer

at the rate for

which it

was

designed.

11.

USE RIGHT

TOOL. Don't

force

tool or attachment

to

do

a

job

for which

it was

not designed.

12.

WEAR PROPER

APPAREL.

No

loose clothing,

gtoves,

neckties,

rings,

bracelets,

or other

jewelry

to

get

caught

in

moving

parts.

Nonslip

footwear.

is recommended.

Wear

protective

hair

covering to

contain long

hair.

13.

ALWAYS

USE

SAFETY

GLASSES. Wear

safety

gtasses.

Everyday

eyeglasses

only have

impact

resistant

lenses;

they are not

safety

glasses.

Also

use face

or

dust mask if

cutting

operation

is dusty.

14.

SECURE WORK.

Use

clamps or a vise

to hotd

work

when

practical.

lt's

safer than

ubing

your

hand

and frees

both hands

to operate

tool.

15.

DON'T

OVERREACH. Keep

proper

footing

and balance

at

all

times.

16.

MAINTAIN TOOLS

lN TOP

CONDITION.

Keep

toots

sharp and clean for

best and safest

performance.

Follow

instructions

for lubricating

and changing

accessories.

17. DISCONNECTTOOLS

before

servicing

and when

changing

accessories such as

blades, bits,

cutters,

etc.

18.

USERECOMMENDEDACCESSORIES.

The

use of

accessories

and attachments not

recommended

by

Delta

may

cause hazards or risk

of injury to

persons.

19. REDUCE

THE RISK

OF UNINTENTIONAL

START.

lNG,

Make

sure switch is in

"OFF"

position

before

plugging

in

power

cord.

20.

NEVER

STAND ON TOOL.

Serious injury

could

occur

if the tool is tipped

or if the

cutting tool is

accidentally

contacted.

21,

CHECK DAMAGED

PARTS. Before

further

use

of

the

tool,

a

guard

or other

part

that

is damaged

should

be care-

fully

checked to ensure that it

will operate

properly

and

perform

its

intended function

-

check for

alignment

of moving

parts,

binding of

moving

parts,

breakage

of

parts,

mounting,

and any other

conditions that may

affect its

operation.

A

guard

or other

part

that is

damaged

should be

properly

repaired

or replaced.

22. DIRECTION

OF FEED. Feed

work into

a blade

or cutter

against the

direction of rotation

of the

blade or cutter

only.

23. NEVER LEAVETOOL

RUNNING

UNATTENDED. TURN

POWER

OFF.

Don't leave

tool

until

it

comes to

a complete

stop.

24.

DRUGS, ALCOHOL,

MEDICATION.

Do

not operate

tool while

under the influence

of drugs,

alcohol

or

any

medication.

25. MAKE

SURE TOOL IS DISCONNECTED

FROM

POWER

SUPPLY while motor is

being mounted,

connected or re-

connected.

26. WARNING: The

dust

generated

by certain woods

and

wood

products

can be injurious to

your

health.

Always

oper-

ate machinery in

well ventilated

areas

and

provide

for

proper

dust

removal.

Use wood

dust collection

svstems

whenever

possible.

Page 4

ADDITIONAL

SAFETY

RULES

FOR

COMPOUND

MITER

SAWS

1. WARNING:

USE

ONLY

CROSS-CUTTING

SAW

BLADES.

WHEN USING

CARBIDE

TIPPED

BLADES,

MAKE SURE

THEY

HAVE

A NEGATIVE

HOOK

ANGLE.

DO NOT USE

BLADES

WITH DEEP GULLETS

AS

THEY CAN

DEFLECT

AND CONTACT

GUARD.

2.

WARNING:

Do not operate

the

miter saw

until

it is

completely

assembled

and

installed according

to the

instructions.

3.

lF

YOU ARE

NOT thoroughly

familiar

with the oper-

ation of

compound

miter saws, obtain

advice

from

your

supervisor,

instructor or

other

qualified person.

4. DO

NOT

pedorm

any operation

freehand.

Secure or

clamp

workpiece

firmly against

fence.

5.

WARNING:

Keep

hands out

of

path

of

saw blade.

lf

the

workpiece

you

are cutting

would cause

your

hand to

be

within

4 inches of

the saw

blade,

the

workpiece

should

be clamped

in

place

before

making

cut.

6.

BE SURE

blade

is sharp,

runs

freely and

is free of

vibration.

7. ALLOW

the

motor to come

up to

full speed

before

starting

cut.

B.

KEEP

motor air slots

clean

and

free of chips.

L

ALWAYS

MAKE SURE

all clamp

handles are

tight

before

cutting,

even

if the table

is

positioned

in one

of the

positive

stops.

10.

BE

SURE

blade

and

flanges

are clean

and

that

arbor

screw

is tightened

securely.

11 . USE

only

blade

flanges specif

ied

for

your

saw.

12.

NEVER use

blades

larger or

smaller

in diameter

than

ten

inches.

13.

NEVER

apply

lubricants

to the blade

when it

is

runnrng.

14. ALWAYS

check

the blade

for cracks

or damage

before

operation.

Replace

cracked or

damaged

blade

immediately.

15.

NEVER use

blades

recommended

for operation

at

less than

6000

RPM.

16.

DO NOT

operate

the saw

without

guards

in

place.

17. ALWAYS

keep

the

lower blade

guard

in

place

and

operating

properly.

18.

NEVER

reach around

or behind

saw

blade.

19.

MAKESURE

blade

is

not contacting

workpiece

before

switch

is turned

on.

20. NEVER

lock the

switch

in the

"ON"

position.

21. IMPORTANT

After completing

cut,

release

power

switch

and

wait for coasting

blade

to stop

before

return-

ing saw

to

raised

Position.

22.

TURN OFF

tool and

wait

for saw

blade

to stop

before

moving

workpiece

or

changing

settings.

23. DO

NOT

remove

jammed

or

cut-off

pieces

until blade

has stopped.

24.

NEVER

cut

ferrous

metals

or

masonry'

25.

NEVER

recut small

Pieces.

26.

PROVIDE

adequate

support

to

the sides

of

the saw

table

for

long

workPieces.

27. NEVER

use

the

miter

saw

in an area

with flammable

liquids or

gases.

28.

NEVER

use solvents

to clean

plastic pafts.

Solvents

could

possibly

dissolve

or othenruise

damage

the

material.

Only

a soft

damp

cloth

should

be

used

to clean

plastic

pans.

29. DISCONNECT

power

before

changing

blades

or

servicing.

30.

DISCONNECT

saw

from

power

source

and clean

the machine

before

leaving

it.

31.

MAKE

SURE

the

work area

is cleaned

before

leav-

ing the

machine.

32.

THE

USE

of attachments

and

accessories

not

rec-

ommended

by

Delta

may

result

in the

risk of

injuries.

33.

SHOULD

any

part

of

your

miter saw

be

missing,

damaged

or

fail

in any

way, or

any electrical

component

fail

to

per{orm

properly,

shut

off switch

and

remove

plug

from

power

supply

outlet.

Replace

missing,

damaged

or

failed

parts

before

resuming

operation.

34.

ADDITIONAL

INFORMATION

regarding

the safe

and

proper

operation

of

this

product

is available

from the

National

Safety

Council,

1121 Spring

Lake

Drive,

ltasca,

lL60143-3201,

in the

Accident

Prevention

Manual

for

Industrial

Operation

and also

in the Safety

Data Sheets

provided

by

the

NSC.

Please

also

refer

to the

American

National

Standard

Institute

ANSI

01.1 Safety

Require-

ments

for

Woodworking

Machinery

and

the U.S.

Depart-

ment of

Labor

OSHA

1910.213

Regulations.

35.

SAVE

THESE

INSTRUCTIONS.

Refer

to them often

and

use

them

to

instruct others.

Page 5

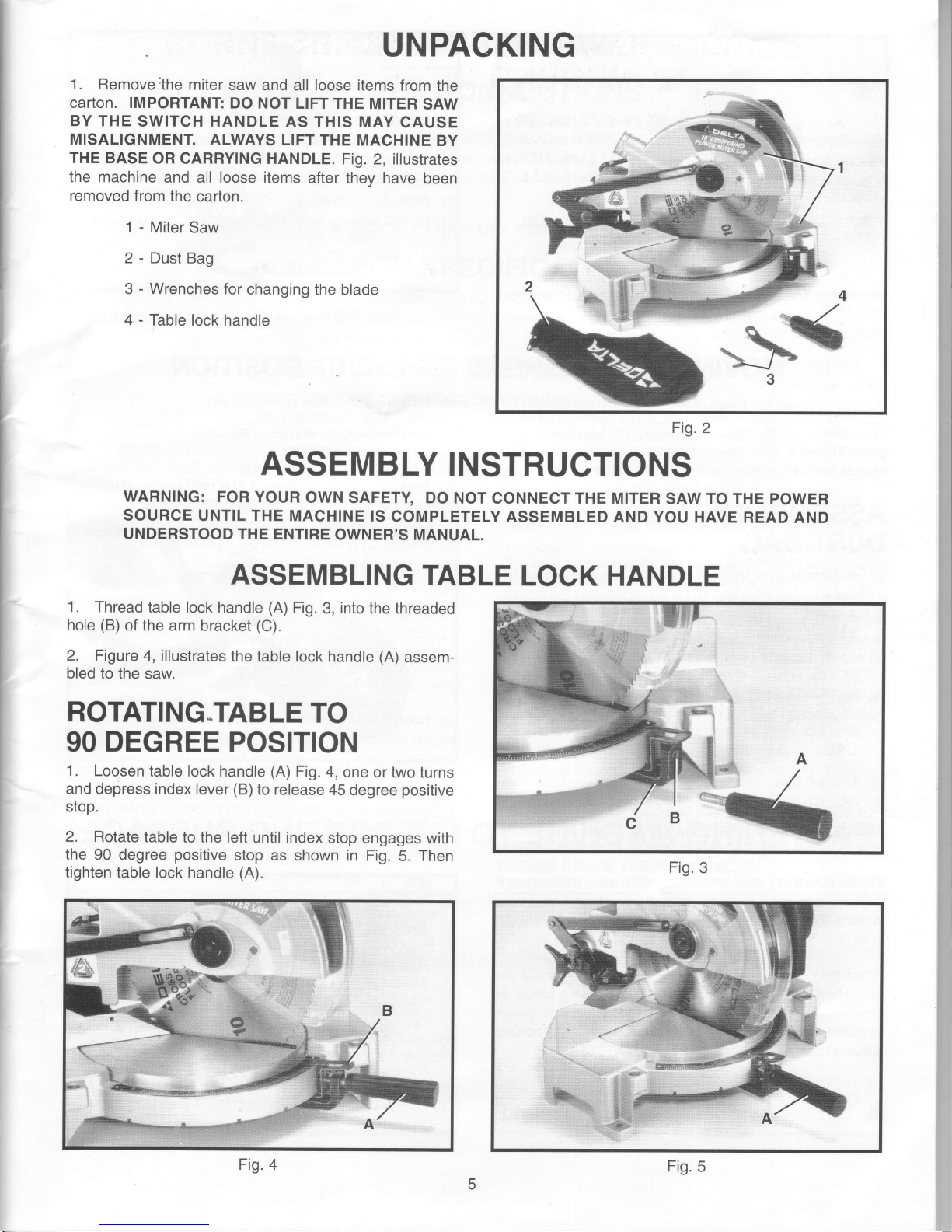

UNPAGKING

1.

Remove;the miter

saw

and all loose items

lrom the

carton. IMPORTANT

DO

NOT LIFT THE

MITER

SAW

BY THE

SWITCH HANDLE

AS THIS

MAY

CAUSE

MISALIGNMENT.

ALWAYS LIFT

THE MACHINE

BY

THE BASE

OR CARRYING HANDLE.

Fig. 2, illustrates

the machine

and all loose items

after they have

been

removed

from the

cafton.

1 - Miter

Saw

2 - Dust Bag

3

-

Wrenches

for

changing

the blade

4

-

Table lock handle

1. Thread

table lock

handle

(A)

Fig.

3,

into

the threaded

hole

(B)

of the

arm bracket

(C).

2. Figure

4, illustrates

the

table lock handle

(A)

assem-

bled to

the saw.

ROTATING.TABLE

TO

90

DEGREE

POSITION

1, Loosen

table lock

handle

(A)

Fig.

4,

one or two turns

and

depr,ess index lever

(B)

to release

45

degree

positive

stop.

2. Rotate

table

to the left

until index

stop engages with

the 90

degree

positive

stop as

shown in Fig.

5. Then

tighten table

lock handle

(A).

4

Fig. 2

ASSEMBLY

INSTRUCTIONS

WARNING: FOR

YOUR

OWN

SAFETY DO

NOT

CONNECT

THE

MITER

SAW

TO

THE POWER

SOURCE

UNTIL THE MACHINE

IS

COMPLETELY

ASSEMBLED AND

YOU HAVE

READ AND

UNDERSTOOD

THE ENTIRE

OWNER'S MANUAL.

ASSEMBLING

TABLE

LOCK

HANDLE

Fig.

3

Fig.

4

Fig.

5

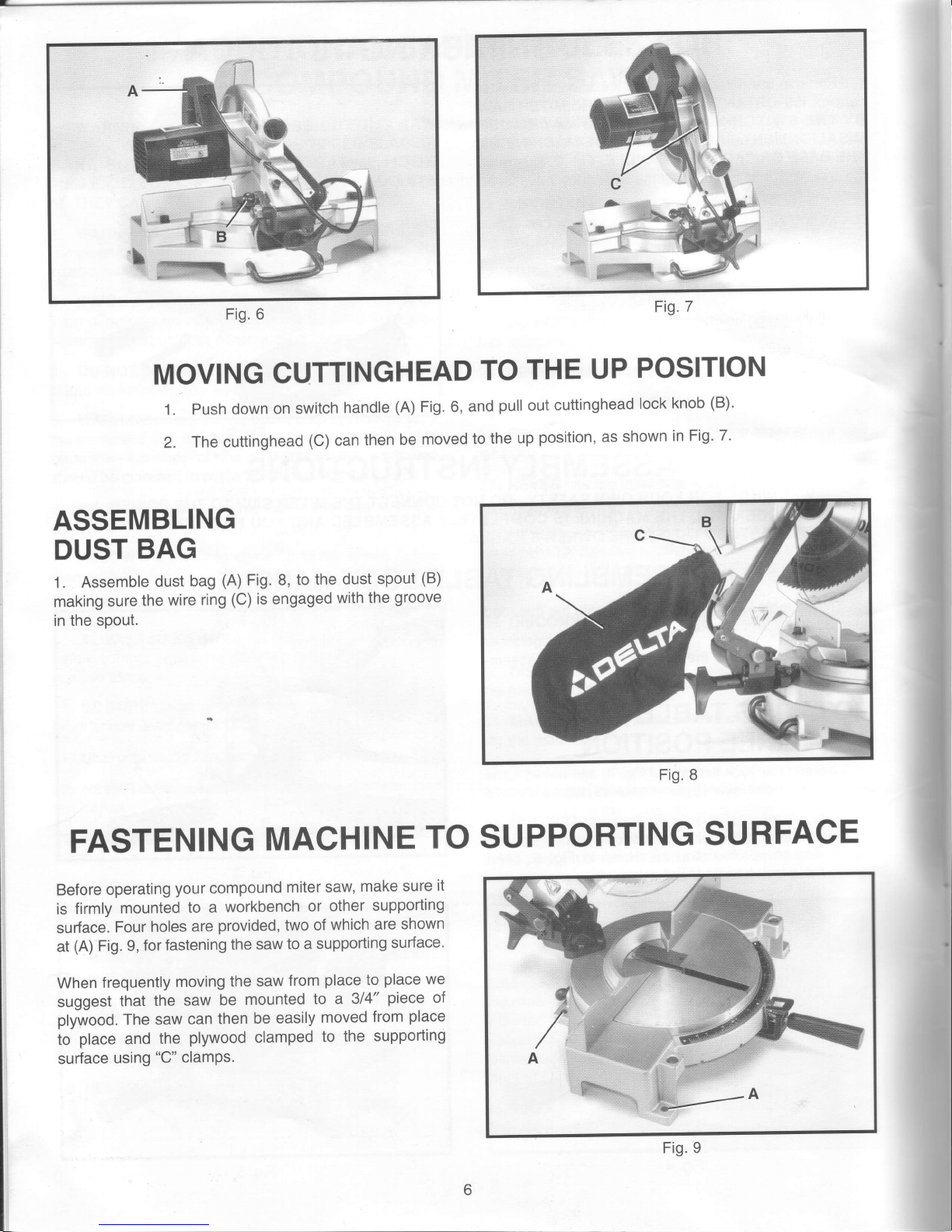

Page 6

Fig. 6

Fig.7

MOVING

CUTTINGHEAD

TO

THE

UP

POSITION

Push

down

on

switch

handle

(A)

Fig.

6, and

pull

out

cuttinghead

lock

knob

(B)'

The

cuttinghead

(c)

can

then

be

moved

to

the

up

position,

as

shown

in Fig.

7.

1.

2.

ASSEMBLING

DUST

BAG

1.

Assemble

dust

bag

(A)

Fig.

8, to

the

dust

spout

(B)

making

sure

the

wire

ring

(C)

is engaged

with

the

groove

in the

spout.

FASTENING

MACHINE

TO SUPPORTING

SURFACE

Before

operating

your

compound

miter

saw,

make

sure

it

is

firmly

mounted

to

a

workbench

or

other

suppofiing

surface.

Four

holes

are

provided,

two

of

which

are

shown

at

(A)

Fig. 9,

for

fastening

the saw

to

a supporting

sudace.

When

frequently

moving

the

saw

from

place

to

place

we

suggest

that

the

saw

be

mounted

lo

a 314"

piece

of

plywood. The saw

can

then

be easily

moved

from

place

to

place

and

the

plywood clamped

to

the

supporting

surface

using

"C"

clamPs.

Fig. 8

Fig. 9

Page 7

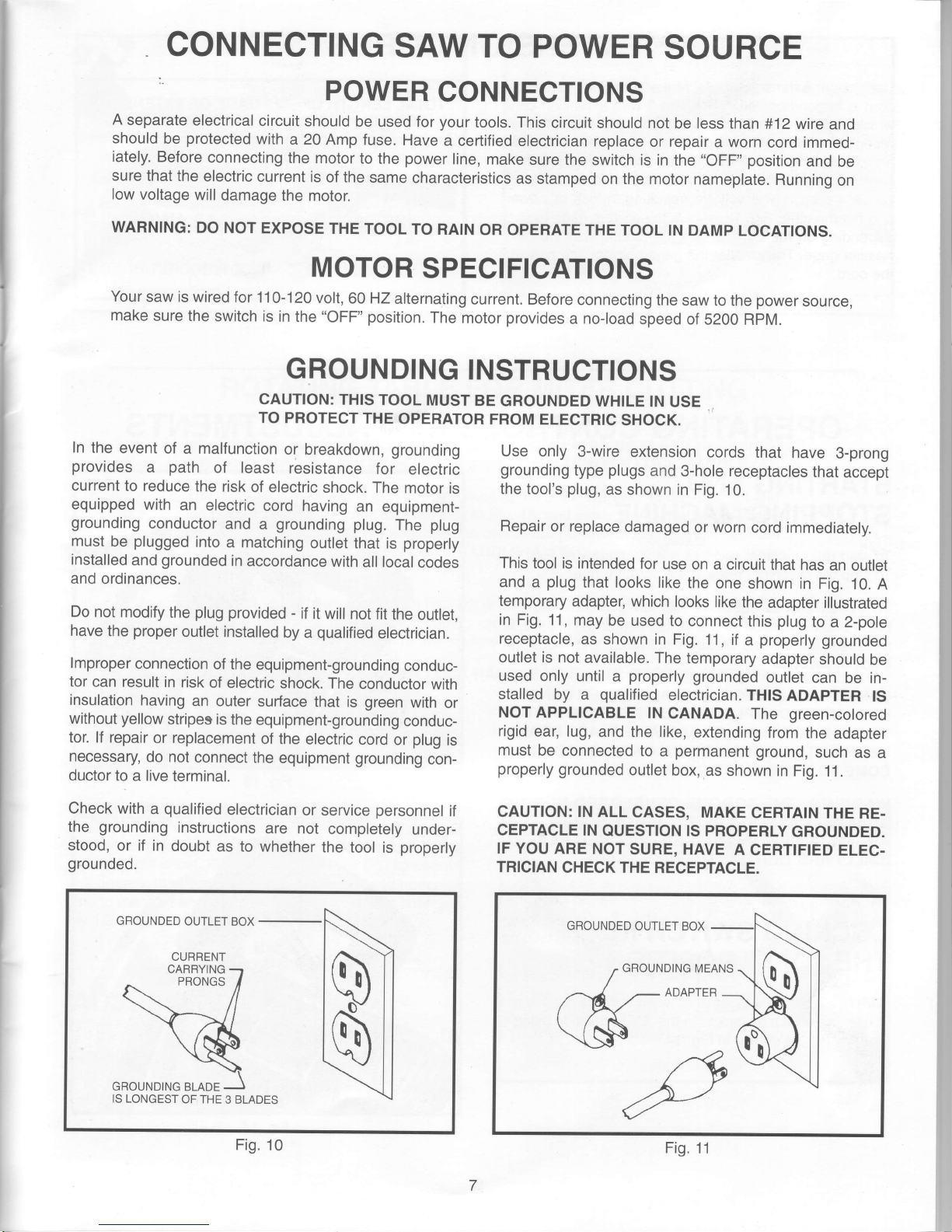

CONNECTING

SAW TO

POWER

SOURCE

POWER

CONNECTIONS

A

separate

electrical

circuit

should

be used

for

your

tools. This

circuit

should not

be less than

#12 wire

and

should

be

protected

with

a 20

Amp fuse.

Have

a

cerlified electrician

replace

or repair

a worn

cord immed-

iately.

Before

connecting

the motor

to

the

power

line,

make sure

the switch is in

the

"OFF" position

and be

sure

that the

electric

current

is

of

the

same

characteristics

as stamped

on the motor

nameplate.

Running

on

low

voltage

will

damage

the motor.

WARNING:

DO NOT

EXPOSE

THE

TOOL

TO RAIN

OR OPERATE THE

TOOL IN

DAMP

LocATIoNs.

MOTOR

SPECIFICATIONS

Your

saw is

wired for

110-120

volt,

60 HZ

alternating

current. Before

connecting

the

saw to the

power

source,

make

sure the

switch

is in

the

"OFF" position.

The

motor

provides

a

no-load

speed of

52OO RPM.

GROUNDING

INSTRUCTIONS

CAUTION:

THIS

TOOL

MUST

BE

GROUNDED WHTLE

tN

USE

.

TO PROTECT

THE

OPERATOR

FROM

ELECTRIC

SHOCK.

In

the

event of

a malfunction

or

breakdown,

grounding

provides

a

path

of least

resistance

for

electric

current

to reduce

the

risk

of electric

shock.

The

motor is

equipped

with

an

electric

cord having

an equipment-

grounding

conductor

and a

grounding

plug.

The

plug

must

be

plugged

into

a matching

outlet that

is

properly

installed

and

grounded

in

accordance

with

all localcodes

and

ordinances.

Do not

modify

the

plug provided

-

if it wiil

not fit

the

ouilet,

have

the

proper

outlet installed

by

a

qualified

electrician.

lmproper

connection

of the

equipment-grounding

conduc-

tor

can result

in risk

of electric

shock. The

conductor

with

insulation

having

an

outer surface

that

is

green

with

or

without

yellow

stripes is

the

equipment-grounding

conduc-

tor.

lf repair

or replacement

of the

electric

cord or

plug

is

necessary

do not

connect

the

equipment

grounding

con-

ductor to

a live terminal.

Check with

a

qualified

electrician

or

service

personnel

if

the

grounding

instructions

are not

completely

under-

stood,

or if in

doubt

as

to whether

the

tool is

properly

grounded.

GROUNDED

OUTLET

BOX

IS LONGEST

OF THE

3 BLADES

Use only

3-wire extension

cords

that have

3-prong

grounding

type

plugs

and

3-hole receptacles

that

accept

the tool's

plug,

as

shown in Fig.

10.

Repair

or replace

damaged

or worn

cord immediately.

This

tool is intended

for

use

on a circuit

that has

an

ouflet

and

a

plug

that looks

like

the

one shown in

Fig.

10. A

temporary

adapter, which

looks

like

the

adapter illustrated

in

Fig. 11,

may

be used to

connect

this

plug

to a 2-pole

receptacle,

as

shown in Fig.

11, if

a

properly

grounded

outlet is not

available. The

temporary

adapter

should

be

used

only until

a

properly

grounded

outlet can

be in-

stalled by

a

qualified

electrician.

TH|S

ADAPTER

lS

NOT

APPLICABLE

lN

CANADA. The

green-cotored

rigid

ear, lug,

and the like,

extending

from

the

adapter

must

be connected

to

a

permanent

ground,

such

as a

properly

grounded

outlet

box,,as

shown in

Fig. 11,

CAUTION:

lN ALL

CASES,

MAKE

CERTATN

THE

RE-

CEPTACLE IN

QUESTION IS PROPERLY

GROUNDED.

IF YOU ARE

NOT

SURE, HAVE

A

CERTIFIED

ELEC.

TRICIAN

CHECK THE

RECEPTACLE.

GBOUNDED

OUTLET BOX

GROUNDING

MEANS

ADAPTER

11

Fig.

10

Fig.

Page 8

Use

proper

extension

cords.

Make sure

your

extension

cord

is in

good

condition

and

is a 3-wire

extension

cord

which has a 3-prong

grounding

type

plug

and a 3-pole

receptacle

which

will accept

the tool's

plug.

When using

an

extension

cord,

be sure

to use one

heavy enough

to

carry

the current

of the

saw.

An

undersized

cord

will

cause a drop

in line voltage,

resulting

in loss of

power

and overheating.

Fig. 12, shows

the correct

gage

to use

depending

on

the cord

length.

lf in

doubt,

use

the next

heavier

gage.

The smaller

the

gage

number,

the

heavier

the cord.

TOTAL

LENGTH OF

GAGE

OF

EXTENSION

CORD

IN FEET

CORD

TO USE

0-25

14AWG

26 - 50

12 AWG

Over

50

Not

Recommended

Fig.

12

13

Fig.

EXTENSION

CORDS

OPERATING

CONTROLS

AND

ADJUSTMENTS

STARTING

AND

STOPPING

MACHINE

To start

the machine,

depress switch

trigger

(A)

Fig.

13.

To

stop

the

machine,

release the switch

trigger.

This miter saw

is equipped

with an automatic

electric

blade brake.

As soon

as the switch

trigger

(A)

Fig.

13, is

released,

the electric

brake

is activated and

stops

the

blade

in seconds.

DANGER:

A

TURNING SAW

BLADE CAN

BE

DANGER.

OUS.

AFTER

COMPLETING

CUT,

RELEASE

SWITCH

TRTGGER

(A)

FlG. 13,

TO ACTIVATE

BLADE

BRAKE.

KEEP CUTTINGHEAD

DOWN UNTIL

BLADE

HAS

COME

TO A COMPLETE

STOP.

WARNING:

THE TORQUE

DEVELOPED

DURING

BRAKING

MAY LOOSEN

THE

ARBOR SCREW.

THE

ARBOR

SCREW

SHOULD

BE CHECKED

PERIOD.

ICALLY

AND TIGHTENED

IF NECESSARY.

LOCKING

SWITCH

IN

THE

"OFF''

POSITION

IMPORTANT

We suggest

that

when the

miter saw

is not

in use,

the switch be

locked

in the

"OFF"

position

using

a

padlock (B),

as shown

in

Fig. 14.

Fig.

14

Page 9

16Fig.

15Fig.

ROTATING

TABLE

FOR MITER

CUTTING

Your miter

saw will

cut any angle from

a straight

90 degree cullo 47 degrees right

and

left.

Simply loosen

lock handle

(A)

Fig. 15,

one ortwo turns,

depress index lever

(B)

and

move

the

control arm to

the desired

angle. THEN TIGHTEN LOCK

HANDLE

(A).

The

miter

saw is equipped

with

positive

stops

at

the

0,22-112, and 45 degree right

and

left

positions.

Simply loosen lock

handle

(A)

Fig. 15,

and

move

the control arm

untilthe

bottom

of the index lever

(B)

engages into

one of the

positive

stops, four

of

which

are

shown at

(C).

THEN

TIGHTEN

LOCK HANDLE

(A).

To

disengage the

positive

stop,

depress index lever

(B).

In

addition,

a triangle indicator

(D)

Fig. 16,

is

provided

on the

miter

scale at the

31-5/8

right

and left miter

positions

for

cutting

crown moulding. Refer

to the "CUTTING

CROWN MOULDING"

section of this manual,

IMPORTANT

ALWAYS

TIGHTEN

LOCK HANDLE

(A)

Ftc. 16, BEFORE

CUTT|NG.

POINTER

AND

SCALE

A

pointer

(E)

Fig.

17, is

supplied

which indicates

the

actual angle

of cut. Each line

on the

scale

(F)

represents

112

degree.In effect,

when the

pointer

is moved

from

one

line to

the next

on the scale,

the angle

of cut is changed

by 112 degree.

ADJUSTING

POINTER

lf it

becomes

necessary

to

adjust the

pointer

(E)

Fig.

17,

simply loosen

screw

(G),

adjust

the

pointer

accordingly

and tighten

screw

(G).

Fig.17

Page 10

1BFig.

TILTING

CUTTINGHEAD

FOR

BEVEL CUTTING

The cuttinghead of

your

compound

miter

saw

can be tilted to cut

any bevel

angle

from

a 90

degree straight

cut off to a

45

degree

left bevel angle by

loosening bevel

lock handle

(A)

Fig. 18, tilting cutting

arm

(B)

to the

desired angle

and tightening

lock handle

(A).

Positive stops are

provided

to rapidly

position

the

saw

blade at 90

and

45

degrees

to the

table. Refer

to the

section of

this manual titled

"ADJUSTING 90

AND 45 DEGREE

BEVEL STOPS."

The bevel angle

of the

cutting arm

is determined by

the

position

of the

pointer (C)

Fig,

18,

on

the scale

(D),

In

addition,

a triangle

indicator is

provided

on the bevel scale

at

the

33-718

degree

bevel angle

for cutting

crown

moulding.

Refer to the "CUTTING CROWN

MOULDING"

section of

this manual.

REAR

SUPPORT/CARRYING

HANDLE

A rear support bar

(A)

Fig.

19, is

provided

to

prevent

the

miter saw

from tipping

to the rear

when the cutting-

head is

returned to the up

position

after

a cut has been

made. For

maximum support

the bar

(A)

should be

pulled

out as

far

as

possible.

The

support

bar

(A)

also acts as

a carrying

handle,

as shown

in Fig. 20,

when transporting

the saw.

Fig.

19

Fig. 20

10

Page 11

ADJUSTING BLADE

PARALLEL TO TABLE

SLOT

1. DISCONNECT

THE SAW FROM THE POWER

SOURCE.

2.

NOTE: This adjustment

should be checked with the

cutting arm

moved

all the way to the right

(blade

90

degrees to the table)

and the table in the 90 degree

straight

cut-off

position

(blade

90 degrees to the fence).

3.

Lower

the cutting arm. The

saw blade

(A)

Fig. 21,

should

be

parallel

to the

left

edge

(B)

of

the table

opening.

4. lf an

adjustment

is necessary,

loosen three

screws

(C)

Fig. 21, and move the

cutting arm until the blade is

parallel

with

the

left

edge

(B)

of the table

opening. Then

tighten the three screws

(C).

ADJUSTING

FENCE

90

DEGREES

TO BLADE

lf the fence

(A)

Fig.

22, is ever removed from

the saw it

should be adjusted

so

it is

90 degrees to the

blade

when

it is replaced,

as

follows:

1.

DISCONNECT THE

SAW

FROM

THE POWER

SOURCE.

2. This

adjustment should be made

only after the blade

has

been adjusted

parallelto

table opening,

as

previous-

ly explained.

3. Using a square

(B)

Fig. 22,

place

one end of the

square against the fence

(A)

and the other

end against

the

slot

in the

table as shown.

4.

lf an adjustment is necessary,

loosen the two

screws

(C)

Fig. 23,

and adjust fence

90 degrees to the table

opening. Then

tighten the two

screws

(C).

ADJUSTING

DOWNWARD

TRAVEL

OF SAW

BLADE

1.

DISCONNECT THE

SAW FROM THE POWER

SOURCE.

2. The

downward travel of the

saw blade can be limited

to

prevent

the saw blade from

contacting any metal

surfaces of the machine. This

adjustment is made

by

loosening locknut

(A)

Fig. 24, and turning

adjusting screw

(B)

in

or out.

3.

When making

this adjustment,

MAKE SURE THE

MACHINE

IS DISCONNECTED

FROM THE POWER

SOURCE

and

lower

the blade as far

as

possible.

Rotate

the

blade by

hand

to make certain the

teeth do not con-

tact

any

metal

surfaces

and adjust

if

necessary.

4. After

the downward travel

of the saw blade has

been

adjusted, tighten

locknut

(A)

Fig.21

Fig.22

Fig. 23

Fig.24

Page 12

rr

I

ADJUSTING

90

AND

45

DEGREE

BEVEL

STOPS

1.

DISCONNECT

THE

SAW

FROM

THE

POWER

SOURCE.

2.

Loosen

bevel

lock

handle

and

move

the

cutting

arm

allthe

way

to the

right,

then

tighten

the

bevel

lock handle'

3.

Using

a square

(A)

Fig.

25,

place

one

end

of

the

square

on

the

table

and

the

other

end

against

the blade'

Check

to see

if the blade

is at

90

degrees

to the

table,

as

shown

in

Fig.

25.

4.

lf an

adjustment

is

necessary,

loosen

locknut

(B)

Fig.

26,

and

turn

screw

(C)

until

head

of screw

(C)

con-

tacts

casting

(D)

when

blade

is

90

degrees

to the

table'

Then

tighten

locknut

(B).

5.

Loosen

bevel

lock

handle

and

move

the

cutting

arm

all

the

way to

the

left bevel

position

and

tighten

bevel

lock

handle.

6.

Using

a combination

square

(A)

Fig.

27, check

to see

if the

blade

is at

45 degrees

to the

table,

as

shown.

7.

lf an

adjustment

is necessary,

loosen

locknut

(E)

Fig.

28, and

turn

screw

(F)

until

screw

(F)

contacts

casting

(G)

when

blade

is 45 degrees

to

the

table.

Then

tighten

locknut

(E).

8.

These

positive

stops

enable

you

to

rapidly

position

the blade

at

the 90

and

45 degree

bevel

angle

to

the

table.

ADJUSTING

TENSION

OF

CUTTINGHEAD

RETURN

SPRING

The

tension

of

the cuttinghead

return

spring

has been

adjusted

at

the

factory

so

the

cuttinghead

returns

to the

up

position

after

a cut

has

been

made.

lf it ever

becomes

nec-

essary

to

re-adjust

the spring

tension,

proceed

as

follows:

1.

Loosen

locknut

(A)

Fig.

28A,

and

turn

screw

(B)

clockwise

to

increase

or counterclockwise

to decrease

the

spring

tension.

After

the

spring

tension

has been

adjusted,

tighten

locknut

(A).

Fig.2BA

Fig.

25

Fig,

26

Fig.27

Fig.

28

12

Page 13

LOCKING

CUTTINGHEAD

IN THE

DOWN

POSITION

When

transporting

the

saw, the

cuttinghead

should always

be locked in

the down

position.

This

can be

accomplished

by lowering

the

cutting arm

(A)

Fig. 29,

and

pushing

in

plunger

(B)

until

other end

of

plunger

(B)

engages

with

hole

in cutting

arm. IMPORTANT

NEVER

CARRY THE

COMPOUND

MITER

SAW

BY

THE

SWITCH HANDLE.

THIS MAY

CAUSE MISALIGNMENT.

ALWAYS

LIFT

THE

MACHINE

BY THE

BASE.

29Fig.

TYPICAL

OPERATIONS

AND HELPFUL

HINTS

1. Before

cutting,

make

certain the

cutting

arm and table

are at their correct

settings

and

firmly

locked

in

place.

2.

Before

cutting,

determine

that the workpiece

is

the

right

size for the

saw,

3. Place

the workpiece

on the table

and hold

or clamp it firmly

against the fence.

Fig.

30,

illustrates

the

accessory

36-221work

clamp

(A)

being used to clamp a workpiece

to the fence.

The

clamp

(A)

can also

be used on the right

side of the machine.

4.

For

best

results,

cut at

a slow, even

cutting rate.

5. WARNING:

lf the

workpiece

you

are cutting would

cause

your

hand

to be within 4

inches

of

the

saw blade, the

workpiece

should

be clamped

in

place

before

making

cut.

See

Fig.

30.

6. Never

attempt

any freehand

cutting

(wood

that is not held firmly

against the fence

and

table).

Fig.

30

13

Page 14

AUXILIARY

WOOD

FENCE

When

performihg

multiple

or

repetitive

cut-off

operations

that

result

in small

cut-off

pieces,

one

inch or

less,

it

is

possible

for the

saw blade

to catch

the

cut-off

pieces

and

project

them

out

of the

machine

or

into the

blade

guard

and

housing,

possibly

causing

damage

or

injury.

In order

to

limit

the

possibility

of

personal injury

or blade

guard

damage,

an

auxiliary

wood

fence can

be

mounted

to

your

saw

as

follows:

Holes

are

provided

in

the

fence

to attach

an

auxiliary

fence

(A)

Fig. 31.

This

auxiliary

fence

is constructed

of

straight

wood

approximately

112

inch thick

by

3

inches

high by

20 inches

long.

NOTE:

The auxiliary

fence

(A)

is

used

ONLY

with the

saw

blade

in the 0

degree

bevel

position

(90

degrees

to the

table).

When bevel

cutting

(blade

tilted)

the auxiliary

fence

will have

to be

removed.

GENERAL

CUTTING

OPERATIONS

1. Your

compound

miter saw

has the

capacity

to cut

standard

2 x 6's

at

the

straight

90

degree

cut-off

position,

as

shown

in Fig. 32,

or

at the

45 degree

bevel

position,

as

shown

in Fig. 33.

2. Cutting

a standard

4

x 4 is easily

accomplished

with

your

compound

miter saw,

as

shown

in Fig. 34.

Fig. 31

Fig. 32

Fig.

33

Fig. 34

Page 15

CUTTING

ALUMINUM

Aluminum extrusions

such as

used for

making aluminum

screens

and storm

windows can easily

be cut

with

your

compound

miter saw.

When cutting aluminum

extrusions,

or other sections

that can be cut

with a saw blade and

are

within the capacity

of the

machine,

position

the material

so

the blade

is

cutting

through

the smallest cross-

section, as shown

in

Fig.

35.

The wrong

way to cut

aluminum

angles

is illustrated in

Fig.

36.

Be sure to apply

a stick

wax

(similar

to

Johnson's

stick

wax #140) to the

blade

before cutting any

aluminum stock.

This stick

wax

is available at

most industrial

mill supply

houses. The

stick

wax

provides proper

lubrication and

keeps chips

from

adhering

to the blade.

NEVER

APPLY LUBRICANT

TO

THE BLADE WHILE

THE MACHINE IS

RUNNING.

t=*"=*

RIGHT

FENCE

+

WRONG

Fig. 36

35

Fig.

CUTTING

BOWED

MATERIAL

When cutting

flat

pieces,

first check

to

see

if the material

is bowed.

lf it is, make sure

the material is

positioned

on

the table as shown

in Fig. 37.

lf the

material is

positioned

the

wrong way, as shown

in Fig. 38,

the workpiece

will

pinch

the blade

near the completion

of the cut.

RIGHT

Fig. 37

WRONG

38Fig.

tc

Page 16

'll

til

lt

CUTTING

CROWN

MOULDING

One

of

the

many

features

of

your

saw

is the

ease

of

cutting

crown

moulding.The

following

is

an

example

of

cutting

both

inside

and

outside

corners

on 53/38

degree

wallangle

crown

moulding.

NOTE:

When

cutting

45 degree

wall

angle

crown

moulding,

the

following

procedure for

inside

and

outside

corners

is the

same

with the

exception

that

the

bevel

position

will always

be

at 30

degrees

and

the

miter

position

will

be 35-114

degrees

to the

right or

left.

1

. Move

the table

to the

31-5/B

degree

right

miter

posi-

tion

and

lock

the

table

in

position.

NOTE:

A triangle

indi-

cator

is

provided on

the

miter

scale

to

find

this

angle

quickly.

2.

Tilt

the

saw

blade

to the

33-718

degree

left

bevel

position

and

tighten

bevel

lock

handle.

NOTE:

A triangle

indicator

is

provided

on

the

bevel

scale

to

find

this angle

quickly.

3.

Place

the

crown

moulding

on

the

table

with

the

CEILING

EDGE

of

the

moulding

against

the

fence,

and

make

the cut,

as

shown

in

Fig. 39.

NOTE:

The

piece

of

crown

moulding

used

for

the outside

corner

will always

be

on

the

right

hand

side

of

the

blade,

as

shown

at

(A)

Fig.

39.

The

piece

of

crown

moulding

used

for the

inside

corner

will

always

be on

the

left

hand side

of

the blade,

as

shown

at

(B)

Fig. 39.

4.

To

make

the

matching

halves

of

the

inside

and

out-

side

corners,

simply

rotate

the

table

to the

31-5/B

degree

left

miter

position

and

tighten

table

lock

handle.

NOTE:

A

triangle

indicator

is

provided

on

the

miter

scale to

find

this

angle

quicklY.

5.

Place

the crown

moulding

on

the

table

with

the

WALL

EDGE

of

the crown

moulding

against

the

fence

and

make

the

cut.

Again,

the

piece

of

crown

moulding

used

for

the outside

corner

will

always

be on

the

right

side

of

the

blade,

as

shown

at

(C)

Fig.

40.

The

piece

of

crown

moulding

used

for the

inside

corner

will

always

be

on

the

left

side

of

the

blade,

as

shown

at

(D)

Fig.

40.

6.

Fig.

41,

illustrates

the

two

outside

corner

pieces;

(A)

being

the

piece

cut

at

(A)

Fig.

39,

and

(C)

being

the

piece

cut

at

(C)

Fig.

40.

7.

Fig.42,

illustrates

the

two

inside

corner

pieces;

(B)

being

the

piece

cut

at

(B)

Fig. 39,

and

(D)

being

the

piece

cut

at

(D)

Fig.

40.

Fig.

39

Fig.

40

Fig.

41

Fig.42

Page 17

MAINTENANCE

CHANGING

THE BLADE

WARNING: USE ONLY CROSS-CUTTING

SAW

BLADES.

WHEN

USING

CARBIDE

TIPPED BLADES,

MAKE

SURE

THEY

HAVE A NEGATIVE

HOOK

ANGLE. DO

NOT

USE

BLADES WITH

DEEP

GULLETS

AS THEY

CAN

DEFLECT

AND

CONTACT

THE

GUARD.

USE ONLY

10"

DIAMETER

SAW

BLADES

WHICH ARE

RATED

FOR

6000

RPM OR HIGHER

AND HAVE

5/8"

DIAMETER ARBOR

HOLES.

1. DISCONNECT

THE MACHINE

FROM THE

POWER

SOURCE.

2.

Loosen

screw

(A)

Fig.

43,

and

rotate cover

(B)

to the

rear as shown

in Fig. 44.

3.

To remove the saw blade,

insert hex

wrench

(C)

Fig.

45, into the hex hole located on the

rear

end of

the

arbor

shaft, to

keep

the shaft

from turning.

4. Using wrench

(D)

Fig. 46, loosen arbor screw

(E)

by

turning it clockwise.

5. Remove arbor screw

(E)

Fig. 46, outside blade

flange

(F)

and saw blade

(G)

from

saw arbor.

6.

Assemble new saw blade

MAKING

CERTAIN

TEETH

OF SAW

BLADE ARE

POINTING DOWN AT THE

FRONT and

reassemble outside blade

flange

(F)

Fig. a6,

and arbor screw

(E)

by turning it counterclockwise using

wrench

(D)

Fig.

46. At

the same

time

use

hex wrench

(C)

Fig. 45, to keep the arbor

from

turning.

7. Reolace cover that

was rotated to the rear in STEP 2.

8. WARNING:

REMOVE WRENCHES

(C)

FIG. 45, AND

(D)

FrG.46, BEFORE

TURNTNG

ON

THE POWER.

Fig. 43

Fig. 45

17

Page 18

BRUSH

INSPECTION

AND

REPLACEMENT

CAUTION:

BEFORE

INSPECTING

THE

BRUSHES'

DISCONNECT

THE

MACHINE

FROM

THE

POWER

SOURCE.

Brush

life varies.

lt depends

on

the

load

on

the

motor.

Check

the brushes

after

the

first

50

hours

of use

for a

new

machine

or after

a

new

set

of brushes

has been

installed.

After the

first

check,

examine

them

after

about

1O

hours

of use

until

such

time

that

replacement

is nec-

essary.

To

inspect

the brushes,

proceed

as

follows:

1.

Remove

three

screws

(A)

Fig.

47, and

remove

motor

cover

(B).

2.

The brushes

are

located

in the

two

holders

(C)

Fig.

aB.

Remove

spade

type

terminal

connector

(D)

and

pull

out

brush

holders

(C).

3.

Fig.

49,

illustrates

one

of

the brushes

(E)

removed

from

the

holder

(C).

When

the carbon

on either

brush

(E)

is

worn

to 3116"

in length

or

if either

spring

(F)

or

shunt

wire

is burned

or

damaged

in any

way,

replace

both

brushes.

lf the

brushes

are

found

serviceable

after

re-

moving,

reinstallthern

in

the same

position

as

removed'

Fig.47

Fig.

48

Fig.

49

Page 19

r-r l-l E t

rrr

a

36-075

h-r r

MB4D

--ts-E

^ r"",",,"".*";

I A

tO"

COfUlpOUtto

pOWen

rulfen

SnW

Pi]*?ollirersrll

o

/

\zl-\

\o

\.o

#{

u"/-

AVAILABLE

AS AN

ACCESSORY

18-r

\

)N-,/

^\

I

r'

ooX-

,''

-./.

"

/_

37

(3)

"'

u"z''-sa

(s)

4E

49

50

S7E?,,,

L..-az

(z)

(3)

tnr

,ol\

\

ry

21

22

ZJ

gr/

//

42\

V .,-3s

>

\al

a/r4o

(2)

AA

-LJ

/

.r''

-"

.r''

.l'

41

(2)

45

46

A1

4

(4)

s

(4)

6

(4)

63-\

|

\rll

v

84:

I

\l

83\

R?-81\

----'t-7g

79

()\

(2)

(t\

Page 1/MB-4D/FPB

\80

Page 20

REPLACEMENT

PARTS

hEr

H'.

PART NUMBER

pEscRtpTtoN

ff

PART

NUMBER

DEscRlPTloN

lXSL

lJ.Yr

.I

134%21 UPPER

ARM ASSY, /NCL..

4

,1349810

STUD

.f

A 1

34991 O DUST DEFLECTOR

(SEE

A/OIE A/

45 13.24ss

(DlN

8s) M5 X

10MM PAN HD

SCR

2

1349826

D|RECT|ON ARROW

6 1246102

(DlN

12s)

M5.3 FLAT WASHER

3

1349822 NAMEPLATE

47 1345467

POINTER

4 13!;9823

WARNTNG LABEL

4

'.t2461',17

(DlN

963) M4 X 10MM

FLAT HD SCR

5 1342930

CLAMP

49 1349808

INSERT

6

',t243394

(DrN

84) M5 X loMM

CHEESE HD SCR

50

1349807

TABLE

7 124ffi16

(DtN

933) M8 X 2sMM

HEX HD SCR 60

1349806

LOVI/ER

GUARD

7A

1243398

(DtN

934)

M8 HEX NUT

61 1243525

(DlN

7980) M4.1 LOCK

WASHER

8 1246004

(DtN

912) M6 X 16MM HEX

SOC HD SCR

62

',t243501

(DlN

84)

M4 X 10MM CHEESE HD

SCR

9

124,3520

(DlN

7980)

M6.1 LOCK WASHER

63 134980s

FENCE

10

1349809 BRACKET

U

1243530

(DlN

912) M8 X 30MM HEX

SOC HD SCR

11

1243525

(DtN

7980) M4.1 LOCKWASHER 65

124f,157

(DrN

7980) M8.1 LOCKWASHER

12 1341235

(DtN

84) M4 X

12MM CHEESE HD SCR

66 1243526

(DlN

125) M8.4 FLAT

WASHER

13

124U56

(DtN

934) M6 HEX NUT

67 1330410

(DlN

1481)

Ms X 20MM SPRING PIN

't4

1246015

(DlN

933) M6 X 20MM

HEX HD SCR

68

1U7123

EXT

BRACE

1s 1349817 SPRTNG

SLEEVE

69 1349804

BASE ASSY /NCL:

16 1349816

SPRTNG

70 1310016

sMM DRIVE SCR

17 13103't1

(DtN

1481)

M4X22MM SPRING PIN

71

1349803

SCALE

18 1349815

HANDLE

72

1U7115

LOCK

PLATE

19 1343545

(DtN

125) M4.1

FLAT

WASHER

73 1310159

(DlN

85)

M4 X 6MM PAN HD SCR

20 1243501

(DlN

84) M4X 10MM CHEESE

HD SCR

74

1347116

POINTER

21

1246045

(DlN

84) M6 X 10MM CHEESE

HD SCR

75

1347'117

BRACKET

22

1340608 M6.4 FLAT

WASHER 76

1347118

HANDLE, /NCI:

23 1349493

PINCH GUARD

T7

1347'119

PAD

24

1349490 LINK

78

',t243526

(DrN

12s) M8.4 FLAT WASHER

25 1343s04

(DtN

985) Ms LOCK NUT

79 12rc157

(DlN

7980) M8.1 LOCK

WASHER

26

1349813 PIVOT

BOLT

80

1246016

(DlN

933) M8 X 25MM HEX HD SCR

27 1246051

(DtN

912) Ms X

12MM HEX SOC HD SCR 81 1341996

(DlN

985) M10 LOCK

NUT

28

13!;9812 PLATE

82

1243502

(DlN

12s)

M10 FLATWASHER

29

1349953

SPECTAL SCR

83

1U3275

(DlN

137A) M10.5

WAVE WASHER

30 1349811 BUMPER

84

1243502

(DlN

125) M10

FLATWASHER

31 1345533 PtN

85 1347120

PIVOT STUD

32 1345534 o-R|NG

33 1313165

(DrN

e8s) M16 LocKNUr

AVAILABLE

AS

AN ACCESSORY

34 1345535

KNOB

35 1345/'82 SCALE

',

36-221

CLAMP

ASSY CONSI OF;

36 1310016

IMM

DRTVE SCR 90

901-02-0'10-0561

#10-32X 3/8',ROUND

HD SCR

37 1246053

(DtN

912) M8 X 25MM HEX SOC HD SCR 91 1340608

M6.4 FLAT WASHER

38 1246157

(DlN

7980) M8.1 LOCK WASHER

92

1345ss0

CLAMP CUP

39 1246175

(DrN

931) M6 X 30MM HEX HD

SCR

93

1345s49

SUPPORT

& 1243/;56

(DtN

934) M6 HEX NUT 94

1U5547

SHAFT

41 1349772

BRACKET 95 134ss46

KNOB

42 1246127

(DtN

916) M6 X 30MM HEX

SOC SET SCR

96

134s548

RETAINER

43 1349773

TRUNNTON 97

901-02-010-0561

#10-32X 3/8',ROUND

HD SCR

'NOT

SHO\i\N ASSEMBLED

NOTE A:

pnnr

NUMBER 134ee1o

(DUsr

DEFLEcToR),

MUST BE

SECURED WITH A SILICON WPE

ADHESIVE

WFIEN BEING SERVICED.

Page

2MB-4D/FPB

Page 21

r

t

t08

(2)-1

1oe

(2)r\n

\1

\0

111

112

(5)

1ts

(2)

1

16

(2)

120

121

122

123

\-;l;

r

s2

(sEE

NOTE

B)

132

(2)

,aa-r'\

.\=

.---l44

1a1_-/

\K

)->,4s

//-l62

a

\.,.,

.\

\'-131

-t

l6

12a---_-_

^125\

129

t26

127

t26

,r>

;T\)

ls\

u"

1561

\

\-hr-

r3E

137

Page

&[fts-4D/FpB

Page 22

REPLACEMENT

PARTS

REF.

NO.

PARTNUMBER DESCRIPTION

MOTOR ASSY. CONST OF:

(DrN

8s) Ms X 72MM PAN HD SCR

(DrN

7980)

Ms.1 LOCKWASHER

(DtN

125) Ms.3

FLATWASHER

3/8'GROMMET

(DlN

79818)M4.2 X 16MM PAN HD SCR

CLAMP

(DlN

79818)M4.2 X

16MM

PAN HD SCR

BRUSH

BRUSH

HOLDER

(DrN

985) M5 LOCK

NUT

MOTOR HOUSING. /NCL:

WARNING

LABEL

FIELD

(DrN

7980) Ms.1 LOCKWASHER

(DrN

85) M5 X 60MM PAN HD SCR

ARMATURE ASSY. /NCL.,

BEARING

BEARING

(DrN

84) M4 X 12MM CHEESE HD SCR

(DrN

7980) M4.1 LOCKWASHER

(DrN

12s) M4.1 FLATWASHER

COVER

HOUSING

NEEDLE BEARING

(DrN

798s) M4 X 18MM PAN HD SCR

(DtN

7980) M4.'t LOCKWASHER

EEF

F

PART NUMBER

DESCRIPTION

JJ.III

128

1347133

JACKSHAFTASSY /NCL:

'129

1243497 EXT RET

RING

130 1347138

FAN

BAFFLE

13.I 1347139

WAVE WASHER

132 1345702

PAD

133 1347144

END COVER

134

1347145 HANDLE

(tH,)

135 1347146

SWTCH

136 1340406

(DrN

7981B) M4.2 X 10MM PAN HD SCR

137

1347147 HANDLE

(RH)

138 1343051

(DlN

79818) M4.2 X 20MM PAN HD SCR

,I4O

'1347148

RED JUMPER

'141 '1347161

BLACK JUMPER

142 1347149

PO\ /ER CORD

143 43&01-007-0042

WRE NUT

't44

1341235

(DtN

84) M4 X 12MM CHEESE HD SCR

14s 1320102

(DrN

67974) M4.3 EXT TOOTH

WASHER

1s0

1347160 DUST BAG

151 13430s3

M5 X 1oMM PAN HD SCR

152

OPTIONAL BLADE

TSEE

NOTE B)

,I53

1347150

OUTER

FLANGE

154 1347151 BLADE BOLT

155 1343054

(DlN

603) M5 X 1oMM CARRTAGE HD SCR

156

',t342998

SPRING

157

,1345460

LO\A/ER BLADE GUARD

158 1349953

SPECTAL SCR

1s9 1349774 PLATE

't60

1343504

(DtN

9E5) M5 LOCK NUT

161 1342906 1l2" BLADE

U/RENCH

162 432-07-101-0004

5MM HEX \ /RENCH

.

NOT SHOWN ASSEMBLED

ror

102

103

104

't05

106

107

108

109

110

111

1't2

114

115

1't 6

117

't18

119

120

121

122

't23

124

125

126

127

1347132

1341770

1 343s38

1246102

1 34301 9

1344952

1343527

1344952

1347143

1347142

1 343504

1347',t 41

't349824

1347'.t40

1 343538

1310148

134Vrc

1347137

1310p42

1341235

1243525

1 343545

1347135

't347'.t34

1 343259

1347162

1243525

NOTE B: use cRoss cur BLADES oNLyr Do Nor usE BLADEs

DESIGNED FOR RIPPING, COMBINATION

BLADES OR

BLADES WTH

EXCESSIVE HOOK ANGLES!

LTAD

BLACK

MOTOR

POWER

WIRING DIAGRAM

i

,Uh\

4V\ 1

rJ

'.

,TANDARD SAFEry EQUIPMENT

In

order to

promote

tool safety, Delta International Machinery Corp. drictly

enforces

the

policy

of

repairing

or replacing any

damaged or missing standard

safety equipment on machines

presented

to Delta Authorized Service Centers for service/repair. Any

product

which is

presented

to a Delta Authorized

Service Center for

repairs which contains missing or damaged standard safety equipment

will have that

equipment repaired or replaced and the customer

will be

charged

for

any such

service/repairs.

Customers can avoid such charges only if the missing

safety

component

is

supplied to the service center at

the time of repair.

This

parts

list is

provided

to aid in

obtaining service

parts.

Copies of the instruction

and maintenance

literature

can be obtained through

the Delta

Technical Publications Department

or through

your

local service

outlet.

WHITE

NO

=@

z.n

ct>

G),

MOTOR

Page 4/MB-40/FPB

Loading...

Loading...