Page 1

КЯОЧЯЮФЫ НРЫЫЬ ЩОЧТЬЫО

@ ª·¬»--» ª¿®·¿¾´»

¼»ª»´±½·¼¿¼

ª¿®·¿¾´»

Ú®¿²9¿·-øïê÷

Û-°¿/±´ øíð÷

©©©òÜ»´¬¿Ó¿½¸·²»®§ò½±³

ײ-¬®«½¬·±² Ó¿²«¿´

Ó¿²«»´ ¼•«¬·´·-¿¬·±²

Ó¿²«¿´ ¼» ·²-¬®«½½·±²»-

ЧТНМОЛЭМЧКС ЬЫ СРЫОЯЭЧMТф ЭЫТМОСН

ЬЫ НЫОКЧЭЧС З РMФЧЖЯ ЬЫ ЩЯОЯТМSЯт

ФWЯНЫЫНМЫ ЧТНМОЛЭМЧКС

ЯТМЫН ЬЫ ЛНЯО ЫФ РОСЬЛЭМСт

онупзк шкуЧ²½¸ч

онупзйшиуЧ²½¸ч

Page 2

МЯЮФЫ СЪ ЭСТМЫТМН

×УРСОМЯТМ НЯЪЫМЗ ЧТНМОЛЭМЧСТН тттттттттттттттттттттттттттттттттттто

НЯЪЫМЗ ЩЛЧЬЫФЧТЫН у ЬЫЪЧТЧМЧСТН ттттттттттттттттттттттттттттттттттттттн

ЩЫТЫОЯФ НЯЪЫМЗ ОЛФЫН тттттттттттттттттттттттттттттттттттттттттттттттттттттттн

ЯЬЬЧМЧСТЯФ НРЫЭЧЪЧЭ НЯЪЫМЗ ОЛФЫН тттттттттттттттттттттттттттттттттм

РСЙЫО ЭСТТЫЭМЧСТН тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттк

УСМСО НРЫЭЧЪЧЭЯМЧСТН ттттттттттттттттттттттттттттттттттттттттттттттттттттттттк

ЩОСЛТЬЧТЩ ЧТНМОЛЭМЧСТН тттттттттттттттттттттттттттттттттттттттттттттттттк

ЫИМЫТНЧСТ ЭСОЬН тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттй

ХЫЗ ЪЫЯМЛОЫН ЯТЬ ЭСУРСТЫТМН ттттттттттттттттттттттттттттттттттттттй

ЪЛТЭМЧСТЯФ ЬЫНЭОЧРМЧСТттттттттттттттттттттттттттттттттттттттттттттттттттттй

РОСЬЛЭМ НРЫЭЧЪЧЭЯМЧСТН тттттттттттттттттттттттттттттттттттттттттттттттттттти

ЛТРЯЭХЧТЩ ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттти

ЯННЫУЮФЗ тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттз

Я¬¬¿½¸ Н°¿®µ Н¸·»´¼ ¿²¼ Щ®·²¼·²¹ Н¸·»´¼ ттттттттттттттттттттттттз

Я¬¬¿½¸ М±±´ О»-¬ тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттз

М±±´ Н¬±®¿¹» ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпр

Э±²º·®³ М·¹¸¬²»-- ±º Я®¾±® Т«¬- тттттттттттттттттттттттттттттттттттттпр

СРЫОЯМЧСТ ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпп

Н¬¿®¬·²¹ Я²¼ Н¬±°°·²¹ тттттттттттттттттттттттттттттттттттттттттттттттттттттпп

Ф±½µ·²¹ ¬¸» У¿½¸·²» тттттттттттттттттттттттттттттттттттттттттттттттттттттттпп

Л-·²¹ ¬¸» К¿®·¿¾´» Н°»»¼ Э±²¬®±´ тттттттттттттттттттттттттттттттттттпп

Л-·²¹ ¬¸» Ъ´»¨·¾´» Ф¿³° ттттттттттттттттттттттттттттттттттттттттттттттттттпп

УЯЧТМЫТЯТЭЫ

Щ®·²¼·²¹ Й¸»»´- тттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпо

Ь®»--·²¹ ¬¸» Й¸»»´- ттттттттттттттттттттттттттттттттттттттттттттттттттттттттпо

О»°´¿½·²¹ ±® Э¸¿²¹·²¹ Щ®·²¼·²¹ Й¸»»´- ттттттттттттттттттттттттпн

СМШЫО ОЫЭСУУЫТЬЫЬ УЯЧТМЫТЯТЭЫ ттттттттттттттттттттттттттттпн

ЯЭЭЫННСОЧЫНтттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпм

ЙЯООЯТМЗ ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпм

ОЫРФЯЭЫУЫТМ РЯОМНтттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпл

НЫОКЧЭЫ ЯТЬ ОЫРЯЧОН ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпл

ЪОЯТYЯЧН ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпк

ЫНРЯOСФ ттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттттнр

ЧУРСОМЯТМ НЯЪЫМЗ ЧТНМОЛЭМЧСТН

ОЫЯЬ ЯТЬ ЛТЬЫОНМЯТЬ ЯФФ ЙЯОТЧТЩН ЯТЬ СРЫОЯМЧТЩ ЧТНМОЛЭМЧСТН ЮЫЪСОЫ ЛНЧТЩ МШЧН

-»®·±«- °»®-±²¿´ ·²¶«®§ ±® °®±°»®¬§ ¼¿³¿¹»ò

ɱ±¼©±®µ·²¹ ½¿² ¾» ¼¿²¹»®±«- ·º -¿º» ¿²¼ °®±°»® ±°»®¿¬·²¹ °®±½»¼«®»- ¿®» ²±¬ º±´´±©»¼ò ß- ©·¬¸ ¿´´

³¿½¸·²»®§ô ¬¸»®» ¿®» ½»®¬¿·² ¸¿¦¿®¼- ·²ª±´ª»¼ ©·¬¸ ¬¸» ±°»®¿¬·±² ±º ¬¸» °®±¼«½¬ò Ë-·²¹ ¬¸» ³¿½¸·²» ©·¬¸

®»-°»½¬ ¿²¼ ½¿«¬·±² ©·´´ ½±²-·¼»®¿¾´§ ´»--»² ¬¸» °±--·¾·´·¬§ ±º °»®-±²¿´ ·²¶«®§ò ر©»ª»®ô ·º ²±®³¿´ -¿º»¬§

°®»½¿«¬·±²- ¿®» ±ª»®´±±µ»¼ ±® ·¹²±®»¼ô °»®-±²¿´ ·²¶«®§ ¬± ¬¸» ±°»®¿¬±® ³¿§ ®»-«´¬ò Í¿º»¬§ »¯«·°³»²¬ -«½¸

¿- ¹«¿®¼-ô °«-¸ -¬·½µ-ô ¸±´¼ó¼±©²-ô º»¿¬¸»®¾±¿®¼-ô ¹±¹¹´»-ô ¼«-¬ ³¿-µ- ¿²¼ ¸»¿®·²¹ °®±¬»½¬·±² ½¿² ®»¼«½» §±«®

°±¬»²¬·¿´ º±® ·²¶«®§ò Þ«¬ »ª»² ¬¸» ¾»-¬ ¹«¿®¼ ©±²•¬ ³¿µ» «° º±® °±±® ¶«¼¹³»²¬ô ½¿®»´»--²»-- ±® ·²¿¬¬»²¬·±²ò ß´©¿§-

«-» ½±³³±² -»²-» ¿²¼ »¨»®½·-» ½¿«¬·±² ·² ¬¸» ©±®µ-¸±°т Чº ¿ °®±½»¼«®» º»»´- ¼¿²¹»®±«-ф ¼±²•¬ ¬®§ ·¬т Ъ·¹«®» ±«¬

¿² ¿´¬»®²¿¬·ª» °®±½»¼«®» ¬¸¿¬ º»»´- -¿º»®т ОЫУЫУЮЫОж З±«® °»®-±²¿´ -¿º»¬§ ·- §±«® ®»-°±²-·¾·´·¬§т Ъ±® ¿¼¼·¬·±²¿´

·²º±®³¿¬·±² °´»¿-» ª·-·¬ ±«® ©»¾-·¬» ©©©òÜ»´¬¿Ó¿½¸·²»®§ò½±³ò

¬¸¿¬ º±® ©¸·½¸ ·¬ ©¿- ¼»-·¹²»¼т Чº §±« ¸¿ª» ¿²§ ¯«»-¬·±²- ®»´¿¬·ª» ¬± ¿ °¿®¬·½«´¿® ¿°°´·½¿¬·±²ф ЬС ТСМ «-» ¬¸»

³¿½¸·²» «²¬·´ §±« ¸¿ª» º·®-¬ ½±²¬¿½¬»¼ ЬЫФМЯr ¬± ¼»¬»®³·²» ·º ·¬ ½¿² ±® -¸±«´¼ ¾» °»®º±®³»¼ ±² ¬¸» °®±¼«½¬т

Чº §±« ¸¿ª» ¿²§ ¯«»-¬·±²- ®»´¿¬·ª» ¬± ·¬- ¿°°´·½¿¬·±² ЬС ТСМ «-» ¬¸» °®±¼«½¬ «²¬·´ §±« ¸¿ª» ©®·¬¬»² ЬЫФМЯr Р±©»®

Ы¯«·°³»²¬ Э±®°±®¿¬·±² ¿²¼ ©» ¸¿ª» ¿¼ª·-»¼ §±«т Э±²¬¿½¬ «- ±²´·²» ¿¬ ©©©тЬ»´¬¿У¿½¸·²»®§т½±³ ±® ¾§ ³¿·´ ¿¬

М»½¸²·½¿´ Н»®ª·½» У¿²¿¹»®ф ЬЫФМЯr Р±©»® Ы¯«·°³»²¬ Э±®°±®¿¬·±²ф пзом Р»¿®³¿² Ь¿·®§ О¼ф Я²¼»®-±² НЭ озколт

ײº±®³¿¬·±² ®»¹¿®¼·²¹ ¬¸» -¿º» ¿²¼ °®±°»® ±°»®¿¬·±² ±º ¬¸·- ¬±±´ ·- ¿ª¿·´¿¾´» º®±³ ¬¸» º±´´±©·²¹ -±«®½»-æ

Р±©»® М±±´ Ч²-¬·¬«¬»ф пнрр Н«³²»® Яª»²«»ф Э´»ª»´¿²¼ф СШ ммпплуоилп±® ±²´·²» ¿¬ ©©©т°±©»®¬±±´·²-¬·¬«¬»т½±³

Т¿¬·±²¿´ Н¿º»¬§ Э±«²½·´ф ппоп Н°®·²¹ Ф¿µ» Ь®·ª»ф Ч¬¿-½¿ф ЧФ крпмнунорп

Я³»®·½¿² Т¿¬·±²¿´ Н¬¿²¼¿®¼- Ч²-¬·¬«¬»ф ол Й»-¬ мн®¼ Н¬®»»¬ф м º´±±®ф Т»© З±®µф ТЗ пррнк ©©©т¿²-·т±®¹ у ЯТНЧ рптп

Í¿º»¬§ λ¯«·®»³»²¬- º±® ɱ±¼©±®µ·²¹ Ó¿½¸·²»-

ËòÍò Ü»°¿®¬³»²¬ ±º Ô¿¾±® ®»¹«´¿¬·±²- ©©©ò±-¸¿ò¹±ª

ЫПЛЧРУЫТМт Ъ¿·´«®» ¬± º±´´±© ¿´´ ·²-¬®«½¬·±²- ´·-¬»¼ ¾»´±©ф ³¿§ ®»-«´¬ ·² »´»½¬®·½ -¸±½µф º·®»ф ¿²¼с±®

М¸·- ³¿½¸·²» ©¿- ¼»-·¹²»¼ º±® ½»®¬¿·² ¿°°´·½¿¬·±²- ±²´§т ЬЫФМЯr Р±©»® Ы¯«·°³»²¬ Э±®°±®¿¬·±²

-¬®±²¹´§ ®»½±³³»²¼- ¬¸¿¬ ¬¸·- ³¿½¸·²» ²±¬ ¾» ³±¼·º·»¼ ¿²¼ñ±® «-»¼ º±® ¿²§ ¿°°´·½¿¬·±² ±¬¸»® ¬¸¿²

î

Page 3

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may

result in property damage.

GENERAL SAFETY RULES

WARNING FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

FOR YOUR OWN SAFETY, READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE OPERATING THE

UNIT.

Learn the unit’s application and limitations as well as the specific hazards peculiar to it.

KEEP WORK AREA CLEAN.

DON’T USE IN DANGEROUS ENVIRONMENT.

work area well-lighted.

KEEP CHILDREN AND VISITORS AWAY.

DISCONNECT UNIT

CHECK DAMAGED PARTS.

before servicing.

Cluttered areas and benches invite accidents.

Don’t use this unit in damp or wet locations, or expose it to rain. Keep

All children and visitors should be kept a safe distance from work area.

Before further use of the unit, properly repair or replace any part that is damaged.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

1. Read and understand the warnings posted on the

machine and in this manual. Failure to comply with all

of these warnings may cause serious injury.

2.Replace the warning labels if they become obscured

or removed.

3.This machine is designed and intended for use by

properly trained and experienced personnel only.

If you are not familiar with the proper and safe

operation of a bench grinder, do not use until proper

training and knowledge have been obtained.

4.Do not use this machine for other than its intended

use. If used for other purposes, DELTA® Power

Equipment Corporation disclaims any real or implied

warranty and holds itself harmless from any injury that

may result from that use.

5.Always wear approved safety glasses/face shields

5.Always wear approved safety glasses/face shields

while using this grinder.

while using this grinder.

6.Before operating this grinder, remove tie, rings,

6.Before operating this grinder, remove tie, rings,

watches and other jewelry, and roll sleeves up past

watches and other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and confine

the elbows. Remove all loose clothing and confine

long hair. Non-slip footwear or anti-skid floor strips are

long hair. Non-slip footwear or anti-skid floor strips are

recommended. Do not wear gloves.

recommended. Do not wear gloves.

7.Wear ear protectors (plugs or muffs) during extended

periods of operation.

8.Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples

of these chemicals are:

Lead from lead based paint.

Crystalline silica from bricks, cement and other masonry

products.

Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often

you do this type of work. To reduce your exposure

to these chemicals, work in a well-ventilated area and

work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out

microscopic particles.

9.Do not operate this machine while tired or under the

influence of drugs, alcohol or any medication.

10.Make certain the switch is in the OFF position before

connecting the machine to the power source.

11.Make certain the machine is properly grounded.

12.Make all machine adjustments or maintenance with

the machine unplugged from the power source.

13.Form a habit of checking to see that all extra

equipment such as adjusting keys, wrenches, scrap,

stock, and cleaning rags are removed away from the

continued on page 4

3

Page 4

ïíòÚ±®³ ¿ ¸¿¾·¬ ±º ½¸»½µ·²¹ ¬± -»» ¬¸¿¬ ¿´´ »¨¬®¿

»¯«·°³»²¬ -«½¸ ¿- ¿¼¶«-¬·²¹ µ»§-ô ©®»²½¸»-ô

-½®¿°ô -¬±½µô ¿²¼ ½´»¿²·²¹ ®¿¹- ¿®» ®»³±ª»¼ ¿©¿§

º®±³ ¬¸» ³¿½¸·²» ¾»º±®» ¬«®²·²¹ ±²ò

ïìòÕ»»° -¿º»¬§ ¹«¿®¼- ·² °´¿½» ¿¬ ¿´´ ¬·³»- ©¸»² ¬¸»

³¿½¸·²» ·- ·² «-»ò ׺ ®»³±ª»¼ º±® ³¿·²¬»²¿²½»

°«®°±-»-ô «-» »¨¬®»³» ½¿«¬·±² ¿²¼ ®»°´¿½» ¬¸»

¹«¿®¼- ·³³»¼·¿¬»´§ ©¸»² ³¿·²¬»²¿²½» ·- ½±³°´»¬»ò

ïëòÓ¿µ» -«®» ¬¸» ¬±±´ ·- º·®³´§ -»½«®»¼ ¬± ¿ -¬¿¾´» ©±®µ

ïëòÓ¿µ» -«®» ¬¸» ¬±±´ ·- º·®³´§ -»½«®»¼ ¬± ¿ -¬¿¾´» ©±®µ

-«®º¿½» ¾»º±®» «-»ò

-«®º¿½» ¾»º±®» «-»ò

ïêòݸ»½µ ¼¿³¿¹»¼ °¿®¬-ò Þ»º±®» º«®¬¸»® «-» ±º ¬¸»

³¿½¸·²»ô ¿ ¹«¿®¼ ±® ±¬¸»® °¿®¬ ¬¸¿¬ ·- ¼¿³¿¹»¼

-¸±«´¼ ¾» ½¿®»º«´´§ ½¸»½µ»¼ ¬± ¼»¬»®³·²» ¬¸¿¬ ·¬ ©·´´

±°»®¿¬» °®±°»®´§ ¿²¼ °»®º±®³ ·¬- ·²¬»²¼»¼ º«²½¬·±²ò

ݸ»½µ º±® ¿´·¹²³»²¬ ±º ³±ª·²¹ °¿®¬-ô ¾·²¼·²¹ ±º

³±ª·²¹ °¿®¬-ô ¾®»¿µ¿¹» ±º °¿®¬-ô ³±«²¬·²¹ ¿²¼

¿²§ ±¬¸»® ½±²¼·¬·±²- ¬¸¿¬ ³¿§ ¿ºº»½¬ ·¬- ±°»®¿¬·±²ò

ß ¹«¿®¼ ±® ±¬¸»® °¿®¬ ¬¸¿¬ ·- ¼¿³¿¹»¼ -¸±«´¼ ¾»

°®±°»®´§ ®»°¿·®»¼ ±® ®»°´¿½»¼ò

ïéòЮ±ª·¼» º±® ¿¼»¯«¿¬» -°¿½» -«®®±«²¼·²¹ ©±®µ ¿®»¿

¿²¼ ²±²ó¹´¿®»ô ±ª»®¸»¿¼ ´·¹¸¬·²¹ò

ïèòÕ»»° ¬¸» º´±±® ¿®±«²¼ ¬¸» ³¿½¸·²» ½´»¿² ¿²¼ º®»» ±º

-½®¿° ³¿¬»®·¿´ô ±·´ ¿²¼ ¹®»¿-»ò

ïçòÕ»»° ª·-·¬±®- ¿ -¿º» ¼·-¬¿²½» º®±³ ¬¸» ©±®µ ¿®»¿ò

Õ»»° ½¸·´¼®»² ¿©¿§ò

îðòÓ¿µ» §±«® ©±®µ-¸±° ½¸·´¼ °®±±º ©·¬¸ °¿¼´±½µ-ô

³¿-¬»® -©·¬½¸»- ±® ¾§ ®»³±ª·²¹ -¬¿®¬»® µ»§-ò

îïòÙ·ª» §±«® ©±®µ «²¼·ª·¼»¼ ¿¬¬»²¬·±²ò Ô±±µ·²¹

¿®±«²¼ô ½¿®®§·²¹ ±² ¿ ½±²ª»®-¿¬·±² ¿²¼ “¸±®-»ó

°´¿§þ ¿®» ½¿®»´»-- ¿½¬- ¬¸¿¬ ½¿² ®»-«´¬ ·² -»®·±«-

·²¶«®§ò

îîòÓ¿·²¬¿·² ¿ ¾¿´¿²½»¼ -¬¿²½» ¿¬ ¿´´ ¬·³»- -± ¬¸¿¬ §±«

¼± ²±¬ º¿´´ ±® ´»¿² ¿¹¿·²-¬ ¬¸» ¬±±´ ±® ·¬- ³±ª·²¹

°¿®¬-ò ܱ ²±¬ ±ª»®®»¿½¸ ±® «-» »¨½»--·ª» º±®½» ¬±

°»®º±®³ ¿²§ ³¿½¸·²» ±°»®¿¬·±²ò

îíòË-» ¬¸» ®·¹¸¬ ¬±±´ ¿¬ ¬¸» ½±®®»½¬ -°»»¼ ¿²¼ º»»¼

®¿¬»ò ܱ ²±¬ º±®½» ¿ ¬±±´ ±® ¿¬¬¿½¸³»²¬ ¬± ¼± ¿ ¶±¾

º±® ©¸·½¸ ·¬ ©¿- ²±¬ ¼»-·¹²»¼ò ̸» ®·¹¸¬ ¬±±´ ©·´´ ¼±

¬¸» ¶±¾ ¾»¬¬»® ¿²¼ -¿º»®ò

îìòË-» ®»½±³³»²¼»¼ ¿½½»--±®·»-å ·³°®±°»®

¿½½»--±®·»- ³¿§ ¾» ¸¿¦¿®¼±«-ò

îëòÓ¿·²¬¿·² ³¿½¸·²»®§ ©·¬¸ ½¿®»ò Ú±´´±© ·²-¬®«½¬·±²-

º±® ´«¾®·½¿¬·²¹ ¿²¼ ½¸¿²¹·²¹ ¿½½»--±®·»-ò

îêòÌ«®² ±ºº ¬¸» ³¿½¸·²» ¾»º±®» ½´»¿²·²¹ò Ë-» ¿ ¾®«-¸

±® ½±³°®»--»¼ ¿·® ¬± ®»³±ª» ¼«-¬ ±® ¼»¾®·- œ ¼±

²±¬ «-» §±«® ¸¿²¼-ò

îéòܱ ²±¬ -¬¿²¼ ±² ¬¸» ³¿½¸·²»ò Í»®·±«- ·²¶«®§ ½±«´¼

±½½«® ·º ¬¸» ³¿½¸·²» ¬·°- ±ª»®ò

îèòÒ»ª»® ´»¿ª» ¬¸» ³¿½¸·²» ®«²²·²¹ «²¿¬¬»²¼»¼ò Ì«®²

¬¸» °±©»® ±ºº ¿²¼ ¼± ²±¬ ´»¿ª» ¬¸» ³¿½¸·²» «²¬·´ ·¬

½±³»- ¬± ¿ ½±³°´»¬» -¬±°ò

îçò߬ ¿´´ ¬·³»-ô ¸±´¼ ¬¸» -¬±½µ º·®³´§ò

íðòܱ²±¬ «-» ¬¸·- ¬±±´ º±® ±¬¸»® ¬¸¿² ·¬ ·²¬»²¼»¼ «-»ò ׺

«-»¼ º±® ±¬¸»® °«®°±-»-ф ЬЫФМЯr Р±©»® Ы¯«·°³»²¬

ݱ®°±®¿¬·±² ¼·-½´¿·³- ¿²§ ®»¿´ ±® ·³°´·»¼ ©¿®®¿²¬§

¿²¼ ¸±´¼- ·¬-»´º ¸¿®³´»-- º±® ¿²§ ·²¶«®§ ±® ¼¿³¿¹»

©¸·½¸ ³¿§ ®»-«´¬ º®±³ ¬¸¿¬ «-»ò

Ú¿³·´·¿®·¦» §±«®-»´º ©·¬¸ ¬¸» º±´´±©·²¹ -¿º»¬§ ²±¬·½»«-»¼ ·² ¬¸·- ³¿²«¿´æ

̸·- ³»¿²- ¬¸¿¬ ·º °®»½¿«¬·±²- ¿®» ²±¬ ¸»»¼»¼ô ·¬ ³¿§

®»-«´¬ ·² ³·²±® ·²¶«®§ ¿²¼ñ±® °±--·¾´» ³¿½¸·²» ¼¿³¿¹»ò

̸·- ³»¿²- ¬¸¿¬ ·º °®»½¿«¬·±²- ¿®» ²±¬ ¸»»¼»¼ô ·¬ ³¿§

®»-«´¬ ·² -»®·±«- ·²¶«®§ ±® °±--·¾´§ »ª»² ¼»¿¬¸ò

ЯЬЬЧМЧСТЯФ НРЫЭЧЪЧЭ НЯЪЫМЗ ОЛФЫН

Ú¿·´«®» ¬± º±´´±© ¬¸»-» ®«´»- ³¿§ ®»-«´¬ ·² -»®·±«- °»®-±²¿´ ·²¶«®§ò

ïò ЬСТСМ ±°»®¿¬» ¬¸·- ³¿½¸·²» «²¬·´ ·¬ ·- ½±³°´»¬»´§

¿--»³¾´»¼ ¿²¼ ·²-¬¿´´»¼ ¿½½±®¼·²¹ ¬± ¬¸»

·²-¬®«½¬·±²-ò ß ³¿½¸·²» ·²½±®®»½¬´§ ¿--»³¾´»¼ ½¿²

½¿«-» -»®·±«- ·²¶«®§ò

îò СЮМЯЧТ ЯЬКЧЭЫ º®±³ §±«® -«°»®ª·-±®ô ·²-¬®«½¬±®ô ±®

¿²±¬¸»® ¯«¿´·º·»¼ °»®-±² ·º §±« ¿®» ²±¬ ¬¸±®±«¹¸´§

º¿³·´·¿® ©·¬¸ ¬¸» ±°»®¿¬·±² ±º ¬¸·- ³¿½¸·²»ò

Õ²±©´»¼¹» ·- -¿º»¬§ò

íò ЪСФФСЙ ЯФФ ЙЧОЧТЩ ЭСЬЫН ¿²¼ ®»½±³³»²¼»¼

»´»½¬®·½¿´ ½±²²»½¬·±²- ¬± °®»ª»²¬ -¸±½µ ±®

»´»½¬®±½«¬·±²ò

ìò ЯФЙЯЗН ЛНЫ МШЫ РОСКЧЬЫЬ ЮФСММЫО ¿²¼

©¸»»´ º´¿²¹»- ¬± ³±«²¬ ¬¸» ¹®·²¼·²¹ ©¸»»´- ±²

¬¸» ¹®·²¼»® -¸¿º¬ ¬± °®»ª»²¬ ©¸»»´ ¼¿³¿¹» ±®

¿½½·¼»²¬¿´ -»°¿®¿¬·±²ò Í»°¿®¿¬·±² ½¿² ®»-«´¬ ·²

º®¿¹³»²¬- º´§·²¹ ±ºº ¬¸» ©¸»»´ ¿¬ ¸·¹¸ -°»»¼-ò

ëò ЛНЫ СТФЗЙШЫЫФН -«·¬¿¾´» º±® ¬¸» -°»»¼ ±º ¬¸»

³¿½¸·²»ò ˲-«·¬¿¾´» ¹®·²¼·²¹ ©¸»»´- ½¿² ½±³»

¿°¿®¬ô ¬¸®±©·²¹ º®¿¹³»²¬- ±«¬ ¿¬ ¸·¹¸ -°»»¼-ò

êò ЛНЫ СТФЗЙШЫЫФН ¬¸¿¬ ¸¿ª» ¿ ¾±®» »¨¿½¬´§

»¯«¿´ ¬± ¬¸» ¿®¾±®- ±º ¬¸» ³¿½¸·²»ò Ò»ª»® ¿¬¬»³°¬

¬± ³¿½¸·²» ¿² «²¼»®-·¦»¼ ©¸»»´ ¬± º·¬ ¿² ¿®¾±®ò

˲-«·¬¿¾´» ¹®·²¼·²¹ ©¸»»´- ½¿² ½±³» ¿°¿®¬ô

¬¸®±©·²¹ º®¿¹³»²¬- ±«¬ ¿¬ ¸·¹¸ -°»»¼-ò

éò ÜÑ ÒÑÌ ±ª»®¬·¹¸¬»² ©¸»»´ ²«¬ò

èò ЬС ТСМ ЛНЫ Я ЙШЫЫФ МШЯМ КЧЮОЯМЫНт Ь®»--

¬¸» ¹®·²¼·²¹ ©¸»»´ô ®»°´¿½» ·¬ô ±® ®»°´¿½» ¬¸»

¾»¿®·²¹- ±º ¬¸» -¸¿º¬ò ˲-«·¬¿¾´» ¹®·²¼·²¹ ©¸»»´-

½¿² ½±³» ¿°¿®¬ô ¬¸®±©·²¹ º®¿¹³»²¬- ¿¬ ¸·¹¸

-°»»¼-ò

çò×ТНРЫЭМЙШЫЫФН ¾»º±®» -¬¿®¬·²¹ ¬¸» ³¿½¸·²»

º±® ½®¿½µ- ±® º®¿¹³»²¬-ò ОЫРФЯЭЫЬЯУЯЩЫЬ

ЙШЫЫФН ·³³»¼·¿¬»´§ò ﮬ- ±º ¬¸» ©¸»»´ ½¿² ¾»

¬¸®±©² ¿¬ ¸·¹¸ -°»»¼- ½¿«-·²¹ -»®·±«- ·²¶«®§ò

ïðò ЯЬЦЛНМ ЫЗЫ НШЧЫФЬН ½´±-» ¬± ¬¸» ¹®·²¼·²¹

©¸»»´ô ¿²¼ ®»ó¿¼¶«-¬ ¿- ¬¸» ©¸»»´ ©»¿®- ¼±©²ò

Ú´§·²¹ -°¿®µ- ¿®» ¼¿²¹»®±«- ¿²¼ ½¿² ½¿«-» º·®»- ±®

»¨°´±-·±²-ò

ì

Page 5

ЯЬЬЧМЧСТЯФ НРЫЭЧЪЧЭ НЯЪЫМЗ ОЛФЫН

ïïò ЯФЙЯЗНУЯХЫНЛОЫ ¬¸»»§»-¸·»´¼-¿®»·²°´¿½»ô

°®±°»®´§ ¿¼¶«-¬»¼ô ¿²¼-»½«®»¼ò

ïîò ЯЬЦЛНММССФОЫНМН ½´±-»¬±¬¸»¹®·²¼·²¹©¸»»´

шпсию-»°¿®¿¬·±²±®´»--чтМ·¹¸¬»²¬¸»¬±±´®»-¬

-»½«®»´§¬±°®»ª»²¬-¸·º¬·²¹°±-·¬·±²-ô¿²¼®»ó¿¼¶«-¬

¿-¬¸»©¸»»´©»¿®-¼±©²ò̸»©±®µ°·»½»½¿²

¾»¼®¿©²·²¬±¬¸»©¸»»´ô½¿«-·²¹¼¿³¿¹»¬±¬¸»

©±®µ°·»½» ¿²¼ñ±® -»®·±«- ·²¶«®§ò

ïíò НМЯТЬМССТЫНЧЬЫ ¾»º±®»¬«®²·²¹¬¸»³¿½¸·²»

юСТютФ±±-»º®¿¹³»²¬-±®©¸»»´°¿®¬-½±«´¼º´§

º®±³¬¸»©¸»»´¿¬ ¸·¹¸ -°»»¼-т

ïìò ТЫКЫОЩОЧТЬСТЯЭСФЬЙШЫЫФт Ϋ²¬¸»

¹®·²¼»®º±®±²»º«´´³·²«¬»¾»º±®»¿°°´§·²¹¬¸»

©±®µ°·»½»òß½±´¼©¸»»´¸¿-¿¬»²¼»²½§¬±½¸·°ò

̸±-»º®¿¹³»²¬-½±«´¼º´§º®±³¬¸»©¸»»´¿¬¸·¹¸

-°»»¼-ò

ïëò ТЫКЫОНМЯОММШЫУЯЭШЧТЫ ©·¬¸¬¸»©±®µ°·»½»

¿¹¿·²-¬¬¸»¹®·²¼·²¹©¸»»´ò̸»©±®µ°·»½»½¿²

¾»¼®¿©²·²¬±¬¸»©¸»»´ô½¿«-·²¹¼¿³¿¹»¬±¬¸»

³¿½¸·²» ¿²¼ñ±® -»®·±«- ·²¶«®§ò

ïêò ЭФЫЯТ МШЫ УЯЭШЧТЫ ¬¸±®±«¹¸´§©¸»²

°®±½»--·²¹¼·ºº»®»²¬¬§°»-±º©±®µ°·»½»-ø©±±¼ô

-¬»»´ф±®¿´«³·²«³чтЭ±³¾·²·²¹©±±¼¿²¼³»¬¿´

¼«-¬½¿²½®»¿¬»¿²»¨°´±-·±²±®º·®»¸¿¦¿®¼тЬСТСМ

ЩОЧТЬ ±® °±´·-¸ ³¿¹²»-·«³т Ъ·®»©·´´®»-«´¬т

ïéò ТЫКЫОЩОЧТЬТЫЯОЪФЯУУЯЮФЫЩЯНСО

ФЧПЛЧЬНт Í°¿®µ- ½¿² ½®»¿¬» ¿ º·®»±® ¿²»¨°´±-·±²ò

ïèò ЯКСЧЬ ¿©µ©¿®¼±°»®¿¬·±²-¿²¼¸¿²¼°±-·¬·±²-òß

-«¼¼»²-´·°½±«´¼½¿«-»¿¸¿²¼¬±³±ª»·²¬±¬¸»

¹®·²¼·²¹ ©¸»»´ò

ïçò ХЫЫРЯОУНфШЯТЬНф ¿²¼º·²¹»®-¿©¿§º®±³¬¸»

©¸»»´ò̸»¿¾®¿-·ª»-«®º¿½»-½¿²½¿«-»-»®·±«-

·²¶«®§ò

îðò ШСФЬМШЫЙСОХРЧЫЭЫЪЧОУФЗ ¿¹¿·²-¬¬¸»¬±±´

®»-¬òÔ±--±º½±²¬®±´±º¬¸»©±®µ°·»½»½¿²½¿«-»

-»®·±«- ·²¶«®§ò

îïò ЬОЫННМШЫЙШЫЫФ ±²¬¸»º¿½»±²´§òÜ®»--·²¹¬¸»

-·¼»±º¬¸»©¸»»´½±«´¼½¿«-»·¬¬±¾»½±³»¬±±¬¸·²

º±® -¿º»«-»ò

îîò ЩОЧТЬЯЙСОХРЧЫЭЫ «-·²¹¬¸»º¿½»±º¬¸»

¹®·²¼·²¹©¸»»´±²´§òÔ±--±º½±²¬®±´±º¬¸»

©±®µ°·»½» ½¿²½¿«-» -»®·±«- ·²¶«®§ò

îíò ТЫКЫОЯРРФЗЭССФЯТМ ¼·®»½¬´§¬±¬¸»¹®·²¼·²¹

©¸»»´òݱ±´¿²¬½¿²©»¿µ»²¬¸»¾±²¼·²¹-¬®»²¹¬¸

±º¬¸»¹®·²¼·²¹©¸»»´¿²¼½¿«-»·¬¬±º¿·´òÜ·°¬¸»

©±®µ°·»½» ·²©¿¬»® ¬±½±±´ ·¬ò

îìò ЬСТСММСЛЭШ ¬¸»¹®±«²¼°±®¬·±²±º¿©±®µ°·»½»

«²¬·´·¬ ¸¿- ½±±´»¼-«ºº·½·»²¬´§ò Ù®·²¼·²¹½®»¿¬»- ¸»¿¬ò

îëò РОСРЫОФЗ НЛРРСОМ ФСТЩ СО ЙЧЬЫ

©±®µ°·»½»-òÔ±--±º½±²¬®±´±º¬¸»©±®µ°·»½»½¿²

½¿«-» -»®·±«-·²¶«®§ò

îêò ТЫКЫОРЫОЪСОУФЯЗСЛМô¿--»³¾´§ô±®-»¬ó«°

©±®µ±²¬¸»¬¿¾´»ñ©±®µ¿®»¿©¸»²¬¸»³¿½¸·²»·®«²²·²¹òß-«¼¼»²-´·°½±«´¼½¿«-»¿¸¿²¼¬±³±ª»

·²¬± ¬¸»©¸»»´òÍ»ª»®» ·²¶«®§½¿²®»-«´¬ò

îéò МЛОТМШЫУЯЭШЧТЫюСЪЪюô¼·-½±²²»½¬¬¸»

³¿½¸·²»º®±³¬¸»°±©»®-±«®½»ф¿²¼½´»¿²¬¸»

¬¿¾´»с©±®µ¿®»¿¾»º±®»´»¿ª·²¹¬¸»³¿½¸·²»т

Ф±½µ¬¸»-©·¬½¸·²¬¸»юСЪЪю°±-·¬·±²¬±°®»ª»²¬

«²¿«¬¸±®·¦»¼«-»тН±³»±²»»´-»³·¹¸¬¿½½·¼»²¬¿´´§

-¬¿®¬¬¸»³¿½¸·²»¿²¼½¿«-»-»®·±«-·²¶«®§¬±

¬¸»³-»´ª»-ò

îèò ЯЬЬЧМЧСТЯФЧТЪСОУЯМЧСТ ®»¹¿®¼·²¹¬¸»-¿º»

¿²¼°®±°»®±°»®¿¬·±²±º°±©»®¬±±´-ш·т»т¿-¿º»¬§

ª·¼»±ч·-¿ª¿·´¿¾´»º®±³¬¸»Р±©»®М±±´Ч²-¬·¬«¬»ф

пнррН«³²»®Яª»²«»фЭ´»ª»´¿²¼фСШммпплуоилп

ш©©©т°±©»®¬±±´·²-¬·¬«¬»т½±³чтЧ²º±®³¿¬·±²·-¿´-±

¿ª¿·´¿¾´»º®±³¬¸»Т¿¬·±²¿´Н¿º»¬§Э±«²½·´фппоп

Н°®·²¹Ф¿µ»Ь®·ª»фЧ¬¿-½¿фЧФкрпмнунорптР´»¿-»

®»º»®¬±¬¸»Я³»®·½¿²Т¿¬·±²¿´Н¬¿²¼¿®¼-Ч²-¬·¬«¬»

ЯТНЧрптпН¿º»¬§О»¯«·®»³»²¬-º±®Й±±¼©±®µ·²¹

У¿½¸·²»-¿²¼¬¸»ЛтНтЬ»°¿®¬³»²¬±ºФ¿¾±®СНШЯ

пзпртопнО»¹«´¿¬·±²-т

CALIFORNIA PROPOSITION 65

!

WARNING

Somedustcreatedbypowersanding,sawing,grinding,drillingandotherconstructionactivitiescontains

chemicalsknowntothestateofCaliforniatocausecancer,birthdefectsorotherreproductiveharm.Some

examples of these chemicals are:

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemical: work in a well ventilated area, and work with approved safety equipment, such as

dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing

and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin

may promote absorption of harmful chemicals.

!

WARNING

Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory or

other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure.

Direct particles away from face and body.

Lead from lead-based paints,

Crystalline silica from bricks and cement and other masonry products, and

Arsenic and chromium from chemically-treated lumber.

НЯКЫ МШЫНЫ ЧТНМОЛЭМЧСТНт

λº»® ¬± ¬¸»³ ±º¬»² ¿²¼ «-» ¬¸»³ ¬± ·²-¬®«½¬ ±¬¸»®-ò

ë

Page 6

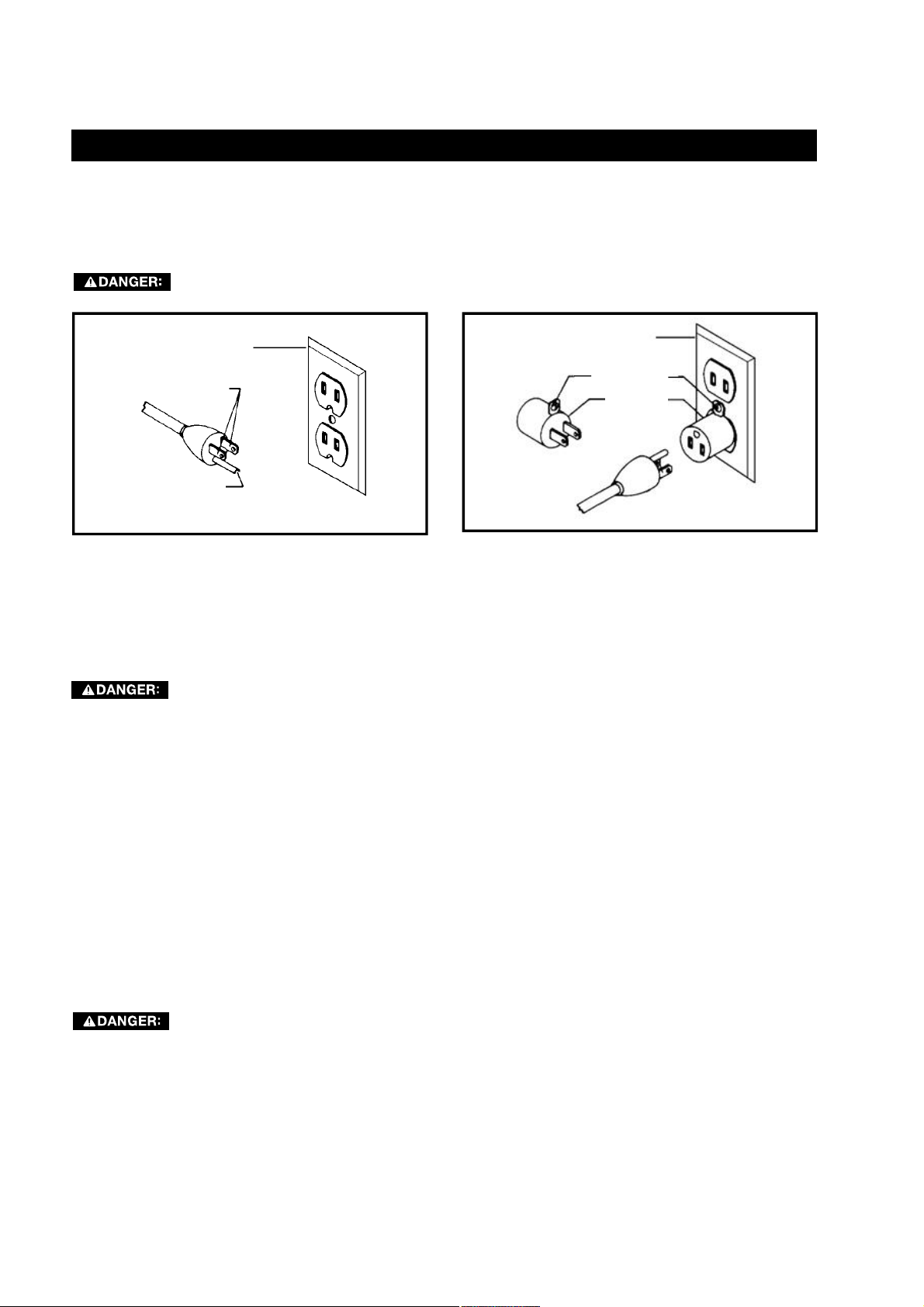

РСЙЫОЭСТТЫЭМЧСТН

ß-»°¿®¿¬»»´»½¬®·½¿´½·®½«·¬-¸±«´¼¾»«-»¼º±®§±«®³¿½¸·²»-ò̸·-½·®½«·¬-¸±«´¼²±¬¾»´»--¬¸¿²ýïî©·®»¿²¼

-¸±«´¼¾»°®±¬»½¬»¼©·¬¸¿орЯ³°¬·³»´¿¹º«-»тЧº¿²»¨¬»²-·±²½±®¼·-«-»¼ф«-»±²´§ну©·®»»¨¬»²-·±²½±®¼©¸·½¸¸¿ª»ну°®±²¹¹®±«²¼·²¹¬§°»°´«¹-¿²¼³¿¬½¸·²¹®»½»°¬¿½´»©¸·½¸©·´´¿½½»°¬¬¸»³¿½¸·²»•-°´«¹тЮ»º±®»

½±²²»½¬·²¹¬¸»³¿½¸·²»¬±¬¸»°±©»®´·²»ф³¿µ»-«®»¬¸»-©·¬½¸ш-ч·-·²¬¸»юСЪЪю°±-·¬·±²¿²¼¾»-«®»¬¸¿¬¬¸»

»´»½¬®·½½«®®»²¬·-±º¬¸»-¿³»½¸¿®¿½¬»®·-¬·½-¿-·²¼·½¿¬»¼±²¬¸»³¿½¸·²»òß´´´·²»½±²²»½¬·±²--¸±«´¼³¿µ»¹±±¼

½±²¬¿½¬ò Ϋ²²·²¹ ±² ´±©ª±´¬¿¹» ©·´´ ¼¿³¿¹»¬¸» ³¿½¸·²»ò

ЬС ТСМ ЫИРСНЫ МШЫ УЯЭШЧТЫ МС ОЯЧТ СО СРЫОЯМЫ МШЫ УЯЭШЧТЫ ЧТ ЬЯУР ФСЭЯМЧСТНт

ЩОСЛТЬЫЬ

СЛМФЫМЮСИ

ЭЛООЫТМ

ЭЯООЗЧТЩ

РОСТЩН

ЩОСЛТЬЧТЩЮФЯЬЫ

ЧНФСТЩЫНМСЪМШЫн ЮФЯЬЫН

ЩОСЛТЬЫЬ СЛМФЫМЮСИ

ЩОСЛТЬЧТЩ

УЫЯТН

ЯЬЯРМЫО

ÞòÙ×ÚßòÙ×Ú

УСМСОНРЫЭЧЪЧЭЯМЧСТН

З±«®³¿½¸·²»·-©·®»¼º±®порª±´¬-фкрШЖ¿´¬»®²¿¬·²¹½«®®»²¬тЮ»º±®»½±²²»½¬·²¹¬¸»³¿½¸·²»¬±¬¸»°±©»®

-±«®½»ф³¿µ»-«®»¬¸»-©·¬½¸·- ·²¬¸» юСЪЪю °±-·¬·±²т

ЩОСЛТЬЧТЩЧТНМОЛЭМЧСТН

МШЧНУЯЭШЧТЫУЛНМЮЫЩОСЛТЬЫЬЙШЧФЫЧТЛНЫМСРОСМЫЭММШЫСРЫОЯМСОЪОСУ

ЫФЫЭМОЧЭ НШСЭХт

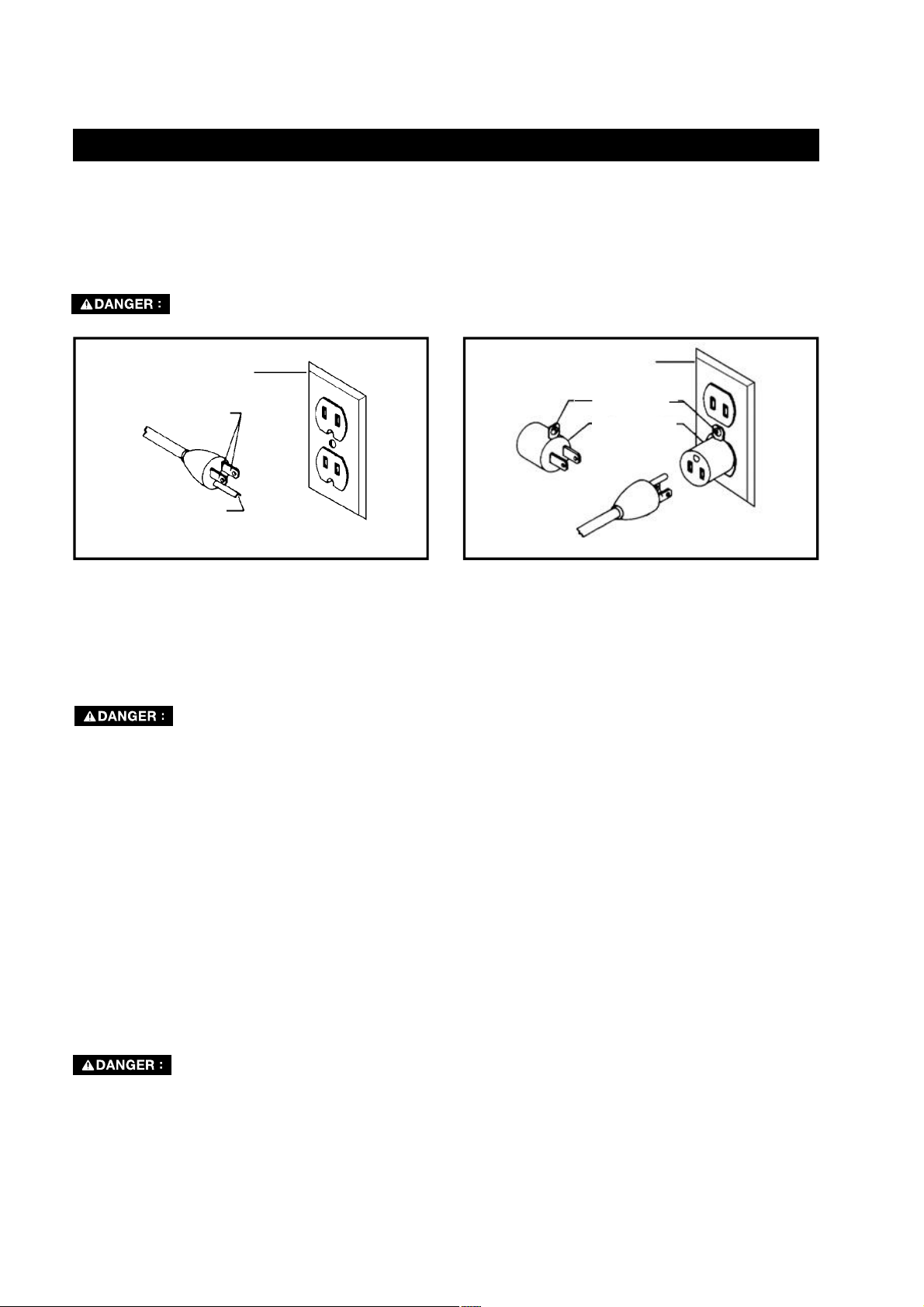

ïòß´´ ¹®±«²¼»¼ô ½±®¼ó½±²²»½¬»¼ ³¿½¸·²»-æ

ײ¬¸»»ª»²¬±º¿³¿´º«²½¬·±²±®¾®»¿µ¼±©²ô¹®±«²¼·²¹°®±ª·¼»-¿°¿¬¸±º´»¿-¬®»-·-¬¿²½»º±®»´»½¬®·½½«®®»²¬¬±

®»¼«½»¬¸»®·-µ±º»´»½¬®·½-¸±½µò̸·-³¿½¸·²»·-»¯«·°°»¼©·¬¸¿²»´»½¬®·½½±®¼¸¿ª·²¹¿²»¯«·°³»²¬ó¹®±«²¼·²¹

½±²¼«½¬±®¿²¼¿¹®±«²¼·²¹°´«¹ò̸»°´«¹³«-¬¾»°´«¹¹»¼·²¬±¿³¿¬½¸·²¹±«¬´»¬¬¸¿¬·-°®±°»®´§·²-¬¿´´»¼¿²¼

¹®±«²¼»¼ ·² ¿½½±®¼¿²½» ©·¬¸ ¿´´ ´±½¿´ ½±¼»-¿²¼ ±®¼·²¿²½»-ò

ܱ²±¬ ³±¼·º§¬¸» °´«¹ °®±ª·¼»¼ó ·º·¬©·´´²±¬ º·¬¬¸»±«¬´»¬ô ¸¿ª» ¬¸» °®±°»® ±«¬´»¬ ·²-¬¿´´»¼ ¾§ ¿ ¯«¿´·º·»¼ »´»½¬®·½·¿²ò

׳°®±°»®½±²²»½¬·±²±º¬¸»»¯«·°³»²¬ó¹®±«²¼·²¹½±²¼«½¬±®½¿²®»-«´¬·²®·-µ±º»´»½¬®·½-¸±½µò̸»½±²¼«½¬±®©·¬¸

·²-«´¿¬·±²¸¿ª·²¹¿²±«¬»®-«®º¿½»¬¸¿¬·-¹®»»²©·¬¸±®©·¬¸±«¬§»´´±©-¬®·°»-·-¬¸»»¯«·°³»²¬ó¹®±«²¼·²¹½±²¼«½¬±®ò

׺®»°¿·®±®®»°´¿½»³»²¬±º¬¸»»´»½¬®·½½±®¼±®°´«¹·-²»½»--¿®§ô¼±²±¬½±²²»½¬¬¸»»¯«·°³»²¬ó¹®±«²¼·²¹½±²¼«½¬±®

¬± ¿ ´·ª» ¬»®³·²¿´ò

ݸ»½µ©·¬¸¿¯«¿´·º·»¼»´»½¬®·½·¿²±®-»®ª·½»°»®-±²²»´·º¬¸»¹®±«²¼·²¹·²-¬®«½¬·±²-¿®»²±¬½±³°´»¬»´§«²¼»®-¬±±¼ô

±® ·º ·² ¼±«¾¬¿- ¬± ©¸»¬¸»® ¬¸» ³¿½¸·²» ·-°®±°»®´§¹®±«²¼»¼ò

Ë-»±²´§íó©·®»»¨¬»²-·±²½±®¼-¬¸¿¬¸¿ª»íó°®±²¹¹®±«²¼·²¹¬§°»°´«¹-¿²¼³¿¬½¸·²¹íó½±²¼«½¬±®®»½»°¬¿½´»-¬¸¿¬

¿½½»°¬¬¸» ³¿½¸·²»•- °´«¹ô ¿--¸±©²·²Ú·¹ò ßò

λ°¿·®±®®»°´¿½»¼¿³¿¹»¼±®©±®² ½±®¼ ·³³»¼·¿¬»´§ò

ЧТЯФФЭЯНЫНфУЯХЫЭЫОМЯЧТМШЫОЫЭЫРМЯЭФЫЧТПЛЫНМЧСТЧНРОСРЫОФЗЩОСЛТЬЫЬт

ЧЪ ЗСЛ ЯОЫ ТСМ НЛОЫф ШЯКЫ Я ПЛЯФЧЪЧЫЬ ЫФЫЭМОЧЭЧЯТ ЭШЫЭХ МШЫ ОЫЭЫРМЯЭФЫт

ê

Page 7

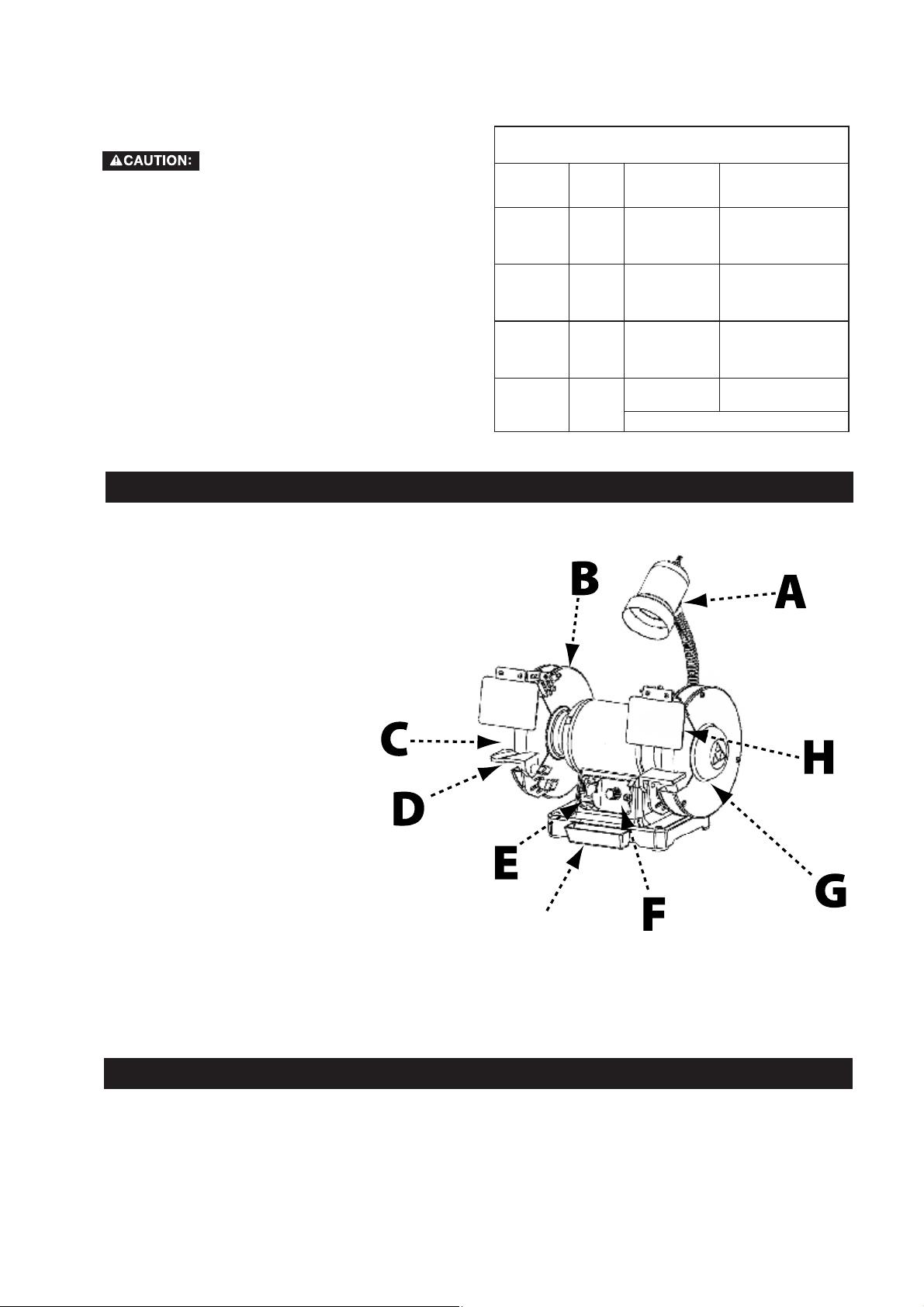

EXTENSIONCORDS

Use proper extension cords. Make

sure your extension cord is in good

condition and is a 3-wire extension cord which has a

3-prong grounding type plug and matching

receptacle which will accept the machine’s plug.

When using an extension cord, be sure to use one

heavy enough to carry the current of the machine.

An undersized cord will cause a drop in line voltage,

resulting in loss of power and overheating. The table

shows the correct gauge to use depending on the

cord length. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord.

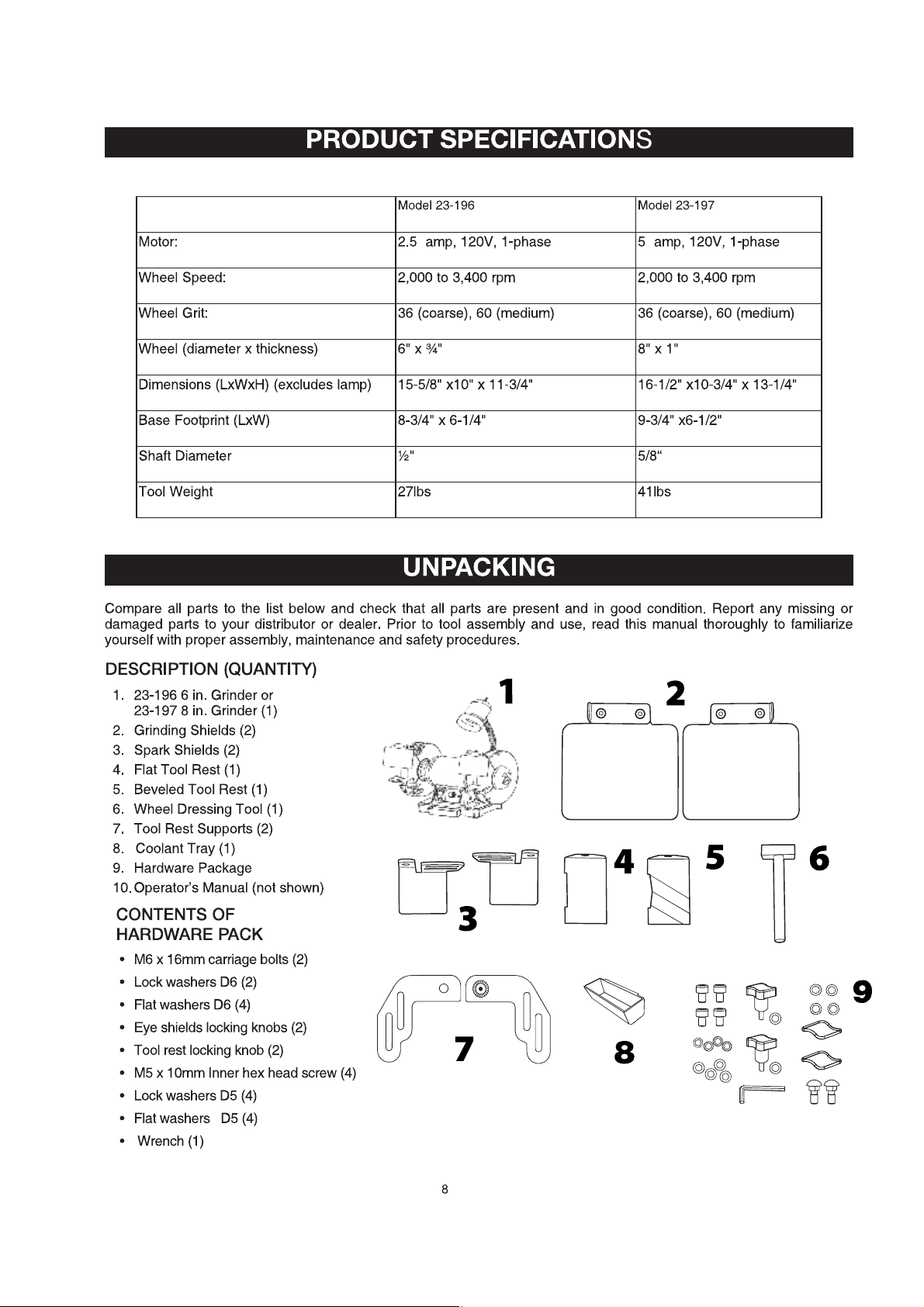

KEY FEATURES AND COMPONENTS

(features start at the top and move

counterclockwise around tool)

A.Flexible work lamp (bulb not

include)

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Rating

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

12-16

Volts Total Length of

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

Cord in Feet

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

GREATER THAN 50 FEET NOT RECOMMENDED

Gauge of Extension

Cord

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

B.Wheel Guard

C.Aluminum oxide grinding wheel

D.Adjustable tool rest

E.On/Off switch with lock-out key

F. Variable speed control

G. Aluminum oxide grinding wheel

H.Adjustable spark shield

I. On-board storage for included

dressing tool (not shown)

J. Coolant Tray

J

FUNCTIONAL DESCRIPTION

The DELTA® 23-196 is a 6 in. Variable Speed Grinder and the DELTA® 23-197 is an 8 in. Variable Speed Grinder. They

offer superior performance in grinding and sharpening operations and, with the proper accessories, allow the user

to remove rust and buff or polish metal. This model comes with a flexible lamp, adjustable tool rests, quick release

arbor nut system, and two large eye shields for added safety.

7

Page 8

Page 9

UNPACKING

Remove any protective materials and coatings from all of the parts and the tool. The protective coatings can be removed

by spraying WD-40 on them and wiping it off with a soft cloth. This may need redone several times before all of the

protective coatings are removed completely.

If any parts are missing, do not attempt to plug in the power cord and turn ON" the machine. The

machine should only be turned ON" after all the parts have been obtained and installed correctly.

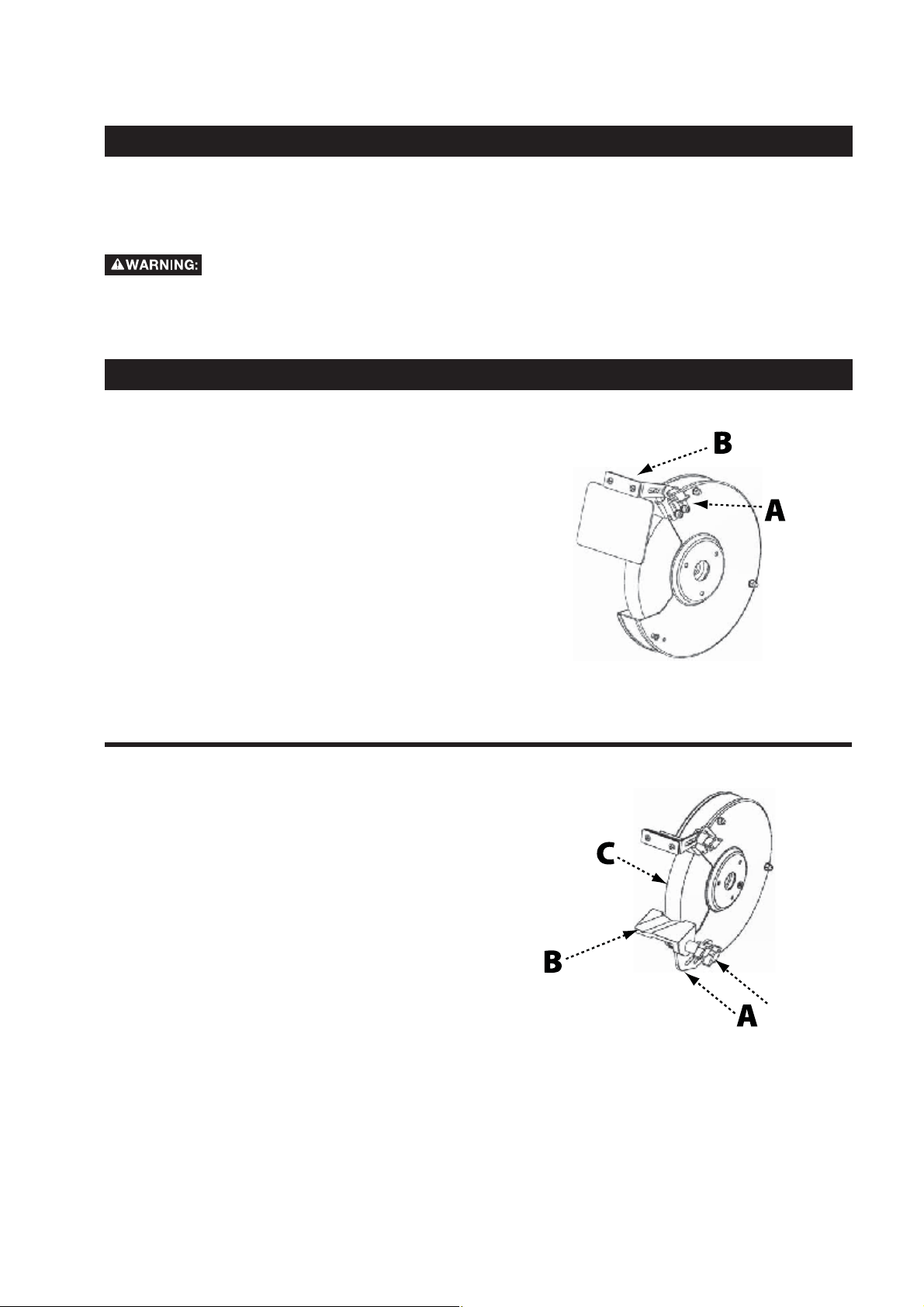

ASSEMBLY

ATTACH SPARK SHIELD AND GRINDING SHIELD

Refer to Figure 1.

1. Fit two M5 x 10mm hex screws with a M5 lock washer

and flat washer. Use assembled hex screws and

washers to secure spark shield (A) to the wheel guard.

Spark shield should be approximately 1/8" from the

grinding wheel.

2. Repeat previous step for second spark shield.

3. Use one M6 x 16 mm carriage bolt, inserted through

the outermost hole in the spark shield, to attach the

grinding shield (B). Secure using one M6 flat washer

and one lock washer and a threaded thumb knob.

4. Repeat previous step for second grinding shield.

ATTACH TOOL REST

Refer to Figure 2.

1. Remove the knob (D), star washer, and washer from

the carriage bolt on the lower portion of wheel guard.

Using the carriage bolt, star washer, washer and

fastening knob, attach the work rest bracket (A) to the

inside of the wheel guard as shown.

2. Attach tool rest (B) to the tool rest support using one

tool rest fasten knob.

3. Adjust the position of the tool rest support so that the

tool rest is approximately 1/8" from the grinding wheel

(C).

4. Repeat above steps for second tool rest.

FIGURE 1

D

FIGURE 2

9

Page 10

ЯННЫУЮФЗ

МССФ НМСОЯЩЫ

З±«® ЬЫФМЯr онупзк шк ·²тч ±® онупзй ши ·²тч Щ®·²¼»® ¸¿½±²ª»²·»²¬ ±²у¾±¿®¼ ¬±±´ -¬±®¿¹» º±® ¬¸» ¼®»--·²¹ ¬±±´

°®±ª·¼»¼т М¸» ¬±±´ ¸±´¼»®ф -¸±©² ·² Ъ·¹«®» нф ·- ´±½¿¬»¼ ±²

¬¸» ®»¿® ±º ¬¸» ¹®·²¼»® ¾¿-»т

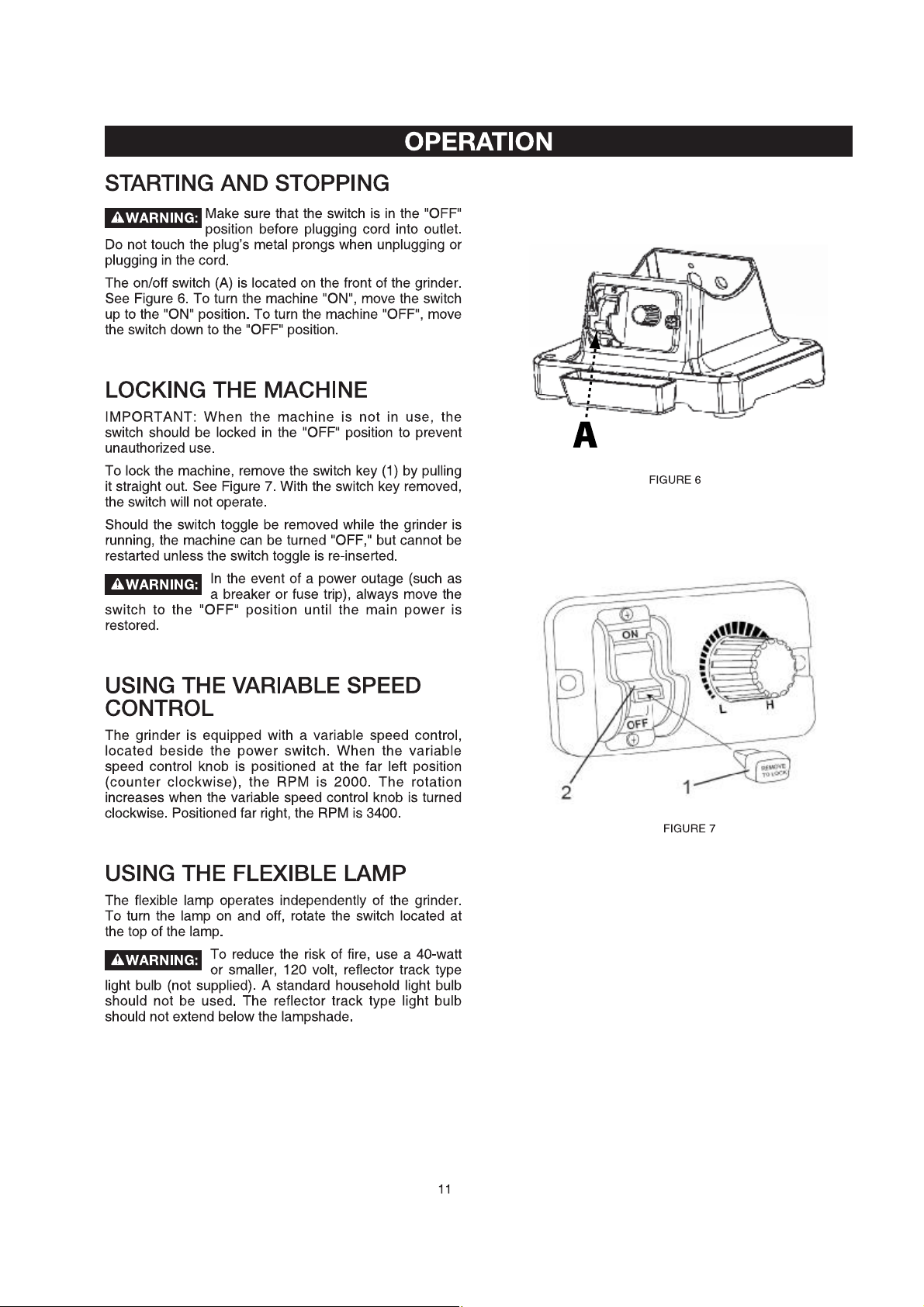

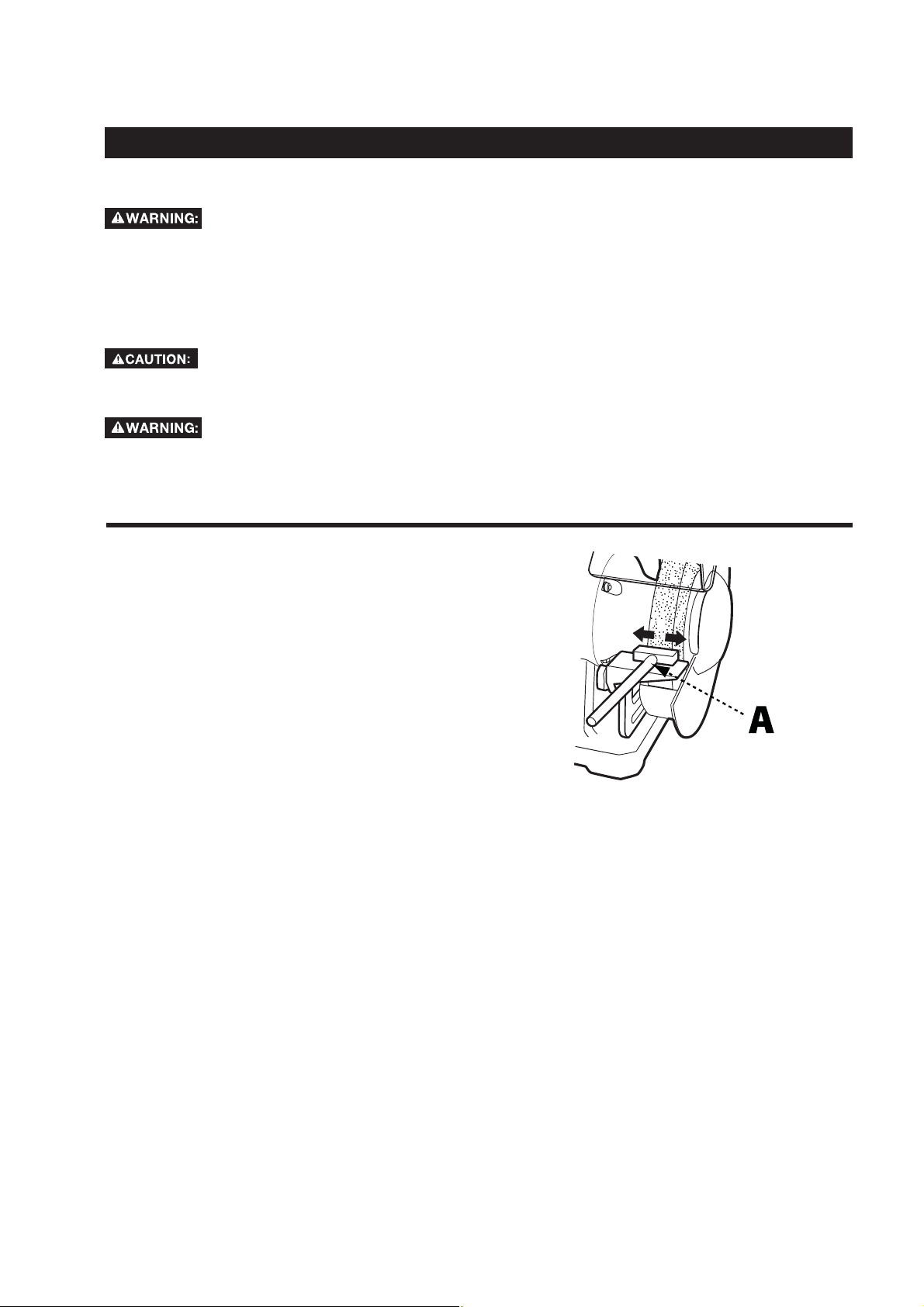

ЭСТЪЧОУ МЧЩШМТЫНН СЪ ЯОЮСО ТЛМН

Ю·±® ¬± «-·²¹ §±«® ¹®·²¼»® º±® ¬¸» º·®-¬ ¬·³»ô ·¬ ·®»½±³³»²¼»¼ ¬¸¿¬ §±« ½¸»½µ ¬¸» ¬·¹¸¬²»-- ±º ¬¸» ¿®¾±®

²«¬-ò ̱ ½¸»½µ ¬¸» ¬·¹¸¬²»-- ±² ¬¸» ¿®¾±® ²«¬-ô ¼± ¬¸»

º±´´±©·²¹æ

ïò λ³±ª» ¬¸» ¬¸«³¾ -½®»©- øß÷ -»½«®·²¹ ¬¸» ±«¬»® º¿½»

±º ¬¸» ©¸»»´ ¹«¿®¼ ¬± ¬¸» ¬±±´ º®¿³»ò Í»» Ú·¹«®» ìò

îò λ³±ª» ¹«¿®¼ò

íò Ë-·²¹ ¿ -«·¬¿¾´» É®»²½¸ô ±² ¬¸» ¿®¾±® ²«¬ øÞ÷

©¸·´» «-·²¹ ¬¸» ±¬¸»® ¸¿²¼ ¬± µ»»° ¬¸» ©¸»»´

º®±³ ³±ª·²¹ò Í»» Ú·¹«®» ëò Ì·¹¸¬»² ¬¸» ¿®¾±® ²«¬ ¿º¿® ¿- §±« ½¿²ò

ЪЧЩЛОЫ н

ТСМЫж М¸» ¿®¾±® ²«¬ ±² ¬¸» ®·¹¸¬ -·¼» ±º ¬¸» ³¿½¸·²»

¬·¹¸¬»²- ¾§ ®±¬¿¬·²¹ ·¬ ½´±½µ©·-»ф ¬¸» ¿®¾±® ²«¬

±² ¬¸» ´»º¬ -·¼» ±º ¬¸» ³¿½¸·²» ¬·¹¸¬»²- ¾§ ®±¬¿¬·²¹ ·¬

½±«²¬»®½´±½µ©·-»т

ìò λ°»¿¬ °®±½»-- º±® ±¬¸»® -·¼»ò

ТСМЫж Я- §±« «-» §±«® ¹®·²¼»®ф ¬¸» º±®½» ¿²¼ ¼·®»½¬·±² ±º

¬¸» ©¸»»´ ©·´´ ½¿«-» ¬¸» ¿®¾±® ²«¬ ¬± ¬·¹¸¬»² ¿«¬±³¿¬·½¿´´§т

Ш±©»ª»®ф ·¬ ·- ®»½±³³»²¼»¼ ¬¸¿¬ §±«® °»®·±¼·½¿´´§ ½¸»½µ

¬¸» ¬·¹¸¬²»-- ±º ¬¸» ²«¬- ¿- °¿®¬ ±º §±«® ®»¹«´¿® ¬±±´

³¿·²¬»²¿²½»т

ЪЧЩЛОЫ м

ЪЧЩЛОЫ л

ïð

Page 11

Page 12

ЩОЧТЬЧТЩ ЙШЫЫФН

УЯЧТМЫТЯТЭЫ

М¸» «-» ±º ¿½½»--±®·»- ¿²¼ ¿¬¬¿½¸³»²¬²±¬ ®»½±³³»²¼»¼ ¾§ ЬЫФМЯr ³¿§ ®»-«´¬

·² ¿ ®·-µ ±º ·²¶«®§ò

Щ®·²¼·²¹ ©¸»»´- «-»¼ ©·¬¸ ¬¸·- ¹®·²¼»® -¸±«´¼ ¾» ®¿¬»¼

º±® нкрр ОРУ ±® ¸·¹¸»® ¿²¼ ¸¿ª» ¿ ©·¼¬¸ ±º пю т Щ®·²¼·²¹

©¸»»´- º±® ¬¸» ЬЫФМЯr онупзк ³«-¬ ¾» кю ·² ¼·¿³»¬»® ©·¬¸

¿ cю ¿®¾±® ¸±´»т Щ®·²¼·²¹ ©¸»»´- º±® ¬¸» ЬЫФМЯr онупзй

³«-¬ ¾» ию ·² ¼·¿³»¬»® ©·¬¸ ¿ лсию ¿®¾±® ¸±´»т

Ë-·²¹ ¿ ©¸»»´ ¬¸¿¬ ·- ´»-- ¬¸¿² bþ ©·¼»

º±® ¬¸» ê ·²ò ¹®·²¼»®ô ±® ïþ ©·¼» º±® ¬¸» è

·²ò ¹®·²¼»®ô ©·´´ ½¿«-» ª·¾®¿¬·±² ¿²¼ ½±«´¼ ¼¿³¿¹» ¬¸»

³¿½¸·²»ò

ЯФЙЯЗН³¿·²¬¿·² ¿ ¼·-¬¿²½» ±º псию ±®

´»-- ¾»¬©»»² ¬¸» ¹®·²¼·²¹ ©¸»»´ ¿²¼ ¬¸»

¬±±´ ®»-¬ò ß¼¶«-¬ ¬¸» ¬±±´ ®»-¬- ¿²¼ -°¿®µ ¹«¿®¼- ¿- ¬¸»

¹®·²¼·²¹ ©¸»»´- ¼»½®»¿-» ·² -·¦» ©·¬¸ «-»ò

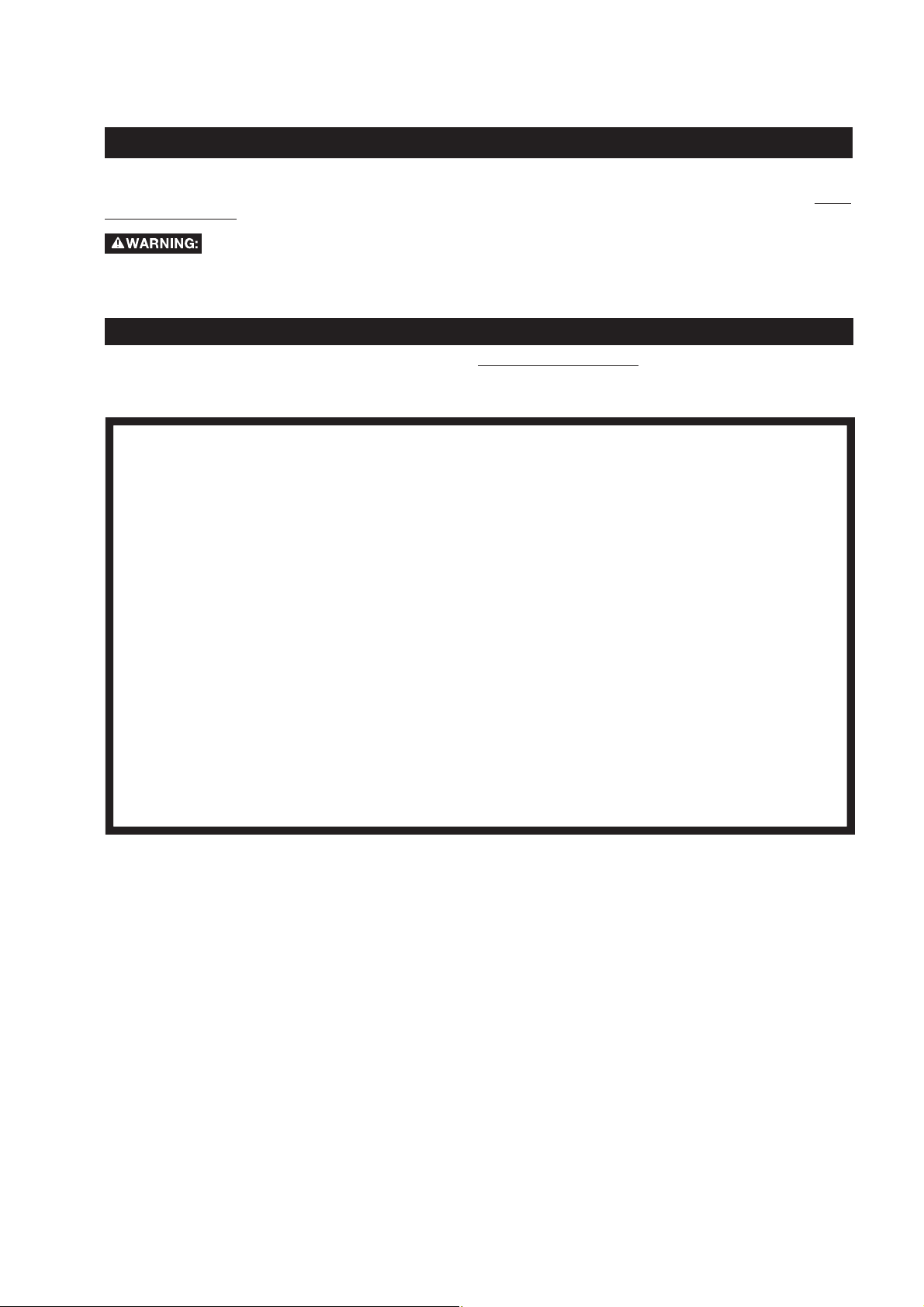

ЬОЫННЧТЩ МШЫ ЙШЫЫФН

З±«® ЬЫФМЯr онупзк шк ·²тч Щ®·²¼»® ±® онупзй ши·²тч

Щ®·²¼»® ½±³» ©·¬¸ ¿ ¼·¿³±²¼у¾¿-»¼ ©¸»»´ ¼®»--»®

·²½´«¼»¼ò ̸»®» ·- ±²ó¾±¿®¼ -¬±®¿¹» º±® ¬¸» ¼®»--»® ¿¬ ¬¸»

®»¿® ±º ¬¸» ³¿½¸·²» º±® »¿-§ ¿½½»--ò Ë-» ¬¸·- ¬±±´ ±® ¿²§

±¬¸»® -«·¬¿¾´» -¬·½µó¬§°» ¼®»--»® ¬± µ»»° §±«® ¹®·²¼·²¹

©¸»»´- ½´»¿² ¿²¼ -¯«¿®»ò

̱ ¼®»-- ¬¸» ©¸»»´ô ®»º»® ¬± Ú·¹«®» è ¿²¼ ¼± ¬¸» º±´´±©·²¹æ

ïò Þ®·²¹ ¬¸» ¼®»--»® øß÷ º±®©¿®¼ ±² ¬¸» ¬±±´ ®»-¬ «²¬·´ ·¬

¶«-¬ ¬±«½¸»- ¬¸» ¸·¹¸ °±·²¬ ±² ¬¸» º¿½» ±º ¬¸» ©¸»»´ò

îò Ü®»-- ¬¸» ©¸»»´ ¾§ ³±ª·²¹ ¬¸» ¼®»--»® ¾¿½µ º±®¬¸ò

íò λ°»¿¬ ¬¸·- ±°»®¿¬·±² «²¬·´ ¬¸» º¿½» ±º ¬¸» ¹®·²¼·²¹

©¸»»´ ·- ½´»¿² ¿²¼ ¬¸» »¼¹»- ¿®» -¯«¿®»ò

М¸» ЬЫФМЯr онупзк ½±³»- ©·¬¸ ¬©± кю ¿´«³·²«³ ±¨·¼»

¹®·²¼·²¹ ©¸»»´ ш¹®¿§ч т

М¸» ЬЫФМЯr онупзй ½±³»- ©·¬¸ ¬©± ию ¿´«³·²«³ ±¨·¼»

¹®·²¼·²¹ ©¸»»´ ш¹®¿§чт

Ú±® ¾»-¬ ®»-«´¬-ô ¿²¼ ¬± °®±°»®´§ ³¿·²¬¿·² ¬¸» ¹®·²¼·²¹

©¸»»´-ô º±´´±© ¬¸»-» ®»½±³³»²¼¿¬·±²-æ

ïò Õ»»° ¬¸» ©¸»»´- °®±°»®´§ ¼®»--»¼ò

îò ܱ ²±¬ º±®½» ¬¸» ©±®µ ¿¹¿·²-¬ ¿ ½±´¼ ©¸»»´ò ß´©¿§- ®«²

¬¸» ¹®·²¼·²¹ ©¸»»´ º±® ±²» º«´´ ³·²«¬» ¾»º±®» ¿°°´§·²¹ ¿

©±®µ°·»½»ò

íò Ë-» ±²´§ ¾¿´¿²½»¼ ©¸»»´- ©·¬¸ §±«® ¹®·²¼»®ò Ë-·²¹

¾¿´¿²½»¼ ©¸»»´- ¿¼¼- §»¿®- ¬± ¬¸» ´·º» ±º ¬¸» ¾»¿®·²¹±² ¬¸» ¹®·²¼»®ò Þ§ »´·³·²¿¬·²¹ ¬¸» ³±-¬ ½±³³±²

-±«®½» ±º ª·¾®¿¬·±²ô §±«® ¹®·²¼·²¹ °®±¶»½¬- ©·´´ ¾» ³±®»

¿½½«®¿¬»ò

ïî

ЪЧЩЛОЫ и

Page 13

УЯЧТМЫТЯТЭЫ

ОЫРФЯЭЧТЩ СО ЭШЯТЩЧТЩ ЩОЧТЬЧТЩ ЙШЫЫФН

Ü·-½±²²»½¬ ¬¸» ³¿½¸·²» º®±³ ¬¸» °±©»®

-±«®½»ò

Ú±® -¬»°- ïóìô ®»º»® ¬± Ú·¹«®»- ì ú ë ±² °¿¹» ïðæ

ïò λ³±ª» ¬¸» øí÷ -½®»©- -»½«®·²¹ ¬¸» ±«¬»® º¿½» ±º ¬¸»

©¸»»´ ¹«¿®¼ ¬± ¬¸» ¬±±´ º®¿³»ò

îò λ³±ª» ¬¸» ¹«¿®¼ò

íò Ë-·²¹ ¿ -«·¬¿¾´» ©®»²½¸ô ±² ¬¸» ¿®¾±® ²«¬ øß÷ ©¸·´»

«-·²¹ ¬¸» ±¬¸»® ¸¿²¼ ¬± µ»»° ¬¸» ©¸»»´ º®±³ ³±ª·²¹ò

Ô±±-»² ¬¸» ¿®¾±® ²«¬ò

ТСМЫж М± ´±±-»² ¬¸» ¿®¾±® ²«¬ ±² ¬¸» ®·¹¸¬ -·¼» ®±¬¿¬» ·¬

½±«²¬»®½´±½µ©·-»т М± ´±±-»² ¬¸» ¿®¾±® ²«¬ ±² ¬¸» ´»º¬ -·¼»

®±¬¿¬» ·¬ ½´±½µ©·-»т

ìò λ³±ª» ¬¸» ¿®¾±® ²«¬ øß÷ô ©¸»»´ ²¹» øÞ÷ô ¿²¼ ±´¼

¹®·²¼·²¹ ©¸»»´ øÝ÷ô ¿- -¸±©² ·² Ú·¹«®» çòò

ëò д¿½» ¬¸» ²»© ¹®·²¼·²¹ ©¸»»´ ±² ¬¸» ¿®¾±®ò

ТСМЫж Щ®·²¼·²¹ ©¸»»´- º±® ¬¸» онупзк ³«-¬ ¾» bю ©·¼»

©¸·´» ¹®·²¼·²¹ ©¸»»´- º±® ¬¸» онупзй ³«-¬ ¾» пю ©·¼»т

êò д¿½» ¬¸» º´¿²¹» ±² ¬¸» ¿®¾±® ¿²¼ ¬¸®»¿¼ ¬¸» ¿®¾±® ²«¬ ±²

¬¸» ¿®¾±® «²¬·´ ¬¸» ¿®¾±® ²«¬ ³¿µ»- ½±²¬¿½¬ ©·¬¸ ¬¸» ¿®¾±®

º´¿²¹»ò

éò Ì·¹¸¬»² ¬¸» ¿®¾±® ²«¬ ¿- ¬·¹¸¬ ¿- §±« ½¿² ¾§ ¸¿²¼ò

èò λ°´¿½» ¬¸» ©¸»»´ ¹«¿®¼ ¿²¼ -»½«®» ©·¬¸ ¬¸» øí÷ -½®»©-

°®»ª·±«-´§ ®»³±ª»¼ò

СМШЫО ОЫЭСУУЫТЬЫЬ УЯЧТМЫТЯТЭЫ

ïò л®·±¼·½¿´´§ ¾´±© ±«¬ ¿´´ ¿·® °¿--¿¹»- ©·¬¸ ¼®§

½±³°®»--»¼ ¿·®т Я´´ °´¿-¬·½ °¿®¬- -¸±«´¼ ¾» ½´»¿²»¼

©·¬¸ ¿ -±º¬ ¼¿³° ½´±¬¸т ТЫКЫО «-» -±´ª»²¬- ¬±

½´»¿² °´¿-¬·½ °¿®¬-т М¸»§ ½±«´¼ °±--·¾´§ ¼·--±´ª» ±®

±¬¸»®©·-» ¼¿³¿¹» ¬¸» ³¿¬»®·¿´ò

îò л®·±¼·½¿´´§ ·²-°»½¬ ¬¸» ¬·¹¸¬²»-- ±º ¬¸» ¿®¾±® ²«¬-ò

íò л®·±¼·½¿´´§ ½¸»½µ ¬·¹¸¬²»-- ±² ¿´´ ±¬¸»® ¸¿®¼©¿®» ¿²¼

´·-¬»² º±® ¿²§ «²«-«¿´ ª·¾®¿¬·±²- ¿- §±« ©±®µ ¿- ¬¸»-»

³¿§ ¾» ¿ -·¹² ±º ´±±-» ¸¿®¼©¿®»ò

ЪЧЩЛОЫ з

ïí

Page 14

ЯЭЭЫННСОЧЫН

Я ½±³°´»¬» ´·²» ±º ¿½½»--±®·»- ·- ¿ª¿·´¿¾´» º®±³ §±«® ЬЫФМЯr Н«°°´·»®ф ЬЫФМЯr Ъ¿½¬±®§ Н»®ª·½» Э»²¬»®-ф ¿²¼

ЬЫФМЯr Ъ¿½¬±®§ Н»®ª·½» Э»²¬»®-ф ¿²¼ ЬЫФМЯr Я«¬¸±®·¦»¼ Н»®ª·½» Э»²¬»®-т Р´»¿-» ª·-·¬ ±«® Й»¾ Н·¬» ©©©т

Ь»´¬¿У¿½¸·²»®§т½±³ º±® ¿² ±²´·²» ½¿¬¿´±¹ ±® º±® ¬¸» ²¿³» ±® §±«® ²»¿®»-¬ -«°°´·»®т

Н·²½» ¿½½»--±®·»- ±¬¸»® ¬¸¿² ¬¸±-» ±ºº»®»¼ ¾§ ЬЫФМЯr ¸¿ª» ²±¬ ¾»»² ¬»-¬»¼ ©·¬¸ ¬¸·- °®±¼«½¬ф «-» ±º

-«½¸ ¿½½»--±®·»- ½±«´¼ ¾» ¸¿¦¿®¼±«-т Ъ±® -¿º»-¬ ±°»®¿¬·±²ф ±²´§ ЬЫФМЯr ®»½±³³»²¼»¼ ¿½½»--±®·»-

-¸±«´¼ ¾» «-»¼ ©·¬¸ ¬¸·- °®±¼«½¬ò

ЙЯООЯТМЗ

̱ ®»¹·-¬»® §±«® ¬±±´ º±® ©¿®®¿²¬§ -»®ª·½» ª·-·¬ ±«® ©»¾-·¬» ¿¬ ©©©òÜ»´¬¿Ó¿½¸·²»®§ò½±³ò

ЪЧКЫ ЗЫЯО ФЧУЧМЫЬ ЙЯООЯТМЗ

Ü»´¬¿r б©»® Û¯«·°³»²¬ ݱ®°±®¿¬·±²

пт ЙШЯМ ЧН ЭСКЫОЫЬт Ь»´¬¿ Р±©»® Ы¯«·°³»²¬ Э±®°±®¿¬·±² ш“Э±³°¿²§’ч ©·´´ ®»°¿·® ±® ®»°´¿½»ф ¿¬ ·¬- ±°¬·±²ф ¿²§ ²»© ±® º¿½¬±®§ ®»º«®¾·-¸»¼ ЬЫФМЯr

³¿½¸·²» ±® -»®ª·½» °¿®¬ ©¸·½¸ ·- °«®½¸¿-»¼ ¿¬ ®»¬¿·´ ·² ¬¸» ˲·¬»¼ ͬ¿¬»- ±® Ý¿²¿¼¿ ¿²¼ ©¸·½¸ ·² ²±®³¿´ «-» ¸¿- °®±ª»² ¬± ¾» ¼»º»½¬·ª» ·² ©±®µ³¿²-¸·°

±® ³¿¬»®·¿´ô -«¾¶»½¬ ¬± ¬¸» ½±²¼·¬·±²- -¬¿¬»¼ ·² ¬¸·- Ô·³·¬»¼ É¿®®¿²¬§ò ̸·- Ô·³·¬»¼ É¿®®¿²¬§ ½±ª»®- ±²´§ ³¿¬»®·¿´- ¿²¼ ´¿¾±®ò ß´´ ¬®¿²-°±®¬¿¬·±² ½±-¬¿®» Ý«-¬±³»®•- ®»-°±²-·¾·´·¬§ò

от ЙЯООЯТМЗ РЫОЧСЬт Я´´ ©¿®®¿²¬§ ½´¿·³- ³«-¬ ¾» -«¾³·¬¬»¼ ©·¬¸·² º·ª» §»¿®- º®±³ ¬¸» ¼¿¬» ±º ®»¬¿·´ °«®½¸¿-»т Ъ±® ¿´´ -»®ª·½» °¿®¬- ¿²¼ º¿½¬±®§

®»º«®¾·-¸»¼ ЬЫФМЯr ³¿½¸·²»-ф ¬¸» ©¿®®¿²¬§ °»®·±¼ ·- пир ¼¿§-т

нт ШСЙ МС СЮМЯЧТ НЫОКЧЭЫтМ± ±¾¬¿·² ©¿®®¿²¬§ -»®ª·½»ф §±« ³«-¬ ®»¬«®² ¬¸» ¼»º»½¬·ª» °®±¼«½¬ф ¿¬ §±«® »¨°»²-»ф ¬± ¿ -»®ª·½» ½»²¬»® ¿«¬¸±®·¦»¼ ¾§

Э±³°¿²§ ¬± °»®º±®³ ©¿®®¿²¬§ -»®ª·½» ш¿ “ЬЫФМЯr Я«¬¸±®·¦»¼ Н»®ª·½» Э»²¬»®’ч ©·¬¸·² ¬¸» ¿°°´·½¿¾´» ©¿®®¿²¬§ °»®·±¼ф ¬±¹»¬¸»® ©·¬¸ ¿½½»°¬¿¾´» °®±±º ±º

°«®½¸¿-»ф -«½¸ ¿- §±«® ±®·¹·²¿´ ®»½»·°¬ ¾»¿®·²¹ ¬¸» ¼¿¬» ±º °«®½¸¿-»ф ±® °®±¼«½¬ ®»¹·-¬®¿¬·±² ²«³¾»®т Э±³°¿²§ ®»-»®ª»- ¬¸» ®·¹¸¬ ¬± ®»-¬®·½¬ ©¿®®¿²¬§

½´¿·³ -»®ª·½» ¬± ¬¸» ½±«²¬®§ ©¸»®» ¬¸» °«®½¸¿-» ©¿- ³¿¼» ¿²¼с±® ¬± ½¸¿®¹» º±® ¬¸» ½±-¬ ¬± »¨°±®¬ -»®ª·½» °¿®¬- ±® °®±ª·¼» ©¿®®¿²¬§ -»®ª·½» ·² ¿ ¼·ºº»®»²¬

½±«²¬®§т С²у´·²» °«®½¸¿-»- ¿®» ¼»»³»¼ ³¿¼» ·² ¬¸» Л²·¬»¼ Н¬¿¬»-т Ъ±® ¬¸» ´±½¿¬·±² ±º §±«® ²»¿®»-¬ ЬЫФМЯr Я«¬¸±®·¦»¼ Н»®ª·½» Э»²¬»®ф ½¿´´ Э±³°¿²§•Э«-¬±³»® Э¿®» Э»²¬»® ¿¬ ширрч оонуйойит

мт ЫИЭФЛНЧСТНт

Э±³°¿²§ ¼±»- ²±¬ ±ºº»® ¿²§ ©¿®®¿²¬§ ±² °®±¼«½¬- °«®½¸¿-»¼ ·² «-»¼ ±® ¼¿³¿¹»¼ ½±²¼·¬·±²т

Э±³°¿²§ ¼±»- ²±¬ ©¿®®¿²¬§ ¿²§ °®±¼«½¬- °«®½¸¿-»¼ ±«¬-·¼» ¬¸» Л²·¬»¼ Н¬¿¬»- ±® Э¿²¿¼¿

Э±³°¿²§ ©·´´ ²±¬ ¾» ®»-°±²-·¾´» º±® ¿²§ ¼¿³¿¹» ¬¸¿¬ ¸¿- ®»-«´¬»¼ º®±³ ²±®³¿´ ©»¿®ф ³·-«-»ф ¿¾«-» ±® ¿²§ ®»°¿·® ±® ¿´¬»®¿¬·±² ³¿¼» ¾§ ¿²§±²» ±¬¸»®

¬¸¿² ¿ ЬЫФМЯr Я«¬¸±®·¦»¼ Н»®ª·½» Э»²¬»® ±® ¿ ¼»-·¹²¿¬»¼ ®»°®»-»²¬¿¬·ª» ±º Э±³°¿²§•- Э«-¬±³»® Э¿®» Э»²¬»®т

Я´´ ЧУРФЧЫЬ ЙЯООЯТМЧЫН ¿®» »¨°®»--´§ ´·³·¬»¼ ¬± ¬¸» ©¿®®¿²¬§ °»®·±¼ ·¼»²¬·º·»¼ ¿¾±ª»т

Л²¼»® ²± ½·®½«³-¬¿²½»- ©·´´ Э±³°¿²§ ¾» ´·¿¾´» º±® ЧТЭЧЬЫТМЯФ СО ЭСТНЫПЛЫТМЧЯФ ¼¿³¿¹» М¸·- ´·³·¬»¼ ©¿®®¿²¬§ ·- Э±³°¿²§•- -±´» ©¿®®¿²¬§ ¿²¼ -»¬- º±®¬¸ ¬¸» ½«-¬±³»®•- »¨½´«-·ª» ®»³»¼§ ©·¬¸ ®»-°»½¬ ¬± ¼»º»½¬·ª» °®±¼«½¬-е ¿´´ ±¬¸»® ©¿®®¿²¬·»-ф

»¨°®»-- ±® ·³°´·»¼ф ©¸»¬¸»® ±º ³»®½¸¿²¬¿¾·´·¬§ф º·¬²»-- º±® °«®°±-»ф ±® ±¬¸»®©·-»ф ¿®» »¨°®»--´§ ¼·-½´¿·³»¼ ¾§ Э±³°¿²§ф »¨½»°¬ ¿- -¬¿¬»¼ ¿¾±ª»т

Н±³» -¬¿¬»- ¼± ²±¬ ¿´´±© ¬¸» »¨½´«-·±² ±® ´·³·¬¿¬·±² ±º ·²½·¼»²¬¿´ ±® ½±²-»¯«»²¬·¿´ ¼¿³¿¹»-ф ±® ¬¸» ´·³·¬¿¬·±² ±º ·³°´·»¼ ©¿®®¿²¬·»-ф -± ¬¸» ¿¾±ª» ´·³·¬¿¬·±²±® »¨½´«-·±²- ³¿§ ²±¬ ¿°°´§ ¬± §±«т М¸·- ©¿®®¿²¬§ ¹·ª»- §±« -°»½·º·½ ´»¹¿´ ®·¹¸¬- ¿²¼ §±« ³¿§ ¸¿ª» ±¬¸»® ®·¹¸¬- ©¸·½¸ ª¿®§ ·² ½»®¬¿·² -¬¿¬»- ±® °®±ª·²½»-т

Ъ±® º«®¬¸»® ¼»¬¿·´- ±º ©¿®®¿²¬§ ½±ª»®¿¹» ¿²¼ ©¿®®¿²¬§ ®»°¿·® ·²º±®³¿¬·±²ф ½¿´´ ширрч оонуйойит М± ®»¹·-¬»® §±«® °®±¼«½¬- ±²´·²»ф ©» »²½±«®¿¹» §±« ¬± ª·-·¬

±«® ©»¾-·¬» ¿²¼ ®»¹·-¬»® º±® ¿ ЪОЫЫ ЬЫФМЯ У»³¾»® Я½½±«²¬ ¿¬ ¸¬¬°жсс©©©т¼»´¬¿³¿½¸·²»®§т½±³с®»¹·-¬»®т

ФЯМЧТ ЯУЫОЧЭЯж М¸·- ©¿®®¿²¬§ ¼±»- ²±¬ ¿°°´§ ¬± °®±¼«½¬- -±´¼ ·² Ф¿¬·² Я³»®·½¿т Ъ±® °®±¼«½¬- -±´¼ ·² Ф¿¬·² Я³»®·½¿ф -»» ½±«²¬®§

-°»½·º·½ ©¿®®¿²¬§ ·²º±®³¿¬·±² ½±²¬¿·²»¼ ·² ¬¸» °¿½µ¿¹·²¹ô ½¿´´ ¬¸» ´±½¿´ ½±³°¿²§ ±® -»» ©»¾-·¬» º±® ©¿®®¿²¬§ ·²º±®³¿¬·±²ò

ïì

Page 15

РЯОМНф НЫОКЧЭЫ СО ЙЯООЯТМЗ ЯННЧНМЯТЭЫ

Я´´ ЬЫФМЯr ³¿½¸·²»- ¿²¼ ¿½½»--±®·»- ¿®» ³¿²«º¿½¬«®»¼ ¬± ¸·¹¸ ¯«¿´·¬§ -¬¿²¼¿®¼- ¿²¼ ¿®» -»®ª·½»¼ ¾§ ¿ ²»¬©±®µ ±º

ЬЫФМЯr Ъ¿½¬±®§ Н»®ª·½» Э»²¬»®- ¿²¼ ЬЫФМЯr Я«¬¸±®·¦»¼ Н»®ª·½» Э»²¬»®-т М± ±¾¬¿·² ¿¼¼·¬·±²¿´ ·²º±®³¿¬·±² ®»¹¿®¼·²¹

§±«® ЬЫФМЯr ¯«¿´·¬§ °®±¼«½¬ ±® ¬± ±¾¬¿·² °¿®¬-ф -»®ª·½»ф ©¿®®¿²¬§ ¿--·-¬¿²½»ф ±® ¬¸» ´±½¿¬·±² ±º ¬¸» ²»¿®»-¬ -»®ª·½»

½»²¬»®ф °´»¿-» ½¿´´ пуирруоонуйойит

ОЫРФЯЭЫУЫТМ РЯОМН

Ë-» ±²´§ ·¼»²¬·½¿´ ®»°´¿½»³»²¬ °¿®¬-ò Ú±® ¿ °¿®¬- ´·-¬ ±® ¬± ±®¼»® °¿®¬-ô ª·-·¬ ±«® ©»¾-·¬» ¿¬ ©©©òÜ»´¬¿Ó¿½¸·²»®§ò½±³ñ

-»®ª·½»т З±« ½¿² ¿´-± ±®¼»® °¿®¬- º®±³ §±«® ²»¿®»-¬ º¿½¬±®§у±©²»¼ ¾®¿²½¸ф Я«¬¸±®·¦»¼ Й¿®®¿²¬§ Н»®ª·½» Э»²¬»® ±®

¾§ ½¿´´·²¹ М»½¸²·½¿´ Н»®ª·½» У¿²¿¹»® ¿¬ пуирруоонуйойи ¬± ®»½»·ª» °»®-±²¿´·¦»¼ -«°°±®¬ º®±³ ±²» ±º ±«® ¸·¹¸´§у

¬®¿·²»¼ ®»°®»-»²¬¿¬·ª»-т

ЪОЫЫ ЙЯОТЧТЩ ФЯЮЫФ ОЫРФЯЭЫУЫТМ

׺ §±«® ©¿®²·²¹ ´¿¾»´- ¾»½±³» ·´´»¹·¾´» ±® ¿®» ³·--·²¹ô

½¿´´

пуирруоонуйойи

º±® ¿ º®»» ®»°´¿½»³»²¬ò

НЫОКЧЭЫ ЯТЬ ОЫРЯЧОН

Я´´ ¯«¿´·¬§ ¬±±´- ©·´´ »ª»²¬«¿´´§ ®»¯«·®» -»®ª·½·²¹ ¿²¼с±® ®»°´¿½»³»²¬ ±º °¿®¬-т Ъ±® ·²º±®³¿¬·±²

¿¾±«¬ ЬЫФМЯr Р±©»® Ы¯«·°³»²¬ Э±®°±®¿¬·±²ф ·¬- º¿½¬±®§у±©²»¼ ¾®¿²½¸»-ф ±® ¬± ´±½¿¬» ¿²

Я«¬¸±®·¦»¼ Й¿®®¿²¬§ Н»®ª·½» Э»²¬»®ф ª·-·¬ ±«® ©»¾-·¬» ¿¬ ©©©тЬ»´¬¿У¿½¸·²»®§т½±³с-»®ª·½»

±® ½¿´´ ±«® Э«-¬±³»® Э¿®» Э»²¬»® ¿¬ пуирруоонуйойит Я´´ ®»°¿·®- ³¿¼» ¾§ ±«® -»®ª·½» ½»²¬»®- ¿®» º«´´§

¹«¿®¿²¬»»¼ ¿¹¿·²-¬ ¼»º»½¬·ª» ³¿¬»®·¿´ ¿²¼ ©±®µ³¿²-¸·°т Й» ½¿²²±¬ ¹«¿®¿²¬»» ®»°¿·®- ³¿¼» ±® ¿¬¬»³°¬»¼ ¾§

±¬¸»®-т Ю§ ½¿´´·²¹ ¬¸·- ²«³¾»® §±« ½¿² ¿´-± º·²¼ ¿²-©»®- ¬± ³±-¬ º®»¯«»²¬´§ ¿-µ»¼ ¯«»-¬·±²- ом ¸±«®-с¼¿§т

З±« ½¿² ¿´-± ©®·¬» ¬± «- º±® ·²º±®³¿¬·±² ¿¬ ЬЫФМЯr Р±©»® Ы¯«·°³»²¬ Э±®°±®¿¬·±²ф пзом Р»¿®³¿² Ь¿·®§ О¼ф

Я²¼»®-±² НЭ озкол у Я¬¬»²¬·±²ж М»½¸²·½¿´ Н»®ª·½» У¿²¿¹»®т Ю» -«®» ¬± ·²½´«¼» ¿´´ ±º ¬¸» ·²º±®³¿¬·±² -¸±©²

±² ¬¸» ²¿³»°´¿¬» ±º §±«® ¬±±´ ш³±¼»´ ²«³¾»®ф ¬§°»ф -»®·¿´ ²«³¾»®ф ¼¿¬» ½±¼»ф »¬½тч

ïë

Page 16

ЭСТНЧЩТЫН ЬЫ НWЭЛОЧМW ЧУРСОМЯТМЫН

ЯННЛОЫЖуКСЛН Ь•ЯКСЧО ЮЧЫТ ФЛ ЫМ ЭСУРОЧН МСЛМЫН ФЫН УЧНЫН ЫТ ЩЯОЬЫ ЫМ ФЫН

®»-°»½¬»® ¬±«¬»- ´»- ·²-¬®«½¬·±²- ½·ó¼»--±«- °±«®®¿·¬ ½¿«-»® «²» 7´»½¬®±½«¬·±²ô ¼»- ·²½»²¼·»-ô »¬ñ±« ¼»- ¾´»--«®»°»®-±²²»´´»- ±« ¼»- ¼±³³¿¹»- ³¿¬7®·»´- ¹®¿ª»-ò

Ô¿ ³»«´»«-» °»«¬ 6¬®» ¼¿²¹»®»«-» -· ¼»- °®±½7¼«®»- ¼•«¬·´·-¿¬·±² -7½«®·¬¿·®»- »¬ ¿¼7¯«¿¬»- ²» -±²¬

°¿- ®»-°»½¬7»-ò ݱ³³» ½•»-¬ ´» ½¿- °±«® ¬±«¬» °·8½» ¼» ³¿½¸·²»®·»ô ´•«¬·´·-¿¬·±² ¼» ½» °®±¼«·¬ ½±³°±®¬»

½»®¬¿·²- ¼¿²¹»®-ò Û² «¬·´·-¿²¬ ½»¬ ¿°°¿®»·´ -»´±² ´»- ¼·®»½¬·ª»- »¬ ¿ª»½ °®«¼»²½»ô ª±«- ®7¼«·®»¦ ¼» º¿9±²

·³°±®¬¿²¬» ´»- ®·-¯«»- ¼» ¾´»--«®»- ½±®°±®»´´»-ò Ý»°»²¼¿²¬ô -· ´»- °®7½¿«¬·±²- ²±®³¿´»- ¼» -7½«®·¬7

-±²¬ ²7¹´·¹7»- ±« ·¹²±®7»-ô ´¿ °»®-±²²» ¯«· «¬·´·-» ´•¿°°¿®»·´ °±«®®¿·¬ 6¬®» ¾´»--7»ò Ô•7¯«·°»³»²¬ ¼» °®±¬»½¬·±²

½±³³» ´»- ¹¿®¼»-ô ´»- °±«--±·®-ô ´»- ¼·-°±-·¬·º- ¼» ®»¬»²«»ô ´»- °´¿²½¸»- ¼» °®±¬»½¬·±²ô ´»- ´«²»¬¬»- ¼» -7½«®·¬7ô

´»- ³¿-¯«»- ¿²¬·°±«--·8®»- »¬ ´¿ °®±¬»½¬·±² °±«® ´•±«1» °»«¬ ®7¼«·®» ´» ®·-¯«» ¼» ¾´»--«®»ò Ý»°»²¼¿²¬ô ³6³» ´»

³»·´´»«® ¼·-°±-·¬·º ¼» °®±¬»½¬·±² ²» °»«¬ ½±³°»²-»® «² ³¿«ª¿·- ¶«¹»³»²¬ô «² ³¿²¯«» ¼» °®«¼»²½» ±« ¼ù·²¿¬¬»²¬·±²ò

ˬ·´·-»¦ ¬±«¶±«®- ´» ¾±² -»²- »¬ -±§»¦ °®«¼»²¬ ¼¿²- ´•¿¬»´·»®т Н· «²» ³¿²„«ª®» ¿ ´•¿·® ¼¿²¹»®»«-»ф ²» ´•»ºº»½¬«»¦

°¿-т Ы--¿§»¦ °´«¬,¬ ¼» ¬®±«ª»® «² ³±§»² °´«- º¿½·´»т ОЯРРЫФЫЖуКСЛН ж ª±«- 6¬»- ®»-°±²-¿¾´» ¼» ª±¬®» -7½«®·¬7

°»®-±²²»´´»т Р±«® ¼»- ®»²-»·¹²»³»²¬- ½±³°´7³»²¬¿·®»-ф ®»²¼»¦уª±«- -«® ²±¬®» -·¬» Й»¾ @ ´•¿¼®»--» -«·ª¿²¬»

©©©тЬ»´¬¿У¿½¸·²»®§т½±³т

¿«¬®»- º·²- ¯«» ½»´´»- °±«® ´»-¯«»´´»- ·´ ¿ 7¬7 ½±²9«т Н· ª±«- ¿ª»¦ ¼»- ¯«»-¬·±²- -«® «²» «¬·´·-¿¬·±² »² °¿®¬·½«´·»®ф

Т•ЛМЧФЧНЫЖ РЯН ´•¿°°¿®»·´ ¿ª¿²¬ ¼•¿ª±·® ¼•¿¾±®¼ ½±³³«²·¯«7 ¿ª»½ ЬЫФМЯУЬ °±«® ¼7¬»®³·²»® -· ½»¬¬» «¬·´·-¿¬·±² °»«¬ ±«

-· »´´» ¼»ª®¿·¬ 6¬®» º¿·¬» -«® ½» °®±¼«·¬т

Н· ª±«- ¿ª»¦ ¼»- ¯«»-¬·±²- ®»´¿¬·ª»³»²¬ @ -±² «¬·´·-¿¬·±²ф Т•ЛМЧФЧНЫЖ РЯН ´» °®±¼«·¬ ¬¿²¬ ¯«» ª±«- ²•¿«®»¦ °¿-

½±³³«²·¯«7 °¿® 7½®·¬ ¿ª»½ ЬЫФМЯУЬ Р±©»® Ы¯«·°³»²¬ Э±®°±®¿¬·±² »¬ ±¾¬»²« «²» ®7°±²-» ¼» -¿ °¿®¬т Э±²¬¿½¬»¦у²±«- »²

´·¹²» @ ©©©тЬ»´¬¿У¿½¸·²»®§т½±³ ±« °¿® ½±«®®·»® @ ´•¿¼®»--» -«·ª¿²¬» ж О»-°±²-¿¾´» ¼« -»®ª·½» ¬»½¸²·¯«»ф ЬЫФМЯУЬ Р±©»®

Ы¯«·°³»²¬ Э±®°±®¿¬·±²ф пзом Р»¿®³¿² Ь¿·®§ О¼ф Я²¼»®-±² НЭ озколт

Ü»- ®»²-»·¹²»³»²¬- ¿« -«¶»¬ ¼» ´•«¬·´·-¿¬·±² -7½«®·¬¿·®» »¬ ¿°°®±°®·7» ¼» ½»¬ ¿°°¿®»·´ -±²¬ ¼·-°±²·¾´»- ¿«°®8- ¼»- -±«®½»-

-«·ª¿²¬»- æ

Р±©»® М±±´ Ч²-¬·¬«¬»ф пнрр Н«³²»® Яª»²«»ф Э´»ª»´¿²¼ф СШ ммпплуоилп ±« »² ´·¹²» -«® ©©©т°±©»®¬±±´·²-¬·¬«¬»т½±³

Т¿¬·±²¿´ Н¿º»¬§ Э±«²½·´ф ппоп Н°®·²¹ Ф¿µ» Ь®·ª»ф Ч¬¿-½¿ф ЧФ крпмнунорп

Я³»®·½¿² Т¿¬·±²¿´ Н¬¿²¼¿®¼- Ч²-¬·¬«¬»ф ол Й»-¬ мн®¼ Н¬®»»¬ф м º´±±®ф Т»© З±®µф ТЗ пррнк ©©©т¿²-·т±®¹ у ЯТНЧ рптп

Í¿º»¬§ λ¯«·®»³»²¬- º±® ɱ±¼©±®µ·²¹ Ó¿½¸·²»-

О7¹´»³»²¬¿¬·±² ¼« Ь7°¿®¬»³»²¬ ¿³7®·½¿·² ¼« ¬®¿ª¿·´ шСНШЯч @ ´•¿¼®»--» ©©©т±-¸¿т¹±ª

ЭСТНЧЩТЫН Ь•ЛМЧФЧНЯМЧСТ ЯКЯТМ Ь•ЛМЧФЧНЫО ЭЫМ WПЛЧРЫУЫТМт Ф» º¿·¬ ¼» ²» °¿-

Э»¬ ¿°°¿®»·´ ¿ 7¬7 ½±²9« -»«´»³»²¬ °±«® ½»®¬¿·²»- «¬·´·-¿¬·±²-т ЬЫФМЯУЬ Р±©»® Ы¯«·°³»²¬

Э±®°±®¿¬·±² ®»½±³³¿²¼» º±®¬»³»²¬ ¯«» ½»¬ ¿°°¿®»·´ ²» -±·¬ °¿- ³±¼·º·7 ²· «¬·´·-7 °±«® ¬±«¬»-

ЭСТНЧЩТЫН ЬЫ НWЭЛОЧМW у ЬWЪЧТЧМЧСТН

Э» ³¿²«»´ ½±²¬·»²¬ ¼»- ®»²-»·¹²»³»²¬- ¯«щ·´ »-¬ ·³°±®¬¿²¬ ¼» ½±²²¿2¬®» »¬ ¼» ½±³°®»²¼®»т Э»- ®»²-»·¹²»³»²¬- ±²¬ °±«®

¾«¬ ¼•¿--«®»® КСМОЫ НWЭЛОЧМW »¬ ¼» РОWКЫТЧО ФЫН РОСЮФXУЫН Ь•WПЛЧРЫУЫТМт Р±«® ª±«- ¿·¼»® @ ®»½±²²¿2¬®» ½»®»²-»·¹²»³»²¬-ф ²±«- «¬·´·-±²- ´»- -§³¾±´»- ½·у¼»--±«-т К»«·´´»¦ ´·®» ´» ³¿²«»´ »¬ °®6¬»® ¿¬¬»²¬·±² @ ½»- -»½¬·±²-т

ײ¼·¯«» «²» -·¬«¿¬·±² »¨¬®6³»³»²¬ ¼¿²¹»®»«-» ¯«·ô -· »´´» ²•»-¬ °¿- 7ª·¬7»ô »²¬®¿2²»®¿ ´¿ ³±®¬ ±« «²»

¾´»--«®» ¹®¿ª»ò

ײ¼·¯«» «²» -·¬«¿¬·±² °±¬»²¬·»´´»³»²¬ ¼¿²¹»®»«-» ¯«·ô -· »´´» ²•»-¬ °¿- 7ª·¬7»ô °±«®®¿·¬ »²¬®¿2²»®

´¿ ³±®¬ ±« «²» ¾´»--«®» ¹®¿ª»ò

ײ¼·¯«» «²» -·¬«¿¬·±² °±¬»²¬·»´´»³»²¬ ¼¿²¹»®»«-» ¯«·ô -· »´´» ²•»-¬ °¿- 7ª·¬7»ô °»«¬ »²¬®¿2²»® «²»

¾´»--«®» ³·²»«®» ±« ³±¼7®7»ò

ˬ·´·-7 -¿²- ´» -§³¾±´» ¼•¿ª»®¬·--»³»²¬ô ·²¼·¯«» «²» -·¬«¿¬·±² °±¬»²¬·»´´»³»²¬ ¼¿²¹»®»«-» ¯«·ô -· »´´»

²•»-¬ °¿- 7ª·¬7»ô °»«¬ »²¼±³³¿¹»® ´•¿°°¿®»·´ò

ïê

Page 17

RÈGLES DE SÉCURITÉ GÉNÉRALES

LE NON-RESPECT DE CES RÈGLES PEUT ENTRAÎNER DES BLESSURES PERSONNELLES

GRAVES.

POUR VOTRE PROPRE SÉCURITÉ, ASSUREZ-VOUS D’AVOIR BIEN LU ET COMPRIS LE MANUEL D’UTILISATION

AVANT DE FAIRE FONCTIONNER L’APPAREIL.

les dangers qui lui sont rattachés.

MAINTENEZ L’AIRE DE TRAVAIL PROPRE.

NE PAS UTILISER DANS UN ENVIRONNEMENT DANGEREUX.

mouillé, et ne l’exposez pas à la pluie. Gardez votre lieu de travail bien éclairé.

MAINTENEZ LES ENFANTS ET LES VISITEURS À L’ÉCART.

distance sécuritaire de l’aire de travail.

DÉBRANCHEZ L’APPAREIL

VÉRIFIEZ LA PRÉSENCE DE PIÈCES ENDOMMAGÉES.

endommagée.

1.Assurez-vous de lire et comprendre les avertissements

affichés sur l’appareil et dans ce manuel. Le non

respect de tous ces avertissements peut entraîner des

blessures graves.

2.Remplacez les étiquettes d’avertissement si elles sont

masquées ou supprimées.

3.Cet appareil est conçu pour l’utilisation par un personnel

qualifié et expérimenté seulement. En cas de non

familiarité avec le bon fonctionnement sécuritaire d’une

meuleuse/affûteuse, ne pas l’utiliser avant d’avoir reçu

la formation et les connaissances appropriées.

4.Ne pas utiliser cet appareil pour autre chose que son

usage prévu. S’il est utilisé à d’autres fins, DELTA

Power Equipment Corporation décline toute garantie

réelle ou implicite et se dégage de toute responsabilité

pour toute blessure qui pourrait résulter de cette

utilisation.

5.Portez toujours des lunettes de protection ou des

écrans faciaux approuvés lors de l’utilisation de cette

meuleuse/affûteuse.

6.Avant d’utiliser cette meuleuse/affûteuse, enlevez

cravate, bagues, montres et autres bijoux, et

retroussez vos manches au-dessus du coude. Retirez

tous les vêtements amples et retenez les cheveux

longs. Il est recommandé de porter des chaussures

antidérapantes ou de poser des bandes de plancher

antidérapantes. Ne portez pas de gants.

7.Portez des protecteurs pour l’ouïe (bouchons

ou manchons) pendant les longues périodes de

fonctionnement.

8.Certaines poussières créées par le ponçage

mécanique, le sciage, le broyage, le perçage et

d’autres activités de construction contiennent des

produits chimiques identifiés comme causes de cancer,

d’anomalies congénitales ou d’autres préjudices liés à la

reproduction. En voici des exemples:

plomb de peintures à base de plomb;

silice cristalline de briques, de ciment et d’autres

produits de maçonnerie;

arsenic et chrome de bois de sciage traité

chimiquement.

avant toute opération d’entretien.

LE NON-RESPECT DE CES RÈGLES PEUT ENTRAÎNER DES BLESSURES GRAVES.

Apprenez à connaître son domaine d’utilisation et ses limites, ainsi que

Les aires et les bancs de travail encombrés sont propices aux accidents.

N’utilisez pas cet appareil dans un endroit humide ou

Tous les enfants et visiteurs doivent demeurer à une

Avant d’utiliser l’appareil, bien réparer ou remplacer toute pièce

Votre risque lié à ces expositions varie selon la

fréquence à laquelle vous faites ce genre d’activité.Pour

réduire l’exposition à ces produits chimiques, travaillez

dans un endroit bien ventilé et avec de l’équipement de

protection approuvé, comme les masques antipoussières

spécialement conçus pour filtrer les particules

microscopiques.

9.N'utilisez pas cet appareil en état de fatigue ou avec

les facultés affaiblies par la drogue, l’alcool ou les

médicaments.

10.Avant de brancher l’appareil sur la source

d’alimentation, assurez-vous que l’interrupteur est en

®

position « OFF » (Arrêt).

11.Assurez-vous que l'appareil est correctement mis

à la terre.

12.Ne faites les réglages de l'appareil ou son entretien

que lorsque celui-ci est débranché de la source

d’alimentation.

13.Prenez l’habitude de vérifier que tout l’équipement

supplémentaire tel que les clés de réglage, les clés

à molette, la ferraille, le matériel et les chiffons de

nettoyage a été éloigné de l'appareil avant de le mettre

en marche.

14.Gardez les dispositifs de protection en place en tout

temps lorsque l’appareil est utilisé. Faites preuve

d’une extrême prudence s’ils sont enlevés à des

fins d’entretien et remettez-les en place dès la fin de

l’entretien.

15.Assurez-vous que l'outil est solidement fixé sur une

surface de travail stable avant de l’utiliser.

16.Vérifiez si des pièces sont endommagées. Avant

d’utiliser l’appareil, il faut vérifier soigneusement

le dispositif de protection ou toute autre pièce

endommagée afin de s’assurer que l’appareil

fonctionnera correctement et remplira sa fonction

prévue. Vérifiez l’alignement des pièces mobiles

et leurs joints, tout bris de pièce et du cadrage et

toute autre condition qui pourrait en modifier le

fonctionnement. Un garde ou une autre pièce

endommagée doivent être réparés ou remplacés sans

tarder.

17.Prévoyez un espace suffisant autour de la zone de

travail et un éclairage en plongée non éblouissant.

17

suite à la page 18

Page 18

ïèòÙ¿®¼»¦ ´» °´¿²½¸»® ¿«¬±«® ¼» ´•¿°°¿®»·´ °®±°®» »¬

»¨»³°¬ ¼» ¼7¾®·-ô ¼•¸«·´» »¬ ¼» ¹®¿·--»ò

ïçòÙ¿®¼»¦ ´»- ª·-·¬»«®- @ «²» ¼·-¬¿²½» -7½«®·¬¿·®» ¼» ´¿

¦±²» ¼» ¬®¿ª¿·´ò Ì»²»¦ ´»- »²º¿²¬- @ ¼·-¬¿²½»ò

îðòλ²¼»¦ ª±¬®» ¿¬»´·»® @ ´•7°®»«ª» ¼»- »²º¿²¬- ¿«

³±§»² ¼» ½¿¼»²¿-ô ¼» ½±³³«¬¿¬»«®- °®·²½·°¿«¨ ±«

»² ®»¬·®¿²¬ ´»- ½´7- ¼» ³·-» »² ³¿®½¸»ò

îïòݱ²½»²¬®»¦óª±«- «²·¯«»³»²¬ -«® ´» ¬®¿ª¿·´ò λ¹¿®¼»®

¿«¨ ¿´»²¬±«®-ô ¬»²·® «²» ½±²ª»®-¿¬·±² »¬ º¿·®»

¼« ½¸¿¸«¬ -±²¬ ¼»- ¿½¬»- ²7¹´·¹»²¬- ¯«· °»«ª»²¬

»²¬®¿2²»® ¼»- ¾´»--«®»- ¹®¿ª»-ò

îîòÓ¿·²¬»²»¦ «²» °±-·¬·±² 7¯«·´·¾®7» »² ¬±«¬ ¬»³°- ¿º·²

¼» ²» °¿- ¬±³¾»® ±« ¼» ²» °¿- ª±«- ¿°°«§»® -«®

´ù±«¬·´ ±« -«® -»- °·8½»- ³±¾·´»-ò Wª·¬»¦ ¼» ª±«- 7¬·®»®

±« ¼•«¬·´·-»® «²» º±®½» »¨½»--·ª» °±«® »ºº»½¬«»® ¬±«¬»

±°7®¿¬·±² ¿ª»½ ´•¿°°¿®»·´ò

îíòˬ·´·-»¦ ´•±«¬·´ ¿°°®±°®·7 @ ´¿ ¾±²²» ª·¬»--» »¬ ¿«

¾±² ¼7¾·¬ò Ò» º±®½»¦ °¿- «² ±«¬·´ ±« «² ¿½½»--±·®»

@ »ºº»½¬«»® «²» ¬>½¸» °±«® ´¿¯«»´´» ·´ ²•¿ °¿- 7¬7

½±²9«ò Ô» ¾±² ±«¬·´ º»®¿ ³·»«¨ ´» ¬®¿ª¿·´ »¬ -»®¿ °´«-

-7½«®·¬¿·®»ò

îìòˬ·´·-»¦ ´»- °·8½»- ®»½±³³¿²¼7»-å ´»- ¿½½»--±·®»-

·²¿¼7¯«¿¬- °»«ª»²¬ 6¬®» ¼¿²¹»®»«¨ò

îëòÛ²¬®»¬»²»¦ ´»- ¿°°¿®»·´- ¿ª»½ -±·²ò Í«·ª»¦

´»- ·²¼·½¿¬·±²- ®»´¿¬·ª»- @ ´¿ ´«¾®·º·½¿¬·±² »¬ ¿«

½¸¿²¹»³»²¬ ¼•¿½½»--±·®»ò

îêòÜ7¾®¿²½¸»¦ ´•¿°°¿®»·´ ¿ª¿²¬ ´» ²»¬¬±§¿¹»ò ˬ·´·-»¦

«²» ¾®±--» ±« ¼» ´•¿·® ½±³°®·³7 °±«® »²´»ª»® ´¿

°±«--·8®» ±« ¼»- ¼7¾®·-å ²•«¬·´·-»¦ °¿- ª±- ³¿·²-ò

îéòÒ» ª±«- ¬»²»¦ °¿- ¼»¾±«¬ -«® ´•¿°°¿®»·´ò Ü»-

¾´»--«®»- ¹®¿ª»- °±«®®¿·»²¬ -» °®±¼«·®» -· ´•¿°°¿®»·´

-» ®»²ª»®-»ò

îèòÒ» ¶¿³¿·- ´¿·--»® ´•¿°°¿®»·´ -¿²- -«®ª»·´´¿²½» ´±®-¯«•·´

»-¬ »² ³¿®½¸»ò Ü7¾®¿²½¸»¦ ´•¿°°¿®»·´ »¬ ²» ´» ´¿·--»¦

°¿- -¿²- -«®ª»·´´¿²½» ¶«-¯«•@ -±² ¿®®6¬ ½±³°´»¬ò

îçòÌ»²»¦ ´¿ °±·¹²7» º»®³»³»²¬ »² ¬±«¬ ¬»³°-ò

íðòÒ•«¬·´·-»¦ °¿- ½»¬ ±«¬·´ °±«® ¼•¿«¬®»- º·²- ¯«» ½»´´»-

°±«® ´»-¯«»´´»- ·´ »-¬ °®7ª«ò Íù·´ »-¬ «¬·´·-7 @ ¼•¿«¬®»-

º·²-ф ЬЫФМЯУЬ Р±©»® Ы¯«·°³»²¬ Э±®°±®¿¬·±²

¼7½´·²» ¬±«¬» ¹¿®¿²¬·» ®7»´´» ±« ·³°´·½·¬» »¬ -»

¼7¹¿¹» ¼» ¬±«¬» ®»-°±²-¿¾·´·¬7 °±«® ¬±«¬» ¾´»--«®»

¯«· °±«®®¿·¬ ®7-«´¬»® ¼» ½»¬¬» «¬·´·-¿¬·±²ò

Ú¿³·´·¿®·-»¦óª±«- ¿ª»½ ´»- ®8¹´»- ¼» -7½«®·¬7

»²-»·¹²7»- ¼¿²- ½» ³¿²«»´æ

Ý»´¿ -·¹²·º·» ¯«» ´» ²±²ó®»-°»½¬ ¼»- °®7½¿«¬·±²°»«¬ »²¬®¿2²»® ¼»- ¾´»--«®»- -«°»®º·½·»´´»- »¬ñ±«

»²¼±³³¿¹»® ´•¿°°¿®»·´ò

Ý»´¿ -·¹²·º·» ¯«» ´» ²±²ó®»-°»½¬ ¼»- °®7½¿«¬·±²- °»«¬

½¿«-»® ¼»- ¾´»--«®»- ¹®¿ª»- °±«ª¿²¬ ³6³» »²¬®¿2²»®

´¿ ³±®¬ò

ОXЩФЫНЬЫ НWЭЛОЧМW НРWЭЧЪЧПЛЫН НЛРРФWУЫТМЯЧОЫН

Ô» ²±²ó®»-°»½¬ ¼» ½»- ®8¹´»- °»«¬ »²¬®¿2²»® ¼»- ¾´»--«®»- ¹®¿ª»-ò

ïò ТщЛМЧФЧНЫЖРЯН ½»¬ ¿°°¿®»·´ ¿ª¿²¬ ¯«•·´ ²» -±·¬

½±³°´8¬»³»²¬ ¿--»³¾´7 »¬ ·²-¬¿´´7 -»´±² ´»-

·²-¬®«½¬·±²-ò ˲ ¿°°¿®»·´ ³¿´ ¿--»³¾´7 °»«¬

»²¬®¿2²»® ¼»- ¾´»--«®»- ¹®¿ª»-ò

îò ЬЫУЯТЬЫЖ ЭСТНЫЧФ @ ª±¬®» -«°»®ª·-»«®ô

»²-»·¹²¿²¬ ±« ¿«¬®» °»®-±²²» ¯«¿´·º·7» -· ª±«- ²»

³¿2¬®·-»¦ °¿- ´» º±²½¬·±²²»³»²¬ ¼» ½»¬ ¿°°¿®»·´ò Ô¿

½±²²¿·--¿²½» ª±«- °®±¬8¹»ò

íò НЛЧКЫЖ МСЛН ФЫН ЭСЬЫН ЬЫ ЮОЯТЭШЫУЫТМ

»¬ ´»- ½±²²»¨·±²- 7´»½¬®·¯«»- ®»½±³³¿²¼7»- °±«®

7ª·¬»® ¬±«¬ ½¸±½ »¬ 7´»½¬®±½«¬·±²ò

ìò ЛМЧФЧНЫЖ МСЛЦСЛОН ФЫ МЯУРСТ ЪСЛОТЧ »¬ ´»-

º´¿-¯«»- ¼» ®±«» °±«® ³±²¬»® ´»- ³»«´»- -«® ´ù¿®¾®»

¼» ´¿ ³»«´»«-» ¿º·² ¼ù7ª·¬»® ´•»²¼±³³¿¹»³»²¬

¼»- ³»«´»- ±« ´»- -7°¿®¿¬·±²- ¿½½·¼»²¬»´´»-ò ˲»

-7°¿®¿¬·±² °»«¬ »²¬®¿2²»® ´¿ °®±¶»½¬·±² ¼» º®¿¹³»²¬¼» ´¿ ³»«´» @ ¹®¿²¼» ª·¬»--»ò

ëò ЛМЧФЧНЫЖ НЫЛФЫУЫТМ ЬЫН УЫЛФЫН ½±²ª»²¿²¬

@ ´¿ ª·¬»--» ¼» ´ù¿°°¿®»·´ò Ü»- ³»«´»- ·²¿¼¿°¬7»°»«ª»²¬ -» -7°¿®»® »¬ ¼»- º®¿¹³»²¬- °»«ª»²¬ 6¬®»

°®±¶»¬7- @ ¹®¿²¼» ª·¬»--»ò

êò ЛМЧФЧНЫЖ НЫЛФЫУЫТМ ЬЫН УЫЛФЫН ¼±¬7»- ¼ù«²

¿´7-¿¹» ½±®®»-°±²¼¿²¬ »¨¿½¬»³»²¬ @ ´•¿®¾®» ¼»

´ù¿°°¿®»·´ò Ò» ¬»²¬»¦ ¶¿³¿·- ¼ù«-·²»® «² ¿´7-¿¹»

·²-«ºº·-¿²¬ ¼ù«²» ³»«´» °±«® ´¿ º¿·®» ¿´´»® -«® ´ù¿®¾®»ò

Ü»- ³»«´»- ·²¿¼¿°¬7»- °»«ª»²¬ -» -7°¿®»® »¬ ¼»-

º®¿¹³»²¬- °»«ª»²¬ 6¬®» °®±¶»¬7- @ ¹®¿²¼» ª·¬»--»ò

éò ТЫ НЫООЫЖ РЯН МОСР ´щ7½®±« ¼» ´¿ ³»«´»ò

èò ТщЛМЧФЧНЫЖ РЯН ЛТЫ УЫЛФЫ ПЛЧ КЧЮОЫт Ь®»--»¦

´¿ ³»«´»ô ®»³°´¿½»¦ó´¿ ±« ®»³°´¿½»¦ ´»- ®±«´»³»²¬-

¼» ´ù¿®¾®»ò Ü»- ³»«´»- ·²¿¼¿°¬7»- °»«ª»²¬ -»

-7°¿®»® »¬ ¼»- º®¿¹³»²¬- °»«ª»²¬ 6¬®» °®±¶»¬7- @

¹®¿²¼» ª·¬»--»ò

çòÊWОЧЪЧЫЖ ФЫН УЫЛФЫН ¿ª¿²¬ ¼щ«¬·´·-»® ´щ¿°°¿®»·´

°±«® ½±²º·®³»® ¯«•»´´»- ²» -±²¬ °¿- º·--«®7»-

±« 7¾®7½¸7»-ò ОЫУРФЯЭЫЖ ФЫН УЫЛФЫН

ЫТЬСУУЯЩWЫН ·³³7¼·¿¬»³»²¬ò Ü»- ³±®½»¿«¨

¼» ´¿ ³»«´» °»«ª»²¬ 6¬®» °®±¶»¬7- »² ´ù¿·® @ ¹®¿²¼»

ª·¬»--» »¬ °®±ª±¯«»® ¼»- ¾´»--«®»- ¹®¿ª»-ò

ïðòЯЦЛНМЫЖ ФЫН КЧНЧXОЫН °®8- ¼»- ³»«´»- »¬

®7¿¶«-¬»¦ó´»- @ ²±«ª»¿« ¿« º«® »¬ @ ³»-«®» ¯«» ´»-

³»«´»- -ù«-»²¬ò Ô»- 7¬·²½»´´»- -±²¬ ¼¿²¹»®»«-»- »¬

°»«ª»²¬ ½¿«-»® ¼»- ·²½»²¼·»- ±« ¼»- »¨°´±-·±²-ò

ïè

Page 19

ОXЩФЫНЬЫ НWЭЛОЧМW НРWЭЧЪЧПЛЫН НЛРРФWУЫТМЯЧОЫН

ïïò ЯННЛОЫЖуКСЛНМСЛЦСЛОН ¯«»´»-ª·-·8®»--±²¬

»² °´¿½»ô ½±®®»½¬»³»²¬¿¶«-¬7-»¬-7½«®·-7-ò

ïîò ОWЩФЫЖФЫНРСОМЫуСЛМЧФН °®8-¼»´¿³»«´»

ø7½¿®¬¼»ïñè°±±«³±·²-÷òÍ»®®»¦¾·»²´»-°±®¬»ó

±«¬·´-°±«®7ª·¬»®¯«ù·´-²»-»¼7°´¿½»²¬»¬®7¿¶«-¬»¦ó

´»-@²±«ª»¿«¿«º«®»¬@³»-«®»¯«»´»-³»«´»-

-ù«-»²¬òÔ¿°·8½»@¿ºº%¬»®°»«¬6¬®»»²¬®¿2²7»¼¿²´¿³»«´»ô°®±ª±¯«¿²¬¼»-¼±³³¿¹»-@´¿°·8½»@

¿ºº%¬»®»¬ñ±« ¼»- ¾´»--«®»- ¹®¿ª»-ò

ïíò УЫММЫЖуКСЛННЛОЛТЭLМW ¿ª¿²¬¼»³»¬¬®»

´ù¿°°¿®»·´-«®uÑÒeøÓ¿®½¸»÷òÜ»-º®¿¹³»²¬¼»--»®®7-±«¼»-³±®½»¿«¨¼»³»«´»°»«ª»²¬6¬®»

°®±¶»¬7- ¼» ´¿ ³»«´» @ ¹®¿²¼» ª·¬»--»ò

ïìò ТЫУЫЛФЫЖЦЯУЯЧНЯКЫЭЛТЫУЫЛФЫЪОСЧЬЫт

Ô¿³»«´»«-»¼±·¬¬±«¶±«®-6¬®»³·-»»²³¿®½¸»¿«

³±·²-«²»³·²«¬»¿ª¿²¬¼»½±³³»²½»®´»³»«´¿¹»ò

˲»³»«´»º®±·¼»@¬»²¼¿²½»@-ù7¾®7½¸»®òÝ»º®¿¹³»²¬-°»«ª»²¬6¬®»°®±¶»¬7-¼»´¿³»«´»@

¹®¿²¼» ª·¬»--»ò

ïëò ТЫУЫММЫЖЦЯУЯЧНЫТОСЛМЫФщЯРРЯОЫЧФ

´±®-¯«»´¿°·8½»@¿ºº%¬»®»-¬¿°°«§7»½±²¬®»´¿

³»«´»òÔ¿°·8½»@¿ºº%¬»®°»«¬6¬®»»²¬®¿2²7»¼¿²´¿³»«´»ô°®±ª±¯«¿²¬¼»-¼±³³¿¹»-@´ù¿°°¿®»·´»¬ñ

±« ¼»- ¾´»--«®»- ¹®¿ª»-ò

ïêò ТЫММСЗЫЖЫТМЧXОЫУЫТМФщЯРРЯОЫЧФ ´±®-

¼«¬®¿ª¿·´-«®¼·ºº7®»²¬-¬§°»-¼»°·8½»-@¿ºº%¬»®

ш¾±·-ф¿½·»®±«¿´«³·²·«³чтФ¿½±³¾·²¿·-±²¼»

´¿°±«--·8®»¼»¾±·-»¬¼»³7¬¿´°»«¬½®7»®«²»

»¨°´±-·±²±«¼»-®·-¯«»-¼щ·²½»²¼·»тТЫУЫЛФЫЖ

РЯН±«²»°±´·--»¦°¿-¼»³¿¹²7-·«³тЛ²·²½»²¼·»

°±«®®¿·¬ 6¬®» °®±ª±¯«7т

ïéò ТЫУЫЛФЫЖЦЯУЯЧНРОXНЬЫФЧПЛЧЬЫНСЛ

ЬЫЩЯЖЧТЪФЯУУЯЮФЫНт Ô»-7¬·²½»´´»-°»«ª»²¬

¼7½´»²½¸»®«²·²½»²¼·» ±««²»»¨°´±-·±²ò

ïèò WКЧМЫЖ «²»«¬·´·-¿¬·±²³¿´¿·-7»±«¼»-°±-·¬·±²-

·²½±³³±¼»-ò˲¹´·--»³»²¬-±«¼¿·²°±«®®¿·¬

»²¬®¿2²»®«²» ³¿·² ª»®- ´¿ ³»«´»ò

ïçò ЩЯОЬЫЖФЫНЮОЯНфФЫНУЯЧТН »¬´»-¼±·¹¬-

´±·²¼»´¿³»«´»òÔ»--«®º¿½»-¿¾®¿-·ª»-°»«ª»²¬

»²¬®¿2²»® ¼»- ¾´»--«®»-¹®¿ª»-ò

îðò МЫТЫЖЪЫОУЫУЫТМФЯРЧXЭЫ`ЯЪЪEМЫО

¿°°«§7»½±²¬®»´»°±®¬»ó±«¬·´-òÔ¿°»®¬»¼»½±²¬®,´»

¼» ´¿ °·8½» °»«¬ °®±ª±¯«»® ¼»- ¾´»--«®»-¹®¿ª»-ò

îïò ЬОЫННЫЖФЯУЫЛФЫ -«®´¿º¿½»-»«´»³»²¬ò

Ü®»--»®´»½,¬7¼»´¿³»«´»°»«¬´¿®»²¼®»¬®±°

³·²½»»¬¿ºº»½¬»®´¿ -7½«®·¬7ò

îîò УЫЛФЫЖЛТЫРЧXЭЫ -«®´¿º¿½»¼»´¿³»«´»

-»«´»³»²¬òÔ¿°»®¬»¼»½±²¬®,´»¼»´¿°·8½»°»«¬

°®±ª±¯«»®¼»-¾´»--«®»-¹®¿ª»-ò

îíò ТщЯРРФЧПЛЫЖ ЦЯУЯЧН ЬЫ ФЧПЛЧЬЫ ЬЫ

ОЫЪОСЧЬЧННЫУЫТМ ¼·®»½¬»³»²¬-«®«²»³»«´»òÔ»

´·¯«·¼»¼»®»º®±·¼·--»³»²¬°»«¬¿ºº¿·¾´·®´»´·¿²¬¼»´¿

³»«´»»¬´ù»²¼±³³¿¹»®òÌ®»³°»¦´¿°·8½»@¿ºº%¬»®

¼¿²-´ù»¿« °±«®´¿®»º®±·¼·®ò

îìò ТЫМСЛЭШЫЖРЯН ´¿°¿®¬·»¿ºº%¬7»¼»´¿°·8½»¬¿²¬

¯«ù»´´»²ù»-¬°¿--«ºº·-¿³³»²¬®»º®±·¼·»òÔ»³»«´¿¹»

½®7» ¼» ´¿½¸¿´»«®ò

îëò ЯРРЛЗЫЖЭСООЫЭМЫУЫТМФЫНРЧXЭЫН

ФСТЩЛЫНСЛФЯОЩЫНòÔ¿°»®¬»¼»½±²¬®,´»¼»´¿

°·8½» °»«¬ °®±ª±¯«»®¼»- ¾´»--«®»-¹®¿ª»-ò

îêò ТЫЪЯЧМЫНЦЯУЯЧНЬщЯООЯТЩЫУЫТМН ±«

¼Ž¿--»³¾´¿¹»-«®´¿¬¿¾´»±«´Ž¿·®»¼»¬®¿ª¿·´¯«¿²¼

´Ž¿°°¿®»·´º±²½¬·±²²»ô»¬²Ž§°®7°¿®»¦°¿-ª±¬®»

¬®¿ª¿·´ò˲ ¹´·--»³»²¬ -±«¼¿·² °±«®®¿·¬»²¬®¿2²»® «²»

³¿·²ª»®-´¿³»«´»òÜ»-¾´»--«®»-¹®¿ª»-°»«ª»²¬

-»°®±¼«·®»ò

îéò WМЫЧЩТЫЖФŽЯРРЯОЫЧФ »¬¼7¾®¿²½¸»¦у´»¼»´¿

-±«®½»¼Ž¿´·³»²¬¿¬·±²òÒ»¬¬±§»¦´¿¬¿¾´»ñ´Ž¿·®»

¼»¬®¿ª¿·´¿ª¿²¬¼»´¿·--»®´Ž¿°°¿®»·´òÊ»®®±«·´´»¦

´Ž·²¬»®®«°¬»«®»²°±-·¬·±²uÑÚÚeøß®®6¬÷°±«®

»³°6½¸»®´»-«¬·´·-¿¬·±²-²±²¿«¬±®·-7»-ò

Ï«»´¯«ù«²¼ù¿«¬®»°±«®®¿·¬¼7³¿®®»®´ù¿°°¿®»·´

¿½½·¼»²¬»´´»³»²¬ »¬ -» ¾´»--»® ¹®¿ª»³»²¬ò

îèò ЬЫРФЛНЯУРФЫНОЫТНЫЧЩТЫУЫТМН -«®

´Ž«¬·´·-¿¬·±²-7½«®·¬¿·®»»¬¿¼7¯«¿¬»¼»-±«¬·´7´»½¬®·¯«»-ш·т»«²»ª·¼7±¼»-7½«®·¬7ч-±²¬

¼·-°±²·¾´»-¿«°®8-¼«Р±©»®М±±´Ч²-¬·¬«¬»фпнрр

Н«³³»®Яª»²«»фЭ´»ª»´¿²¼фСШммпплуоилпш©©©т

°±©»®¬±±´·²-¬·¬«¬»т½±³чтЬ»-®»²-»·¹²»³»²¬--±²¬

7¹¿´»³»²¬¼·-°±²·¾´»-¿«°®8-¼«Э±²-»·´²¿¬·±²¿´

¼»-7½«®·¬7фппопН°®·²¹Ф¿µ»Ь®·ª»фЧ¬¿-½¿ф

ЧФкрпмнунорптК»«·´´»¦½±²-«´¬»®´¿²±®³»ЯТНЧ

рптп¼»´щЯ³»®·½¿²Т¿¬·±²¿´Н¬¿²¼¿®¼-Ч²-¬·¬«¬»

½±²½»®²¿²¬´»-®8¹´»-¼»-7½«®·¬7°±«®´»-³¿½¸·²»@¾±·-¿·²-·¯«»´»®8¹´»³»²¬СНШЯпзпртопн¼«

³·²·-¬8®»¼«М®¿ª¿·´ ¼»- WтуЛт

PROPOSITION 65 DE LA CALIFORNIE

AVERTISSEMENT!

Des étudeseffectuéesenCalifornieontdémontré quelapoussièreproduiteparleponçage,lesciage,le meulage, leperçageetlesautrestravaux

deconstructioncontenaitdesproduitschimiquespouvantcauserle cancer, des anomalies congénitales et autres dommages au système reproducteur.

Voici des exemples de ces produits chimiques :

Le plomb provenant des peintures à base de plomb,

Lescristaux desilices provenant des briqueset du cimentet d’autres

produits demaçonnerie, et

L’arsenicet lechrome provenant des boistraitéschimiquement.

Le niveau de risque dû à cette exposition varie avec la fréquence de ces types de travaux. Pour réduire l’exposition à ces produits chimiques, il faut

microscopiques. Éviter tout contact prolongé avec la poussière produite par le ponçage, le sciage, le meulage, ltrer les particules

le perçage et autres activités de la construction. Porter des vêtements de protection et laver les zones exposées à l’eau et au savon. La pénétration

de la poussière dans la bouche ou les yeux ou le dépôt de la poussière sur la peau peuvent faciliter l’absorption de produits chimiques dangereux.

AVERTISSEMENT!

L’utilisation de cet outil peut produire ou propager de la poussière pouvant entraîner de graves problèmes

respiratoires permanents ou autres lésions. Utiliser toujours un appareil de protection respiratoire approuvé

par NIOSH/OSHA en cas d’exposition à la poussière.

ЭСТНЫОКЫЖ ЭЫН ЭСТНЧЩТЫНтݱ²-«´¬»¦ó´»- -±«ª»²¬ »¬ «¬·´·-»¦ó´»- °±«® »²-»·¹²»® ´»- ¿«¬®»-ò

ïç

Page 20

ОЯЭЭСОЬЫУЫТМН WФЫЭМОЧПЛЫН

˲½·®½«·¬7´»½¬®·¯«»-7°¿®7¼»ª®¿·¬6¬®»«¬·´·-7°±«®ª±-¿°°¿®»·´-òÔ»-º·´-¼«½·®½«·¬¼±·ª»²¬6¬®»¿«³±·²-¼»½¿´·¾®»

ï6¬®»°®±¬7¹7-°¿®«²º«-·¾´»@¿½¬·±²¼·ºº7®7»¼»î𿳰8®»-òÍ·ª±«-«¬·´·-»¦«²»®¿´´±²¹»ô²»°®»²»¦¯«»¼»®¿´´±²¹»-@¬®±·-º·´-¿ª»½¼»-º·½¸»-¼»³·-»@´¿¬»®®»@¬®±·-¾®±½¸»-»¬´»®7½»°¬¿½´»½±®®»-°±²¼¿²¬¯«·¿½½»°¬»®¿´¿

º·½¸»¼»´•¿°°¿®»·´òߪ¿²¬¼»¾®¿²½¸»®´•¿°°¿®»·´-«®´•¿´·³»²¬¿¬·±²ô¿--«®»¦óª±«-¯«»´»½±³³«¬¿¬»«®»-¬»²°±-·¬·±²

uÑÚÚeøuß®®6¬e÷»¬¯«»´»½±«®¿²¬7´»½¬®·¯«»¯«»ª±«-¿´´»¦«¬·´·-»®°±--8¼»´»-³6³»-½¿®¿½¬7®·-¬·¯«»-¯«»½»´«·

·²¼·¯«7-«®´•¿°°¿®»·´ò̱«-´»-®¿½½±®¼»³»²¬-¼±·ª»²¬7¬¿¾´·®«²¾±²½±²¬¿½¬ò˲»«¬·´·-¿¬·±²»²¾¿--»¬»²-·±²

»²¼±³³¿¹»®¿´•¿°°¿®»·´ò

ТЫРЯНЛМЧФЧНЫОФ•ЯРРЯОЫЧФЬЯТНЛТЫТЬОСЧМШЛУЧЬЫСЛУСЛЧФФWЫМТЫРЯН

Ф•ЫИРСНЫО ` ФЯ РФЛЧЫт

ЮСRМЫЬЫ ЭСЛОЯТМ

ЬЫУЧНЫ ` ФЯ МЫООЫ

ЮОСЭШЫН

РСОМЫЛНЫНЬЫ

ЭСЛОЯТМ

ФЯ ЮОСЭШЫЬЫ

УЧНЫ ` ФЯ МЫООЫ ЫНМ ФЯ РФЛН

ФСТЩЛЫЬЫН МОСЧН

ЮСRМЫЬЫ ЭСЛОЯТМ

ЬЫУЧНЫ ` ФЯ МЫООЫ

УСЗЫТНЬЫ УЧНЫ

` ФЯ МЫООЫ

ЯЬЯРМЯМЫЛО

ÞòÙ×ÚßòÙ×Ú

НРWЭЧЪЧЭЯМЧСТНЬЛУСМЫЛО

К±¬®»¿°°¿®»·´»-¬½>¾´7°±«®«²½±«®¿²¬¿´¬»®²¿¬·º¼»пор КфкрШ¦тЯª¿²¬¼»¾®¿²½¸»®´•¿°°¿®»·´@´¿-±«®½»

¼•¿´·³»²¬¿¬·±²ф¿--«®»¦уª±«- ¯«» ´•·²¬»®®«°¬»«® »-¬ »² °±-·¬·±² uСЪЪe шЯ®®6¬чт

ЧТНМОЛЭМЧСТНЬЫУЧНЫ`ФЯМЫООЫ

ЭЫМ ЯРРЯОЫЧФЬСЧМ VМОЫУЧН ` ФЯ МЫООЫ ФСОНПЛ•ЧФ ЫНМ ЛМЧФЧНW РСЛО РОСМWЩЫО

Ф•СРWОЯМЫЛО ЭСТМОЫ Ф•WФЫЭМОСЭЛМЧСТт

ïòб«®¬±«- ´»-¿°°¿®»·´- ¾®¿²½¸7- °¿®«² ½±®¼±² ¼•¿´·³»²¬¿¬·±²»¬ ³·-@´¿ ¬»®®»æ

Û²½¿-¼»³¿«ª¿·-º±²½¬·±²²»³»²¬±«¼»°¿²²»ô´¿³·-»@´¿¬»®®»º±«®²·¬«²½¸»³·²¼»³±·²¼®»®7-·-¬¿²½»¿«½±«®¿²¬

7´»½¬®·¯«»ª·-¿²¬@®7¼«·®»´»®·-¯«»¼•7´»½¬®±½«¬·±²òÝ»¬¿°°¿®»·´»-¬7¯«·°7¼•«²½±®¼±²7´»½¬®·¯«»°±--7¼¿²¬«²

½±²¼«½¬»«®¼»¬»®®»»¬«²»º·½¸»¼»¬»®®»òÔ¿º·½¸»¼±·¬6¬®»¾®¿²½¸7»-«®«²»°®·-»½±®®»½¬»³»²¬·²-¬¿´´7»»¬³·-»@´¿

¬»®®»½±²º±®³7³»²¬ @ ¬±«-´»- ½±¼»- »¬ ®8¹´»³»²¬- ´±½¿«¨ò

Ò»°¿-³±¼·º·»®´¿º·½¸»°®7ª«»òÍ·»´´»²•»²¬®»°¿-¼¿²-´¿°®·-»ôº¿·®»·²-¬¿´´»®«²»°®·-»¿°°®±°®·7»°¿®«²7´»½¬®·½·»²

¿¹®77ò

Ô»®¿½½±®¼»³»²¬·²¿°°®±°®·7¼«½±²¼«½¬»«®¼»¬»®®»¼»´•7¯«·°»³»²¬°»«¬°®±ª±¯«»®´•7´»½¬®±½«¬·±²òÔ»º·´½±²¼«½¬»«®

¿ª»½«²·-±´¿²¬½±³°±®¬¿²¬«²»-«®º¿½»»¨¬7®·»«®»ª»®¬»ô¿ª»½±«-¿²-®¿§«®»-¶¿«²»-ô»-¬´»½±²¼«½¬»«®¼»¬»®®»òÍ·´¿

®7°¿®¿¬·±²±«´»®»³°´¿½»³»²¬¼«½±®¼±²7´»½¬®·¯«»±«¼»´¿º·½¸»»-¬²7½»--¿·®»ô²»¾®¿²½¸»¦°¿-´»½±²¼«½¬»«®¼»

¬»®®»@ «²» ¾±®²» -±«- ¬»²-·±²ò

Í·´»-½±²-·¹²»-¼»³·-»@´¿¬»®®»²»-±²¬°¿-½±³°´8¬»³»²¬½±³°®·-»-±«»²½¿-¼»¼±«¬»½±²½»®²¿²¬´¿³·-»@´¿

¬»®®»¼» ´•¿°°¿®»·´ô -»®»²-»·¹²»® ¿«°®8- ¼•«² 7´»½¬®·½·»² ±« ¼«°»®-±²²»´ ¼» -»®ª·½» ¿¹®77-ò

ˬ·´·-»®«²·¯«»³»²¬¼»-®¿´´±²¹»-@¬®±·-º·´-¿ª»½¼»-º·½¸»-¼»³·-»@´¿¬»®®»@¬®±·-¾®±½¸»-»¬¼»-®7½»°¬¿½´»-@í

½±²¼«½¬»«®-¿¼¿°¬7- @ ´¿º·½¸»¼»´•¿°°¿®»·´ô ½±³³»·²¼·¯«7 @ ´¿ Ú·¹òßò

Î7°¿®»® »¬®»³°´¿½»® ·³³7¼·¿¬»³»²¬¬±«¬½±®¼±² »²¼±³³¿¹7 ±« «-7ò

ЬЯТНМСЛНФЫНЭЯНфЯННЛОЫЖуКСЛНПЛЫФЫОWЭЫРМЯЭФЫЫТПЛЫНМЧСТЫНМЮЧЫТОЫФЧW`

ФЯМЫООЫтНЧКСЛНТ•VМЫНРЯНЭЫОМЯЧТфЪЯЧМЫНКWОЧЪЧЫОФЫОWЭЫРМЯЭФЫРЯОЛТ

WФЫЭМОЧЭЧЫТ ПЛЯФЧЪЧWт

îð

Page 21

RALLONGES

Utilisez des rallonges appropriées.

Assurez-vous que la rallonge est en

bon état et qu’il s’agit d’une rallonge à troisfils avec une

fiche de mise à la terre à troisbroches et d’un

ré ceptacle correspondant à la fiche de l’appareil.

Lorsque vous utilisez une rallonge, assurez-vous qu’elle

soit de calibre suffisamment élevé pour assurer

l’alimentation de l’appareil. Une rallonge d’un calibre

trop petit provoquera une chute de tension, entraînant

une perte de puissance et une surchauffe. Le tableau

indique le bon calibre à utiliser en fonction de la

longueur de la rallonge. En cas de doute, utiliser le

calibre immédiatement supérieur. Plus le numéro de

calibre est petit, plus le cordon est épais.

CALIBRE MINIMUM POUR RALLONGE

CALIBRES RECOMMANDÉS POUR UTILISATION SUR DES APPAREILS

Intensité Volts Longueur totale du

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

12-16

ÉLECTRIQUES STATIONNAIRES

cordon en mètres (pieds)

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

jusqu'à 7,6 (25)

7,6-15,2 (25-50)

15,2-30,5 (50-100)

30,5-45,7 (100-150)

jusqu'à 7,6 (25)

7,6-15,2 (25-50)

15,2-30,5 (50-100)

30,5-45,7 (100-150)

jusqu'à 7,6 (25)

7,6-15,2 (25-50)

15,2-30,5 (50-100)

30,5-45,7 (100-150)

jusqu’à 7,6 (25)

7,6-15,2 (25-50)

UNE LONGUEUR DE PLUS DE 15,2 MÈTRES (50 PIEDS)

N’EST PAS RECOMMANDÉE.

CARACTÉRISTIQUES ET COMPOSANTES IMPORTANTES

(les caractéristiques représentées

commencent du haut et se déplacent

dans le sens antihoraire autour de

l'outil)

A.Lampe de travail flexible (ampoule

comprend pas)

Calibre de la

rallonge

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

B.Carter de meule

C.Meule en oxyde d’aluminium

D.Porte-outils ajustable

E.Interrupteur marche/arrêt (On/Off)

avec bouton de verrouillage

F.Commande de vitesse variable

G. Meule en oxyde d’aluminium

H.Pare-étincelles ajustable

I. Stockage intégré pourde dressage

inclus (non illustré)

J.Bac de refroidissement

J

DESCRIPTION FONCTIONNELLE

Le modèle DELTAMD 23-196 est une meuleuse/affûteuse à vitesse variable de 6 po et le modèle DELTAMD 23-197 est

une meuleuse/affûteuse à vitesse variable de 8 po. Ces appareils offrent une haute performance en matière de meulage

et d'affûtage, et avec les accessoires adaptés, ils permettent à l'utilisateur d'enlever la rouille et le feutre à polir ou de

polir les métaux. Ce modèle est doté d'une lampe flexible, de porte-outils ajustables, d'un système de libération rapide de

l'écrou de l'arbre et de deux grandes visières pour une meilleure sécurité.

21

Page 22

Page 23

DÉBALLAGE

Retirez tout matériau de protection et tout revêtement de l&ensemble des éléments et de l'outil. Les revêtements de

protection peuvent être enlevés en les pulvérisant avec du WD-40 et en les essuyant avec un chiffon doux. Il peut être

nécessaire de refaire cette étape plusieurs fois avant que tous les revêtements de protection soient complètement

enlevés.

S&il y a des pièces manquantes, n&essayez pas de brancher le cordon d&alimentation et de

mettre l&appareil en marche (« ON »). L&appareil doit seulement être mis en marche (« ON »)

quand toutes les pièces auront été obtenues et correctement installées.

MONTAGE

ATTACHER LE PARE-ÉTINCELLES ET LA VISIÈRE

Consultez la Figure 1.

1. Ajustez deux vis à tête hexagonale M5 x 10 mm avec

des rondelles de blocage et plates M5. Utilisez des

vis et des rondelles hexagonales pour fixer le pare-

étincelles (A) au carter de meule. Le pare-étincelles doit

être approximativement à 1/8 po de la meule.

2. Répétez l'étape précédente pour le deuxième pare-

étincelles.

3. Utilisez un boulon de carrosserie M6 de 16 mm inséré

dans le trou le plus à l'extérieur dans le pare-étincelles

pour attacher la visière (B). Fixez avec une rondelle

plate M5 et une molette filetée.

4. Répétez l'étape précédente pour la deuxième visière.

FIGURE 1

ATTACHER LE PORTE-OUTILS

Reportez-vous à la Figure 2.

1. Retirez la molette (D), la rondelle éventail et la

rondelle du boulon de carrosserie de la partie

inférieure du protège-meule.

Utilisez le boulon de carrosserie, la rondelle éventail,

la rondelle et la molette de fixation pour attacher le

support de la pièce à travailler (A) à l&intérieur du

protège-meule, tel que montré.

2. Attachez le porte-outils (B) au support du porte-outils

au moyen d&une molette de fixation.

3. Ajustez la position du support du porte-outils afin que

le porte-outils se trouve approximativement à 1/8 po

de la meule (C).

4. Répétez les étapes ci-dessus pour le deuxième porte-

outils

23

D

FIGURE 2

Page 24

УСТМЯЩЫ

НМСЭХЯЩЫ ЬЫ ФщСЛМЧФ

К±¬®» ³»«´»«-»с¿ºº%¬»«-» ЬЫФМЯУЬ онупзк шк °±ч ±«

онупзй ши °±ч ¼·-°±-» ¼щ«² »³°´¿½»³»²¬ ¼» -¬±½µ¿¹»

¼щ±«¬·´- ·²¬7¹®7 °®¿¬·¯«» °±«® ´щ±«¬·´ ¼» ¼®»--¿¹» º±«®²·т Ф»

°±®¬»у±«¬·´-ф ·²¼·¯«7 @ ´¿ Ъ·¹«®» нф »-¬ -·¬«7 @ ´щ¿®®·8®» ¼» ´¿

¾¿-» ¼» ´¿ ³»«´»«-»т

ЪЧЩЛОЫ н

ЭСТЪЧОУЫО ФЫ НЫООЯЩЫ ЬЫН WЭОСЛН ЬЫ ФщЯОЮОЫ

ߪ¿²¬ ¼ù«¬·´·-»® ª±¬®» ³»«´»«-»ñ¿ºº%¬»«-» °±«® ´¿ °®»³·8®»

º±·-ô ·´ »-¬ ®»½±³³¿²¼7 ¼» ª7®·º·»® ´» -»®®¿¹» ¼»- 7½®±«¼» ´ù¿®¾®»ò б«® ª7®·º·»® ´» -»®®¿¹» ¼»- 7½®±«- ¼» ´ù¿®¾®»ô

ª»«·´´»¦ -«·ª®» ´»- ·²-¬®«½¬·±²- -«·ª¿²¬»- æ

ïò λ¬·®»¦ ´»- ª·- ¼» -»®®¿¹» @ ´¿ ³¿·² øß÷ »² ®»¬»²¿²¬

´¿ º¿½» »¨¬»®²» ¼« ½¿®¬»® ¼» ³»«´» ½±²¬®» ´» ½¿¼®» ¼»

´ù±«¬·´ò ʱ·® Ú·¹«®» ìò

îò λ¬·®»¦ ´» ¹¿®¼»ó³»«´»òò

íò ` ´•¿·¼» ¼•«²» ½´7 ¿°°®±°®·7»ô ¬±«®²»¦ ´•7½®±« ¼»

´•¿®¾®» øÞ÷ ¬±«¬ »² «¬·´·-¿²¬ ´•¿«¬®» ³¿·² °±«® »³°6½¸»®

´¿ ³»«´» ¼» ¾±«¹»®ò ʱ·® Ú·¹«®» ëò Í»®®»¦ ´•7½®±« ¼»

´•¿®¾®»ô ¿«--· ´±·² ¯«» ª±«- ´» °±«ª»¦ò

ОЫУЯОПЛЫ ж ´щ7½®±« ¼» ´щ¿®¾®» -«® ´» ½,¬7 ¼®±·¬ ¼»

´щ¿°°¿®»·´ -» -»®®» »² ´» ¬±«®²¿²¬ ¼¿²- ´» -»²- ¸±®¿·®»ф

´щ7½®±« ¼» ´щ¿®¾®» -«® ´» ½,¬7 ¹¿«½¸» ¼» ´щ¿°°¿®»·´ -» -»®®»

»² ´» ¬±«®²¿²¬ ¼¿²- ´» -»²- ¿²¬·¸±®¿·®»т

ìò Î7°7¬»¦ ´» °®±½»--«- °±«® ´ù¿«¬®» ½,¬7ò

ОЫУЯОПЛЫ ж »² «¬·´·-¿²¬ ª±¬®» ³»«´»«-»с¿ºº%¬»«-»ф ´¿

º±®½» »¬ ´¿ ¼·®»½¬·±² ¼» ´¿ ³»«´» °»®³»¬¬®±²¬ ´» -»®®¿¹»

¿«¬±³¿¬·¯«» ¼» ´щ7½®±« ¼» ´щ¿®¾®»т Э»°»²¼¿²¬ф ·´ »-¬

®»½±³³¿²¼7 ¼» ª7®·º·»® °7®·±¼·¯«»³»²¬ ´» -»®®¿¹» ¼»7½®±«- ¼¿²- ´» ½¿¼®» ¼» ´щ»²¬®»¬·»² ®7¹«´·»® ¼» ª±¬®»

¿°°¿®»·´т

ЪЧЩЛОЫ м

ЪЧЩЛОЫ л

îì

Page 25

Page 26

ЫТМОЫМЧЫТ

УЫЛФЫН

Ôù«¬·´·-¿¬·±²¼ù¿½½»--±·®»-»¬

¼»°·8½»-²±²®»½±³³¿²¼7»-

°¿®ЬЫФМЯУЬ°»«¬ »²¬®¿2²»®«²®·-¯«»¼»¾´»--«®»-т

Ф»-³»«´»-«¬·´·-7»-¿ª»½½»¬¬»³»«´»«-»с¿ %¬»«-»

¼±·ª»²¬6¬®»¿¼¿°¬7»-@«²®7¹·³»¼»нкрр¬®с³·²

±«°´«-»¬¿ª±·®«²»´¿®¹»«®¼»п°±тФ»-³»«´»-¼«

³±¼8´»ЬЫФМЯУЬонупзк¼±·ª»²¬6¬®»¼»к°±¼»

¼·¿³8¬®»¿ª»½«²¿´7-¿¹»½»²¬®¿´¼»c°±тФ»-³»«´»¼«³±¼8´»ЬЫФМЯУЬонупзй¼±·ª»²¬6¬®»¼»и°±¼»

¼·¿³8¬®»¿ª»½«²¿´7-¿¹»½»²¬®¿´¼»лси°±т

ˬ·´·-»®«²»³»«´»¯«·»-¬·²º7®·»«®»

@«²»´¿®¹»«®¼»b°±°±«®«²»

°±«®«²»³»«´»«-» %¬»«-»¼»è°±ô°®±ª±¯«»¼»ª·¾®¿¬·±²- »¬ °±«®®¿·¬ »²¼±³³¿¹»® ´ù¿°°¿®»·´ò

МСЛЦСЛОН ³¿·²¬»²·®«²

7½¿®¬¼»ïñè°±±«³±·²»²¬®»´¿³»«´»»¬´»°±®¬»ó±«¬·´-ò߶«-¬»¦´»-°±®¬»ó

±«¬·´-»¬´»-°¿®»ó7¬·²½»´´»-¿«º«®»¬@³»-«®»¯«»´¿

¬¿·´´» ¼»- ³»«´»- ¼·³·²«»ò

Ф»³±¼8´»ЬЫФМЯУЬонупзк»-¬7¯«·°7¼щ«²»³»«´»

»²±¨§¼»¼щ¿´«³·²·«³¼»к°±ш¹®·-»ч

Ф»³±¼8´»ЬЫФМЯУЬонупзй»-¬7¯«·°7¼щ«²»³»«´»»²

±¨§¼»¼щ¿´«³·²·«³¼»и°±ш¹®·-»чт

б«®¼»³»·´´»«®-®7-«´¬¿¬-ô»¬°±«®»²¬®»¬»²·®´»-³»«´»½±®®»½¬»³»²¬ô-«·ª»¦½»-®»½±³³¿²¼¿¬·±²-æ

ïòÙ¿®¼»¦´»-³»«´»-½±®®»½¬»³»²¬¼®»--7»-ò

îòÒ»º±®½»¦°¿-´»¬®¿ª¿·´-«®«²»³»«´»º®±·¼»òÔ¿

³»«´»¼±·¬¬±«¶±«®-6¬®»³·-»»²³¿®½¸»¿«³±·²«²»³·²«¬»¿ª¿²¬¼»½±³³»²½»®´»³»«´¿¹»ò

íòˬ·´·-»¦-»«´»³»²¬¼»-³»«´»-7¯«·´·¾®7»-¿ª»½ª±¬®»

³»«´»«-»ñ %¬»«-»òˬ·´·-»¦¼»-³»«´»-7¯«·´·¾®7»°®±´±²¹»´¿¼«®7»¼»ª·»¼»-®±«´»³»²¬--«®´¿

³»«´»«-»ñ¿ %¬»«-»òÛ²7´·³·²¿²¬´¿°´«-½±³³«²»

¼»--±«®½»-¼»ª·¾®¿¬·±²ôª±-¬®¿ª¿«¨¼»³»«´¿¹»

-»®±²¬°´«-°®7½·-ò

ЬОЫННЯЩЫЬЫНУЫЛФЫН

К±¬®»³»«´»«-»с¿ %¬»«-»ЬЫФМЯУЬонупзкшк°±ч±«

онупзйши°±чФ¿³»«´»«-»с ¬»«-»»-¬7¯«·°7»¼ù«²

¼®»--»ó³»«´»@¾¿-»¼»¼·¿³¿²¬òб«®«²¿½½8-º¿½·´»ô

´ù»³°´¿½»³»²¬¼»-¬±½µ¿¹»·²¬7¹®7¼«¼®»--»ó³»«´»-»

¬®±«ª»@´ù¿®®·8®»¼»´ù¿°°¿®»·´òˬ·´·-»¦½»¬±«¬·´±«¬±«¬

¿«¬®»¼®»--»ó³»«´»¿¼¿°¬7°±«®³¿·²¬»²·®ª±-³»«´»°®±°®»-»¬¿´·¹²7»-ò

б«®¼®»--»®´¿³»«´»ô½±²-«´¬»¦´¿Ú·¹«®»è»¬º¿·¬»-½»

¯«·-«·¬æ

ïòߪ¿²½»¦´»¼®»--»ó³»«´»øß÷-«®´»°±®¬»ó±«¬·´-

¶«-¯«ù@½»¯«ù·´¬±«½¸»´»°±·²¬´»°´«-7´»ª7-«®´¿

º¿½»¼»´¿³»«´»ò

îòÜ®»--»¦´¿³»«´»»²¼7°´¿9¿²¬´»¼®»--»ó³»«´»¼»

´±²¹»²´¿®¹»ò

íòÎ7°7¬»¦½»¬¬»±°7®¿¬·±²¶«-¯«ù@½»¯«»´¿º¿½»¼»

´¿³»«´»-±·¬°®±°®»»¬´»-½±·²-¾·»²7¯«¿®®·-ò

ЪЧЩЛОЫ и

îê

Page 27

ЫТМОЫМЧЫТ

ОЫУРФЯЭЫО СЛ ЭШЯТЩЫО ФЫН УЫЛФЫН

Ü7½±²²»½¬»¦ ´ù¿°°¿®»·´ ¼» ´¿

-±«®½» ¼ù¿´·³»²¬¿¬·±²ò

б«® ´»- 7¬¿°»- ïóìô ½±²-«´¬»¦ ´»- Ú·¹«®»- ì »¬ ë -«® ´¿

°¿¹» îìæ

ïò λ¬·®»¦ ´»- øí÷ ª·- ¯«· º·¨»²¬ ´¿ °¿®±· »¨¬7®·»«®» ¼«

¹¿®¼»ó³»«´» ¿« ½¸>--·- ¼» ´ù±«¬·´ò

îò λ¬·®»¦ ´» ¹¿®¼»ó³»«´»ò

íò ` ´•¿·¼» ¼•«²» ½´7 ¿°°®±°®·7»ô ¬±«®²»¦ ´•7½®±« ¼»

´•¿®¾®» øß÷ ¬±«¬ »² «¬·´·-¿²¬ ´•¿«¬®» ³¿·² °±«® »³°6½¸»®

´¿ ³»«´» ¼» ¾±«¹»®ò Ü»--»®®»¦ ´•7½®±« ¼» ´•¿®¾®»ò

ìò λ¬·®»¦ ´•7½®±« ¼» ´•¿®¾®» øß÷ô ´¿ º´¿-¯«» ¼» ´¿ ³»«´»

øÞ÷ »¬ ´¿ ª·»·´´» ³»«´» øÝ÷ô ½±³³» ·´´«-¬®7 @ ´¿ Ú·¹«®» çò

ОЫУЯОПЛЫ ж °±«® ¼»--»®®»® ´щ7½®±« ¼» ´щ¿®¾®» -«® ´» ½,¬7

¼®±·¬ф ¬±«®²»¦у´» ¼¿²- ´» -»²- ¿²¬·¸±®¿·®»т Р±«® ¼»--»®®»®

´щ7½®±« ¼» ´щ¿®¾®» -«® ´» ½,¬7 ¹¿«½¸»ф ¬±«®²»¦у´» ¼¿²- ´»

-»²- ¸±®¿·®»ò

ëò д¿½»¦ ´¿ ²±«ª»´´» ³»«´» -«® ´ù¿®¾®»ò

êò д¿½»¦ ´¿ ¾®·¼» -«® ´ù¿®¾®» »¬ ª·--»¦ ´ù7½®±« ¼»´ù¿®¾®»

-«® ½» ¼»®²·»® ¶«-¯«ù@ ½» ¯«» ´ù7½®±«ª·»²²» »² ½±²¬¿½¬

¿ª»½ ´¿ ¾®·¼» ¼» ´щ¿®¾®»т

ОЫУЯОПЛЫ ж ´»- ³»«´»- °±«® ´» ³±¼8´» онупзк ¼±·ª»²¬

6¬®» ¼щ«²» ´¿®¹»«® ¼» b °± ¿´±®- ¯«» ´»- ³»«´»- °±«® ´»

³±¼8´» онупзй ¼±·ª»²¬ 6¬®» ¼» п °± ¼» ´¿®¹»т

éò Í»®®»¦ ´ù7½®±« ¼» ´ù¿®¾®» ¿«¬¿²¬ ¯«» ª±«- ´» °±«ª»¦ò

èò λ³°´¿½»¦ ´» ¹¿®¼» ¼» ³»«´» »¬ º·¨»¦ó´» ¿ª»½ ´»- øí÷

ª·- ®»¬·®7»- °®7½7¼»³³»²¬ò

ЯЛМОЫ ЫТМОЫМЧЫТ ОЫЭСУУЯТЬW

ïò ͱ«ºº´»¦ °7®·±¼·¯«»³»²¬ ¼» ´•¿·® ½±³°®·³7 -»½ ¼¿²-

¬±«- ´»- ½±²¼«·¬- ¼•¿·®ò ̱«¬»- ´»- °·8½»- »² °´¿-¬·¯«»

¼±·ª»²¬ 6¬®» ²»¬¬±§7»- ¿ª»½ «² ½¸·ºº±² ¼±«¨ ¸«³·¼»ò

Тщ«¬·´·-»¦ ЦЯУЯЧН ¼» -±´ª¿²¬ °±«® ²»¬¬±§»® ´»- °·8½»-

»² °´¿-¬·¯«»ò ×´ °±«®®¿·¬ ¼·--±«¼®» ±« »²¼±³³¿¹»® ´»

³¿¬7®·»´ò

îò Ê7®·º·»¦ °7®·±¼·¯«»³»²¬ ´» -»®®¿¹» ¼»- 7½®±«- ¼»

´ù¿®¾®»ò

íò Ê7®·º·»¦ °7®·±¼·¯«»³»²¬ ´» -»®®¿¹» ¼» ¬±«¬» ´¿

¾±«´±²²»®·» »¬ 7½±«¬»¦ ¬±«¬»- ª·¾®¿¬·±²- ·²¸¿¾·¬«»´´»-

»² ¬®¿ª¿·´´¿²¬ ½¿® »´´»- °±«®®¿·»²¬ 6¬®» «² -·¹²» ¼»

¾±«´±²²»®·» ¼»--»®®7»ò

ЪЧЩЛОЫ з

îé

Page 28

ЯЭЭЫННСЧОЫН

Л²» ¹¿³³» ½±³°´8¬» ¼•¿½½»--±·®»- °»«¬ 6¬®» ±¾¬»²«» ¿«°®8- ¼» ª±¬®» º±«®²·--»«® ЬЫФМЯУЬ ф ¼»- ½»²¬®»- ¼»

-»®ª·½» ¼« º¿¾®·½¿²¬ ЬЫФМЯУЬф »¬ ¼»- ½»²¬®»- ¼» -»®ª·½»- ¿¹®77- ЬЫФМЯУЬт О»²¼»¦уª±«- -«® ²±¬®» -·¬» Й»¾ ©©©т

Ь»´¬¿У¿½¸·²»®§т½±³ °±«® ±¾¬»²·® «² ½¿¬¿´±¹«» »² ´·¹²» ±« °±«® ½±²²¿2¬®» ´» ²±³ ¼« º±«®²·--»«® ´» °´«- °®8- ¼» ½¸»¦

ª±«-т

W¬¿²¬ ¼±²²7 ¯«» ´»- ¿½½»--±·®»- ¿«¬®»- ¯«» ½»«¨ ±ºº»®¬- °¿® ЬЫФМЯУЬ ²•±²¬ °¿- 7¬7 ¬»-¬7- ¿ª»½

½» °®±¼«·¬ф ´»«® «¬·´·-¿¬·±² °±«®®¿·¬ -•¿ª7®»® ¼¿²¹»®»«-»т Р±«® ¿--«®»® «²» «¬·´·-¿¬·±² °´«-

-7½«®·¬¿·®»ф -»«´- ´»- ¿½½»--±·®»- ®»½±³³¿²¼7- °¿® ЬЫФМЯУЬ ¼»ª®¿·»²¬ 6¬®» «¬·´·-7- ¿ª»½ ½» °®±¼«·¬т

ЩЯОЯТМЧЫ

б«® ´•»²®»¹·-¬®»³»²¬ ¼» ª±¬®» ±«¬·´ ¿«°®8- ¼« -»®ª·½» ¼» ´¿ ¹¿®¿²¬·»ô ®»²¼»¦óª±«- -«® ²±¬®» -·¬» @ ´•¿¼®»--» ©©©ò

Ü»´¬¿Ó¿½¸·²»®§ò½±³ò

ЩЯОЯТМЧЫ ФЧУЧМWЫ ЬЫ ЭЧТП ЯТН

Ü»´¬¿ÓÜ Ð±©»® Û¯«·°³»²¬ ݱ®°±®¿¬·±²

пт WФWУЫТМН ЭСЛКЫОМН РЯО ФЯ ЩЯОЯТМЧЫт Ь»´¬¿ Р±©»® Ы¯«·°³»²¬ Э±®°±®¿¬·±² шu ´•Ы²¬®»°®·-» eч ®7°¿®»®¿ ±« ®»³°´¿½»®¿ф @ -¿ ¼·-½®7¬·±²ф ¬±«¬»

³¿½¸·²» ±« °·8½» ¼» ®»½¸¿²¹» ЬЫФМЯУЬф ²»«ª» ±« ®»³·-» @ ²»«º »² «-·²»ф ¿½¸»¬7» ¼щ«² °±·²¬ ¼» ª»²¬» ¿«¨ W¬¿¬-уЛ²·- ±« ¿« Э¿²¿¼¿ »¬ ¯«·ф ¼¿²- ¼»½±²¼·¬·±²- ¼щ«-¿¹» ²±®³¿´ф »-¬ ¶«¹7» ¼7º»½¬«»«-» »² ®¿·-±² ¼•«² °®±¾´8³» ¼» º¿¾®·½¿¬·±² ±« ¼» ³¿¬7®·¿«ф -±«- ®7-»®ª» ¼»- ½±²¼·¬·±²- 7²±²½7»- ¼¿²½»¬¬» ¹¿®¿²¬·» ´·³·¬7»т Э»¬¬» ¹¿®¿²¬·» ´·³·¬7» ½±«ª®» «²·¯«»³»²¬ ´»- ³¿¬7®·¿«¨ »¬ ´¿ ³¿·²у¼•„«ª®»т М±«- ´»- ½±%¬- ¼» ¬®¿²-°±®¬ -±²¬ @ ´¿ ½¸¿®¹» ¼« ½´·»²¬т

от РWОЧСЬЫ ЬЫ ЩЯОЯТМЧЫт М±«¬»- ´»- ®7½´¿³¿¬·±²- ¼» ¹¿®¿²¬·» ¼±·ª»²¬ 6¬®» -±«³·-»- ¼¿²- ´»- ½·²¯ ¿²- -«·ª¿²¬ ´¿ ¼¿¬» ¼•¿½¸¿¬ ¼« °®±¼«·¬т Р±«® ¬±«¬»-

´»- °·8½»- ¼» ®»½¸¿²¹» »¬ ³¿½¸·²»- ЬЫФМЯУЬ ®»³·-»- @ ²»«º »² «-·²»ф ´¿ °7®·±¼» ¼» ¹¿®¿²¬·» »-¬ ¼» пи𠶱«®-т

нт СЮМЫТМЧСТ ЬЛ НЫОКЧЭЫт Р±«® ¾7²7º·½·»® ¼« -»®ª·½» ¼» ¹¿®¿²¬·»ф ª±«- ¼»ª»¦ ®»¬±«®²»® ´» °®±¼«·¬ ¼7º»½¬«»«¨ф @ ª±- º®¿·-ф @ «² ½»²¬®» ¼» -»®ª·½»

¿¹®77 °¿® ´•Ы²¬®»°®·-» °±«® »¨7½«¬»® ´» -»®ª·½» ¼» ¹¿®¿²¬·» ш«² u ½»²¬®» ¼» -»®ª·½» ¿¹®77 ЬЫФМЯУЬ e °»²¼¿²¬ ´¿ °7®·±¼» ¼» ¹¿®¿²¬·» ¿°°´·½¿¾´»ф ¿ª»½

«²» °®»«ª» ¼•¿½¸¿¬ ¿½½»°¬¿¾´»ф ½±³³» ª±¬®» ®»9« ±®·¹·²¿´ ·²¼·¯«¿²¬ ´¿ ¼¿¬» ¼•¿½¸¿¬ф ±« ´» ²«³7®± ¼•¸±³±´±¹¿¬·±² ¼« °®±¼«·¬т Ф•Ы²¬®»°®·-» -» ®7-»®ª»

´» ¼®±·¬ ¼» ´·³·¬»® ´» -»®ª·½» ¼» ®7½´¿³¿¬·±² ¼» ¹¿®¿²¬·» ¿« °¿§- ±' ´•¿½¸¿¬ ¿ 7¬7 »ºº»½¬«7 »¬с±« ¼» º¿½¬«®»® ´» ½±%¬ ¼» ¬®¿²-°±®¬ ¼»- °·8½»- ¼» ®»½¸¿²¹»

±« ´¿ º±«®²·¬«®» ¼« -»®ª·½» ¼» ¹¿®¿²¬·» ¼¿²- «² ¿«¬®» °¿§-т Ф»- ¿½¸¿¬- »² ´·¹²» -±²¬ ½±²-·¼7®7- ½±³³» »ºº»½¬«7- ¿«¨ W¬¿¬-уЛ²·-т Р±«® ¬®±«ª»® ´» ½»²¬®»

¼» -»®ª·½» ¿¹®77 ЬЫФМЯУЬ ´» °´«- °®8- ¼» ½¸»¦ ª±«-ф ¿°°»´»¦ ²±¬®» ½»²¬®» ¼» -»®ª·½» @ ´¿ ½´·»²¬8´» ¿« ширрч оонуйойит

мт ЫИЭФЛНЧСТНт

Ф•Ы²¬®»°®·-» ²» ¹¿®¿²¬·¬ °¿- ´»- °®±¼«·¬- ¿½¸»¬7- ¼¿²- «² 7¬¿¬ «-¿¹7 ±« »²¼±³³¿¹7т

Ф•Ы²¬®»°®·-» ²» ¹¿®¿²¬·¬ °¿- ´»- °®±¼«·¬- ¿½¸»¬7- »² ¼»¸±®- ¼»- W¬¿¬-уЛ²·- ±« ¼« Э¿²¿¼¿

Ф•Ы²¬®»°®·-» ²» -»®¿ °¿- ®»-°±²-¿¾´» ¼» ¬±«¬ ¼±³³¿¹» ¼7½±«´¿²¬ ¼» ´•«-«®» ²±®³¿´»ф ¼•«²» ³¿«ª¿·-» «¬·´·-¿¬·±²ф ¼•«² ¿¾«-ф ¼•«²» ®7°¿®¿¬·±² ±«

¼•«²» ¿´¬7®¿¬·±² º¿·¬» °¿® ¯«·½±²¯«» ¿«¬®» ¯«•«² ½»²¬®» ¼» -»®ª·½» ¿¹®77 ЬЫФМЯУЬ ±« «² ®»°®7-»²¬¿²¬ ¼7-·¹²7 ¼« ½»²¬®» ¼» -»®ª·½» @ ´¿ ½´·»²¬8´» ¼»

´•Ы²¬®»°®·-»т

МСЛМЫН ФЫН ЩЯОЯТМЧЫН ЧУРФЧЭЧМЫН -±²¬ »¨°®»--7³»²¬ ´·³·¬7»- @ ´¿ °7®·±¼» ¼» ¹¿®¿²¬·» ·¼»²¬·º·7» ½·у¼»--«-т

Ы² ¿«½«² ½¿-ф ´•Ы²¬®»°®·-» ²» -»®¿ ¬»²«» ®»-°±²-¿¾´» ¼»- ¼±³³¿¹»- ЯЭЭЧЬЫТМЫФН СЛ ЭСТНWЭЛМЧЪНт

Э»¬¬» ¹¿®¿²¬·» ´·³·¬7» »-¬ ´•«²·¯«» ¹¿®¿²¬·» ¼» ´•Ы²¬®»°®·-» »¬ ¼7º·²·¬ °¿® ´¿ °®7-»²¬» ´» ®»½±«®- »¨½´«-·º ¼« ½´·»²¬ »² ½» ¯«· ½±²½»®²» ´»-

°®±¼«·¬- ¼7º»½¬«»«¨å ¬±«¬»- ´»- ¿«¬®»- ¹¿®¿²¬·»-ô »¨°®»--»- ±« ·³°´·½·¬»-ô ¼» ¯«¿´·¬7 ³¿®½¸¿²¼»ô ¼» ½±²º±®³·¬7 ¿«¨ ¾»-±·²- ±« ¿«¬®»ô -±²¬

º±®³»´´»³»²¬ ®»¶»¬7»- °¿® ´•Û²¬®»°®·-»ô -¿«º ·²¼·½¿¬·±² ½±²¬®¿·®» ½·ó¼»--«-ò

Э»®¬¿·²- W¬¿¬- ¿³7®·½¿·²- ²» °»®³»¬¬¿²¬ °¿- ´•»¨½´«-·±² ±« ´¿ ´·³·¬¿¬·±² ¼»- ¼±³³¿¹»- ¿½½·¼»²¬»´- ±« ½±²-7½«¬·º-ф ²· ´¿ ´·³·¬¿¬·±² ¼»- ¹¿®¿²¬·»- ·³°´·½·¬»-ф ´»´·³·¬¿¬·±²- ±« »¨½´«-·±²- ½·у¼»--«- °±«®®¿·»²¬ ¼±²½ ²» °¿- -•¿°°´·¯«»® @ ª±«-т Ф¿ °®7-»²¬» ¹¿®¿²¬·» ª±«- ¼±²²» ¼»- ¼®±·¬- ´7¹¿«¨ °®7½·- »¬ ª±«- °±«ª»¦ ¿ª±·®

¼•¿«¬®»- ¼®±·¬- ¯«· ª¿®·»²¬ -»´±² ´»- W¬¿¬- »¬ ´»- °®±ª·²½»-т Р±«® ¼» °´«- ¿³°´»- ®»²-»·¹²»³»²¬- -«® ´¿ ½±«ª»®¬«®» ¼» ´¿ ¹¿®¿²¬·» »¬ ¼»- ·²º±®³¿¬·±²- -«® ´»®7°¿®¿¬·±²-ф ¿°°»´»¦ ´» ширрч оонуйойит Р±«® »²®»¹·-¬®»® ª±- °®±¼«·¬- »² ´·¹²»ф ²±«- ª±«- »²½±«®¿¹»±²- @ ª·-·¬»® ²±¬®» -·¬» Й»¾ »¬ @ ½®7»® ЩОЯМЛЧМЫУЫТМ

«² ½±³°¬» ¼» ³»³¾®» ЬЫФМЯ -«® ¸¬¬°жсс©©©т¼»´¬¿³¿½¸·²»®§т½±³с®»¹·-¬»®т

ЯУWОЧПЛЫ ФЯМЧТЫ ж Ф¿ °®7-»²¬» ¹¿®¿²¬·» ²» -•¿°°´·¯«» °¿- ¿«¨ °®±¼«·¬- ª»²¼«- »² Я³7®·¯«» ´¿¬·²»т Р±«® ´»- °®±¼«·¬- ª»²¼«»² Я³7®·¯«» ´¿¬·²»ф ª»«·´´»¦ ½±²-«´¬»® ´»- ®»²-»·¹²»³»²¬- ¿« -«¶»¬ ¼» ´¿ ¹¿®¿²¬·» °±«® «² °¿§- °¿®¬·½«´·»® º·¹«®¿²¬ -«® ´•»³¾¿´´¿¹»ф

¿°°»´»® ´¿ ½±³°¿¹²·» ´±½¿´» ±« ½±²-«´¬»® ²±¬®» -·¬» Й»¾ °±«® °´«- ¼» ®»²-»·¹²»³»²¬- ¿« -«¶»¬ ¼» ´¿ ¹¿®¿²¬·»т

îè

Page 29

ЯЧЬЫ РСЛО ФЫН РЧXЭЫНф ФЫ НЫОКЧЭЫ СЛ ФЯ ЩЯОЯТМЧЫ

М±«- ´»- ¿°°¿®»·´- »¬ ¿½½»--±·®»- ЬЫФМЯУЬ -±²¬ º¿¾®·¯«7- -»´±² ¼»- ²±®³»- ¼» ¯«¿´·¬7 7´»ª7»- »¬ -±²¬ -±«¬»²«°¿® «² ®7-»¿« ¼» ½»²¬®»- ¼» -»®ª·½» ¼« º¿¾®·½¿²¬ ЬЫФМЯУЬ »¬ ¼»- ½»²¬®»- ¼» -»®ª·½»- ЬЫФМЯУЬ ¿«¬±®·-7-т Р±«® »²

-¿ª±·® ¼¿ª¿²¬¿¹» -«® ª±¬®» °®±¼«·¬ ¼» ¯«¿´·¬7 ЬЫФМЯУЬ ±« °±«® ±¾¬»²·® ¼»- °·8½»-ф ¼« -»®ª·½»ф ¼» ´•¿·¼» ½±²½»®²¿²¬

´¿ ¹¿®¿²¬·» ±« ´•»³°´¿½»³»²¬ ¼« ½»²¬®» ¼» -»®ª·½» ´» °´«- °®8- ¼» ½¸»¦ ª±«-ф ª»«·´´»¦ ½±³°±-»® ´» п ирр оонуйойит

РЧXЭЫН ЬЫ ОЫЭШЯТЩЫ

Л¬·´·-»¦ «²·¯«»³»²¬ ¼»- °·8½»- ¼» ®»½¸¿²¹» ·¼»²¬·¯«»-т Р±«® ±¾¬»²·® «²» ´·-¬» ¼» °·8½»- ±« ½±³³¿²¼»® ¼»- °·8½»-ф ®»²¼»¦у

ª±«- -«® ²±¬®» -·¬» @ ´•¿¼®»--» ©©©тЬ»´¬¿У¿½¸·²»®§т½±³с-»®ª·½»т К±«- °±«ª»¦ ¿«--· ½±³³¿²¼»® ¼»- °·8½»- ¿«°®8- ¼»

ª±¬®» ®»°®7-»²¬¿²¬ ´±½¿´ф ¼« ½»²¬®» ¼» -»®ª·½» ¼» ¹¿®¿²¬·» ¿«¬±®·-7 ±« »² ¿°°»´¿²¬ ´» ®»-°±²-¿¾´» ¼« -»®ª·½» ¬»½¸²·¯«» ¿«

п ирр оонуйойи °±«® ®»½»ª±·® «²» ¿--·-¬¿²½» °»®-±²²¿´·-7» ¼» ´¿ °¿®¬ ¼•«² ¼» ²±- ®»°®7-»²¬¿²¬- ¸¿«¬»³»²¬ ¯«¿´·º·7т

ОЫУРФЯЭЫУЫТМ ЩОЯМЛЧМ ЬЫН WМЧПЛЫММЫН ЬЫ УЧНЫ ЫТ ЩЯОЬЫ

Н· ª±- 7¬·¯«»¬¬»- ¼» ³·-» »² ¹¿®¼» -±²¬ ¼»ª»²«»- ·´´·-·¾´»- ±« -· ª±«- ´»- ¿ª»¦ °»®¼«»-ф ½±³°±-»¦ ´» п ирр оонуйойи °±«®

«² ®»³°´¿½»³»²¬ ¹®¿¬«·¬т

НЫОКЧЭЫ ЫМ ОWРЯОЯМЧСТН

М±«- ´»- ±«¬·´- ¼» ¯«¿´·¬7 ¿«®±²¬ ¾»-±·² ¼» -»®ª·½» »¬с±« ¼•«² ®»³°´¿½»³»²¬ ¼» °·8½»- @ «² ³±³»²¬ ¼±²²7т Р±«®