Page 1

13 in. BENCH PLANER

RABOTEUSE D'ÉTABLI

DE 330 mm (13 PO)

CEPILLO DE BANCO DE

330 mm (13 PLUG.)

Français (16)

Español (30)

www.DeltaMachinery.com

Instruction Manual

Manuel d’utilisation

Manual de instrucciones

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

22-555

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ................................... 2

SAFETY GUIDELINES - DEFINITIONS .................................... 3

GENERAL SAFETY RULES ...................................................... 3

ADDITIONAL SPECIFIC SAFETY RULES ............................... 4

POWER CONNECTIONS .......................................................... 6

MOTOR SPECIFICATIONS ....................................................... 6

GROUNDING INSTRUCTIONS ................................................ 6

EXTENSION CORDS ................................................................ 7

KEY FEATURES AND COMPONENTS .................................... 7

FUNCTIONAL DESCRIPTION .................................................. 7

PRODUCT SPECIFICATIONS ................................................... 8

UNPACKING ..............................................................................8

ASSEMBLY ................................................................................. 9

Attach Height Adjustment Handle....................................... 9

Attach Reversible Dust Port ................................................ 9

Connecting to Dust Collector .............................................. 9

OPERATION ............................................................................. 10

Starting and Stopping the Planer ...................................... 10

Locking the Planer Using the Safety Key ......................... 10

Resetting the On-Board Circuit Breaker ........................... 10

Adjusting Cutting Height .................................................. 10

Eliminating Snipe ............................................................... 11

MAINTENANCE ...................................................................... 12

Changing the Cutter Knives .............................................. 12

OTHER RECOMMENDED MAINTENANCE .......................... 12

ACCESSORIES ........................................................................ 13

WARRANTY .............................................................................13

REPLACEMENT PARTS .......................................................... 14

SERVICE AND REPAIRS ......................................................... 14

FRANÇAIS ................................................................................ 16

ESPAÑOL .................................................................................30

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING

THIS EQUIPMENT. Failure to follow all instructions listed below, may result in electric shock, fire, and/or

serious personal injury or property damage.

Woodworking can be dangerous if safe and proper operating procedures are not followed. As with all

machinery, there are certain hazards involved with the operation of the product. Using the machine with

respect and caution will considerably lessen the possibility of personal injury. However, if normal safety

precautions are overlooked or ignored, personal injury to the operator may result. Safety equipment such as

guards, push sticks, hold-downs, featherboards, goggles, dust masks and hearing protection can reduce your potential

for injury. But even the best guard won’t make up for poor judgment, carelessness or inattention. Always use common

sense and exercise caution in the workshop. If a procedure feels dangerous, don’t try it. Figure out an alternative

procedure that feels safer. REMEMBER: Your personal safety is your responsibility. For additional information please

visit our website www.DeltaMachinery.com.

This machine was designed for certain applications only. DELTA® Power Equipment Corporation

strongly recommends that this machine not be modified and/or used for any application other than that

for which it was designed. If you have any questions relative to a particular application, DO NOT use the machine until

you have first contacted DELTA® to determine if it can or should be performed on the product.

If you have any questions relative to its application DO NOT use the product until you have written DELTA® Power

Equipment Corporation and we have advised you. Contact us online at www.DeltaMachinery.com or by mail at Technical

Service Manager, DELTA® Power Equipment Corporation, 99 Roush Street, Anderson, SC 29625.

Information regarding the safe and proper operation of this tool is available from the following sources:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www.osha.gov

2

Page 3

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may

result in property damage.

GENERAL SAFETY RULES

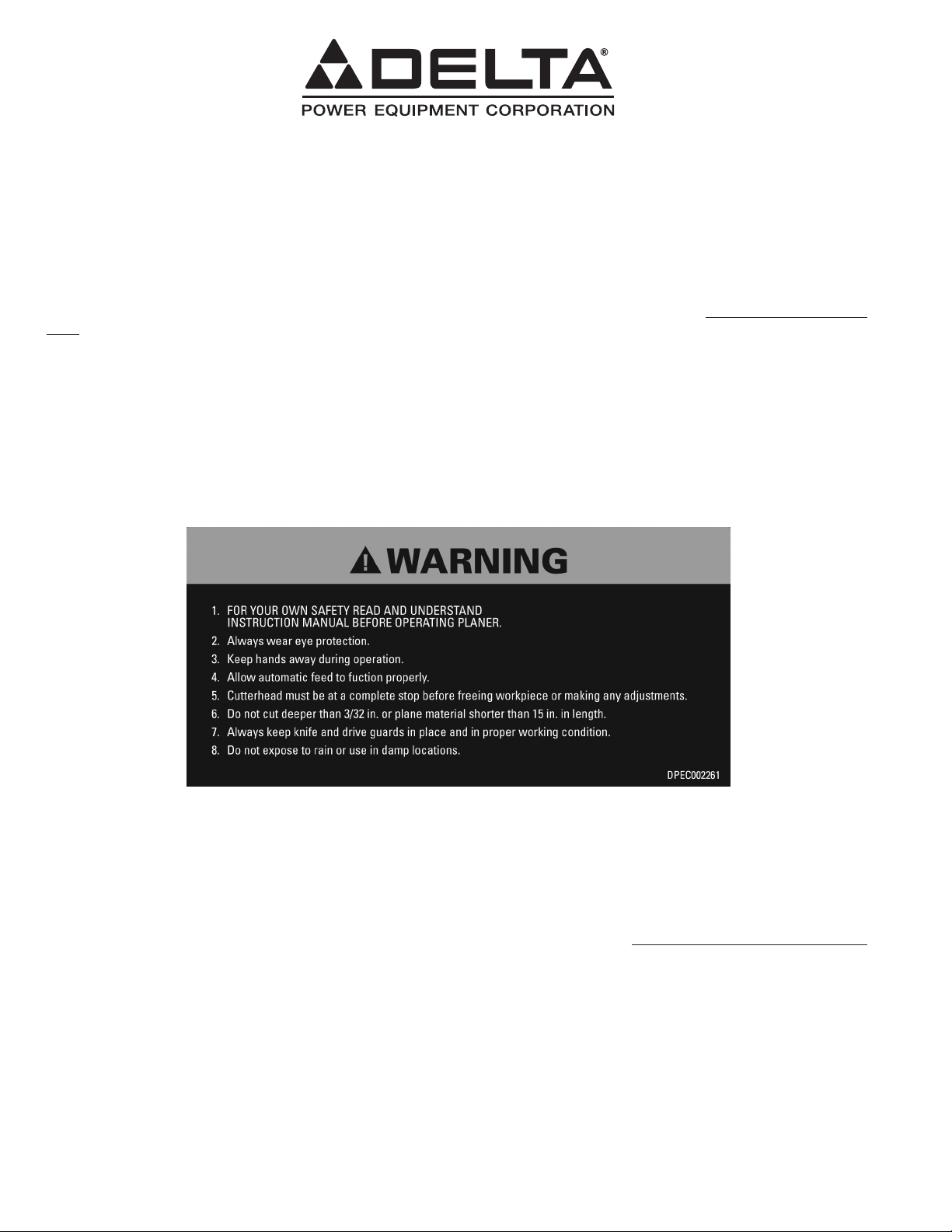

WARNING FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

For your own safety, read and understand the instruction manual before operating the unit.

•

and limitations as well as the specific hazards peculiar to it.

Keep work area clean.

•

Don’t use in dangerous environment.

•

well-lighted.

Keep children and visitors away.

•

Disconnect unit

•

Check damaged parts.

•

Cluttered areas and benches invite accidents.

Don’t use this unit in damp or wet locations, or expose it to rain. Keep work area

All children and visitors should be kept a safe distance from work area.

before servicing.

Before further use of the unit, properly repair or replace any part that is damaged.

Learn the unit’s application

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS INJURY.

1. Read and understand the warnings posted on the

machine and in this manual. Failure to comply with all

of these warnings may cause serious injury.

2. Replace the warning labels if they become obscured

or removed.

3. This machine is designed and intended for use by

3. This machine is designed and intended for use by

properly trained and experienced personnel only.

properly trained and experienced personnel only.

If you are not familiar with the proper and safe

If you are not familiar with the proper and safe

operation of a planer, do not use until proper training

operation of a planer, do not use until proper training

and knowledge have been obtained.

and knowledge have been obtained.

4. Do not use this machine for other than its intended

use. If used for other purposes, DELTA® Power

Equipment Corporation disclaims any real or implied

warranty and holds itself harmless from any injury

that may result from that use.

5. Always wear approved safety glasses/face shields

5. Always wear approved safety glasses/face shields

while using this grinder.

while using this tool.

6. operating this grinder, remove tie, rings, watches

6. Before operating this tool, remove tie, rings, watches

and other jewelry, and roll sleeves up past the

and other jewelry, and roll sleeves up past the

elbows. Remove all loose clothing and confine long

elbows. Remove all loose clothing and confine long

hair. Non-slip footwear or anti-skid floor strips are

hair. Non-slip footwear or anti-skid floor strips are

recommended. Do not wear gloves.

recommended. Do not wear gloves.

7. Wear ear protectors (plugs or muffs) during extended

periods of operation.

8. Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other

masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often

you do this type of work. To reduce your exposure

to these chemicals, work in a well-ventilated area and

work with approved safety equipment, such as face or

dust masks that are specifically designed to filter out

microscopic particles.

9. Do not operate this machine while tired or under the

influence of drugs, alcohol or any medication.

10. Make certain the switch is in the OFF position before

connecting the machine to the power source.

11. Make certain the machine is properly grounded.

12. Make all machine adjustments or maintenance with

the machine unplugged from the power source.

13. Form a habit of checking to see that all extra

equipment such as adjusting keys, wrenches, scrap,

continued on page 4

3

Page 4

stock, and cleaning rags are removed away from the

machine before turning on.

14. Keep safety guards in place at all times when the

machine is in use. If removed for maintenance

purposes, use extreme caution and replace the

guards immediately when maintenance is complete.

15. Make sure the tool is firmly secured to a stable work

surface before use.

16. Check damaged parts. Before further use of the

machine, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A guard

or other part that is damaged should be properly

repaired or replaced.

17. Provide for adequate space surrounding work area

and non-glare, overhead lighting.

18. Keep the floor around the machine clean and free of

scrap material, oil and grease.

19. Keep visitors a safe distance from the work area.

Keep children away.

20. Make your workshop child proof with padlocks,

master switches or by removing starter keys.

21. Give your work undivided attention. Looking around,

carrying on a conversation and “horse-play" are

careless acts that can result in serious injury.

22. Maintain a balanced stance at all times so that you do

not fall or lean against the tool or its moving parts. Do

not overreach or use excessive force to perform any

machine operation.

23. Use the right tool at the correct speed and feed rate.

Do not force a tool or attachment to do a job for

which it was not designed. The right tool will do the

job better and safer.

24. Use recommended accessories; improper

accessories may be hazardous.

25. Maintain machinery with care. Follow instructions for

lubricating and changing accessories.

26. Turn off the machine before cleaning. Use a brush or

compressed air to remove dust or debris — do not

use your hands.

27. Do not stand on the machine. Serious injury could

occur if the machine tips over.

28. Never leave the machine running unattended. Turn

the power off and do not leave the machine until it

comes to a complete stop.

29. At all times, hold the stock firmly.

30. Do not use this tool for other than it intended use. If

used for other purposes, DELTA® Power Equipment

Corporation disclaims any real or implied warranty

and holds itself harmless for any injury or damage

which may result from that use.

Familiarize yourself with the following safety notices

used in this manual:

This means that if precautions are not heeded, it may

result in minor injury and/or possible machine damage.

This means that if precautions are not heeded, it may

result in serious injury or possibly even death.

ADDITIONAL SPECIFIC SAFETY RULES

Failure to follow these rules may result in serious personal injury.

1. Do not operate this machine until it is completely

assembled and installed according to the

instructions. A machine incorrectly assembled can

cause serious injury

2. Obtain advice from your supervisor, instructor, or

another qualified person if you are not thoroughly

familiar with the operation of this machine.

Knowledge is safety.

3. Follow all wiring codes and recommended electrical

connections to prevent shock or electrocution.

4. Keep knives sharp and free from rust and pitch.

Dull or rusted knives work harder and can cause

kickback.

5. Never turn the machine “on” before clearing the table

of all objects (tools, scraps of wood, etc.).

6. Flying debris can cause serious injury.

7. Never turn the machine “on” with the workpiece

contacting the cutter head. Kickback can occur.

8. Secure the machine to a supporting surface to

prevent the machine from sliding, walking or tipping

over.

9. Properly secure the knives in the cutterhead before

turning the power “on”. Loose blades may be thrown

out at high speeds causing serious injury.

10. Avoid awkward operations and hand positions. A

sudden slip could cause a hand to move into the

knives.

11. Keep arms, hands, and fingers away from the cutter

head, the chip exhaust opening, and the feed rollers

to prevent severe cuts.

4

Page 5

ADDITIONAL SPECIFIC SAFETY RULES

12. Never reach into the cutterhead area while the

machine is running. Your hands can be drawn into the

knives.

13. Do not stand in line of the workpiece. Kickback can

cause injury.

14. Allow the cutterhead to reach full speed before

feeding a workpiece.

15. When planing bowed stock, place the concave (cup

down) side of the stock on the table and cut with the

grain to prevent kickback.

16. Do not feed a workpiece that is warped, contains

knots, or is embedded with foreign objects (nails,

staples, etc.). Kickback can occur.

17. Do not feed a short, thin, or narrow workpiece into

the machine. Your hands can be drawn into the

knives and/or the workpiece can be thrown at high

speeds. See the “operation” section of this instruction

manual for details.

18. Do not feed a workpiece into the outfeed end of the

machine. The workpiece will be thrown out of the

opposite side at high speeds.

19. Remove shavings only with the power “off” to prevent

serious injury.

20. Properly support long or wide workpieces. Loss of

control of the workpiece can cause serious injury.

21. Never perform layout, assembly or set-up work on

the table/work area when the machine is running.

Serious injury will result.

22. Turn the machine “off”, disconnect it from the power

source, and clean the table/work area before leaving

the machine. Lock the switch in the “off” position

to prevent unauthorized use. Someone else might

accidentally start the machine and cause injury to

themselves or others..

23. Additional information regarding the safe and

proper operation of power tools (i.E. A safety video)

is available from the power tool institute, 1300

sumner avenue, cleveland, oh 44115-2851 (www.

Powertoolinstitute.Com). Information is also available

from the national safety council, 1121 spring lake

drive, itasca, il 60143-3201. Please refer to the

american national standards institute ansi 01.1 Safety

requirements for woodworking machines and the u.S.

Department of labor osha 1910.213 Regulations.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

5

Page 6

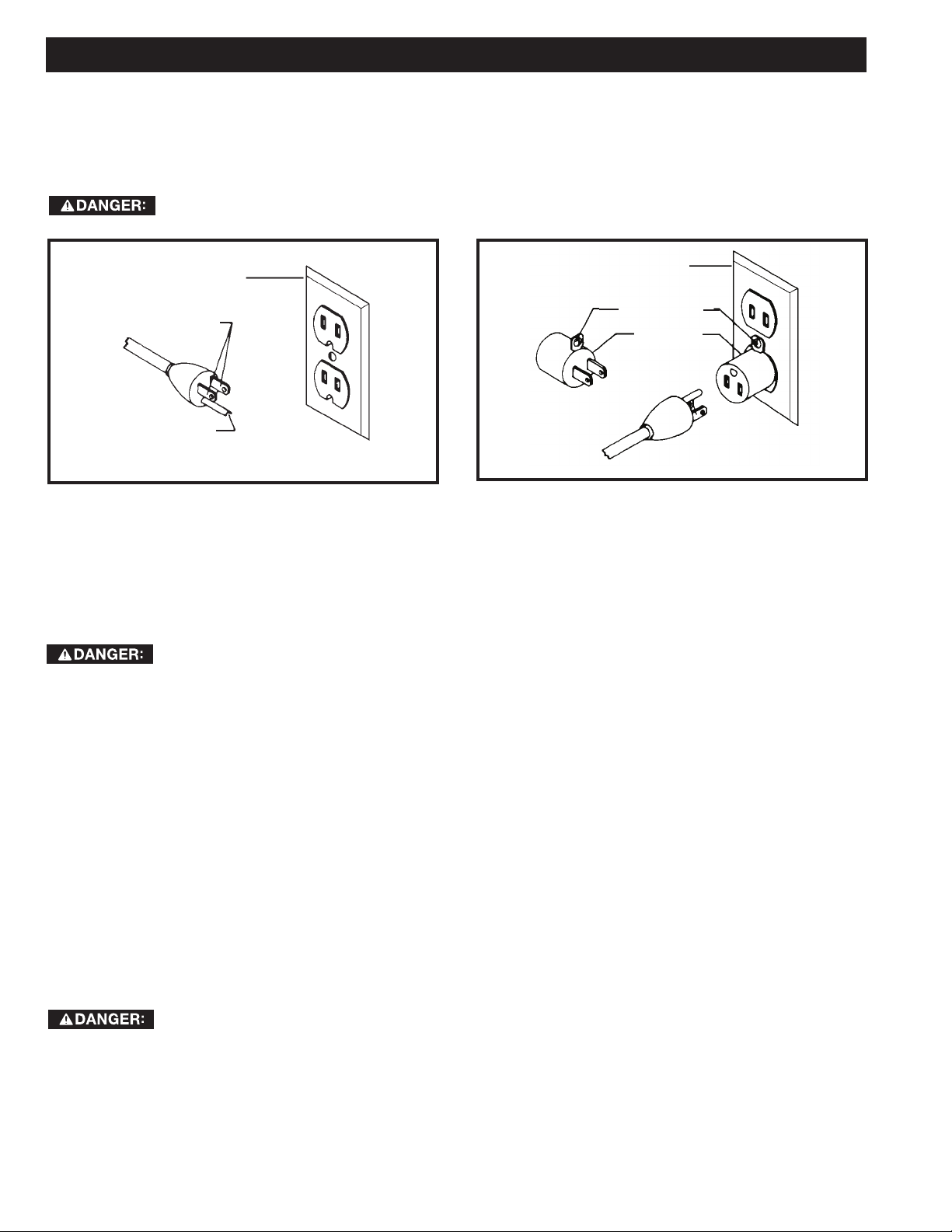

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #14 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have

3-prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch (s) is in the "OFF" position and be sure that the electric current is of

the same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

GROUNDED

OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

FIG. A FIG. B

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

MOTOR SPECIFICATIONS

Your machine is wired for 120 Volts, 60 Hz alternating current. Before connecting the machine to the power source,

make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a

live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if

in doubt as to whether the machine is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that

accept the machine’s plug, as shown in Fig. A.

Repair or replace damaged or worn cord immediately.

IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED.

IF YOU ARE NOT SURE, HAVE A QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

6

Page 7

EXTENSION CORDS

Use proper extension cords. Make

sure your extension cord is in good

condition and is a 3-wire extension cord which has

a 3-prong grounding type plug and matching

receptacle which will accept the machine’s plug.

When using an extension cord, be sure to use one

heavy enough to carry the current of the machine.

An undersized cord will cause a drop in line

voltage, resulting in loss of power and overheating.

The table shows the correct gauge to use

depending on the cord length. If in doubt, use the

next heavier gauge. The smaller the gauge number,

the heavier the cord.

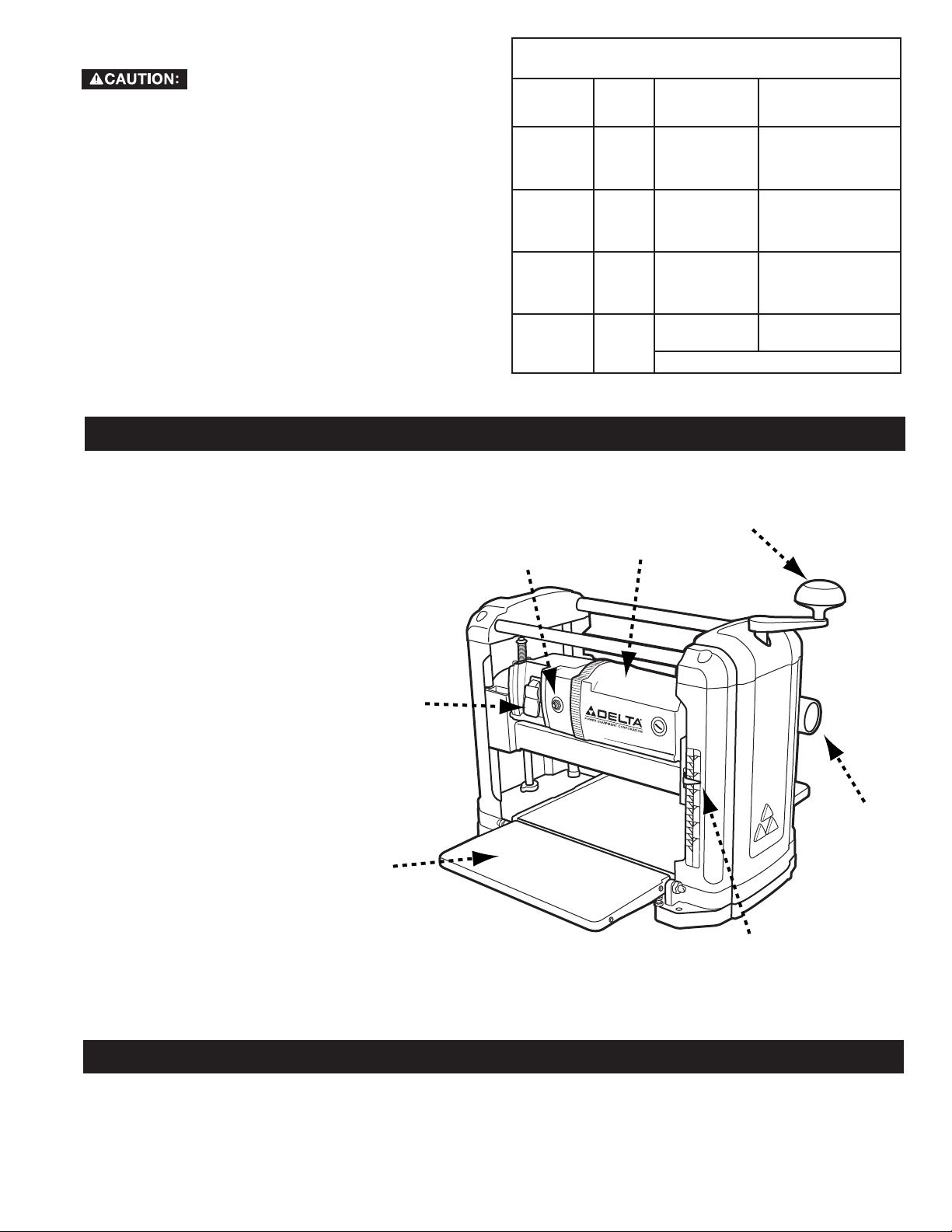

KEY FEATURES AND COMPONENTS

A. Feed Table

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere

Rating

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

12-16

Volts Total Length

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

of Cord in

Feet

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

50-100

100-150

up to 25

25-50

GREATER THAN 50 FEET NOT RECOMMENDED

Gauge of Extension

Cord

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

B. ON/OFF Switch

C. Circuit Breaker Reset

D. 15 Amp, 120V Motor

E. Height Adjustment Handle

F. 2” Reversible Dust Port

G. Height Indicator

A

B

C

D

E

F

G

FUNCTIONAL DESCRIPTION

The DELTA® 22-555 is a 13" (317mm) Portable Planer. This planer can handle workpieces up to 13" (317mm) wide

and 6" (152mm) thick. The maximum depth of cut is 3/32" (2.4 mm). The 22-555 features a powerful 15 Amp, 120 Volt

motor, a two-knife cutter head with double-edged reversible knives, knife-installation tool and wrench.

7

Page 8

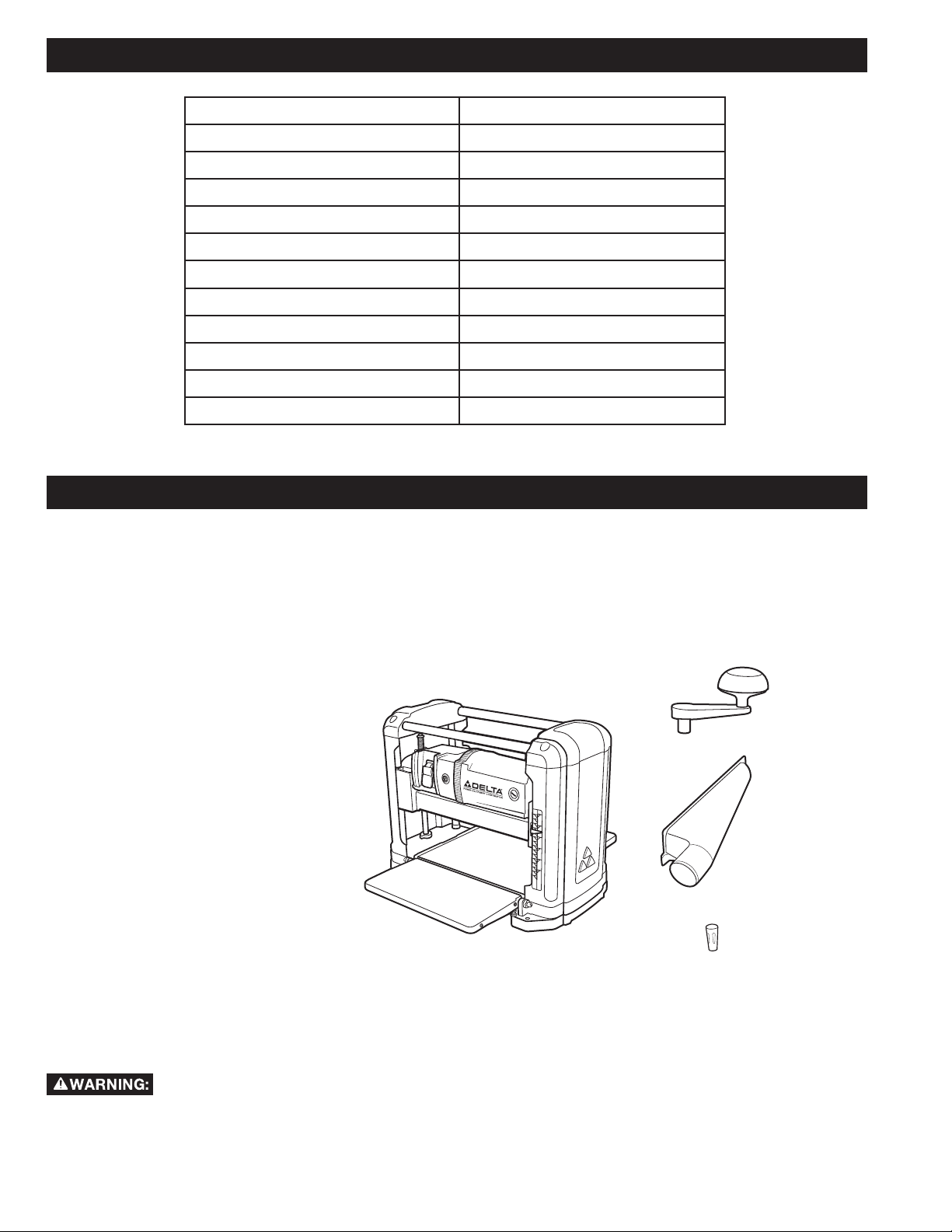

PRODUCT SPECIFICATIONS

4

Cuts Per Minute 18,800

Feed Rate 28ft./min.

Max. Cut Depth (per pass) 3/32”

Max. Cutting Width 12-½“

Max. Cutting Height 6”

Cutterhead Speed 9,400 RPM

Tool Dimensions (LxWxH) 21-5/8” x 23-5/8” x 20-1/8”

Motor 15 Amp, 120V

Net Weight 58 lbs

Knife Type Double-edge reversible

Number of Knives 2

Knife Size (L x W x T) 320mm x12mm x1.5mm

UNPACKING

Compare all parts to the list below and check that all parts are present and in good condition. Report any missing or

damaged parts to your distributor or dealer. Prior to tool assembly and use, read this manual thoroughly to familiarize

yourself with proper assembly, maintenance and safety procedures.

DESCRIPTION (QUANTITY)

1. DELTA® Model #22-555 Planer (1)

2. Height Adjustment Handle (1)

3. Reversible 2” Dust Port (1)

4. Knife Transfer Tool (2)

5. T-wrench (not shown)

HARDWARE PACKAGE

• 4mm T-handle Hex Wrench

• M5x16mm Hex Head Screw (1)

• M5 Flat Washer

• M6x15mm Lock Knob (2)

1

2

3

Remove any protective materials and coatings from all of the parts and the tool. The protective coatings can be removed

by spraying WD-40 on them and wiping it off with a soft cloth. This may need redone several times before all of the

protective coatings are removed completely.

If any parts are missing, do not attempt to plug in the power cord and turn “ON” the machine. The

machine should only be turned “ON” after all the parts have been obtained and installed correctly.

8

Page 9

ASSEMBLY

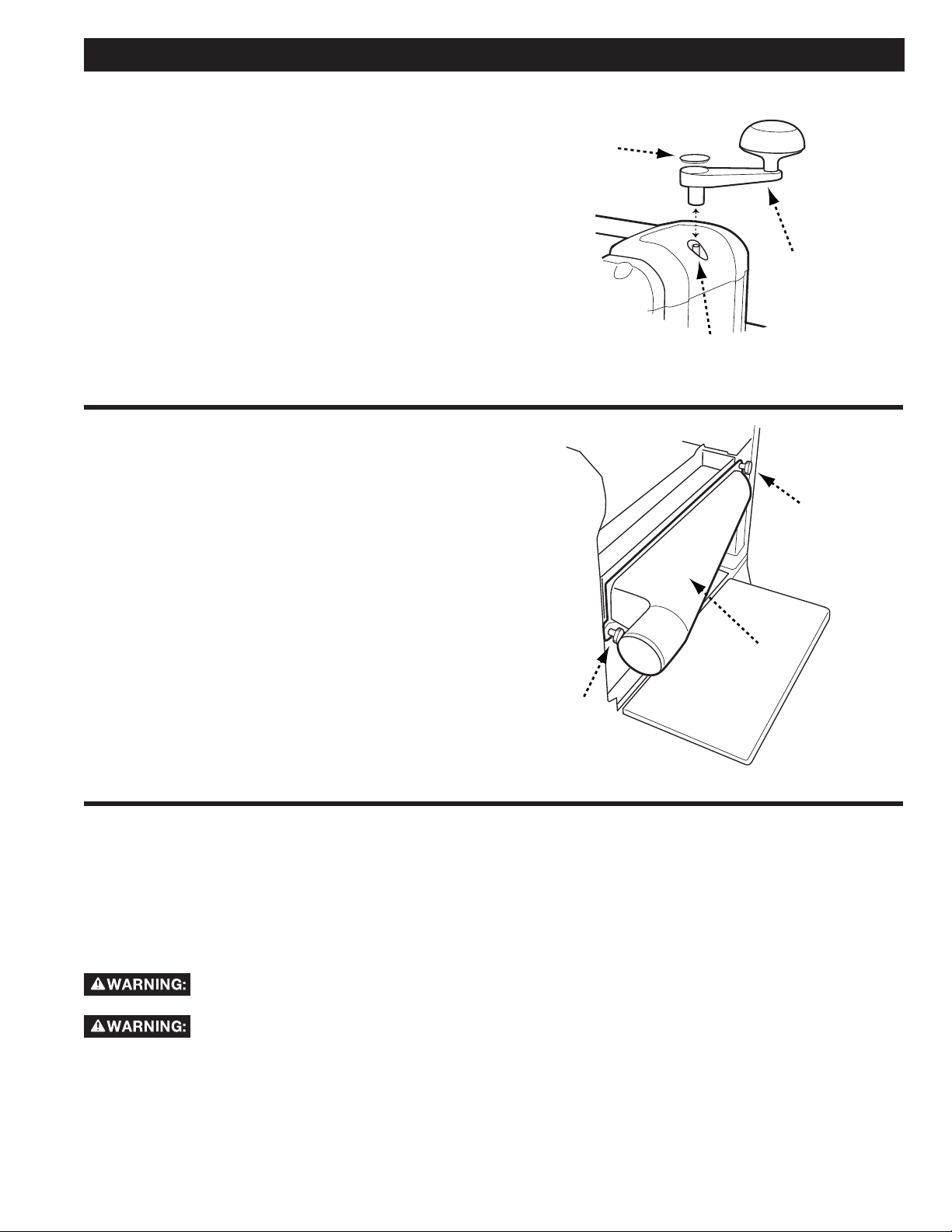

ATTACH HEIGHT ADJUSTMENT HANDLE

Refer to Figure 1

1. Remove the rubber cap (A) from the top of the height

adjustment crank shaft (B).

2. Use an M5 x 16mm hex head screw, M5 flat washer,

and supplied t-handle hex wrench to secure the

height adjustment handle to shaft (C).

3. Replace the rubber cap.

ATTACH REVERSIBLE DUST PORT

Refer to Figure 2

The 22-555 planer features a reversible dust port that can

be attached for left-sided or right-sided dust collection.

To attach the dust port:

1. Secure the dust port (A) to the tool housing on both

ends use the two M6 x 15mm lock knobs (B).

A

B

C

FIGURE 1

B

A

B

FIGURE 2

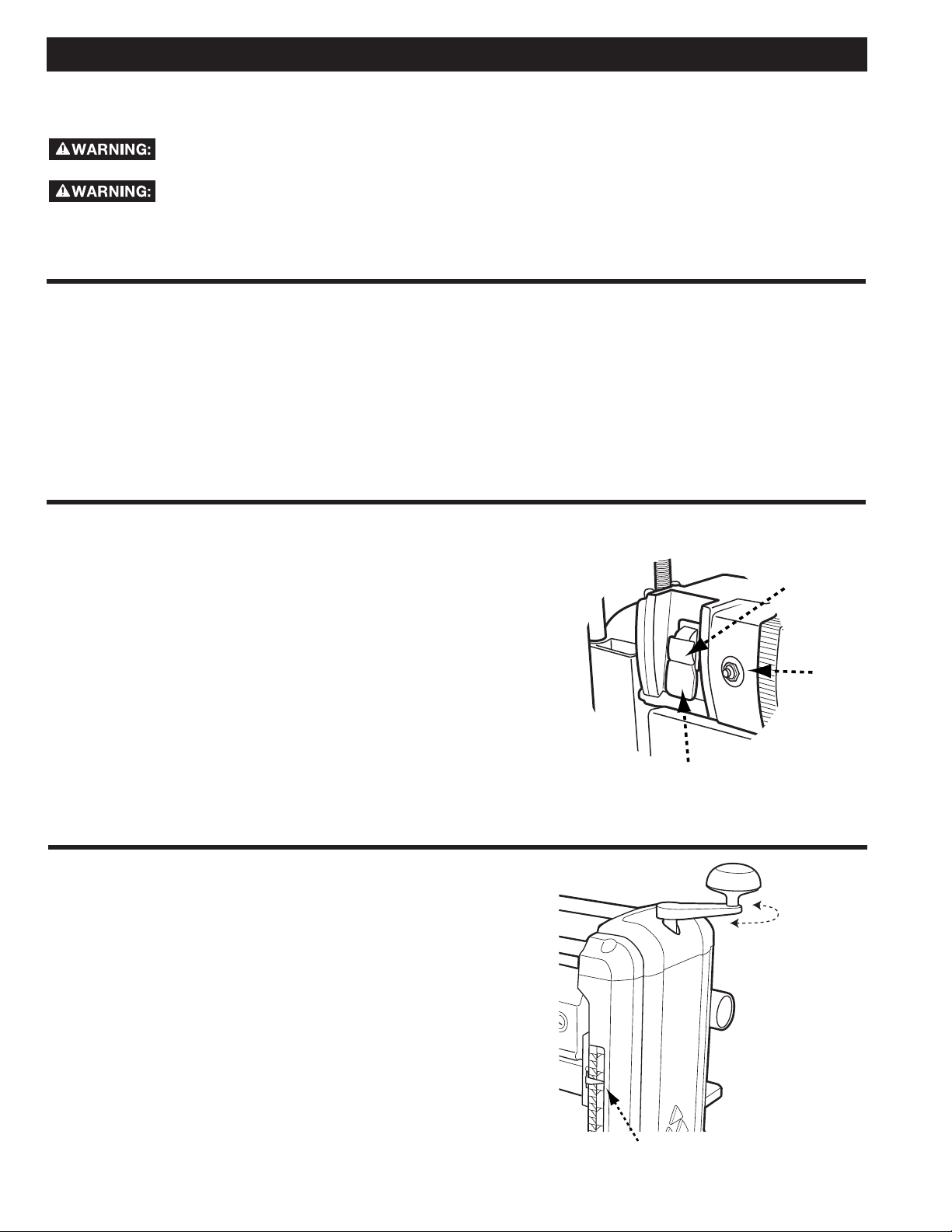

CONNECTING TO DUST COLLECTOR

A planer creates a large amount of fine particles while in use. It is strongly recommended that you connect the planer to

a shop vacuum or dust collector. Your DELTA® Bench Planer is equipped with a 2” dust port that must be connected

to a vacuum hose to ensure safe operation. Using a 2" to 4" adapter, sold separately, will enable you to connect your

planer to most dust collectors that use a 4” hose.

Do not attempt to operate this tool without first connecting it to an adequate dust collection

system.

Always turn on the dust collector before starting the planer and always stop the planer before

turning off the dust collector.

9

Page 10

OPERATION

A

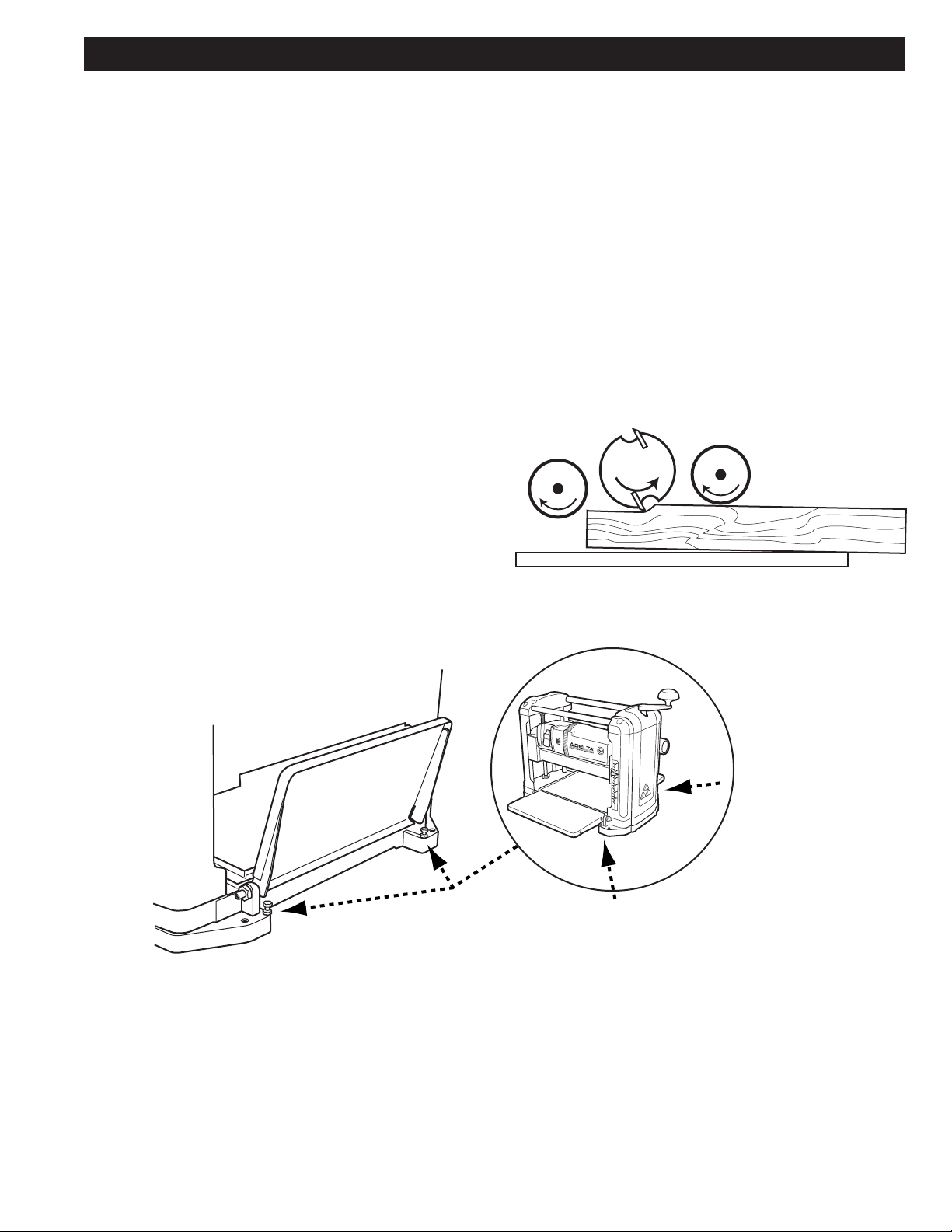

STARTING AND STOPPING THE PLANER

Make sure that the switch is in the "OFF" position before plugging cord into outlet. Do not touch

the plug’s metal prongs when unplugging or plugging in the cord.

In the event of a power outage (such as a breaker or fuse trip), always move the switch to the

"OFF" position until the main power is restored.

The ON/OFF switch (A), indicated in Figure 3, is located on the front of the cabinet. To turn the machine “ON,” move the

switch to the up position. To turn the machine “OFF,” move the switch to the down position.

LOCKING THE PLANER USING THE SAFETY KEY

1. This machine uses a safety key (B), shown in Figure 3,

that enables you to lock the tool in the “OFF” position

when not in use.

IMPORTANT: When the machine is not in use, the

switch should be locked in the "OFF" position to prevent

unauthorized use.

2. To lock the machine, remove the safety key by pulling

it straight out. With the safety key removed, the

switch will not operate.

3. Should the safety key be removed while the tool

is running, the machine can be turned "OFF,"

but cannot be restarted unless the safety key is

re-inserted.

RESETTING THE ON-BOARD CIRCUIT BREAKER

As an additional safety feature, the DELTA® 22-555 has an on-board

circuit breaker (C), shown in Figure 3. Should the motor become

overloaded or should a power surge occur while the machine is

operating, the circuit breaker will trip, cutting power to the machine.

In the event the breaker trips, do the following:

1. Turn the machine off and unplug the power cord.

2. Raise the cutterhead and remove the workpiece from the machine.

3. Wait 2 to 3 minutes or until the motor housing is cool to the touch,

then depress the on-board circuit breaker reset.

4. Plug the power cord in and restart the machine using the ON/OFF

switch.

5. If the machine fails to start, allow the motor to cool further and

attempt to reset the breaker again.

B

C

FIGURE 3

ADJUSTING CUTTING HEIGHT

Refer to Figure 4

Your DELTA® 22-555 Bench Planer can accept stock up

to 6” in height and has a maximum cutting depth of 3/32”

per pass. To adjust the height of the cutterhead:

1. Rotate the Height Adjustment Handle until the Height

Indicator (A) is pointing to the desired height. Turning

the handle clockwise raises the cutterhead while

turning it counterclockwise lowers it. One complete

revolution of the Height Adjustment Handle moves

the cutterhead 1/16”.

FIGURE 4

10

Page 11

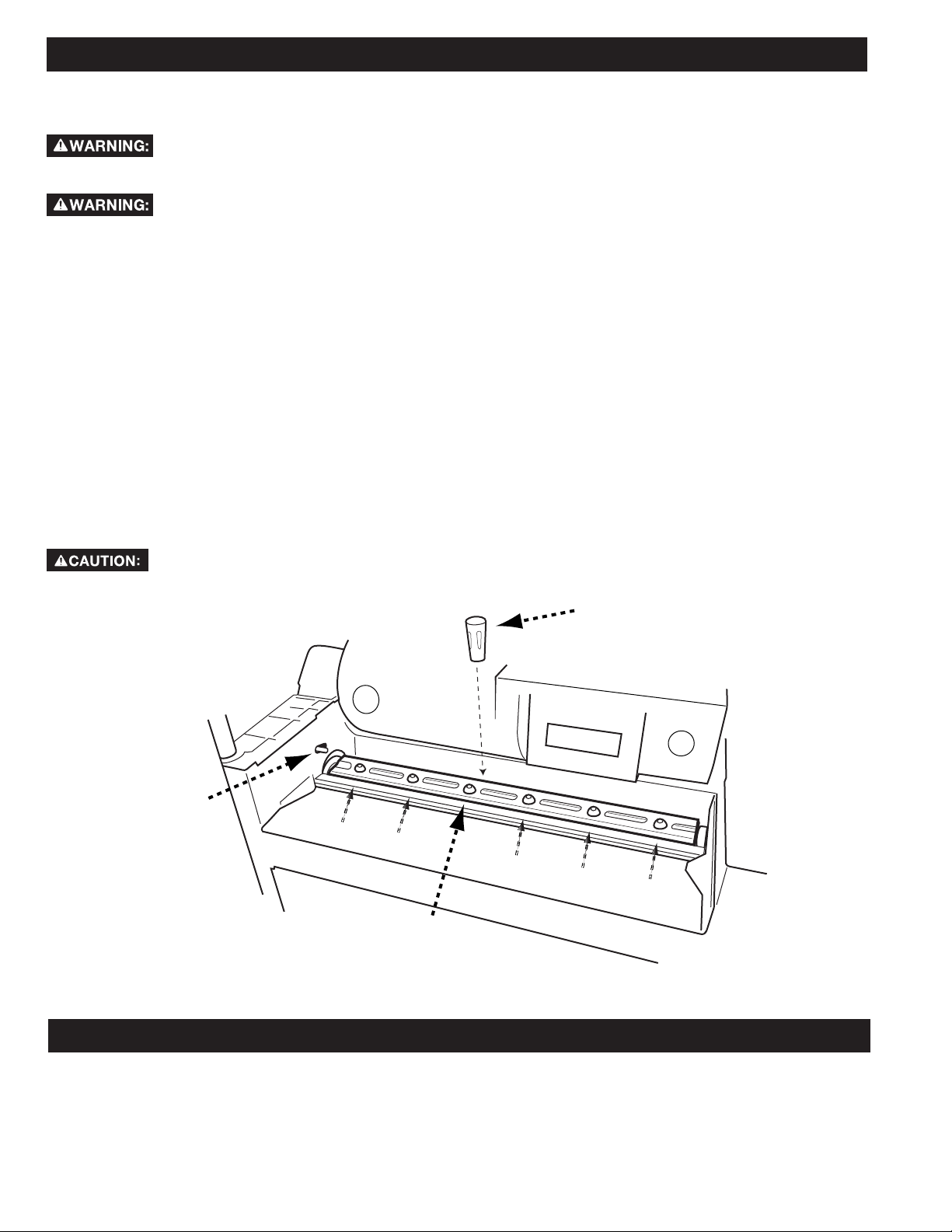

ELIMINATING SNIPE

OPERATION

Snipe is a short depression created at the beginning

and/or end of a board after it passes through the

planer. Figure 5 shows how snipe occurs when a board

enters the cutting area of the planer with the leading

end elevated. The same effect can be created when

the trailing end of the board becomes elevated as the

workpiece exits the planer.

There are a few ways you can control snipe.

The most common cause of snipe is failure to fully

support the workpiece as the leading end enters the

planer and as the trailing end exits the planer. This can

be addressed by securely holding the workpiece to the

surface of the infeed table and not allowing the leading

end to elevate as it contacts the cutterhead.

If, after trying the above, snipe is still present,

try lessening the depth of cut by slightly raising the

height of the cutterhead (see previous section, “Height

Adjustment”).

If the workpiece continues to exhibit snipe, you may

need to adjust the height of the infeed and or outfeed

table. To do this, see Figure 6, then:

1. Fold the infeed and outfeed tables up in order to

locate the two infeed (A) and two outfeed (B) stop

screws.

2. Using a 10mm open wrench, loosen the retaining

nuts.

3. Adjust the stop screws, one set at a time, making

sure that they are at the same height. To check the

screw height, lower the table and confirm that both

screw heads are flush against the bottom of the table.

4. Re-test for snipe.

FIGURE 5

FIGURE 6

11

B

A

Page 12

MAINTENANCE

CHANGING OR REVERSING KNIVES

Disconnect the machine from the

power source before making any

adjustments!

Planer knives are dangerously sharp.

Use extreme caution when inspecting,

removing, sharpening, or replacing knives into the cutter

head. Failure to comply may cause serious injury.

1. Remove the dust chute by unscrewing the two lock

knobs shown in Figure 2.

2. Remove the two lock knobs securing the cutterhead

cover to the main casting and remove the cover. The

cutterhead and the knives will now be exposed.

3. Lock the cutterhead in place. To do this, refer to

Figure 7 and ensure the red spring-loaded lock tab (A)

is in the forward position. Then carefully and slowly

rotate the cutterhead until the tab locks in place and

the cutterhead does not move.

4. Using the T-handle hex wrench supplied, loosen the

six screws (B) securing each knife hold down bar and

the knife to the cutterhead.

5. Use the magnetic end of the knife removal tool (C) to

carefully lift off the hold down bar and then the knife.

Blades are sharp! Use great care when

hands are around blade area!

6. Carefully install the new knife or rotate the existing

knife, ensuring the pins on the cutterhead align with

the elongated holes in the knife.

7. Replace the hold down bar, making sure that the two

pins on the cutterhead are aligned with the two small

holes in the hold down bar.

8. Replace and retighten the six screws.

9. Unlock the cutterhead by moving the red springloaded lock tab forward and carefully rotating the

cutterhead until the second knife is exposed and the

cuttterhead locks into place.

10. Repeat Steps 4 – 8 to replace the second knife.

11. Replace the cutterhead cover. Ensure the notches in

the cover align with the threaded holes and the cover

is fully seated in the recess.

12. Replace the dust chute and re-secure with the two

lock knobs.

C

A

B

FIGURE 7

OTHER RECOMMENDED MAINTENANCE

1. Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp

cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

2. Periodically check tightness on all other hardware and listen for any unusual vibrations as you work as these may be

a sign of loose hardware.

12

Page 13

ACCESSORIES

A complete line of accessories is available from your DELTA® Supplier, DELTA® Factory Service Centers, and DELTA®

Factory Service Centers, and DELTA® Authorized Service Centers. Please visit our Web Site www.DeltaMachinery.

com for an online catalog or for the name or your nearest supplier.

Since accessories other than those offered by DELTA® have not been tested with this product,

use of such accessories could be hazardous. For safest operation, only DELTA® recommended

accessories should be used with this product.

WARRANTY

To register your tool for warranty service visit our website at www.DeltaMachinery.com.

FIVE YEAR LIMITED WARRANTY

Delta® Power Equipment Corporation

1. WHAT IS COVERED. Delta Power Equipment Corporation (“Company”) will repair or replace, at its option, any new or factory refurbished

DELTA® machine or service part which is purchased at retail in the United States or Canada and which in normal use has proven to be defective

in workmanship or material, subject to the conditions stated in this Limited Warranty. This Limited Warranty covers only materials and labor.

All transportation costs are Customer’s responsibility.

2. WARRANTY PERIOD. All warranty claims must be submitted within five years from the date of retail purchase. For all service parts and

factory refurbished DELTA® machines, the warranty period is 180 days.

3. HOW TO OBTAIN SERVICE. To obtain warranty service, you must return the defective product, at your expense, to a service center authorized

by Company to perform warranty service (a “DELTA® Authorized Service Center”) within the applicable warranty period, together with

acceptable proof of purchase, such as your original receipt bearing the date of purchase, or product registration number. Company reserves

the right to restrict warranty claim service to the country where the purchase was made and/or to charge for the cost to export service parts

or provide warranty service in a different country. On-line purchases are deemed made in the United States. For the location of your nearest

DELTA® Authorized Service Center, call Company’s Customer Care Center at (800) 223-7278.

4. EXCLUSIONS.

· Company does not offer any warranty on products purchased in used or damaged condition.

· Company does not warranty any products purchased outside the United States or Canada

· Company will not be responsible for any damage that has resulted from normal wear, misuse, abuse or any repair or alteration made by

anyone other than a DELTA® Authorized Service Center or a designated representative of Company’s Customer Care Center.

· All IMPLIED WARRANTIES are expressly limited to the warranty period identified above.

· Under no circumstances will Company be liable for INCIDENTAL OR CONSEQUENTIAL damages.

· This limited warranty is Company’s sole warranty and sets forth the customer’s exclusive remedy with respect to defective products; all other

warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are expressly disclaimed by Company, except as

stated above.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or the limitation of implied warranties, so the

above limitations or exclusions may not apply to you. This warranty gives you specific legal rights and you may have other rights which vary

in certain states or provinces. For further details of warranty coverage and warranty repair information, call (800) 223-7278. To register your

products online, we encourage you to visit our website and register for a FREE DELTA Member Account at http://www.deltamachinery.com/

register.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local company or see website for warranty information.

13

Page 14

PARTS, SERVICE OR WARRANTY ASSISTANCE

All DELTA® machines and accessories are manufactured to high quality standards and are serviced by a network of

DELTA® Factory Service Centers and DELTA® Authorized Service Centers. To obtain additional information regarding

your DELTA® quality product or to obtain parts, service, warranty assistance, or the location of the nearest service center,

please call 1-800-223-7278.

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at www.DeltaMachinery.

com. You can also order parts from your nearest factory-owned branch, Authorized Warranty Service Center or by

calling Technical Service Manager at 1-800-223-7278 to receive personalized support from one of our highly-trained

representatives.

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing,

call

1-800-223-7278

for a free replacement.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information

about DELTA® Power Equipment Corporation, its factory-owned branches, or to locate

an Authorized Warranty Service Center, visit our website at www.DeltaMachinery.com

or call our Customer Care Center at 1-800-223-7278. All repairs made by our service centers are fully guaranteed

against defective material and workmanship. We cannot guarantee repairs made or attempted by others. By calling

this number you can also find answers to most frequently asked questions 24 hours/day.

You can also write to us for information at D ELTA® Power Equipment Corporation, 99 Roush Street, Anderson,

SC 29625 - Attention: Technical Service Manager. Be sure to include all of the information shown on the

nameplate of your tool (model number, type, serial number, date code, etc.)

141516

Page 15

Page 16

CONSIGNES DE SÉCURITÉ IMPORTANTES

ASSUREZ-VOUS D’AVOIR BIEN LU ET COMPRIS TOUTES LES MISES EN GARDE ET LES

CONSIGNES D’UTILISATION AVANT D’UTILISER CET ÉQUIPEMENT. Le fait de ne pas

respecter toutes les instructions ci-dessous pourrait causer une électrocution, des incendies, et/ou des blessures

personnelles ou des dommages matériels graves.

La meuleuse peut être dangereuse si des procédures d’utilisation sécuritaires et adéquates ne sont pas

respectées. Comme c’est le cas pour toute pièce de machinerie, l’utilisation de ce produit comporte

certains dangers. En utilisant cet appareil selon les directives et avec prudence, vous réduirez de façon

importante les risques de blessures corporelles. Cependant, si les précautions normales de sécurité

sont négligées ou ignorées, la personne qui utilise l’appareil pourrait être blessée. L’équipement de protection

comme les gardes, les poussoirs, les dispositifs de retenue, les planches de protection, les lunettes de sécurité,

les masques antipoussières et la protection pour l’ouïe peut réduire le risque de blessure. Cependant, même le

meilleur dispositif de protection ne peut compenser un mauvais jugement, un manque de prudence ou d'inattention.

Utilisez toujours le bon sens et soyez prudent dans l’atelier. Si une manœuvre a l’air dangereuse, ne l’effectuez

pas. Essayez plutôt de trouver un moyen plus facile. RAPPELEZ-VOUS : vous êtes responsable de votre sécurité

personnelle. Pour des renseignements complémentaires, rendez-vous sur notre site Web à l’adresse suivante

www.DeltaMachinery.com.

Cet appareil a été conçu seulement pour certaines utilisations. DELTAMD Power Equipment

Corporation recommande fortement que cet appareil ne soit pas modifié ni utilisé pour toutes

autres fins que celles pour lesquelles il a été conçu. Si vous avez des questions sur une utilisation en particulier,

N’UTILISEZ PAS l’appareil avant d’avoir d’abord communiqué avec DELTAMD pour déterminer si cette utilisation peut ou

si elle devrait être faite sur ce produit.

Si vous avez des questions relativement à son utilisation, N’UTILISEZ PAS le produit tant que vous n’aurez pas

communiqué par écrit avec DELTAMD Power Equipment Corporation et obtenu une réponse de sa part. Contactez-nous en

ligne à www.DeltaMachinery.com ou par courrier à l’adresse suivante : Responsable du service technique, DELTAMD Power

Equipment Corporation, 99 Roush Street, Anderson, SC 29625.

Des renseignements au sujet de l’utilisation sécuritaire et appropriée de cet appareil sont disponibles auprès des

sources suivantes :

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 ou en ligne sur www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• Réglementation du Département américain du travail (OSHA) à l’adresse www.osha.gov

CONSIGNES DE SÉCURITÉ - DÉFINITIONS

Ce manuel contient des renseignements qu'il est important de connaître et de comprendre. Ces renseignements ont pour

but d’assurer VOTRE SÉCURITÉ et de PRÉVENIR LES PROBLÈMES D’ÉQUIPEMENT. Pour vous aider à reconnaître ces

renseignements, nous utilisons les symboles ci-dessous. Veuillez lire le manuel et prêter attention à ces sections.

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée, entraînera la mort ou une

blessure grave.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner

la mort ou une blessure grave.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, peut entraîner une

blessure mineure ou modérée.

Utilisé sans le symbole d’avertissement, indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, peut endommager l’appareil.

Page 17

RÈGLES DE SÉCURITÉ GÉNÉRALES

LE NON-RESPECT DE CES RÈGLES PEUT ENTRAÎNER DES BLESSURES PERSONNELLES

GRAVES.

POUR VOTRE PROPRE SÉCURITÉ, ASSUREZ-VOUS D’AVOIR BIEN LU ET COMPRIS LE MANUEL D’UTILISATION

•

AVANT DE FAIRE FONCTIONNER L’APPAREIL.

les dangers qui lui sont rattachés.

MAINTENEZ L’AIRE DE TRAVAIL PROPRE.

•

NE PAS UTILISER DANS UN ENVIRONNEMENT DANGEREUX.

•

mouillé, et ne l’exposez pas à la pluie. Gardez votre lieu de travail bien éclairé.

MAINTENEZ LES ENFANTS ET LES VISITEURS À L’ÉCART.

•

distance sécuritaire de l’aire de travail.

DÉBRANCHEZ L’APPAREIL

•

VÉRIFIEZ LA PRÉSENCE DE PIÈCES ENDOMMAGÉES.

•

pièce endommagée.

avant toute opération d’entretien.

LE NON-RESPECT DE CES RÈGLES PEUT ENTRAÎNER DES BLESSURES GRAVES.

Apprenez à connaître son domaine d’utilisation et ses limites, ainsi que

Les aires et les bancs de travail encombrés sont propices aux accidents.

N’utilisez pas cet appareil dans un endroit humide ou

Tous les enfants et visiteurs doivent demeurer à une

Avant d’utiliser l’appareil, bien réparer ou remplacer toute

1. Assurez-vous de lire et comprendre les avertissements

affichés sur l’appareil et dans ce manuel. Le non

respect de tous ces avertissements peut entraîner des

blessures graves.

2. Remplacez les étiquettes d’avertissement si elles sont

masquées ou supprimées.

3. Cet appareil est conçu pour l’utilisation par un

personnel qualifié et expérimenté seulement. En

cas de non familiarité avec le bon fonctionnement

sécuritaire d’une raboteuse, ne l’utilisez pas avant

d’avoir reçu la formation et les connaissances

appropriées.

4. Ne pas utiliser cet appareil pour autre chose que son

usage prévu. S’il est utilisé à d’autres fins, DELTA®

Power Equipment Corporation décline toute garantie

réelle ou implicite et se dégage de toute responsabilité

pour toute blessure qui pourrait résulter de cette

utilisation.

5. Portez toujours des lunettes de protection ou des

écrans faciaux approuvés lors de l’utilisation de cet

outil.

6. Avant d’utiliser cet outil, enlevez cravate, bagues,

montres et autres bijoux, et retroussez vos

manches au-dessus du coude. Retirez tous les

vêtements amples et retenez les cheveux longs.

Il est recommandé de porter des chaussures

antidérapantes ou de poser des bandes de plancher

antidérapantes. Ne portez pas de gants.

7. Portez des protecteurs pour l’ouïe (bouchons

ou manchons) pendant les longues périodes de

fonctionnement.

8. Certaines poussières créées par le ponçage

mécanique, le sciage, le broyage, le perçage et d’autres

activités de construction contiennent des produits

chimiques identifiés comme causes de cancer,

d’anomalies congénitales ou d’autres préjudices liés à

la reproduction. En voici des exemples :

• plomb de peintures à base de plomb;

• silice cristalline de briques, de ciment et d’autres

produits de maçonnerie;

• arsenic et chrome de bois de sciage traité

chimiquement.

Votre risque lié à ces expositions varie selon la

fréquence à laquelle vous faites ce genre d’activité.Pour

réduire l’exposition à ces produits chimiques, travaillez

dans un endroit bien ventilé et avec de l’équipement de

protection approuvé, comme les masques antipoussières

spécialement conçus pour filtrer les particules

microscopiques.

9. N'utilisez pas cet appareil en état de fatigue ou avec

les facultés affaiblies par la drogue, l’alcool ou les

médicaments.

10. Avant de brancher l’appareil sur la source

d’alimentation, assurez-vous que l’interrupteur est en

position « OFF » (Arrêt).

11. Assurez-vous que l'appareil est correctement mis

à la terre.

12. Ne faites les réglages de l'appareil ou son entretien

que lorsque celui-ci est débranché de la source

d’alimentation.

13. Prenez l’habitude de vérifier que tout l’équipement

supplémentaire tel que les clés de réglage, les clés

à molette, la ferraille, le matériel et les chiffons de

nettoyage a été éloigné de l'appareil avant de le mettre

en marche.

14. Gardez les dispositifs de protection en place en tout

temps lorsque l’appareil est utilisé. Faites preuve

d’une extrême prudence s’ils sont enlevés à des

fins d’entretien et remettez-les en place dès la fin de

l’entretien.

15. Assurez-vous que l'outil est solidement fixé sur une

surface de travail stable avant de l’utiliser.

16. Vérifiez si des pièces sont endommagées. Avant

d’utiliser l’appareil, il faut vérifier soigneusement

le dispositif de protection ou toute autre pièce

endommagée afin de s’assurer que l’appareil

fonctionnera correctement et remplira sa fonction

prévue. Vérifiez l’alignement des pièces mobiles

et leurs joints, tout bris de pièce et du cadrage et

toute autre condition qui pourrait en modifier le

fonctionnement. Un garde ou une autre pièce

endommagée doivent être réparés ou remplacés sans

tarder.

17. Prévoyez un espace suffisant autour de la zone de

travail et un éclairage en plongée non éblouissant.

suite à la page 18

17

Page 18

18. Gardez le plancher autour de l’appareil propre et

exempt de débris, d’huile et de graisse.

19. Gardez les visiteurs à une distance sécuritaire de la

zone de travail. Tenez les enfants à distance.

20. Rendez votre atelier à l’épreuve des enfants au moyen

de cadenas, de commutateurs principaux ou en retirant

les clés de mise en marche.

21. Concentrez-vous uniquement sur le travail. Regarder

aux alentours, tenir une conversation et faire du chahut

sont des actes négligents qui peuvent entraîner des

blessures graves.

22. Maintenez une position équilibrée en tout temps afin

de ne pas tomber ou de ne pas vous appuyer sur

l'outil ou sur ses pièces mobiles. Évitez de vous étirer

ou d’utiliser une force excessive pour effectuer toute

opération avec l’appareil.

23. Utilisez l’outil approprié à la bonne vitesse et au bon

débit. Ne forcez pas un outil ou un accessoire à

effectuer une tâche pour laquelle il n’a pas été conçu.

Le bon outil fera mieux le travail et sera plus sécuritaire.

24. Utilisez les pièces recommandées ; les accessoires

inadéquats peuvent être dangereux.

25. Entretenez les appareils avec soin. Suivez les

indications relatives à la lubrification et au changement

d’accessoire.

26. Débranchez l’appareil avant le nettoyage. Utilisez une

brosse ou de l’air comprimé pour enlever la poussière

ou des débris ; n’utilisez pas vos mains.

27. Ne vous tenez pas debout sur l’appareil. Des

blessures graves pourraient se produire si l’appareil

se renverse.

28. Ne jamais laisser l’appareil sans surveillance lorsqu’il

est en marche. Débranchez l’appareil et ne le laissez

pas sans surveillance jusqu’à son arrêt complet.

29. Tenez la poignée fermement en tout temps.

30. N’utilisez pas cet outil pour d’autres fins que celles

pour lesquelles il est prévu. S'il est utilisé à d’autres

fins, DELTAMD Power Equipment Corporation décline

toute garantie réelle ou implicite et se dégage de

toute responsabilité pour toute blessure qui pourrait

résulter de cette utilisation.

Familiarisez-vous avec les règles de sécurité

enseignées dans ce manuel :

Cela signifie que le non-respect des précautions peut

entraîner des blessures superficielles et/ou endommager

l’appareil.

Cela signifie que le non-respect des précautions peut

causer des blessures graves pouvant même entraîner la

mort.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES SUPPLÉMENTAIRES

Le non-respect de ces règles peut provoquer des blessures graves.

1. N'UTILISEZ PAS CET APPAREIL avant qu’il

soit entièrement assemblé et installé selon les

instructions. Un appareil qui n'est pas correctement

assemblé peut provoquer une blessure grave.

2. Demandez conseil, à votre superviseur, enseignant

ou autre personne qualifiée si vous ne savez pas

exactement comment fonctionne cet appareil. La

connaissance c'est la sécurité.

3. Suivez tous les codes sur le branchement et les

connexions électriques recommandées pour éviter

une décharge électrique ou une électrocution.

4. Keep knives sharp and free from rust and pitch.

Les lames non aiguisées ou rouillées travaillent plus

difficilement et peuvent provoquer un rebond.

5. Ne mettez jamais l'appareil en marche avant d'avoir

enlevé tous les objets sur la table (outils, chutes de

bois, etc.).

6. Les projectiles peuvent provoquer une blessure

grave.

7. Ne mettez jamais l'appareil en mawrche si la pièce

à travailler touche le porte-outil. Un rebond peut se

produire.

8. Fixez l'appareil sur une surface de support pour

l'empêcher de glisser, de se déplacer ou de basculer.

9. Fixez correctement les lames dans le porte-outil

avant de mettre l'appareil en marche. Des lames

desserrées peuvent être éjectées à grandes vitesses

et provoquer une blessure grave.

10. Évitez les positions inconfortables de travail et des

mains. Une erreur soudaine peut pousser votre main

sur les lames.

11. Gardez les bras, les mains et les doigts éloignés du

porte-outil, de l'orifice d'évacuation des copeaux

et des rouleaux d'entraînement pour empêcher des

coupures graves.

12. Ne restez jamais à portée du porte-outil pendant que

l'appareil est en marche. Vos mains peuvent être

tirées dans les lames.

13. Ne vous tenez pas debout dans l'alignement de la

18

Page 19

RÈGLES DE SÉCURITÉ SPÉCIFIQUES SUPPLÉMENTAIRES

pièce. Un rebond peut provoquer une blessure.

14. Laissez le porte-outil atteindre sa pleine vitesse avant

d'insérer une pièce.

15. Lorsque vous rabotez un matériel courbé, placez

le côté concave (creux vers le bas) du matériel sur

la table et coupez avec le grain pour empêcher un

rebond.

16. N'insérez pas une pièce qui est déformée, qui

contient des nœuds ou qui est incrustée d'objets

étrangers (clous, agrafes, etc.). Un rebond peut se

produire.

17. N'insérez pas une pièce courte, fine ou étroite dans

l'appareil. Vos mains peuvent être tirées dans les

lames et/ou la pièce peut être éjectée à grandes

vitesses. See the “operation” section of this

instruction manual for details.

18. N'alimentez pas la machine depuis sa sortie. La

pièce sera éjectée du côté opposé à grandes

vitesses.

19. Retirez les rabotures uniquement lorsque l'appareil

est hors tension pour empêcher une blessure grave.

20. Appuyez correctement les pièces qui sont longues

ou larges. La perte de contrôle d’une pièce peut

provoquer des blessures graves.

21. Ne faites jamais d'arrangements ou d'assemblage sur

la table ou l’aire de travail quand l’appareil fonctionne,

et n’y préparez pas votre travail. Cela pourrait

provoquer des blessures graves.

22. Éteignez l'appareil et débranchez l’appareil de la

source d’alimentation, et nettoyez la table/l’aire

de travail avant de laisser l’appareil. Verrouillez

l’interrupteur en position « off » (arrêt) pour empêcher

une utilisation non autorisée. Une autre personne

pourrait accidentellement mettre l'appareil en marche

et se blesser ou blesser les autres...

23. De plus amples renseignements sur l’utilisation

sécuritaire et adéquate des outils électriques (par

exemple, une vidéo sur la sécurité) sont disponibles

auprès du Power Tool Institute, 1300 Summer Avenue,

Cleveland, OH 44115-2851 (www.Powertoolinstitute.

Com). Des informations sont également disponibles

auprès du National Safety Council, 1121 spring lake

drive, itasca, il 60143-3201. Veuillez vous reporter aux

exigences en matière de sécurité 01.1 de l'American

National Standards Institute (ANSI) pour les appareils

à travailler le bois et aux réglementations OSHA

1910.213 du Ministère du Travail des États-Unis.

CONSERVEZ CES CONSIGNES.

Consultez-les souvent et utilisez-les pour enseigner les autres.

19

Page 20

RACCORDEMENTS ÉLECTRIQUES

Un circuit électrique séparé devrait être utilisé pour vos appareils. Les fils du circuit doivent être au moins de calibre 14

et être protégés par un fusible à action différée de 20 ampères. Si vous utilisez une rallonge, ne prenez que des rallonges

à trois fils avec des fiches de mise à la terre à trois broches et le réceptacle correspondant qui acceptera la fiche de

l’appareil. Avant de brancher l’appareil sur l’alimentation, assurez-vous que le commutateur est en position « OFF »

(« Arrêt ») et que le courant électrique que vous allez utiliser possède les mêmes caractéristiques que celui indiqué

sur l’appareil. Tous les raccordements doivent établir un bon contact. Une utilisation en basse tension endommagera

l’appareil.

NE PAS UTILISER L’APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLÉ ET NE PAS

L’EXPOSER À LA PLUIE.

BOÎTE DE COURANT

DE MISE À LA TERRE

BROCHES

PORTEUSES DE

COURANT

LA BROCHE DE

MISE À LA TERRE EST LA PLUS

LONGUE DES TROIS

FIG. A FIG. B

BOÎTE DE COURANT

DE MISE À LA TERRE

MOYENS DE MISE

À LA TERRE

ADAPTATEUR

SPÉCIFICATIONS DU MOTEUR

Votre appareil est câblé pour un courant alternatif de 120 Vca, 60 Hz. Avant de brancher l’appareil sur la source

d’alimentation, assurez-vous que l’interrupteur est en position « OFF » (Arrêt).

INSTRUCTIONS DE MISE À LA TERRE

CET APPAREIL DOIT ÊTRE MIS À LA TERRE LORSQU’IL EST UTILISÉ POUR PROTÉGER

L’OPÉRATEUR CONTRE L’ÉLECTROCUTION.

1. Pour tous les appareils branchés par un cordon d’alimentation et mis à la terre :

En cas de mauvais fonctionnement ou de panne, la mise à la terre fournit un chemin de moindre résistance au courant

électrique visant à réduire le risque d’électrocution. Cet appareil est équipé d’un cordon électrique possédant un

conducteur de terre et une fiche de terre. La fiche doit être branchée sur une prise correctement installée et mise à la terre

conformément à tous les codes et règlements locaux.

Ne pas modifier la fiche prévue. Si elle n’entre pas dans la prise, faire installer une prise appropriée par un électricien

agréé.

Le raccordement inapproprié du conducteur de terre de l’équipement peut provoquer l’électrocution. Le fil conducteur avec

un isolant comportant une surface extérieure verte, avec ou sans rayures jaunes, est le conducteur de terre. Si la réparation

ou le remplacement du cordon électrique ou de la fiche est nécessaire, ne branchez pas le conducteur de terre à une borne

sous tension.

Si les consignes de mise à la terre ne sont pas complètement comprises ou en cas de doute concernant la mise

à la terre de l’appareil, se renseigner auprès d’un électricien ou du personnel de service agréés.

Utiliser uniquement des rallonges à trois fils avec des fiches de mise à la terre à trois broches et des réceptacles

à 3 conducteurs adaptés à la fiche de l’appareil, comme indiqué à la Fig. A.

Réparer et remplacer immédiatement tout cordon endommagé ou usé.

DANS TOUS LES CAS, ASSUREZ-VOUS QUE LE RÉCEPTACLE EN QUESTION EST BIEN RELIÉ À

LA TERRE. SI VOUS N’ÊTES PAS CERTAIN, FAITES VÉRIFIER LE RÉCEPTACLE PAR UN

ÉLECTRICIEN QUALIFIÉ.

20

Page 21

RALLONGES

Utilisez des rallonges appropriées.

Assurez-vous que la rallonge est

en bon état et qu’il s’agit d’une rallonge à trois fils

avec une fiche de mise à la terre à trois broches et

d’un réceptacle correspondant à la fiche de

l’appareil. Lorsque vous utilisez une rallonge,

assurez-vous qu’elle soit de calibre suffisamment

élevé pour assurer l’alimentation de l’appareil. Une

rallonge d’un calibre trop petit provoquera une

chute de tension, entraînant une perte de puissance

et une surchauffe. Le tableau indique le bon calibre

à utiliser en fonction de la longueur de la rallonge.

En cas de doute, utiliser le calibre immédiatement

supérieur. Plus le numéro de calibre est petit, plus le

cordon est épais.

CALIBRE MINIMUM POUR RALLONGE

CALIBRES RECOMMANDÉS POUR UTILISATION SUR DES APPAREILS

Intensité Volts Longueur totale du

0-6

0-6

0-6

0-6

6-10

6-10

6-10

6-10

10-12

10-12

10-12

10-12

12-16

12-16

12-16

ÉLECTRIQUES STATIONNAIRES

cordon en mètres (pieds)

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

jusqu'à 7,6 (25)

7,6-15,2 (25-50)

15,2-30,5 (50-100)

30,5-45,7 (100-150)

jusqu'à 7,6 (25)

7,6-15,2 (25-50)

15,2-30,5 (50-100)

30,5-45,7 (100-150)

jusqu'à 7,6 (25)

7,6-15,2 (25-50)

15,2-30,5 (50-100)

30,5-45,7 (100-150)

jusqu’à 7,6 (25)

7,6-15,2 (25-50)

UNE LONGUEUR DE PLUS DE 15,2 MÈTRES (50 PIEDS)

N’EST PAS RECOMMANDÉE.

CARACTÉRISTIQUES ET COMPOSANTES IMPORTANTES

A. Table d’alimentation

Calibre de la

rallonge

18 AWG

16 AWG

16 AWG

14 AWG

18 AWG

16 AWG

14 AWG

12 AWG

16 AWG

16 AWG

14 AWG

12 AWG

14 AWG

12 AWG

B. Interrupteur ON/OFF (Marche/Arrêt)

C. Réarmement du disjoncteur

D. Moteur 15 A., 12 V

E. Poignée de réglage de la hauteur

F. 50,8 mm (2 po) Reversible Dust Port

G. Indicateur de la hauteur

A

B

C

D

E

F

G

DESCRIPTION FONCTIONNELLE

L'appareil DELTA® 22-555est uneraboteuse portativede 330mm (12-½po). Cetteraboteuse peutaccepter des

pièces de330 mm(12-½ po)de largeur aumaximum etde 152mm (6po) d'épaisseur. Laprofondeur decoupe

maximale est de 2,4 mm (3/32 po). L'appareil 22-555 est équipé d'un moteur de 15 ampères, 120 volts, un porte-outil

bilame avec lames réversibles à deux tranchants, un outil d'installation de la lame et une clé.

21

Page 22

CARACTÉRISTIQUES DU PRODUIT

4

Coupes par minute 18,800

Taux d’alimentation 8,5 m/min. (28 pi/min.)

Profondeur de coupe max. (par passage) 2,4 mm (3/32 po)

Largeur de coupe max. 330 mm (12-1/2 po)

Hauteur de coupe max. 152 mm (6 po)

Vitesse du porte-outil 9 400 T/M

Dimensions de l'outil (LxlxH) 549 mm x 600 mm x 511 mm

(21-5/8 po x 23-5/8 po x 20-1/8 po)

Moteur 15 A, 120 V

Poids net 26,3 kg (58 lb)

Type de lame Réversible à double tranchants

Nombre de lames 2

Taille de la lame (L x l x E) 320 mm x 12 mm x 1,5 mm

DÉBALLAGE

Comparez toutes les pièces à la liste ci-dessous et vérifiez que toutes les pièces sont présentes et en bon état. Signalez

toute pièce manquante ou endommagée à votre distributeur ou revendeur. Avant de passer à l’assemblage de l’appareil

et à son utilisation, lisez attentivement le présent manuel pour vous familiariser avec les procédures d’assemblage,

d’entretien et de sécurité appropriées.

DESCRIPTION (QUANTITÉ)

1. Raboteuse DELTA® Modèle n° 22-555 (1)

2. Poignée de réglage de la hauteur (1)

3. Reversible 50,8 mm (2 po) Dust Port (1)

4. Outil de transfert de la lame (2)

5. Llave en T (no se muestra)

MATÉRIEL

• Clé à 6 pans avec poignée en T de 4 mm

• Vis à tête hexagonale M5x16mm (1)

• Rondelle plate M5

• Bouton de verrouillage M6x15mm (2)

1

2

3

Retirez tout matériau de protection et tout enduit de protection de l’ensemble des éléments et de l'outil. Les enduits

de protection peuvent être enlevés en les pulvérisant de WD-40 et en les essuyant avec un chiffon doux. Il peut être

nécessaire de refaire cette étape plusieurs fois avant que tous les enduits de protection soient complètement enlevés.

S’il y a des pièces manquantes, n’essayez pas de brancher le cordon d’alimentation et de

mettre l’appareil en marche. L’appareil doit seulement être mis en marche (« ON ») quand toutes

les pièces auront été obtenues et correctement installées.

22

Page 23

MONTAGE

FIXER LA POIGNÉE DE RÉGLAGE

DE LA HAUTEUR

Consultez la Figure 1

1. Retirez le capuchon en caoutchouc (A) de la partie

supérieure de l'arbre à vilebrequin de réglage de la

hauteur (B).

2. Utilisez une vis à tête hexagonale M5 x 16 mm, une

rondelle plate M5, et la clé à six pans avec poignée

en T fournie pour fixer la poignée de réglage de la

hauteur à l'arbre (C).

3. Replacez le capuchon en caoutchouc.

FIXER L'ORIFICE RÉVERSIBLE

D'ÉVACUATION DE LA POUSSIÈRE

Consultez la Figure 2

La raboteuse 22-555 est équipée d'un orifice

d'évacuation de la poussière réversible qui peut

être monté à gauche ou à droite du dispositif de

dépoussiérage. Pour fixer l'orifice d'évacuation de la

poussière :

1. Fixez l'orifice d'évacuation de la poussière (A) aux

deux extrémités du logement de l'outil au moyen

des deux boutons de verrouillage M6 x 15 mm (B).

A

B

C

FIGURE 1

B

A

B

FIGURE 2

BRANCHER LE COLLECTEUR DE POUSSIÈRE

Une raboteuse génère une grande quantité de particules fines pendant son utilisation. Il est fortement recommandé

de raccorder la raboteuse à un aspirateur d'atelier ou un collecteur de poussière. Votre raboteuse d'établi DELTA® est

équipée d'un orifice d'évacuation de la poussière de 50,8 mm (2 po) qui doit être raccordé à un tuyau d'aspirateur pour

un fonctionnement sécuritaire. Vous pourrez raccorder votre raboteuse à la plupart des collecteurs de poussière qui

utilisent un tuyau de 101,6 mm (4 po) au moyen d'un adaptateur de 50,8 mm à 101,6 mm (2 po à 4 po) en option (vendu

séparément).

Ne faites pas fonctionner cet appareil sans d’abord l’avoir relié à un système adéquat de

collecte de la poussière.

Allumez toujours le collecteur de poussière avant de mettre en route la raboteuse et

arrêtez toujours la raboteuse avant d’éteindre le collecteur de poussière.

23

Page 24

FONCTIONNEMENT

A

DÉMARRER ET ARRÊTER LA RABOTEUSE

Assurez-vous que l’interrupteur est en position « OFF » (Arrêt) avant de brancher le

cordon dans la prise. Ne touchez pas aux broches métalliques de la fiche au moment

de brancher ou de débrancher le cordon.

En cas de panne de courant (comme un saut de disjoncteur ou de fusible), mettez

toujours l'interrupteur en position « OFF » (Arrêt) jusqu'à ce que le courant soit rétabli.

L’interrupteur ON/OFF (MARCHE/ARRÊT) (A), indiqué dans la figure 3, est situé à l'avant de l'armoire. Pour démarrer

l'appareil (« ON »), mettez l’interrupteur en position haute. Pour éteindre l'appareil (« OFF »), mettez l’interrupteur en

position basse.

VERROUILLER LA RABOTEUSE AU MOYEN DE LA CLÉ DE SÉCURITÉ

1. Cet appareil est équipé d'une clé de sécurité

(B), illustrée dans la figure 3, qui vous permet de

verrouiller l'outil en position « OFF » (arrêt) lorsqu'il

n'est pas utilisé.

IMPORTANT : Quand vous n’utilisez pas l’appareil,

l’interrupteur devrait être verrouillé en position « OFF »

(arrêt) pour empêcher une utilisation non autorisée.

2. Pour verrouiller l'appareil, retirez la clé de sécurité en

la tirant bien droit. Une fois la clé de sécurité retirée,

l’interrupteur ne fonctionnera plus.

3. Si la clé de sécurité est retirée durant le

fonctionnement de l’outil, l’appareil pourra être

positionné sur « OFF » (« ARRÊT ») mais ne pourra

être redémarré qu’en insérant à nouveau la clé de

sécurité.

RÉINITIALISER LE DISJONCTEUR INTÉGRÉ

Le DELTA® 22-555 est équipé d'un disjoncteur intégré (C), un

dispositif de sécurité supplémentaire illustré dans la figure 3. Si le

moteur subit une surcharge ou si une saute de puissance se produit

pendant le fonctionnement de l'appareil, le disjoncteur s'enclenche et

coupe ainsi l'alimentation de l'appareil.

Si le disjoncteur s'enclenche, faites ce qui suit :

1. Éteignez l'appareil et débranchez le cordon d'alimentation.

2. Soulevez le porte-outil et retirez la pièce de l'appareil.

3. Attendez 2 à 3 minutes ou jusqu'à ce que la cage du moteur soit

froide au toucher, puis appuyez sur le bouton de réinitialisation du

disjoncteur intégré.

4. Branchez le cordon d'alimentation et redémarrez l'appareil en

utilisant l'interrupteur ON/OFF.

5. Si l'appareil ne démarre pas, laissez le moteur refroidir plus

longtemps et essayez à nouveau de réinitialiser le disjoncteur.

RÉGLER LA HAUTEUR DE COUPE

Consultez la Figure 4

Votre raboteuse d'établi DELTA® 22-555 peut accepter

un matériel de 152 mm (6 po) de haut au maximum et

a une profondeur de coupe de 2,4 mm (3/32 po) au

maximum par passage. Pour régler la hauteur du porteoutil :

1. Tournez la poignée de réglage de la hauteur jusqu'à

ce que l'indicateur de la hauteur (A) indique la

hauteur souhaitée. Tournez la poignée dans le sens

des aiguilles d'une montre pour lever le porte-outil

et tournez la poignée dans le sens inverse pour le

baisser. Un tour complet de la poignée de réglage de

la hauteur déplace le porte-outil de 1,6 mm (1/16 po).

B

C

FIGURE 3

FIGURE 4

24

Page 25

FONCTIONNEMENT

ÉLIMINER UNE ENTAILLE

Une entaille est un petit creux créé au début et/ou à la

fin de la planche après qu'elle soit passée à travers la

raboteuse. La figure 5 illustre comment une entaille se

crée lorsqu'une planche entre dans la zone de coupe

de la raboteuse avec l'extrémité avant surélevée. Le

même effet peut se créer lorsque l'extrémité arrière de la

planche est surélevée au moment où la pièce sort de la

raboteuse.

Il y a peu de façons de contrôler une entaille.

Le plus souvent, une entaille se crée si la pièce n'est

pas totalement soutenue lorsque l'extrémité avant

entre dans la raboteuse et l'extrémité arrière sort de la

raboteuse. Ceci peut être évité en maintenant fermement

la pièce à la surface de la table d'entrée et en empêchant

l'extrémité avant de se soulever lorsqu'elle touche le

porte-outil.

Si, après avoir essayé la méthode ci-dessus, une

entaille est toujours présente, essayez de diminuer la

profondeur de coupe en augmentant légèrement

la hauteur du porte-outil (voir la section précédente,

« Réglage de la hauteur »).

Si la pièce présente toujours une entaille, vous devez

régler la hauteur de la table d'entrée et/ou de sortie.

Pour faire cela, consultez la figure 6, puis :

1. Pliez les tables d'entrée et de sortie afin de localiser

les deux vis d'arrêt d'entrée (A) et les deux vis d'arrêt

de sortie (B).

2. Au moyen d'une clé à fourche de 10 mm, desserrez

les écrous de serrage.

3. Réglez les vis d'arrêt, un jeu à la fois, en vous

assurant qu'elles sont à la même hauteur. Pour

vérifier la hauteur d'une vis, baissez la table et

confirmez que les deux têtes de vis sont alignées à la

partie inférieure de la table.

4. Réessayez pour voir si une entaille apparaît.

FIGURE 5

FIGURE 6

25

B

A

Page 26

ENTRETIEN

CHANGER OU INVERSER LES LAMES

Débranchez l’appareil de la

source d’alimentation avant

de faire des ajustements!

Les lames de la raboteuse sont

extrêmement tranchantes.

Soyez très prudent lorsque vous inspectez, retirez,

aiguisez ou remplacez les lames dans le porte-outil. Ne

pas suivre ces instructions peut provoquer une blessure

grave.

1. Retirez le capteur de poussière en dévissant les deux

boutons de verrouillage illustrés dans la figure 2.

2. Retirez les boutons de verrouillage qui fixent le

couvercle du porte-outil au coulage principal et

retirez le couvercle. Le porte-outil et les lames sont

désormais apparents.

3. Verrouillez le porte-outil en place. Pour se faire,

consultez la figure 7 et assurez-vous que l'attache de

verrouillage à ressort rouge (A) est en position avant.

Puis tournez prudemment et lentement le porte-outil

jusqu'à ce que l'attache soit verrouillée en place et

que le porte-outil ne bouge plus.

4. En utilisant la clé à 6 pans avec poignée en T fournie,

desserrez les six vis (B) qui fixent chaque barre de

maintien de la lame et la lame au porte-outil.

5. Utilisez l'embout magnétique de l'outil de retrait de

la lame (C) pour soulever prudemment la barre de

maintien puis la lame.

Les lames sont tranchantes! Soyez

très prudent lorsque vos mains se

situent autour de la zone de la lame!

6. Installez prudemment la nouvelle lame ou tournez la

lame existante, en vous assurant que les goujons sur

le porte-outil sont alignés aux trous allongés dans la

lame.

7. Replacez la barre de maintien, en vous assurant que

les deux goujons sur le porte-outil sont alignés avec

les deux petits trous dans la barre de maintien.

8. Replacez et resserrez les six vis.

9. Déverrouillez le porte-outil en déplaçant l'attache

de verrouillage à ressort rouge vers l'avant et en

tournant prudemment le porte-outil jusqu'à ce que

la deuxième lame apparaisse et que le porte-outil se

verrouille en place.

10. Pour remplacer le deuxième couteau, répétez les

étapes 4 à 8.

11. Replacez le couvercle du porte-outil. Assurez-vous

que les encoches dans le couvercle sont alignées

avec les trous filetés et que le couvercle est

totalement inséré dans le logement.

12. Replacez le capteur de poussière et refixez-le avec

les deux boutons de verrouillage.

C

A

B

FIGURE 7

AUTRE ENTRETIEN RECOMMANDÉ

1. Souffle périodiquement de l’air comprimé sec sur tous les conduits d’air. Toutes les pièces en plastique doivent

être nettoyées avec un chiffon doux humide. N'utilisez JAMAIS de solvant pour nettoyer les pièces en plastique. Il

pourrait dissoudre ou endommager le matériel à la longue.

2. Vérifiez périodiquement le serrage de la quincaillerie et guettez les vibrations inhabituelles lorsque vous travaillez car

elles peuvent indiquer qu'un matériel est desserré.

26

Page 27

ACCESSOIRES

Une gamme complète d’accessoires peut être obtenue auprès de votre fournisseur DELTAMD , des centres de

service du fabricant DELTAMD, et des centres de services agréés DELTAMD. Rendez-vous sur notre site Web www.

DeltaMachinery.com pour obtenir un catalogue en ligne ou pour connaître le nom du fournisseur le plus près de chez

vous.

Étant donné que les accessoires autres que ceux offerts par DELTAMD n’ont pas été testés

avec ce produit, leur utilisation pourrait s’avérer dangereuse. Pour assurer une utilisation

plus sécuritaire, seuls les accessoires recommandés par DELTAMD devraient être utilisés avec ce produit.

GARANTIE

Pour l’enregistrement de votre outil auprès du service de la garantie, rendez-vous sur notre site à l’adresse www.

DeltaMachinery.com.

GARANTIE LIMITÉE DE CINQ ANS

1. ÉLÉMENTS COUVERTS PAR LA GARANTIE. Delta Power Equipment Corporation (« l’Entreprise ») réparera ou remplacera, à sa discrétion,

toute machine ou pièce de rechange DELTAMD, neuve ou remise à neuf en usine, achetée d'un point de vente aux États-Unis ou au Canada et qui,

dans des conditions d'usage normal, est jugée défectueuse en raison d’un problème de fabrication ou de matériau, sous réserve des conditions

énoncées dans cette garantie limitée. Cette garantie limitée couvre uniquement les matériaux et la main-d’œuvre. Tous les coûts de transport

sont à la charge du client.

2. PÉRIODE DE GARANTIE. Toutes les réclamations de garantie doivent être soumises dans les cinq ans suivant la date d’achat du produit. Pour

toutes les pièces de rechange et machines DELTAMD remises à neuf en usine, la période de garantie est de 180 jours.

3. OBTENTION DU SERVICE. Pour bénéficier du service de garantie, vous devez retourner le produit défectueux, à vos frais, à un centre de service

agréé par l’Entreprise pour exécuter le service de garantie (un « centre de service agréé DELTAMD » pendant la période de garantie applicable,

avec une preuve d’achat acceptable, comme votre reçu original indiquant la date d’achat, ou le numéro d’homologation du produit. L’Entreprise

se réserve le droit de limiter le service de réclamation de garantie au pays où l’achat a été effectué et/ou de facturer le coût de transport des

pièces de rechange ou la fourniture du service de garantie dans un autre pays. Les achats en ligne sont considérés comme effectués aux ÉtatsUnis. Pour trouver le centre de service agréé DELTAMD le plus près de chez vous, appelez notre centre de service à la clientèle au (800) 223-7278.

4. EXCLUSIONS.

· L’Entreprise ne garantit pas les produits achetés dans un état usagé ou endommagé.

· L’Entreprise ne garantit pas les produits achetés en dehors des États-Unis ou du Canada

· L’Entreprise ne sera pas responsable de tout dommage découlant de l’usure normale, d’une mauvaise utilisation, d’un abus, d’une réparation

ou d’une altération faite par quiconque autre qu’un centre de service agréé DELTAMD ou un représentant désigné du centre de service à la

clientèle de l’Entreprise.

· TOUTES LES GARANTIES IMPLICITES sont expressément limitées à la période de garantie identifiée ci-dessus.

· En aucun cas, l’Entreprise ne sera tenue responsable des dommages ACCIDENTELS OU CONSÉCUTIFS.

· Cette garantie limitée est l’unique garantie de l’Entreprise et définit par la présente le recours exclusif du client en ce qui concerne les produits

défectueux; toutes les autres garanties, expresses ou implicites, de qualité marchande, de conformité aux besoins ou autre, sont formellement

rejetées par l’Entreprise, sauf indication contraire ci-dessus.

Certains États américains ne permettant pas l’exclusion ou la limitation des dommages accidentels ou consécutifs, ni la limitation des garanties

implicites, les limitations ou exclusions ci-dessus pourraient donc ne pas s’appliquer à vous. La présente garantie vous donne des droits légaux