DeLonghi AWR-MTD2-XEH, AWR-MTD2-XE-0031, AWR-MTD2-XE-0041, AWR-MTD2-XE-0051, AWR-MTD2-XE-0061 Installation, Operation And Service Manual

...

INSTALLATION - OPERATING - SERVICE MANUAL

Reverse-cycle air/water heat pumps with

domestic hot water production, axial-flow

fans and water pump assembly.

EN

AWR-MTD2-XE

0011÷0091

2 AWR-MTD2-XE EN 11/2010

U I A

User

Installer

Assistance

Important

Prohibition

Danger voltage

Danger high temperatures

INDEX

U I A

The manufacturer reserves the right to modify the data in this manual without warning.

Eurovent certification program.

The following symbols are used in this publication and inside the unit:

U

I

A

General warnings 3

Waiver of liability 3

Fundamental safety rules 3

Receiving and handling the product 4

Unit identification 5

Description of standard unit 6

Dimensioned drawings 7

Installation 7

Water connections 8

Electrical connections 11

Installer connections 12

Mains power supply connections 15

Installer connections 14

General technical data 32

Operating limits 33

Pump curve 34

Checking and starting up the unit 36

Description of room controller buttons and 38

display

Operation and functions of the room controller 39

Control and operating characteristics 48

System configuration 53

Maintenance and service 59

Peak limiter alarm signals 61

Shutting down for long periods 62

Scheduled maintenance 62

Unscheduled maintenance 63

Disposal 63

List of parameters 64

Installer operations CHECKLIST 66

U I A A

UUI A

I A

I

IU

I A

A

A

I

I

IIA

A

I A

I A

I A

I A

I A

I A

A

A

A

AIU

A

A

A

A

A

A

AIU

AIU

3EN 11/2010 AWR-MTD2-XE

GENERAL WARNINGS

U I A

FUNDAMENTAL SAFETY RULES

U I A

These appliances have been designed to chill and/or

heat water and must be used in applications compatible

with their performance characteristics; these appliances

are designed for residential or similar applications.

Incorrect installation, regulation and maintenance or

improper use absolve the manufacturer from all liability,

whether contractual or otherwise, for damage to people,

animals or things.

Only those applications specifically indicated in this list

are permitted

Read this manual carefully. All work must be carried

out by qualified personnel in conformity with legislation in

force in the country concerned.

The warranty is void if the above instructions are not

respected and if the unit is started up for the first time

without the presence of personnel authorised by the

Company (where specified in the supply contract) who

should draw up a “start-up” report.

The documents supplied with the unit must be consigned to the owner who should keep them carefully for

future consultation in the event of maintenance or service.

All repair or maintenance work must be carried out by

the Company’s Technical Service or qualified personnel

following the instructions in this manual.

The air-conditioner must under no circumstances be

modified or tampered with as this may create situations

of risk. Failure to observe this condition absolves the

manufacturer of all liability for resulting damage.

When operating equipment involving the use of electricity and water, a number of fundamental safety rules must be observed,

namely:

The unit must not be used by children or by unfit persons without suitable supervision.

Do not touch the unit with bare feet or with wet or

damp parts of the body.

Never perform any cleaning operations before having

disconnected the unit from the mains power supply.

Do not modify safety or control devices without authorisation and instructions from the manufacturer.

Do not pull, detach or twist the electrical cables coming

from the unit, even when disconnected from the mains

electricity supply.

Do not open doors or panels providing access to the

internal parts of the unit without first ensuring that the

switch QF1 is in the OFF position (see the wiring diagram).

Do not introduce pointed objects through the air

intake and outlet grills.

Do not dispose of, abandon or leave within reach of

children packaging materials (cardboard, staples, plastic

bags, etc.) as they may represent a hazard.

Respect safety distances between the unit and other

equipment or structures. Guarantee adequate space for

access to the unit for maintenance and/or service operations.

Power supply: the cross section of the electrical cables

must be adequate for the power of the unit and the power supply voltage must correspond with the value indicated on the respective units. All units must be earthed in

conformity with legislation in force in the country concerned.

Terminals 6, 7, 9, 10, 11, 12, 13, 21, 22, 23, 24, may be

live even after the unit is disconnected. Make sure power

is not connected before proceeding.

Water connections should be carried out as indicated in

the instructions to guarantee correct operation of the

unit. Add glycol to the water circuit if the unit is not used

during the winter or the circuit is not emptied.

Handle the unit with the utmost care (see weight distribution table) to avoid damage.

WAIVER OF LIABILITY

This publication is the sole property of Manufacturer. Any

reproduction or disclosure of such is strictly prohibited without the written authorisation of Manufacturer.

This document has been prepared with maximum care and

attention paid to the content shown. Nonetheless, Manufac-

turer waives all liability deriving from the use of such document.

Read this document carefully. All work must be performed,

components selected and materials used in complete accordance with the legislation in force in material in the country

concerned, and considering the operating conditions and

intended uses of the system, by qualified personnel.

U I A

4

AWR-MTD2-XE EN 11/2010

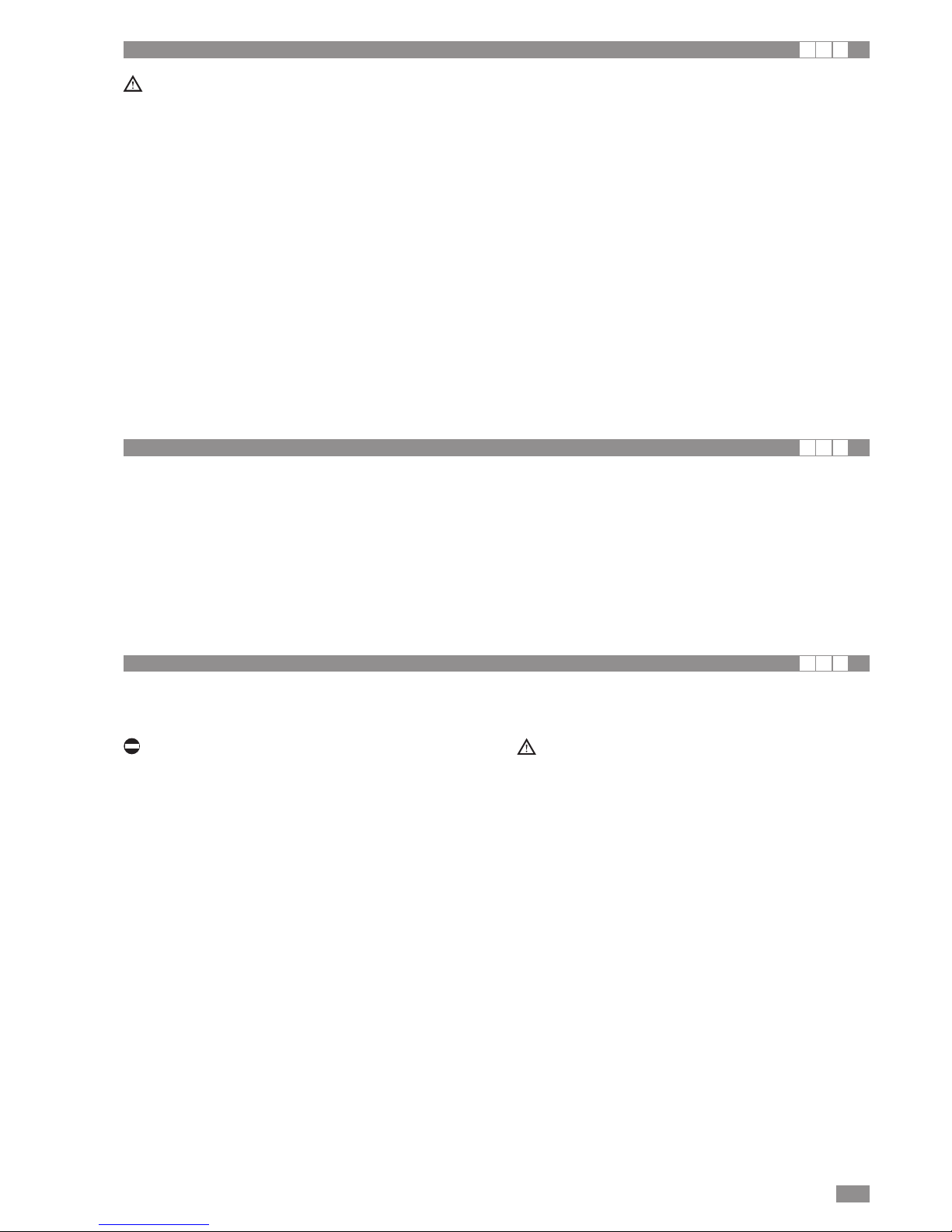

Dimensions 0011 0025 0031 0041 0051 0061 0091

Dimension L mm 970 970 970 970 970 1600 1600

Dimension P mm 525 525 525 525 525 610 610

Dimension H mm 1450 1450 1450 1600 1600 1360 1850

Gross weight Kg 165 170 175 190 200 275 360

VISUAL INSPECTION

When the items are consigned by the carrier:

- make sure that the goods delivered correspond to the

description on the delivery note, comparing this against

the data on the packaging label.

- make sure the packaging and the unit are intact.

If damage or missing components are noted, indicate this on

the delivery note. A formal complaint should be sent via fax

or registered post to the After Sales Department within eight

days from the date of receipt of the items.

HANDLING PACKAGED UNITS

The unit should always be handled by qualified personnel

using equipment adequate for the weight of the unit, in compliance with the safety standards in force (and subsequent

amendments).

• Lifting by forklift (1)

Insert the forks under the long side of base, opening the

forks as fare as possible.

• Lifting by crane (2)

Use slings with hooks suitable for the weight being lifted.

Secure the hook to the lifting bracket fixed to the unit, use

always four equal length slings, as shown in the figure, to

ensure the weight is balanced.

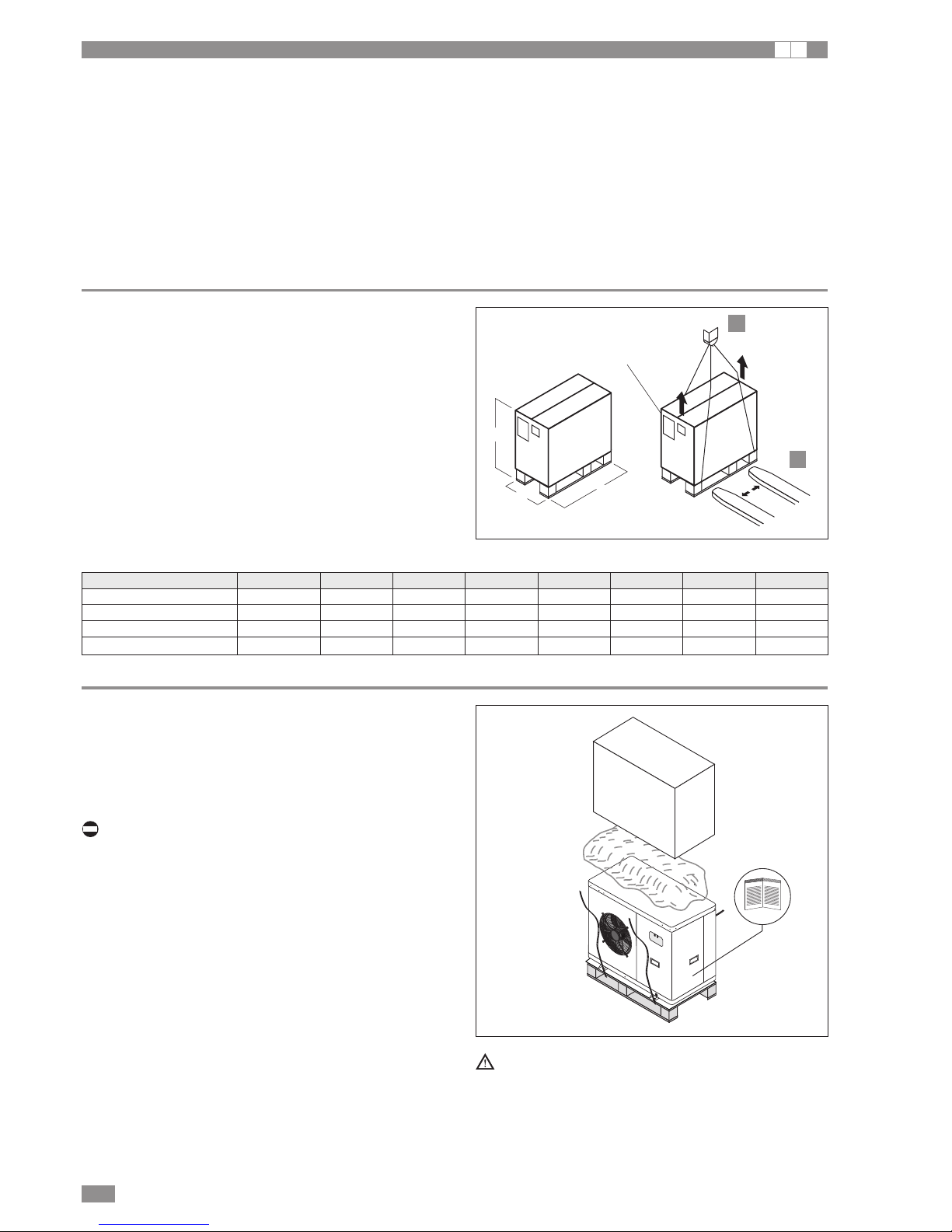

REMOVING THE PACKAGING

The packaging must be removed by the operator using suitable protective equipment (gloves, glasses, etc.).

Take special care not to damage the unit. Observe the local

standards in force as regards disposal of the packaging,

using specialist collection or recycling centres.

Do not dispose of packaging materials in the environment or leave them within reach of children as they may

represent a hazard.

Envelope A, located in the compressor compartment, contains:

• instruction manual;

• warranty certificate;

• CE declaration;

• list of the main components and sub-assemblies fitted on

the product

• remote room control unit A5 (must be installed)

• DHW storage water temperature probe BT8

• outside air temperature probe BT11 (must be installed)

• probe BT9 only to be installed when supplementary

source is available

Make sure the components listed above are not lost or misplaced.

The instruction manual is an integral part of the unit

and should therefore be read and kept carefully.

STORING THE UNITS

The units must be stored sheltered from direct sunlight, rain,

wind or sand.

Avoid exposing the units to direct sunlight, as the pressure

inside the refrigerant circuit may reach dangerous values

and cause the activation of the safety valves, where fitted.

The units cannot be stacked.

RECEIVING AND HANDLING THE PRODUCT

I A

H

P

L

Bar code

(compressor side)

A

1

2

5EN 11/2010 AWR-MTD2-XE

RECEIVING AND HANDLING THE PRODUCT

I A

HANDLING UNPACKAGED UNITS

When the packaging has been removed:

• Remove the wooden base.

• Fit the vibration damping feet (accessories).

• Handle the unit using equipment that is suitable for its

weight (forklift or crane), in compliance with the safety

standards in force (and subsequent amendments).

• Do not drag the unit as the feet may be damaged or break.

Hole Ø22

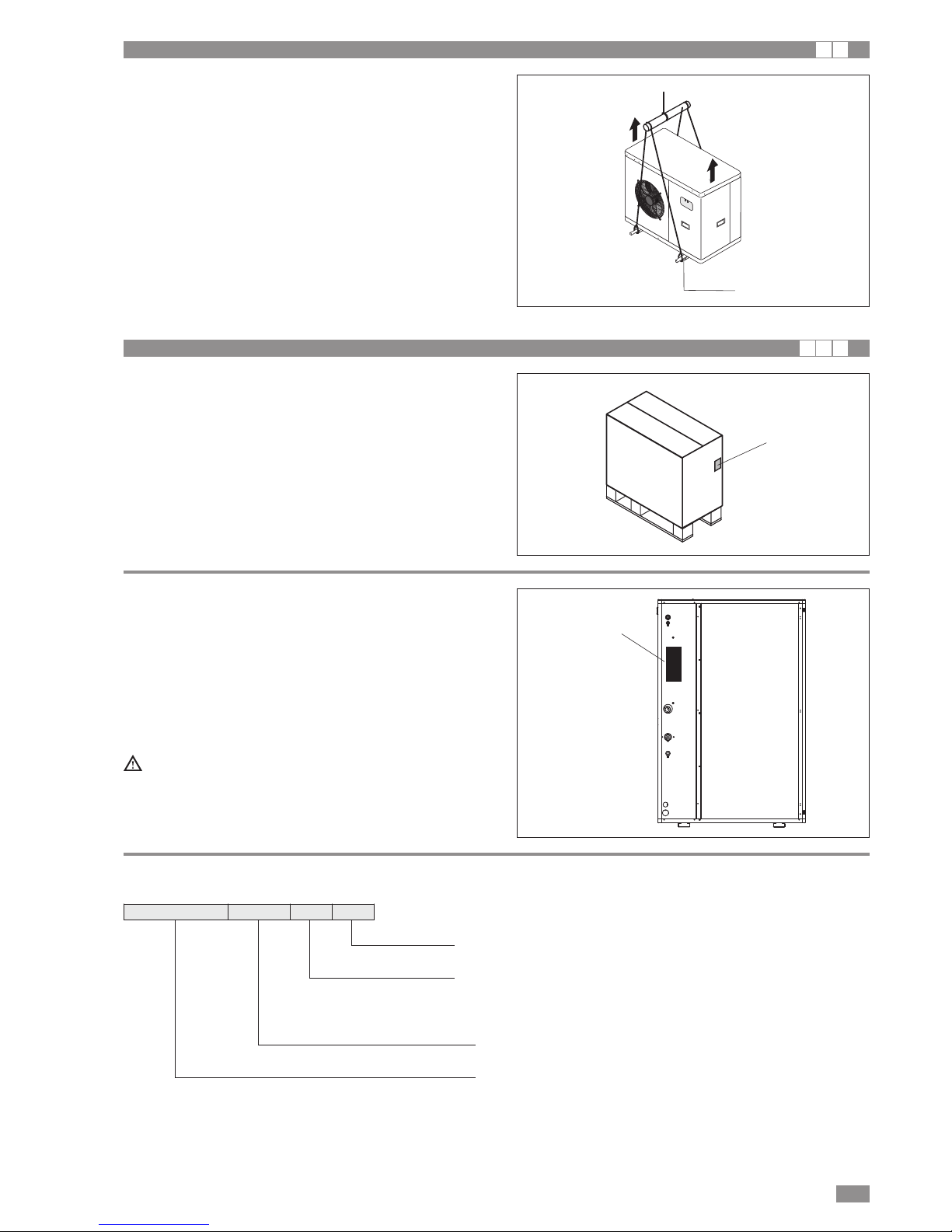

UNIT IDENTIFICATION

U I A

The heat pump can be identified from:

PACKAGING LABEL

Describes the product identification data

RATING PLATE

Describes the unit technical and performance specifications.

Shows the serial number used to uniquely identify the unit.

The serial number is also used to identify the unit’s spare

parts.

If service is required, the following information must be provided to the service centre:

Model, serial number, year of production.

Installation and maintenance operations are much more

difficult if the identification plates or anything else needed to clearly identify the product are tampered with,

removed or missing.

NOMENCLATURE

Packaging label

Rating plate

with serial number

AWR MTD2 XE 0011 m s

Power supply voltage:

m = 230V/50Hz/1ph

t = 400V/3N/50Hz

size

s = peak limiter

Model

6 AWR-MTD2-XE EN 11/2010

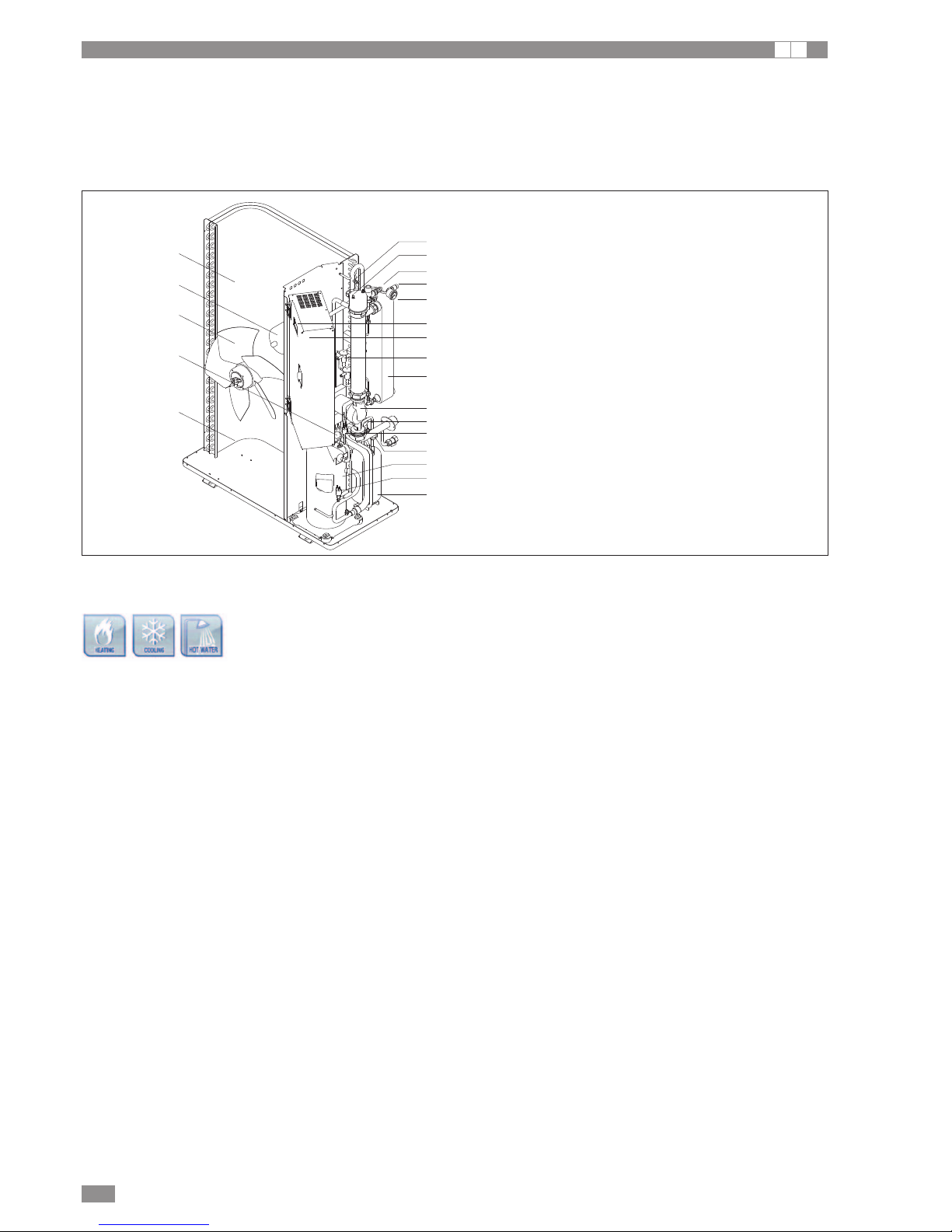

DESCRIPTION OF STANDARD UNIT

I A

These air cooled reverse-cycle chillers with axial-flow fans

operate with R410A refrigerant fluid and are suitable for outdoor installation.

The units are CE marked, as established by the EU directives,

including the latest amendments, and the corresponding

approximated national legislation.

They are factory tested and on site installation is limited to

water and electrical connections.

VERSIONS AVAILABLE

AWR-MTD2-XE

Reverse-cycle air/water heat pump with domestic hot water production. Built-in water pump assembly without electric heaters.

11

10

15

13

4

20

14

6

8

5

12

3

19

18

17

16

21

9

1

2

7

1 Electrical panel

2 NadiSystem controller

3 System plate heat exchanger

4 Low pressure switch

5 High pressure switch

6 Liquid sight glass (0041 - 0061)

7 Scroll compressor

8 Filter

9 Thermostatic valve

10 Axial-flow fan

11 Airside finned heat exchanger

12 Pump

13 Liquid recipient

14 Expansion vessel

15 Reversing valve

17 Safety valve

18 Air vent valve

19 Pressure gauge

20 Base electric heater

21 Pressure transducer

7EN 11/2010 AWR-MTD2-XE

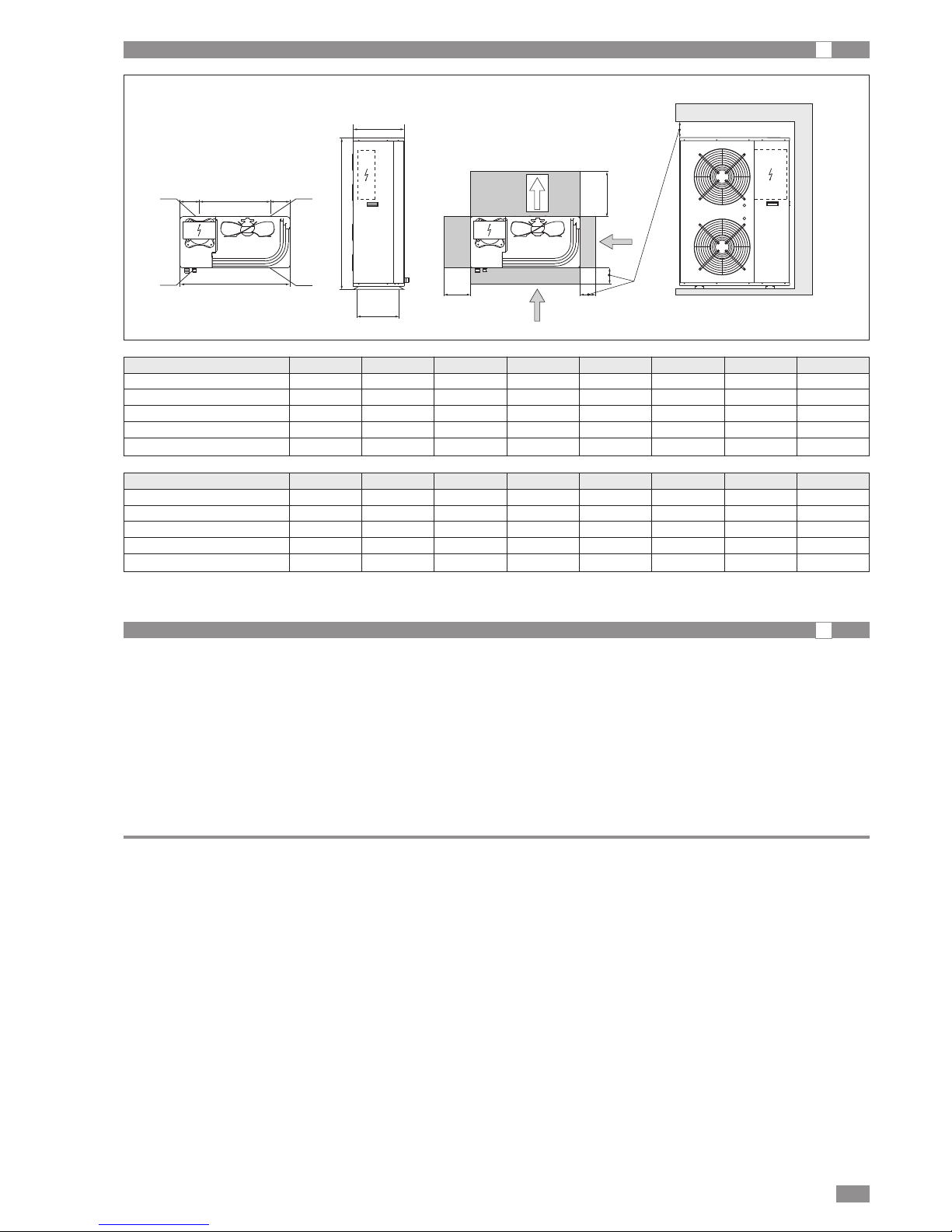

U I A

DIMENSIONED DRAWINGS

I

600

W1

W2

W4

W3

900

D

B

C

=E

A

=

400

Dimensions 0011 0025 0031 0041 0051 0061 0091

A mm 900 900 900 900 900 1550 1550

B mm 1240 1240 1240 1390 1390 1200 1700

C mm 420 420 420 420 420 450 450

D mm 370 370 370 370 370 497 497

E mm 580 580 580 580 580 1477 1477

Weight distribution 0011 0025 0031 0041 0051 0061 0091

W1 lato rear dx kg 60 62 64 67 71 88 117

W2 lato rear sx kg 17 18 20 23 24 39 54

W3 front sx kg 17 18 18 22 22 36 51

W4 front dx kg 51 52 53 58 63 87 113

tot kg 145 150 155 170 180 250 335

INSTALLATION

I

CHOICE OF INSTALLATION SITE

Before installing the unit, agree with the customer the site

where it will be installed, taking the following points into consideration:

• check that the support surface is adequate to support the

weight of the unit;

• respect safety distances between the unit and other equipment or structures so that the fan air intake and outlet are

not blocked in any way.

• Follow the instructions shown in the chapter on DIMENSIONED DRAWINGS to allow room for maintenance operations.

If installing multiple units the clearances must be doubled.

POSITIONING

• Install the vibration damping feet (accessories).

• Check the unit supports and weights before positioning

• Make sure that the unit is level, adjust the height of the

support feet if necessary

• Use the flexible joints supplied for the water connections

• Make sure there is easy access to the water circuit and

electrical parts

• For installation, if the site is exposed to strong winds, fix

the unit adequately using tie rods if necessary.

• In heating mode the unit produces a significant quantity of

condensate, which must be suitably drained.

Condensate drainage must not cause problems to objects

or people.

• If the outside air temperature is less than 0°C, the condensate may freeze; in these case fit a frost protection heater

on the drain line.

• Consider the maximum height that may be reached by

snow to avoid blocking the air intake or outlet (outdoor

installation)

• Unit for outdoor installation

For correct operation of the unit, avoid the following:

• obstacles to air flow, such as leaves that may block the

heat exchange coil

• strong winds that stop or reinforce air flow

• sources of heat too close to the unit

• air recirculation between intake and outlet

• poor air change

• stratification of air

8 AWR-MTD2-XE EN 11/2010

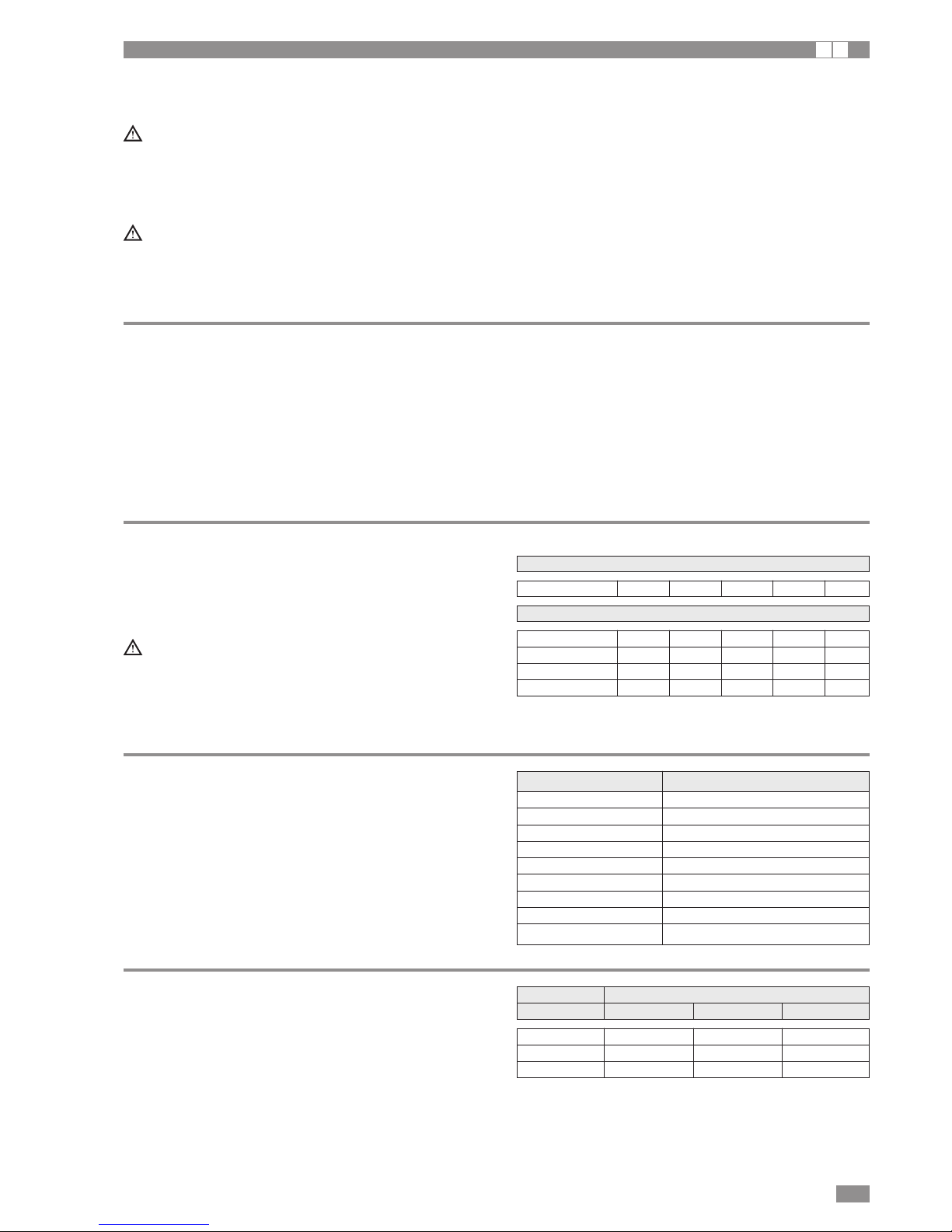

WATER CONNECTIONS

I A

Warnings

- The choice and installation of components is the responsibility of the installer who should follow good working practice and current legislation.

Before connecting the pipes make sure that these:

- do not contain stones, sand, rust, scale or any foreign

objects that may damage the system.

- wash the system with clean water

Water connection dimensions

Components

The following components should be installed for correct

installation of the unit:

1. Two pressure gauges with a suitable scale (inlet and outlet);

2. Two vibration damper joints (inlet and outlet).

3. Shut-off valves at the inlet and outlet.

4. A flow switch at the unit outlet on the system circuit

(compulsory). The flow switch must be calibrated by the

installer to a value equal to 70% of rated flow.

5. Two thermometers (inlet and outlet);

6. An inlet filter (compulsory) as close as possible to the

unit and positioned to allow easy access for scheduled

maintenance (both on the system circuit and domestic

hot water circuit).

7. All the pipes must be insulated with suitable material to

prevent the formation of condensate and heat loss.

The insulating material must be a vapour barrier.

Make sure that the control and shut off devices protrude

from the insulation.

8. At the lowest points in the system, install drain valves for

easy emptying.

9. At the highest points in the system, install automatic or

manual air vent valves.

10. The unit is fitted as standard with an expansion vessel;

make sure this is correctly sized for the water content of

the system and the expected operating temperature, otherwise install an additional expansion vessel.

D

100

B

C

528.5

563.5

A

A = C

D

EB

85

35

328

85

0011-0051

SAFETY VALVE

DISCHARGE

UNIT VENT

WATER INLET

WATER OUTLET

SYSTEM FILL G1/2

0061-0091

SYSTEM FILL G1/2

WATER OUTLET

WATER INLET

UNIT VENT

SAFETY VALVE DISCHARGE

OPENING FOR CONDENSATE DRAIN CONNECTION

Dimensions 0011 0025 0031 0041 0051 0061 0091

A mm 61,5 61,5 61,5 61,5 61,5 90,5 90,5

B mm 617 617 617 717,5 717,5 575 770

C mm 57 57 57 57 57 90,5 90,5

D mm 454,5 454,5 454,5 549,5 549,5 120 120

E mm - - - - - 560 551

Water in fittings Ø 1" 1" 1" 1" 1/4 1" 1/4 1" 1/4 1" 1/4

Water out fittings Ø 1" 1" 1" 1" 1/4 1" 1/4 1" 1/4 1" 1/4

9EN 11/2010 AWR-MTD2-XE

11. The connection piping should be supported in such a way

as to avoid it weighing on the unit.

Failure to install the flow switches will mean the heat

exchangers are not protected in the event of no flow of

liquid. The Manufacturer cannot be held liable for any

damage to the unit and/or the system following the failure to install these devices or the filter.

The correct operation of the components that help

ensure the safety of the appliance and the system

should be checked regularly:

• make sure the filters are clean

• check operation of the flow switches installed.

• Make sure that the frost protection heaters on the heat

exchanger are powered when the unit is OFF

Water flow to the heat pump must conform to the values

shown in the section on “General Technical Data”.

The flow of water must be maintained constant during operation.

The water content of the unit must be such as to avoid disturbing operation of the refrigerant circuits.

Risk of freezing

The unit must be prevented from freezing at outside air temperatures around 0°C.

The following are recommended:

• use suitable percentages of antifreeze (see “Ethylene glycol solutions”)

• protect the piping with heating sheaths,

• empty the system, making sure no water remains at the

lowest points in the circuit or there are closed valves

where water may stagnate.

It is recommended to use non-toxic food grade antifreeze,

compliant with the standards in force in the countries where

the unit is used, if domestic hot water production is also featured.

The antifreeze used must be corrosion inhibited and compatible with the water circuit components.

Ethylene glycol solutions

Water and ethylene glycol solutions used as a heat carrier in

the place of water reduce the performance of the unit.

Multiply the performance figures by the values given in the

following table.

The heat pumps must be fitted with a filling/top-up system connected to the return line and a drain valve in the

lowest part of the system.

Systems containing antifreeze or covered by specific

legislation must be fitted with low-loss headers.

cPf

cQ

cdp

0

1

1

1

12%

0,985

1,02

1,07

20%

0,98

1,04

1,11

28%

0,974

1,075

1,18

35%

0,97

1,11

1,22

40%

0,965

1,14

1,24

0 -5 -10 -15 -20 -25

Freezing point (°C)

Percentage of ethylene glycol by weight

cPf: cooling capacity correction factor

cQ: flow rate correction factor

cdp: pressure drop correction factor

Fouling factors

The performance data given refer to conditions with clean

evaporator plates (fouling factor = 1).

For different fouling factors, multiply the figures in the performance tables by the coefficient given in the following table.

f1: capacity correction factor

fk1: compressor power input correction factor

fx1: total power input correction factor

4,4 x 10

-5

0,86 x 10

-4

1,72 x10

-4

0,96

0,93

0,99

0,98

0,99

0,98

Fouling factors

(m2°C/W) f1

Evaporator

fk1 fx1

Water quality

The water used in the system and domestic hot water circuits must comply with the following characteristics:

PH 6-8

Electrical conductivity less than 200 mV/cm (25°C)

Chlorine ions less than 50 ppm

Sulphuric acid ions less than 50 ppm

Total iron less than 0.3 ppm

Alkalinity M less than 50 ppm

Total hardness less than 50 ppm

Sulphur ions none

Ammonia ions none

Silicon ions less than 30 ppm

WATER CONNECTIONS

I A

10 AWR-MTD2-XE EN 11/2010

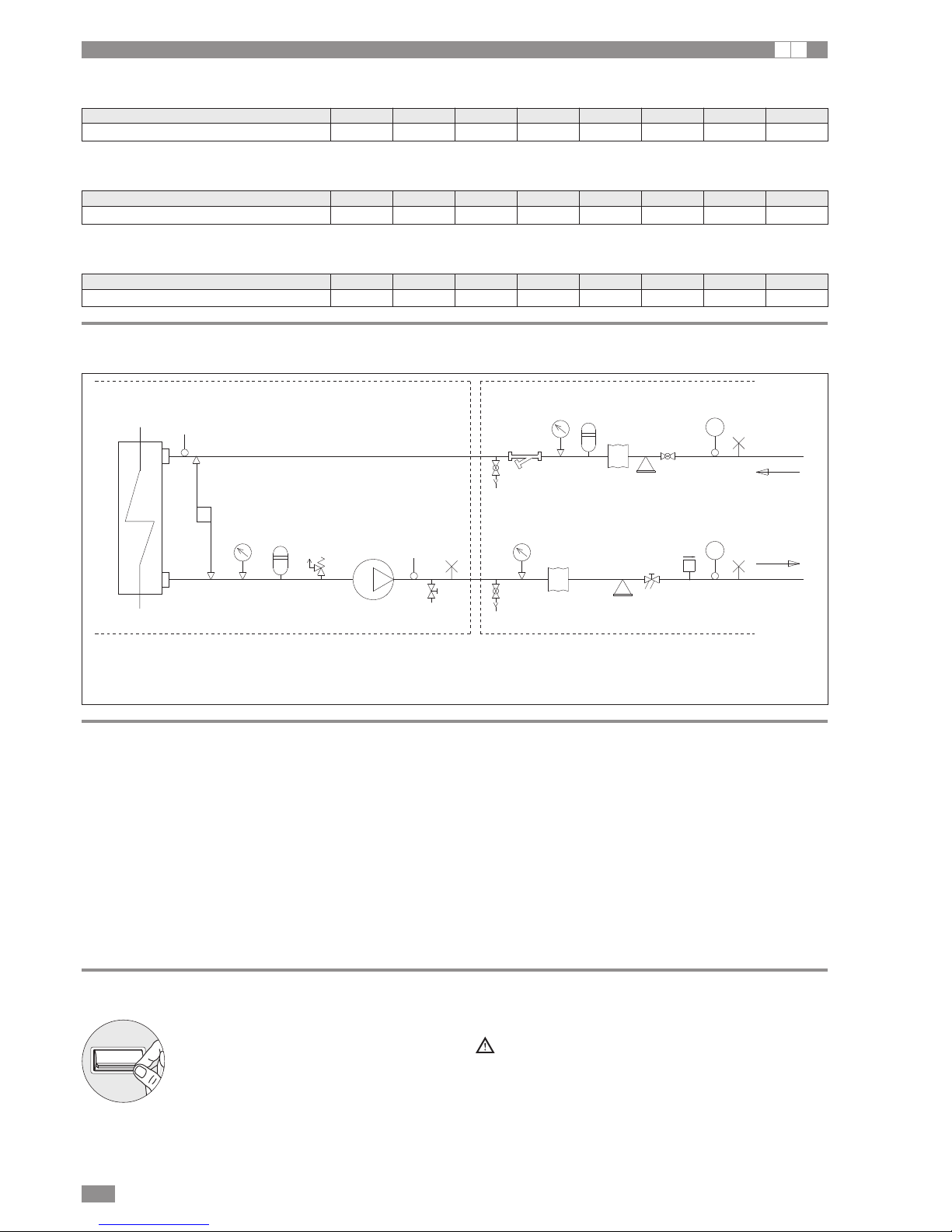

WATER CONNECTIONS

I A

Water content in the system

Size 0011 0025 0031 0041 0051 0061 0091

Minimum water content l 24 31,5 40 46 65 74 110

Expansion vessel size

Size 0011 0025 0031 0041 0051 0061 0091

Expansion vessel l 2222244

Safety valve calibration

Size 0011 0025 0031 0041 0051 0061 0091

Safety valve bars 6666666

Factory connections Installer connections

1

2

12

12

13

14

14

UTILITY

RETURN

UTILITY

OUTLET

9

8

7

16

3

11

T

6

15

16

T

6

F

5

4

2

10

1

1

9

Utility water circuit connection diagram

1 Pressure gauge

2 Vibration damper joint

3 Shut off valve

4 Calibrating valve

5 Flow switch

6 Thermometer

7 Pump

8 Safety valve

9 Expansion vessel

10 Wire mesh filter

11 Unit fill/drain valve

12 Temperature sensor

13 Differential pressure switch

14 Drain / chemical washing valve

15 System vent

Condensate drain

In heating mode the unit produces a significant quantity of

condensate, which must be suitably drained.

Proceed as follows:

• Connect the unit condensate drain

• Make sure the drain hose has a incline of at least 2 cm/m,

without obstructions or choking.

• Connect the condensate drain hose to a rainwater drain.

Do not connect to the sewage system as odours may be

sucked up if the water in the drain trap evaporates.

• After connecting, check correct drainage of the condensate by pouring water into the pan.

• If necessary, suitably insulate the condensate drain hose.

• Condensate drainage must not cause problems to objects

or people.

• If the outside air temperature is less than 0°C, the condensate may freeze.

The unit comes with frost protection for the condensate collection basin inside the unit.

Use hot wires on the condensate drain hose downstream of

the unit to protect against frost.

FILLING THE SYSTEM

- Before starting to fill, place the unit mains

switch QF1 in the OFF position.

- Before filling, check that the system drain

valve is closed.

- Open all system and terminal air vents.

- Open system shut off valves.

- Start filling by slowly opening the system water fill valve outside the unit.

- When water begins to leak out of the terminal air vent valves,

close them and continue filling until the pressure gauge indicates a pressure of 1.5 bar.

The system must be filled to a pressure of between 1

and 2 bars.

It is recommended that this operation be repeated after

the unit has been operating for a number of hours. The

pressure in the system should be checked regularly and

if it drops below 1 bar, the water content should be

topped-up.

Check the tightness of the joints.

ON

OFF

11EN 11/2010 AWR-MTD2-XE

ELECTRICAL CONNECTIONS

I A

The heat pumps must be installed downstream of a main

switch (QF1, see wiring diagram), as required by the standards in force in the country where the unit is installed. Connection to the mains power supply and the connection of the

flow switch to the corresponding terminals must be performed by authorised personnel in compliance with the standards in force.

For all electrical work, refer to the electrical wiring diagrams

in this manual.

It is also recommended to check that:

- The characteristics of the mains electricity supply are adequate for the power ratings indicated in the electrical specifications below, also bearing in mind the possible use of

other equipment at the same time.

Power to the unit must be turned on only after installation work (plumbing and electrical) has been completed.

All electrical connections must be carried out by qualified personnel in accordance with legislation in force in

the country concerned

Respect instructions for connecting phase, neutral and

earth conductors..

The power line should be fitted upstream with a suitable

device to protect against short-circuits and leakage to

earth, isolating the installation from other equipment.

Voltage must be within a tolerance of ±10% of the rated

power supply voltage for the unit (for three phase units,

the unbalance between the phases must not exceed 3%).

If these parameters are not respected, contact the electricity supply company.

For electrical connections, use double insulation cable

in conformity with legislation in force in the country concerned..

A thermal overload switch and a lockable mains disconnect switch, in compliance with the CEI-EN standards (contact opening of at least 3mm), with adequate switching and residual current protection

capacity based on the electrical data table shown

below, must be installed as near as possible to the

appliance.

An efficient earth connection is obligatory.

The manufacturer cannot be held liable for any damage

caused by the failure to correctly earth the unit.

In the case of three phase units, ensure the phases

are connected correctly.

Do not use water pipes to earth the unit.

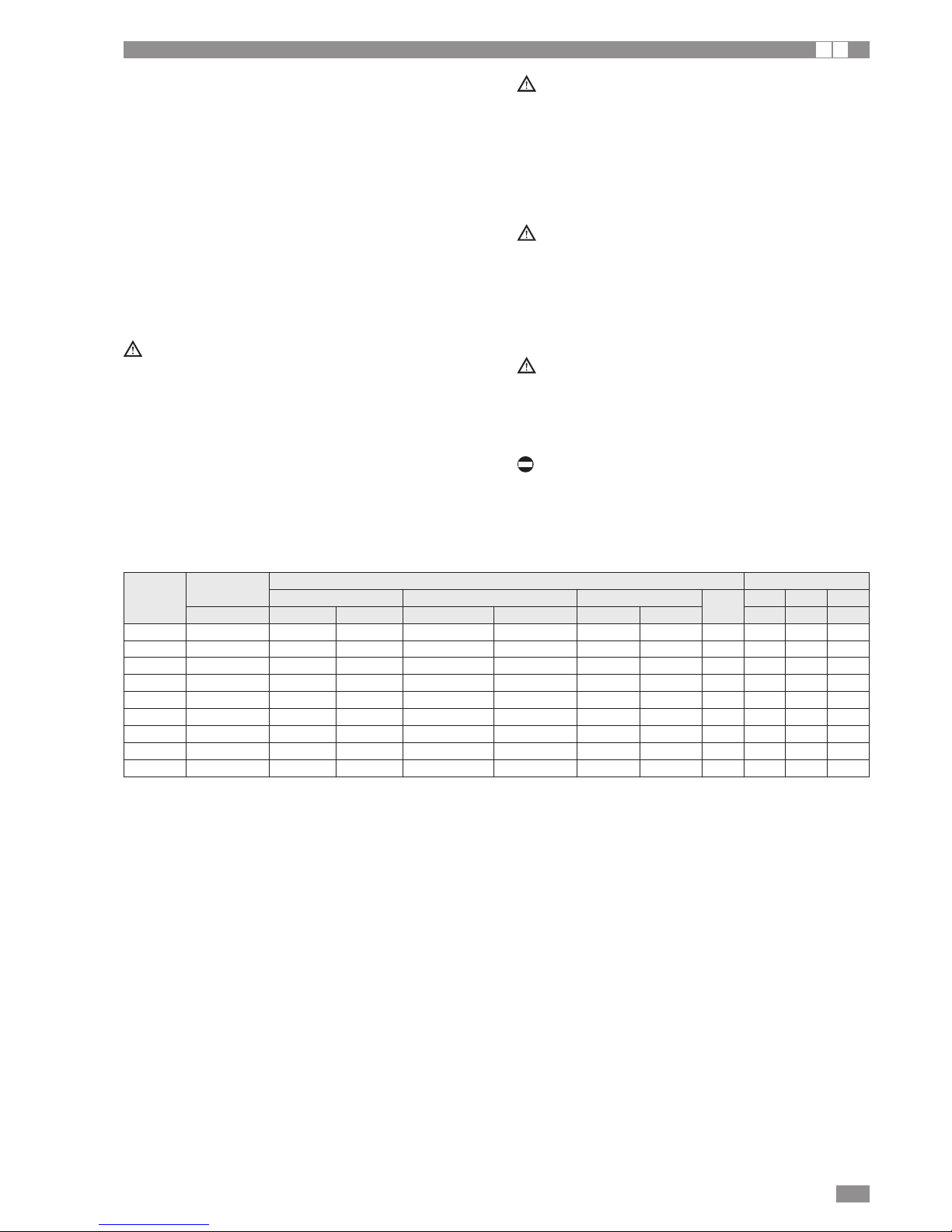

Electrical data at maximum conditions allowed (full load)

F.L.I. Maximum power input

F.L.A. Maximum current input

L.R.A. Start-up current

Maximum values for sizing the protection switches and power supply cables.

Size

Power

supply

Maximum values Fuses

(5x20T 250V)

Heater

Power consumption without heater

Total power consumption

L.R.A.

[A]

FU1 FU5 FU6

(V-Ph-Hz) P MAX [kW] I MAX [A] P MAX TOT [kW] I MAX TOT [A] F.L.I. [kW] F.L.A. [A] [A] [A] [A]

0011ms 230-1N-50 - - - - 2,82 13,5 27 1,6 4 1,25

0025ms 230-1N-50 - - - - 3,56 16,7 30 1,6 4 1,25

0031ms 230-1N-50 - - - - 5,11 23,6 45 1,6 4 1,25

0041ms 230-1N-50 - - - - 6,15 30,1 45 1,6 4 1,25

0031t 400-3N-50 - - - - 4,76 10,0 48 1,6 4 1,25

0041t 400-3N-50 - - - - 6,38 12,4 64 1,6 4 1,25

0051t 400-3N-50 - - - - 6,43 12,7 64 1,6 4 1,25

0061t 400-3N-50 - - - - 7,77 14,8 75 1,6 4 1,25

0091t 400-3N-50 - - - - 10,86 24,6 111 2 4 1,25

12

AWR-MTD2-XE EN 11/2010

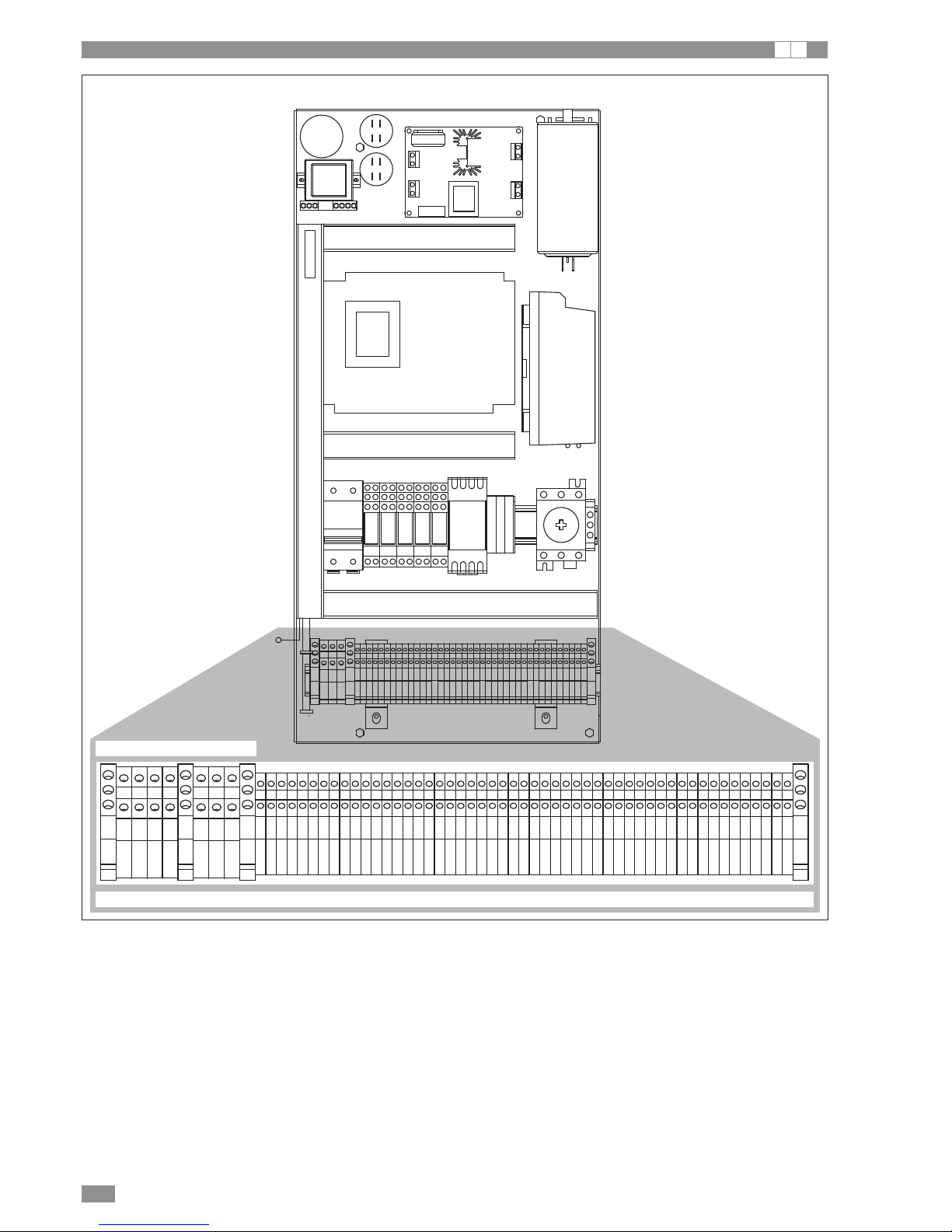

INSTALLER CONNECTIONS

I A

PE

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55

C90051683E_00

A4

A2

FU3

C1

A1

C2

C3

A3

QS1

QM1

KA1

KA1

KA6

KA7

KA15

FU1

FU5

FU6

A7

TC1

INSTALLER TERMINAL BLOCK

Power supply

13EN 11/2010 AWR-MTD2-XE

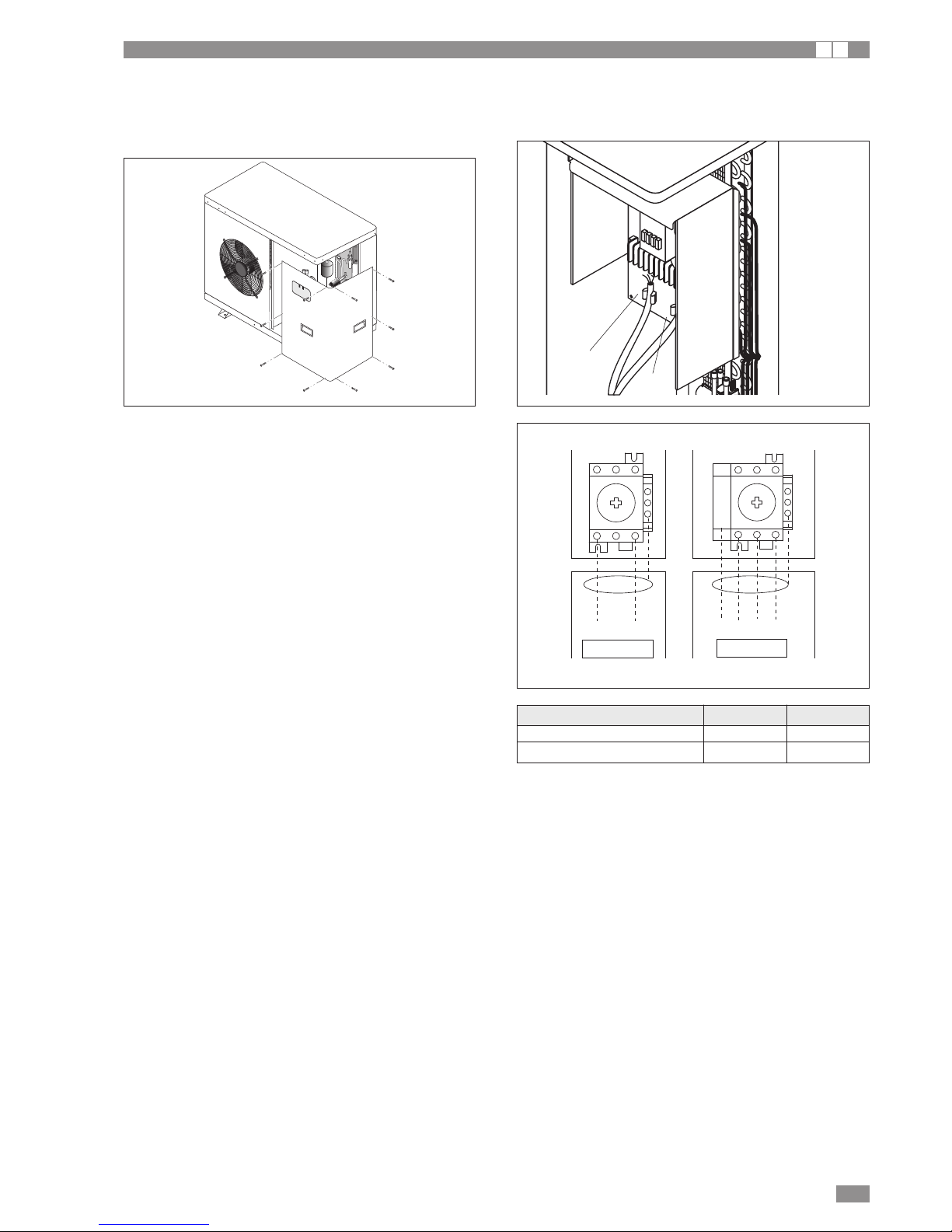

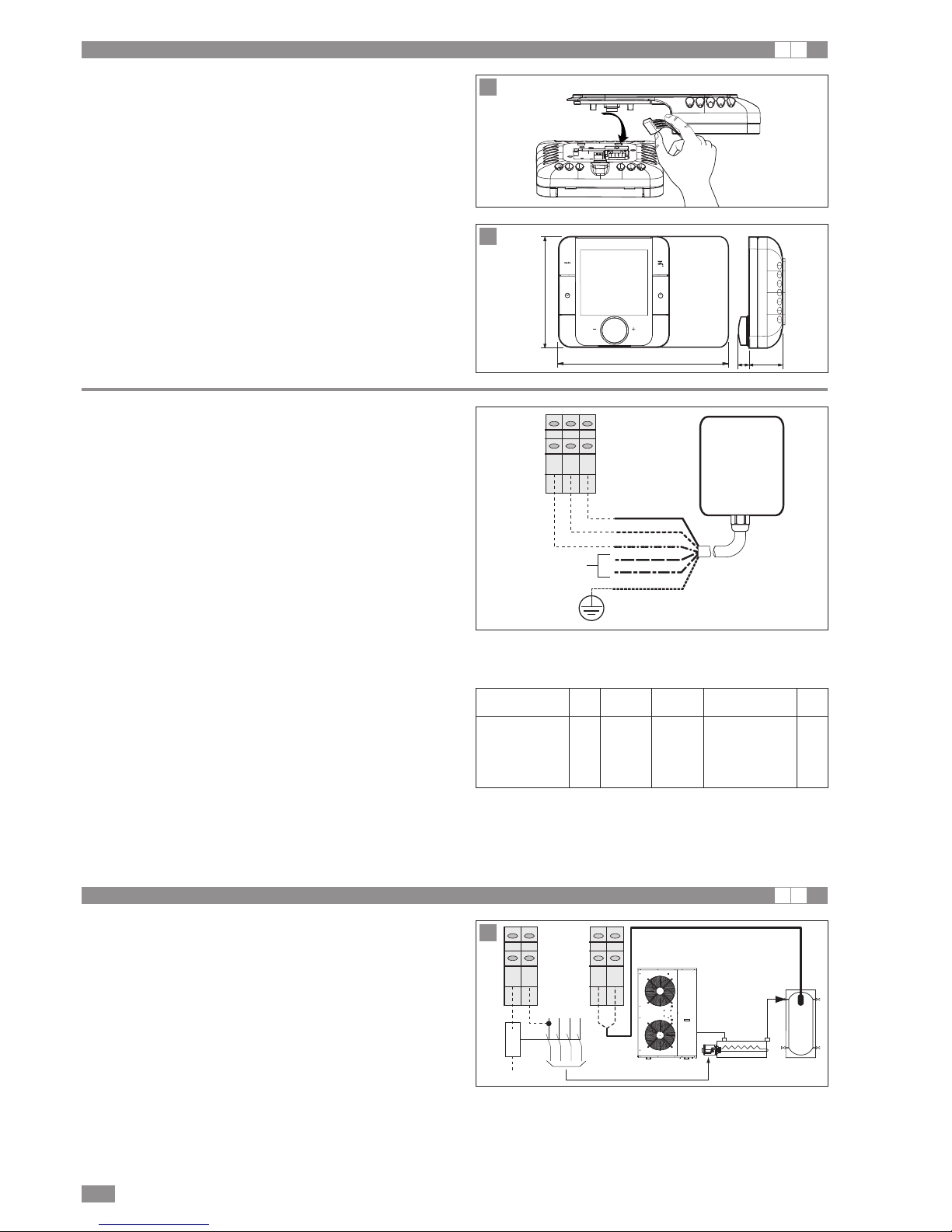

MAINS POWER SUPPLY CONNECTIONS

I A

AWR MTD2 XE heat pump terminal block

Installer connections

UVWN

400V - 3N ~50Hz

U N

PE

230V - 1Ph - 50Hz

QS1

QS1

• Before connecting the unit to the power supply, makes

sure that switch QF1 is open, suitably padlocked and

marked.

• Remove the inspection panel by unscrewing the screws.

• Use cable gland A for the main electrical power cable and

cable gland B for other external cables to be connected by

the installer.

• Identify the terminals used for electrical connections on

the layout drawing shown in this manual.

• Make the connections as shown in the wiring diagram provided in this manual.

• The figures show the power supply connection terminals

for 230V and 400V.

• Replace the covers on the electrical panel and the closing

panel.

• Make sure that all the covers removed to make the electrical connections have been replaced before powering up

the unit.

• Position the main switch QF1 (outside the unit) in the “ON”

position.

• Once the remote terminal has been switched on, “OFF”

and “init” are displayed.

• The room unit is ready to use after a few seconds, when

“init” is shown and the clock is displayed

A

B

* Compliant with standards in force in the place where the unit is installed

Power supply 230V 400V

Number of power wires 2 + PE 4 + PE

Power wire size* 6 mmq 6 mmq

14 AWR-MTD2-XE EN 11/2010

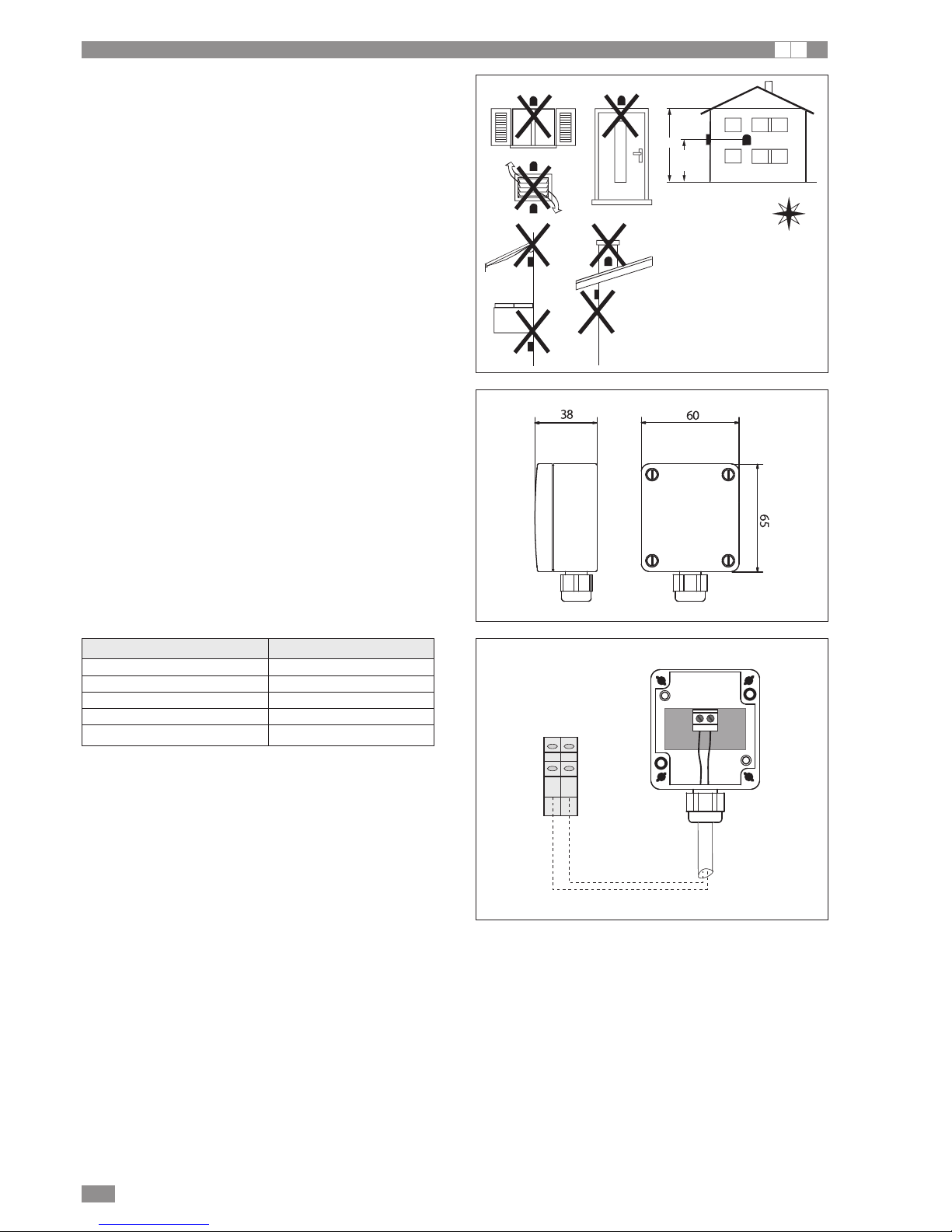

Outside air probe (BT11) connection

The outside air probe allows the system water temperature

set point to be compensated during heating or cooling operation.

Installation instructions

The outside air probe must be installed:

• outside of the home

• not in direct sunlight, away from flue gas discharges, air

outlets, or doors and windows.

• on a perimeter wall facing north/north-west

• at a minimum height of 2.5 metres above the ground or at

most half way up the house.

H

H

2

/

1

N

N-W

m 5,2nim

Mounting method:

• Open the cover of the sensor.

• Attach a probe to the wall and the correct position as

described above.

• For the electrical connections see “Connection diagram”.

• Re-place the cover of the sensor.

INSTALLER CONNECTIONS

I A

12

45 46

BT11

TECHNICAL DATA

Sensing element NTC 10Kohm ± 1% (25°C)

Degree of protection IP65

Perm. ambient / carriage temperatur

e -50°C...+100°C

Measuring range -50°C...+100°C

Materials PA 15% GK, Colour RAL 9010

15EN 11/2010 AWR-MTD2-XE

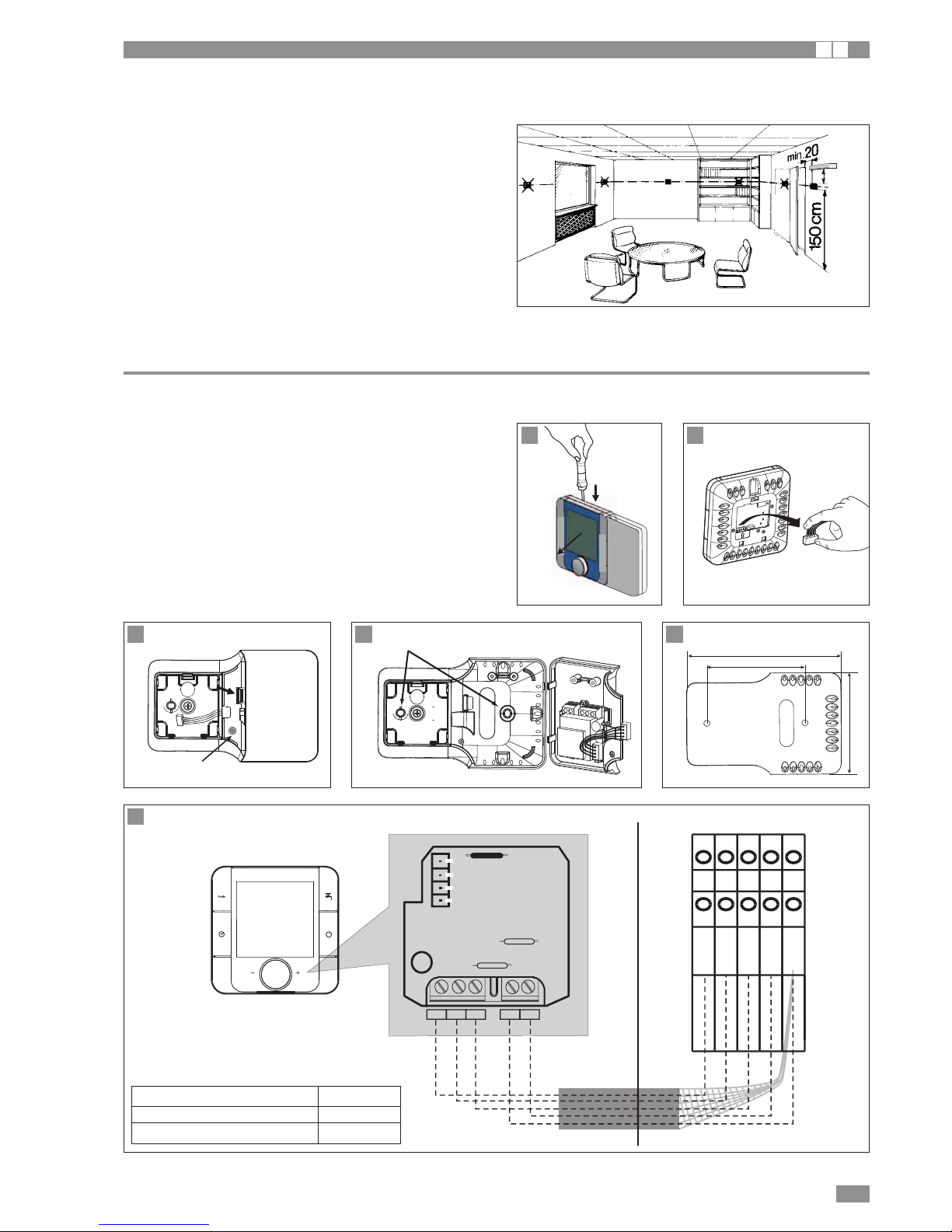

A5 room controller connection

Installation instructions

The room controller must be installed in the best reference

position for temperature control.

Position the room controller as follows:

• around 1.5 metres from the floor, in a part of the room that

allows the sensor to accurately measure the room temperature;

• away from cold air flows, sunlight or other sources of heat.

• leave enough space above the room controller to allow

assembly and removal where necessary.

• If the room controller is removed from its base, it disconnects from the power supply and consequently is no

longer operating.

min.

10 cm

Installation procedure

Assembly

• Separate the front from the rear of the terminal using a

screwdriver r (1)

• Disconnect the 4-pin connector from the front part (2)

• Remove the cover A1, unscrewing the screw A2 (3).

• Fix the controller support to the wall using the holes A3

(4). Support hole size and spacing in figure (5).

• Make the electrical connections as shown in the figure (6),

also see the wiring diagram.

A2

A1

A3

A3

E

131

83,5

86

51

52 53 54 55

TxRx -

TxRx +

GND

24 VAC

GND

A5 room controller terminal block Installer terminal block

Number of wires 5 shielded

Power supply wire size 0.5 mm

2

Maximum distance 500 m

1

3

6

4 5

2

INSTALLER CONNECTIONS

I A

16 AWR-MTD2-XE EN 11/2010

INSTALLER CONNECTIONS

I A

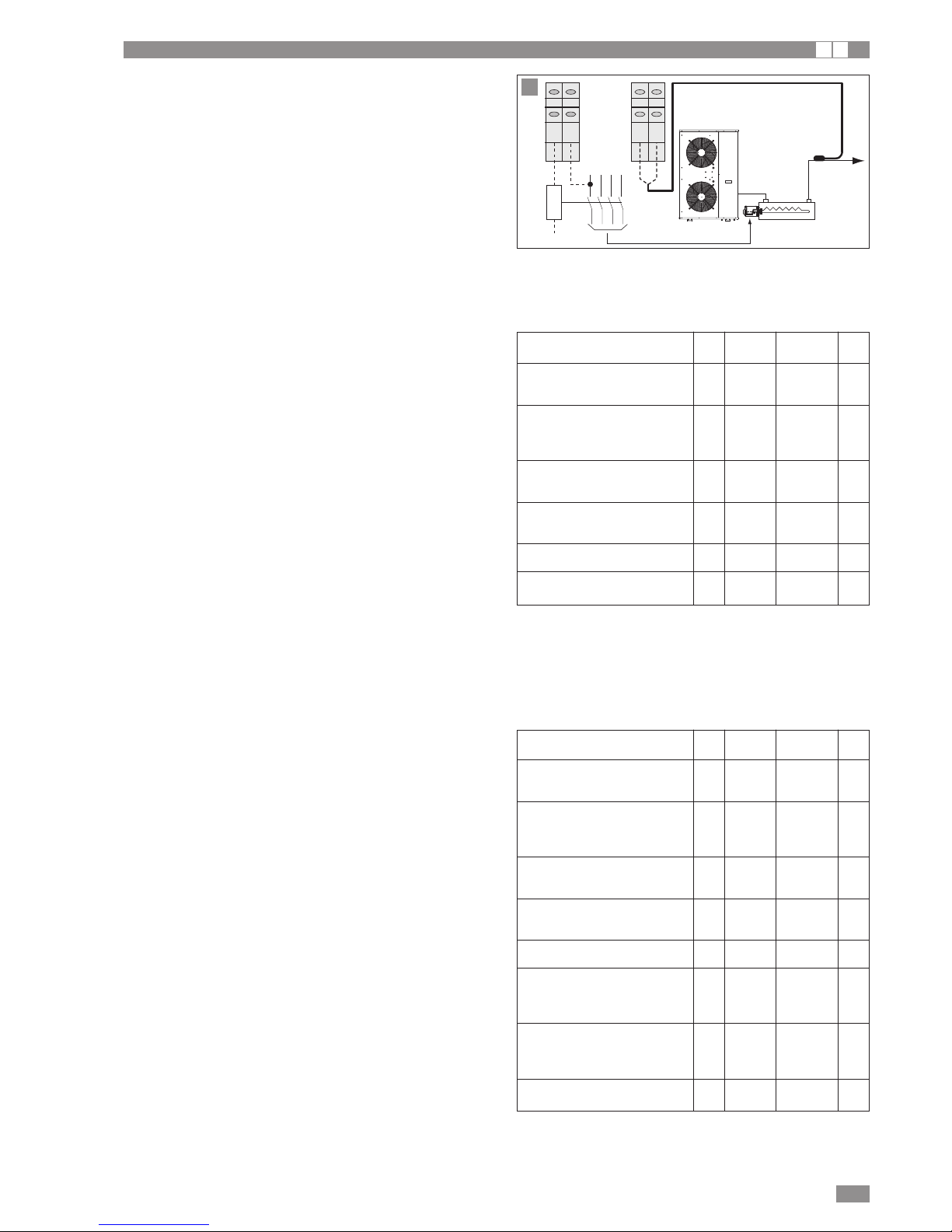

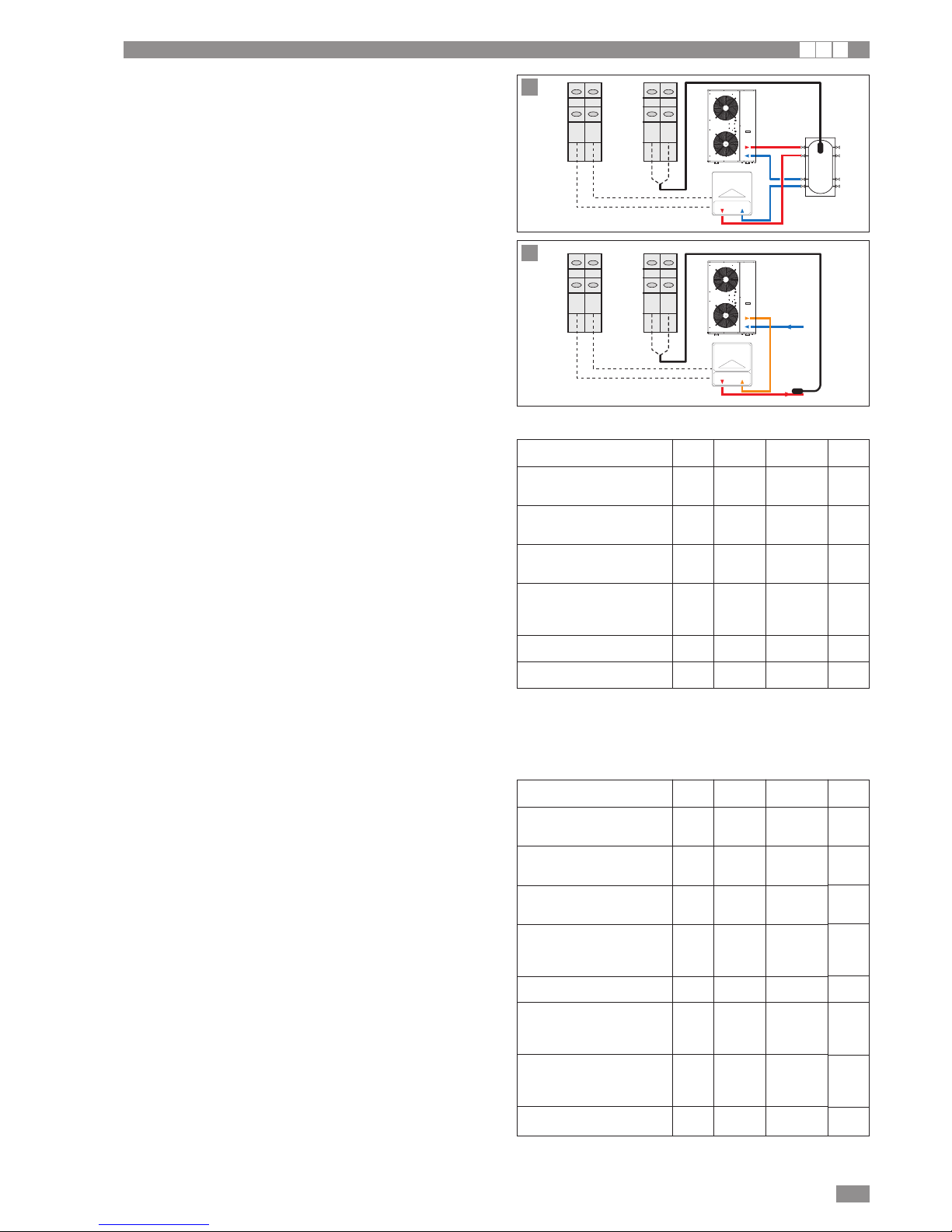

YV5 3-way valve for domestic hot water production

The 3-way valve installed outside of the unit deviates the

flow of hot water produced by the unit to the DHW storage

tank.

During domestic hot water production, the cooling/heating

demand is not satisfied.

Wire the three-way valve supplied as an accessory by Manufacturer following the instructions shown in the figure.

The valve is also fitted with a limit switch. The limit switch

contact is either closed or open based on the position of the

valve.

Limit switch (red and green wires):

Auxiliary contact closed = Valve open

Auxiliary contact open = Valve closed

If not supplied by Manufacturer, the 3-way valve for domestic hot water production should have the following characteristics:

• Voltage 230V AC, 50/60 Hz

• Opening/closing time 10s.

• Delta P 500 kPa

• Fluid temperature 0°C to 90°C

Use three-way valves with pressure drop below 20 kPa.

For further details see the chapter “Operating characteristics”.

If three-way valves with a travel time greater than 10 seconds are used, modify the setting of parameter 0231

• Close the cover A1 and secure it with the screw A2

• Plug in the 4-pin connector, figure (7)

• Replace the terminal, starting with the lower tabs, applying

a hinge movement. Make sure that the electrical wires are

inside to ensure correct fastening (click on).

• Dimensions of A5 room controller figure (8).

68

8 28

143

Wall

7

8

9 12 13

YV5

Yellow/Green

Red

Blue

Green

Black

Brown

Auxiliary contact

INSTALLER CONNECTIONS

I A

43 44

6 7

230V / 400V

BT9

N

1

Description

Three-way valve

travel time for

domestic hot water

production

Menu

Mn02

Parameter

no.

0231

Default

12

Value to be set

Set the travel time

for valves not

supplied by the heat

pump manufacturer

UOM

sec.

Optional connection

KM2 System outlet electric heater

An electric heater installed at the outlet can be activated as

a supplementary heater for the system.

Solution 1

System with heat pump and electric heater with storage

tank.

Position probe BT9 in the storage tank.

17EN 11/2010 AWR-MTD2-XE

INSTALLER CONNECTIONS

I A

B) SUPPLEMENTARY: the electric heater operates in sup-

plementary heating mode, together with the compressor, to

satisfy the heating load.

Supplementary heating for low outside air temperature

The electric heater is enabled only when the outside temperature is less than the value of parameter 0304, figure 3.

To enable supplementary heating for low outside air temperature set parameter 0303 = 1 and 010G = 0

Electric heater operation reflects the trend in water outlet

temperature, as shown on the graph in figure 4.

Description

Activation electrical heater

0 = Electrical Heater not enabled

1 = Electrical Heater enabled

Type of outlet electric heater operation

0 = Supplementary

1 = Replacement

Enable boiler

0 = Boiler not enabled

1 = Boiler enabled

Activation with low outside air temperature

0 = Function not enabled

1 = Function enabled

Outside air temperature to enable electric heater

Minimum outside air temperature for

heat pump operation (make sure the

value set is the same as shown in the

table)

Electric heater delay time (allows the

heat pump to reach steady operation

and thus avoid activating the heater

when not needed)

Integration time to activate outlet electric heaters

Menu

Mn01

Mn03

Mn03

Mn03

Mn03

Mn03

Mn06

Mn06

Parameter

no

0300

010G

0301

0303

0304

0311

0616

0617

Value to be

set

1*

0

0*

1

Example

-5°C

-15

60

600

UOM

°C

°C

min.

°C*sec

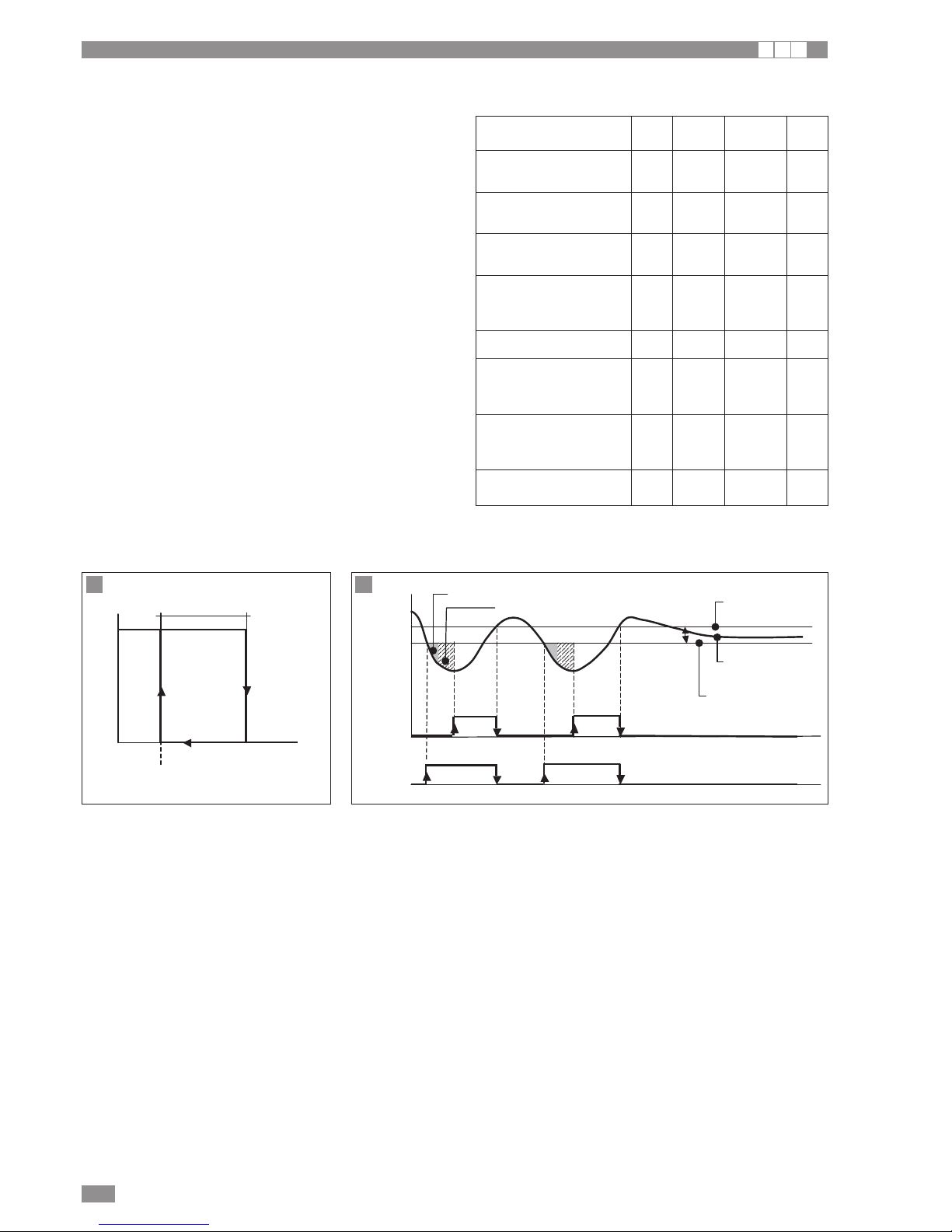

Outlet electric heater control

A) REPLACEMENT: The electric heater is enabled when

the outside temperature is less than the value of parameter

0304 and the compressor is off, figure 3.

To enable heater activation in REPLACEMENT mode set

parameter 0303 = 1 and 010G = 1.

Electric heater operation reflects the trend in water outlet

temperature, as shown on the graph in figure 4.

If the heat pump shuts down due to an alarm, the electric

heater is activated automatically regardless of the outside

air temperature.

In REPLACEMENT mode the electric heater activation

delay time is ignored, and the device is activated immediately if necessary.

Outlet electric heater operating parameters in REPLACEMENT mode

Outlet electric heater operating parameters in SUPPLEMENTARY mode for OUTSIDE AIR TEMP.

Description

Activation electrical heater

0 = Electrical Heater not enabled

1 = Electrical Heater enabled

Type of outlet electric heater operation

0 = Supplementary

1 = Replacement

Enable boiler

0 = Boiler not enabled

1 = Boiler enabled

Activation with low outside air temperature

0 = Function not enabled

1 = Function enabled

Outside air temperature to enable electric heater

Integration time to activate outlet electric heaters

Menu

Mn03

Mn01

Mn03

Mn03

Mn03

Mn06

Parameter

no

0300

010G

0301

0303

0304

0617

Value to be

set

1*

1

0*

1

Example

-5°C

600

UOM

°C

°C*sec

43 446 7

230V / 400V

BT9

N

Solution 2

System with heat pump and outlet electric heater WITHOUT

storage tank.

Position probe BT9 on the system outlet pipe.

2

Set the parameters following the sequence described in

the table

Set the parameters following the sequence described in

the table

18 AWR-MTD2-XE EN 11/2010

INSTALLER CONNECTIONS

I A

Supplementary heating always enabled

Supplementary heating with the electric heater is enabled

for all outside air temperatures.

To enable heating at all times set parameter 0303 = 0 and

010G = 0

Electric heater operation reflects the trend in water outlet

temperature, as shown on the graph in figure 4.

Once the heater is enabled, supplementary heating is activated when the integration time set for parameter 0617 is reached and the delay time 0616 has elapsed.

The delay time is ignored when the unit is first started.

Example:

Value 0617 = 600°C*sec

Outlet temperature set point= 50°C

Actual temperature = 40°C

(50 – 40) x 60 sec = 600°Csec. ----> Electric heater ON

Low values of 0617 mean frequent activation of the heater.

Too high values of 0617 mean long delays in activating the heater

Description

Activation electrical heater

0 = Electrical Heater not enabled

1 = Electrical Heater enabled

Type of outlet electric heater operation

0 = Supplementary

1 = Replacement

Enable boiler

0 = Boiler not enabled

1 = Boiler enabled

Activation with low outside air

temperature

0 = Function not enabled

1 = Function enabled

Minimum outside air temperature

for heat pump operation (make

sure the value set is the same as

shown in the table)

Electric heater delay time

(allows the heat pump to reach

steady operation and thus avoid

activating the heater when not

needed)

Integration time to activate outlet

electric heaters

Menu

Mn03

Mn01

Mn03

Mn03

Mn03

Mn06

Mn06

Parameter

no

0300

010G

0301

0303

0311

0616

0617

Value to be

set

1*

0

0*

0

-15

60

600

UOM

°C

min.

°C*sec

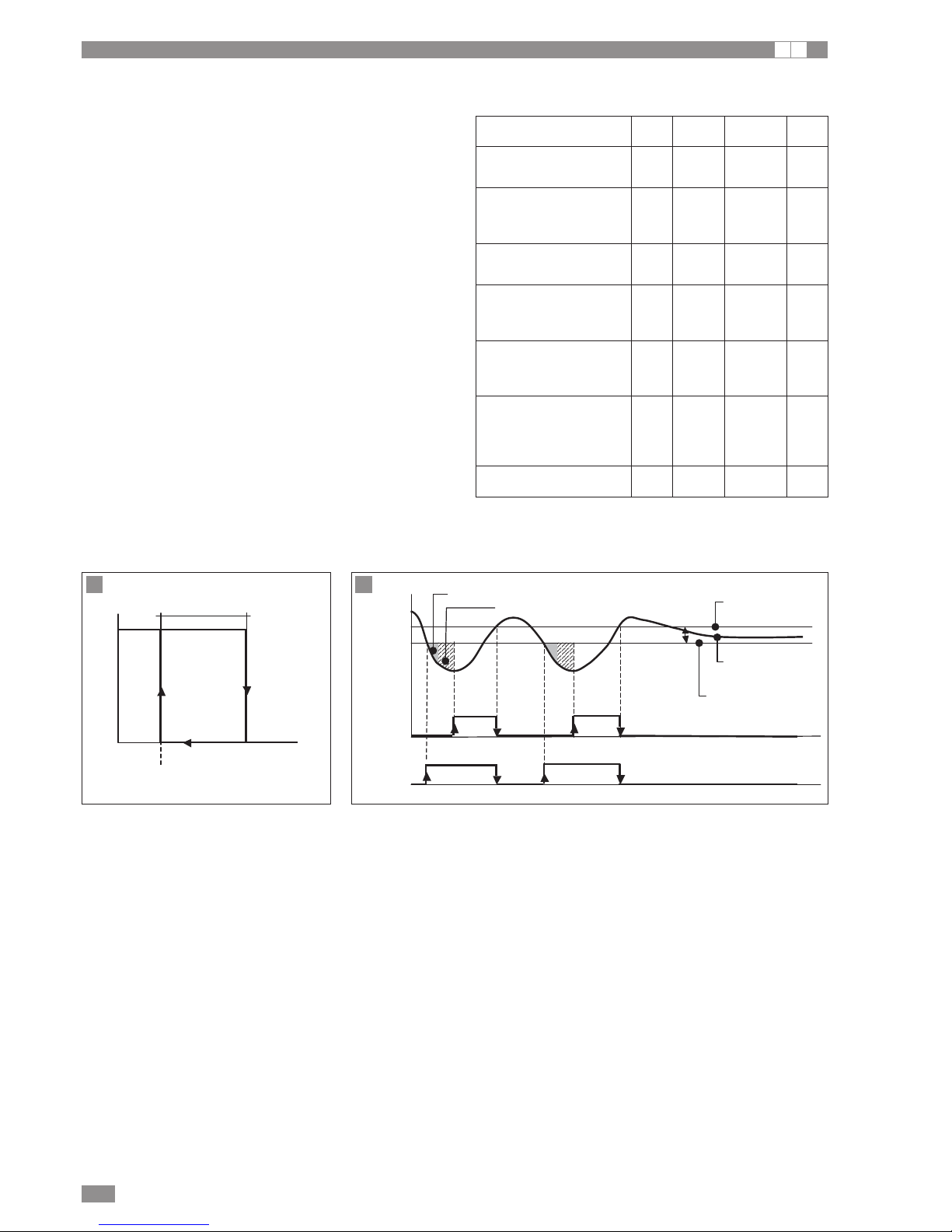

3 4

Outlet electric heater operating parameters in SUPPLEMENTARY mode when always ENABLED

Outside air T

OFF

Enabled

Outlet

heater

0304 Outside temperature

to enable outlet heaters

3°C

OFF

ON

ON

OFF

Compressor

Heater

Electric heater activation delay time 0616

Integration time 0617

System water control

set point

Actual water

temperature

System HP control

hysteresis

Set the parameters following the sequence described in

the table

19EN 11/2010 AWR-MTD2-XE

INSTALLER CONNECTIONS

U I A

Boiler control

A) REPLACEMENT: the boiler is only enabled if the outside

air temperature is less than the value of parameter 0307

and the compressor is off, figure 3.

To enable boiler activation in REPLACEMENT mode set

parameter 0306=1 and 010H = 1

Boiler operation reflects the trend in water temperature, as

shown on the graph in figure 4.

If the heat pump shuts down due to an alarm the boiler is

activated automatically regardless of the outside air temperature.

In REPLACEMENT mode the activation delay time is

ignored, and the boiler is activated immediately if necessary.

Description

Enable electric heater

0 = Heater not enabled

1 = Heater enabled

Activation Boiler

0 = Boiler not enabled

1 = Boiler enabled

Type of boiler operation

0 = Supplementary

1 = Replacemen

Activation with low outside air

temperature

0 = Function not enabled

1 = Function enabled

Outside air temperature to enable

boiler

Integration time to activate boiler

Menu

Mn03

Mn03

Mn01

Mn03

Mn03

Mn06

Parameter

no.

0300

0301

010H

0306

0307

0619

Value to be

set

0

1

1

1

Example

-5°C

600

UOM

°C

°C*sec

B) SUPPLEMENTARY: the boiler operates in supplementary heating mode, together with the compressor, to satisfy

the heating load.

Supplementary heating for low outside air temperature

The boiler is enabled only when the outside air temperature

is less than the value of parameter 0307, figure 3.

To enable the supplementary heating for outside air temperature set parameter 0306 = 1 and 010H = 0

Boiler operation reflects the trend in water temperature, as

shown on the graph in figure 4.

Description

Enable electric heater

0 = Heater not enabled

1 = Heater enabled

Activation Boiler

0 = Boiler not enabled

1 = Boiler enabled

Type of boiler operation

0 = Supplementary

1 = Replacemen

Activation with low outside air

temperature

0 = Function not enabled

1 = Function enabled

Outside air temperature to enable

boiler

Minimum outside air temperature

for heat pump operation (make

sure the value set is the same as

shown in the table)

Boiler activation delay time (allows

the heat pump to reach steady

operation and thus avoid activating the boiler when not needed)

Integration time to activate boiler

Menu

Mn03

Mn03

Mn01

Mn03

Mn03

Mn03

Mn06

Mn06

Parameter

no.

0300

0301

010H

0306

0307

0311

0618

0619

Value to be

set

0

1

0

1

Example

-5°C

-15

60

600

UOM

°C

°C

min.

°C*sec

Boiler operating parameters in REPLACEMENT mode

Boiler operating parameters in SUPPLEMENTARY mode

for outside temperature

Boiler

43 44

BT9

67

BT9

Boiler

43 4467

1

2

Set the parameters following the sequence described in

the table

Set the parameters following the sequence described in

the table

KM2 Boiler

A boiler can be used as a supplementary or replacement

heat source for the system.

Solution 1

System with heat pump and boiler with storage tank.

Solution 2

System with heat pump and boiler without storage tank.

20 AWR-MTD2-XE EN 11/2010

INSTALLER CONNECTIONS

U I A

Supplementary heating always enabled

Supplementary heating by boiler is enabled for all outside

air temperatures.

To enable heating at all times set parameter 0306 = 0 and

010H = 0

Boiler operation reflects the trend in water temperature, as

shown on the graph in figure 4.

Description

Enable electric heater

0 = Heater not enabled

1 = Heater enabled

Activation Boiler

0 = Boiler not enabled

1 = Boiler enabled

Type of boiler operation

0 = Supplementary

1 = Replacement

Activation with low outside air

temperature

0 = Function not enabled

1 = Function enabled

Outside air temperature to enable

boiler

Minimum outside air temperature

for heat pump operation (make

sure the value set is the same as

shown in the table)

Boiler activation delay time (allows

the heat pump to reach steady

operation and thus avoid activating the boiler when not needed)

Integration time to activate boiler

Menu

Mn03

Mn03

Mn01

Mn03

Mn03

Mn03

Mn06

Mn06

Parameter

no.

0300

0301

010H

0306

0307

0311

0618

0619

Value to be

set

0

1

0

0

Example

-5°C

-15

60

600

UOM

°C

°C

min.

°C*sec

3 4

Boiler operating parameters in SUPPLEMENTARY mode

when always ENABLED

Once the boiler has been enabled, supplementary heating is activated when the

integration time set for parameter 0619 is reached and the delay time 0618 has

elapsed. The delay time is ignored when the unit is first started.

Example:

Value 0619 = 600°C*sec

Outlet temperature set point= 50°C

Actual temperature = 40°C

(50 – 40) x 60 sec = 600°Csec. ----> Boiler ON

Low values of 0619 mean frequent activation of the boiler.

Too high values of 0619 mean long delays in activating the boiler

Outside air T

OFF

Enabled

Boiler

0304 Outside temperature to

enable boiler

3°C

OFF

ON

ON

OFF

Compressor

Boiler

Boiler activation delay time 0618

Integration time 0619

System outlet temperature

set point

Actual water

temperature

System HP control

hysteresis

Set the parameters following the sequence described in

the table

ON

OFF

ON

OFF

Heater

Compressor

0023

0209

t

21EN 11/2010 AWR-MTD2-XE

INSTALLER CONNECTIONS

U I A

Description

Domestic hot water heating

0 = heat pump only

1 = electric heater only

2 = heat pump + electric heater

Legionella prevention function

with:

0 = heat pump only

1 = electric heater only

2 = heat pump + electric heater

Domestic hot water temperature

set point for Legionella prevention

Legionella prevention cycle day

MONDAY (0=no; 1=yes)

Legionella prevention cycle day

TUESDAY (0=no; 1=yes)

Legionella prevention cycle day

WEDNESDAY (0=no; 1=yes)

Legionella prevention cycle day

THURSDAY (0=no; 1=yes)

Legionella prevention cycle day

FRIDAY (0=no; 1=yes)

Legionella prevention cycle day

SATURDAY (0=no; 1=yes)

Legionella prevention cycle day

SUNDAY (0=no; 1=yes)

Legionella prevention cycle time

Enable Legionella prevention

function

0 = Not enabled

1 = Enabled

Maximum Legionella prevention

function duration

Menu

Mn02

Mn02

Mn02

Mn02

Mn02

Mn02

Mn02

Mn02

Mn02

Mn02

Mn02

Mn02

Mn02

Parameter

no.

0202

0223

0211

0213

0214

0215

0216

0218

0219

0220

0221

0222

0225

Value to be

set

2

1

Example

65°C

0

0

Example 1

0

0

0

0

02

1

20

UOM

°C

h

min.

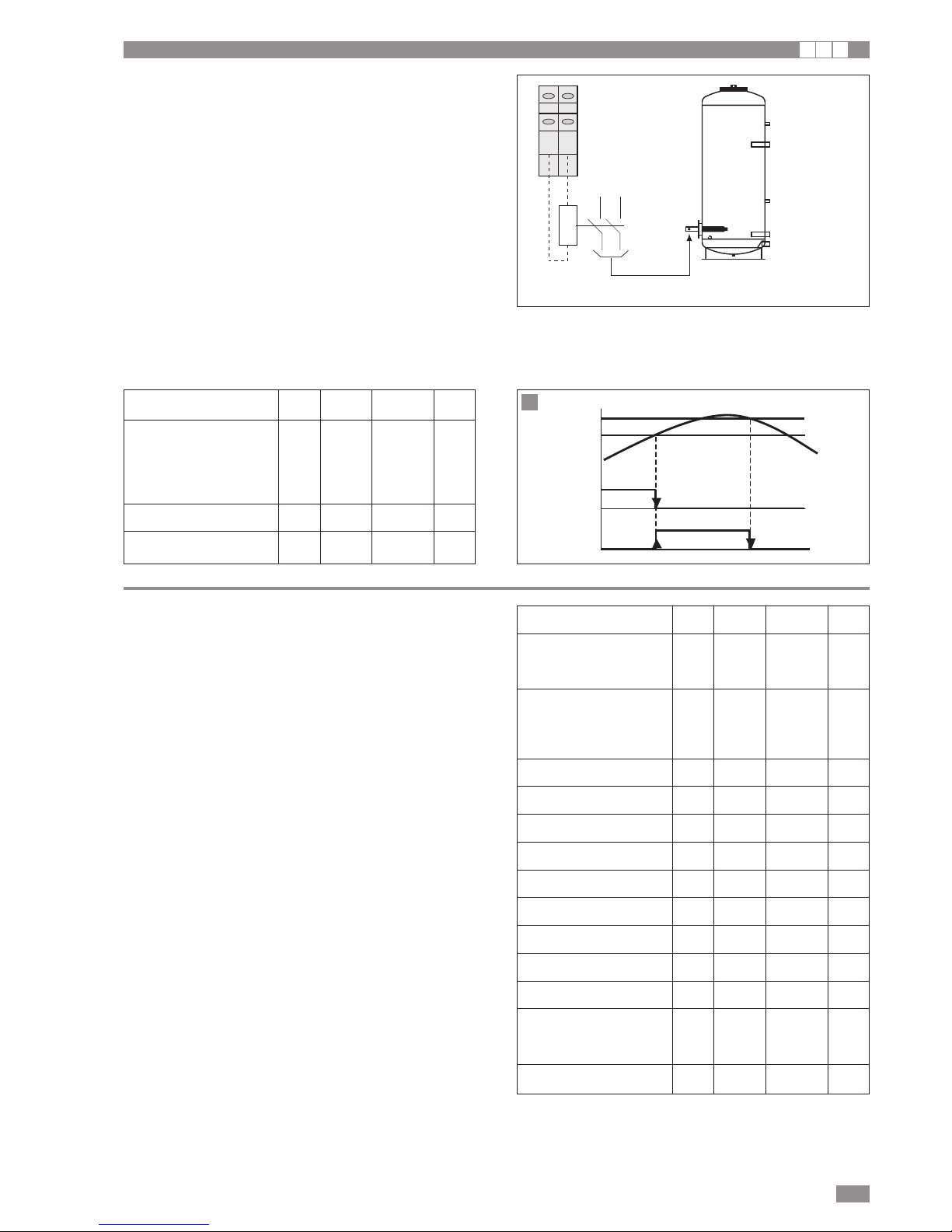

KM4 DHW storage electric heater

An electric heater can be managed for heating the DHW

storage.

DHW storage electric heater control

The electric heater is activated to reach a temperature value

that the heat pump on its own is not able to reach.

Example:

Domestic hot water temperature produced with heat pump

0023 = 55°C

Domestic hot water temperature produced with electric

heater 0209 = 65°C.

The electric heater works so as to increase the DHW storage temperature from 55°C to 65°C, figure 1

Legionella prevention function with electric heater

The Legionella prevention function ensures the elimination

of the Legionella bacteria that reside in domestic water storage tanks. The temperature and duration of the Legionella

prevention cycles are typically:

• 2 minutes > 70°C

• 4 minutes > 65°C

• 60 minutes > 60°C

To enable the Legionella prevention function, set 0222=1

Description

Electric heater operating mode

0 = Heat pump only

1 = Electric heater only

2 = Heat pump + Electric heater

Domestic hot water temperature

set point with heat pump

Domestic hot water temperature

set point with heater

Menu

Mn02

Mn00

Mn02

Parameter

no.

0202

0023

0209

Value to be

set

2

Example

55

Example

65

UOM

°C

°C

1

Domestic hot water

electric heater

NU

10 11

Loading...

Loading...