Page 1

Dell PowerEdge C5220

Systems

Hardware Owner’s

Manual

Regulatory Model: B04S

Page 2

Notes, Cautions, and Warnings

NOTE: A NOTE indicates important information that helps you make better use of

your system.

CAUTION: A CAUTION indicates potential damage to hardware or loss of data if

instructions are not followed.

WARNING: A WARNING indicates a potential for property damage, personal

injury, or death.

Information in this publication is subject to change without notice.

© 2012 Dell Inc. All rights reserved.

Reproduction of these materials in any manner whatsoever without the written permission of Dell Inc.

is strictly forbidden.

Trademarks used in this text: Dell™, the DELL logo, and PowerEdge™ are trademarks of Dell Inc.

®

Intel

and Intel® Xeon® are registered trademarks of Intel Corporation in the U.S. and other countries.

Microsoft

in the United States and/or other countries. Red Hat

trademarks of Red Hat, Inc. in the United States and/or other countries. SUSE™ is a trademark of

Novell Inc. in the United States and other countries.

Other trademarks and trade names may be used in this publication to refer to either the entities claiming

the marks and names or their products. Dell Inc. disclaims any proprietary interest in trademarks and

trade names other than its own.

®

and Windows® are either trademarks or registered trademarks of Microsoft Corporation

®

and Red Hat Enterprise Linux® are registered

Regulatory Model: B04S

2012-06 Rev. A02

Page 3

Important Information

• Your system must have BIOS version 2.0.1 or later to support Intel Xeon

E3-1200 v2 series processors. You can download the latest version of the

BIOS at support.dell.com.

• Your system must have the BMC version 1.13 or later to support Intel

Xeon E3-1200 v2 series processors. You can download the latest version of

the BMC firmware at support.dell.com.

• Your system must have the Backplane firmware version 1.0.9 or later to

support Intel Xeon E3-1200 v2 series processors. You can download the

latest version of the Backplane firmware at

NOTE: PowerEdge C5220 systems with a service tag on the front panel support only

Intel Xeon E3-1200 series.

Identifying Service Tag on the Front Panel of PowerEdge C5220 Systems.

support.dell.com

.

Page 4

Page 5

Contents

1 About Your System . . . . . . . . . . . . . . . . . . . . . . . . 7

Front-Panel Features and Indicators . . . . . . . . . . . . . . . . . . 8

2 Using the System Setup Program . . . . . . . . . . . . . 17

Start Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

BIOS Setup Options at Boot

Console Redirection

Configuring Special Keys

General Help

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Server Platform Setup Utility Screens

Main Menu

Advanced Menu

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Server Management

Boot Menu

Security Menu

Save and Exit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

POST Error Handling

Command Line Interfaces for Setup options

. . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . 58

3 Installing System Components . . . . . . . . . . . . . . . 59

Recommended Tools . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Inside the System

Sled Configuration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5

Page 6

Sleds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Memory Modules

Hard Drives

Hard Drive Boards

Heat Sinks

Processors

Mezzanine Cards

. . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . 76

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

. . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 99

Troubleshooting Sequence . . . . . . . . . . . . . . . . . . . . . . 99

Update Utilities

BIOS System Update

BIOS Recovery Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

. . . . . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . . . . . . . . . 109

5 Jumpers and Connectors. . . . . . . . . . . . . . . . . . 111

System Board Jumpers and Connectors . . . . . . . . . . . . . . . 111

2.5-inch Hard Drive Board Connectors

. . . . . . . . . . . . . . . . 113

3.5-inch Hard Drive Board Connectors

Backplane Connectors

. . . . . . . . . . . . . . . . . . . . . . . . 114

Power Distribution Board Connectors

PDB Power and SMBus Connectors

. . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . 117

. . . . . . . . . . . . . . . . . 118

6 Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

6

Page 7

About Your System

The system includes the following configurations:

• 8-sled system board + 3.5-inch hard drive board + cables.

• 8-sled system board + 2.5-inch hard drive board + cables.

• 8-sled system board + mezzanine card + 3.5-inch hard drive board +

cables.

• 8-sled system board + mezzanine card + 2.5-inch hard drive board +

cables.

• 12-sled system board+ 3.5-inch hard drive board + cables.

• 12-sled system board + 2.5-inch hard drive board + cables.

NOTE: Mixed SATA and SAS hard drives on the 2.5 and 3.5-inch hard drive board

are not supported.

1

About Your System 7

Page 8

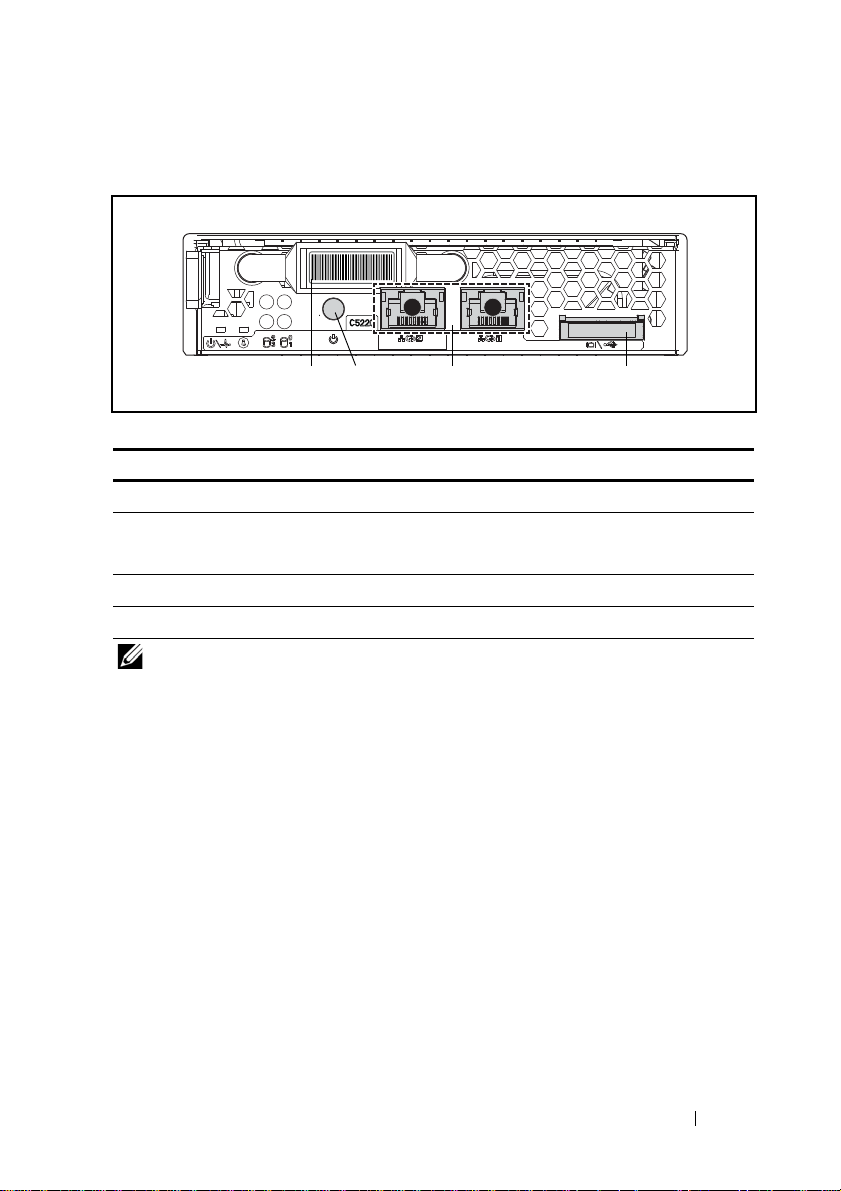

Front-Panel Features and Indicators

12

1

2

345

The Dell PowerEdge C5220 server is available in either a 12-sled or 8-sled,

each supporting either two 3.5-inch or four 2.5-inch hard drives.

There are two sled SKUs available for the PowerEdge C5220 server, an eight

sled SKU and a twelve sled SKU. For information on sled population, see

"Sled Configuration" on page 61.

The following section provides information for the 8-sled, 12-sled, and

mezzanine card options.

Features

Figure 1-1. 8-Sled SKU Front Features (Rotated Counterclockwise 90°)

Item Feature Description

1 Mezzanine card cover Cover for the Mezzanine card

2 VGA/USB connector VGA/USB 2.0 connector

3 NIC LAN ports 10/100/1 Gb NIC LAN connector 1

10/100/1 Gb NIC LAN connector 2

4 Power button On/Off button for sled

5 Service Tag Identifying service tag

NOTE: PowerEdge C5220 systems with a service tag on the front panel support

Intel Xeon E3-1200 series processors only.

8 About Your System

Page 9

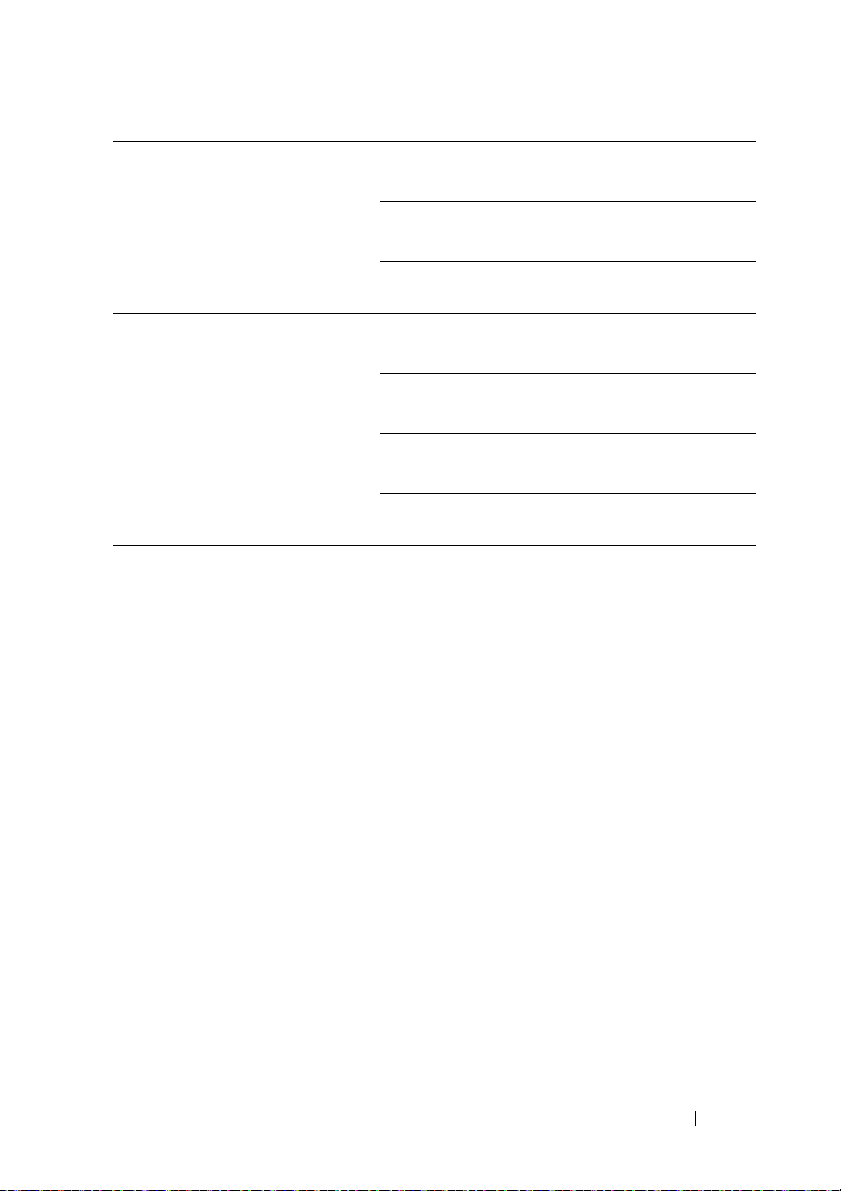

Figure 1-2. 12-Sled SKU Front Features (Rotated Counterclockwise 90°)

12

1234

Item Feature Description

1 VGA/USB connector VGA/USB 2.0 connector

2 NIC LAN ports 10/100/1G NIC LAN connector 1

10/100/1G NIC LAN connector 2

3 Power button On/Off button for sled

4 Service Tag Identifying service tag

NOTE: PowerEdge C5220 systems with a service tag on the front panel support

Intel Xeon E3-1200 series processors only.

About Your System 9

Page 10

Indicators

0

1

3

2

567

1234

Figure 1-3. 8-Sled SKU Front Indicators (Rotated Counterclockwise 90°)

Item Feature Status Description

1, 3 LAN link LED Off No link

2, 4 LAN activity LED Off No activity

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

5 Hard drive activity

LEDs

Green

Off

Green

Off

Blinking green

Green

Blinking green

Amber

Link

No activity

Link

Activity 10 Mb

Link

Activity 100 Mb

Link

Activity 1Gb

Blinking green Hard drive 0 active

Hard drive 1 active

Hard drive 2 active

Hard drive 3 active

10 About Your System

Page 11

Item Feature Status Description

6 Identity LED Blue

On

Blue

Off

Blinking blue

7 Power/Sta tus Gree n

On

Green

Off

Amber

Off

Blinking amber Event occurred in the

Identifies the system

Normal status

Identifies the system

with an interval

System DC On

System DC Off

Normal status

system

About Your System 11

Page 12

Figure 1-4. 12-Sled SKU Indicators (Rotated Counterclockwise 90°)

1234

5

67

2

0

3

1

Item Feature Status Description

1, 3 LAN link LED Off No link

2, 4 LAN activity LED Off No activity

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

5 Hard drive activity

LEDs

Green

Off

Green

Off

Blinking green

Green

Blinking green

Amber

Link

No activity

Link

Activity 10 Mb

Link

Activity 100 Mb

Link

Activity 1Gb

Blinking green Hard drive 0 active

Hard drive 1 active

Hard drive 2 active

Hard drive 3 active

12 About Your System

Page 13

6 Identity LED Blue

On

Blue

Off

Blinking blue Identifies the system

7 Power/Sta tus Gree n

On

Green

Off

Amber

Off

Blinking amber Event occurred in the

Identifies the system

Normal status

with an interval

System DC on

System DC off

Normal status

System

About Your System 13

Page 14

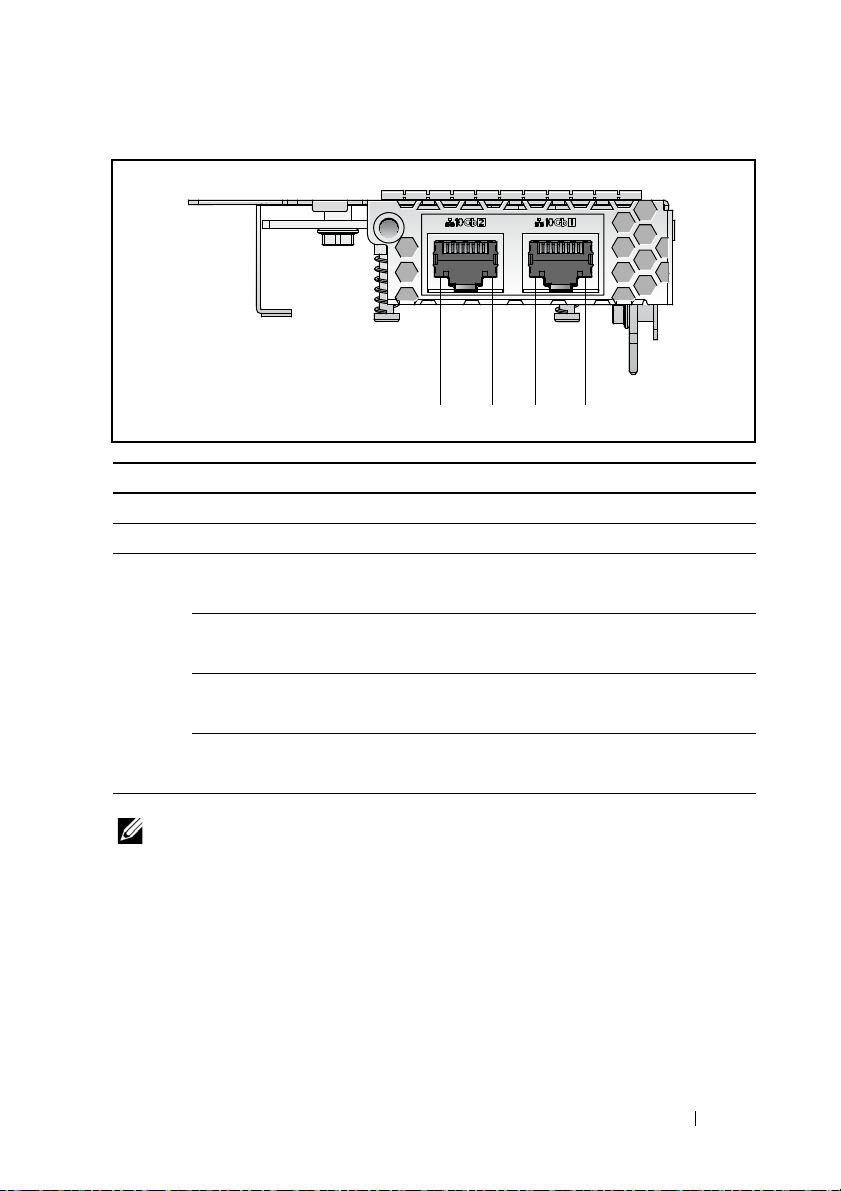

Figure 1-5. 1Gb Mezzanine Indicators (Rotated Counterclockwise 90°)

1234

Item Feature Status Description

1, 3 LAN activity LED Off No activity

2, 4 LAN link LED Off No link

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

Green

Off

Blinking green

Off

Blinking green

Green

Blinking green

Orange

Link

No activity

Link

Activity 10 Mb

Link

Activity 100 Mb

Link

Activity 1 Gb

14 About Your System

Page 15

Figure 1-6. 10Gb Mezzanine Indicators (Rotated Counterclockwise 90°)

1234

Item Feature Status Description

1, 3 LAN link LED Off No link

2, 4 LAN activity LED Off No activity

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

LAN link LED

LAN activity LED

Green

Off

Blinking green

Off

Blinking green

Green

Blinking green

Orange

Link

No activity

Link

Activity 100 Mb

Link

Activity 1Gb

Link

Activity 10 Gb

NOTE: Intel 10Gb mezzanine card is supported by BIOS version 1.0.12 and later.

About Your System 15

Page 16

16 About Your System

Page 17

2

Using the System Setup Program

Start Menu

The system employs the latest AMI Core BIOS, which is stored in Flash

memory. The Flash memory supports the plug-and-play specification, and

contains a BIOS Setup program, the Power On Self Test (POST) routine, and

the PCI auto-configuration utility.

This system board supports system BIOS shadowing enabling the BIOS to

execute from 64-bit onboard write-protected DRAM.

Use the Setup Utility to configure items such as:

• Hard drives and peripherals

• Memory sizing and configuration

• Password protection from unauthorized use

• Protocol and feature enabling/disabling

• Power Management features

This Setup utility should be executed under the following conditions:

• When changing the system configuration

• When a configuration error is detected by the system and you are

prompted to make changes to the Setup utility

• When redefining the communication ports to prevent any conflicts

• When changing the password or making other changes to the security

setup

NOTE: Only items in brackets [ ] can be modified. Items that are not in brackets are

display only.

Using the System Setup Program 17

Page 18

BIOS Setup Options at Boot

The user initiates SETUP by pressing <F2> during POST.

Console Redirection

The console redirection allows a remote user to diagnose and fix problems on

a server, which has not successfully booted to the OS. The centerpiece of the

console redirection is the BIOS Console. The BIOS Console is a Flash ROMresident utility that redirects input and output over a serial or modem

connection.

BIOS supports redirection of both video and keyboard through a serial link

(serial port). After enabling console redirection, the local (host server)

keyboard input and video output are accessible by the local keyboard and

video connections.

Operation through the remote console without the need for a local keyboard

or monitor is also available.

NOTE: Full compatibility and functionality for the available emulation standards

may vary.

Enable/Disable Console Redirection

The console redirection function can be enabled/disabled in the BIOS Setup

menu. See "Remote Access Configuration" on page 46.

18 Using the System Setup Program

Page 19

Configuring Special Keys

Console redirection uses ANSI terminal emulation, which is limited to basic

ASCII characters. There are no function keys, arrow keys, or control keys in

this character set. However, the PowerEdge C5220 software requires the use

of function keys and control keys for ordinary functions. You can emulate a

function key or control key by using a special key sequence called an escape

sequence, to represent a specific key.

For console redirection, an escape sequence starts with an escape character.

This character can be entered in a variety of different ways depending on the

requirements of your terminal emulation software. For example, 0x1b, ^[,

and <Esc> refer to the same escape character.

The following table lists the escape sequence that must be sent to represent a

special key or command.

Key ANSI Escape Sequence Other Sequences

F1 <ESC><Shift>op <ESC>1

F2 <ESC><Shift>oq <ESC>2

F3 <ESC><Shift>or <ESC>3

F4 <ESC><Shift>os <ESC>4

F5 <ESC>5

F6 <ESC>6

F7 <ESC>7

F8 <ESC>8

F9 <ESC>9

F10 <ESC>0

F11 <ESC>!

F12 <ESC>@

Home <ESC>[<Shift>h <ESC>h

End <ESC>[<Shift>k <ESC>k

Ins <ESC>+

Del <ESC>-

Page Up <ESC>?

Using the System Setup Program 19

Page 20

Key ANSI Escape Sequence Other Sequences

Page Down <ESC>/

Reset <ESC>R<ESC>r

<ESC>R

General Help

In addition to the Item Specific Help window, the Setup Utility also provides

a General Help screen. This screen can be called up from any menu by

pressing <F1>. The General Help screen lists the legend keys with their

corresponding alternates and functions. To exit the help window, press the

<Enter> or the <Esc> key.

20 Using the System Setup Program

Page 21

Server Platform Setup Utility Screens

Conventions

The following typographical conventions are used in the tables:

• The text and values in the Setup Item, Options, and Help columns in the

tables are displayed on the BIOS Setup screens.

• Text marked with an * in the Settings column of the tables indicates

default values. These values are not displayed with an * on the setup

screen. The marked text in this document is to serve as a reference point.

• The Comments column provides additional information where it may be

helpful. This information does not appear in the BIOS Setup screens.

• Information in the screen shots that is enclosed in brackets (< >)

indicates variables, depending on the option(s) installed. For example

<Current Date> is replaced by the actual current date.

• Information that is enclosed in square brackets ([ ]) in the tables indicates

areas where the user needs to type in text instead of selecting from a

provided option.

• Whenever information is changed (except Date and Time) the systems

requires a save and reboot to take place. Pressing <ESC> discards the

changes and boot the system according to the boot order set from the last

boot.

Using the System Setup Program 21

Page 22

Main Menu

The Main menu is the screen that is first displayed when you enter BIOS

Setup.

Menu Fields Settings Comments

Main

System Date MM/DD/YYYY Set the Date. Use Tab to

switch between Date

elements.

System Time HH:MM:SS Set the time. Use Tab to

switch between Time

elements.

Product Name Displays the product name.

BIOS Version Displays the BIOS version.

BIOS Build Date Displays the BIOS build

date.

Service Tag Displays the service tag.

22 Using the System Setup Program

Page 23

Menu Fields Settings Comments

Asset Tag Displays the asset tag.

MRC Version Displays the MRC version.

ME Version Displays the ME version.

BMC Version Displays the BMC version.

FAN Control Board FW Displays the fan control

board firmware version.

ePPID Displays the ePPID.

NIC1 MAC Address Displays the NIC1 MAC

address.

NIC2 MAC Address Displays the NIC2 MAC

address.

BMC NIC MAC Address Displays the BMC NIC

MAC address.

Processor Type Displays the processor type.

Processor Speed Displays the processor

speed.

Processor Core Displays the amount of

processor core.

System Memory Size Displays the amount of

system memory.

System Memory Speed Displays the memory

speed.

Using the System Setup Program 23

Page 24

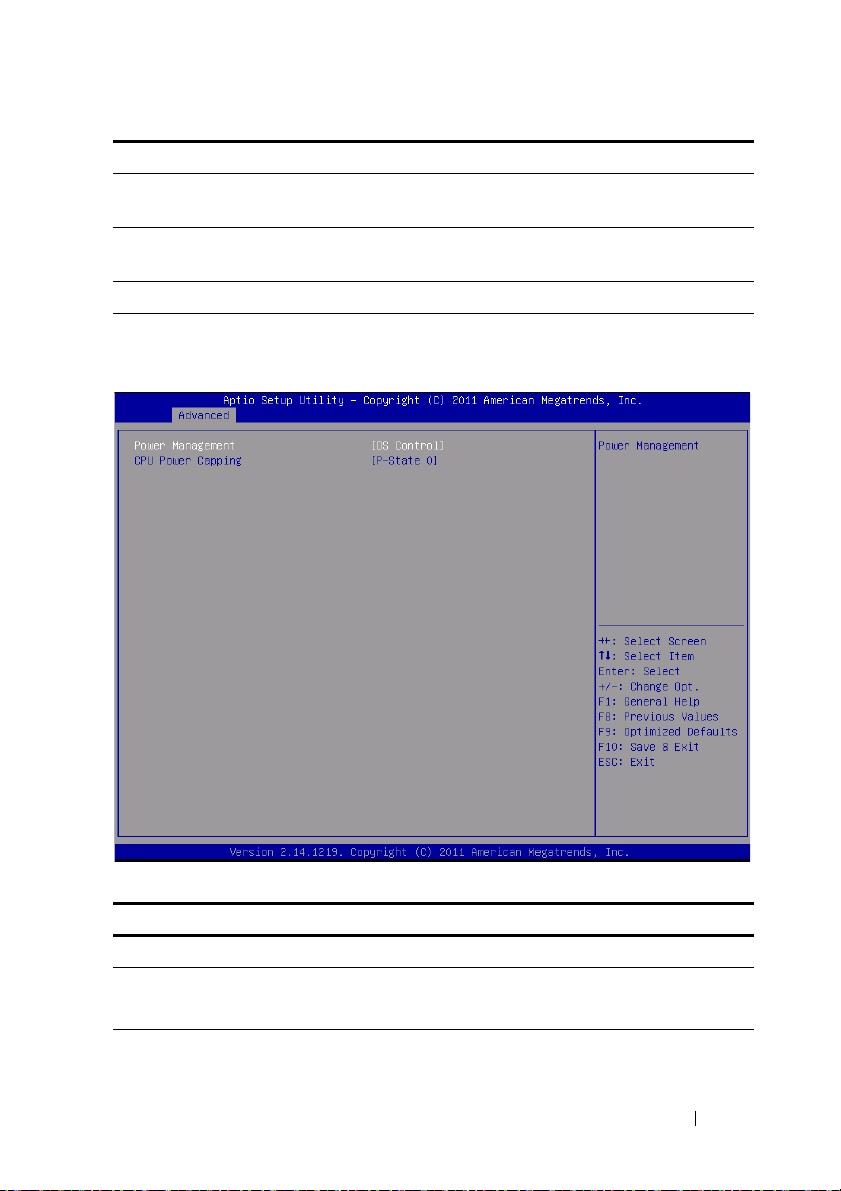

Advanced Menu

The Advanced screen provides an access point to configure several options.

On this screen, the user selects the option that is to be configured.

Configurations are performed on the selected screen, not directly on the

Advanced screen.

CAUTION:

system to malfunction. Unless you have experience adjusting these items, we

recommend that you do not adjust the default values. If the system malfunctions or

does not boot after changing the settings, open BIOS and choose "Load Optimal

Defaults" in the Exit menu to boot up normally.

Menu Fields Settings Comments

Advanced

Power Management Power Management.

CPU Configuration CPU Configuration.

Memory Configuration Memory Configuration.

Incorrect settings to items on the Advanced Menus may cause the

24 Using the System Setup Program

Page 25

Menu Fields Settings Comments

SATA Configuration SATA Devices

Configuration.

PCI Configuration PCI, PCI-X and PCI

Express Settings.

USB Configuration USB Configuration.

Power Management

Menu Fields Settings Comments

Advanced \Power Management

Power management Maximum Performance

OS Control*

Using the System Setup Program 25

Power management.

Page 26

Menu Fields Settings Comments

CPU power capping P-state 0*

P-state 1

P-state 2

P-state 3

P-state 4

CPU power capping.

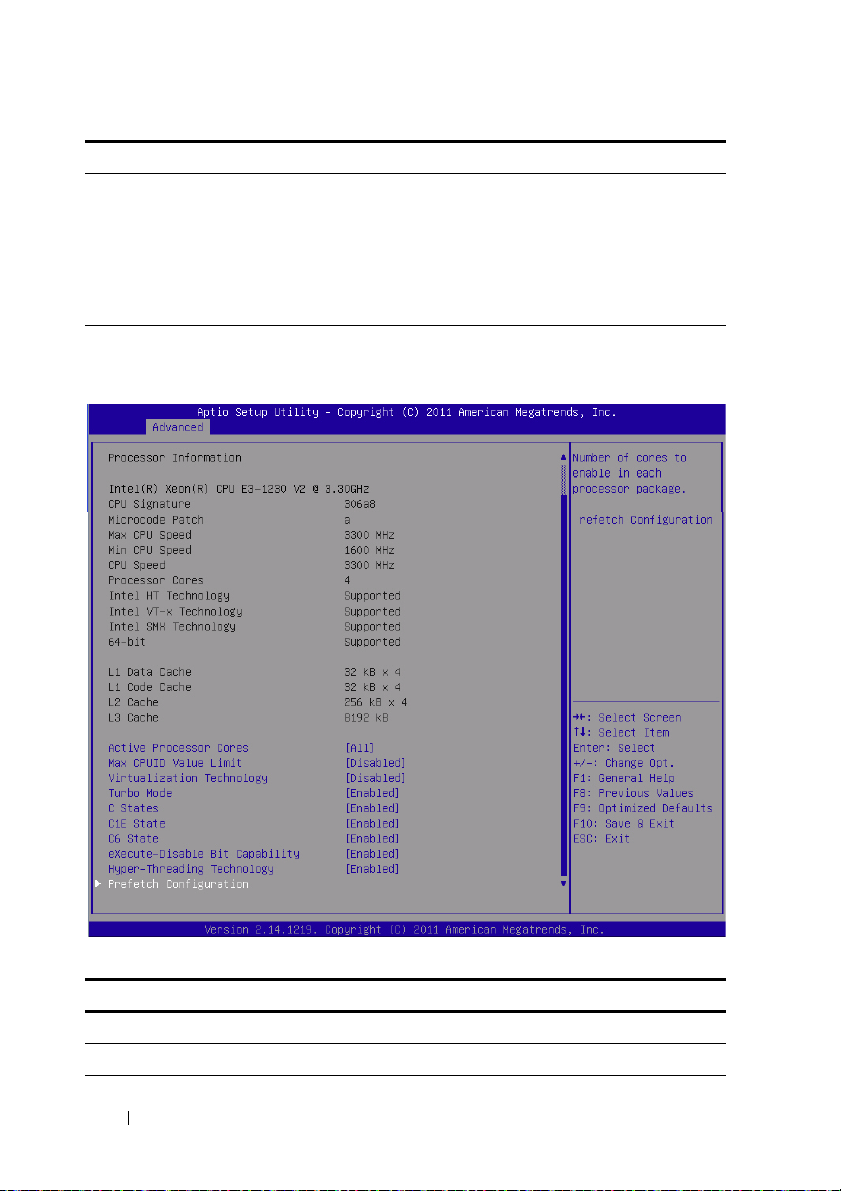

CPU Configuration

Menu Fields Settings Comments

Advanced\CPU Configuration

Processor Information

26 Using the System Setup Program

Page 27

Menu Fields Settings Comments

Active Processor Cores All*

1

2

4

Max CPUID Value Limit Disabled*

Enabled

Virtualization Technology Disabled*

Enabled

Tu r bo Mo de D i sa b le d

Enabled*

C States Disabled

Enabled*

C1E State Disabled

Enabled*

C6 State Disabled

Enabled*

C7 State Disabled

Enabled*

Number of cores to enable

in each processor package.

Some OS’s (NT4) will fail

if the value returned in

EAX is > 3 when CPUID

instruction is executed

with EAX=0. This setting

limits CPUID function to 3

or disable it.

This feature will allow the

users to disable/enable the

VT technology in

applicable CPUs. If disable,

the VT feature is unusable

in any OS.

Tur bo Mo de.

Set to disable, there are no

C states available for the

processor. Set to enable

(default), the processor can

operate in all available

Power C States.

Set C1E disabled/enabled.

Set C6 disabled/enabled.

NOTE: Supported in BIOS

version 2.0.X.

Set C7 disabled/enabled.

NOTE: Supported in BIOS

version 2.0.X.

Using the System Setup Program 27

Page 28

Menu Fields Settings Comments

eXecute-Disable Bit

Capability

Hyper-Threading

Te ch n o lo g y

Prefetch Configuration Prefetch Configuration

Disabled

Enabled*

Disabled

Enabled*

When disable, Intel CPUs

that support the eXecute

Disable (XD) feature will

not report the support to

the operating system.

When enable, Intel CPUs

that support the eXecute

Disable (XD) feature will

report the support to the

operating system.

Disable/Enable HyperThreading Technology.

Prefetch Configuration

28 Using the System Setup Program

Page 29

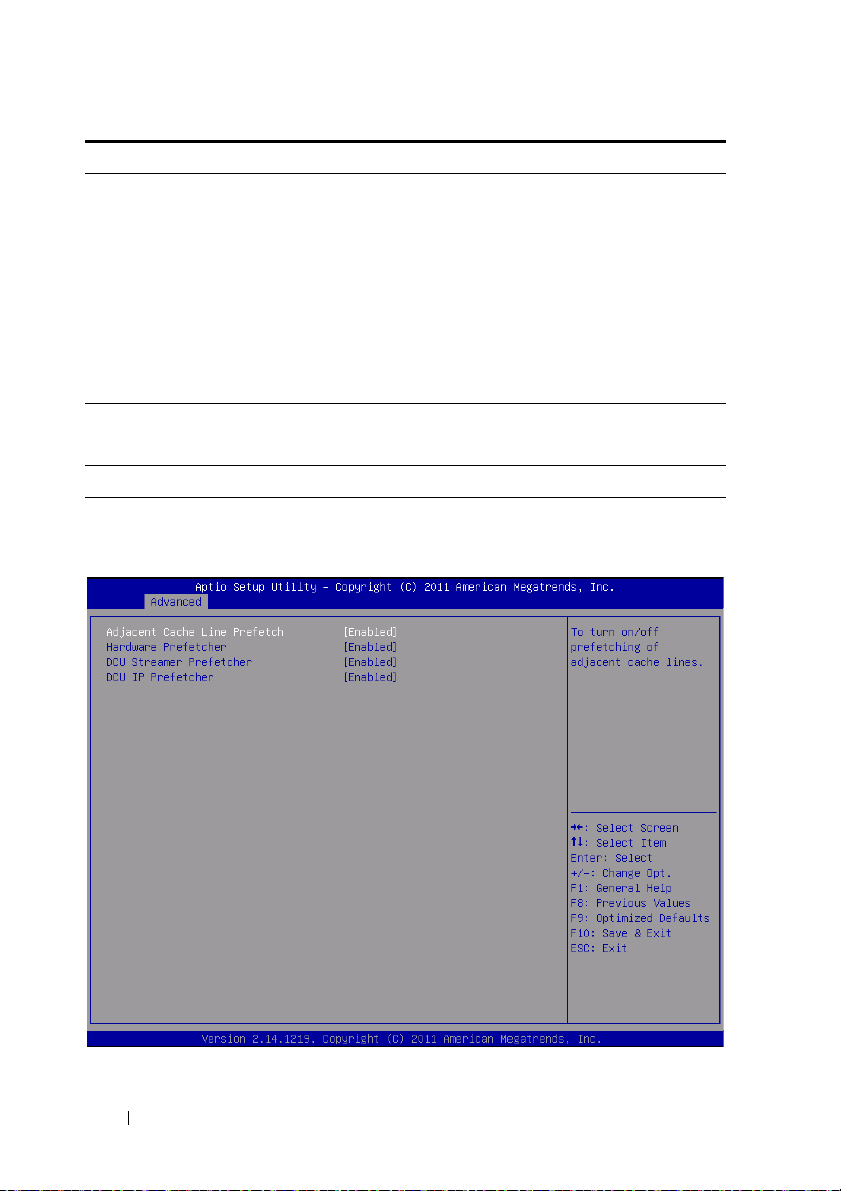

Menu Fields Settings Comments

Advanced\CPU Configuration\Prefetch Configuration

Adjacent Cache Line

Prefetch

Hardware Prefetcher Disable

DCU Streamer Prefetcher Disable

DCU IP Prefetcher Disable

Disable

Enable*

Enable*

Enable*

Enable*

To turn on/off prefetching

of adjacent cache lines.

To turn on/off the Mid

Level Cache (L2) streamer

prefetcher.

Disable/Enable the DCU

Streamer Prefetcher.

Disable/Enable the DCU

IP Prefetcher.

Using the System Setup Program 29

Page 30

Memory Configuration

Menu Fields Settings Comments

Advanced\Memory Configuration

Memory Frequency Auto*

1067 MHz

1333 MHz

Memory Remapping

(3 GB - 4 GB)

Disable*

Enable

Auto-Detect the memory

running speed or set

running speed up to

1067/1333 MHz.

NOTE: Supported detection

and running speed of up to

1600 MHz.

Memory remapping

relocates memory space

3 GB~4 GB to the space

above 4 GB with this

feature disabled/enabled.

30 Using the System Setup Program

Page 31

SATA Configuration

Menu Fields Settings Comments

Advanced\SATA Configuration

Embedded SATA

Controller

Off

IDE

AHCI*

RAID

Disables the SATA

controller or enables it and

sets the device class code as

IDE/AHCI/RAID. This

token applies to the first

on-board SATA controller.

NOTE: Function available

after BIOS 1.0.4.

Using the System Setup Program 31

Page 32

Menu Fields Settings Comments

Embedded SATA Link Rate Auto*

1.5 Gbps

3.0 Gbps

Auto is default mode.

Set SATA port to run on

GEN1 mode by selecting

1.5 Gbps.

NOTE: Function supported

after BIOS 2.0.X.

SATA Port 0/SSI Hard

drive

0

SATA Port1/SSI

drive

1

SATA Port2/

SATA Port3/

SATA Port4/

SATA Port5/

Hard

Hard drive 0 While entering setup,

Hard drive 1 While entering setup,

Hard drive 2 While entering setup,

Hard drive 3 While entering setup,

While entering setup,

BIOS auto detects the

presence of SATA devices

and displays the status of

detected SATA hard drives.

While entering setup,

BIOS auto detects the

presence of SATA devices

and displays the status of

detected SATA hard drives.

BIOS auto detects the

presence of SATA devices

and displays the status of

detected SATA hard drives.

BIOS auto detects the

presence of SATA devices

and displays the status of

detected SATA hard drives.

BIOS auto detects the

presence of SATA devices

and displays the status of

detected SATA hard drives.

BIOS auto detects the

presence of SATA devices

and displays the status of

detected SATA hard drives.

32 Using the System Setup Program

Page 33

Menu Fields Settings Comments

Power Saving Features Disable

Enable*

HDD Security Erase Disable*

Enable

Port Mapping of Cougar Point SATA Controllers

SATA Port0/SSI Hard

Drive 0

SATA Port1/SSI Hard

Drive 1

SATA Port2/Hard Drive 0 Bus0:Dev31:Fun2 SATA Controller

SATA Port3/Hard Drive 1 Bus0:Dev31:Fun2 SATA Controller

SATA Port4/Hard Drive 2 Bus0:Dev31:Fun5 SATA Controller

SATA Port5/Hard Drive 3 Bus0:Dev31:Fun5 SATA Controller

Bus0:Dev31:Fun2 SATA Controller

Bus0:Dev31:Fun2 SATA Controller

Disable/Enable the feature

that allows SATA hard

drives to initiate link power

management transitions.

Not Set Security Freeze

Lock Command.

Using the System Setup Program 33

Page 34

PCI Configuration

Menu Fields Settings Comments

Advanced\PCI Configuration

Embedded Network

Devices

NIC Enumeration Onboard*

Add-in

Active State Power

Management

Configuration

Embedded Network

Devices.

Change the sequence of

NIC OPROM

initialization.

NOTE: Function supported

after BIOS 2.0.X.

Active State Power

Management

Configuration.

34 Using the System Setup Program

Page 35

Menu Fields Settings Comments

PCI Slot Configuration Disable if PCIe card is not

installed.

NOTE: Function supported

after BIOS 2.0.X.

PCIe Generation Gen2*

Gen1

VT for Direct I/O Disable*

Enable

SR-IOV Global Enable Disable*

Enable

Maximum Payload Size Auto*

128 Bytes

256 Bytes

WHEA Support Disable*

Enable

Set PCIe generation.

NOTE: Function supported

after BIOS 2.0.X.

Disable/Enable Intel

Virtualization Technology

for Direct I/O (VT-d) that

enhances I/O support

(DMA) when running a

Virtual Machine Monitor.

Disable/Enable BIOS

support for SR-IOV

devices. To enable this

feature, an add-on NIC

with SR-IOV support is

required.

Auto detects the PCIe

maximum payload size or

sets it to 128/256 Bytes.

Enable or disable Windows

Hardware Error

Architecture (WHEA).

Using the System Setup Program 35

Page 36

Embedded Network Devices

Menu Fields Settings Comments

Advanced\PCI Configuration\Embedded Network Devices

Embedded NIC1 Disabled

Enabled with PXE*

Enabled without PXE

iSCSI Remote Boot

Disable/Enable the

system's primary embedded

network interface

controller (full-function),

w/, w/o including its PXE

boot-ROM or with iSCSI

Remote Boot. To disable

NIC1, NIC2 should be

disabled first. If iSCSI is

enabled, UEFI PXE can

not boot.

36 Using the System Setup Program

Page 37

Menu Fields Settings Comments

Embedded NIC2 Disabled

Enabled with PXE

Enabled without PXE*

iSCSI Remote Boot

Disables/Enables the

system's secondary

embedded network

interface controller (fullfunction), w/, w/o including

its PXE boot-ROM or with

iSCSI Remote Boot. If

iSCSI is enabled, UEFI

PXE can not boot.

Active State Power Management Configuration

Using the System Setup Program 37

Page 38

Menu Fields Settings Comments

Advanced\PCI Configuration\Active State Power Management Configuration

Onboard LAN ASPM Disabled*

L0s

L1

L0s & L1

Mezzing Slot ASPM Disabled*

L0s

L1

L0s & L1

NB-SB Link ASPM Disabled

L0s & L1*

Controls the level of ASPM

supported on the PCI

Express Link.

Controls the level of ASPM

supported on the PCI

Express Link.

Controls the level of ASPM

supported on the PCI

Express Link.

38 Using the System Setup Program

Page 39

PCI Slot Configuration

Menu Fields Settings Comments

Advanced\PCI Configuration\PCI Slot Configuration

Mezzanine slot Disabled

Enabled*

Enabled without OPROM

Using the System Setup Program 39

Disables/Enables controller,

w/ or w/o OPROM.

Page 40

USB Configuration

Menu Fields Settings Comments

Advanced\USB Configuration

Embedded USB Controller Disabled

Enabled*

Legacy USB Support Disabled

Enabled*

Disables/Enables the builtin USB controller at system

startup.

Enables Legacy USB

support. Disable option

keeps USB devices

available only for EFI

applications.

40 Using the System Setup Program

Page 41

Menu Fields Settings Comments

USB PORT with BMC Disabled

Enabled*

External USB PORT1 Disabled

Enabled*

External USB PORT2 Disabled

Enabled*

Internal USB Connetor Disabled

Enabled*

Allows the users to

electrically disable/enable

the internal USB port

which contacts to BMC.

Allows the users to

electrically disable/enable

the external USB port1.

Allows the users to

electrically disable/enable

the external USB port2.

Disables/Enables the

internal USB port.

Using the System Setup Program 41

Page 42

Server Management

Menu Fields Settings Comments

Server Management

ACPI SPMI Table Disabled

Enabled*

Set BMC LAN

Configuration

Remote Access

Configuration

Restore on AC Power Loss Power Off

Power On*

Last State

ACPI SPMI Table.

Configures BMC network

parameters.

Remote Access

Configuration.

System action to take on

AC power loss.

42 Using the System Setup Program

Page 43

Menu Fields Settings Comments

Power Staggering AC

Recovery

Power Button Disabled

View System Event Log Press <Enter> to view

Clear BMC System Event

Log

Event logging Disabled

NMI On Error Disabled

Immediate*

Random

User Defined

Enabled*

Enabled*

Enabled*

Immediate: PowerOn (No

Delay)\Random:

(Auto)\User Defined: user

defined delay time must be

in the range of Minimum

and Maximum Power On

Delay.

Select Disabled to disable

power off function.

system Event Log records.

Select SEL clear method.

Disable PCIE

SERR/DRAM ECC Error

Logging.

Enable or disable NMI

asserted for fatal error.

Using the System Setup Program 43

Page 44

Set BMC LAN Configuration

Menu Fields Settings Comments

Server Management/BMC Network Configuration

BMC LAN Port

Configuration

BMC NIC IP Source Static

Dedicated-NIC

Shared-NIC*

DHCP*

BMC LAN Port

Configuration

NOTE: Dedicated-NIC port

is found on the chassis.

Select to configure LAN

channel parameters

statically or dynamically

(DHCP).

44 Using the System Setup Program

Page 45

Menu Fields Settings Comments

IP Address xxx.xxx.xxx.xxx Enter IP address in the

form of

XXX.XXX.XXX.XXX (XXX

less than 256 and in

decimal only).

Subnet Mask xxx.xxx.xxx.xxx Enter Subnet Mask in the

form of

XXX.XXX.XXX.XXX (XXX

less than 256 and in

decimal only).

GateWay Address xxx.xxx.xxx.xxx Enter Gateway Address in

decimal in the form of

XXX.XXX.XXX.XXX (XXX

less than 256 and in

decimal only).

Using the System Setup Program 45

Page 46

Remote Access Configuration

Menu Fields Settings Comments

Server/Remote Access Configuration

Remote Access Disabled

Enabled*

The settings specify how

the host computer and the

remote system exchanges

data. Both systems should

have the same or

compatible settings.

NOTE: The screen would

keep 100x31 even when

Remote Access is enabled.

Client console utility should

be supported.

46 Using the System Setup Program

Page 47

Menu Fields Settings Comments

Serial Port Number COM1

COM2 as SOL*

Serial Port Address 3F8h/2F8h*

2F8h/3F8h

Flow Control None*

Hardware

Redirection After BIOS

POST

Term i n al Typ e AN S I*

VT-UTF8 Combo Key

Support

Disabled

Always*

VT100

VT-UTF8

Disabled

Enabled*

Serial port number

COM1/COM2 IO port

address

Flow control can prevent

data loss from buffer

overflow. When sending

data, if the receiving

buffers are full, a 'stop'

signal can be sent to stop

the data flow. Once the

buffers are empty, a 'start'

signal can be sent to restart the flow. Hardware

flow control uses two wires

to send start/stop signals.

Redirection After BIOS

POST

Emulation: ANSI:

Extended ASCII char set.

VT100: ASCII char set.

VT-UTF8: Uses UTF8

encoding to map Unicode

chars onto 1 or more bytes.

Enable VT-UTF8

combination key support

for ANSI/VT100 terminals.

NOTE: BIOS setup screens display at 100 (columns) x 31 (lines). Change the client-side

console utility settings to support 100 (columns) x 31 (lines) for accurate screen display.

Using the System Setup Program 47

Page 48

View System Event Log

48 Using the System Setup Program

Page 49

NOTE: Only provides a brief SEL description for the user. If the user needs more

detailed information, refer to the BMC Event Log in the Server Health of WebUI.

Using the System Setup Program 49

Page 50

Boot Menu

This page enables you to set POST boot parameters.

Menu Fields Settings Comments

Boot

Quiet Boot Disabled

Enabled*

Pause On Errors Disabled*

Enabled

Force PXE Boot Only Disabled*

Enabled

Enables or disables Quiet

Boot option

Pause on Errors

Force PXE Boot Only

50 Using the System Setup Program

Page 51

Menu Fields Settings Comments

Boot Mode BIOS*

UEFI

1st Boot Network*

Hard Disk

RAID

USB Storage

CD/DVD

2nd Boot Network

Hard Disk*

RAID

USB Storage

CD/DVD

3rd Boot Network

Hard Disk

RAID*

USB Storage

CD/DVD

4th Boot Network

Hard Disk

RAID

USB Storage*

CD/DVD

5th Boot Network

Hard Disk

RAID

USB Storage

CD/DVD*

If Boot Mode UEFI/BIOS

is selected, only UEFI

legacy boot devices are

selected for bootup.

Set Boot Priority

Set Boot Priority

Set Boot Priority

Set Boot Priority

Set Boot Priority

Using the System Setup Program 51

Page 52

Security Menu

Menu Fields Settings Comments

Security

Change Supervisor

Password

Change User Password Set User Password

52 Using the System Setup Program

Set Supervisor Password

Page 53

Save and Exit

Menu Fields Settings Comments

Save & Exit

Save Change and Exit Exit system setup after

saving the changes.

Discard Changes and Exit Exit system setup without

saving any changes.

Save Changes Save Changes done so far

to any of the setup option.

Discard Changes Discard changes done so far

to any of the setup option.

Using the System Setup Program 53

Page 54

Menu Fields Settings Comments

Load Optimal Defaults Restore/Load Default

values for all the setup

options.

Load Customized Defaults Restore the User Defaults

to all the setup option.

Save Customized Defaults Save the changes done so

far as User Defaults.

Boot Override

Network Hide if Device is not

connected.

Hard Disk Hide if Device is not

connected.

RAID Hide if Device is not

connected.

USB Storage Hide if Device is not

connected.

CD/DVD ROM Hide if Device is not

connected.

Built-in EFI Shell Attempts to Launch EFI

Shell application

(Shellx64.efi) from one of

the available file system

devices.

NOTE: For further specifications see UEFI Shell Specification at uefi.org/specs/.

54 Using the System Setup Program

Page 55

POST Error Handling

This section provides information on POST error message and handling.

Error Messages

Error messages are displayed at POST under the following fail conditions:

• Hard drive is not present in system

• MRC initialization failure in a DIMM module

NOTE: You can enable the Pause on Error function in the BIOS setup menu to

pause the POST Error Message on Screen at time of display.

Error Message

DIMM A1 has been disabled by MRC.

DIMM A2 has been disabled by MRC.

DIMM A3 has been disabled by MRC.

DIMM A4 has been disabled by MRC.

Status Codes

A status code is a data value used to indicate progress during the boot phase.

A subset of these status codes, known commonly as checkpoints, indicate

common phases of the BIOS boot process.

The status codes can be viewed during POST at the right bottom corner of

the screen as shown in Figure 2-1.

Using the System Setup Program 55

Page 56

Figure 2-1. POST Error Codes

Status Codes

Status Code Description

0x90 Boot Device Selection (BDS) phase is started

0x91 Driver connecting is started

0x92 PCI Bus initialization is started

0x94 PCI Bus Enumeration

0x95 PCI Bus Request Resources

0x96 PCI Bus Assign Resources

0x97 Console Output devices connect

0x98 Console input devices connect

0x99 Super IO Initialization

0x9A USB initialization is started

0x9B USB Reset

0x9C USB Detect

56 Using the System Setup Program

Page 57

Status Code Description

0x9D USB Enable

0xA0 IDE initialization is started

0xA1 IDE Reset

0xA2 IDE Detect

0xA3 IDE Enable

0xA4 SCSI initialization is started

0xA5 SCSI Reset

0xA6 SCSI Detect

0xA7 SCSI Enable

0xA8 Setup Verifying Password

0xA9 Start of Setup

0xAB Setup Input Wait

0xAD Ready To Boot event

0xAE Legacy Boot event

0xAF Exit Boot Services event

0xB2 Legacy Option ROM Initialization

0xB3 System Reset

0xB4 USB hot plug

Using the System Setup Program 57

Page 58

Command Line Interfaces for Setup options

The SETUP menu provides setup options through the system configuration

utility (syscfg), included in the Dell OpenManage Deployment Toolkit

(DTK).

Users can use the utility as following:

To change the SETUP option thru D4 token:

./syscfg –t=D4_token_id

Example:

./syscfg -t=0x002D to enable NIC1

To check token active status:

./syscfg --istokenactive=D4_token_id

Example:

./syscfg --istokenactive=0x002D to check the token active status of NIC1

To di rec t ly ch ang e t he S ET UP option thru BMC memory:

./ipmitool raw <command> <data>

Example:

./ipmitool raw 0xc 1 1 3 10 106 42 120 to set IP address of BMC LAN port

as 10.106.42.120

58 Using the System Setup Program

Page 59

3

Installing System Components

Safety Measures

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized is not covered by

warranty. Read and follow the safety instructions that came with the product.

System components and electronic circuit boards can be damaged by

discharges of static electricity. Working on systems that are still connected to

a power supply can be extremely dangerous. To avoid injury to yourself or

damage to system, follow these guidelines:

• If possible, wear a grounded wrist strap when you are working inside the

system chassis. Alternatively, discharge any static electricity by touching

the bare metal chassis of the system chassis, or the bare metal body of any

other grounded appliance.

• Hold electronic circuit boards by the edges only. Do not touch the

components on the board unless it is necessary to do so. Do not flex or

stress the circuit board.

• Leave all components inside the static-proof packaging until you are ready

to use the component for the installation.

Recommended Tools

•Phillips screwdriver #2

Installing System Components 59

Page 60

Inside the System

8

7

6

5

1

3

2

4

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized is not covered by

warranty. Read and follow the safety instructions that came with the product.

CAUTION: This system must be operated with the system cover installed to make

sure of proper cooling.

Figure 3-1. Inside the System

1 PSU 1 2 PSU 2

3 PDB 1 4 PDB 2

5 power socket bracket 6 fan cage

7 backplane 8 sleds (12)

60 Installing System Components

Page 61

Sled Configuration

PSU1 PSU2

PSU1 PSU2

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8 9 10 11 12

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

The following illustrations show the two server sled options and the sled

numbering in each option.

Figure 3-2. PowerEdge C5220 8-Sled SKU

NOTE: Sled SKU may also include an LSI 2008, 1GbE or 10GbE mezzanine card.

Figure 3-3. PowerEdge C5220 12-Sled SKU

Installing System Components 61

Page 62

Sleds

2

1

Removing a Sled

CAUTION:

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

CAUTION: To ensure proper airflow in the system, if a sled is removed it should be

immediately replaced with another sled or sled dummy.

1

Press the release latch down .

2

Pull the sled out of the system .

Many repairs may only be done by a certified service technician. You

62 Installing System Components

Page 63

Installing a Sled

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

CAUTION: To ensure proper airflow in the system, if a sled is removed it should be

immediately replaced with another sled or sled dummy.

Push the sled into the system until flush with the case and the release latch

locks.

Installing System Components 63

Page 64

Memory Modules

Supported DIMM Configuration

The following DIMM configurations are supported by the system.

Figure 3-4. DIMM Slot Configuration

DIMM Population Rules

For a single DIMM, only install in DIMM A1.

For two DIMMs, install in DIMM A1 + A3.

64 Installing System Components

Page 65

Supported Memory

NOTE: Only Intel Xeon E3-1200v2 family of products support 1600 MHz memory.

Supported Memory

Configura-

Memory Type/Size CPU DIMMs Type Memory

tion

8-Sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

8-sled

DDR3 ECC

UDIMM/2048 MB*1

DDR3 ECC

UDIMM/2048 MB*2

DDR3 ECC

UDIMM/2048 MB*3

DDR3 ECC

UDIMM/4096 MB*1

+2048 MB*2

DDR3 ECC

UDIMM/2048 MB*1

+4096 MB*2

DDR3 ECC

UDIMM/4098 MB*3

DDR3 ECC

UDIMM/2048 MB*4

DDR3 ECC

UDIMM/4096 MB*1

DDR3 ECC

UDIMM/4096 MB*2

DDR3 ECC

UDIMM/2048 MB*2

+4096 MB*2

DDR3 ECC

UDIMM/4096 MB*4

DDR3 ECC

UDIMM/8912 MB*1

DDR3 ECC

UDIMM/8912 MB*2

DDR3 ECC

UDIMM/8912 MB*3

DDR3 ECC

UDIMM/8912 MB*4

DDR3 ECC

UDIMM/8912 MB*2

+2048 MB*2

DDR3 ECC

UDIMM/8912

MB*2+4096MB*2

1 1 UDIMM 1333/

1 2 UDIMM 1333/

1 3 UDIMM 1333/

1 3 UDIMM 1333/

1 3 UDIMM 1333/

1 3 UDIMM 1333/

1 4 UDIMM 1333/

1 1 UDIMM 1333/

1 2 UDIMM 1333/

1 4 UDIMM 1333/

1 4 UDIMM 1333/

1 1 UDIMM 1333/

1 2 UDIMM 1333/

1 3 UDIMM 1333/

1 4 UDIMM 1333/

1 4 UDIMM 1333/

1 4 UDIMM 1333/

Rank Type

Speed

(MHz)

1R x8 2 Gb 2G •

1600

1R x8 2 Gb 4G • •

1600

1R x8 2 Gb 6G • • •

1600

2R/1Rx8 2 Gb 8G 2G 4G 2G

1600

1R/2Rx8 2 Gb 10G 2G 4G 4G

1600

2R x8 2 Gb 12G • • •

1600

1R x8 2 Gb 8G • • • •

1600

2R x8 2 Gb 4G •

1600

2R x8 2 Gb 8G • •

1600

1R/2Rx8 2 Gb 12G 2G 4G 2G 4G

1600

2R x8 2 Gb 16G • • • •

1600

2R x8 4 Gb 8G

1600

2R x8 4Gb 16G • •

1600

2R x8 4Gb 24G • • •

1600

2R x8 4Gb 32G • • • •

1600

2R/1Rx8 4Gb/

1600

2R/2Rx8 4Gb/ 2Gb 24G 4G 8G 4G 8G

1600

(x8, x4)

Component

Density

2Gb

Total

Size

20G 2G 8G 2G 8G

DIMM Slot

A1 A2 A3 A4

•

Installing System Components 65

Page 66

Supported Memory

Configura-

Memory Type/Size CPU DIMMs Type Memory

tion

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

12 sled

DDR3 ECC

UDIMM/2048 MB*1

DDR3 ECC

UDIMM/2048 MB*2

DDR3 ECC

UDIMM/2048 MB*3

DDR3 ECC

UDIMM/4096 MB*1

+2048 MB*2

DDR3 ECC

UDIMM/2048 MB*1

+4096 MB*2

DDR3 ECC

UDIMM/4098 MB*3

DDR3 ECC

UDIMM/2048 MB*4

DDR3 ECC

UDIMM/4096 MB*1

DDR3 ECC

UDIMM/4096 MB*2

DDR3 ECC

UDIMM/2048

MB*2+4096 MB*2

DDR3 ECC

UDIMM/4096 MB*4

DDR3 ECC

UDIMM/8912MB*1

DDR3 ECC

UDIMM/8912MB*2

DDR3 ECC

UDIMM/8912MB*3

DDR3 ECC

UDIMM/8912MB*4

DDR3 ECC

UDIMM/8912MB*2

+2048MB*2

DDR3 ECC

UDIMM/8912MB*2

+4096MB*2

11 VLP

12 VLP

13 VLP

13 VLP

13 VLP

13 VLP

14 VLP

11 VLP

12 VLP

14 VLP

14 VLP

11 VLP

12 VLP

13 VLP

14 VLP

14 VLP

14 VLP

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

UDIMM

Rank Type

Speed

(MHz)

1333/

2R x8 1Gb 2G •

1600

1333/

2R x8 1Gb 4G • •

1600

1333/

2R x8 1Gb 6G • • •

1600

1333/

2R x8 2Gb/

1600

1333/

2R x8 1Gb/

1600

1333/

2R x8 2Gb 12G • • •

1600

1333/

2R x8 1Gb 8G • • • •

1600

1333/

2R x8 2Gb 4G •

1600

1333/

2R x8 2Gb 8G • •

1600

1333/

2R x8 1Gb/2Gb 12G 2G 4G 2G 2G

1600

1333/

2R x8 2Gb 16G • • • •

1600

1333/

2R x8 4Gb 8G •

1600

1333/

2R x8 4Gb 16G • •

1600

1333/

2R x8 4Gb 24G • • •

1600

1333/

2R x8 4Gb 32G • • • •

1600

1333/

2R x8 4Gb/2Gb 20G 2G 8G 2G 8G

1600

1333/

2R x8 4Gb/2Gb 24G 4G 8G 4G 8G

1600

(x8, x4)

Component

Density

1Gb

2Gb

Total

Size

8G 2G 4G 2G

10G 2G 4G 4G

DIMM Slot

A1 A2 A3 A4

NOTE: 1600MHz VLP UDIMM will be available by June 2012.

66 Installing System Components

Page 67

Removing a Memory Module

1

2

3

WARNING: The memory modules are hot to touch for some time after the system

has been powered down. Allow time for the memory modules to cool before

handling them. Handle the memory modules by the card edges and avoid touching

the components on the memory module.

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized is not covered by

warranty. Read and follow the safety instructions that came with the product.

1

Remove the sled from the system. See "Sled Configuration" on page 61.

2

Push the locking latches of the DIMM slot outwards. See Figure 3-5.

3

Remove the memory module from the system.

Figure 3-5. Removing and Installing a Memory Module

1 locking latch 2 DIMM slot

3 memory module notch

Installing System Components 67

Page 68

Replacing a Memory Module

WARNING: The memory modules are hot to touch for some time after the system

has been powered down. Allow time for the memory modules to cool before

handling them. Handle the memory modules by the card edges and avoid touching

the components on the memory module.

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized is not covered by

warranty. Read and follow the safety instructions that came with the product.

The system board has four slots in two channels for the installation of

memory modules. See "System Board Jumpers and Connectors" on page 111

for the location of the memory modules.

Follow the instructions given below to install memory modules:

1

Align the memory module correctly with the DIMM slot. Note the notch

and obstruction in Figure 3-5.

2

Press the edge connector of the memory module into the DIMM slot. Press

down firmly on the memory module so that the locking latches of the

DIMM slot are levered upwards to secure the memory module in place.

68 Installing System Components

Page 69

Hard Drives

Bottom of sled

Top of sled

The following are examples showing the installation and removal procedures

for the 2.5-inch and the 3.5-inch hard drives.

Removing a 2.5-inch Hard Drive

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

NOTE: Mixing SATA and SAS hard drive on the 2.5 and 3.5-inch hard drive board is

not supported.

1

Remove the sled from the system. See "Sled Configuration" on page 61.

2

Remove the hard drive from the sled docking bay.

3

Select the hard drive to replace and remove the four hard drive bracket

screws securing it underneath the sled.

Remove the hard drive from the sled docking bay.

4

Installing System Components 69

Page 70

5

HDD0

2.5” HDD

HDD1

2.5” HDD

HDD2

2.5” HDD

HDD3

2.5” HDD

Remove the four screws from the 2.5-inch hard drive bracket, then detach

the hard drive from the bracket.

70 Installing System Components

Page 71

Installing a 2.5-inch Hard Drive

HDD0

2.5” HDD

HDD1

2.5” HDD

HDD2

2.5” HDD

HDD3

2.5” HDD

1

Align the 2.5-inch hard drive bracket on the new hard drive then replace

the four screws.

NOTE: The correct orientation of the bracket with the arrow mark pointing towards

the hard drive connector.

2

Connect the hard drive to the hard drive board in the sled.

Replace the sled hard drive bracket screws underneath the sled.

3

Installing System Components 71

Page 72

Removing a 3.5-inch Hard Drive

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

NOTE: Mixing SATA and SAS hard drives on the 2.5 and 3.5-inch hard drive board is

not supported.

1

Remove the sled from the system. See "Sled Configuration" on page 61.

2

Remove the hard drive bracket screws from underneath the sled.

72 Installing System Components

Page 73

Bottom of sled

Top of sled

HDD0

3.5” HDD

HDD1

3.5” HDD

HDD0

HDD1

SATA0

SATA1

3

Remove the hard drive cables from the cable clips.

3.5” HDD

3.5” HDD

HDD0

HDD0

4

Disconnect the hard drive cables from the hard drive board and system

board

then lift the hard drive out of the sled .

3.5” HDD

3.5” HDD

HDD1

HDD1

2

HDD1

3.5” HDD

HDD0

HDD0

HDD0

5

Disconnect the hard drive cables A and B from the hard drive.

3.5” HDD

HDD1

HDD1

HDD1

1

HDD0

Installing System Components 73

SATA1

SATA1

SATA0

SATA0

Page 74

Installing a 3.5-inch Hard Drive

HDD0HDD0HDD0

HDD1

HDD1HDD1

HDD0

3.5” HDD

HDD1

3.5” HDD

2

1

HDD0

HDD1

SATA0SATA0SATA0

SATA1

SATA1SATA1

1

Connect the hard drive cables A and B to a new hard drive.

2

Place the hard drive in the sled then connect the hard drive cables to

the hard drive board and system board

.

74 Installing System Components

Page 75

3

HDD0HDD0HDD0

3.5” HDD

3.5” HDD3.5” HDD

HDD1

HDD1HDD1

3.5” HDD

3.5” HDD 3.5” HDD

Insert the hard drive cables into the cable clips.

4

Replace the hard drive bracket screws underneath the sled.

Installing System Components 75

Page 76

Hard Drive Boards

HDD0

2.5” HDD

HDD1

2.5” HDD

HDD2

2.5” HDD

HDD3

2.5” HDD

SATA3SATA3SATA3

SATA0

SATA0SATA0

SATA1

SATA1SATA1

SATA2

SATA2SATA2

HDD3HDD3HDD3

HDD0

HDD0HDD0

HDD2

HDD2HDD2

HDD1

HDD1HDD1

Removing a 2.5-inch Hard Drive Board

CAUTION:

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

1

Remove the hard disks. See "Hard Drives" on page 69.

2

Disconnect the four SATA cables between the hard drive board and the

system board.

3

Remove the eight screws from the hard drive board .

4

Disconnect the hard drive board from the system board and lift out of

the sled.

Many repairs may only be done by a certified service technician. You

76 Installing System Components

Page 77

Installing a 2.5-inch Hard Drive Board

HDD0

2.5” HDD

HDD1

2.5” HDD

HDD2

2.5” HDD

HDD3

2.5” HDD

SATA3SATA3SATA3

SATA0

SATA0SATA0

SATA1

SATA1SATA1

SATA2

SATA2SATA2

HDD3HDD3HDD3

HDD0

HDD0HDD0

HDD2

HDD2HDD2

HDD1

HDD1HDD1

1

Holding the board by the edges, place the hard drive board into the sled

and connect to the system board

2

Replace the eight screws to secure it in place .

3

Connect the four SATA cables between the hard drive board and the

system board.

.

Removing a 3.5-inch Hard Drive Board

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

1

Remove the hard drives. See "Removing a 3.5-inch Hard Drive" on page 72.

2

Remove the eight screws from the hard drive board .

3

Disconnect the hard drive board from the system board and lift out of

the sled.

Installing System Components 77

Page 78

Installing a 3.5-inch Hard Drive Board

1

Unpack the new hard drive board.

2

Holding the board by the edges, place the hard drive board into the sled

and connect to the system board

3

Replace the eight screws to secure it in place .

.

78 Installing System Components

Page 79

Heat Sinks

The following procedure as illustrated with an air shroud only applies to the

12-sled SKU system(Table 3-1). The 8-sled SKU does not require an air

shroud.

Table 3-1. Processors Requiring an Air Shroud on C5220 12-Sled SKU

Series Processor

Intel Xeon E3-1200v2

product family

Removing a Heat Sink/Shroud

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

1

Remove the required sled from the system. See "Sled Configuration" on

page 61.

2

Loosen the four captive screws on the heat sink .

Intel Xeon E3-1280v2

Intel Xeon E3-1270v2

Intel Xeon E3-1240v2

Intel Xeon E3-1230v2

Intel Xeon E3-1220v2

Installing System Components 79

Page 80

3

Remove the heat sink/shroud assembly by tilting the backend up to clear

the shroud from under the sled flange and then lift upwards

Figure 3-6. Removing a heat sink/shroud

.

80 Installing System Components

Page 81

Installing a Heat Sink/Shroud

1

Use a lint-free cloth, remove thermal grease from the heat sink.

2

Apply new thermal grease evenly to the center of the top new processor.

CAUTION:

processor shield, which can cause contamination of the processor socket.

3

Position heat sink/shroud assembly at a slight tilt to insure shroud is

inserted below the sled flange (see final installed view), then lower the

assembly onto the four supporting posts on the motherboard

4

Align the four screws of the heatsink to the four threaded posts and tighten

the four screws

Figure 3-7. Installing a heat sink/shroud

Using excess thermal grease can cause grease to contact the

.

.

Final installed view shown in the following illustration.

Installing System Components 81

Page 82

Figure 3-8. Final installed view of a heat sink/shroud

The following procedure as illustrated with an air shroud only applies to the

12-sled SKU system. The 8-sled SKU does not require an air shroud.

82 Installing System Components

Page 83

Removing a Heat Sink

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

1

Remove the required sled from the system. See "Sled Configuration" on

page 61.

2

Loosen the four captive screws on the heat sink .

3

Remove the heat sink .

Figure 3-9. Removing a heat sink

Installing System Components 83

Page 84

Installing a Heat Sink

1

Use a lint-free cloth, remove thermal grease from the heatsink.

2

Apply new thermal grease evenly to the center of the top new processor.

CAUTION: Using excess thermal grease can cause grease to contact the

processor shield, which can cause contamination of the processor socket.

3

Place the new heatsink onto the system board .

4

Tighten the four captive screws on the heatsink .

Figure 3-10. Installing a heat sink

84 Installing System Components

Page 85

Processors

Removing a Processor

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized by Dell is not covered

by your warranty. Read and follow the safety instructions that came with the

product.

1

Remove the heatsink. See "Removing a Heat Sink/Shroud" on page 79.

2

Release the locking latch.

3

Remove the processor.

Installing System Components 85

Page 86

Installing a Processor

CAUTION: Positioning the processor incorrectly can permanently damage the

system board or the processor. Be careful not to bend the pins in the socket.

1

Place the new processor into the socket.

Close the locking latch.

2

86 Installing System Components

Page 87

Mezzanine Cards

Replacing a Mezzanine Card (Optional)

A mezzanine card is an optional component and can only be installed in an

8-sled system board.

CAUTION: Many repairs may only be done by a certified service technician. You

should only perform troubleshooting and simple repairs as authorized in your

product documentation, or as directed by the online or telephone service and

support team. Damage due to servicing that is not authorized is not covered by

warranty. Read and follow the safety instructions that came with the product.

System components and electronic circuit boards can be damaged by

discharges of static electricity. Working on systems that are still connected to

a power supply can be extremely dangerous. Follow the simple guidelines

below to avoid damage to your system or injury to yourself.

• If possible, wear a grounded wrist strap when you are working inside the

system chassis. Alternatively, discharge any static electricity by touching

the bare metal chassis of the system chassis, or the bare metal body of any

other grounded appliance.

• Hold electronic system boards by the edges only. Do not touch the

components on the board unless it is necessary to do so. Do not flex or

stress the system board.

• Leave all components inside the static-proof packaging until you are ready

to use the component for the installation.

Installing a 1 GbE and 10 GbE Mezzanine Card

Prior to installing a mezzanine card, remove the sled board from the chassis,

see "Removing a Sled" on page 62.

1

Remove the mezzanine card from its static-proof packing.

2

With the PCIe connector facing up, place the mezzanine card in the

mezzanine bracket.

3

Secure the card on the bracket with the provided screws.

4

Insert the linking board into the mezzanine card.

5

Secure the linking board to the bracket with the provided screw.

NOTE: 10GbE Mezzanine cards require BIOS 1.0.12 or 2.0.x.

Installing System Components 87

Page 88

Figure 3-11. Installing a Linking Board in a Mezzanine Card

2

3

4

5

6

6

Flip the mezzanine assembly over and align over the two guide pins on the

sled, see following image.

Figure 3-12. Installing a Mezzanine Assembly in a Sled

NOTE: The I/O screw bracket tab must be behind the mezzanine bracket.

7

Align the linking board over the sled and insert as shown in the following

image.

88 Installing System Components

Page 89

Figure 3-13. Securing a Mezzanine Assembly

8

7

8

Secure the assembly to the sled assembly with the provided screw.

Removing a 1 GbE and 10 GbE Mezzanine Card

Prior to removing a mezzanine card, you must first remove the sled board

from the chassis, see "Removing a Sled" on page 62.

1

Remove the single screw to release the assembly.

2

Remove the assembly from the sled.

Installing System Components 89

Page 90

Figure 3-14. Removing a 1/10 GbE Mezzanine Assembly

1

2

5

5

4

3

5

6

3

Flip the assembly over and remove the provided screw securing the linking

board.

4

Remove the linking board from the mezzanine card.

5

Remove the provided screws securing the card.

Figure 3-15. Removing a 1/10 GbE Mezzanine Card

6

Remove the card from the assembly.

90 Installing System Components

Page 91

Installing a SAS Mezzanine Card with 2.5" HDD

2

3

4

5

6

Prior to installing a mezzanine card, you must first remove the sled board

from the chassis, see "Removing a Sled" on page 62.

1

Remove the mezzanine card from its static-proof packing.

2

With the PCIe connector facing up, attach the 2.5-inch SAS cable to the

SAS mezzanine card.

3

Place the mezzanine card in the mezzanine bracket.

4

Secure the card on the bracket with the provided screws.

5

Insert the linking board into the mezzanine card as shown in the following

image.

6

Secure the linking board to the bracket with the provided screw.

Figure 3-16. Inserting a Linking Board in a SAS Mezzanine Card

7

Flip the mezzanine assembly over and align over the two guide pins on the

sled, see following image.

Installing System Components 91

Page 92

Figure 3-17. Installing a SAS Mezzanine Assembly in a Sled

7

8

9

NOTE: The I/O screw bracket tab must be behind the mezzanine bracket.

8

Align the linking board over the sled and insert.

9

Secure the assembly to the sled with the three screws.

92 Installing System Components

Page 93

Routing the 2.5" SAS Mezzanine Cables

routing pathhard drive ports

After installing a mezzanine card, you need to route the SAS cabling as

depicted in the following figure.

Figure 3-18. SAS Mezzanine Cable Routing

Removing a SAS Mezzanine Card with 2.5" HDD

Prior to removing a mezzanine card, you must first remove the sled board

from the chassis, see "Removing a Sled" on page 62.

1

Remove the screws securing the assembly.

2

Remove the assembly from the sled.

Installing System Components 93

Page 94

Figure 3-19. Removing a SAS Mezzanine Assembly in a Sled

1

1

1

3

Flip the assembly over and remove the provided screw securing the linking

board.

4

Remove the linking board from the mezzanine card.

5

Disconnect the SAS cable from the card.

6

Remove the provided screws securing the card.

7

Remove the mezzanine card from the assembly.

94 Installing System Components

Page 95

Figure 3-20. Removing a SAS Mezzanine Card

5

3

6

4

3

6

7

6

Installing a SAS Mezzanine Card with 3.5" HDD

Prior to installing a mezzanine card, you must first remove the sled board

from the chassis, see "Removing a Sled" on page 62.

1

Remove the mezzanine card from its static-proof packing.

2

Place the mezzanine card in the mezzanine bracket.

3

Secure the card on the bracket with the provided screws.

4

Insert the linking board into the mezzanine card as shown in the following

image.

5

Secure the linking board to the bracket with the provided screw.

6

With the PCIe connector facing up, attach the SATA cable 4 to the SAS

mezzanine card.

7

With the PCIe connector facing up, attach the SATA cable 5 to the SAS

mezzanine card.

Installing System Components 95

Page 96

Figure 3-21. Inserting a Linking Board on a 3.5" SAS Mezzanine Card

6

4

5

5

2

7

9

8

10

8

10

10

8

Flip the mezzanine assembly over and align over the two guide pins on the

sled, see following image.

9

Align the linking board over the sled and insert.

10

Secure the assembly to the sled with the three screws.

Figure 3-22. Installing a SAS Mezzanine Assembly in a Sled

NOTE: The I/O screw bracket tab must be behind the mezzanine bracket.

96 Installing System Components

Page 97

Routing the 3.5" SAS Mezzanine Cables

routing path

SATA Cable 4 to

HDD 0

SATA Cable 5 to

HDD 1

After installing a mezzanine card, you need to route the SAS cabling as

depicted in the following figure.

Figure 3-23. SAS Mezzanine Cable Routing

Removing a SAS Mezzanine Card with 3.5" HDD

Prior to removing a mezzanine card, you must first remove the sled board

from the chassis, see "Removing a Sled" on page 62.

1

Remove the screws securing the assembly.

2

Remove the assembly from the sled.

3

Flip the assembly over and remove the provided screw securing the linking

board.

4

Remove the linking board from the mezzanine card.

5

Disconnect the SAS cable from the card.

6

Remove the provided screws securing the card.

7

Remove the mezzanine card from the assembly.

SAS Cable Identification

The following is an outline of the SAS cable types used in the C5220 system

for the mezzanine function.

Installing System Components 97

Page 98

2.5” SAS Cable

335 ± 10 mm

345 ± 10 mm

700 ± 10 mm

195 ± 5 mm

545 ± 10 mm

190 ± 5 mm

Figure 3-24. 2.5" SAS Cable

3.5” SAS Cable 1

The 3.5" SAS cable 1 is connected to the HDD0 connector.

Figure 3-25. 3.5” SAS Cable 1 (SAS to HDD0)

3.5” SAS Cable 2

The 3.5" SAS cable 2 is connected to the HDD1 connector.

Figure 3-26. 3.5" SAS Cable 2 (SAS to HDD1)

98 Installing System Components

Page 99

Troubleshooting

Troubleshooting Sequence

Server Boot Issues

System Does Not Boot After Initial Installation

Power Connector Not Plugged In

Memory Issues

Monitor Issues

Power Supply and Chassis Issues

Cable Issues

Electrical Short or Overload

Defective Components

System Does Not Boot After Configuration Changes

Hardware Changes

Software Changes

BIOS Changes

Viewing System Event Logs for Investigation

Installation Problems

Troubleshooting External Connections

4

System Does Not Boot After Initial Installation

Power Connector Not Plugged In

If the power supply cable is not plugged into the system board processor

power connector, the system cannot boot up, even though chassis front panel

LEDs and the fan may be operational. Verify that the power connections are

good.

Troubleshooting 99

Page 100

Memory Issues

If you have installed incompatible memory modules, the system may not

boot. Verify the memory you've installed has been tested with your system

board. If the installed memory is compatible, remove and reinstall the

memory modules.

Defective memory modules may cause boot errors. To isolate a specific

memory module as defective, boot the system with just one memory module

installed at a time.

Monitor Issues

Monitor configurations can cause boot failure. Run through the following

checklist to verify monitor operation:

• Ensure the monitor is plugged in and turned on.

• Ensure all cables are connected properly between the monitor and the

system.

• Check that the brightness and contrast controls on the monitor are not too

low.

Most monitors employ indicator LEDs showing status. Refer to the monitor's

documentation to confirm operation. If the problem still persists, test or

replace the monitor on a different AC outlet or system.

Power Supply and Chassis Issues

• Verify if the chassis and power supply are compatible with the processor

model.

Table 4-1. Supported Processor List for 8-sled and 12-sled SKU on PowerEdge C5220

Intel Processors 8-Sled SKU 12-Sled SKU