Page 1

METROLOG IC INSTRUM E NTS, INC.

MS6130 Hand Held Laser Scanner

and MX003 Scanner Interfaces

Installation and User’s Guide

Page 2

Page 3

LOCATIONS

CORPORATE HEADQUARTERS ....................................................................................................................................

North America Metrologic Instruments, Inc. Customer Service: 1-800-ID-METRO

EUROPEAN HEADQUARTERS

Germany, Metrologic Instruments GmbH Tel: +49 89 89019 0

Middle East and Africa Dornierstrasse 2 Fax: +49 89 89019 200

Spain Metrologic Eria lbérica SL Tel: +34 913 272 400

Italy Metrologic Instruments Italia srl Tel: +39 0 51 6511978

France Metrologic Eria France SA Tel: +33 (0) 1 48.63.78.78

United Kingdom Metrologic Instruments UK Limited Tel: +44 (0) 1256 365900

ASIA

90 Coles Road Tel: 856-228-8100

Blackwood, NJ 08012-4683 Fax: 856-228-6673

82178 Puchheim b. Email: info@europe.metrologic.com

Munich, Germany Germany Email:

info@de.metrologic.com

Julián Camarillo 29, D-1 Fax: +34 913 273 829

Edificio Diapasón Email: info@es.metrologic.com

28037 Madrid

Via Emilia 70 Fax: +39 0 51 6521337

40064 Ozzano dell’Emilia (BO) Email: info@it.metrologic.com

69 Rue de la Belle Etoile Fax: +33 (0) 1 48.63.24.94

ZI Paris Nord II, BP 50057 Email: info@fr.metrologic.com

95947 – ROISSY CDG CEDEX

58 Tempus Business Centre Fax: +44 (0) 1256 365955

Kingsclere Road, Basingstoke Email: info@uk.metrologic.com

Hampshire RG21 6XG

Email: inf o @ metrolog ic .c o m

Internet: www.metrologic.com

Singapore Metrologic Asia (Pte) Ltd Tel: 65-6842-7155

China Metro (Suzhou) Technologies Co., Ltd. Tel: 86-512-62572511

Japan Metrologic Japan Co., Ltd. Tel: 81-03-3839-8511

SOUTH AMERICA

Brazil Metrologic do Brasil Ltda. Tel: 55-11-5182-8226

Outside Brazil Metrologic South America Tel: 55-11-5182-7273

Copyright

© 2002 by Metrologic Instruments, Inc. All rights reserved. No part of this work may be reproduced, transmitted, or

stored in any form or by any means without prior written consent, except by reviewer, who may quote brief

passages in a review, or provided for in the Copyright Act of 1976.

Products and brand names mentioned in this document are trademarks of their respective companies.

No. 8 Kaki Bukit Place Fax: 65-6842-7166

4th Floor Email: info@sg.metrologic.com

Singapore 416186

221 Xing Hai Street Fax: 86-512-62571517

Suzhou Industrial Park Email: info@cn.metrologic.com

Suzhou, China

215021

Matsunoya Building, 6 Floor Fax: 81-03-3839-8519

3-14-8 Higashiueno Email: info@jp.metrologic.com

Taitou-Ku, Tokyo 110-0015 Japan

Rua da Paz 2059 Fax: 55-11-5182-8315

CEP 04713-002 Email: info@br.metrologic.com

Chácara Santo Antônio

São Paulo, SP, Brasil

Rua da Paz 2059 Fax: 55-1-5182-7198

CEP 04713-002 Email: info@sa.metrologic.com

Chácara Santo Antônio

São Paulo, SP, Brasil

ii

Page 4

TABLE OF CONTENTS

MS6130 Hand Held Bar Code Scanner....................................................... 1

MX003 Series Scanner Interfaces............................................................... 2

Unpacking List.............................................................................................3

Connections of the “MX” Interface to the Host Device................................. 4

Connections of the Keyboard Wedge “MX” Interface to the PC................... 5

Connections of the MS700i/MS720i with “MX” to the Host Device .............. 6

Configuration of the MS700i/MS720i with “MX”...........................................7

Configuration of the MS700i/MS720i with “MX” to the Host System............ 8

Configuration of the “MX” to the ScanPal® Data Collector........................... 9

Configuration of the “MX” to the RS-232 Light Pen or Keyboard Wedge

Host System................................................................................ 10

Keyboard Wedge (KB) Interface................................................................ 11

Configuration of the MS6130 Hand-Held................................................... 15

Enabling the MS700i/MS720i Scanner’s RF Low Speed Option ...............16

Changing the ID......................................................................................... 17

Matching Procedure................................................................................... 18

Parts of the MS6130 Hand-Held Bar Code Scanner.................................. 19

Components of the MS6130 Series Stand................................................. 20

Installation of the MS6130 Series Stand.................................................... 21

Installation of the 6000 Series Universal Charging Stand.......................... 22

NiCd Battery Charger with Reconditioning Feature................................... 23

Visual Indicators........................................................................................ 24

Audible Indicators...................................................................................... 25

Labels........................................................................................................ 27

iii

Page 5

TABLE OF CONTENTS (CONTINUED)

Maintenance.............................................................................................. 27

Troubleshooting......................................................................................... 28

Appendix A

Specifications............................................................................... 29

Appendix B

Default Settings of the MS6130 and “MX” Interface .................... 32

Appendix C

MX003 Series Scanner Interface Pin Assignments .....................36

Appendix D

Warranty and Disclaimer.............................................................. 37

Appendix E

Notices......................................................................................... 38

Appendix F

Patents......................................................................................... 39

Index.......................................................................................................... 40

iv

Page 6

Page 7

THE MS6130 HAND HELD BAR CODE SCANNER

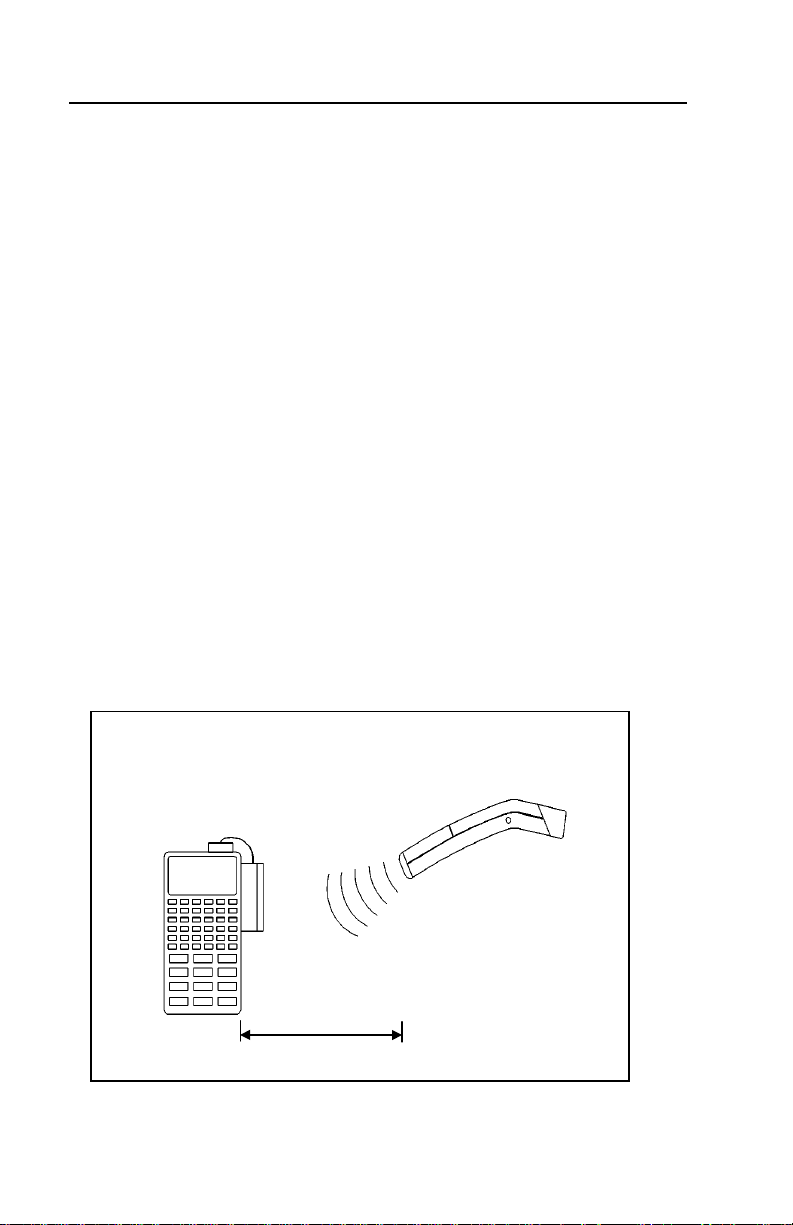

MS6130 Hand Held Bar Code Scanners are wireless scanners with a

mobility range of up to 30 feet from the receiver. When not in use, the

scanner rests in a universal-charging stand. The scanner will be fully

charged in 2 hours when not scanning in the stand. A fully charged MS6130

can provide up to 8 hours of wireless, hand-held scanning. After dormant

periods, the scanner is programmed to enter a timeout mode that will extend

the battery life. There is a reactivation switch conveniently located on the

side of the scanner to turn the unit back on. The scanner has a replaceable

battery pack for added reliability and convenience for your scanning

application.

Metrologic’s scanner uses wirele ss data communication to transfer

information to the host. The MS6130 may be used with Metrologic’s MX003

Series Scanner Interfaces to provide the short range, one-way

communication link between the scanner and an RS-232, Keyboard Wedge

or Light Pen host device.

The MS6130 uses Metrologic’s patented Infrared Object Sensor for

triggerless operation. The scanner, after a specified time, will enter a

standby mode where the VLD and motor will shut off. Simply present an

object in front of the scanner window, the Infrared Sensor will reactivate the

scanner and the unit will be ready to scan.

To indicate the status of the scanner, the MS6130 uses a green and red

LED located on the top of the scanner. By understanding the flashes of the

LED, you can determine a successful read, laser status, low battery power,

sleep mode, and program mode. There are audible indicators on the

scanner as well. The scanner will beep; one, two or three times to indicate

successful power up or scan, low battery, or program mode, respectively, or

give a razzberry tone; which indicates the scanner has failed diagnostics

upon power up.

In this manual, the MS6130 may be referred to as the scanner or transmitter.

1

Page 8

MX003 SERIES SCANNER INTERFACES

Metrologic’s MX003 Series Scanner Interfaces provide a short range, oneway wireless data communication link between a remote portable scanner

and an RS-232 or light pen host device. Specifically, Metrologic’s MS6130

Hand-Held Laser Scanners include a Liberty

Metrologic’s MS700i/MS720i series scanners, TECH series scanners may

be connected to a MX Series scanner interface. The “MX” scanner interface

includes a RF receiver and a digital interface board.

The MS6130 scanner provides two functions:

• Scans and decodes bar codes

• Transmits scanned data to the RF receiver or “MX”

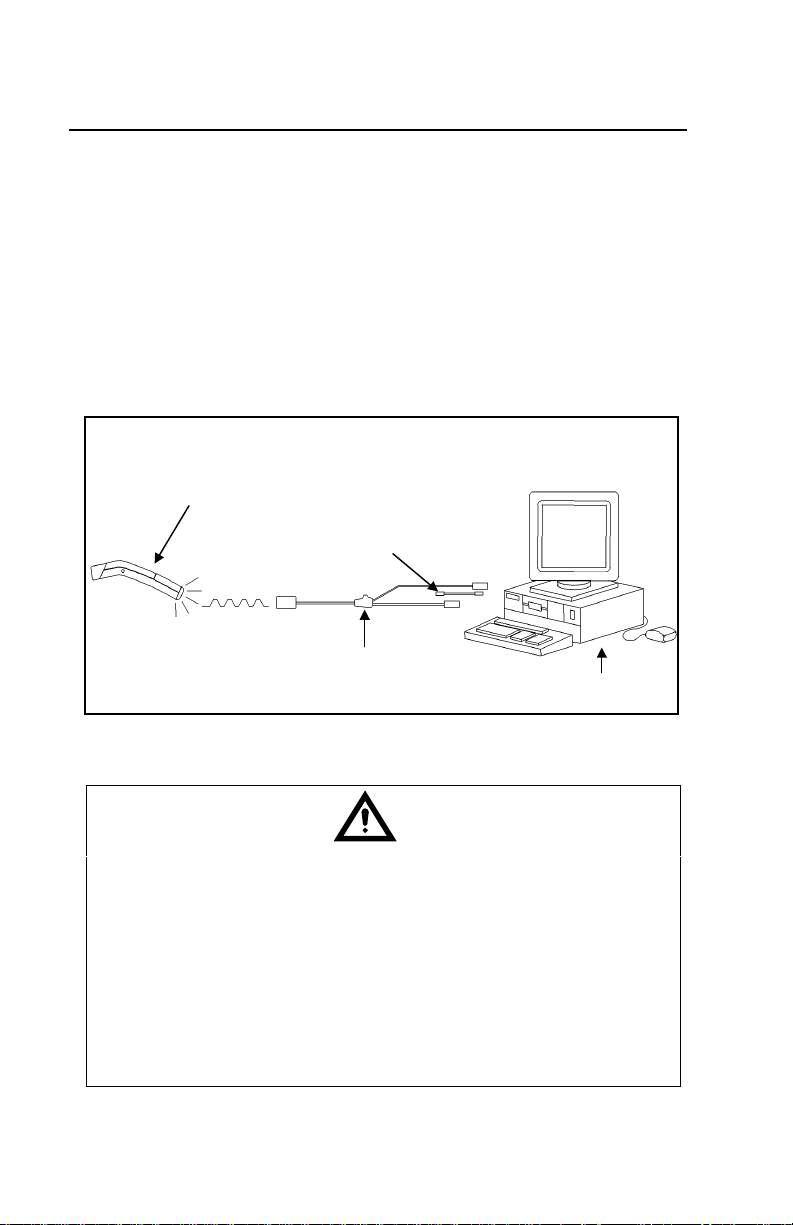

When the “MX” interface is connected to a ScanPal

a portable data terminal (PDT), it provides two functions

(For example, refer to Figure 1):

• Performs the RF receiver function; for example, beeps to show it has

received data from the transmitter

• Communicates with the host device

In this manual, MX003 series scanner interfaces may be referred to as the

“MX”, “MX” interface or receiver. Suffix of the MX003 model designation will

vary due to country of usage.

®

RF transmitter board.

®

or host device such as

Any RS-232C or

Light Pen Device with

MX003 RF Receiver

2

MS6130 with Liberty® RF

Scanner Interface (Transmitter)

Up to 30 Ft.

(conditions permitting)

Figure 1

Page 9

UNPACKING LIST

Your shipment will contain a set of items from the two groups listed below:

Transmitter Group:

• MS6130 Hand-Held Scanner

• Stand #45880 (optional)

• Stand #45558, 45559 and 45560 (optional)

• MS4120 Programming Guide

Receiver Group:

• “MX” Scanner Interface

• MCA951 adapter or adapter cable (if required)

• Regulated 5V power supply, MLPN: 6090/6091

(115/220 V

• “MX” Scanner Interface

• MS700i with Liberty® RF Receiver option cable

• Power supply (optional)

• Communication cable with connection for power

supply (optional) or communication cable only

• Stand #45483 (optional)

• MS700i and MS720i Installation and User’s Guide

• ScanSelect™ Scanner Programming Guide (#2186)

)(optional)

AC

OR

OR

®

• ScanPal

Data Collector

• “MX” Scanner Interface

• Upload cable, MLPN: 51061 and 51236

• MCA951 adapter

• Regulated 5V power supply, MLPN: 6090/6091 (115/220 V

• ScanPal Data Collector Installation and User’s Guide

AC

)

3

Page 10

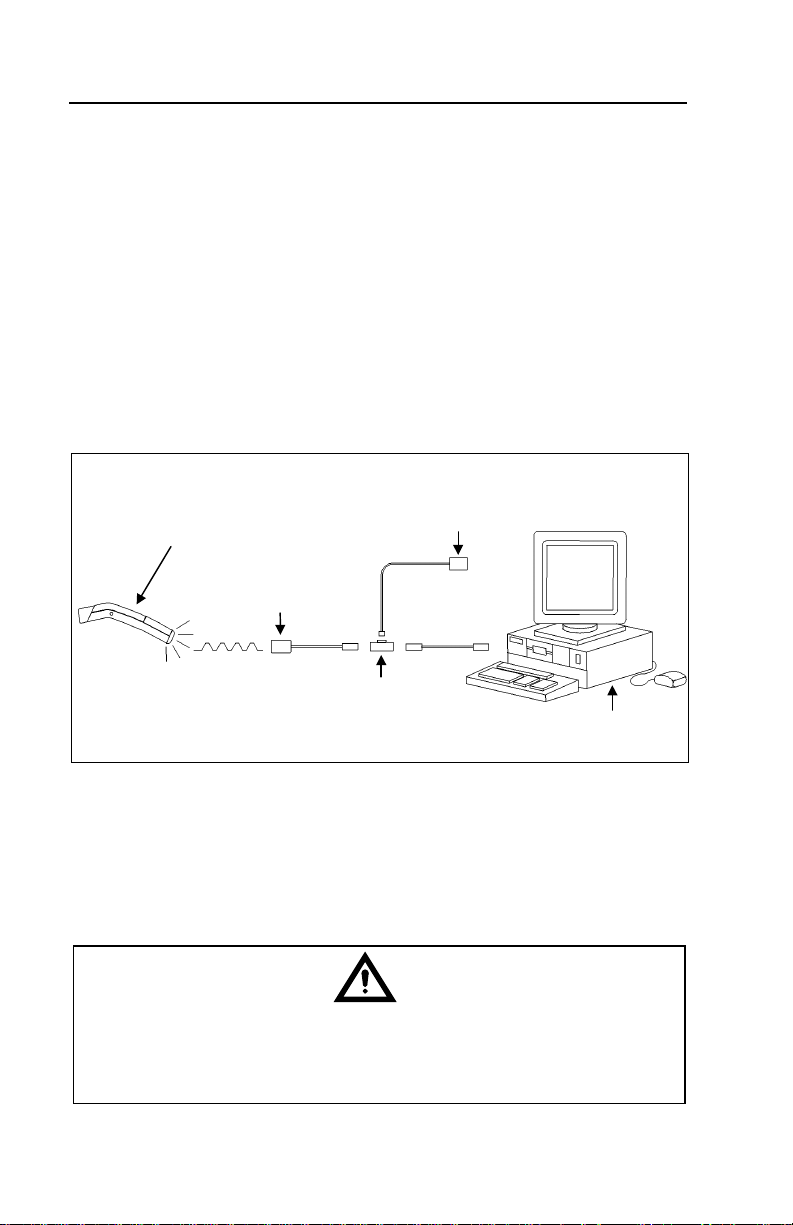

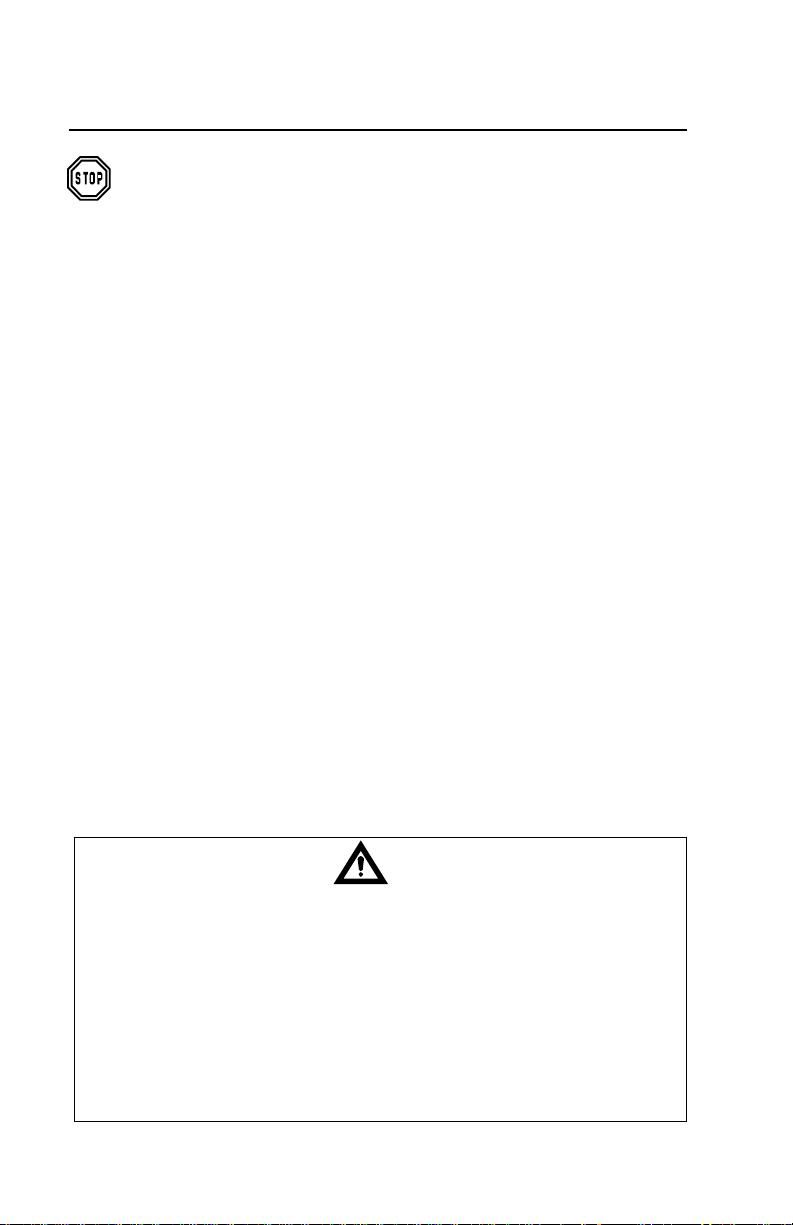

CONNECTIONS OF THE “MX” INTERFACE TO THE HOST DEVICE

Scanne

ace

®

Except version 17

1. Turn off the host system.

2. Connect the MCA to the host device. Connect the “MX” interface to

the MCA.

3. Check the AC input requirements of the transformer to make sure the

voltage matches the AC outlet. The socket outlet should be near the

equipment and easily accessible.

4. Plug the transformer into the side of the MCA and the AC outlet.

5. Power up the host system.

MS6130 with Liberty

Scanner Interface

(Transmitter)

“MX”

Figure 2: Connecting the “MX” (through the MCA) to a host device

To maintain compliance with applicable standards, all circuits connected

to the unit must meet the requirements for SELV (Safety Extra Low

Voltage) according to EN 60950.

RF

r Interf

Transformer

MCA

Host System

4

Page 11

CONNECTIONS OF THE KEYBOARD WEDGE

®

“MX” INTERFACE TO THE PC

Version 17 only

MX003 Scanner Interfaces with a suffix of “17" are Keyboard Wedge

versions used to interface with a PC and keyboard.

1. Turn off the PC.

2. Plug the “MX” receiver adapter cable to the PC keyboard port.

3. Plug the keyboard into the “MX” receiver adapter cable.

4. Power up the PC.

MS6130 with Liberty

Scanner Interface

(Transmitter)

Figure 3: Connecting the “MX” to a PC and keyboard

To maintain compliance with applicable standards, all circuits connected

to the unit must meet the requirements for SELV (Safety Extra Low

Voltage) according to EN 60950.

The following statement is applicable if the scanner will receive power

from a host device such as a computer system.

Caution: To maintain compliance with standards CSA C22.2 No. 950/UL

1950 and norm EN60950, the power source must meet

applicable performance requirements for a limited power

source.

RF

Optional Adapter

“MX” Receiver adapter Cable

Host System

5

Page 12

CONNECTIONS OF THE MS700I/MS720I

“MX” TO THE HOST DEVICE

WITH

To avoid potential problems, do not power up the scanner until the

communication cable is secured to the host.

1. Turn off the host system.

2. Connect the 25-pin D-type connector on the MS700i/MS720i scanner’s

head cable to the communication cable. Connect the other end of the

communication cable to the host device. If the scanner will not receive

power from a transformer, skip to Step 5.

3. If the scanner will receive power from an external power source, check

the AC input requirements of the transformer to make sure the voltage

matches the AC outlet. The socket-outlet should be near the equipment

and easily accessible.

4. Plug the transformer into the side of the female D-type connector

located on the communication cable. Plug the transformer into the AC

outlet to supply power to the scanner.

5. Power up the host system.

6. Attach the “MX” to the MS700i/MS720i scanner via the LSO cable that

terminates to a 10-pin modular connector.

Note: When the MS700i/MS720i scanner firs t rec eives po wer, th e

LEDs will flash and then the scanner will beep once. After the

scanner performs this startup sequence, the green LED will remain

on for a specified time showing that the laser is on.

Refer to the MS700i and MS720i Laser Bar Code Projection

Scanner Installation and User’s Guide for information on how to

operate the scanner.

To maintain compliance with applicable standards, all circuits connected

to the unit must meet the requirements for SELV (Safety Extra Low

Voltage) according to EN 60950.

The following statement is applicable if the scanner will receive power

from a host device such as a computer system.

Caution: To maintain compliance with standards CSA C22.2 No. 950/UL

1950 and norm EN60950, the power source must meet

applicable performance requirements for a limited power

source.

6

Page 13

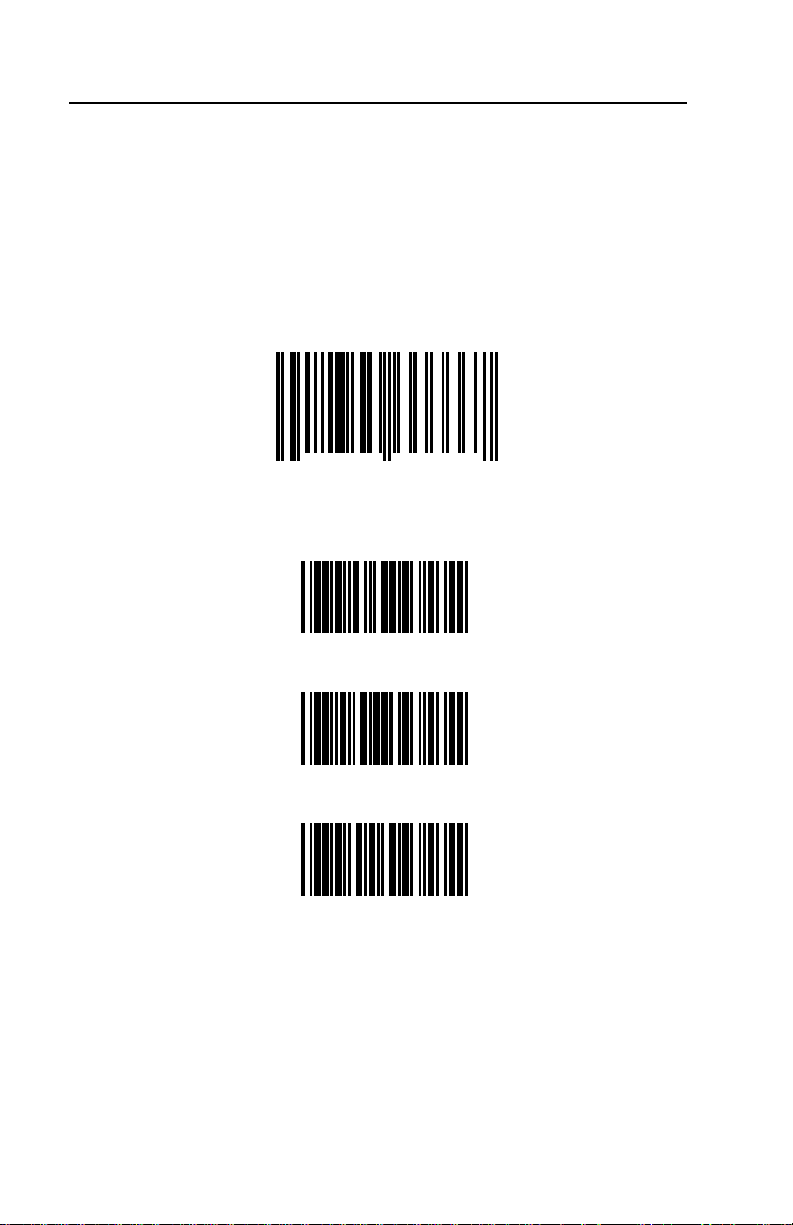

CONFIGURATION OF THE MS700I/MS720I WITH “MX”

To perform matching procedure refer to page 18.

Once the transmitter is assigned an ID number, configure the S700i/MS720i

to accept RF communication. Although the changes made in this section

effect the receiver, the MS6130 performs all scanning.

1. Scan the following bar code to enter the receiver’s program mode.

(The MS700i/MS720i will beep three times):

Enter/Exit Program Mode for the Receiver

12345 66666

0

2. Enable the RF interface by scanning the following bar codes in order:

R01

7

LP1

HH1

3. Exit program mode by scanning the bar code in Step 1 again.

4. Proceed to the procedure on the next page.

7

Page 14

CONFIGURATION OF THE MS700I/MS720I WITH “MX”

TO THE HOST SYSTEM

To perform matching procedure refer to page 18.

Before the MS700i/MS720i scanner ships from the factory, the factory

programs the scanner to a group of default settings noted in the

ScanSelect™ Scanner Programming Guide. An asterisk marks each default

setting. The asterisk appears before the brief definition located near the bar

code. Once RF communication establishes, change the default settings of

your scanner to meet your individual scanning needs or your host system’s

communication requirements. Modify the scanner's settings by entering the

program mode and scanning the appropriate bar codes that appear in the

ScanSelect Scanner Programming Guide.

Note: When the Load Defaults bar code in the ScanSelect Scanner

Programming Guide is chosen, it will automatically disable the RF

low speed option. For the MS6130 to communicate to the

MS700i/MS720i scanner, re-enable the RF Low Speed Option (refer

to the procedure above).

8

Page 15

CONFIGURATION OF THE “MX” TO THE SCANPAL

®

DATA COLLECTOR

To perform matching procedure refer to page 18.

The RS-232 parameters marked with an asterisk ( * ) in the charts are the

default settings of the “MX”. The charts are in the Default Settings of the

MS6130 and “MX” Receiver section of this guide. To communicate with

each other properly, the “MX” and ScanPal must have matching RS-232

parameters. However, the Enter/Exit Program Mode bar code in the

MS4120 Programming Guide will not cause your “MX” to enter or exit

program mode. Scan the Enter/Exit Program Mode for the Receiver bar

code in the following procedure.

Before completing RF communication, program the ScanPal to the same

settings as the IBM® PC XT, AT or PS/2 compatible computer. Once

completed and the receiver and MS6130 have the same assigned ID

number, configure the “MX” to the same settings as ScanPal.

1. Program the ScanPal to the same settings as the PC.

(Refer to the Programming the ScanPal section in the ScanPal

Collector Installation and User’s Guide)

2. Scan the following bar code to enter program mode.

(The “MX” receiver will beep three times):

Enter/Exit Program Mode for the Receiver

12345 66666

0

7

3. Scan the appropriate communication options in the MS4120

Programming Guide.

4. Exit program mode by scanning the bar code in Step 1 again.

Note: Scan the Enter/Exit Program Mode for the Receiver bar

code and exit program mode if the PC uses the same

parameters as the default settings of ScanPal.

Default to ScanPal Communication Parameters

IB5

®

Data

9

Page 16

CONFIGURATION OF THE “MX” TO THE RS-232, LIGHT PEN OR

KEYBOARD WEDGE HOST SYSTEM

To perform matching procedure refer to page 18.

The light pen, RS-232 and Keyboard Wedge parameters marked with an

asterisk ( * ) in the charts are the default settings of the “MX”. The charts are

in the Default Settings of the Transmitter and “MX” Receiver section of this

guide. To communicate with a host system properly, program the “MX” to

match the host system’s requirements. However, the Enter/Exit Program

Mode bar code in the MS4120 Programming Guide will not cause your “MX”

to enter or exit program mode. Scan the Enter/Exit Program Mode for the

Receiver bar code in the following procedure. Once the MS6130 is assigned

an ID number, configure the “MX” to the correct communication protocol.

1. Scan the following bar code to enter program mode.

(The “MX” receiver will beep three times):

Enter/Exit Program Mode for the Receiver

12345 66666

0

2. Scan the following bar code to confirm the receiver is using the

original factory settings.

7

Recall Defaults

DF1

3. Scan the appropriate communication options in the MS4120 and

MS951 Programming Guides.

4. Exit program mode by scanning the following bar code.

(The “MX” receiver will beep three times):

Enter/Exit Program Mode for the Receiver

12345 66666

0

7

10

Page 17

KEYBOARD WEDGE (KB) INTERFACE

Scan the ENABLE KB WEDGE INTERFACE bar code if your communication

requirement is keyboard emulation. The scanner will provide keyboard

emulation by converting the scanned bar code data to the PC keyboard scan

code equivalent.

Enable Keyboard Wedge Interface

R24

KB Parameter - Keyboard Type

The following bar codes are used to define the type of keyboard in use. If

necessary, scan the appropriate bar code.

** AT Keyboard (includes IBM

®

PS/2: Models 50, 55, 60, 80)

LP3

XT Keyboard

LP4

Enable IBM PS/2 Keyboard (Models 30, 70, 8556)

SH4

** Disable IBM PS/2 Keyboard (Models 30, 70, 8556)

SH3

Enable Single-Ended Keyboard Emulation

R57

11

Page 18

KEYBOARD WEDGE (KB) INTERFACE (CONTINUED)

KB Parameter – Keyboard Type

The following bar codes are used to define the keyboard country type. If

necessary, scan the appropriate bar code.

** USA Keyboard

BR8

UK Keyboard

BR2

France Keyboard

BR3

Germany Keyboard

BR4

Italy Keyboard

BR5

Spain Keyboard

12

BR6

Belgium Keyboard

BR1

IBM KB4700 Financial Keyboard

BR7

Swiss Keyboard

BR9

Reserved

BRA

Page 19

KEYBOARD WEDGE (KB) INTERFACE (CONTINUED)

Reserved

BRB

Reserved

BRC

Reserved

BRD

Reserved

BRE

Reserved

BRF

KB Parameter - Caps Lock Mode

When Caps Lock is used on the

keyboard, choose ENABLE CAPS

LOCK. Once enabled, the scanner

will simulate Caps

Lock keyboard input. This mode will

not work with all keyboard types.

Enable Caps Lock

R46

**Disable Caps Lock

To detect automatically if Caps Lock

is used, enable AUTO-DETECTION

CAPS LOCK MODE. This will only

work with an AT computer.

R47

Enable Auto Detection

Caps Lock Mode

R68

**Disable Auto Detection

Caps Lock Mode

R69

13

Page 20

KEYBOARD WEDGE (KB) INTERFACE (CONTINUED)

KB Parameter - Alt Mode

When this option is enabled, the scanner will

duplicate this keyboard sequence: Hold down

the Alt key; type the decimal number that

corresponds to the appropriate keyboard

character. Caution should be observed when

using Alt mode because a scanner to host

application conflict may occur if the host

software application uses the Alt key as a

“Hot” key.

KB Parameter - Inter Scan Code Delay (AT and PS/2 Modes)

The time specified with an interscan code

delay bar code represents the amount of time

between individual 9 bit scan codes. Each

character of a bar code takes between two

and twelve of these scan codes to be passed

through to the PC via the keyboard interface.

This parameter may need to be adjusted for

operation with certain PC keyboard BIOS’s.

Network operating systems often use

microprocessor time slices to service network

information requests instead of the keyboard

interface. While not an issue with manually

entered keystrokes, this timing can be critical

with automatic scanner data entry. Interscan

code delays can be a useful system tuning

tool in these environments.

Enable Alt Mode

HH3

**Disable Alt Mode

HH4

** 800 Microsecond Delay

OC8

7.5 Millisecond Delay

OC9

15 Millisecond Delay

KB Parameter - XT - Clean-Up Bit

Some keyboard BIOS's require a "cleanup

bit" to be transmitted before an actual scan

code being clocked over to the motherboard.

Enabling this feature will cause the scanner to

send this extra bit to the host computer. More

commonly found on older XT style BIOS's,

and some AT BIOS's. (required by some NEC

80286 machines).

14

OC7

Enable Cleanup Bit

HH1

** Disable Cleanup Bit

HH2

Page 21

CONFIGURATION OF THE MS6130 HAND-HELD

To perform matching procedure refer to page 18.

Before the MS6130 scanner ships from the factory, the factory programs the

scanners to a set of default settings. These default settings can be found in

the MS4120 Programming Guide. The default settings have an asterisk that

appears before the brief definition located near the bar code. Once RF

communication establishes, change the default settings of your scanner to

meet your individual scanning needs. Configure the scanner by scanning

the Transmitter Enter/Exit Program Mode bar code and the appropriate bar

codes in the MS4120 Programming Guide.

For example, to program the MS6130 not to read ITF

(Interleaved 2 of 5) bar code types:

• With the MS6130, scan the Enter/Exit Program Mode bar code in the

MS4120 Programming Guide, the Disable ITF bar code, then the

Enter/Exit Program Mode bar code again.

Note: When the MS6130 is in program mode, never scan any of the

RS-232 or light pen options marked with an “R”. The list of

options is in the Default Settings of the Transmitter and “MX”

Receiver section of this guide when using the MS4120

Programming Guide. The MS6130 is in program mode when

scanning the Enter/Exit Program Mode bar code in the

MS4120 Programming Guide.

15

Page 22

ENABLING THE MS700I/MS720I SCANNER’S RF LOW SPEED

OPTION

Before beginning this procedure, perform all steps in the sections, Matching

the Transmitter to the Receiver and Configuration of the MS700i/MS720i

with “MX”.

Use the MS700i/MS720i scanner to scan the following bar codes.

1. Temporarily cover the bar code below Step 3. Scan the following bar

code to enter program mode.

(The MS700i scanner will beep three times):

Enter/Exit Program Mode for the Receiver

12345 66666

0

2. Temporarily cover the bar code in Step 1. Scan the Enable RF Low

Speed Option bar code below Step 3.

7

3. Exit program mode by scanning the bar code in Step 1 again.

Enable RF Low Speed Option

12345 12915

0

5

16

Page 23

CHANGING THE ID

In order for the MS6130 to send data to the correct receiver, they must have

a matching ID number. The ID number is the serial number of the receiver.

When the matching procedure is completed, the receiver will accept data

only from a MS6130 that has the matching ID number. Each receiver is

programmed with its serial number before it leaves the factory.

1. To program a new ID for the receiver, HANDSET

(Version 1.14 or greater) must be used. Type the following at the

DOS prompt:

HANDSET /X

2. Power up the receiver, but DO NOT scan any bar codes.

3. Select “Enter Program Mode”. Select the appropriate SERIAL PORT

(COM 1 or COM 2) on the PC. Make sure the Receiver is connected

to the SERIAL PORT selected.

4. Select “Get Scanners Settings”. A screen will appear showing all of

the options available.

5. Using the arrow keys, move down to the section labeled “Metro ID#”.

Locate the serial number on the case of the receiver. Enter this 10digit number into the “Metro ID#” section.

6. Press the “F5" key to program the receiver.

7. The receiver will beep when programming is completed. The receiver

is now programmed with its proper ID. Exit HANDSET by pressing

“F9" and then press “7".

8. Power Down the receiver.

17

Page 24

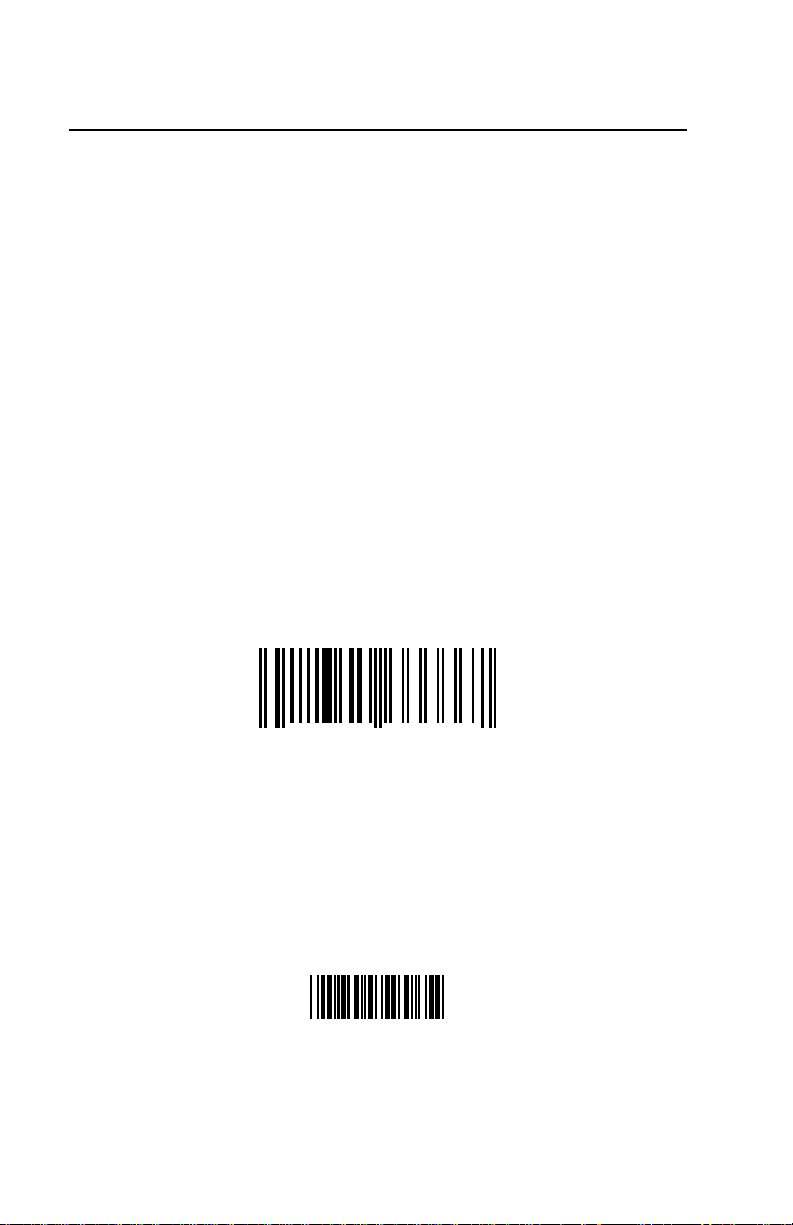

MATCHING PROCEDURE

With the MS6130, scan the following bar codes starting from the top down:

Transmitter Enter/Exit Program Mode

**

Recall Defaults

DF1

Enable RF Communications

R35

Transmitter Enter/Exit Program Mode

**

Locate the model label on the case of the receiver. Scan the serial number

bar code.

The receiver and MS6130 are now matched.

For information on how to configure the receiver, refer to the appropriate

section in this guide.

Note: If using more than one MS6130 with one receiver, perform the

above procedure for each MS6130. Since each MS6130 has the

same ID number, the receiver will accept data from all of the

scanners

18

Page 25

PARTS OF TH E MS6130 HAND-HELD BAR CODE SCANNER

r

y

Becoming familiar with the features of the MS6130 hand-held scanner will

help when operating one of these scanners. The illustration and list explain

the pertinent parts.

Green and Red LED

Replaceable

Pack

Batter

Output

Window

Infra-red (IR)

Senso

Reactivation

Switch

Battery Charge

Figure 4: Scanner Parts

Battery Charge Contacts Receptacle for the battery charger.

Reactivation Switch Turns the unit on after a timeout. Press the

button from the bottom.

Green and Red LEDs When the red LED is on, the laser is on. If the

green LED flashes on, the scanner has read a

bar code successfully. Communication to the

host is complete when the receiver beeps.

Infrared Object Sensor When a specified time has elapsed without any

scanning, the unit will enter a “standby” mode.

To reactivate the unit, remove the current

object and present an object in front of the

output window again.

Output Window This aperture emits laser light.

19

Page 26

COMPONENT S OF TH E MS6130 SERIES STAND

The following are the components used to build the MS6130 series stand

(MLPN: 45880).

1

1. Cradle

2. Stand Charger Pack

3. Pole Cover

4. Flex pole

5. Stand Base Cover

6. Stand Base

7. Charger Transformer

8. Charger Pack Screws

9. Mounting Screws

10. Lock Washer

2

10

8

3

4

5

CABLE

CONNECTS

THROUGH

OPENING

7

9

20

6

Figure 5: Scanner Parts

Page 27

INSTALLATION O F THE M S6130 SERIES STAND

Refer to for numbered components on the previous page

1. Use the stand base (6) as a template to drill and mount the base to the

counter using the mounting screws (9) provided.

2. Feed the wire from the transformer (7) through the slot in the base cover

(5) approximately 9" of the wire.

3. Press the base cover (5) over the base (6).

4. Attach the flex pole (4) to the base (6).

5. Slide the flex cover (3) over the pole (4) and wire.

6. Attach the cradle (1) to the flex pole (4) using the lock washer (10) to

connect the transformer.

7. Insert the transformer plug into the connector inside the stand charger

pack (2).

8. Clip the charger pack to the bottom of the cradle (1) lock in place using

two screws (8).

Stand LED Indicators (with the scanner in the stand)

No LED indicates trickle charge and the green LED indicates fast charge. To

change from trickle charge to fast charge, simply lift the scanner from the

stand and replace.

Note: When both scanner LEDs blink, it is an indication of a

low battery.

21

Page 28

INSTALLATION O F THE 6000 SERIES UNIVERSAL CHARGING STAND

MLPN: 45558 - 115V, 45559 - 230V and 45560 - 240V (UK)

Transformer

Green LED

(Charge Status)

Red LED

(Power)

Figure 6: Universal Charging Stand

PERMANENT COUNTER TOP INSTALLATION

1. Separate weighted base from rotating base by removing the (4) four

screws.

2. Use the rotating base as a drill template.

3. Use the (4) four wood screws provided to mount the base to the counter

top securely.

4. Snap the cup assembly to the base.

Note: For non-permanent installation, snap the cup assembly onto the

weighted base

CHARGE STATE CHARGE LED STATUS

Battery Absent LED off

Charge Pending

Fast-Charge LED on

Charge Complete and Top-Off

LED on for 0.125sec,

off for 1.375sec

LED on for 0.125 sec,

off for 0.125sec

22

Page 29

NICD BATTERY CHARGER WITH RECONDITIONING FEATURE

(

)

MLPN: 45561 - 115V and 45562 - 230V

How to Recondition

Transformer

Discharge

Cycle Switch

1. Place the scanner into the

charge stand.

2. Push the stand tilt cup in

the extreme down position

to expose the hole for the

discharge cycle switch.

3. Use a pin to push the

Red LED

Power

Green LED

(Charge Status)

discharge cycle switch

located beneath the hole.

4. When the discharge mode

is initiated the green LED

Figure 7: Reconditioning

flashes.

RECOMMENDED USE

To maintain charge capacity, the NiCd batterie s mus t be disch arged fully

before charging. We call this process reconditioning.

Recondition if:

• The batteries were not used within 20 days

• The batteries were not discharged (approximately two hours of

continuous operation) at least once a week

• Low battery indicators:

• Both LED’s on the scanner blink

• The scanner quietly beeps twice while scanning

Recondition once a week if:

• The batteries do not get discharged for more than 20%

(approximately ½ hour) of their capacity before recharging.

Recondition once every two weeks if:

• The batteries do not get discharged for more than 50%

(approximately 1 hour) of their capacity before recharging.

Note: The day to day usage of the NiCd batteries will determine the

frequency of the discharges (reconditionin g).

Charge State CHG LED Status

Battery Absent LED off

Charge Pending

Discharge-BeforeCharge

Fast-Charge LED on

Charge Complete Top-

Off

LED on for 0.125sec, off for

1.375sec

LED on for 1.375sec, off for

0.125sec

LED on for 0.125 sec, off for

0.125sec

23

Page 30

VISUAL INDICATORS

The scanner has red and green LEDs. When the scanner is on, the LEDs

indicate the status of the scan and scanner.

No Red or Green The scanner will turn off if the scanner has

been dormant for a specified time. To

reactivate the unit, direct the output window

up then down toward the bar coded product.

If the unit has been dormant for longer than

10 minutes, reactivating the unit by pressing

the button on the side of the MS6130 will be

necessary.

Red Flash; Green Flash; When the scanner first receives power, the

steady red LED will flash, followed by the

green LED.

Steady Red When the laser is on, the red LED will also be

on. This occurs when an object is in the scan

field. If the scanner does not detect a bar

code within approximately 2.5 seconds, the

red LED will shut off indicating that the laser is

no longer on. If the red LED remains on for

longer than 7.5 seconds, then the scanner is

in program mode.

Steady Red; Green Flash When the scanner successfully reads a bar

code, the green LED will flash. If the green

LED does not flash, then the bar code read

was not successful.

Repetitive Red Flashes When the red LED flashes several times while

it lays upon a stationary surface, then an

object is within the scan field and is activating

the IR sensor. This can occur even while the

scanner is lying upon the counter or cradle.

To eliminate this disturbance, direct the scan

window toward a different location.

24

Page 31

AUDIBLE INDICATORS

When the scanner and “MX” receiver are in operation, they provide audible

indications. These sounds indicate the status of the scan and scanner.

One Beep When the “MX” Receiver first receives power, the unit will

beep once.

If the scanner successfully reads a bar code, the green

light will flash. If the “MX” receiver successfully receives

the data from the MS6130, the “MX” will beep once.

Razzberry Tone If, upon power up, the scanner emits a razzberry tone,

then the scanner has failed diagnostics.

The “MX” receiver will emit a razzberry tone if an invalid

bar code is scanned while the receiver is in program

mode.

The “MX” receiver can be programmed to emit a

razzberry tone when the timeout occurs during

communication between the host and receiver.

Refer to the MS4120 Programming Guide section,

Audible Indicators for Communication Timeouts to

program this feature.

Two Beeps The MS6130 scanner will quietly beep twice when

scanning a bar code if the batteries become low.

Three Beeps When scanning the MS6130 Enter/Exit Program Mode

bar code in the MS4120 Programming Guide, the green

LED will flash three times while the scanner

simultaneously beeps three times. When exiting the

program mode, the same visual and audible indications

will occur. After this sequence is completed, the red LED

will turn off. When scanning the Enter/Exit Program Mode

for the Receiver bar code, the “MX” receiver will beep

three times to indicate it is in or exiting out of the program

mode.

(continued next page)

25

Page 32

AUDIBLE INDICATORS (CONTINUED)

The “MX” receiver can be programmed to emit three

beeps when the timeout occurs during communication

between the host and receiver. Refer to the MS4120

Programming Guide section, Audible Indicators for

Communication Timeouts to program this feature.

There are four settings available for the tone of the beep for the receiver.

Refer to the MS4120 Programming Guide section, Beeper Tones to program

the feature to change the tone or turn the beeper off.

26

Page 33

LABELS

The MS6130 scanner is either a CDRH Class II laser system or an IEC

Class 1 Laser System. Your unit will have a CDRH Class II caution label or

LASERKLASSE 1 label affixed below the model number label. The model

number/avoid exposure label is located on the bottom of the scanner’s head.

The following are examples of these labels:

MAINTENAN CE

Smudges and dirt can interfere with the proper scanning of a bar code.

Therefore, the output window will need occasional cleaning.

1. Spray glass cleaner onto lint free, non-abrasive cleaning cloth.

2. Gently wipe the output window.

27

Page 34

TROUBLESHOOT ING

1. The receiver can receive data from a MS6130 with its own ID or 10

zeroes. It’s own ID can be received all the time. When using 10

zeroes, the first scan the receiver gets must have 10 zeroes as its ID

and from that point on the receiver will accept both ID’s.

Power down the receiver. Using the MS6130, scan the bar codes from

section 9 in the Matching MS6130 to the Receiver section and use the

following bar code as the ID number.

Scanner ID Number

0000000000

Note: Use this bar code for troubleshooting purposes only.

2. Power up the receiver.

3. If the user is trying to match a new ID to the receiver and the receiver is

powered up, the receiver will beep 3 times if the ID number it receives

matches its current ID.

4. When the MS6130 is in program mode, never scan any of the RS-232

or light pen options marked with an “R”. The list of options is in the

Default Settings of the MS6130 and “MX” Receiver sect ion of this gui de

when using the MS4120 Programming Guide. The MS6130 is in

program mode when scanning the Enter/Exit Program Mode bar code

in the MS4120 Programming Guide. If a receiver option is chosen while

the MS6130 is in program mode, RF communication between the

MS6130 and receiver may terminate. If this occurs, the only way to

reestablish RF communication is by performing all the RF configuration

procedures again.

28

Page 35

APPENDIX A

Specifications

RF Link Characteristics

Frequencies: One of the following depending on the

country of operation:

418 MHz

434 MHz

912 MHz

Bandwidth: 220 kHz

Modulation: FM

Certification: No FCC licensing required

RF Protocol: One way data transmission

Transmission time at a maximum of 100 ms

50K baud data rate

Dedicated transmitter(s) to receiver link

Operating Range: Up to 30 feet (conditions permitting)

Specifications subject to change without notice

MS6130 Bar Code Scanner Specifications

UL Listed: US and Canada

FCC ID: LW5613 (912 MHz only)

RF Output Power: 20 uW max. (912 MHz only)

Current: Supplied by rechargeable/replace abl e

batteries

Antenna: Integral

Dimensions:

Length 216 mm [8.5”]

Width 63 mm [2.5”] Head and 48 mm [1.9”] Handle

Height 28 mm [1.1”]

Weight: 289 g [10.5 oz]

Maximum Radiant Power: 0.9 mW Peak

VLD Wavelength: 630 nm to 680 nm

29

Page 36

APPENDIX A (CONTINUED)

MX003 Series Scanner Interface Specifications

FCC ID: LW5003

Operating Voltage: 5Vdc

Antenna: Integral

Dimensions: 90 mm [3.54"] x 50 mm [1.97"] x 24 mm [0.94"]

Weight: 80.3 g [2.8 oz]

UL Listed: US and Canada

Model Number

MX003 912 MHZ

MX003-17 912 MHZ

MX0033 418 MHZ

MX0033-17 418 MHZ

MX0034 434 MHZ

MX0034-17 434 MHZ

Model designation may include the suffix “J” used to indicate the addition of

an audio signal output jack.

Operating

Frequency

Data Interface

RS-232

Light Pen

✓

✓

✓

Data Interface

Keyboard

Wedge

✓

✓

✓

30

Page 37

APPENDIX A (CONTINUED)

Specifications of Battery Pack

Battery Type: “AA” NiCd Rechargeable

Configuration: 3 Batteries/Pack

Nominal Voltage: 3.6 VDC

Maximum Voltage: 4.8 VDC

Capacity: 600 mA

Charge Cycles: Over 500 Full Charge/Discharge

Charge Time: 4 Hours

Short Circuit Protection: Auto/Reset Fuse 1.7A Hold Current

Temperature Characteristics (Degrees Celsius) of each Cell:

Charge: 0 to +45

Discharge: -20 to +60

Storage (Long): -30 to +35

UK Compliance

To charge the batteries in the MS6130 - 418MHz, remove the ESD cover

from the bottom of the unit. Refer to the battery charge rate for additional

information. After a full charge, replace the cover over the battery contacts.

The cover should remain in place during operation

31

Page 38

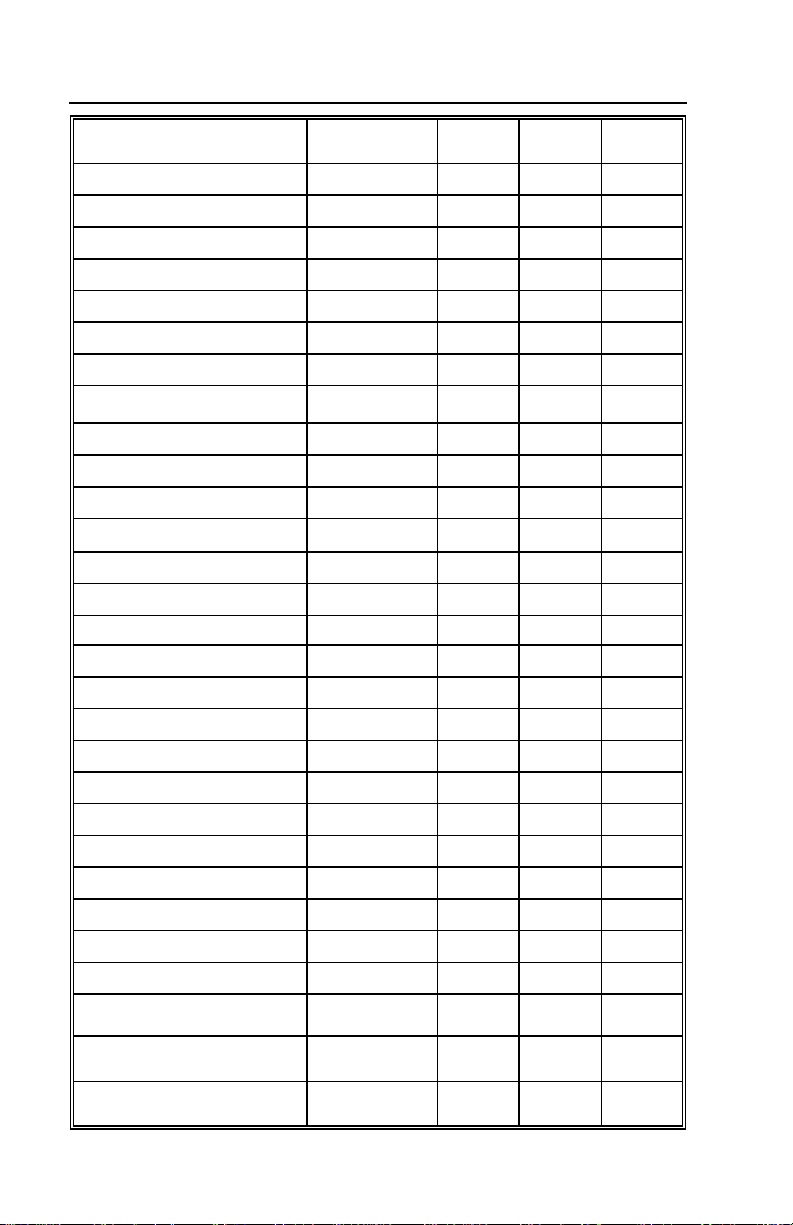

APPENDIX B

Default Settings of the MS6130 and “MX” Receiver

Before the MS6130 hand-held scanner and “MX” Receiver ships from the

factory, the factory programs the scanners to a group of default settings. An

asterisk ( * ) in the charts on the following pages marks the default settings

of the units. If an asterisk is not in the default column then the default setting

is Off or Disabled.

The MS6130 and “MX” receiver do not support every parameter. For those

parameters that are a transmitter function, a letter “T” will appear in the

second column of the charts, for the “MX”, the

letter “R”.

RS-232, light pen and keyboard wedge emulation does not support every

parameter. If your host device’s communication supports a parameter listed

in the charts on the following pages, a check mark will appear.

In order for the “MX” receiver to communicate with your RS-232, light pen or

keyboard wedge host device properly, program it to meet your individual

scanning needs. Since each host system is unique, change the default

settings to match your host system requirements. To modify default settings,

refer to the MS4120 and MS951 Programming Guides.

Note: If your “MX” Interface is connected to a MS700i/MS720i scanner,

use the bar codes in the ScanSelect Programming Guide to match

your scanner’s settings to the host system requirements.

T - Transmitter (MS6130 Hand-held)

R - Receiver (“MX”)

Parameter

Enter/Exit Program Mode T

Recall Defaults R

Enter Program Mode After Any

Scan T *

Enter Program Mode Only on

First Scan T

Short Range Activation Out of the

Stand T

Long Range Activation Out of the

Stand T *

Short Range Activation in the

Stand

T - Transmitter

R - Receiver

T

32

Default RS-232

✓✓

✓✓

✓✓

✓✓

✓✓

Light

Pen

Page 39

APPENDIX B (CONTINUED)

Parameter

Long Range Activation in the

Stand T *

Normal Scan T * ✓✓

Pulsing Scan T ✓✓

Custom Scan T ✓✓

Green LED Rescan Indicator T ✓✓

Short Same Symbol Rescan T

Long Same Symbol Rescan T *

Alternate Beeper Tone 1 R ✓✓

Alternate Beeper Tone 2 R * ✓✓

Alternate Beeper Tone 3 R

No Beeper Tone R

Two Second Time-out R

No Two Second Timeout R * ✓

Razzberry Tone on Timeout R ✓

No Tone on Timeout R * ✓

Three Beeps on Timeout R ✓

Beep Before Transmit R * ✓

Beep After Transmit R ✓

Baud Rate R 960 0 ✓

Parity R Space ✓

8 Data Bits R

7 Data Bits R *

RTS/CTS R

Character RTS/CTS R * ✓

Message RTS/CTS R ✓

ACK/NAK R ✓

XON/XOFF R ✓

No Intercharacter Dela y R * ✓

1 Millisecond Intercharacter

Delay R

5 Millisecond Intercharacter

Delay R

25 Millisecond Intercharacter

Delay R

T - Transmitter

R - Receiver

Default RS-232

✓✓

✓✓

✓✓

✓✓

✓✓

✓

✓

✓

✓

✓

✓

✓

Light

Pen

33

Page 40

APPENDIX B (CONTINUED)

Parameter

DTR Input R ✓

Carriage Return R * ✓

Line Feed R *

ETX Suffix R

Tab Prefix R

Tab Suffix R ✓

Prefix ID for UPC/EAN R ✓

Suffix ID for UPC/EAN R

Bars High R * ✓

Spaces High R

Transmit as Scanned R *

Transmit as Code 39 R

Poll Light Pen 5 Volts R

No Poll Light Pen R * ✓

UPC T * ✓✓

EAN T * ✓✓

Code 39 T * ✓✓

Codabar T * ✓✓

Code 128 T * ✓✓

Code 93 T * ✓✓

Interleaved 2 of 5 (ITF) T * ✓✓

MSI Plessey Decode T

Enable Code 11 Decode T

Enable Airline 2 of 5 T

Full ASCII Code 39 T ✓✓

Italian Pharmaceutical R ✓✓

Minimum 1 Character Code

Length T

Minimum 3 Character Code

Length T *

Minimum 6 Character Code

Length T

T - Transmitter

R - Receiver

Default RS-232

✓

✓

✓

✓

✓✓

✓✓

✓✓

✓✓

✓✓

✓✓

Light

Pen

✓

✓

✓

✓

34

Page 41

APPENDIX B (CONTINUED)

y

y

PARAMETER

Keyboard Type R

AT R *

XT R ✓

PS2 R

Keyboard Country Type R

USA R * ✓

UK R

France R

German

Italy R

Spain R

Belgium R ✓

KB4700 R

Swiss R

Caps Lock R ✓

Autodetection R

User Defined R

Transmit Cleanup Bit

Transmit Alt Mode

Transmit 0F0H Break

Character

Inter Scan Code Dela

0R

800 msec R *

7.5 msec R ✓

15 msec R

Intercharacter Delay

0R✓

1 msec R

10 msec R *

100 msec R * ✓

Stand Alone Scanner Mode R

T - TRANSMITTER

R - RECEIVER

R ✓

R

R

R*

R ✓

R

DEFAULT

KEYBOARD

WEDGE

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

35

Page 42

APPENDIX C

MX003 Series Scanner Interface Pin Assignments

The interfaces are equipped with a shielded, 10-pin modular jack

manufactured by Steward Stamping. The mating connector is a Steward

Stamping shielded plug #937-SP-361010. Caution should be used when

working with cables for this port because there is typically power present for

scanner interface operation.

Models MX003, MX0033 and MX0034:

Pin Function

1 Power (d/c)/Shield Ground

2 RS-232 Transmit Output

3 RS-232 Receiver Input

4 RTS Output

5 CTS Input

6 DTR Input

7LP/DATA

8NC

9 +5Vdc Power to Scanner Interface

10 NC

Models MX003-17, MX0033-17 and MX0034-17:

Pin Function

1 Power (d/c)/Shield Ground

2 RS-232 Transmit Output

3 RS-232 Receiver Input

4 Keyboard Data

5 Keyboard Clock

6 PC Clock

7 PC Data

8NC

9 PC +5V/ External +5V

10 NC

36

Page 43

APPENDIX D

Warranty and Disclaimer

Limited Warranty

The MS6130 scanners are manufactured by Metrologic at its Blackwood, New Jersey,

U.S.A. facility. The MS6130 scanners have a two (2) year limited warranty from the

date of manufacture. Metrologic warrants and represents that all MS6130 scanners

are free of all defects in material, workmanship and design, and have been produced

and labeled in compliance with all applicable U.S. Federal, state and local laws,

regulations and ordinances pertaining to their production and labeling.

This warranty is limited to repair, replacement of Product or refund of Product price at

the sole discretion of Metrologic. Faulty equipment must be returned to the Metrologic

facility in Blackwood, New Jersey, U.S.A. or Puchheim, Germany. To do this, contact

Metrologic’s Customer Service/Repair Departm ent t o obtain a Returned Materi al

Authorization (RMA) number.

In the event that it is determined the equipment failure is covered under this

warranty, Metrologic shall, at its sole option, repair the Product or replace the

Product with a functionally equivalent unit and return such repaired or replaced

Product without charge for service or return freight, whether distributor,

dealer/reseller, or retail consumer, or refund an amount equal to the original

purchase price.

This limited warranty does not extend to any Product which, in the sole judgement

of Metrologic, has been subjected to abuse, misuse, neglect, improper installation,

or accident, nor any damage due to use or misuse produced from integration of the

Product into any mechanical, electrical or computer system. The warranty is void if

the case of Product is opened by anyone other than Metrologic’s repair department

or authorized repair centers.

THIS LIMITED WARRANTY, EXCEPT AS TO TITLE, IS IN LIEU OF ALL OTHER

WARRANTIES OR GU AR AN TEES, EITHER EXPRESS OR IMPLIED, AND

SPECIFICALLY EXCLU DES, WITH OU T LIMIT ATIO N, WARRAN TIES OF

MERCHANTABILITY AND FITNESS F O R A PART ICULAR PURPOSE UNDER

THE UNIFORM COMMERCIAL CODE, OR ARISING OUT OF CUSTOM OR

CONDUCT. THE RIGHTS AND REMEDIES PROVIDED HEREIN ARE

EXCLUSIVE AND IN LIEU OF ANY OTHER RIGHTS OR REMEDIES. IN NO

EVENT SHALL METROLOGIC BE LIABLE FOR ANY INDIRECT OR

CONSEQUENTIAL DAMAGES, INCIDENTAL DAMAGES, DAMAGES TO

PERSON OR PROPERTY, OR EFFECT ON BUSINESS OR PROPERTY, OR

OTHER DAMAGES OR EXPENSES DUE DIRECTLY OR INDIRECTLY TO THE

PRODUCT, EXC EPT AS STATED IN THIS WAR R AN TY. IN NO EVENT SHALL

ANY LIABILITY OF METROLOGIC EXCEED THE ACTUAL AMOUNT PAID TO

METROLOGIC FOR THE PRODUCT. METROLOGIC RESERVES THE RIGHT

TO MAKE ANY CHANGES TO THE PRODUCT DESCR IBED HEREIN.

North America Headquarters

Metrologic Instruments, Inc. Customer Service: 1-800-ID-METRO

90 Coles Road Tel: 856-228-8100

Blackwood, NJ 08012-4683 Email: info@metrologic.com

Website: www.metrolo gic.com

Germany

Metrologic Instruments GmbH Tel: 49-89-89019-0

Dornierstrasse 2 Fax: 49-89-89019-200

82178 Puchheim b. Email: info@europe.metrologic.com

Munich, Germany

37

Page 44

APPENDIX E

Notices

Caution

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous laser light exposure. Under no circumstances shoul d

the customer attempt to service the laser scanner. Never attempt to look at the laser

beam, even if the scanner appears to be nonfunctional. Never open the scanner in an

attempt to look into the device. Doing so could result in hazardous laser light exposure.

The use of optical instruments with the laser equipment will increase eye hazard.

Atención

La modificación de los procedimientos, o la utilización de controles o ajustes distint os

de los especificados aquí, pueden provocar una luz de láser peligrosa. Bajo ninguna

circunstancia el usuario deberá realizar el mantenimiento del láser del escáner. Ni

intentar mirar al haz del láser incluso cuando este no esté operativo. Tampoco deberá

abrir el escáner para examinar el aparato. El hacerlo puede conllevar una exposición

peligrosa a la luz de láser. El uso de instrumentos ópticos con el equipo láser puede

incrementar el riesgo para la vista.

Attention

L'emploi de commandes, réglages ou procédés autres que ceux décrits ici peut

entraîner de graves irradiations. Le client ne doit en aucun cas essayer d'entretenir

lui-même le scanner ou le laser. Ne regardez jamais directement le rayon laser,

même si vous croyez que le scanner est inactif. N'ouvrez jamais le scanner pour

regarder dans l'appareil. Ce faisant, vous vous exposez à une rayonnement laser qú

êst hazardous. L'emploi d'appareils optiques avec cet équipement laser augm ente l e

risque d'endommagement de la vision.

Achtung

Die Verwendung anderer als der hier beschriebenen Steuerungen, Einstellungen oder

Verfahren kann eine gefährliche Laserstrahlung hervorrufen. Der Kunde sollte unter

keinen Umständen versuchen, den Laser-Scanner selbst zu warten. Sehen Sie

niemals in den Laserstrahl, selbst wenn Sie glauben, daß der Scanner nicht aktiv ist.

Öffnen Sie niemals den Scanner, um in das Gerät hineinzusehen. Wenn Sie dies tun,

können Sie sich einer gefährlichen Laserstrahlung aussetzen. Der Einsat z optischer

Geräte mit dieser Laserausrüstung erhöht das Risiko einer Sehschädigung.

Attenzione

L’utilizzo di sistemi di controllo, di regolazioni o di procedimenti di versi da quelli

descritti nel presente Manuale può provocare delle esposizioni a raggi laser rischios e.

Il cliente non deve assolutamente tentare di riparare egli stesso lo scanner las er. Non

guardate mai il raggio laser, anche se credete che lo scanner non sia attivo. Non

aprite mai lo scanner per guardare dentro l’apparecchio. Facendolo potete esporVi ad

una esposizione laser rischiosa. L’uso di apparecchi ottici, equipaggiati con raggi

laser, aumenta il rischio di danni alla vista.

Notice - applicable to 912 MHz devices only

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation. Any unauthorized changes or modifications to this

equipment could void the users authority to operate this device.

Notice - applicable to 912 MHz devices when used in Canad

Operation is subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference, incl udi ng interference

that may cause undesired operation of the device.

a

38

Page 45

APPENDIX F

Patents

“Patent Information

This METROLOGIC product may be covered by one or more of the following

U.S. Patents:

U.S. Patent No. 4,930,848; 4,958,984; 5,081,342; 5,260,553; 5,340,971;

5,340,973; 5,424,525; 5,468,951; 5,484,992; 5,525,789; 5,528,024;

5,591,953; 5,616,908; 5,627,359; 5,661,292; 5,777,315; 5,789,730;

5,789,731; 5,808,285; 5,811,786; 5,825,012; 5,886,337; 5,925,870;

5,925,871; 5,929,419; 5,939,701; 5,979,766; 6,015,019; 6,029,894;

D315,901;

4,360,798; 4,369,361; 4,387,297; 4,460,120; 4,496,831; 4,593,186;

4,607,156; 4,673,805; 4,736,095; 4,758,717; 4,816,660; 4,845,350;

4,896,026; 4,923,281; 4,933,538; 4,992,717; 5,015,833; 5,017,765;

5,059,779; 5,117,098; 5,124,539; 5,130,520; 5,132,525; 5,140,144;

5,149,950; 5,180,904; 5,200,599; 5,229,591; 5,247,162; 5,250,790;

5,250,791; 5,250,792; 5,262,628; 5,280,162; 5,280,164; 5,304,788;

5,321,246; 5,324,924; 5,340,971; 5,340,973; 5,396,053; 5,396,055;

5,408,081; 5,410,139; 5,436,440; 5,449,891; 5,468,949; 5,479,000;

5,532,469; 5,545,889; 5,874,721;

No license right or sublicense is granted, either expressly or by implication,

estoppel, or otherwise, under any METROLOGIC or third party intellectual

property rights (whether or not such third party rights are licensed to

METROLOGIC), including any third party patent listed above, except for an

implied license only for the normal intended use of the specif ic equ ipm ent,

circuits, and devices represented by or contained in the METROLOGIC

products that are physically transferred to the user, and only to the extent of

METROLOGIC’s license rights and subject to any conditions, covenants and

restrictions therein.”

Other worldwide patents pending.

39

Page 46

INDEX

A

AC 4, 6

Adapter 3

Asia ii

Audible indicators 25, 26

B

Battery pack 31

Beep(s) 1, 2, 6, 7, 9, 10, 16

17, 19, 23, 25, 26, 28

C

Cable 3, 6

Changing ID 17

Clean 27

Clean-up bit 14

Compliance 4, 6, 31

Configuration(s) 7-10, 15, 16, 28

Connections 4, 6

Copyright ii

Current 29

Customer Service ii

D

Default settings 32-35

Dimensions 29

Disclaimer 37

E

Email ii

ESD 31

Europe ii

External power source 6

I

ID 7, 9, 10, 17, 18, 28

Indicators 21, 23-25

Installation

Stand 21, 22

Internet ii

K

Keyboard wedge 10-14, 29

L

Labels 27

LASERKLASSE 1 27

LEDs 1, 6, 19, 21-25

®

Liberty

, 16, 29

List 3

Locations ii

Low speed options 8, 16

interface 1-3, 7, 9, 10

M

Maintenance 27

Matching procedure 18

MCA95 13

Model number 27

MS6130 1-3, 7-10, 15, 17-21

24, 25, 27-29, 31, 32

MS700i/MS720i 1, 6-8, 32

“MX” 2-10, 15, 16, 25, 26, 28, 32

N

NiCd battery charger 23, 31

Notices 38

F

Fax ii

Function(s) 2

G

Germany (GmbH) ii

Green LED 6, 19, 21, 23-25

H

Headquarters ii

Host 4, 6, 8, 10, 14, 32

40

O

Output window 19, 24, 27

P

Parts 19

Patents 40

Programming guide 3, 8-10

15,25, 26, 28, 32

Page 47

INDEX (CONTINUE D)

R

Receiver board 2

Red LED 1, 19, 24, 25

Rights property 40

RS-232 9, 10, 28

S

ScanPal

ScanSelect 3, 8, 32

Shipping carton 3

South America ii

Specifications 29-31

Stand 3, 20-23

®

2, 3, 9

T

Temperature 31

Tones 26

Transformer 4, 6, 20, 21

Transmitter 1-3, 7, 10, 15,

16, 18, 29, 32-35

Troubleshooting 28

U

Unpacking list 3

USA corporate headquarters ii

V

Visual indicators 24

Voltage 4-6, 29, 31

W

Weight 29

Window 1, 19, 24, 27

41

Page 48

March 2002

Printed in the USA

00-02212

Loading...

Loading...