Page 1

Dell EMC ML3 Tape Library

User's Guide

Page 2

Information in this document is subject to change without notice.

Copyright © 2020 Dell Inc. or its subsidiaries. All rights reserved.

Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other trademarks

may be trademarks of their respective owners.

Printed September 2020.

ii

Dell EMC ML3 Tape Library: User's Guide

Page 3

Read this FIRST

Regulatory information

• The library must be installed in a restricted area.

• Only personnel with technical and product safety training should have access to the library.

• The library must be properly installed in an ofce or industrial environment with shielded cables and

adequate grounding of SAS interface and input power to comply with regulations and standards.

• Models: 3555-L3A, 3555-E3A

The system complies to all applicable safety standards to allow for shipments worldwide including the

America's, European Union Member States, Middle East, and Asia.

Minimum rmware levels for common library features

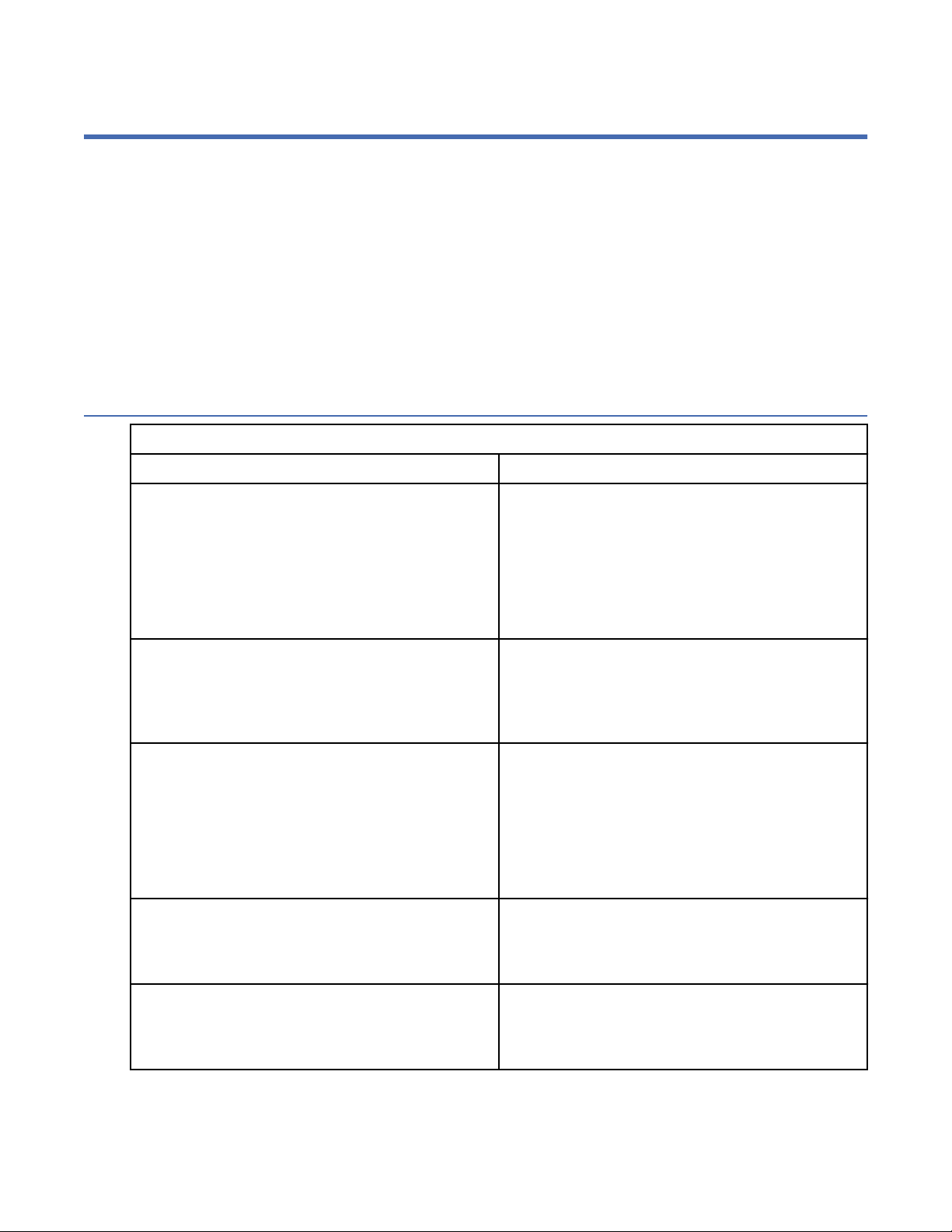

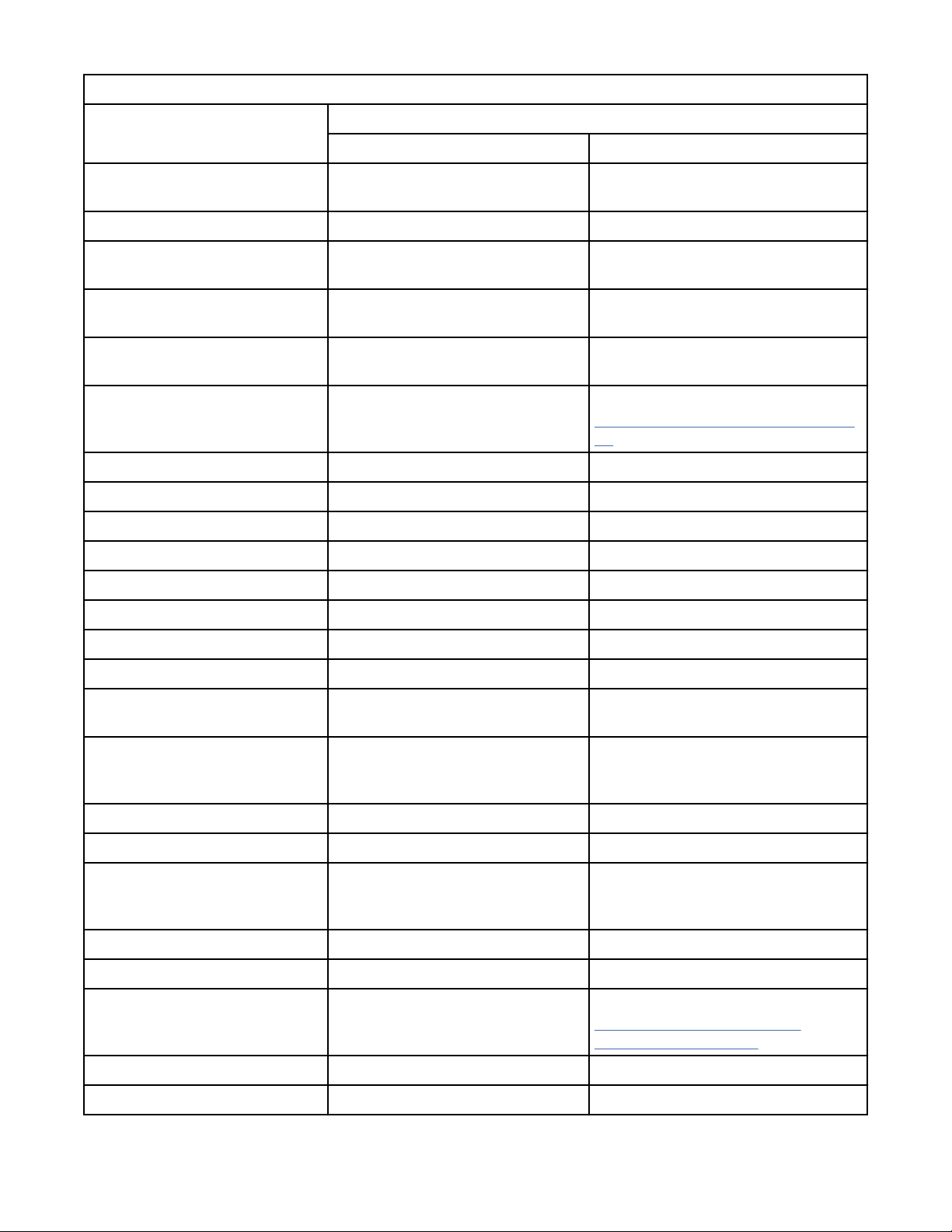

Table 1. Minimum rmware levels for common library features

Feature Minimum Firmware Levels Required

LTO8 (HH/FH) Tape Drives Library Firmware must be at 1.1.1.0 or greater to

support the LTO8 tape drives. Ensure that any host

applications and device drivers are at the minimum

level that is required to support LTO8 tape drives.

Certain non-IBM LTO8 media requires minimum

drive rmware J4D4. Contact your media supplier

for details.

LTO6 (HH/FH) and LTO7 (HH/FH) Tape Drives Library Firmware must be at 1.1.0.1-A00 or greater

to support the LTO6 and LTO7 tape drives. Ensure

that any host applications and device drivers are at

the minimum level that is required to support LTO6

and LTO7 tape drives.

Library-Managed Encryption Library Firmware must be at 1.1.1.0-A00 or greater

to support the Library-Managed Encryption feature.

Ensure that any key manager applications are at

the minimum level that is required to support the

3U library.

SKLM for z/OS encryption requires minimum library

rmware 1.2.0.0-B00.

Path Failover (Control Path and Data Path) Library Firmware must be at 1.1.1.0-A00 or greater

to support the Path Failover feature. Ensure that

any device drivers are at the minimum level that is

required to support the 3U library.

Remote Logging (rsyslog) Library Firmware must be at 1.1.1.0-A00 or greater

to support the Remote Logging feature. Ensure that

any device drivers are at the minimum level that is

required to support the 3U library.

Page 4

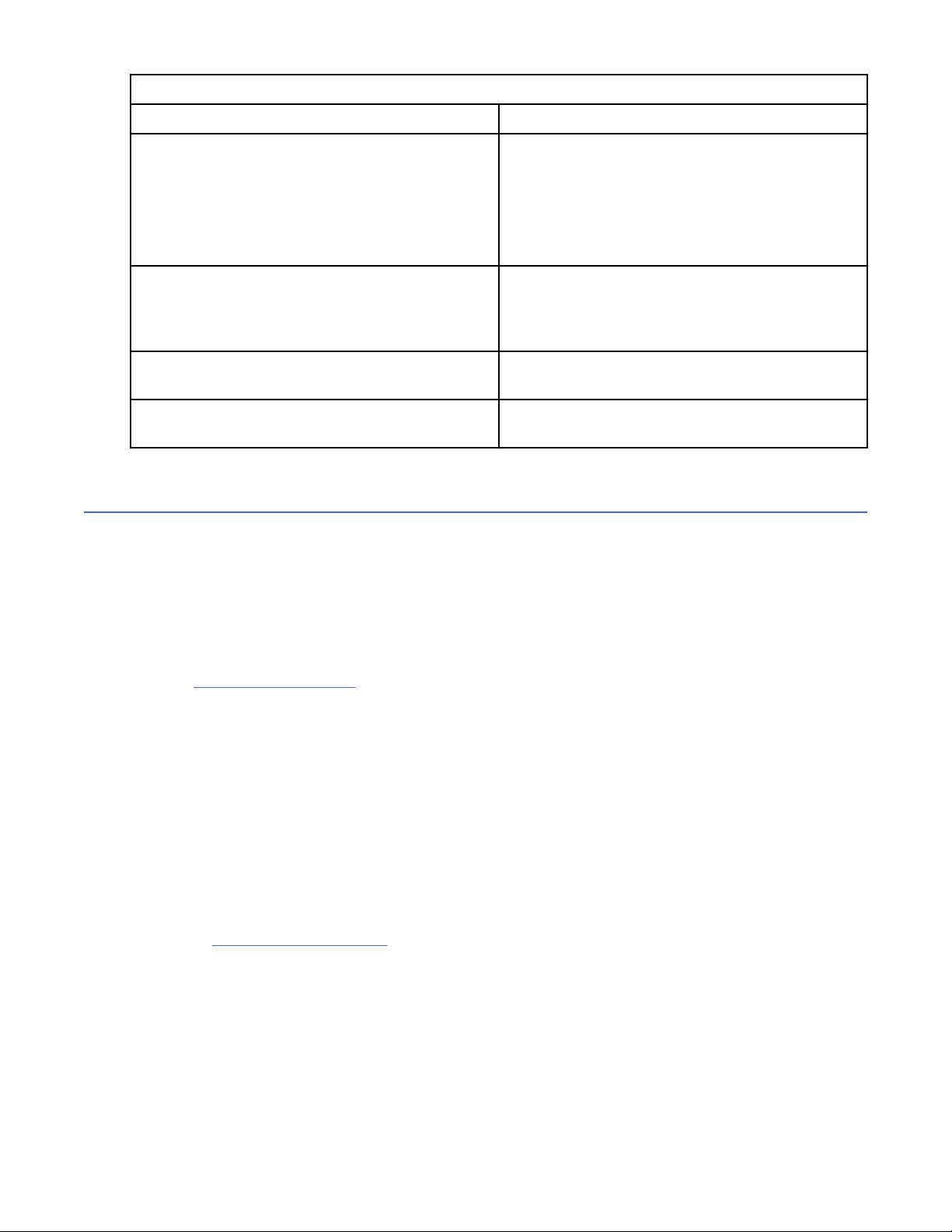

Table 1. Minimum rmware levels for common library features (continued)

Feature Minimum Firmware Levels Required

LTO M8 media

Sequential Mode Library Firmware must be at 1.1.1.2-A00 or greater

Library Serial Number 7800K0K or greater Library rmware must be at 1.2.1.0-A00 or greater

Key Path Diagnostics (KPD) Library Firmware must be at 1.3.0.0-A00 or greater

Contacting Dell

For customers in the United States, call 800-WWW-DELL (800-999-3355).

Note: If you do not have an active Internet connection, you can nd contact information about your

purchase invoice, packing slip, bill, or Dell product catalog.

Library Firmware must be at 1.1.1.1-B00 or greater

to support the M8 media feature. Drive rmware

must be at HB82 or greater to support the M8

media feature. Ensure that any device drivers are

at the minimum level that is required to support

the 3U library.

to support Sequential Mode. Ensure that any host

applications are at the minimum level that is

required to support the 3U library in this mode.

to support newer library serial numbers.

to support KPD.

Dell provides online and telephone-based support and service options. Service availability varies by

country and product, and some services might not be available in your area. To contact Dell for sales,

technical support, or customer service issues follow the steps that are listed:

1. Go to www.Dell.com/support.

2. Select your country from the drop-down menu on the lower right corner of the page.

3. For customized support:

a. Enter your system Service Tag in the Enter your Service Tag eld.

b. Click Submit. The support page that lists the various support categories is displayed.

4. For general support:

a. Select your product category.

b. Select your product segment.

c. Select your product. The support page that lists the various support categories is displayed.

5. For contact details of Dell Global Technical Support:

a. Click Global Technical Support.

b. The Contact Technical Support page is displayed with details to call, chat, or e-mail the Dell

Global Technical Support team.

iv

Dell EMC ML3 Tape Library: User's Guide

Page 5

Contents

............................................................................................................................. ii

Read this FIRST....................................................................................................iii

Minimum rmware levels for common library features............................................................................. iii

Contacting Dell............................................................................................................................................ iv

Figures................................................................................................................. ix

Tables................................................................................................................ xiii

Safety and environmental notices ........................................................................xx

Danger and Caution notices....................................................................................................................... xx

Possible safety hazards............................................................................................................................xxv

Class I laser product.................................................................................................................................xxv

Acclimation.............................................................................................................................................. xxvi

Performing the safety inspection procedure.......................................................................................... xxvi

Rack safety...............................................................................................................................................xxvi

Power Cords..............................................................................................................................................xxx

Preface.............................................................................................................xxxi

Chapter 1. Overview.............................................................................................. 1

Introduction................................................................................................................................................. 1

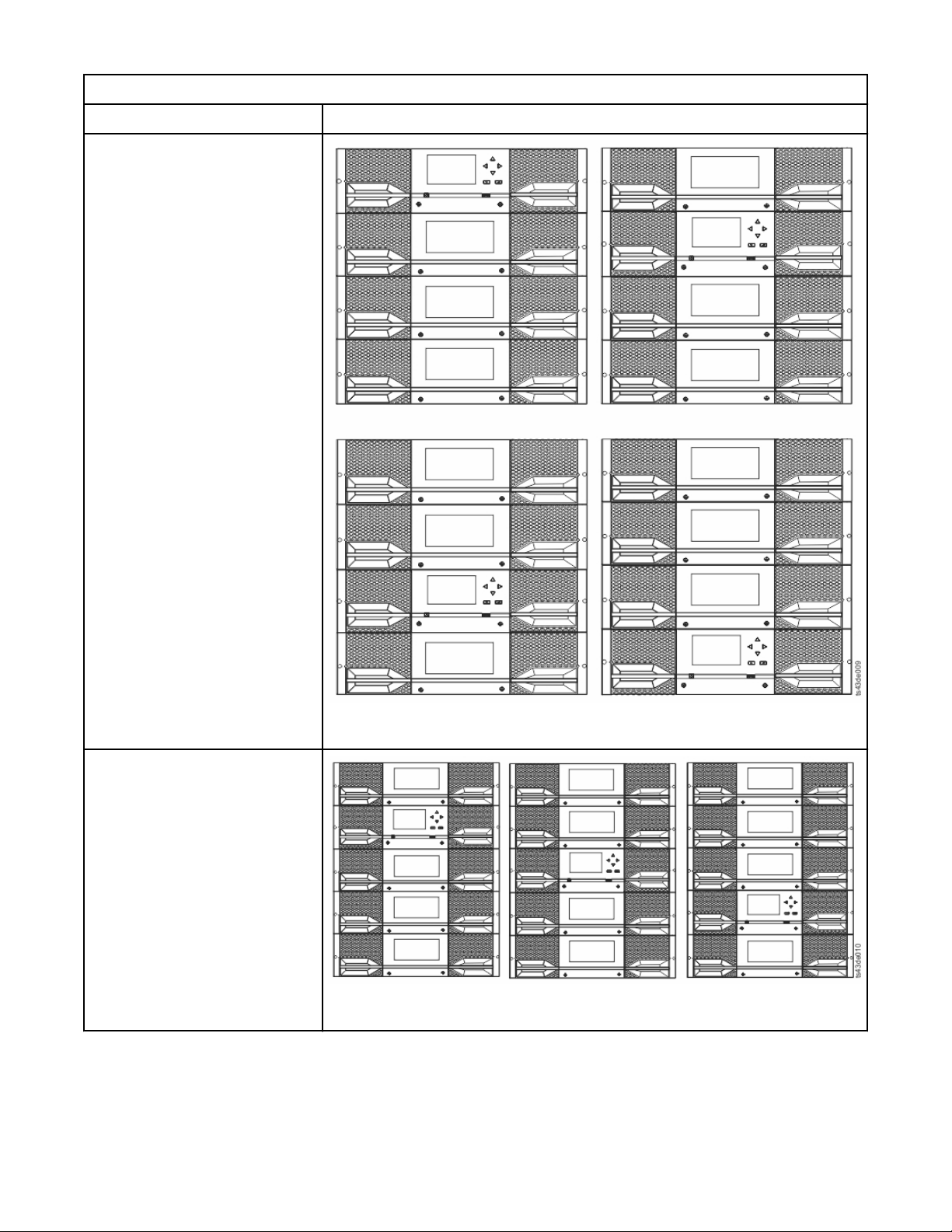

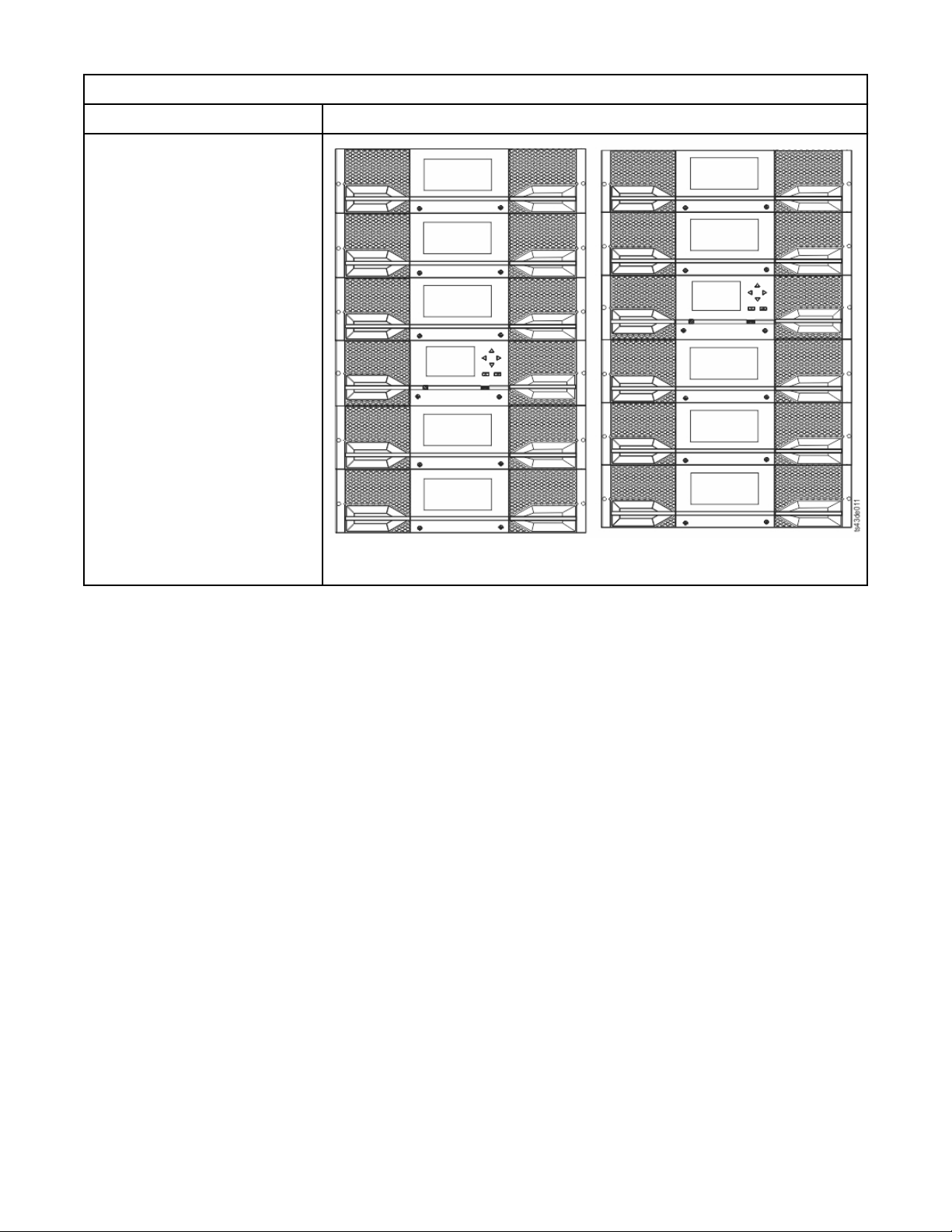

Structure and supported library congurations..........................................................................................2

Components............................................................................................................................................6

User interfaces...........................................................................................................................................11

Supported tape drives............................................................................................................................... 11

Control path drives...............................................................................................................................12

Mixed drives..........................................................................................................................................12

Drive sled back panels......................................................................................................................... 13

Physical and logical addresses of drives............................................................................................. 15

Supported tape cartridges.........................................................................................................................16

Library functions........................................................................................................................................ 16

Random and Sequential Logical Library modes.................................................................................. 16

Encryption.............................................................................................................................................17

Library sharing......................................................................................................................................18

Control path failover, Data path failover, and load balancing.............................................................18

Alerts and logging.................................................................................................................................19

Host connectivity....................................................................................................................................... 20

Network connectivity.................................................................................................................................21

Chapter 2. Planning............................................................................................. 22

Library Layout and Location requirements............................................................................................... 22

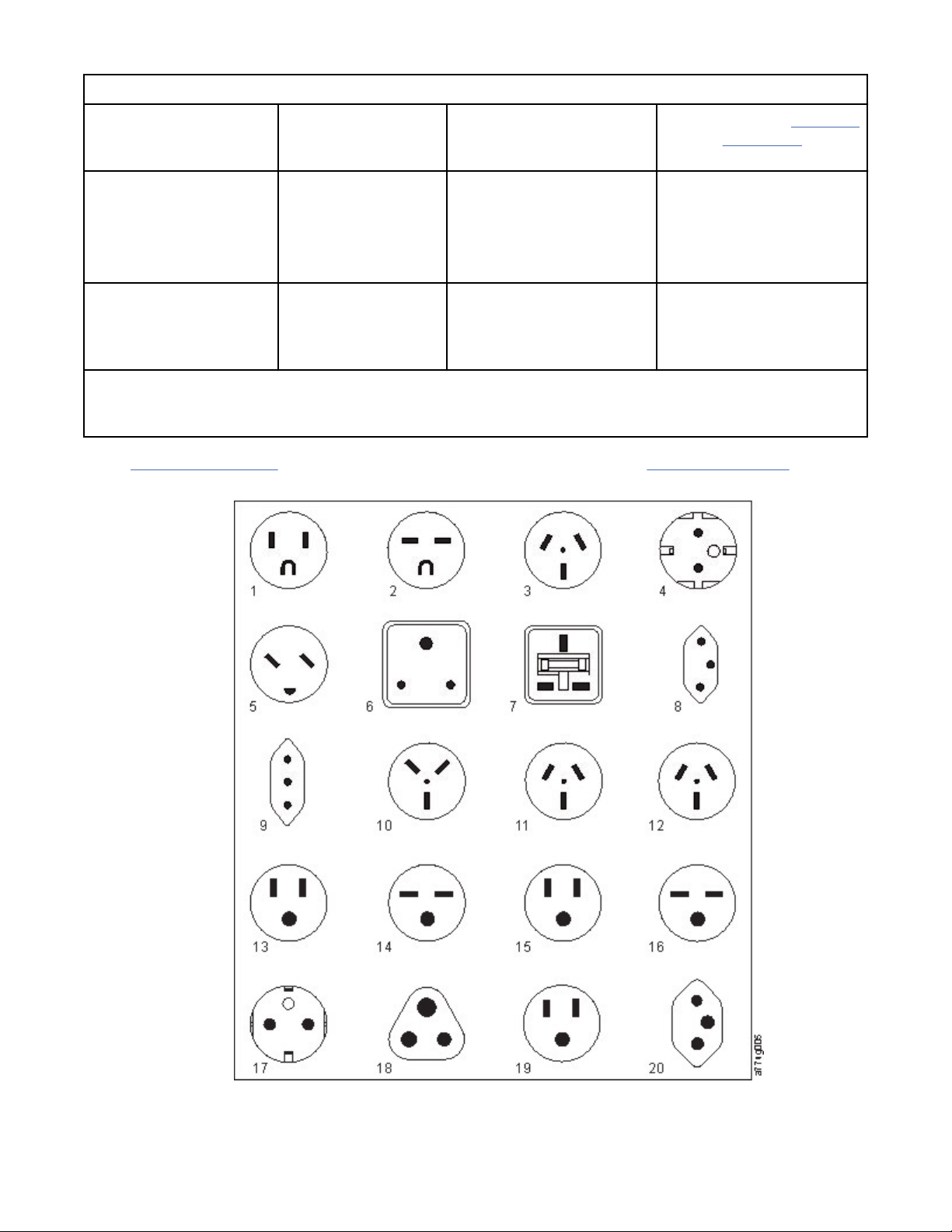

Power cords............................................................................................................................................... 27

Network requirements...............................................................................................................................32

Host requirements.....................................................................................................................................32

Chapter 3. Installing............................................................................................34

Unpacking the Base Module and Expansion Modules.............................................................................. 36

v

Page 6

Identifying Library Module components................................................................................................... 40

Preparing top and bottom modules.......................................................................................................... 40

Installing modules in a rack...................................................................................................................... 43

Installing a tabletop module..................................................................................................................... 47

Aligning and connecting modules............................................................................................................. 47

Validating tape drive installation...............................................................................................................50

Connecting cables......................................................................................................................................51

Powering on the library..............................................................................................................................52

The Initial Setup process...........................................................................................................................53

Initial conguration and customization.................................................................................................... 54

Labeling and loading tape cartridges........................................................................................................ 54

Verifying the installation............................................................................................................................56

Advanced library conguration................................................................................................................. 56

Overview...............................................................................................................................................56

Library partitioning............................................................................................................................... 57

Verifying the host connection....................................................................................................................58

Chapter 4. Managing............................................................................................59

The Management GUI................................................................................................................................59

The Operator Panel....................................................................................................................................62

Locating Management functions............................................................................................................... 63

Default settings.................................................................................................................................... 67

Methods of cleaning drives.................................................................................................................. 70

Accessing cartridges............................................................................................................................ 71

Conguring Library Managed Encryption.............................................................................................72

Chapter 5. Troubleshooting..................................................................................75

Finding event information..........................................................................................................................75

Identifying a failed component................................................................................................................. 75

Running library tests..................................................................................................................................75

Troubleshooting Guide.............................................................................................................................. 75

Pre-call checklist....................................................................................................................................... 79

Contacting Dell...........................................................................................................................................80

Diagnostic information...............................................................................................................................80

The ITDT rmware update, dump retrieval and drive test tool ......................................................... 80

Event codes.......................................................................................................................................... 81

TapeAlert Flags.................................................................................................................................. 105

Sense data..........................................................................................................................................111

Drive Error Codes: Single-character display (SCD)........................................................................... 111

Chapter 6. Upgrading and servicing....................................................................115

Internal view of library............................................................................................................................ 115

Adding, removing, or replacing a tape drive........................................................................................... 116

Adding or replacing a Base or Expansion Module.................................................................................. 120

Adding, removing, or replacing a power supply..................................................................................... 125

Replacing a Base or Expansion controller card...................................................................................... 128

Installing, removing, or replacing an accessor and spooling mechanism............................................. 131

Returning the accessor to the Base Module......................................................................................137

Removing or replacing a spooling mechanism....................................................................................... 138

Removing or replacing a magazine......................................................................................................... 142

Moving the library modules.....................................................................................................................143

vi

Appendix A. Library Conguration Forms........................................................... 146

Library information.................................................................................................................................. 146

Module and drive information................................................................................................................. 148

Logical Library information......................................................................................................................149

Users account information...................................................................................................................... 150

Page 7

Appendix B. Management GUI functions and roles ............................................. 151

Appendix C. LTO media......................................................................................157

Data cartridges........................................................................................................................................ 157

Cartridge Read/Write compatibility...................................................................................................158

LTO Type M Cartridge (M8)................................................................................................................ 158

WORM (Write Once, Read Many) cartridges........................................................................................... 159

WORM media......................................................................................................................................159

Data security on WORM media.......................................................................................................... 160

WORM media errors...........................................................................................................................160

Cleaning cartridge....................................................................................................................................160

Labeling tape cartridges..........................................................................................................................160

Guidelines for bar code labels........................................................................................................... 162

Write-Protect switch................................................................................................................................162

Handling the cartridges........................................................................................................................... 163

Providing training............................................................................................................................... 163

Ensuring proper packaging................................................................................................................ 164

Proper acclimation and environmental conditions........................................................................... 164

Completing a thorough inspection.................................................................................................... 165

Handling the cartridge carefully........................................................................................................ 165

Environmental and shipping specications for tape cartridges.............................................................166

Appendix D. REST API for scalable tape libraries................................................167

Resources................................................................................................................................................ 169

System................................................................................................................................................169

Library information.............................................................................................................................171

Library operations.............................................................................................................................. 179

Library conguration.......................................................................................................................... 183

Library test......................................................................................................................................... 187

Drive information................................................................................................................................190

Drive conguration.............................................................................................................................190

Partition (Logical Library) information...............................................................................................192

Partition (Logical Library) conguration............................................................................................ 197

Denitions................................................................................................................................................198

BaseInfoData..................................................................................................................................... 198

BaseStatusData..................................................................................................................................199

DriveInfo.............................................................................................................................................200

Error....................................................................................................................................................201

EventEntry.......................................................................................................................................... 202

IOStatus............................................................................................................................................. 202

Inventory............................................................................................................................................ 202

LibraryInfo..........................................................................................................................................203

LibraryStatus...................................................................................................................................... 203

LicenseInfo.........................................................................................................................................203

MediaInfoData....................................................................................................................................203

Module................................................................................................................................................204

ModuleStatusData..............................................................................................................................205

Modules..............................................................................................................................................205

PartitionInfo....................................................................................................................................... 205

Slot......................................................................................................................................................207

TestStatus.......................................................................................................................................... 208

Security.................................................................................................................................................... 208

Appendix E. Accessibility...................................................................................210

Glossary............................................................................................................211

vii

Page 8

Index................................................................................................................ 231

viii

Page 9

Figures

1. Two module tape library............................................................................................................................... 1

2. Base Module ................................................................................................................................................. 2

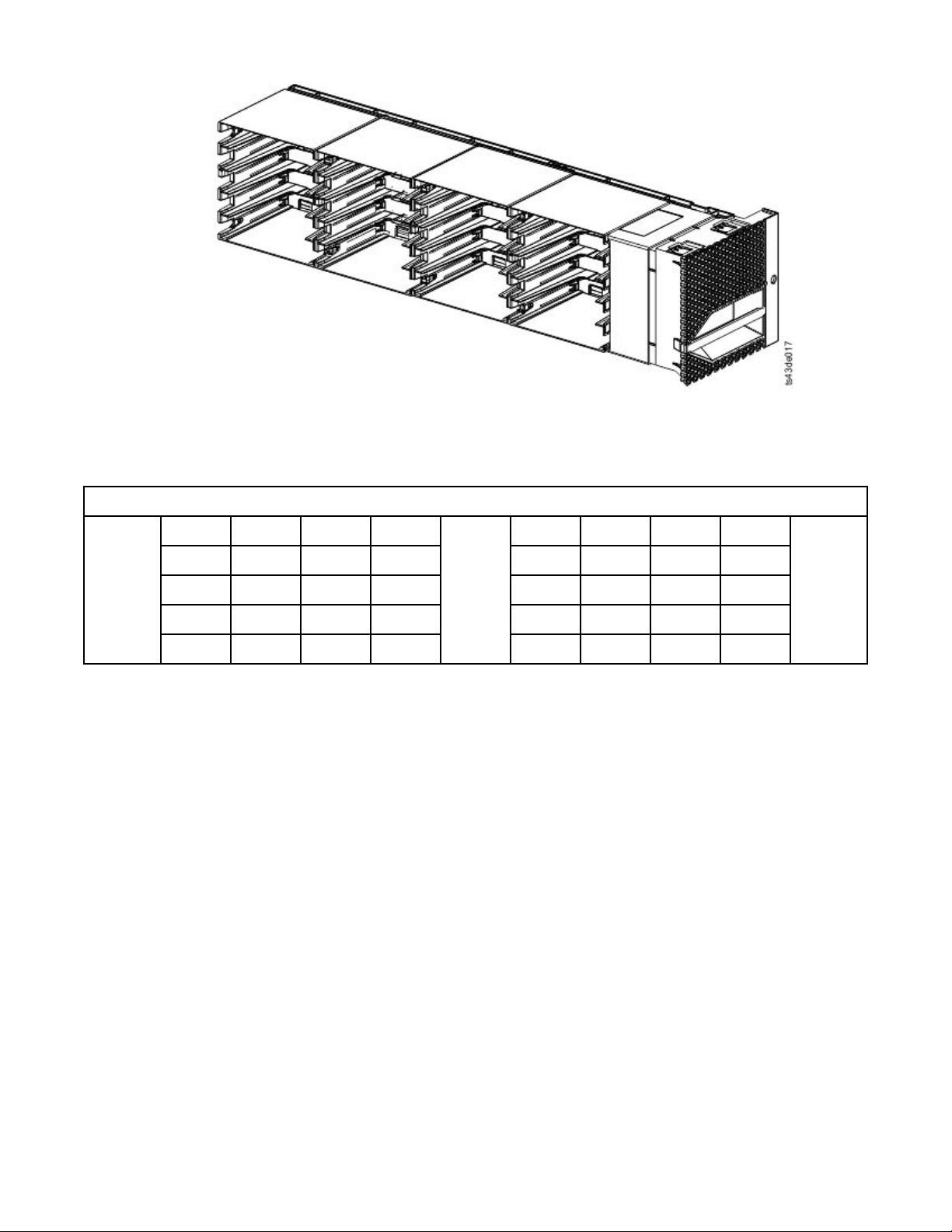

3. Expansion Module......................................................................................................................................... 3

4. Base Module.................................................................................................................................................. 3

5. 2 module library............................................................................................................................................ 3

6. 3 module library............................................................................................................................................ 3

7. 4 module library............................................................................................................................................ 4

8. 5 module library............................................................................................................................................ 4

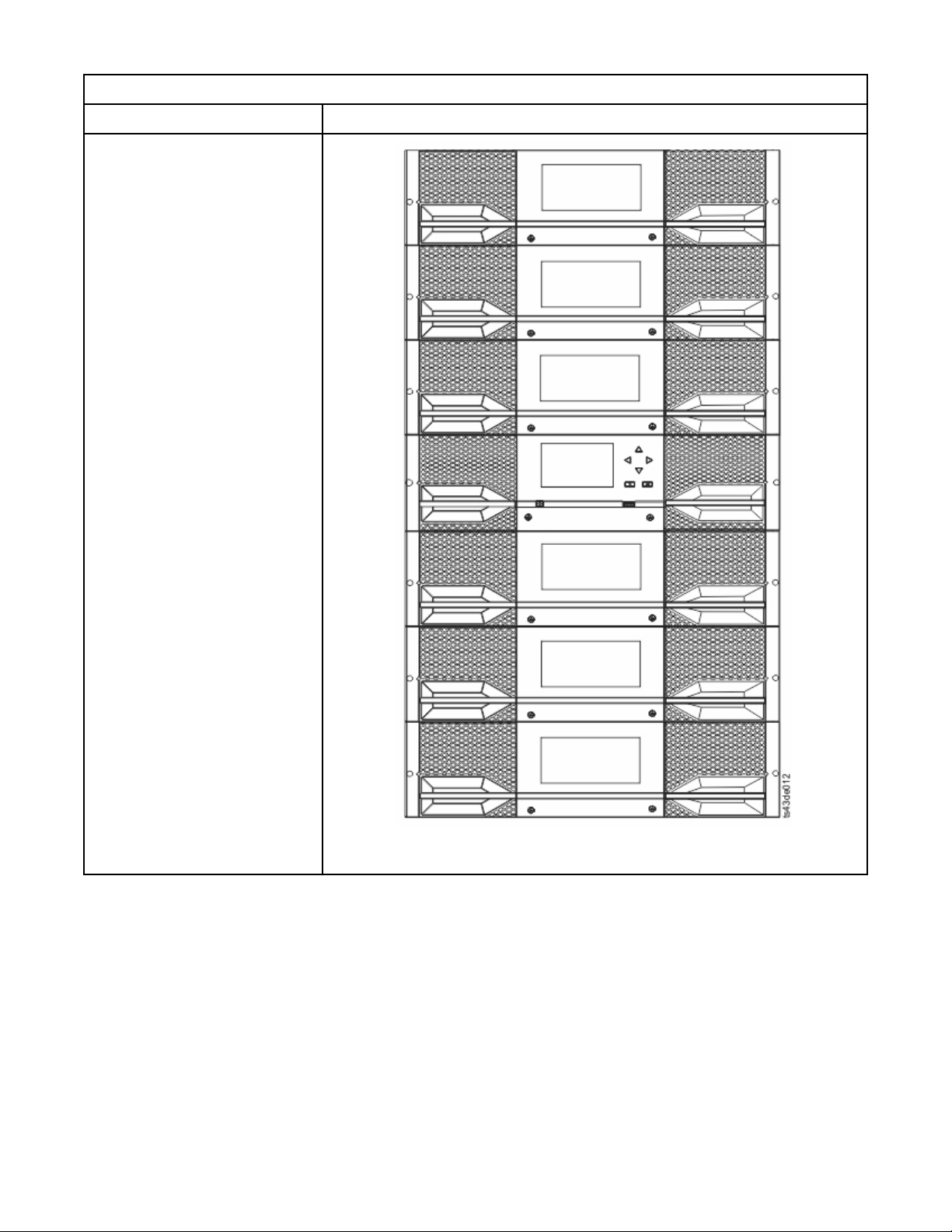

9. 6 Module library.............................................................................................................................................5

10. 7 module library.......................................................................................................................................... 6

11. Front panel ..................................................................................................................................................7

12. Rear panel....................................................................................................................................................8

13. Physical numbering of modules .................................................................................................................9

14. Left magazine.............................................................................................................................................. 9

15. Right magazine..........................................................................................................................................10

16. Power supply rear panel LEDs..................................................................................................................11

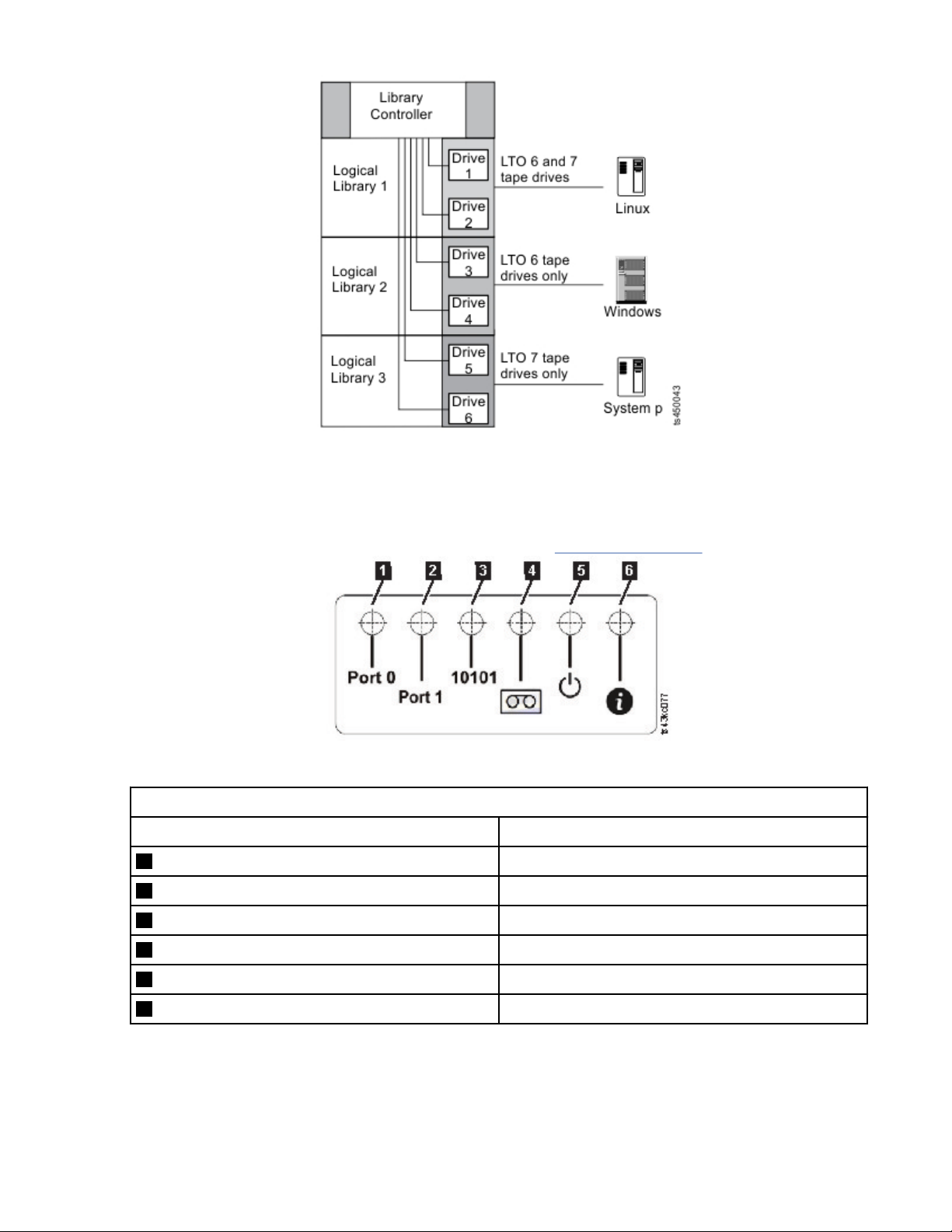

17. Mixed drives in a logical library.................................................................................................................13

18. Drive sled indicators..................................................................................................................................13

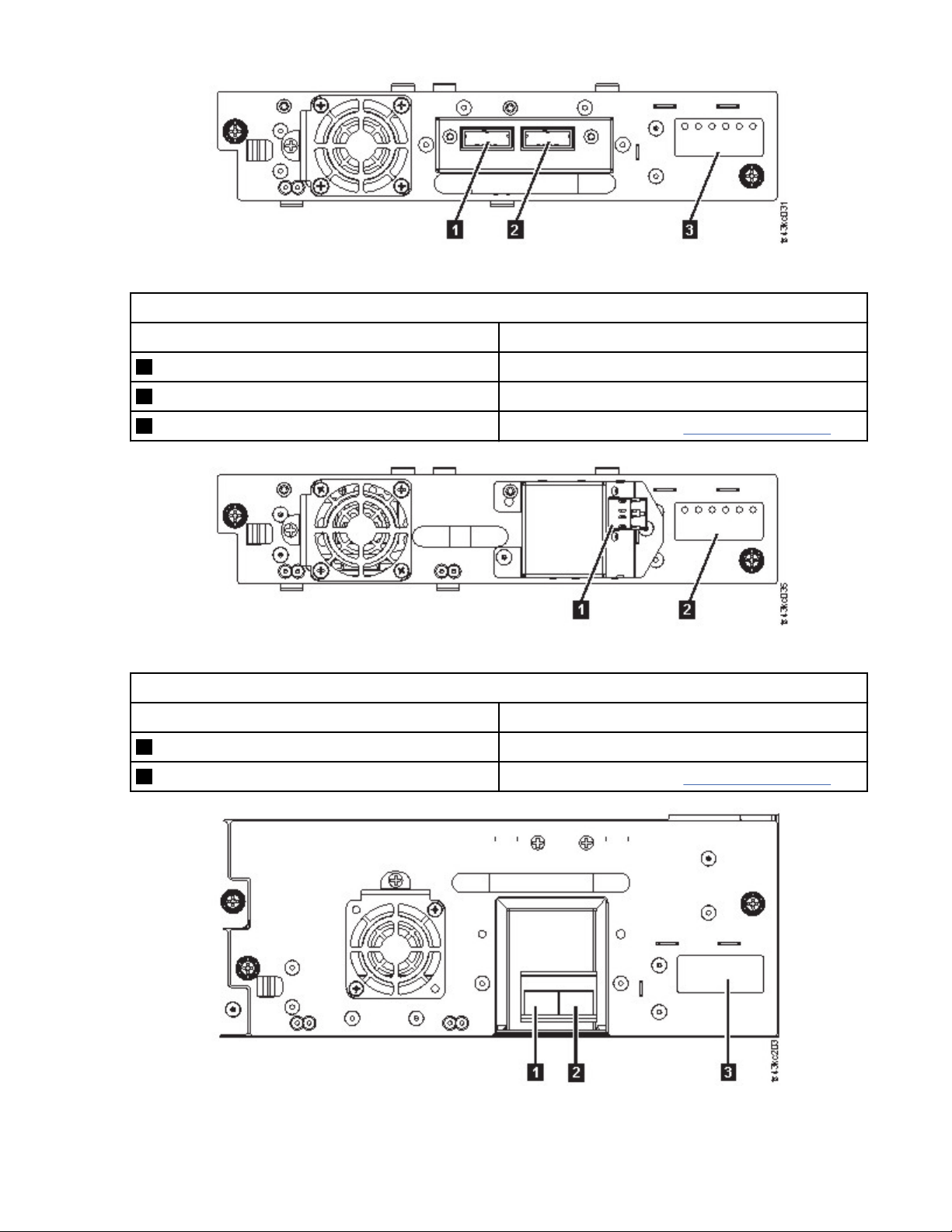

19. Half-height SAS dual port......................................................................................................................... 14

20. Half-height FC single port.........................................................................................................................14

21. Full-height FC dual port............................................................................................................................ 14

22. Physical numbering of drives....................................................................................................................15

ix

Page 10

23. Psychrometric chart showing recommended and allowable operating environments for the tape

library..........................................................................................................................................................25

24. Types of receptacles.................................................................................................................................31

25. Removing the module from the box......................................................................................................... 37

26. The module after removal from the box...................................................................................................37

27. Unlatching the top of the module.............................................................................................................38

28. Removing the top of the module.............................................................................................................. 38

29. The module is opened to show the foam packing................................................................................... 39

30. The foam packing is removed, and the internal components are shown - Base Module.......................39

31. Lowering the front of the top cover.......................................................................................................... 41

32. Unlocking the spring loaded lock............................................................................................................. 42

33. Removing the cover.................................................................................................................................. 42

34. Lifting the cover and locking it..................................................................................................................43

35. Universal rack connector.......................................................................................................................... 43

36. Incorrect connector locations ................................................................................................................. 44

37. Correct connector locations .....................................................................................................................44

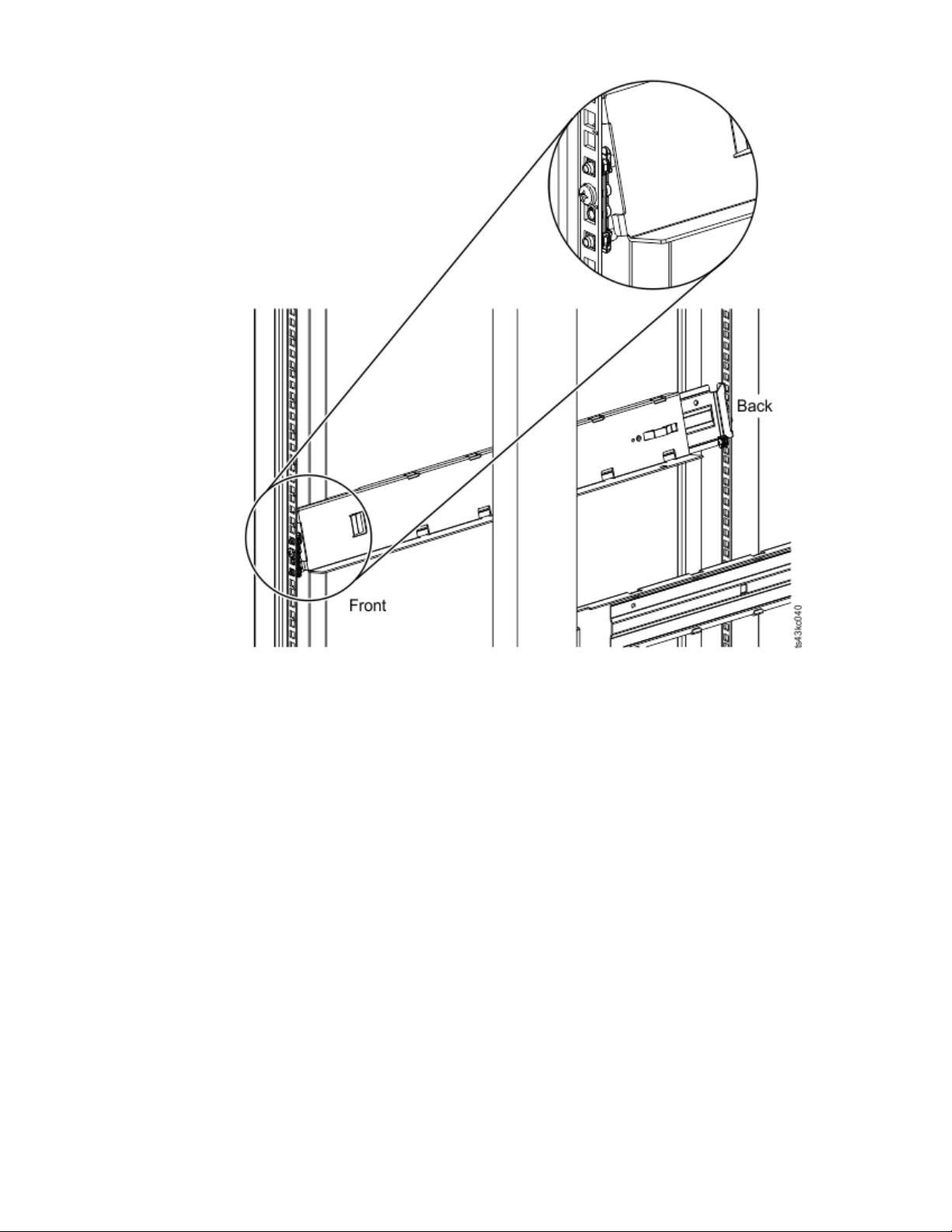

38. Mounting the rails to the connectors........................................................................................................45

39. Side rails installed.....................................................................................................................................46

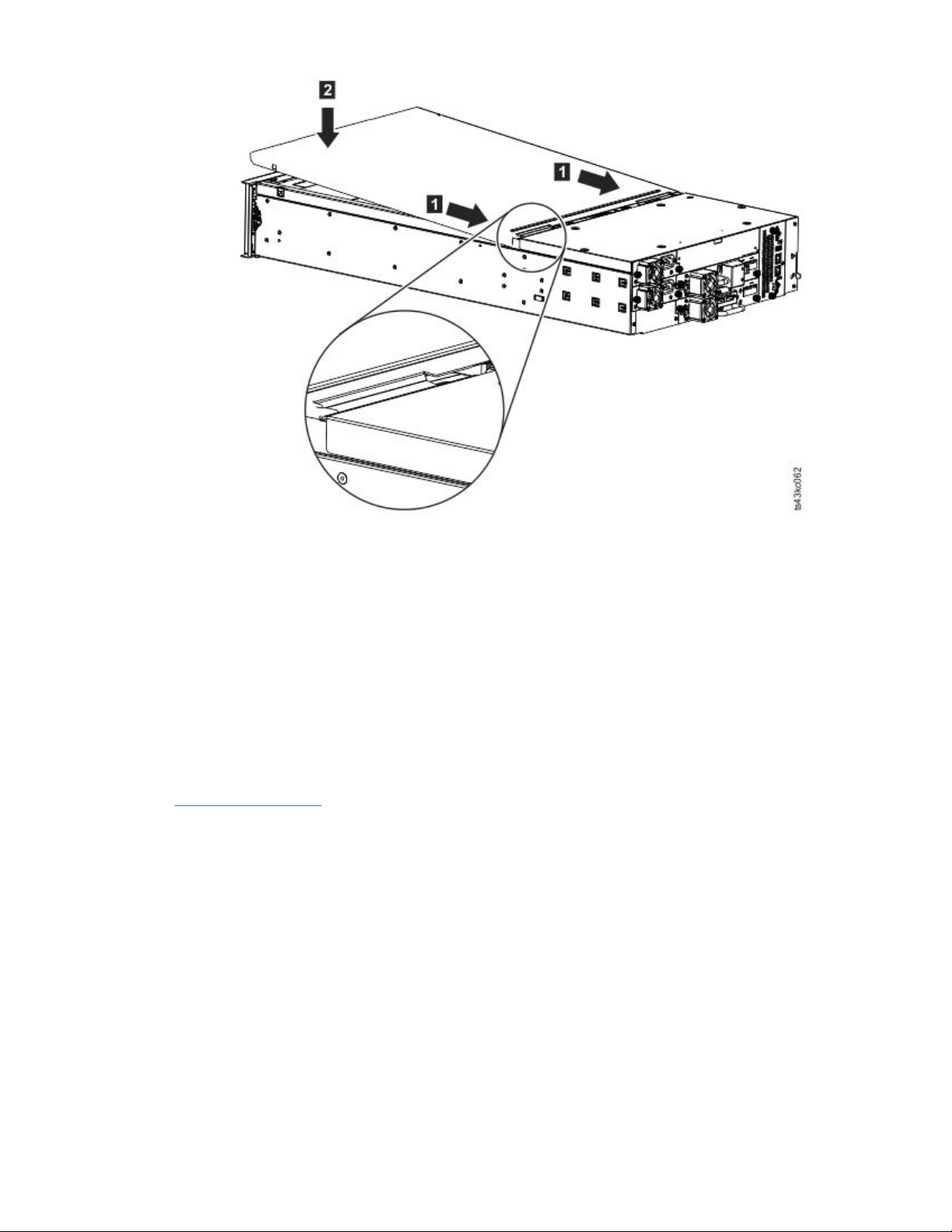

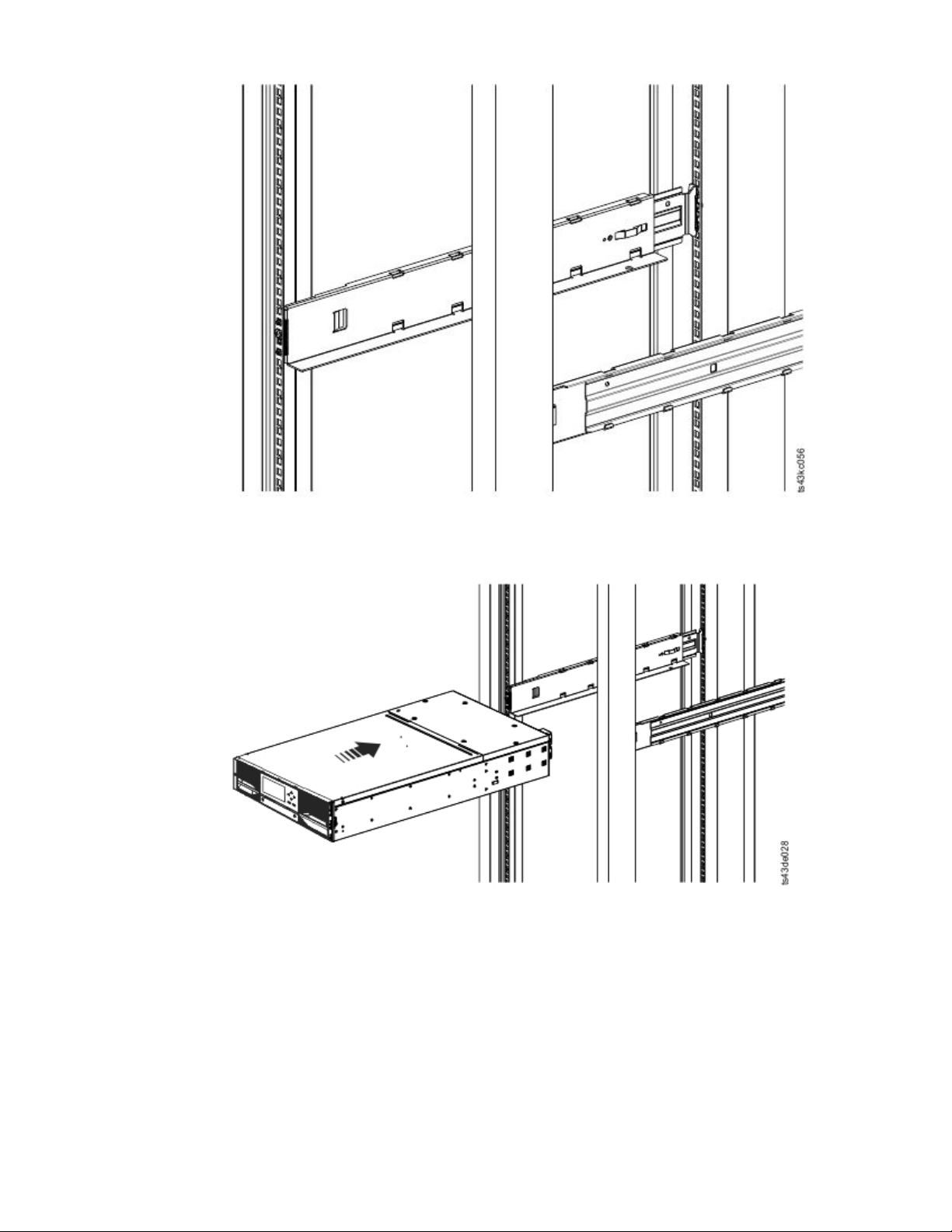

40. Sliding the library into the rack.................................................................................................................46

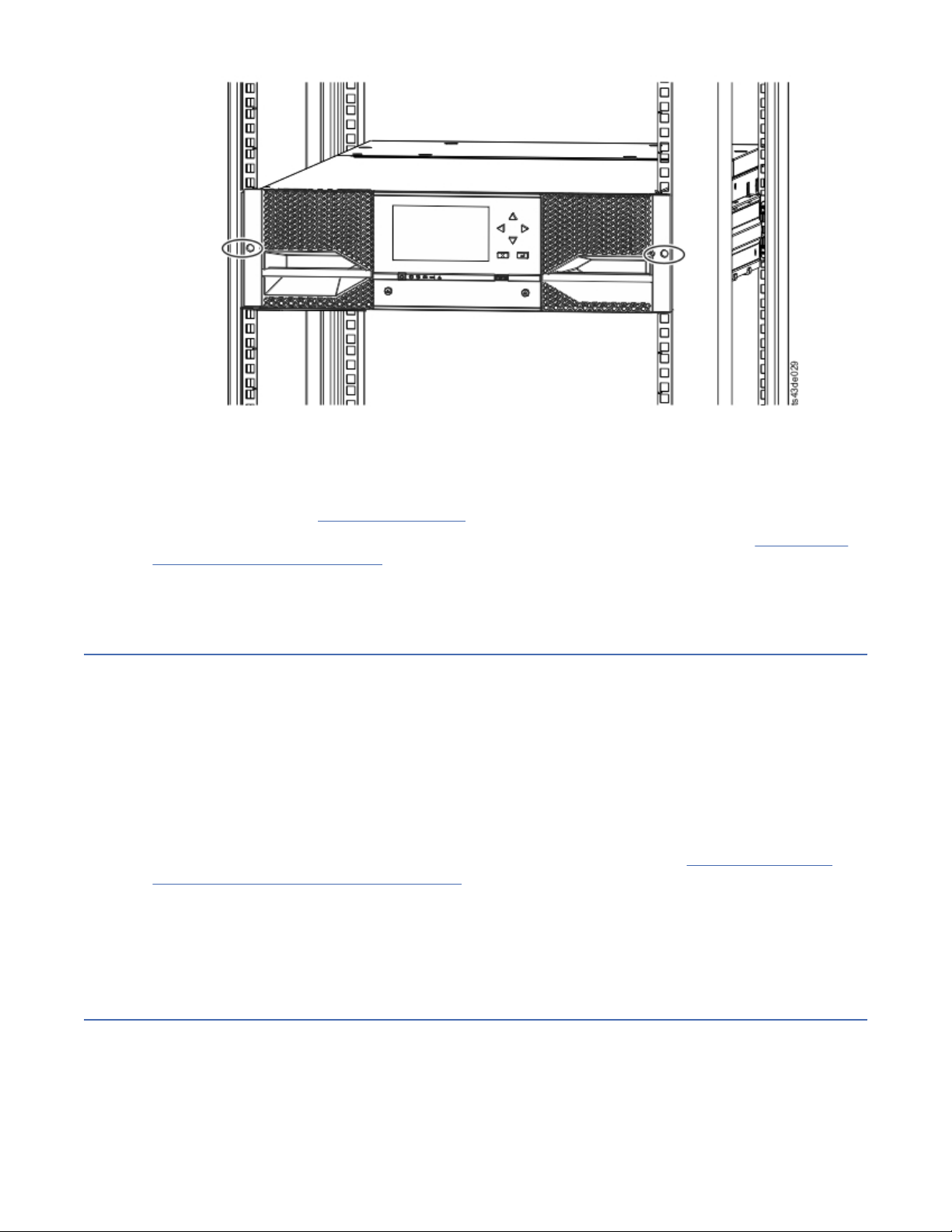

41. Library in the rack......................................................................................................................................47

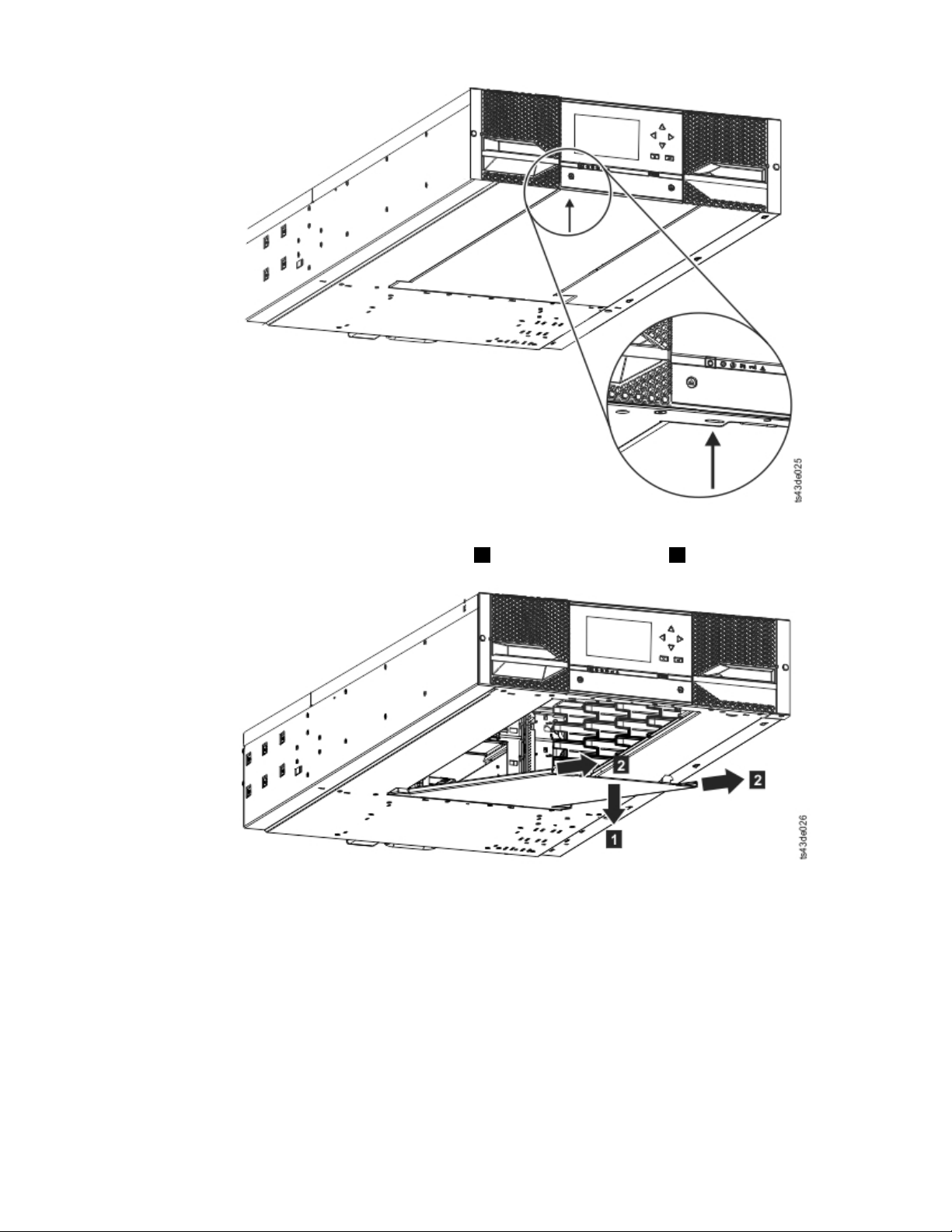

42. Hole for alignment pin...............................................................................................................................48

43. Alignment lever lock................................................................................................................................. 48

44. Alignment lever locked or engaged to lower module.............................................................................. 49

45. Alignment lever unlocked or disengaged.................................................................................................49

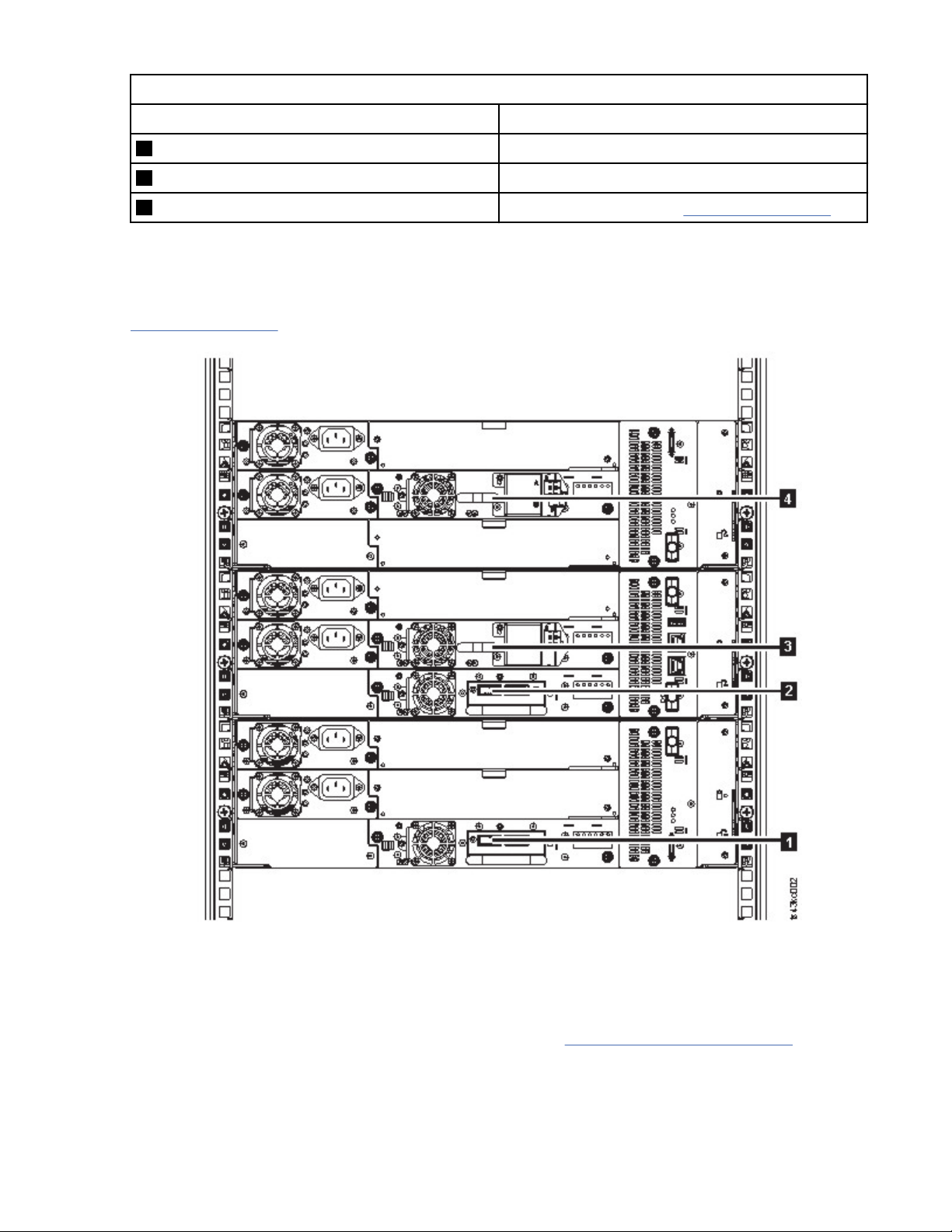

46. Two modules in rack, seen from the rear.................................................................................................50

47. Connected modules.................................................................................................................................. 50

x

Page 11

48. Full-height FC dual port............................................................................................................................ 51

49. Half-height FC single port.........................................................................................................................51

50. Half-height SAS dual port......................................................................................................................... 52

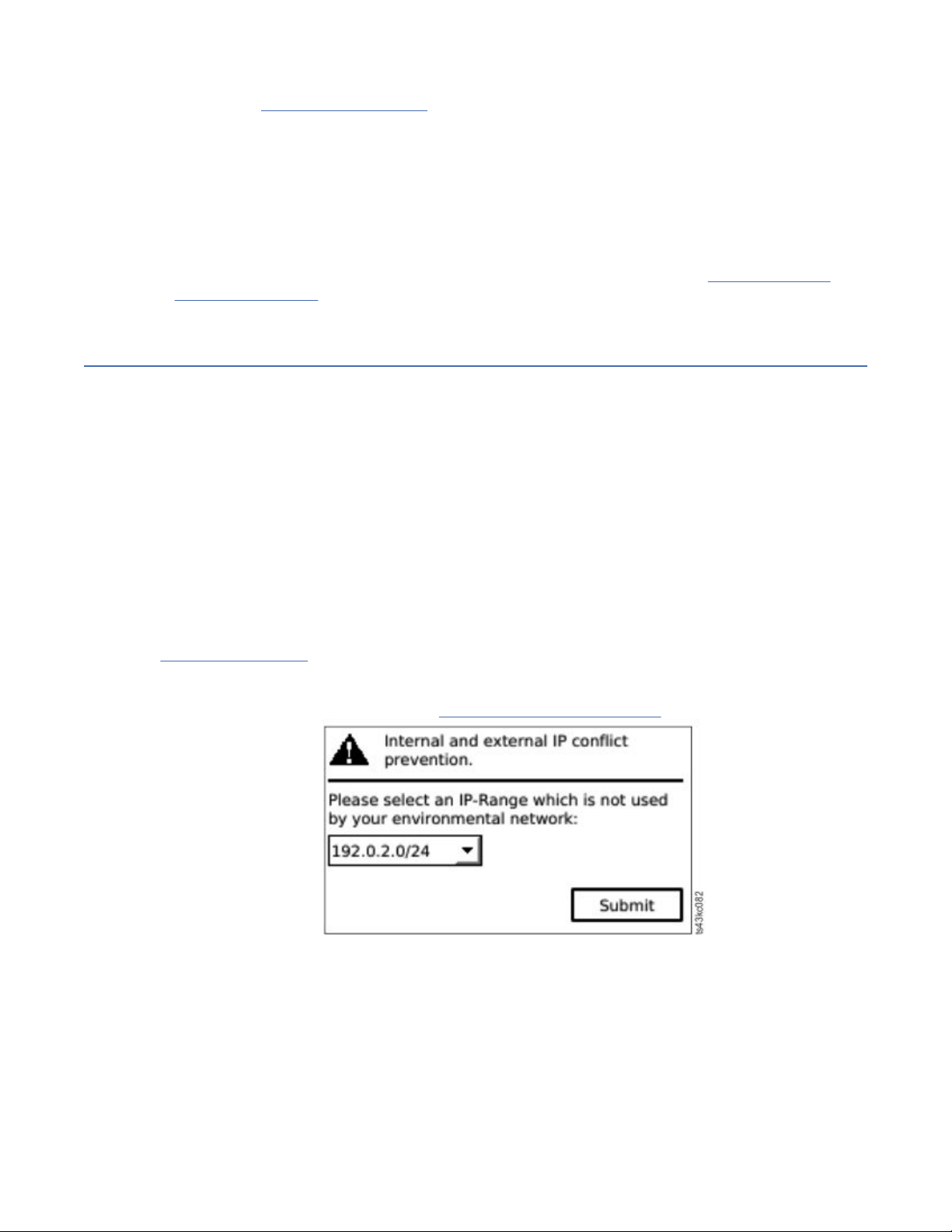

51. IP address selection................................................................................................................................. 53

52. Open I/O station seen from the left..........................................................................................................55

53. Magazine pulled out..................................................................................................................................55

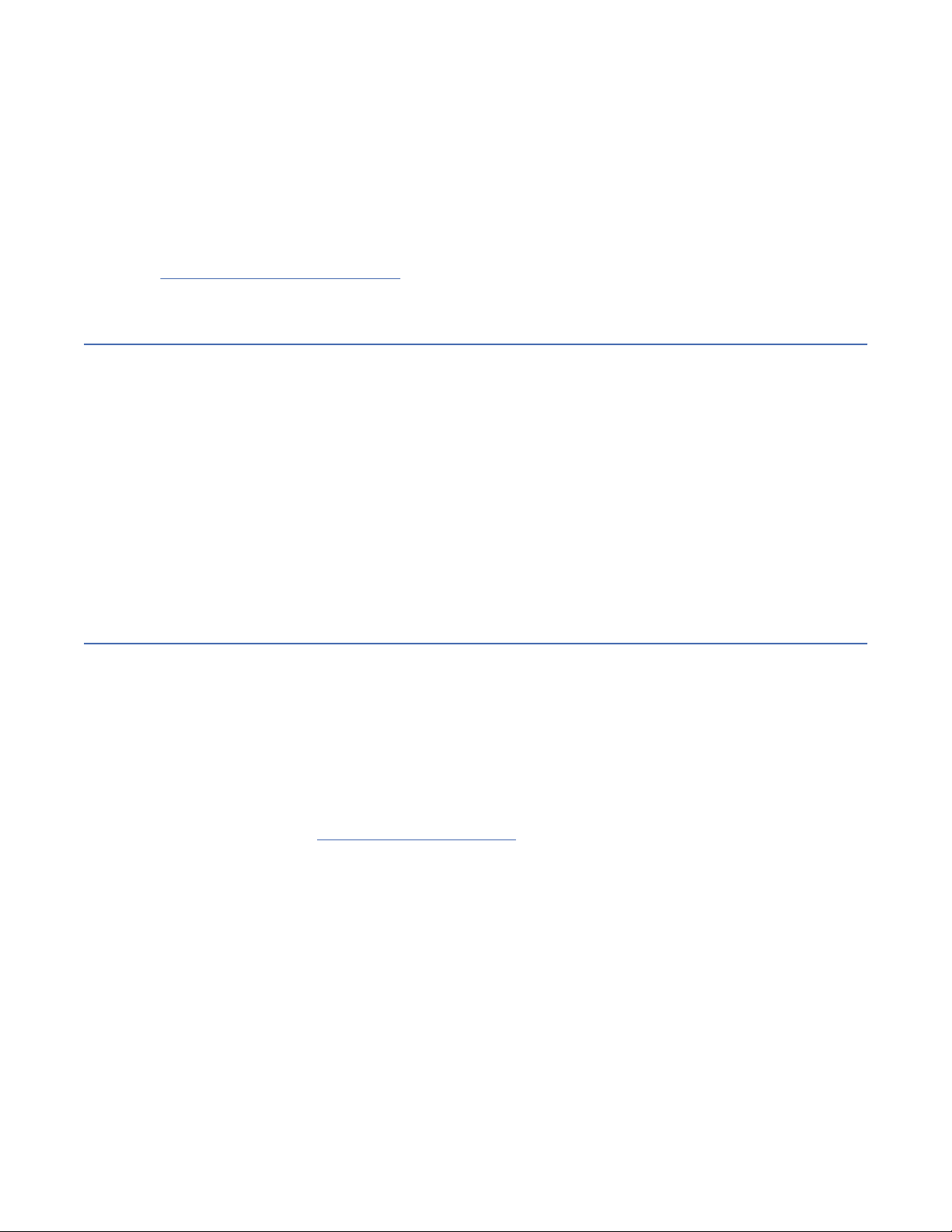

54. Management GUI main screen................................................................................................................. 60

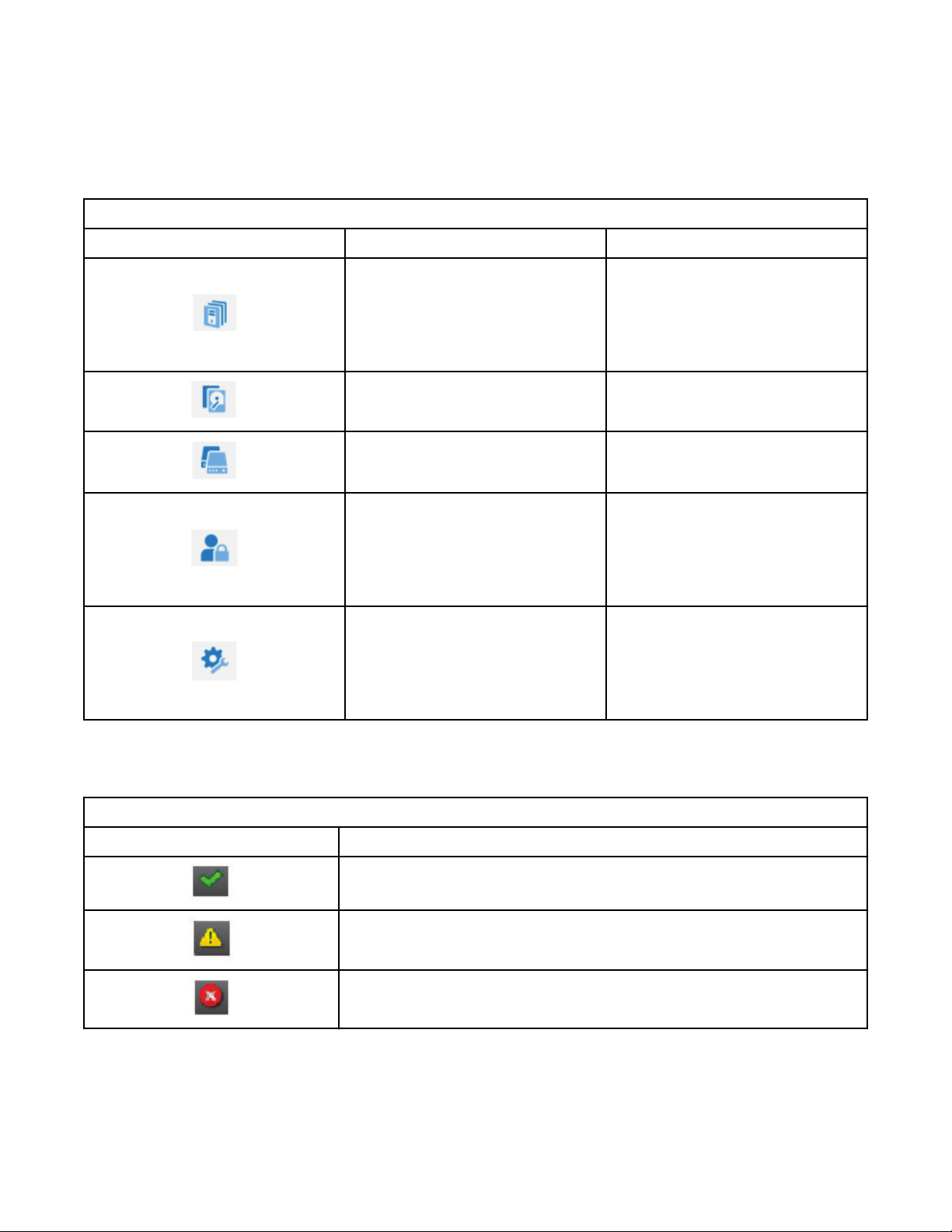

55. Operator Panel main screen..................................................................................................................... 62

56. Front panel LEDs....................................................................................................................................... 63

57. Internal view of the library..................................................................................................................... 115

58. Drive bay covers......................................................................................................................................117

59. Alignment rails........................................................................................................................................ 117

60. Installing a tape drive............................................................................................................................. 118

61. Unlocking the drive................................................................................................................................. 118

62. Interconnect cables................................................................................................................................122

63. Unlocking or disengaging the alignment lever.......................................................................................123

64. Loosening the thumbscrews.................................................................................................................. 124

65. Sliding the module out of the rack......................................................................................................... 124

66. Power supplies........................................................................................................................................126

67. Sliding in the new power supply.............................................................................................................127

68. Controller card components...................................................................................................................129

69. Installing a Controller card.....................................................................................................................130

70. Magazine release levers......................................................................................................................... 132

71. Unlocking the robot................................................................................................................................ 133

72. Finger holes.............................................................................................................................................133

xi

Page 12

73. Unlocking the spooling cable and placing it in its cradle.......................................................................134

74. Spooling cable in park position.............................................................................................................. 134

75. Pins are aligned horizontally.................................................................................................................. 135

76. Installing the spooling cable.................................................................................................................. 136

77. Inserting the screwdriver to manually operate the accessor................................................................137

78. Left magazine opening............................................................................................................................138

79. Unlocking the spooling mechanism....................................................................................................... 139

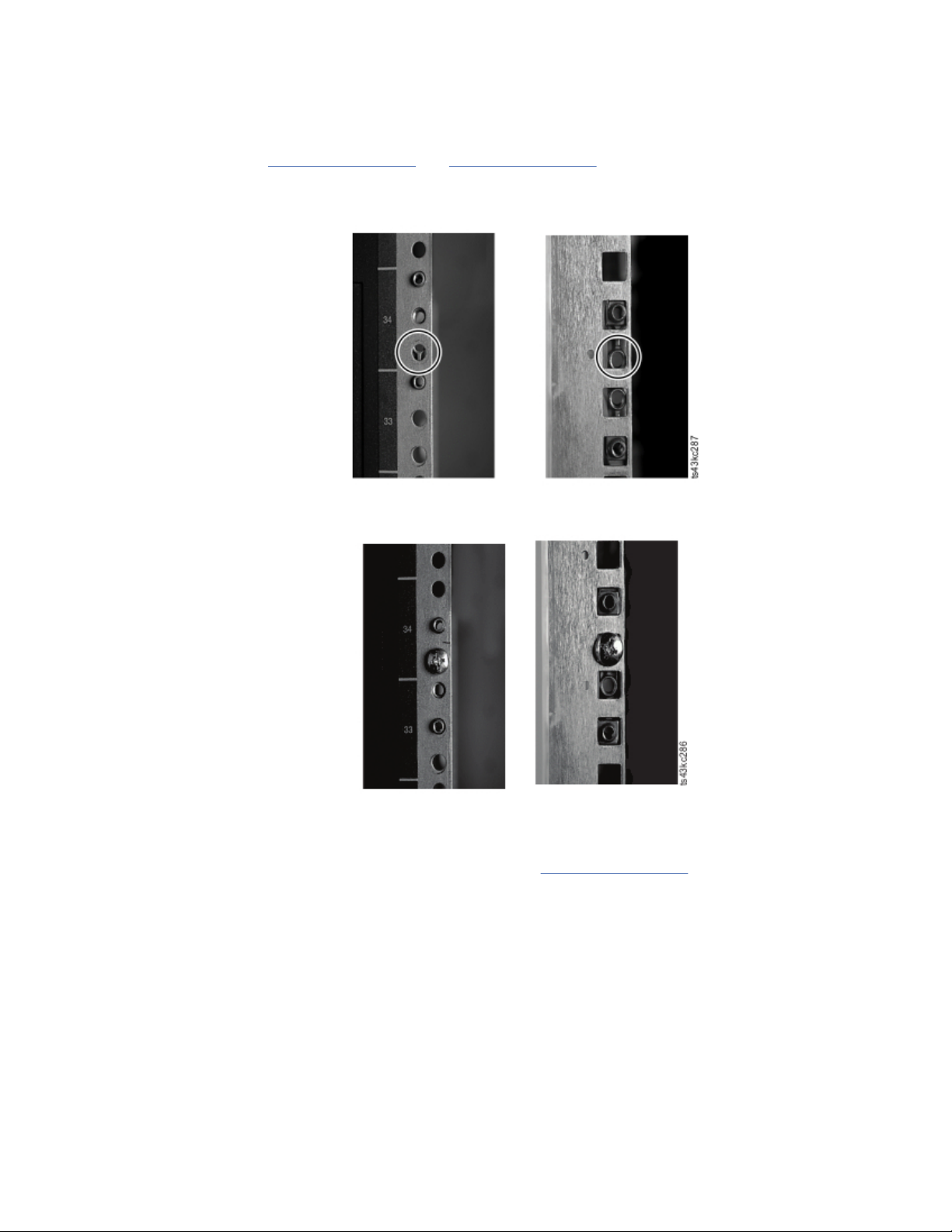

80. Unlocked spooling mechanism - enlarged view.................................................................................... 140

81. Locked spooling mechanism - enlarged view........................................................................................141

82. Removing the spooling mechanism....................................................................................................... 142

83. Manually releasing the right magazine...................................................................................................143

84. Manually releasing the left magazine.....................................................................................................143

85. The LTO data cartridge........................................................................................................................... 157

86. LTO Data and WORM tape cartridges.....................................................................................................160

87. Sample bar code label on the LTO8 Tape Cartridge.............................................................................. 162

88. Setting the write-protect switch.............................................................................................................163

89. Double-boxing tape cartridges for shipping...........................................................................................164

90. Checking for gaps in the seams of a cartridge....................................................................................... 165

xii

Page 13

Tables

1. Minimum rmware levels for common library features...............................................................................iii

2. Module designations..................................................................................................................................... 1

3. Minimum and maximum storage congurations..........................................................................................2

4. Library congurations....................................................................................................................................3

5. Front panel descriptions............................................................................................................................... 7

6. Rear panel descriptions.................................................................................................................................8

7. Physical numbering of storage slots - bottom module.............................................................................. 10

8. Power supply LEDs......................................................................................................................................11

9. Supported tape drives.................................................................................................................................12

10. Drive sled indicators..................................................................................................................................13

11. Half-height SAS dual port......................................................................................................................... 14

12. Half-height FC single port.........................................................................................................................14

13. Full-height FC dual port............................................................................................................................ 15

14. Differences between CPF and DPF...........................................................................................................19

15. Location requirements..............................................................................................................................22

16. Physical specications..............................................................................................................................23

17. Electrical specications for one module (base or expansion).................................................................23

18. Equipment environment specications for the tape library.................................................................... 24

19. Gas and particulate exposure...................................................................................................................26

20. Power cords...............................................................................................................................................27

21. Installation Precautions............................................................................................................................35

22. Full-height FC dual port............................................................................................................................ 51

23. Half-height FC single port.........................................................................................................................51

xiii

Page 14

24. Half-height SAS dual port......................................................................................................................... 52

25. Main screen elements...............................................................................................................................60

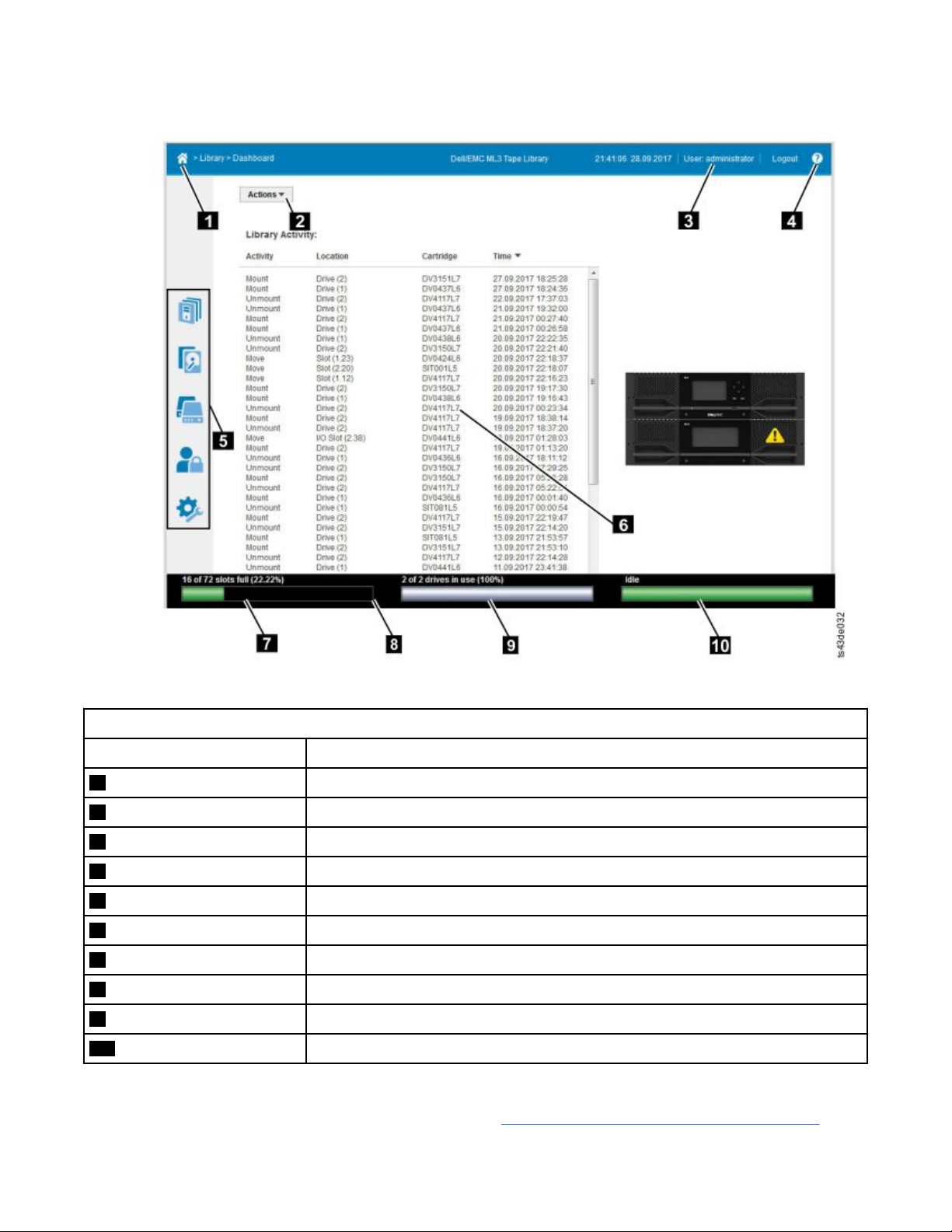

26. Navigation Dock........................................................................................................................................ 61

27. Status icons...............................................................................................................................................61

28. Operator Panel menu tree........................................................................................................................ 62

29. Front panel LEDs ...................................................................................................................................... 63

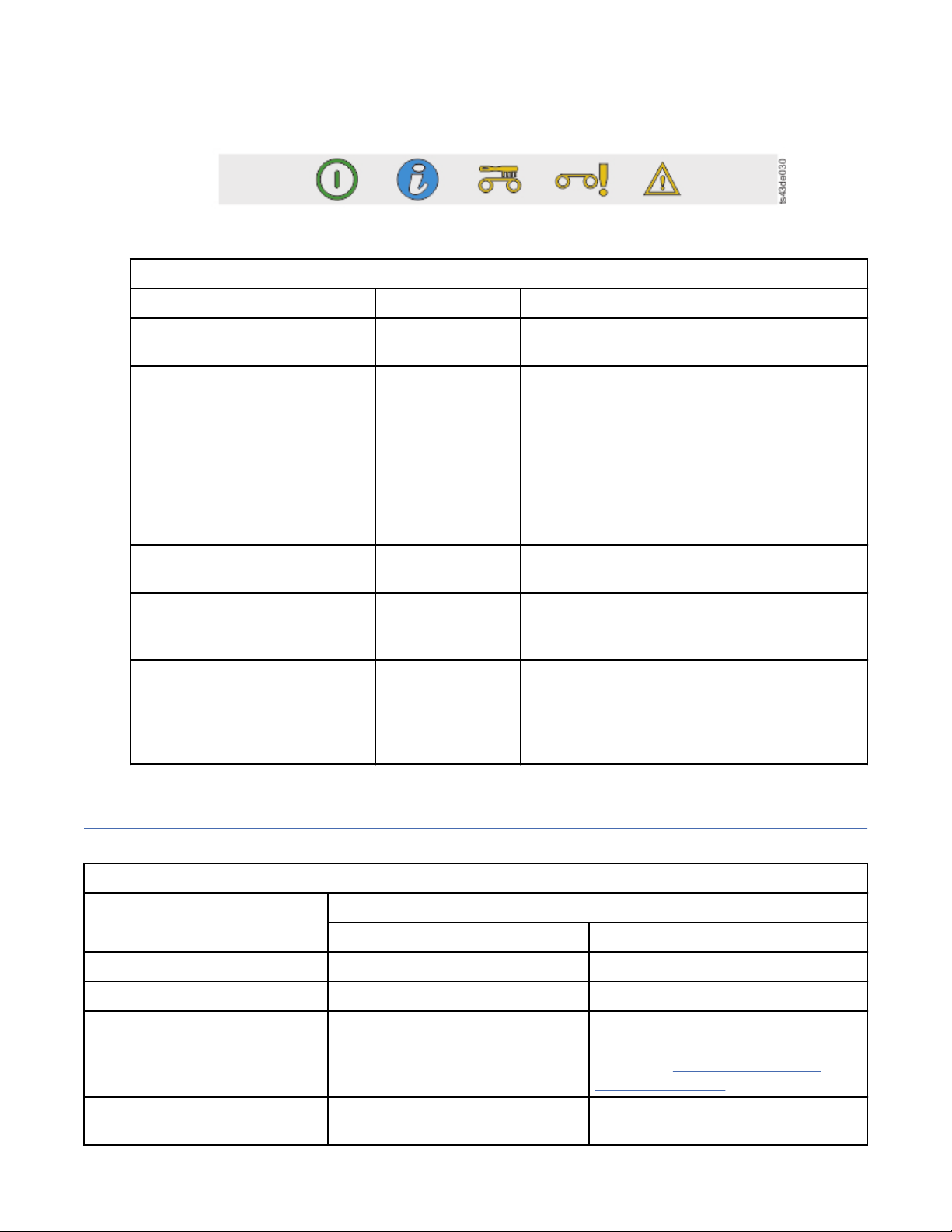

30. Locating Management functions.............................................................................................................. 63

31. Default settings......................................................................................................................................... 67

32. Magazine state.......................................................................................................................................... 71

33. Resolving errors........................................................................................................................................ 76

34. Main error events...................................................................................................................................... 82

35. Warning events..........................................................................................................................................91

36. Conguration Change events..................................................................................................................102

37. Informational Events.............................................................................................................................. 103

38. Error codes on the single-character display.......................................................................................... 112

39. Meaning of Status light and single-character display (SCD)................................................................. 113

40. Internal view description........................................................................................................................115

41. Pinch hazard............................................................................................................................................116

42. Power supply components..................................................................................................................... 126

43. Controller card components...................................................................................................................129

44. Management GUI functions and roles....................................................................................................151

45. Cartridge data capacity and recording formats..................................................................................... 157

xiv

46. Nominal cartridge life: Load/unload cycles........................................................................................... 158

47. Data cartridge compatibility with LTO tape drive.................................................................................. 158

48. LTO Cartridge Types............................................................................................................................... 158

Page 15

49. Cartridges and VOLSERs compatible with the LTO Tape Drives........................................................... 161

50. Location of the write-protect switch...................................................................................................... 163

51. Environment for storage and shipping the LTO tape cartridges............................................................166

52. General REST API information............................................................................................................... 167

53. Synonyms................................................................................................................................................168

54. Product Variants......................................................................................................................................168

55. Responses...............................................................................................................................................169

56. Response 200......................................................................................................................................... 169

57. Parameters..............................................................................................................................................170

58. User......................................................................................................................................................... 170

59. Responses...............................................................................................................................................170

60. Response 201......................................................................................................................................... 170

61. Responses...............................................................................................................................................171

62. Security................................................................................................................................................... 171

63. Parameters..............................................................................................................................................172

64. Responses...............................................................................................................................................173

65. Security................................................................................................................................................... 173

66. Responses...............................................................................................................................................173

67. Security................................................................................................................................................... 174

68. Responses...............................................................................................................................................175

69. Security................................................................................................................................................... 176

70. Responses...............................................................................................................................................176

71. Security................................................................................................................................................... 177

72. Responses...............................................................................................................................................177

73. Security................................................................................................................................................... 177

xv

Page 16

74. Responses...............................................................................................................................................178

75. Security................................................................................................................................................... 178

76. Responses...............................................................................................................................................179

77. Security................................................................................................................................................... 179

78. Parameters..............................................................................................................................................180

79. Module.....................................................................................................................................................180

80. Responses...............................................................................................................................................180

81. Security................................................................................................................................................... 180

82. Parameters..............................................................................................................................................181

83. Elements................................................................................................................................................. 181

84. Responses...............................................................................................................................................181

85. Security................................................................................................................................................... 181

86. Parameters..............................................................................................................................................182

87. RoboticPos.............................................................................................................................................. 182

88. Responses...............................................................................................................................................182

89. Security................................................................................................................................................... 182

90. Responses...............................................................................................................................................183

91. Security................................................................................................................................................... 183

92. Parameters..............................................................................................................................................183

93. mailslotConf............................................................................................................................................183

94. Responses...............................................................................................................................................184

95. Security................................................................................................................................................... 184

xvi

96. Parameters..............................................................................................................................................184

97. LicenseKey.............................................................................................................................................. 184

98. Responses...............................................................................................................................................184

Page 17

99. Security................................................................................................................................................... 185

100. Parameters............................................................................................................................................185

101. ManufacturingMode..............................................................................................................................185

102. Responses.............................................................................................................................................185

103. Security................................................................................................................................................. 185

104. Parameters............................................................................................................................................186

105. SerialNumber........................................................................................................................................186

106. Responses.............................................................................................................................................186

107. Security................................................................................................................................................. 186

108. Parameters............................................................................................................................................187

109. Responses.............................................................................................................................................187

110. Security................................................................................................................................................. 187

111. Parameters............................................................................................................................................187

112. count..................................................................................................................................................... 188

113. Responses.............................................................................................................................................188

114. Security................................................................................................................................................. 188

115. Responses.............................................................................................................................................188

116. Security................................................................................................................................................. 189

117. Parameters............................................................................................................................................189

118. testParameter.......................................................................................................................................189

119. Responses.............................................................................................................................................189

120. Security................................................................................................................................................. 190

121. Responses.............................................................................................................................................190

122. Security................................................................................................................................................. 190

123. Parameters............................................................................................................................................191

xvii

Page 18

124. Responses.............................................................................................................................................191

125. Security................................................................................................................................................. 191

126. Parameters............................................................................................................................................191

127. DriveNumber.........................................................................................................................................192

128. Responses.............................................................................................................................................192

129. Security................................................................................................................................................. 192

130. Responses.............................................................................................................................................192

131. Security................................................................................................................................................. 193

132. Parameters............................................................................................................................................194

133. Responses.............................................................................................................................................194

134. Security................................................................................................................................................. 194

135. Parameters............................................................................................................................................196

136. Responses.............................................................................................................................................196

137. Security................................................................................................................................................. 196

138. Parameters............................................................................................................................................197

139. partitionParameters..............................................................................................................................197

140. Responses.............................................................................................................................................198

141. Security................................................................................................................................................. 198

142. BaseInfoData........................................................................................................................................199

143. BaseStatusData.................................................................................................................................... 200

144. BaseInfoData........................................................................................................................................200

145. Error...................................................................................................................................................... 201

xviii

146. EventEntry.............................................................................................................................................202

147. IOStatus................................................................................................................................................202

148. Inventory...............................................................................................................................................202

Page 19

149. LibraryInfo............................................................................................................................................ 203

150. LibraryStatus.........................................................................................................................................203

151. LicenseInfo........................................................................................................................................... 203

152. MediaInfoData...................................................................................................................................... 203

153. Module.................................................................................................................................................. 205

154. ModuleStatusData................................................................................................................................ 205

155. PartitionInfo..........................................................................................................................................205

156. Slot........................................................................................................................................................ 207

157. TestStatus.............................................................................................................................................208

xix

Page 20

Safety and environmental notices

When this product is used, observe the danger, caution, and attention notices that are contained in this

guide. The notices are accompanied by symbols that represent the severity of the safety condition.

The sections that follow dene each type of safety notice and give examples.

Danger and Caution notices

Danger notices

A danger notice calls attention to a situation that is potentially lethal or extremely hazardous to people. A

lightning bolt symbol always accompanies a danger notice to represent a dangerous electrical condition.

xx Dell EMC ML3 Tape Library: User's Guide

Page 21

To prevent a possible shock from touching two surfaces with different

protective ground(earth), use one hand, when possible, to connect or

disconnect signal cables. (D001)

Overloading a branch circuit is potentially a re hazard and a shock

hazard under certain conditions. To avoid these hazards, ensure that your

system electrical requirements do not exceed branch circuit protection

requirements. Refer to the information that is provided with your device

or the power rating label for electrical specications. (D002)

If the receptacle has a metal shell, do not touch the shell until you have

completed the voltage and grounding checks. Improper wiring or

grounding could place dangerous voltage on themetal shell. If any of the

conditions are not as described, STOP. Ensure the improper voltage or

impedance conditions are corrected before proceeding.(D003)

An electrical outlet that is not correctly wired could place hazardous

voltage on the metal parts of the system or the devices that attach to the

system. It is the responsibility of the customer to ensure that the outlet is

correctly wired and grounded to prevent an electrical shock.(D004)

When working on or around the system, observe the following

precautions:

Electrical voltage and current from power, telephone, and

communication cables are hazardous. To avoid a shock hazard:

• If Dell supplied a power cord(s), connect power to this unit only with

the Dell provided power cord. Do not use the Dell provided power cord

for any other product.

• Do not open or service any power supply assembly.

• Do not connect or disconnect any cables or perform installation,

maintenance, or reconguration of this product during an electrical

storm.

• The product might be equipped with multiple power cords. To remove

all hazardous voltages, disconnect all power cords.

– For AC power, disconnect all power cords from their AC power

source.

– For racks with a DC power distribution panel (PDP), disconnect the

customer’s DC powersource to the PDP.

• When connecting power to the product ensure all power cables are

properly connected.

– For racks with AC power, connect all power cords to a properly wired

and grounded electrical outlet. Ensure that the outlet supplies

proper voltage and phase rotation according to the system rating

plate.

– For racks with a DC power distribution panel (PDP), connect the

customer’s DC power source to the PDP. Ensure that the proper

polarity is used when attaching the DC power and DC power return

wiring.

• Connect any equipment that will be attached to this product to properly

wired outlets.

Safety and environmental notices

xxi

Page 22

• When possible, use one hand only to connect or disconnect signal

cables.

• Never turn on any equipment when there is evidence of re, water, or

structural damage.

• Do not attempt to switch on power to the machine until all possible

unsafe conditions are corrected.

• Assume that an electrical safety hazard is present. Perform all

continuity, grounding, and power checks specied during the

subsystem installation procedures to ensure that the machine meets

safety requirements.

• Do not continue with the inspection if any unsafe conditions are

present.

• Before you open the device covers, unless instructed otherwise in the

installation and conguration procedures: Disconnect the attached AC

power cords, turn off the applicable circuit breakers located in the rack

power distribution panel (PDP), and disconnect any

telecommunications systems, networks, and modems.

• Connect and disconnect cables as described in the following

procedures when installing, moving, or opening covers on this product

or attached devices.

To disconnect:

1. Turn off everything (unless instructed otherwise).

2. For AC power, remove the power cords from the outlets.

3. For racks with a DC power distribution panel (PDP), turn off the circuit

breakers located in the PDP and remove the power from the

Customer's DC power source.

4. Remove the signal cables from the connectors.

5. Remove all cables from the devices.

To connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the signal cables to the connectors.

4. For AC power, attach the power cords to the outlets.

5. For racks with a DC power distribution panel (PDP), restore the power

from the Customer'sDC power source and turn on the circuit breakers

located in the PDP.

6. Turn on the devices.

• Sharp edges, corners and joints may be present in and around the

system. Use care when handling equipment to avoid cuts, scrapes and

pinching. (D005)

Heavy equipment - personal injury or equipment damage might result if

mishandled. (D006)

xxii Dell EMC ML3 Tape Library: User's Guide

Page 23

Uninterruptible power supply (UPS) units contain specic hazardous

materials. Observe the following precautions if your product contains a

UPS:

• The UPS contains lethal voltages. All repairs and service must be

performed only by an authorized service support representative. There

are no user serviceable parts inside the UPS.

• The UPS contains its own energy source (batteries). The output

receptacles might carry live voltage even when the UPS is not

connected to an AC supply.

• Do not remove or unplug the input cord when the UPS is turned on. This

removes the safety ground from the UPS and the equipment connected

to the UPS.

• The UPS is heavy because of the electronics and batteries that are

required. To avoid injury,observe the following precautions:

– Do not attempt to lift the UPS by yourself. Ask another service

representative for assistance.

– Remove the battery, electronics assembly, or both from the UPS

before removing the UPS from the shipping carton or installing or

removing the UPS in the rack.

(D007)

Professional movers are to be used for all relocation activities. Serious

injury or death might occur if systems are handled and moved incorrectly.

(D008)

Ensure that your DC mains supply is earthed at the point of generation

per IEC 60950-1and ITU-T Recommendation K.27. (D009)

Serious injury or death can occur if loaded lift tool falls over or if a heavy

load falls off the lift tool. Always completely lower the lift tool load plate

and properly secure the load on the lift tool before moving or using the

lift tool to lift or move an object. (D010)

DANGER: Multiple power cords. The product might be equipped

with multiple AC power cords or multiple DC power cables. To

remove all hazardous voltages, disconnect all power cords and

power cables. (L003)

Caution notices

A caution notice calls attention to a situation that is potentially hazardous to people because of some

existing condition, or to a potentially dangerous situation that might develop because of some unsafe

practice.

The doors and covers to the product are to be closed at all times except

for service by trained service personnel. All covers must be replaced and

doors closed at the conclusion of the service operation. (C013)

This product is equipped with a 3-wire (two conductors and ground)

power cable and plug. Use this power cable with a properly grounded

electrical outlet to avoid electrical shock. (C018)

This assembly contains mechanical moving parts. Use care when

servicing this assembly. (C025)

Safety and environmental notices xxiii

Page 24

A caution notice can be accompanied by one of several symbols:

If the symbol is... It means...

A generally hazardous condition not represented by other safety

symbols.

A hazardous condition due to the use of a laser in the product. Laser

symbols are always accompanied by the classication of the laser as

dened by the U. S. Department of Health and Human Services (for

example, Class I, Class II, and so forth).

Risk of hand pinching, can trap hands, ngers and cause serious injury.

Keep hands clear during operation (L012).

Caution: moving parts. (L037)

The weight of this part or unit is between 18 and 32 kg (39.7 and 70.5

lb). It takes two persons to safely lift this part or unit. (C009)

xxiv Dell EMC ML3 Tape Library: User's Guide

Page 25

If the symbol is... It means...

The weight of this part or unit is between 32 and 55 kg (70.5 and 121.2

lb). It takes three persons to safely lift this part or unit. (C010)

Possible safety hazards

Possible safety hazards to the operation of this product are:

Electrical

An electrically charged frame can cause serious electrical shock.

Mechanical

Hazards (for example, a safety cover missing) are potentially harmful to people.

Chemical

Do not use solvents, cleaners, or other chemicals that are not approved for use on this product.

Before the library is used, repair any of the preceding problems.

Class I laser product

Before the library is used, review the following laser safety information.

A hazardous condition due to the unit's susceptibility to electrostatic

discharge.

The product might contain a laser assembly that complies with the performance standards set by the US

Food and Drug Administration for a Class I laser product. Class I laser products do not emit hazardous

laser radiation. The product has the necessary protective housing and scanning safeguards to ensure that

laser radiation is inaccessible during operation or is within Class I limits. External safety agencies

reviewed the product and obtained approvals to the latest standards as they apply.

Safety and environmental notices

xxv

Page 26

Acclimation

Server and storage equipment (racks and frames) must be gradually acclimated to the surrounding

environment to prevent condensation.

When server and storage equipment (racks and frames) is shipped in a climate where the outside

temperature is below the dew point of the destination (indoor location), there’s a possibility that water

condensation can form on the cooler inside and outside surfaces of the equipment when the equipment is

brought indoors.

Sufcient time must be allowed for the shipped equipment to gradually reach thermal equilibrium with

the indoor environment before you remove the shipping bag and energize the equipment. Follow these

guidelines to properly acclimate your equipment:

• Leave the system in the shipping bag. If the installation or staging environment allows it, leave the

product in the full package to minimize condensation on or within the equipment.

• Allow the packaged product to acclimate for 24 hours.1 if there are visible signs of condensation (either

external or internal to the product) after 24 hours, acclimate the system without the shipping bag for an

extra 12 - 24 hours or until no visible condensation remains.

• Acclimate the product away from perforated tiles or other direct sources of forced air convection to

minimize excessive condensation on or within the equipment.

1

Unless otherwise stated by product-specic installation instructions.

Note: Condensation is a normal occurrence, especially when you ship equipment in cold-weather