Page 1

Dell

®

PowerEdge

®

4100/180 and 4100/200 Systems

SERVICE MANUAL

®

Page 2

Information in this document is subject to change without notice.

1995–1996 Dell Computer Corporation. All rights reserved.

Reproduction in any manner whatsoever without the written permission of Dell Computer Corporation is strictly forbidden.

Trademarks used in this text: Dell, the DELL logo, and PowerEdge are registered trademarks of Dell Computer Corporation; Intel, Pentium, and LANDesk are

registered trademarks of Intel Corporation; IBM is a registered trademark of International Business Machines Corporation; MS-DOS is a registered trademark of

Microsoft Corporation.

Other trademarks and trade names may be used in this document to refer to either the entities claiming the marks and names or their products. Dell Computer

Corporation disclaims any proprietary interest in trademarks and trade names other than its own.

November 1996 P/N 58562

Page 3

Chapter 1

System Overview

The Dell

upgradable server systems, which use the Intel® Pentium® Pro family of

microprocessors. PowerEdge 4100 systems incorporate the high-performance

peripheral component interconnect (PCI) local bus as well as the extended

industry-standard architecture (EISA) expansion bus. These buses are built into

the system board, which integrates the microprocessor(s) and other elements of the

basic computer system.

PowerEdge 4100 systems may have one or two Pentium Pro microprocessors.

The systems have been designed for better serviceability and increased reliability, with optional redundant power supplies, RAID capability, hot-pluggable

SCSI hard-disk drives, thermal and power supply monitoring, redundant fans,

and ECC memory. The PowerEdge 4100 systems are freestanding or can be

rackmounted to integrate your servers. The microprocessor modules are

installed in zero insertion force (ZIF) sockets on the system board, which allow

you to replace microprocessors faster. Contact Dell for information about Dellsupported microprocessor upgrades.

The Pentium Pro microprocessor contains a built-in clock multiplier circuit,

which increases the microprocessor’s internal operating frequency to a multiple

of the system clock frequency. The microprocessors for each of these systems

and their operating frequencies are as follows:

®

PowerEdge

®

4100 systems covered in this manual are high-speed,

• Dell PowerEdge 4100/180 system — 180 MHz derived from a system clock

frequency of 60 MHz

• Dell PowerEdge 4100/200 system — 200 MHz derived from a system clock

frequency of 66 MHz

System Features

In addition to the standard features found in a traditional personal computer,

Dell PowerEdge 4100 systems include the following new and/or advanced

features:

• 256 KB (PowerEdge 4100/180 systems) or 512 KB (PowerEdge 4100/200

systems) of cache memory internal to the Pentium Pro module

• 64 MB of 72-bit wide, buffered, extended data output (EDO) main memory,

upgradable to 1024 MB (1 GB)

• Hot-pluggable SCSI backplane supporting up to six hard-disk drives

• Optional, redundant hot-pluggable power supplies

System Overview 1-1

Page 4

• Error correction code (ECC) feature built into the memory controller on the

system board

• Advanced combination EISA and PCI expansion subsystem

• Five PCI and three EISA expansion-card slots (none shared)

• Integrated VGA-compatible video subsystem attached to the PCI bus, with

1 MB video memory standard

• BIOS in upgradable flash memory attached to the EISA bus

• Integrated super I/O controller attached to the EISA bus, provides a

bidirectional parallel port, two serial ports, and the diskette drive interface

• Integrated ultra-wide and ultra-narrow SCSI controllers

• Integrated server management circuitry that monitors critical system volt-

ages and temperatures, as well as the operation of the system cooling fans

• CD-ROM drive standard in an externally accessible drive bay

• Recessed power and reset buttons to prevent accidental system interruptions

• New quick-test feature in the system diagnostics

All of these features, except the new quick-test feature, are briefly described in

this chapter. (For more information about the Quick Test option in the CD-ROM

based diagnostics, see “Running the System Diagnostics” in Chapter2.) For a complete

list of system features, see “Technical Specifications” found later in this chapter.

For information about installing the PowerEdge 4100 systems in a rack, see the

“Dell PowerEdge 4100 and 6100 Systems Rack Kit Installation Guide”

(P/N 40722).

1-2 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 5

back of computer

left side

front of computer

right side

Figure 1-1. Computer Orientation

NOTE: When following the text in this manual, assume that the location or

direction relative to the system is as shown in Figure 1-1.

System Overview 1-3

Page 6

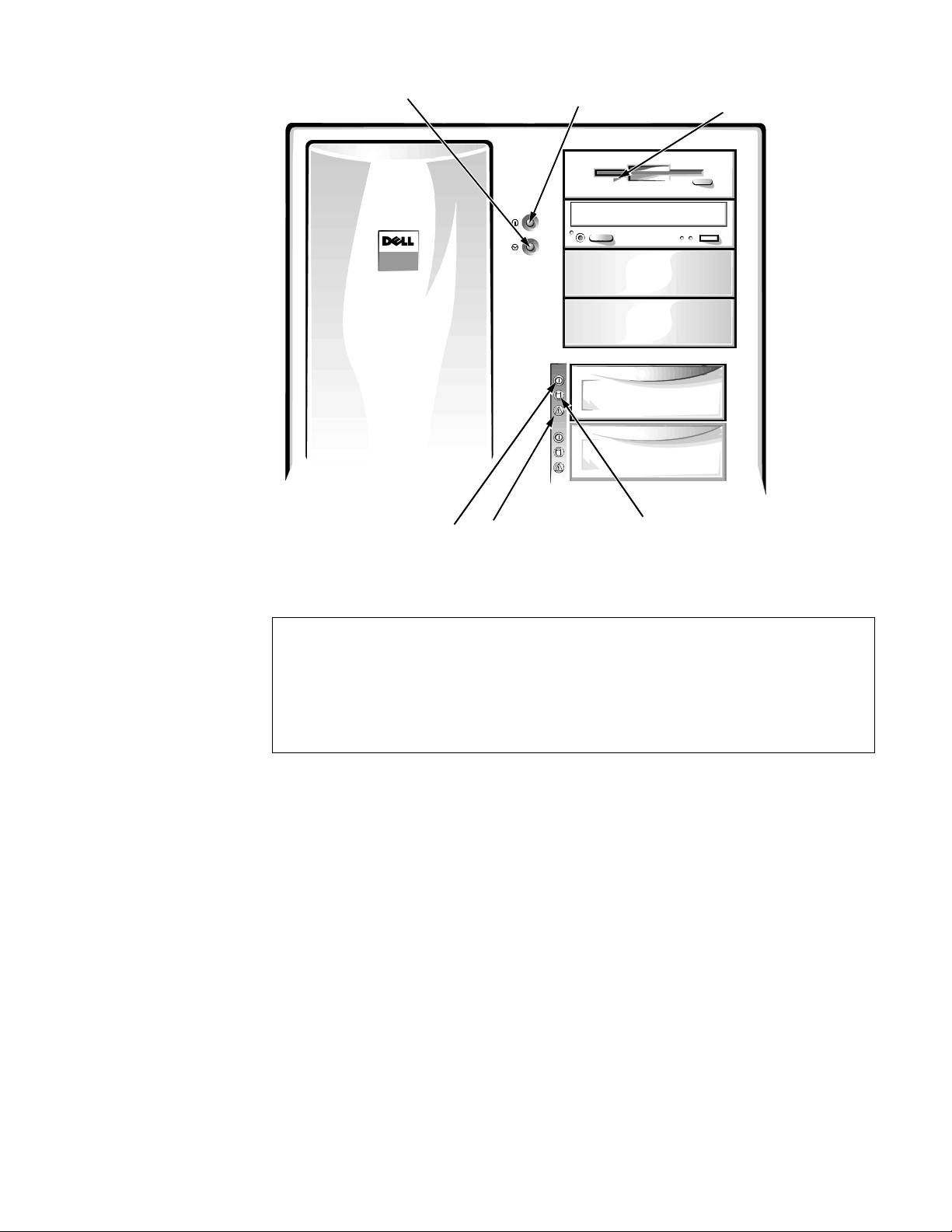

reset button

activity indicator

fault indicator

online indicator

power button and

power-on indicator

diskette-drive access

indicator (typical)

SCSI hard-disk drive

SCSI hard-disk drive

SCSI hard-disk drive

Figure 1-2. Front-Panel Features

CAUTION: To avoid possible data or file structure corruptions, the frontpanel reset button should be used only when restarting the system with a

key combination fails. Before using the reset button to initiate a hardware

reset, close any open application programs and files if possible. If you are

using MS-DOS®, the system can be rebooted by pressing

<Ctrl><Alt><Del>.

1-4 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 7

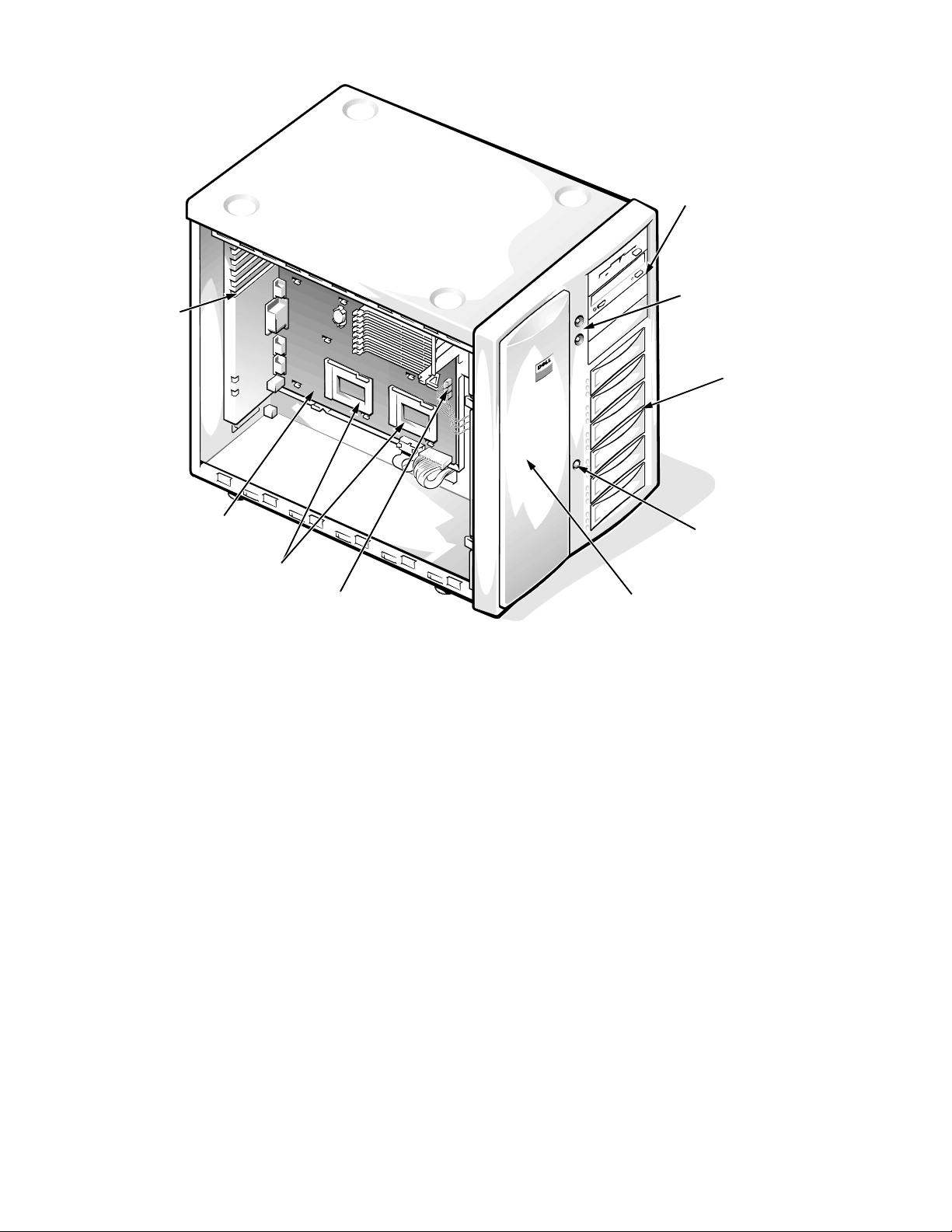

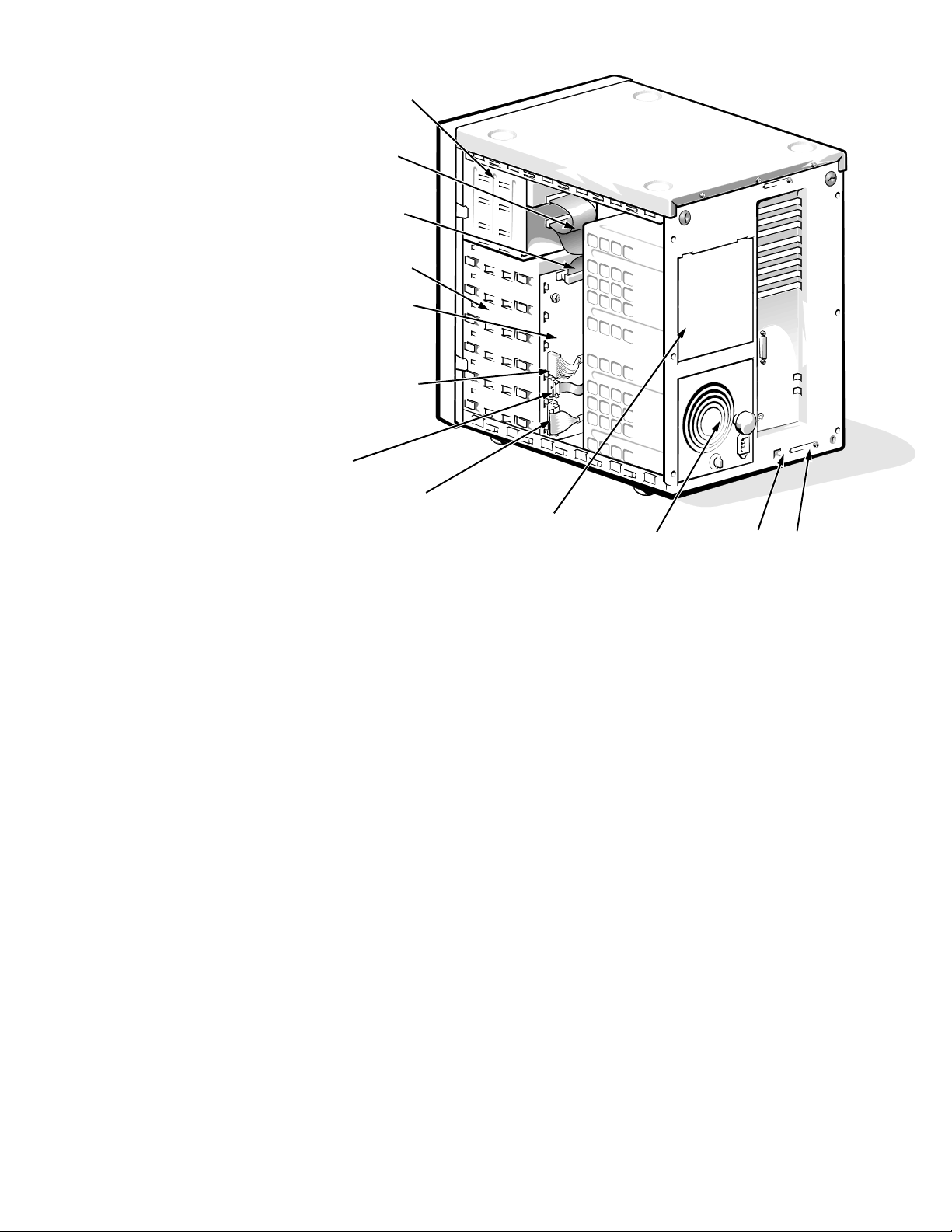

expansion slots

external drive bays (4)

control panel

internal drive

bays (6)

system board

microprocessor sockets

cooling fan connectors (3)

(cooling fans are located

behind the air intake panel)

Figure 1-3. Front/Left Internal View

hard-disk drive

security lock

air intake panel

System Overview 1-5

Page 8

external drive bays (4)

diskette interface

cable (ultra-narrow)

SCSI interface

connector (ultra-wide)

internal drive bays (6)

SCSI backplane board

SCSI power connector

server

management

connector

control panel connector

power supply (optional)

power supply

SMB connector

SCSI connector port

Figure 1-4. Back/Right Internal View

1-6 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 9

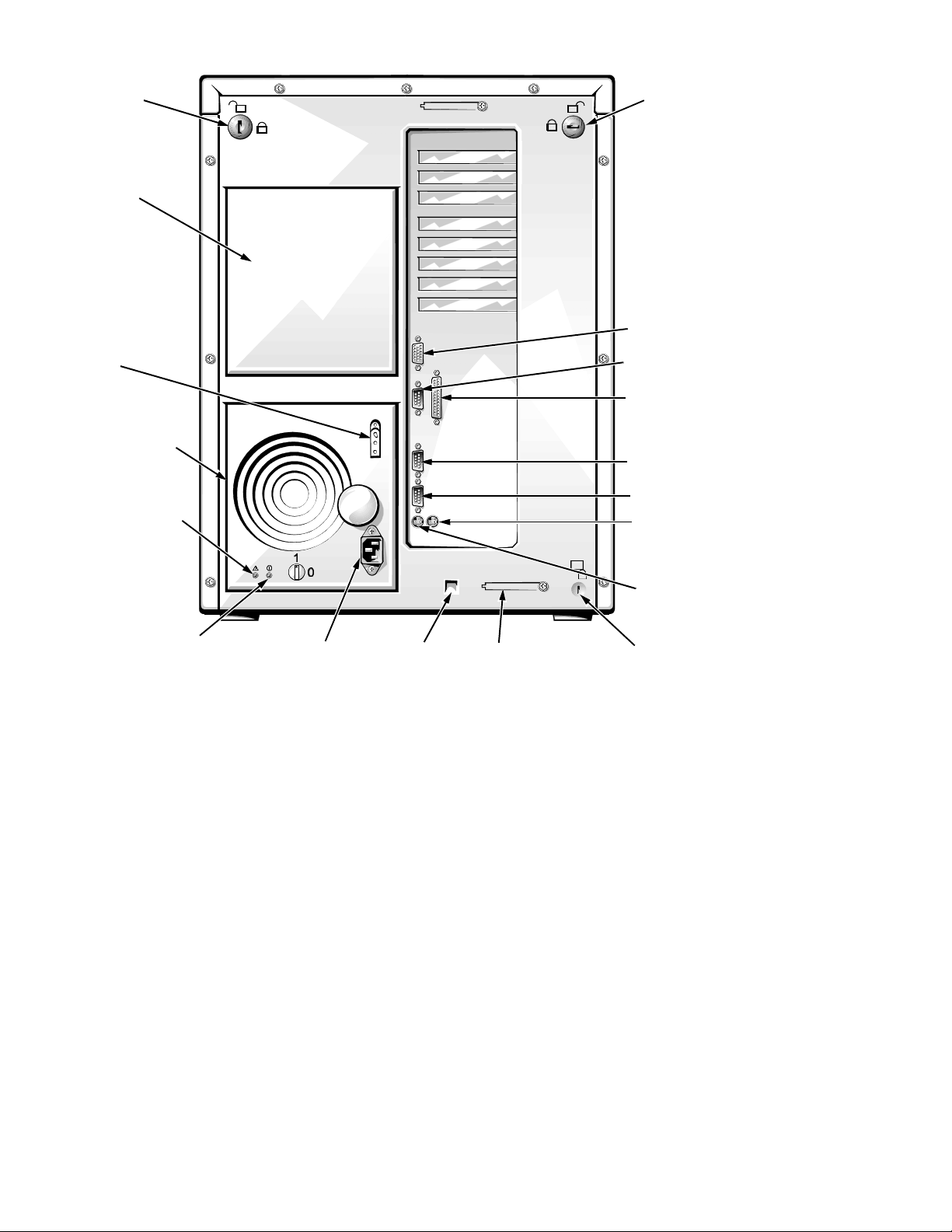

AC power receptacle

security cable slot

keylock

power supply

(optional)

cable strain relief

power supply

red LED

keylock

video connector

server-management

serial port connector

parallel port connector

serial port 2 connector

serial port 1 connector

mouse connector

green LED

Figure 1-5. I/O Panel

SMB connector

keyboard connector

SCSI connector port

System Overview 1-7

Page 10

System Memory

The PowerEdge 4100 systems have a minimum of 64 MB of 72-bit-wide, buffered EDO memory. The system memory capacity can be expanded to 1024 MB

(1 GB) by using combinations of 32- and 128-MB buffered, EDO dual in-line

memory modules (DIMMs) having gold connectors.

The system board has eight 168-pin DIMM sockets. The socket population rules

for the DIMMs are as follows:

• Populate the DIMM sockets in order from DIMM A (upper) to DIMM H

(lower).

• The DIMMs should be obtained from Dell to guarantee compatibility. All

system memory operates at the speed of the slowest DIMM installed.

• DIMMs of both capacities can be installed in the system. However, the

larger-capacity DIMMs should be installed in the top sockets, beginning

with socket DIMM A, with the smaller-capacity DIMMs installed afterwards in order toward socket DIMM H.

The 72-bit wide, buffered EDO DIMMs support the ECC feature, which detects

memory errors and corrects single-bit memory errors. The ECC feature provides more reliable memory and less downtime, and is built into the memory

controller on the system board.

See “DIMMs” in Chapter 4 for information on removing and replacing DIMMs.

Advanced Expansion Subsystem

The computer system offers advanced expansion subsystems that can support a

mixture of traditional EISA expansion cards, Plug and Play ISA expansion cards,

and PCI expansion cards. The EISA Configuration Utility, included with the system,

provides a means of avoiding resource conflicts that might arise from such an

arrangement.

After all legacy cards have been configured with the EISA Configuration Utility ,

the system automatically assigns required memory space, IRQ lines, and DMA

channels to any installed Plug and Play ISA expansion cards and PCI expansion

cards the next time the system is rebooted. Chapter 5, “Using the EISA Configuration Utility,” in the Dell PowerEdge 4100/180 and 4100/200 Systems User’s

Guide describes the EISA Configuration Utility and provides instructions for using it

to configure the system.

The eight expansion-card slots include three EISA expansion-card connectors

and five PCI expansion-card connectors. The expansion-card connectors are

located on the system board (see Figure 1-18).

Integrated Server Management

The system board contains integrated server management circuitry that monitors critical system voltages and temperatures, as well as the operation and

speed of the system cooling fans. The integrated server management circuitry

works in conjunction with the Intel LANDesk® Server Management suite.

1-8 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 11

Video Controller

The video subsystem is built into the system board and consists of a high-speed,

high-resolution, VGA-compatible video subsystem. The video controller is connected to the PCI local bus. The standard video subsystem contains 1 MB of

DRAM memory (the video memory size is not upgradable).

Maximum noninterlaced resolutions are 640 x 480 pixels with 16.7 million colors, 800 x 600 pixels with 65,536 colors, and 1024 x 768 pixels with 256 colors.

Integrated SCSI Controllers

A built-in Adaptec 7880 Ultra/Wide SCSI controller provides an ultra-wide fast

SCSI interface via a 68-pin connector on the system board. This SCSI controller

attaches to the PCI bus to provide a high-performance SCSI bus and also controls the six SCSI hard-disk drives in the SCSI hard-disk drive bays. In the

standard Dell PowerEdge 4100 system configuration, the Ultra/Wide SCSI host

adapter on the system board controls the SCSI backplane board. When used in

combination with an optional PowerEdge Expandable RAID Controller host

adapter card, the SCSI backplane board allows you to remove and insert harddisk drives without shutting down the system. External hard-disk drives are not

supported by the built-in SCSI controller.

A built-in Adaptec 7860 Ultra/Narrow SCSI controller provides a SCSI interface via a 50-pin connector to the CD-ROM drive in the externally accessible

drive bay and to any other SCSI drives installed in the other two bays.

SCSI Hard-Disk Drives

Six internal hot-pluggable hard-disk drive bays are located under the externally

accessible drive bays at the front of the computer (see Figure 1-4). These bays can

contain up to six 1- to 1.6-inch-high SCSI hard-disk drives (either fast/wide or ultra

[fast] wide).

NOTES: The externally accessible drive bays at the front of the computer are

normally used for diskette drives, CD-ROM drives, and/or tape drives. Harddisk drives should be installed in the SCSI hard-disk drive bays. For detailed

information about installing externally accessible drives, see Chapter 9, “Installing

Drives in the External Bays,” in the Dell PowerEdge 4100/180 and 4100/200 Sys-

tems Installation and Troubleshooting Guide. For detailed information about

installing SCSI hard-disk drives, see Chapter 10, “Installing Drives in the Internal

Bays,” in the Installation and Troubleshooting Guide.

Dell supports the drives it furnishes.

SCSI Configuration Guidelines

Although SCSI devices are installed essentially the same way as other devices,

their configuration requirements are different. To configure your SCSI subsystem, follow the general guidelines offered in the following subsections.

System Overview 1-9

Page 12

SCSI ID Numbers

Each device attached to the 7860 Ultra/Narrow SCSI host adapter must have a

unique SCSI ID number from 0 to 7. For additional SCSI addressing information, see Chapter 10, “Installing Drives in the Internal Bays,” in the Installation

and Troubleshooting Guide.

When narrow SCSI devices are shipped from Dell, the default SCSI ID numbers

are assigned as follows:

• The computer’s built-in Ultra/Narrow SCSI host adapter is configured

through the BIOS as SCSI ID 7.

• A SCSI CD-ROM drive (installed in an externally accessible drive bay) is

configured as SCSI ID 5.

• A SCSI tape drive (if installed) is configured as SCSI ID 6.

NOTE: There is no requirement that SCSI ID numbers be assigned sequentially or

that devices be attached to the cable in order by ID number.

Devices attached to the Ultra/Wide SCSI host adapter need no ID settings or termination; ID settings and termination are handled automatically by the SCSI

backplane.

Device Termination

SCSI logic requires that termination be enabled for the two devices at opposite

ends of the SCSI chain and disabled for all devices in between. Therefore,

regardless of whether you are installing internal or external devices, use the following guidelines:

• A single SCSI device (such as the standard CD-ROM drive) is terminated.

• If two or more SCSI devices are installed, connect the devices as follows:

— Attach one of the devices to the end connector on the SCSI cable, and leave the

terminator enabled on that device.

— The other end of the SCSI cable connects to the computer’s built-in Ultra/Narrow

SCSI host adapter or to an optional SCSI host adapter card, which needs no

termination.

— Disable the terminators on all other devices you attach to the cable.

The standard SCSI CD-ROM drive is configured as the last device on the SCSI

cable. Therefore, any additional devices attached to the cable should have their

terminators disabled.

See the documentation provided with the SCSI device for information on disabling the device’s terminator.

1-10 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 13

System Unit

The following subsections provide service-related information about the system

unit.

System Power Supply

The 500-W system power supply can operate from an AC power source of 90 to

265 VAC at 50 or 60 Hz. When the power-supply paralleling board is installed,

the power supplies are hot-pluggable. When the red LED on the power supply is

lit (except during power-up), it indicates that the power supply has failed (see

Figure 1-5). When the green LED is lit, it indicates that +5 VDC is on. The system power supply provides the DC operating voltages and currents listed in

Table 1-1.

NOTE: The power supply produces DC voltages only under its loaded condition. Therefore, when you measure these voltages, the DC power connectors

must be connected to their corresponding power input connectors on the system

board or drives.

.

Table 1-1. DC Voltage Ranges

Maximum Output

Voltage Range

Current

+3.3 VDC +3.135 to +3.465 VDC 15.0 A

+5 VDC +4.90 to +5.25 VDC 50.0 A

+12 VDC +11.40 to +12.60 VDC 25.0 A

–12 VDC –10.80 to –13.20 VDC 0.3 A

–5 VDC –4.50 to –5.50 VDC 0.3 A

+5 VFP

1

Maximum continuous DC output power shall not exceed 500 W.

2

VFP (volts flea power) — sometimes called “standby power.”

2

+4.85 to +5.36 VDC 0.25 A

1

System Overview 1-11

Page 14

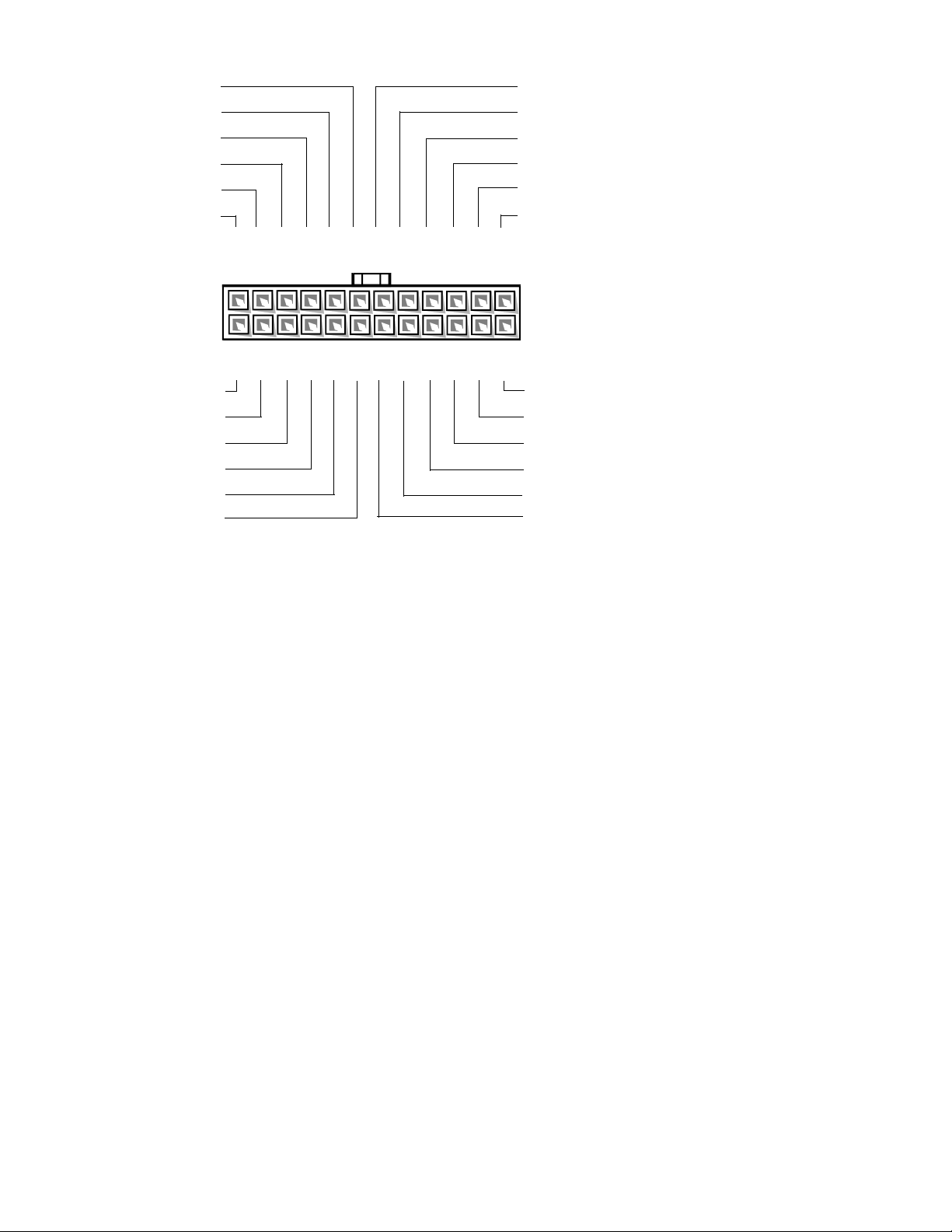

Pin Assignments for the DC Power Connectors (Nonredundant Systems)

The power-supply output voltages for nonredundant systems can be measured

at the connectors on the back of the power supply (P1, P2, P3, P4, and P5) or at

the connectors on the power connector panel (J11, J12, J13, J14, and J15). The

following illustrations show both sets of connectors.

P2

P1

P5

P4

P3

Figure 1-6. Power Supply Connectors

J12 (P2)

J11 (P1)

J15 (P5)

J14 (P4)

J13 (P3)

Figure 1-7. Power Connector Panel

1-12 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 15

+5 VDC (red)

–5 VDC (white)

common (black)

common (black)

common (black)

PSON# 1(gray)

J11 (P1)

+5 VDC (red)

common (black)

+5 VDC sense (red)

–sense (black)

PWRGOOD 2 (orange)

+5 VFP (purple)

13

14 15 16 17 18 19 20 21 22

6

1 2 3 4 5 9 10

7

8

+5 VDC (red)

+5 VDC (red)

+5 VDC (red)

+5 VDC (red)

+3.3 VDC (orange)

+3.3 VDC (orange)

23 24

11 12

+3.3 VDC (orange)

+3.3 VDC sense (orange)

common (black)

common (black)

-12 VDC (blue)

+12 VDC (yellow)

1

Pin 13 — PSON# should measure between +4 and +5 VDC except when the power button on the front

panel is pressed, taking PSON# to its active-low state.

2

Pin 5 — PWRGOOD should measure between +4 and +5 VDC when the power supply is on and oper-

ating to indicate that all power-supply output voltages are within the ranges specified in Table 1-1.

Figure 1-8. DC Power Connector J11 (P1)

System Overview 1-13

Page 16

+5 VDC (red)

common (black)

common (black)

common (black)

common (black)

J12 (P2), J13 (P3),

J14 (P4)

10

11 12 13 14

15 16

common (black)

common (black)

common (black)

+5 VDC (red)

17 18

1 2 3 4 5 6 7

+5 VDC (red)

+3.3 VDC (orange)

+12 VDC (yellow)

+5 VDC (red)

+5 VDC (red)

8 9

+3.3 VDC (orange)

+12 VDC (yellow)

+3.3 VDC (orange)

+5 VDC (red)

Figure 1-9. DC Power Connectors J12 (P2), J13 (P3), and J14 (P4)

+SW1

+12 VDC (red)

+3.3 VDC (orange)

Fail LED cathode (red)

Good LED cathode (green)

6 7 8 9 10

J15 (P5)

1

2 3 4 5

Figure 1-10. DC Power Connector J15 (P5)

1-14 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Good LED anode (green)

Fail LED anode (red)

+5 VDC (red)

+FAN_TACH (gray)

+SW1

Page 17

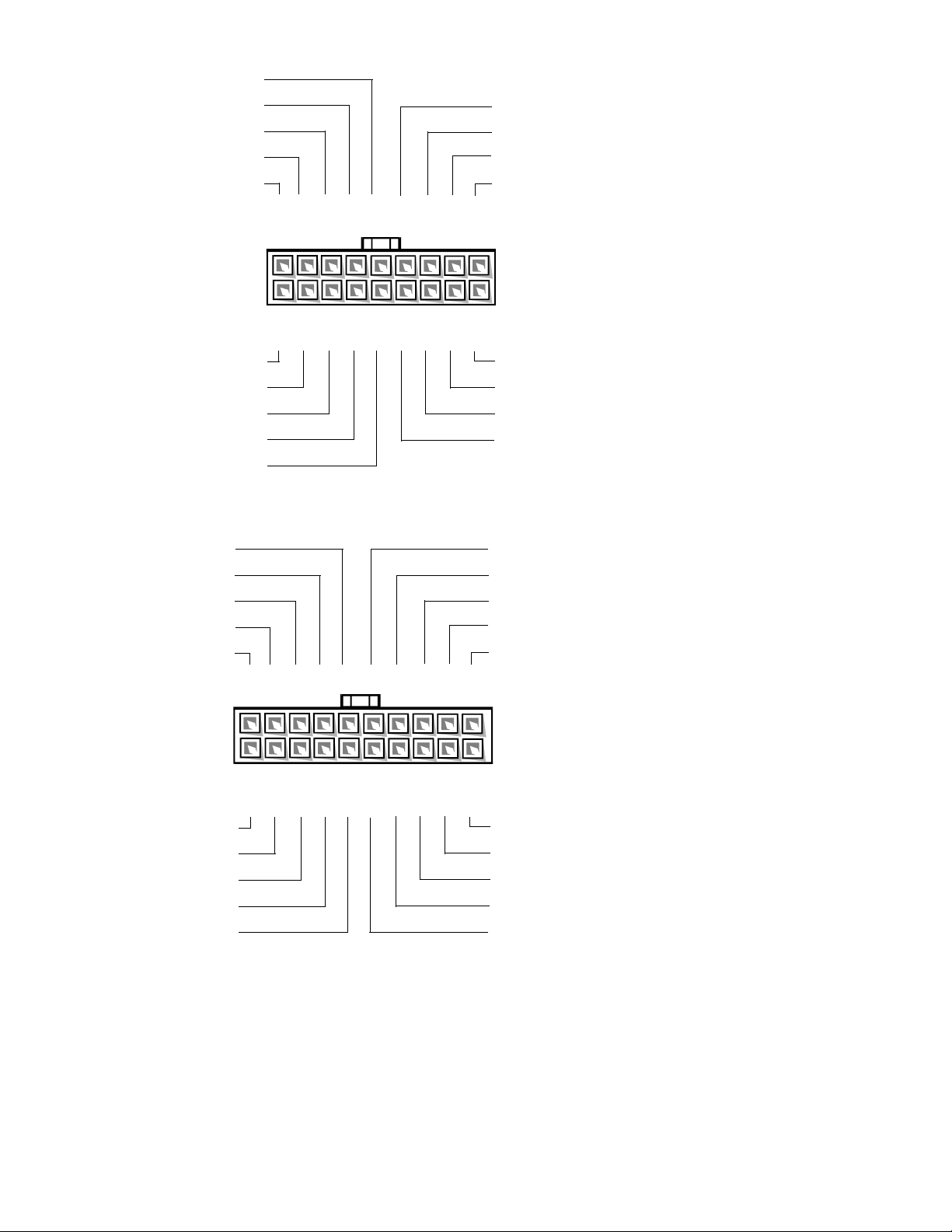

DC Power Distribution (Nonredundant System)

Figures 1-11 provides information about DC power distribution for the

nonredundant PowerEdge 4100 system.

power

supply # 1

P1–5

PSON#

+5 VFP

+5 VDC

–5 VDC

+12 VDC

–12 VDC

+3.3 VDC

power

connector

panel

P1

NRLED

PWRGOOD

PSON#

+5 VFP

+5 VDC

–5 VDC

+12 VDC

–12 VDC

+3.3 VDC

P2

+12 VDC

+5 VDC

+3.3 VDC

P3

+12 VDC

+5 VDC

+3.3 VDC

DDBP

+12 VDC

+5 VDC

FD1–4

+12 VDC

+5 VDC

system board

management

PWRGOOD

PSON#

+5 VFP

+5 VDC

–5 VDC

+12 VDC

–12 VDC

+3.3 VDC

main memory

sockets

DIMM A

through

DIMM H

+3.3 VDC

core VCC (+2.1 to +3.5 VDC)

PROCESSOR1

and

PROCESSOR2

power

logic

RTC/

NVRAM

P6 signal terminators

keyboard

controller

processor

core

regulator (2)

+1.5 VDC

battery

+3.3 VDC

+5 VDC

+12 VDC

–12 VDC

+5 VDC

–5 VDC

+12 VDC

–12 VDC

battery (+3 VDC)

+3.3 VDC

+5 VFP

PWRGOOD

+5 VFP to SCSI backplane

+12 VDC

+12 VDC

+12 VDC

fuse

+5 VDC

+5 VDC

GTL

regulator

PCI4

through

PCI8

EISA1

through

EISA3

REMOTE

FAN1

FAN2

FAN3

MOUSE

KEYBOARD

NOTE: A server management cable

(16-pin) carries the +5 VFP from

the system board to the SCSI

backplane. The control panel cable

(30-pin) carries the +5 VFP from

the backplane to the control panel.

6

3 X 6 LEDs

SCSI backplane

(six drive bays)

5

4

3

control panel

+5 VFP from SCSI backplane

Figure 1-11. Power Distribution (Nonredundant System)

2

reset

1

on/off

CD-ROM

power-on

LED

FLOPPY

speaker

System Overview 1-15

Page 18

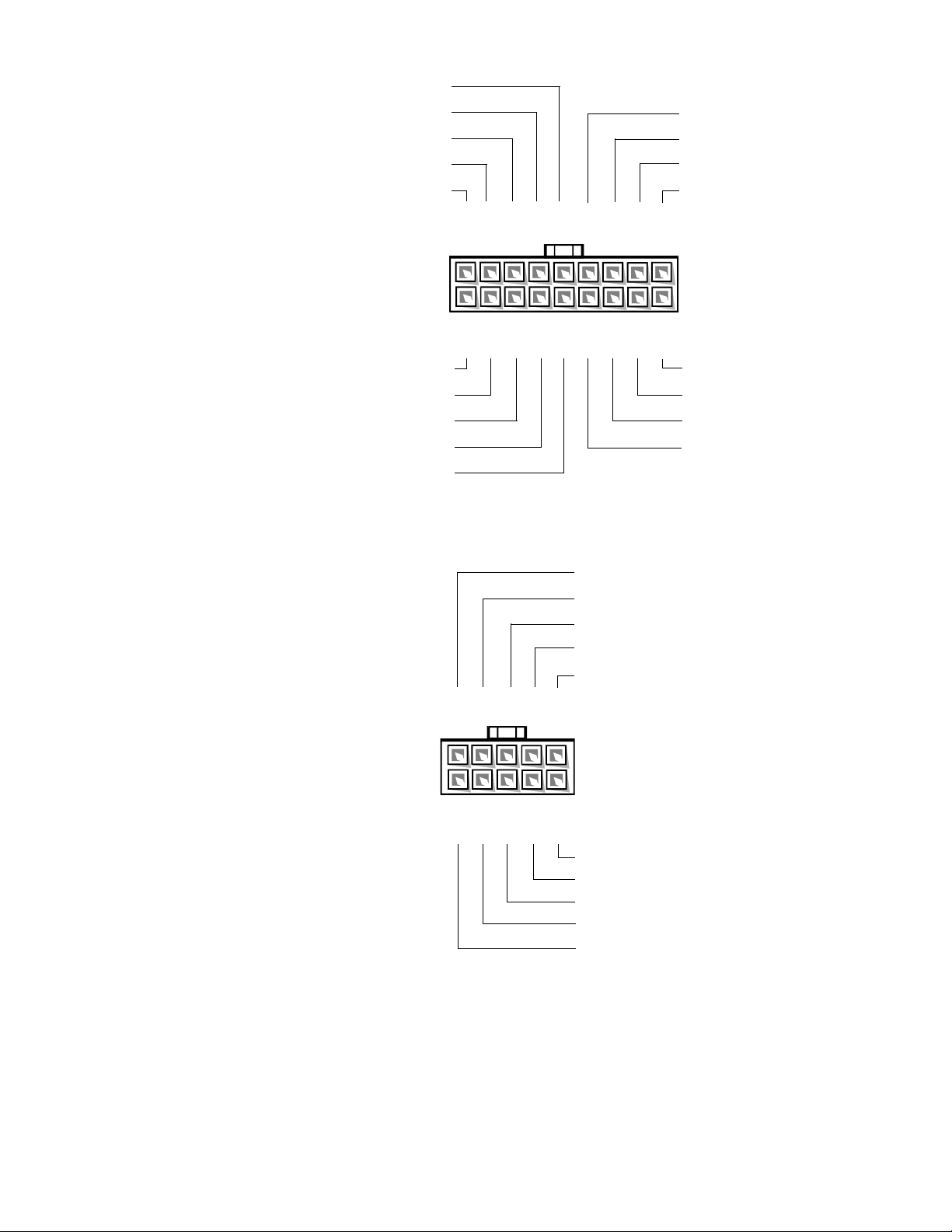

Pin Assignments for the DC Power Connectors (Redundant

Systems)

The power-supply output voltages for redundant systems can be measured at the

connectors on the power-supply paralleling board (PWR1, PWR2, PWR3,

PWRSCSI, and PWRFD) or at the connectors on the end of the wire bundles

extending from these connectors (PWR1, PWR2, PWR3, DDBP, and

FD1–FD4).

PWR1

PWRFD

(FD1–FD4)

PWR2

PWR3

PWRSCSI

diagnostics port

(DDBP)

Figure 1-12. Power-Supply Paralleling Board Connectors

1-16 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 19

NC_3INH

+3.3 VDC (orange)

common (black)

common (black)

POWER_GOOD (gray)

common (black)

+5 VFP (violet)

PWR1

10

11 12 13 14

15 16

+3.3 VDC sense (orange)

-3.3 VDC sense (black)

FAN_TACH (gray)

NC_NRLED

17 18

1 2 3 4 5 6 7

-12 VDC (blue)

-5 VDC (white)

PWR_STAT_BIT (gray)

I 2C_SDA (gray)

I 2C_SCL (gray)

Figure 1-13. DC Power Connector PWR1

common (black)

+12 VDC (yellow)

common (black)

+12 VDC (yellow)

11

12 13 14 15 16

PWR2,

PWR3

17 18 19 20

8 9

BAT_V (gray)

PRES_DET (gray)

NC_+12 sense

+5 VDC sense (red)

+3.3 VDC (orange)

common (black)

+3.3 VDC (orange)

common (black)

Figure 1-14. DC Power Connector PWR2 and PWR3

+5 VDC (red)

common (black)

+5 VDC (red)

common (black)

+5 VDC (red)

1 2 3 4 5 9 10

6 7

8

common (black)

+5 VDC (red)

common (black)

+5 VDC (red)

common (black)

System Overview 1-17

Page 20

common (black)

common (black)

+12 VDC (yellow)

common (black)

common (black)

common (black)

common (black)

common (black)

8

9 10 11 12

13 14

PWRSCSI

(DDBP)

1 2 3 4 5 6 7

+12 VDC (yellow)

+5 VDC (red)

+12 VDC (yellow)

+5 VDC (red)

+12 VDC (yellow)

+5 VDC (red)

+12 VDC (yellow)

Figure 1-15. DC Power Connector PWRSCSI (DDBP)

common (black)

common (black)

+5 VDC (red)

2

5 6 7

8

PWRFD

(FD1–FD4)

1

1

2 3

1

Wires 1 through 4 are connected to FD1 and FD2.

2

Wires 5 through 8 are connected to FD3 and FD4.

4

+5 VDC (red)

common (black)

common (black)

+12 VDC (yellow)

Figure 1-16. DC Power Connector PWRFD (FD1–FD4)

1-18 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 21

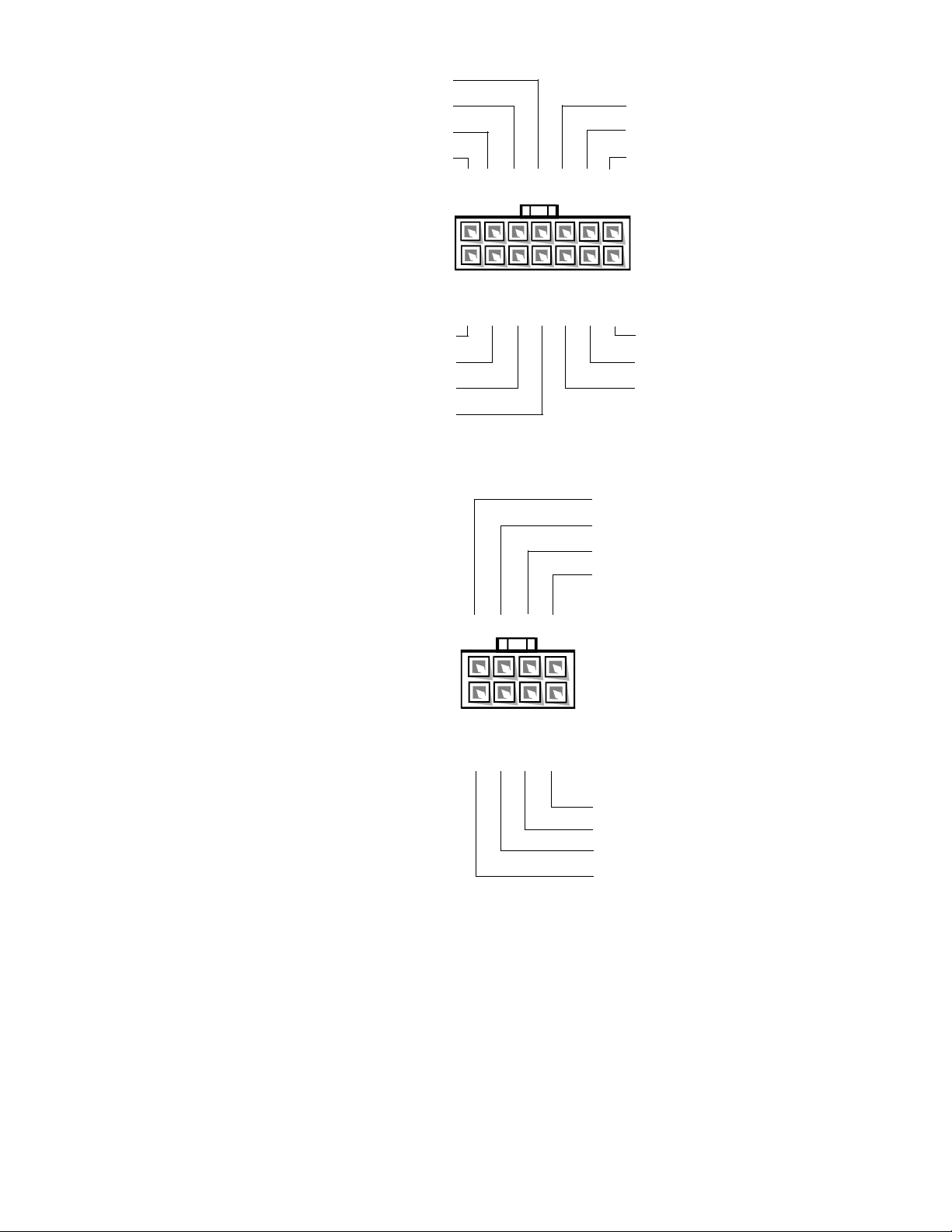

DC Power Distribution (Redundant System)

Figures 1-17 provides information about DC power distribution for the redundant PowerEdge 4100 system.

power

supply # 1

power

supply # 2

P1–5

POK

PSON#

+5 VFP

+5 VDC

–5 VDC

+12 VDC

–12 VDC

+3.3 VDC

P1–5

PSON#

+5 VFP

+5 VDC

–5 VDC

+12 VDC

–12 VDC

+3.3 VDC

PWR1

BATV

PWRGOOD

PSON#

+5 VFP

+5 VDC

–5 VDC

+12 VDC

–12 VDC

+3.3 VDC

PWR2

+12 VDC

+5 VDC

+3.3 VDC

PWR3

+12 VDC

+5 VDC

+3.3 VDC

PWRSCSI

(DDBP)

+12 VDC

+5 VDC

PWRFD

(FD1–4)

+12 VDC

+5 VDC

system board

BATV

PWRGOOD

PSON#

+5 VFP

+5 VDC

–5 VDC

+12 VDC

–12 VDC

+3.3 VDC

main memory

sockets

DIMM A

through

DIMM H

+3.3 VDC

power

management

logic

RTC/

NVRAM

keyboard

controller

battery

+3.3 VDC

+5 VDC

+12 VDC

–12 VDC

+5 VDC

–5 VDC

+12 VDC

–12 VDC

battery (+3 VDC)

PWRGOOD

+5 VFP to SCSI backplane

fuse

processor

core

regulator (2)

+3.3 VDC

+5 VFP

+12 VDC

+12 VDC

+12 VDC

+5 VDC

+5 VDC

PCI4

through

PCI8

EISA1

through

EISA3

REMOTE

FAN1

FAN2

FAN3

MOUSE

KEYBOARD

power-supply

paralleling board

NOTE: A server management cable

(16-pin) carries the +5 VFP from

the system board to the SCSI

backplane. The control panel cable

(30-pin) carries the +5 VFP from

the backplane to the control panel.

PROCESSOR 1

and

PROCESSOR 2

core VCC (+2.1 to +3.5 VDC)

P6 signal terminators

SCSI backplane

(six drive bays)

6

5

4

control panel

+5 VFP from SCSI backplane

3 X 6 LEDs

Figure 1-17. Power Distribution (Redundant System)

3

+1.5 VDC

2

reset

1

on/off

GTL

regulator

power-on

LED

CD-ROM

FLOPPY

speaker

System Overview 1-19

Page 22

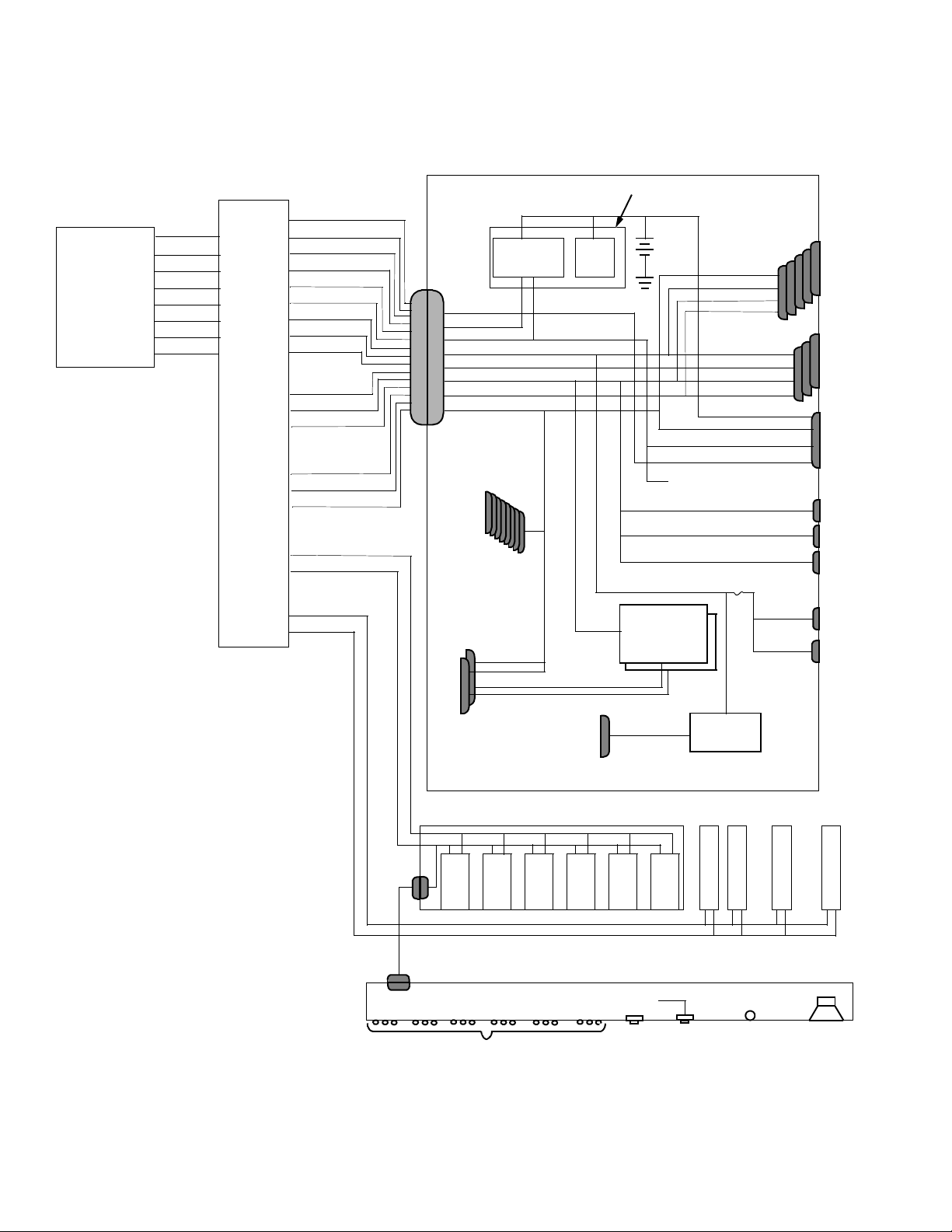

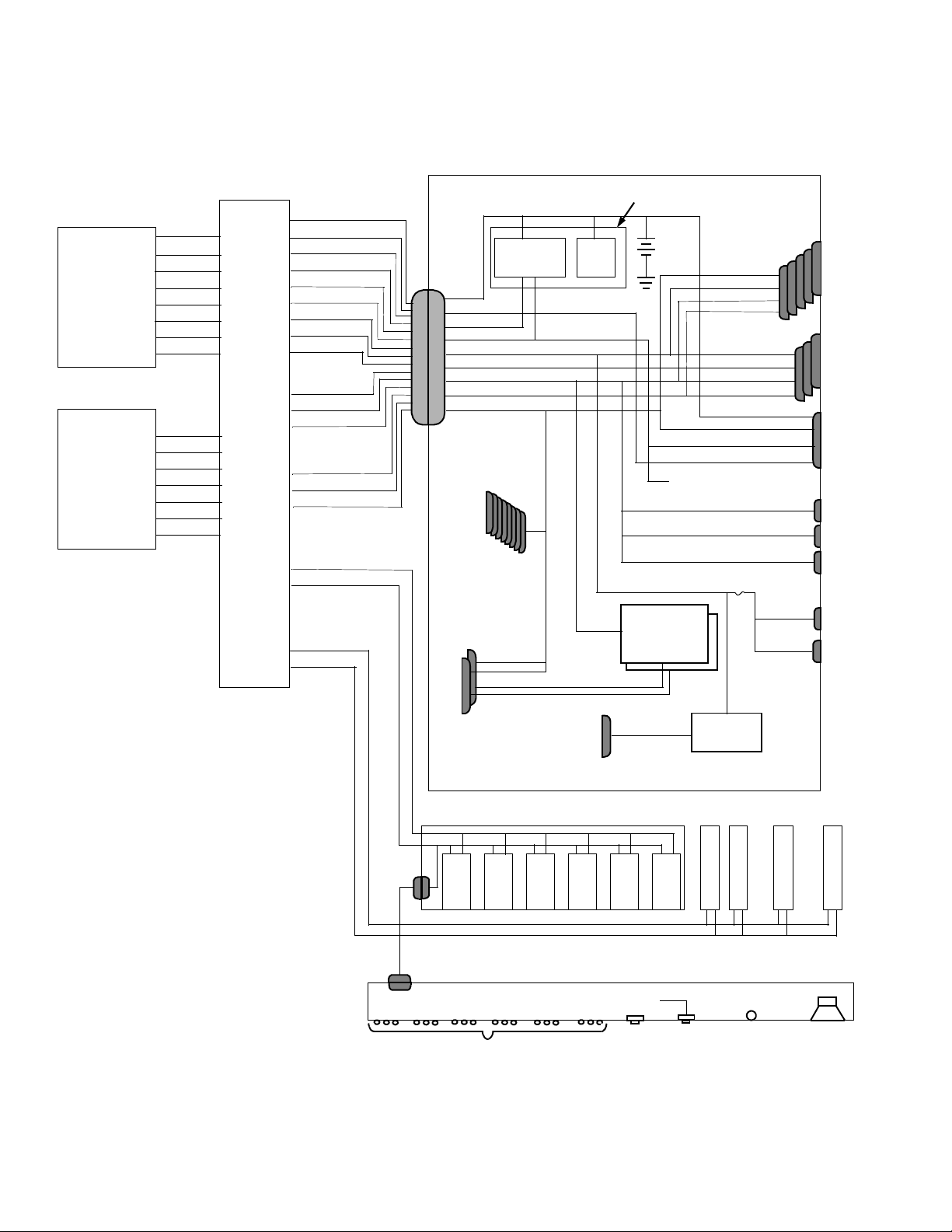

System Board Layout

socket (PROCESSOR2)

The subsections that follow provide service-related information

about the system board components.

diskette/tape drive interface

connector (FLOPPY)

EISA connectors

(EISA1 [top], EISA2,

and EISA3)

PCI connectors

(PCI4 [top]–PCI8)

battery connector

(BATTERY)

video connector

(MONITOR)

server-management

serial port connector

(REMOTE)

parallel port connector

(PARALLEL)

serial port 2 connector

(SERIAL2)

serial port 1 connector

(SERIAL1)

mouse connector

(MOUSE)

keyboard connector

(KEYBOARD)

Ultra/Narrow SCSI host adapter

connector (SCSI2 CD-ROM)

secondary microprocessor

Ultra/Wide SCSI host adapter

connector (BACKPLANE SCSI1)

power supply

connector (POWER2)

power supply

connector (POWER1)

front of

system board

DIMM sockets

(DIMM A [top]–DIMM H)

fan connectors

(FAN1, FAN2, FAN3)

speed and configuration

jumpers

primary microprocessor

socket (PROCESSOR1)

power supply connector

(POWER3)

server-management bus

connector (SMB BACKPLANE)

Figure 1-18. System Board Components

1-20 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 23

Main Memory

The eight DIMM sockets on the system board can accommodate combinations

of 32- and 128-MB DIMMs up to a total memory capacity of 1024 MB (1 GB).

The system is shipped with high-speed (60-ns) 3.3-V EDO DIMMs installed.

When reinstalling DIMMs, use the following guidelines:

• Install a DIMM in socket DIMM A before socket DIMM B, in socket

DIMM B before socket DIMM C, and so on.

• If you are installing DIMMs of different sizes, install them in order of

decreasing capacity, beginning with socket DIMM A.

• DIMMs need not be installed in pairs, but gold connectors are required.

See “DIMMs” in Chapter 4 for information on removing and replacing DIMMs.

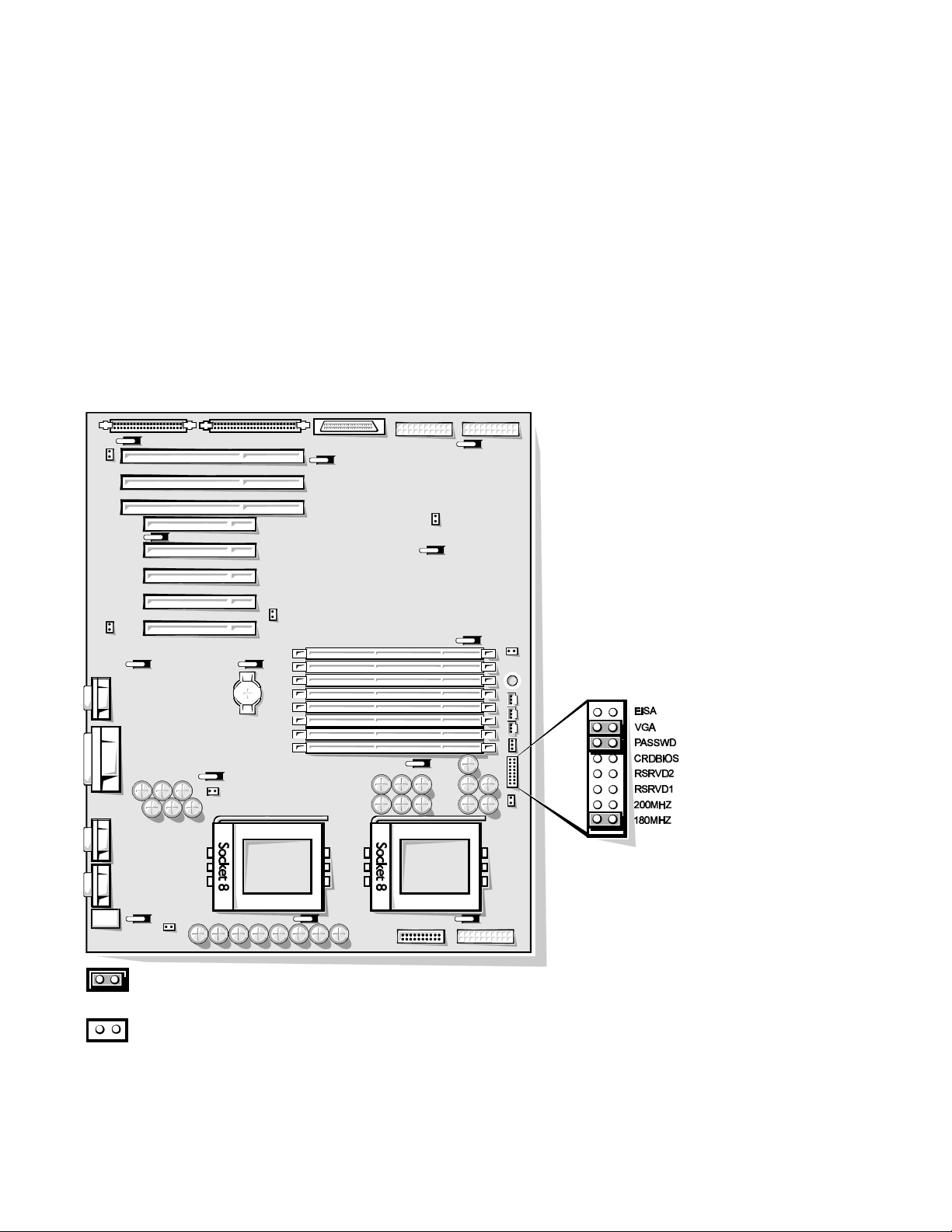

System Board Jumpers

jumpered

unjumpered

Figure 1-19. System Board Jumpers

System Overview 1-21

Page 24

Table 1-2. Jumper Descriptions

Jumper Description Default Setting

EISA EISA Configuration Utility Not installed (utility settings are

retained at system boot)

VGA Integrated video controller Installed (controller is enabled)

PASSWD Password enable/disable Installed (password feature

enabled)

CRDBIOS Reserved Not installed (reserved; do not

change)

RSRVD2

RSRVD1

Reserved Not installed (reserved; do not

change)

200MHZ Microprocessor speed Installed only if the micro-

processor’s internal speed is

200 MHz

180MHZ Microprocessor speed Installed only if the micro-

processor’s internal speed is

180 MHz

Interrupt Assignments

Table 1-3. Interrupt Assignments

IRQ Line Used/Available

IRQ0 Generated by system timer

IRQ1 Generated by keyboard controller to indicate that keyboard’s

output buffer is full

IRQ2 Generated internally by interrupt controller to enable IRQ8

through IRQ15

IRQ3

and

IRQ4

Generated by super I/O controller to indicate that device connected to corresponding serial port requires service (IRQ3 for

COM2 or COM4; IRQ4 for COM1 or COM3)

IRQ5 Available for use by expansion card unless this IRQ line is used by

secondary parallel port

IRQ6 Generated by super I/O controller to indicate that diskette drive

requires service

IRQ7 Generated by super I/O controller to indicate that device con-

nected to parallel port requires service

IRQ8 Generated by keyboard controller for each tick of RTC

IRQ9 Available for use by expansion card

1-22 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 25

Table 1-3. Interrupt Assignments (continued)

IRQ Line Used/Available

IRQ10 Available for use by expansion card

IRQ11 Available for use by expansion card

IRQ12 Generated by keyboard controller to indicate that mouse’s output

buffer is full

IRQ13 Generated by math coprocessor to indicate coprocessor error

IRQ14 Available for use by expansion card

IRQ15 Available for use by expansion card

DMA Channel Assignments

Table 1-4. DREQ Line Assignments

DREQ Line Used/Available

DREQ0 Available

DREQ1 Available

DREQ2 Generated by super I/O controller to initiate DMA cycle for

attached diskette drive

DREQ3 Available

DREQ4 Generated by bus controller chip to activate second DMA

controller

DREQ5 Available

DREQ6 Available

DREQ7 Available

System Overview 1-23

Page 26

Technical Specifications

Table 1-5. Technical Specifications

Microprocessor

Microprocessor type. . . . . . . . single or dual Intel Pentium Pro

microprocessors

Microprocessor speed. . . . . . . 200 MHz internal (66 MHz external)

or 180 MHz internal (60 MHz external)

First-level cache . . . . . . . . . . . 16 KB

Second-level cache. . . . . . . . . 256 KB for 180 MHz; 512 KB for 200 MHz

Math coprocessor . . . . . . . . . . internal to the microprocessor

System Information

System chip set. . . . . . . . . . . . Intel Natoma 82440FX set

Data bus width . . . . . . . . . . . . 64 bits

Address bus width . . . . . . . . . 32 bits

Flash EPROM. . . . . . . . . . . . . 4 Mbits

Expansion Bus

Bus types . . . . . . . . . . . . . . . . PCI and EISA

Bus speed . . . . . . . . . . . . . . . . PCI: 30 MHz (180/60 processor); 33 MHz

(200/66 processor);

EISA: 7.5 MHz (180/60 processor); 8.33 MHz

(200/66 processor)

PCI expansion-card

connectors. . . . . . . . . . . . . . . . five

EISA expansion-card

connectors. . . . . . . . . . . . . . . . three

EISA expansion-card

connector size. . . . . . . . . . . . . 198 pins

EISA expansion-card connector

data width (maximum) . . . . . . 32 bits

PCI expansion-card

connector size. . . . . . . . . . . . . 120 pins

PCI expansion-card connector

data width (maximum) . . . . . . 32 bits

1-24 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 27

Table 1-5. Technical Specifications (continued)

System Clocks

System clock. . . . . . . . . . . . . . 60 or 66 MHz (matches external processor bus

speed)

Diskette/communications

ports . . . . . . . . . . . . . . . . . . . . 24 MHz from the system clock

Memory

Architecture . . . . . . . . . . . . . . 72-bit, noninterleaved

DIMM sockets . . . . . . . . . . . . eight

DIMM capacities . . . . . . . . . . 32 and 128 MB, EDO mode

Standard RAM . . . . . . . . . . . . 64 MB

Maximum RAM . . . . . . . . . . . 1024 MB (1 GB)

BIOS address . . . . . . . . . . . . . F000:0000h–F0000:FFFFh

Drives

Externally accessible bays . . . four 5.25-inch bays for half-height diskette

drives, tape drives, or CD-ROM drives (one

bay for a 3.5-inch diskette drive and one bay

for a CD-ROM [standard])

Internally accessible bays . . . . six 1- to 1.6-inch-high SCSI hard-disk drives,

hot-pluggable with an optional PowerEdge

Expandable RAID Controller host adapter card

System Board Connectors

Externally accessible:

Serial (DTE) . . . . . . . . . . . two 9-pin connectors; 16550-compatible

(UART)

Server Management

(serial). . . . . . . . . . . . . . . . one 9-pin connectors; modem port for

embedded server management

Parallel . . . . . . . . . . . . . . . one 25-hole connector (bidirectional)

Video. . . . . . . . . . . . . . . . . one 15-hole connector (on system board or

add-in video card)

PS/2-style keyboard . . . . . one 6-pin mini-DIN

PS/2-compatible mouse. . . . one 6-pin mini-DIN

Internally accessible:

Diskette drive . . . . . . . . . . one 34-pin connector

Fan . . . . . . . . . . . . . . . . . . three 3-pin connectors

System Overview 1-25

Page 28

Table 1-5. Technical Specifications (continued)

System Board Connectors (continued)

POWER1 . . . . . . . . . . . . .

one 18-pin connector: standby power, I2 C,

PWRGOOD, and miscellaneous power

POWER2 . . . . . . . . . . . . . one 20-pin connector: +3.3 VDC, +5 VDC, or

+12 VDC

POWER3 . . . . . . . . . . . . . one 20-pin connector: +3.3 VDC, +5 VDC, or

+12 VDC

BACKPLANE SCSI1. . . . one 68-pin connector, ultra-wide (fast), to

SCSI backplane

SCSI2 CD-ROM. . . . . . . . one 50-pin connector, ultra-narrow, to

CD-ROM

SMB BACKPLANE. . . . . one 16-pin connector (server management) to

SCSI backplane

SCSI Backplane Connectors

SCSI hard-disk drive connection

sockets . . . . . . . . . . . . . . . . . . six 80-pin connectors

SCSI controller. . . . . . . . . . . . one 68-pin connector

Power . . . . . . . . . . . . . . . . . . . one 14-pin connectors

Video

Video type. . . . . . . . . . . . . . . . embedded PCI (see User’s Guide for

specifications)

Video memory . . . . . . . . . . . . 1 MB

Key Combinations

<Ctrl><Alt><Del>. . . . . . . . . . . . reboots the system (if running MS-DOS)

<F2>. . . . . . . . . . . . . . . . . . . . . . . . starts System Setup program (during POST

only)

Controls and Indicators

Reset control. . . . . . . . . . . . . . push button

Power control . . . . . . . . . . . . . push button

Power indicator. . . . . . . . . . . . green LED

Diskette drive access

indicator . . . . . . . . . . . . . . . . . green LED

CD-ROM busy indicator . . . . green LED

SCSI hard-disk drive online

indicator . . . . . . . . . . . . . . . . . green LED

1-26 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 29

Table 1-5. Technical Specifications (continued)

Controls and Indicators (continued)

SCSI hard-disk drive activity

indicator . . . . . . . . . . . . . . . . . green LED

SCSI hard-disk drive fault

indicator . . . . . . . . . . . . . . . . . yellow LED

Power-supply 5-VDC online

indicator . . . . . . . . . . . . . . . . . green LED

Power-supply failure

indicator . . . . . . . . . . . . . . . . . red LED (flashes at power-on; stays lit in the

event of a power failure)

Power

DC power supply:

Wattage . . . . . . . . . . . . . . . 500 W

Heat dissipation. . . . . . . . . 600 BTUs (nominal)

Voltage . . . . . . . . . . . . . . . 90 to 265 VAC at 50 or 60 Hz

Backup battery . . . . . . . . . . . . 3-V CR2450N coin cell

Physical

Height . . . . . . . . . . . . . . . . . . . 52.5 cm (21 inches)

Width. . . . . . . . . . . . . . . . . . . . 39.4 cm (15.75 inches)

Depth. . . . . . . . . . . . . . . . . . . . 57.5 cm (23 inches)

Weight . . . . . . . . . . . . . . . . . . 45 kg (100 lb) or more, depending on options

installed

Environmental

Temperature:

Operating . . . . . . . . . . . . . 10° to 35°C (50° to 95°F)

Storage . . . . . . . . . . . . . . . –40° to 65°C (–40° to 149°F)

Relative humidity . . . . . . . 8% to 80% (noncondensing)

Maximum vibration:

Operating . . . . . . . . . . . . . 0.25 G at 3 to 200 Hz for 30 min

Storage . . . . . . . . . . . . . . . 0.5 G at 3 to 200 Hz for 30 min

Maximum shock:

Operating . . . . . . . . . . . . . half-sine wave form: 50 G for 2 ms

Storage . . . . . . . . . . . . . . . half-sine wave form: 110 G for 2 ms;

square wave form: 27 G for 15 ms

System Overview 1-27

Page 30

Table 1-5. Technical Specifications (continued)

Environmental (continued)

Altitude:

Operating . . . . . . . . . . . . . –16 to 3048 m (–50 to 10,000 ft)

Storage . . . . . . . . . . . . . . . –16 to 10,600 m (–50 to 35,000 ft)

z

1-28 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 31

Chapter 2

Basic Troubleshooting

This chapter describes basic troubleshooting procedures that can help you

diagnose a computer system problem. These procedures can often reveal the

source of a problem or indicate the correct starting point for troubleshooting the

system. (A brief explanation of how to load and start the system diagnostics is

located near the end of this chapter.) Dell recommends that you perform the following procedures in the order they are presented in this manual.

Initial User Contact

When you first contact a user who has a problem, ask the user to describe the

problem and the conditions under which it occurs. A verbal description can

often indicate the cause of a problem or else the appropriate troubleshooting

procedure to use. After the user describes the problem, follow these steps:

1. Ask the user to back up any data on the hard-disk drive if the system’s

condition permits.

Appendix C, “Maintaining the System,” in the User’s Guide provides information about backing up data.

2. Ask the user to try to duplicate the problem by repeating the operations

he or she was performing at the time the problem occurred.

Can the user duplicate the problem?

Yes. Proceed to step 3.

No. Proceed to the next section, “External Visual Inspection.”

3. Observe the user to determine if he or she is making an error, such as

typing an incorrect key combination or entering a command

incorrectly.

Is the problem a result of user error?

Yes. Instruct the user in the proper procedure, or direct him or her to the

appropriate user documentation for the correct procedure.

No. Proceed to the next section, “External Visual Inspection.”

Basic Troubleshooting 2-1

Page 32

External Visual Inspection

The external visual inspection consists of a quick inspection of the exterior of

the computer, the monitor, the keyboard, any peripherals, and cables. While performing the visual inspection, make any necessary corrections. To perform the

external visual inspection, follow these steps:

1. Turn off the computer, the monitor, and all peripherals.

2. Verify that all power cables are properly connected to the computer, the

monitor and peripherals, and their power sources.

3. Verify that the keyboard and mouse interface cables are firmly

attached to the proper connectors on the back of the computer.

For a PS/2-compatible mouse, the keyboard and mouse interface cable connectors are identical except for their labels (see Figure 1-5).

For a serial mouse, the mouse interface cable must be attached to one of the

serial port connectors, and its captive screws must be secure enough to

ensure a firm connection.

4. Verify that any devices attached to the serial and parallel port connectors are properly connected.

Each of the serial and parallel interface cables must be attached to an appropriate connector on the back of the computer as well as to the interface

connector on the device. The captive screws that secure these connectors at

each end of the interface cable must be secure enough to ensure a firm

connection.

5. Verify that the video interface cable is firmly attached to the connector

on the I/O panel and to the connector on the back of the monitor.

For proper connection of the video interface cable, see the documentation

for the monitor.

6. Inspect all external monitor controls for any obvious damage or

improper settings.

For proper settings of the video monitor controls, see the documentation for

the monitor.

7. Inspect the keyboard to ensure that no keys are sticking.

If one or more keys are sticking, it may be necessary to replace the

keyboard.

8. Inspect the exterior of the computer, including all controls and indicators, and all user-accessible data storage devices for any signs of

physical damage.

Does the inspection reveal any problems?

Yes. Proceed to the appropriate procedure in Chapter 4, “Removing and

Replacing Parts.”

No. Proceed to the next section, “Observing the Boot Routine.”

2-2 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 33

Observing the Boot Routine

After you have performed an external visual inspection as described in the previous section, you should boot the system and, while the boot routine is

running, observe the system for any indications of problems.

NOTE: Most of the steps in this procedure require observation of system functions and indications, some of which can occur simultaneously. It may be

necessary to reboot the system several times in order to complete all of these

steps.

To observe problem indications during the boot routine, follow these steps:

1. If the system is off, turn on all peripherals and the computer. Insert the

Dell Server Assistant CD into the CD-ROM drive. Press the reset button or <Ctrl><Alt><Del> to reboot the system.

2. Check the power supply fans.

Do the fans run normally?

NOTE: The center fan is normally off, unless another fan has failed or is

unplugged, or the temperature of the computer is too high.

Yes. Proceed to step 3.

No. Troubleshoot the system power supply.

3. Watch the Num Lock, Caps Lock, and Scroll Lock indicators on the

upper-right corner of the keyboard. After all three indicators flash

momentarily, and following a long pause (approximately 30 seconds),

the Num Lock indicator should light up and remain on.

Do these indicators flash on and off within approximately 10 seconds after

the boot routine starts?

Yes. Proceed to step 4.

No. Troubleshoot the system power supply . If the troubleshooting procedure

indicates that the system power supply is operational, troubleshoot the

memory.

4. During the boot routine, observe the computer for any of the following:

• Beep codes: A beep code is a series of beeps that indicates an error con-

dition. If the system emits a beep code, see Table 3-1.

NOTE: The system beeps once during the boot routine. This single beep is

normal and is not a beep code.

• System error messages: These messages can indicate problems or pro-

vide status information. If a system error message is displayed, see

Table 3-2.

• Diskette-drive and hard-disk drive activity indicators: These indicators

light up in response to data being transferred to or from the drives. If

either of these indicators fails to light up during the boot routine, troubleshoot the diskette drive or hard-disk drive subsystem, as appropriate.

Basic Troubleshooting 2-3

Page 34

5. Observe the monitor screen for the Dell Server Assistant Menu.

Does the menu appear?

Yes. See “Running the System Diagnostics” found later in this chapter.

No. Proceed to the next section, “Internal Visual Inspection.”

Internal Visual Inspection

CAUTION: Before you proceed with the internal visual inspection

described in this section, ensure that the user has saved all open files and

exited all open application programs if possible.

A simple visual inspection of a computer’s interior hardware can often lead to the

source of a problem, such as a loose expansion card, cable connector, or mounting screw .

When you perform the visual inspection, refer to “System Features” in Chapter 1 to locate

components in the inspection procedure.

To perform the internal visual inspection, follow these steps:

1. Turn off the system, including any attached peripherals, and disconnect

all the AC power cables from their power sources.

2. Remove the left computer cover.

3. Verify that all DIMMs and expansion cards as well as the microprocessor(s) and battery are fully seated in their sockets or connectors.

WARNINGS: The microprocessor can get extremely hot. Be sure the

chip has had sufficient time to cool before you touch it.

To maintain proper air flow and prevent the system from overheating, each power supply bay must have either a power supply or the

power closeout panel installed.

To ensure that the chips are fully seated in their sockets, press firmly on the

top of each chip.

To reseat a microprocessor, first remove it from its socket and then reinstall

it as described in “Microprocessor and Heat Sink” in Chapter 4.

To reseat a DIMM, remove it from its socket and reinstall it as described in

“DIMMs” in Chapter 4.

If you need to reseat an expansion card, use a 1/4-inch nut driver to remove

the screw that secures the card-mounting bracket. Grasp the card by its top

corners, and carefully pull it out of its connector. Reinsert the card in its

connector, and carefully push it in until fully seated. Then reinstall the cardmounting bracket’s retaining screw.

2-4 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 35

4. Verify that all jumpers are set correctly.

For information about these jumpers, see “System Board Jumpers” in Chapter 1.

5. Check all cable connectors inside the computer to verify that they are

firmly attached to their appropriate connectors.

6. Reinstall the computer cover.

7. Reconnect the computer and any attached peripherals to their power

sources, and turn them on.

Does the problem appear to be resolved?

Yes. No further steps are necessary. Terminate the procedure.

No. Proceed to the next section, “Eliminating Resource Conflicts,” and to

“Getting Help” found later in this chapter.

Eliminating Resource Conflicts

Devices within the computer may require dedicated memory spaces, interrupt

levels, or DMA channels, all of which must be allocated during installation of

the devices. Because a device may be installed at a different time, it is possible

that the same resource is assigned to two or more devices.

Resource conflicts can result in disorderly or erratic system operation or failure

of the system to operate at all. If you suspect that resource conflicts might exist,

check the system and reassign the resources as necessary.

Running the System Diagnostics

The system diagnostics (included on the Dell Server Assistant CD) contains

tests that aid in troubleshooting all major components of the computer system.

To start the diagnostics, insert the CD into the CD-ROM drive, and then press

the reset button on the computer.

Restarting the computer causes the Dell Server Assistant logo screen to appear

on the monitor screen, followed by a screen containing icons of the options

available. Selecting the Run System Utilities icon brings up a screen with the

diagnostics icon. Before the Dell Server Assistant loads, a program tests the

portion of main memory (RAM) required for loading the diagnostics. If a main

memory error is detected, a message telling you which DIMM has failed

appears on the screen.

Basic Troubleshooting 2-5

Page 36

If no errors are found in main memory, and the Dell Server Assistant loads,

select the Run System Utilities icon. Then select the Run System Diagnostics

icon by pressing <Enter>. The Diagnostics Menu appears, allowing you to

choose the following options or exit to MS-DOS:

• Run All Tests — Runs all tests for a thorough check of the system

• Run Quick Tests — Runs selected tests from all test groups to quickly locate

a failure or to indicate where further testing is needed to isolate a failure

• Run Specific Tests — Tests a particular area or subsystem

Getting Help

If none of the troubleshooting procedures in this chapter or the tests in the

system diagnostics reveals the source of the problem or leads to the proper troubleshooting steps for determining the source of the problem, call Dell for

technical assistance. For instructions, see Chapter 11, “Getting Help,” in the

Installation and Troubleshooting Guide.

2-6 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 37

Chapter 3

Beep Codes and Error Messages

This chapter describes beep codes and system error messages that can occur

during system start-up or, in the case of some failures, during normal system

operation. The tables in this chapter list faults that can cause a beep code or system error message to occur and the probable causes of the fault in each case.

If a faulty system does not emit beep codes or display system error messages to

indicate a failure, you should use the CD-based diagnostics to run the appropriate tests to help isolate the source of the problem. See “Running the System

Diagnostics” in Chapter 2.

POST Beep Codes

If the monitor cannot display error messages during the POST, the system may

emit a series of beeps that identifies the problem or that can help you identify a

faulty component or assembly. T able 3-1 lists the beep codes that may be generated during the POST. Most beep codes indicate a fatal error that prevents the

system from completing the boot routine until the indicated condition is

corrected.

When the system emits a beep code, record the code and then find it in

Table 3-1. If the table does not lead to the source of the problem, run the appropriate tests in the CD-based diagnostics to assist in troubleshooting the problem.

Table 3-1. Beep Codes

Beep Code Error Probable Causes

1-2 Invalid expansion-card

ROM checksum

1-2-2-3 Invalid BIOS ROM

checksum

1-3-1-1 DRAM refresh failure Defective DIMMs or system

1-3-1-3 Keyboard controller

error

Improperly seated expansion card, or system needs to

be rebooted.

Corrupted BIOS firmware

or defective system board.

board. Reseat DIMMs or

replace system board.

Defective DIMMs or system

board. Reseat DIMMs or

replace system board.

Beep Codes and Error Messages 3-1

Page 38

Table 3-1. Beep Codes (continued)

Beep Code Error Probable Causes

1-3-3-1 No DIMM memory

installed

Defective DIMMs or system

board. Reseat DIMMs or

replace system board.

1-3-4-1 DRAM failure Defective DIMMs or system

board. Reseat DIMMs or

replace system board.

1-3-4-3 DRAM failure Defective DIMMs or system

board. Reseat DIMMs or

replace system board.

1-4-1-1 DRAM failure Defective DIMMs or system

board. Reseat DIMMs or

replace system board.

1-4-2-1 CMOS failure Defective system board.

1-4-3-1 Memory controller or

DIMM failure

Defective DIMMs or system

board. Reseat DIMMs or

replace system board.

2-2-3-1 Unexpected interrupt Improperly seated expan-

sion card, or system needs to

be rebooted.

3-2-2-1

Gate A20 failure Defective system board.

4-2-4-4

4-2-4-3 Keyboard controller

error

Defective DIMMs or system

board. Reseat DIMMs or

replace system board.

3-2 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 39

System Error Messages

Table 3-2 lists system error messages that can appear on the monitor screen.

These messages can help you find the source of a problem. Some of these error

messages indicate fatal errors. When a fatal error occurs, the system cannot usually be rebooted until an appropriate hardware change has been made.

Table 3-2. System Error Messages

Message Definition Action

System battery is dead

- Replace

and run

Setup

System CMOS

checksum

bad - Run

Setup

Incorrect

drive A t ype

- Run Setup

Incorrect

drive B type

- Run Setup

Keyboard

error

Stuck key

System/

Shadow RAM

failed at

offset:

System battery is

dead.

Configuration data

is corrupted.

Diskette drive does

not match diskette

drive type stored in

configuration data.

Cable may be loose,

or keyboard may be

faulty.

One or more

DIMMs may be

improperly seated or

faulty.

Replace battery and

run System Setup program.

Run System Setup program to restore your

system configuration.

Run System Setup program to restore your

system configuration.

Defective keyboard,

keyboard cable, or

system board.

Reseat or replace

DIMMs.

Operating

system not

found

System

cache error

- Cache disabled

System

timer error

System did not find

bootable operating

system.

Microprocessor chip

malfunctioned.

Chip on system

board malfunctioned.

Use diskette with

bootable operating

system in drive A, or

load bootable

operating system

from hard-disk drive.

Defective microprocessor or system

board.

Defective microprocessor or system

board.

Beep Codes and Error Messages 3-3

Page 40

Table 3-2. System Error Messages (continued)

Message Definition Action

Real-time

clock error

Keyboard

controller

error

EISA configuration

NVRAM bad

EISA configuration

error

Invalid CPU

speed

detected check

jumpers

Real-time clock on

system board malfunctioned.

Cable may be loose,

keyboard may be

faulty, or keyboard

controller is defective.

EISA jumper may

have been accidentally installed.

EISA configuration

data in NVRAM

does not match the

installed EISA

expansion cards.

Microprocessor

speed jumper plug

may be absent or

installed on wrong

jumper pins.

Defective microprocessor or system

board.

Defective keyboard,

keyboard cable, or

system board.

Ensure EISA jumper

is removed; then

reboot system and

restore EISA configuration.

Ensure EISA expansion cards are seated

properly; then run

EISA Configuration

Utility.

Check the microprocessor speed

jumpers.

Resource

conflict

Warning:

IRQ not

initialized

Expansion

ROM not

initialized

System configuration

data write

error

System memory size has

changed Run Configuration

Utility

BIOS detected a

resource conflict

while configuring

Plug and Play ISA

or PCI expansion

card.

System board may

be malfunctioning.

DIMM was added or

removed. DIMMs

are improperly

seated.

See “Eliminating

Resource Conflicts”

in Chapter 2.

Defective system

board.

More memory was

added. Make sure

DIMMs are properly

seated; run EISA

Configuration Utility.

3-4 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 41

Table 3-2. System Error Messages (continued)

Message Definition Action

Stepping of

CPU1 is less

than sA1 System halted.

Stepping of

CPU2 is less

than sA1 System halted.

Stepping of

CPU is less

than sA1 System halted.

Nonidentical

CPUs - System

halted.

Invalid CPU

speed detected

- Check speed

jumpers.

System halted.

Wrong microprocessor

installed in

PROCESSOR1 socket.

Wrong microprocessor

installed in

PROCESSOR2 socket.

Wrong microprocessor

installed in system.

Cache memory sizes of

the two Pentium Pro

microprocessors do not

match.

The microprocessor

speed detected is neither

180 MHz or 200 MHz.

Replace microprocessor

with sA1 stepping or

greater.

Replace microprocessor

with sA1 stepping or

greater.

Replace microprocessor

with correct sA1 stepping or greater.

Replace one of microprocessors so that cache size

of both microprocessors

matches.

Check microprocessor

speed jumpers.

Power supply

paralleling

board firmware download

failed

System backplane firmware download

failed

Embedded

server management firmware

download

failed

Server-management bus

cable connection to

SCSI backplane board is

loose.

Embedded server

management memory

temporarily corrupted.

Check servermanagement bus cable

connections to system

board (labeled “SMB

BACKPLANE”) and

SCSI backplane (labeled

“SMB”). Turn off and

then restart system.

Turn off and then restart

the system.

Beep Codes and Error Messages 3-5

Page 42

3-6 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 43

Chapter 4

Removing and Replacing Parts

This chapter provides procedures for removing the components, assemblies,

and subassemblies in the system unit. Unless otherwise noted, each procedure

assumes the following:

• You have performed the steps in “Precautionary Measures” found later in

this chapter.

• You have removed the computer covers.

• You can replace or reinstall a part by performing the removal procedure in

reverse order unless additional information is provided.

Recommended Tools

Most of the procedures in this chapter require the use of one or more of the following tools:

• Small flat-blade screwdriver

• Wide flat-blade screwdriver

• Number 1 and number 2 Phillips-head screwdrivers

• Chip-removal tool

• 1/4-inch nutdriver

• Tweezers or long-nose pliers

• Small plastic scribe

Also, use a wrist grounding strap as explained in the next section, “Precautionary Measures.”

Removing and Replacing Parts 4-1

Page 44

Precautionary Measures

6)

Before you perform any of the procedures in this chapter, take a few moments

to read the following warning for your personal safety and to prevent damage to

the computer system from ESD.

WARNING FOR YOUR PERSONAL SAFETY AND PROTECTION

OF THE EQUIPMENT: Only service technicians trained by Dell should

perform the following procedures. Before you start to work on the computer, perform the following steps in the sequence listed.

1. Turn off the computer and any attached peripherals.

2. Disconnect the computer and any attached peripherals from their

power sources to reduce the potential for personal injury.

3. Disconnect any communications cables.

4. Wear a wrist grounding strap, and clip it to an unpainted metal sur-

face, such as a part of the back panel, on the computer chassis.

If a wrist grounding strap is not available, touch the fan guard or

some other unpainted metal surface on the back of the computer to

discharge any static charge from your body.

Computer Covers

screw (

Figure 4-1. Computer Covers Removal

4-2 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 45

To remove a computer cover, follow these steps:

keylock (2)

1. Turn the cover’s keylocks on the back panel of the computer to the

unlocked position (see Figure 4-2).

Figure 4-2. Keylocks on Computer’s Back Panel

2. Loosen the three screws along the back edge of the cover (see

Figure 4-1).

3. Slide the cover toward the back of the computer an inch or so. Then

grasp the top of the cover at both ends, and lift it straight away from the

chassis.

Removing and Replacing Parts 4-3

Page 46

Front Bezel

tab (4)

front bezel

Figure 4-3. Front Bezel Removal

To remove the front bezel, follow these steps:

1. Remove the computer covers.

2. Release the two tabs on each side of the bezel.

3. Slide the front bezel toward the front of the computer.

4-4 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 47

Drives

3.5-inch diskette drive

Figure 4-4 shows an example of drive hardware that can be installed in the computer. Refer to this figure when you perform any of the procedures in the

following subsections.

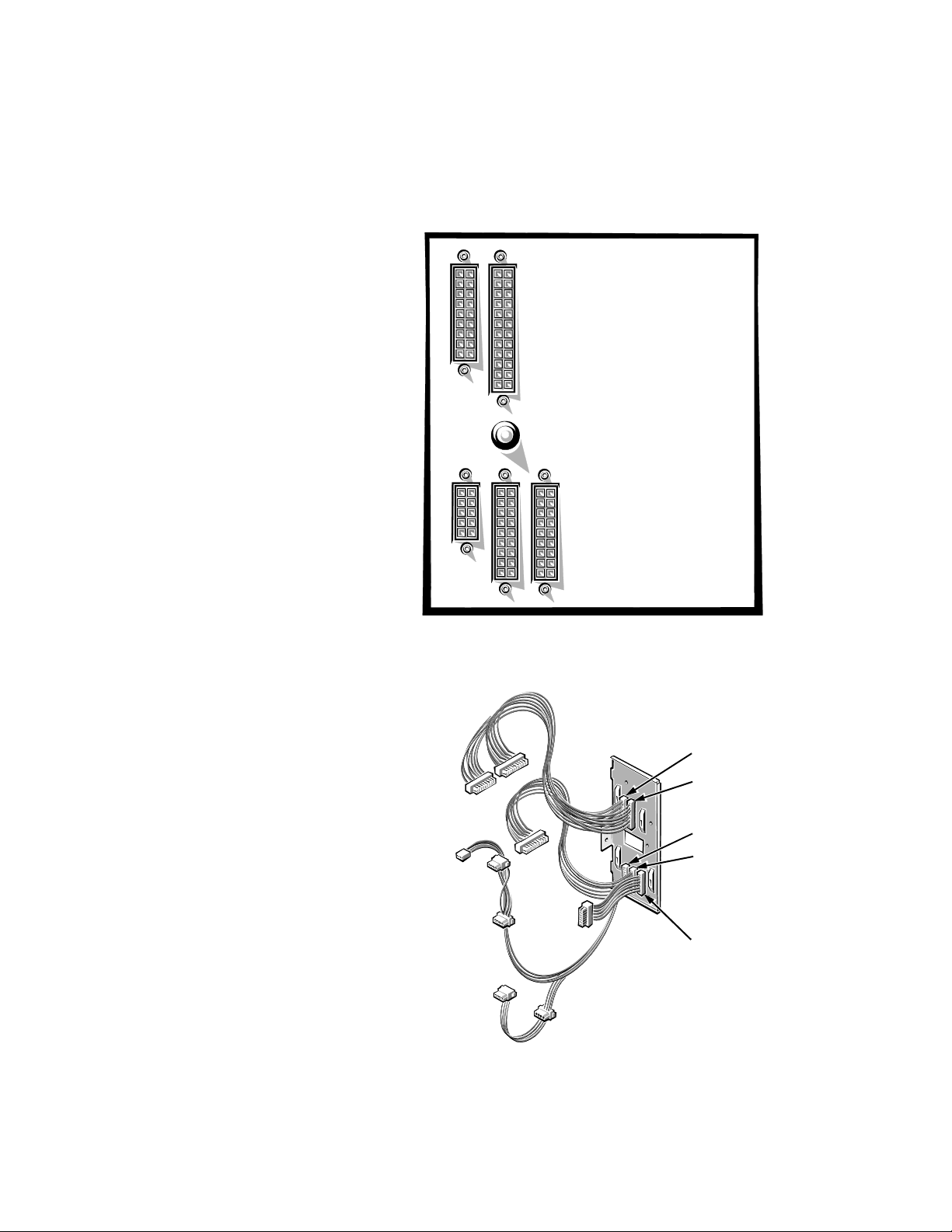

DC power cable

SCSI2 CD-ROM

diskette/tape drive

interface cable

drive

SCSI hard-disk

drive bay (6)

SCSI backplane

board

diskette drive interface

connector (FLOPPY)

SCSI connector

(SCSI2 CD-ROM)

SCSI connector

(BACKPLANE SCSI1)

Figure 4-4. Drive Hardware

SCSI interface

cable

system board

Removing and Replacing Parts 4-5

Page 48

Front-Panel Inserts

front-panel insert

tab (2)

latch (2)

back of the

front bezel

Figure 4-5. Front-Panel Insert Removal

To remove a front-panel insert, follow these steps:

1. Remove the front bezel.

2. From the back of the front bezel, press against the center of the insert

until the tabs come loose from the bezel.

3. Pull the insert out of the bezel.

To replace a front-panel insert, position the insert over the bay opening from the

inside of the front bezel and carefully press the insert into place. A tab on each

side of the insert snaps into a corresponding latch on the inside of the front

bezel.

4-6 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 49

Externally Accessible Drives

3.5-inch diskette

drive in top bay

CD-ROM drive in

middle bay

lower-bay drive

position for optional

drive

drive-release

tab(2)

Figure 4-6. Externally Accessible Drives Removal

All of the externally accessible drives have drive-mounting rails. To remove a

drive assembly from one of the externally accessible drive bays, follow these

steps:

1. Disconnect the DC power cable and the interface cable from the back of

the drive.

Be sure to record the power connector number and interface cable connector

identification.

2. Press inward (toward center of drive) on the two drive-release tabs, and

slide the drive out of the bay.

Removing and Replacing Parts 4-7

Page 50

3. Remove the drive-mounting rails from the drive (see Figure 4-7).

drive-release tabs

drive-mounting

rails (2)

Figure 4-7. Drive-Mounting Rails Removal

4. If the drive is a SCSI drive, record the setting of the SCSI address

jumpers and SCSI bus termination jumper.

Some drives use an adapter between the SCSI cable and the drive connector.

Check the back of the old drive for an adapter. If present, remove the

adapter and retain it for use on the new drive.

When reinstalling the SCSI drive, set the SCSI address jumpers and the

SCSI bus termination jumpers to the settings you recorded.

4-8 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 51

Hard-Disk Drives

drive bay

plastic drive handle

Figure 4-8. Hard-Disk Drive Carrier Removal

The hard-disk drives are mounted inside a hard-disk drive carrier. The hard-disk

drive carrier must be removed before a hard-disk drive can be removed. To

remove a hard-disk drive, follow these steps:

NOTES: Wait 20 seconds for the hard-disk drive to spin down before removing

the hard-disk drive carrier.

Hard-disk drives can be removed with the power on if a PowerEdge Expandable RAID Controller host adapter card is installed.

1. If a PowerEdge Expandable RAID Controller host adapter card is

installed in the computer, wait until the three indicators are off, and

then proceed to Step 2 (refer to Chapter 6, “Installing SCSI Hard-Disk

Drives,” in the User’s Guide for more information). If this host adapter

card is not installed in the computer, turn off the system before proceeding to Step 2.

2. Release the carrier by pulling down on the plastic drive handle.

3. Slide the drive carrier toward the front of the computer until it is free of

the drive bay.

4. Turn the drive carrier over, and place it on a flat work surface.

Removing and Replacing Parts 4-9

Page 52

hard-disk drive

connector

screw (4)

Figure 4-9. Hard-Disk Drive Removal

carrier

5. Remove the four mounting screws that attach the hard-disk drive to the

carrier.

6. Disconnect the hard-disk drive from the connector on the back of the

carrier, and lift the drive from the carrier.

CAUTION: When disconnecting the hard-disk drive from the connector, grasp the connector, not the cable, to avoid damaging the

connector.

After you replace the drive and reinstall the carrier in the bay, turn on the system. The online indicator (green) lights, indicating power is being supplied to

the hard-disk drive. With the controller connected, the activity LED is activated

when the controller spins up the drive.

4-10 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 53

SCSI Backplane Board

hard-disk drive

carrier

thumb screw

hook (10)

SCSI backplane board

Figure 4-10. SCSI Backplane Board Removal

To remove the SCSI backplane board, follow these steps:

1. Disconnect the hard-disk drive carrier connectors from the SCSI backplane board by sliding each carrier toward the front of the computer

approximately 1 inch.

2. Disconnect all cables from the SCSI backplane board.

3. Unscrew the thumb screw.

4. Disengage the board from the ten hooks holding the board to the computer chassis, and lift the board away from the computer.

An insulator (similar to the one for the power-supply paralleling board in

Figure 4-12) is attached to the back of the SCSI backplane board with two

adhesive strips.

Removing and Replacing Parts 4-11

Page 54

Power Supply

The computer may have one or two power supplies.

Figure 4-11. Power Supply Removal

To remove a power supply, follow these steps:

power closeout

panel

power supply

(optional)

power supply

cable strain

relief

insertion screw

AC power cable

connector

locking switch

WARNING: In a redundant system, you can remove and replace a power

supply without turning off the system. When doing so, be careful not to

touch any of the connectors on the power-supply paralleling board.

CAUTION: To maintain proper airflow and prevent the system from

overheating, each power supply bay must have either a power supply or

a power closeout panel installed.

1. Turn the locking switch on the power supply to the Off position

(marked by a “0”).

2. Unhook the cable strain relief to free the AC power cable.

3. Disconnect the AC power cable from the power outlet; then disconnect

the other end of the cable from the power supply.

4. Turn the insertion screw counterclockwise to release the power supply.

5. Slide the power supply out of the chassis.

To replace a power supply, perform these steps in reverse order.

4-12 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 55

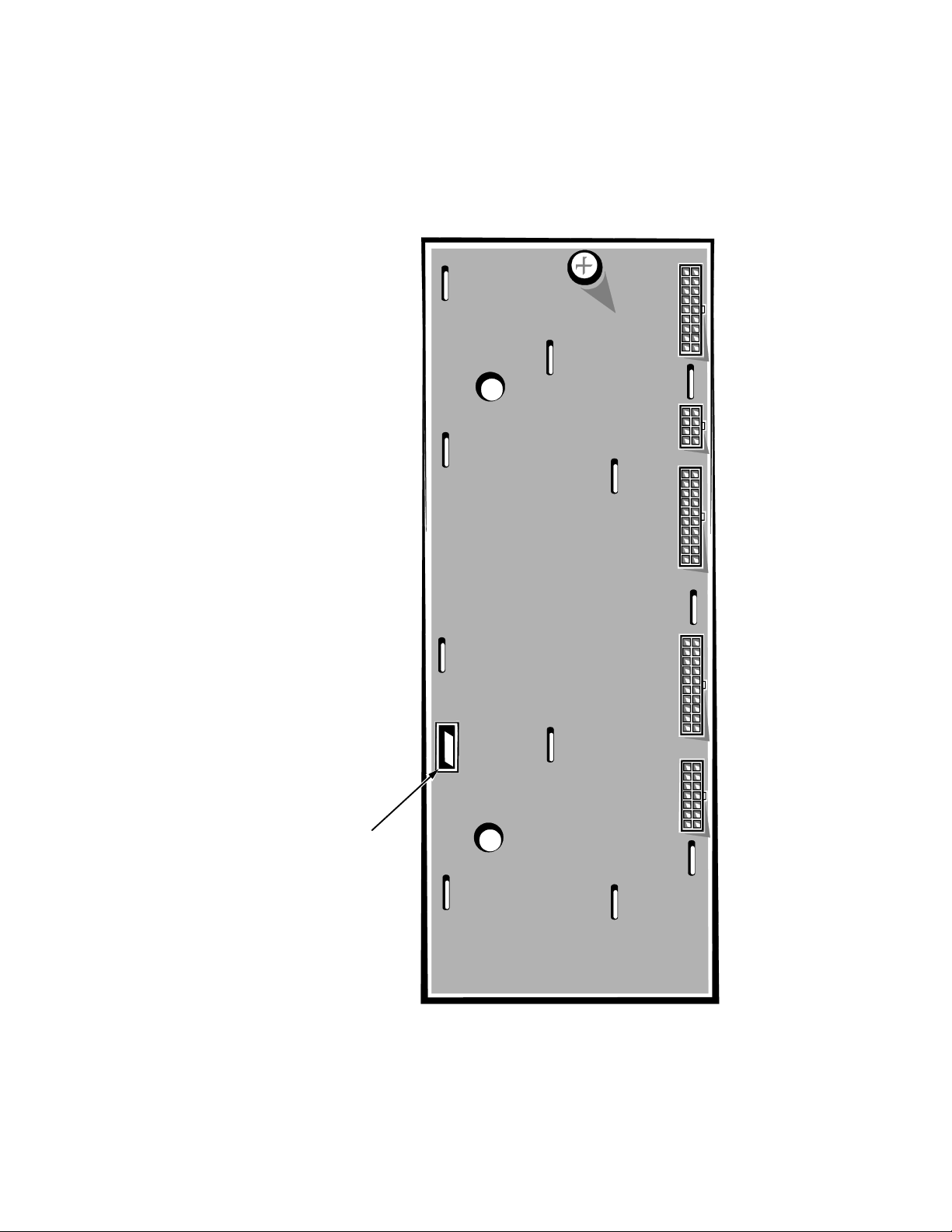

Power-Supply Paralleling Board

cables

thumb screw

power supply (2)

power-supply

paralleling board

insulator

hook slots (11)

power-supply

paralleling board

Figure 4-12. Power-Supply Paralleling Board Removal (Redundant

Systems)

To remove a power-supply paralleling board, follow these steps:

WARNING: Disconnect both power supplies from their AC power

source to prevent the possibility of getting shocked.

1. Disconnect the power supplies from the power-supply paralleling board

by sliding each power supply toward the back of the computer approximately 1 inch.

2. Disconnect all cables from the power-supply paralleling board.

3. Unscrew the thumb screw.

4. Disengage the board from the eleven hooks holding it to the computer

chassis, and then lift the board away from the computer.

Removing and Replacing Parts 4-13

Page 56

Power Connector Panel

power supply

retainer

screw

power

connector

panel

cables (5)

power

connector

panel

hook slots (4)

Figure 4-13. Power Connector Panel Removal (Nonredundant

Systems)

To remove the power connector panel, follow these steps:

1. Disconnect the power supply from the power connector panel by sliding

the power supply toward the back of the computer approximately

1 inch.

2. Disconnect all power connector panel cables (from the system board,

the SCSI backplane board, and so forth).

3. Unscrew the retainer screw.

4. Disengage the panel from the four hooks holding it to the computer

chassis, and then lift the panel away from the computer.

4-14 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 57

Control Panel

screw

control panel

connector BP_to_CP

Figure 4-14. Control Panel Removal

To remove the control panel, follow these steps:

1. Remove the screw holding the control panel to the chassis.

2. Disconnect the cable from connector BP_to_CP.

3. Disengage the panel from the four hooks holding the panel to the

computer chassis, and lift the panel away from the computer.

Removing and Replacing Parts 4-15

Page 58

Cooling Fans

fan carrier

catch

cooling fan

retention

tab (2)

Figure 4-15. Cooling Fan Removal

To remove a cooling fan, follow these steps:

NOTES: This procedure can be performed with the computer turned on.

The middle fan is normally turned off by server management; this fan is turned

on only if one of the other fans fails.

1. Remove the left computer cover.

2. Disconnect the cooling fan’s power cable from its respective FAN connector on the system board.

3. Press down the catch on the fan carrier, and remove the fan carrier

from the chassis.

4. Remove the cooling fan from the fan carrier by releasing the two fan

retention tabs inside the carrier.

4-16 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 59

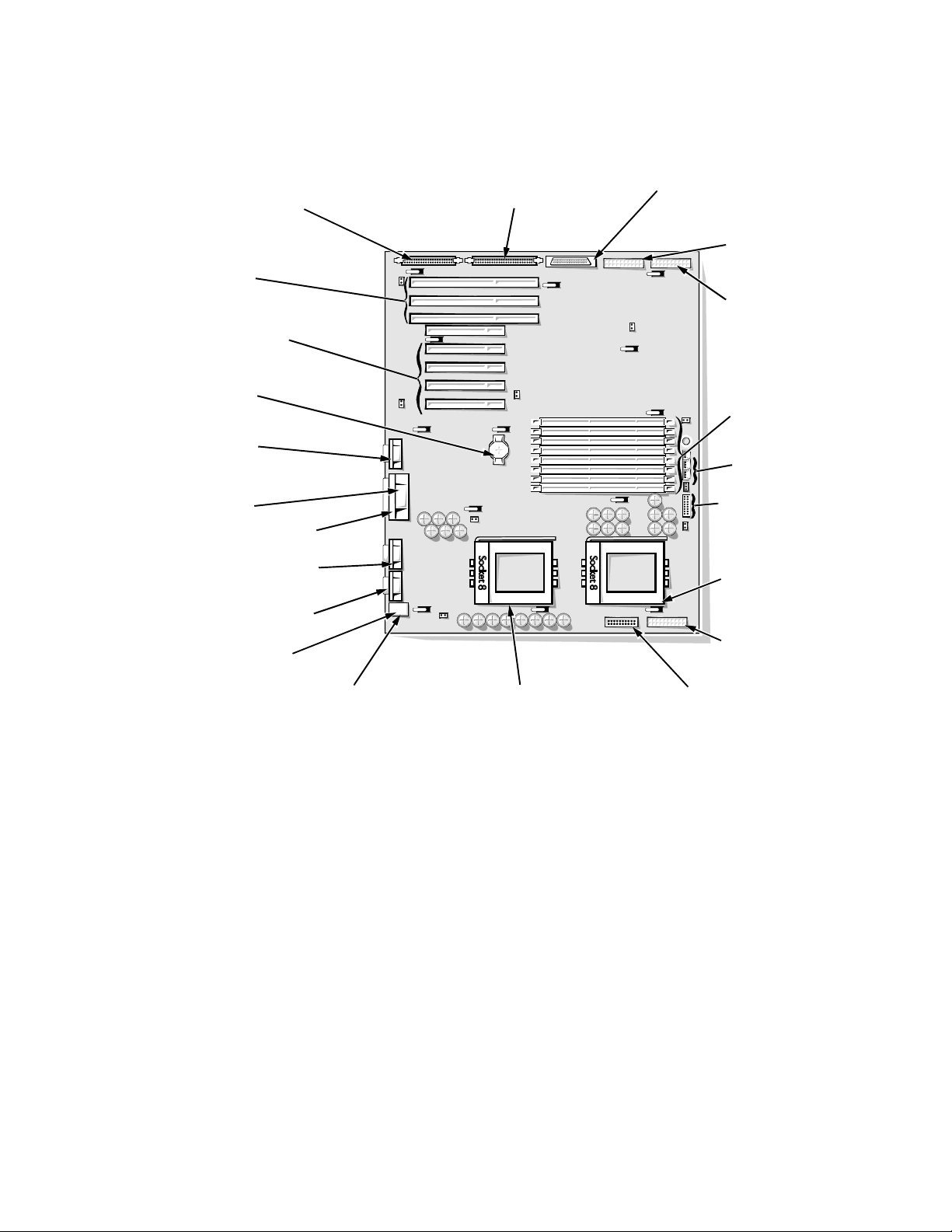

System Board Components

socket (PROCESSOR

Ultra/Narrow SCSI host adapter

Ultra/Wide SCSI host adapter

The subsections that follow contain procedures for removing system board

components.

diskette/tape drive interface

connector (FLOPPY)

connector (SCSI2 CD-ROM)

connector (BACKPLANE SCSI1)

EISA connectors

(EISA1 [top], EISA2,

and EISA3)

PCI connectors

(PCI4 [top]–PCI8)

battery connector

(BATTERY)

video connector

(MONITOR)

server-management

serial port connector

(REMOTE)

parallel port connector

(PARALLEL)

serial port 2 connector

(SERIAL2)

serial port 1 connector

(SERIAL1)

mouse connector

(MOUSE)

keyboard connector

(KEYBOARD)

secondary microprocessor

2)

power supply connector

(POWER2)

power supply connector

(POWER1)

front of

system board

DIMM sockets

(DIMM A [top]–DIMM H)

fan connectors

(FAN1, FAN2, FAN3)

speed and configuration

jumpers

primary microprocessor

socket (PROCESSOR1)

power supply connector

(POWER3)

server-management bus

connector (SMB BACKPLANE)

Figure 4-16. System Board Components

Removing and Replacing Parts 4-17

Page 60

Expansion Cards

card-slot opening

card-mounting

bracket

retaining screw

expansion card

locking card guide

Figure 4-17. Expansion Card Removal

To remove an expansion card, follow these steps:

1. Remove the left computer cover.

2. Disconnect any cables connected to the expansion card.

3. Remove the retaining screw from the card-mounting bracket.

4. If the card is a full-length expansion card, unlock the locking cam on

the locking card guide.

5. Grasp the expansion card by its corners, and carefully remove it from

the expansion-card connector.

4-18 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 61

DIMMs

1.

1.

DIMM

securing clip (2)

2.

Figure 4-18. DIMM Removal

To remove a DIMM, push outward on the DIMM socket’s securing clips until the

DIMM is released from its socket. Then lift the DIMM away from the socket.

DIMM

securing clip (2)

2.

Figure 4-19. DIMM Installation

To replace a DIMM, push outward on the securing clips at each end of the

socket until they snap open. Orient the DIMM to the socket, and press the

DIMM straight down into the socket slot until the securing clips snap into place

around both ends of the DIMM.

Removing and Replacing Parts 4-19

Page 62

Microprocessor and Heat Sink

clip

heat sink

thermal pad

(bonded to heat sink)

microprocessor

socket

microprocessor

pin-1 corner of socket

front tab

Figure 4-20. Microprocessor Configuration

The computer may have two microprocessors. To remove a microprocessor and

heat sink, follow these steps:

1. Remove the microprocessor securing clip from the microprocessor/heat

sink assembly.

WARNING: The microprocessor chip can get extremely hot during

system operations. Be sure the chip has had sufficient time to cool

before touching it.

Press down on the folded part of the clip with a small screwdriver to release

the clip (see Figure 4-21).

4-20 Dell PowerEdge 4100/180 and 4100/200 Systems Service Manual

Page 63

heat sink

microprocessor chip

release lever

press here to

release clip

microprocessor

securing clip

hooks over tabs

on socket

(front and back)

microprocessor

socket

microprocessor