Page 1

Installing the S60 System

Publication Date: December 2013

Page 2

Notes, Cautions, and Warnings

NOTE: A NOTE indicates important information that helps you make better use of your computer.

CAUTION: A CAUTION indicates either potential damage to hardware or loss of data and tells you how to

avoid the problem.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

Information in this publication is subject to change without notice.

© 2013 Dell Force10. All rights reserved.

Reproduction of these materials in any manner whatsoever without the written permission of Dell Inc. is strictly forbidden.

Trademarks used in this text: Dell™, the Dell logo, Dell Boomi™, Dell Precision™ , OptiPlex™, Latitude™, PowerEdge™, PowerV ault™,

PowerConnect™, OpenManage™, EqualLogic™, Compellent™, KACE™, FlexAddress™, Force10™ and Vostro™ are trade marks of D ell

Inc. Intel®, Pentium®, Xeon®, Core® and Celeron® are registered trademarks of Intel Corporation in the U.S. and other countries. AMD®is

a registered trademark and AMD Opteron™, AMD Phenom™ and AMD Sempron™ are trademarks of Advanced Micro Devices, Inc.

Microsoft®, Windows®, W indows Server®, Internet Explorer®, MS-DOS®, W indows Vista® and Active Directory® are either trademarks

or registered trademarks of Microsoft Corporation in the United States and/or other countries. Red Hat® and Red Hat®Enterprise Linux® are

registered trademarks of Red Hat, Inc. in the United States and/or other countries. Novell® and SUSE® are registered trademarks of Novell

Inc. in the United States and other countries. Oracle® is a registered trademark of Oracle Corporation and/or its affiliates. Citrix®, Xen®,

XenServer® and XenMotion® are either registered trademarks or trademarks of Citrix Systems , Inc. in the United States and/or o ther countries.

VMware®, Virtual SMP®, vMotion®, vCenter® and vSphere® are registered trademarks or trademarks of VMware, Inc. in the United States

or other countries. IBM® is a registered trademark of International Business Machines Corporation.

Other trademarks and trade names may be used in this publication to refer to either the entities claiming the marks and names or their products.

Dell Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

December 2013

Page 3

1 About this Guide

Related Publications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 The S60 System

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Orderable S60 Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

LED Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Install the S60 System

Install the S60 System in a Rack or Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Attach the Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Install the Chassis into the Rack or Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Attach the Ground Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Insert Optional Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install the SFP and SFP+ Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connect Stacking Ports (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Important Points to Know. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connect Two S60 Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connect Three or More S60 Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Supply Power and Power Up the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power Up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Hot-swap Units in a Stack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Power Supplies

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Install an AC or DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replace an AC or DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Fans and Filters

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Install a Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replace a Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Install a Fan Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6 Access the Console Ports

| 3

Page 4

www.dell.com | support.dell.com

Access the RJ-45 Console Port (RS-232). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Access the RJ-45 Console Port with a DB-9 Adapter . . . . . . . . . . . . . . . . . . . . 29

Access the USB-B Console Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7 S60 Specifications

Chassis Physical Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Environmental Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

AC Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DC Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

IEEE Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Network Equipment Building Systems (NEBS) Compliance . . . . . . . . . . . . . . . 32

USA Federal Communications Commission (FCC) Statemen t . . . . . . . . . . . . . 33

Canadian Department of Communication Statement . . . . . . . . . . . . . . . . . . . . 33

European Union EMC Directive Conformance Statement. . . . . . . . . . . . . . . . . 34

European Community Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Japan: VCCI Compliance for Class A Equipment . . . . . . . . . . . . . . . . . . . . . . . 34

Korea Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

China Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Safety Standards and Compliance Agency Certifications . . . . . . . . . . . . . . . . . 35

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Product Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SD Card Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Battery Replacement and Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4 |

8 Technical Support

The iSupport Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Accessing iSupport Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Contacting the Technical Assistance Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Requesting a Hardware Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Page 5

1

About this Guide

This guide provides site preparation recommendations, step-by-step procedures for rack mounting and

desk mounting, inserting optional modules, and connecting to a power source.

After you have completed the hardware installation and power-up of the S60 system, for software

configuration information, refer to the FTOS Configuration Guide for the S60 System and for Command

Line Interface (CLI) information, refer to the FTOS Command Line Reference Guide for the S60 System.

NOTE: For information about upgrading your system, refer to the S60 Release Notes. For questions regarding

FTOS versions and upgrades, contact Dell Networking Technical Support.

CAUTION: To avoid electrostatic discharge (ESD) damage, wear grounding wrist straps when handling the

S60 system.

WARNING: Only trained and qualified personnel can install the S60 system. Read this guide before installing

and powering up this equipment. The S60 system contains two power cords. Disconnect both power cords

before servicing.

WARNING: This equipment contains optical transceivers, which comply with the limits of Class 1 laser

radiation.

WARNING: When no cable is connected, visible and invisible laser radiation may be emitted from the

aperture of the optical transceiver ports. Avoid exposure to laser radiation and do not stare into open

apertures.

Related Publications

For more information about the S60 system, refer to the following documents:

• FTOS Configuration Guide for the S60 System

• FTOS Command Line Reference Guide for the S60 System

•

FTOS Release Notes

NOTE: For the most recent documentation and software, visit iSupport (registration for access to some

sections is required):

for the S60 System

https://www.force10networks.com/CSPortal20/Main/SupportMain.aspx

.

About this Guide | 5

Page 6

2

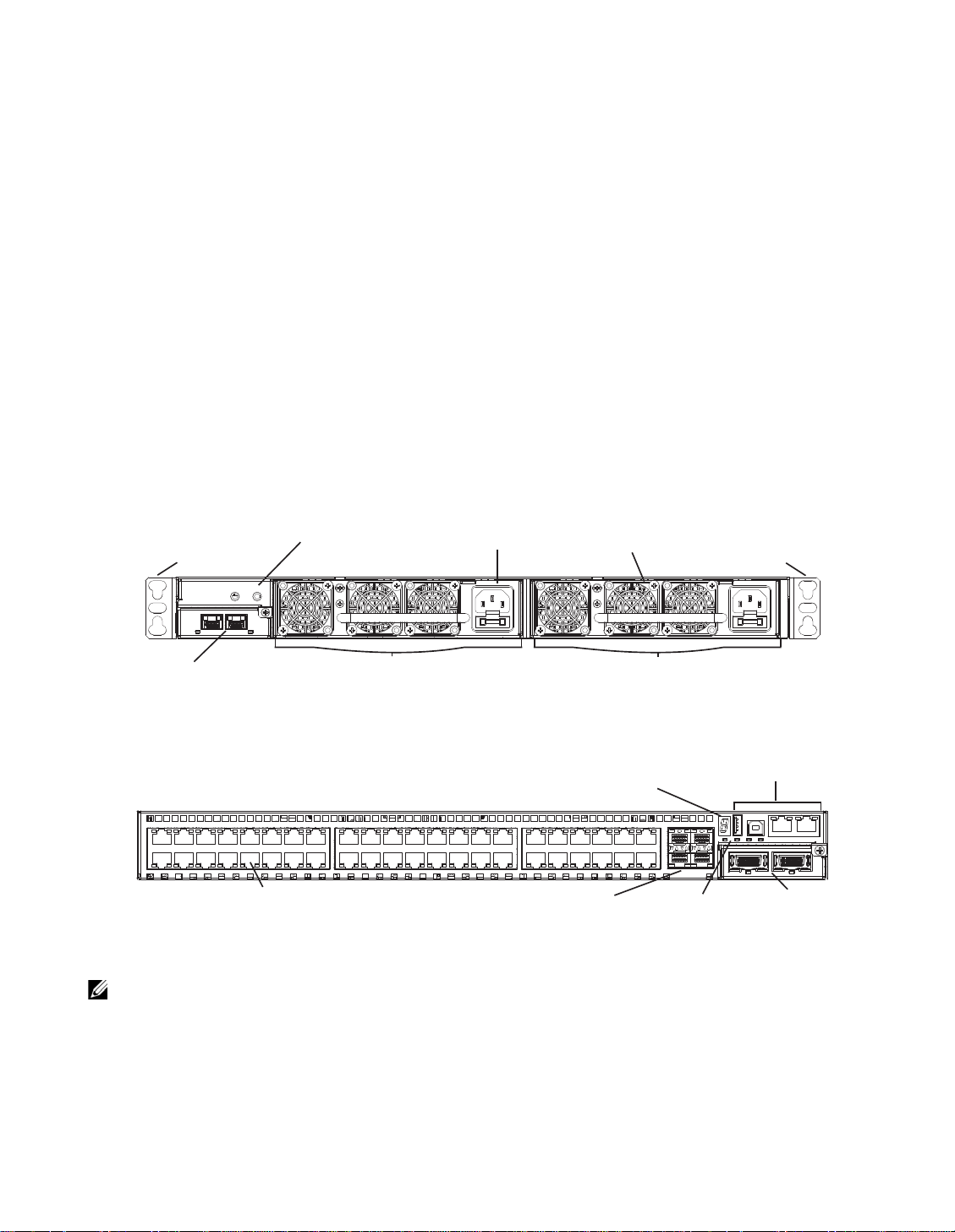

Ethernet Ports

SFP Ports

Optional

Module

(OPT0)

Management

Ports

Stack ID

Alarm

LEDs

The S60 System

Introduction

The Dell Networking S60 system is a high-performance, high-capacity, low-cost, stackable, Layer 2

switch/Layer 3 router that supports 44 built-in 10/100/1000 Base-T ports, four Small Form-Factor

Pluggable (SFP) ports, an optional Small Form-Factor Pluggable Plus (SFP+) module, and optional 12G

or 24G stacking modules.

The front of the S60 (

grounding connectors. The rear of the S60 (

ports, management ports, and displays for alarms and stacking identification.

Figure 2-1. The Front of the S60 System

Mounting Bracket Mounting Bracket

Optional Module

(OPT1)

Figure 2-2. The Rear of the S60 System

Figure 2-1

Ground Connectors

) contains the Power Supply Units (PSUs), optional module slots, and the

Power Supply (PSU0)

Figure 2-2

) contains the 44 ethernet ports, optional module

Power Connector

(AC shown)

Fans

Power Supply (PSU1)

NOTE: The ethernet ports are labeled 0-43. When cabling these ports, be sure not to interfere with the airflow

from the small vent holes above and below the ports.

The S60 System | 6

Page 7

Orderable S60 Systems

You can order the S60 in several different configurations. You can order optional modules separately.

Hardware

S60: 44 port 10/100/1000 Base-T with 4 SFP ports and 2 modular slots

S60: 44 port 10/100/1000 Base-T with 4 SFP ports, 2 modular slots,1 AC PSU and 1 fan subsystem

S60: 44 port 10/100/1000 Base-T with 4 SFP ports, 2 modular slots,1 DC PSU and 1 fan subsystem

S60 Fan Subsystem with airflow from the I/O panel to the PSU

S60 Fan Subsystem with airflow from the PSU to the I/O panel

S60 AC PSU with 1 fan module

S60 AC PSU with 1 reverse-flow fan module

S60 DC PSU with 1 fan module

S60 DC PSU with 1 reverse-flow fan module

S60 2-port, 12 Gigabit stacking module

S60 1-port, 24 Gigabit stacking module

S60 2-port, 10GE SFP+ module

To successfully install the S60 system, ensure that you have the following:

• S60 chassis (or multiple chassis, if stacking)

• At least one grounded AC or DC power source per chassis

• Cable to connect the AC or DC power source to the chassis (the US AC power cable is included)

• Mounting brackets for rack installation (included)

• Screws for rack installation and #1 #2 Phillips screwdrivers (not included)

• Ground cable (not included)

• Ground cable screws (included)

• Copper/fiber cables

Other optional components are:

• Additional PSU

• Additional fan module

• Optional modules, if needed

• Stacking cables, if stacking

The S60 System | 7

Page 8

Features

The S60 offers the following:

• S60 CPU and switch processor

• Up to 12 stacked systems

• Stackable switch features

• 19-inch rack-mountable

• Standard 1U chassis height

• Hot-swappable optional modules, PSUs, and fan modules

• Integrated PSU/fan module (three fans per module)

• Up to 16K MAC address entries supported with hardware-assisted aging

• Supports 9K jumbo frames

Ports

• Optional ports supporting two 2-port, 10G SFP+ modules

• 44 fixed 10/100/1000 Mbps auto-sensing and auto-MDIX RJ45 ports

• Four fixed ports supporting 100/1000 Base-T or 1000 Base-X using auto-media detection

• Optional ports supporting one 2-port, 24G stacking module or two 1-port, 12G stacking modules

• Console port

• Universal Serial Bus (USB)-A port

• USB-B port

System Status

You can view S60 status information in several ways, including physical displays and boot menu options.

You can also view status information through the Command Line Interface (CLI) show commands and

with Simple Network Management Protocol (SNMP) traps. For more information about these options,

refer to the FTOS Command Line Refer ence Guide for the S60 System and the FTOS Configu ration Guide

for the S60 System.

LED Displays

As shown in

Stacking ID is at the top right corner on the rear of the system and is shown in hexidecimal form. A small

decimal at the bottom right of the LED indicates the stack master.

NOTE: The stacking LED display is not applicable to the first release of the S60 system.

Figure 2-3

, the S60 rear panel contains several sets of Light Emitting Diodes (LEDs). The

The S60 System | 8

Page 9

Figure 2-3. Stack ID Hexidecimal Display

• The stack master indicator displays:

• Stack Master—decimal LED ON

• Stack standby—decimal LED blinking

• Member—decimal LED Off

• Below the Stack ID LED and above the optional module ports are four LEDs that display the system

status (Table 2-1). From left to right they are:

• power

•alarm

•PSU0

•PSU1

Table 2-1. System LED Displays

Label LED Color/Display Description

Power (PWR) Green Blinking

Green

Yellow

Power Supply

(PSU0)

Power Supply

(PSU1)

Green

Yellow

Green

Yellow

System is booting up.

System power supply is OK.

System power supply is operating outside the expected parameters.

All fans are OK.

At least one fan is operating outside the expected parameters.

All fans are OK.

At least one fan is operating outside the expected parameters.

The S60 System | 9

Page 10

In addition to the system LEDs, each port has status indicator LEDs.

displays.

T able 2-2. Port LED Displays

Feature Description

10/100/1000 Port LEDs • Link LED (on the left side of each port):

Green—1000M

Yellow—10/100M

Off—No link

• Activity LED (on the right side of each port):

Green—Link up on this port, full traffic

Blinking Green—Activity, transmitting or receiving packet at this port.

Off—No traffic

SFP+ Port LED • Link/Activity LED:

Green—Link up on this port, no activity taking place

Blinking Green—Activity, transmitting or receiving packet at this port.

Off—No link detected at this port

Stacking Module LEDs • Link/Activity LED:

Green—Link up on this port, no activity taking place

Blinking Green—Activity, transmitting or receiving packet in link up state

Off—No Link detected at this port

Table 2-2

lists the port LED

The S60 System | 10

Page 11

3

Install the S60 System

To install the S60 system, Dell Force10 recommends completing the installation procedures in the order

presented in this chapter.

Always handle the S60 system and its components with care. Avoid dropping the system or its Field

Replaceable Units (FRUs).

This chapter describes the installation procedures as follows:

1

Install the S60 System in a Rack or Cabinet

a

Attach the Mounting Brackets

b

Install the Chassis into the Rack or Cabinet

2

Attach the Ground Cable

3

Insert Optional Modules

4

Connect Stacking Ports (Optional)

5

Supply Power and Power Up the System

WARNING: Electrostatic discharge (ESD) damage can occur if the components are mishandled. Always wear

an ESD-preventive wrist or heel ground strap when handling the S60 system and its components. As with all

electrical devices, take all the necessary safety precautions to prevent injury when installing this system.

Install the S60 System in a Rack or Cabinet

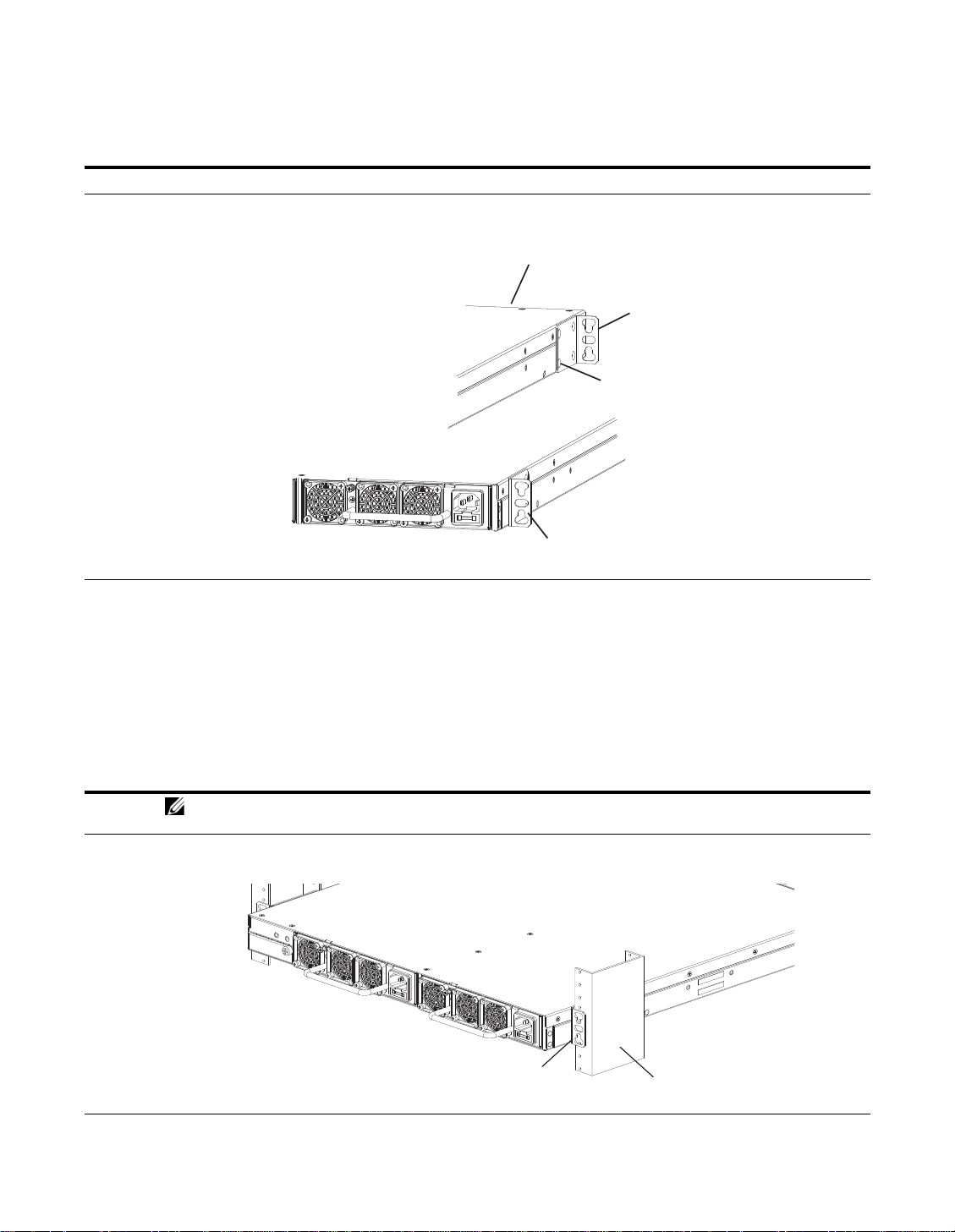

Attach the Mounting Brackets

The S60 system is shipped with mounting brackets (rack ears) and the required screws for rack or cabinet

installation. The brackets are enclosed in a package with the chassis.

NOTE: Dell Networking recommends attaching the brackets to the front of the chassis on the Power Supply

Unit (PSU) side. This provides the greatest weight support for the chassis in the rack or cabinet and is in

compliance with Bellcore Zone 4 earthquake requirements.

Install the S60 System | 11

Page 12

To attach the brackets to the chassis, follow these steps:

Power Supply

Power Supply

Screws

Connect to

rack/cabinet

(ear)

Connect to

rack/cabinet

(ear)

View of chassis front

View from chassis rear

Rack/Cabinet

Post

Rack Mounting

"ears"

PSU0

PSU1

Step Task

1 Take the brackets and screws out of their packaging.

2 Attach the brackets to the rear sides of the chassis using four screws for each bracket. Attach the bracket so that

the “ear” faces to the rear and the outside of the chassis.

Install the Chassis into the Rack or Cabinet

To permit access and airflow, ensure that there is adequate clearance surrounding the rack or within the

cabinet. When you install two S60 systems near each other, to permit proper airflow, position the two

chassis at least five inches (12.7 cm) apart.

T o install a switch into a two-post 19-inch equipment rack, using the already attached mounting brackets,

follow these steps:

Step Task

NOTE: Dell Networking recommends one person holding the S60 chassis in place while another person

attaches the brackets to the posts.

1 Attach the bracket “ears” to the rack or cabinet posts using two screws for each bracket. Ensure the screws are

tightened firmly.

Install the S60 System | 12

Page 13

Attach the Ground Cable

1

2

The S60 system is shipped with two 10-32 screws to attach a ground cable to the system. The cable is not

included. T o properly ground the system, Dell Networking recommends using a 6AWG two-hole lug, #10

hole size, 63" spacing (not included). The two-hole lug must be a UL recognized, crimp-type lug.

NOTE: Coat the two-hole lug with an anti-oxidant compound prior to crimping. Bring any un-plated mating

surfaces to a shiny finish and coat with an anti-oxidant prior to mating. Plated mating surfaces must be clean

and free from contamination.

NOTE: The rack installation “ears” are not suitable for grounding.

CAUTION: Grounding conductors must be made of copper. Do not use aluminum conductors.

To connect the ground cable to the system, follow these steps:

Step Task

1 Take the two 10-32 screws from the package.

2 Cut the cable to the desired length. The cable length must facilitate the proper operation of the fault interrupt

circuits. Dell Networking recommends using the shortest cable route allowable.

3 Attach the two-hole lug to the system using the supplied 10-32 screws with captive internal tooth lock washers.

Torque the screws to 20 in-lbs.

4 Attach the other end of the ground cable to a suitable ground point. The rack installation “ears” are not a suitable

grounding point.

Install the S60 System | 13

Page 14

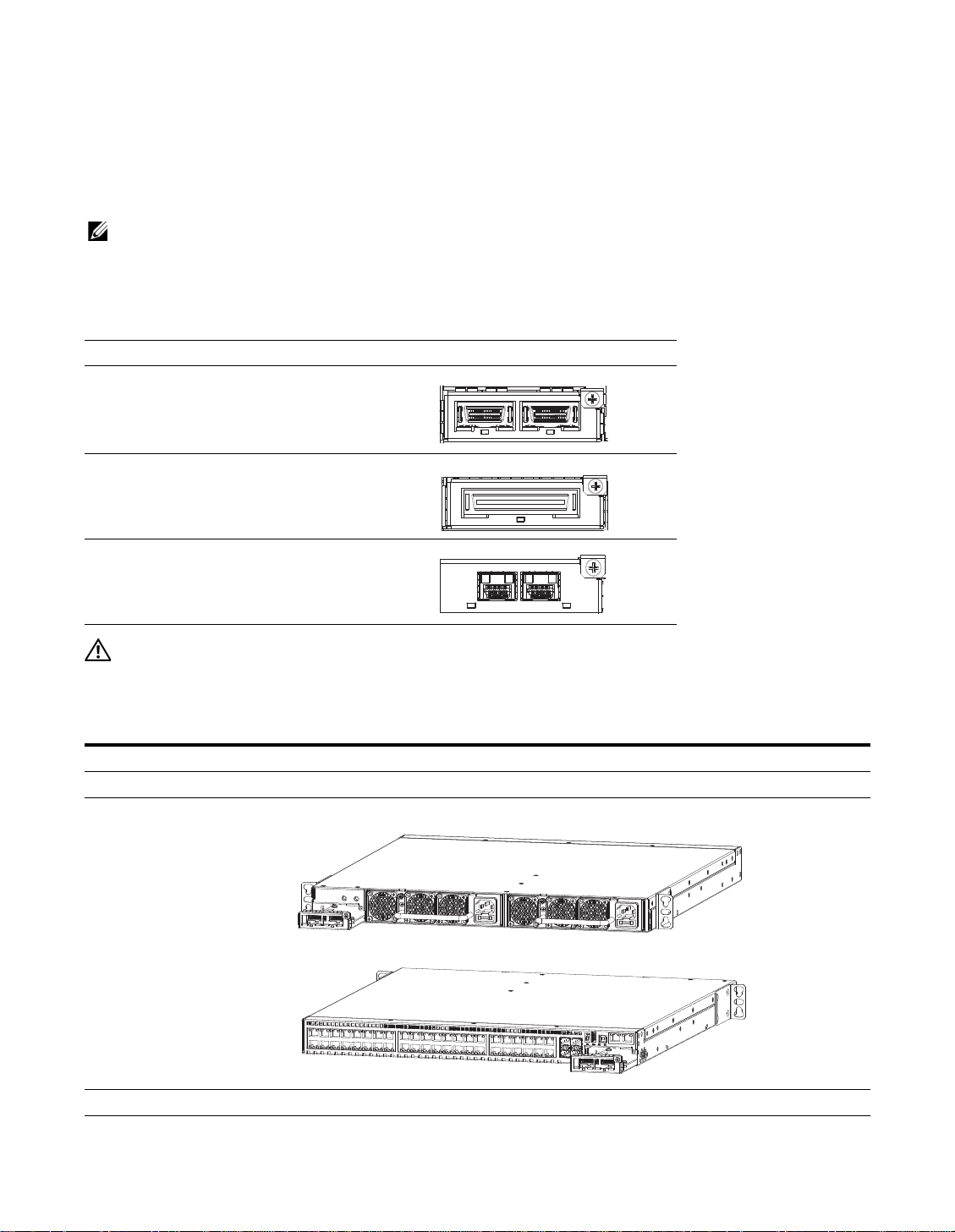

Insert Optional Modules

The S60 system has expansion slots at the front left and rear right of the system that you can use for

stacking modules or for Small Form-Factor Pluggable Plus (SFP+) devices.

modules that you can install into these expansion slots. The optional modules are hot-swappable.

NOTE: Pre-configuring the interfaces for the optical module preserves the configuration if and when you

remove an optical module. The optional 10G optical module is automatically recognized and the interfaces are

created when you insert the module into the slot. However, if the system is not already configured for the

interfaces, when you remove the optional module, the interfaces and their configurations are removed as well.

Table 3-1. Optional Modules

Module Description

2-port, 12G stacking module

1-port, 24G stacking module

2-port, 10G SFP+ optical module

Table 3-1

lists the optional

WARNING: ESD damage can occur if the components are mishandled. Always wear an ESD-preventive wrist

or heel ground strap when handling the S60 system and its components.

To install an optional module, follow these steps:

Step Task

1 Remove the faceplate covering the module slot located at the rear left or front right of the S60 system.

2 Remove the optional module from its packaging.

3 Slide the optional module into the slot.

4 Secure the captive screw on the side of the optional module.

Install the S60 System | 14

Page 15

Install the SFP and SFP+ Optics

In addition to the optional SFP+ optical modules, the S60 system has four Small Form-Factor Pluggable

(SFP) optical ports in the front of the system.

WARNING: ESD damage can occur if the components are mishandled. Always wear an ESD-preventive wrist

or heel ground strap when handling the S60 system and its components.

WARNING: When working with optical fibers, follow all warning labels and always wear eye protection. Never

look directly into the end of a terminated or unterminated fiber or connector as it may cause eye damage.

To install SFP or SFP+ optics into an open port, follow these steps:

Step Task

1 Position the SFP or SFP+ optic so it is in the correct position. The optic has a key that prevents it from being

inserted incorrectly.

2 Insert the optic into the port until it gently snaps into place.

Connect Stacking Ports (Optional)

Before you make your stacking port connections, rack-mount the S60 system or insert it into a cabinet.

Insert one end of the stacking cable into a stacking port and insert the other end into a stacking port of the

adjacent system. To ensure the cable is secure in the connector, hand-tighten all the captive screws.

To configure as a unified system, Dell Networking supports stacking connections of up to 12 S60

systems.

NOTE: The S60 system does not stack with other S-Series systems.

You can connect the stacking systems while they are powered down or up. Both ring topology and

cascade topology connections are supported (

Figure 3-1

and

Figure 3-2

). The stacking ports are

bi-directional.

If you use the 2-port, 12G stacking module, the stacking ports are labeled 48-49 on the rear (ethernet

port) side and 50-51 on the front (PSU) side.

If you use the 2-port, 24G stacking module, the stacking ports are labeled 48 on the rear (ethernet port)

side and 50 on the front (PSU) side.

Important Point s to Know

• Do not mix stacking modules. Use either the 1-port, 24G stacking module or the 2-port, 12G stacking

module within a single stack. You cannot cable from a 1-port module to a 2-port module.

• Y ou can install the S60 optional modules on either the back or front side of the system. Dell Networking

supports cabling between the front and the back side stacking modules. If you need to reach from one

side of the system to the other side, be sure to use a cable of suitable length.

• To connect the systems, use only the supported stacking cables.

The S60 system supports stacking in either a ring or cascade topology (

Figure 3-1

and

Figure 3-2

). When

stacking S60 systems, to provide redundant connectivity, Dell Networking recommends using the ring

topology.

Install the S60 System | 15

Page 16

Figure 3-1. S60 Stacking Topology with 2-port, 12G Stacking Modules

Ring Topology

(with 2-port 12G modules)

Switch 1

Switch 2

Switch 3

Cascade Topology

(with 2-port 12G modules)

Switch 1

Switch 2

Switch 3

48

48

48

49

49

49

48 49

48 49

48 49

Ring Topology

(with 1-port 24G modules)

Switch 1

Switch 2

Switch 3

Cascade Topology

(with 1-port 24G modules)

Switch 1

Switch 2

Switch 3

50

48

48

48

48

48

48

50

50

50

50

50

Figure 3-2. S60 Stacking Topology with 1-port, 24G Stacking Modules

While the diagram shows A-to-B connections, the ports are bi-directional so you can connect A-to-A or

B-to-B, as shown in the examples of two-switch ring topologies (

Figure 3-6

or

Before you make your stacking port connections, rack-mount the stacking systems or insert them into a

cabinet. Insert one end of the stacking cable into a stacking port and insert the other end into a stacking

) ring topologies.

Figure 3-4

) and three-switch (

Figure 3-5

port of the adjacent switch. To ensure the cable is secure in the connector, hand-tighten all the captive

screws.

Install the S60 System | 16

Page 17

Connect Two S60 Systems

2-port, 12G Stacking Modules

As an option, when using the 2-port, 12G stacking modules, insert a second cable into the other open

stack ports (

Figure 3-4

). The second cable provides both backup connectivity and increased data transfer

between the systems.

To connect 2-port, 12G stacking modules, starting with the S60 at the bottom of the stack:

Step Task

1 Insert one end of the first cable into Stack Port 48 (or 50).

2 Insert the other end of the cable into Stack Port 48 (or 50) of the top.

3 Insert a second cable into Stack Port 49 (or 51) of the bottom and top S60 systems.

Figure 3-3. Two S60 Systems with 2-port, 12G Stacking Modules Connected in a Ring Topology

1-port, 24G stacking modules

The 1-port, 24G stacking module requires the S60 systems be cabled across the front-ports-to-rear-port,

or vice versa (

Figure 3-4

).

To connect 1-port, 24G stacking modules, starting with the S60 at the bottom of the stack:

Step Task

1 Insert one end of the first cable into Stack Port 48 (or 50).

2 Insert the other end of the cable into Stack Port 50 (or 48) of the top S60 system.

3 Insert the second cable into Stack Port 50 (or 48) of the middle and top S60 systems.

Figure 3-4. Two S60 Systems with 1-port, 24G Stacking Modules Connected in a Ring Topology

Install the S60 System | 17

Page 18

Connect Three or More S60 Systems

2-port, 12G Stacking Modules

As an option, when using the 2-port, 12G stacking modules, insert a second cable into the other open

stack ports (

Figure 3-5

). The second cable provides both backup connectivity and increased data transfer

between the systems.

To connect 2-port, 12G stacking modules, starting with the S60 system at the bottom of the stack:

Step Task

1 Insert one end of the first cable into Stack Port 48 (or 50).

2 Insert the other end of the cable into Stack Port 48 (or 50) of the middle S60 system.

3 Insert the second cable into Stack Port 49 (or 51) of the middle and top S60 systems.

4 Use the remaining cable to connect the top and bottom S60 systems by inserting one end of the cable into the open

Stack Port 49 (or 51) of the bottom S60 system and the other end of the cable into Stack Port 48 (or 50) of the top

S60 system.

Figure 3-5. Three S60 Systems with 2-port, 12G Stacking Modules Connected in a Ring Topology

1-port, 24G Stacking Modules

The 1-port, 24G stacking module requires the S60 systems be cabled from the front-ports-to-rear-port, or

vice versa (

Figure 3-6

).

To connect 1-port, 24G stacking modules, starting with the S60 system at the bottom of the stack:

Step Task

1 Insert one end of the first cable into Stack Port 48 (or 50).

2 Insert the other end of the cable into Stack Port 48 (or 50) of the middle S60 system.

3 Insert the second cable into Stack Port 50 (or 48) of the middle and top S60 systems.

4 Use the remaining cable to connect the top and bottom S60 systems by inserting one end of the cable into the open

Stack Port 48 (or 50) of the bottom S60 system and the other end of the cable into Stack Port 50 (or 48) of the top

S60 system.

Install the S60 System | 18

Page 19

Figure 3-6. Three S60 Systems with 1-port, 24G Stacking Modules Connected in a Rin g Topology

Supply Power and Power Up the System

Supply power to the S60 system after you have mounted them in a rack (or on a table) and have installed

the optional modules.

Dell Networking recommends re-inspecting your system prior to powering up. Verify that:

• the equipment is properly secured to the rack and properly grounded.

• the equipment rack is properly mounted and grounded.

• the ambient temperature around the system (which may be higher than the room temperature) is within

the limits specified for the S60 system.

• there is sufficient airflow around the system.

• the input circuits are correctly sized for the loads and that you use sufficient over-current protection

devices.

• all the protective covers are in place.

• you have installed blank panels if you did not install optional modules.

NOTE: A US AC power cable is included in the shipping container for powering up an AC PSU. You must

order all other power cables separately.

WARNING: ESD damage can occur if the components are mishandled. Always wear an ESD-preventive wrist

or heel ground strap when handling the S60 system and its components.

Power Up Sequence

When the system powers up, the fans immediately come on at high speed. The fan speed slows as the

system boots up.

Install the S60 System | 19

Page 20

The PWR Light Emitting Diode (LED) blinks until the boot-up sequence is complete. When the boot up

is complete, the PWD LED is steadily lit.

The Stack ID LED displays a digit to show the position of the unit in a stacking chain. For a single

chassis, a 0 displays.

AC Power

Connect the plug to each AC receptacle (

Figure 3-7

). Ensure the power cord is secure.

As soon as the cable is connected between the S60 system and the power source, the system is

powered-up; there is no on/off switch.

Figure 3-7. AC Power Connection

DC Power

To connect DC power (

Step Task

1 Remove the small plastic cover from the DC connectors.

2 Attach the connectors to both the DC PSUs at the rear of the S60 system. Ensure the connection is secure.

3 Replace the plastic cover over the DC connectors.

4 Turn the power switch on.

Figure 3-8

), follow these steps:

Figure 3-8. DC power connection

Install the S60 System | 20

Page 21

Hot-swap Units in a Stack

You can add, remove, or swap units in an existing stack. The units in the stack and the new units can be

already powered up or they can be powered down.

All units in a stack must run the same version of the operating system. If you attempt to attach a unit with

a different version of the operating system to an existing stack, the Command Line Interface (CLI)

displays an error and the unit is not added until you install compatible software.

The order in which the units come on-line or are added to or removed from the stack can affect how the

stack identifies them and how the units identify themselves. This influences the unit numbers,

management addresses, and other elements of the configuration file.

How units are identified within the stack is determined by the selected identification algorithm. The

default algorithm has the units self-identify as Unit 1 through Unit [last] based on the order in which they

come on-line. So, when setting up a new set of switches in a stack, you should have no trouble forcing the

identification of the management unit and unit IDs by methodically supplying power to the units in your

preferred sequence.

Similarly, when you add a brand new unit to the stack, the unit will be gracefully added as Unit [last] (the

lowest unused number) with the current configuration. Attaching the unit causes each unit in the stack to

reload and the subsequent configuration file in each unit includes the awareness of the new unit.

If you have a pre-configured unit that you want to add to the stack, but you want to make sure the

configuration does not override the configuration of the stack, in order to avoid stack management

conflicts, add the unit while it is powered down.

You can use the CLI to make stack identification changes on the fly, such as renumbering units (stack-

unit unit number renumber unit number), assigning a new management unit (redundancy forcefailover stack-unit number), or removing priority or provisioning of a stack unit member (no stack-unit

unit number provision provision type). You can also use commands such as stack-unit unit number

priority value and member that override the default unit identification algorithms.

To see the current assignment of the management unit, use the show system command. To see the serial

number of the designated unit, use the show system stack-unit unit number command.

For more information about removing a unit from a stack and other stacking commands, refer to the

Stacking chapter in the FTOS Configuration Guide for the S60 System and the Stacking Commands

chapter in the FTOS Command Line Reference Guide for the S60 System.

Install the S60 System | 21

Page 22

4

Grab Handle

Securing Screw

AC Power Connector

Fans and Filters

PSU0

PSU1

Power Supplies

The S60 system is designed to support two hot-swappable power supply units (PSUs) with integrated

fans that provide the cooling for the system. There are two types of power supplies (AC or DC) and there

are two airflow directions (normal and reverse). Two PSUs are required for full redundancy, but the

system will operate with a single PSU. You can equip one of the PSU bays with a fan-only module.

For the procedure to replace only a fan module or fan filter, refer to

You can order the S60 system as an empty chassis or with either AC power (

(

Figure 4-2

installed and running), you can remove and replace one PSU while the other PSU is running without

disrupting traffic.

WARNING: To prevent electrical shock, ensure the S60 system is grounded properly. If you do not ground

WARNING: Electrostatic discharge (ESD) damage can occur if the components are mishandled. Always

). Both PSU types are field replaceable. When running with full redundancy (two PSUs

your system correctly, excessive emissions may result. Use a qualified electrician to ensure that the power

cables meet your local electrical requirements.

wear an ESD-preventive wrist or heel ground strap when handling the S60 system and its components.

Chapter 5, Fans and Filters

Figure 4-1

) or DC power

.

Components

The following power supply options are available for the S60 system:

• AC power supply with integrated fans

• AC power supply with integrated reverse flow fans

• DC power supply with integrated fans

• DC power supply with integrated reverse flow fans

Figure 4-1. AC Power Supply

Power Supplies | 22

Page 23

Figure 4-2. DC Power Supply

Grab Handle

Securing Screw

DC Power Connector

Fans and Filters

PSU0

PSU1

Power Switch

Power supply 0 (PSU0) is on the left side of the system; power supply 1 (PSU1) is on the right side of the

system.

Install an AC or DC Power Supply

The PSUs in the S60 system are field replaceable. When both PSUs are up and running, you can remove

one PSU without interrupting traffic.

The PSUs are in a single piece with the fans. You can replace the fan filters individually (in the reverse

[-R] systems), but replacing a PSU also replaces the fans attached to that PSU. For the procedure to

replace only the fan filters, refer to

Chapter 5, Fans and Filters

.

WARNING: Prevent exposure and contact with hazardous voltages. Do not attempt to operate this system

with the safety cover removed.

CAUTION: Remove the power cable from the PSU prior to removing the PSU. Also, do not connect power to

the PSU prior to inserting the PSU in the system.

NOTE: For a Network Equipment Building System (NEBS)-compliant installation, to protect the AC power

supplies from damage due to excessive power line surges, the AC power connections must use a Surge

Protection Device (SPD).

NOTE: To comply with the GR-1089 Lightning Criteria for Equipment Interfacing with AC Power Ports, use an

external SPD at the AC input of the router.

NOTE: You must isolate the DC power return conductor from the chassis or frame when you make

connections to the PSU.

To install a PSU, follow these steps:

NOTE: The PSU module slides into the slot smoothly. Do not force a module into a slot as this may damage

the PSU or the S60 system.

Step Task

1 Take the PSU out of the shipping box.

2 For DC PSUs, remove the small plastic cover over the DC connectors. Do not throw the cover away; you will

replace it when you complete the installation.

3 Use the grab handle to slide the PSU into the power supply bay.

4 Tighten the securing screw at the top of the PSU.

5 Attach the power cables.

Power Supplies | 23

Page 24

Step Task (continued)

6 For DC PSUs, replace the small plastic cover over the DC connectors.

7 • For an AC PSU, the system powers up as soon as the cables are connected between the PSU and the power

source.

• For a DC PSU, turn on the power.

Replace an AC or DC Power Supply

NOTE: If a PSU fails, you must completely replace it. There are no field servicable components in the PSU.

To request a hardware replacement, refer to

To replace a PSU, follow these steps:

Step Task

1 • For an AC PSU: disconnect the power cable from the PSU.

• For a DC PSU: IMPORTANT: Turn OFF the power switch and disconnect the power cord from the PSU.

2 For DC PSUs, remove the small plastic cover over the DC connectors. Do not throw the cover away; you will put

it back on when you complete the PSU replacement.

CAUTION: You must complete steps 3 and 4 within one minute or the system powers down.

3 Use the grab handle to slide the PSU out of the power supply bay.

4 Use the grab handle on the replacement PSU to slide it into the power supply bay.

5 Tighten the securing screws on the replacement PSU. Ensure the PSU is secure.

6 Attach the power cord to the replacement PSU.

7 For DC PSUs, replace the small plastic cover over the DC connectors.

8 • For an AC PSU, the system powers up as soon as the cables are connected between the PSU and the power

source.

• For a DC PSU, turn on the power.

Chapter 8, Technical Support

.

Power Supplies | 24

Page 25

5

Fans and Filters

The S60 system comes from the factory with one Power Supply Unit (PSU) and one fan module installed

in the system (

the integrated fan/PSU are hot-swappable. With redundant PSUs, if you remove a fan module, traffic is

not interrupted.

WARNING: To run the system, both slots must have operating fan units. If a module is not installed in each

slot (either as part of the PSU or as an independent fan module), the system powers down when it exceeds an

internal temperature threshold.

WARNING: Dell Networking recommends replacing the fan tray within five minutes. If the fan tray is left out

for too long, the system may experience traffic disruption.

The S60 system supports two airflow direction options (normal and reverse). Do not mix fan airflow

types; you can only use a single airflow direction in a system. If the airflow directions are mismatched,

the system powers down in one minute.

• Normal—airflow is from the Input/Output (I/O) panel to the PSU

• Reverse—airflow is from the PSU to the I/O panel

Environmental factors can decrease the amount of time required between air filter replacements. Check

the environmental factors regularly. An increase in temperature and/or particulate matter in the air might

affect performance (for example, new equipment installation).

Figure 5-1

). If a second (redundant) PSU is installed and running, both the fan module and

CAUTION: Check the fan air filters at six-month intervals and replace them as necessary. In order to

accurately determine air filter replacement intervals, regularly monitor the speeds of the cooling fans. An

increase in overall fan speed may indicate a clogged filter.

You must replace the S60 fan filters with new filters; you cannot clean and reuse the fan filters.

Replacement filters can be sourced online through third-party component suppliers. The fan filter is

manufactured by Qualtek Electronics Corporation and is stocked at several different online electronics

supply sites. The Qualtek part number is 09150-M/30 (on some sites the part number is referenced as

09150-M30), and provides conformance to the following standards as per the NEBS GR-63-CORE

specification:

• Minimum dust arrestance of 65%, per ASHRAE Standard 52.1-1992

OR

• Minimum Efficiency Rating Value (MERV) of 2, per ANSI/ASHRAE Standard 52.2-2007

Dell Networking does not recommend any one site to procure these filters, but you can find a link on the

filter manufacturer’s site (http://www.qualtekusa.com) that displays a list of distributors and their current

stock. Select Catalog > Fan_Accessories then scroll to part “09150-M/30*.” Click the check mark in the

Distributor Stock Check column. A list of distributors and their reported inventory displays.

CAUTION: For Network Equipment Building System (NEBS)-compliance, use the NEBS-approved filters.

These filters are colored green and are installed exactly the same as the non-NEBS filters.

Fans and Filters | 25

Page 26

Components

Grab Handle

Securing Screw

Fans and Filters

PSU0

Fan Module1

• S60 Fan module

• S60 Fan module - Reverse flow

• S60 Fan filter

• The fan filters are used on the reverse flow (R) fan modules only.

Figure 5-1. The S60 Fan Module

Module slot 0 is on the left side of the system; module slot 1 is on the right side of the system.

Install a Fan Module

The fan modules in the S60 are field replaceable. The PSUs are in a single piece with the fans. For the

procedure to replace the entire PSU, refer to

Chapter 4, Power Supplies

.

To install a fan module, follow these steps:

Step Task

1 Take the fan module out of the shipping box.

2 Use the grab handle to slide the fan module into the bay.

3 Tighten the securing screw at the top of the fan module.

Replace a Fan Module

Dell Networking recommends replacing the fan tray within five minutes. If the fan tray is left out for too

long, the system may experience traffic disruption.

Fans and Filters | 26

Page 27

Error messages appear when the fan tray is removed and when the temperature approaches the threshold.

• When a fan tray is removed, the system displays the following message:

00:00:37: %STKUNIT0-M:CP %CHMGR-2-FAN_TRAY_BAD: Major alarm: fan tray 0 in unit 0

is missing or down

• When the temperature reaches the maximum threshold (3), the system displays the following warning

message:

temperature is current temp;

00:00:38: %STKUNIT0-M:CP %CHMGR-2-TEMP_SHUTDOWN_WARN: WARNING! Unit 0

To replace a fan module, follow these steps:

Step Task

1 Loosen the securing screw at the top of the fan module.

CAUTION: You must complete steps 2 and 3 within five minutes or the system powers down. If a fan

module is not installed in each slot (either as pa rt of the PSU or as an ind ependent fan modu le), the system p owers

down when it exceeds an internal temperature threshold.

2 Use the grab handle to slide the fan module out of the bay.

3 Use the grab handle on the replacement fan module to slide it into the bay.

4 Tighten the captive screws on the replacement fan module. Ensure the fan module is secure.

Install a Fan Filter

Use the fan filters with the reverse (R) flow fan modules and PSU/fan modules only. You can replace

them individually on each fan within the module without powering down a PSU module or disrupting

traffic.

The fan filters and retainers pop into the fan guards on the module. There is no need to unscrew the filter

guard.

To install a fan filter, follow these steps:

Step Task

1 Using your fingernail, gently pry the filter retainer off the filter guard.

2 Remove the filter.

3 Replace the filter and ensure it is pressed firmly into place. Gently press the filter retainer into the filter guard

until it snaps in.

4 Repeat for all the fan filters, if necessary.

Fans and Filters | 27

Page 28

Access the Console Ports

6

You can access the S60 system directly through the console port at rear of the system (

Figure 6-1

Access the RJ-45 Console Port (RS-232)

NOTE: Before starting this procedure, be sure you have a terminal emulation program already installed on

your PC.

The RS-232 console port is labeled on the upper right-hand side on the rear of the S60 system.

Figure 6-1. S60 Serial Console Port Connector

Console

Port

For the console port pin assignments, refer to

To access the RJ-45 console port, follow these steps:.

Step Task

1 Install an RJ-45 copper cable into the console port. Use a rollover cable to connect the S60 console port to a

terminal server.

2 Connect the other end of the cable to the DTE terminal server.

3 Set the default terminal settings as follows:

• 9600 baud rate

• No parity

• 8 data bits

•1 stop bit

• No flow control

Table 6-1

.

).

Access the Console Ports | 28

Page 29

Access the RJ-45 Console Port with a DB-9 Adapter

If the DTE has a DB-9 interface, you can connect to the console port using an RJ-45 to DB-9 adapter

along with the RJ-45 rollover cable.

Table 6-1. Pin Assignments Between the E-Series Console and a DTE Te rminal Server

Table 6-1

lists the pin assignments.

E-Series Console

Port RJ-45 to RJ-45 Rollover Cable

Signal RJ-45 Pinout RJ-45 Pinout DB-9 Pin Signal

RTS 1 8 8 CTS

NC 2 7 6 DSR

TxD 3 6 2 RxD

GND 4 5 5 GND

GND 5 4 5 GND

RxD 6 3 3 TxD

NC 7 2 4 DTR

CTS 8 1 7 RTS

RJ-45 to DB-9

Adapter

Terminal Server Device

Access the USB-B Console Port

The S60 system has two management ports available for system access: a console port and a Universal

Serial Bus (USB)-B port (

settings are the same. When the USB-B drive is connected, the S60 system sends all messages to it.

The USB-B connector port is labeled on the left of the management ports on the rear of the S60 system.

Figure 6-2. S60 USB-B Port Connector

Figure 6-2

). The USB-B ports act exactly as the console port. The terminal

USB-B

Port

When you connect both the console port and the USB-B port, the S60 system defaults to the USB-B port.

If the USB-B port is connected, the console connection is considered inactive.

NOTE: Before starting this procedure, be sure you have a terminal emulation program already installed on

your PC. You will also require the appropriate drivers for the USB device in use. For assistance, contact Dell

Networking Technical Support.

Access the Console Ports | 29

Page 30

To access the USB-B console port, follow these steps:

Step Task

1 Power on the PC (Dell Force 10 recommends using an XP operating system).

2 Connect the USB-A end of cable (included) into an available USB port on the PC.

3 Connect the USB-B end of cable into the USB-B console port on the S60 system.

4 Power on the S60 system.

5 Install the necessary USB device drivers (an internet connection is required). For assistance, contact Dell

Networking Technical Support.

6 Open your terminal software emulation program to access the S60 system.

7 Set the terminal connection settings as follows:

• 9600 baud rate

• No parity

• 8 data bits

•1 stop bit

• No flow control

8 The CLI command prompt appears when you are connected to the S60 system.

Access the Console Ports | 30

Page 31

S60 Specifications

This chapter the following sections:

• Chassis Physical Design

• Agency Compliance

Chassis Physical Design

Parameter Specifications

Height 1.7 inches (4.3 cm)

Width 17.32 inches (44.0 cm)

Depth 16.73 inches (42.5 cm)

Chassis weight with factory-installed components 14.39 pounds (approx.) (6.54 kg)

Rack clearance required Front: 5-inches (12.7 cm)

Rear: 5-inches (12.7 cm)

Thermal dissipation 597 BTU/hr

Power consumption 175 Watts (nominal)

225 Watts (maximum)

7

Environmental Parameters

Parameter Specifications

Temperature 32° to 122°F (0° to 50°C)

-40° to 158°F (-40° to 70°C) non-operating

Maximum altitude No performance degradation to 10,000 feet (3,048 meters)

Relative humidity 10 to 85% non-condensing

5 to 95% non-condensing (non-operating)

Shock MIL-STD-810

Vibratio n Bellcore GR-63

AC Power Requirements

Parameter Specifications

Nominal input voltage 100 to 240 VAC, 50/60 Hz

Maximum AC power supply input current 2 A at 100/120 VAC

Maximum system power input 225 W

S60 Specifications | 31

Page 32

DC Power Requirements

Parameter Specifications

Nominal input voltage –40 to – 60 VDC

Maximum power supply input current 3.6 A at -48 VDC

Maximum system power input 225 W

IEEE Standards

The S60 complies with the following IEEE standards:

• 802.3ae 10 Gigabit Ethernet

• 802.3ab 1000Base-T

• 802.1p L2 Prioritization

• 802.1Q VLAN Tagging, Double VLAN Tagging (Q in Q), GVRP

• 802.1s Multiple Spanning Tree Protocol

• 802.1w Rapid Spanning Tree Protocol

• 802.3ad Link Aggregation with LACP

• 802.1D Bridging, GARP, GMRP

• 802.3x Flow Control

• 802.1ac Frame Extension for VLAN tagging

• 802.1x Port based Network Access Control

Agency Compliance

The S60 system is designed to comply with the following safety and agency requirements.

Network Equipment Building Systems (NEBS) Compliance

• Use shielded cables for ports 0 - 43. The shields must be grounded at both ends.

• You can only use reverse airflow configurations in a NEBS-compliant installation. Use only supported

Dell S60 AC power supply units, DC power supply units, and fans.

• You must fit the Power Supply Units (PSUs) and fan modules with the supported Dell S60 filter kits.

You must replace the fan filters on a regular basis.

• Use this equipment with an external second-level 6kV lightning Surge Protection Device (SPD) at the

AC input of the building.

• For the NEBS-compliant installation, in order to protect the AC PSUs from damage due to excessive

power line surges, AC power connections must use a SPD.

• In order to comply with the GR-1089 Lightning Cri teria for Equipment Interfacing with AC Power

Ports, use an external SPD at the AC input of the router.

S60 Specifications | 32

Page 33

WARNING: Electrostatic discharge (ESD) damage can occur if the components are mishandled. Always

wear an ESD-preventive wrist or heel ground strap when handling the S60 system and its components.

CAUTION: The intra-building port(s) of the equipment or sub-assembly is suitable for connection to

intra-building or unexposed wiring or cabling only. The intra-building port(s) of the equipment or sub-assembly

MUST NOT be metallically connected to interfaces that connect to the OSP or its wiring. These interfaces are

designed for use as intra-building interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE,

Issue 5) and require isolation from the exposed OSP cabling. The addition of Primary Protectors is not

sufficient protection in order to connect these interfaces metallically to OSP wiring.

USA Federal Communications Commission (FCC) Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designated to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy. If it is not installed and used in accordance to the

instructions, it may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case users will be required to take

whatever measures necessary to correct the interference at their own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission

limits. Dell Networking is not responsible for any radio or television interference caused by using other

than recommended cables and connectors or by unauthorized changes or modifications in the equipment.

Unauthorized changes or modification could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Canadian Department of Communication Statement

S60 Specifications | 33

Page 34

European Union EMC Directive Conformance Statement

This product is in conformity with the protection requirements of EU Council Directive 2004/108/EC on

the approximation of the laws of the Member States relating to electromagnetic compatibility. Dell

Networking cannot accept responsibility for any failure to satisfy the protection requirements resulting

from a non-recommended modification of this product, including the fitting of non-Dell Networking

option cards.

This product has been tested and found to comply with the limits for Class A Information Technology

Equipment according to CISPR 22/European Standard EN 55022. The limits for Class A equipment were

derived for commercial and industrial environments to provide reasonable protection against interference

with licensed communication equipment.

WARNING: This is a Class A product. In a domestic environment, this device may cause radio interference, in

which case, you may be required to take adequate measures.

European Community Contact

For regulatory compliance, refer to

www.dell.com/regulatory_compliance

Japan: VCCI Compliance for Class A Equipment

This is Class A product based on the standard of the Voluntary Control Council For Interference by

Information Technology Equipment (VCCI). If this equipment is used in a domestic environment, radio

disturbance may arise. When such trouble occurs, the user may be required to take corrective actions.

WARNING: AC Power cords are for use with Dell Networking equipment only. Do not use Dell Networking AC

power cords with any unauthorized hardware.

S60 Specifications | 34

Page 35

Korea Compliance

Korea Information

China Compliance

Safety Standards and Compliance Agency Certifications

• CUS UL 60950-1, 1st Edition

• CSA 60950-1-03, 2nd Edition

• EN 60950-1, 2nd Edition

• EN 60825-1, 1st Edition

• EN 60825-1 Safety of Laser Products—Part 1: Equipment Classification Requirements and User’s

Guide

S60 Specifications | 35

Page 36

• EN 60825-2 Safety of Laser Products—Part 2: Safety of Optical Fibre Communication Systems

• FDA Regulation 21CFR 1040.10 and 1040.11

• IEC 60950-1, 2nd Ed, including all National Deviations and Group Differences

Electromagnetic Compatibility (EMC)

Emissions

• International: CISPR 22: 2006, Class A

• Australia/New Zealand: AS/NZS CISPR 22: 2006, Class A

• Canada: ICES-003, Issue-4, Class A

• Europe: EN55022 2006 (CISPR 22: 2006), Class A

• Japan: VCCI V3/ 2007.04 Class A

• USA: FCC CFR47 Part 15, Subpart B, Class A

Immunity

• EN 300 386 v1.3.3: 2005 EMC for Network Equipment

• EN55022 2006, Class A

• EN 55024 1998 + A1: 2001 + A2: 2003

• EN 61000-3-2 Harmonic Current Emissions

• EN 61000-3-3 Voltage Fluctuations and Flic ker

• EN 61000-4-2 ESD

• EN 61000-4-3 Radiated Immunity

• EN 61000-4-4 EFT

• EN 61000-4-5 Surge

• EN 61000-4-6 Low Frequency Conducted Immunity

Product Recycling and Disposal

You must recycle or discard this system according to the applicable local and national regulations. Dell

Networking encourages owners of information technology (IT) equipment to responsibly recycle their

equipment when it is no longer needed. Dell Networking offers a variety of product return programs and

services in several countries to assist equipment owners in recycling their IT products.

Waste Electrical and Electronic Equipment (WEEE) Directive for Recovery, Recycle and Reuse of IT and

Telecommunications Products

Dell Networking equipment is labeled in accordance with European Directive 2002/96/EC concerning

waste electrical and electronic equipment (WEEE). The Directive determines the framework for the

return and recycling of used appliances as applicable throughout the European Union. This label is

applied to various products to indicate that the product is not to be thrown away, but rather reclaimed

upon end of life per this Directive.

S60 Specifications | 36

Page 37

Figure 7-1. The European WEEE symbo

l

In accordance with the European WEEE Directive, electrical and electronic equipment (EEE) is to be

collected separately and to be reused, recycled, or recovered at end of life. Users of EEE with the WEEE

marking per Annex IV of the WEEE Directive, as shown above, must not dispose of end of life EEE as

unsorted municipal waste, but use the collection framework available to customers for the return,

recycling and recovery of WEEE. Customer participation is important to minimize any potential effects

of EEE on the environment and human health due to the potential presence of hazardous substances in

EEE.

Dell Networking products, which fall within the scope of the WEEE, are labeled with the crossed-out

wheelie-bin symbol, as shown above, as required by WEEE.

For information on Dell Networking product recycling offerings, see the WEEE Recycling instructions

at:

http://www.euro.dell.com/recycling

For more information, contact the Dell Networking Technical Assistance Center (TAC) (see

the Technical Assistance Center

.

Contacting

).

SD Card Removal

To support high-security environments, you can remove and re-install the SD card. Dell Networking

recommends only removing the card when necessary. Only authorized personnel should remove and

replace the card.

CAUTION: Only remove the SD card to support high-security operations and after discussions with Dell

Networking Technical Support or your Dell Networking representative.

To remove the SD card, follow these steps:

Step Task

1 Remove the small Phillips screws that connect the top to the body. There are three screws evenly spaced across

the rear and three screws evenly spaced along each side of the case.

2 Slide the top backwards until its front flange slides free of the faceplate. Lift it off.

3 Gently push the SD card to release it from the slot.

S60 Specifications | 37

Page 38

Step Task (continued)

4 Remove the card.

Battery Replacement and Recycling

CAUTION: The lithium battery is not field replaceable. Only authorized personnel should remove and replace

the lithium battery. If the battery requires replacement, contact Dell Networking Technical Support.

WARNING: ESD damage can occur if the components are mishandled. Always wear an ESD-preventive

wrist or heel ground strap when handling the S60 system and its components. As with all electrical devices,

take all the necessary safety precautions to prevent injury when installing this system.

To remove the battery, follow these steps:

Step Task

1 Remove the small Phillips screws that connect the top to the body. There are three evenly spaced screws across

the rear and three evenly spaced screws along each side.

2 Slide the top backwards until its front flange slides free of the faceplate. Lift it off.

3 Insert a small, flat screw driver blade under the battery and in one of the slots of the plastic retainer underneath the

battery.

S60 Specifications | 38

Page 39

Step Task (continued)

4 Lever the battery up against the coin cell clip (the hold-down lead on top of the battery) far enough to provide

room for the battery to be lifted above the edge of its retainer, as shown.

Batteries or packaging for batteries are labeled in accordance with European Directive 2006/66/EC

concerning batteries and accumulators and waste batteries and accumulators. The Directive determines

the framework for the return and recycling of used batteries and accumulators as applicable throughout

the European Union. This label is applied to various batteries to indicate that the battery is not to be

thrown away, but rather reclaimed upon end of life per this Directive.

In accordance with the European Directive 2006/66/EC, batteries and accumulators are labeled to

indicate that they are to be collected separately and recycled at end of life. The label on the battery may

also include a chemical symbol for the metal concerned in the battery (Pb for lead, Hg for mercury and

Cd for cadmium). Users of batteries and accumulators must not dispose of batteries and accumulators as

unsorted municipal waste, but use the collection framework available to customers for the return,

recycling and treatment of batteries and accumulators.

The lithium battery in this system contains less than the maximum concentrations of hazardous

materials, as specified in the China RoHS Disclosure Table (included with the chassis).

Customer participation is important to minimize any potential effects of batteries and accumulators on the

environment and human health due to the potential presence of hazardous substances. For proper

collection and treatment, contact your local Dell Networking representative.

S60 Specifications | 39

Page 40

For California:

Perchlorate Material — Special handling may apply.

http://www.dtsc.ca.gov/hazardouswaste/perchlorate

See:

The foregoing notice is provided in accordance with California Code of Regulations Title 22, Division

4.5 Chapter 33. Best Management Practices for Perchlorate Materials.

S60 Specifications | 40

Page 41

8

Technical Support

This appendix contains the following sections:

• The iSupport Website

• Contacting the Technical Assistance Center

• Requesting a Hardware Replacement

The iSupport Website

iSupport provides a range of documents and tools to assist you with effectively using Dell Networking

equipment and mitigating the impact of network outages. Through iSupport you can obtain technical

information regarding Dell Networking products, access to software upgrades and patches, and open and

manage your Technical Assistance Center (TAC) cases. Dell Networking iSupport provides integrated,

secure access to these services.

Accessing iSupport Services

The URL for iSupport is

iSupport services, you must have a userid and password. If you do not have one, you can request one at

the website.

To request a userid and password, follow these steps:

Step Task

1 On the Dell Networking Support page, click the Account Request link.

2 Fill out the User Account Request form, and click Send. You will receive your userid and password by E-mail.

3 To access iSupport services, click the LOGIN link and enter your userid and pass word.

https://www.force10networks.com/CSPortal20/Main/SupportMain.aspx

.

To access

Technical Support | 41

Page 42

Contacting the Technical Assistance Center

How to Contact Dell

Networking TAC

Information to Submit When

Opening a Support Case

Managing Your Case

Downloading Software

Updates

Technical Documentation

Contact Information

Log in to iSupport at http://support.dell.com/force10 and select the Service Request tab.

• Your name, company name, phone number, and E-mail address

• Preferred method of contact

• Model number

• Software version number

• Serial number (required)

• Dell Service Tag (required)

• Chassis color (required)

• Symptom description

• Screen shots show the symptom, including any error messages. These can include:

• Output from the show tech-support [non-paged] command (This report is very long

so set the storage buffer in your terminal program to high.)

• Output from the show logging eventlog [unit] command, where unit is the stack ID of

the member unit that experienced the failure (This report is included as a section in the

output of show tech-support [non-paged] command.)

• Console captures showing the error messages

• Console captures showing the troubleshooting steps taken

• Saved messages to a syslog server, if you use one

Log in to iSupport and select the Service Request tab to view all open cases and Return

Materials Authorizations (RMAs).

Log in to iSupport and select the Software Center tab.

Log in to iSupport and select the Documents tab. Y ou can access this page without logging

in using the Documentation link on the iSupport page.

E-mail: Dell-Force10_Technical_Support@Dell.com

Web: http://support.dell.com/force10.

Telephone:

• US and Canada: 866.965.5800

• International: 408.965.5800

Technical Support | 42

Page 43

Requesting a Hardware Replacement

To request replacement hardware, follow these steps:

Step Task

1 Determine the part number and serial number of the component. To list the numbers for all components installed in

the chassis, use the show hardware command.

2 Request a Return Materials Authorization (RMA) number from the Technical Assistance Center (TAC) by opening a

support case. Open a support case by:

• Using the Create Service Request form on the iSupport page (refer to

• Contacting Dell Networking directly by E-mail or by phone (refer to

Provide the following information when using E-mail or phone:

• Part number, description, and serial number of the component.

• Your name, organization name, telephone number, fax number, and E-mail address.

• Shipping address for the replacement component, including a contact name, phone number, and E-mail address.

• A description of the failure, including log messages. This generally include:

– Output from the show tech-support [non-paged] command (This report is very long so set the storage buffer in

your terminal program to high.)

– Output from the show logging eventlog [unit] command, where the unit is the stack ID of the member unit that

experienced the failure (This report is included as a section in the output of show tech-support [non-paged]

command.)

– Console captures showing the error messages

– Console captures showing the troubleshooting steps taken

– Saved messages to a syslog server, if you use one

Contacting the Technical Assistance Center

Contacting the Technical Assistance Center

).

).

Technical Support | 43

Page 44

Page 45

Printed in the U.S.A.

www.dell.com | support.dell.com

Loading...

Loading...