Page 1

E600i TeraScale

Installation Guide

Page 2

Notes, Cautions, and Warnings

NOTE: A NOTE indicates important information that helps you make better use of your computer.

CAUTION: A CAUTION indicates potential damage to hardware or loss of data if instructions are not

followed.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

Information in this publication is subject to change without notice.

© 2011 Dell Force10. All rights reserved.

Reproduction of these materials in any manner whatsoever without the written permission of Dell Inc. is strictly forbidden.

Trademarks used in this text: Dell™, the DELL logo, Dell Precision™, OptiPlex™, Latitude™, PowerEdge™, PowerVault™,

PowerConnect™, OpenManage™, EqualLogic™, KACE™, FlexAddress™ and Vostro™ are trademarks of Dell Inc. Intel

®

Xeon

, Core™ and Celeron® are registered trademarks of Intel Corporation in the U.S. and other countries. AMD® is a registered trademark

and AMD Opteron™, AMD Phenom™, and AMD Sempron™ are trademarks of Advanced Micro Devices, Inc. Microsoft

Windows Server

States and/or other countries. Red Hat Enterprise Linux

and/or other countries. Novell

®

Oracle

is a registered trademark of Oracle Corporation and/or its affiliates. Citrix®, Xen®, XenServer® and XenMotion® are either registered

trademarks or trademarks of Citrix Systems, Inc. in the United States and/or other countries. VMware

and vSphere

®

, MS-DOS® and Windows Vista® are either trademarks or registered trademarks of Microsoft Corporation in the United

®

is a registered trademark and SUSE ™ is a trademark of Novell Inc. in the United States and other countries.

®

are registered trademarks or trademarks of VMWare, Inc. in the United States or other countries.

®

and Enterprise Linux® are registered trademarks of Red Hat, Inc. in the United States

®

, Virtual SMP®, vMotion®, vCenter®,

®

, Pentium®,

®

, Windows®,

Other trademarks and trade names may be used in this publication to refer to either the entities claiming the marks and names or their products.

Dell Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

December 2011 P/N 101-00040-04

Page 3

Contents

1 About This Guide

Information Symbols and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Site Preparation

Site Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Equipment Rack and Cabinet Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2500W AC Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DC Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Storage Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 The E600i System

Operating Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

E600i System Installation Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Installing the Chassis

Unpacking the E600i System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing the Equipment Rack Shelf Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Standard Front Chassis Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installing the Chassis into an Equipment Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Installing the Fan Tray

Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Power Supply

AC Power Supply Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Cord Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Install the AC Power Supply Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Remove the AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DC Power Entry Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cable and Connector Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Install the DC PEMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Replace the DC PEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Contents | 3

Page 4

7 Installing RPMs, Line Cards, and SFMs

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Line Cards and RPMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

RPMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Line Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Blank Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Preparing and Installing the RPMs and Line Cards . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing a Second RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

RPM Label and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Line Card LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

www.dell.com | support.dell.com

Installing Switch Fabric Modules (SFMs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SFM Front Panel and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8 RPM Ports and Cables

RPM Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connecting the Console and Auxiliary Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cable and Adapter Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Accessing the Console with a DB-9 Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Accessing the Console with a DB-25 Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Accessing the Auxiliary Port by Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Accessing the 10/100 Ethernet Management Port . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9 Powering Up

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Supplying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Booting to the CLI Prompt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Booting from the BOOT_USER Prompt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10 Removing and Replacing Parts

Removing and Replacing the Fan Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Removing and Replacing Power Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replacing 2500W AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replacing DC PEMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Removing and Replacing RPMs, Line Cards, or SFMs . . . . . . . . . . . . . . . . . . . . . . 46

Removing and Replacing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11 Using a Flash Memory Card

External Flash Memory Card Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Inserting the External Flash Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Removing the External Flash Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4 | Contents

Page 5

Formatting an External Flash Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Copying Files to the External Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Displaying Files Stored on the External Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

A System Boot

The E600i System Boot Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Booting from the BOOT_USER Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

B Alarms

AC Power Supplies and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

SFMs and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

C System Specifications

Chassis Physical Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

AC Power Supply Unit Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

DC Power Entry Module Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

SFM and RPM Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Safety Standards and Compliance Agency Certifications . . . . . . . . . . . . . . . . . 69

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Product Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

D Technical Support

The iSupport Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Accessing iSupport Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Contacting the Technical Assistance Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Requesting a Hardware Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Contents | 5

Page 6

www.dell.com | support.dell.com

6 | Contents

Page 7

1

About This Guide

This guide provides site preparation recommendations, step-by-step procedures to rack mount the Dell

Force10 E600i chassis, as well as instructions to install fan tray , power modules, route processor modules

(RPMs), switch fabric modules (SFMs), and line cards.

This guide also includes instructions to remove and install field-replaceable parts. The E600i system is

packaged with components necessary for optimal performance, including panel blanks for RPM, SFM,

and line card slots, and, as required, power supply. Blanks are required in empty slots to ensure adequate

system cooling and for EMI containment during operation.

After you have completed the hardware installation process and power up the system, refer to the FTOS

Configuration Guide for preliminary software configuration information.The E600i systems runs Dell

Force10 OS (FTOS™) software. The FTOS Command Reference provides detailed CLI information and

the FTOS Configuration Guide includes FTOS configuration information.

Information Symbols and Warnings

Table 1-1

Table 1-1. Information Symbols

Symbol Warning Description

describes symbols contained in this guide.

Note This symbol informs you of important operational information.

Caution This symbol informs you that improper handling and installation could result in equipment damage

or loss of data.

Warning This symbol signals information about hardware handling that could result in injury.

WARNING: The installation of this equipment shall be performed by trained and qualified personnel only.

Read this guide before installing and powering up this equipment. This equipment contains two power cords.

Disconnect both power cords before servicing.

WARNING: This equipment contains optical transceivers, which comply with the limits of Class 1 laser

radiation.

WARNING: Visible and invisible laser radiation may be emitted from the aperture of the optical transceiver

ports when no cable is connected. Avoid exposure to laser radiation and do not stare into open apertures.

About This Guide | 7

Page 8

CAUTION: Wear grounding wrist straps when handling this equipment to avoid ESD damage.

CAUTION: Earthing (AKA grounding) connection essential before connecting supply. Always make the

ground connection first and disconnect it last.

CAUTION: Disposal of this equipment should be handled according to all national laws and regulations. See

Product Recycling and Disposal on page 69

.

Related Publications

For more information about the E600i system, refer to the following documents:

•

FTOS Configuration Guide

FTOS Command Reference

•

www.dell.com | support.dell.com

• Release Notes for the E-Series

8 | About This Guide

Page 9

2

Site Preparation

This chapter describes the requirements for the room, rack, and cabinet in which you will install your

system.

• Site Selection

• Equipment Rack and Cabinet Requirements

• Power Requirements

• Storage Requirements

Site Selection

Before you begin, make sure that the area where you intend to install your system meets the following

requirements:

1 The site is in a restricted access area.

2 The site is a dry, clean, well-ventilated, and temperature-controlled room, away from heat sources

such as hot air vents or direct sunlight.

3 The site is away from sources of severe electromagnetic noise.

4 The site is near an adequate power source. Connect the system to the appropriate branch circuit

protection as defined by local electrical codes.

Equipment Rack and Cabinet Requirements

1 Ensure that the rack has adequate space in the front, rear, and sides after the system is installed to

allow proper ventilation, access to cables, and maintenance access. Allow at least 18 inches in the

front and 20 inches in the rear of the rack.

2 Ensure that the rack is bolted to the floor and/or braced to a wall or ceiling.

3 The minimum cabinet size is 30 inches deep and 24 inches wide.

4 Provide a minimum of 20 inches clearance behind the chassis to access the fan trays.

5 Air flows through the system from a filtered intake vent on the bottom front side of the chassis to an

exhaust vent at the top rear. For proper ventilation, position the chassis in an equipment rack or

cabinet so that the minimum air flow is 750 cubic feet per minute (CFM), this requires a minimum of

3 inches between the doors and the cable management system when the cabinet front doors are

closed, and a minimum of 3 inches between the chassis rear and the rear of the cabinet.

Site Preparation | 9

Page 10

Power Requirements

The E600i supports either 2500W AC power supplies (PSUs), or DC Power Entry Modules (PEMs).Do

not mix and match power supplies. Your system must be powered by only AC or DC power, it cannot use

both at the same time

NOTE: Do not use different versions of power supplies. If you are replacing an AC power supply, you must

replace all the PSUs in your system with the new versions. Contact Dell Force10 Technical Support if you

have any question regarding the version of PSU used in your system.

2500W AC Power Requirements

The E600i 2500W AC power supply (CAT# CC-E600i-2500W-AC2) can operate at either 100 VAC or

220 VAC. If the E600i is connected to an 100 VAC power supply, it provides up to 1500W.

www.dell.com | support.dell.com

Parameter Specifications

Nominal Input Voltage 100 - 120 VAC Requires a minimum of 3 Power Supplies Installed

Maximum AC Power Supply Input 16 A @ 100 VAC per module

Maximum System Power Input 4.80 KVA @ 100 VAC

.

200 - 240 VAC Requires a minimum of 2 Power Supplies Installed

12 A @ 200 VAC per module

4.60 KVA @ 220 VAC

DC Power Requirements

Each E-Series system requires at least one DC PEM to operate. Two units are recommended for full

facility redundancy.

Parameter Specifications

Maximum DC PEM Input Current 75 A

System 2800 W (9600 BTU/hour)

Input Voltage -48 to -60 VDC

Storage Requirements

If you do not install all of your system components, store them in the original packaging in an

environment:

• constant temperature between -40°F to 158°F (-40°C to 70°C)

• non-condensing relative humidity between 5 and 95%

• dry, away from direct sunlight, heat, and air conditioning ducts

• dust-free

10 | Site Preparation

Page 11

3

The E600i System

The Dell Force10 E600i system is a carrier-class, high-capacity aggregation router. The 9-slot modular

system provides 2 slots dedicated for route processor modules (RPMs) and 7 slots to accommodate line

cards with Layer 2 and Layer 3 switching and routing capabilities.

Operating Overview

The E600i system requires an RPM, at least one line card, and at least four switch fabric modules (SFMs)

for packet processing. The RPM is the core for routing and control operations. All traffic destined to the

E600i terminates on the RPM. Routing table entries are built on the RPM and directed to the forwarding

information tables on the line cards.

RPM software processes, such as Telnet, SNMP, Layer 2, and Layer 3 functions, are divided among three

CPUs for redundancy and speed. Independent software images run on each CPU. Each CPU has its own

memory, which isolates processes from each other, increasing reliability. Operating the E600i system

with two RPMs enables automatic fail-over redundancy.

Line cards perform all data forwarding operations. Each line card has Dell Force10 proprietary ASICs;

the flexible packet classification (FPC) ASIC and the Buffer and T raf fic Manager (BTM) ASIC. The FPC

accepts packets, feeds packets to input/output ports, handles packet classification (access lists, Layer 2

and Layer 3 lookups) and packet marking (Diffserv or 802.1p). The BTM is responsible for all queuing

operations.

The internal flash memory device shipped with the RPM contains the boot ROM and runtime images.

Each RPM accommodates an external flash memory card that can be used to copy and store system boot,

software images, and configuration files. For information about using a flash card, refer to

Using a Flash Memory Card

.

Chapter 11,

The E600i System | 11

Page 12

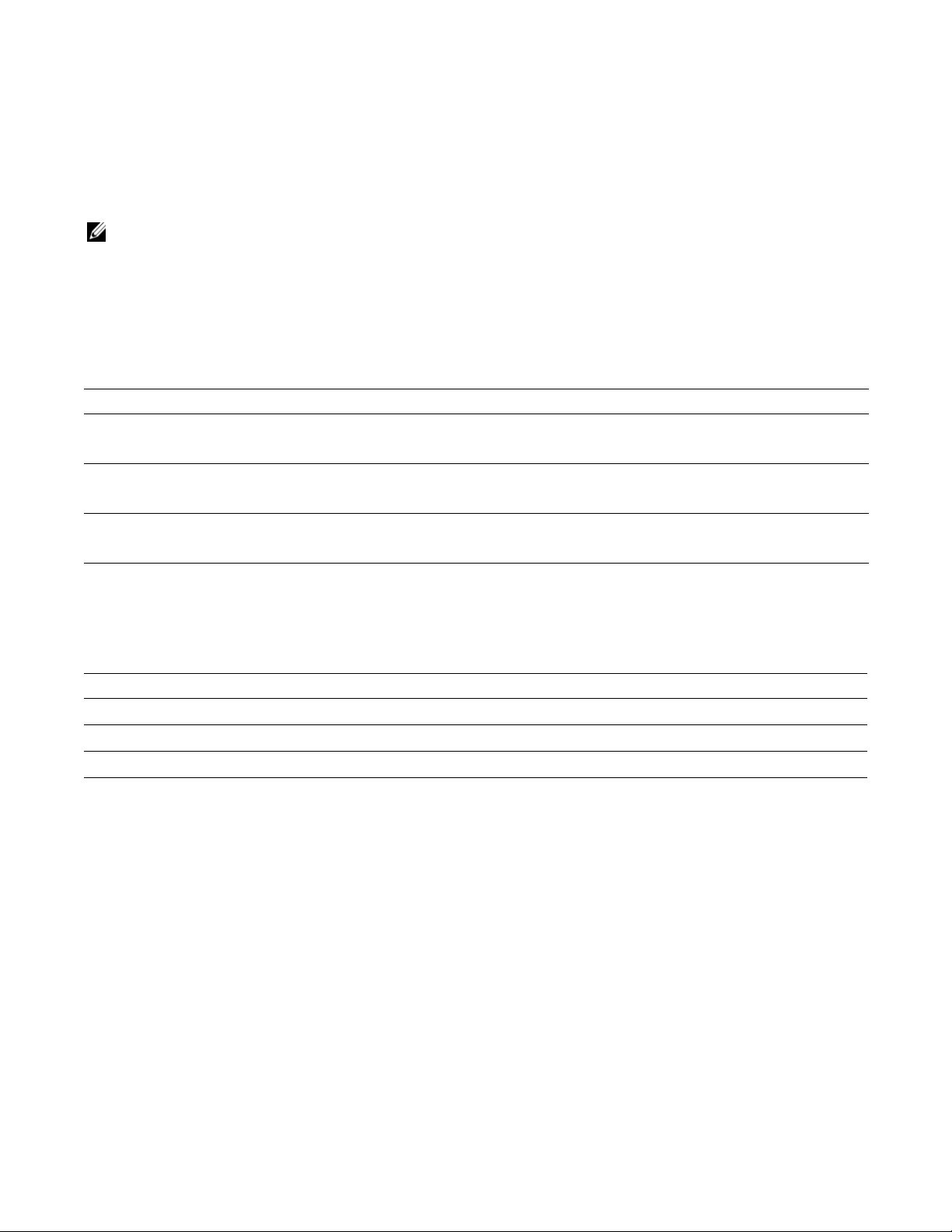

Figure 3-1. E600i Chassis Front View with AC Power Supplies

RPMs

ESD Connector

Line Cards

www.dell.com | support.dell.com

Air Filter

Figure 3-2. E600i Chassis Rear View

Fan Tray

Status LED

AC Power Supplies

SFM3

Fan Tray

Grounding

Holes

12 | The E600i System

Grounding

Holes

Page 13

Table 3-1. E600i Hardware Component Operating Requirements Summary

Component Minimum Maximum Field-Replaceable

Backplane (factory installed) 1 1 N

Air filter (factory installed) 1 1 Y

Fan tray* 1 1 Y

RPMs 1 2 Y

Line cards 1 7 Y

SFMs 4 5 Y

Power Supplies:

2500 AC Power Supply OR

DC PEMs

2

1

4

2

Y

Y

Cable management system 0 1 Y

Cable management system cover 0 1 Y

*Fan tray is field replaceable, but must be replaced within 1 minute of removing it.

E600i System Installation Process

T o install the E600i system, Dell Force10 recommends that you perform the installation procedures in the

following order:

Step Task Section

1 Prepare the site

2 Unpack the chassis and components

3 Mount the chassis

Site Preparation

Unpacking the E600i System

Standard Front Chassis Rack Mounting

Installing the Chassis into an Equipment Cabinet

4 Install components:

• Fan tray

Installing the Fan Tray

Power Supply

• AC Power Supply or DC PEMs

(including power cables)

5 Install card components:

• RPM(s) and line cards

Preparing and Installing the RPMs and Line Cards

Installing Switch Fabric Modules (SFMs)

• SFMs

6 Connect network cable

7 Supply power to the chassis

RPM Ports and Cables

Powering Up

The E600i System | 13

Page 14

www.dell.com | support.dell.com

14 | The E600i System

Page 15

4

Installing the Chassis

This chapter provides instructions to rack mount your E600i system into a standard 19-inch or 23-inch

equipment rack. It contains the following sections:

• Unpacking the E600i System

• Installing the Equipment Rack Shelf Bar

• Standard Front Chassis Rack Mounting

• Installing the Chassis into an Equipment Cabinet

Unpacking the E600i System

WARNING: The E600i packaging and contents weigh approximately 400 pounds. The unpacked chassis and

floater pallet weigh approximately 100 pounds. Do not attempt to lift or move the chassis without the use of a

hand cart, pallet jack, or forklift.

Remove all contents from the shipping packaging and move the chassis with a hand cart, pallet jack or

fork lift to its rack.

CAUTION: Lift the E600i chassis from the bottom only. Lifting by the chassis shelves or fan tray opening will

cause chassis damage. Do not remove the protective front shipping cover until you have completed the

chassis installation.

WARNING: Complete the chassis installation into the rack before you install any other component (fan tray,

AC power supplies or DC PEMs, line cards, RPMs, SFMs, cables).

WARNING: Electrostatic discharge (ESD) damage can occur when components are mishandled. Always

wear an ESD-preventative wrist or foot-heal ground strap when handling RPMs, SFMs, or line cards. After you

remove the original packaging, place RPMs, SFMs, and line cards on an antistatic surface.

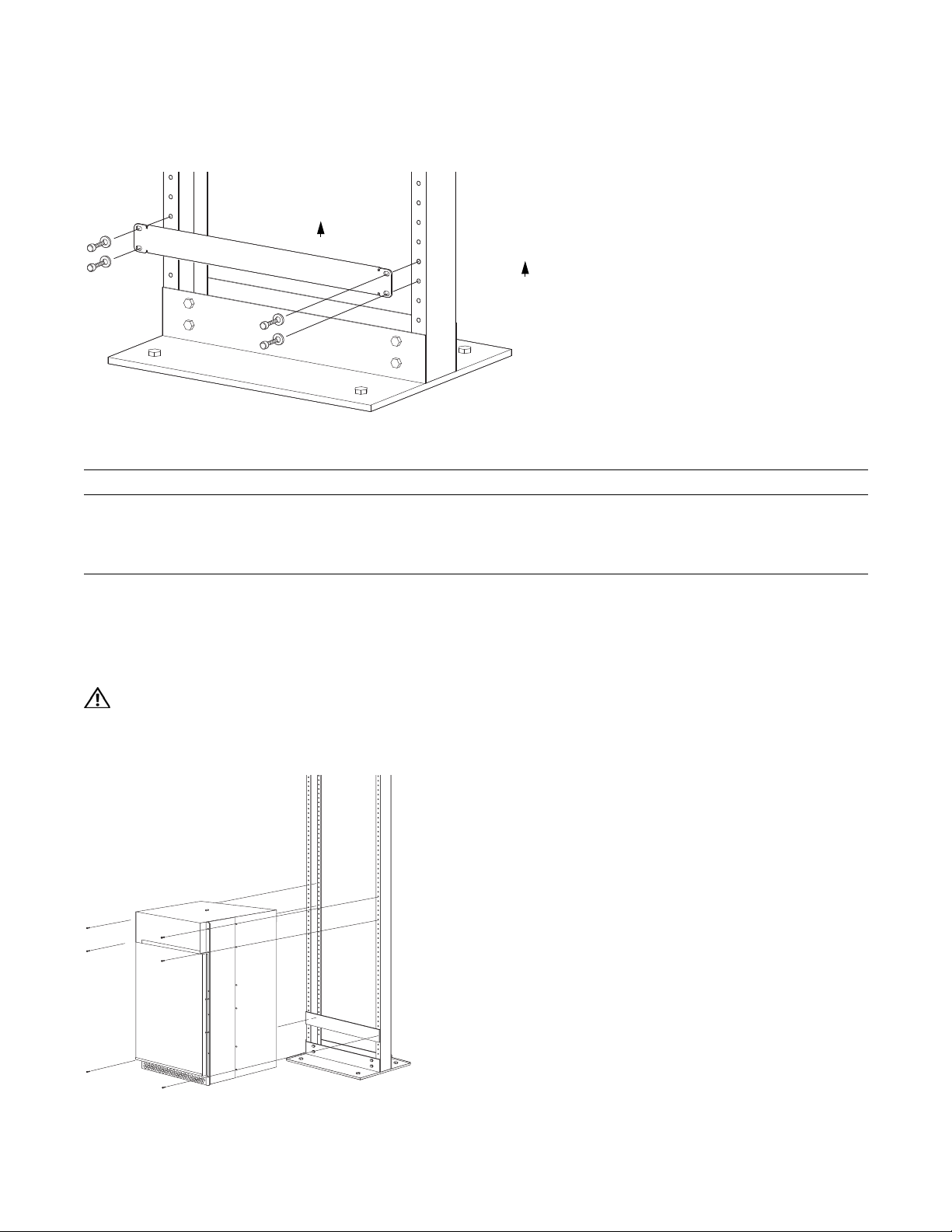

Installing the Equipment Rack Shelf Bar

The rack shelf bar (

unit additional stability in the rack.

Figure 4-1

) enables you to easily position the chassis into the rack and provides the

Installing the Chassis | 15

Page 16

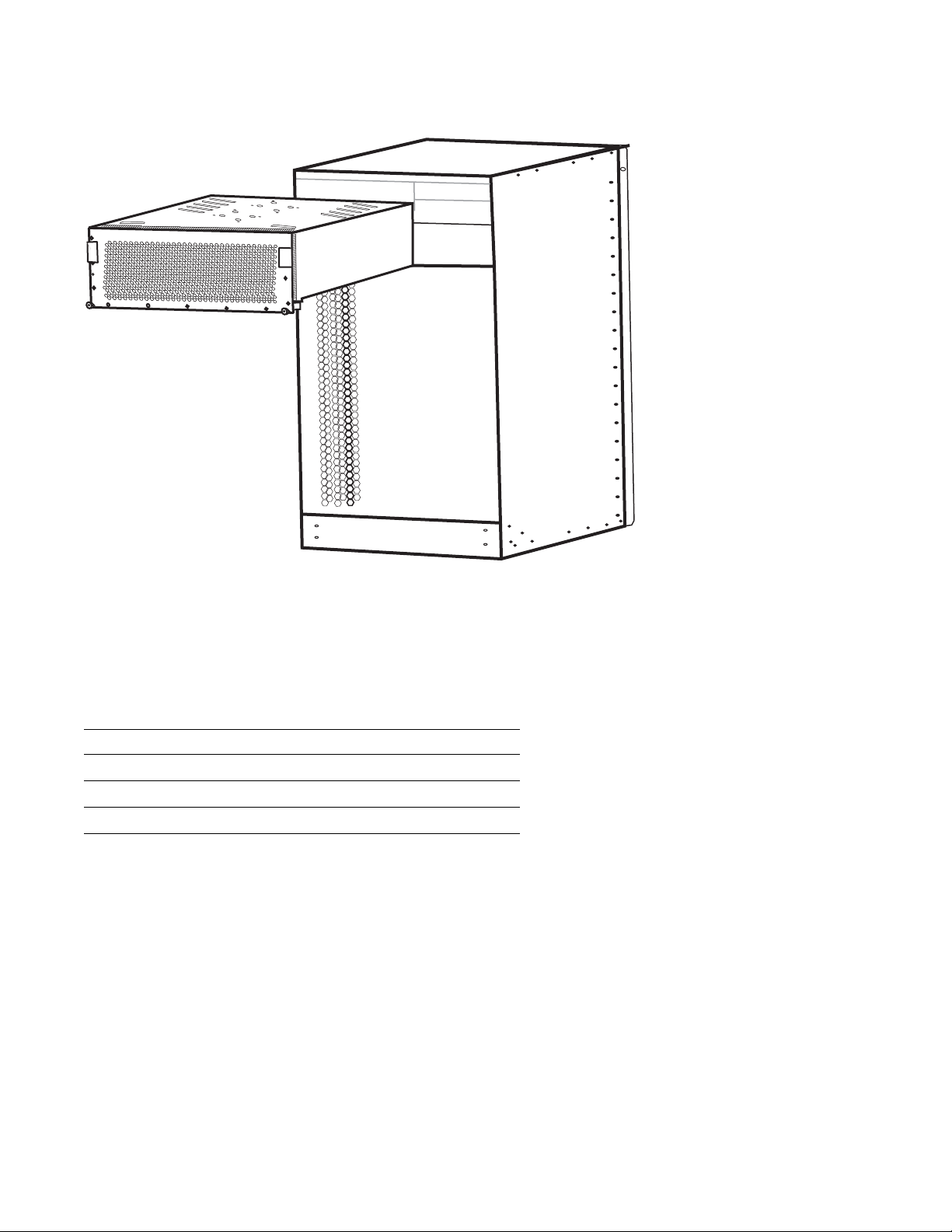

Figure 4-1. Installing the Equipment Rack Shelf Bar

C

UP

UP

www.dell.com | support.dell.com

F

To install a equipment rack shelf bar:

Step Task

1 Determine the chassis mounting location in the equipment rack.

2 Orient the bar with the arrows pointing upward. The smooth side of the bar should face outward.

3 Attach the bar to the equipment rack brackets using the mounting screws provided by the rack manufacturer.

Standard Front Chassis Rack Mounting

Install the E600i system after you secure the equipment rack shelf bar. Load the chassis into the lower

half of an empty rack to avoid a top-heavy rack. (

WARNING: Do not remove the protective front shipping cover during the initial installation process. This

Figure 4-2

protective cover prevents damage to the internal framework and EMI seals.

Figure 4-2. Rack Mounting the Chassis

).

16 | Installing the Chassis

F

Page 17

To install the chassis into a prepared rack:

Step Task

1 If you are center or rear mounting the chassis in a 19-inch rack, make sure that the mounting brackets are properly

positioned.

NOTE: If your are mounting the chassis in a 23-inch rack, install the 23-inch adapters.

2 Using a hand cart, pallet jack, or forklift, align the rack-mount holes with the equipment rack holes, situating the

chassis on top of the equipment rack shelf bar.

3 Insert rack mounting screws in the holes that are not obscured by the front shipping cover. T ighten the screws. See

Figure 4-2

4 Loosen and remove the screws attaching the front shipping cover. Remove the cover.

5 Insert the remaining rack mounting screws and tighten to secure the chassis in the rack.

.

Installing the Chassis into an Equipment Cabinet

Install the E600i system after you secure the rack shelf bar. Load the chassis into the lower half of an

empty rack to avoid a top-heavy rack. (

Figure 4-2

space in the front, rear, and sides of the unit for proper ventilation, access to cables, and access for

maintenance. See

Rack Mounting the Chassis on page 16

To install the chassis into an equipment cabinet:

). Make sure the cabinet is positioned with adequate

for details.

Step Task

1 Install the equipment rack shelf bar.

2 Using a hand cart, pallet jack, or forklift, align the rack-mount holes with the cabinet holes.

3 Insert rack mounting screws in the holes that are not obscured by the front shipping cover. Tighten the screws.

4 Loosen and remove the screws attaching the front shipping cover. Remove the cover.

5 Insert the remaining mounting screws and tighten to secure the chassis in the cabinet.

Installing the Chassis | 17

Page 18

www.dell.com | support.dell.com

18 | Installing the Chassis

Page 19

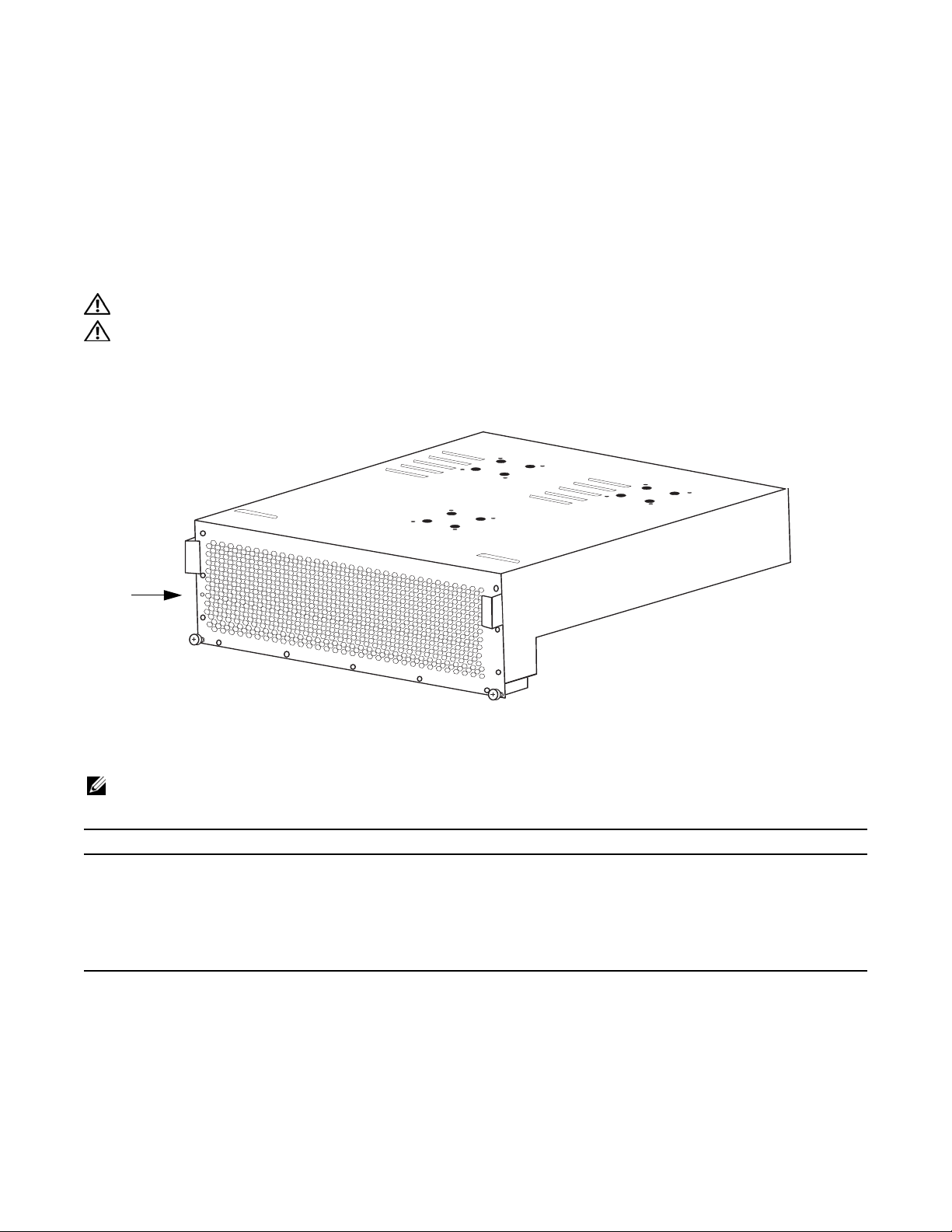

Installing the Fan Tray

5

Access the fan tray from the rear of the chassis (

control, the fan tray must be installed before you supply power to the system.

WARNING: The fan tray must be installed before you supply power to the system.

WARNING: Electrostatic discharge (ESD) damage can occur when components are mishandled. Always

wear an ESD-preventative wrist or foot-heal ground strap when handling chassis components. After you

remove the original packaging, place chassis components on an antistatic surface.

Figure 5-1. The Fan Tray

Status LED

Figure 5-1

). To ensure proper temperature and airflow

FN0076A

Ensure that the power switches on the remote power sources are in the OFF position. Then unpack the fan

tray and follow the step below to install the fan tray.

NOTE: The fan tray weighs 20 lbs (9.072 kg).

Step Task

1 Hold the tray with both hands and slide the connector end several inches into the fan slot, located in the rear of the

chassis

2 Push the tray until it stops and its handle end is flush with the chassis rear.

3 Secure the fan tray into place by tightening the screws. You can either tighten the screws with a Phillips

screwdriver or with your fingers. Do not over tighten.

(Figure 5-2)

.

Installing the Fan Tray | 19

Page 20

Figure 5-2. Inserting Fan Tray into Fan Slot

www.dell.com | support.dell.com

FN00080A

Fan Speed

Fan speed is driven by temperatures measured at the sensor in the fan tray alone. The sensor is located on

the fan tray controller located in the fan tray.

Table 5-1

shows the sensor temperature that determines the

fan speed.

Table 5-1. Fan Speed and Temperature

Degrees Celsius Fan Speed

Less than 25C (Low) 1800 RPM

Between 25 and 45 (Med) 2400 RPM

Above 45C (High) 3000 RPM

20 | Installing the Fan Tray

Page 21

Power Supply

This chapter provides instructions to install AC Power Supply Units (PSUs) and DC Power Entry

Modules (PEMs):

• AC Power Supply Units

• DC Power Entry Modules

E-Series systems may contain only one type of power module—AC or DC. The E600i requires a

minimum of one DC Power Entry Module or a minimum of two AC Power Supplies

Table 6-1. Minimum Power Supply Requirements

Power Supply Input Minimum (N) Redundancy

220VAC 2 N + 1

110VAC 3 N + 1

DC 1 N + 1

.

6

The chassis has four power supply slots (

may install AC power supplies in any slot.

WARNING: Class 1 laser product.

ATTENTION: Produit laser de classe 1.

WARNUNG: Laserprodukt der Klasse 1.

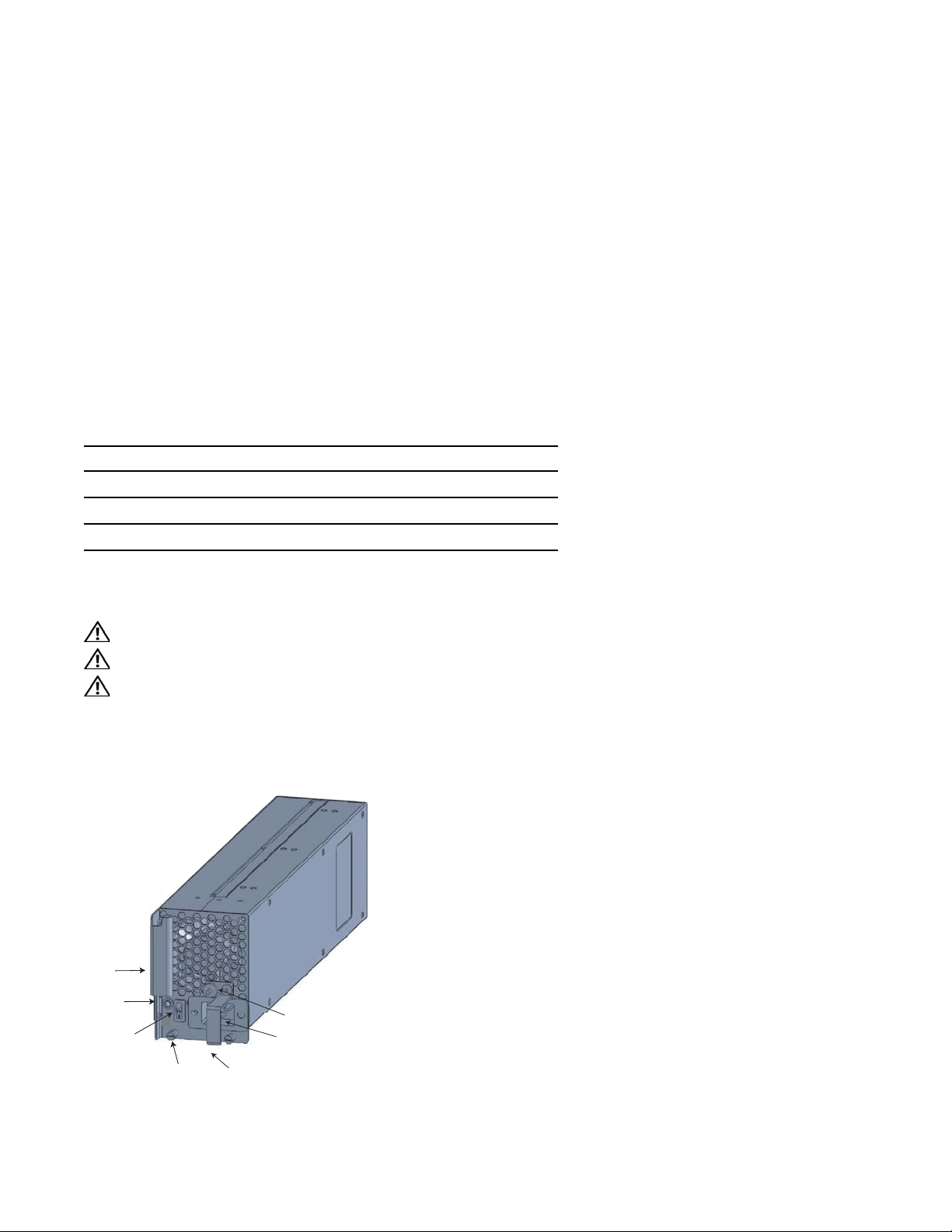

Figure 6-1. Power Supply Slots

Handle

Status LED

Green Power On

Amber Fault

Power Switch

Thumb Screw

Power Cord Socket

Figure 6-1

). You may install DC PEMs in slots 1 and 3 only; you

Locking Screws (2)

Cord Retainer

Power Supply | 21

Page 22

AC Power Supply Units

The 2500W AC Power Supply Unit is capable of operating at either 100 VAC or 220 VAC. If the system

is connected to a 100 VAC power supply, each unit provides up to 1500W, and three power supply

modules are required to power the system; four power supply units are required for power supply

redundancy.

If the system is connected to a 220 VAC power supply, two power supply units are required for providing

power to the system, three power supply units are required for power supply redundancy , and four power

supply units are required for full facility redundancy.

Full facility redundancy requires two independent power sources (feeds) with two power supplies on

each feed. Each independent power source should have a dedicated circuit breaker sized in accordance

with your local electrical codes.

www.dell.com | support.dell.com

CAUTION: Before removing and replacing a power supply unit, determine if the E600i is in full redundancy or

non-redundant mode. Operating in non-redundant mode will require a complete system power off when

removing and replacing a power supply.

NOTE: Do not mix power supplies. Installing a 2500W-AC2 power supply into a chassis with 2500W-AC

power supplies already installed may result in unpredictable behavior. FTOS version 8.3.1.2 and later will

declare an alarm when the PSUs are mixed.

Figure 6-2. AC Power Supply Unit

Handle

Status LED

Green Power On

Amber Fault

Power Switch

22 | Power Supply

Locking Screws (2)

Thumb Screw

Power Cord Socket

Cord Retainer

Page 23

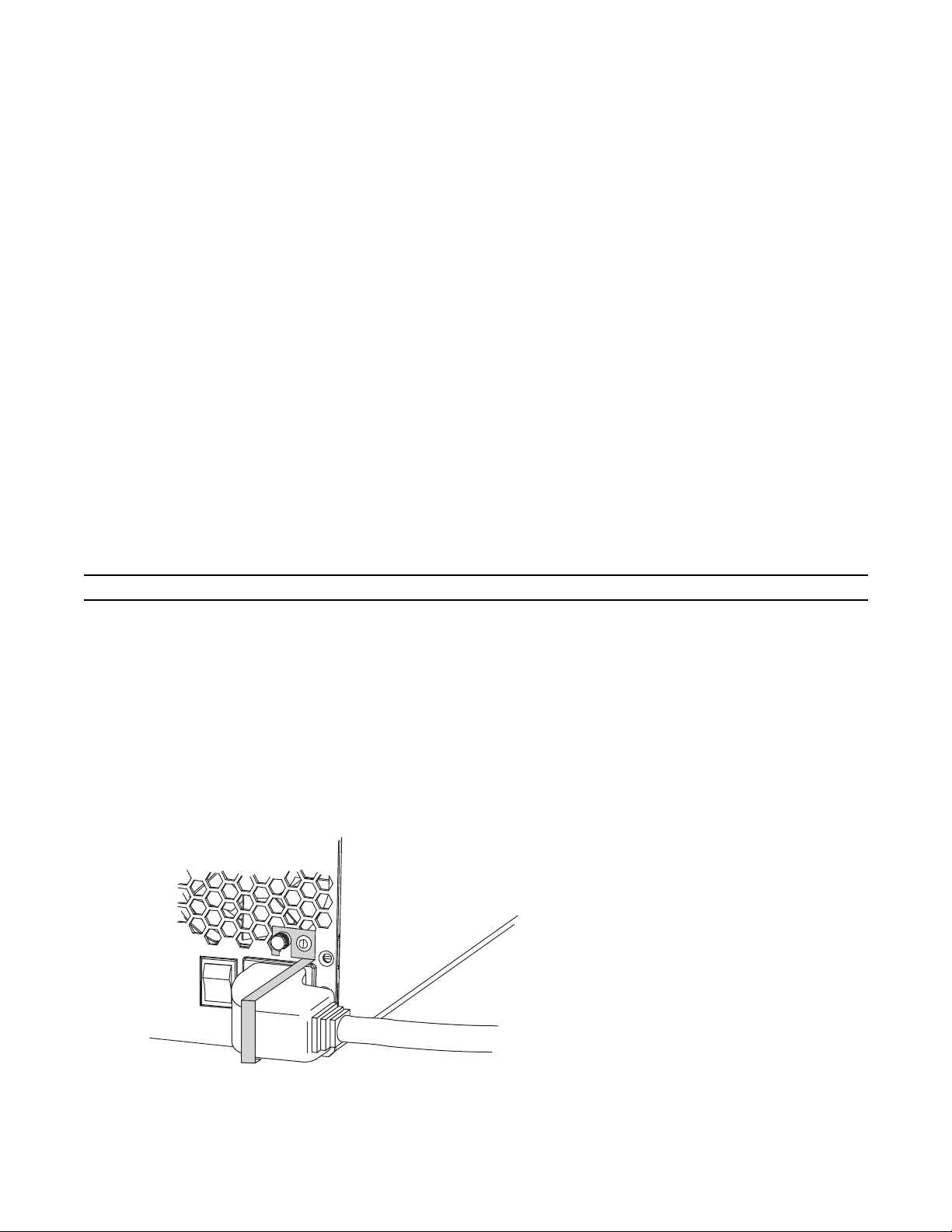

Power Cord Requirements

If using a power cord other then a Dell Force10 supplied power cord, the cord must terminate at a right

angle (IEC320 C19 connector) to the power module, see

Figure 6-3

. The power source end of the power

cord must have an appropriately sized plug that complies with your local electrical codes. Conductor size

must also conform to your local electrical codes.

The following are Dell Force10 supplied plug types.

• EU: CEE 7/7

• UK:CEE7/7, BS 1363

• SWZ: CEE7/7, 309

• JAP: NEMA 5-20

• JAP 220: NEMA 6-20, L6-20

• US: C14, C20, NEMA 5-20, L5-20

• US 220: NEMA 6-20, L6-20, L6-30 (30A)

Install the AC Power Supply Units

To install an AC power supply unit:

Step Task

1 Verify that the power switch on the power supply is in the OFF position.

2 Orient the power supply handle to the left, and slide the backplane connector end into a power supply slot.

3 Secure the power supply into place by tightening the two locking screws to 5 in-lbs.

4 Plug an AC power cord into the socket on the front of the unit:

a Loosen the power cord retainer thumb screw.

b Rotate the retainer clockwise away from the socket and plug the power cord into the socket.

c Rotate the retainer counter clockwise over the power cord, and tighten the thumb screw to secure the power

cord.

Figure 6-3. Securing the AC Power Cord

Power Supply | 23

Page 24

Step Task

5 Plug the AC power cord into an AC outlet.

6 Toggle the power supply switch to the ON position, and verify that Status LED lights green.

Remove the AC Power Supply

CAUTION: This unit has more than one power supply connection; all connections must be removed to remove all power

from the unit.

ATTENTION: Cette unité est équipée de plusieurs raccordements d'alimentation. Pour supprimer tout courant

électrique de l'unité, tous les cordons d'alimentation doivent être débranchés.

WARNUNG: Diese Einheit verfügt über mehr als einen Stromanschluß; um Strom gänzlich von der Einheit

fernzuhalten, müssen alle Stromzufuhren abgetrennt sein.

www.dell.com | support.dell.com

To remove an AC power supply unit:

Step Task

1 Determine if the system is operating in power supply redundancy. If the system is operating with non-redundant

power, removing a power supply powers down the system.

2 Toggle the power switch on the on the unit to the OFF position.

3 Unplug the power cord from the AC Power Supply and the AC power outlet.

a Loosen the power cord retainer thumb screw.

b Rotate the retainer clockwise away from the socket and unplug the power cord from the socket.

Figure 6-4. Removing the AC Power Cord

Thumb Screw

Cord Retainer

4 Loosen the locking screws.

5 Slide the power supply out of the slot.

6 If you are not replacing the power supply, place a power supply blank in the empty slot.

Power Cord

24 | Power Supply

Page 25

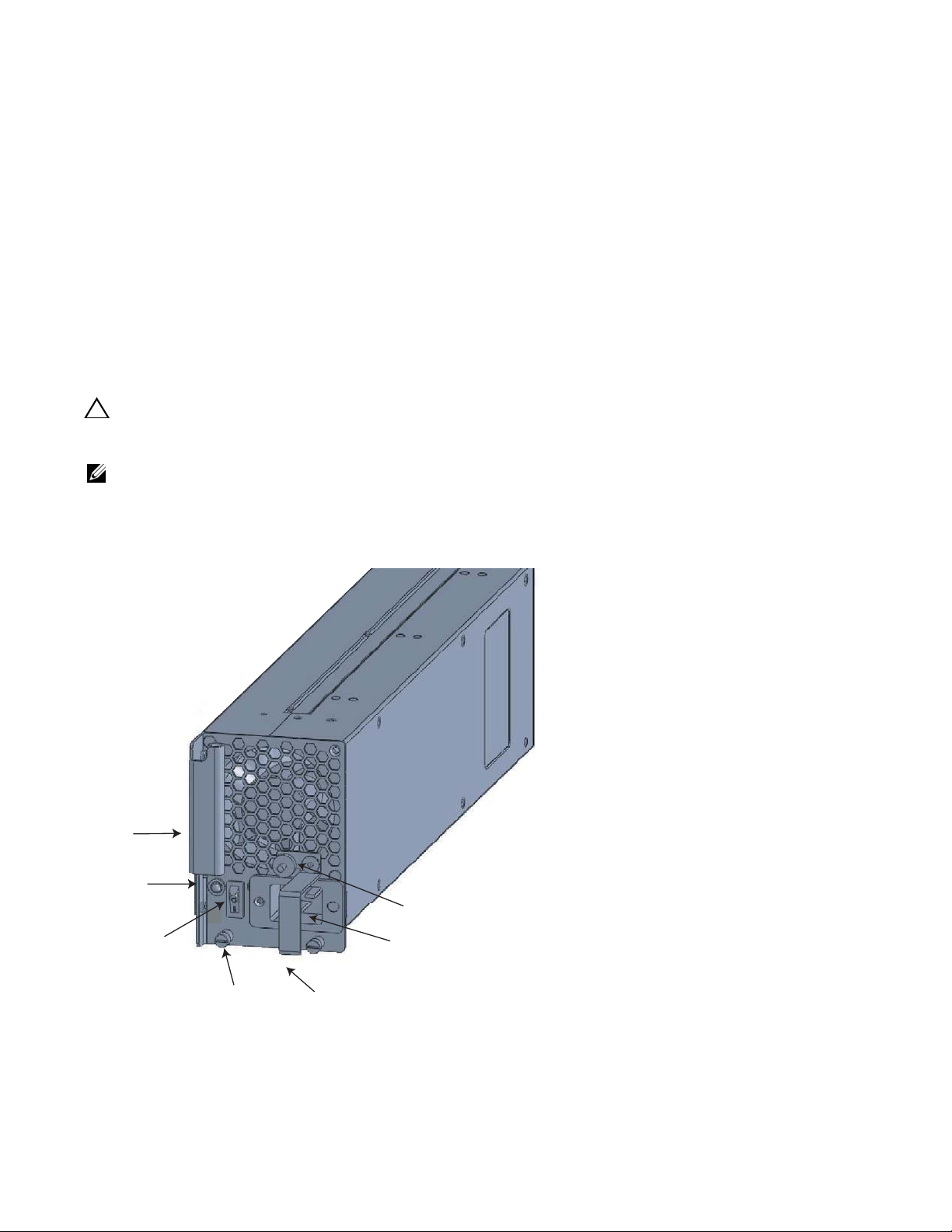

DC Power Entry Modules

48V in

Status

-48/-60Vdc 75A

CAUTION -

Use copper

conductors only

r

The system requires a minimum of one load-sharing PEM to operate, but two are recommended for

redundancy. Connect the E600 PEMs to the appropriate branch circuit protection as defined by local

electrical codes.

For full redundancy , each PEM must be attached to an independent power source with a dedicated circuit

breaker.

Figure 6-5. DC Power Entry Module

Voltage LED

Handle

Studs

48V in

Status LED

CC-E600-PWR-DC

CAUTION -

Use copper

conductors only

-48/-60Vdc 75A

Status

Over Current Protecto

Finger Barrier

Locking Screws

Cable and Connector Requirements

1 You must provide your own cables to connect to a remote power source in your equipment rack.

Verify that your cables are:

• rated for at least 80A service to allow for a fully loaded E600i system at low input voltage per

your local electrical codes

• limit voltage drop across the cable length to 0.5V or less

2 Before you make the cable connections, apply a coat of anti-oxidant paste to unplated metal contact

surfaces.

3 File unplated connectors, braided straps, and bus bars to a shiny finish. It is not necessary to file and

coat tinned connectors or other plated connection surfaces, such as on the PEM studs.

Install the DC PEMs

To install a DC PEM:

Step Task

1 Make sure that the remote power source (the circuit breaker panel) is in the OFF position.

2 Make sure that the over current protector (located on the PEM front panel) is in the OFF position.

Power Supply | 25

Page 26

3 Loosen the retaining screw and remove PEM safety cover (

r

Figure 6-6. Removing the DC PEM Safety Cover

www.dell.com | support.dell.com

C

A

U

T

IO

N

-

T

u

r

n

o

b

ff

r

e

p

a

o

k

w

e

r

e

b

r

s

e

o

fo

u

r

r

e

c

a

e

c

c

c

e

s

s

in

g

te

N

G

rm

-

V

in

e

r

je

d

e

r W

a

r

tu

n

g

H

T

IO

N

-

Unit may have more than one power

C

C

ir

c

u

it

a

ls

.

a

u

p

ts

c

h

a

lte

r

-E

60

0

-C

V

R

-P

E

M

A

C

H

T

U

Always replace safety cover

after servicing

C

A

U

source connection. Remove all supply connections

Do not plug in while energized.

4 Slide the backplane connector end of the PEM into Power Supply Slot 1 or 3. Secure the PEM to the chassis by

tighten the two locking screws.

5 Secure the chassis ground connection:

Remove one outer nut and one washer from each of the six studs. The inner nut should remain tight on the stud, at

no more than 25 inch-lbs.

Locate the chassis ground connector studs on the PEM front panel (see

ground connection.

Attach the grounding cable onto the ground studs. The grounding cable must comply with your local electrical

codes in size and color (typically the color is green or green with yellow stripe), and the grounding cable must be

terminated only with a UL-listed 2-hole lug with 1/4-inch holes on 3/4-inch spacing (see

Replace the two washers and nuts.

With a 7/16-inch box or socket wrench, tighten the nuts to 25 in-lbs.

Connect the opposite end of the grounding cable to the nearest appropriate facility grounding post.

Figure 6-6

).

Figure 6-5

). The two bottom studs are the

Figure 6-7

).

Figure 6-7. Cable Connector for DC Power Entry Modules

High-strand-count

conductor

0.750

0.267

diamete

2 Holes

Replace the DC PEM

The PEM Status LED is unlit or amber if the unit fails. In this case, replace the entire unit. There are no

field serviceable parts inside the PEM unit.

26 | Power Supply

Page 27

To remove a PEM:

Step Task

1 If the system is operating with power supply redundancy, you may remove either PEM at any time. If the system is

operating without power supply redundancy, power down the system before removing the PEM.

2 Power off the remote power source, and then verify that the PEM status LED and Voltage LED are unlit. To be

completely sure that power is off, measure the voltage across the negative (-) and positive (+) source DC leads using

a voltmeter. The measurement across the positive and negative leads must be zero (0) volts before you proceed.

3 Toggle the Over Current Protector (located on the PEM front panel) to the OFF position.

4 Loosen the PEM safety cover retaining screw, and remove the cover.

5 Disconnect power cables attached to the PEM.

6 Slide the PEM out of the slot.

7 If you are not replacing the PEM, place a power supply blank in the empty slot.

Power Supply | 27

Page 28

www.dell.com | support.dell.com

28 | Power Supply

Page 29

7

Installing RPMs, Line Cards, and SFMs

This chapter provides instructions to install cards into the E600i chassis and includes the following

sections:

• Unpacking

• Preparing and Installing the RPMs and Line Cards

• RPM Label and LEDs

• Installing Switch Fabric Modules (SFMs)

Unpacking

WARNING: Electrostatic discharge (ESD) damage can occur when components are mishandled. Always

wear an ESD-preventive wrist or foot-heel ground strap when handling RPMs, SFMs, or line cards. After you

remove the original packaging, place RPMs, SFMs, and line cards on an antistatic surface.

WARNING: To avoid an over-temperature situation, do not supply power to your E600i system until the fan

tray, RPMs, SFMs, line cards, and any required blanks are installed.

Dell Force10 recommends that you keep all components in the original packaging until you are ready to

install them.

Important notes:

• It is important that you do not remove the cards from their protective bags until you are ready to install

them in a chassis.

• When you are ready to install the cards, unwrap and install one card at a time, starting with the right

most slot (Slot 6 for line cards, Slot R1 for RPMs, and Slot 2 or Slot 4 for SFMs) ending with the

leftmost slot (Slot 0 for line cards, Slot R0 for RPMs, and Slot 0 or Slot 3 for SFMs)

Line Cards and RPMs

At a minimum, the E600i requires one RPM and one line card to operate.

CAUTION: Any slot not filled with a line card or RPM must be filled with a blank to ensure adequate cooling

and EMI containment.

RPMs

The E600i system requires the installation of at least one RPM, although two are recommended for

redundancy. RPMs are designed to be installed in either the R0 or R1 slots. Do not force RPMs into line

cards slots. RPMs are keyed differently than line cards to prevent improper installation.

Installing RPMs, Line Cards, and SFMs | 29

Page 30

You can hot-insert a second RPM into a running system without performance interruption or software

intervention. A second RPM for redundant functionality provides uninterrupted operability if the system

transitions from the active RPM to the standby RPM. The standby RPM constantly performs updates and

receives the same configuration information received by the active RPM. The standby RPM also

performs diagnostics on its subsystems. In the event of a switch over, the standby RPM immediately

takes over and resumes the control activities that the active RPM was performing.

provides more information on the second RPM.

RPM

Installing a Second

The RPM Major and Minor alarm LEDs are controlled by software which sets the threshold levels for

triggering the different stages of alarms.

Line Cards

www.dell.com | support.dell.com

Your E600i configuration requires a minimum of one line card. Line cards are hot swappable. The line

card ports provide external interface functions for connections to other systems (for example, a router or

switch). Each line card has an onboard CPU for line card management which updates packet forwarding

information, obtains statistical information, and performs synchronization tasks with the RPM, as well as

Force10 Networks custom-built ASICs, which enable line-rate forwarding.

Line Card Port Numbering

There are seven line card slots available in the E600i chassis. A minimum of one line card is required for

operation. Line cards are installed in slots 0 through 6. Ports on line cards are numbered from the top,

starting from 0.

Blank Panels

CAUTION: To avoid chassis over-temperature condition, install blanks for RPMs, SFMs, and line cards slots

that are not in use. Always replace cards or blanks immediately.

Blank panels for RPMs, SFMs, and line cards must be installed in empty slots to control airflow. If a slot

is not filled for more than five minutes, the following message appears on the console:

%CHMGR-2-MINORTEMP: Minor alarm: chassis temperature high (SFM temperature

reaches or exceeds threshold of 65C)

Blank panels are shipped with the system to ensure that all chassis slots are installed with operational

modules or blanks.

Preparing and Installing the RPMs and Line Cards

To install line cards and RPMs:

Step Task

1 Remove the line card from its box and carefully remove the line card from the anti-static packaging.

2 Align the RPM with the guide and gently slide it into the slot until you feel the connectors engage with the chassis

backplane.

NOTE: Hold the card by the edges. Avoid touching the printed circuit board and connector pins. Extend the

top and bottom card levers before you insert the card into the slot.

3 Rotate the levers to seat the backplane connectors and line card in place.

4 Secure card and blanks in place by tightening the top and captive screws on each card.

30 | Installing RPMs, Line Cards, and SFMs

Page 31

Step Task

A

5 Follow the same installation procedure for the remaining cards and slots, in the appropriate order.

NOTE: The blank panels do not have circuit boards or levers. Align the blank with the guides and gently slide

toward the backplane.

Figure 7-1. Installing RPM into the E600i

FN00079

To install line cards and RPMs:

Step Task

1 Remove the line card from its box and carefully remove the line card from the anti-static packaging.

2 Align the RPM with the guide and gently slide it into the slot until you feel the connectors engage with the chassis

backplane.

NOTE: Hold the card by the edges. Avoid touching the printed circuit board and connector pins. Extend the

top and bottom card levers before you insert the card into the slot.

3 Rotate the levers to seat the backplane connectors and line card in place.

4 Secure card and blanks in place by tightening the top and captive screws on each card.

5 Follow the same installation procedure for the remaining cards and slots, in the appropriate order.

NOTE: The blank panels do not have circuit boards or levers. Align the blank with the guides and gently slide

toward the backplane.

Installing RPMs, Line Cards, and SFMs | 31

Page 32

Installing a Second RPM

Install a second RPM either before the system is powered on or after the Primary RPM is up and stable.

After the second RPM is installed, wait several seconds until the connection between the two RPMs is

established before configuring any commands. Below is an example of the messages that appear:

%POLLMGR-2-ALT_RPM_STATE: Alternate RPM is present

%IRC-6-IRC_COMMUP: Link to peer RPM is up

%RAM-6-RAM_TASK: RPM1 is in Standby State.

Once the link between the two RPMs is established, copy the running configuration to the startup

configuration.

www.dell.com | support.dell.com

RPM Label and LEDs

Table 7-1

describes the RPM LED states and the RPM front panel.

RPMs control the routing and switching functions for the entire E600i system. The E600i operates with a

minimum of one RPM module. You can hot-insert a second RPM into a running system without

performance interruption or software intervention. A second RPM for redundant functionality provides

uninterrupted operability if the system transitions from the primary RPM to the secondary (standby)

RPM. The secondary RPM constantly performs updates and receives the same information received by

the primary RPM. The secondary RPM also performs diagnostics on its subsystems. In the event of a

switchover, the secondary RPM immediately takes over and resumes the control activities that the

primary RPM was performing.

Table 7-1. RPM LEDs

Section Label Description

Management 10/100

Ethernet

Alarms Major Red: a critical condition exists, such as a severe over temperature condition, a fan tray

Minor Amber: a serious condition exists, such as an over temperature condition, a single fan failure,

ACO/LT Allows you to test the operability of LEDs to verify that they are able to light.

L: Green: link is up

A: Green: activity on port

failure, an over temperature condition in a power supply, or an out-of-tolerance voltage.

The RPM LEDs are controlled by software which sets the threshold levels for triggering the

different stages of alarms.

Unlit: no major conditions.

or a line card failure. The RPM LEDs are controlled by software, which sets the threshold

levels for triggering the different stages of alarms.

Unlit: no minor alarm conditions.

Press the ACO/LT button to temporarily illuminate the LEDs on the RPM.

If you press this button when the alarm status LED is lit, the alarm relay contacts are reset

until the next alarm event.

32 | Installing RPMs, Line Cards, and SFMs

Page 33

Table 7-1. RPM LEDs

Flash In Use Green: flash memory card is in the process of a read or write process. Do not remove the

flash card when the In Use LED is lit.

Unlit: not in use.

Primary Green: primary

Unlit: secondary (or standby)

Status This is a bi-color LED.

Green: operational

Amber: fault detected

Flashing green: booting

Unlit: in secondary mode or power is off

Line Card LEDs

Line card LEDs are described in the documentation specific to each line card. Refer to the installation

documentation that came with the card for to understand LED appearance and meaning.

Installing Switch Fabric Modules (SFMs)

A minimum of four SFMs are required in order for the E600i system to operate properly. There is an

additional slot available for a redundant SFM. SFMs carry traffic between line cards or between RPMs

and a line card. SFMs plug directly into the backplane, which provides high-speed access to the line

cards. The switch fabric receives user data packets and redirects them to the appropriate destinations

according to the routing information.

CAUTION: If you are not operating your E600i system with redundancy, your SFM package will include a

blank panel. Blanks do not have board components or connector pins.

You must install SFMs starting on the left (slots 3 or 0) moving to the right (slots 2 or 4).

Step Task

1 Remove an SFM from the anti-static packaging.

2 Align the SFM with the guide and gently slide it into the slot until you feel the connectors engage with the chassis

backplane.

NOTE: Hold the SFM by the edges. Avoid touching the printed circuit board and connector pins. Extend

the top and bottom card levers before you insert the card into the slot.

3 Rotate the lever to seat the backplane connectors and card in place.

4 Secure each SFM in place by tightening the captive screw.

5 Continue the process for the remaining SFMs.

6 Align any blank panels with the guides and gently slide toward the backplane. Secure each blank panel by

tightening the single captive screw.

Installing RPMs, Line Cards, and SFMs | 33

Page 34

Figure 7-2. Installing SFMs

8

www.dell.com | support.dell.com

Load SFMs from

right to left

FN000

34 | Installing RPMs, Line Cards, and SFMs

Page 35

SFM Front Panel and LEDs

Serial

Assy

Table 7-2

defines the SFM front panel and LED displays.

Table 7-2. SFM Front Panel and LED Descriptions

LED Description

Active Green: active and passing traffic

Unlit: in standby mode

CC-E-SFM3

Status Flashing Green: booting

Green: operational

Flashing Amber: communication failure

Amber: fault detected

Active

Status

Unlit: no power

Switch Fabric

Assy

Serial

Installing RPMs, Line Cards, and SFMs | 35

Page 36

www.dell.com | support.dell.com

36 | Installing RPMs, Line Cards, and SFMs

Page 37

8

RPM Ports and Cables

This chapter describes standard RPM cables and adapter pin assignments. It contains the following

sections:

• RPM Ports

• Cable and Adapter Pin Assignments

• Accessing the 10/100 Ethernet Management Port

RPM Ports

There are three ports on the RPM. They are labeled and described as:

• Console. A Universal Asynchronous Receiver/Transmitter (UART) port with an RJ-45 jack, is used for

system configuration and monitoring. Modem connections are not supported on this port.

• Auxiliary. A UART port with an RJ-45 jack, allows modem access to the E600i system from a remote

location.

• 10/100 Ethernet. A 10/100 Ethernet port is the Management port, which is a channel to download

images and manage the system, as well as FTP and Telnet operations. You must provide a cable

terminated with an RJ-45 style connector to attach to the Ethernet receptacle.

Connecting the Console and Auxiliary Ports

NOTE: Always wear an ESD-preventive wrist or foot-ground strap when handling components.

The console and auxiliary ports are asynchronous serial ports. If you connect a device to these ports, it

must be capable of asynchronous transmission. Your terminal or terminal emulation mode must be set to

VT100 with the following settings:

• 9600 baud rate (to avoid autobaud input, the default is set to a 9600 bps baud rate)

• No parity

• 8 data bits

• 1 stop bit

• Window Terminal Emulator option set to NO

• 24 lines X 80 characters

• No flow control (console port only)

• Hardware flow control (RTS/CTS) (for auxiliary port only)

RPM Ports and Cables | 37

Page 38

Cable and Adapter Pin Assignments

Use the E600i Console port on the RPM to connect to a terminal port, PC serial port, or a terminal server

to configure and monitor your system. Use the E600i Auxiliary port on the RPM to connect to a modem.

Both the Console and Auxiliary port are RJ-45 ports.

Figure 8-1. Pinouts for an RJ-45 Connector End of Adaptor

www.dell.com | support.dell.com

87654321

Table 8-1

displays the RJ-45 console port pin assignments.

assignments.

Table 8-1. Console Port (RJ-45) Pin Assignments

Pin Signal Input/Output

1 NC (unused) 2 DTR Output

3 TxD Output

4 GND 5 GND 6 RxD Input

7 DSR Input

8 NC (unused) -

Figure 8-1

Table 8-2

displays the pinouts in an RJ-45 port.

displays the RJ-45 auxiliary port pin

Table 8-2. Auxiliary Port (RJ-45) Pin Assignments

Pin Signal Input/Output

1 RTS Output

2 DTR Output

3 TxD Output

4 GND 5 GND 6 RxD Input

7 DSR Input

8 CTS Input

38 | RPM Ports and Cables

Page 39

Accessing the Console with a DB-9 Adapter

You can connect to the console using a RJ-45 to RJ-45 rollover cable and a RJ-45 to DB-9 female DTE

adapter (labeled “TERMINAL”) to a terminal server (for example, PC).

Table 8-3

lists the pin

assignments.

Table 8-3. Pin Assignments Between the E600i Console and a DTE Terminal Server

E600i Console

Port

Signal RJ-45 pinout RJ-45 Pinout DB-9 Pin Signal

RTS 1 8 8 CTS

DTR 2 7 6 DSR

TxD 3 6 2 RxD

GND 4 5 5 GND

GND 5 4 5 GND

RxD 6 3 3 TxD

DSR 7 2 4 DTR

CTS 8 1 7 RTS

RJ-45 to RJ-45 Rollover Cable RJ-45 to DB-9

Adapter

Terminal Server

Device

Accessing the Console with a DB-25 Adapter

You can connect to the console using a RJ-45 to RJ-45 rollover cable and a RJ-45 to a DB-25 female DTE

adapter.

Table 8-4. Pin Assignments Between E600i Console and DB-25 Adapter

E600i Console

Port

Signal RJ-45 Pinout RJ-45 Pinout DB-25 Pinout Signal

RTS 1 8 5 CTS

DTR 2 7 6 DSR

TxD 3 6 3 RxD

GND 4 5 7 GND

GND 5 4 7 GND

RxD 6 3 2 TxD

DSR 7 2 20 DTR

CTS 8 1 RTS

Table 8-4

lists the pin assignments.

RJ-45 to RJ-45 Rollover Cable RJ-45 to DB-25

Modem Adapter

Terminal Server

Device

RPM Ports and Cables | 39

Page 40

Accessing the Auxiliary Port by Modem

You can access the auxiliary port using a dial-up modem using a RJ-45 to RJ-45 rollover cable and a RJ-

45 to a DB-25 male DCE adapter (labeled “MODEM”).

Table 8-5. RJ-45 to DB-25 Adapter Pin (Modem) Assignments

Table 8-5

lists the pin assignments.

E600i Auxiliary

Port

Signal RJ-45 Pinout RJ-45 Pinout DB-45 Pinout Signal

RTS 1 8 4 RTS

DTR 2 7 20 DTR

TxD 3 6 3 TxD

www.dell.com | support.dell.com

GND 4 5 7 GND

GND 5 4 7 GND

RxD 6 3 2 RxD

DSR 7 2 8 DCD

CTS 8 1 5 CTS

RJ-45 to RJ-45 Rollover Cable RJ-45 to DB-25

Modem Adapter

Modem

Accessing the 10/100 Ethernet Management Port

Configure the 10/100 Ethernet management port, labeled 10/100 Ethernet on the primary RPM card in

order to obtain network access capability, such as downloading a runtime image onto your system. You

can connect this port to an Ethernet hub or Fast Ethernet port on a router.

Table 8-6. 10/100 Ethernet Management Port LEDs

Label Description

L (Link) Lit: Link is up.

Unlit: No connection

A (Activity) Lit: Activity on port.

Unlit: No activity

40 | RPM Ports and Cables

Page 41

9

Powering Up

This chapter provides instructions for powering up your E600i system once you have installed all the

chassis components and made your power and network connections. It covers the following topics:

• Preparation

• Supplying Power

• Booting to the CLI Prompt

Preparation

NOTE: Make sure that the switch on the remote power source is in the OFF position until you are ready to

supply power to the chassis.

Before you supply power to your chassis, Dell Force10 recommends that you re-inspect your equipment

rack and chassis.

Verify that:

• The equipment rack is properly secured and grounded.

• The chassis is bolted and secured into your equipment rack.

• Each power supply module (AC or DC) is properly installed and grounded.

• Each power supply module’s switch is in the OFF position.

• The safety covers are installed on each DC PEM.

• Power cables connect to a compliant remote power source.

• The fan tray is installed and cannot be removed by pulling on the fan tray handles.

• All line cards, RPMs, and SFMs are properly installed and secured.

• All chassis slots are filled. Blank panels and covers are installed in all empty slots.

Supplying Power

To supply power to the E600i system:

Step Task

1 Energize the remote power source.

2 Flip the switch on the AC power supplies or DC PEM to the ON position.

3 In a DC PEM, the Status LED should be green.

In an AC Power Supply, the top Input AC and Output DC LEDs should be green.

If these LEDs are not lit or the Status LED is amber on a DC PEM, check that the unit is properly installed. Verify

the power source. If the LEDs remain unlit, power off all modules and replace the unit.

Powering Up | 41

Page 42

Step Task

4 The fan tray LED should be green (online). Verify that air is flowing through the chassis.

If the fans are not operating properly or air is not flowing through the chassis, power off the chassis at the power

module. Ensure that the fan is properly installed. Verify the power source. If the fan impeller LED remains unlit,

replace the fan impeller.

To turn the power off on the power modules, use one of the following methods:

• On the DC PEMs, flip the switch to the OFF position. Make sure the AC power supplies Status LEDs

are not lit.

• On the AC Power Supplies, flip the switch to the OFF position and unplug the power cord from the

socket on the front of the Power Supply. Make sure the Input AC and Output DC LEDs are not lit (they

www.dell.com | support.dell.com

may flash as they power down.)

Booting to the CLI Prompt

After you supply power to the system, the following should occur:

• The fans should be operating.

• The green (online) fan tray, power module, RPM, SFM, and line card LEDs should be lit and remain lit

as long as the system is receiving power and is operational.

When you supply power to the E600i system, the system performs a series of power-on self tests. RPM,

line card, and SFM LEDs blink as the diagnostic programs run. No user interaction is required at this

point. Observe the process on your console monitor. When the boot process is complete, the card LEDs

remain online (green) and the console monitor displays the Command Line Interface (CLI) prompt.

NOTE: Do not press any keys or control sequences at any time during the boot process. Doing so may cause

the boot process to terminate.

Refer to the FTOS Configuration Guide found on the technical publications CD, for initial configuration

procedures and configuration instructions.

Booting from the BOOT_USER Prompt

The initial boot operation automatically brings up the system to the runtime CLI. To interrupt the

automatic boot process, issue a break key sequence (CNTL ^). The console monitor will display the

default

BOOT_USER # prompt. Refer to

Chapter A,

for instructions to continue the boot process.

42 | Powering Up

Page 43

10

Removing and Replacing Parts

This chapter provides instructions for removing and replacing E600i components. It covers the following

topics:

• Removing and Replacing the Fan Tray

• Removing and Replacing Power Modules

• Removing and Replacing RPMs, Line Cards, or SFMs

• Removing and Replacing the Air Filter

When a component fails, the E600i system triggers major or minor alarm LEDs (located on the RPM),

sends events to the SNMP trap and show alarms table, disables or changes component Status LEDs or

triggers an audible alarm. Refer to

Appendix B, Alarms, on page 61

Removing and Replacing the Fan Tray

In the event of a fan tray failure, recognized by an amber LED, an SNMP trap, or major alarm event, the

entire fan tray must be replaced. While you replace the fan tray, the E600i system will operate safely for

up to approximately 1 minute at an ambient temperature of 95° F (35° C). If one or more fans within a fan

tray fail, the system generates a minor alarm and an SNMP trap.

for more information on alarms.

CAUTION: Replace the fan tray within 1 minute of removing it when chassis is running.

WARNING: Electrostatic discharge (ESD) damage can occur when components are mishandled. Always

wear an ESD-preventative wrist or foot-heal ground strap when handling chassis components. After you

remove the original packaging, place chassis components on an antistatic surface.

The fan tray is hot-swappable. To remove and replace the fan tray , you must have access to the rear of the

chassis and be able to pull the fan tray completely out of the slot (at least 20 inches).

To remove and replace a fan tray:

Step Task

1 Unpack the new fan tray from its box.

NOTE: The fan tray weighs 20 lbs (9.072 kg).

2 Loosen the captive screws on the fan tray in the E600i with a #2 Phillips screwdriver.

3 Grip both handles and pull the fan tray halfway out of the chassis.

4 Grip the sides of the fan tray and pull it from chassis.

5 Hold the new fan tray with both hands and slide the small end several inches into the fan slot.

6 Push on the rear, near the handles, until the fan tray stops and it is flush with the chassis rear.

7 Secure the fan tray into place by gently tightening the screws. You can either tighten the screws with a #2 Phillips

screwdriver or with your fingers.

8 Verify that the fan tray LED is lit green (online).

Removing and Replacing Parts | 43

Page 44

Figure 10-1. Fan Tray

FN0076A

www.dell.com | support.dell.com

Removing and Replacing Power Modules

The E600i supports a minimum of one DC PEM or three 100 VAC Power Supplies (two for 200 VAC).

You must have one type of power module in the chassis; you cannot install a mixture of power supply

modules (see

AC Power Supply Units on page 22

slot.

Replacing 2500W AC Power Supply

). Blanks must be installed in any empty power supply

The E600i 2500W AC Power Supply (CAT# CC-E600-2500W-AC2) is capable of operating at either 1 10

VAC or 220 VAC.

CAUTION: Before removing and replacing a power supply module, determine if the E600i is in power supply

redundancy or non-redundant power. Operating in non-redundant power will require a complete system power

off when removing or replacing a power supply.

44 | Removing and Replacing Parts

Page 45

Follow the steps below to remove and replace a 2500W AC Power Supply.

Step Task

1 Flip the switch on the power supply to the OFF position.

2 Unplug the power cord from the AC Power Supply and the AC power outlet. The power supply cord is the main

disconnect device.

Loosen the power cord retainer thumb screw.

Rotate the retainer clockwise away from the power cord and remove the power cord from the socket.

Figure 10-2. Removing the Power Cord

Thumb Screw

FN00075CCH

Cord Retainer

3 Loosen the locking screws, using a #2 Phillips screwdriver.

4 Slide the power supply out of the slot.

5 If you are replacing the power supply, see

Power Cord

Install the AC Power Supply Units

. If you are not replacing the power

supply, replace the empty slot with a power supply blank cover.

Replacing DC PEMs

If you are operating your E600i chassis with redundant DC PEMs, you can install, remove, or replace a

DC PEM without affecting system operation. If you are operating your E600i system with only one DC

PEM (the minimum), you must completely power off the system.

Removing and Replacing Parts | 45

Page 46

Figure 10-3. DC PEM Label

48V in

Status

-48/-60Vdc 75A

CAUTION -

Use copper

conductors only

r

Voltage 'good' LED

Handle

Studs

48V in

Status LED

Status

CC-E600-PWR-DC

www.dell.com | support.dell.com

CAUTION -

Use copper

conductors only

-48/-60Vdc 75A

NOTE: If there is a PEM failure (the PEM status LED is not lit or amber, major alarm LED is lit, and audible

alarm sounds), the entire PEM must be replaced. There are no field serviceable parts inside the PEM unit.

WARNING: Do not remove the PEM safety cover until the power supplied by the remote power source is

OFF.

Over Current Protecto

Finger Barrier

FN00095a

Locking Screws

WARNING: To be completely sure that power has been turned off, use a voltmeter to measure the voltage

across the negative (-) and positive (+) source DC leads. The measurement across the positive and negative

leads should be zero (0) volts before you proceed with the replacement.

To remove a PEM:

Step Task

1 Ensure that the remote power source is in the OFF position and that the PEM status LED and Voltage LED are off.

2 Switch the Over Current Protector (located on the PEM front panel) to the OFF position.

3 Loosen the retaining screw and remove PEM safety cover.

4 Disconnect power cables attached to the PEM.

5 Slide the PEM out of the slot.

6 If you are replacing a PEM, go to

If you are not replacing the PEM, replace the empty slot with a PEM blank.

Removing and Replacing RPMs, Line Cards, or SFMs

WARNING: Do not remove a panel blank unless you are ready to install a line card, RPM, or SFM into that

slot. If you remove a card, immediately replace the empty slot with a panel blank. Blanks are required to

control airflow and electromagnetic interference.

WARNING: Electrostatic discharge (ESD) damage can occur when components are mishandled. Always

wear an ESD-preventive wrist or foot-heel ground strap when handling RPMs, SFMs, or line cards. After you

remove the original packaging, place RPMs, SFMs, and line cards on an antistatic surface.

Power Supply

.

46 | Removing and Replacing Parts

Page 47

NOTE: If you operate your E600i without redundant RPMs, the system enters a software-defined power-down

state when you remove the only RPM for replacement.

NOTE: Your E600i system will not function with fewer than four SFMs.

You can add, replace, or remove modules without interrupting the system power or system operations.

RPMs, line cards, and SFMs are hot-swappable. The E600i system generates major alarm events for

module failures and high temperatures (over 70°C for RPMs and over 80°C for line cards) depending on

the module and whether or not it is redundant. Minor alarms are generated for component temperatures

over 65°C for RPMs and 75°C for line cards. SNMP traps are sent for both alarm types. Refer to

Chapter B,

for more details.

To remove and replace RPMs and line cards:

Step Task

1 Unplug the network interface cables connected to the line card or RPM.

2 Loosen the captive screws and pull the ejector levers simultaneously toward you to disengage the backplane

connections.

3 Slide the card out of the slot and store the card in the original anti-static packaging.

4 If you are immediately installing a replacement card, align the new card with the guide and gently slide the card

into the slot until you feel the connectors engage with the chassis backplane.

If you are not planning to install a new card immediately, install a blank panel.

5 If you are installing a line card, follow these procedures:

• If you are hot swapping (replacing the line card with the same card type), no additional configuration is

required.

• If you are installing a different line card type, enter following configuration command:

linecard number card-type where number is a slot number from 0 to 6, and card-type is the five-

character code for the card type. Refer to the <ItalicText>FTOS Command Line Interface Reference for more

information.

• If you are replacing the line card with a blank panel, delete the line card information from the configuration by

entering:

no linecard number

6 If you are not operating your system with redundant cards (with only one line card, one RPM, and four SFMs) you

must power off your system until the cards are replaced.

To remove and install an SFM:

Step Task

1 Loosen the captive screw and pull the ejector lever towards you to disengage the backplane connections.

2 Slide the card out of the slot and store in the original anti-static packaging. System messages appear on the

console, including the following:

%TSM-6-SFM_REMOVE: Removed SFM

Wait 5 to 10 seconds to install a new SFM or reinsert an SFM. *

3 Remove the new SFM from the antistatic packaging.

Removing and Replacing Parts | 47

Page 48

Step Task (continued)

4 Align the new SFM with the guide and gently slide the card into the slot until you feel the connectors engage with

the chassis backplane.

NOTE: Hold the SFM by the edges. Avoid touching the printed circuit board and connector pins. Extend the

card lever before you insert the card into the slot.

5 Rotate the lever to seat the backplane connectors and SFM in place.

6 Secure the SFM in place using the provided screw.

7 If you are not operating your E600i system with redundancy, replace the empty slot with a filler panel blank.

Blanks do not have board components or connector pins. Align the blank with the guides and gently slide toward

the backplane. Rotate the lever to secure the blank in place.

* If you mistakenly insert an SFM too quickly after removing it, traffic flow is interrupted. To correct the

www.dell.com | support.dell.com

situation, remove an active SFM or the standby SFM, wait several seconds, and reinsert. System

messages stating that the active interfaces’ status changed and the switch fabric is up appear when an fifth

SFM is inserted correctly and traffic is flowing.

Removing and Replacing the Air Filter

A factory-installed air filter is shipped with the E600i system. The hot-swappable air filter prevents large

particles, debris, and dust from entering and circulating through the system, and ensures proper air flow

through the system. Filters should be inspected monthly and replaced every twelve months or as required.

Figure 10-4. Replacing the E600i Air Filter

WARNING: An improperly installed air filter will restrict air flow and will generate thermal problems throughout

the chassis. Ensure the air filter is oriented correctly and seated securely in the slot.

WARNING: Do not operate without a filter for any longer than 3 minutes to avoid card over-temperature

conditions.

48 | Removing and Replacing Parts

Page 49

To remove and replace the air filter:

Step Task

1

Pull the air filter straight out of the chassis to remove.

2

Rotate the replacement filter so that the side with the label “This Side Up” is facing upward. Guide the filter firmly

into the slot until it stops.

Removing and Replacing Parts | 49

Page 50

www.dell.com | support.dell.com

50 | Removing and Replacing Parts

Page 51

11

Using a Flash Memory Card

This appendix provides information about using an external flash memory card and contains the

following sections:

• External Flash Memory Card Overview

• Formatting an External Flash Card

• Inserting the External Flash Memory Card

• Removing the External Flash Memory Card

• Copying Files to the External Flash

• Displaying Files Stored on the External Flash

External Flash Memory Card Overview

Each RPM card is designed with a slot to accommodate an external flash memory card (slot0:). You can

use a flash card to copy the image and configuration files for storage and backup purposes. For complex

configurations, use the copies for other E600i systems in your network. Configure your boot execution

process to use the images stored on a flash card as the primary (active), secondary (standby), or default

boot order preference. Optional external flash memory cards are shipped blank.

Inserting the External Flash Memory Card

NOTE: Only insert the external flash before system boot or after the system has completed its boot and is run-

time mode.

To install the flash memory card:

Step Task

1 Press the ejector button to ensure it is in the extended position. Hold the flash card vertically (with the manufacturers

able on the left and the barcode on the right).

2 Gently insert the flash card into the primary RPM flash slot until the is card is flush with the front panel. Do not

force the flash card into the slot.

3 The In Use LED illuminates only during read or write operations.

Removing the External Flash Memory Card

To remove the flash memory card:

Step Task

1 Extend the ejector button by pressing the ejector button. Then press the ejector button again to eject the memory

card.

2 Remove the card and store it in an antistatic bag.

Using a Flash Memory Card | 51

Page 52

Formatting an External Flash Card

New external flash cards must be formatted in the E600i before use.

Flash cards used on systems other than the E600i as well as cards formatted on PCs must be reformatted

in the E600i flash slot before they can be used. Similar to formatting a new diskette, formatting erases all

information stored on the flash card. To format the flash card:

Step Task

1 Insert the flash card into the flash slot on the primary RPM.

2 In the EXEC CLI mode, enter format slot0:

3 The formatted flash card is ready to use.

www.dell.com | support.dell.com

Copying Files to the External Flash

Copy files to the flash when you want keep a backup image. The In Use LED illuminates during a read or

write operation. Do not eject the flash card from the slot while this LED is lit.

To copy files to the external flash card use the following command:

Command Syntax Command Mode Purpose

copy file-url1 file-url2 EXEC Privilege Configure the following parameters:

• file-url1: the file source

• file-url2: enter slot0://

Displaying Files Stored on the External Flash

Flash cards can be used to copy and store system images, boot images, and configuration files. Optional

flash memory cards are shipped blank.

To display files stored on a flash use the following command:

Command Syntax Command Mode Purpose

dir [filesystem] EXEC Privilege Configure the following optional parameters to view files on the

flash card:

• filesystem: enter either flash: for the internal flash or

slot0: for the external flash.

The default is flash: (the internal flash). To view the external

flash, enter dir slot0:

52 | Using a Flash Memory Card

Page 53

Figure 11-1. dir Command Example

Force10#dir slot0:

Directory of slot0:

1 -rwx 6478482 Sep 7 101 16:54:34 E1200.BIN