Page 1

Dell Force10

E300, E600i, and E1200i

Systems

Quick Start Guide

Regulatory Model: E300/E600i

TeraScale/E600i ExaScale/

E1200i TeraScale/E1200i

ExaScale

Page 2

Page 3

Dell Force10

E300, E600i, and E1200i

Systems

Quick Start Guide

Regulatory Model: E300/E600i

TeraScale/E600i ExaScale/

E1200i TeraScale/E1200i

ExaScale

Page 4

Notes, Cautions, and Warnings

NOTE: A NOTE indicates important information that helps you make better use

of your computer.

CAUTION: A CAUTION indicates potential damage to hardware or loss of

data if instructions are not followed.

WARNING: A WARNING indicates a potential for property damage,

personal injury, or death.

If you purchased a Dell n Series computer, any references in this publication to

Microsoft

Windows operating sys tems are not applicable.

____________________

Information in this publication is subject to change without notice.

© 2011 Dell Inc.Allrightsreserved.

Reproduction of these materials in any manner whatsoever without the written permission of Dell Inc.

is strictly forbidden.

Trademarks used in this text: Dell™, the DELL logo, Dell Precision™, OptiPlex™, Latitude™,

PowerEdge™, PowerVault™, PowerConnect™, OpenManage™, EqualLogic™, KACE™,

FlexAddress™ and Vostro™ are trademarks of Dell Inc. Intel

®

Celeron

registered trademark and AMD Opteron™, AMD Phenom™, and AMD Sempron™ are trademarks

of Advanced Micro Devices, Inc. Microsoft

Windows V ista

States and/or other countries. Red Hat Enterprise Linux

trademarks of Red Hat, Inc. in the United States and/or other countries. Novell

trademark and SUSE ™ is a trademark of Novell Inc. in the United States and other countries. Oracle

is a registered trademark of Oracle Corporation and/or its affiliates. Citrix

XenMotion

and/or other countries. VMware

trademarks or trademarks of VMWare, Inc. in the United States or other countries.

Other trademarks and trade names may be used in this publication to refer to either the entities claiming

the marks and names or their products. Dell Inc. disclaims any proprietary interest in trademarks and

trade names other than its own.

Regulatory Model: E300/E600i TeraScale/E600i ExaScale/E1200i TeraScale/E1200i ExaScale

2011 - 9 P/N 08VJV0 Rev. A00

are registered trademarks of Intel Corporation in the U.S. and other countries. AMD® is a

®

®

are either trademarks or registered trademarks of Microsoft Corporation in the United

®

are either registered trademarks or trademarks of Citrix Systems, Inc. in the United States

®

, Virtual SM P®, vMotion®, vCenter®, and vSphere® are registered

, Windows®, Windows Server®, MS-DOS® and

®

, Pentium®, Xeon®, Core™ and

®

and Enterprise Linux® are registered

®

is a registered

®

, Xen®, XenServer® and

®

Page 5

About this Guide

This document is intended as a Quick Start Guide to get new systems up and

running and ready for configuration. For complete installation and configuration

information, refer to the following documents:

Documentation E300 E600i E1200i

Hardware

installation and

power-up

instructions

Software

configuration

Command line

interface

Latest updates FTOS Release Notes

Installing and

Maintaining the

E300 System

FTOS Configuration

Guide

FTOS Command

Line Reference

Guide

E600i System

Installation Guide

E600i TeraScale

Installation Guide

FTOS Configuration

Guide

FTOS Configuration

Guide for ExaScale

FTOS Command

Line Reference

Guide

FTOS Command

Line Reference

Guide for ExaScale

for the E-Series

TeraScale

FTOS Release Notes

for the E-Series

ExaScale

E1200i ExaScale

Installation Guide

Installing and

Maintaining the

E1200i System

FTOS Configuration

Guide

FTOS Configuration

Guide for ExaScale

FTOS Command

Line Reference

Guide

FTOS Command

Line Reference

Guide for ExaScale

FTOS Release Notes

for the E-Series

TeraScale

FTOS Release Notes

for the E-Series

ExaScale

About this Guide 3

Page 6

4 About this Guide

Page 7

1

Installing the Hardware

This guide assumes all site preparation has been performed before installing the

chassis.

Installing the Chassis

To install an E-Series chassis, Dell Force10 recommends that you complete the

installation procedures in the order presented below.

NOTE: Unless stated otherwise, the installation instructions below apply to all of

the E-Series chassis.

Always handle the system and its components with care. Avoid dropping the

switch or its field replaceable units.

CAUTION: The E-Series systems are packaged in one or two separate

containers. Use an equipment lift or pallet jack to lift or install the chassis.

Lifting the system by its shelves will cause damage to the chassis.

NOTE: If you are installing the chassis without using an equipment lift or pallet

jack, remove all AC power supplies, the fan tray , line cards, RPMs and SFMs from

the chassis prior to lifting it.

CAUTION: Always wear an ESD-preventive wrist or heel ground strap when

handling the chassis and its components. As with all electrical devices of this

type, take all necessary safety precautions to prevent injury when installing

this system. Electrostatic discharge (ESD) damage can occur if components

are mishandled.

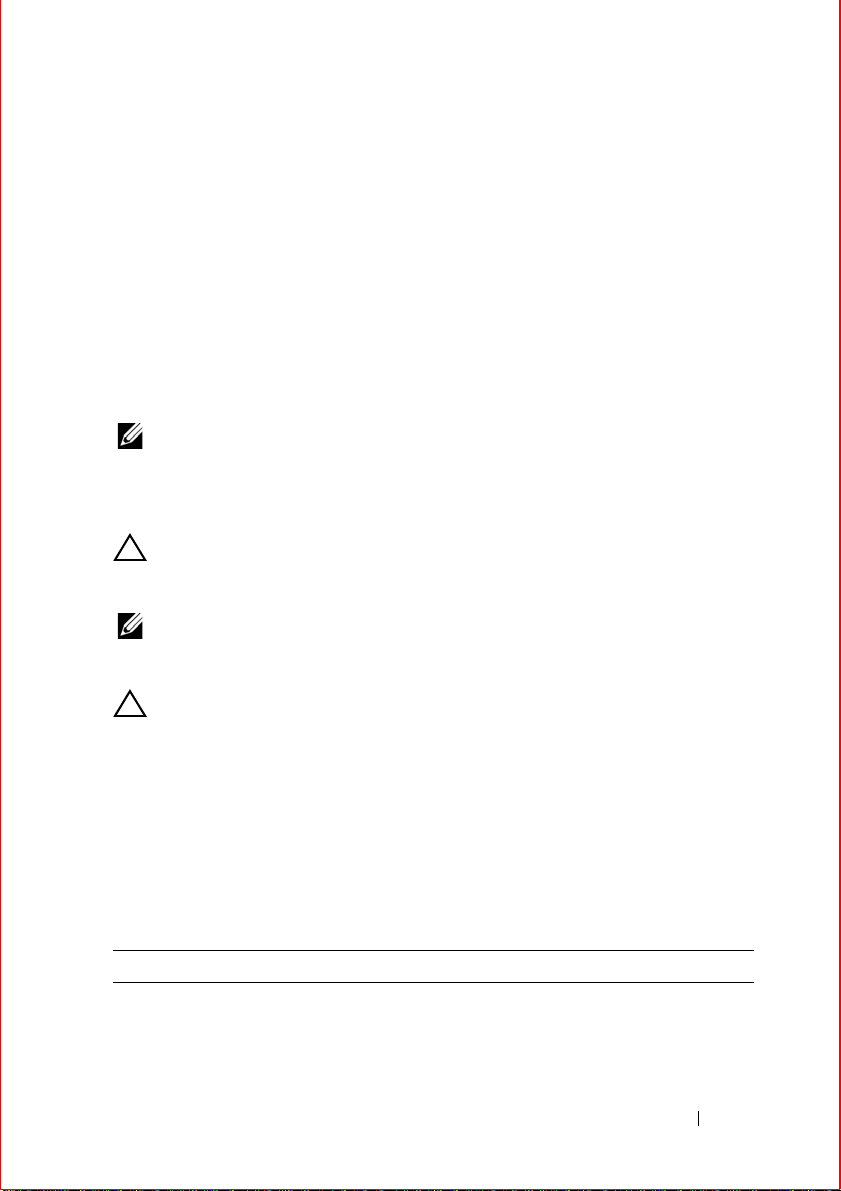

Installing the Equipment Rack Shelf Bar

The equipment rack shelf bar must be installed first for all of the E-Series

chassis.

Step Task

1 Determine the chassis mounting location in the equipment rack.

2 Orient the bar with the arrows pointing upward. The smooth side of the

bar should face outward.

Installing the Hardware 5

Page 8

Step Task

3 Attach the bar to the equipment rack brackets using the mounting screws

provided by the rack manufacturer.

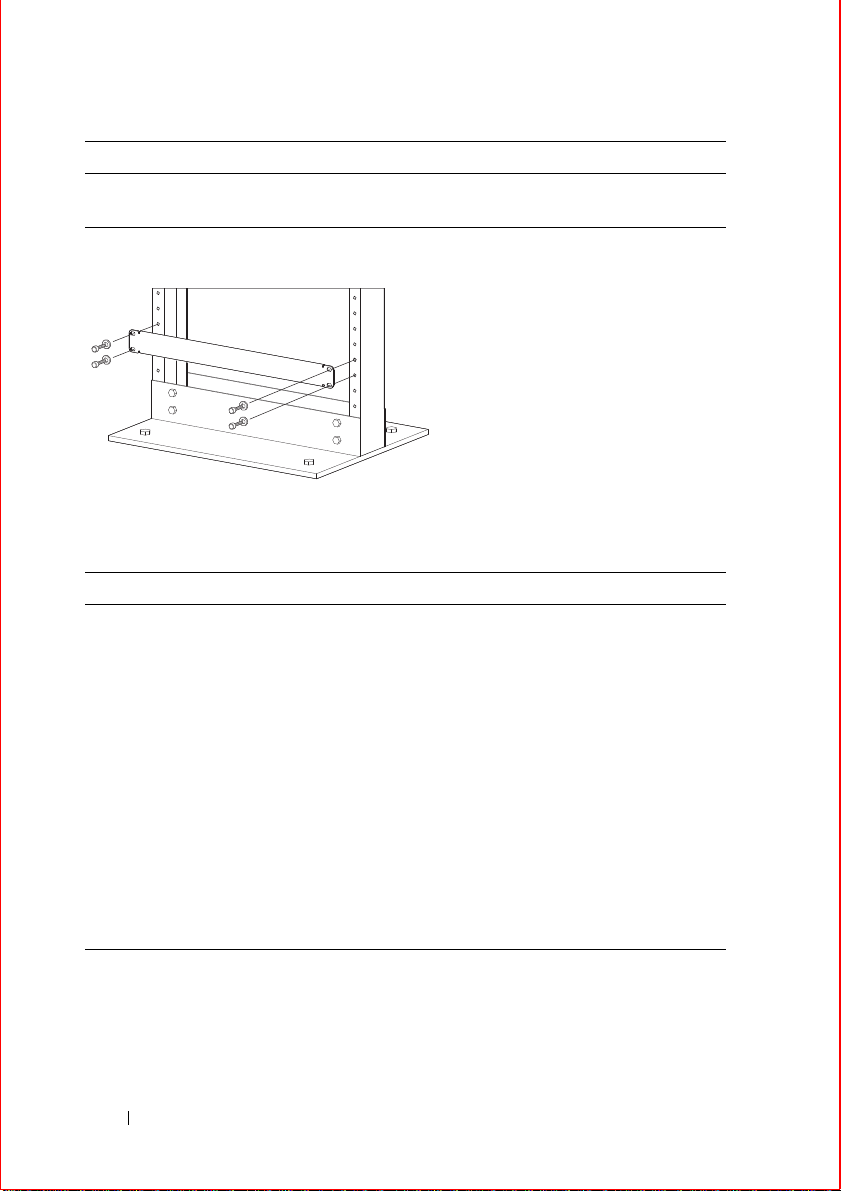

Installing the Chassis in a Two-Post Rack

Step Task

1 If you are center or rear mounting the chassis in a 19-inch rack, make

sure that the mounting brackets are properly positioned.

If your are mounting the chassis in a 23-inch rack, install the 23-inch

adapters.

2 Using a hand cart, pallet jack, or forklift, align the rack-mount holes

with the equipment rack holes, situating the chassis on top of the

equipment rack shelf bar.

3 Insert rack mounting screws in the holes that are not obscured by the

front shipping cover. Tighten the screws.

4 Loosen and remove the screws attaching the front shipping cover.

Remove the cover.

5 Insert the remaining rack mounting screws and tighten to secure the

chassis in the rack.

6 Installing the Hardware

Page 9

Installing E300 Chassis into Rack

FN00046d

Installing E600i and 1200i into Rack

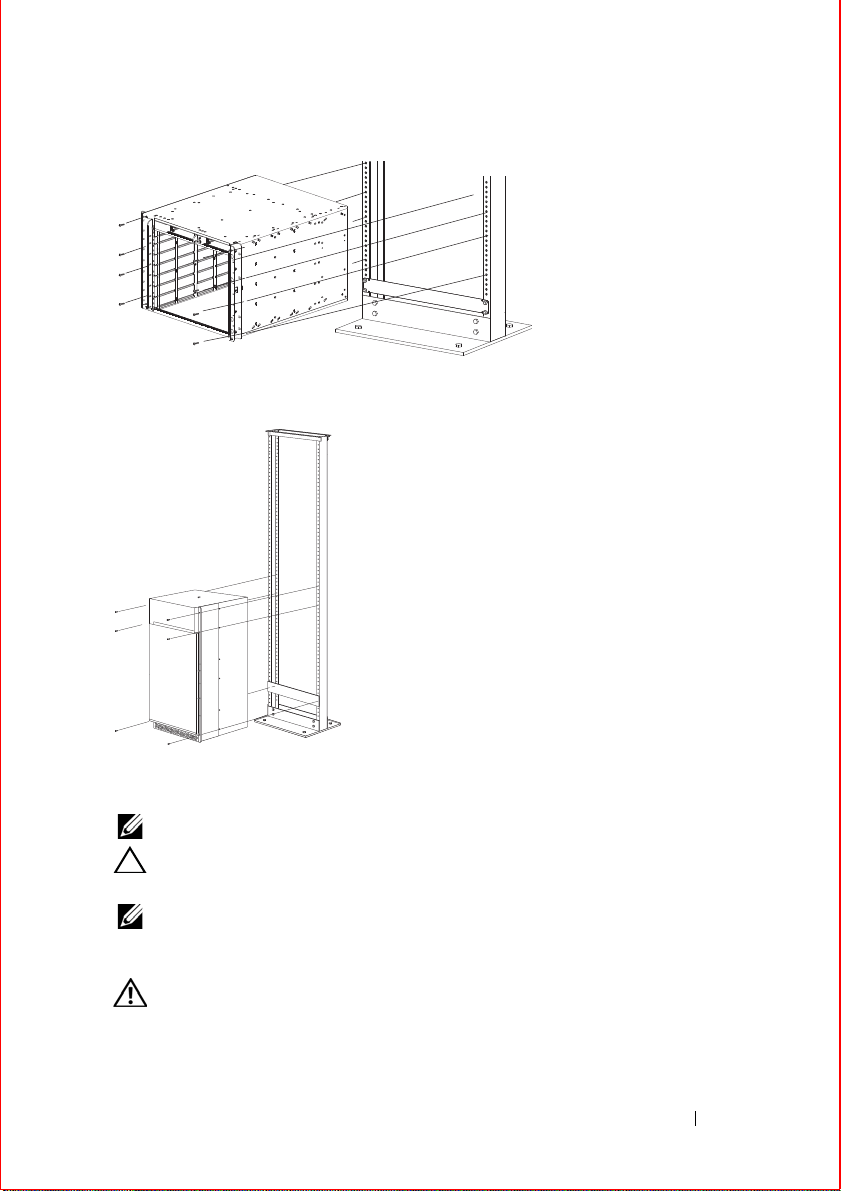

Attach a Ground Cable to the Chassis

NOTE: The rack installation ears are not suitable for grounding.

CAUTION: Grounding conductors must be made of copper. Do not use

aluminum conductors.

NOTE: Coat the lugs with an anti-oxidant compound prior to crimping. Bring any

un-plated mating surfaces to a shiny finish, and coat with an anti-oxidant prior to

mating. Plated mating surfaces must be clean and free from contamination.

WARNING: You must complete the ground connection before proceeding

with the DC PEM installation. It is also recommended that you complete the

grounding before connecting the AC PSU power.

Installing the Hardware 7

Page 10

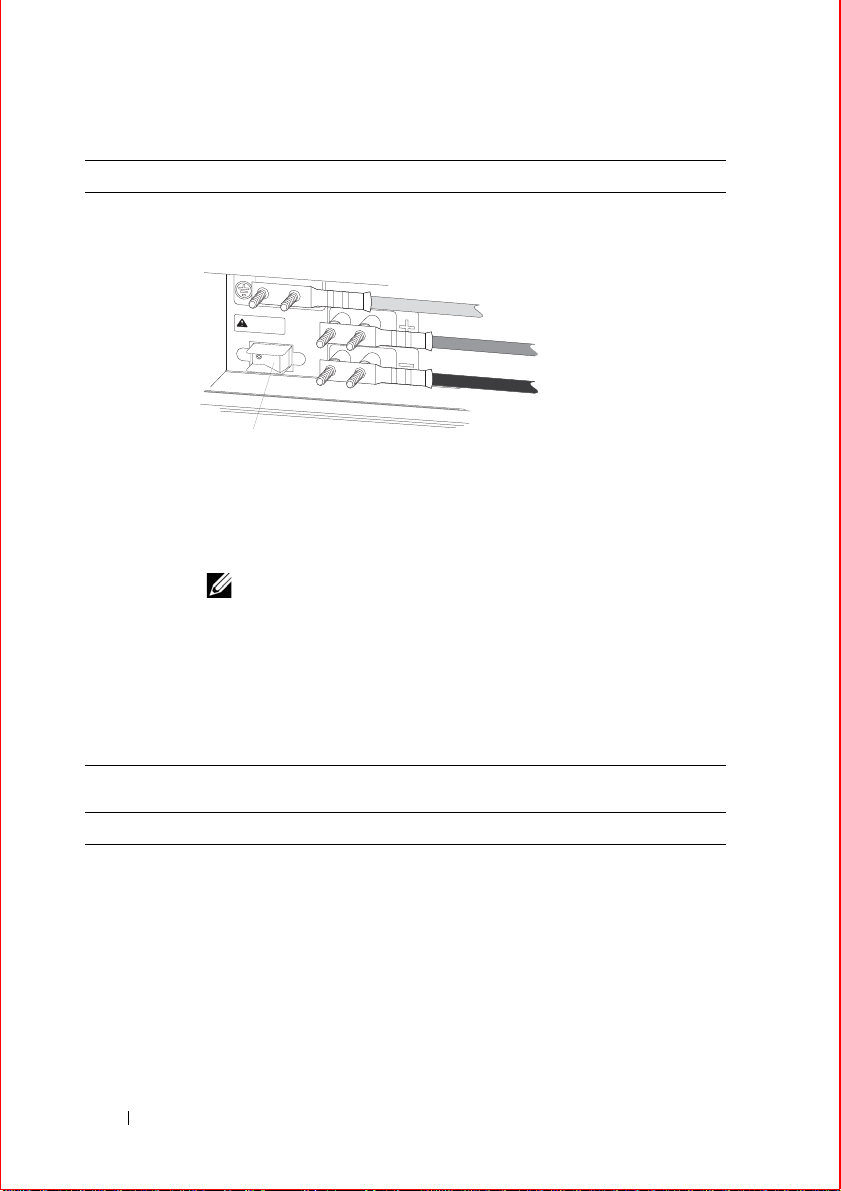

E300 DC PEM Chassis Ground

MAKE GROUND CONNECTION FIRST

CAUTION - CAUTION -

Use copperUse copper

conductors onlyconductor

s only

(-) -48V cable, typically black

Ground cable, typically green or

green with yellow stripes

(+) Return cable, typically red

Over-current protector switch

Step Task

1 Locate the chassis ground connector studs on the PEM front panel. The

two studs on the upper left are the ground connection.

2 Remove all nuts and washers from the two ground studs.

3 Apply a coat of anti-oxidant paste to the connector studs.

4 Install the grounding cable. This cable is typically green or green and

yellow.

NOTE: T e rmination points require UL-listed 2-ho le lug with 1/4-

inch holes on 3/4-inch spacing.

5 Replace the two washers and nuts on the studs.

6 Secure the nuts with a nut driver or torque wrench (not to exceed 4

ft/lbs).

7 Connect the opposite end of the grounding cable to the appropriate

nearest grounding.

E600i TeraScale and ExaScale DC Chassis Ground

Step Task

1 Remove one outer nut and one washer from each of the six studs. The

2 Locate the chassis ground connector studs on the PEM front panel. The

8 Installing the Hardware

inner nut should remain tight on the stud, at no more than 25 inch-lbs.

two bottom studs are the ground connection.

Page 11

Step Task

0.750"

High-strand-count

conductor

diameter

2 Holes

All measurements in inches.

FN00011A

0.267

3 Attach the grounding cable onto the ground studs. The grounding cable

must comply with your local electrical codes in size and color (typically

the color is green or green with yellow stripe),

NOTE: Grounding cables must be terminated only with a UL-

listed 2-hole lug with 1/4-inch holes on 3/4-inch spacing.

Cable Connector Required for E600i DC

4

Replace the two washers and nuts.

5 With a 7/16-inch box or socket wrench, tighten the nuts to 25 in-lbs.

6 Connect the opposite end of the grounding cable to the nearest

appropriate facility grounding post.

Installing the Hardware 9

Page 12

E1200i TeraScale and ExaScale AC Chassis Ground

0.750"

High-strand-count

conductor

diameter

2 Holes

All measurements in inches.

FN00011A

0.267

Step Task

1 Locate the chassis ground connector nuts on the rear of the chassis.

2 Install the grounding cables to the ground nuts. The grounding cable

must comply with your local electrical codes in size and color (typically

the color is green or green with yellow stripe).

NOTE: Grounding cables must be terminated only with a UL-

listed 2-hole lug with 1/4-inch holes on 3/4-inch spacing.

Cable Connector Required for E1200i AC

3

4 Tighten the bolt (torque should not exceed 25 inch/lbs).

5 Connect the opposite end of the grounding cable to the nearest

E1200i TeraScale and ExaScale DC Chassis Ground

Step Task

1 Remove one outer nut and one washer from each of the six studs. One

2

10 Installing the Hardware

Use ANSI UNC 1/4-20 x 12 bolt.

appropriate facility grounding post.

nut should remain, tight on the stud. If the inner nut is loose, re-tighten it

to 25 inch/lbs, maximum.

Locate the chassis ground connector stud s on the PEM fron t p anel. The

two rightmost studs are the ground connection.

Page 13

Step Task

0.750"

High-strand-count

conductor

diameter

2 Holes

All measurements in inches.

0.267

3

Install the grounding cables to the ground studs. The grounding cable must

comply with your local electrical codes in size and color (typically the

color is green or green with yellow stripe).

NOTE:

Grounding cables must be terminated only with a UL-

listed 2-hole lug with 1/4-inch holes on 3/4-inch spacing.

Cable Connector Required for E1200iDC PEM

4 Replace the two washers and nuts on the studs.

5 With a 7/16-inch box or socket wrench, tighten the nuts (torque should

not exceed 25 inch/lbs).

6 Connect the opposite end of the grounding cable to the nearest

appropriate facility grounding post.

Installing Power Modules

This section provides instructions to install AC Power Supply Units (PSUs) and

DC Power Entry Modules (PEMs) in each E-Series system. E-Series systems

may contain only one type of power module—AC or DC.

Unless otherwise stated, each AC and DC power supply for each E-Series

system is shipped with a Dell Force10-approved power cord and only that cord

should be used to connect the power supply to the appropriate outlet.

E300 AC Power Modules

The E300 system requires a minimum of two AC Power Supplies.

WARNING: To prevent electrical shock, make sure the system is grounded

properly . If you do not ground your equipment correctly, excessive emissions

may result. Use a qualified electri cian to en su re that the power cables meet

your local electrical requirements.

Installing the Hardware 11

Page 14

WARNING: Electrostatic discharge (ESD) damage can occur when

components are mishandled. Always wear an ESD-preventive wrist or footheal ground strap when handling chassis components.

CAUTION: Before removing and replacing a power supply module,

determine if the E300 is in full facility redundancy or non-redundant power.

Operating in non-redundant power will require a complete system power off

when removing and replacing a power supply.

CAUTION: The power cord is the main power disconnect device; ensure that

the socket-outlet is located/installed near the equipment and is easily

accessible.

The E300 contains four power supply slots in the rear of the chassis.

Each AC power supply contains two LEDs: Status and AC.

To install an AC power supply:

Step Task

1 Togg le the Standby Switch of the power supply to the standby position.

NOTE: If the E300 is already operating in redundant mode, you

can insert a new power supply without shutting down the E300.

2 Slide the power supply into any open power supply slot.

CAUTION: Fill all four power supply slots with power

supplies or filler blanks before tightening the power supply

screws. Doing this ensures that each power supply is aligned

correctly . Attempting to tighten screws without all power

supply slots filled will cause misalignment with screw holes,

which might damage the chassis permanently.

12 Installing the Hardware

Page 15

Step Task

3 For bottom units, ensure that the EMI gasket along the edge of each

power supply is compressed smoothly before securing each power

supply into place using the captive screws.

For top units, it may be necessary to lift the unit slightly to install the

captive screws.

As a best practise, insert the two captive screws of each power supply by

hand before tightening them all.

CAUTION: Tighten the screws with a #2 Phillips screwdriver.

Use no more than eight pounds of torque (light torque with a

manual screwdriver). Too much torque can damage fasteners

and that improper use of power drivers can cause even greater

damage.

4 Plug the AC power cord into the AC power inlet in the face of the powe r

supply.

5 Plug the AC power cord into an AC power outlet.

6 Toggle the standby switch of the power supply to the On position.

NOTE: Power modules are not field serviceable.

E300 DC Power Modules

The E300 supports a minimum of one DC PEM. Y ou must have only one type of

power module in the chassis; you cannot install a mixture of power modules.

You must provide your own cables to connect to a remote power source (a

circuit breaker panel, for example) in your equipment rack or facility. Cables

must be sized to meet the following criteria:

• Rated for 60A service to allow for a fully lo aded E300 system per NEC in the

United States or internationally, per local safety codes.

• Limit voltage drop across the cable length to 0.5V or less.

Before you make the cable connections, apply a coat of anti-oxidant paste to

unplated metal contact surfaces. File unplated connectors, braided straps, and

bus bars to a shiny finish. It is not necessary to file and coat tinned, solderplated, or silver-plated connectors or other plated connection surfaces, such as

those on the PEM studs.

Installing the Hardware 13

Page 16

NOTE: Please take precautions against over-tightening the screws or nuts on this

device.

Installing a DC PEM

Step Task

1 Turn the remote power source (the circuit breaker panel) to the OFF

position.

2 Turn the over current protector (located on the PEM front panel) to the

OFF position.

3 Loosen the PEM safety cover retaining screw and remove the cover.

4 Slide the PEM into power slot 0 or 1.

CAUTION: Fill all power supply slots with power supplies or

filler blanks before tightening the power supply screws. Doing

this ensures that each power suppl y is ali g n ed correctly.

Attempting to tighten screws without all power supply slots

filled will cause misalignment with screw holes, which might

damage the chassis permanently. If you are only installing one

PEM, replace the empty slot with two blank panels. (CCE300-BLNK-PWR.)

5 Tighten the two locking screws on each module with a #2 Phillips

screwdriver to secure the PEM in place. As a best practise, insert all

screws before tightening each one.

6 Remove the outer nut and washer from each of the remaining studs.

7 Connect the -48 VDC and Return cables from each PEM to the remote

power sources.

a

Verify that the remote power source is in the OFF position.

b

Locate the appropriate studs on the PEM front panel. The two top

studs are the return (+) connection. The cable attach ed to thes e s tu ds

is typically red. The two bottom studs on the PEM are the -48 VD C () connection. The cable attached to these studs is ty pica lly b la ck .

Power cables must be terminated only with a UL-listed 2-hole lug to

accommodate 1/4-inch studs with 3/4-inch spacing.

c

Apply a coat of anti-oxidant paste to the connector studs.

d

Replace the washers and nuts on the studs.

e

Route the terminated cables out toward the rack rail.

f

Secure the nuts with a nut driver or torque wrench (no t to exce ed 4

ft/lbs).

14 Installing the Hardware

Page 17

Step Task

8 Replace the safety cover and tighten the captive screw with a #2 Phillips

screwdriver.

9 Turn the Over Current Protector to the ON position.

10 Turn the remote power source (the circuit breaker panel) to the ON

position.

E600i AC Power Modules

The E600i requires a minimum of two AC Power Supplies.

Power Supply Input Minimum (N) Redundancy

220 VAC 3 N+1

100 VAC 2 N+1

The chassis has four power supply slots. You may install AC power suppl ies in

any slot.

WARNING: Class 1 laser product.

The 2500W AC Power Supply Unit is capable of operating at either 100 V AC or

220 VAC.

CAUTION: Before removing and replacing a power supply unit, determine if

the E600i is in full redundancy or non-redundant mode. Operating in nonredundant mode will require a complete system power off when removing and

replacing a power supply.

NOTE: Do not mix power supply versions. Installing a 2500W-AC2 power supply

into a chassis with 2500W-AC power supplies already installed may result in

unpredictable behavior. FTOS will declare an alarm when the PSUs are mixed.

To install an AC power supply:

Step Task

1 Verify that the power switch on the power supply is in the OFF position.

2 Orient the power supply handle to the left, and slide the backplane

connector end into a power supply slot.

Installing the Hardware 15

Page 18

Step Task

3 Secure the power supply into place by tightening the two locking screws

to 5 in-lbs.

4 Plug an AC power cord into the socket on the front of the unit:

a

Loosen the power cord retainer thumb screw.

b

Rotate the retainer clockwise away from the socket and plug the

power cord into the socket.

c

Rotate the retainer counter clockwise over the power cord, and

tighten the thumb screw to secure the power cord.

5 Plug the AC power cord into an AC outlet.

6 Toggle the power supply switch to the ON position, and verify that

Status LED lights green.

E600i DC Power Modules

The system requires a minimum of one load-sharing PEM to operate, but two

are recommended for redundancy. Connect the E600 PEMs to the appropriate

branch circuit protection as defined by local electrical codes.

You must provide your own cables to connect to a remote power source in your

equipment rack. Verify that your cables are:

• Rated for at least 80A service to allow for a fully load ed E600i system at low

input voltage per your local electrical codes.

• Limit voltage drop across the cable length to 0.5V or less.

Before you make the cable connections, apply a coat of anti-oxidant paste to

unplated metal contact surfaces.

File unplated connectors, braided straps, and bus bars to a shiny finish. It is not

necessary to file and coat tinned connectors or other plated connection surfaces,

such as on the PEM studs.

Installing a DC PEM

Step Task

1 Make sure that the remote power source (the circuit breaker panel) is in

the OFF position.

2 Make sure that the over current protector (located on the PEM front

panel) is in the OFF position.

16 Installing the Hardware

Page 19

Step Task

3 Loosen the retaining screw and remove PEM safety cover.

4 Slide the backplane connector end of the PEM into Power Supply Slot 1

or 3. Secure the PEM to the chassis by tighten the two locking screws.

E1200i AC Power Modules

When installing the AC power supplies in the E1200i system, make note of the

following:

• E1200i ExaScale AC system: The E1200i AC system requires a minimum of

3 AC power supplies in a shelf (0, 1, 2 or 3, 4, 5) to operate. For full

redundancy use 6 power supplies so that if one power supply fails in one

shelf, the system remains operational operates with the 3 power supplies in

the other shelf. T o comp ly with safety agency and E MI regulations, you mus t

install the AC-cord retainer over all power cords. The E1200i AC chassis

contains 6 AC power supply slots.

• E1200iT e raScale AC system: T he E1200i A C system requires a minimum of

two AC power supplies to operate, three for power redundancy, four for

facility redundancy (2+2), and 6 for 3+3 redundancy. To comply with safety

agency and EMI regulations, you must install the AC-cord retainer over all

power cords. The E1200i AC chassis contains six AC power supply slots.

NOTE: If you are installing only two power supplies, they must be installed in the

same row. FT OS will generate an error me ssage if the two power supplies are not in

the same row.

NOTE: The On/Standby switch disconnects power to the rest of the chassis from

all 6 AC power supplies. When the AC cord is attached, power supply fans will

spin and the LEDs will indicate status while the On/Standby switch is in Standby.

CAUTION: An E1200i AC power supply still has power after extraction, and

has completely powered off when the fans have stopped rotating. When

replacing a power supply, to avoid arcing and discoloration of the supply and

the chassis pins, please wait for the fans to stop rotating before reinserting the

supply.

Step Task

1 Make sure that the On/Standby switch, located on the left side of plug

AC-0, is in the Standby (up) position.

Installing the Hardware 17

Page 20

Step Task

2 Loosen the cord retainers locking screws (if needed) and tilt the AC-

cord retainer up approximately 15 degrees and gently slide the cover

away from the chassis.

3 Slide the power supplies into their slots until the module front is flush

with the shelf front.

4 Connect the Power Supply cord to the designated socket.

5 Re-install the AC-cord Retainer by tilting approximately 15 degrees and

gently sliding in the long edge just above the AC cords.

6 Secure the retainer by tighten the locking screws on either side of the

retainer.

WARNING: Leakage Current (High T ouch Current) in AC-powered systems:

AC power cords are secured to the power inlet using the provided brackets.

The power cord plugs must be secured to the building outlets by the qualified

chassis installer or a qualified electrician.

E1200i DC Power Modules

The E1200i DC system requires a minimum of one DC Power Entry Module

(PEM) to operate, but two are recommended for redundancy. To comply with

safety agency and EMI regulations, you must install covers on all power supply

slots not containing a PEM. Connect the PEMs to the appropriate branch circuit

protection as defined by local electrical codes.

The E1200i DC chassis contains two DC PEM slots.

You must provide your own cables to connect to a remote power source (for

example, a circuit breaker panel) in your equipment rack or office. Cables must

be sized to meet the following criteria:

• Rated for at least 150A service to allow for a fully loaded E 1200i DC sy stem

at low input voltage per your local electrical codes.

• Limits voltage drop across the cable length to 0.5V or less.

Before you make the cable connections, apply a coat of antioxidant paste to unplated metal contact surfaces. File un-plated connectors, braided straps, and bus

bars to a shiny finish. It is not necessary to file and coat tinned connectors or

other plated connection surfaces, such as on the E1200i DC PEM studs.

18 Installing the Hardware

Page 21

WARNING: An external disconnect shall be provided and shall be easily

accessible. Dell Force10 recommends that you use a 150A circuit breaker.

Use the following steps to install a DC PEM:

Step Task

1 Make sure that the remote power source (the circuit breaker panel) is in

the OFF position.

2 Make sure that the over-current protector (located on the PEM front

panel) is in the OFF position.

3 Loosen the retaining screw and remove the PEM safety cover.

4 Slide the PEM into the 0 or 1 slot:

a

Lift up and hold the PEM interlock lever and carefully push the unit

inward to fully seat it to the backplane. When the PEM is fully

inserted, the interlock lever will drop to hold the PEM in position.

b

Tighten the tw o l o c k i ng screws with a #2 Phillips screw driv er to

secure the PEM. Do not exceed 5 inch/lbs torque.

5 Connect the -48 VDC and Return cables from each PEM to the remote

power sources (circuit breakers A and B).

a

Check that the remote power sources (for example, circ uit bre ak ers)

are in the OFF position.

b

Locate the appropriate studs on the PEM front panel.

c

The two left most studs on the PEM are the -48 VDC (-) connection.

The cable attached to these studs is typically black. The two m iddle

studs are the return (+) connection. The cable attache d to th es e studs

is typically red.

d

Install the -48 VDC and Return cables on the studs. The cables

should be of the size and color to comply with local electrical codes.

NOTE: Power cables must be terminated only with a UL-listed 2-

hole lug with 1/4-inch studs with 3/4-inch spacing.

e

Replace the washers and nuts on the studs.

f

With a 7/16-inch box or socket wrench, tighten the nuts.

6 Route the terminated cables down and toward the rack rail.

7 Replace the safety cover and tighten the captive screw with a #2 Phillips

screwdriver.

Installing the Hardware 19

Page 22

Step Task

8 Check that the over-current protector (located on the PEM front panel)

is in the OFF position. Energize the remote power source. The Voltage

LED should be green. If it is amber, the -48 VDC and Return cables are

connected incorrectly or are reversed.

Installing RPMs, Line Cards, and SFMs

Unpacking Cards

WARNING: Electrostatic discharge (ESD) damage can occur when

components are mishandled. Always wear an ESD-preventive wrist or footheel ground strap when handling RPMs, SFMs, or line cards. Connect your

ESD strap to the grounding plug located on the front of the chassis. See Figure

2 for ESD strap connector location. After you remove the original packaging,

place RPMs, SFMs, and line cards on an antistatic surface.

CAUTION: Do not supply power to your system until the power supplies and

fan tray(s) are installed and verified, and RPMs, SFMs, line cards, and any

blank panels are installed.

Blank Panels

CAUTION: To avoid a chassis over-temperature condition, install blanks for

RPMs, SFMs, and line card slots not in use. Always replace cards or blanks

immediately.

Blank panels for RPMs, SFMs, and line cards must be installed in empty slots to

control airflow. Blank panels are shipped with the system to ensure that all

chassis slots are installed with operational modules or blanks.

E300

RPMs

The E300 system requires the installation of at least one RPM, although two are

recommended for redundancy. RPMs are designed to be installed in either the

R0 or R1 slot. Do not force RPMs into line card slots. RPMs are keyed

differently than line cards to prevent improper installation.

20 Installing the Hardware

Page 23

Installing the RPMs and Line Cards

CAUTION: Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous laser exposure.

NOTE: Line cards are hot swappable.

Step Task

1 Hold the card by the edges. A void touching the printed circuit board and

connector pins. Extend the left and right card levers before you insert

the card into the slot.

2 Align the card with the guide and gently slide it into the slot until you

feel the connectors engage with the chassis backplane.

3 Rotate the levers to seat the backplane connectors and line card in place.

4 Secure card and blanks in place by tightening the left and right captive

screws on each card.

5 Follow the same installation procedure for the remaining cards and slots.

Installing Switch Fabric Modules (SFMs)

Two SFMs are required for the E300 system to operate optimally.

Step Task

1 Remove an SFM from the anti-static packaging. Hold the card by the

edges. Avoid touching the printed circuit board and connector pins.

Extend the card lever before you insert the card into the slot.

2 Align the SFM with the guide and gently slide it into the slot until you

feel the connectors engage with the chassis backplane.

3 Rotate the lever to seat the backplane connectors and card in place.

4 Secure each SFM in place by tightening the captive screw.

5 Continue the process for the remaining SFMs.

6 Install blank panels in all unused slots.

NOTE: If you are not operating the system with SFM redundancy, install a blank

panel in the unused slot.

Installing the Hardware 21

Page 24

E600i

RPMs

The E300 system requires the installation of at least one RPM, although two are

recommended for redundancy. RPMs are designed to be installed in either the

R0 or R1 slot. Do not force RPMs into line card slots. RPMs are keyed

differently than line cards to prevent improper installation.

Line Cards

Your E600i configuration requires a minimum of one line card. Line cards are

hot swappable.

Installing the RPMs and Line Cards

CAUTION: Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous laser exposure.

NOTE: Line cards are hot swappable.

Step Task

1 Hold the card by the edges. A void touching the printed circuit board and

connector pins. Extend the left and right card levers before you insert

the card into the slot.

2 Align the card with the guide and gently slide it into the slot until you

feel the connectors engage with the chassis backplane.

3 Rotate the levers to seat the backplane connectors and line card in place.

4 Secure card and blanks in place by tightening the left and right captive

screws on each card.

5 Follow the same installation procedure for the remaining cards and slots.

Installing Switch Fabric Modules (SFMs)

A minimum of four SFMs are required in order for the E600i system to operate

properly. There is an additional slot available for a redundant SFM.

NOTE: If you are not operating the system with SFM redundancy, install a blank

panel in the unused slot.

22 Installing the Hardware

Page 25

Step Task

1 Remove an SFM from the anti-static packaging. Hold the card by the

edges. Avoid touching the printed circuit board and connector pins.

Extend the card lever before you insert the card into the slot.

2 Align the SFM with the guide and gently slide it into the slot until you

feel the connectors engage with the chassis backplane.

3 Rotate the lever to seat the backplane connectors and card in place.

4 Secure each SFM in place by tightening the captive screw.

5 Continue the process for the remaining SFMs.

E1200i

RPMs

The E1200i system requires the installation of at least one RPM, although two

are recommended for redundancy.

• Do NOT remove the cards from their protective bags until you are ready to

install them in a chassis.

• When you are ready to install the cards, unwra p and install one card at a time,

starting with the right-most slot (Slot 13 for line cards, Slot R1 for RPMs,

and Slot 9 for SFMs) ending with the l eft-most slot (Slot 0 for line cards, S lot

R0 for RPMs, and Slot 0 for SFMs).

RPMs are designed to be installed in either the center R0 or R1 slots. Since

FTOS searches for an RPM in slot 0 first, Force 10 recommends you install your

RPM in slot 0 when only running with one RPM. Do not force RPMs into line

card slots. RPMs are keyed differently than line cards to prevent improper

installation.

Line Cards

Your E1200i configuration requires a minimum of one line card. Line cards are

hot-swappable. There are 14 line card slots available in the E1200i chassis. A

minimum of one line card is required for operation. Line cards are installed in

slots 0 through 13. Ports on line cards are numbered from the top, starting from

0.

Installing the Hardware 23

Page 26

Preparing and Installing RPMs and Line Cards

To prolong the life of the EMI seals, begin installing cards in the right-most slot

(slot 13), filling the slots leftward (slot 12, then slot 11, then slot 10, and so on).

Step Task

1 Remove the line card from its box and carefully remove the line card

from the anti-static packaging.

2 Align the RPM with the guide and gently slide it into the slot until you

feel the connectors engage with the chassis backplane.

NOTE: Hold the card by the edges. Avoid touching the printed

circuit board and connector pins. Extend the top and bottom card

levers before you insert the card into the slot.

3 Rotate the levers to seat the backplane connectors and line card in place.

4 Secure card and blanks in place by tightening the top and captive screws

on each card.

5 Follow the same installation procedure for the remaining cards and slots,

in the appropriate order.

Installing Switch Fabric Modules (SFMs)

A minimum of eight SFMs are required in order for the E1200i system to

operate properly. Slot 9 allows for a redundant SFM, allowing up to ten SFMs in

the E1200i system.

CAUTION: If you are not operating your system with a redundant (tenth)

SFM, you must install an SFM blank to avoid overheating and ensure EMI

containment.

Install SFMs from the right-most slot (9) to the left-most slot (0).

Step Task

1 Remove an SFM from the anti-static packaging.

2 Align the SFM with the guide and gently slide it into the slot until you

feel the connectors engage with the chassis backplane.

NOTE: Hold the SFM by the edges. Avoid touching the printed

circuit board and connector pins. Extend the top and bottom card

levers before you insert the card into the slot.

24 Installing the Hardware

Page 27

Step Task

3 Rotate the lever to seat the backplane connectors and card in place.

4 Secure each SFM in place by tightening the captive screw.

5 Continue the process for the remaining SFMs.

6 Align any blank panels with the guides and gently slide toward the

backplane. Secure each blank panel by tightening the single captive

screw.

Power Up Sequence

WARNING: Make sure that the switch on the remote power source is in the

OFF position until you are ready to supply power to the chassis.

Follow the instructions in this section to power up all E-Series TeraScale and ESeries ExaScale systems.

Preparation

Before you supply power to your chassis, re-inspect your equipment rack and

chassis, verify that:

• The equipment rack is properly secured and grounded.

• The chassis is bolted and secured into your equipment rack.

• Each power supply module (AC or DC) is properly installed and grounded.

• Each power supply module’s switch is in the OFF position.

• The safety covers are installed on each DC PEM.

• Power cables connect to a compliant remote power source.

• The fan tray is installed and cannot be removed by pulling on the fan tray

handles.

• All line cards, RPMs, and SFMs are properly installed and secured.

• All chassis slots are filled. Blank panels and covers are installed in all empty

slots.

Installing the Hardware 25

Page 28

Supplying Power

Step Task

1 Energize the remote power source.

2 Flip the switch on the AC power supplies or DC PEM to the ON

position.

3 In a DC PEM, the Status LED should be green.

In an AC Power Supply, the top Input AC and Output LEDs should be

green. If these LEDs are not lit or the Status LED is amber on a DC

PEM, check that the unit is properly installed. Verify the power source.

If the LEDs remain unlit, power off all modules and replace the unit.

4 The fan tray LED should be green (online). Verify that air is flowing

through the chassis.

If the fans are not operating properly or air is not flowing through the

chassis, power off the chassis at the power module. Ensure that the fan is

properly installed. Verify the power source. If the fan impeller LED

remains unlit, replace the fan impeller.

To turn the power off on the power modules, use one of the following met hods:

• On the DC PEMs, flip the switch to the OFF position. Make sure the AC

power supplies Status LEDs are not lit.

• On the AC Power Supplies, flip the switch to the OFF position and unplug

the power cord from the socket on the front of the Power Supply. Make sure

the Input AC and Output DC LEDs are not lit (they may flash as they power

down.)

Booting to the CLI Prompt

After you supply power to the system, the following should occur:

• The fans should be operating.

• The green (online) fan tray, power module, RPM, SFM, and line card LEDs

should be lit and remain lit as long as the system is receiving power and is

operational.

When you supply power to the system, the system performs a series of power-on

self tests. RPM, line card, and SFM LEDs blink as the diagnostic programs run.

No user interaction is required at this point. Observe the process on your console

26 Installing the Hardware

Page 29

monitor. When the boot process is complete, the card LEDs remain online

(green) and the console monitor displays the Command Line Interface (CLI)

prompt.

NOTE: Do not press any keys or control sequences at any time during the boot

process. Doing so may cause the boot process to terminate.

CAUTION: Leakage Current (High T ouch Curr ent): The AC power cords are

secured to the power inlet using the provided bracket. The power cord plugs

must be secured to the building outlets by the chassis installer or a qualified

electrician.

Fans

For complete information on installing system FAN trays, refer to your system's

installation guide.

E300

Your E300 chassis contains one field-replaceable fan tray. Air flows through the

system toward the fans and is exhausted on the fan side of the chassis. Air

circulates from the right side to the left. Minimum air flow is 665 cubic feet per

minute (CFM).

E600i TeraScale and E600i ExaScale

Your E600i chassis contains one field-replaceable fan tray. Air flows through

the system from a filtered intake vent located in the lower part of the chassis. Air

circulates from the bottom front side to the back side and exhausts primarily

through a top rear vent. The variable speed fan rate is reduced at normal

operating temperatures and fans reach full speed at 40° C (104° F).

E1200i TeraScale and E1200i ExaScale

Your E1200i chassis contains two field-replaceable fan trays. Air flows through

the system from a filtered-intake vent located in the lower part of the chassis.

Air circulates from the bottom front (and sides) to the back and exhausts through

a top rear vent. The variable fan speed is reduced at normal operating

temperatures and increases to full speed as operating temperatures increase, up

to 104° F (40° C).

Installing the Hardware 27

Page 30

E300 Specifications

E300 Chassis Physical Design

Parameter E1200i AC Specifications

Height 14 inches (35.6 cm)

Width 17.4 inches (44.2 cm)

Depth (without cable management

system)

Chassis weight with factory-installed

components (backplane and air filter)

Weight fully loaded (backplane, air

filter, 1 fan tray, 2 SFMs, 2 RPMs, and 6

line cards)

Thermal Output

Maximum for fully loaded chassis 2500 W (8500 BTU/hour)

Normal operating conditions (25 deg.C,

-48V-line)

Minimum for chassis with one 24-port

1GE line card

E300 Environmental Parameters

Parameter Specifications

Operating

Temperature 40° to 105°F (5° to 40°C)

Maximum altitude No performance degradation to 10,000 feet (3,048 meters)

Relative humidity 5 to 85 percent, non-condensing

Non-operating

Temperature -40° to 158°F (-40° to 70°C)

Maximum Altitude 15,000 feet (4,572 meters)

Relative Humidity 5 to 95 percent, non-condensing

24 inches (61 cm)

90 pounds (approx.) (41 kg)

170 pounds (approx.) (77 kg)

2000 W (6800 BTU/hour)

800 W (2700 BTU/hour)

28 Installing the Hardware

Page 31

E300 AC Power Supplies Power Requirements

Parameter Specifications

Nominal input voltage 100 - 240 VAC 50/60 HZ

Maximum AC Power Supply Input

Current (based on 800W output for

100/120V line and 1200W output for

200/240V line.)

Maximum System Power Input

3 AC Power Supply Operation

3 AC Power Supply Operation

10 A @ 100 VAC per AC Power Supply

8.3 A @ 120 VAC per AC Power Supply

7 A @ 200 VAC per AC Power Supply

5.8 A @ 240 VAC per AC Power Supply

3000W

1000W @ 100V

950W @ 200V

E300 DC PEM Power Requirements

Parameter Specifications

Maximum System Power Dissipation 2400W

Maximum DC PEM Input Current 60A

Maximum System Power Input

3 AC Power Supply Operation

3 AC Power Supply Operation

3000W

1000W @ 100V

950W @ 200V

E300 Module Power Requirements

Module Power Requirement in Watts (in

BTU/hour)

SFM 55W (188 BTU/hour)

E300 RPM 115W (BTU/hour)

E300 fan tray 85 W

E600i Specifications

E600i TeraScale Chassis Physical Design

Parameter Specifications

Height 28 inches (71.1 cm)

Installing the Hardware 29

Page 32

Parameter Specifications

Width 17.4 inches (44.2 cm)

Depth (without cable management

system)

Chassis weight with factory-installed

components (backplane and air filter)

Weight fully loaded (backplane, air

filter, fan tray, SFMs, RPMs, and 7 line

cards)

Maximum Thermal Output

NOTE: Thermal output is directly proportional to system configuration and

number of line cards.

Maximum for fully loaded chassis 120 VAC powered: 4705W (16,065

21.5 inches (54.6 cm)

81 pounds (36.7 kg)

242 pounds (109.8 kg)

BTU/hour)

200/240 VAC powered: 4250W (14,500

BTU/hour)

DC powered: 2800W (9600 BTU/hour)

E600i TeraScale Environmental Parameters

Parameter Specifications

Operating

Temperature 32° to 104°F (0° to 40°C)

Maximum altitude No performance degradation to 10,000 feet (3,048 meters)

Relative humidity 5 to 85 percent, non-condensing

Non-operating

Temperature -40° to 158°F (-40° to 70°C)

Maximum Altitude 15,000 feet (4,572 meters)

Relative Humidity 5 to 95 percent, non-condensing

E600i TeraScale AC Power Supply Unit Requirements

Parameter Specifications

Nominal input voltage 120 - 240 VAC 50/60 Hz

30 Installing the Hardware

Page 33

Parameter Specifications

Maximum AC Power Supply Input 16 A @ 100 VAC per module

12 A @ 200 VAC per module

Maximum Thermal Output (3,172 W)

Maximum Thermal Output (2,906 W)

Maximum AC Supply Input Current

(based on 2500 W output for 100/120V

and 200/240V lines.)

Maximum System Power Input 3.5 KVA @ 100/120 VAC

Maximum Power Consumption 3,422 W at 100/120 VAC

10,822 BTU/hour at 100/120 VAC

9,914 BTU/hour at 200/240 VAC

11.6 A @ 100 VAC

9.7 A @ 120 VAC

8.0 A @ 200 VAC

6.7 A @ 240 VAC

3.2 KVA @ 220/240 VAC

3,156 W at 200/240 VAC

E600i ExaScale Chassis Physical Design

Parameter Specifications

Height 28 inches (71.1 cm)

Width 17.4 inches (44.2 cm)

Depth (without cable management

system)

Chassis weight with factory-installed

components (backplane and air filter)

Weight fully loaded (backplane, air

filter, fan tray, SFMs, RPMs, and 7 line

cards)

Maximum Thermal Output

21.5 inches (54.6 cm)

81 pounds (36.7 kg)

242 pounds (109.8 kg)

NOTE: Thermal output is directly proportional to system configuration and

number of line cards.

Installing the Hardware 31

Page 34

Parameter Specifications

Maximum for fully loaded chassis 120 VAC powered: 4705W (16,065

BTU/hour)

200/240 VAC powered: 4250W (14,500

BTU/hour)

DC powered: 2800W (9600 BTU/hour)

E600i ExaScale Environmental Parameters

Parameter Specifications

Operating

Temperature 32° to 104°F (0° to 40°C)

Maximum altitude No performance degradation to 10,000 feet (3,048 meters)

Relative humidity 5 to 85 percent, non-condensing

Non-operating

Temperature -40° to 158°F (-40° to 70°C)

Maximum Altitude 15,000 feet (4,572 meters)

Relative Humidity 5 to 95 percent, non-condensing

E600i ExaScale AC Power Supply Unit Requirements

Parameter Specifications

Nominal input voltage 120 - 240 VAC 50/60 Hz

Maximum AC Power Supply Input 16 A @ 100 VAC per module

12 A @ 200 VAC per module

Maximum Thermal Output (3,172 W)

Maximum Thermal Output (2,906 W)

Maximum AC Supply Input Current

(based on 2500 W output for 100/120V

and 200/240V lines.)

Maximum System Power Input 3.5 KVA @ 100/120 VAC

10,822 BTU/hour at 100/120 VAC

9,914 BTU/hour at 200/240 VAC

11.6 A @ 100 VAC

9.7 A @ 120 VAC

8.0 A @ 200 VAC

6.7 A @ 240 VAC

3.2 KVA @ 220/240 VAC

32 Installing the Hardware

Page 35

Parameter Specifications

Maximum Power Consumption 3,422 W at 100/120 VAC

3,156 W at 200/240 VAC

E1200i Specifications

E1200i TeraScale Chassis Physical Design

Parameter E1200i AC Specifications E1200i DC Specifications

Height 42 inches (106.68 cm) 36.75 inches (93.35 cm)

Width 17.40 inches (44.20 cm) 17.40 inches (44.20 cm)

Depth (without cable

management system)

Chassis weight with factory-

installed components

(backplane and air filter)

Weight fully loaded

(backplane, air filter, 2 fan

trays, 10 SFMs, RPMs, and 14

line cards)

Thermal Output

Maximum for fully loaded

chassis

Minimum for chassis with one

48-port 1GE line card

22.25 inches (56.51 cm) 21.25 inches (53.98 cm)

139 pounds (approx.)

(63.05kg)

394 pounds (approx.)

(178.7 kg)

7,784W (26,578BTU/HR) 6850W (23,389 BTU/HR)

1,450W (4,951 BTU/HR) 1,450W (4,951 BTU/HR)

97 pounds (approx.) (44.00

kg)

319 pounds (approx.)

(144.70 kg)

E1200i TeraScale Environmental Parameters

Parameter Specifications

Operating

Temperature 32° to 104°F (0° to 40°C)

Maximum altitude No performance degradation to 10,000 feet (3,048 meters)

Relative humidity 5 to 85 percent, non-condensing

Shock Designed to meet Telcordia GR-63 CORE

Installing the Hardware 33

Page 36

Parameter Specifications

Vibration Designed to meet Telcord ia GR-63 CORE

Non-operating

Temperature -40° to 158°F (-40° to 70°C)

Maximum Altitude 15,000 feet (4,572 meters)

Relative Humidity 5 to 95 percent, non-condensing

Vibration Bellcore GR-63

E1200i TeraScale Power Requirements

Parameter E1200i AC Specifications E1200i DC Specifications

Nominal input voltage 200-240 VAC 50/60 Hz -44 to 60 VDC

Maximum Power

Consumption

Maximum Thermal

Output

5,734 @ 200/240 VAC 5,210 W

18,710 BTU/hour (5,484 W) 16,924 BTU/hour (4,910 W)

Maximum Input

Current

Maximum System

Power Input

(per power supply)

15.0 A @ 200 VAC

12.5 A @ 240 VAC

5.8 KVA @ 200/240 VAC

(per DC PEM)

150 A

E1200i ExaScale Chassis Physical Design

Parameter E1200i AC Specifications E1200i DC Specifications

Height 42 inches (106.68 cm) 36.75 inches (93.35 cm)

Width 17.40 inches (44.20 cm) 17.40 inches (44.20 cm)

Depth (without cable

management system)

Chassis weight with factory-

installed components

(backplane and air filter)

34 Installing the Hardware

22.25 inches (56.51 cm) 21.25 inches (53.98 cm)

139 pounds (approx.)

(63.05kg)

97 pounds (approx.) (44.00

kg)

Page 37

Parameter E1200i AC Specifications E1200i DC Specifications

Weight fully loaded

(backplane, air filter, 2 fan

trays, 10 SFM3s, RPMs, and

14 line cards)

Thermal Output

Maximum (fully-loaded

chassis with 10-port 10GE

line cards)

Minimum (chassis with one

10-port 10GE line card)

422 pounds (approx.)

(191.2 kg)

18,368 BTU/hr 16,446 BTU/hr

2,313 BTU/hr 1,997 BTU/hr

319 pounds (approx.)

(144.70 kg)

E1200i ExaScale Environmental Parameters

Parameter Specifications

Operating

Temperature 32° to 104°F (0° to 40°C)

Maximum altitude No performance degradation to 10,000 feet (3,048 meters)

Relative humidity 5 to 85 percent, non-condensing

Shock Designed to meet Telcordia GR-63 CORE

Vibration Designed to meet Telcordia GR-63 CORE

Non-operating

Temperature -40° to 158°F (-40° to 70°C)

Maximum Altitude 15,000 feet (4,572 meters)

Relative Humidity 5 to 95 percent, non-condensing

Vibration Bellcore GR-63

E1200i ExaScale Power Requirements

Parameter E1200i AC Specifications E1200i DC Specifications

Nominal input voltage 200-240 VAC 50/60 Hz -44 to 60 VDC

Maximum Power

Consumption

6,634 W 5,400 W

Installing the Hardware 35

Page 38

Parameter E1200i AC Specifications E1200i DC Specifications

Maximum Thermal

Output

19,449 BTU/hour (5,700 W) 17,402 BTU/hour (5,100 W)

Maximum Input

Current

Maximum System

Power Input

(per power supply)

15.0 A @ 200 VAC

12.5 A @ 240 VAC

6.0 KVA @ 200/240 VAC

(per DC PEM)

150 A

36 Installing the Hardware

Page 39

2

Installing the Software

Navigating CLI Modes

The FTOS prompt changes to indicate the CLI mode. You must move linearly

through the command modes, with the exception of the end command which

takes you directly to EXEC Privilege mode; the exit command moves you up

one command mode level.

Console Access

RPM Ports and Cables

There are three ports on the RPM: the Console port, the Auxiliary port, and the

10/100 Ethernet port. This chapter includes information to connect to the system

using the console port. For information about connecting with the other ports,

refer to your system's Installation Guide.

Connecting the Console

NOTE: Before starting this procedure, be sure you have a terminal emulation

program already installed on your PC.

Step Task

1

2

Install an RJ-45 copper cable into the console port. Use a rollover cable

to connect the S4810 console port to a terminal server.

Connect the other end of the cable to the DTE terminal server.

Installing the Software 37

Page 40

Step Task

3

Default terminal settings on the console are set as follows:

• 9600 baud rate (to avoid autobaud input, the default is set to a 9600 bps

baud rate)

•No parity

• 8 data bits

• 1 stop bit

• Window Terminal Emulator option set to NO

• 24 lines X 80 characters

• No flow control (console port only)

• Hardware flow control (RTS/CTS) (for auxiliary port only)

Accessing the Console with a DB-9 Adapter

You can connect to the console using a RJ-45 to RJ-45 rollover cable and a RJ45 to DB-9 female DTE adapter (labeled “TERMINAL”) to a terminal server

(for example, PC).

Pin Assignments Between the E-Series Console and a DTE Terminal Server

Console Port RJ-45 to RJ-45 Rollover Cable RJ-45 to DB-9

Adapter

Signal RJ-45 Pinout RJ-45 Pinout DB-9 Pin Signal

RTS 1 8 8 CTS

DTR 2 7 6 DSR

TxD 3 6 2 RxD

GND 4 5 5 GND

GND 5 4 5 GND

RxD 6 3 3 TxD

DSR 7 2 4 DTR

CTS 8 1 7 RTS

38 Installing the Software

Terminal

Server Device

Page 41

Accessing the Console with a DB-25 Adapter

You can connect to the console using an RJ-45 to RJ-45 rollover cable and RJ45 to DB-25 female DTE adapter.

Pin Assignments Between the E-Series Console and a DB-25 Adapter

Console Port RJ-45 to RJ-45 Rollover Cable RJ-45 to DB-25

Modem Adapter

Signal RJ-45 Pinout RJ-45 Pinout DB-25 Pinout Signal

RTS 1 8 5 CTS

DTR 2 7 6 DSR

TxD 3 6 3 RxD

GND 4 5 7 GND

GND 5 4 7 GND

RxD 6 3 2 TxD

DSR 7 2 20 DTR

CTS 8 1 RTS

Terminal

Server Device

E1200i ExaScale Universal Serial Bus Ports

There are 2 USB ports, labeled A and B. The A port is a host port and allows a

user to install a flash memory stick for use as external flash. The B port is a

device port and allows a user to hook up an external PC for console access.

Refer to the E1200i ExaScale Installation Guide for complete information

regarding these ports.

Default Configuration

A version of FTOS is pre-loaded onto the chassis, however the system is not

configured when you power up for the first time (except for the default host

name, which is Force10). You must configure the system using the CLI.

Installing the Software 39

Page 42

Configure Layer 2 (Data Link) Mode

Use the switchport command in INTERFACE mode to enable Layer 2 data

transmissions through an individual interface. The user cannot configure

switching or Layer 2 protocols such as the spanning tree protocol on an interface

unless the interface has been set to Layer 2 mode.

Step Task Command Syntax Command Mode

1 Enable the interface. no shutdown INTERFACE

2 Place the interface in

Layer 2 (switching)

mode.

To view the interfaces in Layer 2 mode, use the show interfaces switchport

command in the EXEC mode.

switchport INTERFACE

Configure a Host Name

The host name appears in the prompt. The default host name is Force10.

• Host names must start with a letter and end with a letter or digit.

• Characters within the string can be letters, digits, and hyphens.

Task Command Syntax Command Mode

Create a new host name. hostname name CONFIGURATION

Access the System Remotely

You can configure the system to be accessed remotely by Telnet.

The E-Series systems have a dedicated management port and a management

routing table that is separate from the IP routing table.

Configuring the system for Telnet is a three-step process:

• Configure an IP address for the management port.

• Configure a management route with a default gateway.

• Configure a username and password.

40 Installing the Software

Page 43

Configure the Management Port IP Address

Assign IP addresses to the management ports in order to access the system

remotely.

NOTE: Assign different IP addresses to each RPM’s management port.

Step Task Command Syntax Command Mode

1 Enter INTERFACE mode for the

Management port.

2 Assign an IPv4 or IPv6 address

to the interface.

3 Enable the interface. no shutdown INTERFACE

interface

ManagementEthernet

slot/port

ip address {ipv4-

address | ipv6address}/mask

CONFIGURATION

INTERFACE

Configure a Management Route

Define a path from the system to the network from which you are accessing the

system remotely. Management routes are separate from IP routes and are only

used to manage the system through the management port.

Task Command Syntax Command Mode

Configure an IPv4 or

IPv6 management

route to the network

from which you are

accessing the system.

management route {ipv4-address | ipv6-

address}/mask gateway

CONFIGURATION

Configure a Username and Password

Configure a system username and password to access the system remotely.

Installing the Software 41

Page 44

Task Command Syntax Command Mode

Configure a username

and password to

access the system

remotely.

username username password

[encryption-type] password

CONFIGURATION

Configure the Enable Password

The EXEC Privilege mode is accessed by the enable command. Configure a

password as a basic security measure. When using a console connection, EXEC

Privilege mode is unrestricted by default; it cannot be reached by a VTY

connection if no password is configured. There are two types of enable

passwords:

• enable password stores the password in the running/startup configuration

using a DES encryption method.

• enable secret is stored in the running/startup configuration in using a

stronger, MD5 encrypti on method.

Dell Force10 recommends using the enable secret password.

Task Command Syntax Command Mode

Create a password to

access EXEC

Privilege mode.

enable [password | secret] [level level]

[encryption-type] password

CONFIGURATION

Create a VLAN

The Default VLAN is part of the system startup configuration, and is by default,

VLAN 1. You may make another VLAN the Default VLAN. The Default

VLAN cannot be deleted, disabled, or configured (you cannot assign it an IP

address), and only untagged interfaces can belong to it.

42 Installing the Software

Page 45

When an interface is configured, a switchport automatically places it in the

Default VLAN as an untagged interface. All switchports must belong to at least

one VLAN, so to remove a switchport from the Default VLAN, you must place

it as tagged or untagged in some other VLAN, or remove the switchport

configuration.

Task Command Syntax Command Mode

Create a VLAN interface vlan vlan-id CONFIGURATION

Display all VLANs. show vlan vlan-id EXEC Privilege

Assign Interfaces to a VLAN

A port may either be an untagged member of a single VLAN, or a tagged

member of perhaps multiple VLANs.

• Untagged Ports — ports that do not append an 802.1Q VLAN tag to frames

on egress, and do not accept tagged frames on ingress (tagged frames are

dropped). Untagged ports must be connected to VLAN-unaware devices .

• Tagged Ports — ports that append an 802.1Q tag to frames on egress, and

accept only tagged frames on ingres s (untag ged frame s are drop ped). Tagged

ports must be connected to VLAN-aware devices.

When you configure an enabled port as a switchport, the port is placed in the

default VLAN. To remove a switchport from the default VLAN, remove the

switchport configuration. To move the port to another VLAN, add it to the

desired VLAN as either a tagged or untagged member.

To view just the interfaces that are in Layer 2 mode, enter the show interfaces

switchport command in the EXEC mode.

Step Task Command Syntax Command Mode

1 Assign a switchport to

a VLAN.

2 Display all

switchports and the

VLANs of which they

are members.

[tagged | untagged] interface INTERFACE VLAN

show vlan EXEC Privilege

Installing the Software 43

Page 46

Assign an IP Address to a VLAN

NOTE: An IP address cannot be assigned to the Default VLAN, which, by default,

is VLAN 1. To assign another VLAN ID to the Default VLAN, use the default

vlan-id vlan-id command.

Task Command Syntax Command Mode

Configure an IP address and mask on

the interface.

ip address ip-address

mask [secondary]

INTERFACE

Connecting the Chassis to the Network

Once you have completed the hardware installation and software configuration,

you can connect to your company network by following your company’s cabling

requirements.

44 Installing the Software

Page 47

Installing the Software 45

Page 48

46 Installing the Software

Page 49

Page 50

www.dell.com | support.dell.com

Printed in the U.S.A.

Loading...

Loading...