Dell EMC ML3, 3555-L3A, 3555-E3A, EMC ML3E User Manual

Dell EMC ML3 Tape Library

User's Guide

Information in this document is subject to change without notice.

Copyright © 2017 Dell Inc. or its subsidiaries. All rights reserved.

Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other trademarks may

be trademarks of their respective owners.

Printed December 2017

iii

iv Dell EMC ML3 Tape Library: User's Guide

Contents

iii

Figures .............. vii

Tables ............... ix

Read this first ............ xi

Minimum firmware levels for common library

features ................ xi

Contacting Dell ............. xii

Safety and environmental notices ... xiii

Danger and Caution notices ........ xiii

Possible safety hazards .......... xvi

Class I laser product ........... xvi

Performing the safety inspection procedure ... xvii

Rack safety .............. xvii

Power Cords.............. xix

Preface .............. xxi

Overview .............. 1

Introduction .............. 1

Structure and supported library configurations ... 2

Components ............. 7

Front panel ............. 7

Rear panel ............. 8

Magazines ............. 9

Power supply............ 11

Bar code reader ........... 11

User interfaces ............. 11

Supported tape drives ........... 12

Control path drives ........... 12

Mixed drives ............. 12

Drive sled back panels.......... 13

Physical and logical addresses of drives .... 15

Supported tape cartridges ......... 16

Library functions ............ 17

Encryption ............. 17

Library sharing ............ 17

Path failover and load balancing ...... 18

Alerts and logging ........... 19

Host connectivity ............ 20

Network connectivity ........... 20

Planning .............. 23

Library Layout and Location requirements .... 23

Power cords .............. 25

Network requirements........... 30

Host requirements ............ 31

Installing .............. 33

Unpacking the Base Module and Expansion

Modules ............... 34

Identifying Library Module components ..... 39

Preparing top and bottom modules ...... 39

Installing modules in a rack ......... 42

Installing a tabletop module ......... 46

Aligning and connecting modules ....... 46

Validating tape drive installation ....... 49

Connecting cables ............ 49

Powering on the library .......... 51

The Initial Setup process .......... 52

Initial configuration and customization ..... 53

Labeling and loading tape cartridges ...... 53

Verifying the installation .......... 55

Advanced library configuration........ 55

Overview .............. 56

Library partitioning .......... 57

Verifying the host connection ........ 58

Managing ............. 59

The Management GUI ........... 59

The Operator Panel ............ 61

Locating Management functions ....... 63

Default settings ............ 66

Methods of cleaning drives ........ 69

Accessing cartridges .......... 70

Configuring Library Managed Encryption (KMIP) 70

Troubleshooting........... 73

Finding event information ......... 73

Identifying a failed component ........ 73

Running library tests ........... 73

Troubleshooting Guide .......... 73

Pre-call checklist ............. 76

Contacting Dell ............. 77

Diagnostic information .......... 77

The ITDT firmware update, dump retrieval and

drive test tool ............ 77

Event codes ............. 78

Main error events .......... 79

Warning error events ......... 86

Configuration Change events ...... 93

Informational events ......... 94

TapeAlert flags ............ 95

TapeAlert flags supported by the library... 95

TapeAlert flags supported by the drive ... 97

Sense data ............. 100

Drive Error Codes: Single-character display

(SCD) ............... 100

SCD dot ............. 102

Status light ............ 102

Upgrading and servicing ...... 105

Internal view of library .......... 105

v

Adding, removing, or replacing a tape drive ... 106

Adding or replacing a Base or Expansion Module 109

Adding, removing, or replacing a power supply 114

Replacing a Base or Expansion controller card .. 117

Installing, removing, or replacing an accessor and

spooling mechanism ........... 120

Returning the accessor to the Base Module .. 127

Removing or replacing a spooling mechanism .. 129

Removing or replacing a magazine ...... 133

Moving the library modules ........ 135

Appendix A. Library Configuration

Forms .............. 137

Library information ........... 138

Module and drive information ....... 139

Logical Library information ........ 140

Users account information ......... 141

Appendix B. LTO media ....... 143

Data cartridges ............. 143

Cartridge Read/Write compatibility ..... 144

WORM (Write Once, Read Many) cartridges ... 144

WORM media ............ 144

Data security on WORM media ...... 145

WORM media errors .......... 145

Cleaning cartridge............ 145

Labeling tape cartridges .......... 145

Guidelines for bar code labels ....... 147

Write-Protect switch ........... 147

Handling the cartridges .......... 148

Providing training ........... 148

Ensuring proper packaging ........ 148

Proper acclimation and environmental

conditions ............. 149

Completing a thorough inspection ..... 150

Handling the cartridge carefully ...... 150

Environmental and shipping specifications for tape

cartridges .............. 151

Appendix C. Accessibility ...... 153

Glossary ............. 155

Index ............... 175

vi Dell EMC ML3 Tape Library: User's Guide

Figures

1. Two module tape library ........ 1

2. Base Module ............ 2

3. Expansion Module .......... 3

4. Base Module ............ 3

5. 2 module library ........... 3

6. 3 module library ........... 3

7. 4 module library ........... 4

8. 5 module library ........... 4

9. 6 Module library ........... 5

10. 7 module library ........... 6

11. Front panel ............. 7

12. Rear panel ............. 8

13. Physical numbering of modules ...... 9

14. Left magazine ............ 10

15. Right magazine ........... 10

16. Power supply rear panel LEDs ...... 11

17. Mixed drives in a logical library ..... 13

18. Drive sled indicators ......... 13

19. Half-height SAS dual port........ 14

20. Half-height FC single port ....... 14

21. Full-height FC dual port ........ 15

22. Physical numbering of drives ...... 16

23. Types of receptacles .......... 30

24. Removing the module from the box .... 34

25. The module after removal from the box 35

26. Unlatching the top of the module ..... 36

27. Removing the top of the module ..... 36

28. The module is opened to show the foam

packing............... 37

29. The foam packing is removed, and the internal

components are shown - Base Module. ... 37

30. Top cover sensor ........... 38

31. Incorrect top cover insertion - too high 38

32. Correct top cover insertion ....... 39

33. Lowering the front of the top cover .... 40

34. Unlocking the spring loaded lock ..... 41

35. Removing the cover.......... 41

36. Lifting the cover and locking it ...... 42

37. Universal rack connector ........ 43

38. Incorrect connector locations ....... 43

39. Correct connector locations ....... 44

40. Mounting the rails to the connectors .... 44

41. Side rails installed .......... 45

42. Sliding the library into the rack ...... 45

43. Library in the rack .......... 46

44. Alignment lever lock ......... 47

45. Alignment lever locked or engaged to lower

module .............. 47

46. Alignment lever unlocked or disengaged 48

47. Two modules in rack, seen from the rear 48

48. Connected modules .......... 49

49. Full-height FC dual port ........ 50

50. Half-height FC single port ....... 50

51. Half-height SAS dual port........ 51

52. IP address selection .......... 52

53. Open I/O station seen from the left .... 54

54. Magazine pulled out ......... 55

55. Management GUI main screen ...... 60

56. Operator Panel main screen ....... 62

57. Front panel LEDs .......... 63

58. Internal view of the library ....... 105

59. Drive bay covers .......... 107

60. Alignment rails ........... 107

61. Installing a tape drive......... 108

62. Unlocking the drive ......... 108

63. Interconnect cables .......... 111

64. Unlocking or disengaging the alignment lever 112

65. Loosening the thumbscrews....... 113

66. Sliding the module out of the rack .... 113

67. Power supplies ........... 115

68. Sliding in the new power supply ..... 116

69. Controller card components ....... 118

70. Installing a Controller card ....... 119

71. Magazine release levers ........ 121

72. Unlocking the robot ......... 122

73. Finger holes ............ 122

74. Unlocking the spooling cable and placing it in

its cradle ............. 123

75. Spooling cable in park position ..... 124

76. Pins are aligned horizontally ...... 125

77. Installing the spooling cable ...... 126

78. Inserting the screwdriver to manually operate

the accessor ............ 128

79. Left magazine opening ........ 128

80. Unlocking the spooling mechanism .... 130

81. Unlocked spooling mechanism - enlarged

view .............. 131

82. Locked spooling mechanism - enlarged view 132

83. Removing the spooling mechanism .... 133

84. Manually releasing the right magazine 134

85. Manually releasing the left magazine 134

86. The LTO data cartridge ........ 143

87. LTO Data and WORM tape cartridges 145

88. Sample bar code label on the LTO 8 Tape

Cartridge ............. 147

89. Setting the write-protect switch ..... 148

90. Double-boxing tape cartridges for shipping 149

91. Checking for gaps in the seams of a cartridge 150

vii

viii Dell EMC ML3 Tape Library: User's Guide

Tables

1. Regulatory marks .......... xi

2. Minimum firmware levels for common library

features .............. xi

3. Module designations .......... 1

4. Minimum and maximum storage configurations 2

5. Library configurations ......... 3

6. Front panel descriptions......... 7

7. Rear panel descriptions ......... 8

8. Physical numbering of storage slots - bottom

module .............. 10

9. Power supply LEDs .......... 11

10. Supported tape drives ......... 12

11. Drive sled indicators ......... 13

12. Half-height SAS dual port........ 14

13. Half-height FC single port ....... 14

14. Full-height FC dual port ........ 15

15. Differences between CPF and DPF ..... 18

16. Location requirements ......... 23

17. Physical specifications ......... 24

18. Electrical specifications ......... 24

19. Equipment environmental specifications 24

20. Gas and particulate exposure ...... 25

21. Power cords ............ 26

22. Installation Precautions ........ 33

23. Full-height FC dual port ........ 50

24. Half-height FC single port ....... 50

25. Half-height SAS dual port........ 51

26. Main screen elements ......... 60

27. Navigation Dock ........... 61

28. Status icons ............ 61

29. Operator Panel menu tree........ 62

30. Front panel LEDs .......... 63

31. Locating Management functions ..... 63

32. Default settings ........... 66

33. Magazine state ........... 70

34. Resolving errors ........... 73

35. Main error events .......... 79

36. Warning events ........... 86

37. Configuration Change events ...... 93

38. Informational Events ......... 94

39. Error codes on the single-character display 101

40. Meaning of Status light and single-character

display (SCD) ........... 102

41. Internal view description ....... 105

42. Pinch hazard............ 106

43. Power supply components ....... 115

44. Controller card components ....... 118

45. Cartridge data capacity and recording formats 143

46. Nominal cartridge life: Load/unload cycles 144

47. Data cartridge compatibility with LTO tape

drive .............. 144

48. Cartridges and VOLSERs compatible with the

LTO Tape Drives .......... 146

49. Location of the write-protect switch .... 148

50. Environment for operating, storing, and

shipping the LTO Ultrium Tape Cartridge .. 151

ix

x Dell EMC ML3 Tape Library: User's Guide

Read this first

Regulatory information

v The library must be installed in a restricted area.

v Only personnel with technical and product safety training should have access to the library.

v To comply with the regulations and standards, the library must be properly installed in an office or

industrial environment with shielded cables and adequate grounding of SAS interface and input

power.

v Models: 3555-L3A, 3555-E3A

Table 1. Regulatory marks

The CE mark is a mandatory conformity mark on many products that are

placed on the single market in the European Economic Area (EEA). The

CE marking certifies that a product meets EU consumer safety, health, or

environmental requirements.

CSA C22-2 No.60950-1 - Electrical safety - UL 60950-1 68475

Minimum firmware levels for common library features

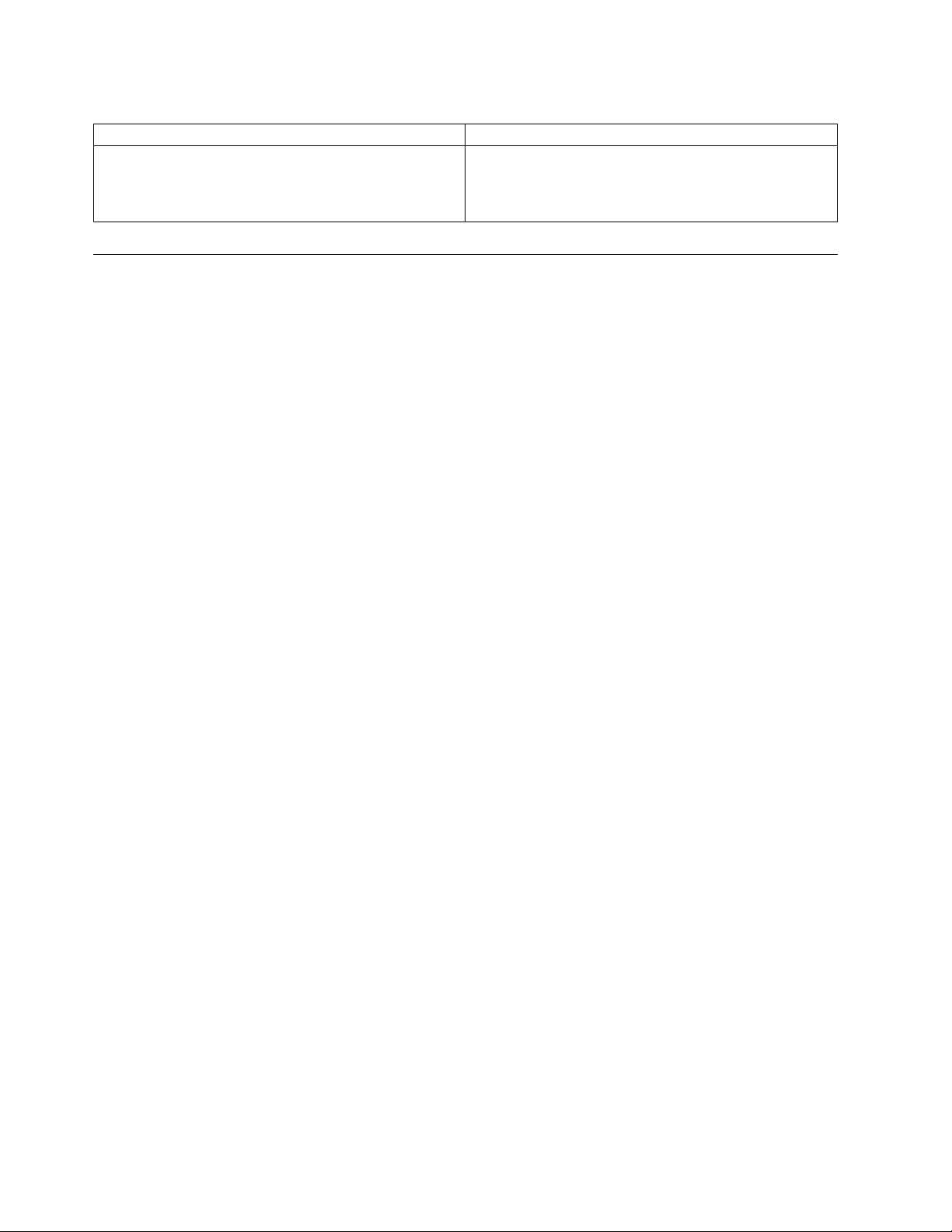

Table 2. Minimum firmware levels for common library features

Feature Minimum Firmware Levels Required

LTO8 (HH/FH) Tape Drives Library Firmware must be at 1.1.1.0 or greater to support

the LTO8 tape drives. Ensure that any host applications

and device drivers are at the minimum level that is

required to support LTO8 tape drives.

LTO6 (HH/FH) and LTO7 (HH/FH) Tape Drives Library Firmware must be at 1.1.0.1-A00 or greater to

support the LTO6 and LTO7 tape drives. Ensure that any

host applications and device drivers are at the minimum

level that is required to support LTO6 and LTO7 tape

drives.

Library Managed Encryption Library Firmware must be at 1.1.1.0-A00 or greater to

support the Library Managed Encryption feature. Ensure

that any key manager applications are at the minimum

level that is required to support the 3U library.

Path Failover (Control Path and Data Path) Library Firmware must be at 1.1.1.0-A00 or greater to

support the Path Failover feature. Ensure that any device

drivers are at the minimum level that is required to

support the 3U library.

xi

Table 2. Minimum firmware levels for common library features (continued)

Feature Minimum Firmware Levels Required

Remote Logging (rsyslog) Library Firmware must be at 1.1.1.0-A00 or greater to

support the Remote Logging feature. Ensure that any

device drivers are at the minimum level that is required

to support the 3U library.

Contacting Dell

For customers in the United States, call 800-WWW-DELL (800-999-3355).

Note: If you do not have an active Internet connection, you can find contact information about your

purchase invoice, packing slip, bill, or Dell product catalog.

Dell provides online and telephone-based support and service options. Service availability varies by

country and product, and some services might not be available in your area. To contact Dell for sales,

technical support, or customer service issues follow the steps that are listed:

1. Go to www.Dell.com/support.

2. Select your country from the drop-down menu on the lower right corner of the page.

3. For customized support:

a. Enter your system Service Tag in the Enter your Service Tag field.

b. Click Submit. The support page that lists the various support categories is displayed.

4. For general support:

a. Select your product category.

b. Select your product segment.

c. Select your product. The support page that lists the various support categories is displayed.

5. For contact details of Dell Global Technical Support:

a. Click Global Technical Support.

b. The Contact Technical Support page is displayed with details to call, chat, or e-mail the Dell

Global Technical Support team.

xii Dell EMC ML3 Tape Library: User's Guide

Safety and environmental notices

When this product is used, observe the danger, caution, and attention notices that are contained in this

guide. The notices are accompanied by symbols that represent the severity of the safety condition.

The sections that follow define each type of safety notice and give examples.

Danger and Caution notices

Danger notices

A danger notice calls attention to a situation that is potentially lethal or extremely hazardous to people. A

lightning bolt symbol always accompanies a danger notice to represent a dangerous electrical condition.

xiii

To prevent a possible shock from touching two surfaces with different

protective ground (earth), use one hand, when possible, to connect or

disconnect signal cables. (D001)

Overloading a branch circuit is potentially a fire hazard and a shock hazard

under certain conditions. To avoid these hazards, ensure that your system

electrical requirements do not exceed branch circuit protection requirements.

Refer to the information that is provided with your device or the power

rating label for electrical specifications. (D002)

If the receptacle has a metal shell, do not touch the shell until you have

completed the voltage and grounding checks. Improper wiring or grounding

could place dangerous voltage on the metal shell. If any of the conditions

are not as described, STOP. Ensure the improper voltage or impedance

conditions are corrected before proceeding. (D003)

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the devices that attach to the system. It is

the responsibility of the customer to ensure that the outlet is correctly wired

and grounded to prevent an electrical shock. A lightning bolt symbol always

accompanies a danger notice to represent a dangerous electrical condition.

(D004)

When working on or around the system, observe the following precautions:

Electrical voltage and current from power, telephone, and communication

cables are hazardous. To avoid a shock hazard:

v If Dell supplied a power cord(s), connect power to this unit only with the

Dell provided power cord. Do not use the Dell provided power cord for

any other product.

v Do not open or service any power supply assembly.

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical storm.

v The product might be equipped with multiple power cords. To remove all

hazardous voltages, disconnect all power cords.

v Connect all power cords to a properly wired and grounded electrical

outlet. Ensure that the outlet supplies proper voltage and phase rotation

according to the system rating plate.

v Connect any equipment that will be attached to this product to properly

wired outlets.

v When possible, use one hand only to connect or disconnect signal cables.

v Never turn on any equipment when there is evidence of fire, water, or

structural damage.

v Do not attempt to switch on power to the machine until all possible

unsafe conditions are corrected.

v Assume that an electrical safety hazard is present. Perform all continuity,

grounding, and power checks specified during the subsystem installation

procedures to ensure that the machine meets safety requirements.

v Do not continue with the inspection if any unsafe conditions are present.

v Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

v Connect and disconnect cables as described in the following procedures

when installing, moving, or opening covers on this product or attached

devices.

xiv Dell EMC ML3 Tape Library: User's Guide

To disconnect:

1. Turn off everything (unless instructed otherwise).

2. Remove the power cords from the outlets.

3. Remove the signal cables from the connectors.

4. Remove all cables from the devices.

To connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the power cords to the outlets.

4. Turn on the devices.

v Sharp edges, corners and joints may be present in and around the system.

Use care when handling equipment to avoid cuts, scrapes and pinching.

(D005)

Heavy equipment - personal injury or equipment damage might result if

mishandled. (D006)

DANGER: Multiple power cords. The product might be equipped with

multiple power cords. To remove all hazardous voltages, disconnect all

power cords. (L003)

Caution notices

A caution notice calls attention to a situation that is potentially hazardous to people because of some

existing condition, or to a potentially dangerous situation that might develop because of some unsafe

practice.

The doors and covers to the product are to be closed at all times except for

service by trained service personnel. All covers must be replaced and doors

closed at the conclusion of the service operation. (C013)

This product is equipped with a 3-wire (two conductors and ground) power

cable and plug. Use this power cable with a properly grounded electrical

outlet to avoid electrical shock. (C018)

This assembly contains mechanical moving parts. Use care when servicing

this assembly. (C025)

A caution notice can be accompanied by one of several symbols:

If the symbol is... It means...

A generally hazardous condition not represented by other safety symbols.

A hazardous condition due to the use of a laser in the product. Laser

symbols are always accompanied by the classification of the laser as defined

by the U. S. Department of Health and Human Services (for example, Class

I, Class II, and so forth).

Safety and environmental notices xv

If the symbol is... It means...

Risk of hand pinching, can trap hands, fingers and cause serious injury.

Keep hands clear during operation (L012).

The weight of this part or unit is between 18.1 and 33.6 kg (40 and 74 lb). It

takes two persons to safely lift this part or unit. (C009)

The weight of this part or unit is between 33.6 and 46.3 kg (74 and 102 lb).

It takes three persons to safely lift this part or unit. (C010)

A hazardous condition due to the unit's susceptibility to electrostatic

discharge.

Possible safety hazards

Possible safety hazards to the operation of this product are:

Electrical

An electrically charged frame can cause serious electrical shock.

Mechanical

Hazards (for example, a safety cover missing) are potentially harmful to people.

Chemical

Do not use solvents, cleaners, or other chemicals that are not approved for use on this product.

Before the library is used, repair any of the preceding problems.

Class I laser product

Before the library is used, review the following laser safety information.

xvi Dell EMC ML3 Tape Library: User's Guide

The product might contain a laser assembly that complies with the performance standards set by the US

Food and Drug Administration for a Class I laser product. Class I laser products do not emit hazardous

laser radiation. The product has the necessary protective housing and scanning safeguards to ensure that

laser radiation is inaccessible during operation or is within Class I limits. External safety agencies

reviewed the product and obtained approvals to the latest standards as they apply.

Performing the safety inspection procedure

Before you service the unit, complete the following safety inspection procedure.

1. Stop all activities between the host and the library’s tape drives.

2. Turn off the power to the library by pushing in the Power button on the front of the tape library for 4

seconds.

3. Unplug the library’s power cord from the electrical outlet and the library’s power supply unit.

4. Check the library’s power cords for damage, such as a pinched, cut, or frayed cord.

5. If drives are FC/SAS attached, check the tape drive's FC/SAS cable for damage.

6. Check the top and bottom covers of the library for sharp edges, damage, or alterations that expose its

internal parts.

7. Check the top and bottom covers of the library for proper fit. They must be in place and secure.

8. Check the product label at the rear of the library to make sure that it matches the voltage at your

outlet.

Rack safety

The following general safety information must be used for all rack-mounted devices.

DANGER

Observe the following precautions when working on or around your IT rack system.

v Heavy equipment - personal injury or equipment damage might result if mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install the heaviest devices

in the bottom of the rack cabinet. Always install servers and optional devices starting from the bottom

of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not place objects on top of

rack-mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect all power cords in the

rack cabinet when directed to disconnect power during servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the same rack cabinet. Do

not plug a power cord from a device installed in one rack cabinet into a power device installed in a

different rack cabinet.

Safety and environmental notices xvii

v An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts of the

system or the devices that attach to the system. It is the responsibility of the customer to ensure that

the outlet is correctly wired and grounded to prevent an electrical shock. (R001 part 1 of 2)

Caution

v Do not install a unit in a rack where the internal rack ambient temperatures might exceed the

manufacturer's recommended ambient temperature for all your rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not blocked

or reduced on any side, front, or back of a unit that is used for air flow through the unit.

v Consideration must be given to the connection of the equipment to the supply circuit so that

overloading of the circuits does not compromise the supply wiring or overcurrent protection. To

provide the correct power connection to a rack, refer to the rating labels on the equipment in the rack

to determine the total power requirement of the supply circuit.

v (For sliding drawers) Do not pull out or install any drawer or feature if the rack stabilizer brackets are

not attached to the rack. Do not pull out more than one drawer at a time. The rack might become

unstable if you pull out more than one drawer at a time.

v (For fixed drawers) This drawer is a fixed drawer and must not be moved for servicing unless

specified by the manufacturer. Attempting to move the drawer partially or out of the rack might cause

the rack to become unstable or cause the drawer to fall out of the rack. (R001 part 2 of 2)

Caution

Removing components from the upper positions in the rack cabinet improves rack stability during

relocation. Follow these general guidelines whenever you relocate a populated rack cabinet within a room

or building:

v Reduce the weight of the rack cabinet by removing equipment, starting at the top of the rack cabinet.

When possible, restore the rack cabinet to the configuration of the rack cabinet as you received it. If

this configuration is not known, you must do the following:

– Remove all devices in the 32U position (compliance ID RACK-001) or 22U (compliance ID RR001)

and above.

– Ensure that the heaviest devices are installed in the bottom of the rack cabinet.

xviii Dell EMC ML3 Tape Library: User's Guide

– Ensure that there are little-to-no empty U-levels between devices installed in the rack-cabinet below

the 32U (compliance ID RACK-001) or 22U (compliance ID RR001) level, unless the received

configuration specifically allowed it.

v If the rack cabinet you are relocating is part of a suite of rack cabinets, detach the rack cabinet from the

suite.

v If the rack cabinet you are relocating was supplied with removable outriggers, they must be reinstalled

before the cabinet is relocated.

v Inspect the route that you plan to take to eliminate potential hazards.

v Verify that the route that you choose can support the weight of the loaded rack cabinet. Refer to the

documentation that comes with your rack cabinet for the weight of a loaded rack cabinet.

v Verify that all door openings are at least 760 x 2032 mm (30 x 80 in.).

v Ensure that all devices, shelves, drawers, doors, and cables are secure.

v Ensure that the four leveling pads are raised to their highest position.

v Ensure that no stabilizer bracket is installed on the rack cabinet during movement.

v Do not use a ramp that is inclined at more than 10 degrees.

v When the rack cabinet is in the new location, complete these steps.

– Lower the four leveling pads.

– Install stabilizer brackets on the rack cabinet.

– If you removed any devices from the rack cabinet, repopulate the rack cabinet from the lowest

position to the highest position.

v If a long-distance relocation is required, restore the rack cabinet to the configuration of the rack cabinet

as you received it. Pack the rack cabinet in the original packaging material, or equivalent. Also, lower

the leveling pads to raise the casters off the pallet and bolt the rack cabinet to the pallet. (R002)

Power Cords

For your safety, Dell provides a power cord with a grounded attachment plug to use with this Dell

product. To avoid electrical shock, always use the power cord and plug with a properly grounded outlet.

Dell power cords used in the United States and Canada are listed by Underwriter’s Laboratories (UL)

and certified by the Canadian Standards Association (CSA).

For units intended to be operated at 115 volts: Use a UL-listed and CSA-certified cord set consisting of a

minimum 18 AWG, Type SVT or SJT, three-conductor cord, a maximum of 15 feet in length and a parallel

blade, grounding-type attachment plug rated 15 amperes, 125 volts.

For units intended to be operated at 230 volts (U.S. use): Use a UL-listed and CSA-certified cord set

consisting of a minimum 18 AWG, Type SVT or SJT, three-conductor cord, a maximum of 15 feet in

length and a tandem blade, grounding-type attachment plug rated 15 amperes, 250 volts.

For units intended to be operated at 230 volts (outside the U.S.): Use a cord set with a grounding-type

attachment plug. The cord set should have the appropriate safety approvals for the country in which the

equipment will be installed.

Dell power cords for a specific country or region are usually available only in that country or region.

Safety and environmental notices xix

xx Dell EMC ML3 Tape Library: User's Guide

Preface

This manual contains information and instructions necessary for the installation, operation, and service of

the Dell™EMC ML3 Tape Library.

Related Publications

Refer to the following publications for more information.

v Dell™EMC ML3 Tape Library Getting Started Guide provides unpacking and initial setup information.

v IBM Security Key Lifecycle Manager Knowledge Center, which is located at http://www-01.ibm.com/

support/knowledgecenter/SSWPVP/welcome?lang=en, contains information to help you install,

configure, and use the IBM®Security Key Lifecycle Manager.

xxi

xxii Dell EMC ML3 Tape Library: User's Guide

Overview

Introduction

The Dell™EMC ML3 Tape Library provides compact, high-capacity, low-cost solutions for simple,

unattended data backup. The installation begins with the 3U high Base Module, with capacity for 32 tape

cartridges and 3 half-height LTO tape drives, or one full-height and one half-height tape drive.

Each module type has its special designation.

Table 3. Module designations

Product Description

Dell EMC ML3 Base Module

Dell EMC ML3E Expansion Module

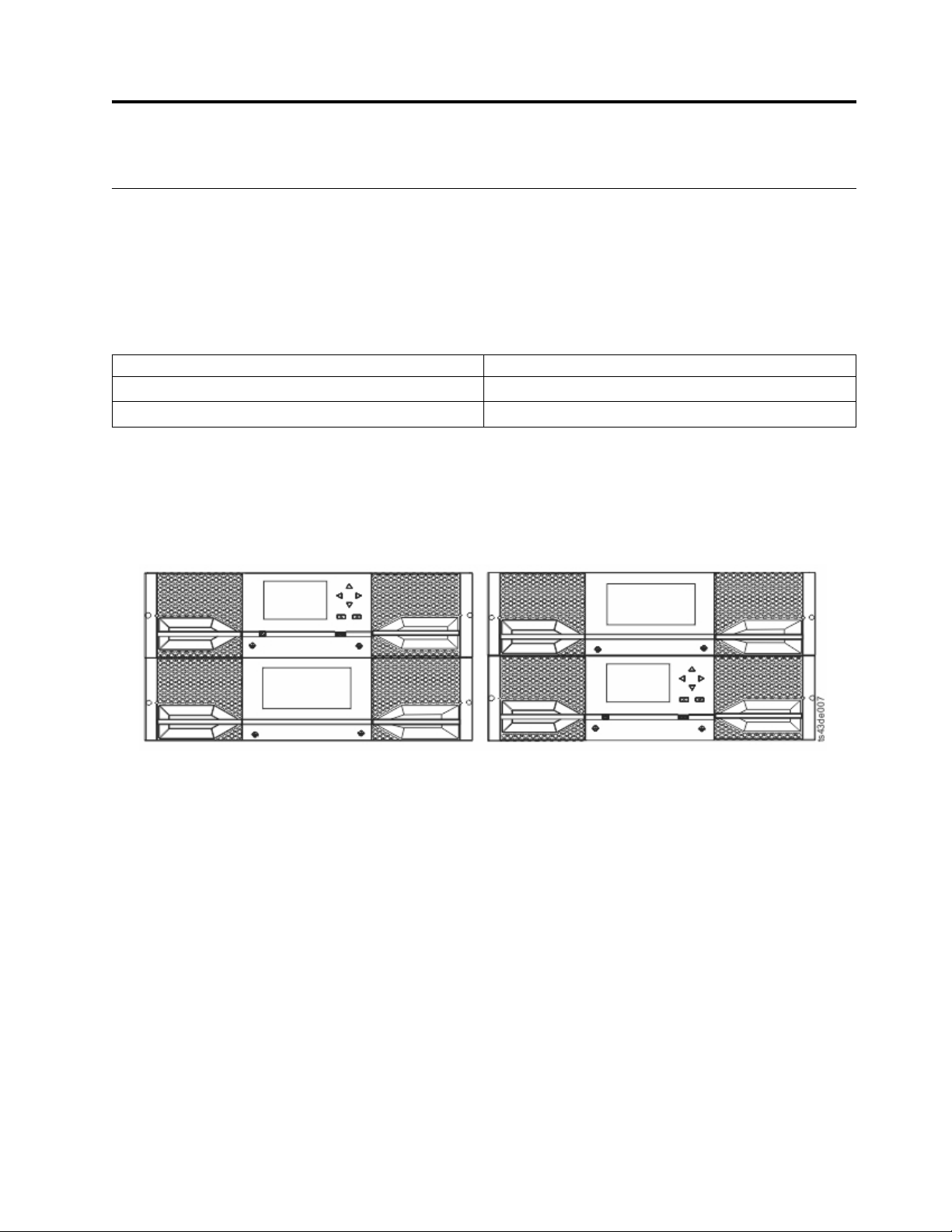

Figure 1 shows a two-module version of the tape library. The library on the left shows the base module

above the expansion module. The library on the right shows the base module below the expansion

module. An individual library can consist of one base module and up to 6 expansion modules. See

“Structure and supported library configurations” on page 2 for supported configurations.

Figure 1. Two module tape library

The library provides the following capabilities:

v New user interface for improved usability

v Updated library communication system

v I/O magazines to allow individual cartridge handling to be done independent of the library.

v Mixed media types

v Integrated management tools

v Scalability to seven modules

v Remote management with the management GUI

v Remote monitoring with Simple Network Management Protocol (SNMP)

v Multipath architecture

v Host-based path failover

v Graphical management interface

1

Table 4. Minimum and maximum storage configurations

Configuration Capacity

Cartridges

Minimum

1 Module Library

Base Module only

Maximum

7 Module Library

Base Module

6 Expansion Modules

Notes:

v1A single module (or the lowest module in a library) can have a 4-slot I/O Station. The lowest slot is inaccessible

to the accessor.

v2HH = Half height. FH = Full height.

v3Every module except the lowest one can contain a 5-slot I/O Station. If a seven Module library has an I/O

Station for each module, the maximum number of slots that can be configured as I/O slots are 34 (six modules

with 5-slot I/O Stations, and the lowest module with a 4-slot I/O Station).

HH2Tape Drives 3

FH2Tape Drives 1

HH/FH Tape Drive Mix 1/1

Cartridges

HH Tape Drives 21

FH Tape Drives 7

HH/FH Tape Drive Mix

28 with 4-slot I/O Station enabled

268 with one 4-slot I/O Station enabled

Nineteen half-height drives

to one full-height drive, or

Seven half-height drives

to seven full-height drives

32

272

1

3

Structure and supported library configurations

Supported library configurations

The library supports a single base module tabletop configuration or a scalable rackmount configuration.

All libraries start with a Base Module. Up to six Expansion Modules can be added as needed to support

customer requirements. The architecture is designed to support a maximum of three Expansion Modules

above the Base Module and three Expansion Modules below the Base Module. Table 5 on page 3 shows

the supported configurations for libraries, ranging 1 - 7 total modules.

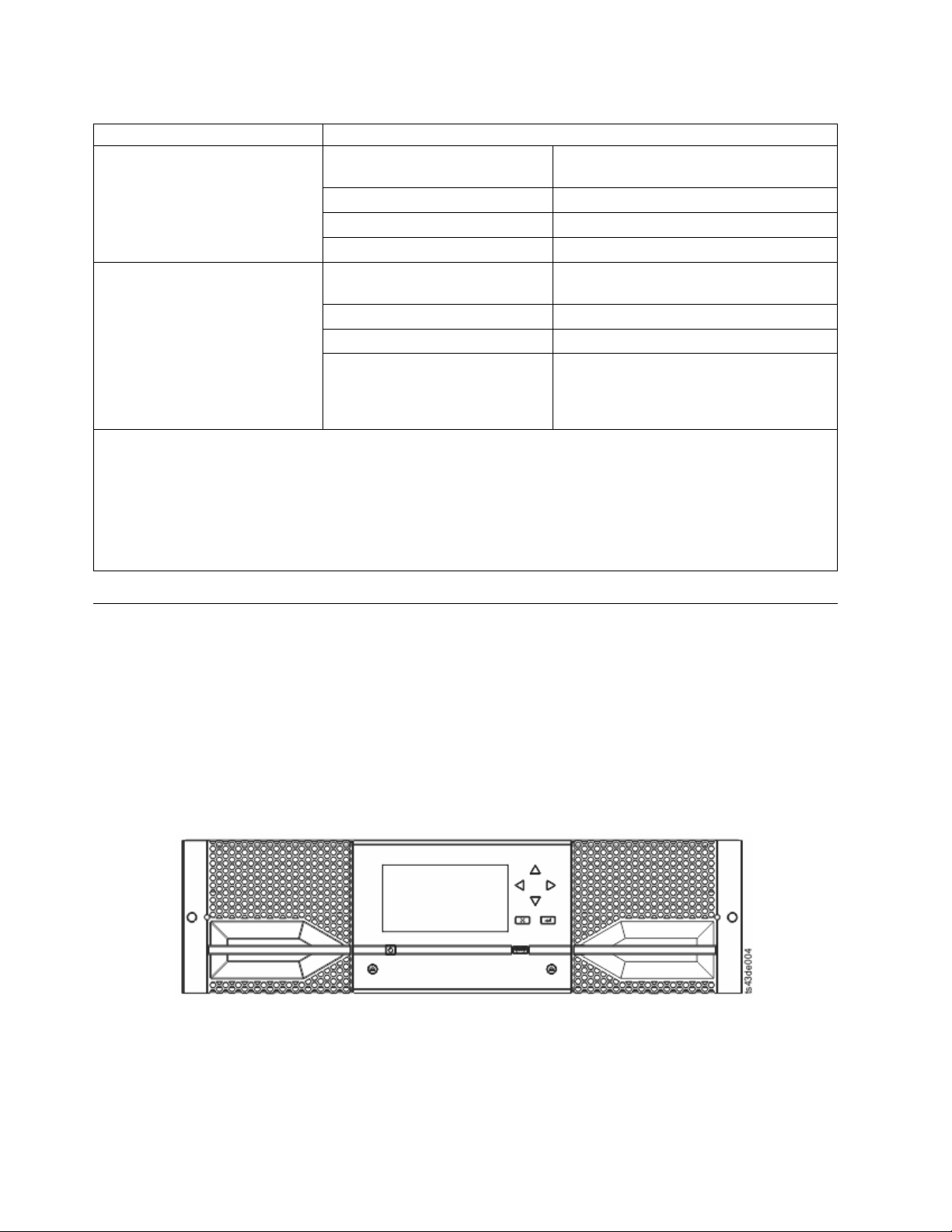

Figure 2. Base Module

2 Dell EMC ML3 Tape Library: User's Guide

Figure 3. Expansion Module

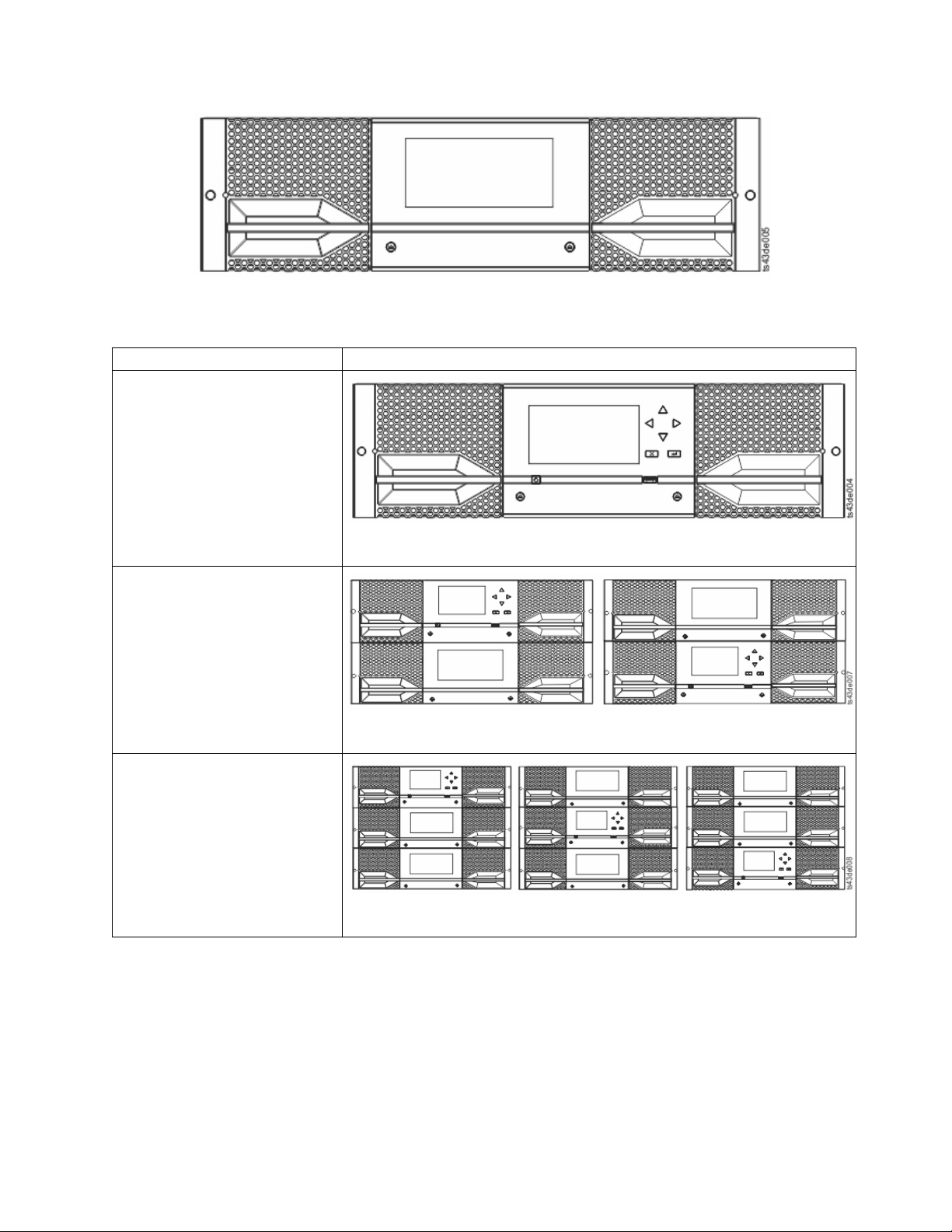

Table 5. Library configurations

Module quantity Supported library configuration

1 module library

Base Module only

Figure 4. Base Module

2 module library

Base Module, and

1 Expansion Module

Figure 5. 2 module library

3 module library

Base Module, and

2 Expansion Modules

Figure 6. 3 module library

Overview 3

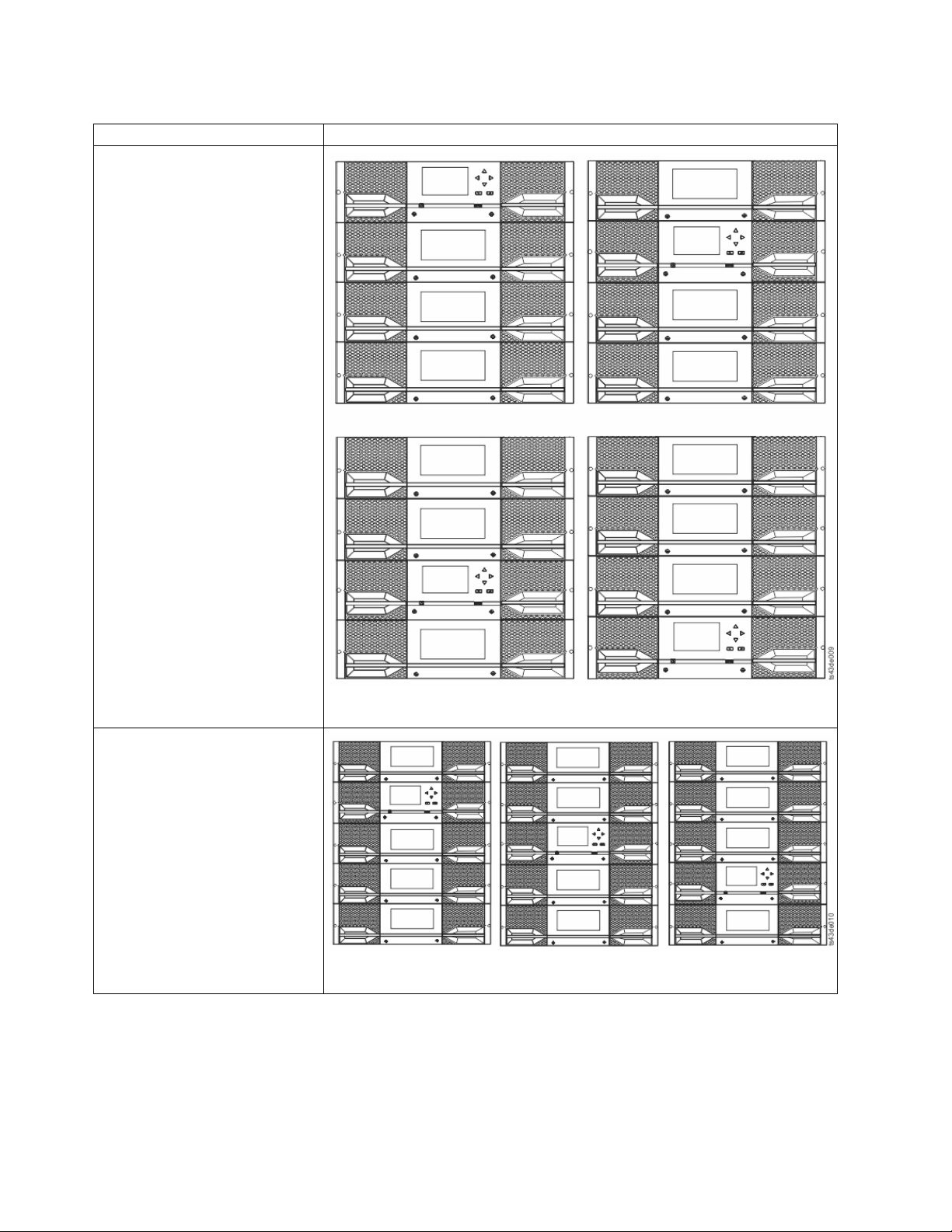

Table 5. Library configurations (continued)

Module quantity Supported library configuration

4 module library

Base Module, and

3 Expansion Modules

5 module library

Base Module, and

4 Expansion Modules

Figure 7. 4 module library

Figure 8. 5 module library

4 Dell EMC ML3 Tape Library: User's Guide

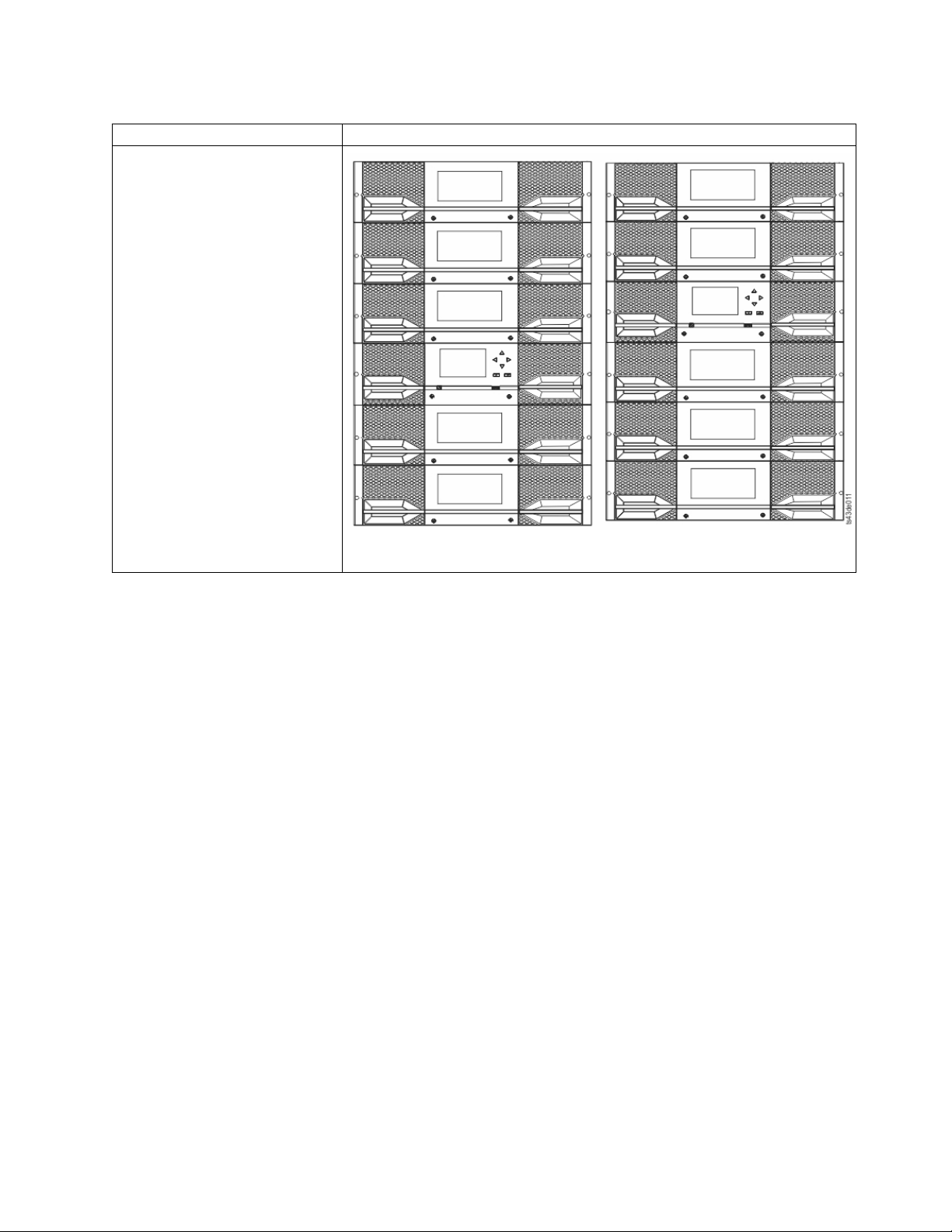

Table 5. Library configurations (continued)

Module quantity Supported library configuration

6 module library

Base Module, and

5 Expansion Modules

Figure 9. 6 Module library

Overview 5

Table 5. Library configurations (continued)

Module quantity Supported library configuration

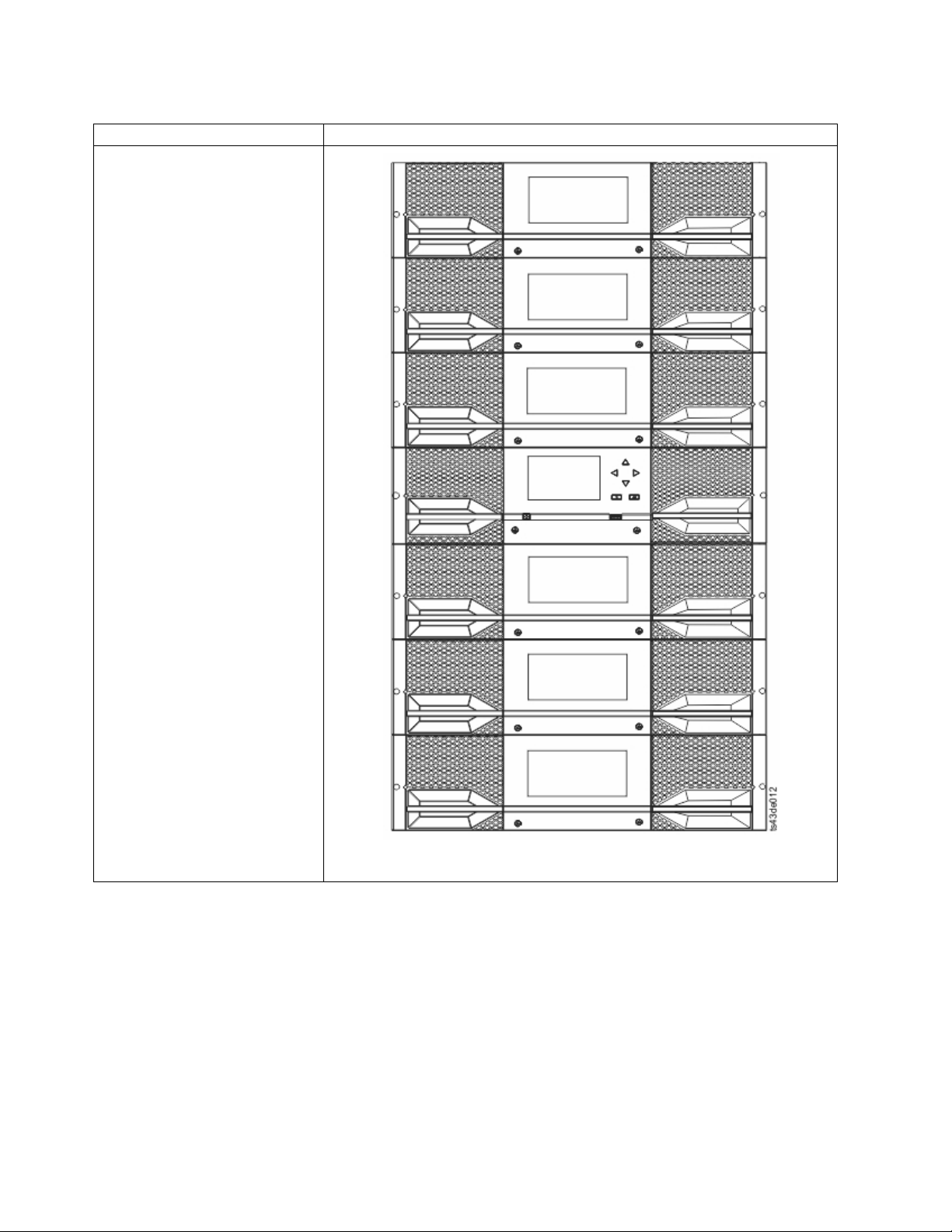

7 module library

Base Module, and

6 Expansion Modules

Figure 10. 7 module library

6 Dell EMC ML3 Tape Library: User's Guide

Components

Front panel

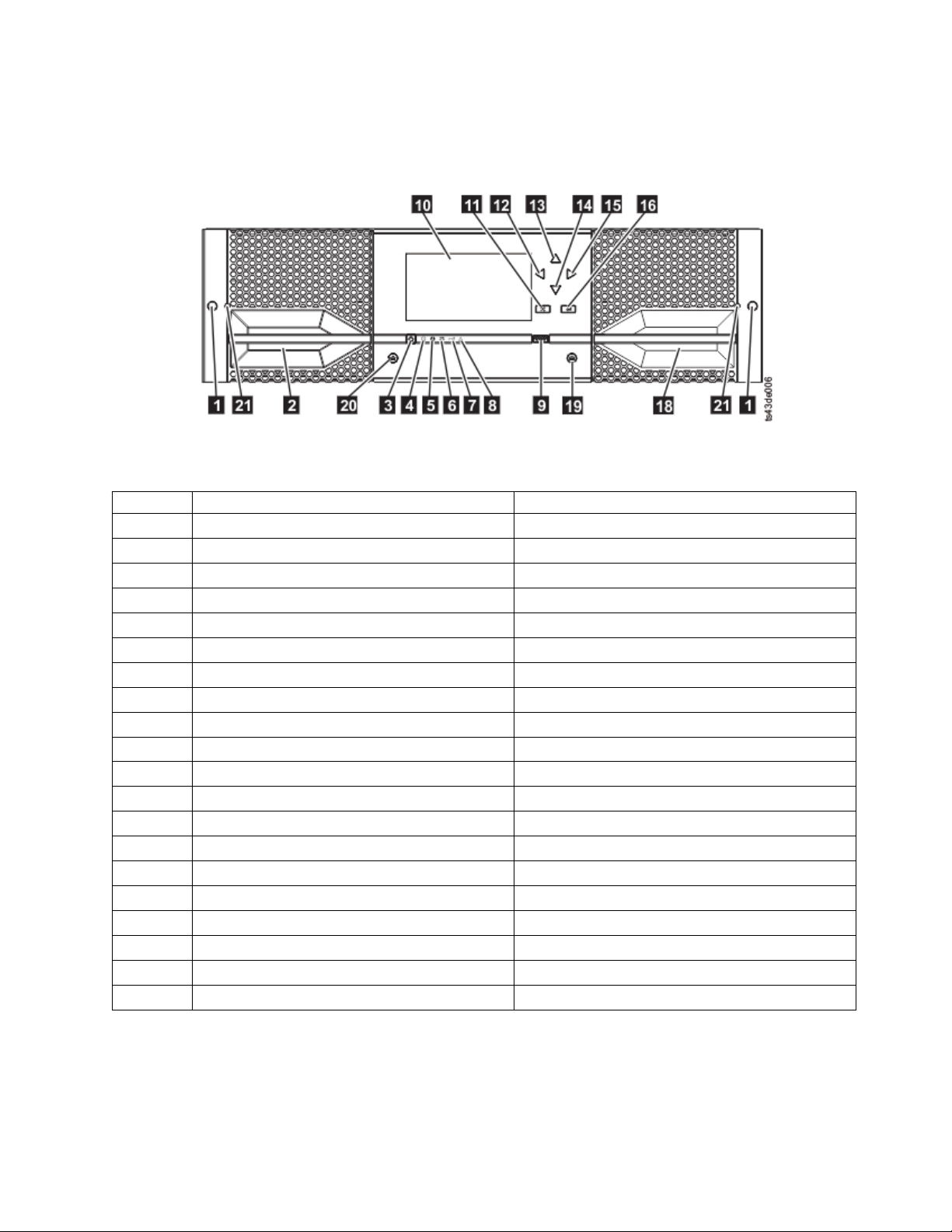

Figure 11. Front panel

Table 6. Front panel descriptions

Number Item Comments

▌1▐ Screw holes for attachment to a rack

▌2▐ Left magazine access handle

▌3▐ Power Base Module only

▌4▐ Ready LED, Green Base Module only

▌5▐ Unit Identification LED, Blue Base Module only

▌6▐ Clean LED, Amber Base Module only

▌7▐ Attention LED, Amber Base Module only

▌8▐ Error LED, Amber Base Module only

▌9▐ USB port Base Module only

▌10▐ Operator Panel display Base Module only

▌11▐ Back/Return button Base Module only

▌12▐ Navigation button - Left Base Module only

▌13▐ Navigation button - Up Base Module only

▌14▐ Navigation button - Down Base Module only

▌15▐ Navigation button - Right Base Module only

▌16▐ Enter button Base Module only

▌18▐ I/O station/Right magazine access handle

▌19▐ Right magazine button

▌20▐ Left magazine button

▌21▐ Manual magazine release hole

Overview 7

Rear panel

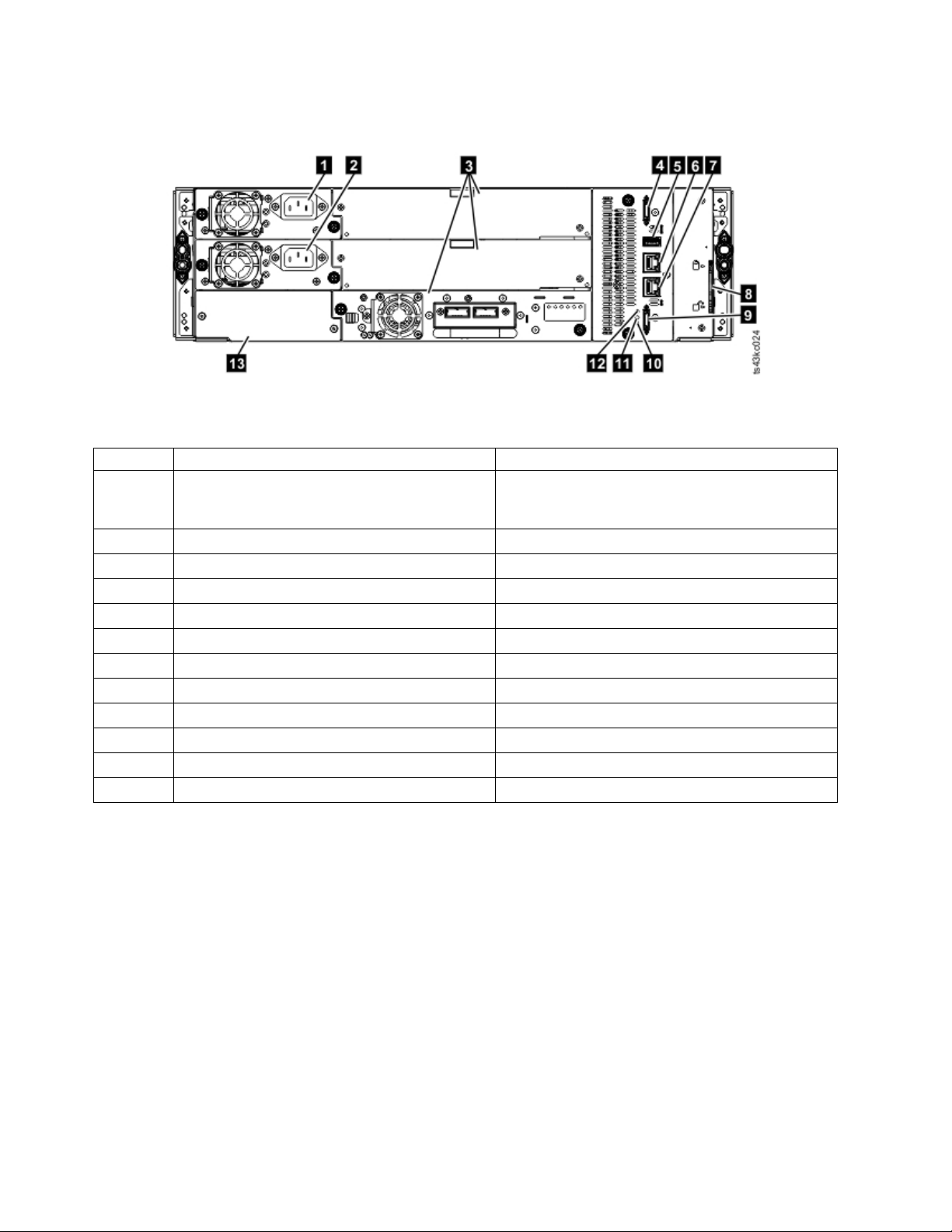

Figure 12. Rear panel

Table 7. Rear panel descriptions

Number Item Comments

▌1▐ Power supply 1 Standard on Base Module

Optional on Expansion Module (required

if drives are present)

▌2▐ Power supply 2 Optional on Base Module and Expansion Modules

▌3▐ Tape drive bays

▌4▐ Upper Expansion Module connection port

▌5▐ USB port Base Module only

▌6▐ Ethernet port B Base Module only (secondary port for service usage)

▌7▐ Ethernet port A Base Module only

▌8▐ Module alignment mechanism

▌9▐ Lower Expansion Module connection port

▌10▐ Unit Identifier LED, Blue

▌11▐ Controller Error LED, Yellow

▌13▐ Product Serial Number, Tag location

Physical and logical addresses of modules

The library assigns each module a unique address to indicate its physical location, shown in Figure 13 on

page 9. The physical numbering is bottom up on all modules.

8 Dell EMC ML3 Tape Library: User's Guide

Loading...

Loading...