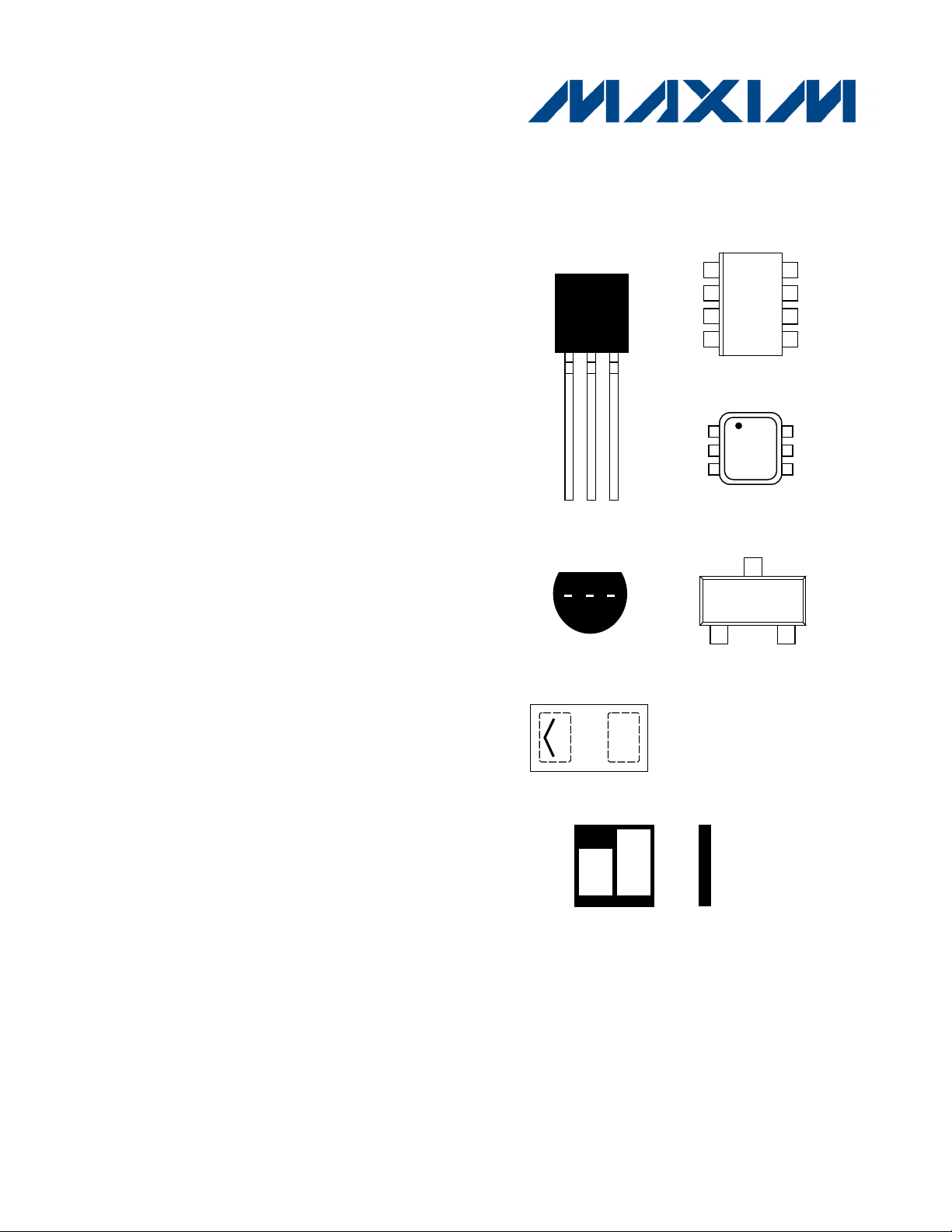

Dell DS2502 Service Manual

1 2

09rrd

Flip Chip, Top View

with Laser Mark,

Contacts Not Visible.

“rrd” = Revision/Date

1 = DATA

2 = GND

SFN (APPROX. 6.0mm x 6.0mm x 0.9mm)

BOTTOM VIEW

SIDE VIEW

1 2

SFN PINOUT:

PIN 1: IO

PIN 2: GND

DATA

1 2 3

6 5 4

TSOC PACKAGE

GND

NC

NC

NC

NC

1

2

3

4

8

7

6

5

NC

NC

NC

NC

NC

NC

DATA

GND

8-PIN SO (150 MIL)

DS2502

1Kb Add-Only Memory

GND

DATA

NC

BOTTOM VIEW

TO-92

DS2502

2

3

SOT-23 Package

Top View

1 2

3

09rr

1 = DATA; 2, 3 = GND

19-5075; Rev 12/11

FEATURES

1024 bits Electrically Programmable Read

Only Memory (EPROM) communicates with

the economy of one signal plus ground

Unique, factory-lasered and tested 64-bit

registration number (8-bit family code + 48bit serial number + 8-bit CRC tester) assures

absolute traceability because no two parts are

alike

Built-in multidrop controller ensures

compatibility with other MicroLAN products

EPROM partitioned into four 256-bit pages

for randomly accessing packetized data

Each memory page can be permanently

write-protected to prevent tampering

Device is an “add only” memory where

additional data can be programmed into

EPROM without disturbing existing data

Architecture allows software to patch data by

superseding an old page in favor of a newly

programmed page

Reduces control, address, data, power, and

programming signals to a single data pin

Directly connects to a single port pin of a

microprocessor and communicates at up to

16.3 kbits per second

8-bit family code specifies DS2502

communications requirements to reader

Presence detector acknowledges when the

reader first applies voltage

Low cost TO-92, SFN, or 8-pin SO, SOT-23

(3-pin), TSOC and flip chip surface mount

package

Reads over a wide voltage range of 2.8V to

6.0V from -40°C to +85°C; programs at

11.5V to 12.0V from -40°C to +50°C

PIN ASSIGNMENT

NOTE: THE SFN PACKAGE IS QUALIFIED FOR ELECTRO-MECHANICAL

CONTACT APPLICATIONS ONLY, NOT FOR SOLDERING. FOR MORE

INFORMATION, REFER TO APPLICATION NOTE 4132: ATTACHMENT

METHODS FOR THE ELECTRO-MECHANICAL SFN PACKAGE.

“rr” = Revision

1 of 24

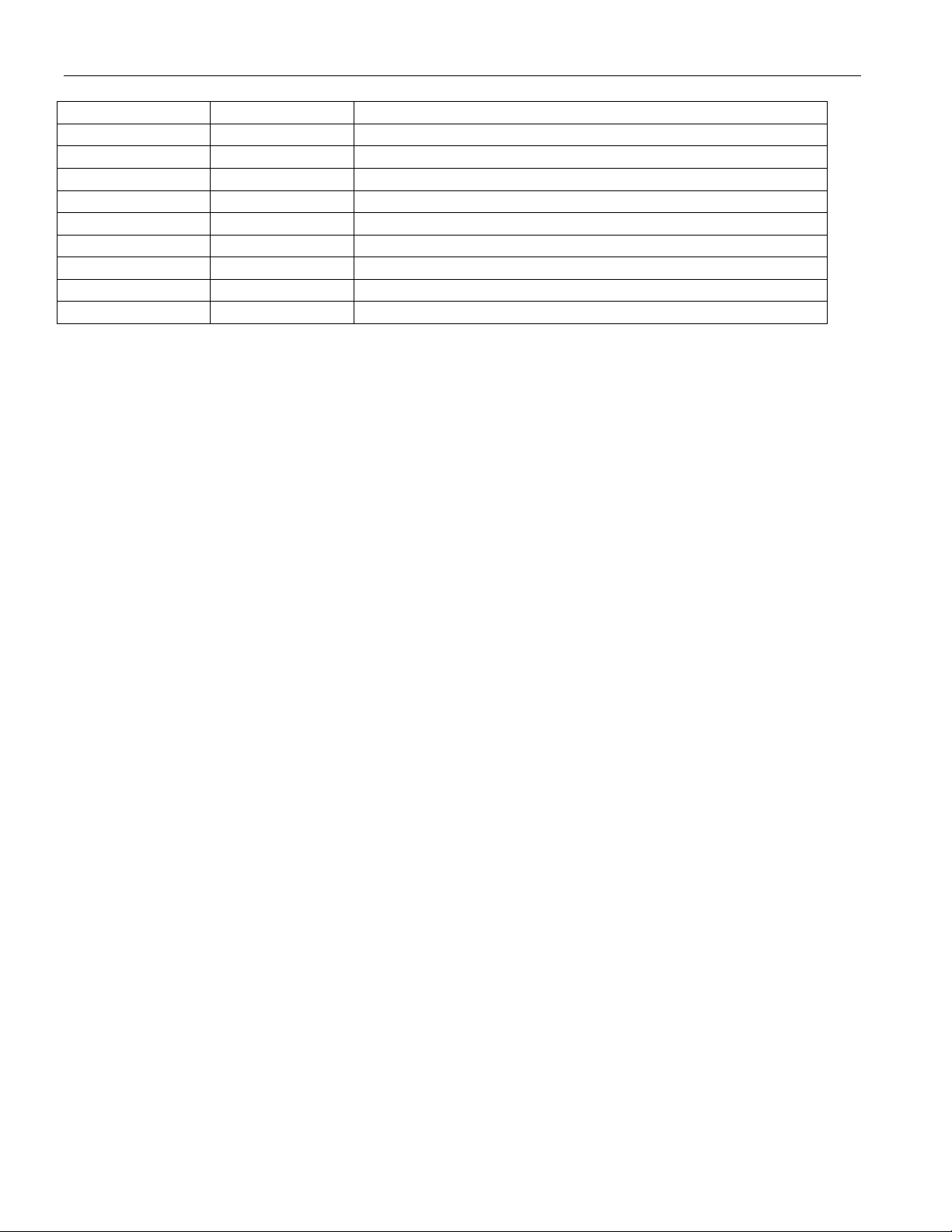

DS2502

PART

TEMP RANGE

PIN-PACKAGE

DS2502+

-40°C to +85°C

3 TO-92 (straight leads)

DS2502+T&R

-40°C to +85°C

3 TO-92 (formed leads, 2k pieces)

DS2502G+T&R

-40°C to +85°C

2 SFN (2.5k pieces)

DS2502P+

-40°C to +85°C

6 TSOC

DS2502P+T&R

-40°C to +85°C

6 TSOC (4k pieces)

DS2502R+T&R

-40°C to +85°C

3 SOT-23 (3k pieces)

DS2502S+

-40°C to +85°C

8 SO

DS2502S+T&R

-40°C to +85°C

8 SO (2.5k pieces)

DS2502X1

-40°C to +85°C

2 Flip Chip (10k pieces)

1-Wire is a registered trademark of Maxim Integrated Products, Inc.

ORDERING INFORMATION

+Denotes a lead(Pb)-free/RoHS-compliant package.

T&R = Tape and reel.

DESCRIPTION

The DS2502 1Kb Add-Only Memory identifies and stores relevant information about the product to

which it is associated. This lot- or product-specific information can be accessed with minimal interfacefor example, a single port pin of a microcontroller. The DS2502 consists of a factory-lasered registration

number that includes a unique 48-bit serial number, an 8-bit CRC, and an 8-bit Family Code (09h) plus

1Kb of EPROM which is user-programmable. The power to program and read the DS2502 is derived

ent irely from the 1-Wire communication line.

Data is transferred serially via the 1-Wire protocol which requires only a single data lead and a ground

return. The entire device can be programmed and then write-protected if desired. Alternatively, the part

may be programmed multiple times with new data being appended to, but not overwriting, existing data

with each subsequent programming of the device. Note: Individual bits can be changed only from a

logical 1 to a logical 0, never from a logical 0 to a logical 1. A provision is also included for indicating

that a certain page or pages of data are no longer valid and have been replaced with new or updated data

that is now residing at an alternate page address. This page address redirection allows software to patch

data and enhance the flexibility of the device as a stand-alone database. The 48-bit serial number that is

factory-lasered into each DS2502 provides a guaranteed unique identity which allows for absolute

traceability. The familiar TO-92 or SOIC or TSOC packages provide a compact enclosure that allows

standard assembly equipment to handle the device easily for attachment to printed circuit boards or

wiring. Typical applications include storage of calibration constants, maintenance records, asset tracking,

product revision status, and access codes.

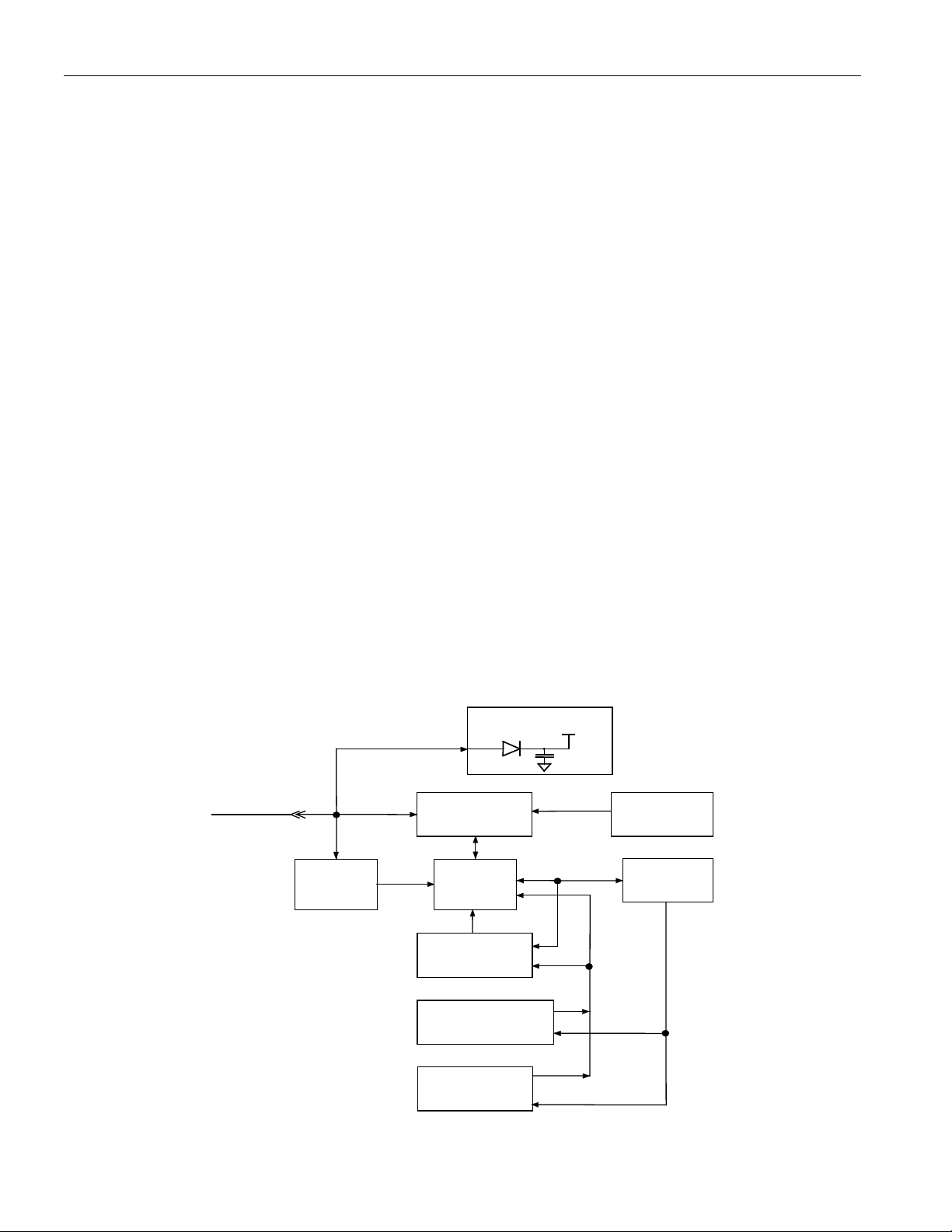

OVERVIEW

The block diagram in Figure 1 shows the relationships between the major control and memory sections of

the DS2502. The DS2502 has three main data components: 1) 64-bit lasered ROM, 2) 1024-bit EPROM,

and 3) EPROM Status Bytes. The device derives its power for read operations entirely from the 1-Wire

communication line by storing energy on an internal capacitor during periods of time when the signal line

is high and continues to operate off of this “parasite” power source during the low times of the 1-Wire

line until it returns high to replenish the parasite (capacitor) supply. During programming, 1-Wire

communication occurs at normal voltage levels and then is pulsed momentarily to the programming

voltage to cause the selected EPROM bits to be programmed. The 1-Wire line must be able to provide 12

volts and 10 milliamperes to adequately program the EPROM portions of the part. Whenever

programming voltages are present on the 1-Wire line a special high voltage detect circuit within the

DS2502 generates an internal logic signal to indicate this condition. The hierarchical structure of the 1Wire protocol is shown in Figure 2. The bus master must first provide one of the six ROM Function

Commands, 1) Read ROM, 2) Match ROM, 3) Search ROM, 4) Skip ROM. These commands operate on

the 64-bit lasered ROM portion of each device and can singulate a specific device if many are present on

2 of 24

DS2502

PARASITE POWER

DATA

1-WIRE BUS

64-BIT LASERED

ROM

1-WIRE FUNCTION

CONTROL

PROGRAM

VOLTAGE

DETECT

MEMORY

FUNCTION

CONTROL

8-BIT

SCRATCHPAD

8-BIT CRC

GENERATOR

1024-BIT EPROM

(4 PAGES OF 32 BYTES)

STATUS BYTES

EPROM

the 1-Wire line as well as indicate to the bus master how many and what types of devices are present. The

protocol required for these ROM Function Commands is described in Figure 9. After a ROM Function

Command is successfully executed, the memory functions that operate on the EPROM portions of the

DS2502 become accessible and the bus master may issue any one of the five Memory Function

Commands specific to the DS2502 to read or program the various data fields. The protocol for these

Memory Function Commands is described in Figure 5. All data is read and written least significant bit

first.

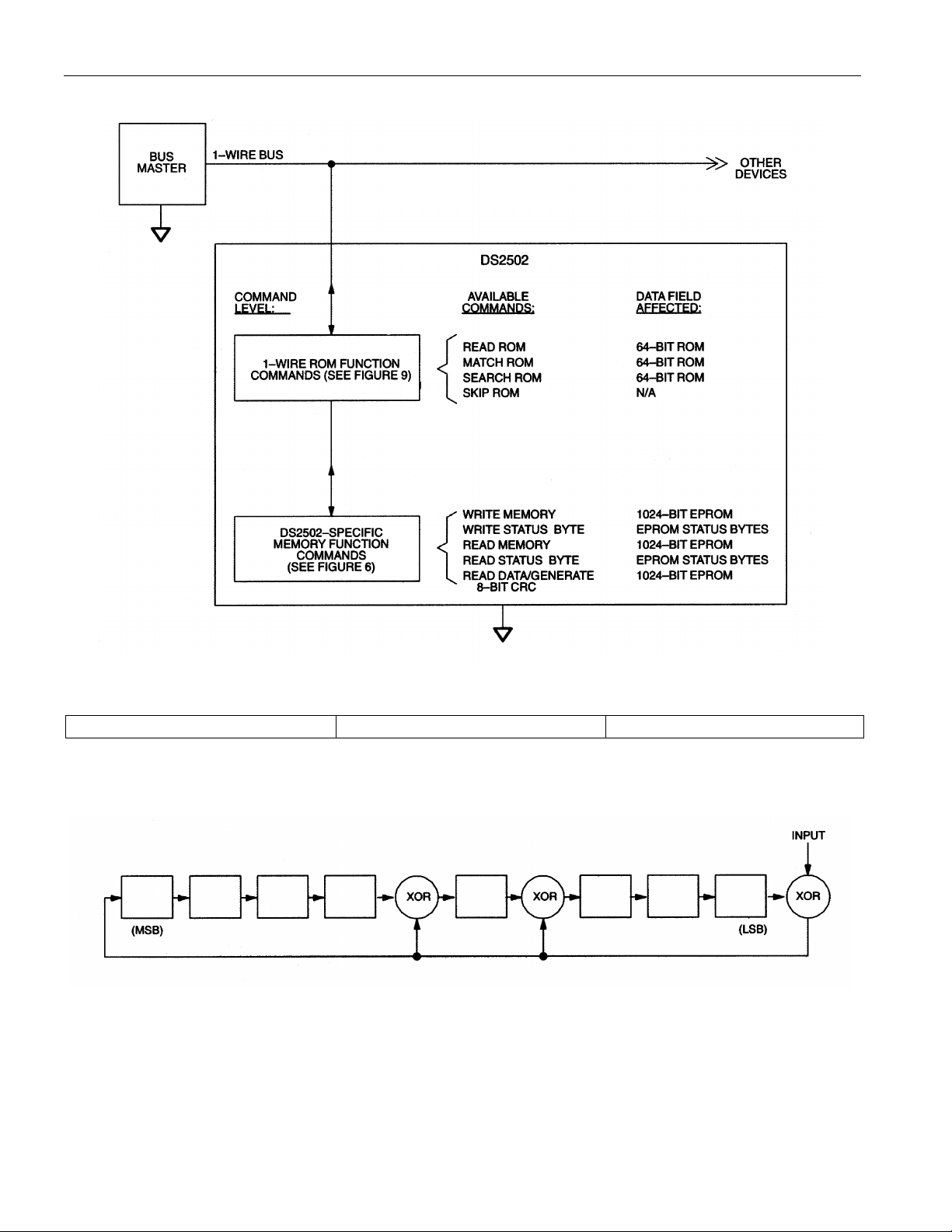

64-BIT LASERED ROM

Each DS2502 contains a unique ROM code that is 64 bits long. The first 8 bits are a 1-Wire family code.

The next 48 bits are a unique serial number. The last 8 bits are a CRC of the first 56 bits. (See Figure 3).

The 64-bit ROM and ROM Function Control section allow the DS2502 to operate as a 1-Wire device and

follow the 1-Wire protocol detailed in the section “1-Wire Bus System.” The memory functions required

to read and program the EPROM sections of the DS2502 are not accessible until the ROM function

protocol has been satisfied. This protocol is described in the ROM functions flow chart (Figure 9). The 1Wire bus master must first provide one of four ROM function commands: 1) Read ROM, 2) Match ROM,

3) Search ROM, or 4) Skip ROM. After a ROM function sequence has been successfully executed, the

bus master may then provide any one of the memory function commands specific to the DS2502 (Figure

6).

The 1-Wire CRC of the lasered ROM is generated using the polynomial X8 + X5 + X4 + 1. Figure 4

shows a hardware implementation of this CRC generator. Additional information about the Maxim

1-Wire Cyclic Redundancy Check is available in Application Note 27. The shift register acting as the

CRC accumulator is initialized to 0. Then starting with the least significant bit of the family code, 1 bit at

a time is shifted in. After the 8th bit of the family code has been entered, then the serial number is

entered. After the 48th bit of the serial number has been entered, the shift register contains the CRC

value. Shifting in the 8 bits of CRC should return the shift register to all 0s.

DS2502 BLOCK DIAGRAM Figure 1

3 of 24

DS2502

8–Bit CRC Code

48–Bit Serial Number

8–Bit Family Code (09h)

MSB

LSB

MSB

LSB

MSB

LSB

HIERARCHICAL STRUCTURE FOR 1-WIRE PROTOCOL Figure 2

64-BIT LASERED ROM Figure 3

1-WIRE CRC GENERATOR Figure 4

4 of 24

DS2502

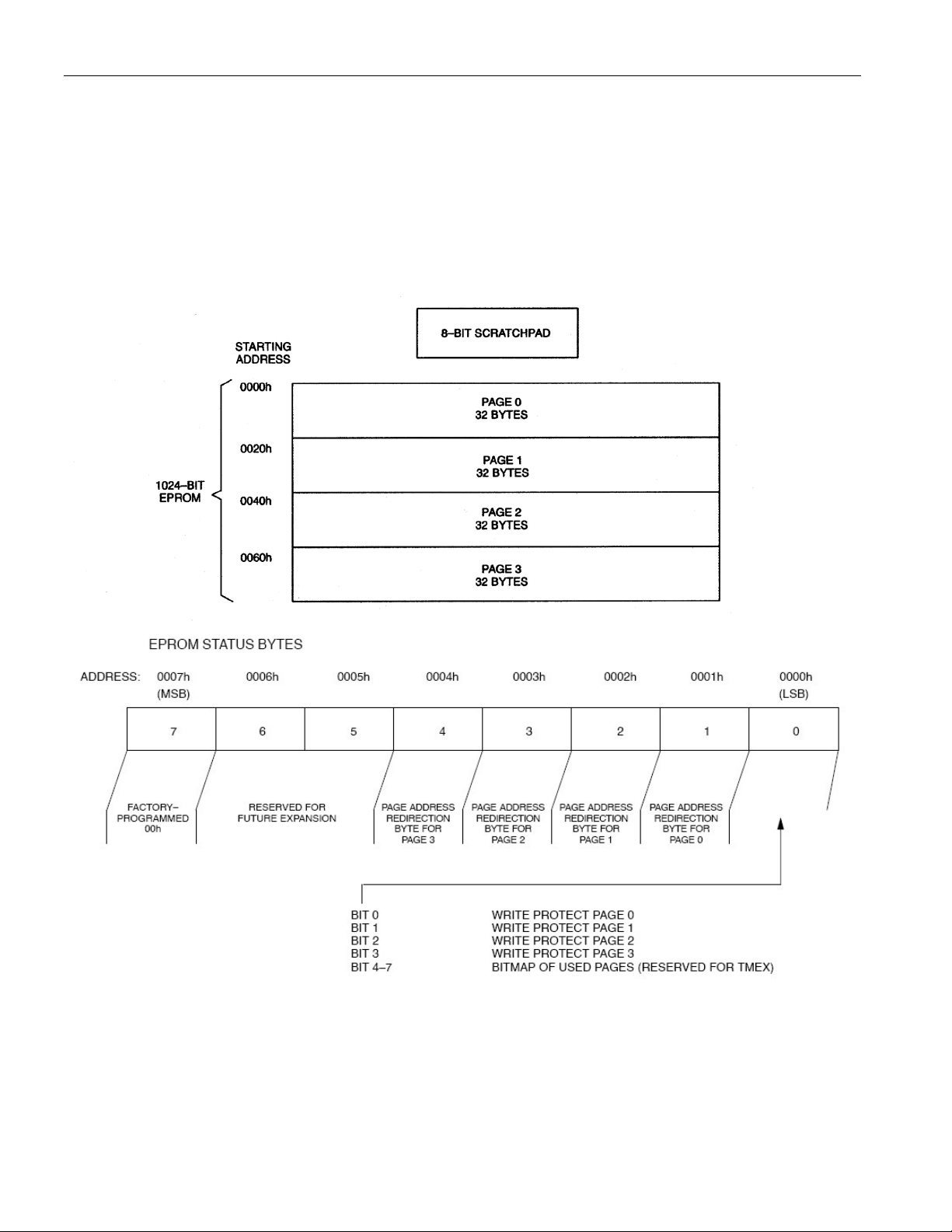

1024-BITS EPROM

The memory map in Figure 5 shows the 1024-bit EPROM section of the DS2502 which is configured as

four pages of 32 bytes each. The 8-bit scratchpad is an additional register that acts as a buffer when

programming the memory. Data is first written to the scratchpad and then verified by reading an 8-bit

CRC from the DS2502 that confirms proper receipt of the data. If the buffer contents are correct, a

programming voltage should be applied and the byte of data will be written into the selected address in

memory. This process ensures data integrity when programming the memory. The details for reading and

programming the 1024-bit EPROM portion of the DS2502 are given in the Memory Function Commands

section.

EPROM STATUS BYTES

In addition to the 1024 bits of data memory the DS2502 provides 64 bits of Status Memory accessible

with separate commands.

The EPROM Status Bytes can be read or programmed to indicate various conditions to the software

interrogating the DS2502. The first byte of the EPROM Status Memory contain the Write Protect Page

bits which inhibit programming of the corresponding page in the 1024-bit main memory area if the

appropriate write protection bit is programmed. Once a bit has been programmed in the Write Protect

Page byte, the entire 32-byte page that corresponds to that bit can no longer be altered but may still be

read.

The next 4 bytes of the EPROM Status Memory contain the Page Address Redirection Bytes, which

indicate if one or more of the pages of data in the 1024-bit EPROM section have been invalidated and

redirected to the page address contained in the appropriate redirection byte. The hardware of the DS2502

makes no decisions based on the contents of the Page Address Redirection Bytes. These additional byte s

of Status EPROM technology, bits within a page can be changed from a logical 1 to a logical 0 by

programming, but cannot be changed back. Therefore, it is not possible to simply rewrite a page if the

data requires changing or updating, but with space permitting, an entire page of data can be redirected to

another page within the DS2502 by writing the one’s complement of the new page address into the Page

Address Redirection Byte that corresponds to the original (replaced) page.

This architecture allows the user’s software to make a “data patch” to the EPROM by indicating that a

particular page or pages should be replaced with those indicated in the Page Address Redirection Bytes.

If a Page Address Redirection Byte has an FFH value, the data in the main memory that corresponds to

that page is valid. If a Page Address Redirection Byte has some other hex value, the data in the page

corresponding to that redirection byte is invalid, and the valid data can now be found at the one’s

complement of the page address indicated by the hex value stored in the associated Page Address

Redirection Byte. A value of FDH in the redirection byte for page 1, for example, would indicate that the

updated data is now in page 2. The details for reading and programming the EPROM status memory

portion of the DS2502 are given in the Memory Function Commands section.

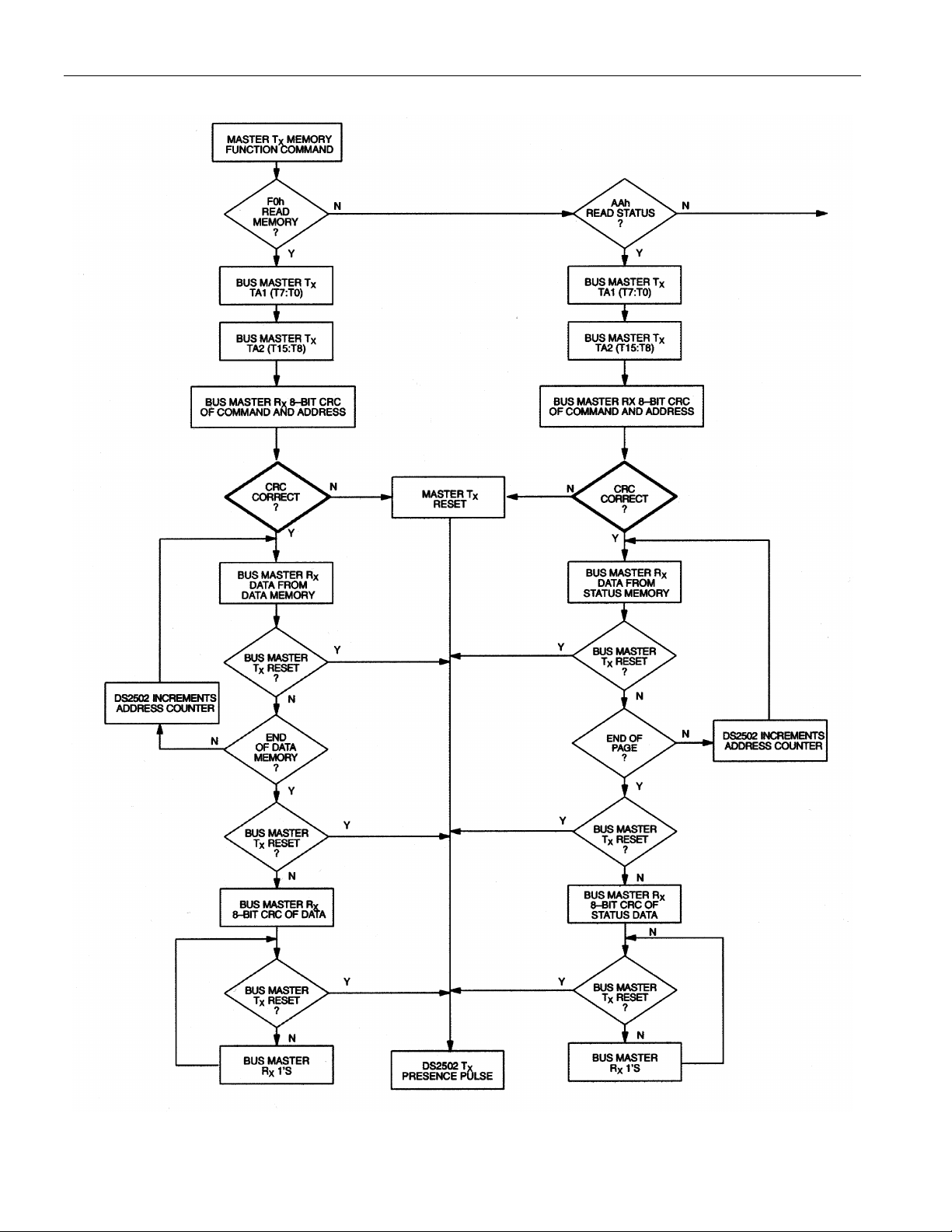

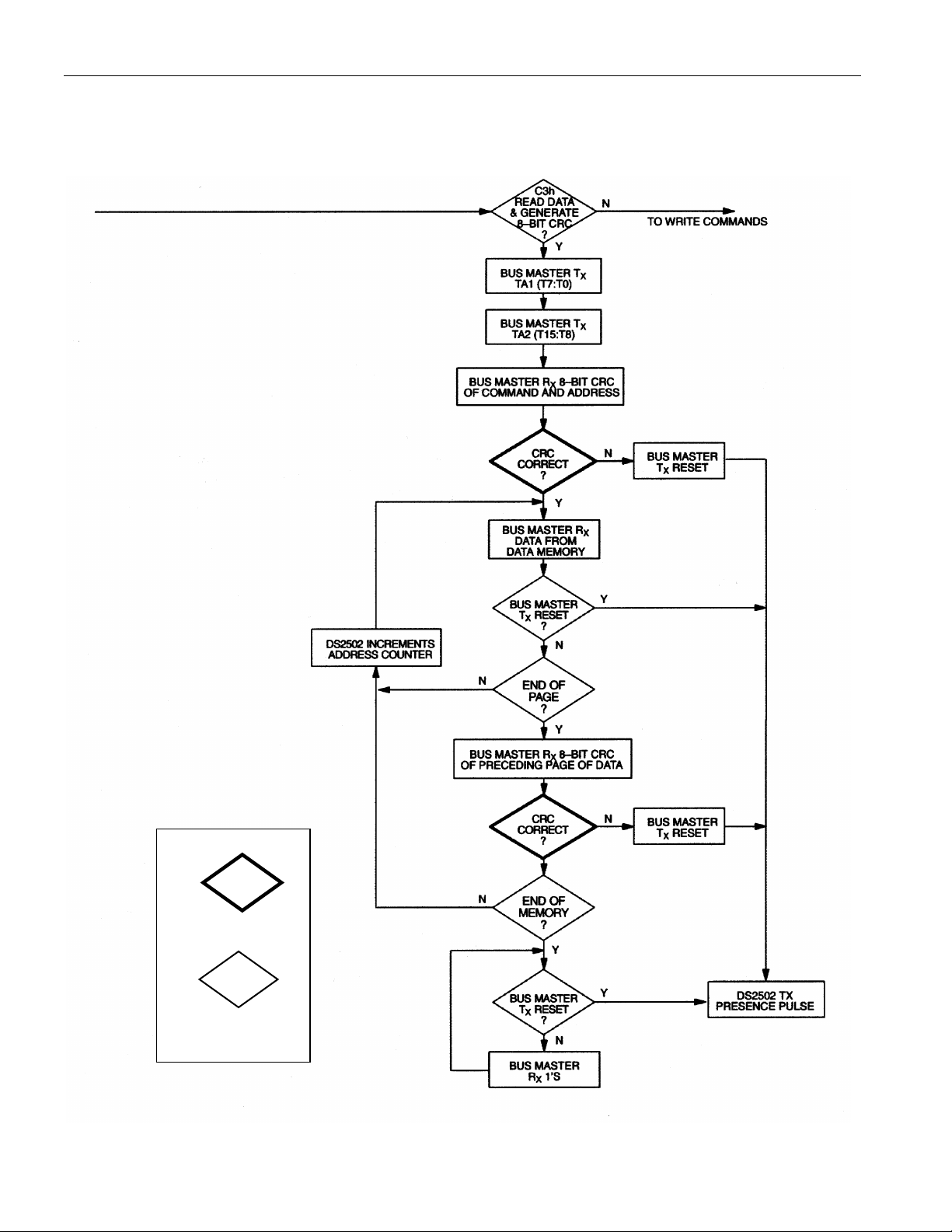

MEMORY FUNCTION COMMANDS

The “Memory Function Flow Chart” (Figure 6) describes the protocols necessary for accessing the

various data fields within the DS2502. The Memory Function Control section, 8-bit scratchpad, and the

Program Voltage Detect circuit combine to interpret the commands issued by the bus master and create

the correct control signals within the device. A 3-byte protocol is issued by the bus master. It is comprised

of a command byte to determine the type of operation and two address bytes to determine the specific

starting byte location within a data field. The command byte indicates if the device is to be read or

5 of 24

DS2502

written. Writing data involves not only issuing the correct command sequence by also providing a 12-vo lt

programming voltage at the appropriate times. To execute a write sequence, a byte of data is first loaded

into the scratchpad and then programmed into the selected address. Write sequences always occur a byte

at a time. To execute a read sequence, the starting address is issued by the bus master and data is read

from the part beginning at that initial location and continuing to the end of the selected data field or until

a reset sequence is issued. All bits transferred to the DS2502 and received back by the bus master are sent

least significant bit first.

DS2502 MEMORY MAP Figure 5

6 of 24

DS2502

MEMORY FUNCTION FLOW CHART Figure 6

7 of 24

DS2502

LEGEND:

MEMORY FUNCTION FLOW CHART Figure 6 (cont’d)

DECISION MADE

BY THE MASTER

DECISION MADE

BY DS2502

8 of 24

Loading...

Loading...