Page 1

Drop Ins

8100-EF, N8000, N8000N, N8000-R, N8100B,

N8100-BR, N8100-FA, N8200, N8200G, N8200-ST,

N8600, N8700-D, N8700-DESP, N8700-R, N8800

Original Instructions

Service Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

Part Number: 8000_SM 07/18

Page 2

Safety Notices

Warning

n

Read this manual thoroughly before operating, installing

or performing maintenance on the equipment. Failure

to follow instructions in this manual can cause property

damage, injury or death.

DANGER

Keep power cord AWAY from HEATED surfaces. DO NOT

immerse power cord or plug in water. DO NOT let power

cord hang over edge of table or counter.

DANGER

Do not lift the condensing unit by the refrigerant tubing

or other components. These features will not support

the condensing unit weight. Injury and unit damage

may occur!

DANGER

Do not install or operate equipment that has been

misused, abused, neglected, damaged, or altered/

modified from that of original manufactured

specifications.

DANGER

All utility connections and fixtures must be maintained

in accordance with Local and national codes.

Warning

n

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

concerning use of the appliance by a person responsible

for their safety. Do not allow children to play with this

appliance.

Warning

n

This product contains chemicals known to the State

of California to cause cancer and/or birth defects or

other reproductive harm. Operation, installation, and

servicing of this product could expose you to airborne

particles of glasswool or ceramic fibers, crystalline

silica, and/or carbon monoxide. Inhalation of airborne

particles of glasswool or ceramic fibers is known to the

State of California to cause cancer. Inhalation of carbon

monoxide is known to the State of California to cause

birth defects or other reproductive harm.

Warning

n

Do not use electrical appliances or accessories other

than those supplied by the manufacturer.

Warning

n

Use caution when handling metal surface edges of all

equipment.

Warning

n

DO NOT touch refrigeration lines inside units; some may

exceed temperatures of 200°F (93.3°C).

Note

Proper installation, care and maintenance are

essential for maximum performance and trouble-free

operation of your equipment. Visit our website www.

mtwkitchencare.com for manual updates, translations,

or contact information for service agents in your area.

Warning

n

Do not store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

Never use flammable oil soaked cloths or combustible

cleaning solutions, for cleaning.

Warning

n

Authorized Service Representatives are obligated to

follow industry standard safety procedures, including,

but not limited to, local/national regulations for

disconnection / lock out / tag out procedures for all

utilities including electric, gas, water and steam.

Page 3

Section 1

General Information

Section 2

Installation

Section 3

Operation

Table of Contents

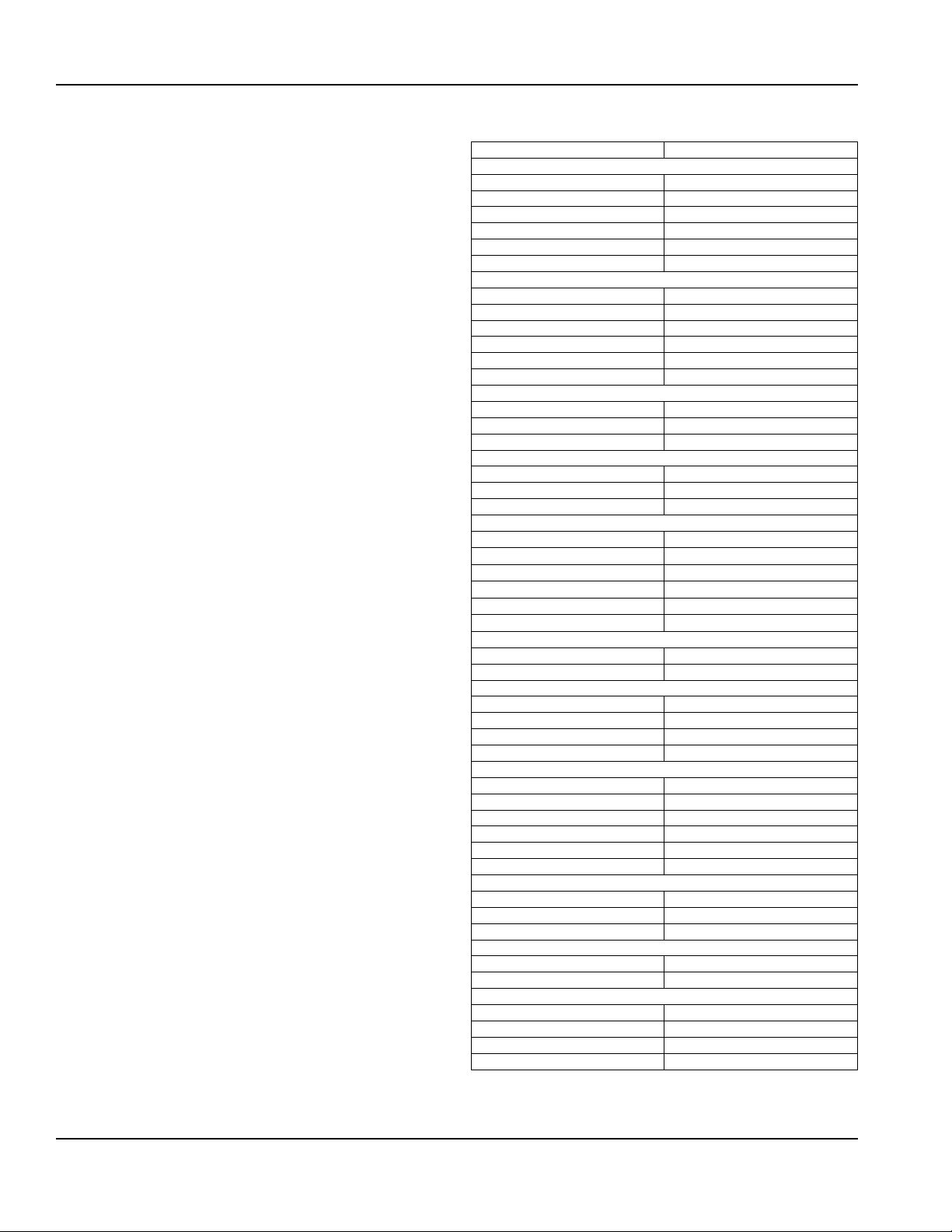

Model Numbers .................................................................................................................. 5

Serial Number Location ..................................................................................................... 6

Warranty Information ........................................................................................................ 6

Regulatory Certifications ..................................................................................................6

Domestic Models ....................................................................................................................................6

Export Models .........................................................................................................................................6

Location ..............................................................................................................................8

Weight Of Equipment ........................................................................................................8

Dimensions ....................................................................................................................... 10

Clearance Requirements ..................................................................................................11

Cutout Installation Dimensions ......................................................................................12

Curved Drop-In Cutout Details ....................................................................................................... 15

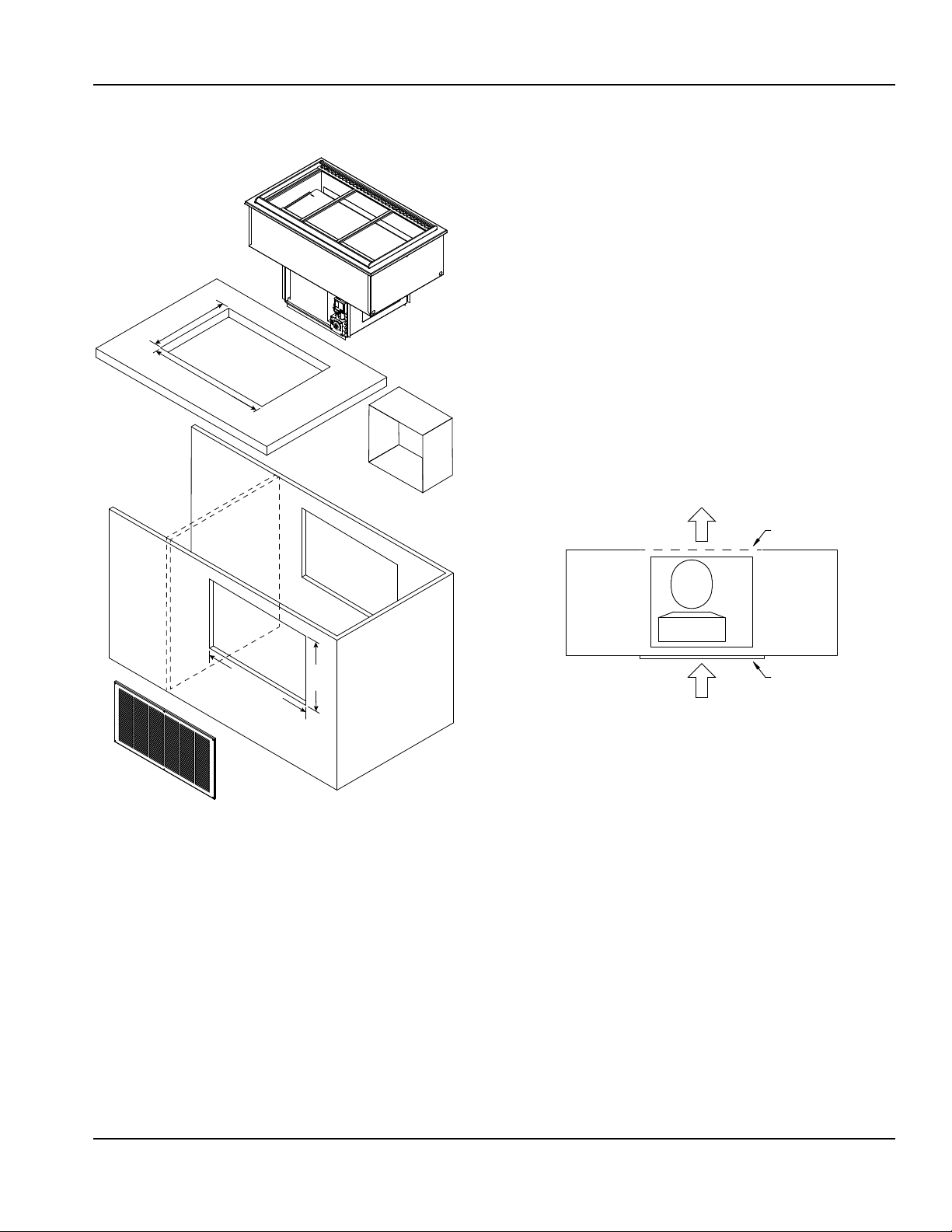

Drop-In Counter Installation ...........................................................................................16

Ice Cooled Drop-In Units .................................................................................................................. 16

Self-Contained Refrigerated Drop-In Units ................................................................................ 17

Forced-Air Refrigerated Drop-In Units ......................................................................................... 19

Self-Contained Combo Hot/Cold Drop-In Units ...................................................................... 21

Hot Food Well Drop-In Units ........................................................................................................... 22

Electrical Service ..............................................................................................................23

Voltage .................................................................................................................................................... 23

Ground Fault Circuit Interrupter .................................................................................................... 23

Electrical Specifications Chart ........................................................................................................ 23

Refrigeration ....................................................................................................................25

Optional Auto Fill Installation .........................................................................................26

Applicable to N8600 & N8800 Models ......................................................................................... 26

Applicable to N8700 Models ........................................................................................................... 27

Product Quality in Cold Pans ...........................................................................................29

8100-EF(N) Series Operation ...........................................................................................30

Temperature Control & Display ...................................................................................................... 30

Changing Display from Fahrenheit to Celsius on ERC112 Control .................................... 31

N8100B, N8100-BR & N8100NB Operation ....................................................................32

N8100-FA Operation ........................................................................................................33

N8200 & N8200-ST Operation .........................................................................................33

Operation N8200G ...........................................................................................................33

8600 Hot/Cold Series Operation .....................................................................................34

N8700-D, N8700N, N8700-R & N8800 Series Operation ...............................................35

N8700-DESP Operation....................................................................................................36

Part Number: 8000_SM 07/18 3

Page 4

Section 4

Maintenance

Cleaning and Sanitizing Procedures ...............................................................................37

General .................................................................................................................................................... 37

Exterior Cleaning ................................................................................................................................. 38

Cleaning the Condenser Coil .......................................................................................................... 38

N8100-FA Series Drain Maintenance ............................................................................................ 38

Section 5

Troubleshooting

Problem -> Cause -> Correction Chart ............................................................................39

Section 6

Refrigeration

R404A

Refrigerant Recovery / Evacuation & Recharging .......................................................... 40

Charging Procedures .......................................................................................................40

System Contamination Clean-up ....................................................................................41

Mild System Contamination Clean-Up Procedure ......................................................... 42

Severe System Contamination Clean-Up Procedure .....................................................42

Filter Driers .......................................................................................................................43

Section 7

Component Check Procedures

Table of Contents (continued)

Mechanical Refrigeration Control ..................................................................................44

Electric/Solid State Refrigeration Control .....................................................................44

Unit Air Flow Design ........................................................................................................44

Section 8

Wiring Diagrams

Drop-In Series 8100-EF & 8100-EFN ...............................................................................45

Export Drop-In Series 8100-EF-E & 8100-EFN-E .............................................................47

Drop-In Series N8100B, N8100NB & N8100-BR .............................................................48

Export Drop-In Series N8100B-E & N8100NB-E .............................................................48

N8100-FA Series Models .................................................................................................49

Drop-In Frost Tops Series N8200 & N8200-ST ................................................................ 50

Drop-In Granite Cold Slabs Series N8200G ....................................................................50

Export Drop-In Frost Tops Series N8200-E ..................................................................... 51

Export Drop-In Granite Cold Slabs Series N8200G-E .....................................................51

N8600 Series ..................................................................................................................... 52

N8700D, N8700DESP, N8700-R & N8700N Series ..........................................................55

8700UM Series Models ....................................................................................................59

N8800 Series Models ....................................................................................................... 60

Section 9

Replacement Procedures

Self-Contained Refrigerated Drop-In Units & Self-Contained Combo Hot/Cold Drop-In

Units ......................................................................................................................................................... 44

Forced-Air Refrigerated Drop-In Units ......................................................................................... 44

Plumbing...........................................................................................................................62

Wiring ................................................................................................................................62

4 Part Number: 8000_SM 07/18

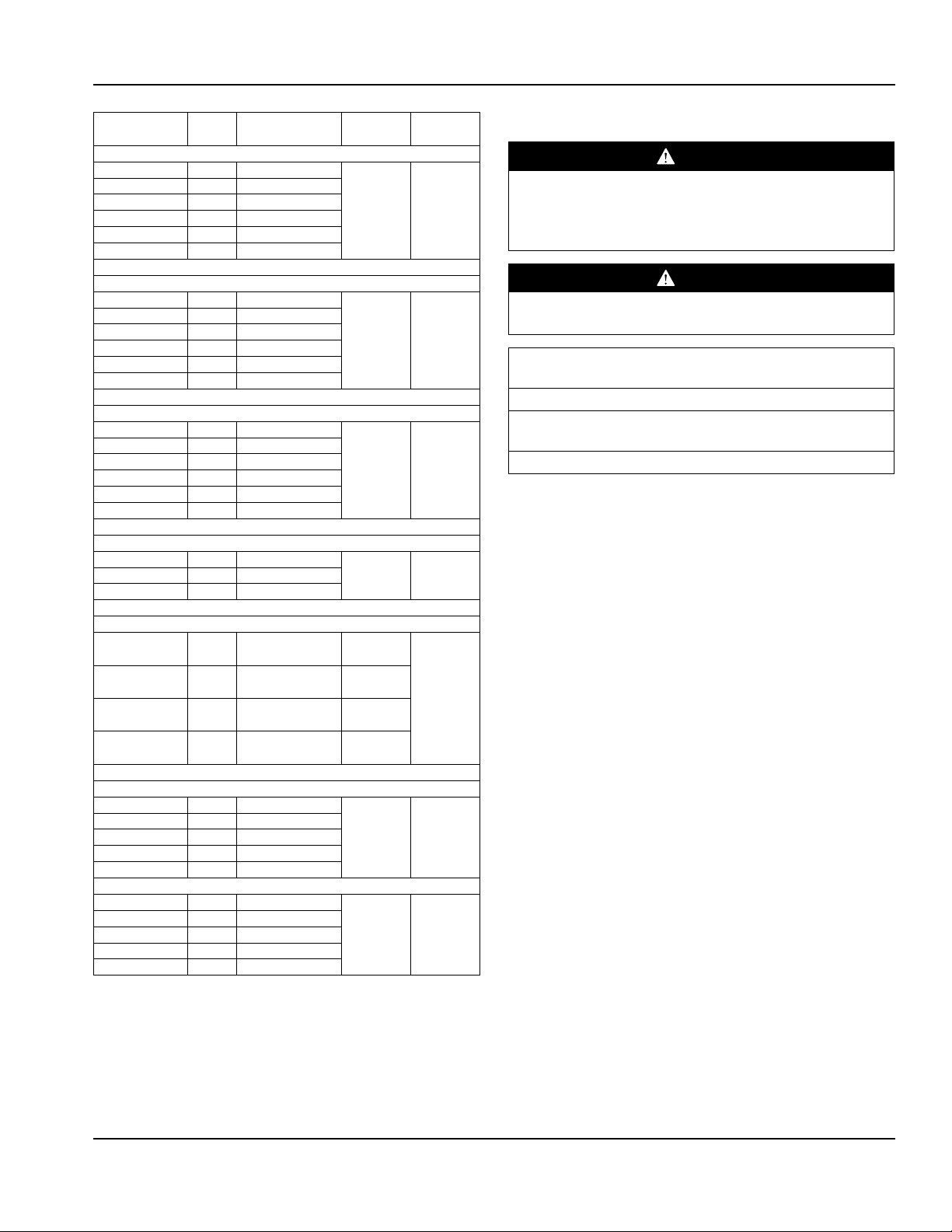

Page 5

Section 1

General Information

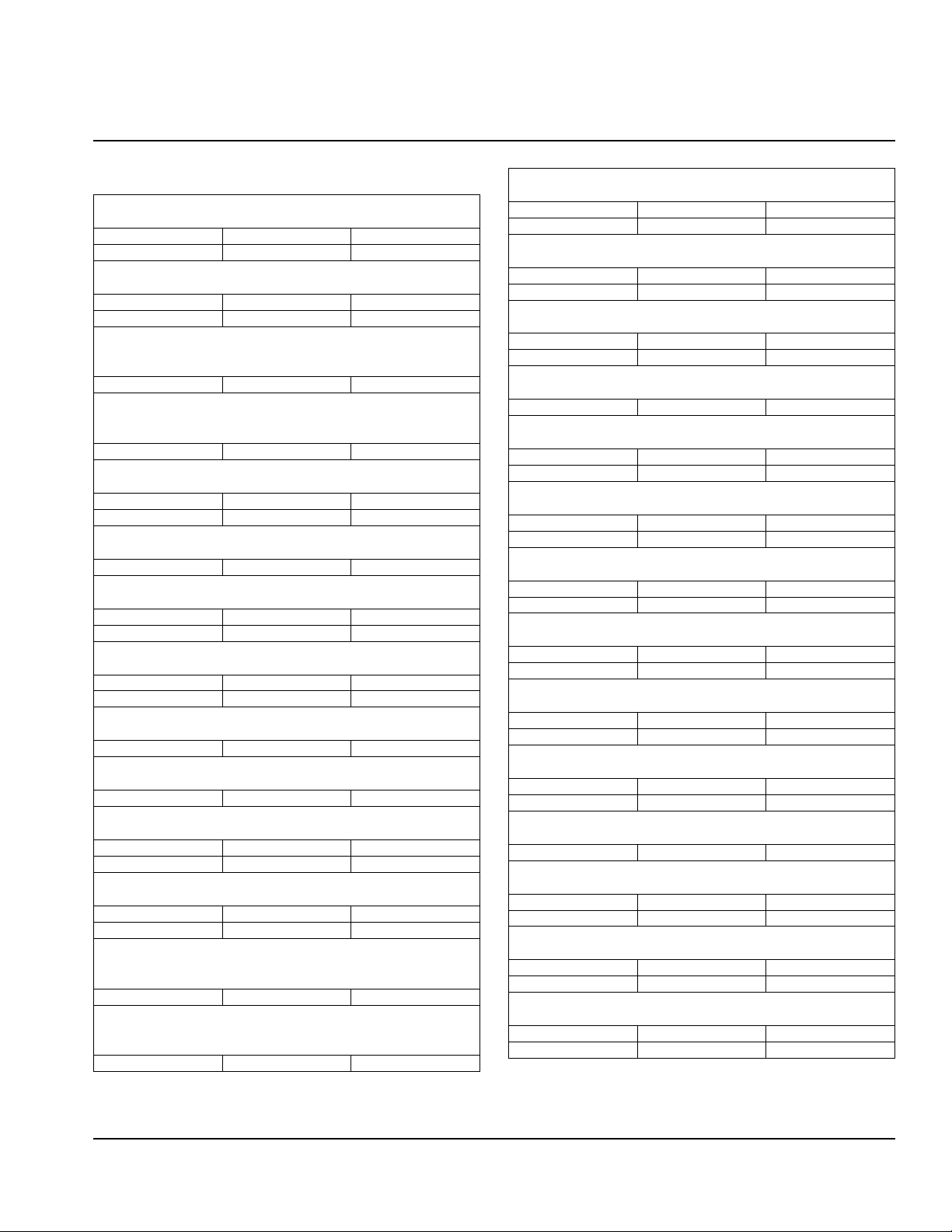

Model Numbers

8100-EF Series

LiquiTec® Eutetic Fluid Refrigerated Cold Pans - R404A

8118-EF 8132-EF 8145-EF

8159-EF 8172-EF 8186-EF

8100-EF-E Export Series

LiquiTec® Eutetic Fluid Refrigerated Cold Pans - R404A

8118-EF-E 8132-EF-E 8145-EF-E

8159-EF-E 8172-EF-E 8186-EF-E

8100-EFN Series

LiquiTec® Slim Line Eutetic Fluid Refrigerated Cold Pans -

R404A

8148-EFN 8169-EFN 8191-EFN

8100-EFN-E Export Series

LiquiTec® Slim Line Eutetic Fluid Refrigerated Cold Pans -

R404A

8148-EFN-E 8169-EFN-E 8191-EFN-E

N8000 Series

Ice Cooled Cold Pans

N8018 N8030 N8043

N8056 N8069 N8081

N8000N Series

Narrow Ice Cooled Cold Pans

N8046N N8068N

N8000-R Series

Curved Ice Cooled Cold Pans

N8044-R N8059-R N8076-R

N8094-R

N8100B Series

Self-Contained Mechanically Cooled Pans - R404A

N8118B N8130B N8143B

N8156B N8169B N8181B

N8100B-E Export Series

Self-Contained Mechanically Cooled Pans - R404A

N8118B-E N8130B-E N8143B-E

N8100B-E Export Series

Self-Contained Mechanically Cooled Pans - R134A

N8156B-E N8169B-E

N8100BR Series

Curved Self-Contained Mechanically Cooled Pans - R404A

N8144-BR N8159-BR N8176-BR

N8194-BR

N8100-FA Series

Forced Air Drop-In Mechanically Cooled Cold Pans - R404A

N8131-FA N8144-FA N8157-FA

N8169-FA N8182-FA

N8100NB Series

Self-Contained Mechanically Cooled Pans Narrow Style -

R404A

N8146NB N8168NB

N8100NB-E Export Series

Self-Contained Mechanically Cooled Pans Narrow Style -

R404A

N8146NB-E N8168NB-E

N8200 Series

Self-Contained Frost Tops - R404A

N8231 N8245 N8259

N8273 N8287

N8200-E Export Series

Self-Contained Frost Tops - R404A

N8231-E N8245-E N8259-E

N8273-E N8287-E

N8200G Series

Self-Contained Granite Cold Slabs

N8231G N8245G N8259G

N8273G

N8200G-E Export Series

Self-Contained Granite Cold Slabs - R404A

N8231G-E N8245G-E N8259G-E

N8200-ST Series

Self-Contained Frost Tops - R404A

N8230-ST N8240-ST N8256-ST

N8258-ST N8275-ST

N8600 Series

Self Contained Combination Hot/Cold Food Wells - R404A

N8630 N8643 N8656

N8669 N8681

N8700D Series

Individually Controlled Heated Food Wells

N8717-D N8731-D N8745-D

N8759-D N8773-D N8787-D

N8700D-E Export Series

Individually Controlled Heated Food Wells

N8717-D-E N8731-D-E N8745-D-E

N8759-D-E N8773-D-E N8787-D-E

N8700DESP Series

Individually Controlled Energy Savings Heated Food Wells

N8717-DESP N8731-DESP N8745-DESP

N8759-DESP N8773-DESP N8787-DESP

N8700-D-ESP-E Export Series

Individually Controlled Energy Savings Heated Food Wells

N8717-D-ESP-E N8731-D-ESP-E N8745-D-ESP-E

N8759-D-ESP-E N8773-D-ESP-E N8787-D-ESP-E

N8700N Series

Individually Controlled Heated Narrow Food Wells

N8746ND N8768N N8768ND

N8700-R Series

Curved Individually Controlled Heated Food Wells

N8744-R N8759-R N8776-R

N8794-R

N8800 Series

Single Tank Electric Hot Food Wells

N8831 N8845 N8859

N8873 N8887

N8800-E Export Series

Single Tank Electric Hot Food Wells

N8831-E N8845-E N8859-E

N8873-E N8887-E

Part Number: 8000_SM 07/18 5

Page 6

General Information Section 1

Serial Number Location

Ther serial number is listed on the serial tag. If applicable it

will also list the refrigerant used and the amount of charge.

• The serial tag on self-contained refrigerated units is

located near the condensing unit.

• The serial tag on ice cooled units and remote

refrigerated units is on the outside bottom of the food

well.

• On hot food pans and hot/cold combination pans, the

serial tag is located on the back of the control raceway

or remote panel.

Always have the serial number of your unit available

when calling for parts or service.

Warranty Information

• Register your product for warranty,

• Verify warranty information,

• View and download a copy of your warranty,

at www.delfield.com/warranty

Regulatory Certifications

DOMESTIC MODELS

All domestic models are certified by:

•

All domestic electrical models are certified by:

•

•

Domestic N8700DESP models are also certified by:

• Technical Inspection Association

• European Conformity

EXPORT MODELS

All export models are certified by:

•

• Technical Inspection Association

National Sanitation Foundation (NSF)

Underwriters Laboratories (UL)

Underwriters Laboratories of Canada (cUL)

National Sanitation Foundation (NSF)

• European Conformity

6 Part Number: 8000_SM 07/18

Page 7

Section 2

Installation

DANGER

Installation must comply with all applicable fire and

health codes in your jurisdiction.

DANGER

Use appropriate safety equipment during installation

and servicing.

Warning

n

Remove all removable panels before lifting and

installing.

Warning

n

If a refrigerated base does not have a condensate

evaporator supplied, you must connect the condensate

line to a suitable drain. Otherwise, water will collect on

the floor, causing a potentially hazardous situation.

Warning

n

Moisture collecting from improper drainage can create a

slippery surface on the floor and a hazard to employees.

It is the owner’s responsibility to provide a container or

outlet for drainage.

Warning

n

This equipment is intended for indoor use only. Do not

install or operate this equipment in outdoor areas.

Caution

,

The units with LiquiTec technology cold pans contain a

non-toxic eutectic fluid within a sealed inner liner. This

fluid may leak if the tank is punctured so care must be

taken when uncrating and setting in place. The eutectic

fluid is non-toxic and may be flushed down a disposal

drain. Units with a Eutectic Fluid Cold Pan require the

same precautions. The fluid is NOT refillable and loss of

fluid due to a puncture would cause irreparable damage.

If the LiquiTec unit cold pans leak, immediately call the

Delfield service department directly at 1-800-733-8821

not your local service agent.

Caution

,

Do not position the air intake vent near steam or heat

exhaust of another appliance.

Warning

n

Do not damage the refrigeration circuit when installing,

maintaining or servicing the unit.

Warning

n

This equipment must be positioned so that the plug is

accessible unless other means for disconnection from

the power supply (e.g., circuit breaker or disconnect

switch) is provided.

Warning

n

Adequate means must be provided to limit the

movement of this appliance without depending on or

transmitting stress to the electrical conduit.

Warning

n

To avoid instability the installation area must be capable

of supporting the combined weight of the equipment

and product. Additionally the equipment must be level

side to side and front to back.

Part Number: 8000_SM 07/18 7

Page 8

Installation Section 2

Location

The location selected for the equipment must meet the

following criteria. If any of these criteria are not met, select

another location.

• Units are intended for indoor use only.

• The location MUST be level, stable and capable of

supporting the weight of the equipment.

• The location MUST be free from and clear of

combustible materials.

• Equipment MUST be level both front to back and side to

side.

• Position the equipment so it will not tip or slide.

• Recommended air temperature is 41° - 86°F (5° - 30°C).

• Proper air supply for ventilation is REQUIRED AND

CRITICAL for safe and efficient operation. Refer to

Clearance Requirements chart on page 11.

• Do not obstruct the flow of ventilation air. Make sure the

air vents of the equipment are not blocked.

• Do not install the equipment directly over a drain.

Steam rising up out of the drain will adversely affect

operation, air circulation, and damage electrical /

electronic components.

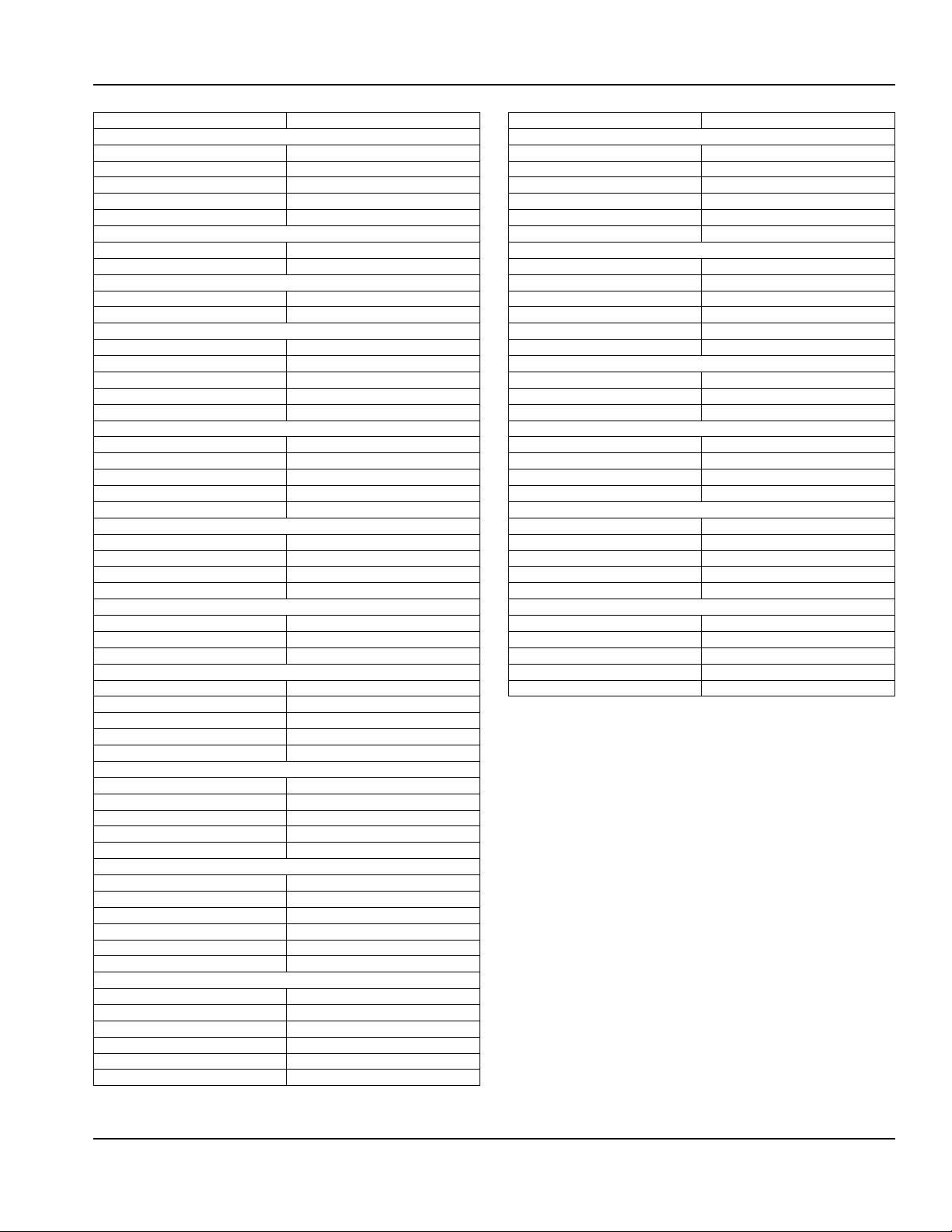

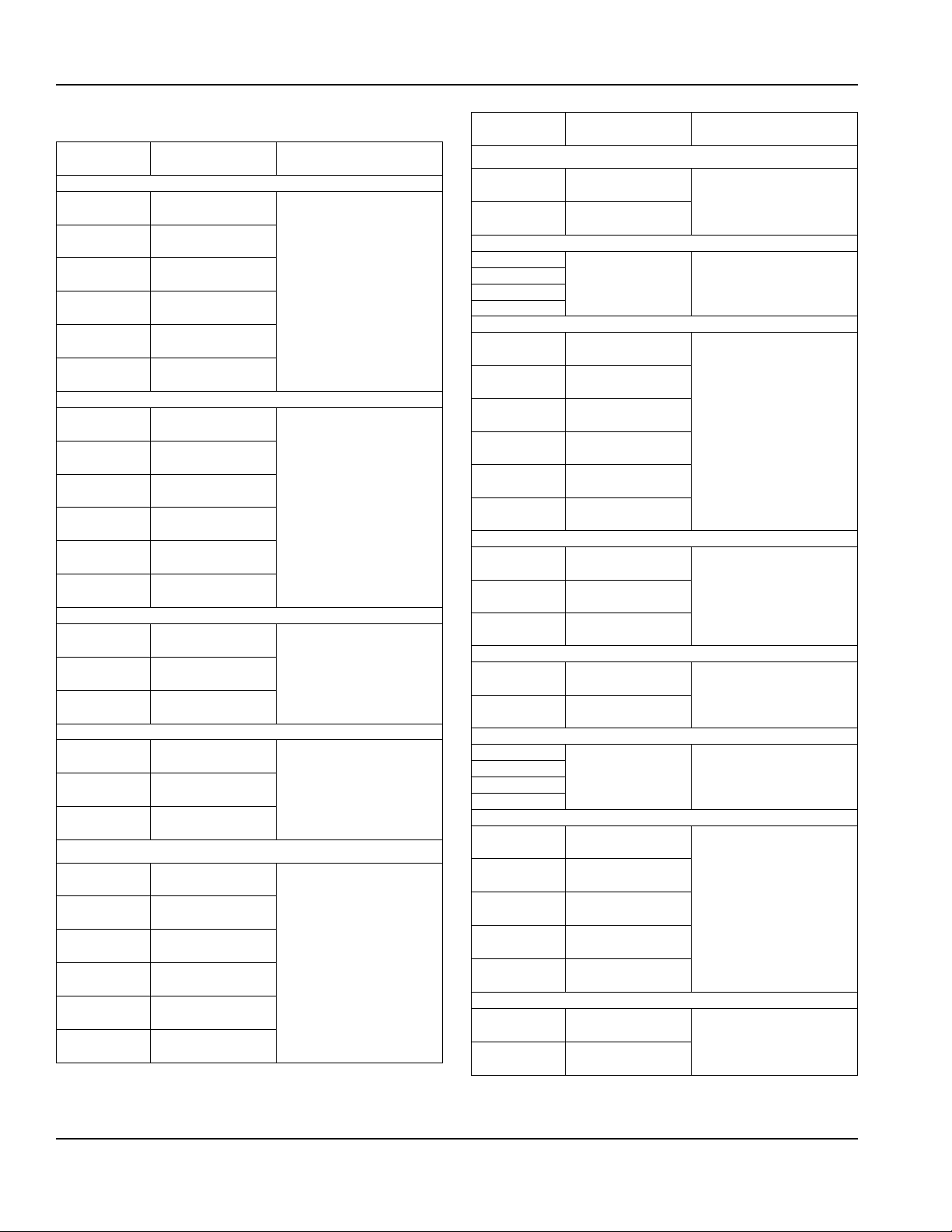

Weight Of Equipment

Model Ship Weight

8100-EF Series

8118-EF 169lbs (77kg)

8132-EF 215lbs (98kg)

8145-EF 265lbs (120kg)

8159-EF 285lbs (130kg)

8172-EF 295lbs (134kg)

8186-EF 394lbs (179kg)

8100-EF-E Export Series

8118-EF-E 169lbs (77kg)

8132-EF-E 215lbs (98kg)

8145-EF-E 265lbs (120kg)

8159-EF-E 285lbs (130kg)

8172-EF-E 295lbs (134kg)

8186-EF-E 394lbs (179kg)

8100-EFN Series

8148-EFN 235lbs (107kg)

8169-EFN 285lbs (130kg)

8191-EFN 295lbs (134kg)

8100-EFN-E Export Series

8148-EFN-E 235lbs (107kg)

8169-EFN-E 285lbs (130kg)

8191-EFN-E 295lbs (134kg)

N8000 Series

N8018

N8030

N8043

N8056

N8069

N8081

N8000N Series

N8046N 100lbs (45kg)

N8068N 120lbs (55kg)

N8000-R Series

N8044-R 100lbs (45kg)

N8059-R 118lbs (53kg)

N8076-R 145lbs (65kg)

N8094-R 164lbs (74kg)

N8100B Series

N8118B 100lbs (45kg)

N8130B 140lbs (64kg)

N8143B 173lbs (78kg)

N8156B 205lbs (93kg)

N8169B 225lbs (102kg)

N8181B 258lbs (117kg)

N8100B-E Export Series - R404A

N8118B-E 100lbs (45kg)

N8130B-E 140lbs (64kg)

N8143B-E 173lbs (78kg)

N8100B-E Export Series - R134A

N8156B-E 205lbs (93kg)

N8169B-E 225lbs (102kg)

N8100BR Series

N8144-BR 161lbs (72kg)

N8159-BR 184lbs (83kg)

N8176-BR 233lbs (105kg)

N8194-BR 243lbs (109kg)

38lbs (17kg)

84lbs (38kg)

110lbs (50kg)

139lbs (63kg)

160lbs (73kg)

197lbs (89kg)

8 Part Number: 8000_SM 07/18

Page 9

Section 2 Installation

Model Ship Weight

N8100-FA Series

N8131-FA 168lbs (76kg)

N8144-FA 175lbs (79kg)

N8157-FA 225lbs (102kg)

N8169-FA 235lbs (107kg)

N8182-FA 406lbs (184kg)

N8100NB Series

N8146NB 175lbs (80kg)

N8168NB 240lbs (109kg)

N8100NB-E Export Series

N8146NB-E 175lbs (80kg)

N8168NB-E 240lbs (109kg)

N8200 Series

N8231 142lbs (64kg)

N8245 168lbs (76kg)

N8259 193lbs (88kg)

N8273 209lbs (95kg)

N8287 239lbs (108kg)

N8200-E Export Series

N8231-E 142lbs (64kg)

N8245-E 168lbs (76kg)

N8259-E 193lbs (88kg)

N8273-E 209lbs (95kg)

N8287-E 239lbs (108kg)

N8200G Series

N8231G 219lbs (99kg)

N8245G 284lbs (129kg)

N8259G 338lbs (153kg)

N8273G 425lbs (193kg)

N8200G-E Export Series

N8231G-E 219lbs (99kg)

N8245G-E 284lbs (129kg)

N8259G-E 338lbs (153kg)

N8200-ST Series

N8230-ST 142lbs (64kg)

N8240-ST 168lbs (76kg)

N8256-ST 193lbs (88kg)

N8258-ST 209lbs (95kg)

N8275-ST 239lbs (108kg)

N8600 Series

N8630 164lbs (74kg)

N8643 198lbs (90kg)

N8656 233lbs (106kg)

N8669 266lbs (121kg)

N8681 301lbs (137kg)

N8700D Series

N8717-D 41lbs (19kg)

N8731-D 99lbs (45kg)

N8745-D 134lbs (61kg)

N8759-D 166lbs (75kg)

N8773-D 186lbs (84kg)

N8787-D 236lbs (107kg)

N8700D-E Export Series

N8717-D-E 41lbs (19kg)

N8731-D-E 99lbs (45kg)

N8745-D-E 134lbs (61kg)

N8759-D-E 166lbs (75kg)

N8773-D-E 186lbs (84kg)

N8787-D-E 236lbs (107kg)

Model Ship Weight

N8700DESP Series

N8717-DESP 41lbs (19kg)

N8731-DESP 99lbs (45kg)

N8745-DESP 134lbs (61kg)

N8759-DESP 166lbs (75kg)

N8773-DESP 186lbs (84kg)

N8787-DESP 236lbs (107kg)

N8700-D-ESP-E Export Series

N8717-D-ESP-E 41lbs (19kg)

N8731-D-ESP-E 99lbs (45kg)

N8745-D-ESP-E 134lbs (61kg)

N8759-D-ESP-E 166lbs (75kg)

N8773-D-ESP-E 186lbs (84kg)

N8787-D-ESP-E 236lbs (107kg)

N8700N Series

N8746ND 100lbs (45kg)

N8768N 130lbs (59kg)

N8768ND 130lbs (59kg)

N8700-R Series

N8744-R 99lbs (45kg)

N8759-R 134lbs (61kg)

N8776-R 166lbs (75kg)

N8794-R 186lbs (84kg)

N8800 Series

N8831 100lbs (45kg)

N8845 136lbs (62kg)

N8859 158lbs (72kg)

N8873 195lbs (88kg)

N8887 224lbs (102kg)

N8800-E Export Series

N8831-E 100lbs (45kg)

N8845-E 136lbs (62kg)

N8859-E 158lbs (72kg)

N8873-E 195lbs (88kg)

N8887-E 224lbs (102kg)

Part Number: 8000_SM 07/18 9

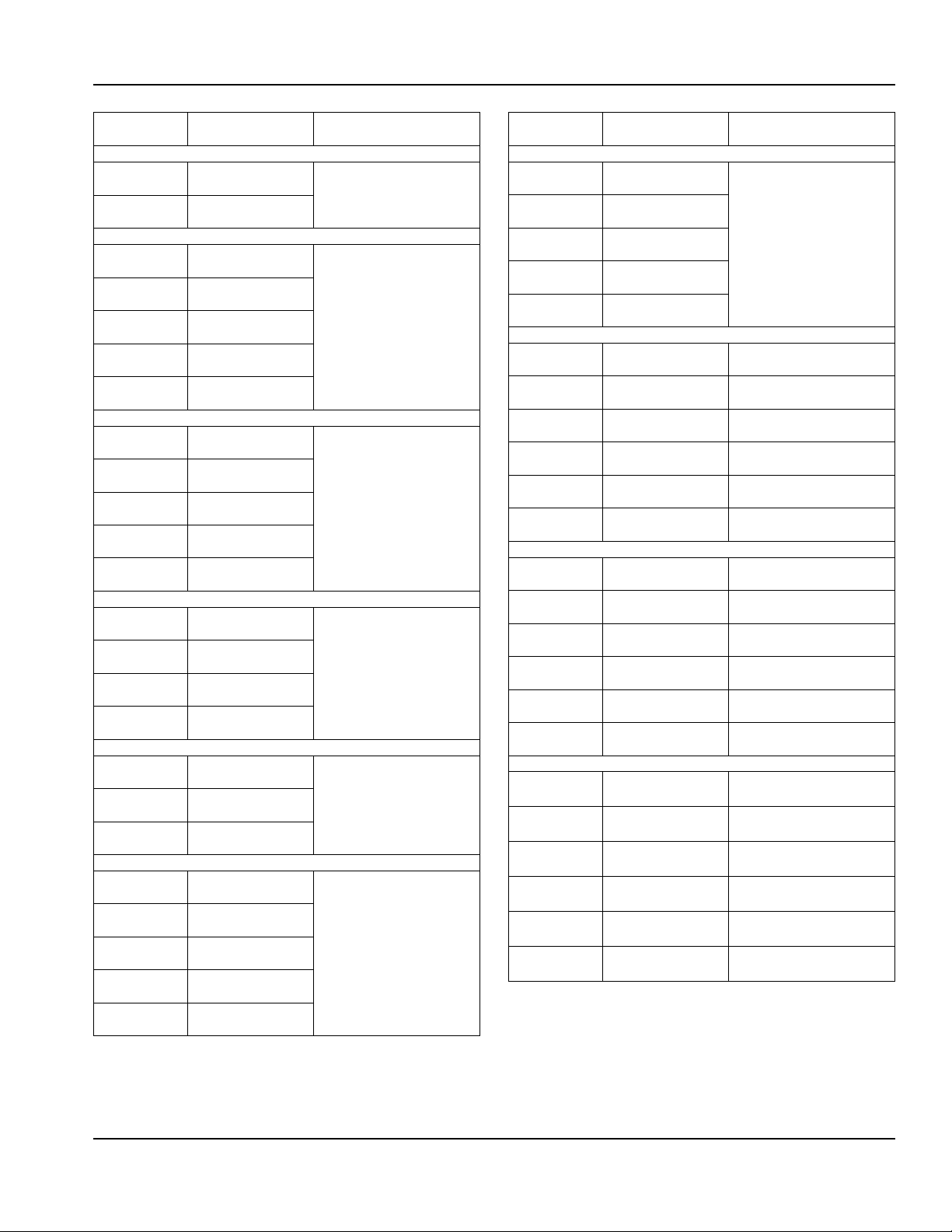

Page 10

Installation Section 2

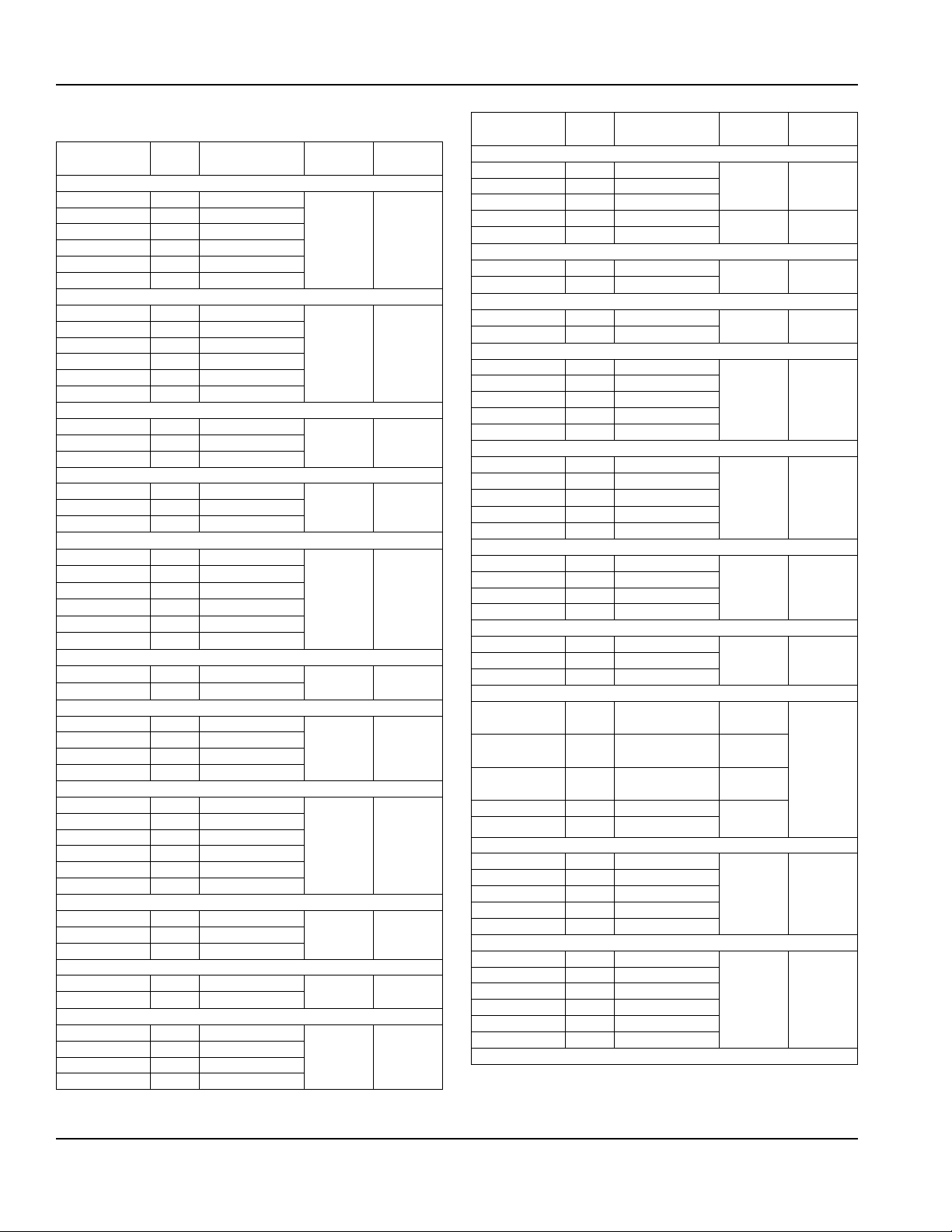

Dimensions

Model 12x20

Pans

8118-EF 1 18.20” (46cm)

8132-EF 2 31.76” (81cm)

8145-EF 3 45.32” (115cm)

8159-EF 4 58.88” (150cm)

8172-EF 5 72.44” (184cm)

8186-EF 6 86” (218cm)

8100-EF-E Export Series

8118-EF-E 1 18.20” (46cm)

8132-EF-E 2 31.76” (81cm)

8145-EF-E 3 45.32” (115cm)

8159-EF-E 4 58.88” (150cm)

8172-EF-E 5 72.44” (184cm)

8186-EF-E 6 86” (218cm)

8148-EFN 2 47.66” (121cm)

8169-EFN 3 69.22” (176cm)

8191-EFN 4 90.78” (231cm)

8100-EFN-E Export Series

8148-EFN-E 2 47.66” (121cm)

8169-EFN-E 3 69.22” (176cm)

8191-EFN-E 4 90.78” (231cm)

N8018 1 18“ (46cm)

N8030 2 30.75“ (78cm)

N8043 3 43.5“ (110cm)

N8056 4 56.25“ (143cm)

N8069 5 69“ (175cm)

N8081 6 81.75“ (208cm)

N8046N 2 46.75“ (119cm) 18“

N8068N 3 67.5“ (171cm)

N8044-R 2 40.48” (103cm)

N8059-R 3 57.22” (145cm)

N8076-R 4 73.68” (187cm)

N8094-R 5 89.89” (228cm)

N8118B 1 18” (46cm)

N8130B 2 30.75” (78cm)

N8143B 3 43.5” (110cm)

N8156B 4 56.25” (143cm)

N8169B 5 69” (175cm)

N8181B 6 81.75” (208cm)

N8100B-E Export Series - R404A

N8118B-E 1 18” (46cm)

N8130B-E 2 30.75” (78cm)

N8143B-E 3 43.5” (110cm)

N8100B-E Export Series - R134A

N8156B-E 4 56.25” (143cm) 26”

N8169B-E 5 69” (175cm)

N8144-BR 2 40.43” (103cm)

N8159-BR 3 57.22” (145cm)

N8176-BR 4 73.68” (187cm)

N8194-BR 5 89.86” (228cm)

Length Depth Height

8100-EF Series

8100-EFN Series

N8000 Series

N8000N Series

N8000-R Series

N8100B Series

N8100BR Series

26”

(66cm)

26”

(66cm)

18”

(46cm)

18”

(46cm)

26”

(66cm)

(46cm)

26.05”

(66cm)

26”

(66cm)

26”

(66cm)

(66cm)

26.05”

(66cm)

23.25”

(59cm)

23.25”

(59cm)

23.25”

(59cm)

23.25”

(59cm)

10.75”

(27cm)

10.75“

(27cm)

10.77”

(27cm)

21.87”

(56cm)

21.87”

(56cm)

21.87”

(56cm)

21.81”

(55cm)

Model 12x20

Pans

N8131-FA 2 31.25” (79cm)

N8144-FA 3 44” (112cm)

N8157-FA 4 56.75” (144cm)

N8169-FA 5 69.5” (177cm) 26.67”

N8182-FA 6 82.25” (209cm)

N8146NB 2 46.75” (119cm) 18”

N8168NB 3 67.5” (171cm)

N8100NB-E Export Series

N8146NB-E 2 46.75” (119cm) 18”

N8168NB-E 3 67.5” (171cm)

N8231 NA 31.75" (81cm)

N8245 NA 45.63” (116cm)

N8259 NA 59.5” (151cm)

N8273 NA 73.38" (186cm)

N8287 NA 87.25” (222cm)

N8200-E Export Series

N8231-E NA 31.75" (81cm)

N8245-E NA 45.63” (116cm)

N8259-E NA 59.5” (151cm)

N8273-E NA 73.38" (186cm)

N8287-E NA 87.25” (222cm)

N8231G NA 31.75” (81cm)

N8245G NA 45.63” (116cm)

N8259G NA 59.5” (151cm)

N8273G NA 73.38” (186cm)

N8200G-E Export Series

N8231G-E NA 31.75” (81cm)

N8245G-E NA 45.63” (116cm)

N8259G-E NA 59.5” (151cm)

N8230-ST NA 29.60" (75cm) 22”

N8240-ST NA 39.70” (101cm) 29.60”

N8256-ST NA 55.60” (141cm) 22”

N8258-ST NA 57.60" (146cm) 29.60”

N8275-ST NA 75.50" (192cm)

N8630 2 30.75” (78cm)

N8643 3 43.5” (110cm)

N8656 4 56.25” (143cm)

N8669 5 69” (175cm)

N8681 6 81.75” (208cm)

N8717-D 1 17.88” (45cm)

N8731-D 2 31.75” (81cm)

N8745-D 3 45.63” (116cm)

N8759-D 4 59.5” (151cm)

N8773-D 5 73.38” (186cm)

N8787-D 6 87.25” (222cm)

*14” Overall height including drain connection

Length Depth Height

N8100-FA Series

26.67”

(68cm)

(68cm)

N8100NB Series

(46cm)

(46cm)

N8200 Series

26”

(66cm)

26”

(66cm)

N8200G Series

25.87”

(66cm)

25.87”

(66cm)

N8200-ST Series

(56cm)

(75cm)

(56cm)

(75cm)

N8600 Series

26”

(66cm)

N8700D Series

26”

(66cm)

26.62”

(68cm)

28.62”

(73cm)

21.81”

(55cm)

21.81”

(55cm)

15.75”

(40cm)

15.75”

(40cm)

19”

(48cm)

19”

(48cm)

15.70”

(40cm)

23.75”

(60cm)

9.09”

(23cm)*

10 Part Number: 8000_SM 07/18

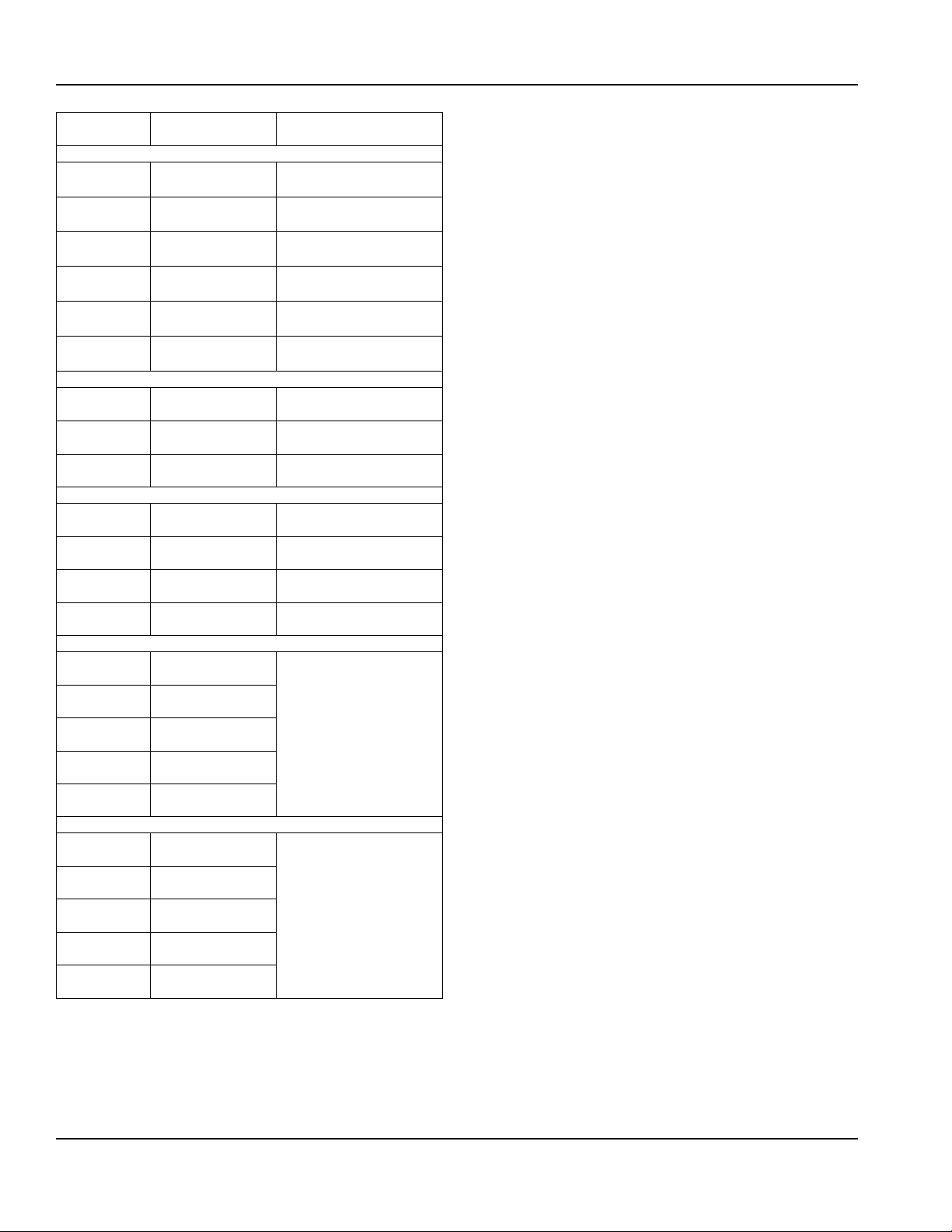

Page 11

Section 2 Installation

Model 12x20

Pans

N8700D-E Export Series

N8717-D-E 1 17.88” (45cm)

N8731-D-E 2 31.75” (81cm)

N8745-D-E 3 45.63” (116cm)

N8759-D-E 4 59.5” (151cm)

N8773-D-E 5 73.38” (186cm)

N8787-D-E 6 87.25” (222cm)

*14” Overall height including drain connection

N8717-DESP 1 17.89” (45cm)

N8731-DESP 2 31.76” (81cm)

N8745-DESP 3 45.63” (116cm)

N8759-DESP 4 59.50” (151cm)

N8773-DESP 5 73.37” (186cm)

N8787-DESP 6 87.24” (222cm)

*14” Overall height including drain connection

N8700-D-ESP-E Export Series

N8717-D-ESP-E 1 17.89” (45cm)

N8731-D-ESP-E 2 31.76” (81cm)

N8745-D-ESP-E 3 45.63” (116cm)

N8759-D-ESP-E 4 59.50” (151cm)

N8773-D-ESP-E 5 73.37” (186cm)

N8787-D-ESP-E 6 87.24” (222cm)

*14” Overall height including drain connection

N8746ND 2 45.61” (116cm)

N8768N 3 67.48” (172cm)

N8768ND 3 67.48” (172cm)

*14” Overall height including drain connection

N8744-R 2 40.48” (103cm) 26.05”

N8759-R 3 57.22” (145cm) 26.05”

N8776-R 4 73.68” (187cm) 26”

N8794-R 5 89.80” (228cm) 25.91”

*14” Overall height including drain connection

N8831 2 31.75” (81cm)

N8845 3 45.63” (116cm)

N8859 4 59.5” (151cm)

N8873 5 73.38” (186cm)

N8887 6 87.25” (222cm)

N8800-E Export Series

N8831-E 2 31.75” (81cm)

N8845-E 3 45.63” (116cm)

N8859-E 4 59.5” (151cm)

N8873-E 5 73.38” (186cm)

N8887-E 6 87.25” (222cm)

Length Depth Height

N8700DESP Series

N8700N Series

N8700-R Series

N8800 Series

26”

(66cm)

26”

(66cm)

26”

(66cm)

15.87”

(40cm)

(66cm)

(66cm)

(66cm)

(66cm)

26”

(66cm)

26”

(66cm)

9.09”

(23cm)*

7.83”

(20cm)*

7.83”

(20cm)*

9.09”

(23cm)*

9.09”

(23cm)*

11”

(28cm)

11”

(28cm)

Clearance Requirements

DANGER

Minimum clearance requirements are the same for

noncombustible locations as for combustible locations.

The flooring under the appliance must be made of a

noncombustible material.

DANGER

Risk of fire/shock. All minimum clearances must be

maintained. Do not obstruct vents or openings.

Heated & Combination Hot/Cold Food Wells

Bottom & Side Clearance

3” (76mm)

Cooled Pans, Frost Tops & Granite Cold Slabs

Clearance

0” (0cm)

• Keep the vents clean and free of obstruction.

Part Number: 8000_SM 07/18 11

Page 12

Installation Section 2

Cutout Installation Dimensions

Model Counter Cutout

Dimensions

8100-EF Series

8118-EF 17” x 25”

(43cm x 64cm)

8132-EF 30.75” x 25”

(78cm x 64cm)

8145-EF 44.25” x 25”

(112cm x 64cm)

8159-EF 57.87” x 25”

(147cm x 64cm)

8172-EF 71.5” x 25”

(182cm x 64cm)

8186-EF 85” x 25”

(216cm x 64cm)

8100-EF-E Export Series

8118-EF-E 17” x 25”

(43cm x 64cm)

8132-EF-E 30.75” x 25”

(78cm x 64cm)

8145-EF-E 44.25” x 25”

(112cm x 64cm)

8159-EF-E 57.87” x 25”

(147cm x 64cm)

8172-EF-E 71.5” x 25”

(182cm x 64cm)

8186-EF-E 85” x 25”

(216cm x 64cm)

8100-EFN Series

8148-EFN 46.88” x 17.25”

(119cm x 44cm)

8169-EFN 68.5” x 17.25”

(174cm x 44cm)

8191-EFN 90” x 17.25”

(229cm x 44cm)

8100-EFN-E Export Series

8148-EFN-E 46.88” x 17.25”

(119cm x 44cm)

8169-EFN-E 68.5” x 17.25”

(174cm x 44cm)

8191-EFN-E 90” x 17.25”

(229cm x 44cm)

N8000 Series

N8018

N8030

N8043

N8056

N8069

N8081

17” x 25”

(43cm x 64cm)

29.75” x 25”

(76cm x 64cm)

42.5” x 25”

(108cm x 64cm)

55.25” x 25”

(140cm x 64cm)

68” x 25”

(173cm x 64cm)

80.75” x 25”

(205cm x 64cm)

Control Panel Cutout

Dimensions

NA

NA

NA

NA

NA

Model Counter Cutout

Dimensions

N8000N Series

N8046N

N8068N

N8044-R

N8059-R

N8076-R

N8094-R

N8118B 17” X 25”

N8130B 29.75” x 25”

N8143B 42.50” X 25”

N8156B 55.25” x 25”

N8169B 68” X 25”

N8181B 80.75” x 25”

N8118B-E 17” X 25”

N8130B-E 29.75” x 25”

N8143B-E 42.50” X 25”

N8156B-E 55.25” x 25”

N8169B-E 68” X 25”

N8144-BR

N8159-BR

N8176-BR

N8194-BR

N8131-FA 30.25” x 25.5”

N8144-FA 43” x 25.5”

N8157-FA 55.75” x 25.5”

N8169-FA 68.5” x 25.5”

N8182-FA 81.25” x 25.5”

N8146NB 45.75” x 17”

N8168NB 66.5” x 17”

45.75” x 17”

(116cm x 43cm)

66.50” x 17”

(169cm x 43cm)

N8000-R Series

See drawing on

page 15

N8100B Series

(43cm x 64cm)

(76cm x 64cm)

(108cm x 64cm)

(140cm x 64cm)

(173cm x 64cm)

(205cm x 64cm)

N8100B-E Export Series - R404A

(43cm x 64cm)

(76cm x 64cm)

(108cm x 64cm)

N8100B-E Export Series - R134A

(140cm x 64cm)

(173cm x 64cm)

N8100BR Series

See drawing on

page 15

N8100-FA Series

(77cm x 65cm)

109cm x 65cm)

(142cm x 65cm)

174cm x 65cm)

(206cm x 65cm)

N8100NB Series

(116cm x 43cm)

(169cm x 43cm)

Control Panel Cutout

Dimensions

NA

NA

NA

NA

NA

NA

NA

NA

12 Part Number: 8000_SM 07/18

Page 13

Section 2 Installation

Model Counter Cutout

Dimensions

N8100NB-E Export Series

N8146NB-E 45.75” x 17”

(116cm x 43cm)

N8168NB-E 66.5” x 17”

(169cm x 43cm)

N8200 Series

N8231 30.75” x 25"

(78cm x 64cm)

N8245 44.63” x 25”

(113cm x 64cm)

N8259 58.50” x 25”

(149cm x 64cm)

N8273 72.38” x 25”

(184cm x 64cm)

N8287 86.25” x 25”

(219cm x 64cm)

N8200-E Export Series

N8231-E 30.75” x 25"

(78cm x 64cm)

N8245-E 44.63” x 25”

(113cm x 64cm)

N8259-E 58.50” x 25”

(149cm x 64cm)

N8273-E 72.38” x 25”

(184cm x 64cm)

N8287-E 86.25” x 25”

(219cm x 64cm)

N8200G Series

N8231G 30.75” X 25”

(78cm x 64cm)

N8245G 44.63” x 25”

(113cm x 64cm)

N8259G 58.5” x 25”

(149cm x 64cm)

N8273G 72.38” x 25”

(184cm x 64cm)

N8200G-E Export Series

N8231G-E 30.75” X 25”

(78cm x 64cm)

N8245G-E 44.63” x 25”

(113cm x 64cm)

N8259G-E 58.5” x 25”

(149cm x 64cm)

N8200-ST Series

N8230-ST 28.60” x 21.10"

(73cm x 54cm)

N8240-ST 38.65” x 28.75”

(98cm x 73cm)

N8256-ST 54.60” x 21.10”

(139cm x 54cm)

N8258-ST 56.60” x 28.75”

(144cm x 73cm)

N8275-ST 74.50" x 28.75"

(189cm x 73cm)

Control Panel Cutout

Dimensions

NA

NA

NA

NA

NA

NA

Model Counter Cutout

Dimensions

N8600 Series

N8630 29.75” X 25”

(76cm x 64cm)

N8643 42.50” x 25”

(108cm x 64cm)

N8656 55.25” x 25”

(140cm x 64cm)

N8669 68” x 25”

(173cm x 64cm)

N8681 80.75” x 25”

(205cm x 64cm)

N8700D Series

N8717-D 16.88” X 25”

(43cm x 64cm)

N8731-D 30.75” x 25”

(78cm x 64cm)

N8745-D 44.62” x 25”

(113cm x 64cm)

N8759-D 58.5” x 25”

(149cm x 64cm)

N8773-D 72.37” x 25”

(184cm x 64cm)

N8787-D 86.25” x 25”

(219cm x 64cm)

N8700D-E Export Series

N8717-D-E 16.88” X 25”

(43cm x 64cm)

N8731-D-E 30.75” x 25”

(78cm x 64cm)

N8745-D-E 44.62” x 25”

(113cm x 64cm)

N8759-D-E 58.5” x 25”

(149cm x 64cm)

N8773-D-E 72.37” x 25”

(184cm x 64cm)

N8787-D-E 86.25” x 25”

(219cm x 64cm)

N8700DESP Series

N8717-DESP 16.87” X 25”

(43cm x 64cm)

N8731-DESP 30.75” x 25”

(78cm x 64cm)

N8745-DESP 44.62” x 25”

(113cm x 64cm)

N8759-DESP 58.50” x 25”

(149cm x 64cm)

N8773-DESP 72.37” x 25”

(184cm x 64cm)

N8787-DESP 86.25” x 25”

(219cm x 64cm)

Control Panel Cutout

Dimensions

12.25” x 4.25” x 7”

(31cm x 11cm x 18cm)

7” x 4.62” x 7”

(18cm x 12cm x 18cm)

10.31” x 4.62” x 7”

(26cm x 12cm x 18cm)

14.5” x 4.62” x 7”

(37cm x 12cm x 18cm)

18.69” x 4.62” x 7”

(47cm x 12cm x 18cm)

22.88” x 4.62” x 7”

(58cm x 12cm x 18cm)

27” x 4.62” x 7”

(69cm x 12cm x 18cm)

7” x 4.62” x 7”

(18cm x 12cm x 18cm)

10.31” x 4.62” x 7”

(26cm x 12cm x 18cm)

14.5” x 4.62” x 7”

(37cm x 12cm x 18cm)

18.69” x 4.62” x 7”

(47cm x 12cm x 18cm)

22.88” x 4.62” x 7”

(58cm x 12cm x 18cm)

27” x 4.62” x 7”

(69cm x 12cm x 18cm)

5” x 6.88” x 7.50”

(13cm x 17cm x 19cm)

5” x 11.88” x 7.50”

(13cm x 30cm x 19cm)

5” x 17.38” x 7.50”

(13cm x 44cm x 19cm)

5” x 22.88” x 7.50”

(13cm x 58cm x 19cm)

5” x 28.38” x 7.50”

(13cm x 72cm x 19cm)

5” x 33.88”x 7.50”

(13cm x 86cm x 19cm)

Part Number: 8000_SM 07/18 13

Page 14

Installation Section 2

Model Counter Cutout

Dimensions

N8700-D-ESP-E Export Series

N8717-D-ESP-E 16.87” X 25”

(43cm x 64cm)

N8731-D-ESP-E 30.75” x 25”

(78cm x 64cm)

N8745-D-ESP-E 44.62” x 25”

(113cm x 64cm)

N8759-D-ESP-E 58.50” x 25”

(149cm x 64cm)

N8773-D-ESP-E 72.37” x 25”

(184cm x 64cm)

N8787-D-ESP-E 86.25” x 25”

(219cm x 64cm)

N8700N Series

N8746ND 44.62” x 15.0”

(113cm x 38cm)

N8768N 66.50” x 15.0”

(169cm x 38cm)

N8768ND 66.50” x 15.0”

(169cm x 38cm)

N8700-R Series

N8744-R See drawing on

page 15

N8759-R See drawing on

page 15

N8776-R See drawing on

page 15

N8794-R See drawing on

page 15

N8800 Series

N8831 30.75” X 25”

(78cm x 64cm)

N8845 44.63” x 25”

(113cm x 64cm)

N8859 58.5” x 25”

(149cm x 64cm)

N8873 72.38” x 25”

(184cm x 64cm)

N8887 86.25” x 25”

(219cm x 64cm)

N8800-E Export Series

N8831-E 30.75” X 25”

(78cm x 64cm)

N8845-E 44.63” x 25”

(113cm x 64cm)

N8859-E 58.5” x 25”

(149cm x 64cm)

N8873-E 72.38” x 25”

(184cm x 64cm)

N8887-E 86.25” x 25”

(219cm x 64cm)

Control Panel Cutout

Dimensions

5” x 6.88” x 7.50”

(13cm x 17cm x 19cm)

5” x 11.88” x 7.50”

(13cm x 30cm x 19cm)

5” x 17.38” x 7.50”

(13cm x 44cm x 19cm)

5” x 22.88” x 7.50”

(13cm x 58cm x 19cm)

5” x 28.38” x 7.50”

(13cm x 72cm x 19cm)

5” x 33.88”x 7.50”

(13cm x 86cm x 19cm)

10.31” x 4.62” x 7”

(26cm x 12cm x 18cm)

14.50” x 4.62” x 7”

(37cm x 12cm x 18cm)

14.50” x 4.62” x 7”

(37cm x 12cm x 18cm)

10.31” x 4.62” x 7”

(26cm x 12cm x 18cm)

14.5” x 4.62” x 7”

(37cm x 12cm x 18cm)

18.69” x 4.62” x 7”

(47cm x 12cm x 18cm)

22.88” x 4.62” x 7”

(58cm x 12cm x 18cm)

12.25” x 4.25” x 7”

(31cm x 11cm x 18cm)

12.25” x 4.25” x 7”

(31cm x 11cm x 18cm)

14 Part Number: 8000_SM 07/18

Page 15

Section 2 Installation

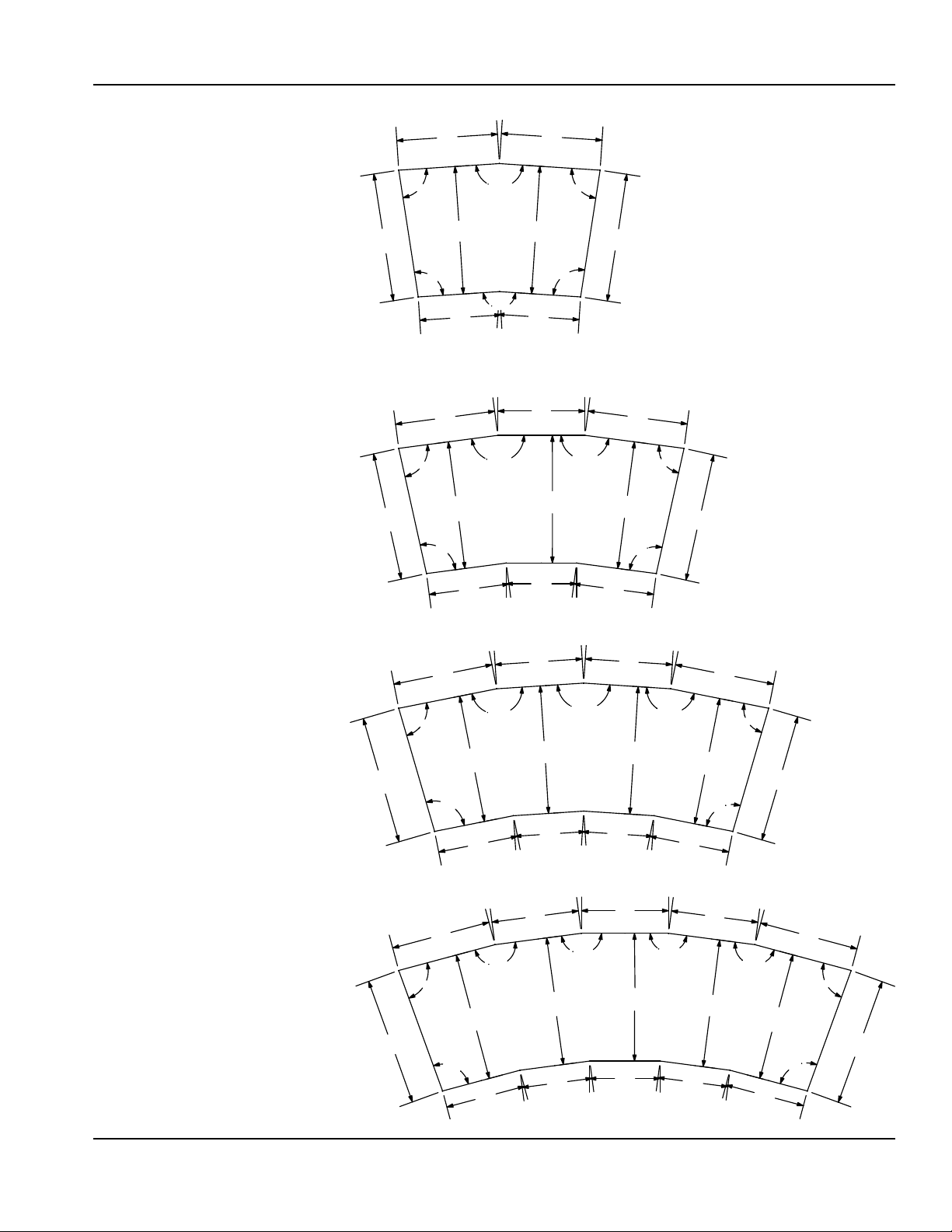

CURVED DROPIN CUTOUT DETAILS

2 pan standard curved drop-in cutout detail

for models:

• N8044-R

• N8144-BR

• N8744-R

3 pan standard curved drop-in cutout detail

for models:

• N8059-R

• N8159-BR

• N8759-R

25.10”

64cm

25.10”

64cm

85˚

85˚

95˚

19.75”

50cm

19.56”

50cm

95˚

25.00”

64cm

15.92”

40cm

25.00”

64cm

172.50˚

172.50˚

172.50˚

25.00”

64cm

15.92”

40cm

17.06”

43cm

19.75”

50cm

25.00”

64cm

95˚

85˚

172.50˚

25.10”

64cm

25.00”

64cm

19.56”

50cm

95˚

85˚

25.10”

64cm

4 pan standard curved drop-in cutout detail

for models:

• N8076-R

• N8176-BR

• N8776-R

5 pan standard curved drop-in cutout detail

or models:

• N8094-R

• N8194-BR

• N8794-R

25.10”

64cm

25.10”

64cm

85˚

172.50˚

172.50˚

13.78”

35cm

17.06”

43cm

25.00”

64cm

17.06”

43cm

13.78”

35cm

25.00”

64cm

13.78”

35cm

15.73”

40cm

19.56”

50cm

25.00”

64cm

95˚

15.73”

40cm

19.50”

50cm

85˚

25.00”

64cm

95˚

15.67”

40cm

172.50˚

172.50˚

15.73”

40cm

13.78”

35cm

17.06”

13.78”

17.06”

43cm

25.00”

64cm

43cm

25.00”

64cm

35cm

172.50˚

172.50˚

15.73”

40cm

13.78”

35cm

25.00”

64cm

17.06”

43cm

25.00”

64cm

19.56”

50cm

95˚

85˚

172.50˚

15.67”

40cm

25.10”

64cm

25.00”

64cm

95˚

19.50”

50cm

85˚

25.10”

64cm

Part Number: 8000_SM 07/18 15

Page 16

Installation Section 2

Counter Cutout Dimensions

Are Model Specic

Drop-In Counter Installation

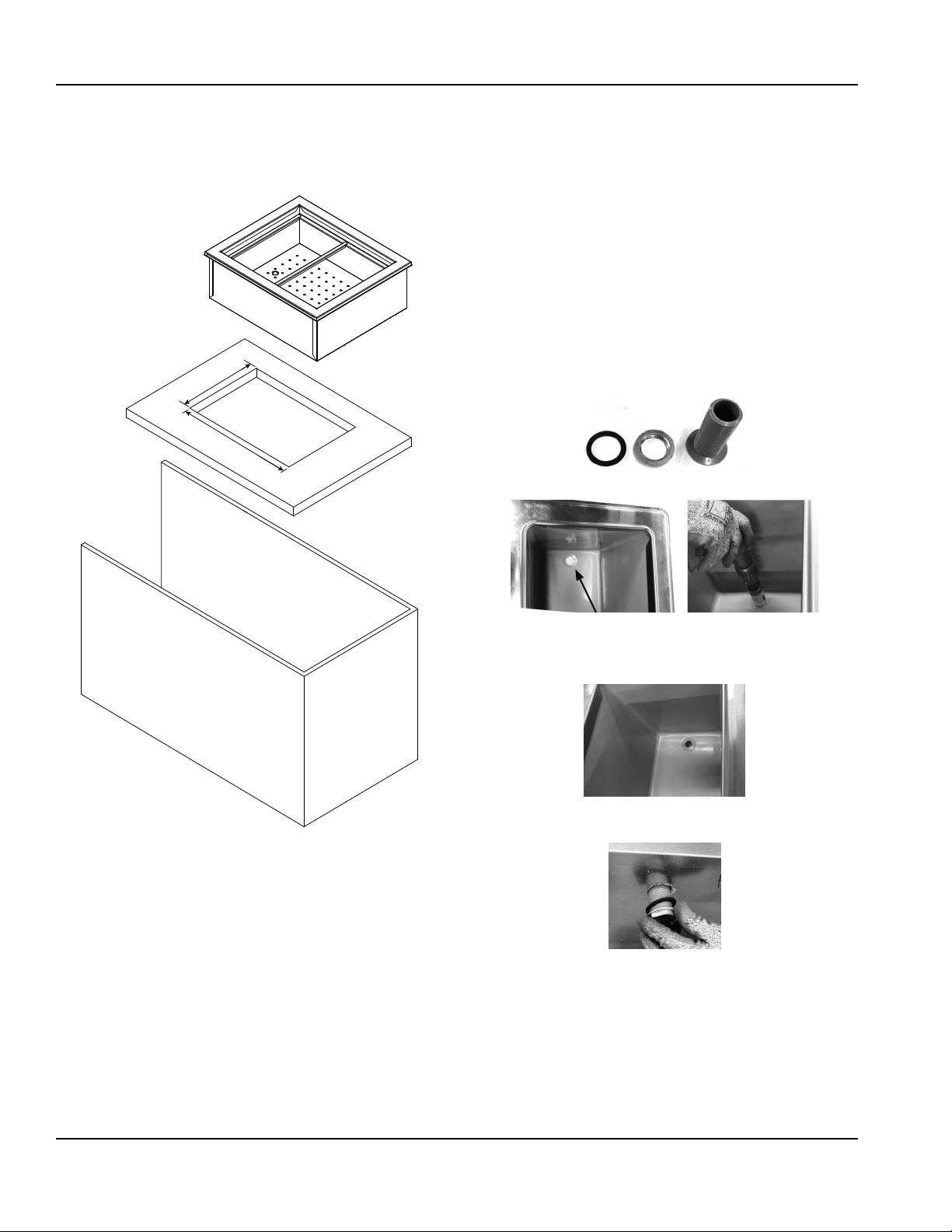

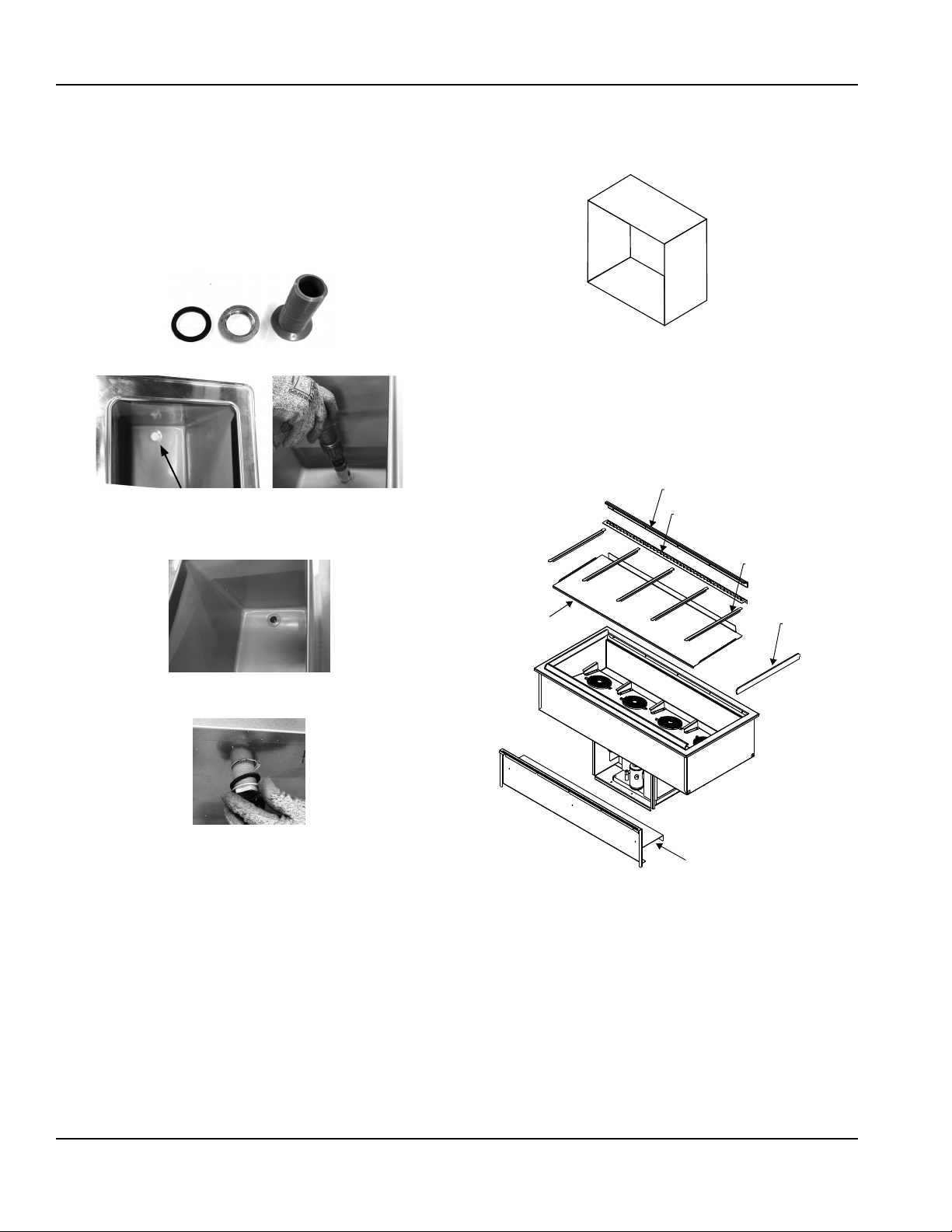

ICE COOLED DROPIN UNITS

N8000, N8000N, N8000-R

1. Place the ice cooled drop-in unit through the counter

cutout.

2. A gasket is installed in the flange of each unit.

The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out

opening.

3. The 1” diameter drain on N8000, N8000N, N8000-R

models is shipped loose and must be connected during

installation.

A. Provided 1” (25mm) drain, nut and washer must

be field installed to an appropriate container or

floor drain following local code requirements.

Sinks come standard with 1-1/2” basket strainer

assemblies.

B. Remove/drill foam out of drain hole.

C. Apply thin ring of plumbers putty around the

drain.

D. From the inside drop the drain into the drain hole.

E. From the outside secure the drain with the washer

and nut.

F. Tighten the nut with channel locks, use a fork to

hold the drain in place if necessary.

G. Clean up excess plumbers putty.

16 Part Number: 8000_SM 07/18

Page 17

Section 2 Installation

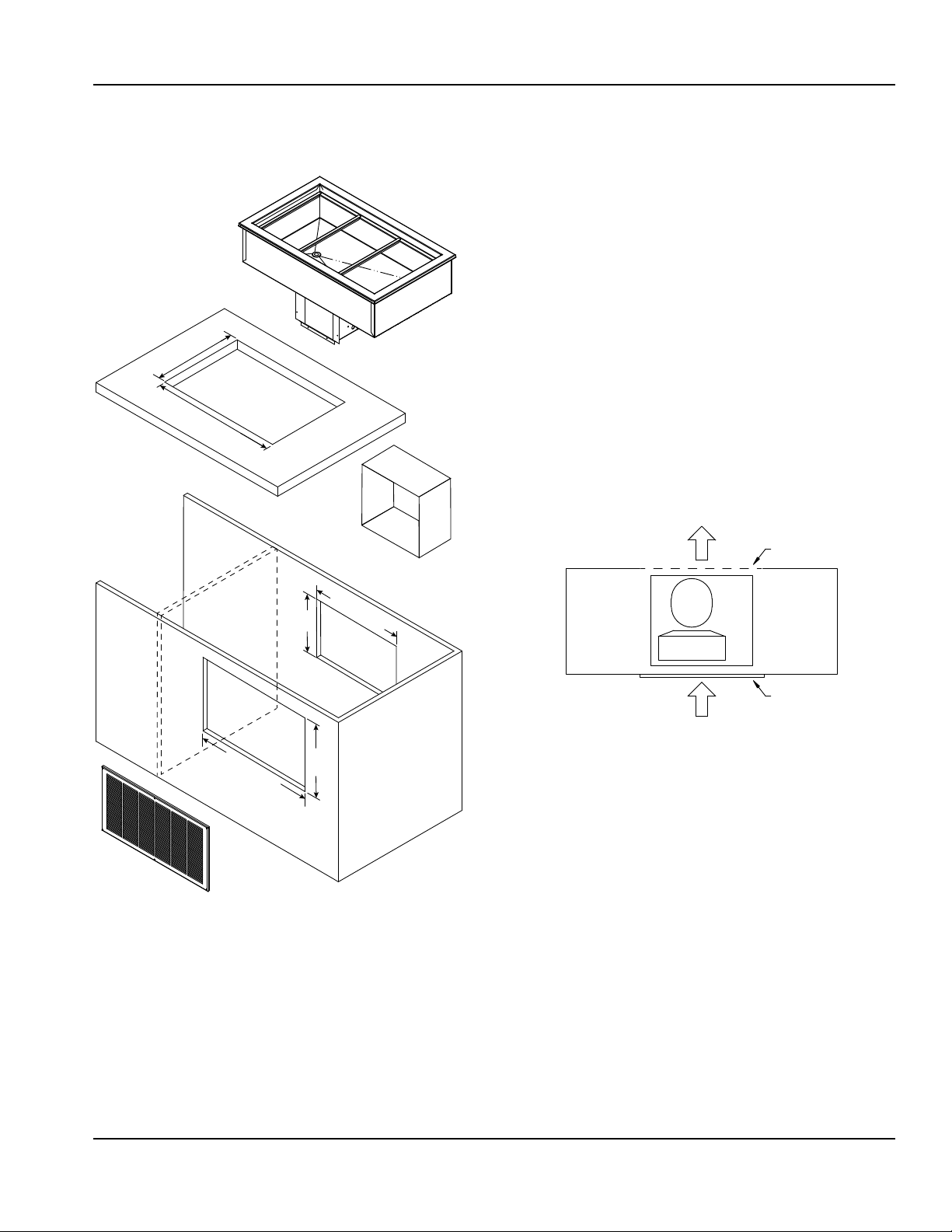

SELFCONTAINED REFRIGERATED DROPIN UNITS

8100-EF(N), N8100B, N8100-BR, N8100NB, N8200,

N8200G, N8200-ST

Counter Cutout Dimensions

Are Model Specic

Air duct dimensions

to match condenser face

11.00” (28cm)

8.00”

(20cm)

1. Install partitions between self-contained refrigerated

drop-in units and other electrical appliances if they

are located in the same cabinet. Partitions must fully

extend front to back and top to bottom.

2. Install a GFCI receptacle a minimum of 14” (36cm) up

from the cabinet bottom inside the partitions. Run the

outlet to a switch. With limited access to the control, a

switch will make it easy to turn the unit off for defrost.

3. The unit requires airflow to the compressor. One louver

is provided with each unit.

NOTE: Any restriction to the proper air flow will void the

compressor warranty.

• A 13” x 25” (33 cm x 64 cm) louver is provided by

Delfield and must be installed in the counter in front

of the condenser. The louver cutout dimension is 22”

x 11” (56 cm x 28 cm).

• The rear must have an opening for removal of

heated air. The opening must be at least 11” x 8”, a

total of 88 square inches (28cm x 20cm, a total of

566 square centimeters).

Discharge Air

Cutout

Condenser

22.0” (56cm)

11.00”

(28cm)

Louver

Fresh Air

4. Place the condensing unit through the counter cutout.

5. A gasket is installed in the flange of each unit.

The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out

opening.

6. Plumb to a floor drain.

• 8100-EF(N) models have a 1/2” ID PVC drain.

• N8200 and N8200-ST models have a 1/2” OD

stainless steel drain. Use clear flexible tubing.

• N8200G models have a 3/4” drain located on end/

center. Use a 3/4” female coupling.

Part Number: 8000_SM 07/18 17

Page 18

Installation Section 2

to match condenser face

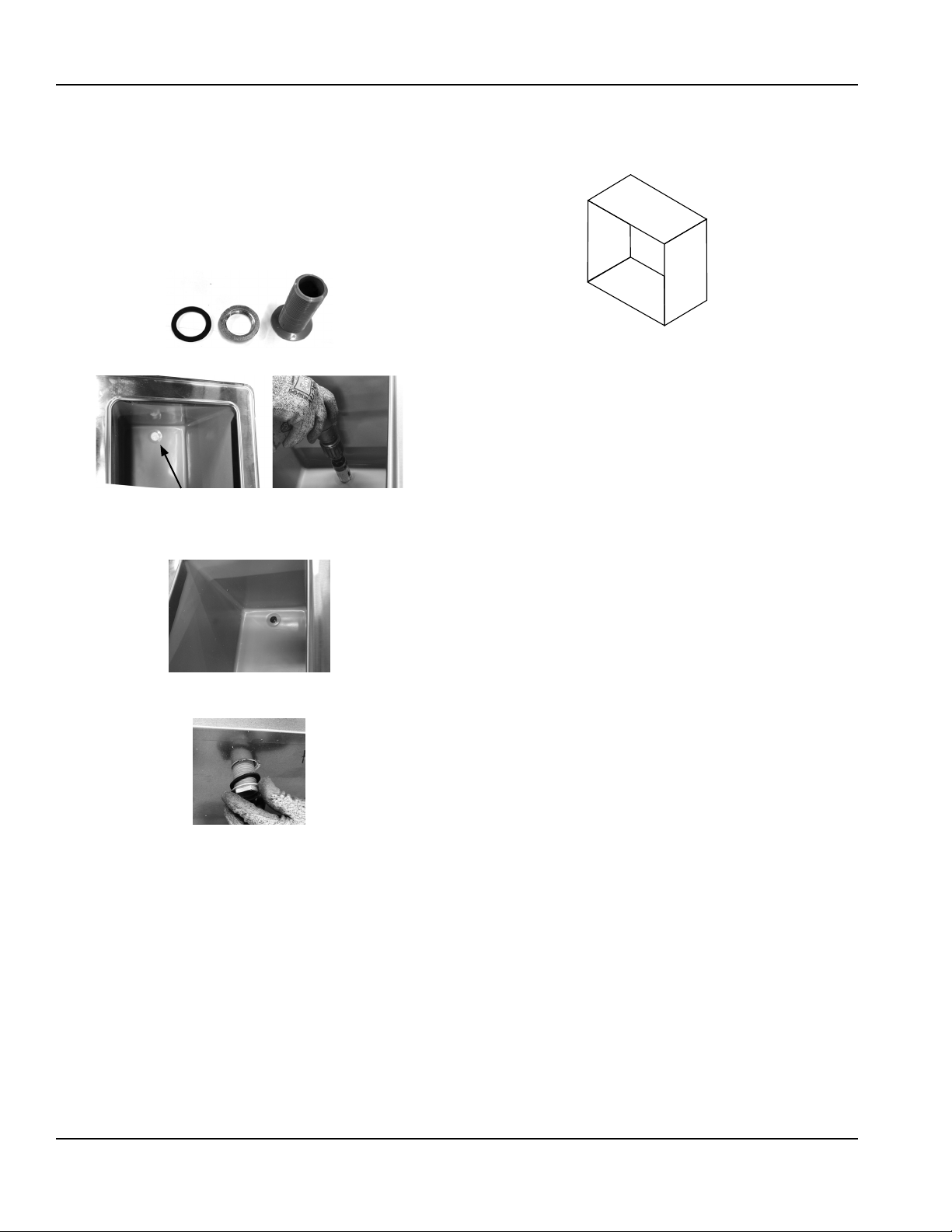

7. The 1” diameter drain on N8100B, N8100-BR and

N8100NB models is shipped loose and must be

connected during installation.

A. Provided 1” (25mm) drain, nut and washer must

be field installed to an appropriate container or

floor drain following local code requirements.

Sinks come standard with 1-1/2” basket strainer

assemblies.

B. Remove/drill foam out of drain hole.

C. Apply thin ring of plumbers putty around the

drain.

D. From the inside drop the drain into the drain hole.

8. Construct an air duct (not provided) connecting

the condenser face to the louver. This will prevent

recirculation of discharge air.

Air duct dimensions

E. From the outside secure the drain with the washer

and nut.

F. Tighten the nut with channel locks, use a fork to

hold the drain in place if necessary.

G. Clean up excess plumbers putty.

18 Part Number: 8000_SM 07/18

Page 19

Section 2 Installation

FORCEDAIR REFRIGERATED DROPIN UNITS

N8100-FA

Counter Cutout Dimensions

Are Model Specic

Air duct dimensions

to match condenser face

1. Install partitions between self-contained refrigerated

drop-in units and other electrical appliances if they

are located in the same cabinet. Partitions must fully

extend front to back and top to bottom.

2. Install a GFCI receptacle a minimum of 14” (36cm) up

from the cabinet bottom inside the partitions. Run the

outlet to a switch. With limited access to the control, a

switch will make it easy to turn the unit off for defrost.

3. The unit requires airflow to the compressor. One louver

is provided with each unit.

NOTE: Any restriction to the proper air flow will void the

compressor warranty.

• A 13” x 25” (33 cm x 64 cm) louver is provided by

Delfield and must be installed in the counter in front

of the condenser. The louver cutout dimension is 22”

x 11” (56 cm x 28 cm).

• The rear must have an opening for removal of

heated air. The opening must be at least 174in2

(1123cm2).

Discharge Air

Cutout

22.0” (56cm)

11.00”

(28cm)

Condenser

Louver

Fresh Air

4. Place the condensing unit through the counter cutout.

5. A gasket is installed in the flange of each unit.

The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out

opening.

Part Number: 8000_SM 07/18 19

Page 20

Installation Section 2

6. The 1” diameter drain on N8100-FA models is shipped

loose and must be connected during installation.

N8157-FA, N8169-FA and N8182-FA have two 1” drains.

A. Provided 1” (25mm) drain, nut and washer must

be field installed to an appropriate container or

floor drain following local code requirements.

Sinks come standard with 1-1/2” basket strainer

assemblies.

B. Remove/drill foam out of drain hole.

C. Apply thin ring of plumbers putty around the

drain.

D. From the inside drop the drain into the drain hole.

7. Construct an air duct (not provided) connecting

the condenser face to the louver. This will prevent

recirculation of discharge air.

8. Inside the well, the fan assembly has standoff brackets

with tabs. The tabs should be bent up.

9. Place the coil assembly cover slots over the bracket

tabs. This will secure the cover is in the correct location

and will not disrupt the air flow.

10. The upright air diffuser will only fit one way on the

drain side.

Black Airow Extrusions

Perforated Pan Clip

Adapter Bars

E. From the outside secure the drain with the washer

and nut.

F. Tighten the nut with channel locks, use a fork to

hold the drain in place if necessary.

G. Clean up excess plumbers putty.

Coil Assembly Cover

Plexiglas

End Caps

Upright Air Diuser

With Air Deector

20 Part Number: 8000_SM 07/18

Page 21

Section 2 Installation

to match condenser face

SELFCONTAINED COMBO HOT/COLD DROPIN UNITS

N8600

Counter Cutout Dimensions

Are Model Specic

Air duct dimensions

to match condenser face

11.00” (28cm)

8.00”

(20cm)

Control Panel

Cutout Dimensions

Are Model Specic

22.0” (56cm)

11.00”

(28cm)

NOTE: Any restriction to the proper air flow will void the

compressor warranty.

• A 13” x 25” (33 cm x 64 cm) louver is provided by

Delfield and must be installed in the counter in front

of the condenser. The louver cutout dimension is 22”

x 11” (56 cm x 28 cm).

• The rear must have an opening for removal of

heated air. The opening must be at least 11” x 8”, a

total of 88 square inches (28cm x 20cm, a total of

566 square centimeters).

Discharge Air

Cutout

Condenser

Louver

Fresh Air

4. Orient the control panel with the indicator light for

each control to the right of the control. N8600 series

units have 40” (102cm) of conduit.

5. Place the control panel into the cutout from inside the

cabinet. Place the collar into the cutout from outside

the cabinet. Secure with two screws.

6. Place the condensing unit through the counter cutout.

7. A gasket is installed in the flange of each unit.

The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out

opening.

8. N8600 wells are sloped to a 1” (25mm) male NPT

stainless steel drain. Plumb to a floor drain. Use a 1”

female coupling.

9. Construct an air duct (not provided) connecting

the condenser face to the louver. This will prevent

recirculation of discharge air.

1. Install partitions between self-contained refrigerated

drop-in units and other electrical appliances if they

are located in the same cabinet. Partitions must fully

extend front to back and top to bottom.

2. Install a GFCI receptacle a minimum of 14” (36cm) up

from the cabinet bottom inside the partitions.

3. The unit requires airflow to the compressor. One louver

is provided with each unit.

Part Number: 8000_SM 07/18 21

Air duct dimensions

Page 22

Installation Section 2

HOT FOOD WELL DROPIN UNITS

N8700-D, N8700-DESP, N8700N, N8700-R, N8800

Counter Cutout Dimensions

Are Model Specic

Control Panel

Cutout Dimensions

Are Model Specic

1. Orient the control panel with the indicator light for

each control to the right of the control.

• N8700 series units have 48” (122cm) of conduit.

• N8800 Series units have 34” (86cm) of conduit.

2. N8700 control panel is designed to be installed on the

side opposite the drains.

• Installed on the same side as the drains, the control

panel will either be upside down or the knobs will

control the opposite wells.

Control

panel

installed

opposite

drains

Drains

Infinite control shown, directions also apply to digital control

3. Place the control panel into the cutout from inside the

cabinet. Place the collar into the cutout from outside

the cabinet. Secure with two screws.

4. Place the hot food well drop-in unit through the

counter cutout.

5. A gasket is installed in the flange of each unit.

The weight of the unit on the gasket forms a seal

preventing liquids from seeping into the cut-out

opening.

6. Plumb to a floor drain.

• All N8700 series are equipped with 1/2” (13mm)

female NPT drains, one per well located right rear

corner, manifold to 1/2” (13mm) gate valve.

• N8800 wells are sloped to a 1” (25mm) male NPT

stainless steel drain. Use a 1” female coupling.

22 Part Number: 8000_SM 07/18

Page 23

Section 2 Installation

Electrical Service

DANGER

Check all wiring connections, including factory

terminals, before operation. Connections can become

loose during shipment and installation.

Warning

n

This appliance must be grounded and all field wiring

must conform to all applicable local and national

codes. Refer to rating plate for proper voltage. It is the

responsibility of the end user to provide the disconnect

means to satisfy the authority having jurisdiction.

VOLTAGE

All electrical work, including wire routing and grounding,

must conform to local, state and national electrical codes.

The following precautions must be observed:

• The equipment must be grounded.

• A separate fuse/circuit breaker must be provided for

each unit.

• A qualified electrician must determine proper wire size

dependent upon location, materials used and length

of run (minimum circuit ampacity can be used to help

select the wire size).

• The maximum allowable voltage variation is ±10% of

the rated voltage at equipment start-up (when the

electrical load is highest).

• Check all green ground screws, cables and wire

connections to verify they are tight before start-up.

GROUND FAULT CIRCUIT INTERRUPTER

Ground Fault Circuit Interrupter (GFCI/GFI) protection is

a system that shuts down the electric circuit (opens it)

when it senses an unexpected loss of power, presumably

to ground. Manitowoc does not recommend the use of

GFCI/GFI circuit protection to energize our equipment. If

code requires the use of a GFCI/GFI then you must follow

the local code. The circuit must be dedicated, sized

properly and there must be a panel GFCI/GFI breaker. We

do not recommend the use of GFCI/GFI outlets to energize

our equipment as they are known for more intermittent

nuisance trips than panel breakers.

ELECTRICAL SPECIFICATIONS CHART

Units with plugs are supplied with approximately 6ft

(183cm) cords.

Model Amps Watts V, Hz, Ph Plug

8100-EF Series

8118-EF

8132-EF

8145-EF

8159-EF

8172-EF

8186-EF 8.0

8118-EF-E

8132-EF-E

8145-EF-E

8159-EF-E

8172-EF-E

8186-EF-E

8148-EFN

8191-EFN

8148-EFN-E

8169-EFN-E

8191-EFN-E

N8118B

N8130B

N8143B

N8156B

N8169B

N8181B 7.3

N8118B-E

N8130B-E

N8143B-E

N8156B-E

N8169B-E

N8144-BR 4.0

N8159-BR 7.0

N8176-BR 7.3

N8194-BR 8.0

N8131-FA 7.8

N8144-FA

N8157-FA

N8169-FA

N8182-FA

N8146NB 3.7

N8168NB 5.6

7.5

8100-EF-E Export Series

2.5 600 230-240, 50, 1

7.5 - 115, 60, 1 NEMA 5-15P8169-EFN

8100-EFN-E Export Series

2.5 600 230-240, 50, 1

N8000N Series - NA

N8000-R Series - NA

3.7

5.6

N8100B-E Export Series - R404A

1.5 360 230-240, 50, 1

N8100B-E Export Series - R134A

2.5 600 230-240, 50, 1

9.2

14.8

- 115, 60, 1 NEMA 5-15P

8100-EFN Series

N8000 Series - NA

N8100B Series

- 115, 60, 1 NEMA 5-15P

N8100BR Series

- 115, 60, 1 NEMA 5-15P

N8100-FA Series

- 115, 60, 1 NEMA 5-15P

N8100NB Series

- 115, 60, 1 NEMA 5-15P

Varies Per

Destination

Varies Per

Destination

Varies Per

Destination

Varies Per

Destination

Part Number: 8000_SM 07/18 23

Page 24

Installation Section 2

Model Amps Watts V, Hz, Ph Plug

N8100NB-E Export Series

N8146NB-E

N8168NB-E

N8231

N8245

N8259

N8273

N8287 8.0

N8231-E

N8245-E 360

N8259-E

N8273-E 600

N8287-E 2.8 650

N8231G

N8245G

N8259G 8.0

N8273G 9.0

N8231G-E

N8245G-E

N8259G-E 2.8 672

N8230-ST

N8240-ST

N8256-ST

N8258-ST

N8275-ST

N8630 24.0 - 120, 60, 1

N8643

N8656

N8669

N8681

N8717-D 8.3

N8731-D 16.6

N8745-D 15.0/16.0

N8759-D 20.0/22.0

N8773-D 24.0/27.0

N8787-D 29.0/32.0

N8717-D-E 6.0 1450

N8731-D-E 12.1 2900

N8745-D-E 18.1 4350

N8759-D-E 24.2 5800

N8773-D-E 30.2 7250

N8787-D-E 36.3 8700

N8717-DESP 2.4/2.7

N8731-DESP 4.8/5.4

N8745-DESP 7.2/8.1

N8759-DESP 9.6/10.8

N8773-DESP 12.0/13.5

N8787-DESP 14.4/16.2

1.5 360 230-240, 50, 1

N8200 Series

7.5

N8200-E Export Series

1.5

2.5

7.5

N8200G-E Export Series

1.5 360

7.5 - 115, 60, 1 NEMA 5-15P

21.0

43.0

N8700D-E Export Series

- 115, 60, 1 NEMA 5-15P

360

230-240, 50, 1

600

N8200G Series

- 115, 60, 1 NEMA 5-15P

230-240, 50, 1

N8200-ST Series

N8600 Series

- 120/240, 60, 1

N8700D Series

- 120, 60, 1

- 208-230, 60, 1

240, 50, 1 Hard Wire

N8700DESP Series

- 208-230, 60, 1 Hard Wire

Destination

Destination

Destination

Varies Per

Varies Per

Varies Per

Hard Wire

Hard Wire

Model Amps Watts V, Hz, Ph Plug

N8700-D-ESP-E Export Series

N8717-D-ESP-E 2.1 500

N8731-D-ESP-E 4.2 1000

N8745-D-ESP-E 6.3 1500

N8759-D-ESP-E 8.4 2000

N8773-D-ESP-E 10.5 2500

N8787-D-ESP-E 12.6 3000

N8700N Series

N8746ND 17.0 - 120, 60, 1

N8768ND

N8744-R 16.6 - 120, 60, 1

N8759-R 15.0/16.0

N8794-R 24.0/27.0

N8831 17.0 - 120, 60, 1

N8845 15.0/16.0

N8859 20.0/22.0

N8873 24.0/27.0

N8887 29.0/32.0

N8831-E 12.1 2900

N8845-E 18.1 4350

N8859-E 24.2 5800

N8873-E 30.2 7250

N8887-E 36.3 8700

15.0/16.0 - 208-230, 60, 1

N8700-R Series

- 208-230, 60, 1N8776-R 20.0/22.0

N8800 Series

- 208-230, 60, 1

N8800-E Export Series

240, 50, 1 Hard Wire

240, 50, 1 Hard Wire

Hard WireN8768N

Hard Wire

Hard Wire

24 Part Number: 8000_SM 07/18

Page 25

Section 2 Installation

BTU

Refrigeration

Temperature Class for all Export units is N.

BTU

Model H.P.

8100-EF Series R404A

8118-EF 1/4 204 19/50º/-15° 928

8132-EF 1/4 379 26/42º/-7° 1112

8145-EF 1/4 569 35/36º/-1° 1259

8159-EF 1/4 758 43/32º/3° 1373

8172-EF 1/4 948 51/29º/6° 1469

8186-EF 1/3 1138 59/26º/9° 1529 24.0oz

8100-EF-E Export Series R404A

8118-EF-E 1/4 204 19/50º/-15° 928

8132-EF-E 1/4 379 26/42º/-7° 1112

8145-EF-E 1/4 569 35/36º/-1° 1259

8159-EF-E 1/4 758 43/32º/3° 1373

8172-EF-E 1/4 948 51/29º/6° 1469

8186-EF-E 1/3 1138 59/26º/9° 1529

8100-EFN Series R404A

8148-EFN 1/4 379 26/42º/-7° 1112

8191-EFN 1/4 758 43/32º/13° 1373

8100-EFN-E Export Series R404A

8148-EFN-E 1/4 379 26/42º/-7° 1112

8191-EFN-E 1/4 758 43/32º/13° 1373

N8000N Series - NA

N8000-R Series - NA

N8100B Series R404A

N8118B 1/5 204 19/38º/-3º 1010 6.0oz

N8130B 1/5 379 26/31º/4° 1298 7.5oz

N8143B 1/5 569 35/26º/9º 1298 9.2oz

N8156B 1/4 758 43/32º/3º 1961 6.5oz

N8169B 1/4 948 51/29º/6º 2088 6.5oz

N8181B 1/3 1138 59/32º/3º 2088 7.5oz

N8100B-E Export Series R404A

N8118B-E 1/5 204 19/38º/-3º 708

N8143B-E 1/5 569 35/26º/9º 889

N8100B-E Export Series R134A

N8156B-E 1/4 758 43/32º/3º 1373

N8169B-E 1/4 948 51/29º/6º 1469

N8100BR Series R404A

N8144-BR 1/5 379 26/31º/4° 812 9.4oz

N8159-BR 1/4 569 35/26º/9º 889 6.5oz

N8176-BR 1/3 758 43/32º/3º 1373 7.5oz

N8194-BR 1/3 948 51/29º/6º 1469 7.9oz

N8100-FA Series R404A

N8131-FA 1/4 1339 140/15º/20º 2154 16.0oz

N8144-FA 1/2 2035 140/22º/13º 3142 32.0oz

N8157-FA 1/2 2731 280/14º/21° 3806 32.0oz

N8169-FA 3/4 3374 280/20º/15° 5545 48.0oz

N8182-FA 3/4 4070 280/20º/15° 5545 48.0oz

N8100NB Series R134A

N8146NB 1/5 454 17/40º/-5º 680 8.5oz

N8168NB 1/5 676 26/31º/4º 804 6.5oz

N8100NB-E Export Series R404A

N8146NB-E 1/5 454 17/40º/-5º 680

N8168NB-E 1/5 676 26/31º/4º 804

Evap BTU/TD/

Load

N8000 Series NA

TEMP

Sys Cap

Refrig.

Charge

16.0oz

454g

16.0oz8169-EFN 1/4 569 35/36º/-1° 1259

454g8169-EFN-E 1/4 569 35/36º/-1° 1259

454gN8130B-E 1/5 379 26/31º/4° 812

227g

454g

Model H.P.

N8200 Series R404A

N8231 1/4 379 26/42º/-7° 1112

N8245 1/4 569 35/36º/-1° 1259

N8259 1/4 758 43/32º/3° 1373

N8273 1/4 948 51/29º/6° 1469

N8287 1/3 1138 59/30º/5° 1787 24.0oz

N8200-E Export Series R404A

N8231-E 1/5 379 26/42º/-7° 1112

N8245-E 1/5 569 35/36º/-1° 1259

N8259-E 1/4 758 43/32º/3° 1373

N8273-E 1/4 948 51/29º/6° 1469

N8287-E 1/3 1138 59/30º/5° 1787

N8200G Series R404A

N8231G 1/4 379 26/42º/-7° 1112 16.0oz

N8245G 1/4 569 35/36º/-1° 1259 16.0oz

N8259G 1/3 758 43/37º/-2° 1572 24.0oz

N8273G 1/2 948 51/43º/-8° 2183 40.0oz

N8200G-E Export Series R404A

N8231G-E 1/5 379 26/42º/-7° 1112

N8259G-E 1/3 758 43/37º/-2° 1572

N8200-ST Series R404A

N8230-ST 1/4 332 26/44°/-9° 1128

N8240-ST 1/4 559 35/37°/-2° 1295

N8256-ST 1/4 624 39/35°/0° 1359

N8258-ST 1/4 870 44/33°/2° 1422

N8275-ST 1/4 1140 53/29°/6° 1520

N8600 Series R404A

N8630 1/4 379 26/42º/-7° 1112

N8643 1/4 569 35/36º/-1° 1259

N8656 1/4 758 43/32º/3° 1373

N8669 1/4 948 51/29º/6° 1469

N8681 1/3 1138 59/30º/5° 1787 24.0oz

N8700D Series - NA

N8700D-E Export Series - NA

N8700DESP Series - NA

N8700-D-ESP-E Export Series - NA

N8700N Series - NA

N8700-R Series - NA

N8800 Series - NA

N8800-E Export Series

Load

Evap BTU/TD/

TEMP

Sys Cap

Refrig.

Charge

16.0oz

454g

454gN8245G-E 1/5 569 35/36º/-1° 1259

16.0oz

16.0oz

Part Number: 8000_SM 07/18 25

Page 26

Installation Section 2

Optional Auto Fill Installation

• Option is a loose parts kit. Installation requires a plumber.

• The purpose of the auto fill assembly is to maintain the level of water lost throughout operation as it steams away. If

using it to fill an empty unit it will fill slowly and you may want to start by manually filling the unit.

APPLICABLE TO N8600 & N8800 MODELS

1. Locate mounting holes on outside operator drop-in body and mount float and bracket using thumb screws.

2. Install drain plumbing as shown.

3. Connect clear plastic tubing to 1/2” copper stub and connect to the float. Use hose clamps to secure.

4. Connect fill line to 1/4” compression fitting.

5. Loosen thumb screws to achieve desired water level.

NO CONNECTION

NEEDED

26 Part Number: 8000_SM 07/18

Page 27

Section 2 Installation

Optional Auto Fill Installation

• Option is a loose parts kit. Installation requires a plumber.

• The purpose of the auto fill assembly is to maintain the level of water lost throughout operation as it steams away. If

using it to fill an empty unit it will fill slowly and you may want to start by manually filling the unit.

APPLICABLE TO N8700 MODELS

1. Locate mounting holes on outside operator drop-in body and mount float and bracket using thumb screws.

2. Install drain plumbing as shown.

3. Connect clear plastic tubing to 1/2” copper stub and connect to the float. Use hose clamps to secure.

4. Connect fill line to 1/4” compression fitting.

5. Loosen thumb screws to achieve desired water level.

NO CONNECTION

NEEDED

Part Number: 8000_SM 07/18 27

Page 28

Installation Section 2

THIS PAGE INTENTIONALLY LEFT BLANK

28 Part Number: 8000_SM 07/18

Page 29

Section 3

Operation

DANGER

The on-site supervisor is responsible for ensuring that

operators are made aware of the inherent dangers of

operating this equipment.

DANGER

Do not operate any appliance with a damaged cord

or plug. All repairs must be performed by a qualified

service company.

DANGER

Never stand on the unit! They are not designed to

hold the weight of an adult, and may collapse or tip if

misused in this manner.

Warning

n

Do not contact moving parts.

Warning

n

All covers and access panels must be in place and

properly secured, before operating this equipment.

Product Quality in Cold Pans

Warning

n

The operator of this equipment is solely responsible

for ensuring safe holding temperature levels for all

food items. Failure to do so could result in unsafe food

products for customers.

These units are not designed to cool warm food products.

Items should be placed in the unit pre-cooled at least to the

desired holding temperature, if not slightly colder. In some

applications, a gradual warming of product may occur,

particularly at the exposed top of the product. Stirring or

rotation of the product is necessary to maintain overall

temperature.

Warming of food product can occur very quickly outside of

the unit. When loading or rotating product, avoid leaving

food items in a non-refrigerated location for any length of

time to prevent warming or spoilage. To ensure product

quality product must be rotated every four hours.

Warning

n

Damp or wet hands may stick to cold surfaces.

Warning

n

Never use sharp objects or tools to remove ice or frost.

Do not use mechanical devices or other means to

accelerate the defrosting process.

Warning

n

Do not block the supply and return air grills or the air

space around the air grills. Keep plastic wrappings,

paper, labels, etc. from being airborne and lodging in

the grills. Failure to keep the air grills clear will result in

unsatisfactory operation of the system.

Caution

,

Units with pans should be operated with pans in place.

Operating the unit without all pans in place will lower

efficiency and may damage the unit.

Part Number: 8000_SM 07/18 29

Page 30

Operation Section 3

8100-EF(N) Series Operation

Note

The cold pan is not intended to be used with ice.

There is a switch on the compressor housing front to turn

the 8100-EF units on and off. The unit must be turned off

when not in use or overnight for defrosting and cleaning.

8100-EF Series LiquiTec® Eutetic fluid cold pans are adjusted

at the factory to provide proper operation without any

further adjustments.

The temperature control is located on the condensing

housing.

Power Switch & Temperature Control

1. At initial start-up or anytime power is disconnected,

then reconnected to the unit, the control will go into

normal cooling mode.

2. The temperature control will cycle the compressor and

condenser fan motor to maintain proper temperature.

Notice

Temperature displayed is for refrigeration set point

purposes only. Display does not reflect air or product

temps in unit.

TEMPERATURE CONTROL & DISPLAY

V

V

Operation / Indication

Status Displayed

Normal (°C) Temp. [°C] Unit depends on setting

Normal (°F) Temp. [°F]

Show set-point Temp.

Sensor 1 defect

Sensor 2 defect

Sensor 3 defect

Sensor 4 defect

High temperature

alarm

Low temperature alarm

Line voltage too high,

above 140 volts

Line voltage too low,

below 96 volts

Control calls for cooling

for more than 24 hours

straight

All alarms sound for approximately 10 seconds and then

E01

E02

E03

E04

Hi

Lo

uHi

uLi

LEA

X Air sensor

X Coil sensor

X Open

X Open

X Automatically switching

X

X

X

X Time includes defrost.

are silent for 50 seconds. It will do that for 15 cycles and

then remain silent. The alarm code will still be present on

the display until the fault clears.

Comments

(parameters in control)

at 2 sec rate

Error will go away if the

control cycles off the

compressor or if the

power is shut off. If error

is on a cold pan it could

be related to a high

ambient temperature or

not shutting the rail off

nightly.

30 Part Number: 8000_SM 07/18

Page 31

Section 3 Operation

Press upper or lower right button.

• Display show actual set-point (blinking).

• If buttons untouched for 3 seconds returns to

normal.

• Increase set-point by pressing upper button. Max value

depends on parameters in control.

• Decrease set-point by pressing lower button. Min value

depends on parameters in control.

• If buttons untouched for 3 seconds returns to

normal and stores new set-point.

Press lower left button for 5 seconds.

• Unit goes into stand-by mode.

• The display will read Off, then a period.

• Press the lower left button again for 5 seconds.

• The display will read On.

• The unit will then start up in normal cooling

mode.

Temperature Alarm

The alarm will sound and flash HI or LO 90 minutes after the

unit has reached its alarm temperature point or after any

power interruption if the temperature is above or below the

alarm set points.

CHANGING DISPLAY FROM FAHRENHEIT TO CELSIUS

ON ERC112 CONTROL

1. Simultaneously hold the up and down arrows for

5 seconds to access menu for password protected

parameters.

2. Screen should temporarily flash PAS and then move to

a numeric screen.

3. Scroll to 187 using the up/down arrows and push the

stand-by button (lower left button) to enter.

4. Scroll to dis using the up/down arrows and push the

stand-by button (lower left button) to enter into the

display menu.

5. Scroll to CFu using the up/down arrows and push the

stand-by button (lower left button) to enter the display

unit menu.

Part Number: 8000_SM 07/18 31

Page 32

Operation Section 3

6. -F should be displayed indicating Fahrenheit. Use

the down arrow to change it to -C for Celsius and hit

the stand-by button (lower left button) to enter the

change.

7. Push the defrost button (upper left button) to move

out of the display unit menu.

N8100B, N8100-BR & N8100NB Operation

The temperature control is used to turn the unit on and

off as well as control the temperature of the cold pan. The

control is located in the machine compartment. To turn the

cold pan off, turn the knob to the off position. The unit must

be turned off when not in use or overnight for defrosting

and cleaning.

If the cold pan is to be used with ice, it is recommended

that the optional perforated bottoms be used. These will

allow ice to melt properly.

These mechanically cooled cold pans are adjusted at

the factory to provide proper operation. However, if it

is necessary to adjust the temperature, turn the knob

clockwise as indicated on the control. Settings are from 1

thru 7 (7 being the coldest).

• Adjustments should be made gradually.

• Several small adjustments will be more effective than

one large adjustment.

• It may take an hour or longer to realize the temperature

change depending on the application and location of

the unit.

8. Push the defrost button (upper left button) to move

out of the display menu and back to the normal display.

NOTE: For steps 7 and 8, display will return back to normal

display after 30 seconds of inactivity.

32 Part Number: 8000_SM 07/18

Page 33

Section 3 Operation

N8100-FA Operation

There is a switch on the compressor housing front to turn

the N8100-FA units on and off. The unit must be turned off

when not in use or overnight for defrosting and cleaning.

NOTE: Food in the N8100-FA pans should not be loaded in

such a way as to interfere with the air curtain flowing over

the cold pans.

Defrost Timer

The recommended defrost timer setting is every 2 hours for

15 minutes.

Pressure Control

The temperature is controlled by an adjustable pressure

control located in the machine compartment and

adjustable control has the word COLDER near the knob,

with an arrow to indicate the adjustment direction. This

control is field adjustable and does not require a service

agent. If you have any questions, call an authorized service

agent.

In attempting to adjust the pressure control, you can

do damage to the unit by accidentally adjusting the

differential.

NOTE: Delfield is not responsible for charges incurred while

adjusting the pressure control.

Factory settings are:

• 30 psi (207 kPa) differential

• 80 psi (552 kPa) cut-in

• 50 psi (345 kPa) cut-out

N8200 & N8200-ST Operation

N8200 and N8200-ST series frost tops are designed to

maintain an even layer of frost to pleasantly display