Project __________________________________

Item ____________________________________

Quantity ________________________________

CSI Section 11400

Production Centers

Approved _______________________________

Date ____________________________________

Pasta Production Center

Models

• F18RC93-BPL - 93” pasta station with refrigerated base, liquitec cold pan, built-in induction wok

cookers, rethermalizers, sauce warmer and utility bin

Standard Features

• Self contained refrigerated base with heavy

duty drawers

• Drawers are backed by a 10-year warranty

on the track assembly

• Self contained liquitec cold pan

• Built-in wok style induction cooker

• Two pasta rethermalizers

• Sauce warmer, sized for 1/3 pan

• Utility bin, sized for 1/3 pan

• Environmentally friendly R404A refrigerant

• Adapter bars for drawers provided

F18RC93-BPL

• Mounted on casters for easy cleaning and

installation

• High density foamed in place

environmentally friendly, Kyoto Protocol

Compliant, Non ODP (Ozone Depletion

Potential), Non GWP (Global Warming

Potential) polyurethane keeps energy costs

low

• One year parts and labor, five year

compressor standard warranty

Production Centers: Pasta Production Center

Specifications

Exterior top is one-piece, 14-gauge stainless steel, with

integral 2.12” (5.4cm) high square nosing on front. Top has a

self contained Liquitec® cold pan. It also features four built-in

wok style induction cooker, two pasta rethermalizers, a sauce

warmer (sized for 1/3 pan) and utility bin (sized for 1/3 pan).

Cold pan top opening temperature to maintain 33°F (1°C) to

41°F (5°C) at 86° ambient room temperature, meeting NSF7

certification.

Exterior Back is 18-gauge galvanized steel. Exterior ends are

finished with 22-gauge stainless steel.

Base Interior has 22-gauge stainless steel back and

bottom. Refrigerated base interior ends and door frames are

thermoformed ABS plastic. Base is insulated with 1.5” (3.8cm)

high density foamed in place environmentally friendly, Kyoto

Protocol Compliant, Non ODP (Ozone Depletion Potential),

Non GWP (Global Warming Potential) polyurethane.

Drawers have a 22-gauge stainless steel exterior with

thermoformed ABS plastic interior liner. Drawer frames are

12-gauge stainless steel. Drawer slides are 11-gauge stainless

steel with Delrin bearings. 19” drawers hold one full size 12” x

980 S. Isabella Rd.

Mt. Pleasant, Michigan 48858

Phone: 800-733-8948 or 989-773-7981

Fax: 800-669-0619

20” pan, 4”- 6” (10.1cm - 15.2cm) deep, each. 27” drawers hold

two full size 12” x 20” (30.5cm x 50.8cm) pans, 4”- 6” (10.1cm -

15.2cm) deep. Pans are supplied by others.

Refrigeration System uses HFC-404A refrigerant. Cabinet has

a blower coil assembly located behind door mullion. Base is

equipped with independently controlled thermostat, solenoid

valve and condensate evaporator. On/off switch for unit is

located on panel above louver. Refrigeration system in the

base will maintain 36°F (2°C) to 40°F (4°C).

Casters: Unit is mounted on 5” casters (6.12” ride height),

diameter plate casters with front locking.

Electrical connections are 120/208 volt, 60 Hertz, three

phase. Unit must be hard wired.

ICES

www.delfield.com

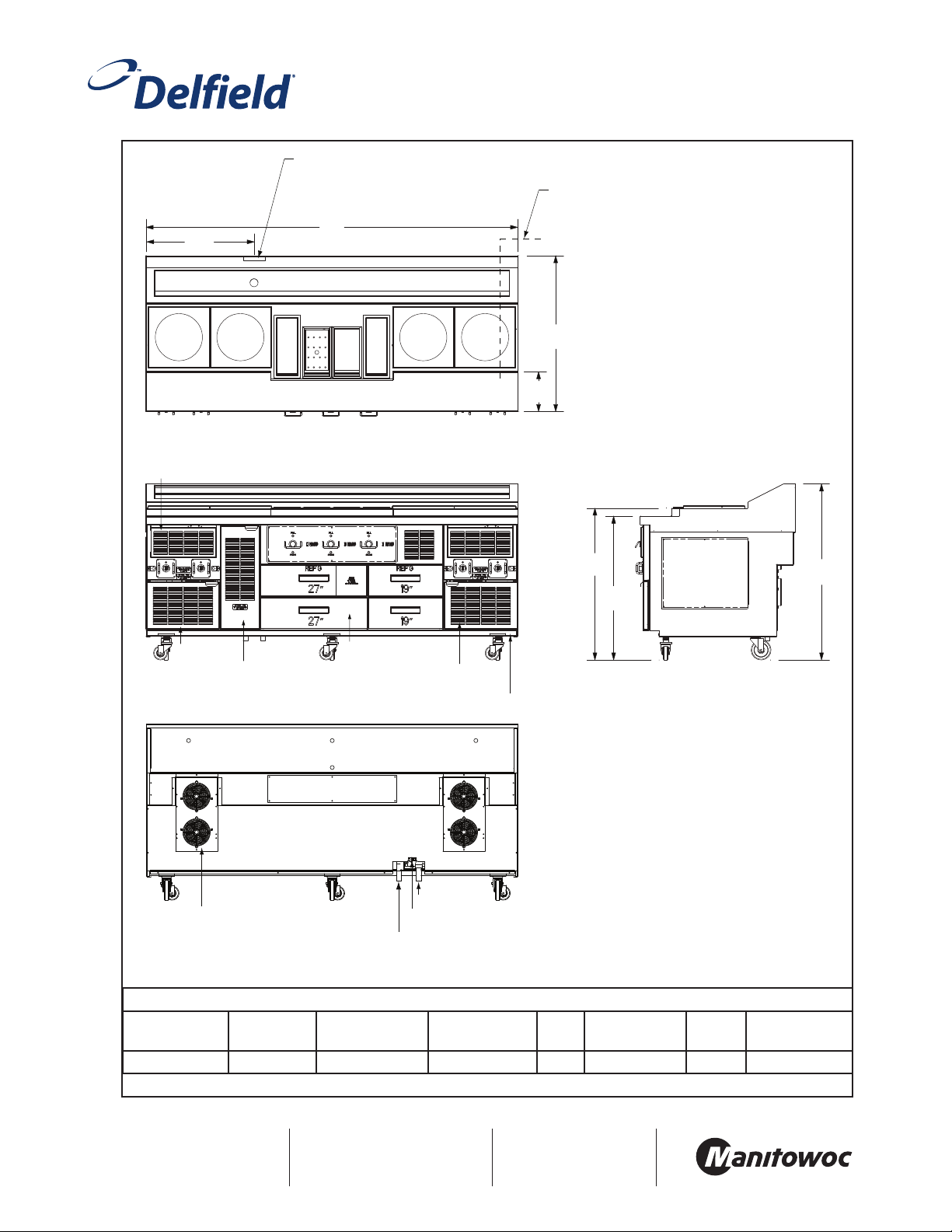

27.50”

70cm

6ft Flexible Supply Line Provided with 3/4”

Female Garden Hose Thread (FGHT)

Cold Pan Drain: 1” PVC

Pasta/Sauce Drain & Overflow Combined:

1” Rigid Copper

93.00”

236cm

A

8ft waterproof conduit and

straight connector supplied with

wire required for field connection.

Wire to extend 6” beyond conduit.

Pasta Production Center

B B B

C D E C

Plan View

Louvered Panel Each Side with

Removable Filter(1) For Woks

1/2HP

Compressor

All Drain & Supply

Line Valves

Self Contained

Refrigerated Base

Front Elevation View

B

Breaker panel

behind door

Wall Tether Provided

10.00”

25cm

39.00”

A– Self Contained Liquitec Cold Pan

99cm

B– Wok Style Induction Cooker

C– Pasta Rethermalizer

D– Sauce Warmer, sized for 1/3 pan

E– Utility Bin, sized for 1/3 pan

38.00”

97cm

36.00”

91cm

Side View

44.00”

112cm

Access To Drain Connections

(2) Exhaust Fans on Each Side

Rear Elevation View

Rail Drain 1” PVC

Water Supply Connection

6’ Flexible Hose Provided

Pasta & Sauce Well Drain 1” Copper

Specifications

Model

1/6 Size Pan

Cap. In Rail

Full Size Pan

Cap. In Drawers*

# of Installed

Induction Woks

H.P. V-Hz-Ph Amps Ship Weight

F18RC93-BPL 14 6 4 1/2 120/208-60-3 84 1,255lbs/569kg

* Adapter bars for drawers provided

Production Centers

Deleld reserves the right to make changes to the design or specications without prior notice.

980 S. Isabella Rd.

Mt. Pleasant, Michigan 48858

Phone: 800-733-8948 or 989-773-7981

Fax: 800-669-0619

www.delfield.com

Printed in the U.S.A.

DSPASTACENTER

03/12

Loading...

Loading...