Page 1

Production Centers

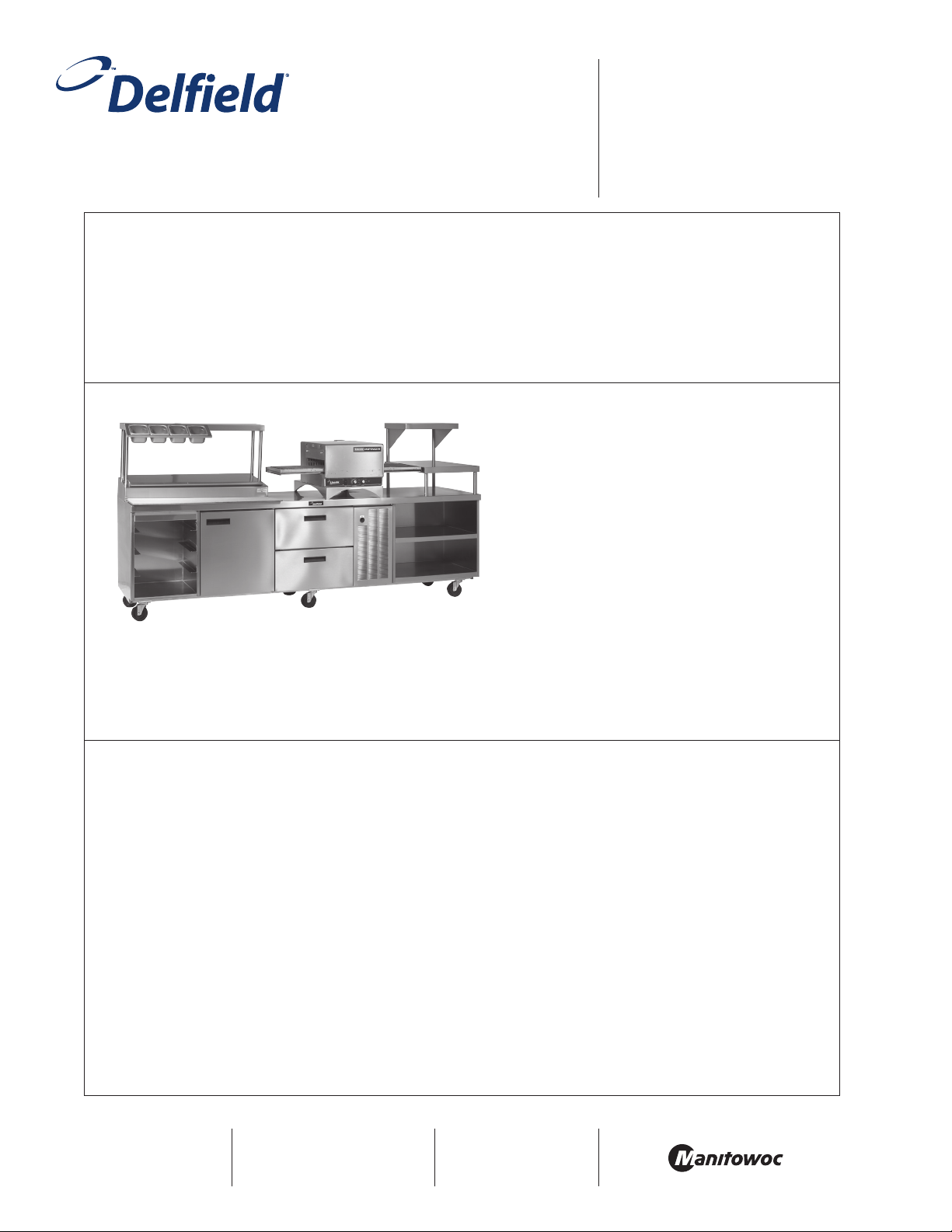

Pizza Production Center

Custom Models

• F18RC119-ES1L 119” pizza production center, product workflow to the left

• F18RC119-ES1R 119” pizza production center, product workflow to the right

Project ______________________________________

Item ________________________________________

Quantity _____________________________________

CSI Section 11400

Approved ___________________________________

Date ________________________________________

Production Centers:

F18RC119-ES1R

Standard Features

• Top is constructed of 16-gauge stainless steel

• High density environmentally friendly, Kyoto

Protocol Compliant, Non ODP (Ozone Depletion

Potential), Non GWP (Global Warming Potential)

polyurethane foam throughout unit

• Snap-in dart style vinyl magnetic gaskets

• Recessed black plastic handle held in with a posi-

tive lock system

• 14 gauge leg rails that run the entire length of

the unit

• Built-in Lincoln CTI oven

• Overstructure with ambient pan rack

• Ambient panslides accommodate 18”x26” sheets

pans in base

• 6.12” casters

• 8’ long electrical cord

• 36” standard work height

• Environmentally friendly HFC-404A refrigerant

Oven Standard Features

• Hot air under pressure surrounds the food with

small jets of hot air. This allows for rapid heating,

cooking, baking and crisping of foods

• Uniform heating/cooking of food products offer

a wide tolerance for rapid baking at a variety of

temperatures

Warranty

• One year parts and labor standard warranty

• Five year compressor warranty

Pizza Production Center

Options &

Accessories

• Stainless steel back

• Tray racks

• Locks

• Additional shelf (specify

door size)

• Pans and adapter bars

980 S. Isabella Rd.

Mt. Pleasant, Michigan 48858

Phone: 800-733-8948 or 989-773-7981

Fax: 800-669-0619 www.delfield.com

Page 2

F18RC119-ES1R

77.94”

198cm

119.00”

302cm

Plan View

F18RC119-ES1R

8.00”

20cm

33.00”

84cm

0.06”

1.5mm

32.00”

81cm

47.00”

119cm

15.00”

38cm

Elevation View

F18RC119-ES1R

21.00”

53cm

24.00”

61cm

36.00”

91cm

14.31”

36cm

9.69”

25cm

7.62”

19cm

6.12”

16cm

Right Side View

F18RC119-ES1R

Page 3

F18RC119-ES1L

0.06”

1.5mm

32.00”

81cm

33.00”

84cm

8.00”

20cm

119.00”

302cm

Plan View

F18RC119-ES1L

77.94”

198cm

21.00”

53cm

F18RC119-ES1

15.00”

38cm

Elevation View

F18RC119-ES1L

47.00”

119cm

24.00”

61cm

36.00”

91cm

7.62”

19cm

6.12”

16cm

Right Side View

F18RC119-ES1L

Specifications

Custom Model L W H H.P. Amps Nema Plug Ship Weight

F18RC119-ES1L,

F18RC119-ES1R

Deleld reserves the right to make changes to the design or specications without prior notice.

119”

(302cm)

32”

(81cm)

60”

(152cm)

1/3 41.0 14-60 980lbs

(445kg)

Page 4

Production Centers

Pizza Production Center

Specifications

Exterior top is one-piece, 16-gauge stainless steel, with

integral 2.12” (5.4cm) high square nosing on front. Top

has a mechanically cooled refrigerated raised rail at rear

with openings to accommodate 1/6 size pans. Pans and

adapter bars are provided by others. Pans are recessed

2” (5.1cm). Rail interior is 22-gauge stainless steel. Raised

rail openings have 18-gauge stainless steel removable

lids. Unit is equipped with separate expansion valve and

on/off switch for refrigerated cold pan. Temperature in

top opening to maintain 33°F (1°C) to 41°F (5°C) with pans

recessed 2” (5.1cm) at 86° ambient room temperature,

meeting NSF7 requirements.

Exterior Back and Bottom are 24-gauge galvanized steel.

Exterior ends are finished with 22-gauge stainless steel.

Base Interior has 22-gauge stainless steel back and

bottom. Refrigerated base interior ends and door frames

are thermoformed ABS plastic. Base is insulated with 1.5”

(3.8cm) high density foamed in place environmentally

friendly, Kyoto Protocol Compliant, Non ODP (Ozone

Depletion Potential), Non GWP (Global Warming Potential)

polyurethane.

Door(s) have a 22-gauge stainless steel exterior front, with

thermoformed ABS plastic interior liner, black recessed

handle and snap in magnetic gasket which is easily

replaceable. Each interior door section has (1) removable

epoxy coated wire shelf.

Drawers have a 24-gauge stainless steel exterior with

thermoformed ABS plastic interior liner. Drawer frames

are 12-gauge stainless steel. Drawer slides are 11-gauge

stainless steel with Delrin bearings. Each drawer holds two

full size 12” x 20” (30.5cm x 50.8cm) pans, 4”- 6” (10.1cm -

15.2cm) deep. Pans are supplied by others.

Refrigeration System uses HFC-404A refrigerant. Cabinet

has a blower coil assembly with expansion valve located

behind door mullion. Base is equipped with independently

controlled thermostat, solenoid valve and condensate

evaporator. On/off switch for unit is located on panel above

louver. Refrigeration system in the base will maintain 36°F

(2°C) to 40°F (4°C).

Casters: Unit is mounted on 5” casters (6.12” ride height),

diameter plate casters with front locking.

Electrical connections are 120/208 volt, 60 Hertz, single

phase. Unit is wired with 8’ (2.4m) cord and NEMA 14-60

plug.

Electric Baking/Finishing Oven is self-contained and

conveyorized. Temperature is adjustable from 200°F (93°C)

to 550°F (288°C). Conveyor speed is adjustable from 1

minute to 24 minutes cooking time. Conveyor and air

distribution fingers are removable through the side-access

panels for easy cleaning. Crumb pans are located below the

conveyor belt outside the baking chamber.

A power on/off switch, temperature control and conveyor

speed control are located on the front of the oven. A

heating indicator light illuminates when heating.

Exterior is fabricated from No. 4 finish stainless steel. The air

distribution system consists of an axial type fan powered by

1/10 hp AC motor. The headed air is forced through four (4)

distribution fingers located in the baking chamber with two

(2) above the conveyor belt and two (2) below. Each finger

has required number of holes to create the air impingement

effect on the food product passing through the baking

chamber on the conveyor belt. The conveyor belt is a

flexible stainless steel design with capacity for 16” (406mm)

wide product and a travel distance of 50” (1269mm) on the

extended conveyor, of which 20” (508mm) is in the baking

chamber. The fuses for the controls and blower motor are

located on the side of the control box.

Heat is supplied by one (1) element at 5600 watts. Each

oven is rated at 6kW.

980 S. Isabella Rd.

Mt. Pleasant, Michigan 48858

Phone: 800-733-8948 or 989-773-7981

Fax: 800-669-0619

www.delfield.com

Printed in the U.S.A.

DSPIZZACENTER

03/12

Loading...

Loading...