Delfield F2862, F2875, F2880, F2887, F2899 Service, Installation And Care Manual

...

F2000 and F17 Series Equipment Stands

De lfield

™

®

Service, Installation and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of

damage! Inspect all components immediately. See page 2.

Warning

To assure proper operation a 2" airspace must be maintained between the bottom of any cooking equipment

and the top of this unit. Cooking equipment must have a barrier (i.e. bottom, drip pan) between its heat

source and the top of the equipment stand. Failure to comply with this could severely damage the equipment

stand and void all warranties.

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

Effective Date December 2007

F2000/F17 Series Equipment Stand Service and Installation Manual

Delfield

™

®

Contents Serial Number Location

RECEIVING AND INSPECTING ...................................................2

SPECIFICATIONS ................................................................... 3-4

INSTALLATION ....................................................................... 5-6

PRESSURE CONTROL SETTINGS .......................................... 6-7

OPERATION ........................................................................... 6-7

PARAGON TIME CLOCK DIAL ....................................................7

CARE AND CLEANING ...............................................................8

THERMOMETER .........................................................................8

WIRING DIAGRAMS ..................................................................9

WALL ANCHOR ASSEMBLY .....................................................10

CONDENSING UNIT ASSEMBLY DRAWING .............................11

MULLION COIL ASSEMBLY DRAWINGS

REMOTE REFRIG. .................................................................12

SELF CONTAINED REFRIG. ...................................................13

FREEZERS ............................................................................14

DOOR ASSEMBLY ....................................................................15

DRAWER ASSEMBLY DRAWING .............................................15

REPLACEMENT PARTS ...................................................... 16-17

STANDARD WARRANTIES ................................................. 18-20

NOTES ............................................................................... 21-23

The serial number on remote models is located behind the 6"

(15.2 cm) stainless steel panel.

The serial number on self-contained models is located in the

compressor housing.

The serial number tag shows the refrigerant used and the

amount of charge and amperage.

Always have the serial number of your unit available when calling for parts and service.

©2007 The Delfield Company. All rights reserved. Reproduction without written permission is prohibited. “Delfield” is a registered trademark of The Delfield Company.

Receiving and Inspecting the Equipment

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally as

well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10 days

from receipt of the equipment.

5. Check the lower portion of the unit to be sure legs or

casters are not bent.

6. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

7. Freight carriers can supply the necessary damage forms

upon request.

8. Retain all crating material until an inspection has been

made or waived.

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid. If the unit is on casters it

can be "rolled" off the skid.

2

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

F2000/F17 Series Equipment Stand Service and Installation Manual

Delfield

™

®

Specifications

MODEL # OF # OF VOLTAGE/ NEMA BTU BTU EVAP. CAP.

NUMBER PANS DRAWERS HERTZ/PHASE AMPS H.P. PLUG WEIGHT LOAD SYSTEM BTU

Low-Profile Freezer Base Equipment Stands

F2748 4 2 115/60/1 10.0 1/2* N/S 295 1032 — 160

F2776 8 4 115/60/1 10.0 3/4* N/S 375 1770 — 160

F2660 4 2 115/60/1 12.0 1/2 5-15P 418 925 1776 —

F2694 8 4 115/60/1 16.0 3/4 5-20P 500 1558 2713 —

*Recommended horsepower N/S=Not Supplied, unit must be hard wired

12x20 RECOMMENDED NEMA BTU EVAP CAP

# OF PANS VOLTS AMPS H.P. PLUG WEIGHT LOAD BTU

Low-Profile Refrigerator Base Equipment Stands

REMOTE

F2852 4 115/60/1 3.0 1/5 N/S 278 461 120

F2856 4 115/60/1 3.0 1/5 N/S 299 461 120

F2862 6 115/60/1 3.0 1/5 N/S 331 518 120

F2875 8 115/60/1 6.0 1/4 N/S 401 717 120

F2880 8 115/60/1 6.0 1/4 N/S 428 726 240

F2887 10 115/60/1 6.0 1/4 N/S 466 859 240

F2899 12 115/60/1 6.0 1/3 N/S 530 973 240

F28110 12 115/60/1 6.0 1/3 N/S 588 1143 240

MODEL 12x20 NEMA BTU BTU EVAP CAP

NUMBER # OF PANS VOLTS AMPS H.P. PLUG WEIGHT LOAD SYSTEM BTU

SELF CONTAINED

F2952C 4 115/60/1 8.0 1/5 5-15P 418 461 1727 NA

F2956C 4 115/60/1 8.0 1/5 5-15P 439 461 1727 NA

F2962C 6 115/60/1 8.0 1/5 5-15P 487 518 1727 NA

F2975C 8 115/60/1 10.0 1/4 5-15P 589 717 2341 NA

F2980C 8 115/60/1 10.0 1/4 5-15P 600 726 2341 NA

F2987C 10 115/60/1 10.0 1/4 5-15P 637 859 2341 NA

F2999C 12 115/60/1 12.0 1/3 5-15P 725 973 2341 NA

F29110C 12 115/60/1 12.0 1/3 5-15P 744 1143 2341 NA

MODEL NUMBER SHELF MODEL

NUMBER OF SHELVES SQUARE FEET LENGTH WEIGHT

Open Shelf Equipment Stands

F17OS36 1 5.6 36” (91.4cm) 200

F17OS48 1 7.6 48” (121.9cm) 250

F17OS60 1 9.6 60” (152.4cm) 300

F17OS72 1 11.6 72” (182.9cm) 350

F17OS84 1 13.6 84” (213.4cm) 400

F17OS96 1 15.7 96” (243.8cm) 475

MODEL NUMBER 12 X 20 X 6 MODEL

NUMBER OF DRAWERS PAN CAPACITY LENGTH WEIGHT

Dry Drawer Equipment Stands

F17DD32 (1) 32” 2 32" (81.28cm) 290

F17DD46 (1) 19” & (1) 27” 3 46" (116.84cm) 350

F17DD54 (2) 27” 4 54" (137.16cm) 390

F17DD64 (2) 32” 4 64" (162.56cm) 430

F17DD73 (1) 19” & (2) 27” 5 73" (185.42cm) 475

F17DD81 (3) 27” 6 81" (205.74cm) 520

F17DD96 (3) 32” 6 96" (243.84cm) 600

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

3

F2000/F17 Series Equipment Stand Service and Installation Manual

Delfield

™

®

Specifications

MODEL NUMBER OF NUMBER OF VOLTS/HERTZ/ NEMA BTU DESIGN BTU SYSTEM

NUMBER PANS DRAWERS PHASE AMPS H.P. PLUG WEIGHT LOAD CAPACITY

Self-Contained Refrigerated Base Equipment Stands

F17C52 (2) 32” 4 115/60/1 8.0 1/5 5-15P 410 452 1727

F17C60 (2) 19” & (2) 27” 6 115/60/1 8.0 1/5 5-15P 460 556 1727

F17C68 (4) 27” 8 115/60/1 8.0 1/5 5-15P 500 632 1727

F17C78 (4) 32” 8 115/60/1 8.0 1/5 5-15P 580 726 1727

F17C87 (2) 19” & (4) 27” 10 115/60/1 10.0 1/4 5-15P 625 868 2341

F17C95 (6) 27” 12 115/60/1 10.0 1/4 5-15P 700 1001 2341

F17C110 (6) 32” 12 115/60/1 12.0 1/3 5-15P 750 1143 2341

*12” X 20” X 4” deep pans, supplied and installed by others.

MODEL NUMBER OF PAN* RECOMMENDED VOLTS/HERTZ/ BTU DESIGN EVAP. CAP.

NUMBER DRAWERS CAPACITY HP PHASE AMPS LOAD BTU WEIGHT

Remote Refrigerated Base Equipment Stands

F17R44 (2) 32” 4 1/5 115/60/1 3.0 452 120 300

F17R52 (2) 19” & (2) 27” 6 1/5 115/60/1 3.0 556 120 350

F17R60 (4) 27” 8 1/5 115/60/1 3.0 632 120 396

F17R70 (4) 32” 8 1/5 115/60/1 3.0 726 120 450

F17R79 (2) 19” & (4) 27” 10 1/4 115/60/1 6.0 868 240 525

F17R87 (6) 27” 12 1/4 115/60/1 6.0 1001 240 560

F17R102 (6) 32” 12 1/3 115/60/1 6.0 1143 240 610

*12” X 20” X 4” deep pans, supplied and installed by others.

MODEL NUMBER OF PAN* VOLTS/HERTZ/ NEMA BTU DESIGN BTU SYSTEM

NUMBER DRAWERS CAPACITY H.P. PHASE AMPS PLUG LOAD CAPACITY WEIGHT

Self-Contained Freezer Base Equipment Stands

F17FC60 (2) 32” 4 1/2 115/60/1 12.0 5-15P 1242 1776 450

F17FC76 (2) 19” & (2) 27” 6 3/4 115/60/1 16.0 5-20P 1461 2713 600

F17FC84 (4) 27” 8 3/4 115/60/1 16.0 5-20P 1647 2713 635

F17FC94 (4) 32” 8 3/4 115/60/1 16.0 5-20P 1879 2713 710

*12” X 20” X 4” deep pans, supplied and installed by others.

MODEL NUMBER OF PAN* RECOMMENDED VOLTS/HERTZ/ BTU DESIGN EVAP. CAP.

NUMBER DRAWERS CAPACITY HP PHASE AMPS LOAD BTU WEIGHT

Remote Freezer Base Equipment Stands

F17FR48 (2) 32” 4 1/2 115/60/1 10.0 1242 160 360

F17FR58 (2) 19” & (2) 27” 6 3/4 115/60/1 10.0 1461 160 400

F17FR66 (4) 27” 8 3/4 115/60/1 10.0 1647 160 475

F17FR76 (4) 32” 8 3/4 115/60/1 10.0 1879 160 560

*12” X 20” X 4” deep pans, supplied and installed by others.

4

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

Delfield

™

®

Installation

C A U T I O N

Location

This unit is intended for indoor use only. Be sure the location chosen

has a floor strong enough to support the total weight of the cabinet,

cooking equipment and contents. Re in force the floor as necessary to

provide for maximum loading, for complete weight chart, please refer to

page 7.

Good refrigeration is based on good air circulation inside and out.

Inside cabinet: Do not pack refrigerator so full that air cannot circulate.

Outside cabinet: Be sure that the unit has access to ample air to and

from the unit. If air flow is available to the rear of the unit that will help

dissipate exhaust air. In the event the unit is attached to the wall mount

brackets, it is important that air flow is available to the compressor

compartment. Allow air flow to the bottom of the unit as well, avoid hot

corners when possible. Allowing for the proper air flow and ventilation

to the compressor compartment will extend the life of the compressor as

well as ensure proper operation.

Cooking Equipment: WARNING! To assure proper operation a 2"

airspace must be maintained between the bottom of any cooking

equipment and the top of this unit. Cooking equipment must have

a barrier (i.e. bottom, drip pan) between its heat source and the top

of the equipment stand. Failure to comply with this could severely

damage the equipment stand and void all warranties.

Leveling

A level cabinet looks better and will perform better because the drain

pan will drain properly, the doors will line up with the frames properly,

and the cabinet will not be subject to undue strain.

A unit on legs will have an adjustable bullet foot on each leg, adjust

each for a level unit. A unit on casters will not be adjustable. Be sure

the unit is on a level floor, make necessary changes to the floor for

proper level.

Lock all front casters to ensure the stability of the unit.

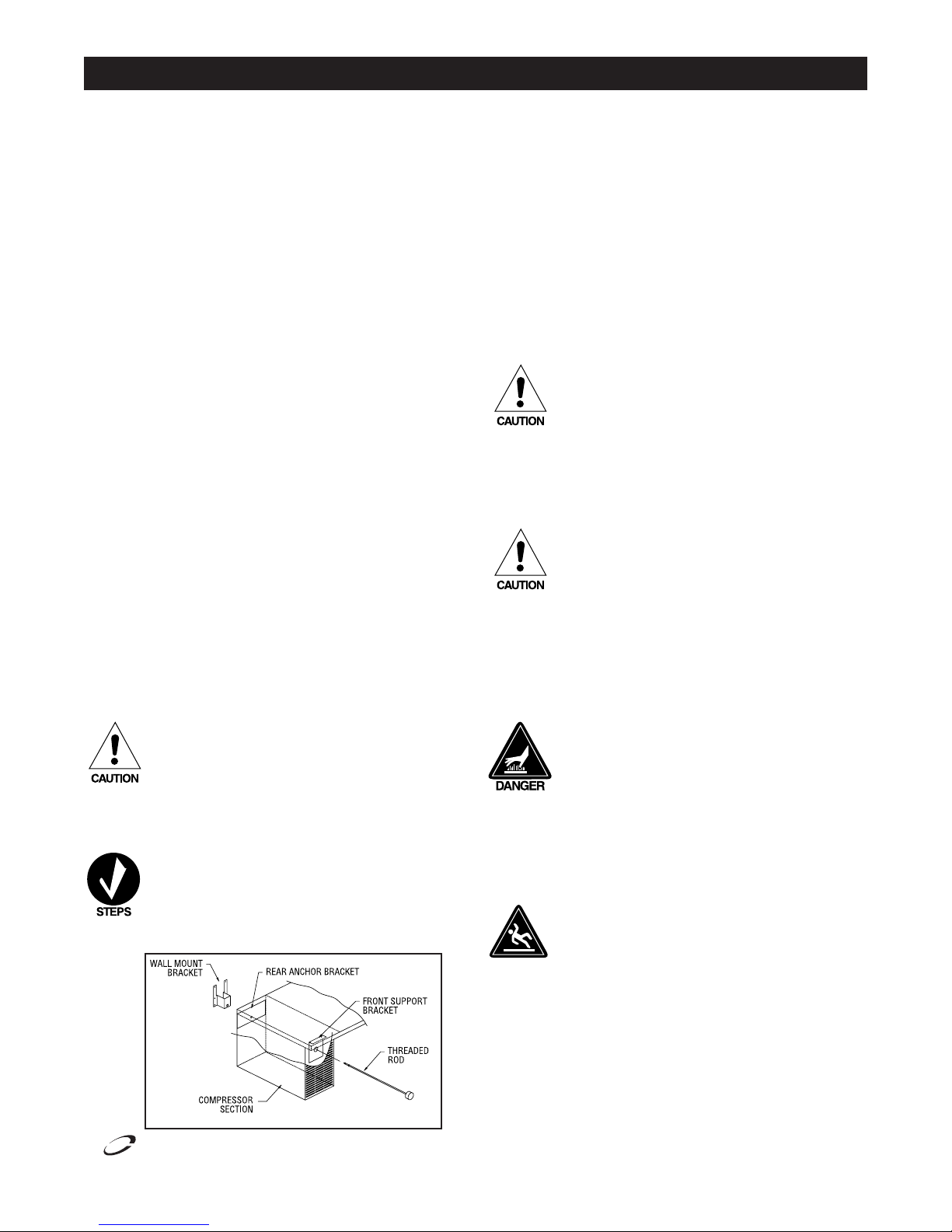

Wall bracket installation

A wall bracket kit is supplied to secure the equipment stand to an

interior wall.

The wall bracket must be installed properly and the

equipment stand firmly secured to it before using

this unit! Failure to observe this warning may result

in damage to the equipment and/or injury to the

operator! Never use the drawers as steps!

Do not overload the drawers or drop or throw product into the drawer

pans.

To install the wall bracket, follow these instructions:

1) Place the threaded rod through the front and rear

brackets in the compressor section (see diagram #1).

Thread the rod into the wall bracket, making sure the

longer bracket tabs are above the height of the unit.

2) Tighten the rod until the bracket is held snug against

the back of the unit.

Diagram #1.

Installation

of wall

bracket kit

See page 9

for part #'s

F2000/F17 Series Equipment Stand Service and Installation Manual

3) Move the unit against the wall at the desired location.

4) Secure the wall mount bracket to the wall using the top two holes

provided in the bracket tabs exposed above the unit.

The wall material must be capable of supporting a minimum load of

300 pounds (136 kilograms) in the vertical direction. All screws must

be 1/4" diameter and be capable of transferring the load from the

bracket to the wall.

5) Remove the threaded rod from the wall mount bracket and move the

unit away from the wall, leaving the bracket attached to the wall.

6) Secure the bracket to the wall using the remaining four holes.

7) Move the unit back into place and thread the rod back into the wall

mount bracket.

8) The unit should now be secured to the wall. Test the mounting by

pulling on the unit and checking that all screws are tightened and the

unit is firmly in place. If the unit is secured, you may now place other

equipment on top of the stand and use the unit as required.

Never place any equipment on top of this unit without

first installing the wall bracket as shown above and

ensuring that the equipment is securely anchored and

stable.

9) To remove the unit in order to clean behind it, first remove any

equipment placed on top of the stand. Then rotate the knob on the

threaded rod counter-clockwise to loosen and remove the rod from the

bracket.

Before removing any cooking equipment (including

cooking oils) from the equipment stand, allow time for

the equipment to cool thoroughly. Use extreme care in

moving cooking equipment.

The threaded rod must be reinstalled and tightened

before returning the unit to service!

Some models are supplied on optional casters. These units must also

have the wall bracket installed during use. Equipment stands have a

standard marine edge top.

Be sure all cooking equipment resting on the

equipment stand is properly anchored. Consult the

manufacturer’s instructions for the cooking equipment

to determine the proper mounting technique. It is

the owner’s and operator’s responsibility to securely

anchor cooking equipment to the equipment stand.

Plumbing

Self-contained equipment stands come standard with a condensate

evaporator. If the condensate evaporator fails, the unit’s drain must

have an outlet to an appropriate drainage area or container.

Moisture collecting from improper drainage can

create a slippery surface on the floor and a hazard

to employees. It is the owner’s and operator’s

responsibility to provide a con tain er or outlet for

drainage.

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

5

F2000/F17 Series Equipment Stand Service and Installation Manual

Delfield

™

®

Installation — Continued

Electrical connection

Refer to the amperage data on page 3 & 4, the serial tag, your

local code or the National Electrical Code to be sure the unit

is connected to the proper power source. A protected circuit

of the correct voltage and amperage must be run for con nection of the line cord, or permanent connection to the unit.

Operation: Refrigerated Base Equipment Stands

The on/off switch must be turned to OFF and

the unit disconnected from the power source

whenever performing service, maintenance

functions or cleaning the refrigerated area.

Under no circumstances is a self-contained

unit be operated without the louvered panel in

place.

Drawer base equipment stands are designed and pre-set at the

factory to maintain a temperature of 36°F to 40°F (2°C to 4°C).

A solar-powered digital thermometer is located on the front of

the unit to allow monitoring of the drawer housing temperature.

Pressure Control Settings

The drawer housing temperature is controlled by a pressure

control located in the machine compartment.

Minor adjustments can be made to the pressure

control setting by turning the knob in a clockwise

direction for a colder temperature or counter

clockwise for a warmer temperature. In attempting to adjust the pressure control, you can do

damage to your unit by accidentally adjusting the

differential. If you are uncertain of this procedure, we strongly recommend that adjustments

be made by a qualified service agent. Delfield is

not responsible for charges incurred while having

the pressure control adjusted.

Operation: Freezer Base Equipment Stands

Freezer base equipment stands are designed and pre-set at the

factory to maintain a temperature of 0° F (-18° C) to -5° F (-21°

C) interior cabinet temperature at 100° F (38° C) ambient room

temperature. Self-contained units have a digital thermometer

installed in the removable louver. The digital thermometer for

remote units is located in the removable access panel.

Freezers use a Paragon time clock dial (see page 7) for

automatic defrosting of the evaporator coil. See below for

instructions on setting the time of day and general operating

instructions.

T

o Set Time of Day:

Turn the knob of the Paragon time clock dial in the center of the

inner (2 hour) dial and rotate it in a counter-clockwise di rec tion.

This will rotate the outer dial. Continue turning until the correct

time of day on the outer dial lines up with the time pointer.

Operation of Paragon Timer:

The Paragon timer is preset at the factory to provide four defrosts

per day at 6:00 am., 12:00 pm, 6:00 pm and 12:00 mid night. If

it is nec es sary to change the number of de frosts due to unusual

operating conditions it can be accomplished by placing the pins in

the outer dial at the appropriate time of day that defrost initiation is

desired.

Continuous opening and closing of the drawers will hamper the

unit’s ability to maintain optimum refrigeration temperature.

Excess weight on top of the unit will adversely affect the operation of the drawers.

The cooling coil is coated in epoxy to provide long-lasting

service. However, storing all acidic items, such as peppers and

tomatoes with lids that are sealable and immediately wiping up

all spills of either acid or base items will greatly extend the life

of your unit.

Never stand on the unit or its drawers! They are

not designed to hold the weight of an adult, and

may collapse or unit may tip if misused in this

manner.

These units use HFC-404A refrigerant and have a

lock-out high pressure limiting device. Under severe

overloading conditions, in the event of a condenser

fan failure or a plugged or blocked condenser, this

device may shut down the refrigeration system.

When the defrost control goes into defrost, power to the

condensing unit and evap o ra tor fans is in ter rupt ed, and the

defrost heater is energized. The defrost heater warms the

evaporator coil thereby melting all frost ac cu mu lat ed during

the previous refrigeration cycle. Once all frost is eliminated, the

temperature of the coil continues to rise until it reaches 70°F

(27°C). When this temperature is sensed by the defrost limit

control, the defrost control switches to refrigeration mode.

If for any reason the timer remains in defrost for a period of

time greater than 40 minutes, a back-up defrost termination is

also provided.

This back-up is an integral part of the time clock and is set at

the factory at 40 min utes.

It can be changed in the field as fol lows: push down and rotate

pointer on inside (2 hour) dial until it is opposite desired time

period (in min utes).

Caution: Even under the most severe op er at ing con di tions, it

should not be necessary to set the back-up time greater than

60 min utes. Consult the factory if com plete de-icing of the coil

is not ac com plished within this time pe ri od.

6

For customer service, call (800) 733-8829, (800) 733-8821, Fax (989) 773-3210, www.delfield.com

Loading...

Loading...