Page 1

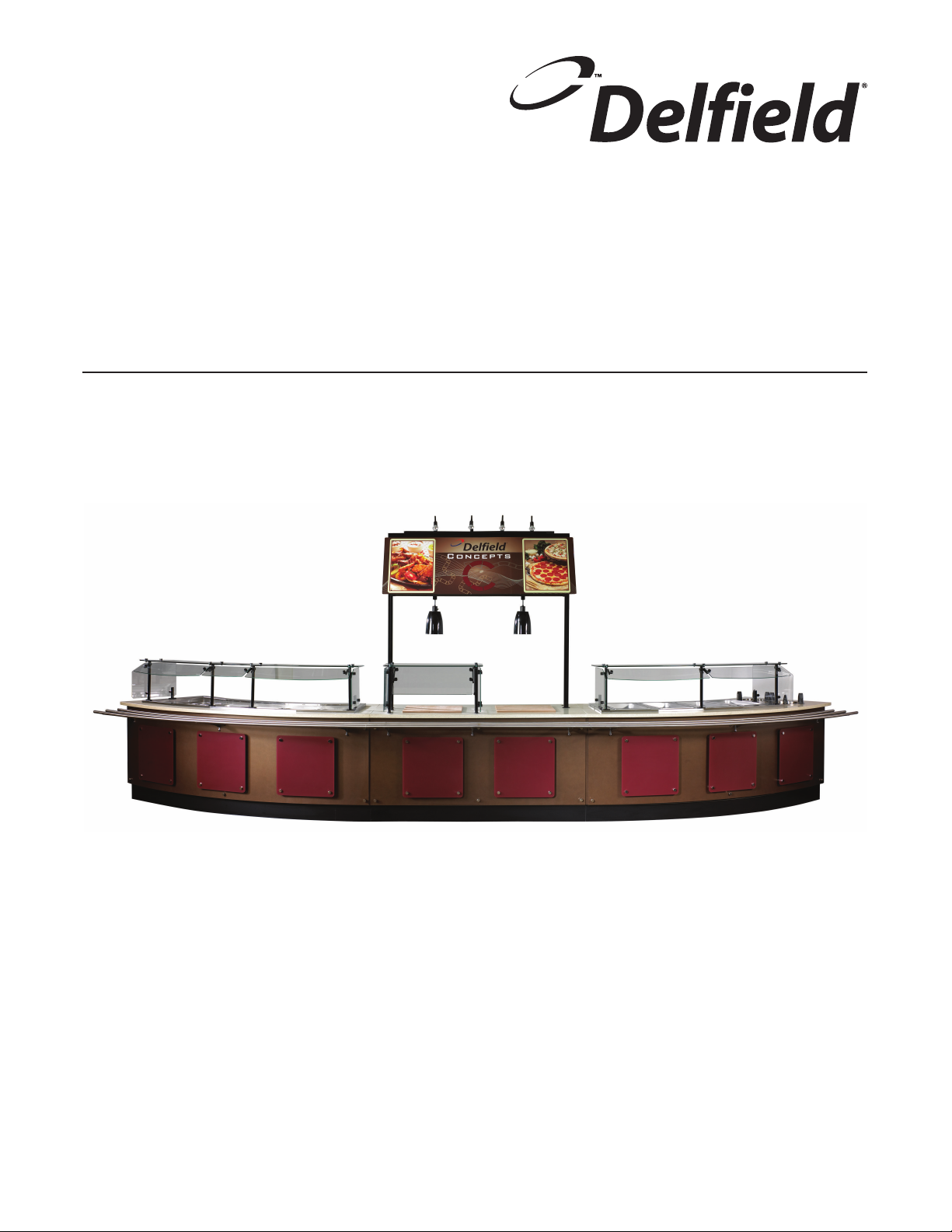

Concepts Serving Systems

Installation Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately.

February 2013

Page 2

Concepts Installation Manual

Important Warning And Safety Information

WARNING Read This Manual Thoroughly Before Operating, Installing, Or Performing Maintenance On The Equipment.

WARNING Failure To Follow Instructions In This Manual Can Cause Property Damage, Injury Or Death.

WARNING Do Not Store Or Use Gasoline Or Other Flammable Vapors Or Liquids In The Vicinity Of This Or Any Other

Appliance.

WARNING Unless All Cover And Access Panels Are In Place And Properly Secured, Do Not Operate This Equipment.

WARNING This Appliance Is Not Intended For Use By Persons Who Lack Experience Or Knowledge, Unless They Have

Been Given Supervision Or Instruction Concerning Use Of The Appliance By A Person Responsible For Their

Safety.

WARNING This Appliance Is Not To Be Played With.

WARNING Do Not Clean With Water Jet.

WARNING Do Not Use Electrical Appliances Inside The Food Storage Compartment Of This Appliance.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

• Keep the equipment area free and clear of combustible material.

• Allow adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification plate.

• Unplug the unit before making any repairs.

• Retain this manual for future reference.

2

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 3

Contents

Receiving & Inspecting The Equipment ....................................3

Serial Number Information ........................................................ 4

Warranty Information ................................................................. 4

Regulatory Certifications ............................................................ 4

Tools & Supplies Required ........................................................ 5

Line Up Installation ................................................................6-7

Beverage Counter Installation .................................................... 8

Tower Module Installation .......................................................... 9

Fixed Height Signage Installation ............................................10

Signage Lighting Installation ..................................................11

FlexiShield® Food Shields Installation ................................... 12

Mobile Hand Sink Installation ................................................. 12

Wiring Diagrams .................................................................13-15

Concepts Installation Manual

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should be

taken during unloading so the equipment is not damaged while

being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported to

the delivering carrier immediately.

2. If damaged, open and inspect the contents with the carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally as

well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10 days

from receipt of the equipment.

5. Check the lower portion of the unit to be sure legs or

casters are not bent.

6. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

7. Freight carriers can supply the necessary damage forms

upon request.

8. Retain all crating material until an inspection has been

made or waived.

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid. If the unit is on casters it

can be "rolled" off the skid.

The units with LiquiTec technology cold pans contain

a non-toxic eutectic fluid within a sealed inner liner.

This fluid may leak if the tank is punctured so care

must be taken when uncrating and setting in place.

The eutectic fluid is non-toxic and may be flushed

down a disposal drain. If the LiquiTec unit cold pans

leak, immediately call the Delfield service department

directly at 1-800-733-8821 not your local service

agent.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

3

Page 4

Concepts Installation Manual

Serial Number Information

If your unit is heated, the serial tag is located above the louvered

panel near the on/off switch.

Refrigerated units have the serial tag located in the compressor

area near the on/off switch.

Understorage units often have the serial tag located on the left

inside the storage area.

All purpose counters, utility equipment or delivery carts do

not require serial numbers but a model tag is placed at the top

of the pylon on the back of the unit.

Always have the serial number of your unit available when

calling for parts or service.

This manual covers standard units only. If you have a custom

unit, consult the customer service department at the number

listed below.

©2013 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited.

“Delfield” is a registered trademarks of The Delfield Company.

Warranty Information

Visit http://www.delfield.com/minisite/service/warranty_info to:

• Register your product for warranty.

• Verify warranty information.

• View and download a copy of your warranty.

Regulatory Certifications

All Models are certified by:

National Sanitation Foundation (NSF)

Electical models are also certified by:

Underwriters Laboratories (UL)

Underwriters Laboratories of Canada (ULC)

4

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 5

Tools And Supplies Required

The following tools are either required or will make the installation

easier:

1) A scissor jack to lift and hold heavy units off the floor so that legs can be

adjusted, allowing the proper leveling of the units.

2) A level is needed to assist in the leveling of each unit from front to back and

left to right. A 2’ (61cm) level is a must; a 4’ (122cm) level is also desirable.

3) Two 6’ (183cm) pipe clamps are useful in pulling equipment tightly together

while fasteners are installed. This results in a better spline.

4) Vise grips will hold backsplash bars together as they are being bolted together.

5) A steel hammer and a block of wood can be used to make minor alterations of

the stainless steel along the seam between two units, in order to perfect the

seam. This is used after the units are splined.

Concepts Installation Manual

6) A rubber mallet.

7) A socket set.

8) Phillips, hex head and straight blade screwdrivers.

9) 7/16” (1.1cm), 9/16” (1.4cm) and 1/2” (1.3cm) open end wrenches.

10) Silicone sealant; Dow Corning #732 is ideal.

11) Drill motor.

12) Electrical test meter.

13) 5/16 nut driver to remove shipping braces.

14) Adjustable wrench for leg adjustments.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

5

Page 6

Concepts Installation Manual

Line Up Installation

1. Identify where the equipment will be installed.

• Units represented in this manual are for indoor use only.

• Be sure the location chosen has a floor strong enough to support

the total weight and contents. Call the factory if necessary to

determine total weight. Reinforce the floor as necessary to

provide for maximum loading.

• Do not install heated units near combustible objects or surfaces

affected by heat or moisture.

• For the most efficient refrigeration, be sure to provide good air

circulation inside and out.

• Inside refrigerated cabinet: Do not pack unit so full that air cannot

circulate. Take care not to block air flow to the fans and allow

space along the sides.

• Outside refrigerated cabinet: Be sure the unit has access to ample

air; avoid hot corners and locations near stoves and ovens. It is

suggested the rear of the unit be no less than two inches from

any wall, partition or any other object which will restrict exhaust

air flow.

• Lift units by ribs at designated places. Stickers provided. See

Photos 1 and 2.

Photo 1. The units should be lifted

by the bracing only

2. Study lineup, floor plan and utility connections to determine order of

installation. Place Unit #1.

3. Remove the galvanized shipping braces from the bottom of the unit.

4. Screw adjustable feet all the way in on the first unit. Level to work

height, usually 36” or as specified.

5. Level Unit #1 front to back and left to right by adjusting the bullet feet.

6. Use caution when placing units together to protect against damaging

the laminate.

7. Place Unit #2.

8. There are (approximately 3) holes along the top and bottom sides.

Thread a 1/4-20 x 1” bolt through the unit 1 bracing hole, two supplied

washers and unit 2 bracing hole. Secure with a nut. Repeat for each

hole. Do not tighten until Unit #2 is level.

9. Level Unit #2 front to back and left to right by adjusting the bullet feet.

10. Tighten the nuts and bolts that connect Unit #1 and #2.

Photo 2. DO NOT lift the units by

anything but the bracing

11. Repeat steps 6-10 as you add each additional unit.

11. Connect the electrical quick connects in the bases.

12. Have the top installed. Verify it is secure and level.

6

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Photo 3. First view of units placed

next to each other

Page 7

Line Up Installation, continued

13. Install cold pans into unit. Ensure the gasket is visible. If there is no

gasket, silicone the seams.

14. Install hot wells into unit. Ensure the gasket is visible. If there is no

gasket, silicone the seams.

15. Make plumbing and drain connections on cold pans and hot wells.

Moisture collecting from improper drainage can create a

slippery surface on the floor and a hazard to employees. It is the

CAUTION

owner’s responsibility to provide proper drainage.

Concepts Installation Manual

16. Plumb drains if necessary.

17. Plumb water lines if necessary.

18. Make electrical connections on cold pans and hot wells. Install hot

well control panel.

19. Install the kick plate (if required) by placing the shoulder bolt into the

key hole slot. See Photo 6. Install screws on end caps as necessary.

The kick plate will stay in place but can also be easily removed for

cleaning under the units.

20. Back panels may be removed by unscrewing the hex head screws.

21. Install counter protector as necessary.

22. Install signage, lighting and food shields as required. Instructions are

found on the following pages.

23. Unit is ready for final utility hookups.

24. Install tray slides.

25. Before the heated units are used the first time for serving:

Turn the temperature knob to “10” and heat the well for 15 minutes.

Do not be alarmed if small amount of smoke appears; this preheat

should burn off any residue or dust that has adhered to the food well

element.

Photo 4. Second view of units

placed next to each other

Photo 5. Third view of units placed

next to each other

26. Check electrical outlets for proper operation.

27. Function test all equipment.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Photo 6. Kick plate shoulder bolt

installed in the key hole slot

7

Page 8

Concepts Installation Manual

Beverage Counter Installation

1. Identify where the equipment will be installed.

2. Remove the galvanized shipping braces from the bottom of the unit.

3. Place Unit #1.

4. Screw adjustable feet all the way in on the first unit. Level to work

height, usually 36” or as specified.

5. Level Unit #1 front to back and left to right by adjusting the bullet feet.

6. Use caution when placing units together to protect against damaging

the laminate.

7. Place Unit #2.

8. There are (approximately 3) holes along the top and bottom sides.

Thread a 1/4-20 x 1” bolt through the unit 1 bracing hole, two supplied

washers and unit 2 bracing hole. Secure with a nut. Repeat for each

hole. Do not tighten until Unit #2 is level.

9. Level Unit #2 front to back and left to right by adjusting the bullet feet.

10. Tighten the nuts and bolts that connect Unit #1 and #2.

11. Repeat steps 6-10 as you add each additional unit.

12. Have the top installed. Verify it is secure and level.

13. Plumb drains if necessary.

14. Plumb water lines if necessary.

15. Install the kick plate (if required) by placing the shoulder bolt into the

key hole slot. See Photo 6. Install screws on end caps as necessary.

The kick plate will stay in place but can also be easily removed for

cleaning under the units.

16. Back panels may be removed by unscrewing the hex head screws.

17. Beverage counter weight limit is 600 pounds per 48 linear inches.

18. If the beverage counter has a drop in unit, ensure the gasket in visible.

If there is no gasket, silicone the seams around the drop in.

8

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 9

Tower Module Installation

1. Identify where the equipment will be installed.

2. Level the flanged feet and bolt to the floor.

3. Install the gooseneck lighting:

Note: The side of the connection post with (2) metallic tabs

aligns with the side of the track with the (2) copper strips.

A. Pull down on the connection box collar, push the connection

post into the track and then rotate it 90 degrees until it locks

into place.

B. If the light is mounted with the (2) metallic tabs toward the

side of the track with only (1) copper strip, the light will not

work. To correct this, simply pull down on the connection

box collar and twist it until it is released from the track.

Then, rotate it 180 degrees and mount back into the track

using the directions above.

C. To move the light, pull down on the connection box collar

and twist 90 degrees. Slide to the desired location and turn

back 90 degrees.

Concepts Installation Manual

4. Follow installation instructions provided with menu boards (if

this option was ordered with the tower module).

5. Verify the module is plugged into a receptacle and the Reach-In

is plugged into the GFCI receptacle. If lights were provided, turn

on the ON/OFF switch on the back of the tower.

6. Slide the Reach-In in place.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

9

Page 10

Concepts Installation Manual

Fixed Height Signage Installation

1. Verify that black square collars are mounted in the 2”

square holes in the unit top. If they are not, locate them

in the crate and place them back in the holes in top.

2. Make sure the push pins are removed from the mounting

brackets in the bottom of the base.

3. With a person supporting each post of the signage, pick

up and hold vertically over top of the collared holes in

top.

4. If electrical cord is coming out the bottom of one of the

posts, lower it through the collared hole.

5. Next, lower signage posts down through collared holes

in top.

6. Secure in place by sliding push pin through bracket and

post.

7. If electrical cord is present, plug into the outlet in the

base.

Prepare base.

Signage post installed in base.

10

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 11

Signage Lighting Installation

To mount decorative lamps:

Note: The connection post with (2) metallic tabs aligns with

the side of the track with the (2) copper strips

1. Pull down on the tab on the side of the lamp’s connection

box, push the connection post up into the track, then

rotate it 90 degrees until the connector locks into place.

2. If the light is mounted with the (2) metallic tabs toward

the side of the track with only (1) copper strip, the light

will not work. To correct this, simply pull down on the

tab on the side of the lamp’s connection box and twist it

90 degrees until it releases from the track. Then, rotate

it 180 degrees and mount back into the track using the

directions above.

Concepts Installation Manual

Locate the metallic tabs and strips.

To mount flexible spotlights:

Note: The side of the connection post with (2) metallic tabs

aligns with the side of the track with the (2) copper strips.

1. Pull down on the connection box collar, push the connection

post up into the track and then rotate it 90 degrees until it

locks into place.

2. If the light is mounted with the (2) metallic tabs toward

the side of the track with only (1) copper strip, the light

will not work. To correct this, simply pull down on the

connection box collar and twist it until it is released from

the track. Then, rotate it 180 degrees and mount back into

the track using the directions above.

3. To move the light, pull down on the connection box collar

and twist 90 degrees. Slide to the desired location and turn

back 90 degrees.

4. Turn switch ON.

Decorative lamp installation steps.

5. Check for proper operation.

Flexible spotlight installation steps.

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

11

Page 12

Concepts Installation Manual

FlexiShield® Food Shields Installation

1. Set food shield on base unit. See Figure 1.

2. Line base over holes.

• Install screws (provided) into predrilled holes. See Figure 2.

• Place 2 dabs of silicone on screws and place cover over screws.

3. Make any necessary electrical connections.

4. If applicable test lights, heat lamps etc.

5. Adjust glass for proper alignment and ensure that all hardware is

tightened securely.

6. Clean food shield and glass with mild soap and water.

FlexiShield® food shields are to be used as food and counter protection

only and should not be used in any other way.

Mobile Hand Sink Installation

The hand sink is to be used for hand washing

only, not for consumption.

Hot water heater MUST be filled with water

before connecting the water heater to power

to prevent damage to the heater.

The fresh water and waste water containers are located in

the base of the sink compartment on the right. The fresh

water containers are on the left with clear vinyl tubing

and waste water tanks are on the right with a rigid drain

tube. Two fresh water and two waste water containers

are provided with each unit.

To add water to the fresh water container, remove the

cap the vinyl tubing is connected to on the container by

pressing the button on the cap and pull out the cap from

the container. Pull the container out of the sink base and

unscrew the cap of the fill access hole at the back of the

container. Fill the container with water and screw the cap

back on at the back of the container and push the cap with

the vinyl tubing back into place at the front. Make sure

there are no kinks in the clear vinyl tubing.

Verify the black waste arm at the end of the drain line is in

the hole on the waste container.

Before Operating The Sink:

Water heater MUST be filled with water before connecting

the water heater to power to prevent damage to the heater.

Before plugging the sink into a wall receptacle, verify the

water pump only is plugged into the GFCI receptacle in

the base of the unit. If the water heater is plugged in,

unplug it until the heater has been filled with water. Put

the switch and the breaker to the “ON” position in the

base of the unit. Make sure the GFCI receptacle is ON.

To fill the water heater with water, turn on the hot water

handle on the faucet until water flows. When water flows

into the sink, the water heater is filled with water. The

water heater can now be plugged into the GFCI receptacle.

Verify the water heater power switch on the front of the

heater is ON. The red light on the switch will stay on until

it has reached the set temperature.

Figure 1. Food shield over holes

Figure 2. Flange dimensions

12

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 13

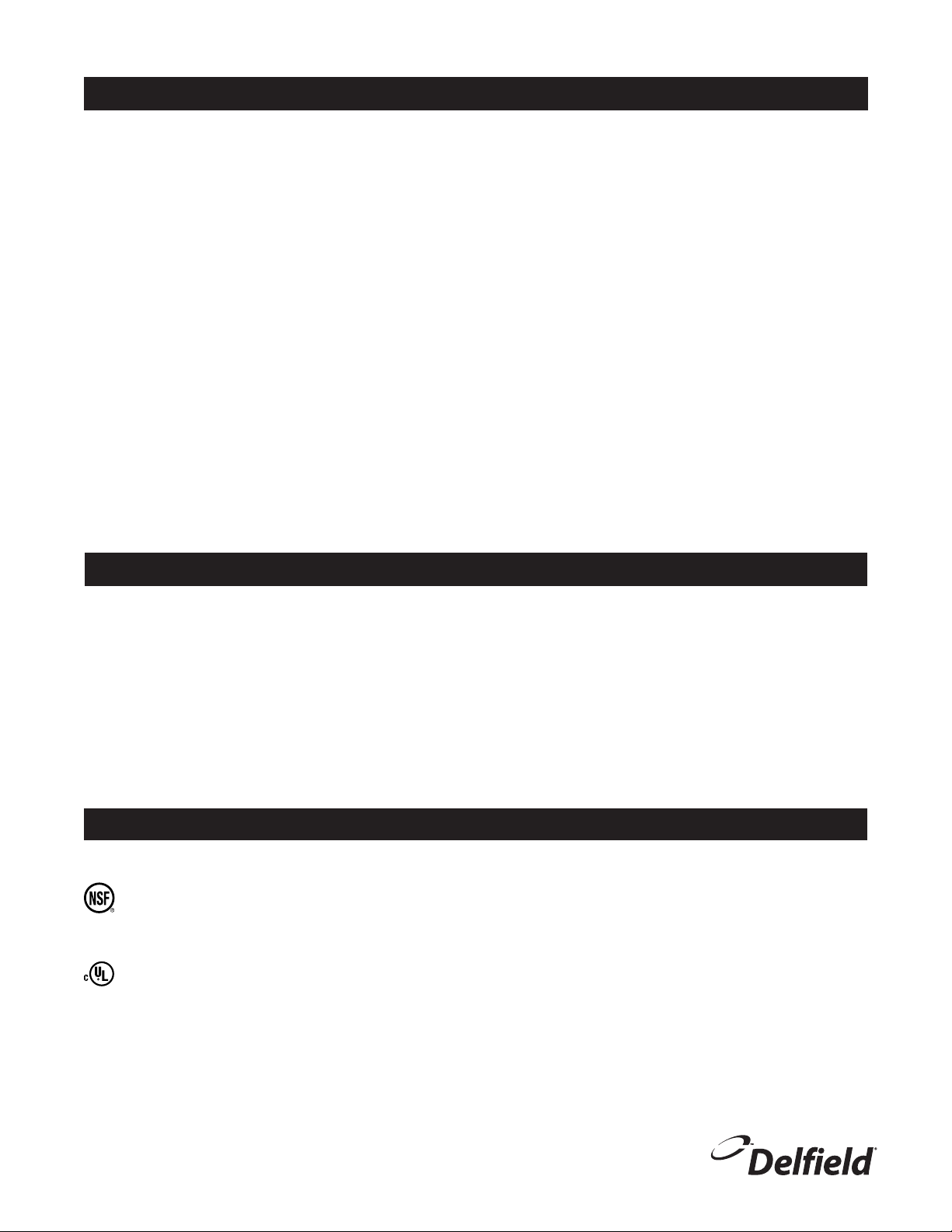

Wiring Diagram, Heated Serving Counter

PILOT LIGHT

(FURNISHED)

Concepts Installation Manual

LINE

WIRES

#

OF

WARMERS

1

2

3

4

5

6

L1 G L2

TO ADDITIONAL

FOOD WARMERS

AMPERES

120V,

PHASE

1

1 PHASE

H1

H2

208V,

P

L1

L2

INFINITE CONTROL

WITH “OFF”

POSITION

IN LINE

WIRES

230V,

PHASE

1

8.3 4.8 5.3

16.7 9.6 10.6

25 14.4 15.9 14.4/15.9

33.3 19.2 21.3

24 26.6

28.8 31.3

19.2/21.3

24/26.1

28.8/31.3

1000 W - 120V

OR 1000/1222 W -

208-230 V

HEATING ELEMENT

208-230V, 3 PHASE

L1 L2 L3

14.4/15.9

19.2/21.3

19.2/21.3

28.8/31.3

14.4/15.9

14.4/15.9

19.2/21.3

28.8/31.3

L1 L2 G L3

30A SWITCH

(OPTIONAL)

HA–1

HA–2

HA–3

HA–4

HA–5

HA–6

HA = HEATER ASSEMBLY

20A, 3–POLE SWITCH

(OPTIONAL)

HA–1

HA–2

HA–4

HA–5

ALL WIRING

MINIMUM 14 AWG

HA = HEATER ASSEMBLY

Standard Single Phase Optional Three Phase

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

250C

HA–3

HA–6

13

Page 14

Concepts Installation Manual

Wiring Diagram, Self-Contained Mechanically Cooled Serving Counter

CONDENSER FAN

S

L1

COOLING T'STAT

N

G

C

R

COMPRESSOR

115V

Wiring Diagram, Self-Contained LiquiTec® Cold Pan Serving Counter

ON/OFF SWITCH

L1

CONDENSER FAN

S

C

R

COOLING T'STAT

COMPRESSOR

120V

N

G

Wiring Diagram, Self-Contained Frost Top Serving Counter

ON/OFF SWITCH

L1

N

G

CONDENSER FAN

S

C

R

COMPRESSOR

115V

14

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

Page 15

Wiring Diagram, Tower Module

Concepts Installation Manual

Wiring Diagram, Mobile Hand Sink

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.deleld.com

15

Page 16

Mt. Pleasant, MI

Covington, TN

Thank you for choosing Delfield!

Help is a phone call away. Help our team of professional, courteous customer

service reps by having your model number and serial number available at the time

of your call (800) 733-8829.

Model: _______________________ S/N: ______________________

Installation Date: _______________

For a list of Delfield’s authorized parts depots,

visit our website at www.delfield.com

Register your Deleld warranty

online. Go to www.deleld.com

under the service tab to complete.

980 S. Isabella Rd., Mt. Pleasant, MI 48858, U.S.A. • (989) 773-7981 or (800) 733-8829 • Fax (989) 773-3210 • www.deleld.com

Deleld reserves the right to make changes in design or specications without prior notice. ©2013 The Deleld Company. All rights reserved. Printed in the U.S.A.

DMCNCPTInstall 02/13

9291466

Loading...

Loading...