DeDietrich MODULENS O AFC 18, MODULENS O AFC 24, MODULENS O AFC 30 Installation And Service Manual

Page 1

Export

MODULENS O

Oil-fired condensing boilers

®

AFC 18 - AFC 24 - AFC 30

EN

Installation and

Service Manual

300026439-07

Page 2

Declaration of conformity [

C003918-A

The device complies with the standard type described in

the EG declaration of conformity. It was manufactured and

commissioned in accordance with European directives.

The original declaration of conformity is available from the

manufacturer.

Page 3

Contents

1 Safety instructions .....................................................................................6

1.1 Safety instructions ...............................................6

1.2 Recommendations ................................................7

1.3 Liabilities ...............................................................8

1.3.1 Manufacturer’s liability .............................................8

1.3.2 Installer’s liability .....................................................8

2 About this manual ......................................................................................9

2.1 Symbols used .......................................................9

2.1.1 Symbols used in the manual ...................................9

2.1.2 Symbols used on the equipment .............................9

2.2 Abbreviations ......................................................10

2.3 After Sales Service Internet Site .......................10

3 Technical specifications ..........................................................................11

3.1 Homologations ....................................................11

3.1.1 Certifications .........................................................11

3.1.2 Oil category ...........................................................11

3.1.3 Additional Directives ..............................................11

3.1.4 Factory test ...........................................................12

3.2 Technical specifications ....................................12

3.2.1 Boiler specifications ..............................................12

3.2.2 Burner specifications .............................................14

3.2.3 Sensor characteristics ...........................................14

4 Product description .................................................................................15

4.1 General description ............................................15

4.2 Operating principle .............................................15

4.2.1 Skeleton Diagrams ................................................15

4.2.2 Circulation pump ...................................................20

4.2.3 Water flow rate ......................................................20

4.2.4 Burner operating cycle ..........................................20

09/07/2015 - 300026439-07

4.3 Main parts ............................................................25

4.3.1 Boiler .....................................................................25

4.3.2 Fuel oil burner .......................................................26

4.4 Package list .........................................................26

4.4.1 Standard delivery ..................................................26

4.4.2 Accessories ...........................................................27

1

Page 4

Contents

5 Installation ................................................................................................29

5.1 Regulations governing installation ...................29

5.2 Choice of the location ........................................30

5.2.1 Type plate .............................................................30

5.2.2 Positioning of the appliance ..................................30

5.2.3 Ventilation .............................................................32

5.2.4 Main dimensions ...................................................33

5.3 Positioning the appliance ..................................36

5.3.1 Positioning the boiler on its own ............................36

5.3.2 Fitting the boiler to a DHW tank ............................39

5.3.3 Positioning the boiler to the left or right of a DHW

tank .......................................................................39

5.3.4 Reversal of the direction the control panel access

door opens ............................................................40

5.4 Hydraulic connections .......................................43

5.4.1 Flushing the system ..............................................43

5.4.2 Connecting the expansion vessel

(Depending on country, standard delivery or

optional) ................................................................44

5.4.3 Installing the deaerator ..........................................45

5.4.4 Hydraulic connection of the heating circuit ............46

5.4.5 Connection of the water circuit for domestic

use ........................................................................46

5.4.6 Connecting the condensate discharge pipe ..........46

5.4.7 Filling the condensate trap ....................................48

5.5 Oil connection .....................................................48

5.5.1 General .................................................................48

5.5.2 Connecting ............................................................49

5.5.3 Diameter and length of the oil pipes ......................49

5.6 Flue gas system connections - Depending on

country .................................................................50

5.6.1 Connections for the air and exhaust pipes - Forced

flow (forced flue) - Type C .....................................50

5.6.2 Connections for the air and exhaust pipes - Single

flow (chimney) - Type B ........................................52

5.7 Installing the outside sensor .............................57

5.7.1 Choice of the location ............................................57

5.7.2 Connecting the outside sensor ..............................58

5.8 Electrical connections ........................................59

5.8.1 Control unit ............................................................59

5.8.2 Recommendations ................................................60

5.8.3 Accessing the connection terminal blocks ............60

5.8.4 Connecting a direct heating circuit ........................62

5.8.5 Connecting a direct circuit and a circuit with 3-way

valve ......................................................................63

5.8.6 Connecting a direct heating circuit and a domestic hot

water tank ..............................................................65

5.8.7 Connecting a direct heating circuit and an

independent domestic hot water tank ...................68

09/07/2015 - 300026439-07

2

Page 5

5.8.8 Connecting two circuits and a domestic hot water

tank .......................................................................70

5.8.9 Connecting two heating circuits with pressure

breaker ..................................................................72

5.8.10 Hot water storage tank connection ........................73

5.8.11 Pool connection .....................................................80

5.8.12 Connecting a mixed tank .......................................82

5.8.13 Connecting the options .........................................83

5.8.14 Connection in cascade ..........................................84

5.9 Electrical diagram ...............................................86

5.9.1 Boiler .....................................................................86

5.9.2 Burner ...................................................................88

5.10 Filling the system ...............................................89

5.10.1 Water treatment ....................................................89

5.10.2 Filling the heating circuit ........................................90

5.10.3 Filling the drinking water circuit .............................91

6 Commissioning ........................................................................................92

6.1 Control panel .......................................................92

6.1.1 Description of the keys ..........................................92

6.1.2 Description of the display ......................................93

6.1.3 Access to the various browsing levels ..................96

6.1.4 Browsing in the menus ..........................................97

6.2 Checks and settings before

commissioning ...................................................98

6.2.1 Preparing the boiler for commissioning .................98

6.3 Putting the appliance into operation ................98

6.4 Setting the burner ...............................................99

6.4.1 Operations to be carried out before any attempt to set

the burner ..............................................................99

6.4.2 Setting the burner’s 3 operating outputs .............100

6.4.3 Checking combustion ..........................................101

6.5 Checks and adjustments after

commissioning .................................................102

6.5.1 Displaying the parameters in extended

mode ...................................................................102

6.5.2 Setting the parameters specific to the

installation ...........................................................102

6.5.3 Naming the circuits and generators ....................107

6.5.4 Setting the heating curve ....................................108

6.5.5 Finalizing work ....................................................110

6.6 Reading out measured values .........................110

09/07/2015 - 300026439-07

6.7 Changing the settings ......................................111

6.7.1 Language selection .............................................112

6.7.2 Calibrating the sensors .......................................112

6.7.3 Professional settings ...........................................114

6.7.4 Configuring the network ......................................122

6.7.5 Return to the factory settings ..............................125

3

Page 6

Contents

7 Switching off the appliance ...................................................................126

7.1 Installation shutdown .......................................126

7.2 Antifreeze protection ........................................126

8 Checking and maintenance ...................................................................128

8.1 General instructions .........................................128

8.2 Chimney sweep instructions ...........................128

8.3 Customising maintenance ...............................129

8.3.1 Maintenance message ........................................129

8.3.2 Contact details of the professional for After Sales

Support ................................................................131

8.4 Standard inspection and maintenance

operations .........................................................131

8.4.1 Checking the hydraulic pressure .........................132

8.4.2 Checking the tightness of the flue gas discharge, the

air inlet and the condensates discharge ..............132

8.4.3 Checking the automatic air vent ..........................132

8.4.4 Cleaning of the heating body ..............................133

8.4.5 Cleaning the siphon ............................................137

8.4.6 Checking and replacing the installation’s oil

filter .....................................................................138

8.4.7 Maintenance of the burner ..................................138

8.5 Specific maintenance operations ....................142

8.5.1 Replacing the ignition electrodes ........................143

8.5.2 Maintenance of the air/flue gas drain connection

flues .....................................................................144

9 Troubleshooting .....................................................................................145

9.1 Anti-hunting ......................................................145

9.2 Messages (Code type Bxx or Mxx) ..................145

9.3 Message history ................................................148

9.4 Faults (Code type Lxx or Dxx) .........................148

9.4.1 Deletion of sensors from the memory in the

PCB .....................................................................154

9.5 Failure history ...................................................155

9.6 Parameter and input/output check (mode

tests) ..................................................................156

9.6.1 Control system sequence ....................................159

09/07/2015 - 300026439-07

4

Page 7

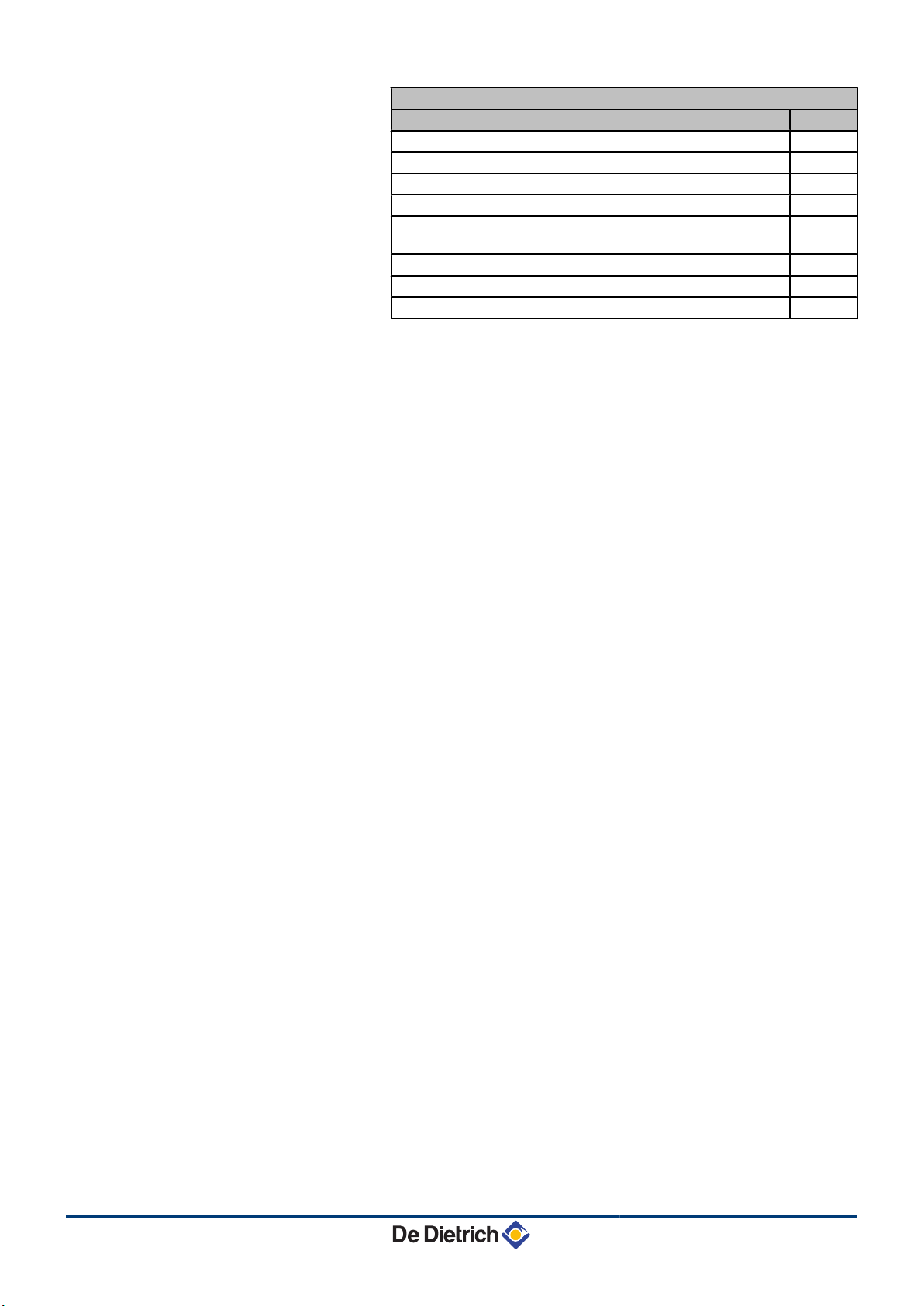

10 Spare parts ..............................................................................................161

10.1 General ..............................................................161

10.2 Spare parts ........................................................162

10.2.1 Boiler body - Tank - Base - Fuel oil burner .........162

10.2.2 Hydraulics ...........................................................165

10.2.3 Expansion vessel 18 litres (Depending on country,

standard delivery or optional) ..............................166

10.2.4 Casing .................................................................167

10.2.5 Control panel .......................................................168

10.2.6 Fuel oil burner (Details) .......................................169

10.2.7 Spare parts list ....................................................170

11 Appendix – Information on the Ecodesign and Energy Labelling

Directives ................................................................................................174

09/07/2015 - 300026439-07

5

Page 8

1. Safety instructions AFC 18 - AFC 24 - AFC 30

1 Safety instructions

1.1 Safety instructions

DANGER

This appliance can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they have

been given supervision or instruction concerning

use of the appliance in a safe way and

understand the hazards involved. Children shall

not play with the appliance. Cleaning and user

maintenance shall not be made by children

without supervision.

DANGER

If you smell flue gases:

1. Switch the appliance off.

2. Open the windows.

3. Trace possible leaks and seal them

immediately.

WARNING

Depending on the settings of the appliance:

4 The temperature of the flue gas conduits

may exceed 60°C.

4 The temperature of the radiators may reach

95°C.

4 The temperature of the domestic hot water

may reach 80°C (depending on the set point

temperature and activation of the

antilegionella function).

CAUTION

4 Before any work, switch off the mains supply

to the appliance.

4 Avoid direct contact with the flame viewport.

6

09/07/2015 - 300026439-07

Page 9

AFC 18 - AFC 24 - AFC 30

1.2 Recommendations

1. Safety instructions

WARNING

4 Installation and maintenance of the boiler

must be carried out by a qualified

professional in compliance with prevailing

local and national regulations.

4 When carrying out work on the boiler,

always switch off the boiler at the mains and

close the main oil inlet.

4 After maintenance or repair work, check all

installations to ensure that there are no

leaks.

CAUTION

The boiler must be installed in a frost-free

environment.

Keep this document close to the place where the

boiler is installed.

Casing components

Only remove the casing for maintenance and repair

operations. Put the casing back in place after

maintenance and repair operations.

Instructions stickers

The instructions and warnings affixed to the appliance

must never be removed or covered and must remain

legible during the entire lifespan of the appliance.

Immediately replace damaged or illegible instructions and

warning stickers.

Modifications

Modifications to the boiler may only be carried out with the

written approval of your supplier.

09/07/2015 - 300026439-07

7

Page 10

1. Safety instructions

1.3 Liabilities

AFC 18 - AFC 24 - AFC 30

1.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the

requirements of the various applicable European

Directives. They are therefore delivered with [ marking

and all relevant documentation.

In the interest of customers, we are continuously

endeavouring to make improvements in product quality.

All the specifications stated in this document are therefore

subject to change without notice.

Our liability as the manufacturer may not be invoked in the

following cases:

4 Failure to abide by the instructions on using the

appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the

appliance.

1.3.2. Installer’s liability

The installer is responsible for the installation and

commissioning of the appliance. The installer must

respect the following instructions:

4 Read and follow the instructions given in the manuals

provided with the appliance.

4 Carry out installation in compliance with the prevailing

legislation and standards.

4 Perform the initial start up and carry out any checks

necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the

obligation to check the appliance and maintain it in

good working order.

4 Give all the instruction manuals to the user.

8

09/07/2015 - 300026439-07

Page 11

D000241-C

AFC 18 - AFC 24 - AFC 30

2 About this manual

2.1 Symbols used

2.1.1. Symbols used in the manual

In these instructions, various danger levels are employed to draw the

user’s attention to particular information. In so doing, we wish to

safeguard the user’s safety, highlight hazards and guarantee correct

operation of the appliance.

2. About this manual

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

2.1.2. Symbols used on the equipment

4

~

Protective earthing

Alternating current

Before installing and commissioning the device, read

carefully the instruction manuals provided.

Dispose of the used products in an appropriate recovery

and recycling structure.

09/07/2015 - 300026439-07

This appliance must be connected to the protective earth.

9

Page 12

1 2

M002628-A

2. About this manual AFC 18 - AFC 24 - AFC 30

Caution: danger, live parts.

Disconnect the mains power prior to any operations.

2.2 Abbreviations

4 3CE: Collective conduit for sealed boiler

4 3WV: 3-way valve

4 PCU: Primary Control Unit - PCB for managing burner operation

4 PSU: Parameter Storage Unit - Parameter storage for PCBs

PCU and SU

4 SCU: Secondary Control Unit - DIEMATIC iSystem control panel

PCB

4 SU: Safety Unit - Safety PCB

4 DHW: Domestic hot water

4 Hi: Lower heating value LHV (Nett)

4 Hs: Higher heating value HHV (Gross)

4 HL: High Load - DHW tank with plate exchanger

4 SL: Standard Load - DHW tank with coil

4 SHL: Solar High Load - Solar DHW tank with plate exchanger

4 MC: Boiler module

4 CFC: Chlorofluorocarbon

2.3 After Sales Service Internet Site

The QR code or flashcode is used to access the internet site

containing the documentation and technical information regarding the

product. The QR code also appears on the appliance’s nameplate.

10

09/07/2015 - 300026439-07

Page 13

AFC 18 - AFC 24 - AFC 30 3. Technical specifications

3 Technical specifications

3.1 Homologations

3.1.1. Certifications

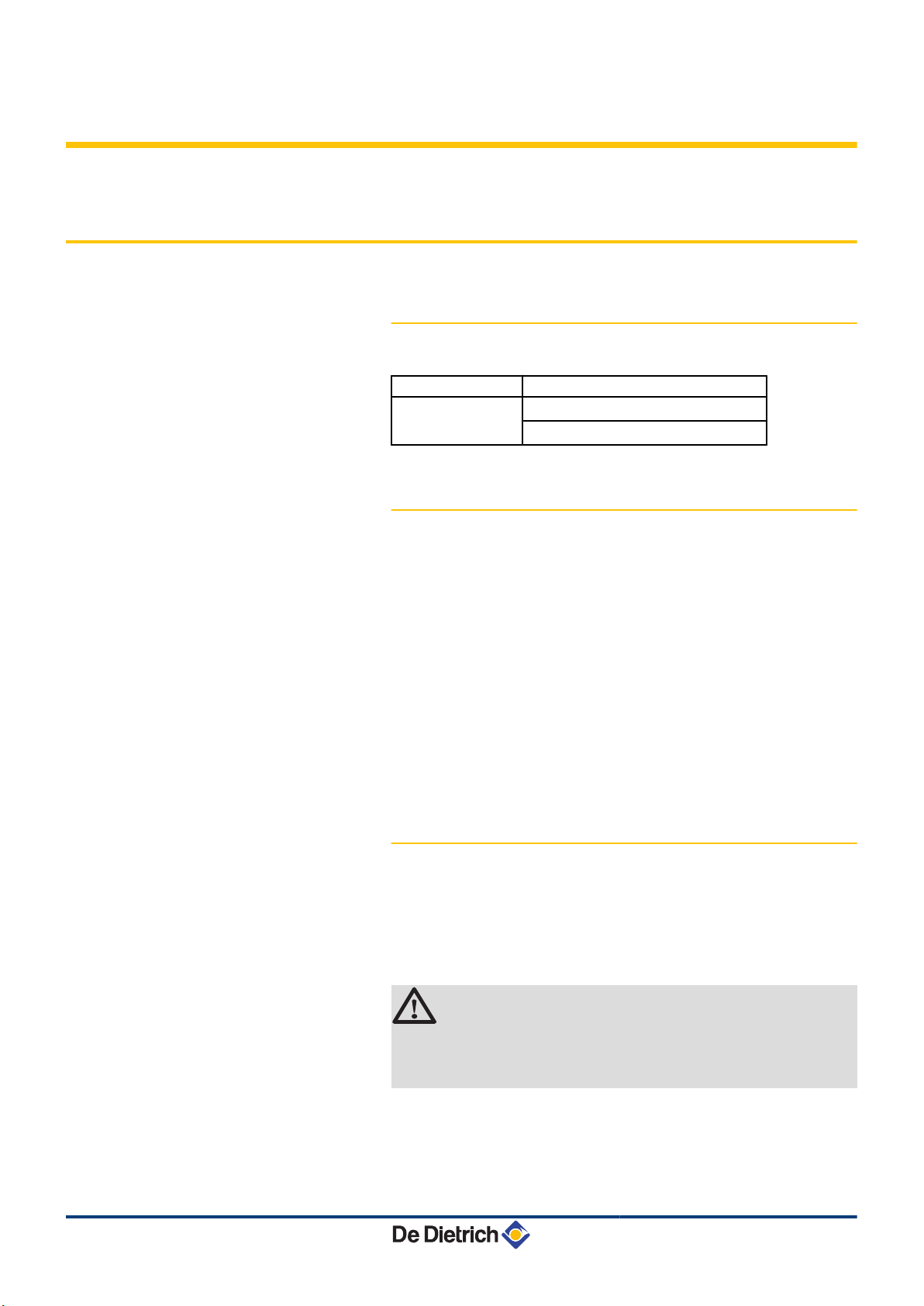

CE identification no

Type of connection Chimney: B23, B

CE : 1312 CN 5691

Flue gas outlet: C

23P

13(x)

, C

33(x)

, C

93(x)

3.1.2. Oil category

4 Standard oil as well as low sulfur content oil (max. viscosity 6 mm²/

s at 20°C)

4 Bio-oil max. B10 (max. viscosity 6 mm2/s at 20°C).

- The bio-fuel oil B10 (or Bio 10) is a mixture of fuel oil with low

sulfur content (< 50 mg/kg) supplemented with 5.9 to 10.9 %

FAME* (% in volume).

- The bio-fuel oil B5 (or Bio 5) is a mixture of fuel oil with low sulfur

content (< 50 mg/kg) supplemented with 3 to 5.9 % FAME* (%

in volume).

- FAME* is produced from vegetable oil or processed animal fat.

EMAG: Fatty Acid Methyl Ester (also called EMAG : Ester

Méthylique d’Acide Gras).

3.1.3. Additional Directives

09/07/2015 - 300026439-07

Apart from the legal provisions and Directives, the additional

Directives described in these instructions must also be observed.

For all provisions and Directives referred to in these instructions, it is

agreed that all addenda or subsequent provisions will apply at the

time of installation.

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

11

Page 14

3. Technical specifications AFC 18 - AFC 24 - AFC 30

3.1.4. Factory test

Before leaving the factory, each boiler is set for optimum performance

and tested to check the following items:

4 Electrical safety

4 Adjustment (CO2)

4 Water tightness

4 Oil tightness

4 Checked the tightness of the combusted gas outlet and air inlet

4 Parameter settings.

On commissioning, the installer is responsible for checking

the items mentioned above and, where necessary,

correcting them.

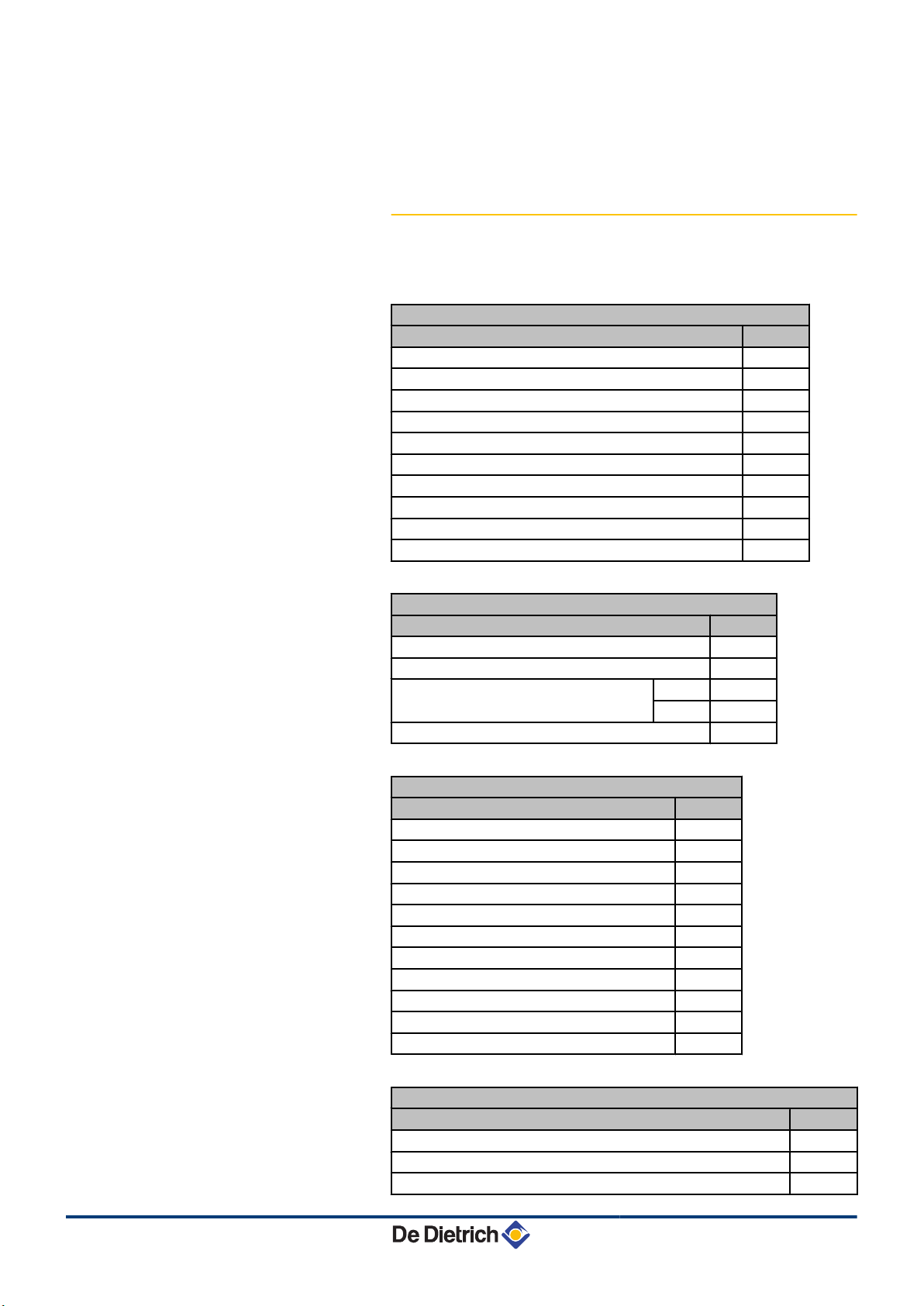

3.2 Technical specifications

3.2.1. Boiler specifications

Test conditions:

4 CO2 of 12% at min output and 13% at max output with oil.

4 Maximum operating pressure - Primary circuit (heating water):

3 bar (0.3 MPa)

4 Maximum operating temperature: 85 °C

4 Boiler temperature: Adjustable from 30 to 90 °C

4 Safety thermostat: 105 °C

4 Min flow temperature: 20°C

4 Min. return temperature : 20°C

4 Ambient temperature: 20 °C

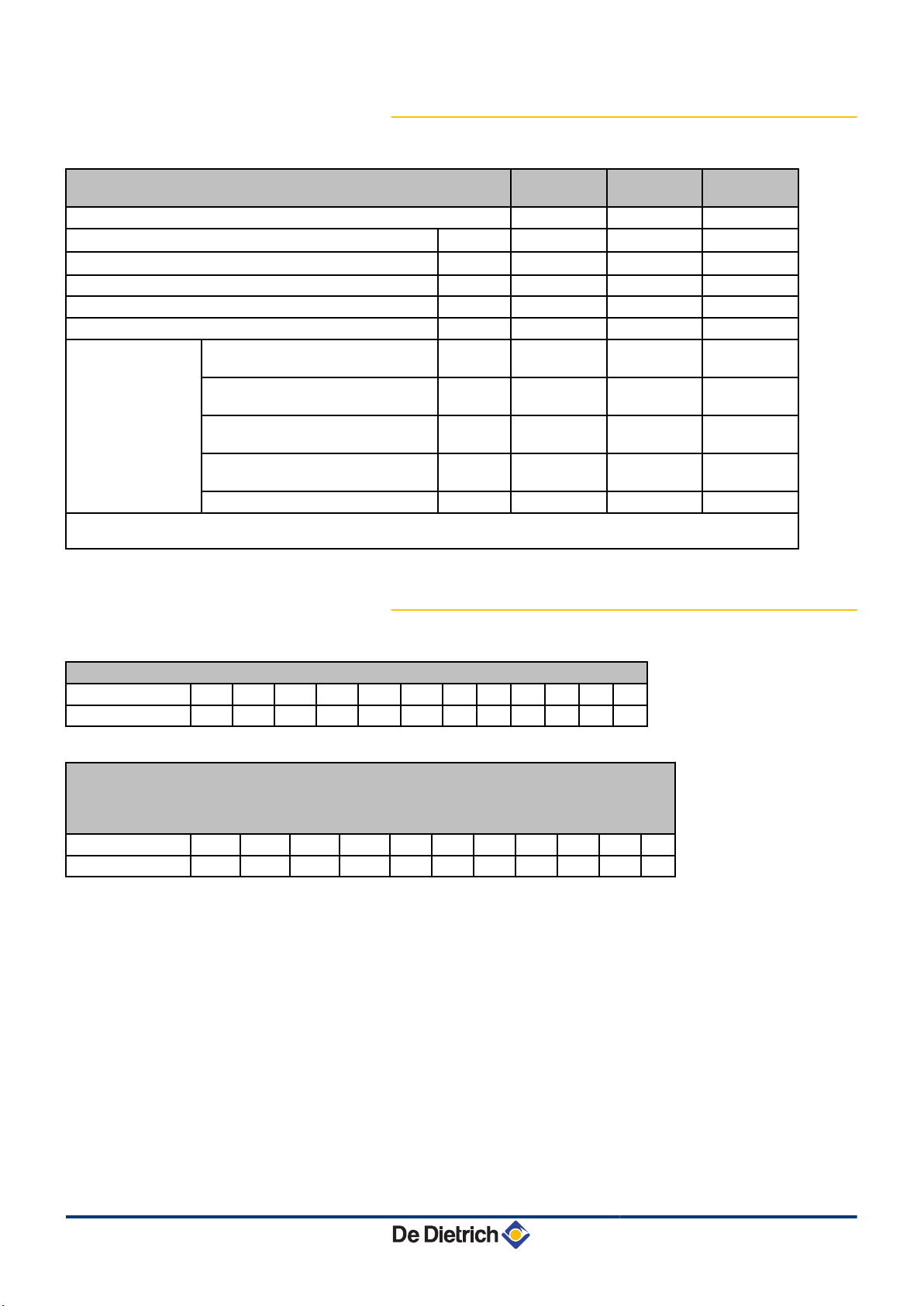

Boiler

Power input (Hi) kW 10.4 17.6 13.9 23.5 17.4 29.4

Nominal output (Pn) at 40/30°C kW 10.7 18.2 14.3 24.3 17.8 30.3

Nominal output (Pn) at 50/30°C

Nominal output (Pn) at 80/60°C kW 10 17.1 13.4 22.8 16.7 28.6

(1) These values are pertinent for flexible flue gas evacuation systems with a diameter of 80 mm (rigid ducts). The length of rigid flue gas

evacuation systems is restricted to 18 metres for technical reasons relating to start-up.

(2) 1 mbar = 10 mmWG = 100 Pa

kW

AFC 18 AFC 24 AFC 30

Minimum

power

10.6 18 14.1 24 17.6 30

Full

power

Minimum

power

Full

power

Minimum

power

Full

power

12

09/07/2015 - 300026439-07

Page 15

AFC 18 - AFC 24 - AFC 30 3. Technical specifications

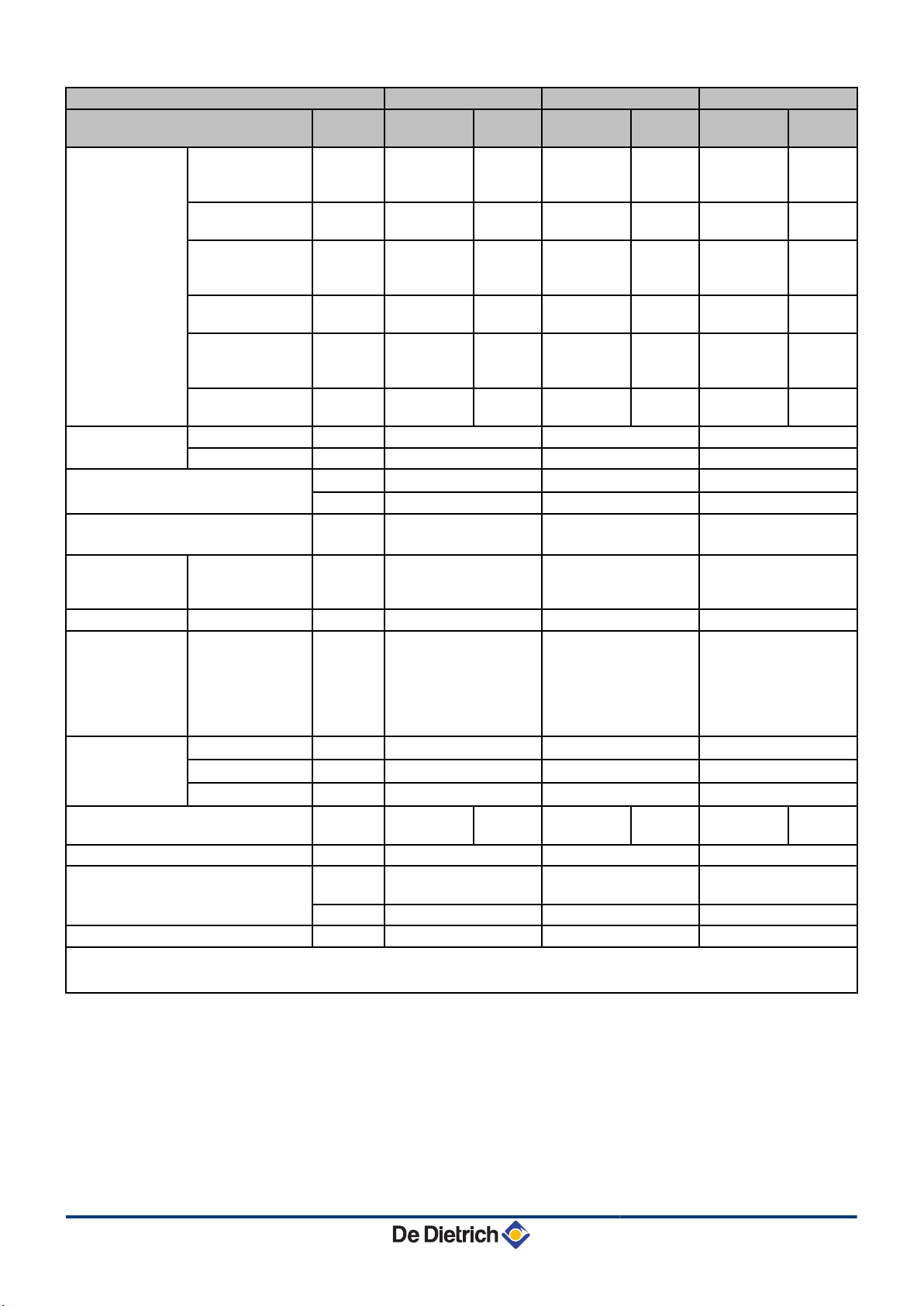

Boiler AFC 18 AFC 24 AFC 30

LHV efficiency 100 % Nominal

Minimum

power

% 96.3 97.2 96.4 97.1 95.9 97.4

Full

power

Minimum

power

Full

power

Minimum

power

Full

power

output (Pn) at

80/60°C

Flue gas

°C <60 <70 <60 <70 <65 <75

temperature

100 % Nominal

% 101.5 102.1 101.4 102 101.1 101.6

output (Pn) at

50/30°C

Flue gas

°C <40 <45 <40 <45 <45 <50

temperature

100 % Nominal

% 102.9 103.5 102.6 103.2 102.5 103

output (Pn) at

40/30°C

Flue gas

°C <40 <45 <40 <45 <45 <50

temperature

Annual efficiencyHiat 75/60°C % 101.1 100.9 100.7

at 40/30°C % 105.3 105.1 104.6

Pressure available at the flue gas

nozzle (Pn)

CO2 content (Minimum output - Start-

(1)

mbar

0.14 0.22 0.33

Pa 14 22 33

% 12 - 13 - 13 12 - 13 - 13 12 - 13 - 13

up output - Maximum output

Nominal water

ΔT = 20K

m3/h

0.773 1.032 1.291

flow rate at Pn

(50/30 °C)

Stand-by losses ΔT = 30K W 109 109 128

Percentage of

ΔT = 30K % 61 61 63

losses through

the walls

compared with

the stand-by

losses

Loss of load

hydraulic circuit

(Pn)

ΔT = 10K

ΔT = 15K

ΔT = 20K

Electrical power of the boiler only with

(2)

mbar

mbar

mbar

66.0 117.0 183.0

(2)

29.0 52.0 81.0

(2)

16.0 29.0 46.0

W 128 272 128 272 128 272

no accessories

Water content litres 47 47 58

Mass flue gas flow rate (Nominal

output Pn 50/30 °C)

kg per

sec

0.0075 0.01 0.0125

Kg/h 27 36 45

Net weight (without packaging) kg 117 117 135

(1) These values are pertinent for flexible flue gas evacuation systems with a diameter of 80 mm (rigid ducts). The length of rigid flue gas

evacuation systems is restricted to 18 metres for technical reasons relating to start-up.

(2) 1 mbar = 10 mmWG = 100 Pa

09/07/2015 - 300026439-07

13

Page 16

3. Technical specifications AFC 18 - AFC 24 - AFC 30

3.2.2. Burner specifications

Modulating burner F10E2-5.18 +

AFC 18

F10E2-5.24 +

AFC 24

F10E2-5.30 +

AFC 30

Operation Modulating Modulating Modulating

Nominal output

Fuel flow

(2)

(1)

kW 10.4 - 17.6 13.9 - 23.5 17.4 - 29.4

Kg/h 0.9 - 1.5 1.2 - 2.0 1.5 - 2.5

Modulation range % 59 - 100 59 - 100 59 - 100

air nozzle Ø 19 22 26

Nozzle Danfoss (80°S) USG 0.30 0.40 0.50

Modulating oil pump Manufacturer’s pressure margin bar (MPa) 7 - 20

(0.7 - 2.0)

Max depression bar (MPa) 0.35

(0.035)

Max permitted pressure on entry bar (MPa) 2

(0.2)

Max permitted pressure on blocking bar (MPa) 2

(0.2)

7 - 22

(0.7 - 2.2)

0.35

(0.035)

2

(0.2)

2

(0.2)

7 - 22

(0.7 - 2.2)

0.35

(0.035)

2

(0.2)

2

(0.2)

Max pump air flow at 10 bar (1 MPa) l/h 45 45 45

(1) Power at an altitude of 400 m and at a temperature of 20°C. Heating value of fuel oil: LHV = 11,86 kWh/kg

(2) Bio-oil max. B10 (max. viscosity 6 mm2/s at 20°C)

3.2.3. Sensor characteristics

Outside sensor

Temperature in °C -20 -16 -12 -8 -4 0 4 8 12 16 20 24

Resistance in Ω 2392 2088 1811 1562 1342 1149 984 842 720 616 528 454

Outlet sensor circuit B+C

Domestic hot water sensor

System sensor

Flow sensor - Return sensor NTC

Temperature in °C 0 10 20 25 30 40 50 60 70 80 90

Resistance in Ω 32014 19691 12474 10000 8080 5372 3661 2535 1794 1290 941

14

09/07/2015 - 300026439-07

Page 17

C003130-G

2

1

4

5

6

8

9

7

10

3

11

AFC 18 - AFC 24 - AFC 30 4. Product description

4 Product description

4.1 General description

Floor-standing condensing oil boiler

4 Heating only (Optional domestic hot water production in

combination with a DHW tank).

4 High efficiency heating.

4 Low pollutant emissions.

4 Modulating oil burner preassembled and preset.

4 Stainless steel heating body.

4 Top of the range electronic DIEMATIC iSystem control panel.

4 Flue gas discharge via a forced flue or chimney type connection.

4.2 Operating principle

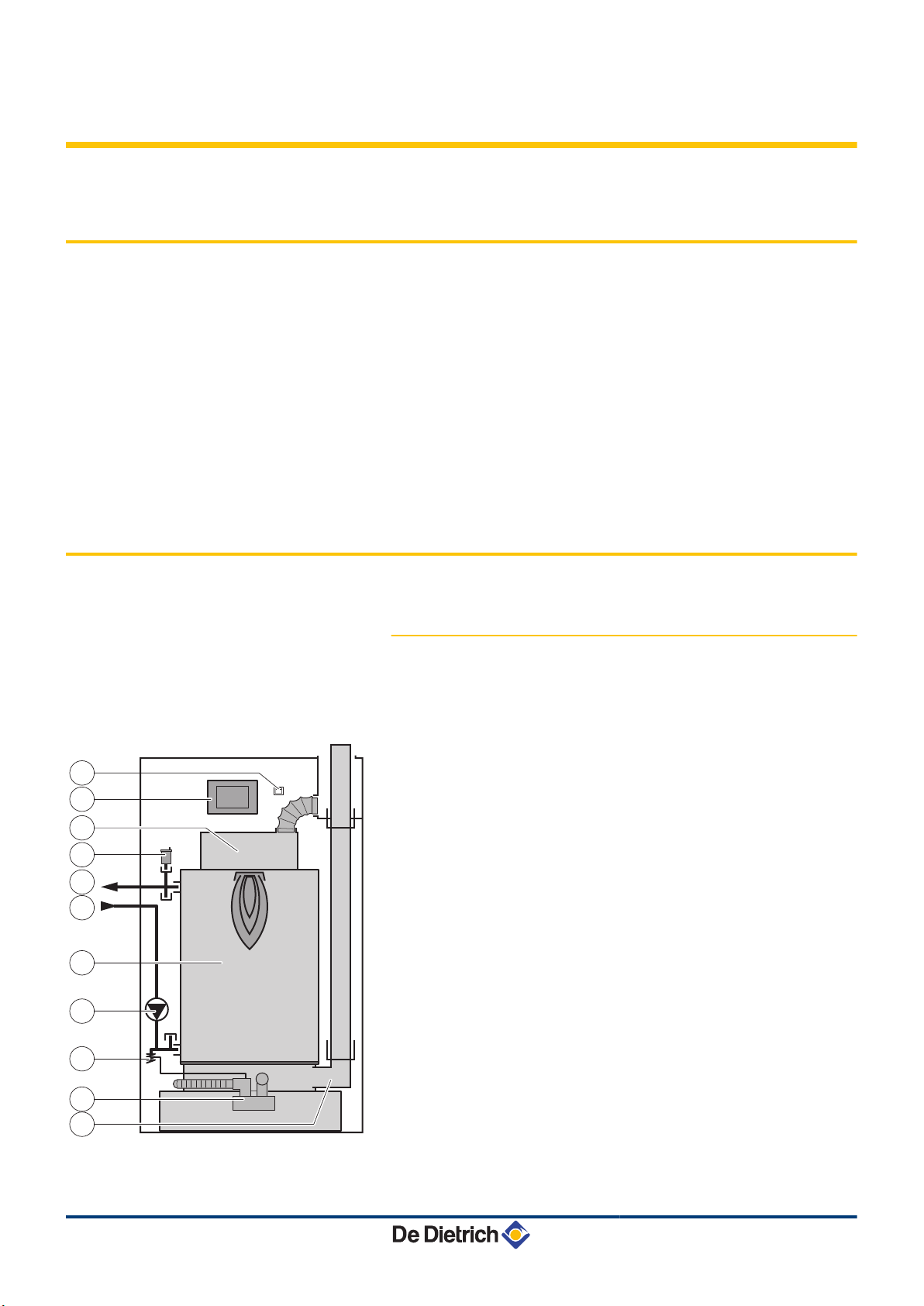

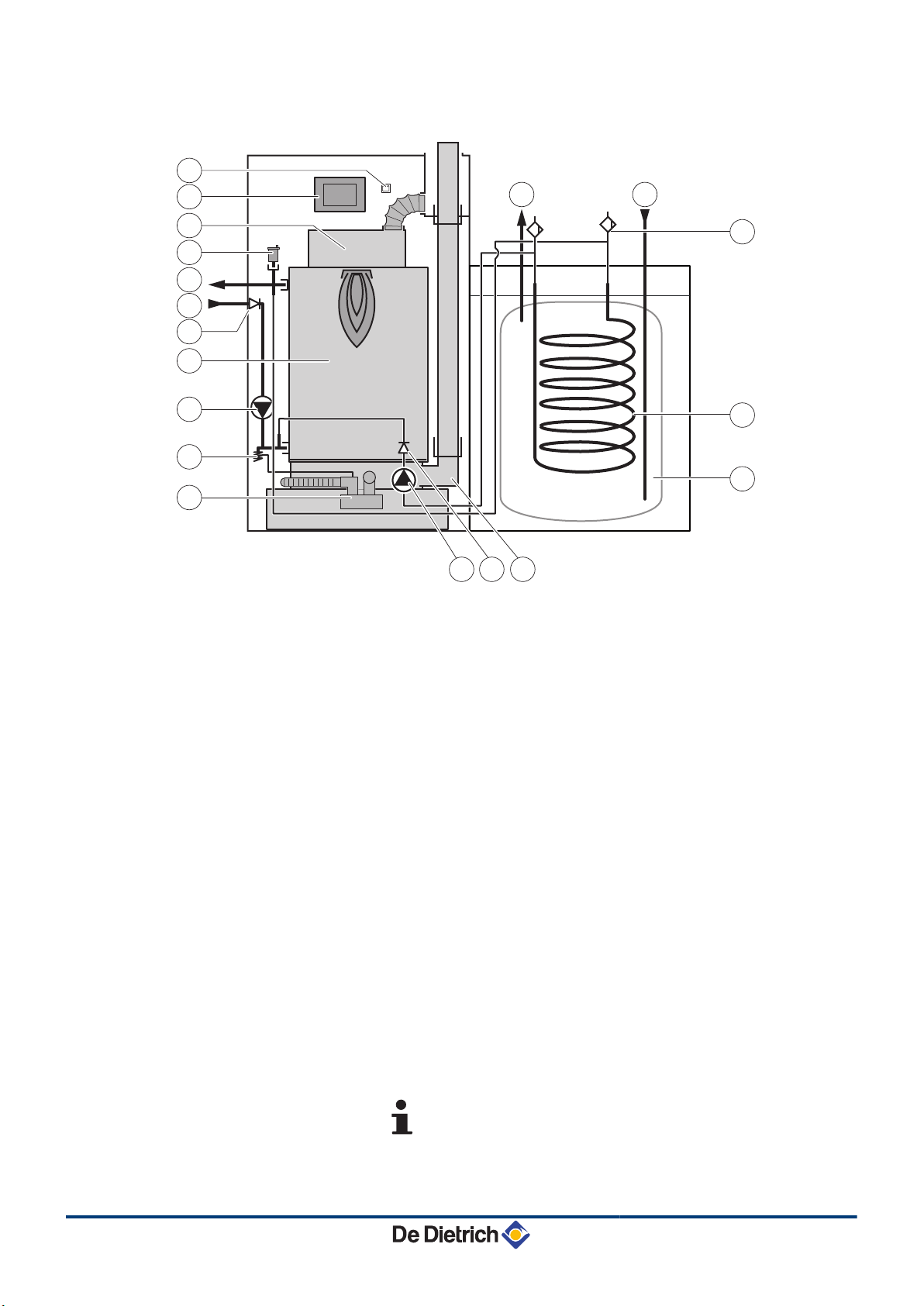

4.2.1. Skeleton Diagrams

Boiler self-standing - Circuit A

n

1

2

3

4

5

6

7

8

9

10

11

On/Off switch

Control panel

Burner

Automatic air vent

Heating flow

Heating return

Heating body

Circulation pump

0.3 MPa safety valve (3 bar)

Condensate trap

Flue gas discharge

09/07/2015 - 300026439-07

15

Page 18

12

C003131-i

4

5

6

3

8

9

7

13

14

15 1110

2

1

16

16

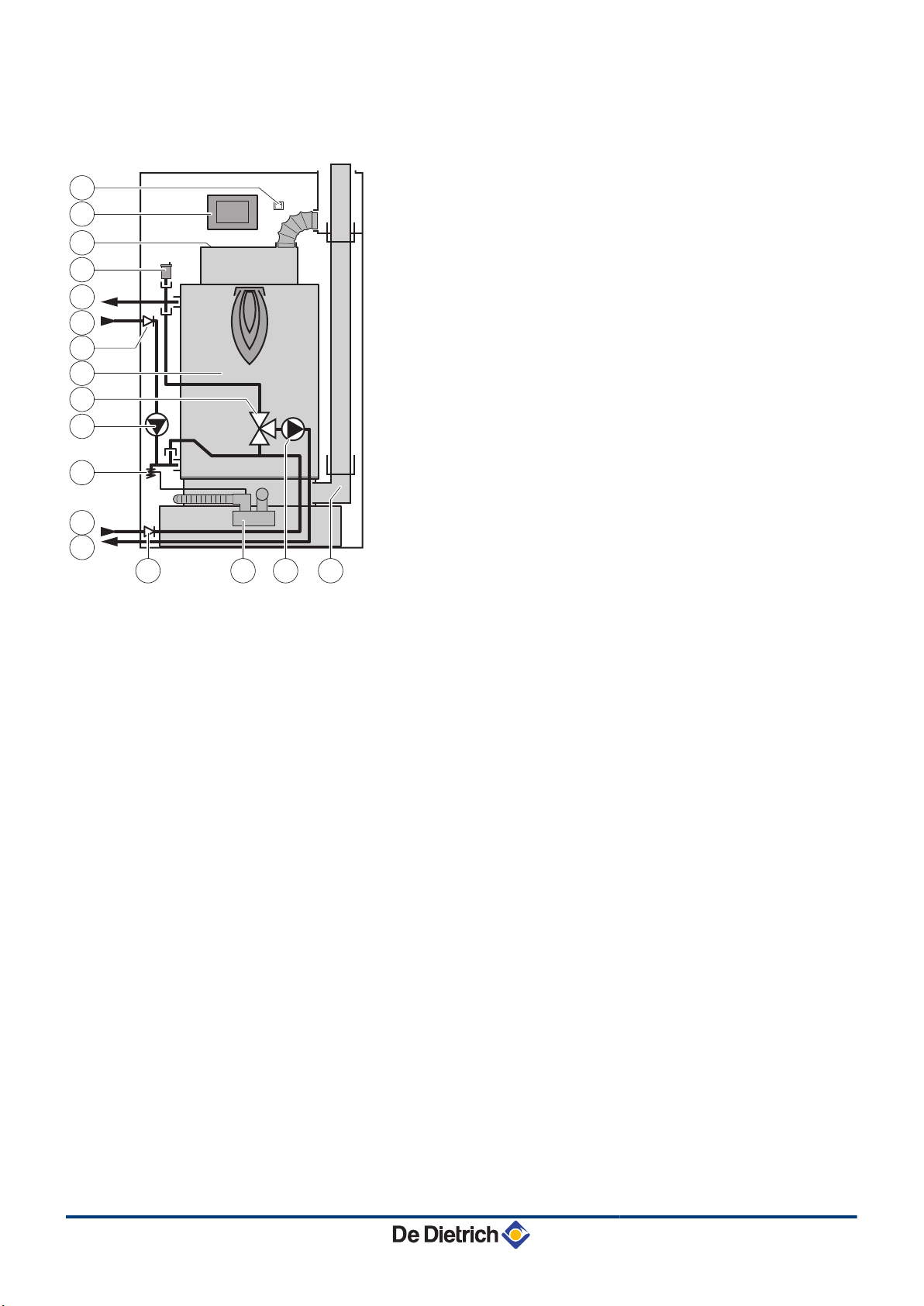

4. Product description AFC 18 - AFC 24 - AFC 30

Boiler with 3-way valve option - Circuit B (Option

n

integrable)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

On/Off switch

Control panel

Burner

Automatic air vent

Heating flow direct circuit

Heating return direct circuit

Heating body

Direct circuit circulating pump

0.3 MPa safety valve (3 bar)

Condensate trap

Flue gas discharge

3-way valve

Heating return valve circuit

Heating flow valve circuit

Heating pump circuit mixing valve

Non-return valve

16

09/07/2015 - 300026439-07

Page 19

M002429-G

2

1

4

5

6

3

16

8

9

7

10

19

20

18

17

11

16

21

22

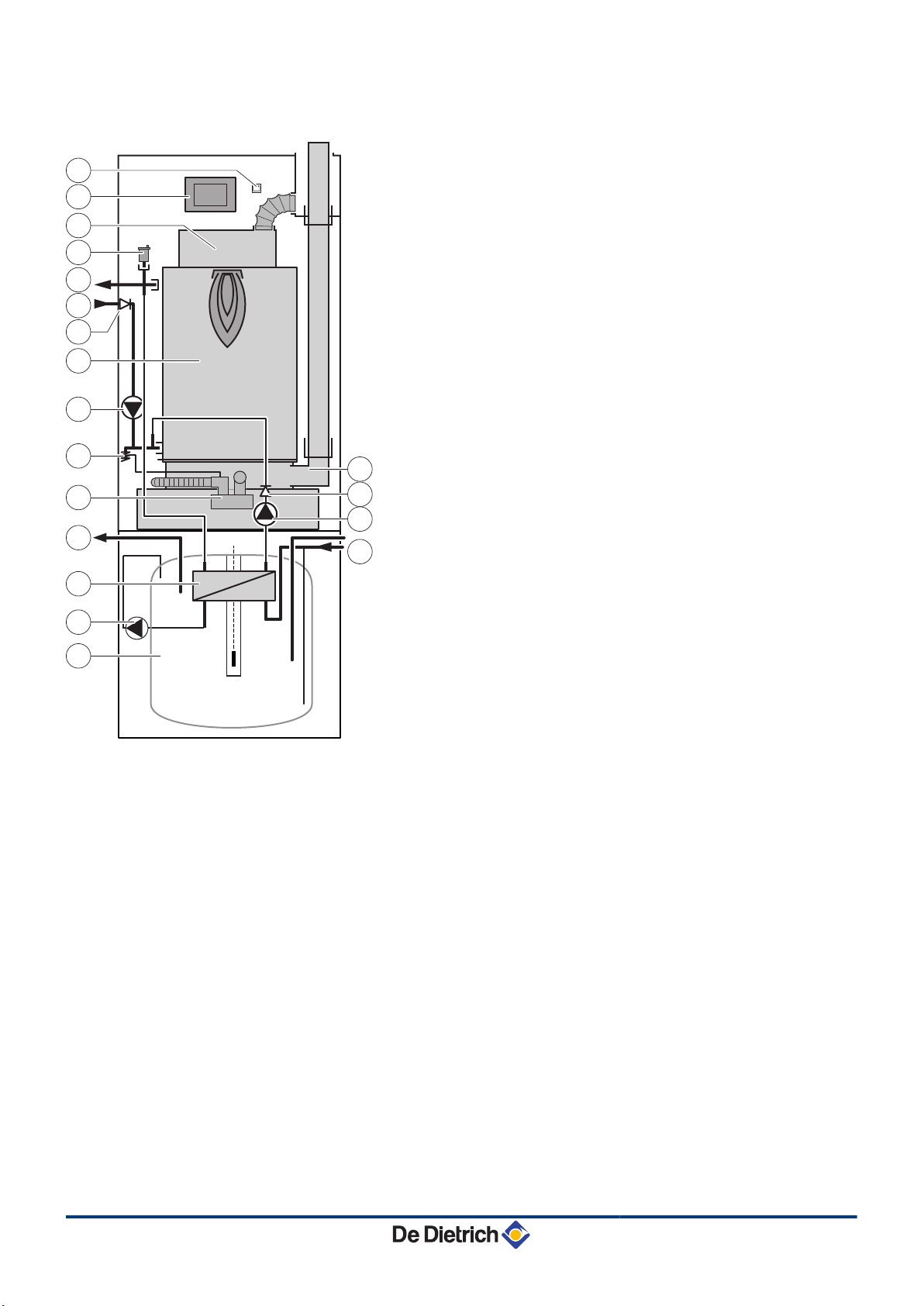

AFC 18 - AFC 24 - AFC 30 4. Product description

Boiler with 100HL type domestic hot water tank

n

1

2

3

4

5

6

7

8

9

10

11

16

17

18

19

20

21

On/Off switch

Control panel

Burner

Automatic air vent

Heating flow

Heating return

Heating body

Circulation pump

0.3 MPa safety valve (3 bar)

Condensate trap

Flue gas discharge

Non-return valve

Domestic hot water outlet

Plate heat exchanger

Domestic hot water pump

Domestic hot water tank

Primary domestic hot water load pump

22

Domestic cold water inlet

09/07/2015 - 300026439-07

17

Page 20

M002430-F

5

6

2

1

4

3

9

10

8

11

18 17

14

15

16

13712

7

4. Product description AFC 18 - AFC 24 - AFC 30

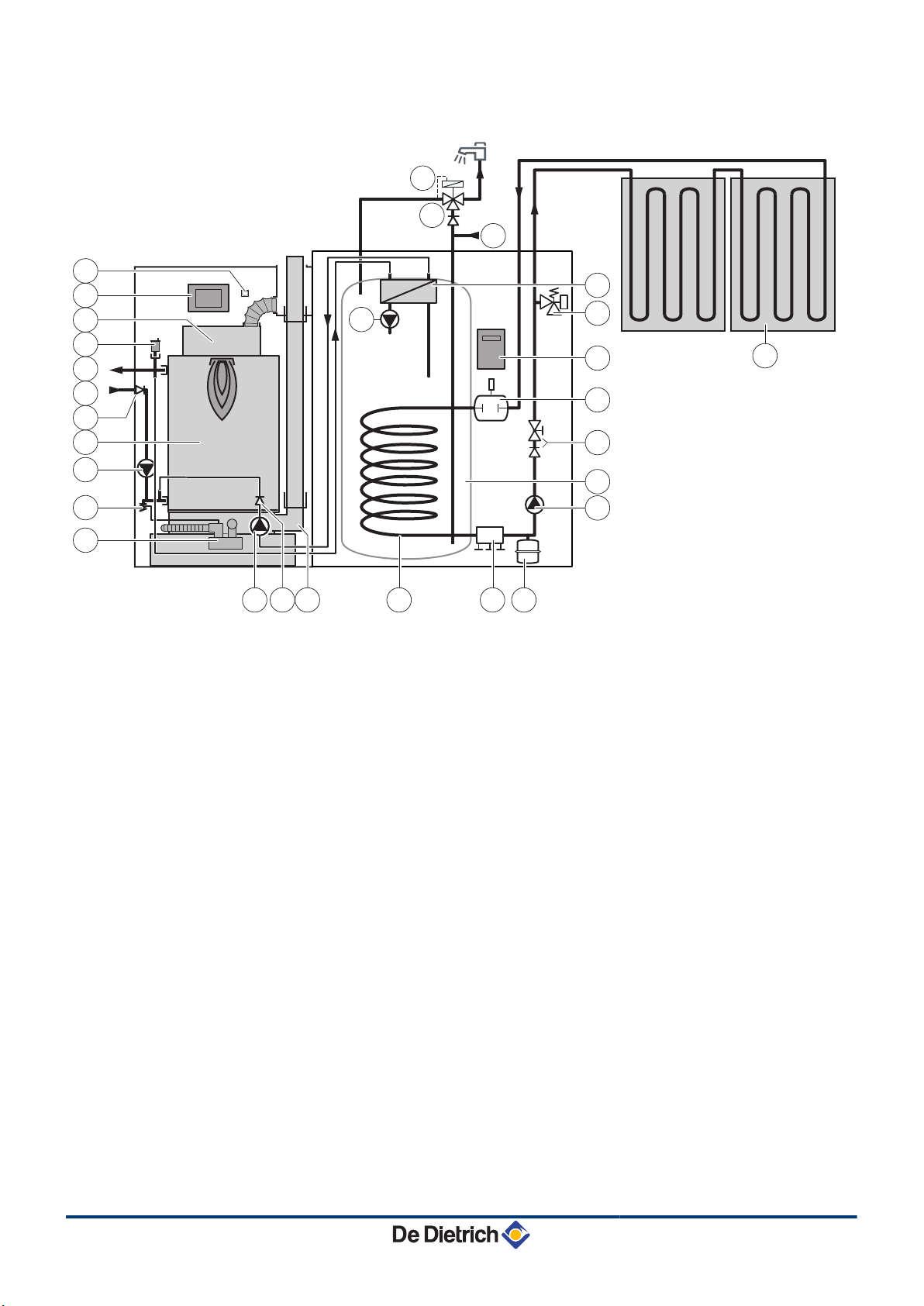

Boiler with 160SL type domestic hot water tank

n

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

On/Off switch

Control panel

Burner

Automatic air vent

Heating flow

Heating return

Non-return valve

Heating body

Circulation pump

0.3 MPa safety valve (3 bar)

Condensate trap

Calorifier load pump

Flue gas discharge

Domestic hot water tank

Domestic water coil

Manual bleed valve

Domestic cold water inlet

Domestic hot water outlet

Configuration with a DHW tank also enables the

connection of a circuit with mixing valve.

18

09/07/2015 - 300026439-07

Page 21

C003834-C

2

1

3

4

5

6

8

9

7

10

11

12 7 13 1514

24

25

27

28

26

16

17

18

19

20

21

22

23

AFC 18 - AFC 24 - AFC 30 4. Product description

Boiler with 220SHL type domestic hot water tank

n

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

On/Off switch

Control panel

Burner

Automatic air vent

Heating flow

Heating return

Non-return valve

Heating body

Circulation pump

0.3 MPa safety valve (3 bar)

Condensate trap

Calorifier load pump

Flue gas discharge

Domestic water solar coil

Primary solar circuit filling and draining device

Solar expansion vessel 12 l

solar circulation pump

Domestic hot water tank

Antithermosiphon valve operated by the spherical plug

valve

Degasser with manual purge to the solar circuit drain

valve

09/07/2015 - 300026439-07

19

Page 22

M003250-A

(mbar)

(m3/h)

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

0 0,2 0,4 0,6 0,8 1 1,2 1,4 1,6 1,8 2 2,2 2,4 2,6 2,8 3 3,2 3,4 3,6

a

b

c

4. Product description AFC 18 - AFC 24 - AFC 30

21

22

23

24

25

26

27

28

Solar regulator

Solar safety valve

Plate heat exchanger

Solar collectors

Domestic cold water inlet

Non-return valve

Domestic hot water thermostatic mixing valve

DHW pump

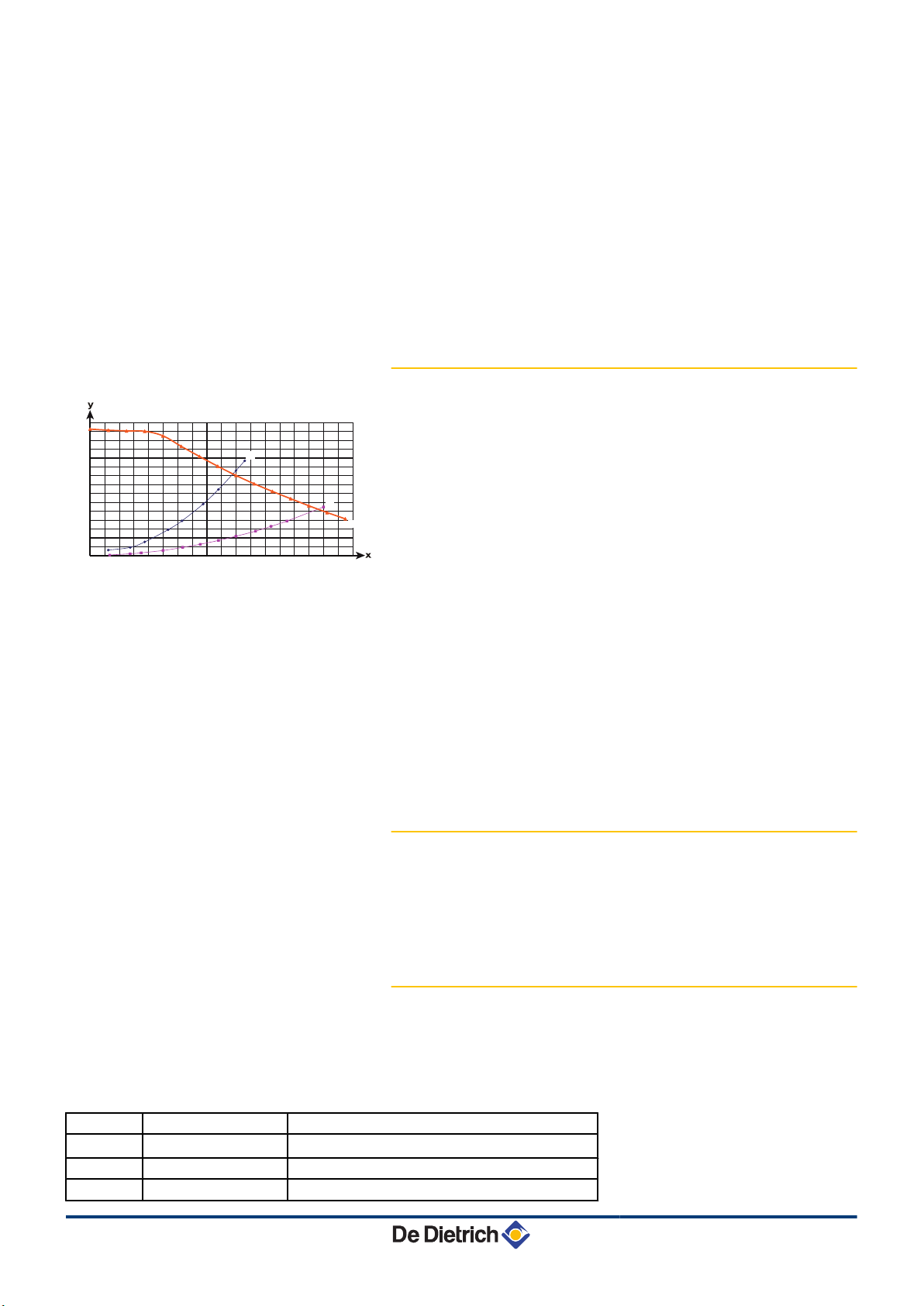

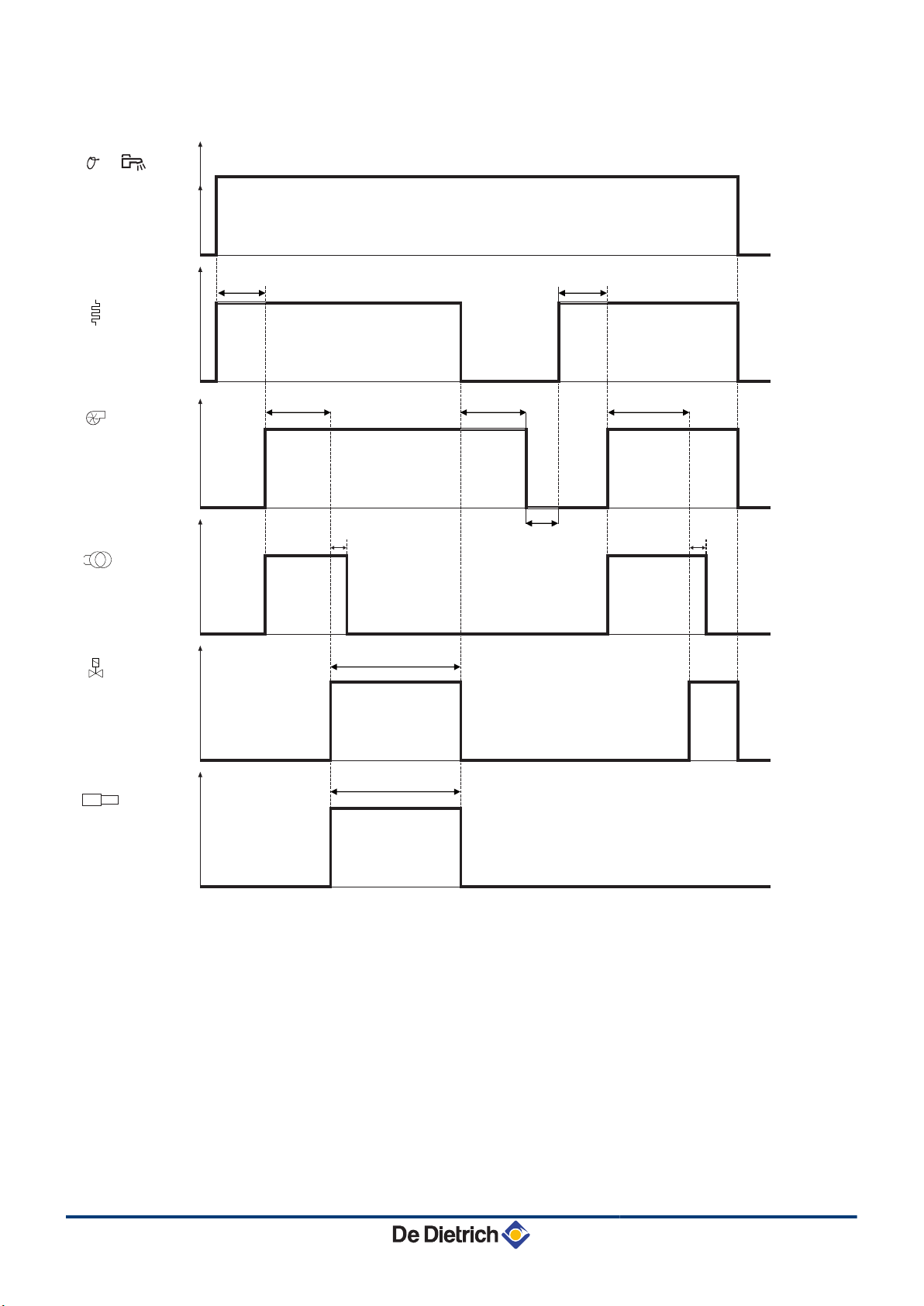

4.2.2. Circulation pump

a

b

c

x

y

Boiler pressure drop (with valve)

Boiler pressure drop (without valve)

Circulation pump (Class A pump)

Water flow

Manometric height central heating circuit

The boiler is fitted with a modulating pump which is regulated by the

control panel as a function of ΔT= (Flow T °C - Return T °C).

The graph shows the manometric height at various outputs. The

parameters MIN.PUMP SPEED and MAX.PUMP SPEED are used to

modify the pump settings. If flow noise can be heard in the system, it

is possible to reduce the maximum pump speed with the parameter

MAX.PUMP SPEED (First of all, vent the heating system). If

circulation in the radiators is too low or the radiators do not fully heat

up, increase the minimum pump speed with the parameter

MIN.PUMP SPEED.

¼See chapter: "Professional settings", page 114.

4.2.3. Water flow rate

The boiler’s modulating control system limits the maximum difference

in temperature between the heating flow and return and the maximum

speed at which the flow temperature increases. In this way, the boiler

does not require a minimum water flow rate.

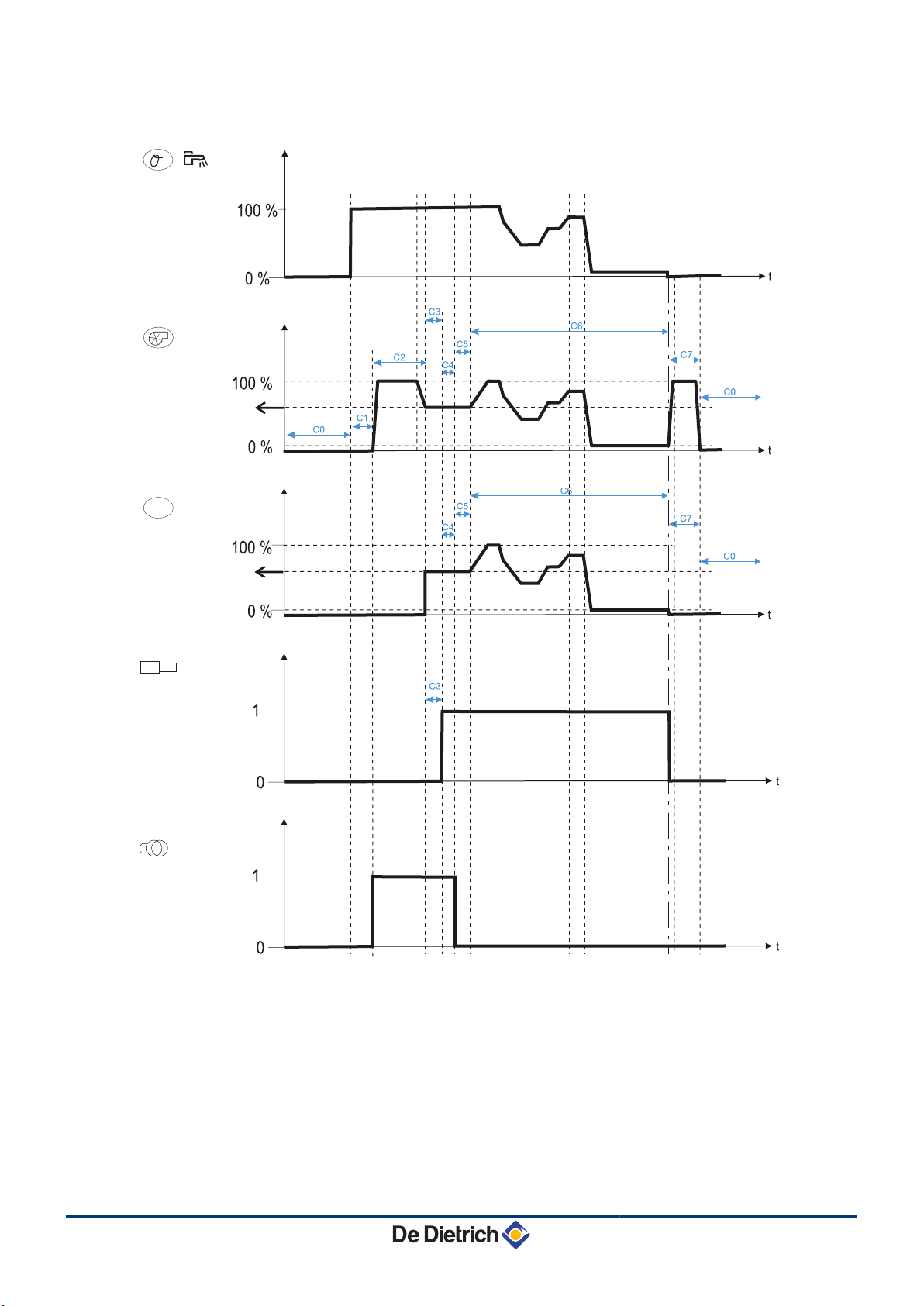

4.2.4. Burner operating cycle

Sequence

0r

2

1

20

Sequence displayed Description

x - x Heating request - Domestic hot water mode

x - x Fan speed

x - x Fuel oil pressure

Legend

n

09/07/2015 - 300026439-07

Page 23

AFC 18 - AFC 24 - AFC 30 4. Product description

3

Arc

D

OV

?

C0

C1

C2

C3

C4

C5

C6

C7

x - x Flame detection

x - x Ignition stage

x - x Start-up threshold

x - x Fuel pre-heater

x - x Anti-short cycle

x - x Burner off

2 - 13 Reheat fuel oil (Max 400 seconds)

2 - 14 Pre-ignition and preventilation time (15 seconds)

2 - 15 Electro-valve opening (No flame presence)

Max time: Safety time (TS = 5 seconds)

2 - 16 Post-ignition time (7 seconds)

2 - 17 Flame stabilisation (for 20 sec)

x - x Output modulation

5 - 41 Post-ventilation (120 seconds)

09/07/2015 - 300026439-07

21

Page 24

D

D

°

ITR

C003259-E

P. Oil

( )

Arc

4. Product description AFC 18 - AFC 24 - AFC 30

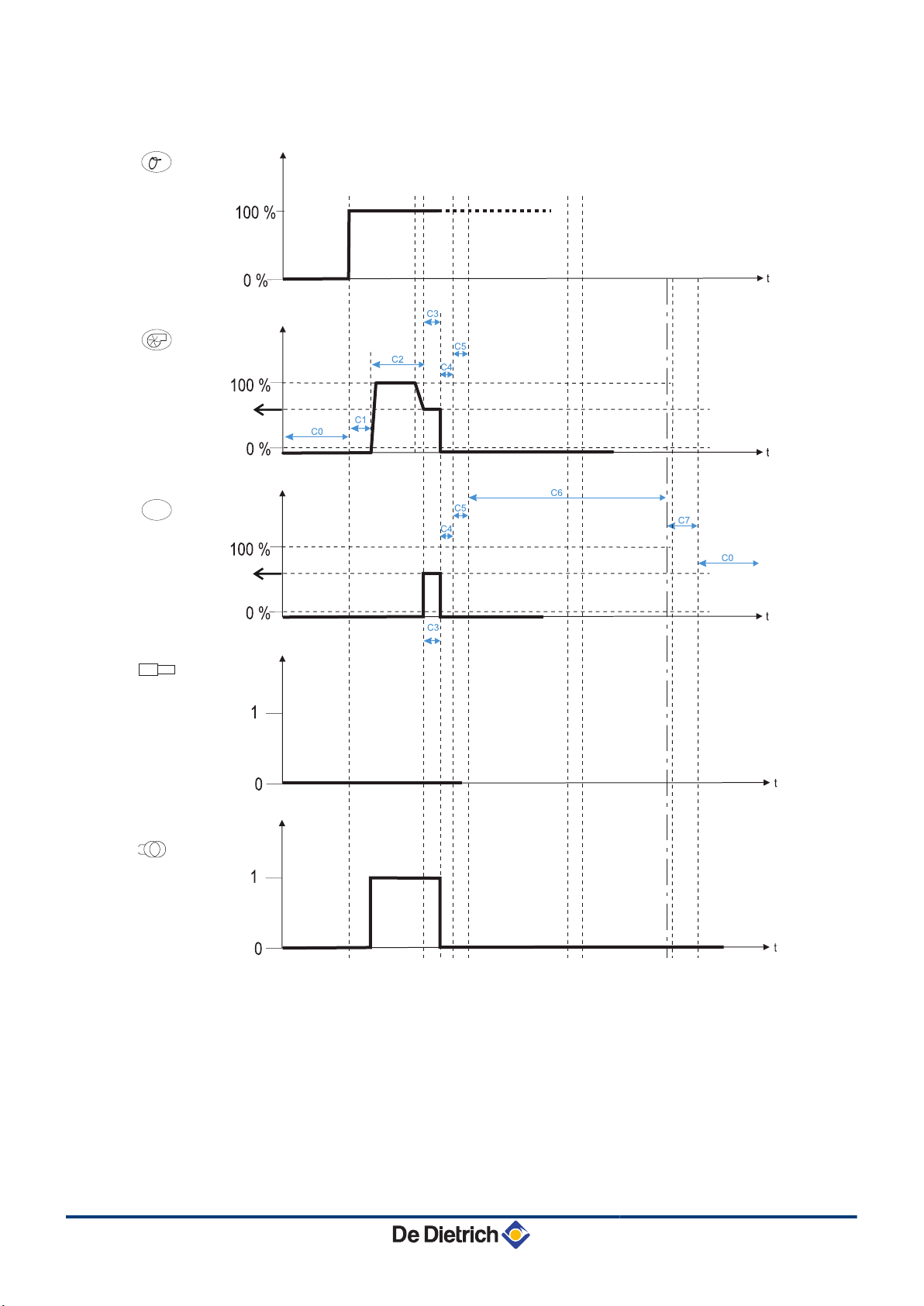

Normal start-up

n

22

09/07/2015 - 300026439-07

Page 25

D

C003223-E

D

°

ITR

P. Oil

Arc

AFC 18 - AFC 24 - AFC 30 4. Product description

Start-up without flame detection

n

09/07/2015 - 300026439-07

23

Page 26

M003249-B

°

ITR

Arc

OV

( )

1

0

1

C1

C7

?

C1

0

1

0

1

0

1

0

1

0

C2

C4 C4

C2

C3

C5

4. Product description AFC 18 - AFC 24 - AFC 30

Loss of the flame signal whilst in operation

n

24

09/07/2015 - 300026439-07

Page 27

C003129-G

56

7

17

18

16

8

9

13

14

19

15

11

10

34 12

12

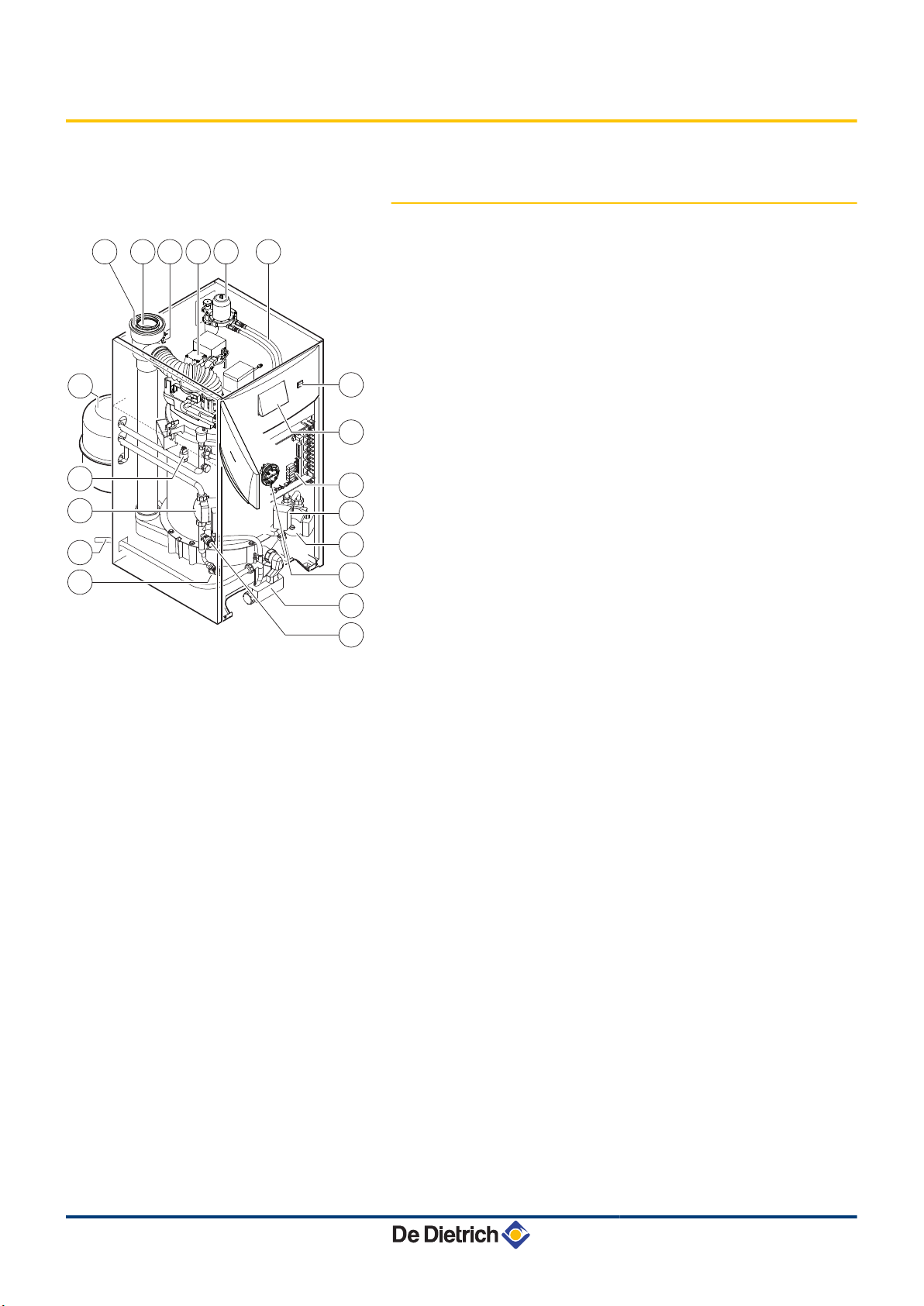

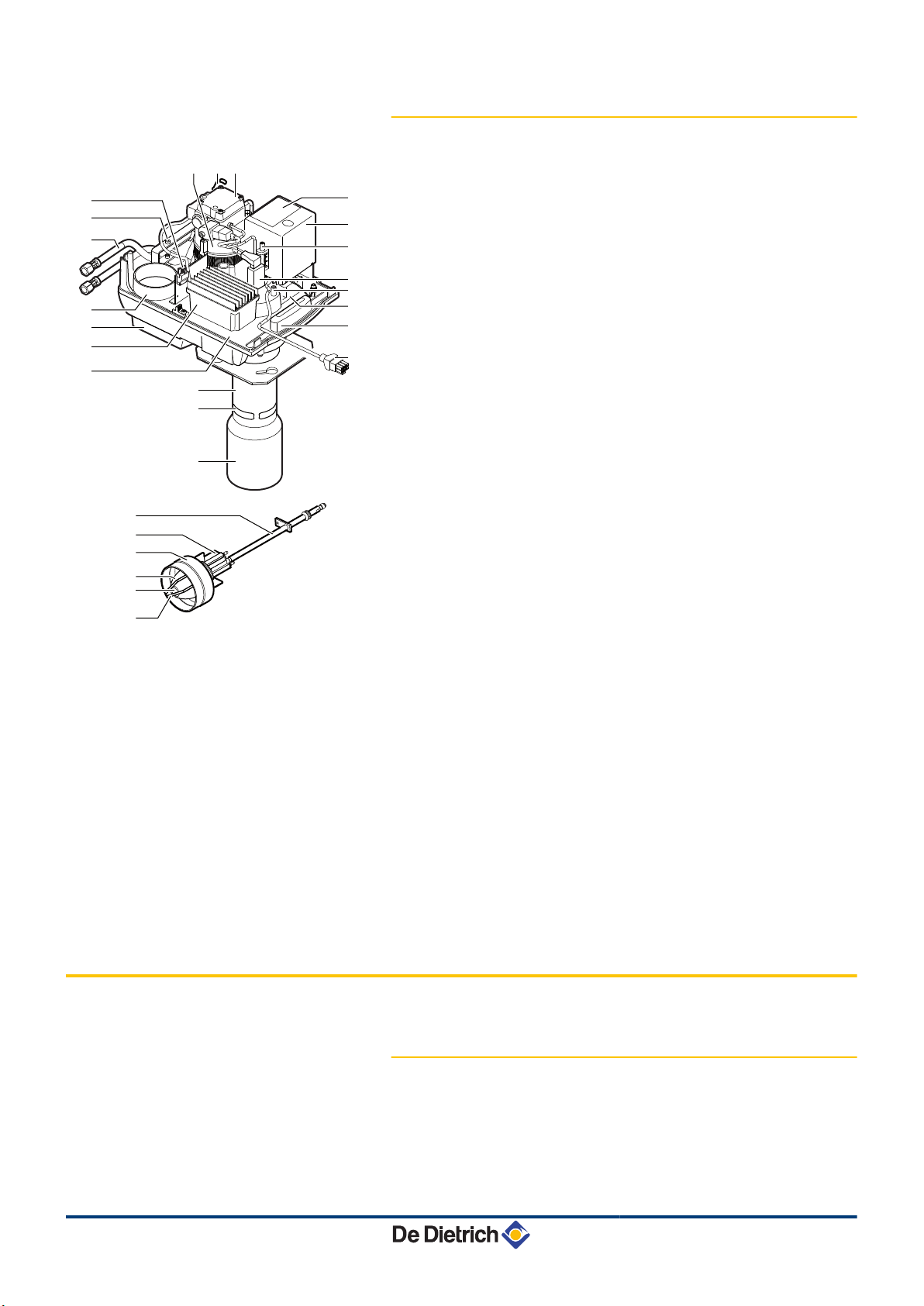

AFC 18 - AFC 24 - AFC 30 4. Product description

4.3 Main parts

4.3.1. Boiler

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Fuel supply pipes

Oil filter (40 µm) + deaerator + stop valve

Modulating oil burner preassembled and preset

Flue gas measuring point / Combustive air

Flue gas discharge pipe (Diameter 80 mm)

Air intake (Diameter 125 mm)

Expansion vessel 18 litres

Electronic pressure sensor (Pressure in the heating

circuit)

Modulating heating pump

Condensates evacuation pipe

Drain cock

0.3 MPa safety valve (3 bar)

Condensate trap

Heating pump circuit mixing valve (Option)

Motorised 3-way mixing valve (Option)

Connection PCBs (PCU + SCU)

17

18

19

Command module

On/Off switch

Flue gas pressure switch

09/07/2015 - 300026439-07

25

Page 28

13

14

12

20

19

21

18

17

16

15

7

8

9

6

5

4

10

11

321

25

24

23

22

26

27

C003219-G

4. Product description

AFC 18 - AFC 24 - AFC 30

4.3.2. Fuel oil burner

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Modulating motor

Pressure sensor

Modulating oil pump

Control box display - Not used

Burner control and safety box

Recirculation slot adjustment screw

Flame detection cell (IRD at 18 kW and BST at 24–30

kW)

Head air pressure measurement point

Ignition transformer

Door handle

BUS cable for connection to the control system

Flame tube

Recirculation slot

Burner pipe

Component plate

Modulating motor management box

4.4 Package list

17

18

19

20

21

22

23

24

25

26

27

Air enclosure

Air inlet

Fuel supply pipes

Door handle + Flexible mounting flange

Connector 230 V

Filling line

Pre-heater

Combustion head

air nozzle

Nozzle

Ignition electrode

4.4.1. Standard delivery

The delivery includes:

26

4 The assembled boiler with the burner

4 The oil filter + the deaerator + the stop valve

4 The outside sensor

09/07/2015 - 300026439-07

Page 29

AFC 18 - AFC 24 - AFC 30 4. Product description

4 The horizontal or vertical terminal (depending on the version)

4 The installation and maintenance instructions

4 The user instructions

4.4.2. Accessories

Various options are available depending on the configuration of the

installation (Depending on country) :

Boiler options

Description package

Condensates neutralisation station FM155

Refill of 5 kg of granules and 0.5 kg of activated carbon FM156

Bracket for neutralisation station FM157

Condensates lift pump FM158

3-way internal valve kit MV5

External circuit kit MV6

Adapter kit for external heating pump MV30

3-way internal valve kit HEE - Class A pump MV31

DHW thermostatic mixing valve kit MV10

18-litre expansion vessel MV4

Flue gas system options

Description package

Chimney connection kit PPS diameter 80/110 mm DY876

Air/flue gas terminal horizontal forced flue FM183

Air/flue gas terminal vertical forced flue Black DY843

Red DY844

Back flue gas outlet kit MV9

Control system options

Description package

RX12 cable AD134

TELCOM2 voice remote monitoring module AD152

Flow sensor AD199

DHW sensor AD212

Optional PCB for 3-way valve AD249

Hot water storage tank sensor AD250

Outside radio-controlled temperature sensor AD251

Boiler radio module AD252

Radio remote control AD253

Interactive remote control AD254

Room sensor FM52

09/07/2015 - 300026439-07

Domestic hot water tank options

Description package

Domestic hot water tank 100HL ER225

Domestic hot water tank 160SL ER223

Solar domestic hot water calorifier 220SHL ER220

27

Page 30

4. Product description AFC 18 - AFC 24 - AFC 30

Domestic hot water tank options

Description package

100HL recirculation kit ER218

160SL/220SHL recirculation kit ER219

Boiler/DHW tank hydraulic connecting kit 100HL MV7

Boiler/DHW tank hydraulic connecting kit 160SL MV8

Boiler/DHW tank hydraulic connecting kit 160SL - HEE -

MV32

Class A pump

Connecting kit for external DHW tank - HEE - Class A pump MV33

Boiler/solar DHW tank hydraulic connecting kit 220SHL MV11

Boiler/DHW tank hydraulic connecting kit MV18

28

09/07/2015 - 300026439-07

Page 31

AFC 18 - AFC 24 - AFC 30

5 Installation

5.1 Regulations governing installation

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

France:

Residential buildings

Statutory terms and conditions of installation and maintenance:

4 DTU 65-17

4 Local Sanitary Regulations

4 For appliances connected to the electricity network:

NF C 15-100 standards Low voltage electrical installation - Rules.

5. Installation

Establishments open to the public

Statutory terms and conditions of installation:

4 Safety regulations against fire and panic in establishments open

to the public

- General regulations:

Articles GZ - Installations operating on combustible gases and

liquefied hydrocarbons

Articles CH-Heating, ventilation, refrigeration, air conditioning

and production of steam and domestic hot water

- Instructions specific to each type of establishment open to the

public (hospitals, stores, etc.)

Germany:

Standards to be respected:

4 FeuVo decree, paragraph 3

4 DIN EN 12828 (June 2003 edition): heating systems in buildings.

Planning of hot water heating installations (up to a maximum

operating temperature of 105°C and a maximum output of 1 MW)

4 DIN 4753: drinking and industrial water heating installations

4 DIN 1988: technical rules on drinking water installations (TRW)

Switzerland:

09/07/2015 - 300026439-07

Standards to be respected:

4 Directives of the Association des Etablissements Cantonaux

d’Assurance Incendie AEAI.

4 Local and cantonal regulations.

29

Page 32

C003289-C

5. Installation

5.2 Choice of the location

AFC 18 - AFC 24 - AFC 30

The safety distance between combustible substances and the boiler

and gaseous effluents must comply with the requirements of the AEAI

standard.

5.2.1. Type plate

The nameplates must be accessible at all times. The nameplates

identify the product and provide the following information:

4 Type of product

4 Manufacturing date (Year - Week)

4 Serial number

4 CE identification no

30

One nameplate is affixed to the back of the appliance.

Affix the nameplate provided in the document bag to the

boiler casing where it can be seen.

5.2.2. Positioning of the appliance

CAUTION

When installing the appliance, respect the IP21

environmental rating.

4 Place the appliance on a base frame to facilitate cleaning of the

premises.

4 Allow enough space around the appliance to facilitate accessibility

and maintenance. The minimum recommended dimensions are

shown in the illustration in mm.

09/07/2015 - 300026439-07

Page 33

M002360-E

1700

min.500

320

min.

250

A

500

1100

min.500

320

min.

250

C

500

1100

min.500

320

685

min.

250

A

500

C003133-B

B

AFC 18 - AFC 24 - AFC 30 5. Installation

4 Install the appliance as close as possible to the drawing off points

in order to minimise energy losses through the pipes.

4 Make sure there is a connection to the sewage system close to

the boiler to evacuate the condensates.

CAUTION

Allow some free space behind the boiler to install the

following components:

4 The heating circuit expansion vessel

4 The oil filter + the deaerator + the stop valve

DHW calorifier type Boiler model

AFC 18 AFC 24 AFC 30

A (mm) - 1130 1130 1200

B (mm) 100HL - - -

160SL 921 921 921

220SHL 1201 1201 1201

C (mm) 100HL 1686 1686 1756

160SL - - 220SHL - - -

09/07/2015 - 300026439-07

31

Page 34

5. Installation AFC 18 - AFC 24 - AFC 30

5.2.3. Ventilation

CAUTION

In order to avoid damage to the boiler, it is necessary to

prevent the contamination of combustion air by chlorine

and/or fluoride compounds, which are particularly

corrosive. These compounds are present, for example, in

aerosol sprays, paints, solvents, cleaning products,

washing products, detergents, glues, snow clearing salts,

etc. Therefore:

4 Do not pull in air evacuated from premises using such

products: hairdressing salons, dry cleaners,

industrial premises (solvents), premises containing

refrigeration systems (risk of refrigerant leakage),

etc.

4 Do not stock such products close to the boilers.

If the boiler and/or peripheral equipment are corroded

by such chloride or fluoride compounds, the

contractual guarantee cannot be applied.

Type C - Forced flue version

n

If the evacuation of combusted gases and the intake of combustive

air are done using a concentric conduit, ventilation of the boiler room

is not necessary.

Condensing boilers require a flue gas discharge system or a fresh air

inlet specially adapted to the method of operation. Installation must

be carried out in accordance with current laws.

CAUTION

Do not block the air inlet, combustion product evacuation

or condensation water flow pipes (even partially).

Avoid any low points in the flue gas and condensates

discharge circuit in order to prevent any condensates

accumulation.

Type B - Open flue

n

Condensing boilers require a flue gas discharge system or a fresh air

inlet specially adapted to the method of operation. Installation must

be carried out in accordance with current laws.

32

Position the air inlets in relation to the high ventilation vents in order

that the air is refreshed throughout the boiler room.

CAUTION

4 Avoid any low points in the flue gas and condensates

discharge circuit in order to prevent any condensates

accumulation.

4 Do not block the air inlets in the room or the

combustion products evacuation or condensation

water flow pipes (even partially).

09/07/2015 - 300026439-07

Page 35

AFC 18 - AFC 24 - AFC 30 5. Installation

The minimum cross-sections and the positions of the fresh air inlet

and the air outlet must comply with prevailing regulations.

Generator installed in a building for collective use

n

(installations less than 70 kW)

4 The fresh air inlet must:

- Come out in the lower section of the premises,

- Have a free minimum cross section calculated on the basis of

0.03 dm² per kilowatt installed output and at least equal to 2.5

dm².

4 The air discharge must:

- Be located in the upper section of the premises,

- Rise above the roof (unless using an equivalent system which

does not cause a nuisance to neighbours),

- Have a free cross section (corresponding to 2/3 of that of the

air inlet and at least equal to 2.5 dm²).

Generator installed in a builing for individual use

n

Markers

A

Z

E

R

T

Y

P

a

z

4 An adequate supply of fresh air must be provided as close as

possible to the appliances. Its cross section must be at least 0.5

dm².

4 In the upper section of the premises, an air outlet must ensure

effective ventilation.

Establishments open to the public

n

4 New establishment: Refer to the order of 25/06/1980 (installations

of more than 20 kW and less than or equal to 70 kW).

4 Existing establishment: Refer to the order of 25/06/1980

(installations less than 70 kW).

5.2.4. Main dimensions

Legend

n

Description Size

Heating flow direct circuit G 1

Heating return direct circuit G 1

Primary flow independent DHW tank (Option) G 3/4

Primary return independent DHW tank (Option) G 3/4

Heating flow circuit with mixing valve (Option) G 1

Heating return circuit with mixing valve (Option) G 1

Domestic cold water inlet G 3/4

Domestic hot water outlet G 3/4

DHW circulation loop return (Option) G 3/4

09/07/2015 - 300026439-07

33

Page 36

681

983

45

6998

302

600

A

B

472

(1)

410

160

83

346

6071005

681

83

2

1

6

16

19

5

4

3

C003135-H

520 435 163

93

84,5

(2)

308

69

102

54

56

128

17

128

18

5. Installation AFC 18 - AFC 24 - AFC 30

Markers Description Size

e

r

t

y

u

i

o

DHW drain valve External diameter: 14 mm

Primary solar coil inlet - Copper diameter: 18 mm

Primary solar coil outlet - Copper diameter: 18 mm

Oil supply G 3/8

Condensate discharge pipe External diameter: 25 mm

Low flue gas outlet diameter: 80 mm

Concentric air / flue gas connection diameter: 80/125 mm

(1) Adjustable feet 0 to 20 mm

(2) If mounting the oil filter with deaerator inside the casing

Boiler self-standing

n

Models

A (mm)

B (mm)

AFC 18 AFC 24 AFC 30

1130 1130 1200

1175 1175 1245

34

09/07/2015 - 300026439-07

Page 37

681

75

983

45

6998

302

600

A

B

472

(1)

(2)

1164

1240

640

300

584

1553

2

1

6

5

M002424-E

84,5

308

128

13

710

56

128

906

17

245 70

40

10

11

16

19

12

18

M002427-E

681

45

6998

983

302

1200

A

472

600

911

(1)

607

681

B

83

1005

2

1

5 6

84,5

308

(2)

78

300

870

245 69

12

16

19

13

10

11

520

435 163

93 69

128

160

56

54

17

346

126

18

AFC 18 - AFC 24 - AFC 30 5. Installation

Boiler with 100HL type domestic hot water tank

n

Models AFC 18 AFC 24 AFC 30

A (mm)

B (mm)

n

1686 1686 1756

1731 1731 1801

Boiler with 160SL type domestic hot water tank

Models

A (mm)

B (mm)

AFC 18 AFC 24 AFC 30

1130 1130 1200

1175 1175 1245

09/07/2015 - 300026439-07

35

Page 38

C003833-C

302

1005

83

128

160

55

346

245 70

40

11

10

12

15

14

6

5

(2)

B

45

983

681

6998

435 163

157

115

84,5

308

1105

1150

18,5

78

93 69

126

83

607

681

54

300

2

1

13

16

19

17

18

(1)

A

600600

472

1200

520 520

C003136-D

1

2

notice

handleiding

5. Installation AFC 18 - AFC 24 - AFC 30

Boiler with 220SHL type domestic hot water tank

n

Models AFC 18 AFC 24 AFC 30

A (mm)

B (mm)

1130 1130 1200

1175 1175 1245

5.3 Positioning the appliance

CAUTION

4 Have 2 people available.

4 Handle the appliance with gloves.

5.3.1. Positioning the boiler on its own

1. Remove the packaging from the boiler but leave the shipping pallet

in place.

2. Remove the protective packaging.

The technical documentation is housed in the protective

block.

The outside temperature sensor is housed in the protective

block.

36

09/07/2015 - 300026439-07

Page 39

C003137-G

4

3

C003138-G

6

6

5

AFC 18 - AFC 24 - AFC 30 5. Installation

3. Open the access door on the control panel.

4. Remove the front panel by pulling firmly from both sides.

5. Close the door.

6. Remove the front and back holding screws.

09/07/2015 - 300026439-07

37

Page 40

C003139-H

7

7

8

7

7

9

9

C003140-E

(1)

5. Installation AFC 18 - AFC 24 - AFC 30

7. Lower the boiler from the transport pallet using lifting bars. Use

steel tubes 3/4" in diameter and 1400 mm in length.

8. Install the appliance on the base provided.

9. Level the appliance using the adjustable feet.

(1) Adjustable feet, Basic dimension 30 mm

Can be adjusted from 20 mm to 40 mm.

10.Refit the front panel.

38

09/07/2015 - 300026439-07

Page 41

M002428-D

4

5

3

3

3

3

AFC 18 - AFC 24 - AFC 30

5. Installation

5.3.2. Fitting the boiler to a DHW tank

1. Put the DHW tank in place.

Refer to the DHW tank’s installation, use and maintenance

¼

instructions.

2. Carry out steps 1 to 8 described above.

See chapter "Positioning the boiler on its own"

¼

3. Lower the boiler from the transport pallet using lifting bars. Use

steel tubes 3/4" in diameter and 1400 mm in length.

4. Position the boiler on the DHW tank.

5. Put the retaining screws in place.

6. Refit the front panel.

5.3.3. Positioning the boiler to the left or right of

a DHW tank

1. Put the DHW tank in place.

Refer to the DHW tank’s installation, use and maintenance

¼

instructions.

2. Put the boiler in place.

See chapter "Positioning the boiler on its own".

¼

09/07/2015 - 300026439-07

39

Page 42

1

C003099-D

C003121-C

2

C003285-B

3

3

5. Installation AFC 18 - AFC 24 - AFC 30

5.3.4. Reversal of the direction the control panel

access door opens

As standard, the control panel access door opens to the left. To open

the control panel access door to the right, proceed as follows:

1. Open and remove the control panel door.

2. Take the control system module out of its housing and disconnect

it.

3. Unscrew the mounting screws at the back of the top panel:

- Boiler 18 kW / 24 kW = 2 screws

- Boiler 30 kW = 3 screws.

Remove the top panel.

40

09/07/2015 - 300026439-07

Page 43

C003160-F

4

5

5

4

C003161-C

180°

6

6

C003162-E

8

7

7

AFC 18 - AFC 24 - AFC 30 5. Installation

4. Tilt the control panel forwards.

5. Unscrew the screws holding the front of the control unit.

6. Pivot the holder by 180°.

7. Retighten the fastening screws on the control panel.

8. Tilt the control panel.

09/07/2015 - 300026439-07

41

Page 44

C003286-B

9

9

C003163-B

10

C003164-D

11

5. Installation AFC 18 - AFC 24 - AFC 30

9. Replace the top.

10.Reconnect and put the control system module back in place.

11.Refit the control panel door.

42

09/07/2015 - 300026439-07

Page 45

AFC 18 - AFC 24 - AFC 30 5. Installation

5.4 Hydraulic connections

5.4.1. Flushing the system

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions.

Fitting the appliance to new installations

n

4 Clean the installation with a universal cleaner to eliminate debris

from the system (copper, hemp, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

Fitting the appliance to existing installations

n

4 Remove sludge from the installation.

4 Flush the installation.

4 Clean the installation with a universal cleaner to eliminate debris

from the system (copper, hemp, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

5.4.2. Connecting the expansion vessel

09/07/2015 - 300026439-07

43

Page 46

C003141-F

4

4

3

2

2

1

A B

C003142-E

5. Installation AFC 18 - AFC 24 - AFC 30

(Depending on country, standard delivery

or optional)

We recommend mounting the expansion vessel behind the

boiler. If there is not enough space, mount the expansion

vessel on the wall.

1. Fold back the precut stop pin in the back panel by 90°

2. Insert the screws.

3. Hook the support to the back of the boiler or to the wall (according

to the installation).

4. Tighten the screws .

44

A

B

Mounting the expansion vessel behind the boiler

Mounting the expansion vessel to the wall

09/07/2015 - 300026439-07

Page 47

BA

C003144-F

30 kW

18 kW

24 kW

FloCo-Top

FloCo-Top

C004948-A

E

E

AFC 18 - AFC 24 - AFC 30 5. Installation

5.4.3. Installing the deaerator

To guarantee optimum degassing of the oil feed line:

4 Fit the de-aerator with filter (delivered as standard).

4 Replace the filtration element (40 µm) before each heating season

It is imperative that you follow the recommendations and

instructions given in the manual for the deaerator.

CAUTION

The use of a fibre-based filter must be avoided at all costs.

We recommend mounting the deaerator outside the

boiler (A). If circumstances do not allow this, it is possible

to mount the deaerator inside the boiler (B).

09/07/2015 - 300026439-07

A

B

E

Mounting the deaerator outside the boiler

Mounting the deaerator inside the boiler

Marking on the hose intended for connection of the oil

supply

CAUTION

Connect the hose fitted with the blue ring marked E to the

oil supply fitting on the burner.

45

Page 48

C003276-C

5. Installation AFC 18 - AFC 24 - AFC 30

5.4.4. Hydraulic connection of the heating circuit

CAUTION

Between the boiler and the safety valves there must be no

complete or partial closing device.

CAUTION

CAUTION

In the case of installations with thermostatic protection,

only safety valves bearing the letter "H" may be

connected, and this only to the boiler’s flow safety

connection; their drainage capacity must match the

boiler’s useful nominal output

.

4 Install a T-piece fitted with a 1/4 turn valve on the heating return

circuit to fill the circuit.

4 A disconnector must be installed for filling the heating circuit in

accordance with the regulations in force.

5.4.5. Connection of the water circuit for

domestic use

¼If need be, refer to the DHW tank’s installation, user and

maintenance manual.

5.4.6. Connecting the condensate discharge pipe

Discharge the condensed water directly into the drain using a

syphon. In view of the acidity level (pH 2,5 to 3), only use plastic

material for the discharge pipe.

46

09/07/2015 - 300026439-07

Page 49

2

C003281-D

pH > 6,5

1

AFC 18 - AFC 24 - AFC 30 5. Installation

The installation must be constructed in accordance with prevailing

technical regulations. Depending on prevailing regulations, it is

possible to use a neutralisation station to bring the pH down to a value

of more than 6,5.

1. Mount a standard drainage pipe, DN 32 or more, leading to the

mains drainage system.

2. Connect the condensates discharge pipe with a gradient sufficient

to ensure flow through the siphon to the wastewater network.

3. Mount a trap or a siphon in the discharge pipe.

CAUTION

Do not make a permanent rigid connection owing to

maintenance work on the condensate trap.

4 The condensate drain must be connected openly to

the drain.

4 Set the discharge pipe at a gradient of at least 30 mm

per metre, maximum horizontal length 5 metres.

4 Do not drain condensation water into a roof gutter at

any time.

4 Connect the condensate discharge pipe in

accordance with prevailing standards.

09/07/2015 - 300026439-07

47

Page 50

C003257-A

e

1

2

5. Installation

AFC 18 - AFC 24 - AFC 30

5.4.7. Filling the condensate trap

CAUTION

If operating with the siphon empty, combustion products

will escape into the premises in which the boiler is

installed.

1. Pour water into the flue gas conduit (central pipe) until it flows out

of the condensates discharge pipe 2.

5.5 Oil connection

5.5.1. General

4 Use a single-pipe system and mount the oil filter with the deaerator

and the stop valve (provided with the boiler). The negative

pressure required for the oil supply must be less than 0.35 bar

(0.035 MPa).

4 Use of a floating strainer is strongly recommended to prevent

deposits being sucked up from the bottom of the tank.

4 If replacing the boiler, clean the tank.

48

09/07/2015 - 300026439-07

Page 51

C003277-F

3

7

2

2

4

5

4

5

1 6

C003271-C

1

AFC 18 - AFC 24 - AFC 30

5. Installation

4 Use of the 40 µm filtration cartridge, delivered as standard, is

recommended. For an 18 kW boiler, replace the 40 µm Siku filter

with the 20 µm paper filter (provided with the boiler).

A

Z

E

R

T

Y

U

Oil filter (20 µm) + deaerator + stop valve FloCo-Top

Oil suction pipe between the cistern and the filter

Oil suction strainer

Oil flow hose from the burner

Oil return hose to the burner

Fuel oil burner

Oil cistern

5.5.2. Connecting

1. Connect the oil supply pipe to the deaerator filter.

09/07/2015 - 300026439-07

5.5.3. Diameter and length of the oil pipes

¼Refer to the instructions delivered with the package FloCo-Top

49

Page 52

3

2

2

2

1

3

Lmax

0 80/125

Lmax

Lmax

Lmax

Xmin.

Xmin.

Lmax

Lmax

Lmax

C

13

(x)

C

33

(x)

C

33

(x)

C

33

(x)

C

93

(x)

C

93

(x)

C003175-H

5. Installation AFC 18 - AFC 24 - AFC 30

5.6 Flue gas system connections - Depending on country

CAUTION

To obviate any transmission of boiler operating noise into

the home, the flue gas connection pipes must not be

bricked into the walls. Use a sleeve.

WARNING

Fix the concentric conduits to the wall using clamps and

brackets. The conduits come under stress at each startup and may eventually work free of their fitments. Should

this happen, the boiler continues to operate and pollutes

the air in the premises. This risk is even higher when the

length of the flue gas connection pipe to the wall or

chimney is significant. The horizontal flue gas pipes must

be installed with a minimum gradient of 1% to allow the

flow of the condensates that form in the pipes to the boiler

siphon.

5.6.1. Connections for the air and exhaust pipes -

Forced flow (forced flue) - Type C

When it leaves the factory, the connection configuration of the boiler

is so-called "forced flow": air/flue gas connection type C

C

.

93(x)

Classification

n

13(x)

, C

33(x)

,

50

09/07/2015 - 300026439-07

Page 53

AFC 18 - AFC 24 - AFC 30 5. Installation

1

Configuration C

13(x)

Air/flue gas connection by means of concentric pipes to a

horizontal terminal (so-called forced flue).

2

Configuration C

33(x)

Air/flue gas connection by means of concentric pipes to a

vertical terminal (roof outlet).

3

Configuration C

93(x)

Air/flue gas connection by concentric pipes in the boiler

room and straight pipes in the chimney (rigid or flex)

(combustive air in counter current in the chimney).

C63 type appliances have not been shown as

they are marketed without conduit systems.

When they are installed, these appliances end up

with a configuration similar to the ones shown for

the other C type appliances.

WARNING

4 Only factory components are authorised for

connecting the boiler and the terminal.

4 The clear section must comply with the

standard.

4 The chimney must be swept before the

installation of the evacuation conduit.

Lengths of the air/flue gas pipes

n

CAUTION

The maximum lengths (Lmax) given in the table are valid

for pipes on which the horizontatal sections do not exceed

one metre in total. For each additional metre of horizontal

pipe, a multiplication coefficient of 1.2 must be applied

when calculating the total length L. The total length L is

calculated by adding the lengths of the straight air/flue gas

pipes and the equivalent lengths of the other components.

Type of air/flue gas connection Diameter Maximum length in metres

Lmax (m)

AFC 18 AFC 24 AFC 30

C

C

C

Concentric pipes connected to a horizontal

13(x)

terminal

Concentric pipes connected to a vertical

33(x)

terminal

Concentric pipes in the boiler room

93(x)

Single conduits in the chimney (combustive air

in counter-current)

Minimum cross section for the air supply - Xmin. Square flue mm 140 140 140

PPS (Flue gases)

Alu (Air)

PPS (Flue gases)

Alu (Air)

PPS (Flue gases)

Alu (Air)

Round flue mm 160 160 160

80/125 mm (Rigid

duct)

80/125 mm (Rigid

duct)

80/125 mm

80 mm (Rigid duct)

80/125 mm

80 mm (Flexible

duct)

8 8 8

8 8 8

18 18 18

15 15 15

09/07/2015 - 300026439-07

51

Page 54

Lmax

Lmax

Lmax

Lmax

C003176-E

B

23

1

2 2

3

B

23P

B

23P

B

23P

5. Installation AFC 18 - AFC 24 - AFC 30

WARNING

Always ensure that L is less than Lmax.

For the list of flue gas system accessories and the equivalent lengths,

refer to the current price list.

5.6.2. Connections for the air and exhaust pipes -

Single flow (chimney) - Type B

Classification

n

52

1

Configuration B

23

Connection to a chimney under negative pressure

(combustive air taken from the boiler room).

2

Configuration B

- Top outlet

23P

Connection to a chimney under pressure (combustive air

taken from the boiler room).

3

Configuration B

- Bottom outlet

23P

Connection to a chimney under pressure (combustive air

taken from the boiler room).

WARNING

4 Only factory components are authorised for

connecting the boiler and the terminal.

4 The clear section must comply with the

standard.

4 The chimney must be swept before the

installation of the evacuation conduit.

09/07/2015 - 300026439-07

Page 55

M001872-B

x mini

DY717

1

2

2

3

6

7

8 9

10

5

L

4

3°

AFC 18 - AFC 24 - AFC 30

5. Installation

Rigid B23 and B

n

Use package DY717

type connection

23P

09/07/2015 - 300026439-07

DY717 Composition of the package

A

Z

E

R

U

T

Y

I

O

P

Terminal with flashing

Centring stars

Elbow at 87°

Support rail

DN80 extension - Length 0,5 m

Options

Ventilation grate

Sleeve - Diameter 124 - Length 0,5 m (DY753)

Closing plate (DY757)

DN80 extension

Boiler

Flexible B23 and B

n

type connection

23P

Use package DY895

53

Page 56

M003162-B

DY897

10

3°

DY895

1

2

2

2

5

4

3

6

7

8

9

5. Installation AFC 18 - AFC 24 - AFC 30

DY895 Composition of the package

A

Z

E

R

U

T

Y

I

O

P

Terminal with flashing

Centring stars

Elbow at 87°

Support rail

DN80 extension - Length 0,5 m

Options

Ventilation grate

Sleeve - Diameter 124 - Length 0,5 m (DY753)

Closing plate (DY757)

DN80 extension

Boiler

54

09/07/2015 - 300026439-07

Page 57

AFC 18 - AFC 24 - AFC 30 5. Installation

Lengths of the air/flue gas pipes

n

CAUTION

The maximum lengths (Lmax) given in the table are valid

for pipes on which the horizontatal sections do not exceed

one metre in total. For each additional metre of horizontal

pipe, a multiplication coefficient of 1.2 must be applied

when calculating the total length L. The total length L is

calculated by adding the lengths of the straight air/flue gas

pipes and the equivalent lengths of the other components.

Lmax (m) - Configuration B

Diameter 80 mm rigid 18 18 18

Diameter 80 mm Flexible 15 15 15

Equivalent length of PPS pipes (m) internal Ø 80 mm

Elbow at 87° 1,9

Elbow at 45° 1,2

Right inspection tube 0,3

87° inspection elbow 1,9

AFC 18 AFC 24 AFC 30

23P

WARNING

Always ensure that L is less than Lmax.

For the list of flue gas system accessories and the equivalent lengths,

refer to the current price list.

09/07/2015 - 300026439-07

55

Page 58

C003154-F

3

1

2

C003155-F

4

4

5

5

5. Installation AFC 18 - AFC 24 - AFC 30

Adapting the boiler to top outlet

n

WARNING

The boiler must be adapted to switch to a single flow

configuration (air/flue gas connection type B23 + B

(combustive air taken from the boiler room).

1. Open the access door on the control panel.

2. Remove the access door from the control panel.

3. Remove the front panel by pulling firmly from both sides..

23P

)

4. Unscrew the mounting screws at the back of the top panel:

- 18 kW / 24 kW = 2 screws

- 30 kW = 3 screws.

Remove the top panel.

5. Unclip the control panel.

56

09/07/2015 - 300026439-07

Page 59

C003156-G

0 80

7

8

7

6

AFC 18 - AFC 24 - AFC 30

5. Installation

6. Tilt the control panel.

7. Unfasten the 2 clamping collars on the air connection to dismantle

it.

8. Put the flue gas evacuation pipe in place.

n

¼Refer to the instructions delivered with the package MV9

5.7 Installing the outside sensor

5.7.1. Choice of the location

It is important to select a place that allows the sensor to measure the

outside conditions correctly and effectively.

Advised positions:

4 on one face of the area to be heated, on the north if possible

4 half way up the wall in the room to be heated

4 under the influence of meteorological variations

4 protected from direct sunlight

4 easy to access

Adapting the boiler to bottom outlet

WARNING

The boiler must be adapted to switch to a single flow

configuration (air/flue gas connection type B23 - B

(combustive air taken from the boiler room).

23P

)

09/07/2015 - 300026439-07

57

Page 60

8800N001-C

8800N002-C

8800N003-C

2

5. Installation

AFC 18 - AFC 24 - AFC 30

A

B

H

Z

Recommended position

Possible position

Inhabited height controlled by the sensor

Inhabited area controlled by the sensor

Positions to be avoided:

4 masked by a building element (balcony, roof, etc.)

4 close to a disruptive heat source (sun, chimney, ventilation grid,

etc.)

5.7.2. Connecting the outside sensor

Mount the sensor using the screws and dowels provided.

A

Z

Inserts

Ø4 wood screw

¼For the connection of the outside temperature sensor, refer to

the chapter "Electrical Connections".

58

09/07/2015 - 300026439-07

Page 61

C003849-B

1

2

PCU

SCU

AFC 18 - AFC 24 - AFC 30 5. Installation

5.8 Electrical connections

5.8.1. Control unit

The boiler is fully pre-wired. The electricity supply is made via

connection cable to the mains (hard mounted). All other external

connections can be made to the connection connectors (low

voltage).

Power the appliance via a circuit which includes a remote omnipolar

switch with a gap of more than 3 mm.

Single phase power supply: 230 V (+6% / -10%) - 50 Hz. Power

supply cable premounted.

Connect the boiler to a 6-amp circuit breaker - Type C.

CAUTION

Keep to the polarity shown on the terminals: phase (L),

neutral (N) and earth *.

A

Z

Routing of the 230 V cables

Routing of the sensor cables

CAUTION

Disconnect the power supply at the mains before carrying

out any work on the appliance or accessories connected

to the appliance.

09/07/2015 - 300026439-07

59

Page 62

5. Installation

AFC 18 - AFC 24 - AFC 30

5.8.2. Recommendations

WARNING

4 Only qualified professionals may carry out electrical

connections, always with the power off.

4 Disconnect the appliance from the mains before any

work on it.

4 The boiler is entirely pre-wired. Do not modify the

connections inside the control panel.

4 Earth the appliance before making any electrical

connections.

WARNING