Page 1

Export

HPI EVOLUTION

EN

Air / water heat pump

AWHP-2 MIT-IN-2 iSystem

Installation and

Service Manual

7616371-001-04

Page 2

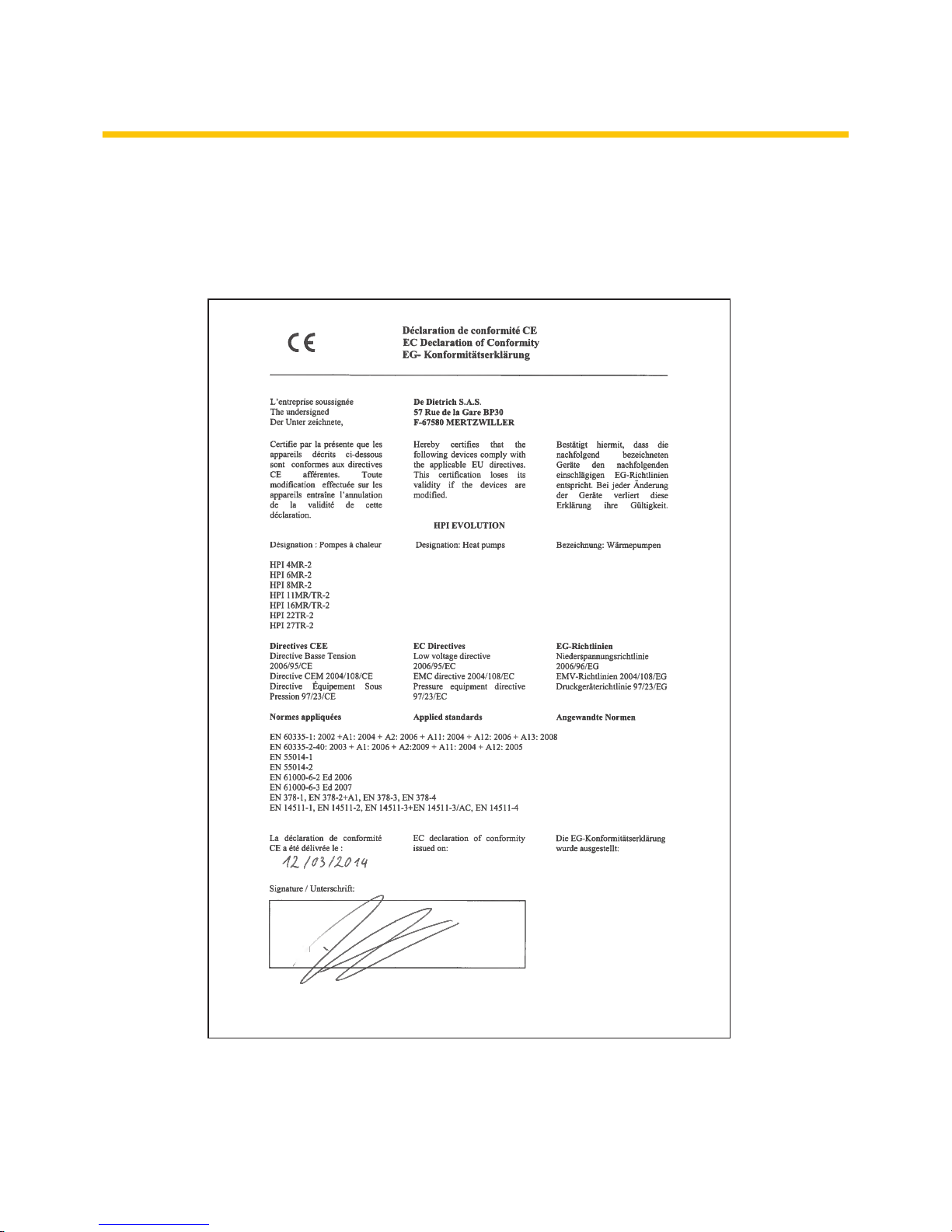

Declaration of conformity

The device complies with the standard type described in the EG

declaration of conformity. It was manufactured and commissioned in

accordance with European directives.

The original declaration of conformity is available from the

manufacturer.

C004793-A

Page 3

Contents

1 Introduction ................................................................................................6

1.1 Symbols used .......................................................6

1.1.1 Symbols used in the manual ...................................6

1.1.2 Symbols used on the equipment .............................6

1.2 Abbreviations ........................................................7

1.3 Liabilities ...............................................................7

1.3.1 Manufacturer’s liability .............................................7

1.3.2 Installer’s liability .....................................................7

1.4 Homologations ......................................................8

1.4.1 Certifications ...........................................................8

2 Safety instructions and recommendations ..............................................9

2.1 Safety instructions ...............................................9

2.2 Recommendations ................................................9

3 Technical description ..............................................................................11

3.1 General description ............................................11

3.2 Main parts (Indoor module) ...............................11

3.2.1 MIT-IN-2/H ............................................................11

3.2.2 MIT-IN-2/E .............................................................12

3.3 Operating principle .............................................12

3.3.1 General .................................................................12

3.3.2 Skeleton Diagrams ................................................13

3.3.3 Pressure available .................................................14

3.4 Technical specifications ....................................14

3.4.1 Electricity supply ...................................................14

3.4.2 Heat pump .............................................................15

3.4.3 Sensor characteristics ...........................................16

4 Installation ................................................................................................17

4.1 Regulations governing installation ...................17

4.2 Package list .........................................................17

4.2.1 Standard delivery ..................................................17

4.2.2 Accessories ...........................................................18

4.3 Type plate ............................................................19

4.3.1 Outdoor unit ..........................................................19

4.3.2 Indoor module .......................................................19

25/06/2014 - 7616371-001-04

1

Page 4

4.4 Installing the outdoor module ...........................20

4.4.1 Positioning of the appliance ..................................20

4.4.2 Main dimensions ...................................................22

4.4.3 Locating the outside module ................................26

4.5 Installing the indoor module ..............................27

4.5.1 Positioning of the appliance ..................................27

4.5.2 Main dimensions ...................................................27

4.5.3 Assembly of the indoor module ............................28

4.6 Installing the outside sensor .............................29

4.6.1 Choice of the location ............................................29

4.6.2 Connecting the outside sensor ..............................29

4.7 Combination with a DHW tank ...........................30

4.8 Installing the refrigerant piping .........................30

4.8.1 Installing the pipes ................................................30

4.8.2 Water tightness test ..............................................35

4.8.3 Evacuation ............................................................35

4.8.4 Opening the valves ...............................................35

4.8.5 Adding refrigerant ..................................................36

4.9 Hydraulic connections .......................................36

4.9.1 Flushing the system ..............................................36

4.9.2 Connection of the heating circuit ...........................37

4.9.3 Hydraulic connection diagrams .............................37

4.10 Filling the heating system ..................................40

4.10.1 Water treatment in the heating circuit ...................40

4.10.2 Filling the system ..................................................42

4.11 Electrical connections ........................................42

4.11.1 Recommendations ................................................42

4.11.2 Recommended cable cross section ......................43

4.11.3 Accessing the connection terminal blocks ............44

4.11.4 Position of the PCBs .............................................46

4.11.5 Location of the fuse ...............................................47

4.11.6 Connecting the outdoor module ............................47

4.11.7 Connecting the communication cable between the

inside and outside modules ...................................47

4.11.8 Description of the terminal block on the inside

module ..................................................................48

4.11.9 Connecting the mains supply to the inside

module ..................................................................49

4.11.10 Connecting the electrical back-up to the inside

module ..................................................................49

4.11.11 Connecting the hydraulic auxilary on the inside

module ..................................................................51

4.11.12 Connection example for a system with hydraulic back-

up ..........................................................................52

4.11.13 Connection example for a system with electrical back-

up ..........................................................................57

4.11.14 Connection example in cooling mode ...................59

4.11.15 Pool connection .....................................................61

4.11.16 Connecting the options .........................................63

4.11.17 Connecting the "energy metering" option ..............64

4.11.18 Connection in cascade ..........................................67

Contents

25/06/2014 - 7616371-001-04

2

Page 5

4.11.19 Connection example in power cut off EVU ............69

4.12 Electrical principle diagram ...............................71

4.12.1 Legend ..................................................................71

4.12.2 Hydraulic additional heating ..................................73

4.12.3 Electrical back-up ..................................................74

5 Commissioning ........................................................................................75

5.1 Control panel .......................................................75

5.1.1 Description of the keys ..........................................75

5.1.2 Description of the display ......................................76

5.1.3 Access to the various browsing levels ..................79

5.1.4 Browsing in the menus ..........................................80

5.2 Check points before commissioning ................81

5.2.1 Hydraulic connections ...........................................81

5.2.2 Electrical connection .............................................81

5.3 Checklist for commissioning (HP) ....................82

5.4 Putting the appliance into operation ................83

5.5 Checks and adjustments after

commissioning ...................................................84

5.5.1 Displaying the parameters in extended

mode .....................................................................84

5.5.2 Setting the heating pump speed on the heat

pump .....................................................................84

5.5.3 Setting the flow rate threshold ...............................85

5.5.4 Setting the parameters specific to the

installation .............................................................86

5.5.5 Naming the circuits and generators ......................91

5.5.6 Setting the heating curve ......................................92

5.5.7 Setting the speed of the heating pump on the inside

module ..................................................................94

5.6 Reading out measured values ...........................94

5.7 Changing the settings ........................................96

5.7.1 Language selection ...............................................96

5.7.2 Calibrating the sensors .........................................96

5.7.3 Professional settings .............................................98

5.7.4 Configuring the network ......................................109

5.7.5 Return to the factory settings ..............................112

25/06/2014 - 7616371-001-04

3

Page 6

6 Switching off the appliance ...................................................................113

6.1 Installation shutdown .......................................113

6.2 Turning on the antifreeze function ..................113

7 Checking and maintenance ...................................................................114

7.1 General instructions .........................................114

7.2 Maintenance operations to be performed ......114

7.3 Cleaning the 400 µm filter ................................114

7.4 Customising maintenance ...............................115

7.4.1 Maintenance message ........................................115

7.4.2 Contact details of the professional for After Sales

Support ................................................................116

8 Troubleshooting .....................................................................................118

8.1 Anti-hunting ......................................................118

8.2 Messages ...........................................................118

8.3 Message history ................................................120

8.4 Faults (Code type Lxx or Dxx) .........................121

8.4.1 Deletion of sensors from the memory in the

PCB .....................................................................124

8.5 Failure history ...................................................125

8.6 Parameter and input/output check (mode

tests) ..................................................................125

9 Spare parts ..............................................................................................131

9.1 General ..............................................................131

9.2 Spare parts ........................................................132

9.2.1 Outdoor unit 4 and 6 kW .....................................132

9.2.2 Outdoor unit 8 kW ...............................................135

9.2.3 Outdoor unit 11 and 16 kW .................................138

9.2.4 Outdoor unit 22 and 27 kW .................................143

9.2.5 Indoor module .....................................................147

Contents

25/06/2014 - 7616371-001-04

4

Page 7

25/06/2014 - 7616371-001-04

5

Page 8

1 Introduction

1.1 Symbols used

1.1.1. Symbols used in the manual

In these instructions, various danger levels are employed to draw the

user’s attention to particular information. In so doing, we wish to

safeguard the user’s safety, highlight hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

1.1.2. Symbols used on the equipment

4

Protective earthing

~

Alternating current

Before installing and commissioning the device, read

carefully the instruction manuals provided.

Dispose of the used products in an appropriate recovery

and recycling structure.

Caution: danger, live parts.

Disconnect the mains power prior to any operations.

1 2

M002628-A

1. Introduction

AWHP-2 MIT-IN-2 iSystem

6

25/06/2014 - 7616371-001-04

Page 9

1.2 Abbreviations

4 DHW: Domestic hot water

4 PPS: Polypropylene hardly inflammable

4 PCU: Primary Control Unit - PCB contoller for heat pump operation

4 PSU: Parameter Storage Unit - Parameter storage for PCBs

PCU and SU

4 SCU: Secondary Control Unit - DIEMATIC iSystem control panel

PCB

4 SU: Safety Unit - Safety PCB

4 3WV: 3-way valve

4 EVU: Power supply company

4 AWHP: Outdoor module connected by connection cable to the

indoor module

4 MIT-2: Indoor module fitted with a DIEMATIC iSystem control

panel

4 HP: Heat pump

4 EER: Frigorific efficiency ratio

4 COP: Performance coefficient

4 EER: Frigorific efficiency ratio

1.3 Liabilities

1.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.3.2. Installer’s liability

The installer is responsible for the installation and commissioning of

the appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

AWHP-2 MIT-IN-2 iSystem

1. Introduction

25/06/2014 - 7616371-001-04

7

Page 10

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.4 Homologations

1.4.1. Certifications

This product complies to the requirements to the european directives

and following standards:

4 2006/95/EC Low Voltage Directive. Reference Standards:

EN60335-1 / EN60335-2-40.

4 2004/108/EC Electromagnetic Compatibility Directive. Generic

standards: EN1000-6-3 , EN 61000-6-1.

1. Introduction AWHP-2 MIT-IN-2 iSystem

8

25/06/2014 - 7616371-001-04

Page 11

2 Safety instructions and

recommendations

2.1 Safety instructions

DANGER

If smoke is released or in case of refrigerant leak:

1. Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches ( doorbell,

light, motor, lift, etc..).

Contact between refrigerant and a flame may result

in emissions of toxic gases.

2. Open the windows.

3. Trace possible leaks and seal them immediately.

WARNING

Before any work, switch off the mains supply to the

appliance.

WARNING

Do not touch the refrigeration connection pipes with your

bare hands while the appliance is running. Danger of

burns or frost injury.

2.2 Recommendations

WARNING

4 Any intervention on the appliance and heating

equipment must be carried out by a qualified

engineer.

4 For a proper operating of the boiler, follow carefully

the instructions.

AWHP-2 MIT-IN-2 iSystem 2. Safety instructions and recommendations

25/06/2014 - 7616371-001-04

9

Page 12

Keep this document close to the place where the boiler is

installed.

CAUTION

4 Use tools and pipe components especially designed

for use with R410A refrigerant.

4 Install the appliance on a solid, stable structure able

to bear its weight.

4 Use phosphorous-deoxidised copper for pipes

without welds and copper alloy to connect the pipes

carrying the refrigerant.

4 Use only R410A gas to fill the pipes with refrigerant.

4 Do not install the appliance in a place where it may

be exposed to steam, sulphuric gas or combustion,

an atmosphere with a high salt content, or which may

be covered by snow.

4 Ensure correct earthing.

4 Store the refrigeration connection pipes away from

dust and humidity (danger of damage to the

compressor) and cover both ends until the expansion

process is complete.

4 Do not use a load cylinder.

CAUTION

4 Activate the main switch at least 12 hours before the

appliance starts to function. Using the appliance just

after it is switched on may seriously damage the

internal parts.

4 When switching off the appliance, wait for at least 5

minutes of post-operation before deactivating the

main switch. Danger of breakdown or water leak.

CAUTION

In order to limit the risk of being scalded, the installation of

a thermostatic mixing valve on the domestic hot water flow

piping is compulsory.

Before carrying out any maintenance work requiring the

shutdown of the inside module, also cut the power supply

to the outside module to prevent any errors in

communication.

2. Safety instructions and recommendations AWHP-2 MIT-IN-2 iSystem

10

25/06/2014 - 7616371-001-04

Page 13

3 Technical description

3.1 General description

The AWHP-2 MIT-IN-2 iSystem heat pump is composed of two

elements:

4 The outside unit handles energy production in hot or cold mode.

4 The inside module handles thermal exchange between the R410A

fluid and the hydraulic circuit.

The two units are connected by means of refrigeration and electrical

connections.

The system offers the following advantages:

4 The heating circuit is housed in the insulated volume within the

home. There is no danger of the pipes freezing.

4 Thanks to the DC inverter system, the heat pump modulates its

output to adapt to the needs of the home.

4 The control panel uses the outside temperature sensor to adjust

the temperature of the heating circuit according to the outside

temperature.

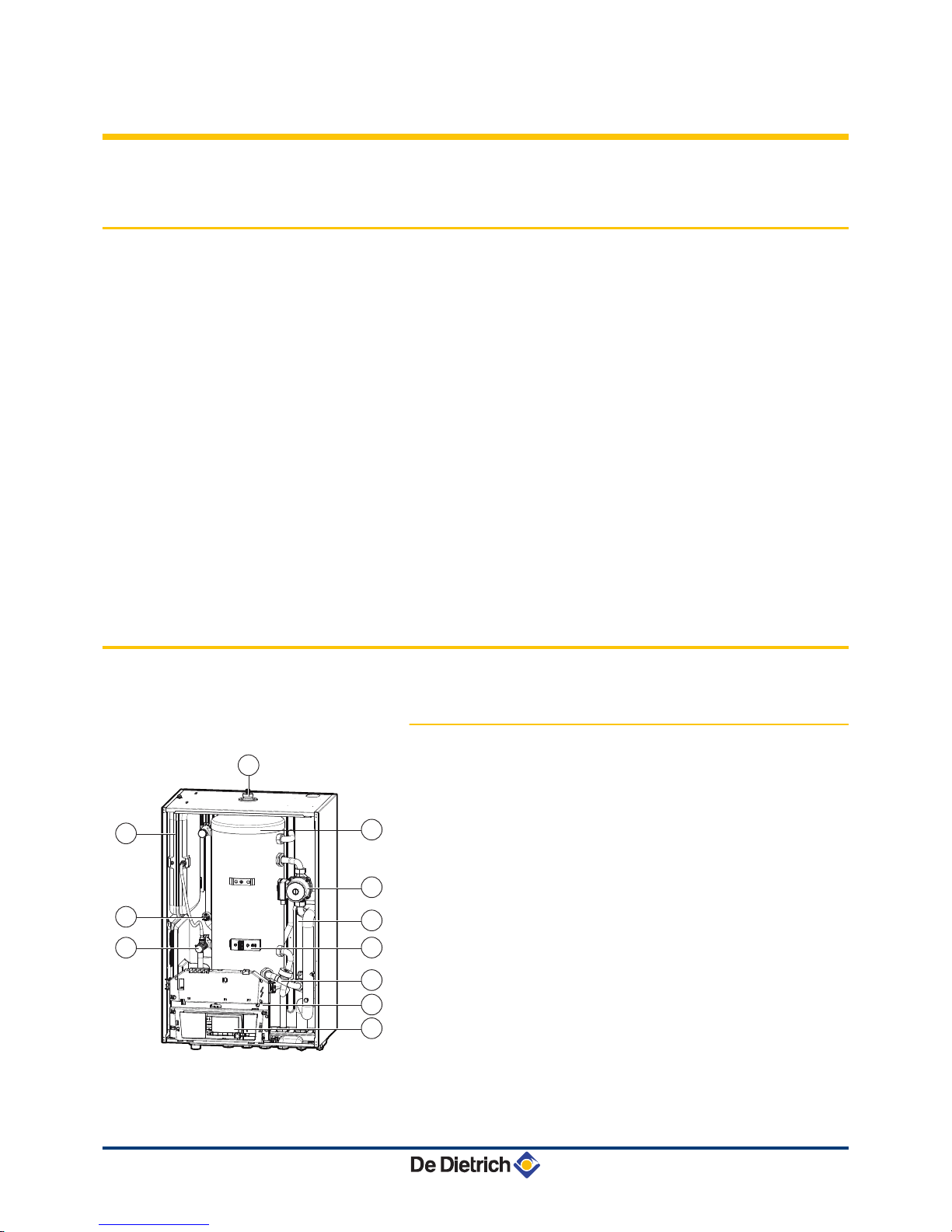

3.2 Main parts (Indoor module)

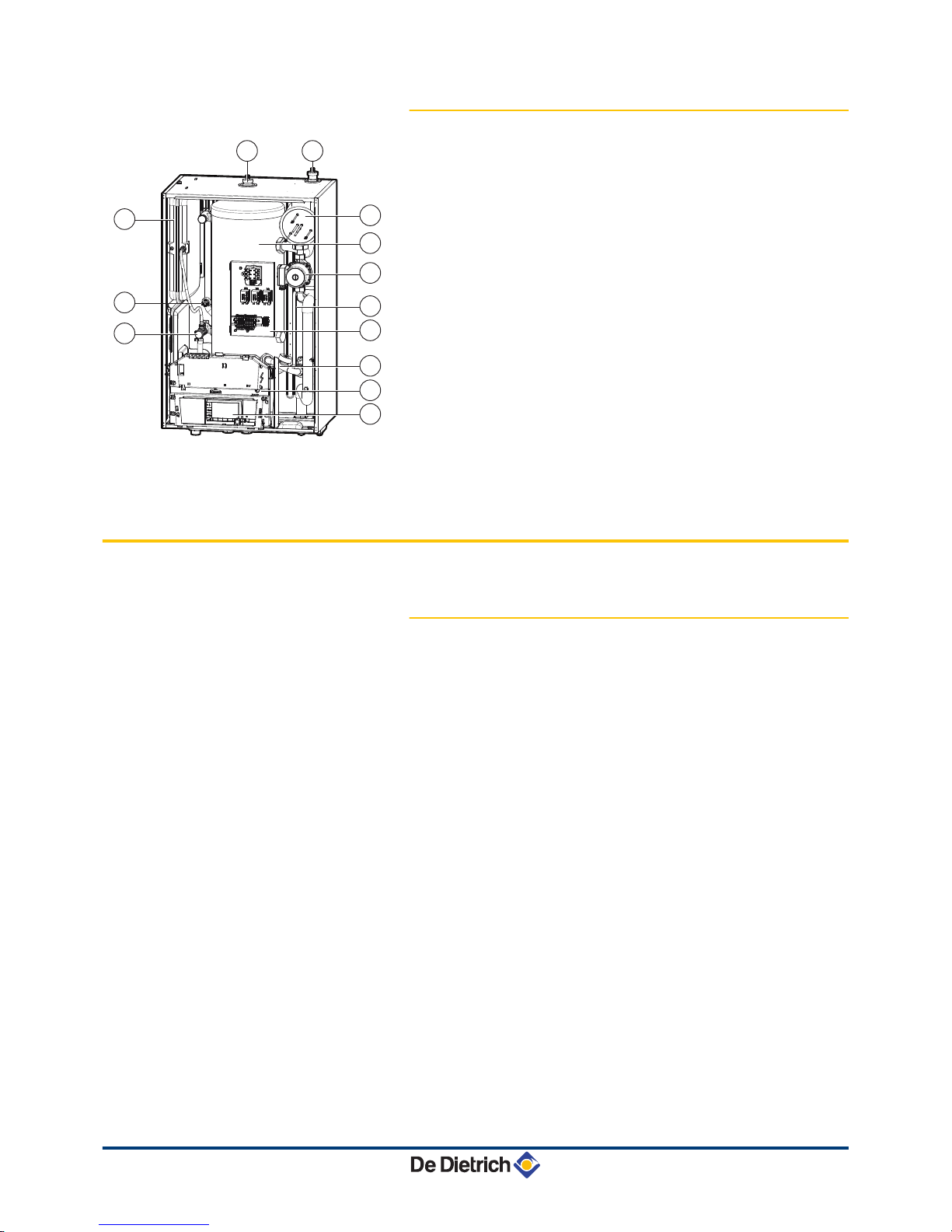

3.2.1. MIT-IN-2/H

1

Automatic air bleed

2

tank

3

High energy efficient heating pump

4

Plate heat exchanger

5

electrical support

6

Flowmeter

7

Table cover unit

8

Control panel

9

Safety valve

10

Pressure gauge

11

Expansion vessel

M002483-A

2

3

5

4

8

7

6

11

10

9

1

AWHP-2 MIT-IN-2 iSystem 3. Technical description

25/06/2014 - 7616371-001-04

11

Page 14

3.2.2. MIT-IN-2/E

1

Automatic air bleed

2

tank

3

High energy efficient heating pump

4

Plate heat exchanger

5

electrical support

6

Flowmeter

7

Table cover unit

8

Control panel

9

Safety valve

10

Pressure gauge

11

Expansion vessel

12

Automatic air bleed

13

Electric heater

3.3 Operating principle

3.3.1. General

The outside module produces heat or cold (in reversible versions) and

transmits it to the heating circuit via the refrigerant in the plate

exchanger.

The outside module is capable of operating at outside temperatures

down to -20°C (-15°C in the case of a 4 kW or 6 kW heat pump).

The DIEMATIC iSystem control panel is used to programme and

regulate the heat pump according to the outside temperature.

By activating the pumps and, where necessary, the mixer valve, the

regulator handles the regulation of the heating.

Connection of a CDR4 simplified remote control or a CDI4 interactive

remote control enables the auto-adaptivity of the gradient and the

parallel offset of the heating curve.

The antifreeze function on the installation is active whatever the

operating mode. It is triggered as soon as the outdoor temperature

reaches the limiting value preset to +3°C.

The installation of a buffer tank is not necessary if the volume of water

in the circuit is higher than or equal to 3 litres/kW: Therefore, for a

heat pump with an output of less than 11 kW, with a water volume of

less than 33 litres, the installation of a buffer tank is necessary.

M002484-A

13

2

3

5

4

8

7

6

11

10

9

1

12

3. Technical description

AWHP-2 MIT-IN-2 iSystem

12

25/06/2014 - 7616371-001-04

Page 15

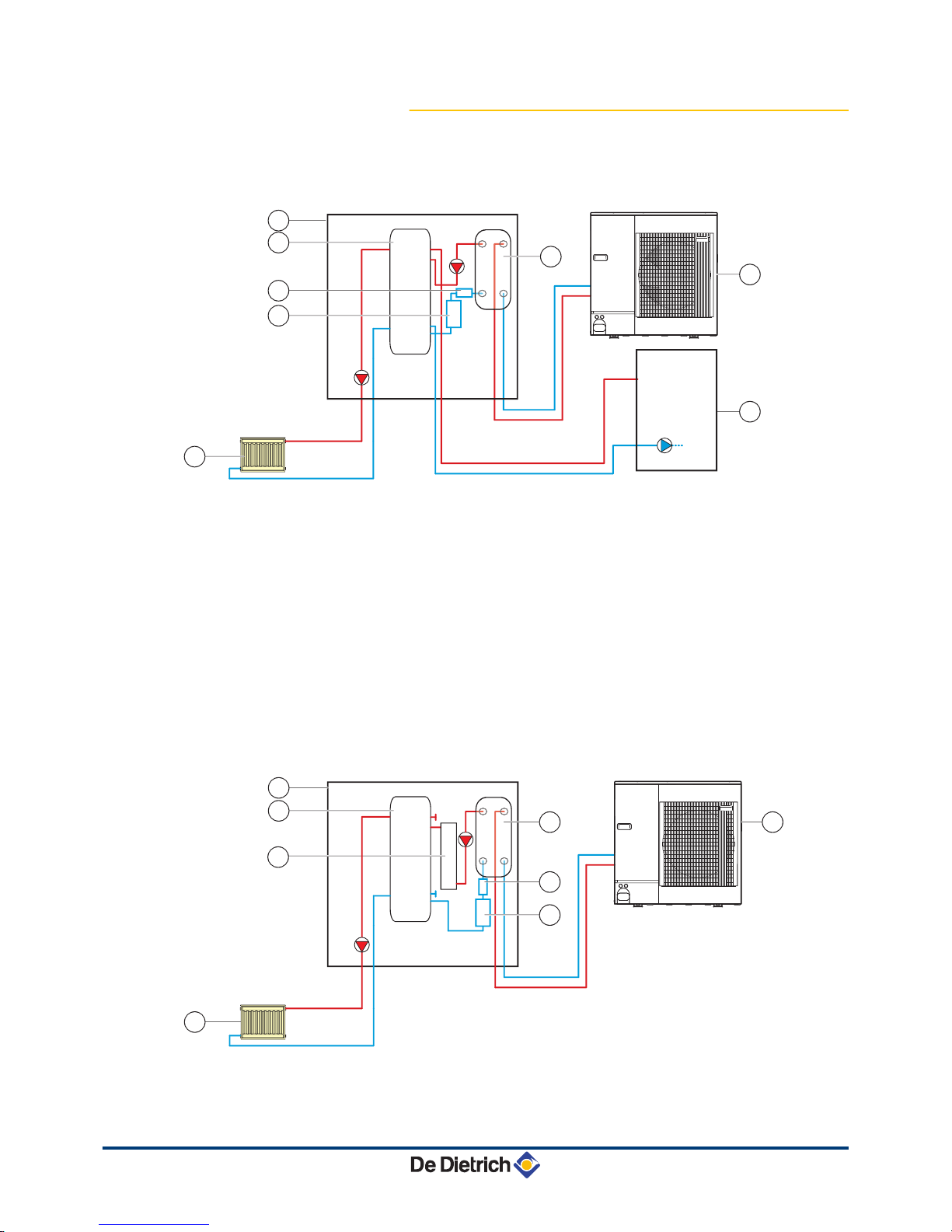

3.3.2. Skeleton Diagrams

n

MIT-IN-2/H

1

Inside module with hydraulic back-up

2

tank

3

Filter

4

Flowmeter

5

Radiator

6

Plate heat exchanger

7

Outdoor unit

8

Boiler

n

MIT-IN-2/E

1

Inside module with electrical back-up

2

tank

3

Electrical back-up

M002487-E

2

1

3

4

5

8

7

6

M002488-E

2

1

3

4

5 8

6

7

AWHP-2 MIT-IN-2 iSystem 3. Technical description

25/06/2014 - 7616371-001-04

13

Page 16

4

Radiator

5

Plate heat exchanger

6

Filter

7

Flowmeter

8

Outdoor unit

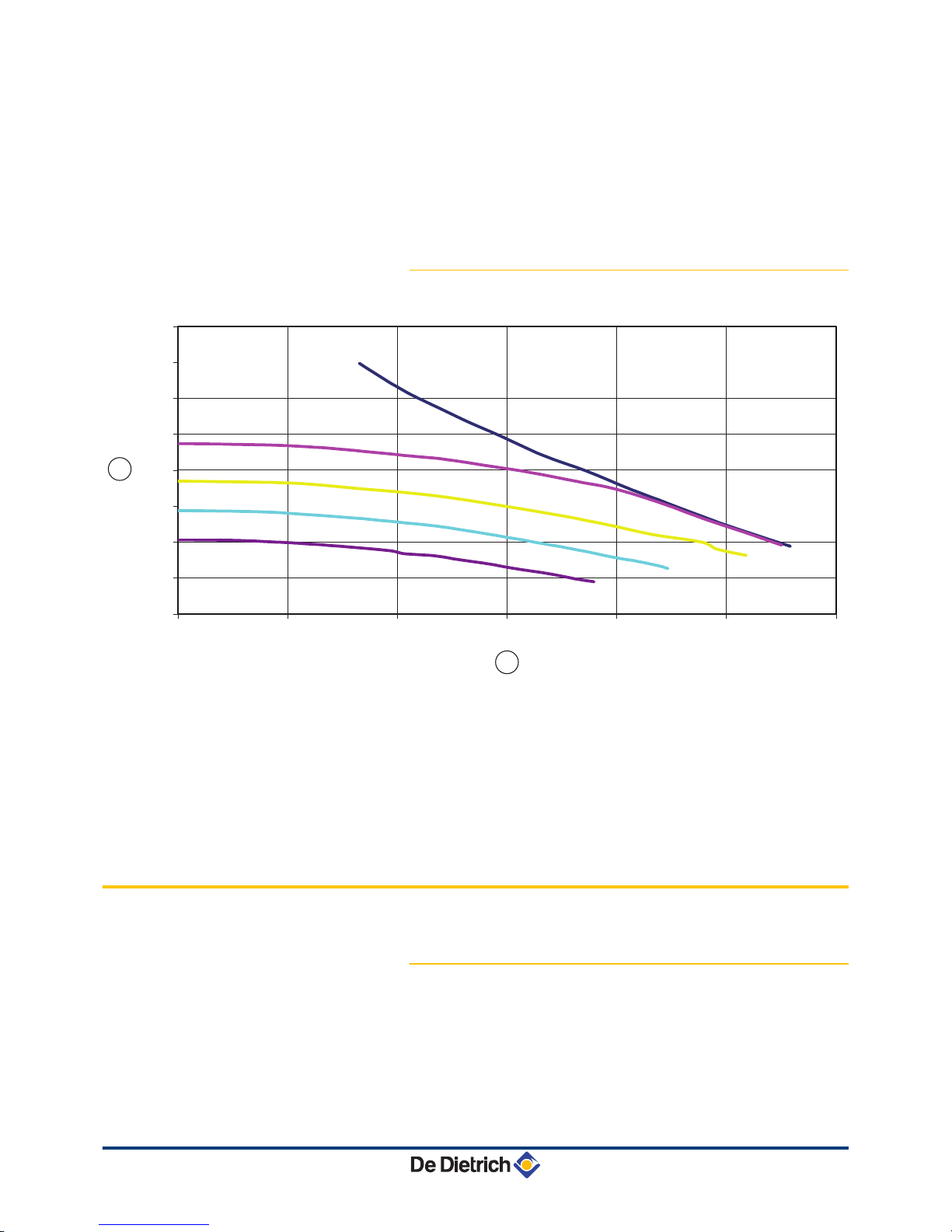

3.3.3. Pressure available

A

Pressure available (mbar)

Z

Water flow rate (m3/h)

1 - 5

Setting the pump

¼To set the speed of the heating pump correctly, refer to

chapter: "Setting the speed of the heating pump on the inside

module", page 94.

3.4 Technical specifications

3.4.1. Electricity supply

230 V AC (+/- 10%) - 50 Hz

400 V AC (+ 6%, - 10%) - 50 Hz (depending on the model)

M002627-C

0

100

200

300

400

500

600

700

800

0 0,5 1 1,5 2 2,5 3

1

2

4

3

2

1

5

3. Technical description

AWHP-2 MIT-IN-2 iSystem

14

25/06/2014 - 7616371-001-04

Page 17

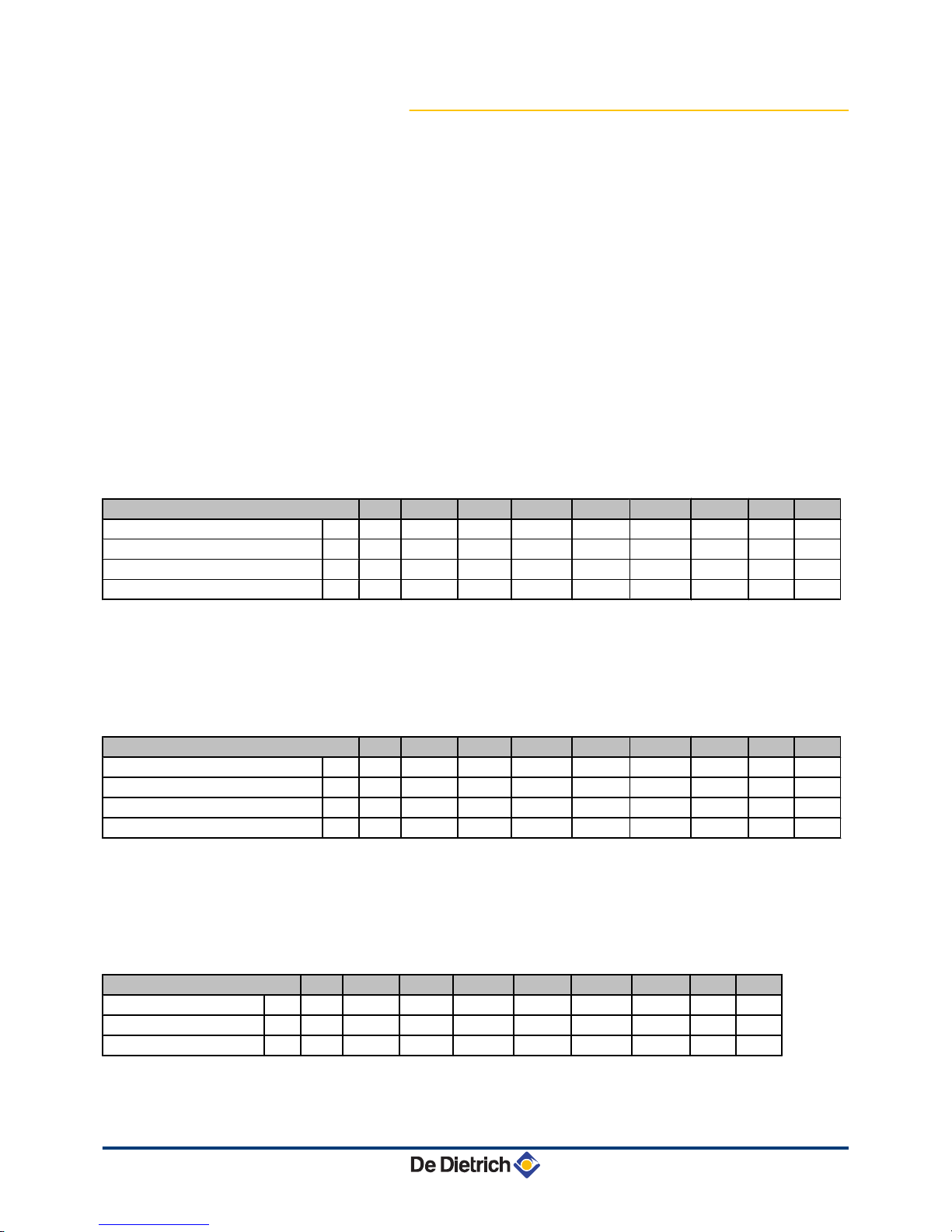

3.4.2. Heat pump

Conditions of use:

4 Limit operating temperatures in Hot mode:

- Water: +18 °C / +60 °C

- Outside air:

-15 °C / +35 °C (4, 6 kW)

-20 °C / +35 °C (8, 11, 16, 22, 27 kW)

4 Limit operating temperatures in Cooling mode:

- Water: +7 °C / +25 °C

- Outside air: +15 °C / +40 °C (At less than 18°C, it is necessary

to use the HK24 insulation kit option)

4 Maximum operating pressure: 3 bar

n

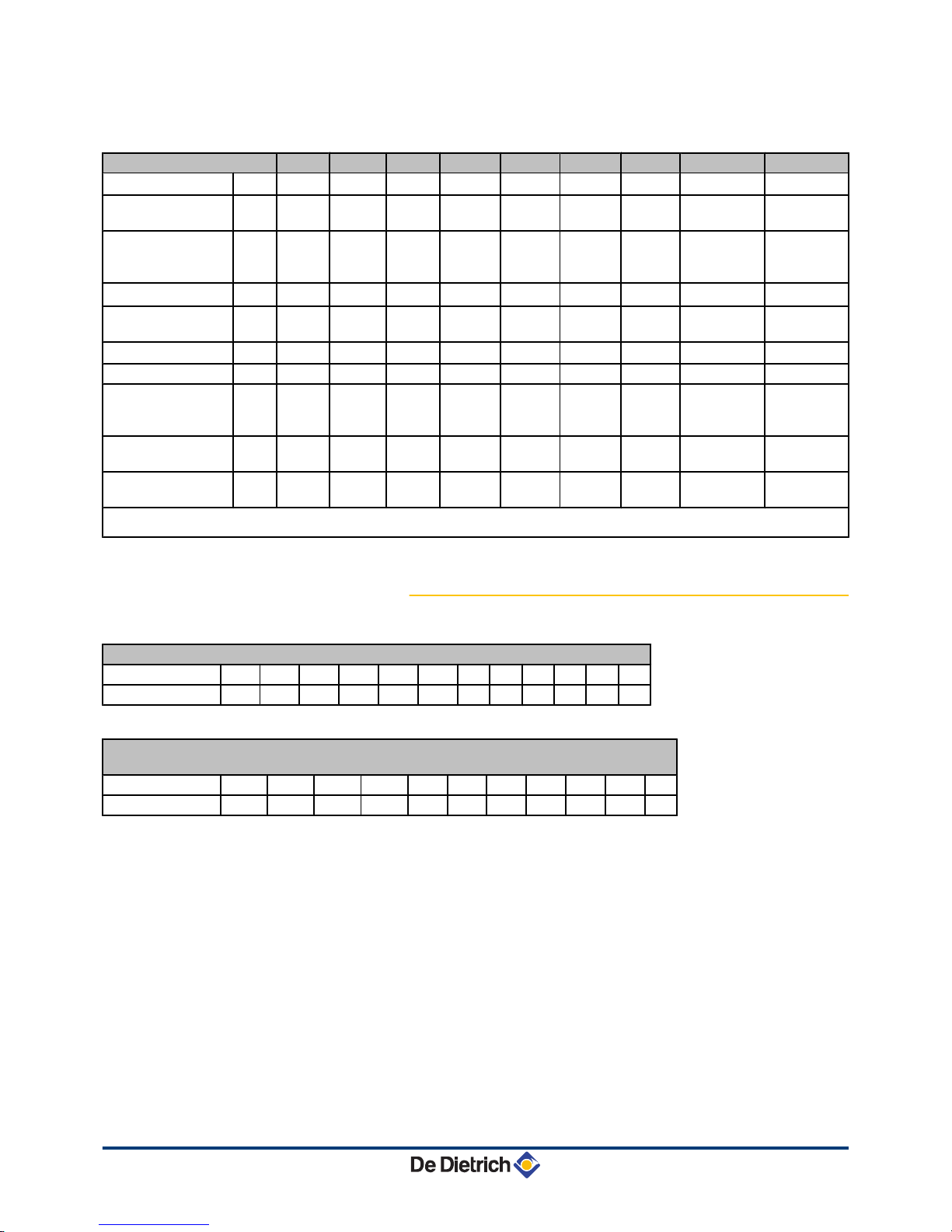

Performances in hot mode with outside air temperature

at +7°C and outlet water temperature at +35°C (in

accordance with EN 14511–2)

AWHP

4 MR 6 MR -2 8 MR-2 11 MR-2 11 TR-2 16 MR-2 16 TR-2 22 TR 27 TR

Calorific output - A7/W35 kW 3.72 5.87 8.26 10.56 10.56 14.19 14.19 19.4 24.4

COP hot - A7/W35

4.30 4.18 4.27 4.30 4.30 4.22 4.22 3.94 3.90

Absorbed electrical power - A7/W35 kWe 0.87 1.41 1.93 2.46 2.46 3.36 3.36 4.92 6.25

Nominal amperage - A7/W35 A 4.11 6.57 8.99 11.81 11.81 16.17 16.17 7.75 9.86

n

Performances in hot mode with outside air temperature

at +2°C and outlet water temperature at +35°C (in

accordance with EN 14511–2)

AWHP

4 MR 6 MR -2 8 MR-2 11 MR-2 11 TR-2 16 MR-2 16 TR-2 22 TR 27 TR

Calorific output - A2/W35 kW 3.76 3.87 5.93 10.19 10.19 11.38 11.38 12.10 14.70

COP hot - A2/W35

3.32 3.26 3.20 3.20 3.20 3.27 3.27 3.10 3.10

Absorbed electrical power - A2/W35 kWe 1.13 1.19 1.85 3.19 3.19 3.48 3.48 3.91 4.70

Nominal amperage - A2/W35 A 6.1 6.1 8.2 10.7 6.2 14.6 8.4 9.7 11.8

n

Performances in cold mode with outside air

temperature at +35°C and outlet water temperature at

+18°C (in accordance with EN 14511–2)

AWHP

4 MR 6 MR -2 8 MR-2 11 MR-2 11 TR-2 16 MR-2 16 TR-2 22 TR 27 TR

Cooling output kW 3.84 4.69 7.90 11.16 11.16 14.46 14.46 17.65 22.2

EER

3.80 3.80 3.99 4.68 4.68 4.43 4.43 3.8 3.8

Absorbed electrical power kWe 0.72 1.15 2.0 2.35 2.35 3.65 3.65 4.65 5.84

AWHP-2 MIT-IN-2 iSystem 3. Technical description

25/06/2014 - 7616371-001-04

15

Page 18

n

General values

AWHP 4 MR 6 MR -2 8 MR-2 11 MR-2 11 TR-2 16 MR-2 16 TR-2 22 TR 27 TR

Sound pressure

(1)

dB(A) 41.7 41.7 43.2 43.4 43.4 47.4 47.4 51.8 53

Nominal water flow

(ΔT = 5K)

m3/h

1.04 1.04 1.47 1.88 1.88 2.67 2.67 3.8 4.6

Manometric height

available at nominal

flow rate

mbar 618 618 493 393 393 213 213 - -

Nominal air flow rate

m3/h

2100 2100 3000 6000 6000 6000 6000 8400 8400

Power voltage of the

outdoor unit

V 230 V~ 230 V~ 230 V~ 230 V~ 400 V3~ 230 V~ 400 V3~ 400 V3~ 400 V3~

Sound output

(2)

dB(A) 63.7 63.7 65.2 65.4 65.4 69.4 69.4 73.8 75

R410A refrigerant kg 2.1 2.1 3.2 4.6 4.6 4.6 4.6 7.1 7.7

refrigerant piping

connection (LiquidGas)

inch 1/4-1/2 1/4-1/2 3/8-5/8 3/8-5/8 3/8-5/8 3/8-5/8 3/8-5/8 3/8-3/4 or

3/8-1

1/2-3/4 or

1/2-1

Max pre-loaded

length

m 10 10 10 10 10 10 10 30 30

Weight (empty) Outside unit

kg 42 42 75 118 118 130 130 135 141

(1) 5 m from the appliance, free field.

(2) Test conducted in accordance with the standard NF EN 12102

3.4.3. Sensor characteristics

Outside sensor

Temperature in °C -20 -16 -12 -8 -4 0 4 8 12 16 20 24

Resistance in Ω 2392 2088 1811 1562 1342 1149 984 842 720 616 528 454

DHW sensor

Flow sensor

Temperature in °C 0 10 20 25 30 40 50 60 70 80 90

Resistance in Ω 32014 19691 12474 10000 8080 5372 3661 2535 1794 1290 941

3. Technical description AWHP-2 MIT-IN-2 iSystem

16

25/06/2014 - 7616371-001-04

Page 19

4 Installation

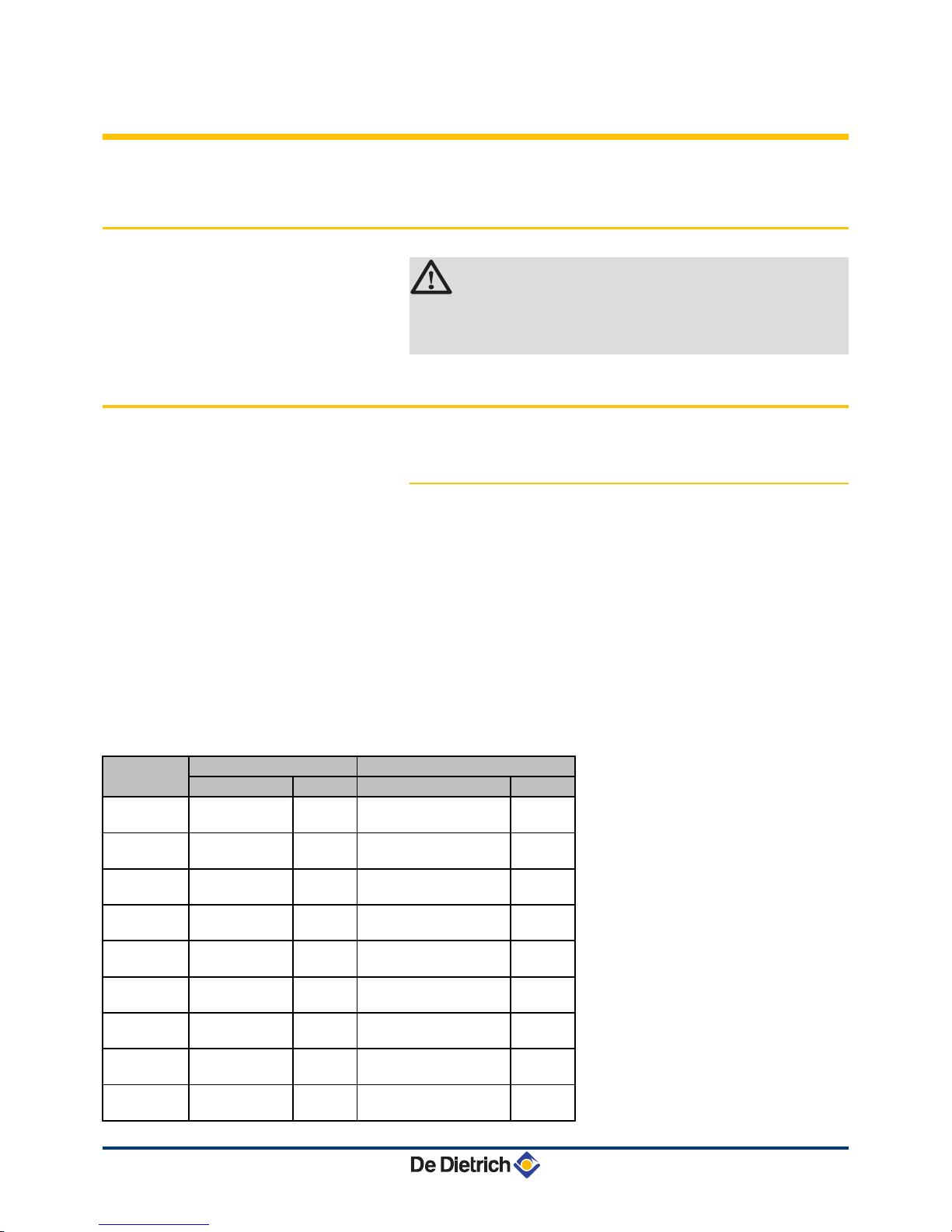

4.1 Regulations governing installation

CAUTION

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

4.2 Package list

4.2.1. Standard delivery

The delivery includes:

4 An outside module (See below)

4 An inside hydraulic module (See below)

4 An outside sensor

4 Refrigerant adapter fitting 4, 6 and 22 kW

4 A mounting rail (screwed to the pallet)

4 The installation and maintenance instructions

4 The user instructions

Combinations possible:

Models

Outdoor unit Indoor module

Description Pack no. Description Pack no.

HPI 4 MR-2

AWHP 4 MR EH336

MIT-IN-2/H 4 - 8 ISYS

MIT-IN-2/E 4 - 8 ISYS

EH386

EH389

HPI 6 MR-2

AWHP 6 MR-2 EH380

MIT-IN-2/H 4 - 8 ISYS

MIT-IN-2/E 4 - 8 ISYS

EH386

EH389

HPI 8 MR-2

AWHP 8 MR-2 EH381

MIT-IN-2/H 4 - 8 ISYS

MIT-IN-2/E 4 - 8 ISYS

EH386

EH389

HPI 11 MR-2

AWHP 11 MR-2 EH382

MIT-IN-2/H 11 - 16 ISYS

MIT-IN-2/E 11 - 16 ISYS

EH387

EH390

HPI 11 TR-2

AWHP 11 TR-2 EH383

MIT-IN-2/H 11 - 16 ISYS

MIT-IN-2/E 11 - 16 ISYS

EH387

EH390

HPI 16 MR-2

AWHP 16 MR-2 EH384

MIT-IN-2/H 11 - 16 ISYS

MIT-IN-2/E 11 - 16 ISYS

EH387

EH390

HPI 16 TR-2

AWHP 16 TR-2 EH385

MIT-IN-2/H 11 - 16 ISYS

MIT-IN-2/E 11 - 16 ISYS

EH387

EH390

HPI 22 TR-2

AWHP 22 TR EH225

MIT-IN-2/H 22 - 27 ISYS

MIT-IN-2/E 22 - 27 ISYS

EH388

EH391

HPI 27 TR-2

AWHP 27 TR EH226

MIT-IN-2/H 22 - 27 ISYS

MIT-IN-2/E 22 - 27 ISYS

EH388

EH391

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

17

Page 20

4.2.2. Accessories

Various options are available depending on the configuration of the

installation:

n

Heat pump options

Description package

160 L storage tank EH 60

80 L storage tank EH 85

Wall-hanging kit for outside units 6 - 10 kW EH 95

Condensate receiver tank for wall bracket EH 111

Ground mounting supports for outside units EH 112

Electrical resistor for the condensate receiver tank EH 113

Frigorific ducts with insulation (5/8" - 3/8"); Length: 5 m EH 114

Frigorific ducts with insulation (5/8" - 3/8"); Length: 10 m EH 115

Frigorific ducts with insulation (5/8" - 3/8"); Length: 20 m EH 116

Insulated copper pipe (1/2" - 1/4") 10 m EH 142

1/4" 1/2" - 3/8" 5/8" adapter fittings EH 146

Heat pump hydraulic connection kit - DHW storage tank EH 149

Wall-hanging kit for outside units 11 - 27 kW EH 250

3-way valve module with standard pump EA 63

3-way valve module with electronic pump EA 67

Collector for 2/3 circuits EA140

Wall console EA141

Wall console for hydraulic module EA142

Direct circuit with pump HEE EA143

V3V circuit with HEE pump EA144

Wiring kit for connecting a safety thermostat for underfloor

heating

HA 249

3-way valve kit HK 21

2-circuit kit HK 22

Reversal valve kit HK 23

Insulation kit cold mode HK 24

3-way valve insulation kit HK 25

n

Control system options

Description

package

BUS connection cable (length 12 m) AD134

voice remote monitoring module AD152

Outlet sensor V3V AD199

DHW sensor AD212

Optional PCB for 3-way valve AD249

System sensor AD250

Outside radio-controlled temperature sensor AD251

Radio module AD252

CDR iSystem radio remote control AD284

4. Installation AWHP-2 MIT-IN-2 iSystem

18

25/06/2014 - 7616371-001-04

Page 21

Description package

Interactive radio remote control with LCD display CD12/CD14 AD285

Radio remote control AD253

Interactive remote control AD254

A simplified remote control with room sensor FM52

Condensation detector kit HK 27

Energy metering option HK 29

4.3 Type plate

4.3.1. Outdoor unit

The type plate must be accessible at all times. The type plate

identifies the product and provides the following information:

4 Appliance type

4 Manufacturing date (Year - Week)

4 Serial number.

4 Nature of the power supply voltages

4.3.2. Indoor module

1

This data plate is affixed to the inside side panel of the

appliance in the factory.

2

When installation has been completed, affix the data plate

provided in the instructions bag to the casing of the

appliance in a position where it can be seen.

The type plate must be accessible at all times. The type plate

identifies the product and provides the following information:

4 Appliance type

4 Manufacturing date (Year - Week)

4 Serial number.

4 Nature of the power supply voltages

MW-M001832-2

M002624-A

Auf ERDGAS H eingestellt

für DE: Erdgas E

Réglé au gaz naturel H

Geregeld voor aardgas H

Preset for natural gas H

G20 - 20 mbar

8366-4038

1 2

AWHP-2 MIT-IN-2 iSystem

4. Installation

25/06/2014 - 7616371-001-04

19

Page 22

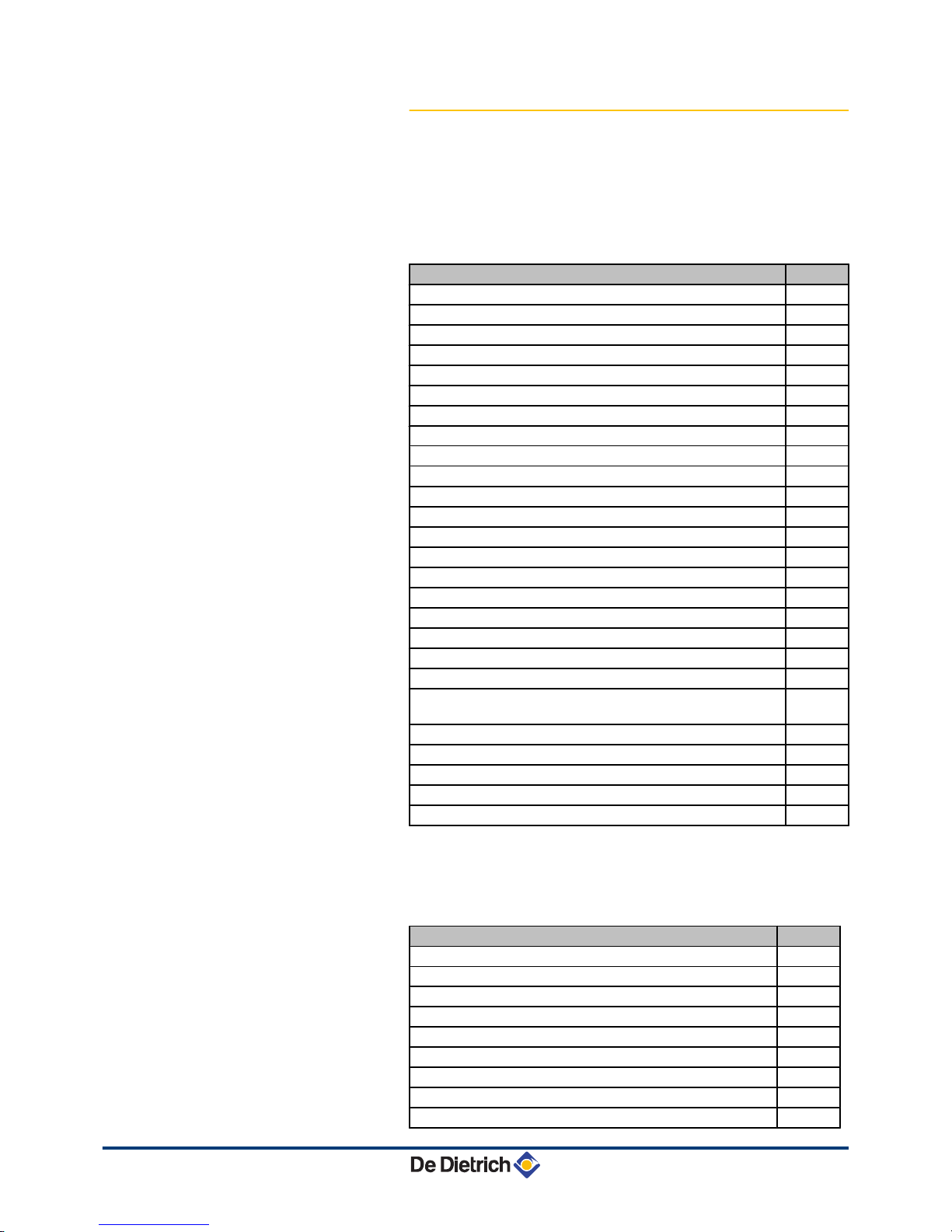

4.4 Installing the outdoor module

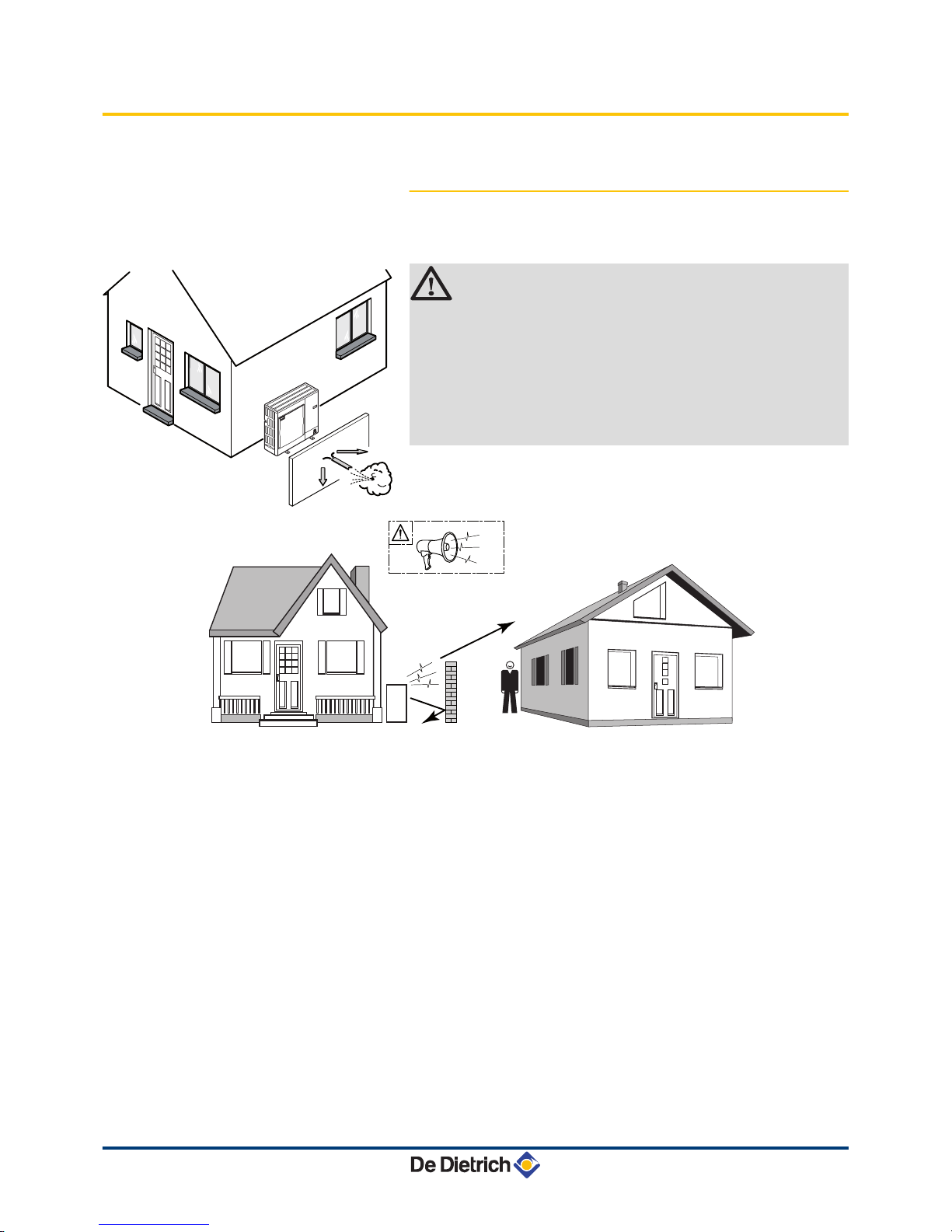

4.4.1. Positioning of the appliance

Ensure that the outside module is optimally positioned in relation to

neighbours as it is a source of noise.

CAUTION

4 There must be no obstacles hindering the free

circulation of air around the outdoor module (intake

and output).

4 No not locate the outside unit close to where people

sleep.

4 Do not locate the unit opposite a wall with windows.

4 Avoid placing it close to a terrace, etc..

Choose a location away from prevailing winds.

C000373-B

Brrrrr....

Brrrrr....

Brrrrr....

Brrrrr....

In some cases, additional precautions are necessary owing to the

fact, for example, of too short a distance between you and your

neighbours.

When installing a noise reduction screen, respect the following

recommendations:

4 Locate the noise reduction screen as close as possible to the noise

source whilst allowing for the free circulation of air in the

exchanger on the outside unit and maintenance work.

Place the outside unit on a base (concrete base frame, sill,

concrete blocks, etc.) with no rigid connection with the building

served in order to prevent any transmission of vibrations. Ensure

sufficient above ground elevation (100 to 150 mm) to keep it above

water.

For regions where heavy snowfalls occur, raise this above ground

protection by at least 200 mm compared with the average depth of

the covering of snow.

M001448-A

4. Installation

AWHP-2 MIT-IN-2 iSystem

20

25/06/2014 - 7616371-001-04

Page 23

CAUTION

4 If the outside temperatures become negative, take

the necessary precautions to prevent the risk of

freezing in the evacuation pipes.

4 Prevent any risk of the condensates freezing in an

area through which they flow.

4 The heating cord keeps the condensates from

freezing: See EH113 leaflet.

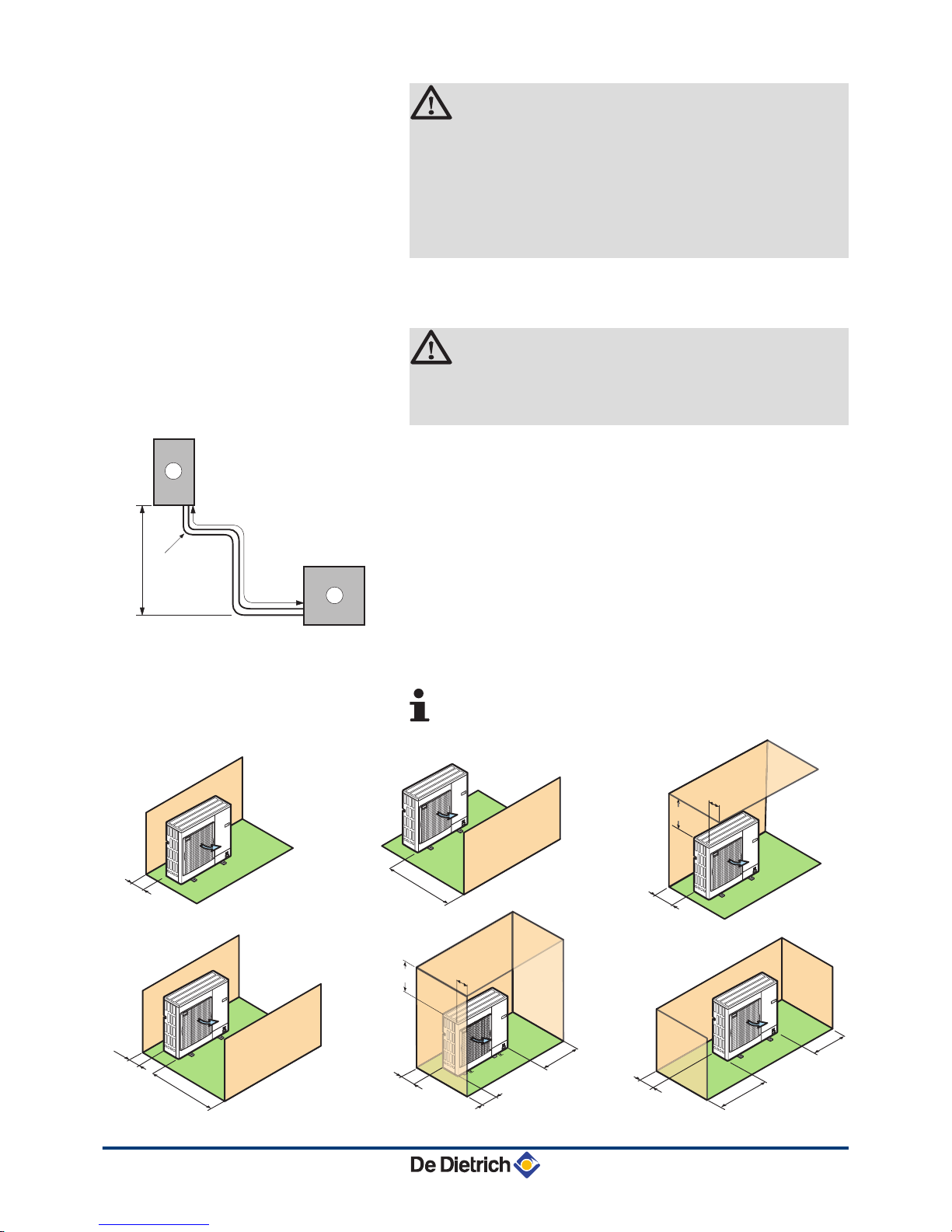

n

Distances to be observed

WARNING

To ensure that the heat pump functions correctly, respect

the minimum and maximum connection lengths between

the heat pump and the indoor module.

A

Outdoor unit

Z

Indoor module

A

Minimum length 5 m

Maximum length:

40 m for 4, 6, 8 kW,

75 m for 11, 16 kW,

20 m for 22, 27 kW.

B

Max height difference 10 m For 4, 6, 8 kW

Max height difference 30 m For 11, 16, 22, 27 kW

C

Max number of elbows: 15

Respect the minimum curve radii of 100 to 150 mm

¼See chapter: "Installing the pipes", page 30.

M00 1439-A

A

B

2

1

C

MW-M001450-2

G

F

F

G

A

C

B

B

C

E

A

1000

D

M

ax. 500

M

ax. 500

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

21

Page 24

Dimension (mm) 4, 6, 8 kW 11, 16, 22, 27 kW

A

100 150

B

500 1000

C

200 300

D

1000 1500

E

300 500

F

150 250

G

100 200

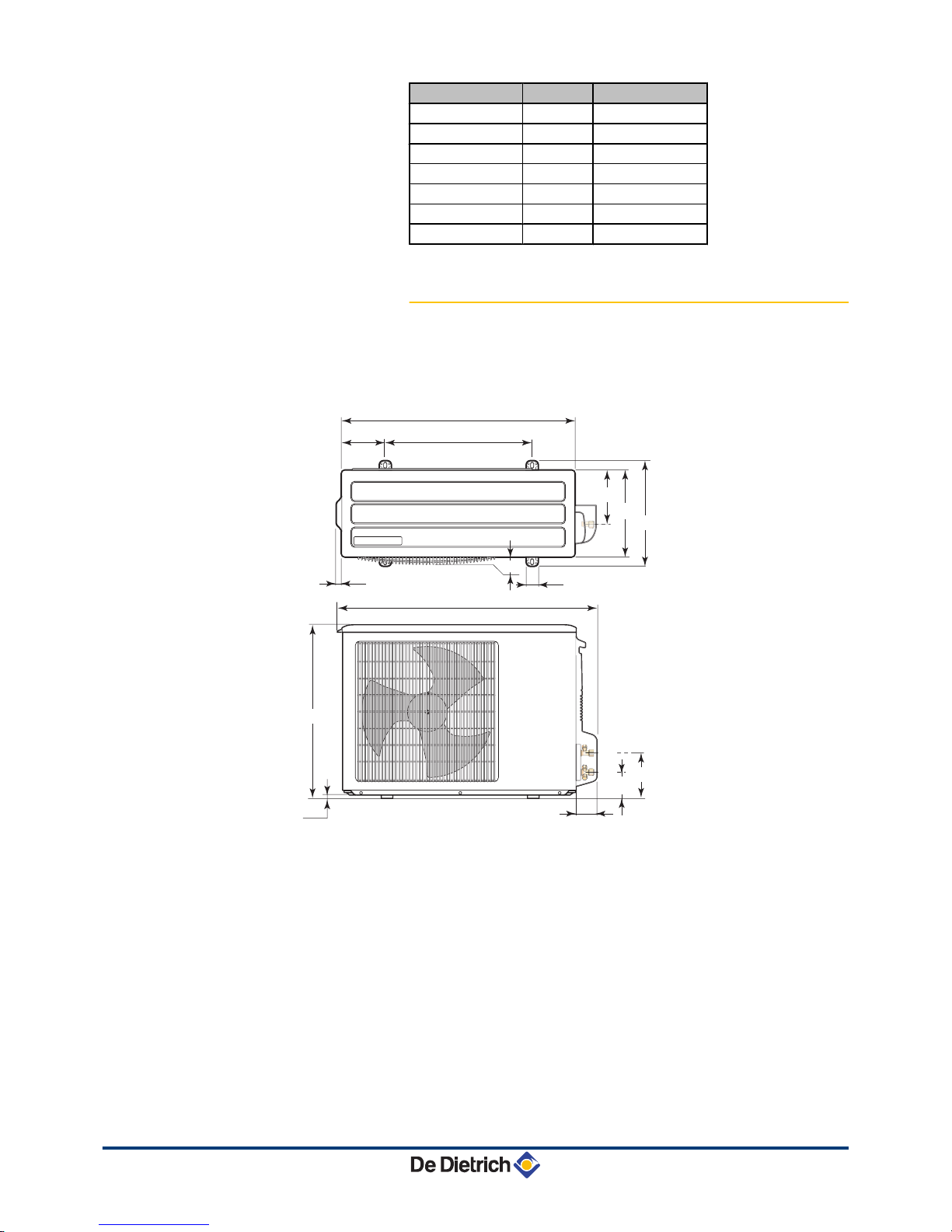

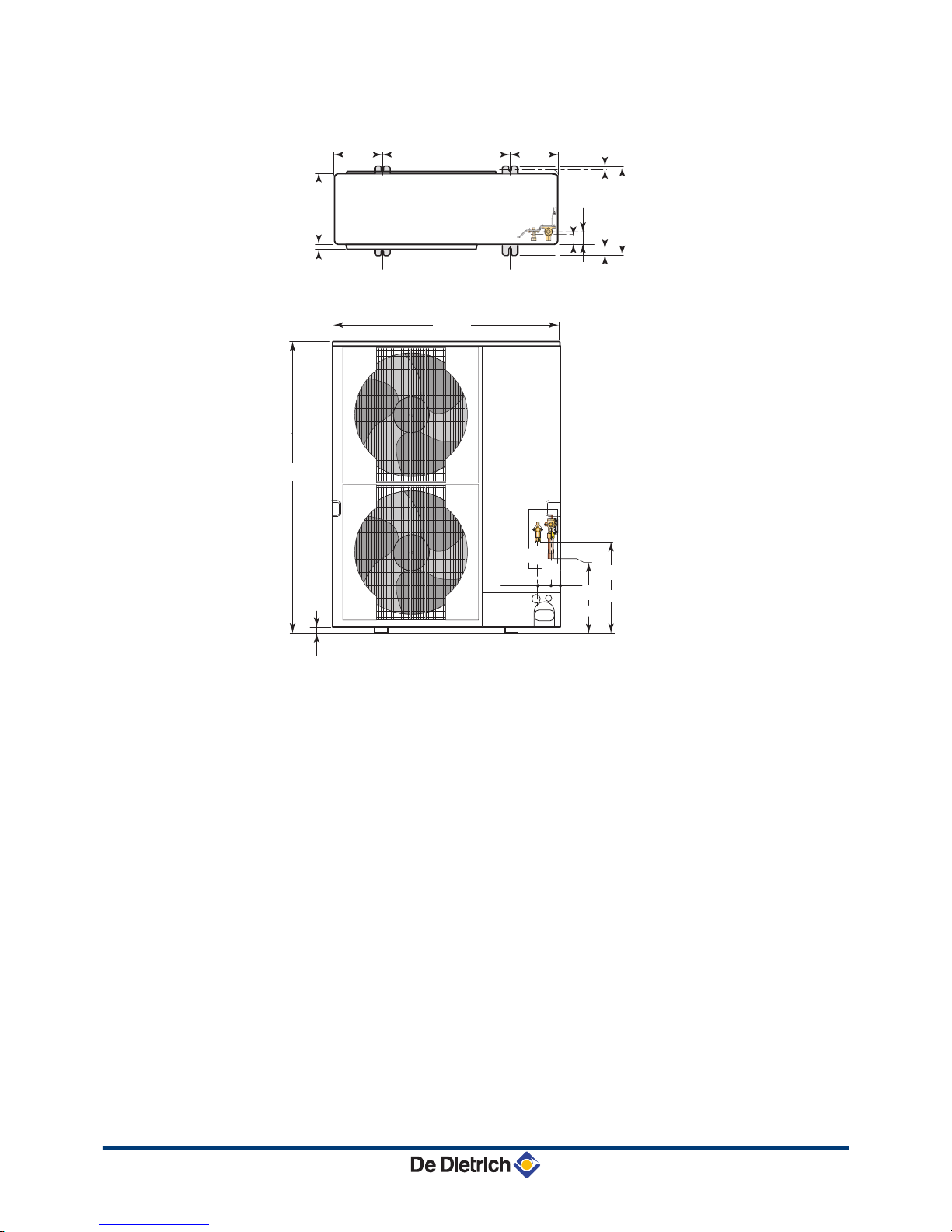

4.4.2. Main dimensions

n

AWHP 4 and 6 MR-2

A

1/4" flare refrigerant fitting

Z

1/2" flare refrigerant gas fitting

150 500

800

887

300

183

155

365

600

40

10

23

69

18

90

MW-M002199-2

1

2

4. Installation AWHP-2 MIT-IN-2 iSystem

22

25/06/2014 - 7616371-001-04

Page 25

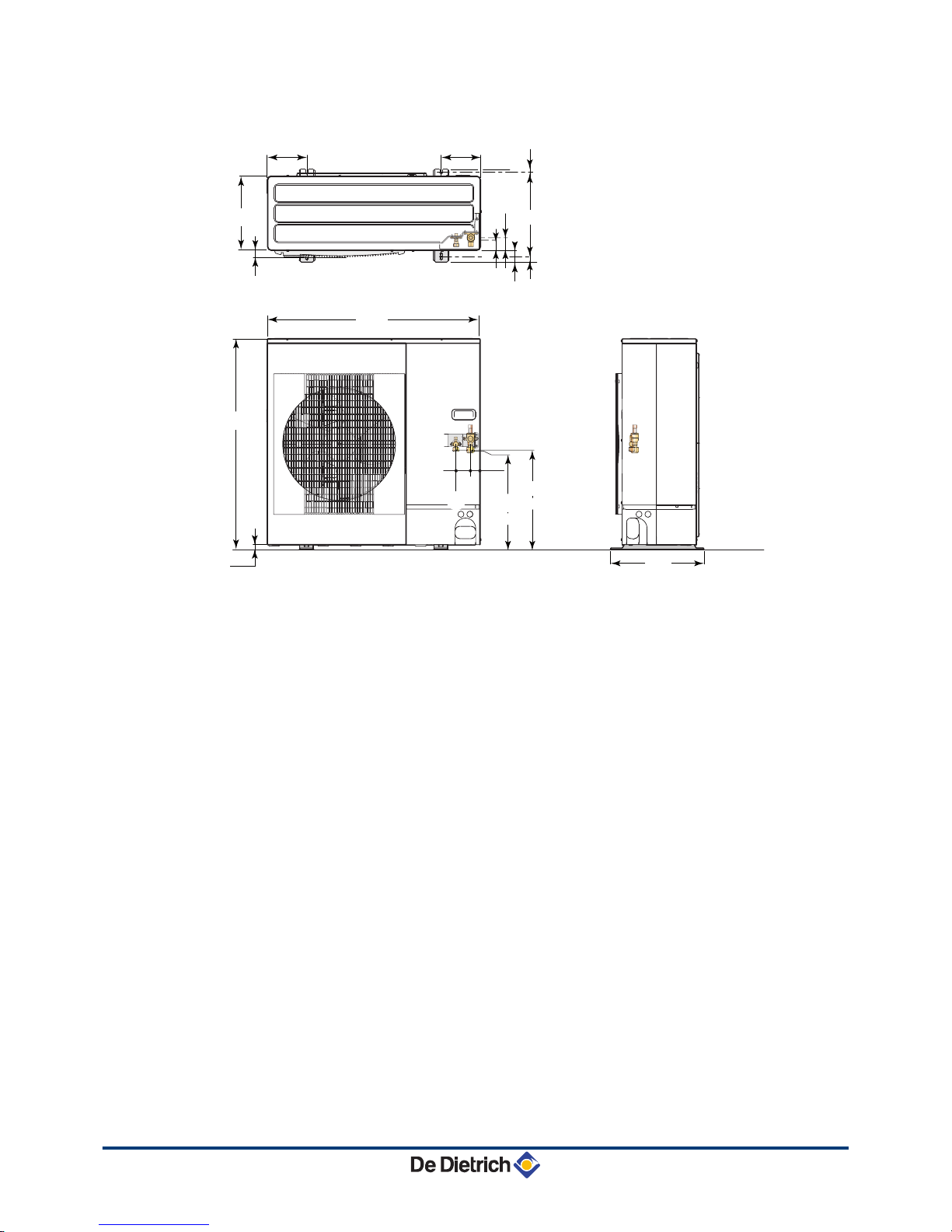

n

AWHP 8 MR-2

A

3/8" flare refrigerant fitting

Z

5/8" flare refrigerant gas fitting

943

950

45

56

53 28

19

23

417

175

330

370

30

443

447

175

65 42

2

(1)

(2)

MW-M001442-2

1

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

23

Page 26

n

AWHP 11 and 16 MR/TR-2

A

3/8" flare refrigerant fitting

Z

5/8" flare refrigerant gas fitting

1350

950

45

56

53 28

19

23

417

175 600

330

370

30

443

447

175

65 42

2

(1)

(2)

1

MW-M001443-2

4. Installation AWHP-2 MIT-IN-2 iSystem

24

25/06/2014 - 7616371-001-04

Page 27

n

AWHP 22 and 27 TR

A

450 mm : 22 kW

424 mm : 27 kW

A

3/8" flare refrigerant fitting (22 kW)

1/2" flare refrigerant fitting (27 kW)

Z

3/4" flare refrigerant gas fitting + adapter 1" (to be

brazed)

MW-M002629-1

1338

1050

40

56

26

342

A

225

330

370

417

30

600

225

19

28

60

42

(1)

(2)

2

1

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

25

Page 28

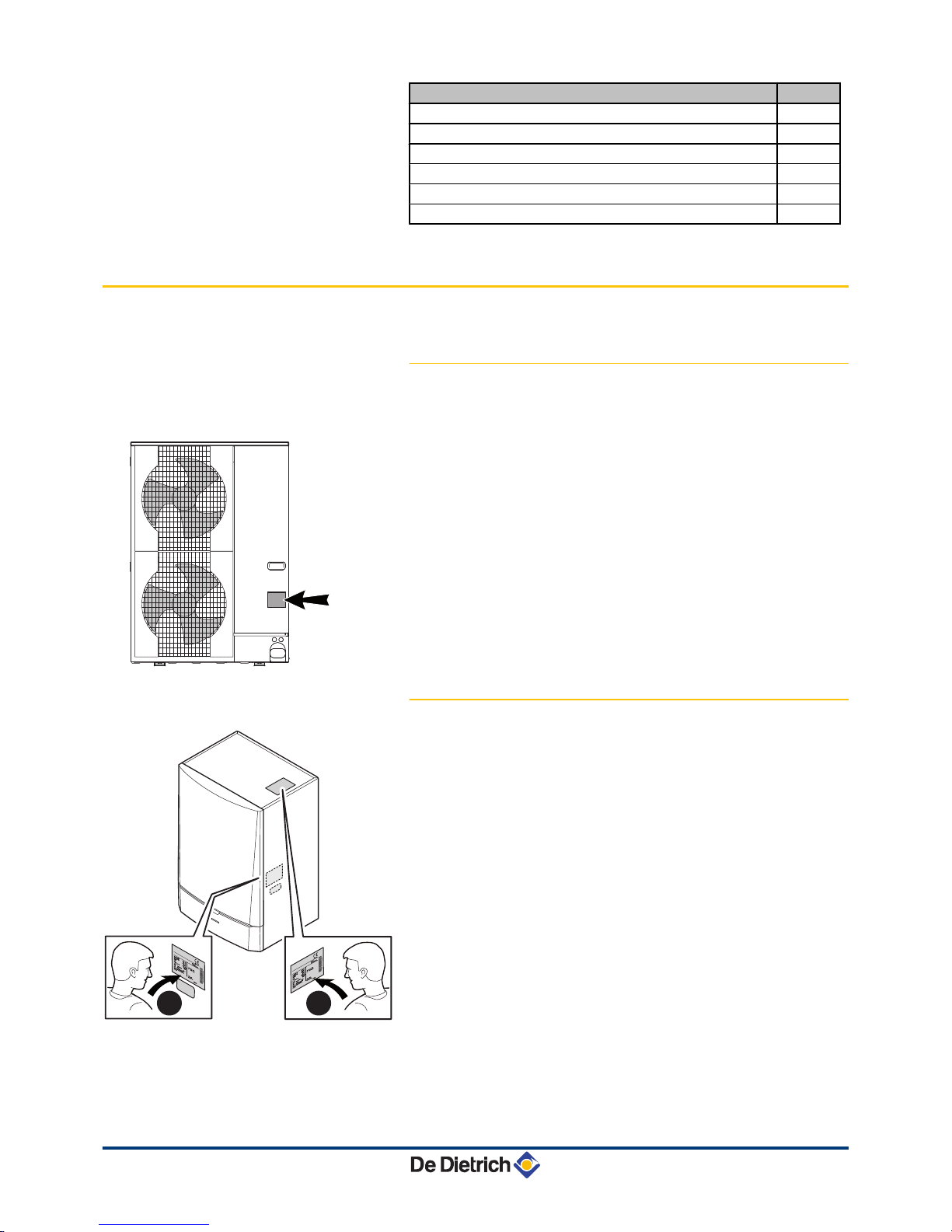

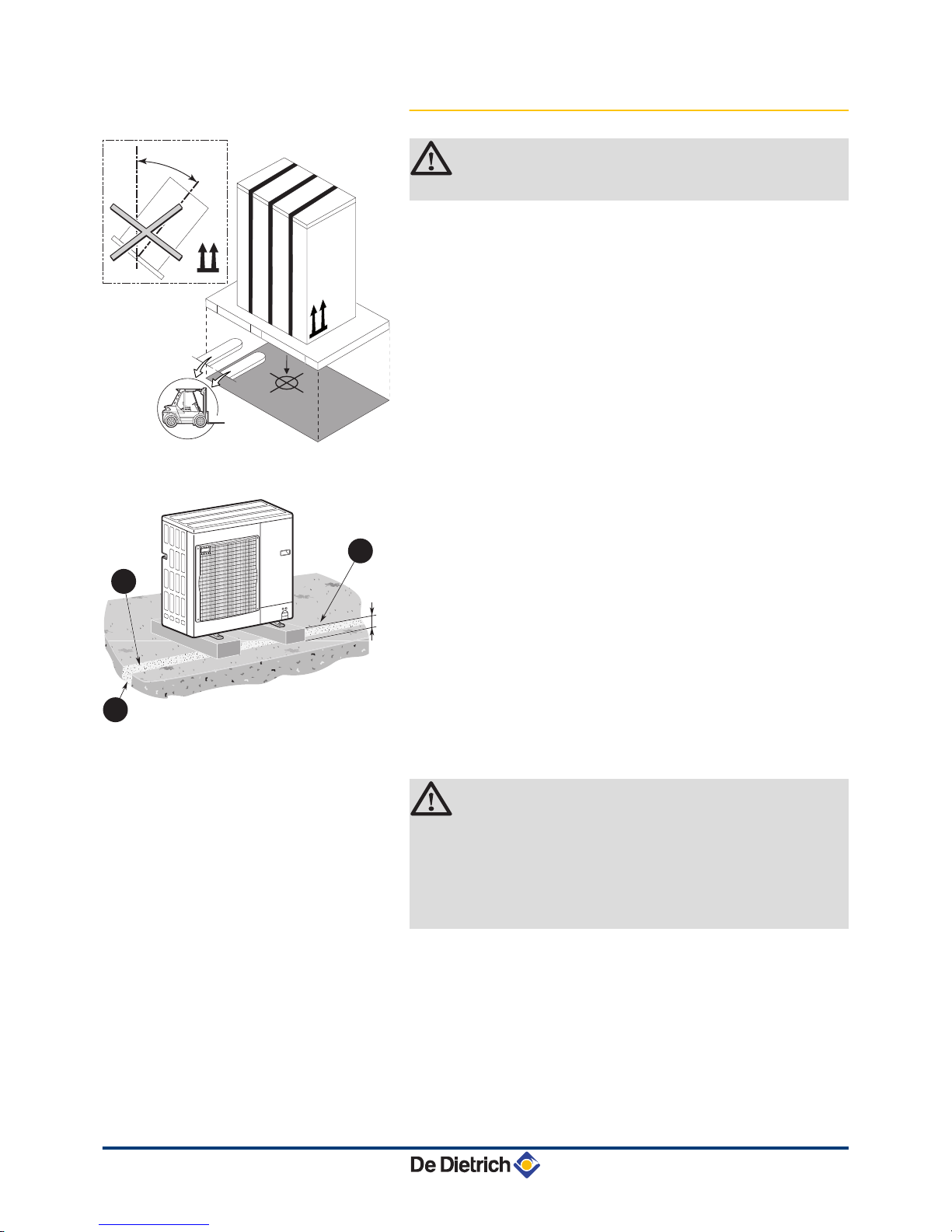

4.4.3. Locating the outside module

CAUTION

Keep the appliance vertical during transport.

n

Installation on the ground

1

Concrete base frame

2

Condensates run-off

3

Install a run-off channel with pebble bed

4 Use the ground installation base kit available as optional

equipment: Package EH112.

4 Install the appliance on a solid, stable structure able to bear its

weight.

n

Condensates discharge

CAUTION

If the outside temperatures become negative, take the

necessary precautions to prevent the risk of freezing in the

evacuation pipes. Use package EH113 (Electrical resistor

for the condensate receiver tank).

Prevent any risk of the condensates freezing in an area

through which they flow.

>45°

M001456-A

200

1

2

3

M001452-A

4. Installation AWHP-2 MIT-IN-2 iSystem

26

25/06/2014 - 7616371-001-04

Page 29

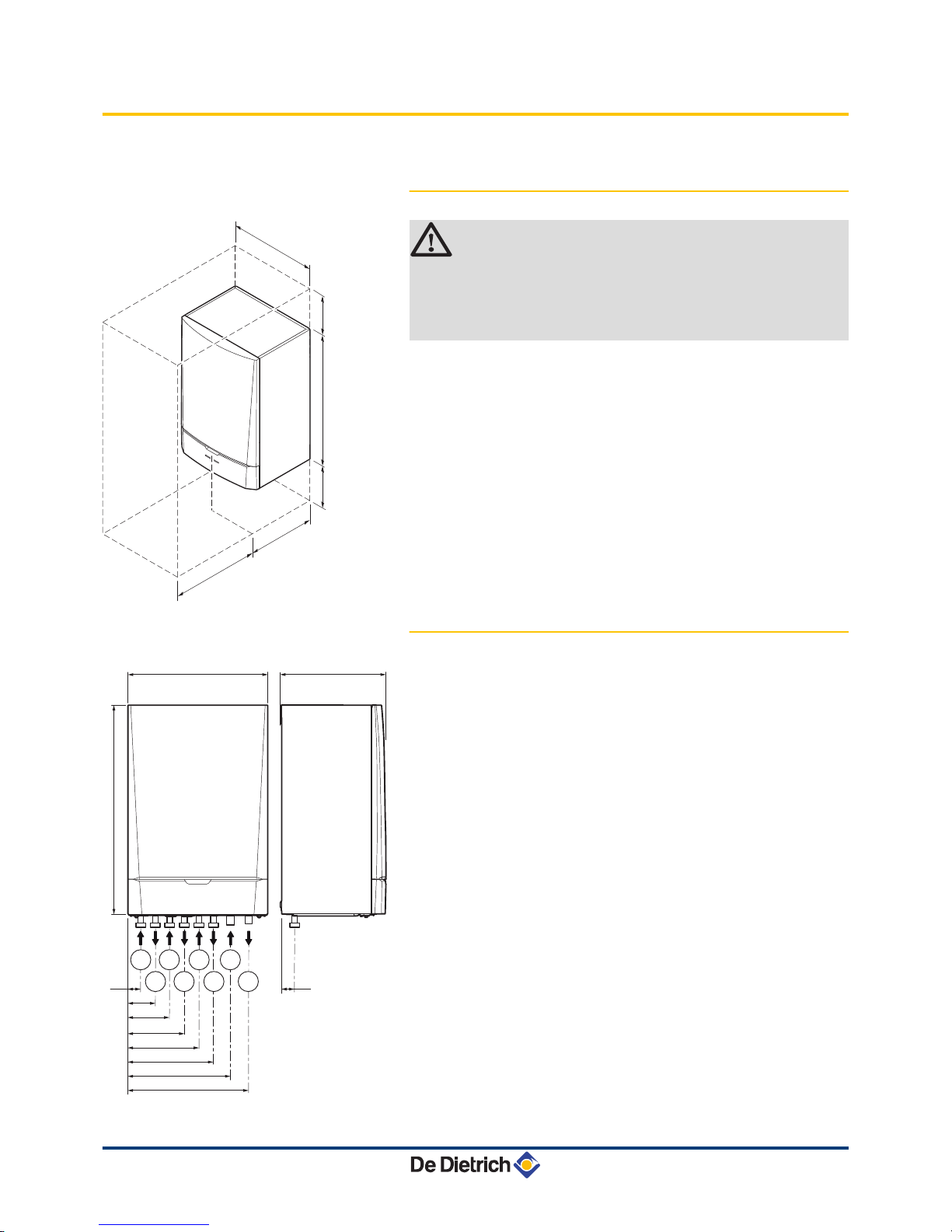

4.5 Installing the indoor module

4.5.1. Positioning of the appliance

CAUTION

4 Install the appliance in frost-free premises.

4 Fix the appliance to a solid wall capable of bearing

the weight of the appliance when full of water and fully

equipped.

4.5.2. Main dimensions

A

3-way valve circuit return (Option) - G1"

Z

3-way valve circuit outlet (Option) - G1"

E

Return direct circuit - G1"

R

Direct circuit flow - G1"

T

Back-up boiler inlet - G1"

Only for hydraulic back-up - Version H

Y

Return to the back-up boiler - G1"

Only for hydraulic back-up - Version H

U

Gas line

5/8" flare connection: 4, 6, 8, 11, 16 kW

3/4" flare connection: 22, 27 kW (Use 1" braze-on

adapter)

I

Liquid line

3/8" flare connection: 4, 6, 8, 11, 16 kW

1/2" flare connection: 22, 27 kW

G

Exterior cylindrical threading, sealed by sheet gasket

T001898-C

600

min.1000

500

min.

250

min.

250

900

M002497-B

122

192

262

332

402

472

542

49 48

900

600

498

1234567

8

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

27

Page 30

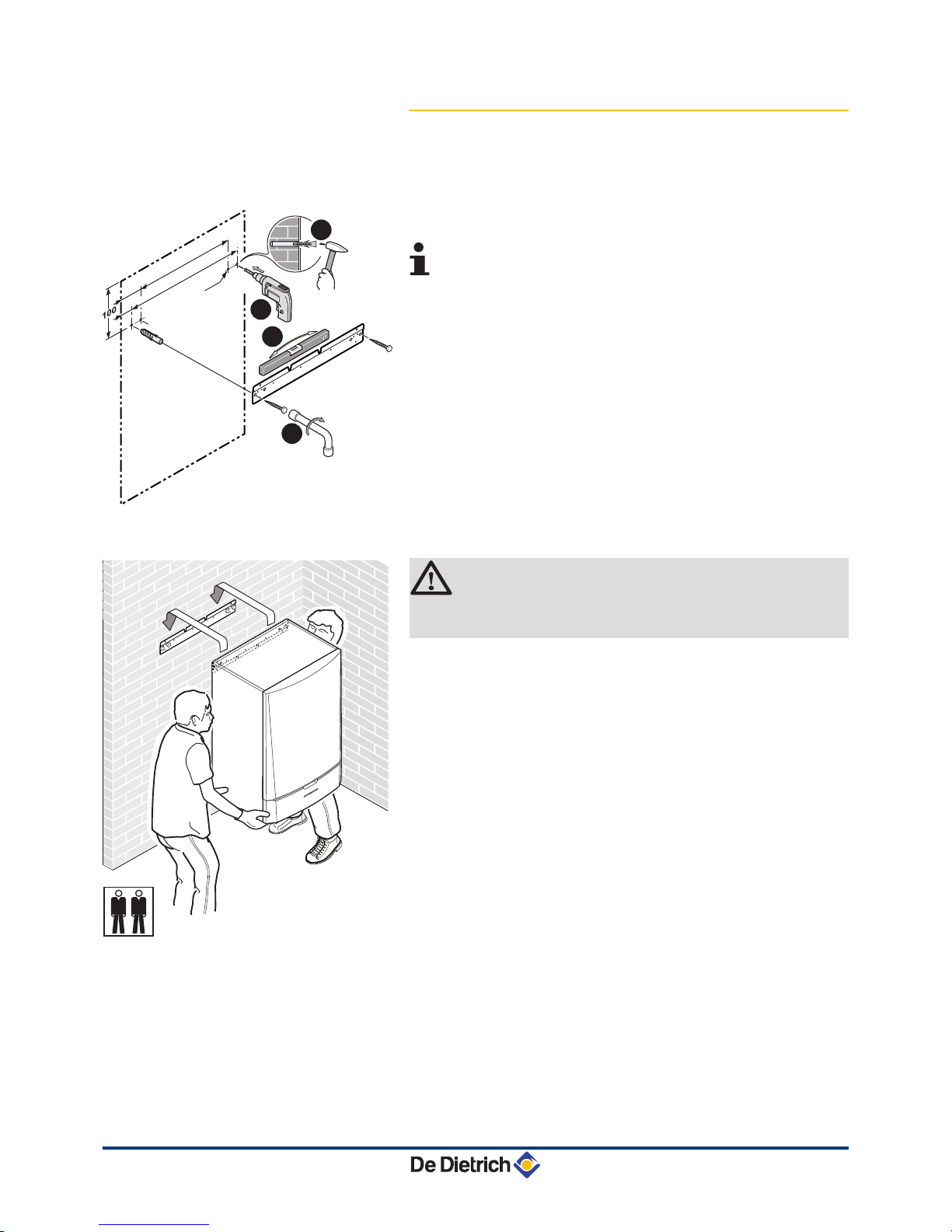

4.5.3. Assembly of the indoor module

n

Fitting the mounting rail

1. Drill 2 holes with a Ø of 10 mm.

Additional holes are provided in case one or other of the

standard locating holes prevents the correct location of the

plugs.

2. Put the plugs in place.

3. Fix the mounting rail to the wall using the hexagonal head screws

provided for this purpose. Set the level using a spirit level.

n

Fixing to the wall

CAUTION

Weight (empty): 74 kg

Shipping weight: 112 kg

1. Present the indoor module above the mounting rail until it rests

firmly against it.

2. Gently lower the indoor module.

1

2

3

3

M002380-B

458

61

11

558

Ø10

M002381-C

4. Installation AWHP-2 MIT-IN-2 iSystem

28

25/06/2014 - 7616371-001-04

Page 31

4.6 Installing the outside sensor

4.6.1. Choice of the location

It is important to select a place that allows the sensor to measure the

outside conditions correctly and effectively.

Advised positions:

4 on one face of the area to be heated, on the north if possible

4 half way up the wall in the room to be heated

4 under the influence of meteorological variations

4 protected from direct sunlight

4 easy to access

A

Recommended position

B

Possible position

H

Inhabited height controlled by the sensor

Z

Inhabited area controlled by the sensor

Positions to be avoided:

4 masked by a building element (balcony, roof, etc.)

4 close to a disruptive heat source (sun, chimney, ventilation grid,

etc.)

4.6.2. Connecting the outside sensor

Mount the sensor using the screws and dowels provided.

8800N001-C

8800N002-C

AWHP-2 MIT-IN-2 iSystem

4. Installation

25/06/2014 - 7616371-001-04

29

Page 32

A

Inserts

Z

Ø4 wood screw

¼For the connection of the outside temperature sensor, refer to

the chapter "Electrical Connections".

4.7 Combination with a DHW tank

In order to optimise domestic hot water production, the recommended

combinations of heat pumps and DHW tanks are:.

4 MR 6 MR-2 8 MR-2 11 MR-TR 2 16 MR-TR 2 22 TR 27 TR

BLC150 X X X X

BLC200

X X X X

BLC300

X X X X

WARNING

An incorrect DHW tank/heat pump combination may

adversely affect user comfort.

An incorrect combination may lead to overconsumption

subsequent to the repeated tripping of the back-ups.

4.8 Installing the refrigerant piping

4.8.1. Installing the pipes

DANGER

Only a qualified professional may carry out the installation

in conformity with in force legislation and standards.

4 Install the frigorific connection pipes between the inside and

outside modules.

4 Respect the minimum curve radii of 100 to 150 mm.

4 Only for 22 - 27 TR models:

If the length of the piping is less than 20 m, it is possible to use

annealed pipe for the gas pipe with a diameter of 3/4 without using

braze-on adapters. The output in cooling mode may be reduced

to 20% depending on the length used.

4 Respect the minimum and maximum lengths. ¼See chapter:

"Positioning of the appliance", page 20.

If the frigorific connection between the outside module and the

inside module is less than 5 m, the following disruptions may

occur:

8800N003-C

2

4. Installation

AWHP-2 MIT-IN-2 iSystem

30

25/06/2014 - 7616371-001-04

Page 33

- Functional disruptions caused by a fluid overload

- Noise pollution caused by the circulation of the refrigerant

In this case, fit a refrigerant connection of at least 5 m by making

1 or 2 horizontal loops, as necessary, in order to limit such

annoyance and oil traps.

If the refrigeration connection pipes are more than 10 metres long,

refrigerant R410A must be added.

Add refrigerant via the refrigerant shut off valve using a safety loader.

¼See chapter: "Adding refrigerant", page 36.

4 Cut the pipes with a pipe cutter and deburr them, point the opening

in the pipe downwards to prevent the introduction of particles.

4 Prevent oil traps.

WARNING

If the pipes are not to be connected immediately, they

should be plugged to prevent the infiltration of humidity.

Use a flat spanner to hold the hoses during the various

operations.

1. Partially unscrew the 5/8" or 3/4" "gas" nut, depending on the

model.

2. A release noise should be heard, which is proof that the exchanger

is watertight.

MW-2000076-1

M002395-B

1

M002396-B

OK

Pfffff...

2

AWHP-2 MIT-IN-2 iSystem

4. Installation

25/06/2014 - 7616371-001-04

31

Page 34

3. Unscrew the screws.

CAUTION

Keep the frigorific connection in place on the MIT-IN-2 with

a spanner so as not to twist the internal pipe.

4. Remove and discard the gates.

5.

Only for 4 - 6 MR-2 models

Fit the 1/4" to 3/8" and 1/2" to 5/8" adapter fittings (Package

EH146).

Use the copper gaskets.

Use a torque wrench.

¼

See "torque" table (step 9).

Only for the 22 TR model

Fit a 3/8" to 1/2" adapter to the liquid connection.

Use the copper gaskets.

Use a torque wrench.

¼

See "torque" table (step 9).

CAUTION

Keep the frigorific connection in place on the MIT-IN-2 with

a spanner so as not to twist the internal pipe.

6.

Models 8 to 16 MR/TR-2 and 27 TR

Slip the nuts onto the pipes.

Models 4 and 6 MR-2and 22 TR

Slip the nuts provided with the adapters onto the pipes.

7. Bead the pipes.

M002397-C

3

M002498-A

4

M002398-D

4MR - 6MR-2

5

M002399-D

22TR

5

M002207-B

6

7

4. Installation

AWHP-2 MIT-IN-2 iSystem

32

25/06/2014 - 7616371-001-04

Page 35

8.

Models 22 TR and 27 TR

If the length of the piping is less than 20 m, it is possible to use

annealed pipe for the gas pipe with a diameter of 3/4 without using

braze-on adapters. The output in cooling mode may be reduced

to 20% depending on the length used.

Using the 1" braze-on gas pipe:

Braze the 1" gas pipe on to the braze-on adapter, circulating

dehydrated nitrogen inside the pipe to prevent oxidation.

CAUTION

Do not overheat the pipe, protect the insulation and the

inside module when brazing.

Use hard solder.

Using the 3/4" crown gas pipe:

Slip the nut onto the pipe. Bead the pipes.

9.

A

Only for 4 - 6 MR-2 models

B

Only for 8 - 11 - 16 MR-2 models

C

Only for 22 TR models

D

Only for 27 TR models

Apply refrigerant oil to the beaded parts to facilitate tightening and

improve watertightness.Apply refrigerant oil to the beaded parts to

facilitate tightening and improve watertightness.

Connect the pipes and tighten the nuts with a dynamometric

spanner.

CAUTION

Keep the frigorific connection in place on the MIT-IN-2 with

a spanner so as not to twist the internal pipe.

External diameter of the

pipe (mm-inch)

External diameter of

the cone connection

(mm)

Torque load (Nm)

6.35 - 1/4 17 14 - 18

9.52 - 3/8 22 34 - 42

12.7 - 1/2 26 49 - 61

15.88 - 5/8 29 69 - 82

19.05 - 3/4

100 - 120

10.Remove the protective side panels from the outdoor module.

M002400-B

8

22TR - 27TR

M002401-G

9

9

A B

9

9

C D

10

10

M002402-A

AWHP-2 MIT-IN-2 iSystem

4. Installation

25/06/2014 - 7616371-001-04

33

Page 36

11.Unscrew the nuts on the shut off valves.

12.Slip the nuts onto the pipes.

13.Bead the pipes.

Models 22 and 27 TR (Braze-on 1" fitting): Braze the connecting

pipe to the local pipe without oxygen. Braze in a nitrogen

atmosphere.

14.Apply refrigerant oil to the beaded parts to facilitate tightening and

improve watertightness.

Connect the pipes and tighten the nuts with a dynamometric

spanner.

A Do not use a spanner on this part of the valve, danger of the

refrigerant leaking.

B Recommended position of the spanners for tightening the nut.

CAUTION

Tighten the nuts using a dynamometric spanner.

External diameter of the

pipe (mm-inch)

External diameter of

the cone connection

(mm)

Torque load (Nm)

6.35 - 1/4 17 14 - 18

9.52 - 3/8 22 34 - 42

12.7 - 1/2 26 49 - 61

15.88 - 5/8 29 69 - 82

19.05 - 3/4

100 - 120

M002403-A

11

12

13

M002405-A

11

12

13

22TR - 27TR

M002404-A

14

A

B

B

M002406-A

14

A

B

B

22TR - 27TR

4. Installation AWHP-2 MIT-IN-2 iSystem

34

25/06/2014 - 7616371-001-04

Page 37

4.8.2. Water tightness test

1. Check that the shut off valves A and B are closed.

2. Connect the pressure gauge valve and the nitrogen cylinder to the

operating connection C on the shut off valve A.

3. Progressively pressurise the refrigerant connection pipes and the

indoor module in steps of 5 bar until you reach 35 bar.

4. Check the watertightness of the connections with a "leak detector"

spray. If leaks occur, redo and recheck tightness.

5. Release the pressure and release the nitrogen.

4.8.3. Evacuation

1. Check that the shut off valves A and B are closed.

2. Connect the vacuum gauge and the vaccuum pump to the

operating connection C and the shut off valve A.

3. Produce a vacuum in the indoor module and the refrigerant

connection pipes.

4. Check the pressure according to the recommendations table

below:

Outside temperature (°C)

ª

20

10 0 - 10

Pressure to be reached (Pa) 1000 600 250 200

Draw-off evacuation time after reaching the

pressure (h)

1 1 2 3

5. Close the valve between the vacuum gauge/vaccuum pump and

the shut off valve A.

6. After shutting off the vaccuum pump, immediately open the valves.

4.8.4. Opening the valves

1. Remove the cap D on the refrigerant off valve A.

2. Open the valve with a hexagonal spanner by turning anticlockwise until it stops.

3. Put the cap back in place.

4. Remove the cap D on the refrigerant gas shut off valve B.

5. Open the valve with a pair of pliers, turning it anticlockwise by a

quarter turn.

6. Put the cap back in place.

7. Disconnect the vacuum gauge and the vaccuum pump. Put the

cap back in place.

M002297-A

A

B

C

35 bar

M001470-B

M002297-A

A

B

C

M002499-B

M002295-B

A

B

D

D

AWHP-2 MIT-IN-2 iSystem

4. Installation

25/06/2014 - 7616371-001-04

35

Page 38

8. Tighten the caps with a dynamometric spanner with a torque load

of 20 to 25 N·m.

9. Check the watertightness of the connections using a leak detector.

4.8.5. Adding refrigerant

If the refrigeration connection pipes are more than 10 metres long,

refrigerant R410A must be added. See table below.

Add refrigerant via the refrigerant shut off valve using a safety loader.

Model

(Outdoor

unit)

Quantity of refrigerant to be added

11 to 20m21 to 30m31 to 40m41 to

50 m

51 to

60 m

61 to

75 m

4 - 6 kW 0.2 kg 0.4 kg 0.6 kg / / /

8 kW 0.2 kg 0.4 kg 1.0 kg / / /

11-16 kW 0.2 kg 0.4 kg 1.0 kg 1.6 kg 2.2 kg 2.8 kg

22 kW 0.9 kg 1.8 kg 1.8 kg 1.8 kg 2.7 kg 3.6 kg

27 kw 1.2 kg 2.4 kg 2.4 kg 2.4 kg 3.6 kg 4.8 kg

4.9 Hydraulic connections

¼See chapter: "Main dimensions", page 27

4.9.1. Flushing the system

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions.

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions.

n

Fitting the appliance to new installations

4 Clean the installation with a universal cleaner to eliminate debris

from the system (copper, hemp, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

n

Fitting the appliance to existing installations

4 Remove sludge from the installation.

4 Flush the installation.

4 Clean the installation with a universal cleaner to eliminate debris

from the system (copper, hemp, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

4. Installation

AWHP-2 MIT-IN-2 iSystem

36

25/06/2014 - 7616371-001-04

Page 39

4 Prior to connection, rinse the domestic water inlet pipes so as

not to introduce metal or other particles into the DHW coil.

4.9.2. Connection of the heating circuit

1. Connect the heating water return pipe to the heating return

connection.

z

: Screw-on connection ∅ 1"

2. Connect the heating water outlet pipe to the heating flow

connection.

{

: Screw-on connection ∅ 1"

4 The device is factory-fitted with a safety valve.

CAUTION

4 The heating pipe must be mounted in accordance

with prevailing provisions.

4.9.3. Hydraulic connection diagrams

CAUTION

The maximum volume scheduled for the installation is

215 litres. If this volume is exceeded in relation to the

internal expansion vessel, add an external expansion

vessel.

M002537-A

1 2

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

37

Page 40

n

Example of connecting a system with MIT-IN-2/H

A

Outdoor unit

Z

Inside module with hydraulic back-up

E

boiler back-up

R

DHW tank

3

3-bar safety valve

4

Pressure gauge

7

Automatic air vent

9

Isolating valve

11a

Automatically regulated electronic pump for direct heating

circuit

11b

Pump for heating circuit with mixing valve

16

Closed expansion vessel

17

Drain cock

18

Filling the heating circuit

21

Exterior temperature sensor

22

Boiler temperature sensor

23

Mixing valve outlet temperature sensor

24

DHW calorifier exchanger primary inlet

25

DHW calorifier heat exchanger primary outlet

26

DHW load pump

27

Non-return valve

M003026-C

230V

50Hz

BUS

21

51

230V

50Hz

EA63

9

11b

10

27

9

°C

°C

EA61

65

115

23

52

52

64

64

51

51

EA59

44

9

°C

27

°C

9

11a

2

3

4

1

4. Installation AWHP-2 MIT-IN-2 iSystem

38

25/06/2014 - 7616371-001-04

Page 41

28

Domestic cold water inlet

29

Pressure reducer if supply pressure exceeds 80 % of the

safety valve pressure setting

30

Calibrated and sealed safety unit

33

Domestic hot water temperature sensor

34

Primary pump

44

Safety thermostat

50

Disconnector

51

Thermostat valve

52

Differential valve

56

Domestic hot water circulation loop return

57

Domestic hot water outlet

64

Direct heating circuit

65

Heating circuit with mixing valve

89

Heat transfer fluid container

115

Thermostatic distribution valve for each zone

n

Example of connecting a system with MIT-IN-2/E

A

Outdoor unit

Z

Inside module with electrical back-up

E

DHW tank

3

3-bar safety valve

M003027-B

230V

50Hz

230V

50Hz

BUS

21

65

115

23

64

51

44

2

3

1

A

B

A/B

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

39

Page 42

4

Pressure gauge

7

Automatic air vent

9

Isolating valve

11a

Automatically regulated electronic pump for direct heating

circuit

11b

Pump for heating circuit with mixing valve

16

Closed expansion vessel

17

Drain cock

18

Filling the heating circuit

21

Exterior temperature sensor

22

Boiler temperature sensor

23

Mixing valve outlet temperature sensor

24

DHW calorifier exchanger primary inlet

25

DHW calorifier heat exchanger primary outlet

26

DHW load pump

27

Non-return valve

28

Domestic cold water inlet

29

Pressure reducer if supply pressure exceeds 80 % of the

safety valve pressure setting

30

Calibrated and sealed safety unit

33

Domestic hot water temperature sensor

34

Primary pump

44

Safety thermostat

50

Disconnector

51

Thermostat valve

52

Differential valve

56

Domestic hot water circulation loop return

57

Domestic hot water outlet

64

Direct heating circuit

65

Heating circuit with mixing valve

89

Heat transfer fluid container

115

Thermostatic distribution valve for each zone

4.10 Filling the heating system

4.10.1. Water treatment in the heating circuit

In a number of cases, the heat pump and the central heating system

can be filled with normal tap water and no water treatment is

necessary.

4. Installation

AWHP-2 MIT-IN-2 iSystem

40

25/06/2014 - 7616371-001-04

Page 43

WARNING

4 Do not add chemical products to the central heating

water without first consulting a water treatment

professional. For example: antifreeze, water

softeners, products to increase or reduce the pH

value, chemical additives and/or inhibitors. Chemical

products may cause malfunctions on the heat pump

and damage the heat exchanger.

4 Do not use hydrochloric acid-based cleaning or

descaling products.

CAUTION

4 Check the compatibility of the product with the

materials used in the installation.

4 Check the compatibility of the product with stainless

steel and copper.

4 Respect the manufacturer’s instructions (use, dose,

etc.) to obviate any hazards (corporal, material,

environmental).

4 An uncleaned installation or an installation using

water of unsuitable quality may bring about the

cancellation of the warranty.

4 Flush the central heating installation with at least 3x

the volume of the central heating installation.

4 Flush the DHW pipes with at least 20 times the volume

of the pipes.

For an optimum functioning of the boiler, the water of the installation

must comply with following characteristics:

Output ≤ 70 kW

Acidity (pH)

7.5 - 9

Conductivity at 25°C µS/cm 10 to 500

Chlorides mg/l < 50

Other components mg/l < 1

Hardness of the water of the installation °f 7- 15

°dH 4- 8.5

If a water treatment is necessary, De Dietrich

Thermique recommends the following manufacturers:

4 Cillit

4 Climalife

4 Fernox

4 Permo

4 Sentinel

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

41

Page 44

4.10.2. Filling the system

CAUTION

Do not use glycol.

The heat pump components are not designed to be used

with glycol.

The use of glycol in the heating circuit invalidates the

warranty.

4 Fill the installation until a pressure of 1.5 to 2 bars is reached.

Water pressure display: See chapter: ¼ "Reading out

measured values", page 94.

4 Check for any water leaks.

4 Completely vent any air in the inside module and the installation

for optimum running.

4.11 Electrical connections

4.11.1. Recommendations

WARNING

4 Only qualified professionals may carry out electrical

connections, always with the power off.

4 Earth the appliance before making any electrical

connections.

Make the electrical connections of the appliance according to:

4 The instructions of the prevailing standards,

4 The instructions on the circuit diagrams provided with the

appliance,

4 The manufacturer’s instructions.

The earthing shall comply with local standards.

CAUTION

4 Separate the sensor cables from the 230/400 V

circuit cables.

4 The installation must be fitted with a circuit breaker

disconnecting switch.

4 Three phase models must always be fitted with

neutral.

Power the appliance via a circuit which includes a remote omnipolar

switch with a gap of more than 3 mm.

4 Single phase models: 230 V AC (+6%/-10%) 50 Hz

4 Three phase models: 400 V AC (+6%/-10%) 50 Hz

4. Installation

AWHP-2 MIT-IN-2 iSystem

42

25/06/2014 - 7616371-001-04

Page 45

When making electrical connections to the mains, respect the

following polarities:

4 Brown wire: Live

4 Blue wire: Neutral

4 Green/yellow wire: Earth

WARNING

Secure the cable with the cable clamp provided.

Be careful that you do not invert the wires.

4.11.2. Recommended cable cross section

The electrical characteristics of the mains power supply available

must correspond to the values given on the rating plate.

The cable will be carefully chosen according to the following

information:

4 Maximum intensity of the outdoor module. See table below.

4 Distance of the appliance from the original power supply.

4 Upstream protection.

4 Neutral operating conditions.

Appliance

AWHP MIT-IN-2 4 MR 6 MR-2 8 MR-2 11 MR-2 11 TR-2 16 MR-2 16 TR-2 22 TR 27 TR

Outdoor unit Absorbed

electrical

power

kW 1.50 1.50 2.10 2.59 2.59 4.03 4.03 5.6 6.9

Nominal

amperage

A 6.8 6.8 9.34 11.2 3.98 17.7 5.99 13.9 17.2

Maximal

amperage

A 13 13 19 28 13 29 13 19 21

Type

(1)

1 ~ 1 ~ 1 ~ 1 ~ 3 ~ 1 ~ 3 ~ 3 ~ 3 ~

Power supply

S-C

(2)

3 x 2.5 3 x 2.5 3 x 4 3 x 6 5 x 2.5 3 x 10 5 x 2.5 5 x 4 5 x 6

Curve D

DJ

(3)

16 A 16 A 25 A 32 A 16 A 40 A 16 A 25 A 32 A

Indoor module Power supply

S-C

(2)

3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5

Curve C

DJ

(3)

10 A 10 A 10 A 10 A 10 A 10 A 10 A 10 A 10 A

Cable BUS

(4)

S-C

(2)

3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5 3 x 1.5

(1) 1 ~ : Single phase, 3 ~ : Three-phase

(2) Cable cross section (mm²)

(3) Circuit breaker

(4) Connection cable between outdoor and indoor module

n

Connecting the electrical back-up

Type

S-C

(1)

Curve C DJ

(2)

Single phase 3 x 6 32 A

Three-phase 5 x 4 25 A

(1) Cable cross section (mm²)

(2) Circuit breaker

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

43

Page 46

4.11.3. Accessing the connection terminal blocks

n

Outdoor unit

Only for 4, 6 kW models

1. Unscrew the holding screws.

2. Remove the protection cap.

Only for 8, 11, 16, 22, 27 kw models

1. Unscrew the holding screws.

2. Remove the protection cap.

CAUTION

Secure the cables with cable clamps to obviate any

contact with the centre of the protective cover or the gas

valve.

n

Indoor module

To access the connection terminal blocks, proceed as follows:

1. Unscrew the 2 screws under the front panel by a quarter turn.

MW-2000052-1

MW-2000055-1

M002382-B

1

2

4. Installation AWHP-2 MIT-IN-2 iSystem

44

25/06/2014 - 7616371-001-04

Page 47

2. Remove the front panel.

3. Open the holding clips located on the sides.

4. Tilt the control panel forwards.

5. Lift the clip located in front of the control panel.

6. Lift the control panel cover.

7. Unclip the PCB cover.

M002383-B

3

3

4

M002491-A

5

5

6

M002492-A

7

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

45

Page 48

4.11.4. Position of the PCBs

On/off

OT BL S ECS

BUS

A B 0VS EXT

2

4

3

1

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

TS + C AUXC

SCU

PCU

M002490-B

PCU

SCU

A

Do not connect anything to the terminal block.

Z

Optional PCB (Package AD249)

E

The BL inlet must always be connected to a dry contact

(potential-free).

R

Do not connect anything to the terminal block.

4. Installation AWHP-2 MIT-IN-2 iSystem

46

25/06/2014 - 7616371-001-04

Page 49

4.11.5. Location of the fuse

A

F1 6,3 AT fuse 250 V AC

Z

Spare fuse

4.11.6. Connecting the outdoor module

M001478-B

N

L

L N S1 S2 S3

L1 L2 L3 N

L2L1 L3 N S1 S2 S3

1 2

A

Single phase power supply

Z

Three-phase power supply

4.11.7. Connecting the communication cable

between the inside and outside modules

Communication cable liaison: 3 x 1.5 mm

2

Cable to be supplied by the installer.

M002494-B

PCU

1

2

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

47

Page 50

WARNING

Be careful that you do not invert the wires.

1 Connect to terminals S2, S3 and *.

2 Connect to terminals S2, S3 and *. (Outdoor unit)

4.11.8. Description of the terminal block on the

inside module

n

Inside module with hydraulic back-up

A

Bus for communication with the outside module

M002407-B

L N S1 S2 S3

S2 S3

S2S3

1

2

S2 S3

M002410-B

1

S2 S3

4. Installation AWHP-2 MIT-IN-2 iSystem

48

25/06/2014 - 7616371-001-04

Page 51

n

Inside module with electrical back-up

A

Ouput configuration of electric back-ups

Z

Auxiliary electrical power supply

E

Bus for communication with the outside module

4.11.9. Connecting the mains supply to the inside

module

A

L (Live: Brown)

Z

N (Neutral: Blue)

E * (Earth: Green/yellow wire)

X1

Power connector

CAUTION

The earth conductor must be longer than the live and

neutral conductors.

CAUTION

Use the cable clamps provided in the instructions bag.

4.11.10. Connecting the electrical back-up to the

inside module

M002408-D

S2 S3

BUS<>HPBUS<>HP

L1 L2 L3 N L N

1 2

C3

Configuration

C2 C1 L1

Alim appoint électriqueAlim appoint électrique

L2 L3 CN

S2 S3

BUS<>HPBUS<>HP

C3

Configuration

C2 C1 L1

Alim appoint électriqueAlim appoint électrique

L2 L3 CN

A

Three-phase power supply: 400 V AC

M002409-B

C3

Configuration

C2 C1 L1

Alim appoint électriqueAlim appoint électrique

L2 L3 CN

1 2 3

S2 S3

M002489-C

1

2

3

PCU

X1

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

49

Page 52

Z

Single phase power supply: 230 V AC

CAUTION

The earth conductor must be longer than the live and

neutral conductors.

n

Fitting the jumpers and bridges

M002393-E

S2 S3

BUS<>HPBUS<>HP

1 2

C3

Configuration

C2 C1 L1

Alim appoint électriqueAlim appoint électrique

L2 L3 CN

S2 S3

BUS<>HPBUS<>HP

C3

Configuration

C2 C1 L1

Alim appoint électriqueAlim appoint électrique

L2 L3 CN

* *

A

Three-phase

Z

Single phase

*

For the various options for setting the bridge, see the

paragraph below, "Setting the output".

CAUTION

Check that the clips are correctly connected to the tab as

poor contact may lead to the connection overheating.

n

Output control

¼For setting the BACKUP TYPE parameter, see: "Professional

settings", page 98

Type

BACKUP TYPE

setting

Back-up Output Bridge

Single phase

/E2

Stage 1 2 kW between C2 and

C1

Stage 2 4 kW

Stage 1 + 2 6 kW

/E1

Stage 1 2 kW

4. Installation AWHP-2 MIT-IN-2 iSystem

50

25/06/2014 - 7616371-001-04

Page 53

Type BACKUP TYPE

setting

Back-up Output Bridge

Three-phase

/E2

Stage 1 4 kW between C3 and

C2

Stage 2 8 kW

Stage 1 + 2 12 kW

Stage 1 8 kW between C2 and

C1

Stage 2 4 kW

Stage 1 + 2 12 kW

Stage 1 4 kW Remove bridge

Stage 2 4 kW

Stage 1 + 2 8 kW

/E1

Stage 1 8 kW between C2 and

C1

4 kW Remove bridge

4.11.11. Connecting the hydraulic auxilary on the

inside module

WARNING

Respect the polarity of the terminals: Live (P), neutral

(N), and earth (*).

A

Back-up pump

Z

Burner (Volt free contact)

M002423-B

LN 21

1

2

PCU

AWHP-2 MIT-IN-2 iSystem 4. Installation

25/06/2014 - 7616371-001-04

51

Page 54

4.11.12. Connection example for a system with

hydraulic back-up

n

Boiler fitted with a control panel with a TAM and/or

I.TEL input

M003032-C

BUS

EA63

°C

°C

EA61

EA59

°C

°C

13

14

On/off

OT BL S ECS

BUS

A B 0V

S EXT

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

SCU

PCU

1 2

3

8

9

E.TEL

TAM /

K

5 6

7

4

10

12

N L

NL

11

A

Not used: Do not connect anything to the terminal block.

Z

CAUTION

Do not connect anything to the DHW pump

outlet.

E

Connect the outside temperature sensor.

R

Connect the heating pump (Circuit A).

T

Connect the 3-way valve motor (Circuit B).

Y

Connect the heating pump (Circuit B).

4. Installation AWHP-2 MIT-IN-2 iSystem

52

25/06/2014 - 7616371-001-04

Page 55

U

Connect a safety thermostat if the heating circuit is for

underfloor heating: Remove the bridge. Connect the wires

from the safety thermostat to the connector.

I

Not used: Do not connect anything to the terminal block.

O

Connect the BUS cable between the outside module and

the terminal block on the inside module.

P

Connect the outlet sensor (Circuit B).

a

Connect the heating pump and the K relays to the AL1

connector on the PCU PCB.

z

Connect the boiler’s room thermostat to the AL2

connector on the PCU PCB.

e

Inside module with hydraulic back-up

r

Outdoor unit

Settings to be made on the inside module for this type of installation

Parameters Access Settings to be made See chapter

INSTALLATION

Installer level

#SYSTEM menu

EXTENDED

¼ "Displaying the parameters in extended

mode", page 84

O.PUMP A

(1)

Installer level

#SYSTEM menu

CH.PUMP A

¼ "Setting the parameters specific to the

installation", page 86

CIRC.A

(1)

Installer level

#SYSTEM menu

DIRECT

¼ "Setting the parameters specific to the

installation", page 86

PUMP MIT/MHR

Installer level

#SYSTEM menu

CIRC.A

¼ "Setting the parameters specific to the

installation", page 86

CIRC.B

(1)

Installer level

#SYSTEM menu

3WV

¼ "Setting the parameters specific to the

installation", page 86

CIRC.CURVE A

Installer level

#SECONDARY INSTAL.P menu

1.5

¼ "Professional settings", page 98

CIRC.CURVE B

Installer level

#SECONDARY INSTAL.P menu

0.7

¼ "Professional settings", page 98

HP BUS

Installer level

#PRIMARY INSTAL.P menu

TOR

¼ "Professional settings", page 98

BACKUP TYPE

Installer level

#PRIMARY INSTAL.P menu

/H

¼ "Professional settings", page 98

(1) The parameter is only displayed if INSTALLATION parameter is set to EXTENDED

Setting the back-up boiler

The setting of the back-up boiler depends on its type of control panel.

4 Diematic 3

Set the following installer settings on the boiler control panel:

- I.TEL: THERM A

- HCZP D / HCZP N: same value as the parameter HEAP

MAX: on the Diematic iSystem control panel on the MIT.

- CIRC.CURVE A: 0.0

- OUT.ANTIFREEZE: -8 °C

Access to parameters:

- Press the - key for 5 seconds.

- Press the ( key 2 times.

- Use key ’ to select the desired parameter.

AWHP-2 MIT-IN-2 iSystem

4. Installation

25/06/2014 - 7616371-001-04

53

Page 56

4 SVmatic

Heating temperature setting = HEAP MAX:.

4 B control panel

Set the boiler thermostat to the same value as HEAP MAX:.

4 Other

Heating temperature setting = HEAP MAX:.

Operating principle

4 No back-up requested:

The boiler continues to provide DHW. Contacts AL1 and AL2 are

both open.

4 Back-up requested:

The AL2 contact closes.

The AL1 outlet is powered up: If the boiler is in domestic hot water

mode, the back-up pump is not tripped as the K relay is open. The

back-up pump is tripped when the domestic hot water load pump

stops.

4. Installation AWHP-2 MIT-IN-2 iSystem

54

25/06/2014 - 7616371-001-04

Page 57

n

Boiler fitted with a control panel without TAM input

(Modulating room thermostat)

M003033-B

BUS

EA63

°C

°C

EA61

EA59

°C

°C

13

14

On/off

OT BL S ECS

BUS

A B 0V

S EXT

TS + B AB

0-10V

S AMB C

4 3 2 1 2 1

+ -

S AMB B

2 1

S AMB A

2 1

S SYST + TA -

S ECS S EXT S DEP C

2 12 12 12 1 2 1

S DEP B

2 1

SCU

PCU

1 2

3

8

9

5 6

7

4

10

N L

NL

11

CS

12

A

Not used: Do not connect anything to the terminal block.

Z

CAUTION

Do not connect anything to the DHW pump

outlet.

E

Connect the outside temperature sensor.

R

Connect the heating pump (Circuit A).

T

Connect the 3-way valve motor (Circuit B).

Y

Connect the heating pump (Circuit B).

U

Connect a safety thermostat if the heating circuit is for

underfloor heating: Remove the bridge. Connect the wires