DeDietrich GT 530-11, GT 530-8, GT 530-12, GT 530-13, GT 530-14 Installation And Service Manual

...

GT 530

Fuel oil/gas boilers

Installation and

Service Manual

300011906-001-D

EN

2

GT 530 25/01/2012 - 300011906-001-D

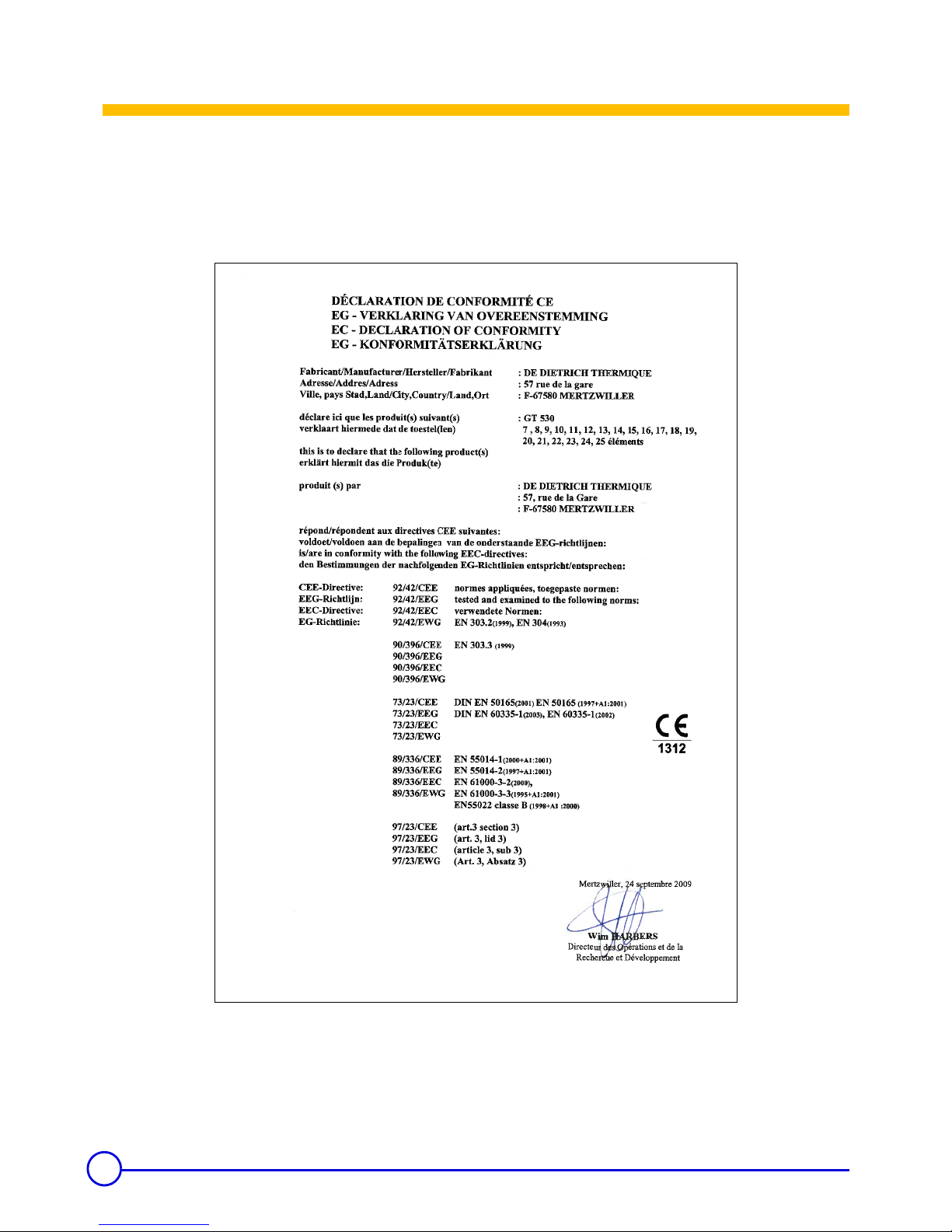

Declaration of conformity CE

The appliance complies with the standard model described in

declaration of compliance 1. It is manufactured and distributed

pursuant to the requirements of european directives.

The original of the declaration of compliance is available from the

manufacturer.

C002722-A

3

25/01/2012 - 300011906-001-D GT 530

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Symbols and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.3.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.3.2 Directive 97/23/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 Safety instructions and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.1 Fire hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.2 Risk of intoxication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.3 Risk of being burnt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.4 Risk of damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2 Composition of the range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2.1 Standard control panel- S3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2.2 K3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2.3 DIEMATIC-m3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2.4 B3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3.1 Boilers for following countries: France, Algeria, Belgium, Bulgaria, China, Cyprus, Spain, Greece, Luxemburg, Poland,

Portugal, Czech Republic, Romania, Tunisia10

3.3.2 Boilers for following countries: Germany, Austria, Serbia, Slovenia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.3 Boilers for following countries: Switzerland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.4 Boilers for following countries: Russia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1 Regulations governing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.1 In general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.2 In particular for France . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1.3 In particular for Germany . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2 Package list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3.1 Main dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3.2 Data plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3.3 Boiler location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.3.4 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.4 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.4.1 Dimensional information required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.4.2 Hydraulic connection of the water circuit for domestic use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.4.3 Hydraulic connection of the heating circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.5 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.6 Sludge removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.7 Chimney connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.7.1 Flue size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.7.2 Connection to the flue gas pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.8 Fuel-oil or gas connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.9 Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4

GT 530 25/01/2012 - 300011906-001-D

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

1.1 Symbols and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6 Switching off the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.1 Precautions required in the case of long boiler stops (one or more years) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.2 Precautions required if the heating is stopped when there is a risk of freezing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7 Checking and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.1 System maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.1.1 Water level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.1.2 Draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.2 Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.2.1 Sweeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.2.2 Chemical sweeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

7.2.3 Maintenance of the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.3 Cleaning the casing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

8 Spare parts - GT 530 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5

25/01/2012 - 300011906-001-D GT 530

1Introduction

1.1 Symbols and abbreviations

Caution danger

Risk of injury and damage to equipment.Attention must be

paid to the warnings on safety of persons and equipment.

Specific information

Information must be kept in mind to maintain comfort.

Z

Reference

Refer to another manual or other pages in this instruction

manual.

DHW: Domestic hot water

1.2 General

We congratulate you for having chosen a quality product. We

advise you warmly to read the instructions below in oder to

ensure the optimal operation of your burner. We are convinced

that it will give you complete satisfaction and meet all your

expectations.

` Keep these instructions in a safe place close to the appliance.

` In the interest of customers, De Dietrich Thermique SAS are

continuously endeavouring to make improvements in product

quality. All the specifications stated in this document are

therefore subject to change without notice.

1.2.1 Manufacturer's liability

The liability of De Dietrich Thermique SAS as the manufacturer may

not be invoked in the following cases:

- Failure to abide by the instructions on using the appliance.

- Faulty or insufficient maintenance of the appliance.

- Failure to abide by the instructions on installing the appliance.

1.2.2 Installer's liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

` Read and follow the instructions given in the manuals provided

with the appliance.

` Carry out installation in compliance with the prevailing

legislation and standards.

` Perform the initial start up and carry out any checks necessary.

When handing over the installation to the user, the installer will draw

the user's particular attention to the following points:

- The safety of the installation.

- The functioning of the installation and the boiler.

- Periodic maintenance to be done.

1.2.3 User's liability

To ensure the optimum operation of your appliance, we strongly

recommend that you abide by the following instructions:

` Read and follow the instructions given in the manuals provided

with the appliance.

` Call on qualified professionals to:

- Carry out installation in compliance with the prevailing legislation

and standards.

- Perform the initial start up.

- Carry out work on the appliance and the installation.

- To carry out inspections and maintenance required by a qualified

professional.

` Get your installer to explain your installation to you.

6

GT 530 25/01/2012 - 300011906-001-D

1.3 Homologations

1.3.1 Certifications

Certificate of compliance (For France)

In application of Article 25 of the Order of 27 April 2009 amending the

Order of 2 August 1977 amended and Article 1 of the amended Order

of 05/02/1999, the installer is required to draw up certificates of

conformity approved by the Ministers responsible for construction

and gas safety:

- Different forms (forms 1, 2 or 3) for a new gas installation,

- Model 4 in particular after replacing a furnace with a new one.

CE identification no: 1312 AQ 954 (France).

CE identification no: 1312 AQ 953 (Germany, Switzerland).

1.3.2 Directive 97/23/EC

Gas and oil boilers with a maximum operating temperature of 110°C

and hot water tanks with a maximum operating pressure of 10 bar

pertain to article 3.3 of the directive, and therefore, cannot be CEmarked to certify compliance with the directive 97/23 EC.

The boilers and hot water tanks are designed and manufactured in

accordance with the sound engineering practice, as requested in

article 3.3 of the directive 97/23/EC, it is certified by compliance with

the directives 90/396/EC, 92/42/EC, 2006/95/EC and 2004/108/EC.

7

25/01/2012 - 300011906-001-D GT 530

2 Safety instructions and recommendations

2.1 Safety instructions

For a proper operating of the boiler, follow carefully the

instructions.

Only qualified professionals are authorised to work on the

appliance and the installation.

Incorrect use or unauthorised modifications to the

installation or the equipment itself invalidate any right to

claim.

Before any work, switch off the mains supply to the

appliance.

Keep to the polarity shown on the terminals: phase (L),

neutral (N) and earth

4

.

Keep children away from the boiler.

2.1.1 Fire hazard

It is forbidden to store inflammable products and materials

in the boiler room or close to the boiler, even temporarily.

If you smell gas, do not use a naked flame, do not smoke,

do not operate electrical contacts or switches (doorbell,

lights, motor, lift, etc.).

1.Shut off the gas supply.

2.Open the windows.

3.Extinguish all flames.

4.Evacuate the premises.

5.Contact a qualified professional.

6.Inform the gas supplier.

2.1.2 Risk of intoxication

Do not obstruct the air inlets in the room (even partially).

If you smell flue gases:

1.Switch the appliance off.

2.Open the windows.

3.Evacuate the premises.

4.Contact a qualified professional.

2.1.3 Risk of being burnt

Depending on the settings of the appliance:

- The temperature of the flue gas conduits may exceed 60°C.

- The temperature of the radiators may reach 95°C.

- The temperature of the domestic hot water may reach 65°C.

2.1.4 Risk of damage

Do not stock chloride or fluoride compounds close to the

appliance.

Install the appliance in frost-free premises.

Do not neglect to service the appliance: Contact a qualified

professional or take out a maintenance contract for the

annual servicing of the appliance.

2.2 Recommendations

` Check regularly that the installation contains water and is

pressurised.

` Keep the appliance accessible at all times.

` Avoid draining the installation.

` The appliance should be on Summer or Antrifreeze mode rather

than switched off to guarantee the following functions:

- Anti blocking of pumps

- Frost protection

- Protection against corrosion on domestic hot water tanks fitted

with a titanium anode

8

GT 530 25/01/2012 - 300011906-001-D

3 Technical description

3.1 General description

The boilers of the GT 530 range are pressurised hot water boilers

designed for connecting to a flue pipe which require a separate

automatic fuel-oil or gas burner.

3.2 Composition of the range

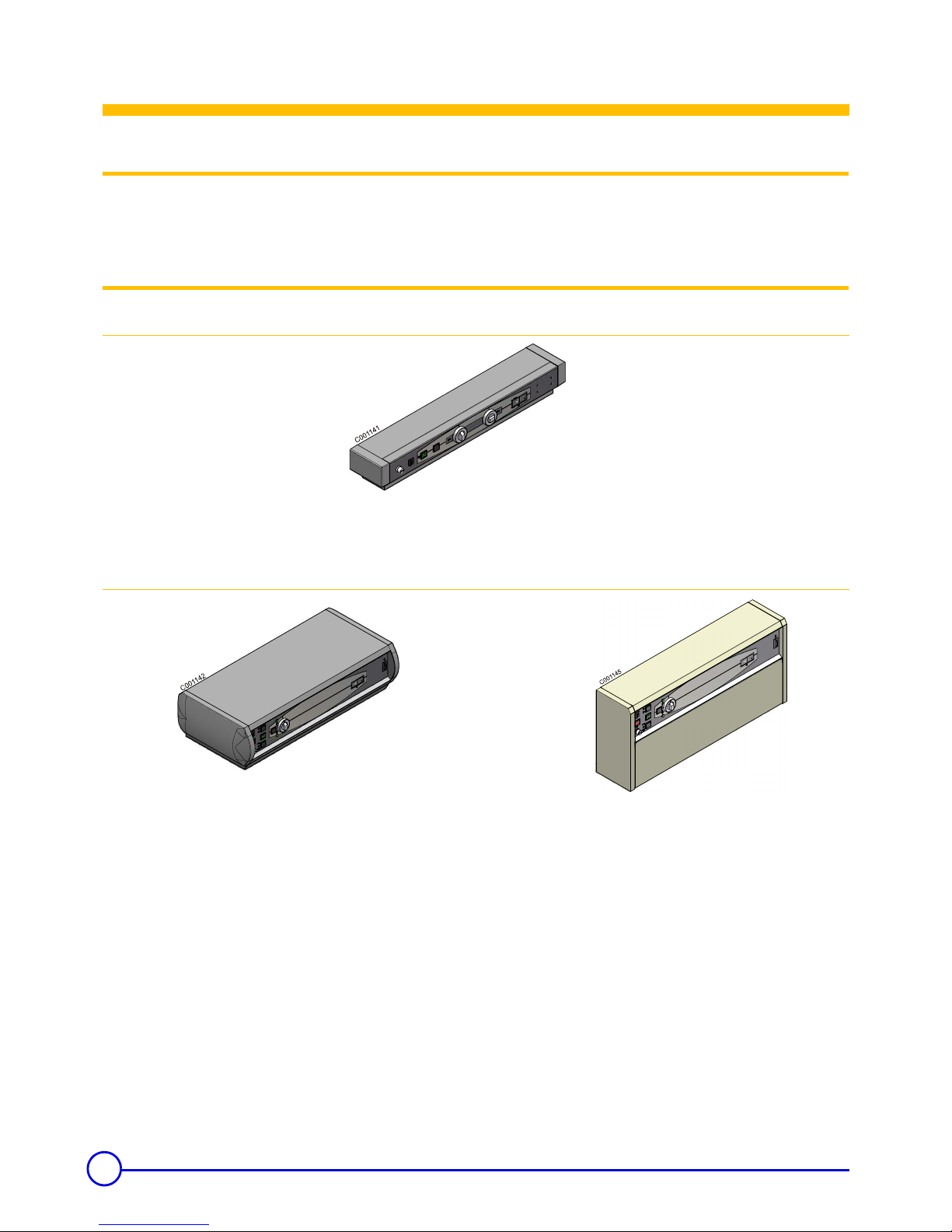

3.2.1 Standard control panel- S3

Standard panel to be fitted

Panel comprising the settings, control and safety devices allowing

the boiler to operate autonomously, without regulation.

The standard panel is used to connect the boiler to the boiler room

control cabinet.

This cabinet can be fitted with control units.

3.2.2 K3 control panel

Separate panel

Panel comprising the settings, control and safety devices allowing

the boiler to operate autonomously.

Control panel K3 also allows the boiler to be used as a secondary

boiler for installations with 2 to 10 boilers in cascade, one of which is

fitted with a "DIEMATIC-m3" control panel.

Side panel

A version of the K3 control panel with lateral attachment is also

available.

9

25/01/2012 - 300011906-001-D GT 530

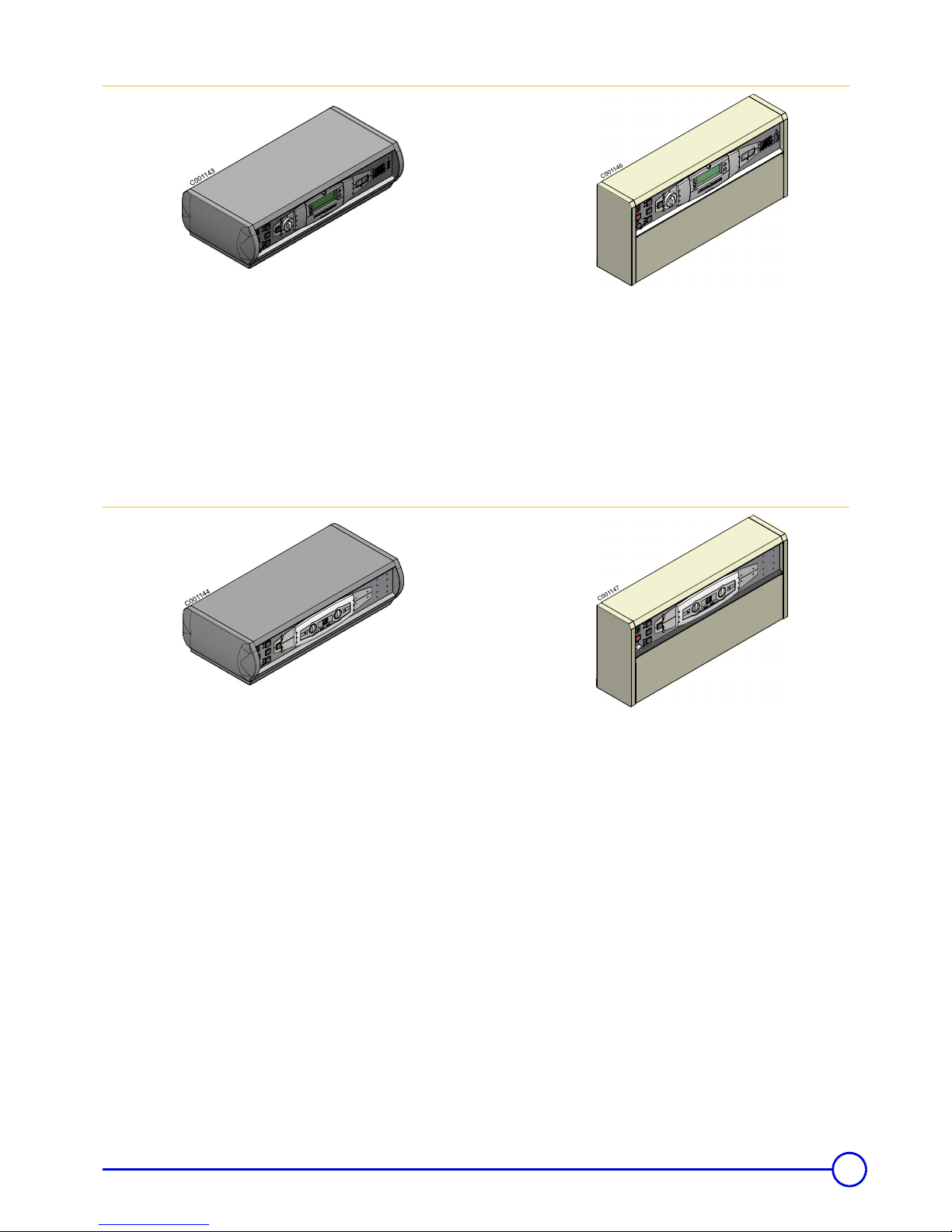

3.2.3 DIEMATIC-m3 control panel

Separate panel

Top of the range electronic control panel with digital display,

comprising the settings, control and safety devices allowing the boiler

to operate autonomously.

The DIEMATIC-m3 panel is fitted as standard with a control unit

which operates according to the outside temperature.

The DIEMATIC-m3 panel also allows the boiler to be used as a

master boiler for installations with 2 to 10 boilers in cascade.

The other boilers (1 to 9) must be fitted with a "K3" control panel.

Side panel

A version of the DIEMATIC-m3 control panel with lateral

attachment is also available.

3.2.4 B3 control panel

Separate panel

Top of the range electronic control panel with digital display,

comprising the settings, control and safety devices allowing the boiler

to operate autonomously.

This panel makes it possible to give priority to DHW.

Side panel

A version of the B3 control panel with lateral attachment is also

available.

10

GT 530 25/01/2012 - 300011906-001-D

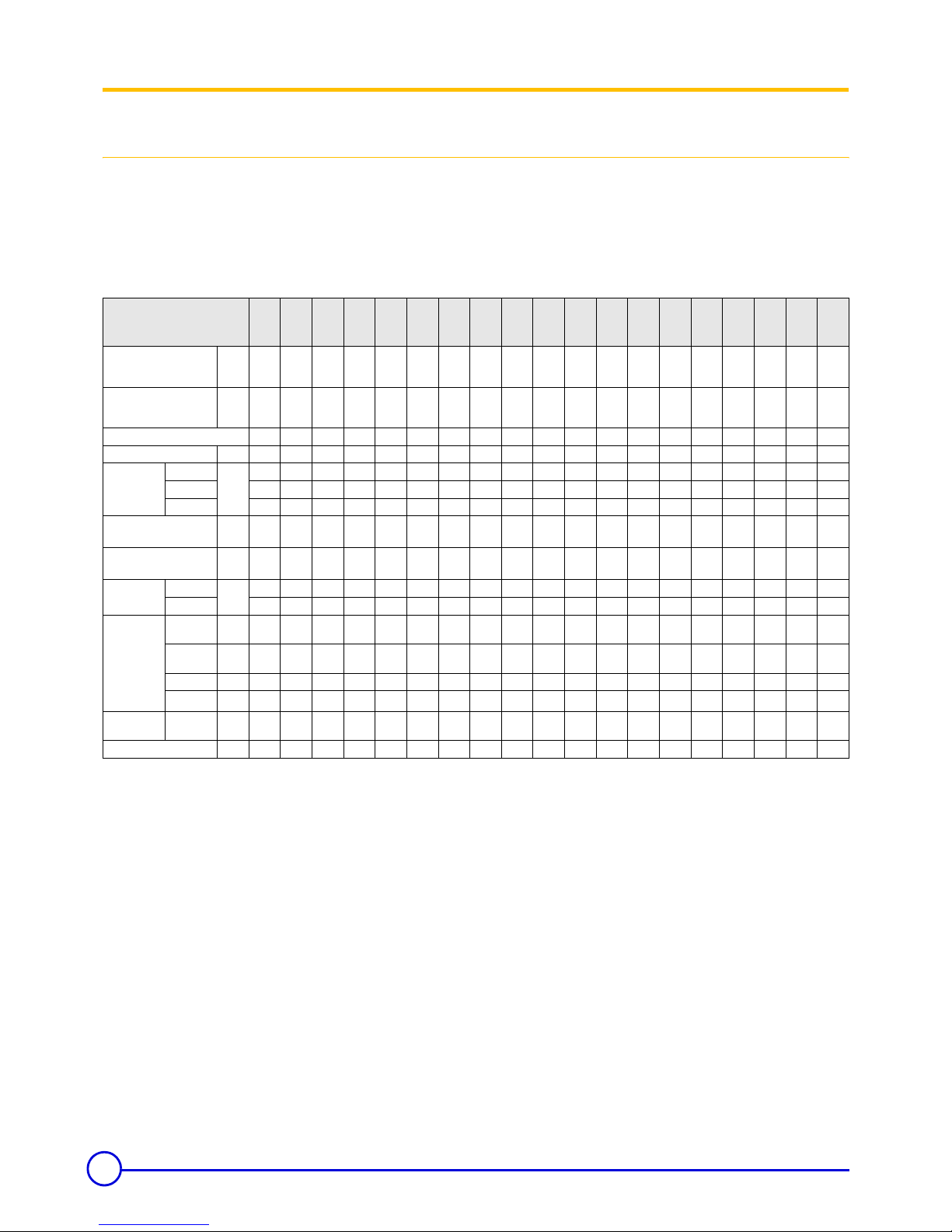

3.3 Technical specifications

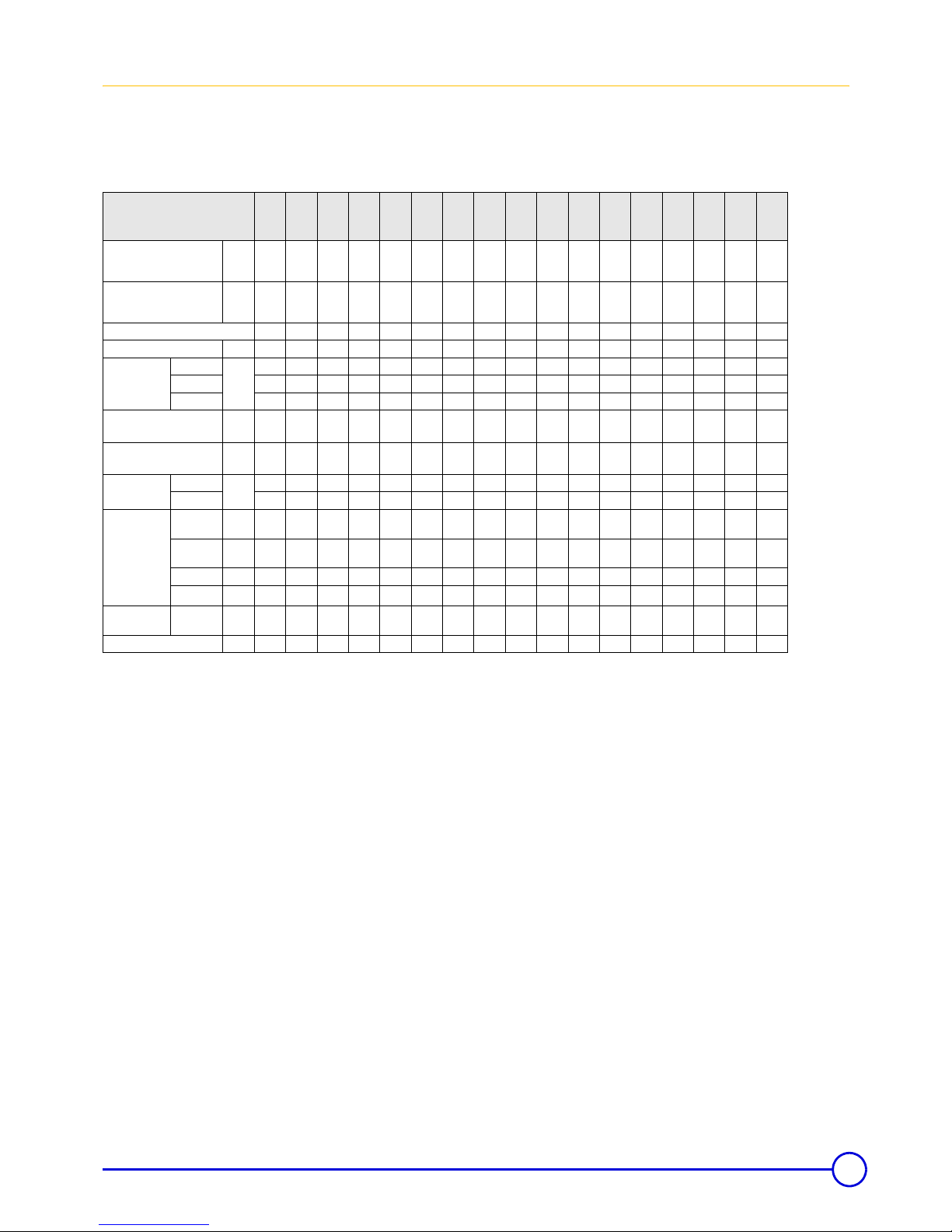

3.3.1 Boilers for following countries: France, Algeria, Belgium, Bulgaria, China, Cyprus, Spain, Greece,

Luxemburg, Poland, Portugal, Czech Republic, Romania, Tunisia

Conditions of use:

Maximum operating pressure: 6 bar

Maximum operating temperature: 100 °C

Boiler thermostat setting: 30 to 90°C

Safety thermostat setting: 110 °C

*Maintenance consumption: total heat emission when the burner is

off as a percentage of the nominal input power when the difference

between the mean boiler temperature and the room temperature is

30 K - in accordance with DIN 4702 - EN 303.

Boiler

GT

530

-7

GT

530

-8

GT

530

-9

GT

530

-10

GT

530

-11

GT

530

-12

GT

530

-13

GT

530

-14

GT

530

-15

GT

530

-16

GT

530

-17

GT

530

-18

GT

530

-19

GT

530

-20

GT

530

-21

GT

530

-522

GT

530

-23

GT

530

-24

GT

530

-525

Useful output kW 348

to

406

406

to

464

464

to

522

522

to

580

580

to

638

638

to

696

696

to

754

754

to

812

812

to

870

870

to

928

928

to

986

986

to

1044

1044

to

1102

1102

to

1160

1160

to

1218

1218

to

1276

1276

to

1334

1334

to

1400

1400

to

1450

Power input kW 380

to

447

442

to

508

505

to

571

566

to

632

635

to

703

701

to

769

763

to

831

821

to

890

897

to

967

954

to

1024

1022

to

1093

1077t

o

1147

1146

to

1216

1198

to

1268

1265

to

1336

1333

to

1404

1393

to

1464

1463t

o

1544

1532

to

1595

Number of sections 7 8 9 10111213141516171819202122232425

Water content l 389 427 465 503 541 579 617 655 693 731 769 807 845 905 943 981 1019 1057 1095

Water

resistance

(1)

∆ T = 10K mbar 18 22 28.4 34.8 42 50 57.6 67.2 77.6 26.2 30.2 35.8 41.4 48.0 53.6 59.2 64.8 71.6 78.4

∆ T = 15K 8 9.9 12.6 15.5 18.7 22.4 25.8 30 34.7 11.7 13.5 14.0 18.5 21.5 24 26.5 29 32 35

∆ T = 20K 4.5 5.5 7.1 8.7 10.5 12.5 14.4 16.8 19.4 6.5 7.6 9.0 10.4 12.0 13.4 14.8 16.2 17.9 19.6

Pressure in the furnace for

nozzle pressure = 0

(4)

mbar

1.7 1.75 1.8 1.9 2 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.85 3 3.1 3.2 3.3 3.4 3.5

Flue gas temperature Ambient temperature

(1) (3)

K

<190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190

Mass flue gas

flow rate

(1) (2)

Fuel oil Kg/h 690 790 790 980 1080 1180 1380 1380 1480 1580 1670 1770 1870 1970 2070 2170 2260 2360 2460

Gas 720 830 930 1030 1140 1240 1340 1450 1550 1650 1760 1860 1960 2070 2170 2270 2380 2480 2580

Combustion

chamber

Inscribed

diameter

mm

614 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614

Equivalent

diameter

mm

694 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694

Depth mm 706 817 928 1039 1150 1261 1372 1483 1594 1705 1816 1927 2038 2189 2300 2411 2522 2633 2744

Volume

m

3

0.28 0.32 0.36 0.40 0.45 0.49 0.53 0.57 0.61 0.65 0.70 0.74 0.78 0.84 0.88 0.92 0.96 1.00 1.05

Maintenance

consumption*

∆ T = 30K

%

0.11 0.10 0.09 0.08 0.08 0.08 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.06 0.06 0.06 0.06 0.06 0.06

Weight (empty) kg 1852 2046 2237 2412 2601 2810 3000 3171 3364 3561 3756 3955 4124 4343 4538 4734 4930 5107 5297

(1) Nominal operation (top boiler power)

(2) CO

2

= 13.1 to 13.5% with fuel oil and 9.5% with natural gas.

(3) Boiler temperature: 80 °C

Ambient temperature: 20 °C

(4)

In order for the boiler to operate correctly, it is

imperative to respect the draught at the nozzle.

11

25/01/2012 - 300011906-001-D GT 530

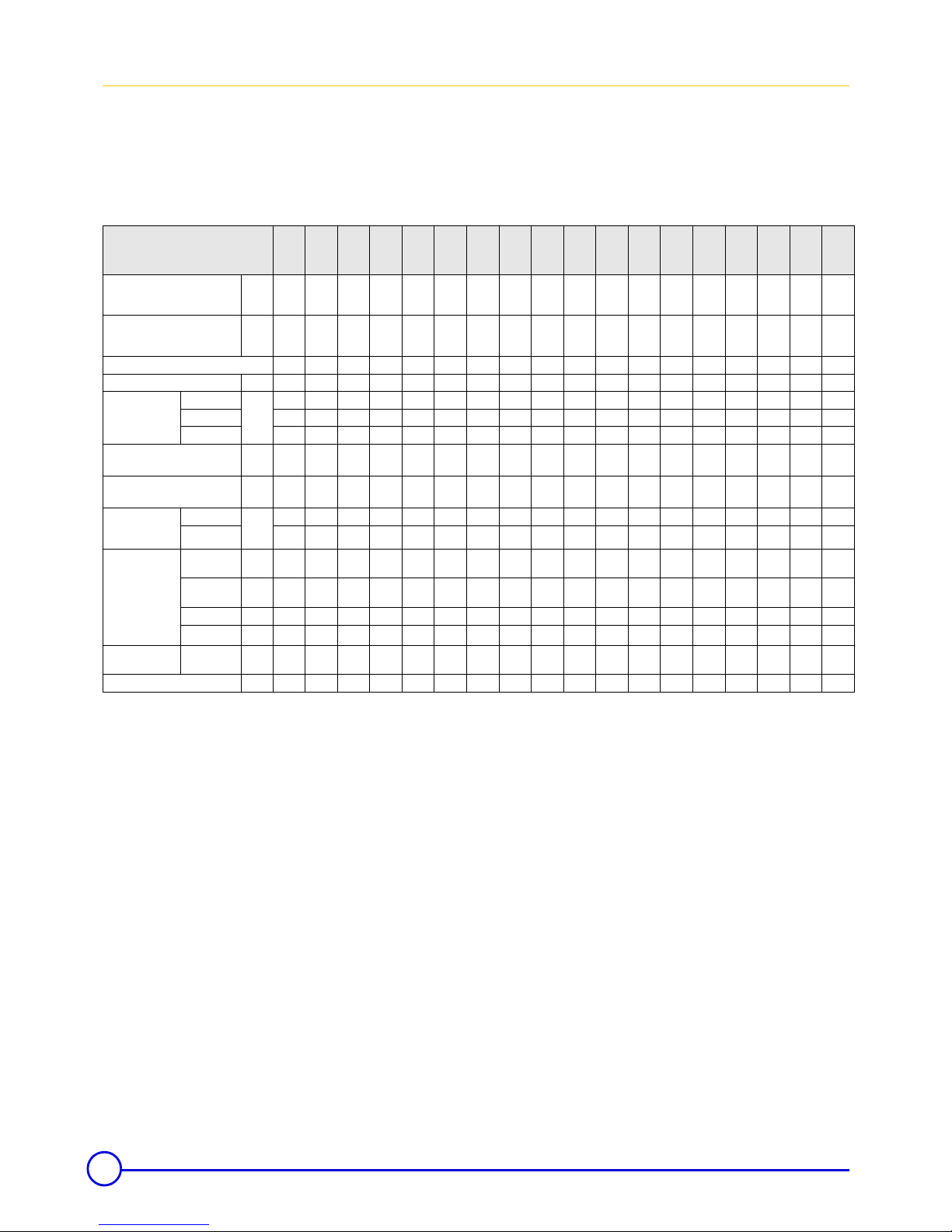

3.3.2 Boilers for following countries: Germany, Austria, Serbia, Slovenia

Conditions of use:

Maximum operating pressure: 6 bar

Maximum operating temperature: 100 °C

Maximum operating temperature: 120 °C

(in accordance with TRD 702)

Boiler thermostat setting: 30 to 90°C

Safety thermostat setting: 110 °C

*Maintenance consumption: total heat emission when the burner is

off as a percentage of the nominal input power when the difference

between the mean boiler temperature and the room temperature is

30 K - in accordance with DIN 4702 - EN303.

Boiler

GT

530

-9

GT

530

-10

GT

530

-11

GT

530

-12

GT

530

-13

GT

530

-14

GT

530

-15

GT

530

-16

GT

530

-17

GT

530

-18

GT

530

-19

GT

530

-20

GT

530

-21

GT

530

-522

GT

530

-23

GT

530

-24

GT

530

-525

Useful output kW 415

to

460

460

to

505

505

to

550

550

to

595

595

to

640

640

to

685

685

to

730

730

to

775

730

to

820

820

to

865

865

to

910

910

to

955

955

to

1000

1000

to

1045

1045

to

1090

1090

to

1135

1135

to

1180

Power input kW 448

to

500

494

to

546

547

to

599

597

to

649

643

to

696

689

to

741

743

to

797

790

to

842

790

to

892

886

to

938

935

to

987

982

to

1034

1034

to

1085

1082

to

1133

1131

to

1182

1180t

o

1231

1227

to

1278

Number of sections 9 10111213141516171819202122232425

Water content l 465 503 541 579 617 655 693 731 769 807 845 905 943 981 1019 1057 1095

Water

resistance

(1)

∆ T = 10K

mbar

22 25.9 30.5 37 43.5 50 55.8 21.8 24.2 26.8 30 33 35.6 38.9 42.9 45.6 48.9

∆ T = 15K 9.8 11.5 13.6 16.4 19.3 22.2 24.8 9.7 10.8 11.9 13.3 14.7 15.8 17.3 19.1 20.3 21.9

∆ T = 20K 5.5 6.9 8.1 9.2 10.6 12 13.9 4.5 5.8 6.5 7.2 7.9 8.6 9.4 1.6 11.8 12.4

Pressure in the furnace for

nozzle pressure = 0

(4)

mbar 1.4 1.45 1.5 1.55 1.6 1.65 1.7 1.75 1.8 1.85 1.95 2.05 2.1 2.15 2.2 2.25 2.3

Flue gas temperature Ambient temperature

(1) (3)

K <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190 <190

Mass flue gas

flow rate

(1) (2)

Fuel oil

Kg/h

770 850 920 1000 1070 1150 1220 1300 1370 1450 1520 1600 1670 1750 1820 1900 1970

Gas 810 890 970 1040 1120 1200 1280 1360 1440 1520 1590 1670 1750 1830 1910 1990 2070

Combustion

chamber

Inscribed

diameter

mm 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614

Equivalent

diameter

mm 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694

Depth mm 928 1039 1150 1261 1372 1483 1594 1705 1816 1927 2038 2189 2300 2411 2522 2633 2744

Volume

m

3

0.36 0.40 0.45 0.49 0.53 0.57 0.61 0.65 0.70 0.74 0.78 0.84 0.88 0.92 0.96 1.00 1.05

Maintenance

consumption*

∆ T = 30K % 0.16 0.15 0.14 0.13 0.13 0.12 0.12 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.10 0.10

Weight (empty) kg 2205 2391 2567 2771 2945 3120 3314 3494 3684 3872 4040 4266 4444 4639 4817 4994 5168

(1) Nominal operation (top boiler power)

(2) CO

2

= 13.1 to 13.5% with fuel oil and 9.5% with natural gas.

(3) Boiler temperature: 80 °C

Ambient temperature: 20 °C

(4)

In order for the boiler to operate correctly, it is

imperative to respect the draught at the nozzle.

12

GT 530 25/01/2012 - 300011906-001-D

3.3.3 Boilers for following countries: Switzerland

Conditions of use:

Maximum operating pressure: 6 bar

Maximum operating temperature: 100 °C

Boiler thermostat setting: 30 to 90°C

Safety thermostat setting: 110 °C

*Maintenance consumption: total heat emission when the burner is

off as a percentage of the nominal input power when the difference

between the mean boiler temperature and the room temperature is

30 K - in accordance with DIN 4702 - EN 303.

Boiler

GT

530

-8

GT

530

-9

GT

530

-10

GT

530

-11

GT

530

-12

GT

530

-13

GT

530

-14

GT

530

-15

GT

530

-16

GT

530

-17

GT

530

-18

GT

530

-19

GT

530

-20

GT

530

-21

GT

530

-522

GT

530

-23

GT

530

-24

GT

530

-525

Useful output kW 250

to

365

275

to

395

300

to

435

330

to

470

360

to

510

390

to

550

420

to

580

440

to

620

470

to

660

495

to

690

530

to

730

550

to

770

580

to

810

610

to

840

640

to

880

670

to

920

690

to

960

720

to

1000

Power input kW 260

to

390

291

to

425

315

to

465

346

to

495

381

to

550

409

to

590

440

to

620

460

to

650

492

to

710

519

to

740

557

to

785

578

to

825

609

to

870

642

to

905

679

to

945

705

to

990

728

to

1030

764

to

1075

Number of sections 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Water content l 427 465 503 541 579 617 655 693 731 769 807 845 905 943 981 1019 1057 1095

Water resistance

(1)

∆ T = 10K

mbar

13.9 15.8 19.1 23.1 27.6 32.2 35.2 40.3 15.7 17.1 19.3 21.5 23.4 25.1 28.0 30.2 32.1 37.0

∆ T = 15K 6.2 7 8.5 10.3 12.3 14.3 15.7 17.9 7 7.6 8.6 9.5 10.4 11.2 12.4 13.3 14.5 16.5

∆ T = 20K 3.5 4.2 5.1 5.7 6.7 7.7 8.8 10 3.8 4.1 4.6 5.1 5.6 6.1 7.6 7.8 8.2 9.3

Pressure in the furnace for nozzle

pressure = 0

(4)

mbar 1.05 1.05 1.1 1.1 1.15 1.2 1.2 1.25 1.3 1.3 1.35 1.4 1.5 1.5 1.55 1.6 1.6 1.65

Flue gas temperature - Ambient

temperature

(1) (3)

K <160 <160 <160 <160 <160 <160 <160 <160 <160 <160 <160 <160 <160 <160 <160 <160 <160 <160

Mass flue gas flow

rate

(1) (2)

Fuel oil kg

per

sec

0.160 0.174 0.191 0.203 0.226 0.242 0.254 0.267 0.291 0.304 0.322 0.339 0.357 0.371 0.388 0.406 0.423 0.441

Gas 0.174 0.190 0.207 0.221 0.245 0.263 0.276 0.290 0.316 0.330 0.350 0.367 0.388 0.403 0.421 0.441 0.459 0.479

Combustion

chamber

Inscribed

diameter

mm 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614 614

Equivalent

diameter

mm 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694 694

Depth mm 817 928 1039 1150 1261 1372 1483 1594 1705 1816 1927 2038 2189 2300 2411 2522 2633 2744

Volume

m

3

0.32 0.36 0.40 0.45 0.49 0.53 0.57 0.61 0.65 0.70 0.74 0.78 0.84 0.88 0.92 0.96 1.00 1.05

Maintenance

consumption*

∆ T = 30K % 0.13 0.12 0.12 0.11 0.11 0.11 0.11 0.10 0.10 0.10 0.10 0.10 0.10 0.09 0.09 0.09 0.09 0.09

Weight (empty) kg 2046 2237 2412 2601 2810 3000 3171 3364 3561 3756 3955 4124 4343 4538 4734 4930 5107 5297

(1) Nominal operation (top boiler power)

(2) CO

2

= 13.1 to 13.5% with fuel oil and 9.5% with natural gas.

(3) Boiler temperature: 80 °C

Ambient temperature: 20 °C

(4)

In order for the boiler to operate correctly, it is

imperative to respect the draught at the nozzle.

Loading...

Loading...