DeDietrich GT 400 A Assembly And Installation Instructions Manual

82N529 09

2

1

GT 400 A

Fuel oil/gas hot water boiler

English

11/03/09

94863449

Assembly and installation instructions

Warning:

Before putting the boiler into operation read this manual

carefully.

Warning:

The operating manual is part of the documentation that is

delivered to the installation’s operator. Go through the

information in this manual with the owner/operator and

make sure that he or she is familiar with all the necessary

operating instructions.

Notice:

This manual must be retained for future reference. Improper

installation, adjustment, alteration, service or maintenance can

cause injury, loss of life or property damage. Refer to this

manual. For assistance or additional information consult a

qualified installer, service agency or the gas supplier.

2

GT 400 A 21/09/06 - 94863449 - 82294154E

Guideline of Notices

Warning:

indicates presence of hazards that can cause, if not

avoided, severe personal injury, death or substantial

property damage.

! Caution:

indicates presence of hazards that will or can cause, if not

avoided, minor personal injury or property damage.

Notice:

Application comment for optimum use of equipment and

adjustment as well as useful information.

Z

Reference to an other instruction book.

Observe the following symbols

DANGER

due to explosion of gas.

- Work only on gas components when you have a license to do so.

- Note that the assembly of gas and vent connections, the initial

start-up, the electrical connections, the maintenance and service

can only be performed by a licensed service contractor or

technician.

DANGER

due to electricity.

- Prior to doing any work on the heating system, disconnect all

electrical power to the boiler at the emergency switch.

- It is NOT sufficient to shut off only the boiler control!

! CAUTION!

SYSTEM DAMAGE

due to improper installation.

- Observe local and state codes as well as common industry

practices during the installation and operation of the heating

appliance.

! CAUTION!

SYSTEM DAMAGE

due to inadequate cleaning and maintenance.

- A boiler cleaning and maintenance should be performed annually.

Verify complete system operation at the same time.

- Correct the problem immediately to prevent damage to the

system!

! Caution:

Refer to User’s Manual regarding the carcinogenic hazard of

crystalline silica that may be found during installation, servicing

and removal of this boiler.

Safety Considerations

Please observe the following safety instructions.

Read this manual carefully.

Correct installation and adjustment of the burner and the control

panel is a precondition for safe, efficient operation of the gas boiler.

Read this manual and the specifications on the safety label carefully

before attempting to put the burner into operation.

Do not store or use gasoline or other flammable liquids in

the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electric switch, do not use any phone in

your building.

- Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the Fire

Department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

Warning:

Improper installation, adjustment, and/or operation could

cause carbon monoxide poisoning resulting in injury or

death.

This product must be installed and serviced by a

professional service technician who is experienced and

qualified in hot water boiler installation and gas

combustion.

! Caution: Strict compliance with these instructions is a

precondition for the correct operation of the boiler.

! IMPORTANT

Service on this boiler should be undertaken only by trained and

skilled personnel.

Keep boiler area clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

Do not place any obstruction in the boiler room that will hinder

the flow of combustion and ventilating air.

Read these instructions carefully before proceeding with the

installation of boiler. Post instructions near boiler for reference

by owner and serviceman.

Maintain instructions in legible condition.

3

21/09/06 - 94863449 - 82294154E GT 400 A

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Regulations and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1 Boilers covered by this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Packing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4 Technical specifications of boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Main Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Boiler Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2 Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

1 Dimensional information required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3 Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4 Ancillaries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Combustion and ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

1 Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

2 Replacement procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3 Dimensional information required for connection of the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Oil or gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

1 Specific technical information supplied with the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

1 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2 Wiring procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3 Wiring boiler panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Start up procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

1 Shut-down procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

1 Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2 Shut down procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Service and maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Isometric views and list of spare parts - GT 400 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4

GT 400 A 21/09/06 - 94863449 - 82294154E

Regulations and guidelines

The installation and operating instructions shown here are given as a

guide for installation and operation and are not meant to replace any

State or Local Codes that may apply to the individual installation.

Good engineering practice should be used. Any deviation from laws

or regulations or industry Code or these instructions will void the

boiler warranty and any other responsability or liability of the De

Dietrich Thermiques S.A.

Installation codes

• THE BOILER SHALL BE ASSEMBLED AND INSTALLED BY A

QUALIFIED PROFESSIONAL ONLY. STRICT COMPLIANCE WITH

THESE INSTALLATION AND OPERATING INSTRUCTIONS IS A

PRECONDITION FOR THE CORRECT AND GUARANTEE OF THE

BOILER.

• THE INSTALLATION MUST CONFORM TO THE

REQUIREMENTS OF THE AUTHORITY HAVING JURISTRICTION

OR, IN THE ABSENCE OF SUCH REQUIREMENTS, TO THE CAN/

CGA B-149 FUEL GAS INSTALLATION CODES AND CSA B-139

OIL INSTALLATION CODES.

• WHERE REQUIRED BY THE AUTHORITY HAVING

JURISTRICTION, THE INSTALLATION MUST CONFORM TO THE

STANDARD FOR CONTROLS AND SAFETY DEVICES FOR

AUTOMATICALLY FIRED BOILERS ANSI/ASME CSD-1.

• THE INSTALLATION OF THE RELIEF VALVE SHALL BE

CONSISTENT WITH ANSI/ASME BOILER PRESSURE VESSEL

CODE, SECTION IV CSA B51.

• THE BOILER MUST NOT BE INSTALLED ON CARPETING.

• IF AN EXTERNAL ELECTRICAL SOURCE IS UTILIZED, THE

BOILER WHEN INSTALLED, MUST BE ELECTRICALLY BONDED

TO GROUND IN ACCORDANCE WITH THE REQUIREMENTS OF

THE AUTHORITY HAVING JURISTRICTION OR, IN THE

ABSENCE OF SUCH REQUIREMENTS, WITH THE CANADIAN

ELECTRICAL CODE PART 1, CSA C22.1, ELECTRICAL CODE.

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING CAN CAUSE IMPROPER

OPERATION AFTER SERVICINGS. “VERIFY PROPER

OPERATION AFTER SERVICE”.

General

The boilers of the GT400 A range are automatic independent hotwater boilers designed for connecting to a flue which require a

separate fuel oil or gas burner.

1 Boilers covered by this document

The GT 400 A boilers are pressurized hot water heating boilers,

connected to a flue, fitted with an independent burner using domestic

fuel oil or gas.

The boiler is equipped with standard control panel.

2 Uncrating

Upon arrival, check shipment to ensure all parts have been shipped.

Inspect all items for delivery damage. Report all damage and

shortages to the delivery carrier. Report any damage and shortages

to the Distributor.

5

21/09/06 - 94863449 - 82294154E GT 400 A

3 Packing

Before installing the boiler, check the chart below to ensure you have

all the components.

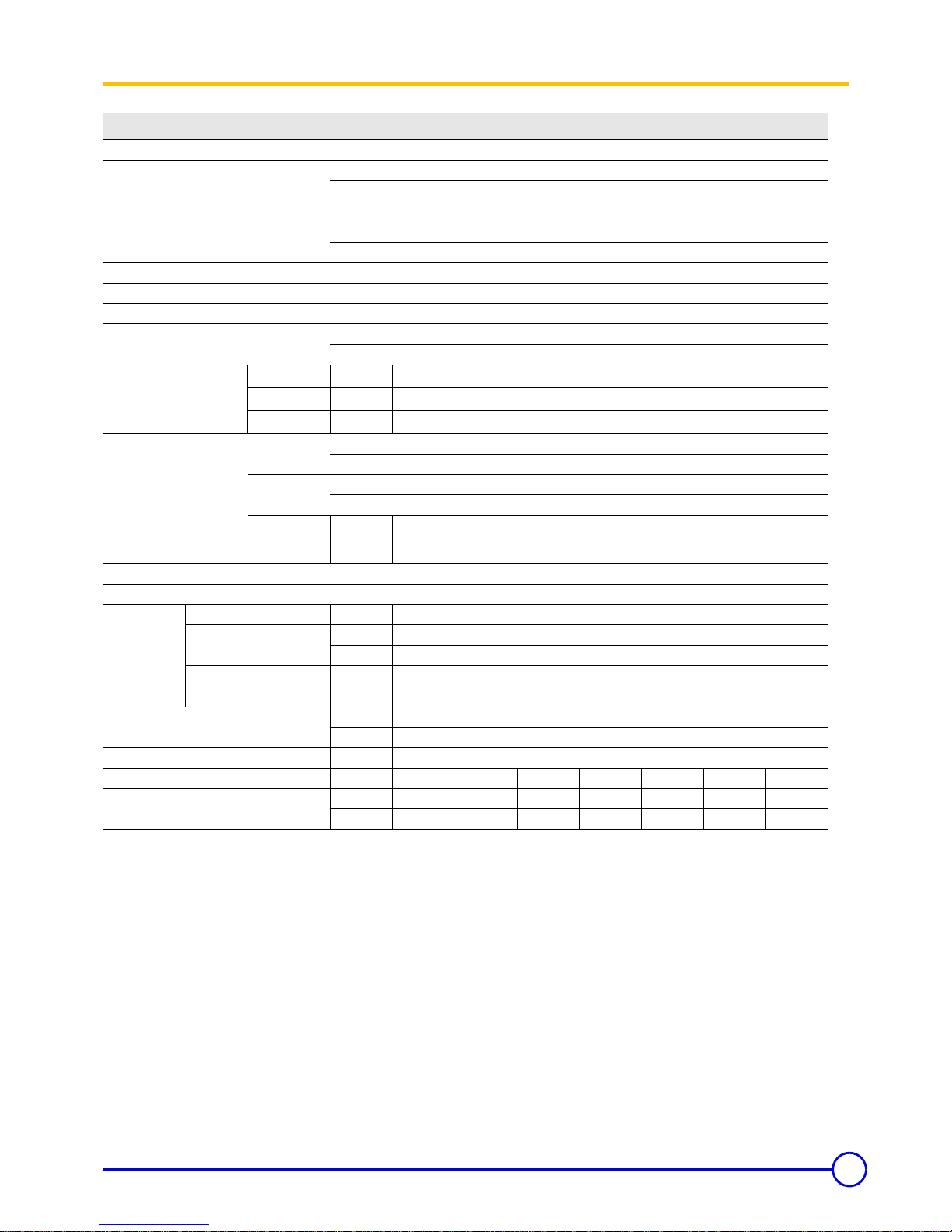

ITEM Box nr. GT 408A GT 409A GT 410A GT 411A GT 412A GT 413A GT 414A

Underframe (dimensions according to model) 1111111

Front section 1111111

Normal intermediate section 567891011

Special intermediate section 1111111

Rear section 1111111

Common accessories CS 20 1111111

Accessories (composition according to model) 1111111

Baffles

CS 30 1

CS 31 11

CS 34 1

CS 35 11

CS 36 1

Inner body insulation

CS 51 1

CS 53 11

CS 55 11

CS 57 11

Casing : common parts

CS 428 1

CS 429 1

CS 430 1

CS 431 1

CS 432 1

CS 433 1

CS 434 1

Casing : varying parts

CS 11 11

CS 12 111

CS 13 111222

CS 14 11

Wiring ducts

CS 41 1

CS 42 1

CS 43 1

CS 44 1

CS 45 1

CS 46 1

CS 47 1

Standard control panel FA 122 1111111

6

GT 400 A 21/09/06 - 94863449 - 82294154E

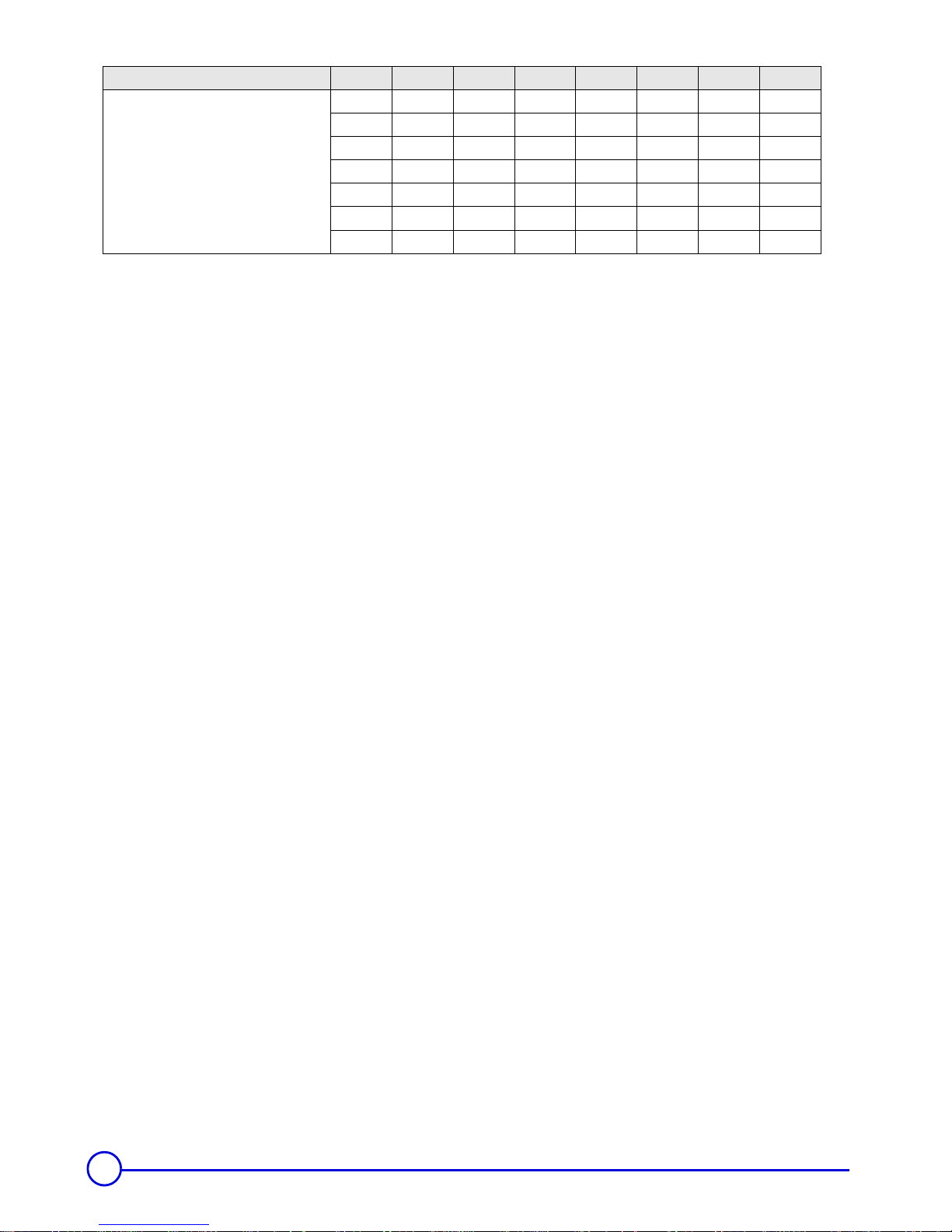

Technical documents

CS 418 1

CS 419 1

CS 420 1

CS 421 1

CS 422 1

CS 423 1

CS 424 1

ITEM Box nr. GT 408A GT 409A GT 410A GT 411A GT 412A GT 413A GT 414A

7

21/09/06 - 94863449 - 82294154E GT 400 A

4 Technical specifications of boilers

- CSA - MBH Output based on Thermal Efficiency Test According to

ANSI Z21.13a/CSA 4.9a-2005

- [NET] MBH Output Factor 1.15, Allowance for Piping and Pickup

Losses

- Chamber Resistance Based on Neutral Chimney-Vent Pressure

- Gas Vent Category Based on Several Factors [CO2 content, Vent

Pressure & Net-Flue Gas Temp]

- Approved for Direct-Vent, Use Only Approved Venting as Listed

- Natural Draft Applications, Approved for Type L vent [Gas-Oil] or

Type B Vent [Gas Only]

- Conversion Btu to kW = 3,412 Btu per kW

- All Models are Design Certified & Eligible to Bear Approval Marking

as Shown.

- All Models Certified to Fire; # 2 oil, Natural & Propane Gases.

Consult factory for Available Burners.

- All Models Comply and Certified in Accordance to the latest

Canadian & US standards

- To Obtain Current IBR Ratings, consult their publications and

website.

Item Unit GT 408 A GT 409 A GT 410 A GT 411 A GT 412 A GT 413 A GT 414 A

Firing Sequence Consult Burner Technical Data

[CSA] - Gas Input

MBH 1730 1947 2278 2567 2826 3100 3389

kW 507.0 570.5 667.6 752.3 828.3 908.6 993.3

[CSA] - # 2 Fuel Oil Input US GPH 12.00 13.50 15.80 17.80 19.60 21.50 23.50

[CSA] - Output [Gas-Oil]

MBH 1471 1655 1937 2182 2402 2635 2880

kW 431.1 485.0 567.6 639.4 704.1 772.3 844.2

[NET] - Output [Gas-Oil] MBH 1279 1439 1684 1897 2089 2292 2505

Cast Iron sections # 8 9 10 11 12 13 14

Flue-way baffles #16161624202020

Water capacity

US Gal 96.72 108.08 119.45 130.81 142.17 153.54 164.90

Liter 366 409 452 495 538 581 624

Water resistance

[

∆t = °F]

18° F

Ft. H

2

O

1.24 1.84 2.88 3.51 4.55 5.39 6.82

27° F

Ft. H

2

O

0.669 0.903 1.24 1.57 2.09 2.63 3.68

36° F

Ft. H

2

O

0.318 0.452 0.753 0.903 1.12 1.34 1.81

Combustion chamber

Dimensions

Diameter

[equivalent]

Inch 20.87

mm 530

Depth

Inch 46.57 52.87 59.17 65.47 71.77 78.07 84.87

mm 1183 1343 1503 1663 1823 1983 2143

Volume

ft

3

10.95 12.50 13.98 15.50 16.99 18.47 19.95

m

3

0.31 0.354 0.396 0.439 0.481 0.523 0.565

MAWP [Water] PSI ASME IV Rating Class 30 - (90 PSI) [See Canadian Provincial CRN approvals]

Min. Safety Relief Capacity MBH 1471 1655 1937 2182 2402 2635 2880

FA 122 Panel

Electrical connection V/P/H 120/1/60

Max. Water Temp. Safety

Limit [MR]

°F 248

°C 120

Operating Water

Temperature Range

°F 86 - 185

°C 30 - 85

Chamber resistance

Inch w.c. 0.44 0.60 0.80 1.00 1.00 1.00 1.00

mbar

1.1 1.5 2 2.5 2.5 2.5 2.5

Gas-Vent Category # I, II - III or IV

Boiler Vent Connection Inch 10 10 10 12 12 12 12

Weight [Dry]

lb 3241 3638 4034 4431 4828 5225 5622

kg 1470 1650 1830 2010 2190 2370 2550

8

GT 400 A 21/09/06 - 94863449 - 82294154E

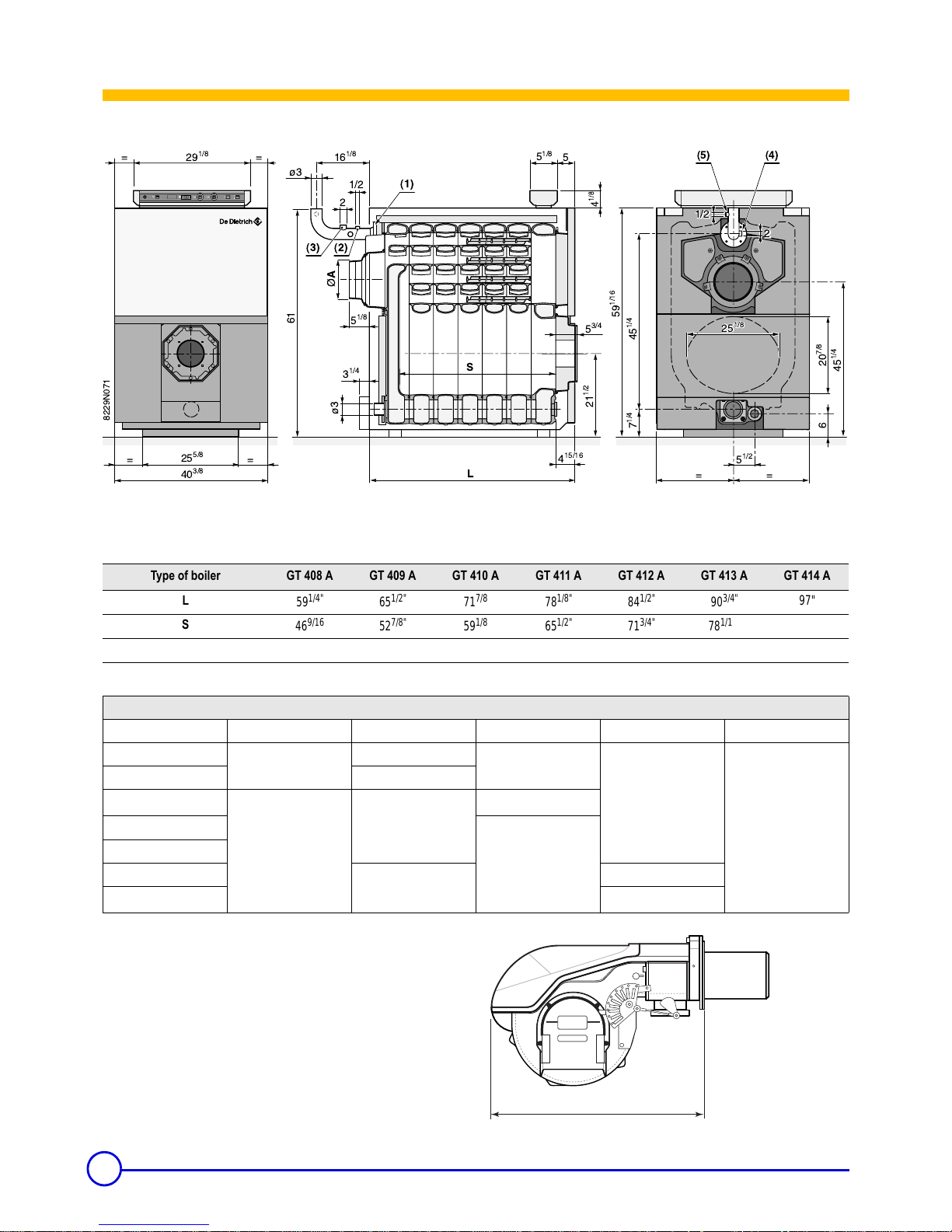

Main Dimensions

GT 400 A

(1) 3” 150# weld neck flange

(2) 1/2” NPT tapping for temp sensing well, etc…

(3) 2” NPT tapping for safety relief valve

(4) 3/4” NPT tapping for low water cutoff probe type

(5) 1/2” NPT tapping for combination pres/temp gauge

Notes:

-Dimension are for gas burners only

-Oil and combination oil/gas burner, refer to burner manufacturer

specifications

2

25

1/8

L

==

S

¯

A

==

==

6

20

7/8

5

1/2

5

3/4

4

15/16

40

3/8

25

5/8

3

1/4

¿3

61

5

1/8

16

1/8

5

1/8

5

¿3

1/2

29

1/8

25

1/8

45

1/4

7

1/4

21

1/2

45

1/4

59

1/16

4

1/8

8229N071

2

2

1/2

0

I

6A

(4)(5)

(1)

(3) (2)

Type of boiler GT 408 A GT 409 A GT 410 A GT 411 A GT 412 A GT 413 A GT 414 A

L

59

1/4"

65

1/2"

71

7/8

78

1/8"

84

1/2"

90

3/4"

97"

S

46

9/16

52

7/8"

59

1/8

65

1/2"

71

3/4"

78

1/16"

84

3/8"

Ø A out.

9

7/8

9

7/8

9

7/8

11

13/16"

11

13/16"

11

13/16"

11

13/16"

Dimension "X" Maximum Burner Length (inches)

Boiler Model Riello Weishaupt Power flame Fuel Master Gordon Piatt

GT408A

22

13/16

23

26

32

1/2

26

GT409A 32

GT410A

33

1/16

31

3/16

25

1/8

GT411A

30

1/8

GT412A

GT413A

37

7/16

35

GT414A

38

1/2

G50_0001

X

9

21/09/06 - 94863449 - 82294154E GT 400 A

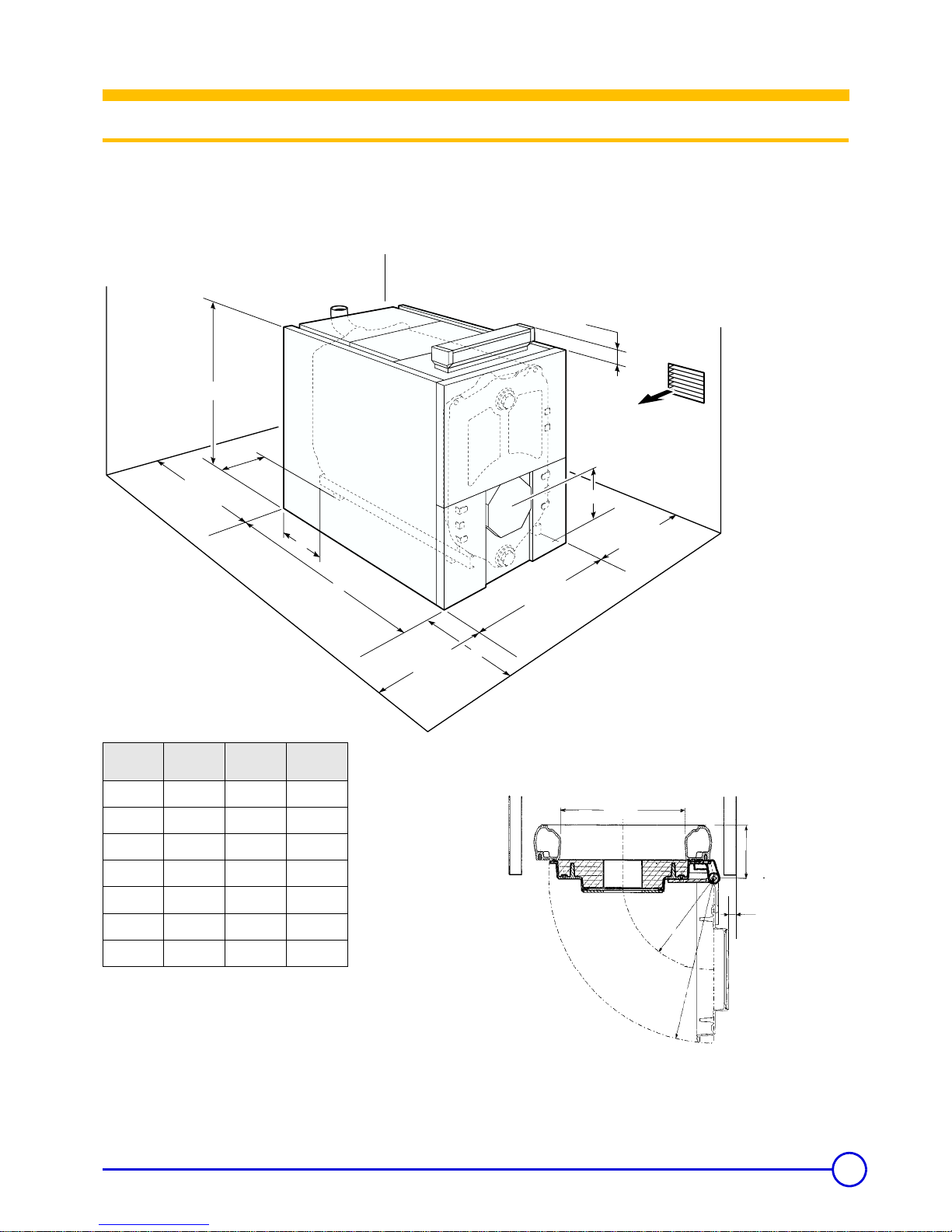

Boiler Installation

1Installation

The GT 400 A boiler has a sturdy underframe, it does not need any

special base although a housekeeping pad is recommended to keep

steel parts out of casual water. Its furnace is closed, so it is not

necessary to place it on a fireproof floor, but the floor must be able to

bear the weight.

Additional

the space required when the burner door is open.

Top view

Burner door open

Combustion air

per local codes

21 1/2"

59

1/16"

4

1/8

"

40

1/8

"

7

1/8

"

20

3/8

"

40

3/8

"

20

3/8

"

B

L

X

S

Dimension LDimension BDimension

C

GT 408 A

59

1/4"

5

3/8"

24"

GT 409 A

65

1/2"

1

5/8"

71"

GT 410 A

71

7/8"

4

1/8"

71"

GT 411 A

78

1/8"

1

5/8"

71"

GT 412 A

84

1/2"

4

1/8"

76"

GT 413 A

90

3/4"

1

5/8"

76"

GT 414 A 97"

4

1/8"

76"

25 1/8"

R = 17"

R = 30

5/8

"

5/8"

10 1/8"

10

GT 400 A 21/09/06 - 94863449 - 82294154E

2 Combustion Air Supply

Boilers operating in atmospheres that contain fluorides or chlorides

such as beauty shops and automotive repair garages where air

conditioning services are performed or industrial applications that

may have corrosive elements in the air must have a clean source of

combustion and ventilation air. Boiler damage by contaminants will

void the warranty and any other responsibility or liability of De Dietrich

Thermique/FES Ltd.

Note: Ensure boiler room is adequately ventilated and clear

and free from combustible materials, gasoline and other

flammable vapours and liquids.

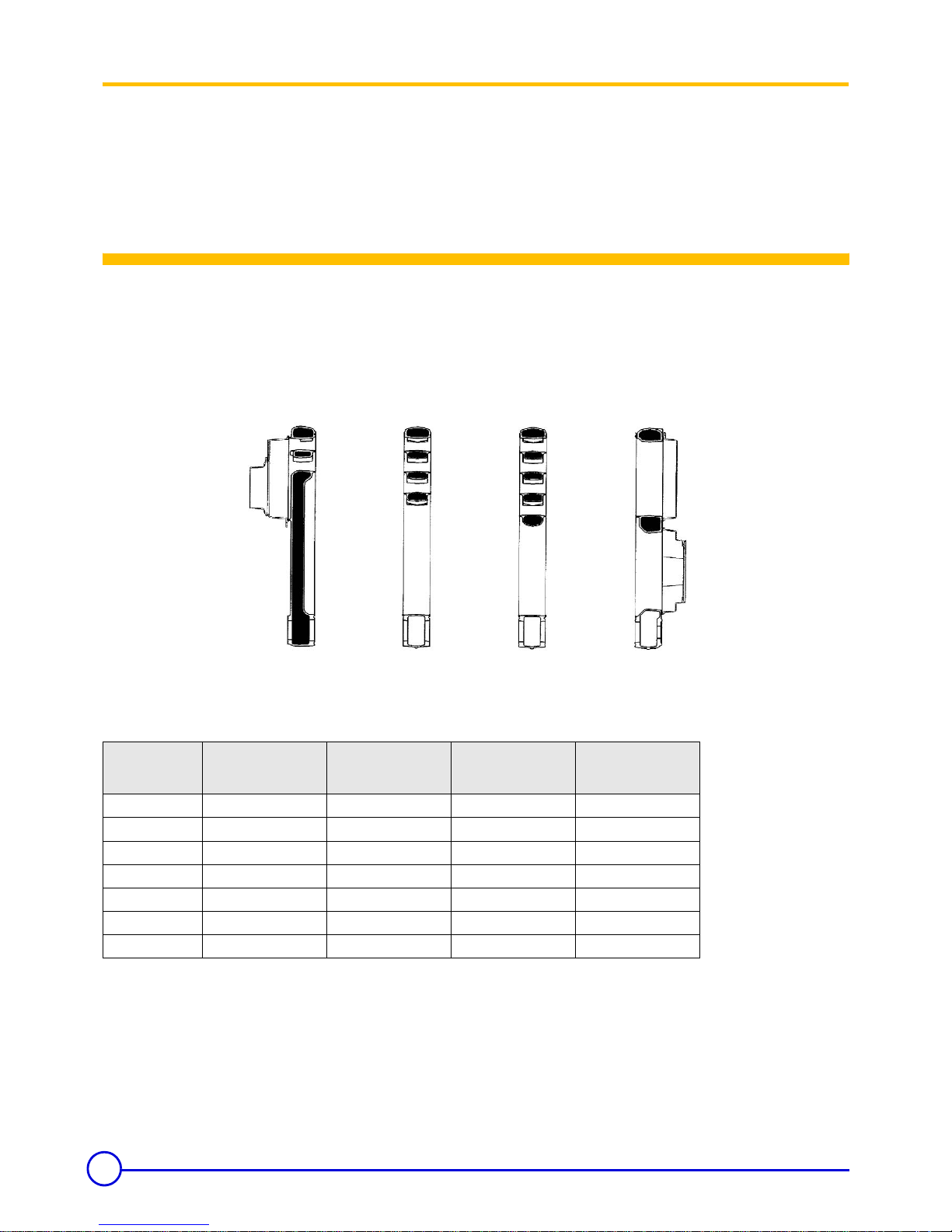

Assembly

To fit the sections, proceed in the following order :

- fit the rear section

- fit the special intermediate section

-fit all of the normal intermediate sections

- fit the front section

.

1: rear

2: front

8229 025AN

1

2

8229-0043

8229-0045

8229-0041 8229-0042

Boiler model

Rear section

n° 8229-0043

Special intermediate

section

8229-0045

Normal intermediate

section

8229-0041

Front section

8229-0042

GT 408 A 1 1 5 1

GT 409 A 1 1 6 1

GT 410 A 1 1 7 1

GT 411 A 1 1 8 1

GT 412 A 1 1 9 1

GT 413 A1 1101

GT 414 A1 1111

11

21/09/06 - 94863449 - 82294154E GT 400 A

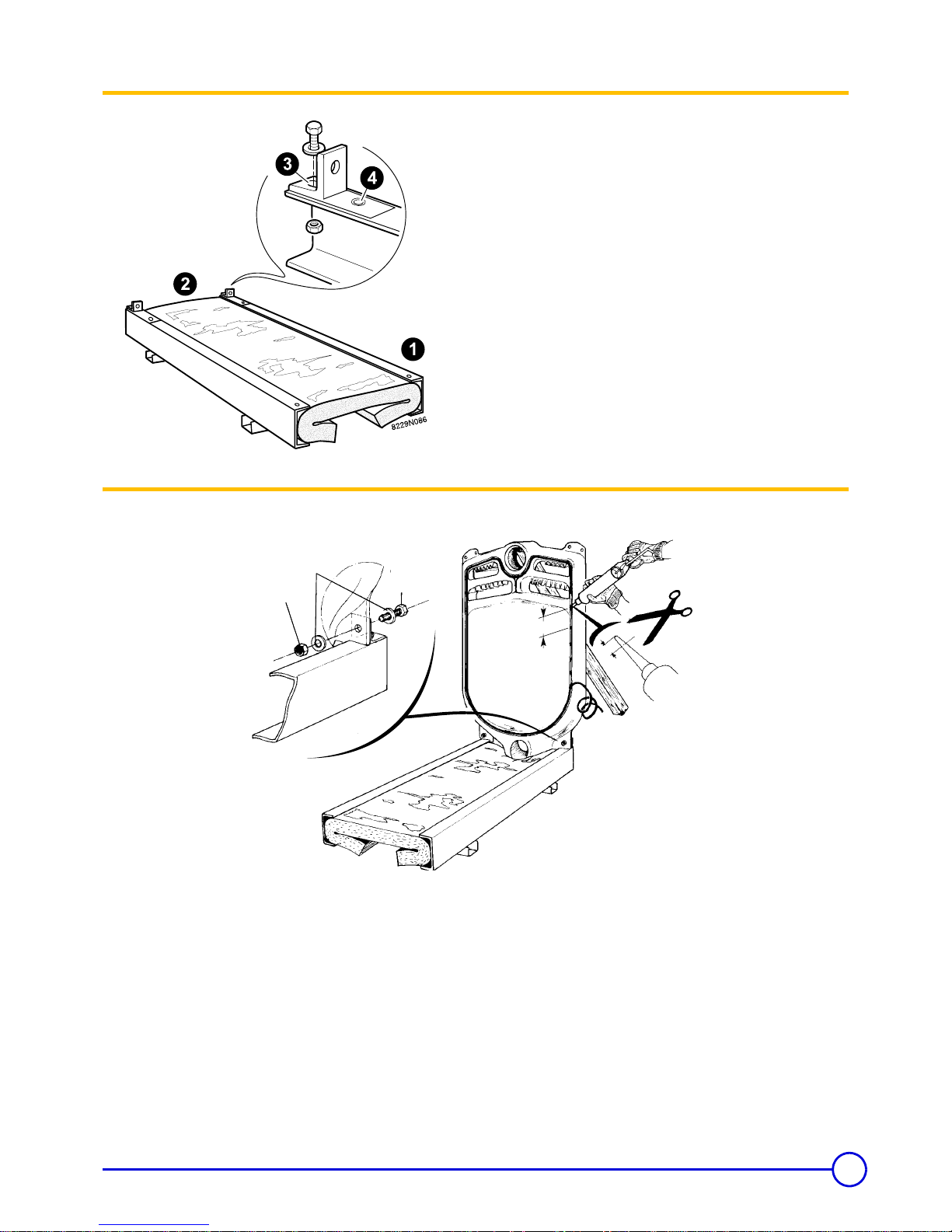

Step one

Front - Rear

GT 408 - GT 410 - GT 412 - GT 414

GT 409 - GT 411 - GT 413

- Fit the 2 rear attachment brackets (in the body accessories pack)

and attach them onto the framework using 2 bolts HM 12X25/25 +

4 washers L12 and 2 nuts HM 12.

Use the corresponding holes following the indication on

the frame.

- Put the lower insulation in place (fabric to the top) packs CS 51 to

CS 57. Adapt length if necessary or fold the lower insulation after

the casing has been completely assembled.

Step two

Mounting of framework and thermocord

• Locate the framework depending on the direction in which the

burner door will be opened and the length of the burner.

• Put the rear section in position on the framework and support it.

Attach it at the brackets using 2 bolts HM 12x40/40 + 4 washers

L 12 + 2 nuts HM 12.

• Using a silicone gun, put silicone mastic points (1 cartridge

supplied with the accessory pack CS 20) into the sealing

groove of the section (approx. every 5 to 10 cm) then carefully

put the thermocord in place in the sealing groove.

do not pull on the cord when it is being put in, to avoid

stretching to preserve its thickness. Avoid to locate the

junction point at the bottom of the section.

HM 12

40x40

HM 12

L 12

2/5"

8"

12

GT 400 A 21/09/06 - 94863449 - 82294154E

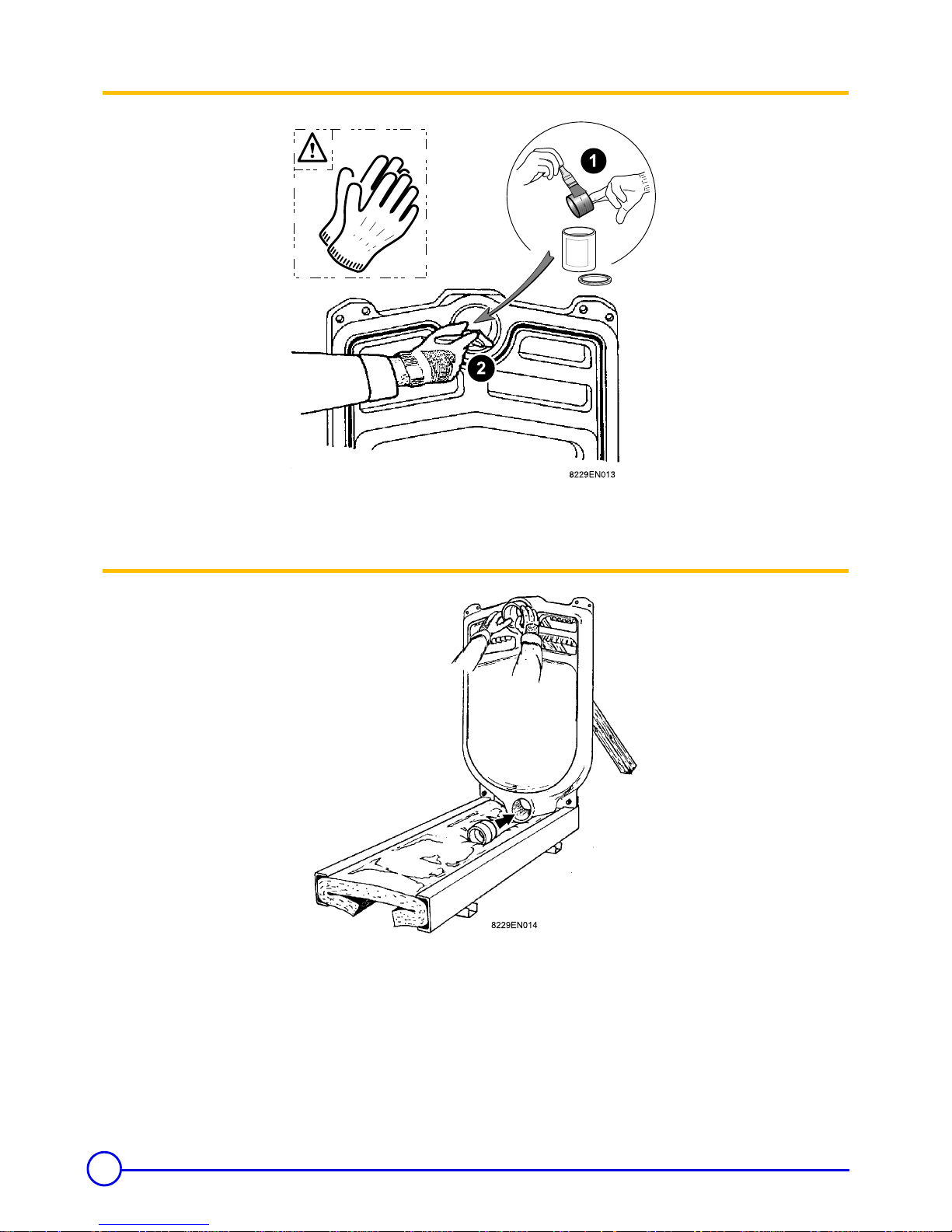

Step three

Handle the nipples with gloves, there might be sharp

edges.

Clean the bores and nipples with a solvent.

Coat them with the lubricant supplied with the sections.

Step four

- Drive in the 2 nipples gently.

13

21/09/06 - 94863449 - 82294154E GT 400 A

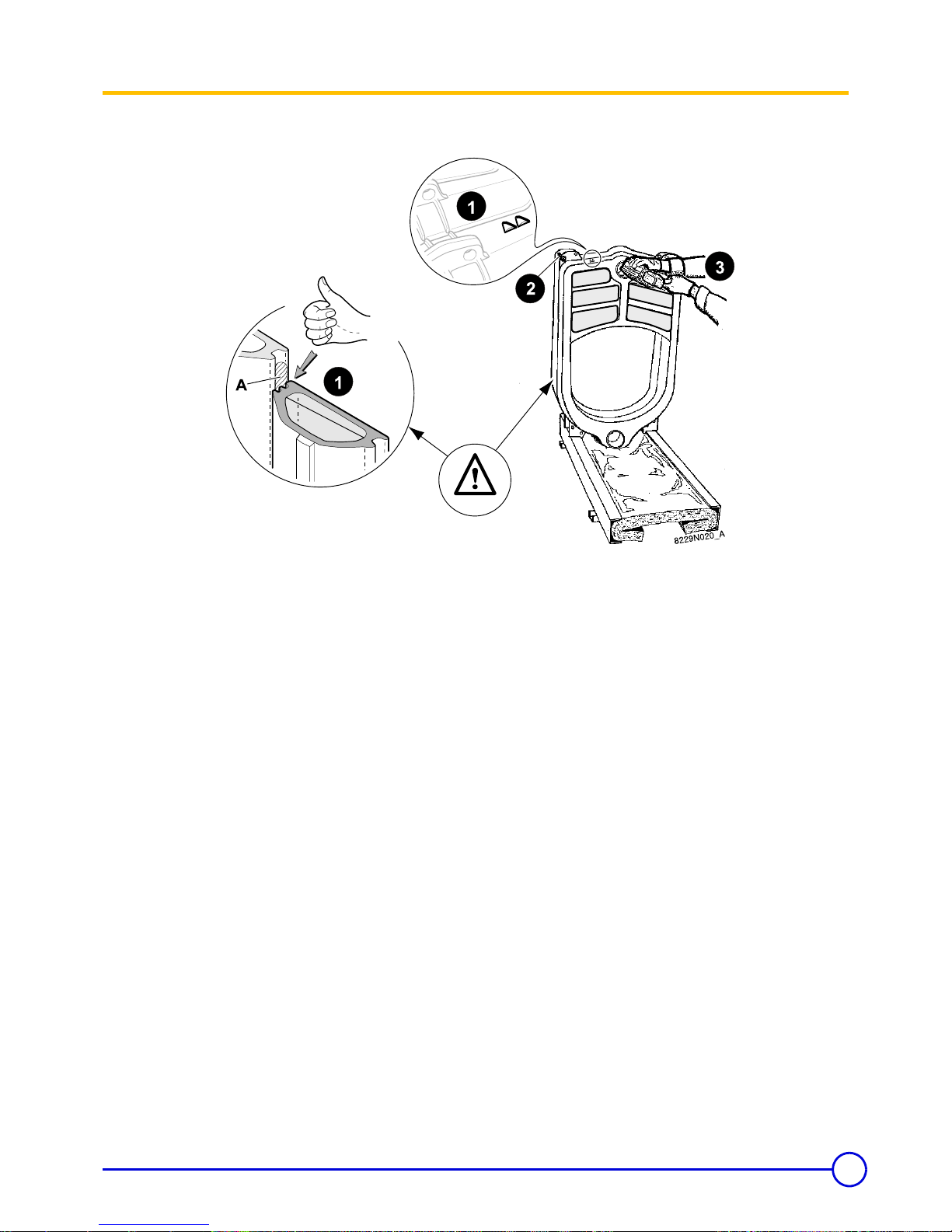

Step five

Assembling the sections

A : thermocord

Special intermediate section before rear section.

Place the special intermediate section, note front back

relationship with the sealing groove against the thermocord.

For safety, insert an upper assembly rod (body accessories

pack) into the holes in the 2 sections.

Gently and at the same time drive in the 2 nipples of the rear

section using a hammer and a piece of wood.

14

GT 400 A 21/09/06 - 94863449 - 82294154E

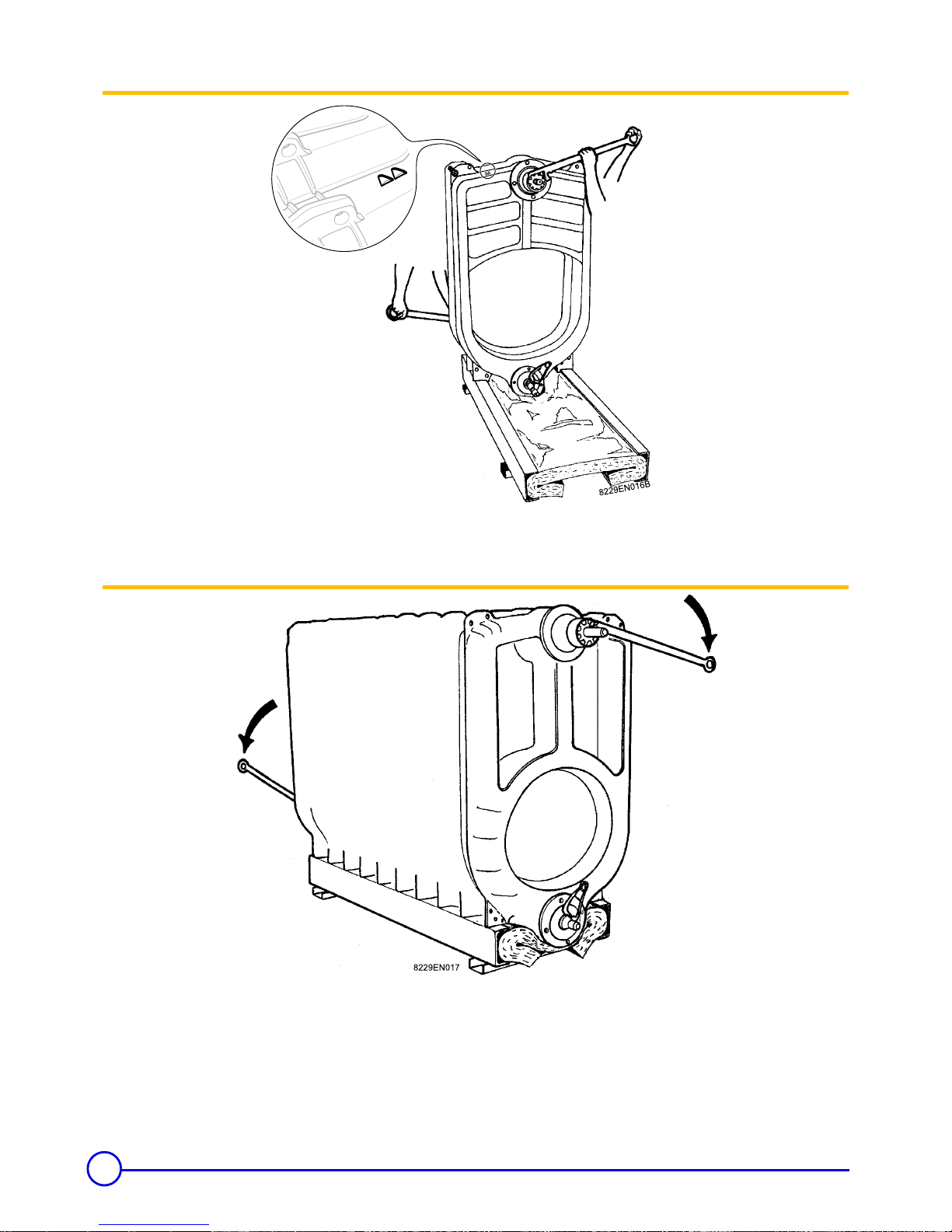

Step six

- Put the special assembly tool in place. - Tighten progressively so the upper and lower connections come

together equally at the same time.

Step seven

- Fit the remaining sections one by one in the order given,

proceeding as per steps 3-4-5-6.

- Leave the assembly tool in place.

15

21/09/06 - 94863449 - 82294154E GT 400 A

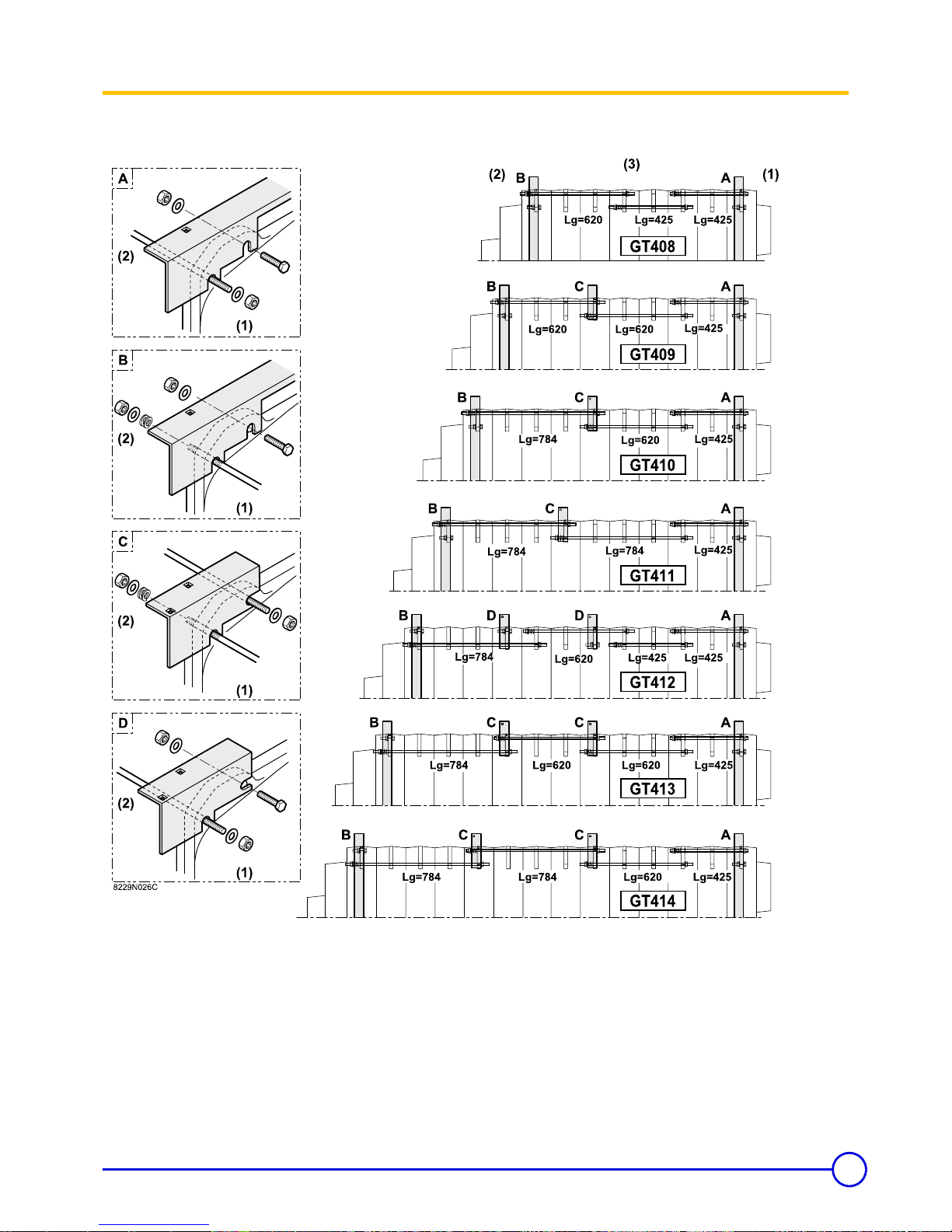

Step eight

Installing the assembly rods and upper casing supports

(1) Front - (2) Rear - (3) Top view

- Install the upper assembly rods (body accessories pack) in the

order given in the figure above. Place the expansion spring and its

washer on each rod towards the rear. Stop tightening the nuts

when the free space between the threads is about 1/16" to 1/

8".

- Install the upper casing supports (pack CS13) and the upper cross-

pieces (packs CS428 to CS434 and CS11 to CS14) with the

assembly rods (body accessories pack) as shown in details A-B-

C-D.

- Install the lower assembly rods in the order given in the figure.

- Remove the assembly tool.

16

GT 400 A 21/09/06 - 94863449 - 82294154E

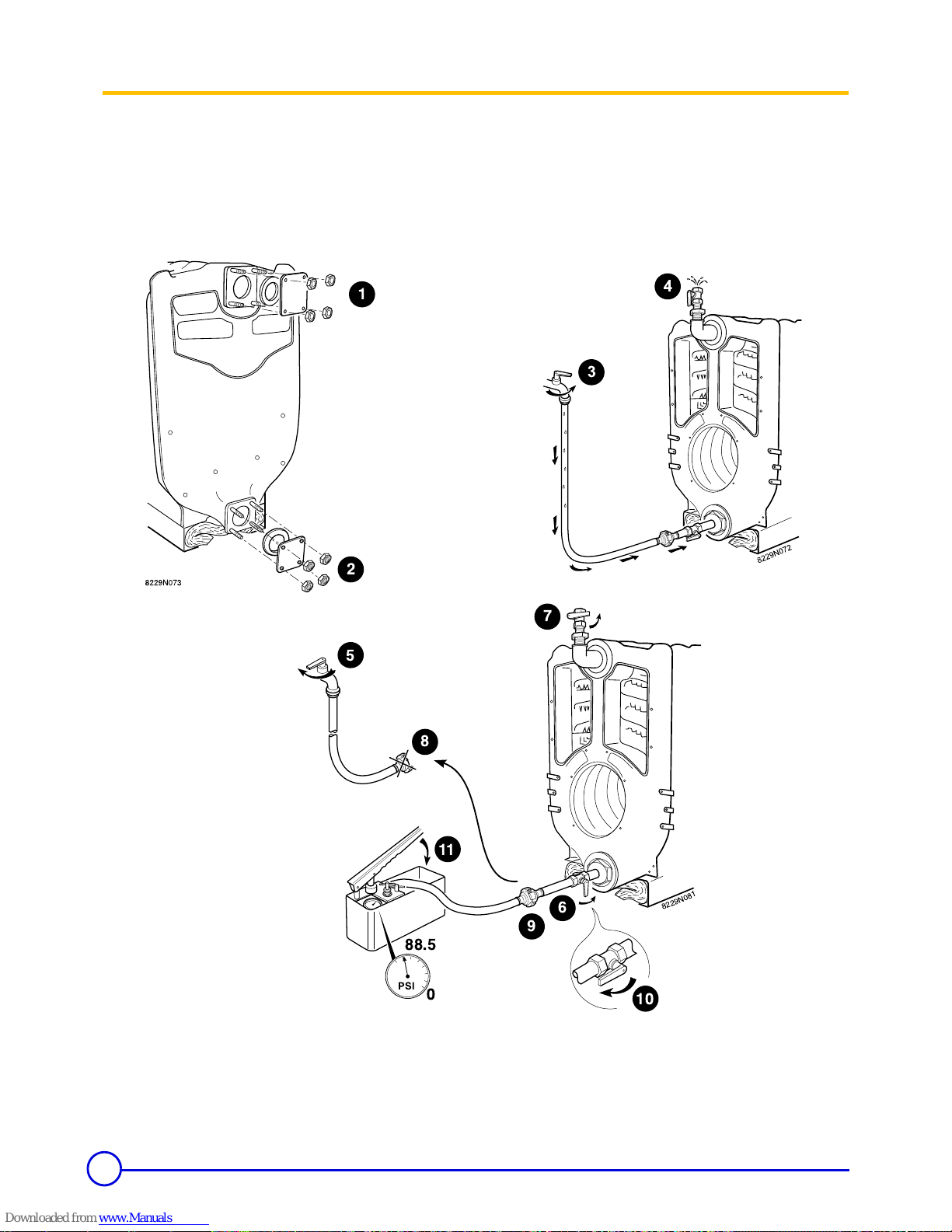

Step nine

Hydraulic test

After assembling the boiler body, the installer must carry

out a water tightness test at a pressure equal to 1.5 times

the operating pressure (that is 137 PSI minimum - 113 PSI

in Alberta) for 30 minutes at least. The test must be done at

room temperature.

Any drop in pressure indicates a leakage in the boiler body.

Ensure that all the air in the boiler is vented to avoid any bursting of the body.

After the tightness test, drain the boiler and remove all the parts used for the test.

8229N081

7

PSI

88.5

0

7

5

8

11

9

10

6

6

Loading...

Loading...