DeDietrich GT 300 A, GT 300 II, GT 304 A/II, GT 305 A/II, GT 306 A/II Operating Instructions Manual

...

GT 300 A/II

Please Read & Save

these instructions for

Future Reference

Oil-Gas Fired Hot Water boiler

English

03/14/08

Installation and operating instructions

Warning:

Before putting the boiler into operation read this manual

carefully.

Warning:

The operating manual is part of the documentation that is

delivered to the installation’s operator. Go through the

information in this manual with the owner/operator and

make sure that he or she is familiar with all the necessary

operating instructions.

Notice:

This manual must be retained for future reference. Improper

installation, adjustment, alteration, service or maintenance can

cause injury, loss of life or property damage. Refer to this

manual. For assistance or additional information consult a

qualified installer, service agency or the gas supplier.

94863873

Guideline of Notices

"All installations of this appliance must be be in accordance to all national and local codes and

authorities having jurisdiction"

[Canadian Installation] CSA B139 for Oil & CSA B149 for Gas

[USA Installations] NFPA 54/ANSI Z223.1 for Gas & NFPA 31 for Oil

This boiler must be connected to a venting that will safely and effectively discharge all flue

gases to the outside in an effective manner.

Never burner garbage or paper in the unit, and never leave combustible materials around it.

Do not use gasoline, crankcase draining, or any other oil containing gasoline

Safety Considerations

Warning:

indicates presence of hazards that can cause, if not

avoided, severe personal injury, death or substantial

property damage.

! Caution:

indicates presence of hazards that will or can cause, if not

avoided, minor personal injury or property damage.

Notice:

Application comment for optimum use of equipment and

adjustment as well as useful information.

Reference to an other instruction book.

Z

Observe the following symbols

DANGER

due to explosion of gas.

- Work only on gas components when you have a license to do so.

- Note that the assembly of gas and vent connections, the initial

start-up, the electrical connections, the maintenance and service

can only be performed by a licensed service contractor or

technician.

DANGER

due to electricity.

- Prior to doing any work on the heating system, disconnect all

electrical power to the boiler at the emergency switch.

- It is NOT sufficient to shut off only the boiler control!

! CAUTION!

SYSTEM DAMAGE

due to improper installation.

- Observe local and state codes as well as common industry

practices during the installation and operation of the heating

appliance.

! CAUTION!

SYSTEM DAMAGE

due to inadequate cleaning and maintenance.

- A boiler cleaning and maintenance should be performed annually.

Verify complete system operation at the same time.

- Correct the problem immediately to prevent damage to the

system!

Please observe the following safety instructions.

Read this manual carefully.

Correct installation and adjustment of the burner and the control

panel is a precondition for safe, efficient operation of the gas boiler.

Read this manual and the specifications on the safety label carefully

before attempting to put the burner into operation.

Do not store or use gasoline or other flammable liquids in

the vicinity of this or any other appliance.

Installation and service must be peformed by a qualified

installer, service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electric switch, do not use any phone in

your building.

- Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the Fire

Department.

Warning:

Improper installation, adjustment, and/or operation could

cause carbon monoxide poisoning resulting in injury or

death.

This product must be installed and serviced by a

professional service technician who is experienced and

qualified in hot water boiler installation and gas

combustion.

! Caution: Strict compliance with these instructions is a

precondition for the correct operation of the boiler.

! IMPORTANT

Service on this boiler should be undertaken only by trained and

skilled personnel.

Keep boiler area clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

Do not place any obstruction in the boiler room that will hinder

the flow of combustion and ventilating air.

Read these instructions carefully before proceeding with the

installation of boiler. Post instructions near boiler for reference

by owner and serviceman.

Maintain instructions in legible condition.

2

GT 300 A/II 06/10/06 - 94863873 - 85534150E

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Regulations and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1 Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Packing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Technical specifications of boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4 Main Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Boiler Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2 Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1 Dimensional information required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3 Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 Ancillaries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Combustion and ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1 Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2 Replacement procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3 Dimensional information required for connection of the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Oil or gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1 Specific technical information supplied with the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

1 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2 Wiring procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3 Wiring boiler panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Start up procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

1 Start up procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2 Shut-down procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1 Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Service and maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Spare parts - GT 300 A/II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

06/10/06 - 94863873 - 85534150E GT 300 A/II

3

Regulations and guidelines

Only a qualified and licenced heating professional is to carry out the

removal, installation, startup and maintenance of this boiler. The boiler must

be installed according to all national and local codes having jurisdiction. The

operation of the boiler must be verified and all safety controls checked. Any

defect or abnormal operations must be corrected immediately. The entire

system requires annual service and cleaning at least once a year.

The installation and operating instructions shown here are given as a

guide for installation and operation and are not meant to replace any

State or Local Codes that may apply to the individual installation.

Good engineering practice should be used. Any deviation from laws

or regulations or industry Code or these instructions will void the

boiler warranty and any other responsability or liability of the De

Dietrich Thermiques S.A.

Installation codes

• THE BOILER SHALL BE ASSEMBLED AND INSTALLED BY A

QUALIFIED PROFESSIONAL ONLY. STRICT COMPLIANCE WITH

THESE INSTALLATION AND OPERATING INSTRUCTIONS IS A

PRECONDITION FOR THE CORRECT AND GUARANTEE OF THE

BOILER.

• THE INSTALLATION MUST CONFORM TO THE

REQUIREMENTS OF THE AUTHORITY HAVING JURISTRICTION

OR, IN THE ABSENCE OF SUCH REQUIREMENTS, TO THE CAN/

CGA B-149 FUEL GAS INSTALLATION CODES AND CSA B-139

OIL INSTALLATION CODES.

• WHERE REQUIRED BY THE AUTHORITY HAVING

JURISTRICTION, THE INSTALLATION MUST CONFORM TO THE

STANDARD FOR CONTROLS AND SAFETY DEVICES FOR

AUTOMATICALLY FIRED BOILERS ANSI/ASME CSD-1.

The GT300 A/II are series of oil or gas fired, cast iron, automatic

boilers.

1 Uncrating

Upon arrival, check shipment to ensure all parts have been shipped.

Inspect all items for delivery damage. Report all damage and

shortages to the delivery carrier. Report any damage and shortages

to the Distributor.

• THE INSTALLATION OF THE RELIEF VALVE SHALL BE

CONSISTENT WITH ANSI/ASME BOILER PRESSURE VESSEL

CODE, SECTION IV CSA B51.

• THE BOILER MUST NOT BE INSTALLED ON CARPETING.

• IF AN EXTERNAL ELECTRICAL SOURCE IS UTILIZED, THE

BOILER WHEN INSTALLED, MUST BE ELECTRICALLY BONDED

TO GROUND IN ACCORDANCE WITH THE REQUIREMENTS OF

THE AUTHORITY HAVING JURISTRICTION OR, IN THE

ABSENCE OF SUCH REQUIREMENTS, WITH THE CANADIAN

ELECTRICAL CODE PART 1, CSA C22.1, ELECTRICAL CODE.

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING CAN CAUSE IMPROPER

OPERATION AFTER SERVICINGS. “VERIFY PROPER

OPERATION AFTER SERVICE”.

General

2 Packing

See the separate assembly instruction book.

For the optional equipment you may use with this boiler, see the

current price list.

4

GT 300 A/II 06/10/06 - 94863873 - 85534150E

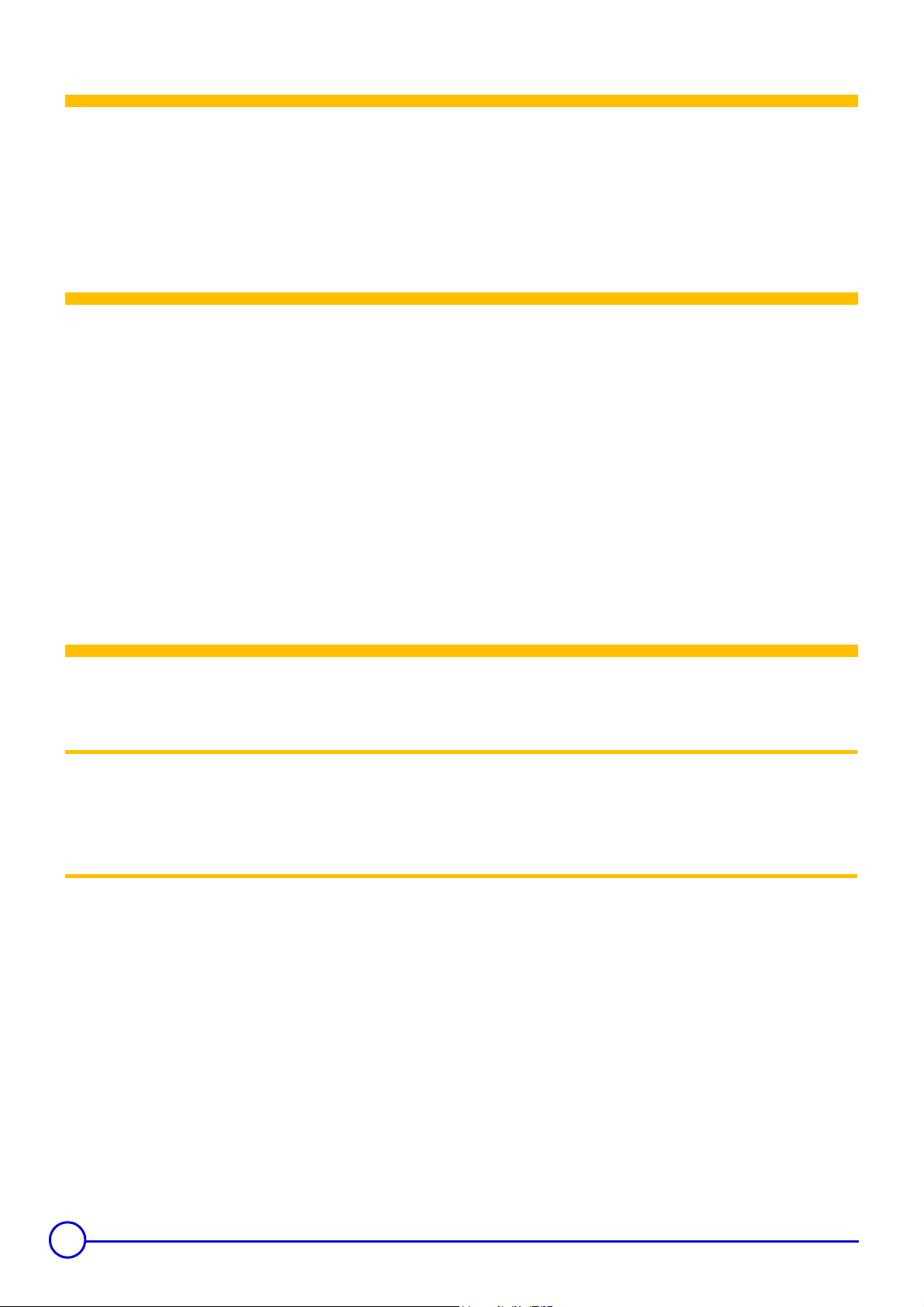

Item

GT 300 A/II Technical Specification Table

Firing Sequence

[CSA] - Gas Input

[CSA] - # 2 Fuel Oil Input

[CSA] - Output [Gas-Oil]

[NET] - Output [Gas-Oil]

Cast Iron Sections

Flue-way baffles

Water Capacity

18° F

Water

Resistance

27° F

[∆T = °F]

36° F

Diameter

[equivalent]

Combustion

Chamber

Depth

Dimensions

Volume

MAWP [Water]

Min. Safety Relief Capacity

Electrical Connection

Max. Water Temp.

Safety Limit [MR]

Water Operating

FA 122 Panel

Temperature Range

Chamber Resistance

Gas-Vent Category

Boiler Vent Connection

Weight [Dry]

Model

Unit

GT 304 A/II

GT 305 A/II

GT 306 A/II

GT 307 A/II

GT 308 A/II

GT 309 A/II

Consult Burner Technical Data

MBH 404 598 808 1,024

1,226

1,442

kW 118 175 237 300 359 423

US GPH

MBH 343 509 686 870 1,042

kW 100.6

2.80 4.15 5.60 7.10 8.50 10.00

1,226

149.1

201.2

255.1

305.3

359.2

MBH 298 442 597 757 906 1,066

#456789

# 6 10 10 10 12 12

US Gal

25.37

30.65

35.94

41.22

46.51

51.80

Liter 96 116 136 156 176 196

Ft. H

Ft. H

Ft. H

Inch

mm

O

2

O

2

O

2

0.368 0.60221 1.0371 1.539 2.275 3.5129

0.1539 0.24758 0.47508 0.6524 1.007 1.539

0.0869 0.1405 0.26765 0.36802 0.56876 0.86986

14.84

377

Inch 24.45 30.75 37.05 43.35 49.65 54.96

mm 621 781 941 1,101 1,261 1,396

Ft

m

PSI

3

3

3.39 4.31 5.23 6.14 7.06 7.98

0.096 0.122 0.148 0.174 0.2 0.226

ASME IV Rating Class 30 - (81 PSI) [See Canadian Provincial CRN approvals]

MBH 343 509 686 870 1,042 1,226

V/P/H

° F

° C

° F

° C

120/1/60

248

120

104 - 185

40 - 85

Inch w.c. 0.80 0.16 0.28 0.48 0.72 0.88

mbar 0.2 0.4 0.7 1.2 1.8 2.2

#

I, II - III or IV

Inch 777888

lb 1,124 1,340 1,530 1,744 1,953 2,154

kg 510 608 694 791 886 977

Note:

• CSA - MBH Output based on Thermal Efficiency Test According to ANSI Z21.13a/CSA 4.9a-2005

• All Models Certified for 0 - 2,000 feet ASL installation altitude, consult factory for higher altitudes

• [NET] MBH Output Factor 1.15, Allowance for Piping and Pickup Losses

• Chamber Resistance Based on Neutral Chimney-Vent Pressure

Gas Vent Category Based on Several Factors [CO

•

• Approved for Direct-Vent, Use Only Approved Venting as Listed

• Natural Draft Applications, Approved for Type L vent [Gas-Oil] or Type B Vent [Gas Only]

• Conversion Btu to kW = 3,412 Btu per kW

• All Models are Design Certified & Eligible to Bear Approval Marking as Shown.

• All Models Certified to Fire; # 2 oil, Natural & Propane Gases. Consult factory for Available Burners.

• All Models Comply and Certified in Accordance to the latest Canadian & US standards

• To Obtain Current IBR Ratings, consult their publications and website.

Due to ongoing and continuous product improvements, Flexible Eutectic Sales Ltd. Reserves all rights to amend and delete information provided on this product specification table.

06/10/06 - 94863873 - 85534150E GT 300 A/II

content, Vent Pressure & Net-Flue Gas Temp]

2

5

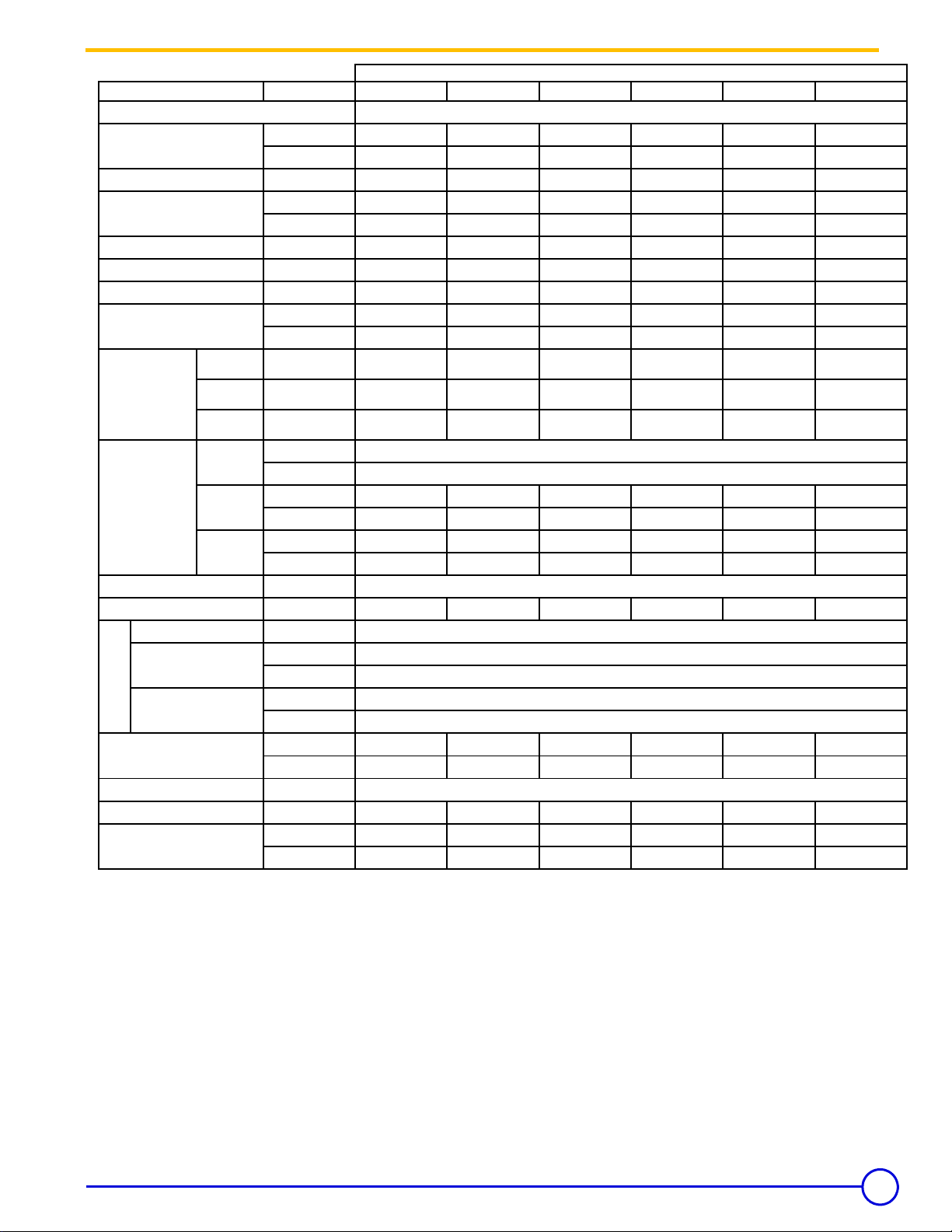

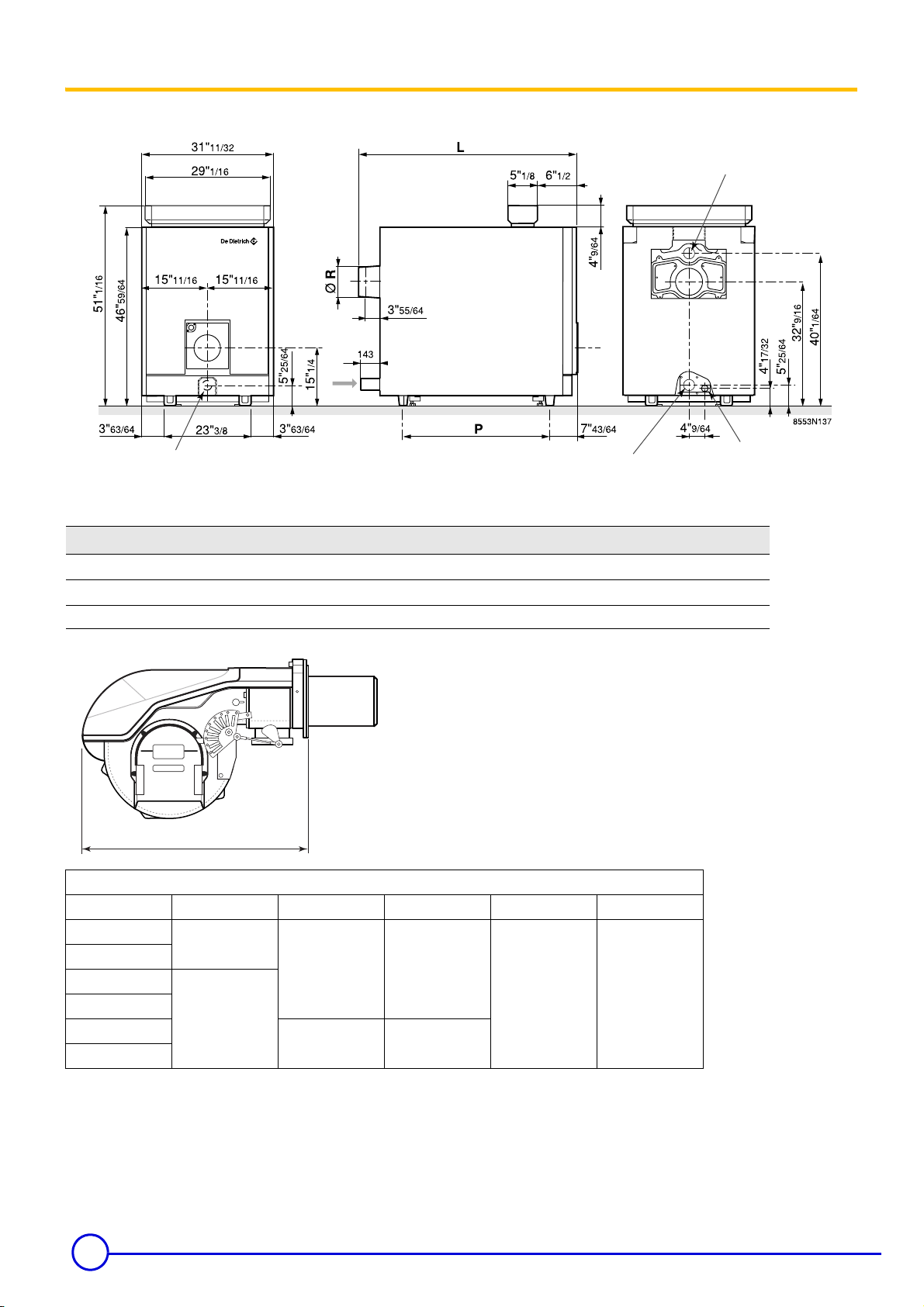

4 Main Dimensions

GT 300 A/II

A

A

D

A Water flow tapping 2 1/2" NPSC

B Water return 2 1/2" NPSC

C Drain 1 1/2" FPT

D Rp 2 1/2 diameter sludge removal hole

B

Type of boiler GT 304 A/II GT 305 A/II GT 306 A/II GT 307 A/II GT 308 A/II GT 309 A/II

L

P

Ø R

5/8"

38

9/32

19

7" 7" 7" 8" 8" 8"

44

25

G50_0001

59/64"

19/32"

51

31

7/32

7/8

57

38

33/64"

3/16"

63

44

X

Dimension "X" Max. Burner Length (inches)

Boiler Model Riello Weishaupt Power Flame Fuel Master Gordon Piatt

GT304 A/II

GT305 A/II

GT306 A/II

GT307 A/II

GT308 A/II

GT309 A/II

26

10

15/32

19

23

22

25

1/4

1/4

19

1/8

Notes:

13/16"

31/64"

C

7/64"

70

25/32"

50

26

- Dimension are for gas burner only

- Oil and combination oil/gas, refer to burner manufacturer

specifications

6

GT 300 A/II 06/10/06 - 94863873 - 85534150E

Boiler Installation

Combustion air supply must be provided according to

national and local codes:

CSA B149.1 -.2 & CSA B139

ANSI Z223.1 & NFPA 31

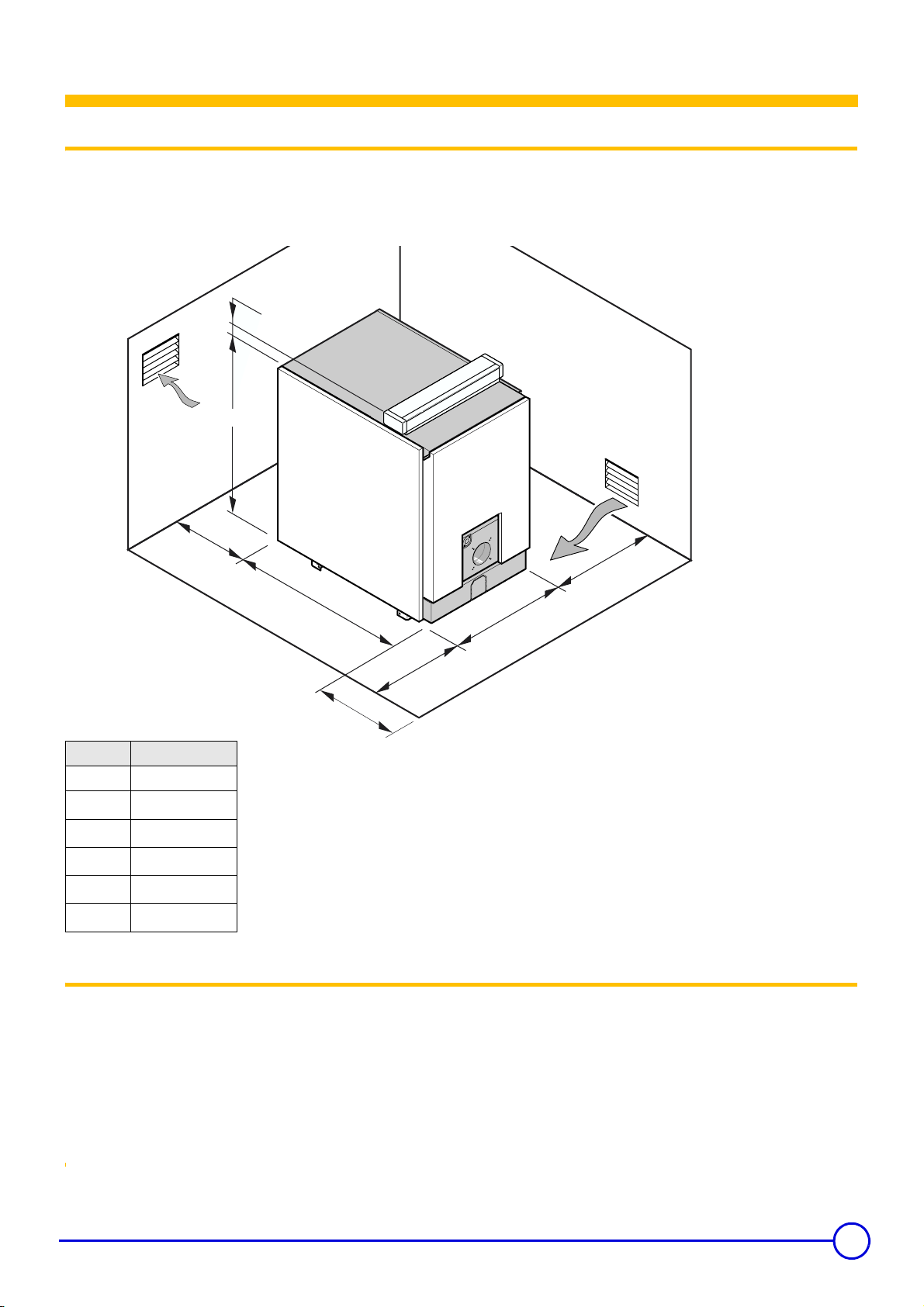

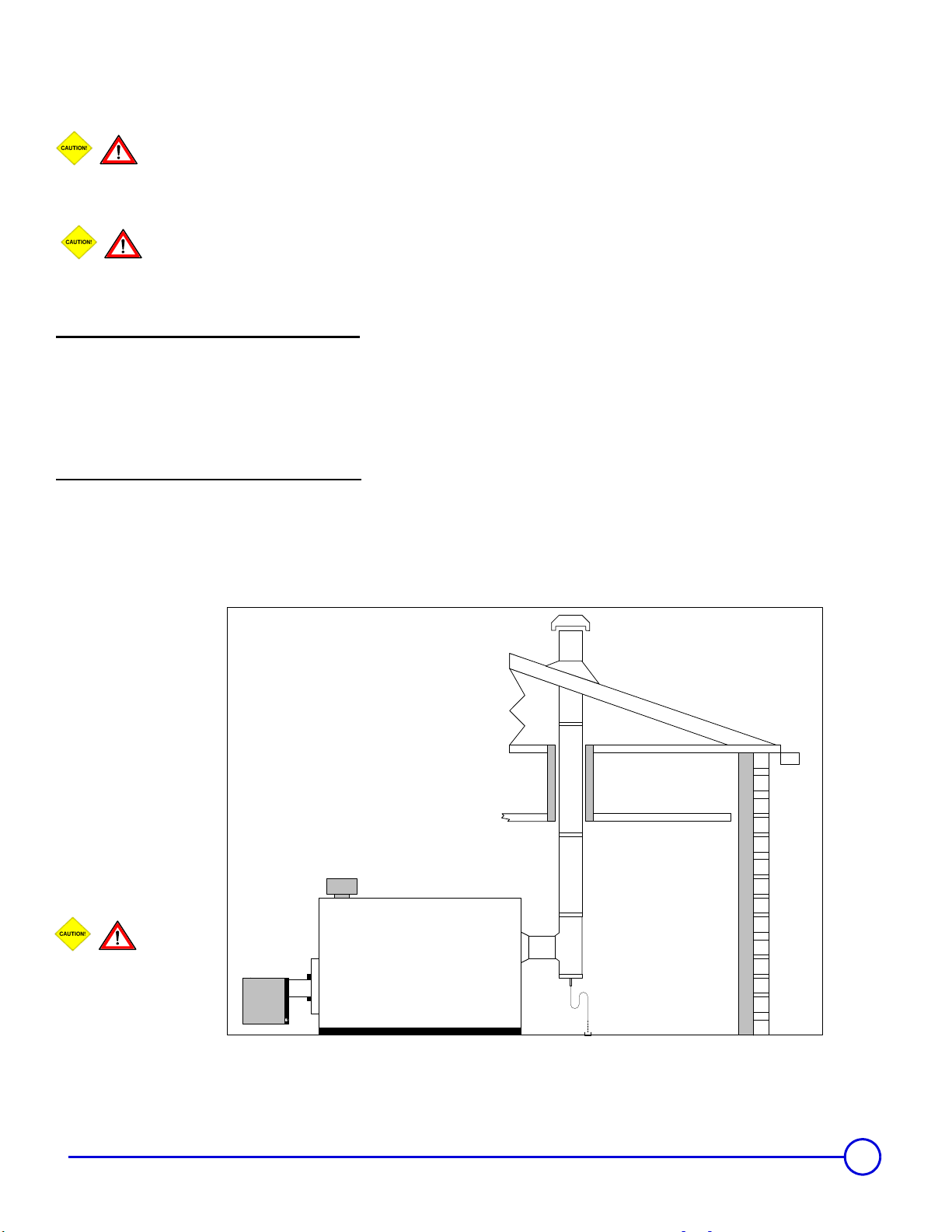

Illustration above showing minimum distances to combustible

materials and servicing.

Boiler must not be installed on combustible material or on carpet.

1Installation

The GT 300 A/II boiler has a base frame, although a housekeeping

pad is recommended to keep steel parts out of casual water. Its

furnace is closed, so it is not necessary to place it on a fireproof floor,

but the floor must be able to bear the weight.

4"

1/8

46"

59/64

8553N138

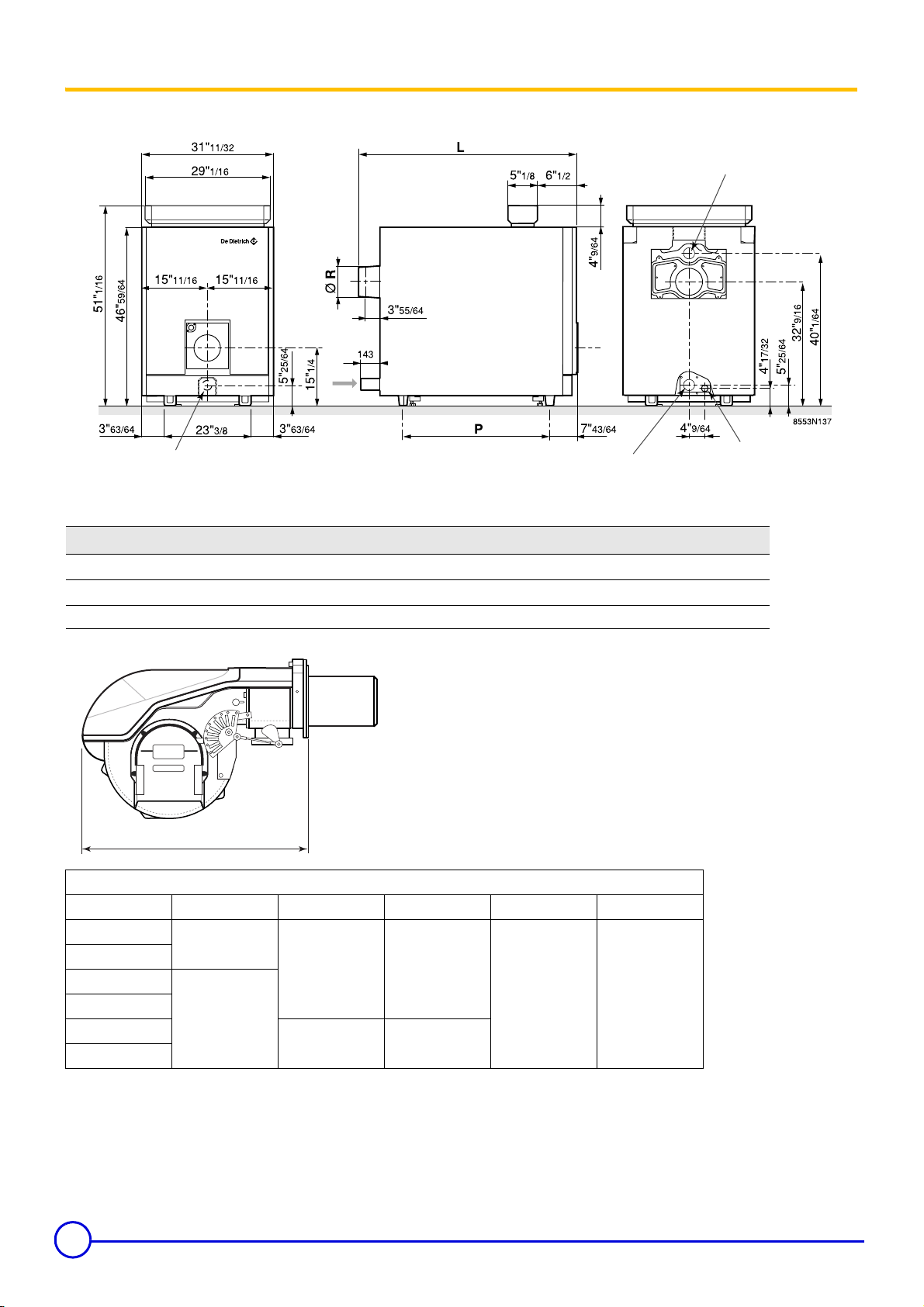

Boiler type L

GT 304 A/II 33"

GT 305 A/II

GT 306 A/II

GT 307 A/II

GT 308 A/II

GT 309 A/II

40"

5/16"

39

9/16"

45

7/8"

51

3/16"

58

1/2"

64

2 Combustion Air Supply

20"

L

11/32

31"

20"

X

Dimension 'X', consult burner info. additional 24 inches for servicing

Caution : note addtional space required when the burner door is open.

Multiple installation of several boilers side by side, these dimensions

need to be modified.

Boilers operating in atmospheres that contain fluorides or chlorides

such as beauty shops and automotive repair garages where air

conditioning services are performed or industrial applications that

may have corrosive elements in the air must have a clean source of

combustion and ventilation air. Boiler damage by contaminants will

void the warranty and any other responsibility or liability of De Dietrich

Thermique/FES Ltd.

Warning: Ensure boiler room is adequately ventilated and

clear and free from combustible materials, gasoline and

other flammable vapours and liquids.

7

4 Main Dimensions

GT 300 A/II

A

A

D

A Water flow tapping 2 1/2" NPSC

B Water return 2 1/2" NPSC

C Drain 1 1/2" FPT

D Rp 2 1/2 diameter sludge removal hole

B

Type of boiler GT 304 A/II GT 305 A/II GT 306 A/II GT 307 A/II GT 308 A/II GT 309 A/II

L

P

Ø R

5/8"

38

9/32

19

7" 7" 7" 8" 8" 8"

44

25

G50_0001

59/64"

19/32"

51

31

7/32

7/8

57

38

33/64"

3/16"

63

44

X

Dimension "X" Max. Burner Length (inches)

Boiler Model Riello Weishaupt Power Flame Fuel Master Gordon Piatt

GT304 A/II

GT305 A/II

GT306 A/II

GT307 A/II

GT308 A/II

GT309 A/II

26

10

15/32

19

23

22

25

1/4

1/4

19

1/8

Notes:

13/16"

31/64"

C

7/64"

70

25/32"

50

26

- Dimension are for gas burner only

- Oil and combination oil/gas, refer to burner manufacturer

specifications

8

GT 300 A/II 06/10/06 - 94863873 - 85534150E

Venting

5. Boiler Venting & Chimney General

.

Caution & Warning:

It is advised and recommended that the heating contractor-professional apply vent materials that are approved and agency listed.

Installation of any venting must follow all local codes in conj unction with vent manufacturer instructions and appliance manufacturer

instructions.

All De Dietrich GT series oil-gas fired cast iron boilers are high performance boilers that could operate under all 4 vent

categories as established by ANSI Z21.13/CSA 4.9 Standard. To assist with application where the vent category is

unknown a graph below has been provided to assist you in determining the vent category and what venting materials

would be acceptable. Although the gas vent categories were developed specifically for gas fired appliances, using this

information is helpful for oil fired boilers. It is very important the venting be selected according to the conditions that the

boiler will operate under, minimum and maximum firing conditions of the boiler must be respected. The venting installed

must comply and be certified to all applicable codes and standards for each jurisdiction.

Gas-Vent Category [4] Definitions:

Cat. I

A Boiler, which operates with a non-positive vent (breech) pressure

and flue gas temperatures which avoids excessive condensation

production in the chamber and venting.

Cat. II

A Boiler, which operates with a non-positive vent (breech) pressure

and flue gas temperatures produce condensation production in the

chamber and venting.

Chart created by Craig Holdforth

Cat. III

A Boiler, which operates with a positive vent (breech) pressure and

flue gas temperatures which avoids excessive condensation

production in the chamber and venting.

Cat. IV

A Boiler, which operates with a positive vent (breech) pressure and

flue gas temperatures produces condensation production in the

chamber and venting.

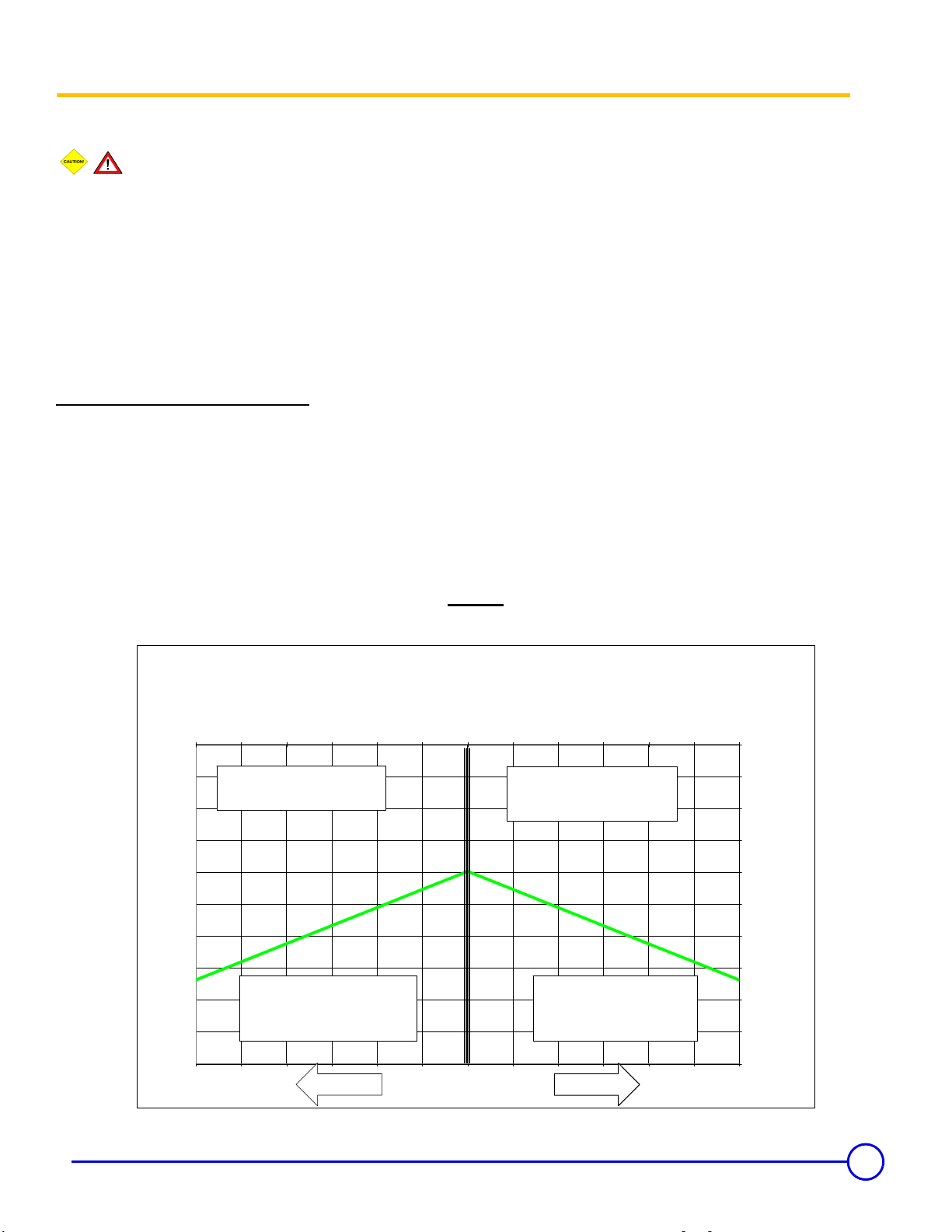

Chart A

Gas-Fired Appliance Vent Categorization

[According to ANSI Z21.13/CSA 4.9 Gas Boiler Standard]

Carbon Dioxide [CO2] Content %

6 7 8 9 10 11 12 11 10 9 8 7 6

(Net, Minus Room Temperature)

Chimney-Vent Flue Gas Temperature °F

500

456

412

368

324

280

236

192

148

104

Typical Vent Types [A,B,C & L]

[BH, AL294C®, 304-316L SS]

60

Category I

Category II

Typical Vent Types

Negative

Chimney-Vent Pressure

[Inches w.c.]

Category III

Typical Vent Types

[BH, AL294C®, 304-316L SS]

Category IV

Typical Vent Types

[BH, AL294C®, 304-316L SS]

Positive

260

236

211

187

162

138

113

89

64

40

15

(Net, Minus Room Temperature)

Chimney-Vent Flue Gas Temperature °C

9

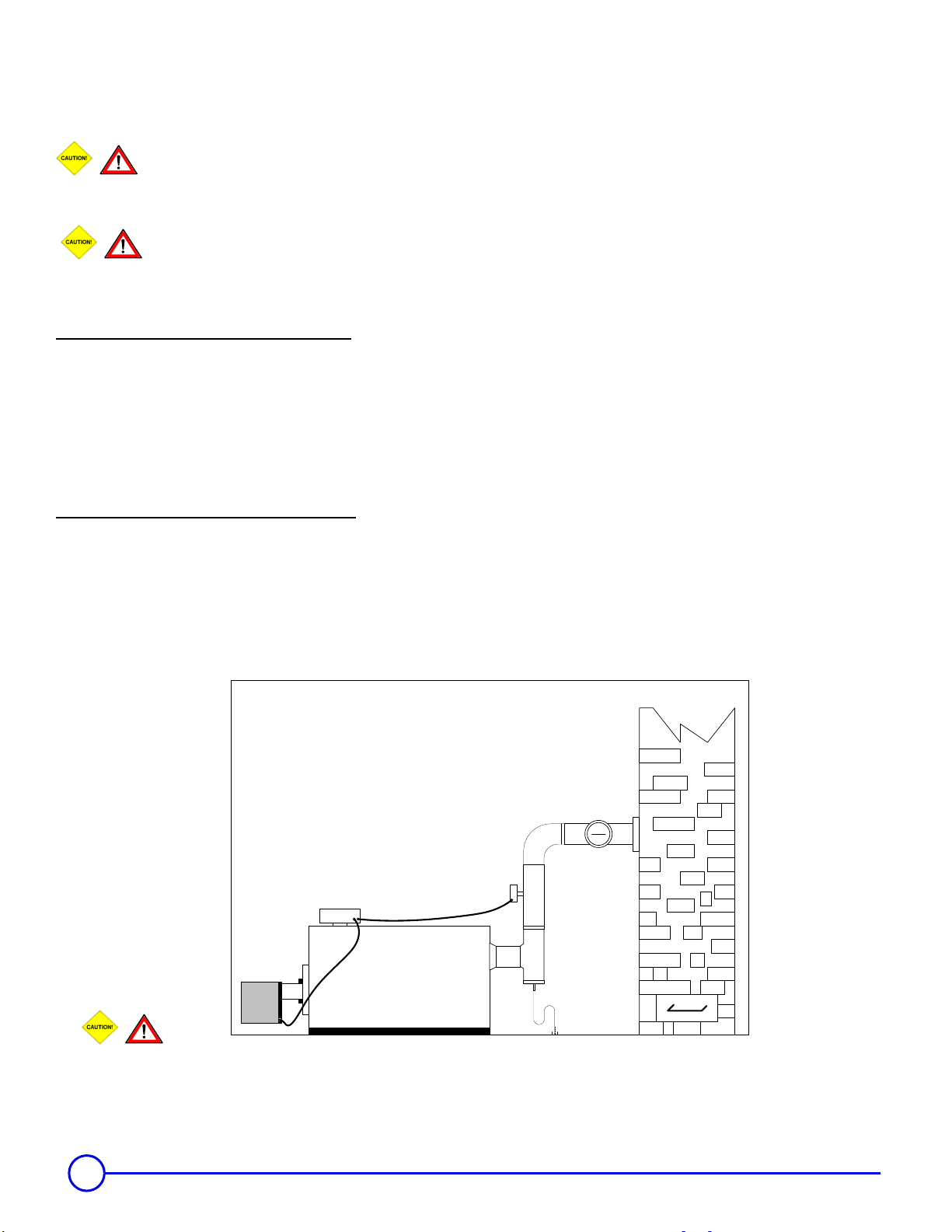

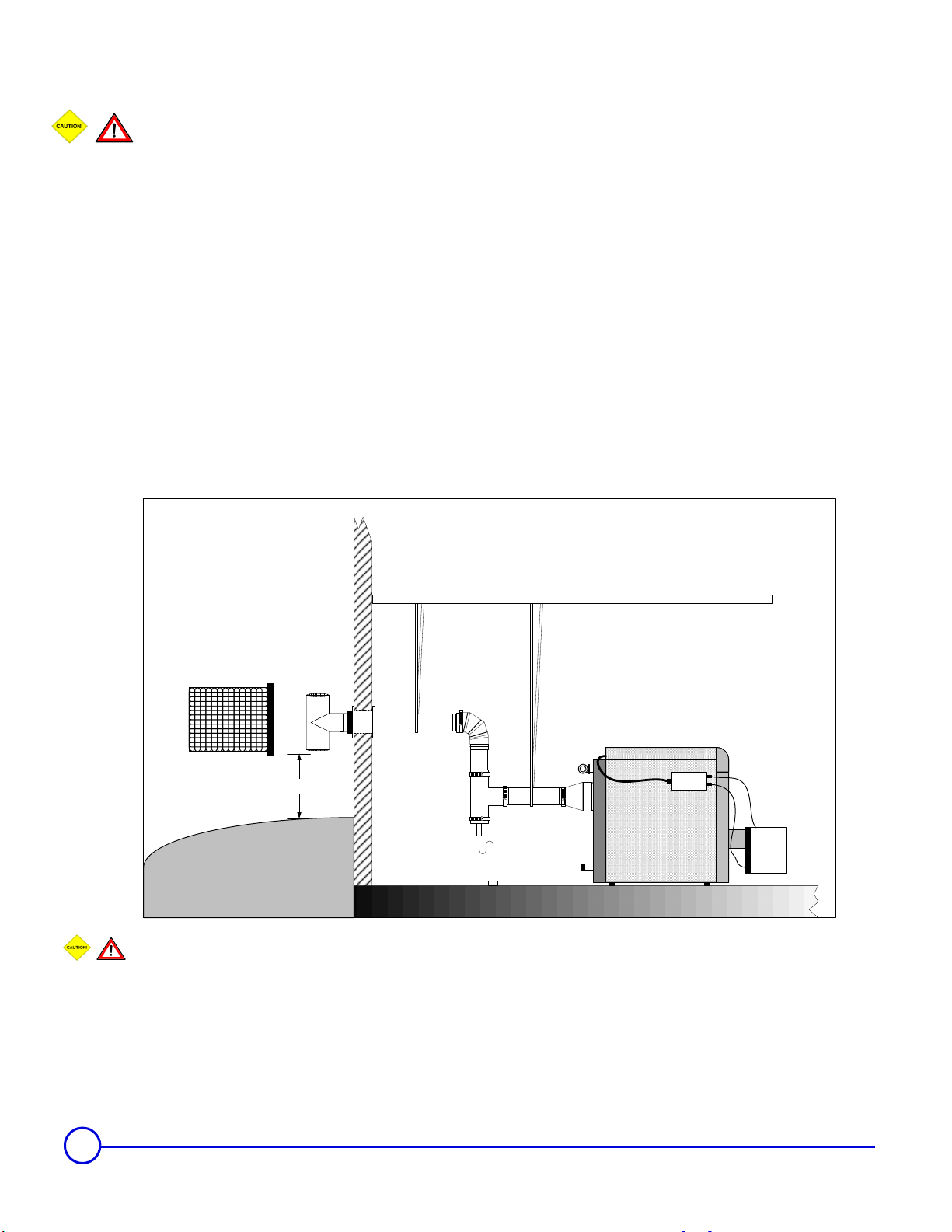

5.1 Boiler Venting – Category I & II Typical Layouts and Requirements.

Caution & Warning:

Improperly sealed venting system could result in carbon monoxide [CO] poisoning; ensure adequate

support and fastening of the system. Ensure venting can safely exhaust all flue gases outside in an effective manner.

These systems must operate under a negative vent pressure condition that is stable.

Warning & Cautions for Co-Venting:

Co-venting with other appliances shall conform latest ANSI Z223.1 & CAN/CGA 149 installation codes, any

improper operation shall be corrected, the common venting shall be sized according to the appropriate tables in Part II of

the above mentioned codes.

Category I Vent Systems Requirements:

1. Flue gas temperatures above the green line shown in chart A.

2. Approved type of venting for category I appliances.

3. A barometric draft control maybe employed as required, but is not necessary for correct boiler operation. Consult

a chimney-vent specialist for correct application and usage.

4. Breeching and chimney vent sized in accordance to local and national codes or by good engineering methods.

5. Vent safety device equipped on the venting or as equipped on burner.

6. Condensate TEE fitting supplied on the boiler breeching as close as possible and be orientated to avoid

accumulation of flue gas condensation in the boiler or venting is also used to determine flue gas emissions.

Category II Vent Systems Requirements:

1. Flue gas temperatures below the green line shown in chart A.

2. Approved type of venting for category II appliances.

3. A barometric draft control maybe employed as required, but is not necessary for correct boiler operation. Consult

a chimney-vent specialist for correct application and usage.

4. Breeching and chimney vent sized in accordance to local and national codes or by good engineering methods.

5. Vent safety device equipped on the venting or as equipped on burner.

6. Condensate TEE fitting supplied on the boiler breeching as close as possible and be orientated to avoid

accumulation of flue gas condensation in the boiler or venting is also used to determine flue gas emissions.

Lined Masonry Chimney

Caution-Warning:

Flue gas condensation is very aggressive and corrosive which could lead to failure of the venting system or drains, consult local and national codes

regarding flue gas condensation disposal. The P-trap assembly must be properly filled with water to avoid escape of flue gas emissions. The flue gas

condensation may require neutralization prior to entering the drain.

10

GT 300 A/II 06/10/06 - 94863873 - 85534150E

5.2 Boiler Venting – Category III & IV Vent Systems Typical Layouts and Requirements.

Caution & Warning:

Improperly sealed venting system could result in carbon monoxide [CO] poisoning; ensure adequate

support and fastening of the system. Ensure venting can safely exhaust all flue gases outside in an effective manner.

These systems must operate under a positive vent pressure condition that is stable.

Warning & Cautions for Co-Venting:

Co-venting with other appliances shall conform latest ANSI Z223.1 & CAN/CGA 149 installation codes, any

improper operation shall be corrected, the common venting shall be sized according to the appropriate tables in Part II of

the above mentioned codes.

Category III Vent Systems Requirements:

1. Flue gas temperatures above the green line shown in chart A.

2. Approved type of venting for category III appliances

3. Breeching and chimney diameter sized in accordance to national & local codes or by good engineering methods.

4. Vent safety device equipped on burner [MR]

5. Condensate TEE fitting supplied on the boiler breeching as close as possible and be orientated to avoid

accumulation of flue gas condensation in the boiler or venting.

Category IV Vent Systems Requirements:

1. Flue gas temperatures below the green line shown in chart A.

2. Approved type of venting for category IV appliances

3. Breeching and chimney diameter sized in accordance to national & local codes or by good engineering methods.

4. Vent safety device equipped on burner [MR]

5. Condensate TEE fitting supplied on the boiler breeching as close as possible and be orientated to avoid

accumulation of flue gas condensation in the boiler or venting.

Caution-Warning:

Flue gas condensation is very aggressive and corrosive which could lead to failure of the venting system or drains, consult local and national codes

regarding flue gas condensation disposal. The P-trap assembly must be properly filled with water to avoid escape of flue gas emissions. The flue gas

condensation may require neutralization prior to entering the drain.

06/10/06 - 94863873 - 85534150E GT 300 A/II

11

5.3 Boiler Venting – Side-Wall or Direct Vent Systems Typical Layouts and Requirements.

Caution & Warning:

Improperly sealed venting system could result in carbon monoxide [CO] poisoning; ensure adequate support

and fastening of the system. Ensure venting can safely exhaust all flue gases outside in an effective manner. These

systems must operate under a positive vent pressure condition that is stable. Do not Co-Vent with any other appliance,

the venting system was designed for single appliance venting only.

Side-wall & Direct Vent Systems:

These systems do not fall under any of the gas vent categories, these systems are pre-engineere d. These applications of

this venting system must be followed exactly, for safe, efficient and trouble free operation.

System Requirements:

1. Venting sized accordance to direct vent table

2. Type “BH” [AL294C®] vent material

3. Condensate TEE fitting supplied on the boiler breeching as close as possible and be orientated to avoid

accumulation of flue gas condensation in the boiler or venting is also used for determining flue gas emission s.

4. Vent termination TEE

5. Vent safety device equipped on burner [MR]

Vent Termination Locations & Warning – See Section 5.5

Caution-Warning:

Flue gas condensation is very aggressive and corrosive which could lead to failure of the venting system or drains, consult local and national codes

regarding flue gas condensation disposal. The P-trap assembly must be properly filled with water to avoid escape of flue gas emissions. The flue gas

condensation may require neutralization prior to entering the drain.

12

GT 300 A/II 06/10/06 - 94863873 - 85534150E

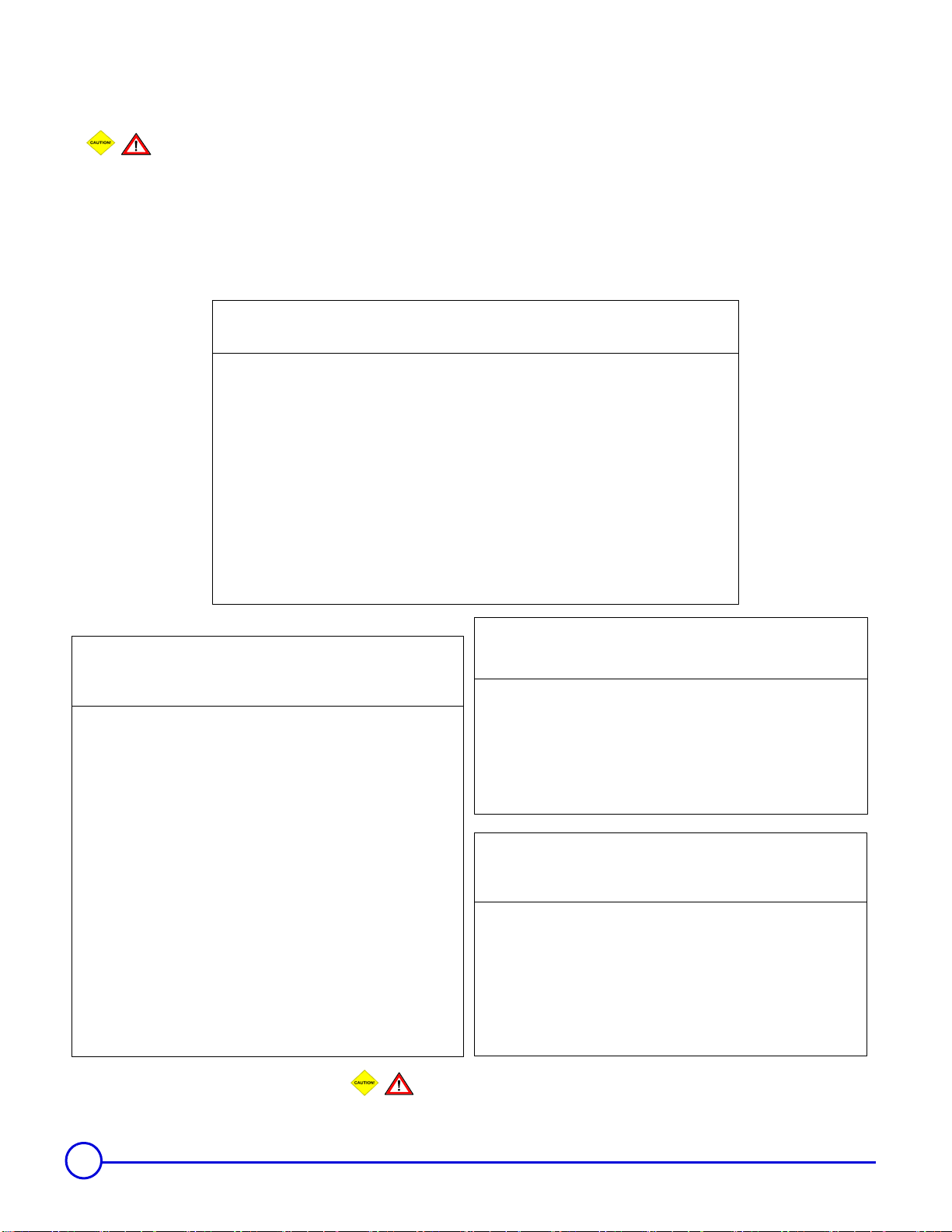

5.4 Boiler Venting – Side-wall or Direct Vent Systems Sizing Tables & Vent Safety Device

• All venting lengths must be calculated to equivalent lengths,

all application must include at least one 90° elbow

• Venting must be a type ‘BH” [AL294C® material]

• Maximum vent length [equivalent] = 30 ft. [9m]

• Minimum vent length [equivalent] 5 ft. [1.5m]

• Maximum number of 90° elbows = 2 or 3 45° elbows, each

90° elbow is equivalent to 10 ft. or straight pipe, the 45°

elbow is equivalent = 5 ft.

• Condensate TEE must be provided [equivalent length = 7 ft.]

• Appliance reducing adapter [equivalent length 3 ft.]

• Sealed combustion, combustion air intake sizing, must be

sized according to the burner manufacturers instructions

• Vent [breeching] pressure shall not exceed 0.20 inches w.c.

[0.50 mbar]

Determining vent length [equivalent] Example:

Appliance reducing adapter [x1] = 3 ft.

Condensate TEE [x1] = 7 ft.

12” vent straight vent pipe [x3] = 3 ft.

Elbow 90° [x1] = 10 ft.

Termination TEE [x1] = 0 ft.

Length [equivalent] = 23 ft.

• Vent termination must be a TEE type, follow warning

regarding termination locations. Do not include the

termination TEE length in the vent length calculation.

• Venting shall be sloped, so any condensation developed will

drain through the condensate TEE fitting

• Vent safety device, differential air pressure switch [manual

reset] NC switch opens on rise of pressure.

• Optional function of power burners which can employ an

post purge function to exhaust flue gases for a fixed time [1

minute to 4 minutes maximum]

• Burner employing a standby air damper closed position, the

closed position should be slightly opened to allow hot flue

gases to escape upward through venting and not be

entrapped in the combustion head. Important note, that in

negative building pressures, the observation and odor of flue

gases may enter the boiler room.

GT 300 A/II Series

Model

GT 304 A/II 7 inch 5 inch

GT 305 A/II 7 inch 5 inch

GT 306 A/II 7 inch 5 inch

GT 307 A/II 8 inch 6 inch

GT 308 A/II 8 inch 6 inch

GT 309 A/II 8 inch 6 inch

Boiler

Connection ø

Oil-Gas

Vent ø

[∆p] Pressure switch

Setting [inches w.c.]

Set vent safety

pressure switch

150% above burner

gas manifold or

head pressure

setting

Model

GT 408 A 10 inch 8 inch

GT 409 A 10 inch 8 inch

GT 410 A 10 inch 8 inch

GT 411 A 12 inch 10 inch

GT 412 A 12 inch 10 inch

GT 413 A 12 inch 10 inch

GT 414 A 12 inch 10 inch

GT 400 A Series

Boiler

Connection

ø

Oil-Gas

Vent ø

GTE 500 A Series

Model

GTE 515 A 16 inch 12 inch GTE 521 A 16 inch 12 inch

GTE 516 A 16 inch 12 inch GTE 522 A 18 inch 14 inch

GTE 517 A 16 inch 12 inch GTE 523 A 18 inch 14 inch

GTE 518 A 16 inch 12 inch GTE 524 A 18 inch 14 inch

GTE 519 A 16 inch 12 inch GTE 525 A 18 inch 14 inch

GTE 520 A 16 inch 12 inch

Boiler

Connection ø

Oil-Gas

Vent ø

[∆p] Pressure

switch Setting

[inches w.c.]

Set vent safety

pressure switch

150% above

burner gas

manifold or

head pressure

setting

Model

Boiler

Connection ø

Oil-Gas

Vent ø

[∆p] Pressure

switch Setting

[inches w.c.]

Set vent safety

pressure switch

150% above

burner gas

manifold or

head pressure

setting

[∆p] Pressure

switch Setting

[inches w.c.]

Set vent safety

pressure switch

150% above

burner gas

manifold or

head pressure

setting

13

5.5 All Side-wall and direct Vent termination locations installation precautions:

Warning/Caution:

In all cases avoid potential vent termination locations where excess debris or snow could accumulate and bock the

vent termination to any degree.

Minimum clearance of 4 ft. [1.22m] horizontally from, and in no case above or below, unless a 4 foot [1.22m]

horizontal distance is maintained, from electric meters, gas meters, regulators & relief equipment.

Do Not Co-Vent Any Direct Vent or Sidewall Venting System

A VENT SHALL NOT TERMINATE…..

Directly above a paved sidewalk or driveway which serves 2 buildings.

Less than 7 ft. any paved sidewalk or drive way

Less than 6 ft. of a combustion air inlet to any building

Less than 4 ft. above a meter/regulator assembly [horizontally] of the vertical center-line of the

regulator vent outlet to a maximum vertical distance of 15 ft.

Less than 4 ft. of any gas service regul a t or vent outlet

Less than 1 ft. above grade or normal anticipated snow level for the area

Less than 3 ft. from windows, doors [that can be opened], combustion air supply or any appliance

or building.

Underneath a veranda, porch or deck unless:

1. The veranda, porch or deck is fully open on a minimum of 2 sides beneath the floor

&

2. The distance between the top of the vent

termination and the underside of the veranda, porch or deck is greater than 1 ft.

(GAS INSTALLATIONS CANADA)

B149.1

(OIL INSTALLATIONS CANADA)

A VENT SHALL NOT TERMINATE…..

B139-00

Directly above a paved sidewalk or driveway which serves 2

buildings.

Less than 7 ft. any paved sidewalk or drive way

Less than 6 ft. from an open-able window, door or mechanical

combustion air supply

Less than 6 ft. of any combustion air inlet

Less than 3 ft. of the vertical centerline of the meter/regulator

assembly on a horizontal plane perpendicular to the regulator

Less than 6 ft. of gas service regulator vent outlet

Less than 4 ft. of oil tank vent or oil tank fill inlet

Less than 1 ft. above grade or normal anticipated snow level for the

area.

Within 6 ft. of a property line

Underneath a veranda, porch or deck

Flue gases are within 6 ft. of combustible material or any openings of

surrounding buildings.

Less than 3 ft. from an inside corner or L-shaped structure

Where flue gases may be directed towards brickwork, siding or other

construction that may cause damaged from heat or condensate from

the flue gases.

A VENT SHALL NOT TERMINATE…..

ٛ Less than 3 ft. of any combustion air inlet source located within 10 ft.

ٛ Less than 1 ft. from any obstructions

ٛ Less than 1 ft. above grade or normal anticipated snow level for the area .

ٛ Over public walkways, driveways or other areas where condensate or

vapor could create nuisance or hazard or could be detrimental to the

operation of regulators, relief's, valves or other equipment

A VENT SHALL NOT TERMINATE…..

ٛ Less than 5 ft. from vent outlet of the supply tank

ٛ Less than 7 ft. above walkways

ٛ Less than 1 ft. from any door, window or air inlet source

ٛ Less than 1 ft. from grade or snow level.

ٛ Less than 3 ft. from a air intake that is within 10 ft

ٛ Less than 1 ft. from soffit of the roof

ٛ Less than 3 ft. from any building corner or L shape structure

NFPA 54 / ANSI Z223

(GAS INSTALLATIONS USA )

NFPA 31

(OIL INSTALLATIONS USA)

WARNING-CAUTION

Consult Local Codes & Authorities for other Requirements not mentioned

14

GT 300 A/II 06/10/06 - 94863873 - 85534150E

6 Dimensional information required for connection of the boiler

The boiler must be connected to venting system

that will safely and effectively discharge all flue

gases to the outside in an effective manner.

Consult local and national codes regarding the

boiler breeching and chimney sizing.

Follow the information and documentation as supplied with

the burner, regarding:

The specific installation requirements, wiring, fuel supply and

piping and all adjustments of the air and fuel and start-up

procedure as be followed as supplied with the burner

documentation

Consult the burner manufacturer regarding the required

maintenance of the burner and the service intervals.

The entire heating system must be check once each heating

season.

Do not start the burner/boiler unless all access cover and

panels are in place.

53N14 A 85 0

5"

1/611

15"

/165

A

A : chimney connection :

GT 304 A/II to GT 306 A/II : 7"

GT 307 A/II to GT 309 A/II : 8"

ø

ø

1 Specific technical information supplied with the burner

• The boiler and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 psi (3.5kPa),

• The boiler must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa),

• The boiler shall be installed such that the gas ignition system

components are protected from water (dripping, spraying, rain,

etc.) during appliance operation and service (circulator

replacement, condensate trap, control replacement, etc.),

• The boiler and its gas connection must be leak tested before

placing the boiler in operation,

• After placing the boiler in operation, the ignition system safety

shutoff device must be tested,

• Provision for vent, bleed and gas relief lines (when applicable),

• A sediment trap must be provided upstream of the gas controls,

• Location of manual main shutoff valve outside the jacket when

codes require.

06/10/06 - 94863873 - 85534150E GT 300 A/II

9/16

32"

Oil or gas connections

15

1 Wiring

Warning/Caution:

Label all wiring prior to disconnection for servicing controls. Wiring

errors can cause improper and dangerous operation.

"Verify Proper Operation After Serving"

Wiring in accordance with the requirements of the authority having

jurisdiction or, in the absence of such requirements, with the

Canadian Electrical Code Part 1, CSA C22.1, Electrical Codes.

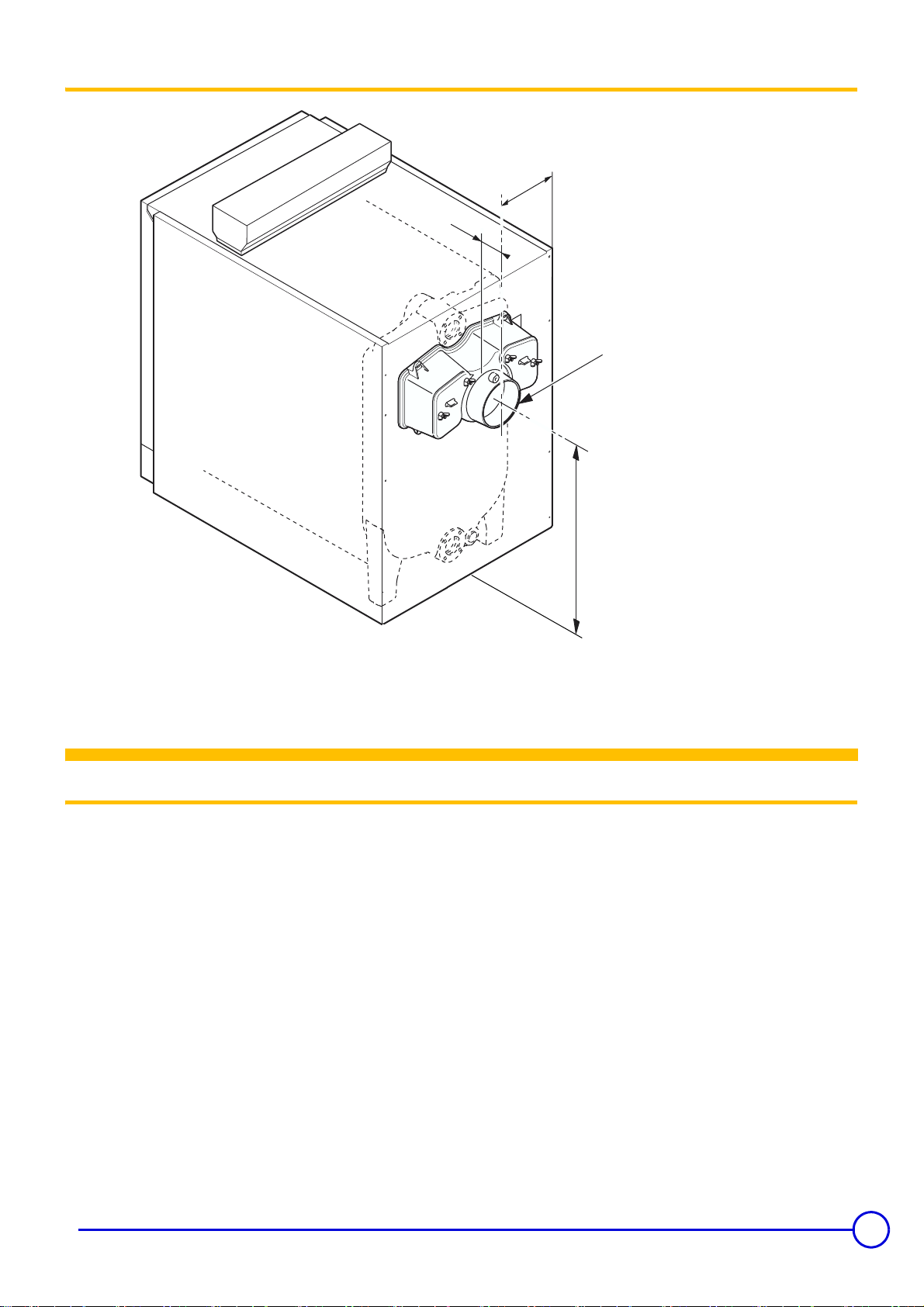

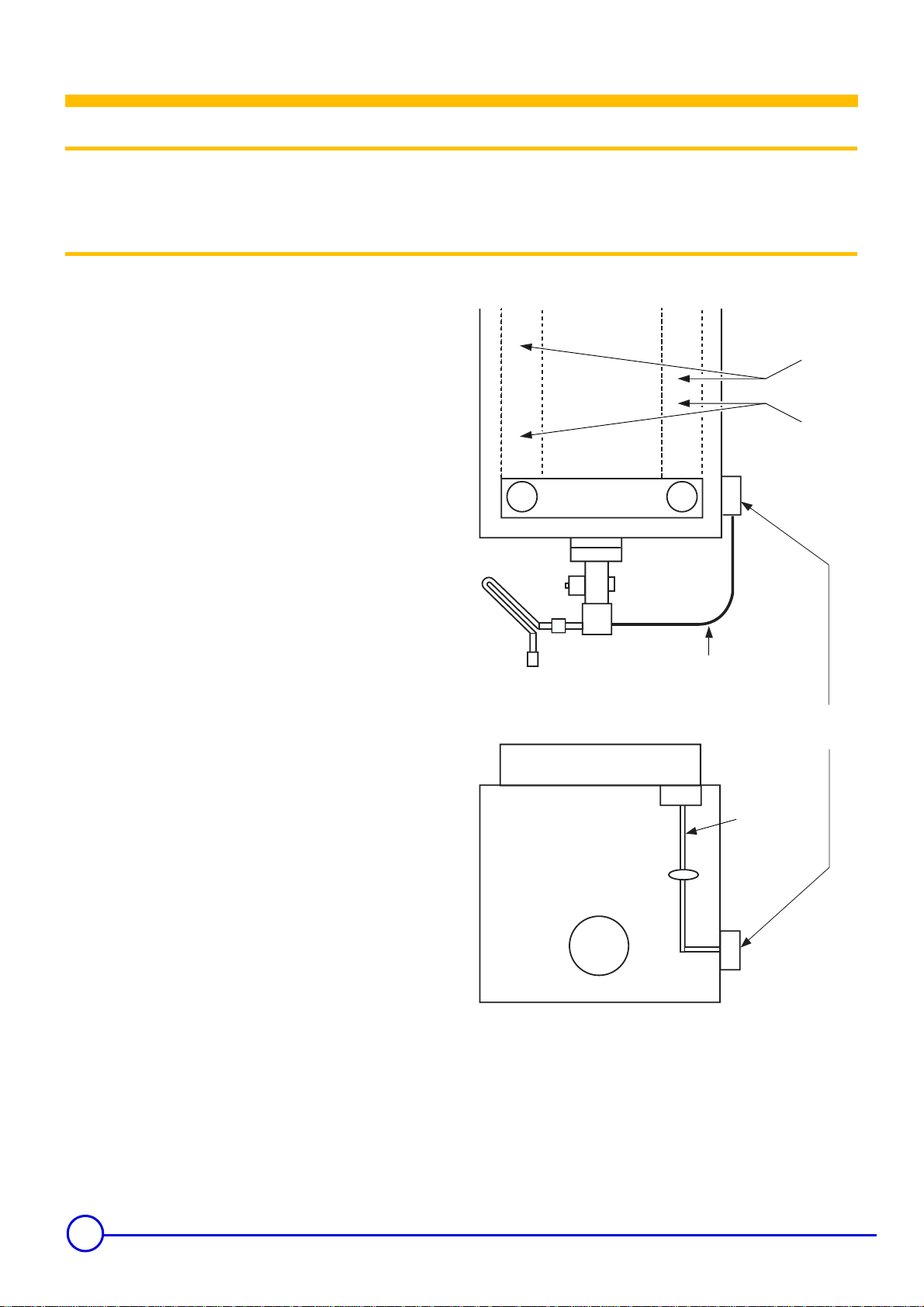

2 Wiring procedure

De Dietrich boiler suggested field wiring procedure.

Electrical

A

1

1 : Top view

2 : Boiler panel

3 : Front

A : Race ways located under top panel of boiler

B : Wiring to be run in electrical race way to boiler control panel from

ancillaries

Main power to 4x4 junction box or enter rear of boiler through race

way.

C : 4x4 junction box location

D : Run BX cable between insulation and casing from boiler panel

E : Allow extra cable to swing burner open

B

E

C

2

D

16

3

GT 300 A/II 06/10/06 - 94863873 - 85534150E

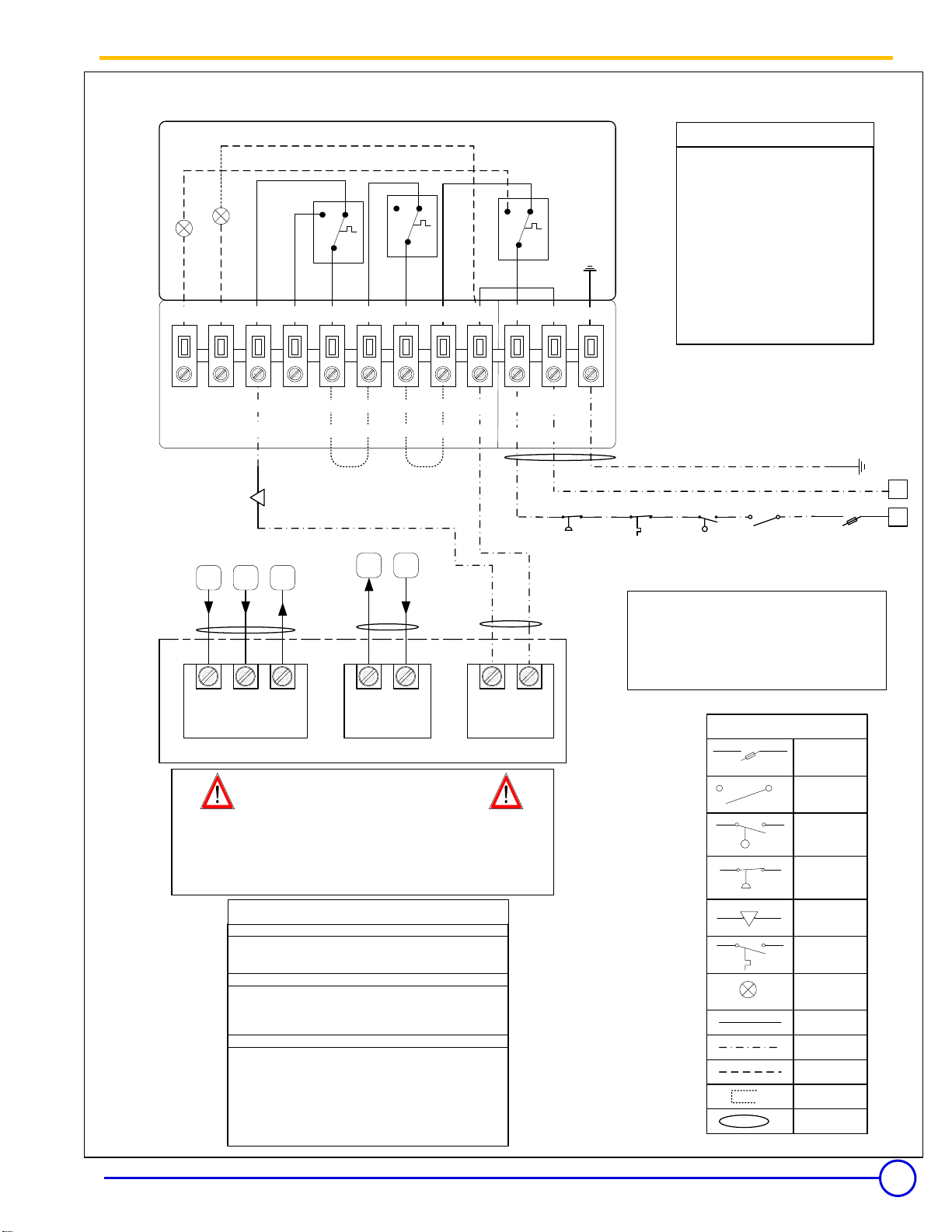

Flexible Eutectic Sales Ltd. [De Dietrich North America] FA 122 Panel – Boiler Controller

Boiler Control Wiring

Wiring Legend

L – Main Line 120v

N – Main Neutral

N – Burner Neutral

2

2

4

A1

A2

C

TCH2

10 5

1

C

TCH1

6

1

2

Internal

C

TS

3

1

278912 411

L1 – Burner Line 120v

T1 – Boiler Limit

T2 – Burner Limit

T6 – Boiler Operating Limit

T7 – Burner Low Fire – As Required

T8 – Burner Hi Fire

S3 – Optional Burner Alarm

VA – Optional Hi Temp Alarm

A1-A2 – Optional Alarm Device

[Supplied by Others]

J1-J2 – Field Supplied jumpers

12 11

VA S3

10 9 8 7 6

T8 T7 T6 T2 T1

J1J2

T6 T7 T8

T1T2

Limit CircuitFiring Rate Circuit

Burner Connections

WARNING – CAUTION:

ALL ELECTRICAL CONNECTIONS

MAYBE FROM MULTIPLE SOURCES

Application Note for BMS or BAS systems:

The Local-Remote switch or enable/disable forced relay,

must interrupt the TCH2 control . TheTS & TCH1 limits

must remain in the limit circuit.

Panel Wiring Options:

On-Off Control [Single stage burners]

use jumper as shown

2 Stage Control [2 Stage burners]

Remove jumper 2 install firing rate control from burner

T6 – T8

Progressive Modulating Control

[Multi-Stage burners]

Remove jumpers 1

Installed burner limit circuit between T1 & T2

Remove jumper 2

Install burner firing rate control between T6 [common]

T7 [min rate] & T8 [max rate]

L15N

L

4

120v 60Hz.

L N

Burner Power

N

Vent Safety

Device

Auxiliary Hi-

Limit [Optional]

LWCO

Service

Switch

Consult burner manufacturer:

All burner wiring

Modulating Signal and required Controls

Burner Motor May require additional

power source

BMS Local-Remote Control Wiring.

Wiring Symbols

Fused

Disconnect

Main fuse

disconnect

6A 120V max

Service Switch

[Others]

LWCO

Device

[As required]

Vent Safety

Device [NC]

Burner Safety

Interlock –

Optional [Others]

Auxiliary limit –

Optional [Others]

120V Alarm

indicator [Others]

Factory Wiring

Field Wiring

[Others]

Alarm Wiring

[Others]

Jumper Wiring

[Others]

Strain Relief

[Others]

N

L

06/10/06 - 94863873 - 85534150E GT 300 A/II

17

1 Wiring

Wiring in accordance with the requirements of the authority having

jurisdiction or, in the absence of such requirements, with the

Canadian Electrical Code Part 1, CSA C22.1, Electrical Codes.

2 Wiring procedure

De Dietrich boiler suggested field wiring procedure.

Electrical

A

1

1 : Top view

2 : Boiler panel

3 : Front

A : Race ways located under top panel of boiler

B : Wiring to be run in electrical race way to boiler control panel from

ancillaries

Main power to 4x4 junction box or enter rear of boiler through race

way.

C : 4x4 junction box location

D : Run BX cable between insulation and casing from boiler panel

E : Allow extra cable to swing burner open

B

E

C

2

D

18

3

GT 300 A/II 06/10/06 - 94863873 - 85534150E

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly,

a fire or explosion may result causing properly damage,

personal injury or loss of life.

A. This appliance does not have a pilot. It is equipped with an ignition

device wich automatically lights the burner. Do not

burner by hand.

B. BEFORE OPERATING smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is heavier

than air and will settle on the floor.

1 Start up procedures

• Inspect for proper baffling insertion into flue passes. All cleanout doors properly sealed. Burner door closed and properly

latched.

• Gas and oil systems ready. Proper vent connections. Required

combustion and ventilation air provided.

• Waterside of system properly filled and vented of air.

• Lighting instruction followed.

try to light the

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob. Never

use tools. If the knob will not push in or turn by hand, don’t try to repair

it: call a qualified service technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified technician to inspect the appliance

and to replace any part of the control system and any gas control

which has been under water.

• To be performed by a licensed tradesperson in accordance with

the guidelines shown in this manual. Follow burner

manufactures instructions.

• Mandatory factory start-up report to be completed and returned

to comply with the warranty process.

• Proper operating instructions of equipment to be related to

operating personnel.

2 Shut-down procedures

• Disengage all electrical power switches to heating system

burners, pumps. Isolate all boiler valves and fuel valves.

• For off-season shutdown, open boiler combustion flue ways and

clean. Ensure venting, chimney, combustion and ventilation air

openings free from blockage. Do not drain waterside of system.

- Shutoff fuel supply lines

1 Boiler

Ensure all access cover and doors are in place prior to

starting the boiler-burner.

Maintenance

It is not advisable to drain an installation, except in case of

absolute necessity. Check the water level of the installation and

top it off if necessary, avoiding a sudden inlet of cold water in the

hot boiler.

Check for system leaks.

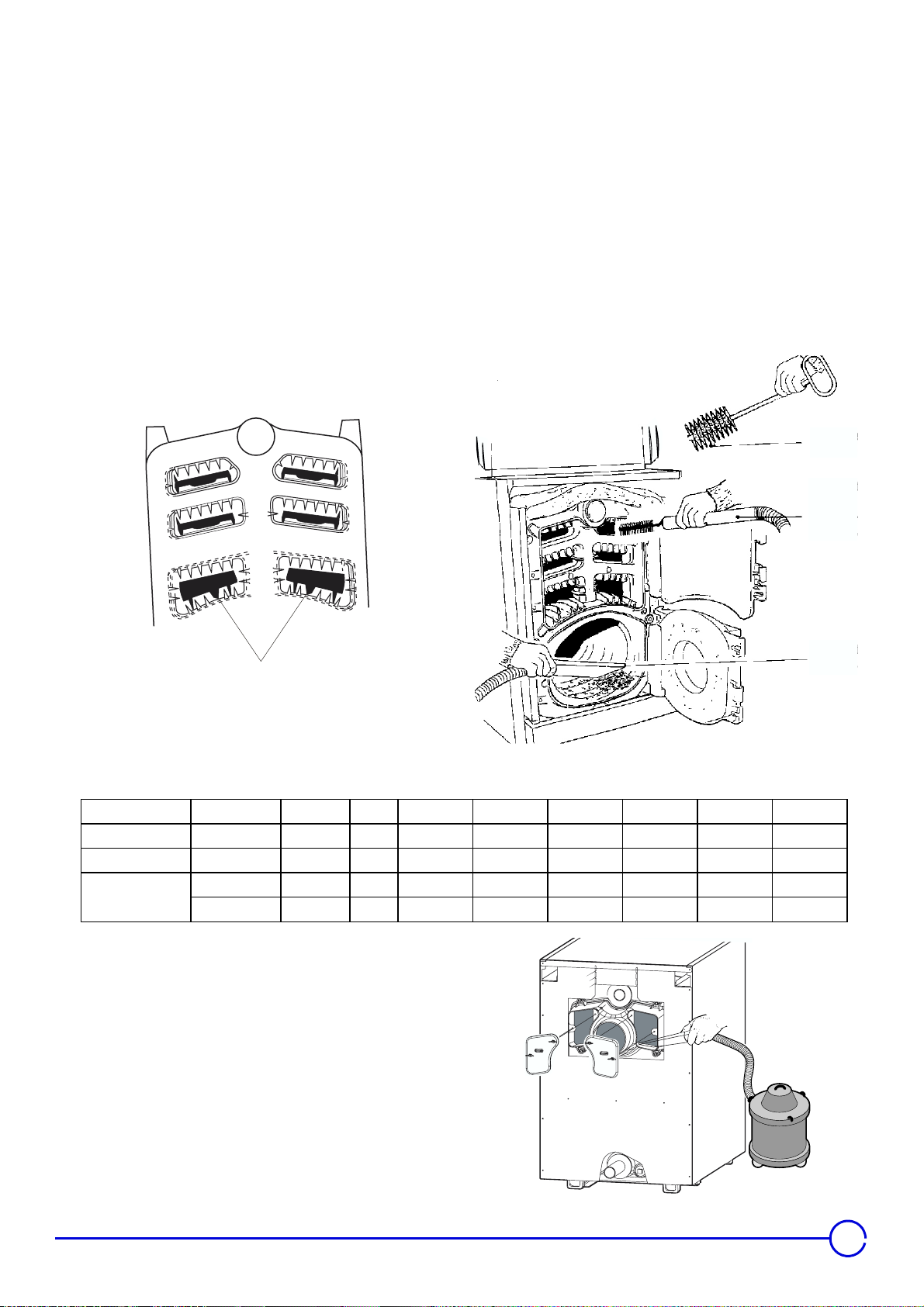

• Cleaning of the flue gas circuit :

- switch off the electricity supply to the boiler

- unhook the front cover

Professional water treatment is recommended.

The good performance of the boiler depends on cleanliness.

Cleaning the boiler must be carried out as often as required and at

least, as for the flue once a year. The following operations are always

carried out with the boiler and the power supply shut off.

20

GT 300 A/II 06/10/06 - 94863873 - 85534150E

- open the sweeping door (upper door) by unscrewing the 4 lock nuts.

- remove the convection baffles,

- using the brush supplied, carefully sweep the 6 flue sections,

- also brush the convection baffles and the front face,

- if possible use a vacuum cleaner,

- put the convection accelerators back in place (pay attention to their

direction),

- shut the door.

• Maintenance of the combustion chamber

- open the combustion chamber door (lower door) by unscrewing the

4 lock nuts

- brush the inside of the combustion chamber

1

- using a vacuum cleaner, vacuum up the soot deposits which have

accumulated in the combustion chamber

- close the door and replace the front cover

2

3

4

1 : stop pins

2 : brush

Baffle Position Baffle Fraction mm GT 304 A/II GT 305 A/II GT 306 A/II GT 307 A/II GT 308 A/II GT 309 A/II

Upper [3rd Pass]

Middle [2nd Pass]

Lower

[1st Pass]

8219-0017 16 1/4 410

8219-0018 22 7/16 570

8219-0019 16 1/4 412 222242

8219-0020 22 1/2 572 000002

3 : vacuum cleaner brush

4 : vacuum cleaner

088400

400488

• Cleaning the smoke box (Flue Hood)

For this purpose :

-remove the sweeping left and right hand covers of the smoke box (2

wing nuts) and remove the soot which has accumulated using a

vacuum cleaner

-replace the sweeping covers.

• Burner maintenance :

In accordance with the directions supplied with the burner.

8553N136

21

Loading...

Loading...