DeDietrich GT 224, GT 225, GT 226, GT 227, GT 228 Installation And Service Manual

GT 220 - GT 2200

Fuel oil/gas-fired boilers

Installation and

Service Manual

300008281-001-E

EN

2

GT 220 - GT 2200 22/01/09 - 300008281-001-E

.

Declaration of conformity CE

C002209-A

3

22/01/09 - 300008281-001-E GT 220 - GT 2200

.

Contents

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 Regulations for France . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 Regulations for other countries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Composition of the range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.3 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.5 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.6 Main dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.6.1 Boiler and tank dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.6.2 Installation dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.7 Aeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.7.1 If using fuel oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.7.2 If using gas (GT 220 fitted with a forced draught gas-fired burner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Chimney connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.4 Connecting the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.5 Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.6 Filling the installation with water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.1 Checking and cleaning the main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.2 Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3 Burner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.4 Domestic hot water tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5 Stopping the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6 Spare parts - GT 220 - GT 2200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Used symbols

Caution danger

Risk of injury and damage to equipment. Attention must be paid to the warnings on

safety of persons and equipment

Specific information Information must be kept in mind to maintain comfort

Z

Reference Refer to another manual or other pages in this instruction manual

4

GT 220 - GT 2200 22/01/09 - 300008281-001-E

1. General

1 General

The boiler shall be assembled and installed by a qualified

professional only. For a proper operating of the boiler,

follow carefully the instructions.

1.1 Regulations for France

Certificate of compliance

` Only concerns GT 220/2200 boilers fitted with a forced draught

gas-fired burner:

For the application of article 25 of the modified decree dated 02/08/

1977 and of article 1 of the modifed decree dated 05/02/1999, the

installation engineer must be in possession of the certificates of

compliance approved by the Ministries in charge of construction and

gas safety:

- Different forms (forms 1, 2 or 3) for a new gas installation,

- "Model 4" in particular after replacing a furnace with a new one.

Residential buildings

Statutory terms and conditions of installation and maintenance:

The installation and maintenance of the appliance must be carried

out by a qualified professional in compliance with the statutory texts

of the codes of conduct in force, particularly:

- Order of 2 August 1977

Technical and safety rules applicable to combustible gas and

liquefied hydrocarbon installations situated inside residential

buildings and their annexes.

- NF P 45-204 standards

Gas installation, (formerly DTU 61-1, gas installations: April 1982,

addendum no 1: July 1984).

- Local Sanitary Regulations

For appliances connected to the electricity network:

- NF C 15-100 standards Low voltage electrical installation - Rules..

Establishments open to the public (Statutory

terms and conditions of installation)

The installation and maintenance of the appliance must be carried

out in compliance with the statutory texts and rules of the codes of

conduct in force, particularly:

Safety regulations against fire and panic in establishments open to

the public:

• General regulations:

- For all appliances: Articles GZ - Installations operating on

combustible gases and liquefied hydrocarbons.

- Then, depending on use: Articles CH-Heating, ventilation,

refrigeration, air conditioning and production of steam and

domestic hot water.

• Instructions specific to each type of establishment open to the

public (hospitals, stores, etc.).

1.2 Regulations for other countries

The installation and maintenance of the boiler must be done by a

qualified professional in compliance with the prevailing local and

national regulations.

5

22/01/09 - 300008281-001-E GT 220 - GT 2200

2. Description

2 Description

2.1 General

Boilers in the GT 220 range have the following characteristics:

- Autonomous automatic hot water boilers

-Boiler ** CE.

- Connecting to a chimney

- Boiler to be fitted with an independent burner using fuel oil or gas

- B, B2, X, or DIEMATIC 3 control panel

Boilers in the GT 2200 range have the following characteristics:

- Autonomous automatic hot water boilers

-Boiler ** CE.

- Connecting to a chimney

- Boiler to be fitted with an independent burner using fuel oil or gas

- B, B2, or DIEMATIC 3 control panel

- Domestic hot water production by 160 / 250-litre tank positioned on

the floor under the boiler

2.2 Composition of the range

2.3 Homologations

` CE identification no: CE1312BR4657

` User country: This product may be sold in the member states

of the European Union as well as in Switzerland, Iceland,

Norway and Romania.

` 97/23/EC Directive:

Gas and oil boilers with a maximum operating temperature of

110°C and hot water tanks with a maximum operating pressure

of 10 bar pertain to article 3.3 of the directive, and therefore,

cannot be CE-marked to certify compliance with the directive 97/

23 EC.

De Dietrich boilers and DHW tanks conform to the regulations in

article 3.3 of the 97/23/CEE Directive and is backed by the CE

mark for the 90/396/CEE, 92/42/CEE, 2006/95/EC and 2004/

108/EC directives.

GT 220/2200 B Boiler with electronic control panel.

GT 220/2200 B2 Boiler with B2 basic electronic control panel for

controlling a 2-stage burner.

GT 220/2200 D Boiler with DIEMATIC 3 electronic control panel

GT 220/2200 D + AD217 Boiler with DIEMATIC 3 control panel for

controlling a 2-stage or modulating burner.

GT 220 X Boiler with X electronic control panel

6

GT 220 - GT 2200 22/01/09 - 300008281-001-E

2. Description

2.4 Technical characteristics

12.5 % on fuel oil and 9.5 % on natural gas

- Flow temperature: 80 °C.

- Return temperature: 60 °C.

- Maximum operating pressure: 4 bar

- Maximum operating temperature: 100 °C

- Boiler thermostat setting: 30 - 90 °C

- Setting the safety thermostat: 110 °C

Boiler type

GT 224

GT 2204

160

GT 2204

250

GT 225

GT 2205

160

GT 2205

250

GT 226 GT 227 GT 228

Nominal output Pn kW 50 50 64 64 78 92 100

Useful output range kW 40-50 40-50 50-64 50-64 64-78 78-92 92-100

Input range kW 43.2-54.5 43.2-54.5 54.0-69.7 54.0-69.7 69.7-84.8 84.2-100.1 99.6-108.9

PCI efficiency - at 100% Pn

(Average temperature: 70 °C)

% 91.791.791.891.892.091.991.8

PCI efficiency - at 30% Pn

(Average temperature: 50 °C)

% 93.993.993.793.793.693.894.1

PCI efficiency - at 30% Pn

(Average temperature: 40 °C)

% 94.194.194.394.394.694.694.7

Fuel oil burner (Option)

1 stage

M200/1S(1) M200/1S(1) M200/1S(1) M200/1S(1) M201/2S M201/2S M201/2S

1 stage

M201/2N M201/2N M201/2N M201/2N

2 stages

M202/2S(1) M202/2S(1) M202/2S(1)

1 stage (Belgium)

M100/3S M100/3S M100/3S(2) M100/3S(2)

1 stage

G200/1S G200/1S G200/1S G200/1S G200/1S(3)

Gas burner (Option) 1 stage

G201/2N(4) G201/2N G201/2N

2-stage or modulating

G203/2N(4) G203/2N G203/2N

Number of cast iron parts 4455678

Nominal water flow (Nominal output) ∆ T = 20K

m3/h

2.151 2.151 2.754 2.754 3.356 3.959 4.303

Stand-by losses ∆ T = 30K W 197 197 213 213 226 238 247

Losses through the outer casing ∆ T = 30K % 64646868707273

Auxiliary electrical power

( Nominal output - ex circulating pump)

W 10101010101010

Water content litres36364343505764

Water resistance ∆ T = 15K mbar*11.011.017.817.826.536.743.4

Flue gas circuit volume litres 54 54 68 68 83 97 111

Combustion chamber

Inscribed Ø mm 309 309 309 309 309 309 309

Depth mm 446 446 573 573 700 827 954

Volume litres 33 33 42 42 51 60 69

Mass flue gas flow rate

Fuel oil Kg/h 83 83 106 106 129 152 166

Gas Kg/h 91 91 117 117 143 168 183

Pressure in the furnace for nozzle pressure = 0 mbar mbar 0.2-0.5 0.2-0.5 0.3-0.6 0.3-0.6 0.3-0.8 0.4-0.8 0.6-0.9

Smoke temperature (Boiler temperature

=70 °C)

°C <195 <195 <195 <195 <195 <205 <205

Weight (empty)

GT 220 kg 218 218 257 257 297 336 375

GT 2200 kg 318 348 357 387 - - Tank capacity GT 2200 litres 160 250 160 250 - - Power exchanged

(5) (7) GT 2200 kW 28 36 28 36

Specific flow **

(6) (7) ∆ T = 30K

litres per

min.

20.5 30 20.5 30

Flow per hour ** (6) (7) ∆ T = 35K l/h 690 885 690 885

Flow in 10 minutes***

(6) (7) ∆ T = 30K

litres per

10 min.

255 385 255 385

Cooling constant Cr

Wh/

24h·L·K

0.26 0.23 0.26 0.23

Losses through the outer casing (DHW) ∆ T = 45K kW 78 108 78 108 690 810 690

Auxiliary electrical power (DHW) kW 80 80 80 80 255 385 255

7

22/01/09 - 300008281-001-E GT 220 - GT 2200

2. Description

2.5 Rating plate

The rating plate identifies the product and provides information on:

- The date of manufacture: XX (Year) - XX (Week).

- The serial number.

(1) Except Belgium

*

1 mbar = 10 mmCE = 10 daPa = 100 Pa / 1 K =1 °C

(2) up to 60 kW

(3) up to 70 kW

(4) above 70 kW

** Specific flow: Minimum average rise in temperature of 30K that the appliance

can provide in the course of two successive draw-offs of 10 minutes

separated by a stop of 20 minutes.

(5) Heat exchanger inlet temperature: 80 °C

Domestic hot water temperature: 45 °C

(6) DHW setting = 60 °C - Average domestic hot water temperature:

40 °C - Boiler setting: 80 °C

*** Draw-off capacity: Hot water flow at which water can be drawn off during a

period of 10 minutes at a temperature of 30°C.

Outlet status: Water at 10°C in the boiler.

(7)

Cold water temperature: 10 °C

A

8

GT 220 - GT 2200 22/01/09 - 300008281-001-E

2. Description

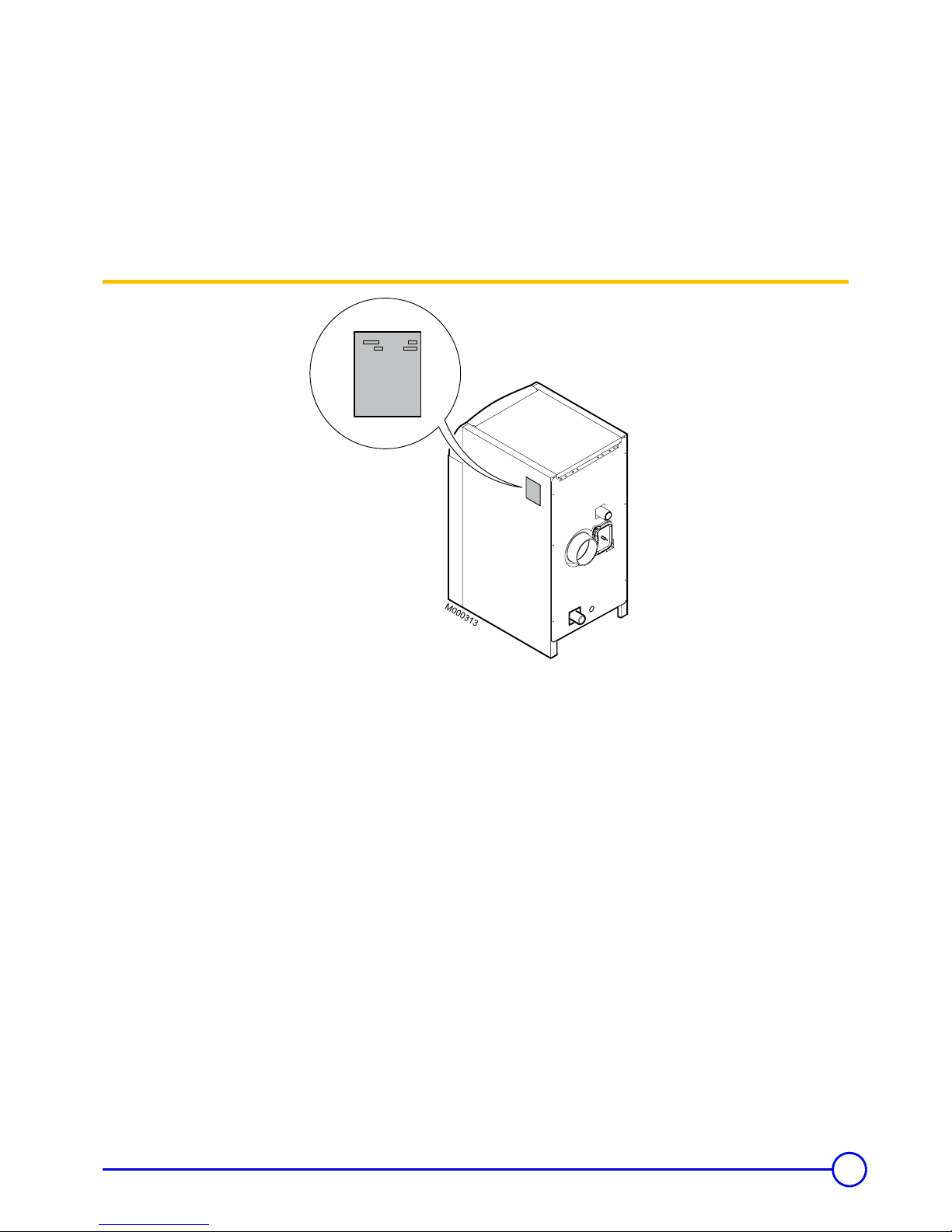

2.6 Main dimensions

2.6.1 Boiler and tank dimensions

• GT 220

• GT 2200

(*) Boiler and DHW calorifier connection kit

A

A

GT 224

GT 2204/160

GT 2204/250

GT 225

GT 2205/160

GT 2205/250

GT 226 GT 227 GT 228

A

700 700 827 827 954 1081 1208

B

772 772 899 899 1026 1153 1280

Ø C

153 153 153 153 180 180 180

R1 1/4 R1 1/2 R1 1/4 R1 1/2 R1 1/2 R1 1/2 R1 1/2

E

380 380 507 507 634 761 888

9

22/01/09 - 300008281-001-E GT 220 - GT 2200

2. Description

1. Heating outlet

2. Heating return

3. Drainage / filling orifice

Rp 3/4

4. Flue gas nozzle ø C

5. Domestic hot water outlet - G 1

6. Domestic cold water inlet - G 1

7. Domestic hot water circulation loop return - G 3/4

8. Filling and emptying tap

(connection for 14 mm interior diameter pipe)

9. 4xM8 on Ø 150 and 4 markings on Ø 170

10. Drilling Ø 110 - Precut Ø 130

R = Thread

Rp = Exterior cylindrical threading, sealed by flat joint

(1) Adjustable feet: Basic dimension 35 mm. Can be adjusted from

35 mm to 50 mm

(2) Adjustable feet: Basic dimension 35 mm. Can be adjusted from

35 mm to 40 mm

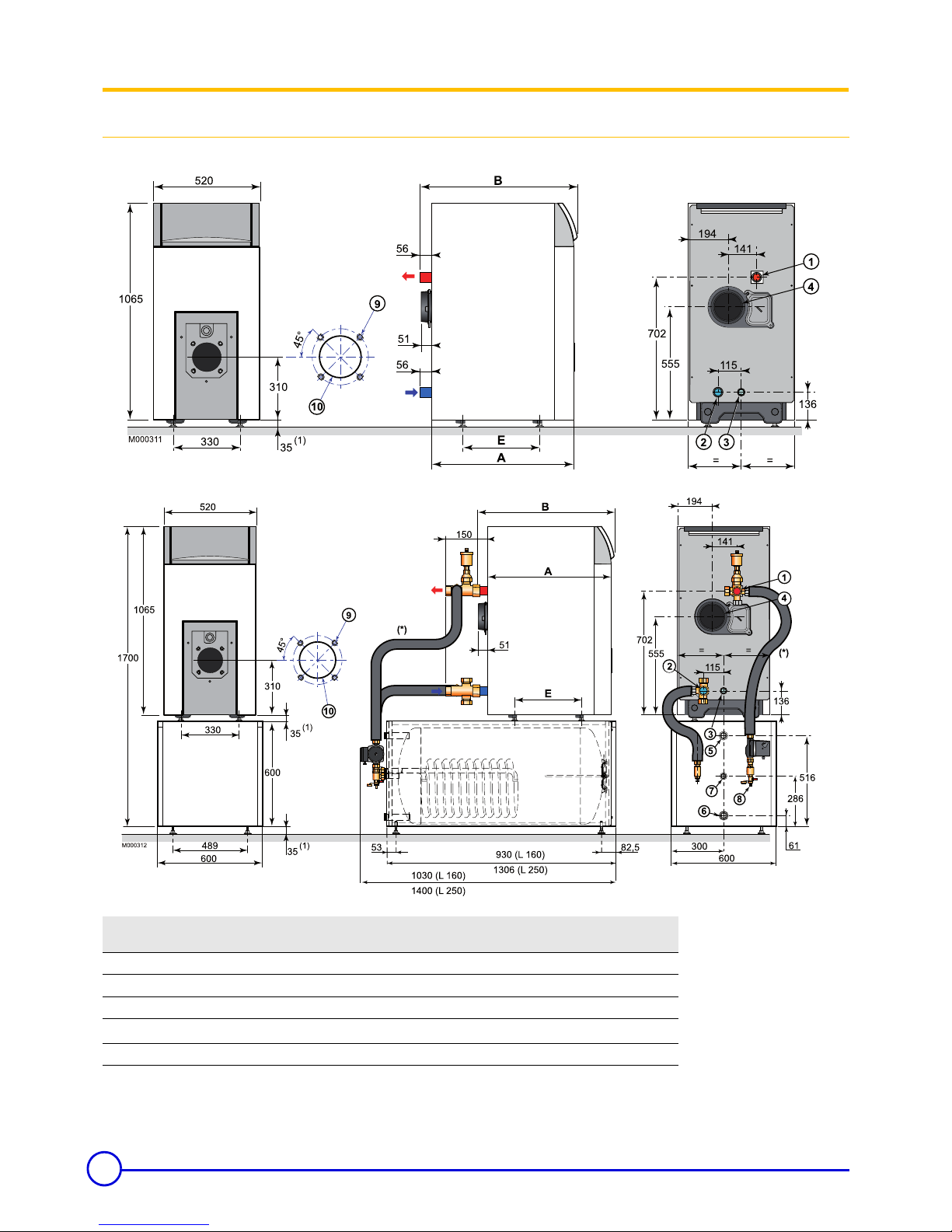

2.6.2 Installation dimensions

Keep space free around the boiler to ensure good accessibility to the appliance.

Minimum recommended dimensions (in mm):

• GT 220 • GT 2200

Boiler A (mm)

GT 224 700

GT 225 827

GT 226 954

GT 227 1081

GT 228 1208

Boiler A (mm)

GT 2204/160 930

GT 2204/250 1306

GT 2205/160 930

GT 2205/250 1306

Loading...

Loading...