DeDietrich GT 210 A, GT 214 A, GT 215 A, GT 216 A, GT 217 A Operating Manual

...

GT 210 A

Oil-Gas Fired Hot Water Boiler

English

11/03/09

Warning:

Before putting the boiler into operation read this manual

carefully.

Warning:

The operating manual is part of the documentation that is

delivered to the installation’s operator. Go through the

information in this manual with the owner/operator and

make sure that he or she is familiar with all the necessary

operating instructions.

Notice:

This manual must be retained for future reference. Improper

installation, adjustment, alteration, service or maintenance can

cause injury, loss of life or property damage. Refer to this

manual. For assistance or additional information consult a

qualified installer, service agency or the fuel supplier.

Installation & Operating Manual

Please Read & Save this Manual for Future Reference

8227-4096-F

8227-4096-F

2

GT 210 A 08/0121/08/06 - 94863106 - 82274096E

Guideline of Notices

Warning:

indicates presence of hazards that can cause, if not

avoided, severe personal injury, death or substantial

property damage.

! Caution:

indicates presence of hazards that will or can cause, if not

avoided, minor personal injury or property damage.

Notice:

Application comment for optimum use of equipment and

adjustment as well as useful information.

Z

Reference to an other instruction book.

Observe the following symbols

DANGER

due to explosion of gas.

- Work only on gas components when you have a license to do so.

- Note that the assembly of gas and vent connections, the initial

start-up, the electrical connections, the maintenance and service

can only be performed by a licensed service contractor or

technician.

DANGER

due to electricity.

- Prior to doing any work on the heating system, disconnect all

electrical power to the boiler at the emergency switch.

- It is NOT sufficient to shut off only the boiler control!

! CAUTION!

SYSTEM DAMAGE

due to improper installation.

- Observe local and state codes as well as common industry

practices during the installation and operation of the heating

appliance.

! CAUTION!

SYSTEM DAMAGE

due to inadequate cleaning and maintenance.

- A boiler cleaning and maintenance should be performed annually.

Verify complete system operation at the same time.

- Correct the problem immediately to prevent damage to the

system!

! Caution:

Refer to User’s Manual regarding the carcinogenic hazard of

crystalline silica that may be found during installation, servicing

and removal of this boiler.

Safety Considerations

Please observe the following safety instructions.

Read this manual carefully.

Correct installation and adjustment of the burner and the control

panel is a precondition for safe, efficient operation of the boiler.

Read this manual and the specifications on the safety label carefully

before attempting to put the burner into operation.

Do not store or use gasoline or other flammable liquids in

the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electric switch, do not use any phone in

your building.

- Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the Fire

Department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

Warning:

Improper installation, adjustment, and/or operation could

cause carbon monoxide poisoning resulting in injury or

death.

This product must be installed and serviced by a

professional service technician who is experienced and

qualified in hot water boiler installation and gas

combustion.

! Caution: Strict compliance with these instructions is a

precondition for the correct operation of the boiler.

! IMPORTANT

Service on this boiler should be undertaken only by trained and

skilled personnel.

Keep boiler area clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

Do not place any obstruction in the boiler room that will hinder

the flow of combustion and ventilating air.

Read these instructions carefully before proceeding with the

installation of boiler. Post instructions near boiler for reference

by owner and serviceman.

Maintain instructions in legible condition.

"Installation of this equipment must be in accordance to all local and national codes or authorities having jurisdiction”

[Canadian Installations]

• CSA B149 for gas fired boilers

• CSA B139 for oil fired boilers

[USA Installations]

• NFPA 54/ANSI Z223.1 for gas fired boiler

• NFPA 31 for oil fired boilers.

ATTENTION-WARNING:

The boiler must be connected to a

venting system that will safely discharge

all flue gas to the outside in a safe and

effective manner.

Do not use gasoline, crankcase draining,

or any other oil containing gasoline.

The boiler is certified to burn fuels as

listed on the boiler rating plate. Never

burn garbage or paper in the unit, and

never leave combustible materials in the

vicinity of the boiler.

3

01/08/08 - 82274096F GT 210 A

Contents

Regulations and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1 Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Technical specifications of boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Main Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2 Aeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3 Levelling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 Water connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Chimney connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1 Flue size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2 Connecting to the flue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Connecting the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1 Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2 Domestic hot water (GT 2100). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3 Precautions required in the case of long boiler stops (one or more years) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4 Precautions required if the heating is stopped when there is a risk of freezing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5 Identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Spare parts - GT 210 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4

GT 210 A 21/08/06 - 94863106 - 82274096E

Regulations and guidelines

The installation must conform to the requirements of the authority

having jurisdiction or, in the absence of such requirements, to the

National Fuel Gas Code, ANSI Z 223.1 / NFPA 54. In Canada,

installation must be in accordance with the requirements of CAN/

CGA B149.1 or 2 Installation Code for Gas Burning Appliances and

Equipment. Where required by the authority having jurisdiction, the

installation must conform to the Standard for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME CSD-1.

Install CO detectors per local regulations. Boiler requires yearly

maintenance, see "Connecting the burner", page 24.

Only a qualified installing contractor may carry out the installation, the

initial start-up, the connection for fixed gas and vent gas, and

conversion to another type of gas. The hot water distribution system

must comply with the applicable codes and regulations. When

replacing an existing boiler, it is important to check the entire hot

water distribution system to insure safe operation. Maintenance and

cleaning must be carried out at least once a year by a trained service

technician. The entire installation must be tested for proper

operation. Any defects detected must be fixed immediately.

General

1 Uncrating

Upon arrival, check shipment to ensure all parts have been shipped.

Inspect all items for delivery damage. Report all damage and shortages to the delivery carrier. Report any damage and shortages to

the Distributor.

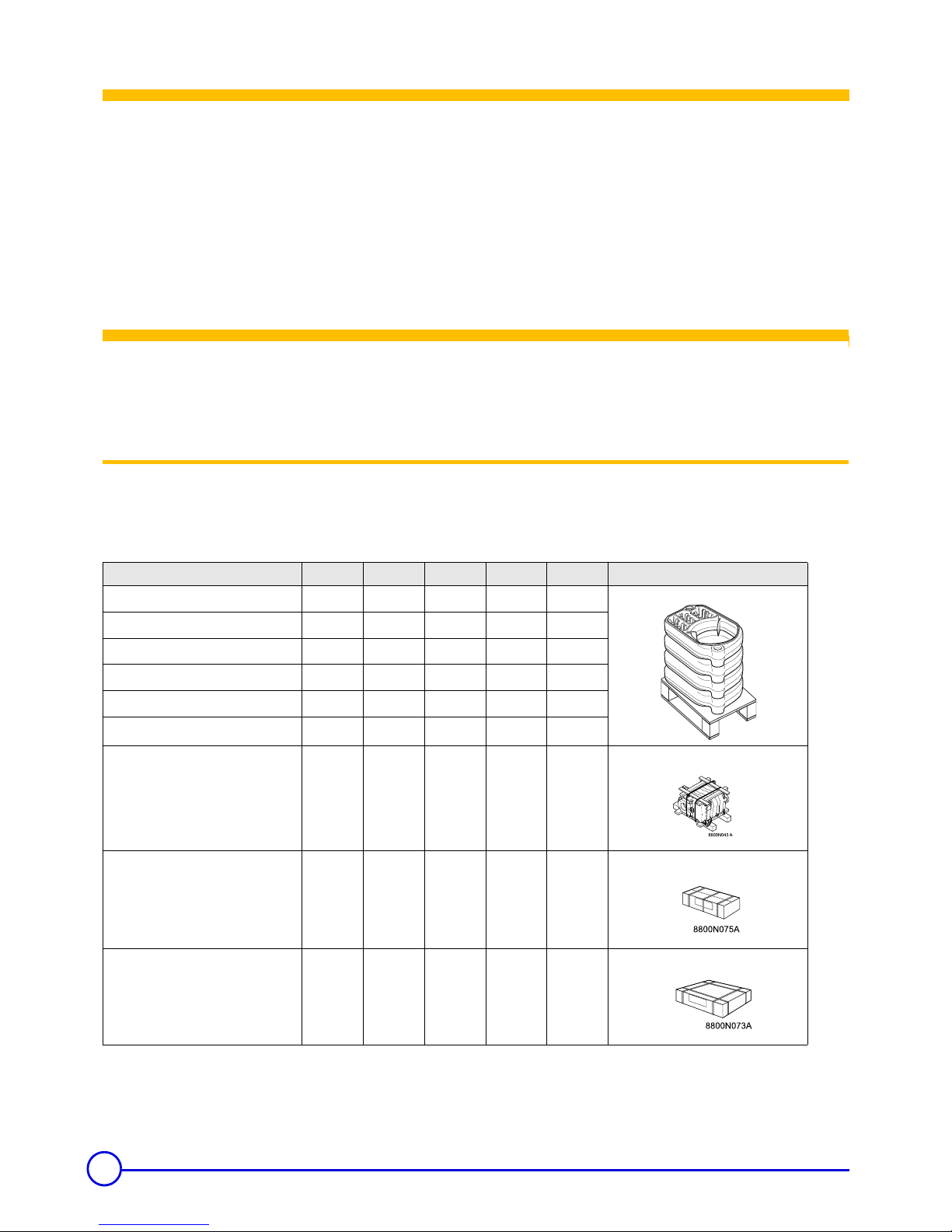

Boiler GT 214 A GT 215 A GT 216 A GT 217 A GT 218 A

• Unassembled boiler body

- front section

11111

- intermediate section

23456

- rear section

11111

- set of assembly rods

--111

- accessory package

DR 64 DR 65 DR 66 DR 67 DR 68

• Assembled boiler body

with accessories

DR 84 DR 85 DR 86 DR 87 DR 88

Control panel

DR 90 DR 90 DR 90 DR 90 DR 90

Casing

DR 74

DR 75

DR 76

DR 77

DR 78

8800N072

The GT210A series is a cast iron sectional boiler designed for space and domestic and hot water heating requirements, the

boiler is automatically fired and control

led by the boiler control panel. The boiler is certified to burn all the fuels as listed on the rating

plate by separat

e burner. The boiler must always be connected to a vent system that will discharge all flue gases to the outside

in a safe and effective manner. Refer to the specific sections in the manual for further details.

5

21/08/06 - 94863106 - 82274096E GT 210 A

2 Technical specifications of boilers

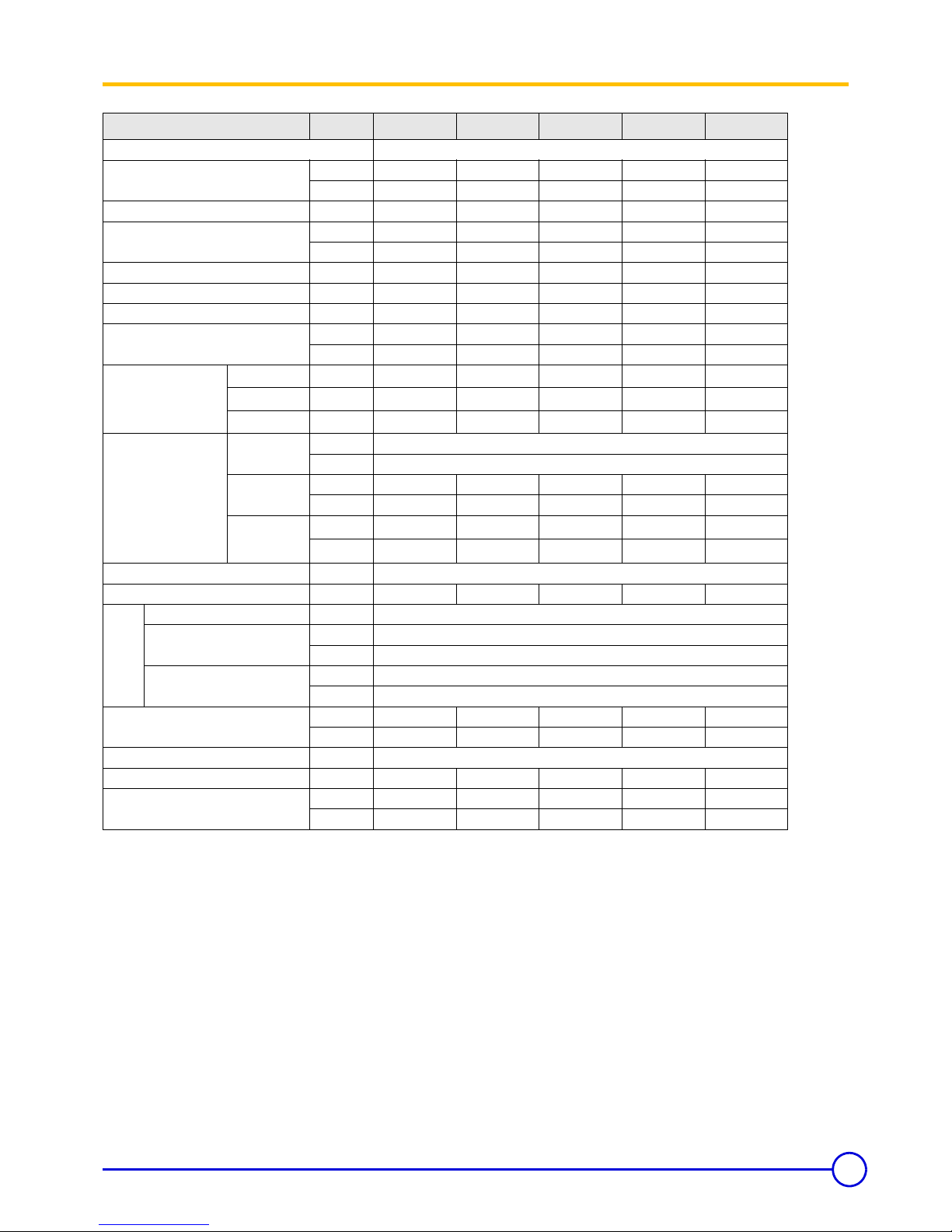

Item Unit GT 214 A GT 215 A GT 216 A GT 217 A GT 218 A

Firing Sequence Consult Burner Technical Data

[CSA] - Gas Input

MBH 173 224 274 324 361

kW 50.7 65.7 80.3 95.0 105.8

[CSA] - # 2 Fuel Oil Input US GPH 1.20 1.55 1.90 2.25 2.50

[CSA] - Output [Gas-Oil]

MBH 147 190 233 276 306

kW 43.1 55.7 68.3 80.8 89.8

[NET] - Output [Gas-Oil] MBH 128 165 203 240 266

Cast Iron sections #45678

Flue-way baffles #32222

Water capacity

US Gal 9.5 11.4 13.2 15.1 16.9

Liter3643505764

Water resistance

[

∆t = °F]

18° F

Ft. H

2

O

0.82 1.34 1.99 2.77 3.4

27° F

Ft. H

2

O

0.365 0.596 0.887 1.23 1.51

36° F

Ft. H

2

O

0.204 0.335 0.498 0.693 0.85

Combustion chamber

Dimensions

Diameter

[equivalent]

Inch 12.17

mm 309

Depth

Inch 17.6 22.6 27.6 32.6 37.6

mm 446 573 700 827 954

Volume

ft

3

1.1653 1.4831 1.8009 2.1188 2.4366

m

3

0.033 0.042 0.051 0.060 0.069

MAWP [Water] PSI ASME IV Rating Class 30 - (60 PSI) [See Canadian Provincial CRN approvals]

Min. Safety Relief Capacity MBH 147 190 233 276 306

DR 90 Panel

Electrical connection V/P/H 120/1/60

Max. Water Temp. Safety Limit

[MR]

°F 230

°C 110

Operating Water Temperature

Range

°F 86 - 185

°C 30 - 85

Chamber resistance

Inch w.c. 0.08 - 0.16 0.20 - 0.24 0.08 - 0.24 0.16 - 0.24 0.24 - 0.32

mbar

0.2 - 0.4 0.5 - 0.6 0.2 - 0.6 0.4 - 0.6 0.6 - 0.8

Gas-Vent Category # I, II - III or IV

Boiler Vent connectionInch66777

Weight (dry)

lb 481 567 655 741 827

kg 218 257 297 336 375

6

GT 210 A 01/08/08 - 82274096F

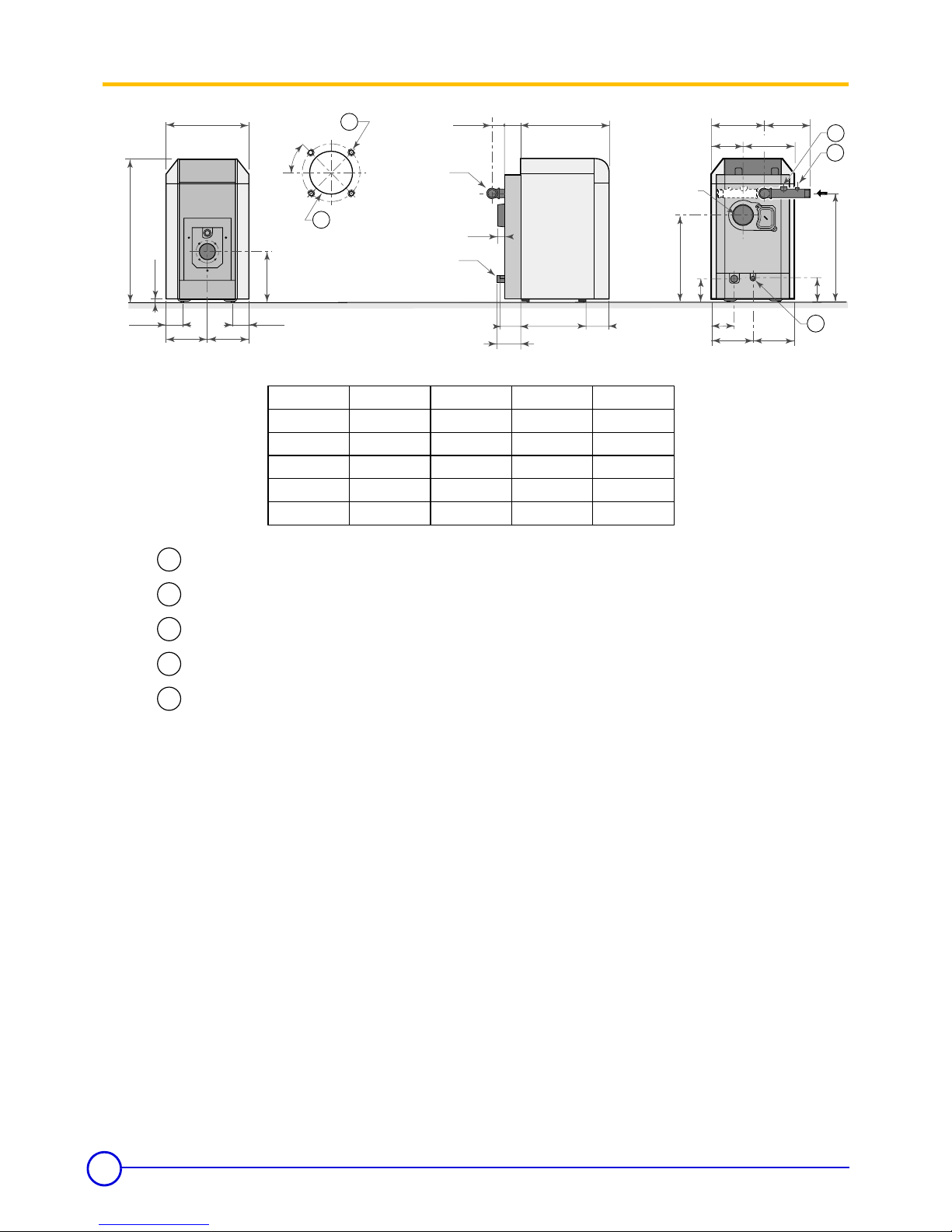

3 Main Dimensions (less applied burner)

22

1

/16

38

7

/8

2" (1)

7

7

/16

29

11

/16

7

7

/16

23

15

/16

8

7

/16

A4

7

/16

2

7

/8

13

5

/8

9

7

/16

14

=

=

heating

outlet

D Ø

heating

return

D Ø

4

1

/2

4

1

/2

5

1

/8

1

13

/16

6

3

/16

5

9

/16

C

6

1

/2

==

B Ø

flue gas

nozzle

14

3

/16

1

2

3

4

5

Model

GT 214A

GT 215A

GT 216A

GT 217A

A*

23 5/16 in.

28 5/16 in.

33 5/16 in.

38 5/16 in.

B = ø

6

6

7

7

C

16 11/16 in.

21 11/16 in.

26 11/16 in.

31 11/16 in.

D

1¼ in.

1 ¼ in.

1 ½ in.

1 ½ in.

GT 218A 43 5/16 in. 7 36 11/16 in. 1 ½ in.

2

3

Bolt Ø = 5 15/16 inch M8 x 1.25 Bolt diameter threading predrilled, additional

marking @ 6 ¾ inch for larger mounting requirements.

4

5

Combustion head Ø = 4 7/16 inch precut, additional marking @ 5 1/8 inch for larger

combustion heads.

Supply manifold ¾” port for safety relief valve

Supply manifold ¼ inch port for temperature and pressure gauge

Drain port ¾ inch.

1

A* = Dimension will increase with applied burner, consult supplied burner documentation for dimensions

and clearances for service/ combustibles.

D** = OD Dimension will for breeching connection only actual vent diameter sizing will depend on

specific vent application and code requirements.

(1) = Adjustable hot water tank feet for leveling, minimum height =1 3/16 inch, adjustable from 1 3/16 to 2 1/2 inch.

7

01/08/08 - 82274096F GT 210 A

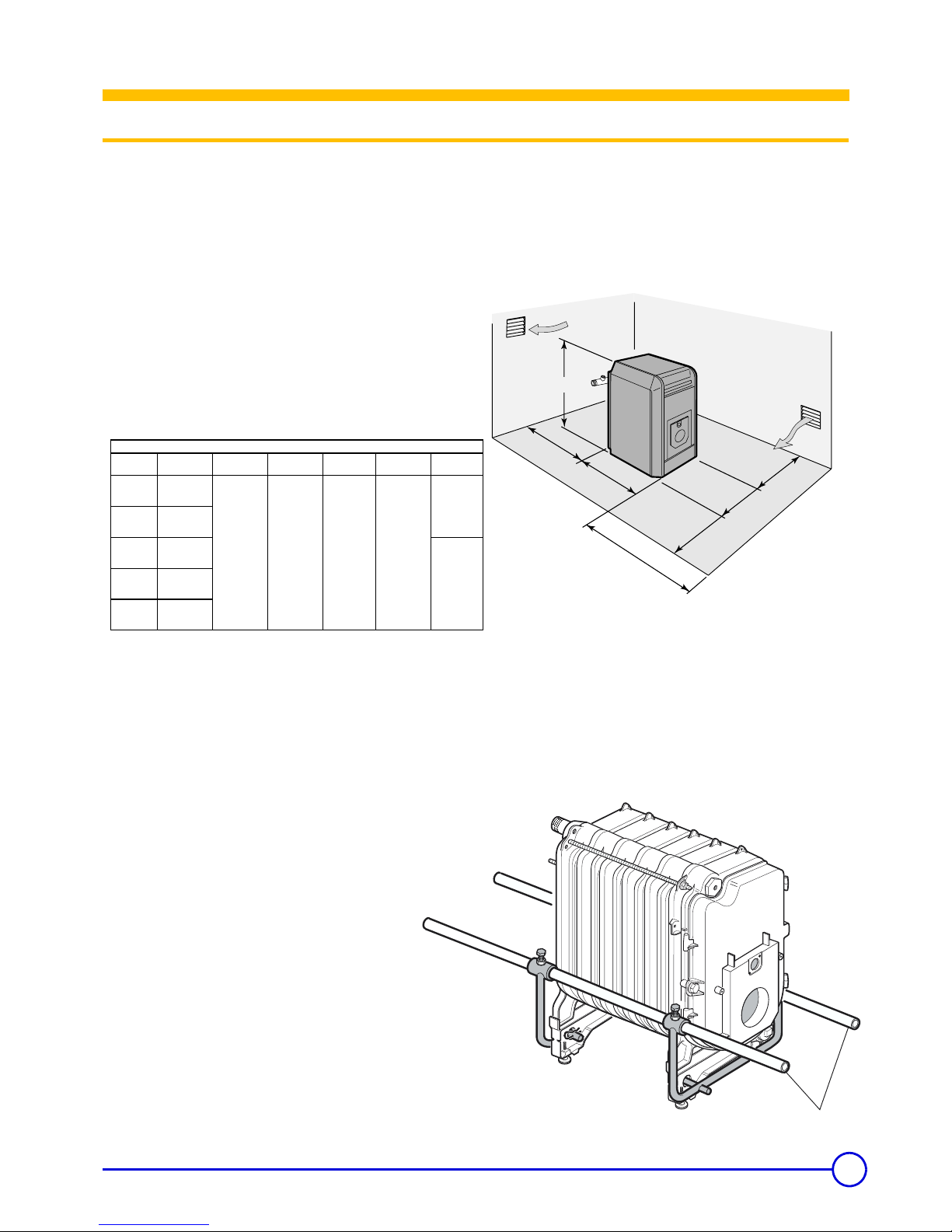

L

X

8227N058A

3/4"-1"

To facilitate boiler transportation into the final installation site, a

special handling tool (package BG 45, no.8218-7723) may be used

as shown to transport the boiler or the boiler on the MLS horizontal

domestic hot water tank. The two 3/4” or 1” pipes are shown are not

supplied with the package BG45, they are supplied by others.

Installation

1 Installing the boiler

The boiler does not require any special housekeeping pad as it has been provided with a study frame and leveling bolts for the

final installation, but a non combustible pad is suggested to keep occasional water away from the boiler. The boiler requires

clearance for combustibles and for servicing, the recommended clearance as shown in the table below. Do not install the boiler

on combustible flooring or carpet.

Proper combustion air and ventilation are required for the boiler, inadequate combustion air or makeup air provisions may result

in foul boiler room odors, incomplete combustion resulting in carbon monoxide (CO) development or creation of negative building

pressure.

Particular attention must be observed if the boiler is operating near or within vicinity of beauty shops, paint shops or

industrial plant where known pollutants, corrosive element may containment affect the quality of combustion air supply, failure to

observe this warnings will result in void of warranty of the boiler and any responsibility of De Dietrich.

Consult local codes for combustion air and ventilation requirements, each installation must comply with all local and national

codes having jurisdiction.

Model

L = overall

len

g

th

Sides Rear

X = Front

burner

Top Vent

GT214A

29

11/16

[754mm]

GT215A

34

11/16

[881mm]

GT216A

39

11/16

[1008mm]

GT217A

32

11/16

[1135mm]

GT218

33

11/16

[1262mm]

20 inches

[500mm]

20 inches

[500mm]

34 inches

[800mm]

24 inches

[600mm] in

front of burner

Combustible & Service Clearances

GAS =

6 inches

[150mm]

OIL =

9 inches

[230mm]

Loading...

Loading...