Page 1

DD 3009 GLASS

EFFICIENCY

PROVED BY TIME

Page 2

EQUIPMENT, SYSTEMS, SERVICES

DD 3009 GLASS

Glass-lined steel is mandatory when

service conditions of the process are

particularly difficult. With the DD 3009

glass, De Dietrich® offers an excellent resistance to corrosion, abrasion,

mechanical and thermal shocks.

To increase productivity or to succeed

in new syntheses, the chemical industry continually extends the limits of its

processes: higher temperatures, lower

temperatures, higher pressures, higher

concentrations. This trend is possible

only if at the same time the chemical

and mechanical resistances of the

glass that protects vessels, tanks and

parts follow these requirements.

This is the reason why De Dietrich® has

always invested in research and development of new glass formulas with

greater capabilities. The result of our

ongoing research enabled us to offer

the DD 3009 glass. The formulation

of this multipurpose glass gives the

optimum properties of chemical resistance to acidic and alkaline mediums,

of mechanical resistance to shocks

and abrasion, of easy cleaning and

anti-adhesion.

Across the world, all De Dietrich®

plants apply the same quality of glass,

the production of which is centralized

in France. During the preparation

of each batch of DD 3009 glass,

numerous tests assure us a perfect

and reproducible quality, suppressing

any risk of production defect. Thanks

to su ch rig orous contr ol, we can

confidently state that, at De Dietrich®,

“Quality” is an everyday occurrence.

Monitoring R&D and production of

our own glass in for De Dietrich® an

emblem of quality, of competence, of

independence.

ONE GLASS

WITH OPTIMUM QUALITY

DD 3009, ONE GLASS WITH OPTIMUM

QUALITY FOR ALL PRODUCTS ALL

OVER THE WORLD:

• HIGHLY CORROSIVE PROCESSES

• MULTIPURPOSE MATERIAL /

VARIETY OF USES

• ADAPTED TO

MENTS, CLEANING, CLEANLINESS,

STERILIZATION

• IMPERVIOUS: NO CATALYTIC

EFFECT, NO CONTAMINATION

• ANTI-ADHESIVE: POLYMERIZATION

PROCESSES

cGMP REQUIRE-

ONE GLASS WITH

OPTIMUM QUALITY ALL

OVER THE WORLD

Page 3

CHEMICAL PROPERTIES

190

180

170

160

150

140

130

120

110

10 40 60

°C

20 30 50 70

HNO

3

Weight %

0.2 mm/year

0.1 mm/year

210

200

190

180

170

160

150

140

130

10 40 60

0.2 mm/year

°C

20 30 50 70 80

H2SO

4

Weight %

0.1 mm/year

180

170

160

150

140

130

120

110

10 20 30

Weight %

°C

HCI

0.2 mm/year

0.1 mm/year

190

180

170

160

150

140

130

120

110

10 40 60

Weight %

°C

20 30 50 70 80

H3PO

4

0.2 mm/year

0.1 mm/year

230

220

210

200

190

180

170

160

140

10 40 60

0.2 mm/year

°C

20 30 50 70 80

CH3COOH

90 100

0.1 mm/year

Weight %

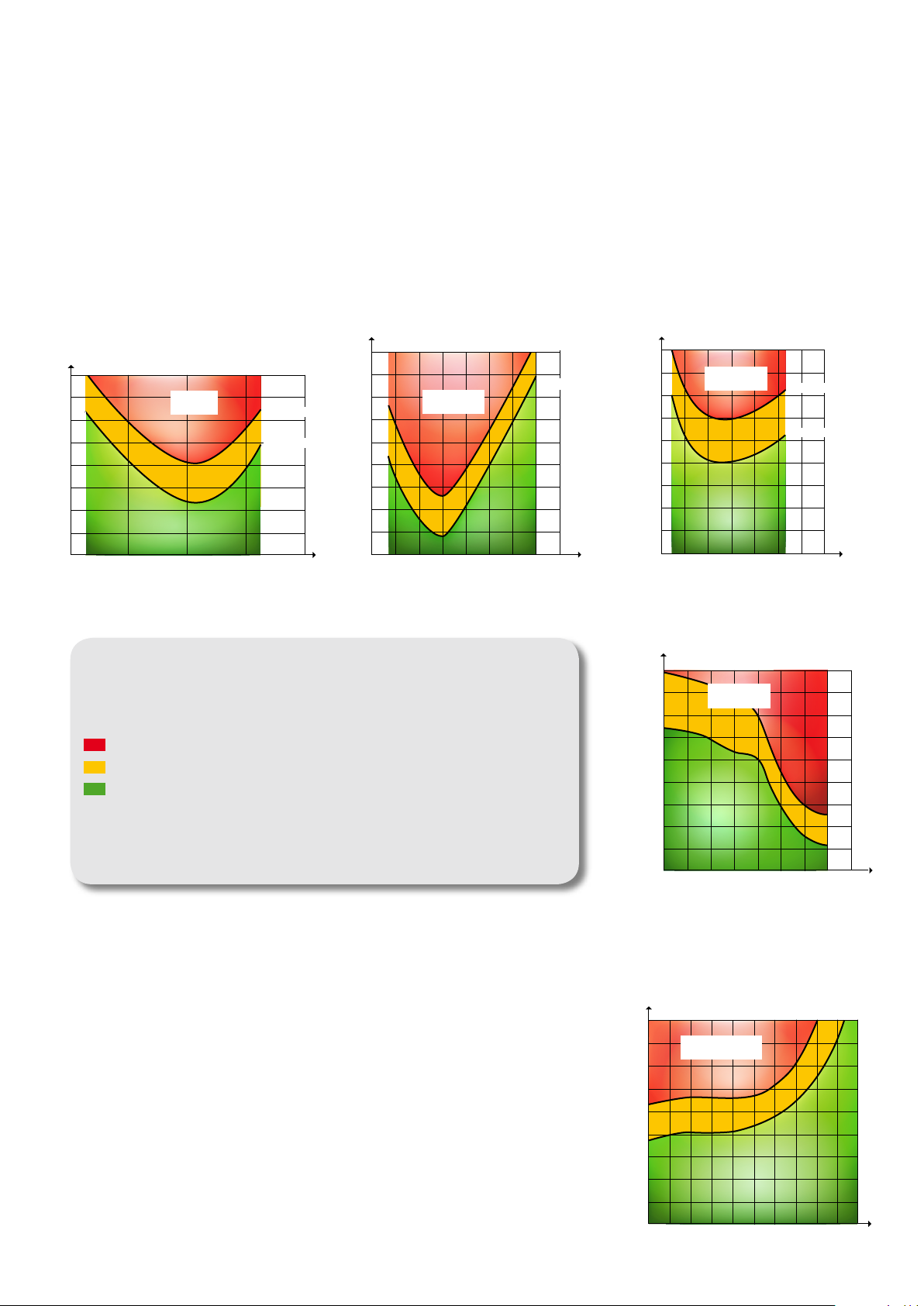

RESISTANCE TO ACIDS

Generally, DD 3009 glass has a high

degree of resistance to acids whatever

their concentration, up to relatively

high temperatures. For most of the

inorganic acids, the resistance of the

glass passes through a minimum for a

concentration of 20-30% weight, then

increases with the acid concentration.

For example, the 0.1 mm/year rate is

found at 128°C in H2SO4 30% and at

180°C in H2SO4 60%. Exceptionally,

in the case of phosphoric acid, the

speed of attack increases with the

concentration: 0.1 mm/year at 163°C

for 10% concentration and at 112°C for

70% concentration.

Hy dro flu ori c ac id c omp let ely and

quickly dissolves the glass whatever

the temperature is. Its concentration in

the product must not exceed 0.002%

(20 ppm).

RESISTANCE

TO ORGANIC SUBSTANCES

Chemical attack is very low in organic

substances. If water is given off during

the reaction, the rate of attack will

depend on the amount of water in the

solution. In the case of 0.1N sodium

hydroxide in anhydrous alcohol at

ISOCORROSION CURVES

OUR ISOC ORROSION CURVES ARE ESTABLISHED FOR MOST CURRENT PRODUCTS. THEY

SHO W AS A FUNCTION OF PRODUCT CONCENTRATION THE TEMPERATURES AT WHICH

THE WEIG HT LOSSES CORRESPOND TO 0.1 AND 0.2 MM/YEAR.

TH E USE OF GLASS IS NOT ADVISABLE

CA RE MU ST BE TAKEN OF THE ADVANCE OF THE CORROSION

GL ASS C AN BE USED WITHOUT PROBLEMS

ALL THE TEST HAVE B EEN PERFORMED IN TANTALUM LINED REACTORS AND USING A

RATIO VOLUME OF P RODUC T / SURFACE OF ENAMEL (V/S) > 20 TO AVOID THE INHIBI

TIO N OF THE ATTACK BY D ISSOLVED SILIC A.

80°C, the rate of attack is virtually nil.

In methanol, there has to be more than

10% water before the loss of weight can

be measured, whereas in ethanol with

5% water, the weight loss is already half

of what it is in aqueous solution.

-

Page 4

RESISTANCE TO ALKALIS

110

100

90

80

70

60

50

40

10

-2

10

-1

1 10 30

Weight %

0.2 mm/year

0.1 mm/year

°C

Na2CO

3

120

110

100

90

80

70

60

50

10

-3

10

-2

10-10,4 4

0.2 mm/year

0.1 mm/year

°C

0,04 1 10 30 50

11 12 13 14 pH

NaOH

Weight %

150

140

130

120

110

100

90

80

10

-2

0,4 4

0.2 mm/year

0.1 mm/year

°C

0,04 1 10 3010

-1

NH

3

Weight %

100

80

60

40

20

20

Speed of attack (%)

HCI 20 % at 160°C

Micronised silica

(Levilite)

40 60 80 100

ppm of added silica

%

100

80

60

40

20

50

H2SO4 30% at 160 °C

Micronised silica

(Levilite)

100 150 200 250

Speed of attack (%)

ppm of added silica

HCI 20 % at 160°C: 0.5 mm/year

With 100 ppm SiO2: 0.05 mm/year

180

160

140

120

100

10 20 30 40

0.2 mm/year

0.1 mm/year

°C

Weight %

Here the permissible temperature limits

are lower than for acids. At pH = 13

(NaOH 0.1N) this maximum is 70°C.

Therefore, it is important to be cautious

when using hot alkalis. Temperature

must be controlled, as an increase

of 10°C doubles the rate of attack of

the glass. Care must be taken for the

introduction of alkalis into a vessel.

Avoid the flow of alkalis along the warm

vessel wall by using a dip pipe.

RESISTANCE TO WATER

VAPOR

Resistance to water is excellent. The

behavior of glass in neutral solutions

depends on each individual case but in

general is very satisfactory.

CORROSION INHIBITION

Chemical reactions are sometimes so

severe they cause a rapid wear on the

enamel surface. The use of additives

NaOH 1N 80 °C 0.18 mm/year 0.09 mm/year

Buffer pH= 1 ; 100°C + HF 430 ppm 1.5 mm/year 0.42 mm/year

HCI 20 % vapor 110 °C 0.036 mm/year < 0.005 mm/year

to the reacting substance can inhibit

this corrosion permitting the use of

glass-lined equipment. When using

acids, several tens or several hundreds

ppm of silica protect th e enamel

and considerably reduce the rate of

corrosion during the liquid phase.

The same result can be obtained at

the vapor stage by adding silicon oils.

Generally speaking, the higher the

temperature, the greater the quantity

of silica required, and more the acid

Pure Product 500 ppm CaCO

is concentrated, the more the amount

of silica can be reduced. In presence

of fluorine, silica also has a favorable

influence. We always recommend a

pre-test as each reaction is different.

An attack inhibitor can be useful in one

case and yet non-effective in another.

3

300 ppm SiO

2

Silicon Oil 2 ml/l

Page 5

MECHANICAL PROPERTIES

Ena mel is a gl ass wit h its qualitie s but also its main weaknesses

whi ch are brittleness and low tensil e strength. Since the res istan ce of

gla ss to compression is well above

its tensi le strength , one of the solutio ns to improve the mec hanic al

res istan ce is to put the glazed layer

und er compressive pre-stress. This

is achieved during controlled cooling

after each firing. During mechanical work

(de forma tion, mechanical or thermal

sho ck) the compressive stress must

fir st be offset by an equivalent tensil e befo re the glass could be put

und er da ngerous tensile stress.

ABRASION

The abrasion test (DIN 51152) is far

from the actual working conditions of

a glass-lined reactor where the effects

of the chemical attack enhance those

of abrasion. Nevertheless, it allows a

comparison between glasses, showing

DD 3009 advantageously. Statistically,

it has been shown that in practice the

cases of destruction by abrasion are

negligible. However, should any doubt

arise when an abrasive substance is

being used, only a comparative test

performed with that product could lead

to a conclusion.

MECHANICAL SHOCK

The different experimental arrangements used for measuring the mechanical shock resistance produce results

which cannot be compared to each

other. Therefore, there is little use

trying to give intrinsic values of the

mechanical shock resistance. The only

way to compare different glasses is to

use the same method and the same

criteria.

In our method, a 1 kg mass equipped

with a 15 mm ball is dropped onto

a glass-lined plate (glass thickness:

1.5 mm). This plate is locked onto

a magnetic base, thereby making

it thicker and increasing the shock

ef fici ency ( n o ener gy abs orpt ion

through steel vibrations). The plate is

electrically grounded, and the electric

current going through an electrolyte

deposited at the shock location is used

as assessment criteria. When tested to

this procedure, which is close to the

real service conditions, the mechanical

shock resistance of the DD 3009 glass

is about 80 % greater than that of the

former glass.

UNITS DD 3009 GLASS

HCI – Vapor – DIN 51157 - ISO 2743 mm/year 0.036

HCI – 20 % 140 °C – V/S = 20 mm/year 0.2

NaOH 1N 80 °C – DIN 51158 – ISO 2745 mm/year 0.19

NaOH 1N 80 °C – V/S = 20 mm/year 0.35

NaOH 0.1 N 80 °C – V/S = 20 mm/year 0.18

H2O – Vapor – DIN 51165 – ISO 2744 mm/year 0.017

Thermal shocks – Statiflux surface cracks °C 220

Abrasion – DIN 51152 mg/cm2/h 2.35

Mechanical shocks Improvement against former glass: 80 %

Page 6

THERMAL PROPERTIES

The large majority of equipment that we

manufacture is designed with a system

that enables the heating and cooling of

their contents. As heat transfers may

cause serious damage to the enamelled

coating, the user should respect the

limits described in this chapter, which

take account both of the data in the

EN 15159 standard (parts 1, 2 and 3)

and our experience as a constructor of

glass-lined equipment.

A DISTINCTION SHOULD BE

MADE BETWEEN :

• The “thermal shock” proper, which

is characterised by an abrupt change

in temperature applied either to the

surface of the enamel (introduction of

a product into the appliance: reagent,

cleaning water), or to the steel (such as

jacket nozzle location when introducing

for example super-heated steam).

• The «thermal stresses», which are

mechanical stresses related to temperature gradients which appear temporarily in the steel during phases of

temperature changes. These are related

to the design of equipment and may

generate stresses in the enamel, which

may cause its rupture, and/or result in

fissuring of the passivation layer in coils

and foster the development of corrosion

under stresses, which may lead to the

appearance of transverse cracks.

are different from standard (very high

temperature, very low temperature,

high pressure, …), or because of a

particular material or design such as

The maximum ΔT values given in

these tables MUST be respected. They

are limit values which must not be

exceeded.

glass-lined stainless steel equipment,

columns without compensator, dissymmetrical appliances (lyre and lateral

nozzle), non-standard thicknesses,

non-standard lengths, jacketed piping,

etc...

NOTE

Instructions devoted entirely to the

thermal properties of the enamel are

attached to the Maintenance Manual of

our equipment to enable their installaThe following table is provided to

enable you to validate your operating

conditions and obviate the creation of

tion and use in complete safety, as far

as both your operators and the equip-

ment are concerned.

excessive thermal shocks when introducing products into standard equipment or on changes in temperature in

the thermal fluid (Multifluid system).

GENERAL CASE OF STANDARD VESSELS CALCULATED FROM -25°C

TO +200°C EN 15159 NORM

WHEN INTRODUCING

THE THERMAL FLUID

IN THE JACKET

A

WHEN LOADING

PRODUCT

INTO THE VESSEL

B

Glass-lined equipment is more or less

sensitive to thermal shocks and thermal

stress es, depend ing on their geo metrical or structural characteristics.

This requires us to make a distinction

between:

• On one hand, standard equipment, in

which the calculation data are –25°C to

+200°C regarding the temperature, and

–1 to 6 bar regarding the pressure.

• On the other hand, specific equipment, either because of their calculation and/or operating conditions, which

Example A

If the product and the glass-lined wall are

at 170°C, the fluid temperature should be

between +30°C and +200°C.

Example B

If the glass-lined wall and the thermal

fluid are at 20°C, products between -25°C

and +165°C may be safely introduced.

Thermal fluid

T° not to exceed

T° T°

mini maxi

-25 120 -25

-25 125 -20

-25 135 -10

-25 145 0

-25 155 10

-25 165 20

-25 170 30

-25 175 40

-25 180 50

-25 185 60

-25 190 70

-25 195 80

-25 200 90

-25 200 100

-25 200 110

-20 200 120

-10 200 130

0 200 140

10 200 150

20 200 160

30 200 170

40 200 180

50 200 190

60 200 200

Product

and wall T°

Product T°

not to exceed

T° T°

mini maxi

-25 125 -25

-25 130 -20

-25 140 -10

-25 150 0

-25 157 10

-25 165 20

-25 175 30

-25 180 40

-25 190 50

-25 200 60

-25 200 70

-25 200 80

-25 200 90

-25 200 100

-25 200 110

-25 200 120

-25 200 130

-5 200 140

5 200 150

20 200 160

30 200 170

45 200 180

60 200 190

75 200 200

Thermal fluid

and wall T°

Page 7

GUARANTEED TRACEABILITY

PRODUCTION OF ENAMEL

Each batch of enamel is comprised of

carefully selected and rigidly controlled raw materials, which are melted

in a rotary furnace at approximately

1.400°C. The melted glass is then

poured into water. This sudden tempering breaks the enamel into grains,

whic h are dri ed and then groun d

and screened. To prevent any contamination, each batch is processed

separately, between each operation, in

closed containers.

GLASSING

A suspension is prepared with enamel

powder and sprayed like a paint on the

surfaces to be glass-lined. After this

coat, called “biscuit”, is air dried, the

parts are charged into a furnace and

fired at temperatures that affect fusion

between glass particles.

After cooling, the result is an impervious, smooth coating of glass. The coat

is then submitted to various controls:

thickness, spark testing and visual

inspection.

Then the item is sprayed with another

coat that will be air dried, fired and

Q.C. tested. These cycles are repeated,

always by the same technician who will

adjust and complete his work, until

obtaining perfect glass lining:

• Thickness between 1 and 2 mm

• Minimum spark test contact

• Good visual quality, smooth without

any color variation

COLOUR

DD 3009 glass is available in two colours

having exactly the same chemical and

mechanical properties:

• Blue (DD 3009)

• White (DD 3009U)

Page 8

DE DIETRICH SAS

Château de Reichshoffen

F 67891 Niederbronn Cedex

Phone +33 3 88 80 26 00

Fax +33 3 88 80 26 95

www.dedietrich.com

SAS. All rights reserved. 001-04/09. © endostock - Fotolia.com

®

BENELUX

De Dietrich Process Systems N.V.

B - Heverlee-Leuven

Phone +32 16 40 5000

Fax +32 16 40 5500

info@benelux.dedietrich.com

BRAZIL

De Dietrich Do Brasil Ltda

São Paulo

Phone +55 11 2703 7380

Fax +55 11 2702 4284

brasil@dedietrich.com.br

CHINA

De Dietrich Process Systems Co. Ltd

Wuxi

Phone +86 510 8855 7500

Fax +86 510 8855 9618

info@dedietrichchina.com

FRANCE

De Dietrich S.A.S.

Zinswiller

Phone +33 3 88 53 23 00

Fax +33 3 88 53 23 99

sales@dedietrich.com

De Dietrich S.A.S.

Evry

Phone +33 1 69 47 04 00

Fax +33 1 69 47 04 10

eivs@dedietrich.com

De Dietrich Process Systems Semur

S.A.S.

Semur-en-Auxois

Phone +33 3 80 97 12 23

Fax +33 3 80 97 07 58

info@rosenmund.com

GERMANY

De Dietrich Process Systems GmbH

Mainz

Phone +49 6131 9704 0

Fax +49 6131 9704 500

mail@qvf.de

GREAT BRITAIN

De Dietrich Process Systems Ltd

Stafford

Phone +44 1785 609 900

Fax +44 1785 609 899

sales@qvf.co.uk

INDIA

De Dietrich Process Systems (India)

Pvt, Ltd

Mumbai

Phone +91 22 28 505 794

Fax +91 22 28 505 731

ddps.india@dedietrich.com

IRELAND

De Dietrich Process Systems Ireland

Ltd

Shannon

Phone +353 61 366924

Fax +353 61 366854

sales@dedietrich.ie

ITALY

De Dietrich Process Systems Srl

San Dona’ Di Piave (VE)

Phone. +39 0421 222 128

Fax +39 0421 224 212

info-it@dedietrich.com

RUSSIA

De Dietrich Rep. Office

Moscow

Phone +7 495 663 9904

Fax +7 495 663 9905

info@ddps.ru

SINGAPORE

De Dietrich Singapore (PTE) Ltd

Singapore

Phone +65 68 61 12 32

Fax +65 68 61 61 12

info.sg@dedietrich.com

SOUTH AFRICA

De Dietrich South Africa (PTY) Ltd

Dunswart

Phone +27 11 918 4131

Fax +27 11 918 4133

info.za@dedietrich.com

SPAIN

De Dietrich Equipos Quimicos S.L.

Barcelona

Phone +34 93 292 0520

Fax +34 93 21 84 709

comercial@dedietrich.es

SWITZERLAND

De Dietrich Process Systems AG

Liestal

Phone +41 61 925 11 11

Fax +41 61 921 99 40

info@rosenmund.com

UNITED STATES

De Dietrich Process Systems Inc.

Mountainside, NJ

Phone +1 908 317 2585

Fax +1 908 889 4960

sales@ddpsinc.com

Charlotte, NC

Phone +1 704 587 04 40

Fax +1 704 588 68 66

rosenmund@ddpsinc.com

The information contained in this brochure is for general guidance only and is not contractual. We reserve the right to modify, alter, delete or supersede any of the products and services

described herein without notice or liability. © 2009 De Dietrich

The international business group De Dietrich Process Systems is

the leading provider of system solutions and reactors for corrosive

applications as well as plants for mechanical solid/liquid separation

and drying. The system solutions from De Dietrich Process Systems are

used in the industrial areas of pharmaceuticals, chemicals and allied

industries.

www.dedietrich.com

contain no solvents, are environmentally-friendly and free of volatile organic compounds.

This document has been printed on paper from sustainably managed forests. Inks being used

Loading...

Loading...