DEAN MF90AU-110 Service Manual

MF90 Series Portable Filters (CE)

Operation, Service & Parts Manual

MF90-110

"U" & "AU" CONFIGURATIONS

CE ONLY

Dean, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

Price: $6.00

819-5711

05-99

Please read all sections of this manual and retain for future reference.

HORIZONTAL SURFACE.

Installation, maintenance, and repairs should be performed by your Dean Factory

Authorized Service Agency.

WARNING!

SAFE AND SATISFACTORY OPERATION OF YOUR EQUIPMENT DEPENDS ON

ITS PROPER INSTALLATION. INSTALLATION MUST CONFORM TO LOCAL

CODES, OR IN THE ABSENCE OF LOCAL CODES, WITH THE U.S. NATIONAL

ELECTRIC CODE, NFPA 70-1984 (OR LATEST EDITIONS) OR APPROPRIATE

EUROPEAN COMMUNITY/NATIONAL CODES/STANDARDS.

WARNING!

ELECTRICAL GROUNDING INSTRUCTIONS

THIS FILTER IS EQUIPPED WITH A THREE-PRONG, GROUNDED PLUG FOR

YOUR PROTECTION AGAINST SHOCK HAZARD AND SHOULD BE PLUGGED

DIRECTLY INTO A PROPERLY GROUNDED, THREE-HOLE RECEPTACLE. DO

NOT CUT OFF, REMOVE OR OTHERWISE BYPASS THE GROUNDING PRONG

ON THIS PLUG.

IF IT IS NECESSARY TO USE AN EXTENSION CORD, IT MUST BE A THREECONDUCTOR, GROUNDED CORD OF 16 GAUGE OR GREATER.

CAUTION

DO NOT FILTER MORE THAN ONE FRY TANK AT A TIME.

HOT FLUID – DO NOT FILL BEYOND MAXIMUM FILL LINE

LOCATED ON THE OIL CONTAINER.

CAUTION

THIS FILTER UNIT IS NOT SUITABLE FOR OUTDOOR USE.

WHEN OPERATING THIS UNIT, IT MUST BE PLACED ON A

CAUTION

THIS FILTER UNIT IS NOT SUITABLE FOR INSTALLATION IN AN

AREA WHERE A WATER JET COULD BE USED, AND THAT THIS

APPLIANCE MUST NOT BE CLEANED BY A WATER JET.

IF THIS FILTER UNIT IS CLEANED WITH WATER, DISCONNECT

THE UNIT FROM POWER SOURCE BEFORE CLEANING AND

THOROUGHLY DRY THE FILTER UNIT BEFORE

RECONNECTING TO ELECTRICAL POWER SOURCE.

Micro Flo - 90 Series (CE) Portable Filtration Systems

Models MF90-U/110 & MF90-AU/110

OPERATION, SERVICE AND PARTS MANUAL

TABLE OF CONTENTS

PAGE

1. Parts Ordering And Service Information……………….…........... 2

2. Important Information……………………………………….......... 3

3. Installation………………………………………………….........…. 4

4. Daily Operation……………………...…………………….........….. 5

5. Cleaning and maintenance………………………………..........….. 8

6. Troubleshooting …………………....………………….........….….. 9

7. Parts Guide……...……………………………………….........……. 13

8. Wiring Diagrams for MF90-U/110 and MF90-AU/110 Filters...... 16

1. PARTS ORDERING AND SERVICE INFORMATION

1.1 ORDERING PARTS:

Customers may order parts directly from their

local Authorized Parts Distributor. For this

address and phone number, contact your

Maintenance & Repair Center or call the

factory. The factory address and phone number

are on the cover of this manual.

To speed up your order, the following

information is required:

Model Number

Type

Serial Number

With/Without Heater

Optional Equipment

Item Part Number

Quantity Needed

1.2 SERVICE INFORMATION:

Call the Dean Service Hotline number on the

cover of this manual or 1-318-865-1711 for the

location of your nearest Maintenance & Repair

Center. Always give the model and serial

numbers of your filter and fryer.

To assist you more efficiently, the following

information will be needed:

Model Number

Type

Serial Number

With/Without Heater

Optional Equipment

Nature of Problem

Any other information which may be helpful in

solving your service problem

2

2. IMPORTANT INFORMATION

2.1 GENERAL: The MF-90 portable oil

filters may be used with a variety of Dean

fryers, as well as other manufacturers’

equipment.

The used oil may be drained by gravity

(MF90-U/110) from the fryer into the

filter pan, or, on some models, MF90AU/110, removed from the fryer by use of

a suction/return hose. It is then pumped

back into the fryer vessel by means of the

suction/return hose and nozzle assembly.

Filtering is accomplished through two

sheets of replaceable filter paper assisted

by a micro pre-coat filter powder.

CAUTION

The on-site supervisor is responsible for

ensuring that operators are made aware of the

inherent dangers of operating a hot oil filter

system, particularly aspects of oil filtration,

draining, and cleaning of the filter.

2.2 OPERATING CONTROLS:

Two types of portable filters are available.

The most common is “return only”.

Primary filter control on the MF90-U/110

model is a two-position switch (on/off), or

on units with the optional heater, a threeposition switch (on/off/heater) is used.

The other type is “suction/return”.

Control on the MF90-AU/110 is by a

three-position switch (in/off/out). A pair

of swing-type check valves controls the

direction of oil flow. If any of these units

has an optional pan heater, the heater

switch is also mounted on the panel.

In many cases, a 60-minute timer may also

be activated to start the unit.

2.3 SAFETY FEATURES: On the

larger capacity filters, a 5-amp (230V) or a

7-amp (115V) circuit breaker switches the

power OFF if an overload occurs.

NOTE: If circuit breaker is triggered, depress

the reset button to activate the circuit

after the failure has been detected and

fixed.

2.4 RATING PLATE: Information on

this plate includes the model and serial

numbers as well as electrical requirements.

This data is essential when contacting the

factory about a unit or ordering special

parts.

2.5 PRE-INSTALLATION:

a. STANDARDS: Usage of this filter

unit must be in accordance with all

applicable state and local codes.

b. ELECTRICAL CONNECTIONS:

This unit requires connection to a

230V, 15 amp electrical supply. The

unit is equipped with a 3-wire, 16

AWG power cord. If an extension

cord must be used, it must be a three

conductor, grounded power cord of at

least 16 AWG.

2.6 UNPACKING THE FILTER:

Before unpacking, make certain the

container is upright. Unpack the filter

carefully and remove all accessories from

the carton, being careful not to discard or

misplace any parts, as they will be needed.

Loose parts include a starter kit and

accessories that may have been ordered.

These are packaged inside the filter tank.

The tank top is strapped to the shipping

frame.

After unpacking, immediately check the

equipment for visible signs of shipping

damage. If such damage has occurred,

contact the carrier and file the appropriate

freight claims. Do not contact the factory,

the responsibility of shipping damage is

between the carrier and the dealer or enduser.

3

3. INSTALLATION:

3.1 GENERAL: On initial installation and

before each use, remove all loose parts from

the filter, wash the filter pan and all

accessories in hot, soapy water and dry

thoroughly.

WARNING!

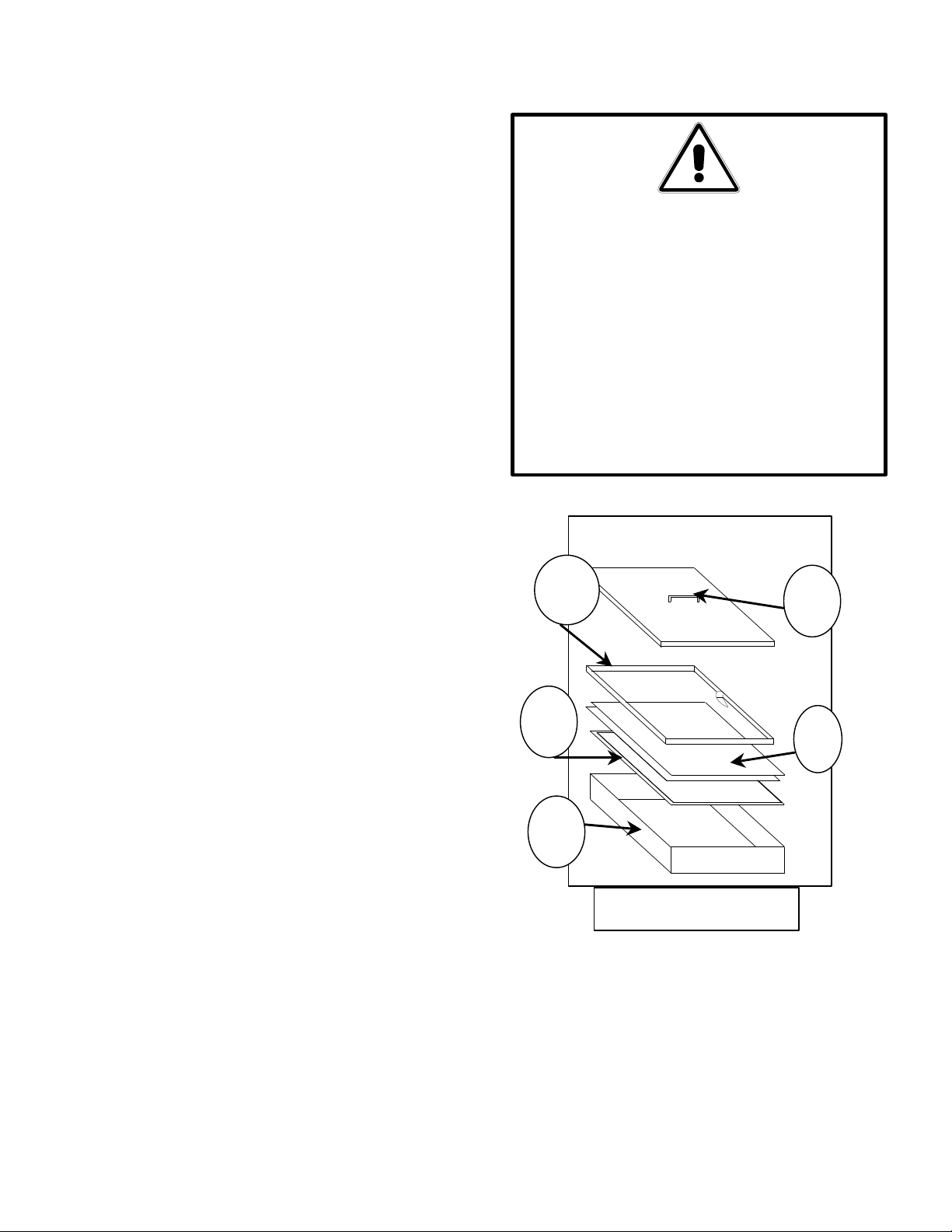

3.2 ASSEMBLING THE FILTER:

The MF90 Filter uses a filter support grid,

filter paper and a hold-down ring to secure

the filter paper in place.

Filter Paper Configuration:

a. Figure 3-1 shows the proper assembly of

these parts:

1. Filter Pan Cover

2. Hold-Down Ring

3. Filter Paper (2 sheets)

4. Screen/Support Grid

5. Filter Pan Assembly

b. First, place the support grid in the bottom

of filter pan.

c. Put two filter paper sheets on top of the

support grid. Be sure the paper covers the

whole filter pan bottom.

DO NOT RUN WATER THROUGH

THE FILTERING SYSTEM. THE

FILTER PUMP IS NOT DESIGNED

TO HANDLE WATER. THIS WILL

VOID THE WARRANTY FOR

THAT SYSTEM, DAMAGE THE

PUMP AND CAUSE ACCIDENTS

IF WATER MIXES WITH HOT

OIL.

2

1

d. Position the hold-down ring on top of the

filter papers and latch the hold-down ring

and filter papers securely against the filter

pan bottom, forming a tight seal.

e. Sprinkle 16 ounces of filter powder on the

top filter sheet. Ensure that the powder

covers the filter paper evenly.

f. Place the crumb catcher screen (if used)

in the filter pan. Allow the crumb catcher

to rest on the top edges of the hold-down

ring.

g. Place filter pan cover onto the filter pan

assembly.

h. Position filter underneath the fryer drain

pipe for gravity drain operations, or

nearby for suction operations.

4

3

5

Figure 3-1

4

5

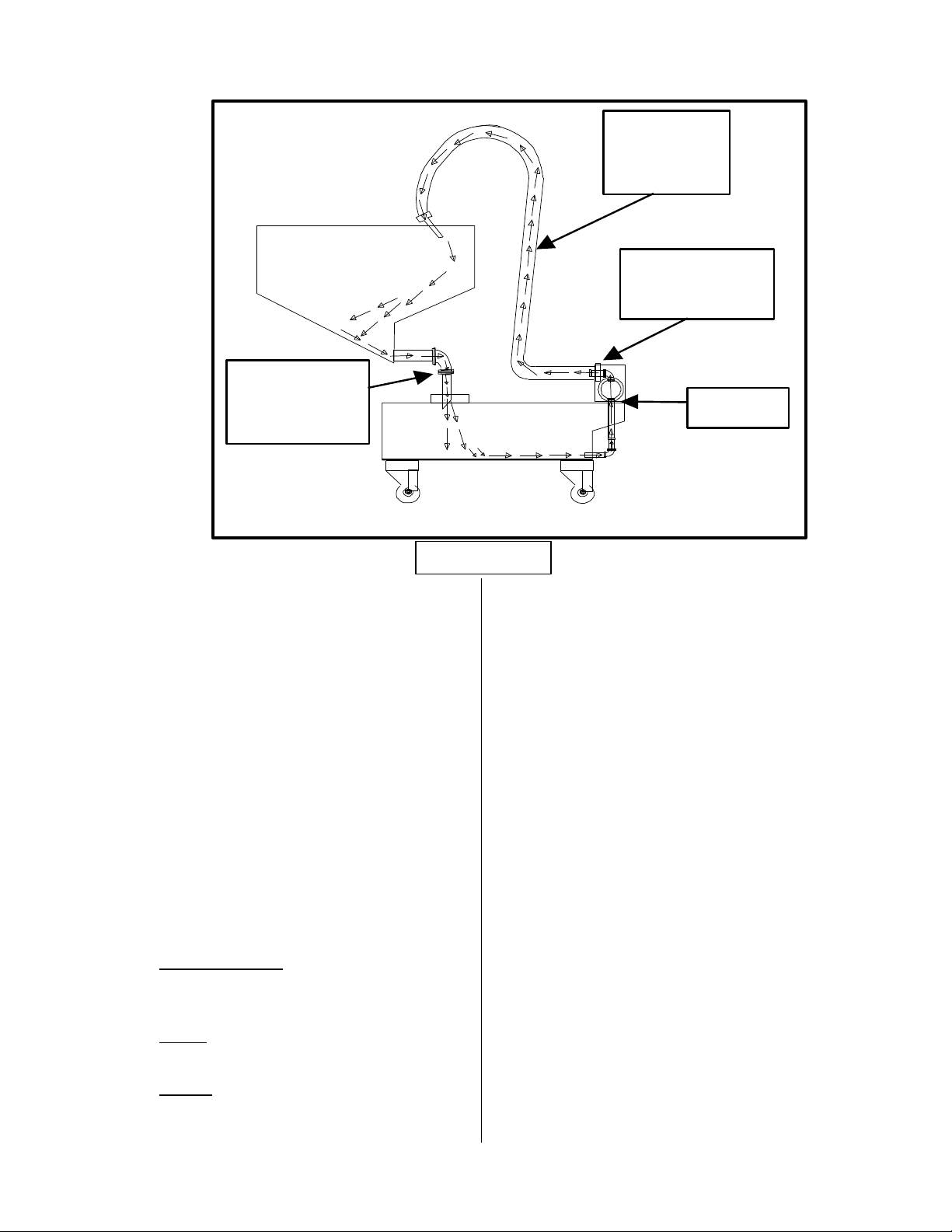

4. DAILY OPERATIONS:

Arrows show

flow.

Figure 4.1

direction of oil

Fryer Vessel

Drain Valve

with

Extension

Oil

Return

Hose

Quick

Disconnect

Pump

Filter

4.1 GENERAL:

The Dean Portable Filters are designed to

operate primarily as an independent filter

unit. Operations always start by ensuring

the unit is properly plugged in, then rolling

the filter to the fryer to be filtered. The

filter will work directly under the fryers’

drain valves. Figure 4-1 shows the general

layout of a generic MF90 Series Portable

Filter System with major components

identified.

4.2 FILTERING TOOLS:

These tools are not required, but are

recommended to make the filtering task

easier.

a. Measuring Cup: Used to measure

sixteen (16) ounces by volume of filter

powder.

b. Apron To protect user from possible

splashing hot oil.

4.3 FILTER PREPARATION:

a. Pull the filter unit close to the fryer.

Remove the filter pan cover.

b. Make certain filter power switches are

in “OFF” position.

c. Plug filter into electrical outlet (if unit

has a heater) and turn on heater switch

to allow pan to preheat.

d. Visually inspect the filter paper.

Scrape debris off the filter paper. If

the filter paper appears scuffed or

darkened, replace the filter paper per

instructions found in Section 4.4 of

this manual.

e. Sprinkle 16 ounces of filter powder on

the top filter sheet. Ensure the top

filter paper sheet is covered evenly.

f. Place filter-pan cover on top of the

filter pan and slide the portable filter

unit under the fryer drain.

c. Gloves: Used to expedite filtering and

prevent burns from splashing oil.

Loading...

Loading...