Page 1

®

System Processor with Advanced Feedback Suppression

220i

User Manual

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING FOR YOUR PROTECTION

READ THE FOLLOWING:

KEEP THESE INSTRUCTIONS

HEED ALL WARNINGS

The symbols shown above are internationally accepted symbols that warn of

potential hazards with electrical products. The lightning flash with arrowpoint in

an equilateral triangle means that there are dangerous voltages present within

the unit. The exclamation point in an equilateral triangle indicates that it is

necessary for the user to refer to the owner’s manual.

These symbols warn that there are no user serviceable parts inside the unit.

Do not open the unit. Do not attempt to service the unit yourself. Refer all

servicing to qualified personnel. Opening the chassis for any reason will void

the manufacturer’s warranty. Do not get the unit wet. If liquid is spilled on the

unit, shut it off immediately and take it to a dealer for service. Disconnect the

unit during storms to prevent damage.

SAFETY INSTRUCTIONS

NOTICE FOR CUSTOMERS IF YOUR UNIT IS EQUIPPED WITH A POWER CORD.

WARNING: THIS APPLIANCE SHALL BE CONNECTED TO A MAINS SOCKET OUTLET WITH A PROTECTIVE

EARTHING CONNECTION.

THE CORES IN THE MAINS LEAD ARE COLOURED IN ACCORDANCE WITH THE FOLLOWING CODE:

GREEN AND YELLOW - EARTH BLUE - NEUTRAL BROWN - LIVE

AS COLOURS OF THE CORES IN THE MAINS LEAD OF THIS APPLIANCE MAY NOT CORRESPOND WITH

THE COLOURED MARKINGS IDENTIFYING THE TERMINALS IN YOUR PLUG, PROCEED AS FOLLOWS:

FOLLOW ALL INSTRUCTIONS

the apparatus shall not be exposed to dripping or splashing liquid and no object filled

with liquid, such as vases, shall be placed on the apparatus.

CLEAN ONLY WITH A DRY CLOTH.

DO NOT BLOCK ANY OF THE VENTILATION OPENINGS. INSTALL IN ACCORDANCE WITH

THE MANUFACTURER’S INSTRUCTIONS.

DO NOT INSTALL NEAR ANY HEAT SOURCES SUCH AS RADIATORS, HEAT REGISTERS,

STOVES, OR OTHER APPARATUS (INCLUDING AMPLIFIERS) THAT PRODUCE HEAT.

ONLY USE ATTACHMENTS/ACCESSORIES SPECIFIED BY THE MANUFACTURER.

UNPLUG THIS APPARATUS DURING LIGHTNING STORMS OR WHEN UNUSED FOR LONG

PERIODS OF TIME.

Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized

plug has two blades with one wider than the other. A grounding type plug has two

blades and a third grounding prong. The wide blade or third prong are provided for your

safety. If the provided plug does not fit your outlet, consult an electrician for replacement of the obsolete outlet.

Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles, and the point where they exit from the apparatus.

Use only with the cart stand, tripod bracket, or table specified by the manufacture,

or sold with the apparatus. When a cart is used, use caution when moving the cart/

apparatus combination to avoid injury from tip-over.

• THE CORE WHICH IS COLOURED GREEN AND YELLOW MUST BE CONNECTED TO THE TERMINAL

IN THE PLUG MARKED WITH THE LETTER E, OR WITH THE EARTH SYMBOL, OR COLOURED GREEN,

OR GREEN AND YELLOW.

• THE CORE WHICH IS COLOURED BLUE MUST BE CONNECTED TO THE TERMINAL MARKED N OR

COLOURED BLACK.

• THE CORE WHICH IS COLOURED BROWN MUST BE CONNECTED TO THE TERMINAL MARKED L OR

COLOURED RED.

THIS EQUIPMENT MAY REQUIRE THE USE OF A DIFFERENT LINE CORD, ATTACHMENT PLUG, OR BOTH,

DEPENDING ON THE AVAILABLE POWER SOURCE AT INSTALLATION. IF THE ATTACHMENT PLUG NEEDS

TO BE CHANGED, REFER SERVICING TO QUALIFIED SERVICE PERSONNEL WHO SHOULD REFER TO THE

TABLE BELOW. THE GREEN/YELLOW WIRE SHALL BE CONNECTED DIRECTLY TO THE UNITS CHASSIS.

CONDUCTOR

L LIVE BROWN BLACK

N NEUTRAL BLUE WHITE

E EARTH GND GREEN/YEL GREEN

WARNING: IF THE GROUND IS DEFEATED, CERTAIN FAULT CONDITIONS IN THE UNIT OR IN THE

SYSTEM TO WHICH IT IS CONNECTED CAN RESULT IN FULL LINE VOLTAGE BETWEEN CHASSIS AND

EARTH GROUND. SEVERE INJURY OR DEATH CAN THEN RESULT IF THE CHASSIS AND EARTH GROUND

ARE TOUCHED SIMULTANEOUSLY.

WIRE COLOR

Normal Alt

Refer all servicing to to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, such as power-supply cord or plug is damaged,

liquid has been spilled or objects have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally, or has been dropped.

POWER ON/OFF SWITCH: The Power switch used in this piece of equipment DOES NOT

break the connection from the mains.

MAINS DISCONNECT: The plug shall remain readily operable. For rack-mount or installation where plug is not accessible, an all-pole mains switch with a contact separation

of at least 3 mm in each pole shall be incorporated into the electrical installation of the

rack or building.

If connected to 240V supply, a suitable CSA/UL certified power cord shall be used for

this supply.

This Equipment is intended for rack mount use only.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

ELECTROMAGNETIC COMPATIBILITY

This device complies with part 15 of the FCC Rules and the Product Specifications noted on the Declaration of Conformity.

Operation is subject to the following two conditions:

• this device may not cause harmful interference, and

• this device must accept any interference received, including

interference that may cause undesired operation.

Operation of this unit within significant electromagnetic fields

should be avoided.

• use only shielded interconnecting cables.

U.K. MAINS PLUG WARNING

A molded mains plug that has been cut off from the cord is

unsafe. Discard the mains plug at a suitable disposal facility.

NEVER UNDER ANY CIRCUMSTANCES SHOULD

YOU INSERT A DAMAGED OR CUT MAINS PLUG

INTO A 13 AMP POWER SOCKET.

Do not use the mains plug without the fuse cover in place.

Replacement fuse covers can be obtained from your local retailer.

Replacement fuses are 13 amps and MUST be ASTA approved to

BS1362.

If you want to dispose this product, do n ot mix it with general household waste. There is a

separate collection system for used electronic products in accordance with legislation that

requires proper treatment, recovery and recycling.

Private household in the 25 member states of the EU, in Switzerland and Norway may return their used

electronic products free of charge to designated collection facilities or to a retailer (if you purchase a similar

new one).

For Countries not mentioned above, please contact your local authorities for a correct method of disposal.

By doing so you will ensure that your disposed product undergoes the necessary treatment, recovery and

recycling and thus prevent potential negative effects on the environment and human health.

DECLARATION OF CONFORMITY

Manufacturer’s Name: dbx Professional Products

Manufacturer’s Address: 8760 S. Sandy Parkway

Sandy, Utah 84070, USA

declares that the product:

Product name: dbx DriveRack 220i

Note: Product name may be suffixed by the EU.

Product option: None

conforms to the following Product Specifications:

Safety: IEC 60065 -01+Amd 1

EMC: EN 55022:2006

EN 55024:1998

FCC Part 15

Supplementary Information:

The product herewith complies with the requirements of the:

Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC.

RoHS Directive 2002/95/EC

WEEE Directive 2002/96/EC

With regard to Directive 2005/32/EC and EC Regulation 1275/2008

of 17 December 2008, this product is designed, produced, and

classified as Professional Audio Equipment and thus is exempt from this

Directive.

Roger Johnsen

Director, Engineering

Signal Processing

8760 S. Sandy Parkway

Sandy, Utah 84070, USA

Date: May 31, 2012

European Contact: Your local dbx Sales and Service Office or

Harman Signal Processing

8760 South Sandy Parkway

Sandy, Utah

84070 USA

Ph: (801) 566-8800

Fax: (801) 568-7583

Page 4

Table Of Contents

220i

Introduction

0.1 - Defining the 220i System .........................................................2

0.2 - Service Contact Info ................................................................. 3

0.3 - Warranty ......................................................................................4

Getting Started

1.1 - Rear Panel ...................................................................................6

1.2 - Front Panel .................................................................................7

1.3 - Connections ...............................................................................8

1.4 - PC GUI Installation ..................................................................8

Software Operation

2.1 - DriveRack 220i Philosophy ...................................................10

2.2 - PC Connection ........................................................................10

2.3 - Views .........................................................................................10

2.4 - Configuration ...........................................................................11

2.5 - Editing .......................................................................................11

2.6 - Copy and Paste ........................................................................12

2.7 - Meters and Mutes ....................................................................12

2.8 - Loading .....................................................................................12

2.9 - Storing .......................................................................................13

2.10 - Importing and Exporting ....................................................13

2.11 - Utilities ....................................................................................14

2.12 - Online/Offline ......................................................................14

2.13 - Preferences .............................................................................14

Utilities

4.1 - Program List/Program Change ............................................ 34

4.2 - ZC Setup ...................................................................................34

4.3 - Front Panel Lockout ...............................................................36

Application Guide

5.1 - Mic Processing/Mixing ..........................................................38

5.2 - Stereo/Dual Mono System Processing ................................39

5.3 - Room Combining ....................................................................40

5.4 - BGM/Paging ............................................................................41

Appendix

A.1 - Factory Reset/Flash Update .................................................44

A.2 - Specifications ..........................................................................45

A.3 - Program List ...........................................................................46

A.4 - Block Diagram ........................................................................47

A.5 - Gain and Relay Jumpers ........................................................48

A.6 - Tips, Tricks and Troubleshooting ........................................49

A.7 - Zone Controller Wiring and Install .....................................50

Detailed Parameters

3.1 - Input Routing .........................................................................16

3.2 - Pre-Matrix EQ .........................................................................16

3.3 - Advanced Feedback Suppression .........................................18

3.4 - Automatic Gain Control (AGC) ...........................................20

3.5 - De-Esser ...................................................................................21

3.6 - Ducker .......................................................................................22

3.7 - Compressor ..............................................................................22

3.8 - Noise Gate ...............................................................................24

3.9 - Notch Filters ............................................................................25

3.10 - Matrix Mixer ..........................................................................26

3.11 - Post-Matrix PEQ ..................................................................26

3.12 - Bandpass Filter ......................................................................28

3.13 - Limiter .....................................................................................28

3.14 - Delay .......................................................................................30

3.15 - Output .....................................................................................30

3.16 - Subharmonic Synthesizer .....................................................31

Table of Contents

DriveRack® User Manual

Page 5

220i

Introduction

INTRO

CUSTOMER SERVICE INFO

Defining the

DriveRack

WARRANTY INFO

Page 6

Introduction

Congratulations on your purchase of the dbx® 220i! The dbx 220i processor was designed to provide

Installers with programmable system processing along with dbx’s Advanced Feedback Suppression™

(AFS™) algorithm for superior system control and performance. While the 220i offers all the tools

necessary for processing a system, from EQ and De-Essing to Limiting and Ducking, the thing that

sets this product apart from the competition is the inclusion of our patent-pending AFS™ algorithm

that offers feedback filters with Qs up to 1/80th of an octave. This ensures that the music, or speech

that comes in, goes out unblemished by the feedback detection and elimination process. In hundreds of

demonstrations of this patent-pending algorithms, people have tried to discern between the original and

processed signal, but to no avail.

Beyond the processing that the 220i is capable of, the 220i also offers control from the ZC series wall

panel controllers. These controllers provide convenient remote control capability of Program change,

Zone output volume and Muting. The zone controllers are easy to install using CAT5 cable and fit in

standard wall boxes.

This manual will be your guide to understanding the full functionality of the powerful 220i. By

combining the different components, the configuration possibilities are limitless. After you have become

familiar with the unit, we encourage you to experiment and find the most effective and efficient way to

run your system by utilizing the powerful processing of the 220i.

220i

0.1 - Defining the 220i System

The dbx 220i is the most effective way to manage all aspects of post mixer processing and signal routing.

The 220i essentially becomes the only device that you will need between the mixer and the power amps.

The following are just some of the features of the 220i.

220i features:

• Advanced Feedback Suppression (AFS™)

• Graphic and Parametric EQ

• Compressor

• Limiting

• Auto Gain Control (AGC)

• Noise Gate

• De-Esser

• Ducker

• Bandpass Filters

• 2x2 Matrix Mixer

• 1.3 Seconds of Delay

• RS-232 PC GUI control

• Mic/Line Inputs

• Wall Panel Control

• Security Lockout

2

DriveRack® User Manual

Page 7

220i

Introduction

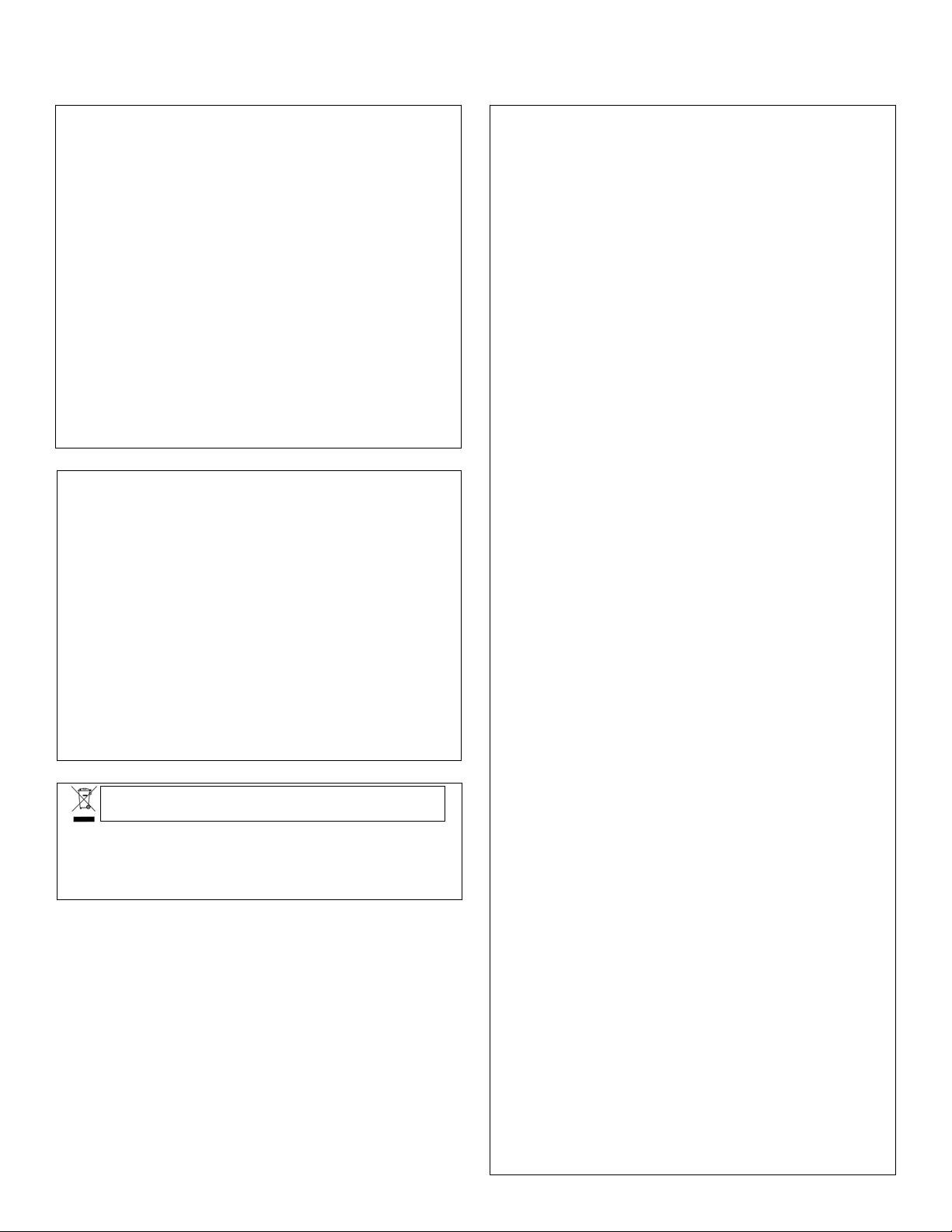

In addition to the amazing menu of processing available, the 220i also affords you the luxury of utilizing

dbx Zone-Controller series wall-mounted control panels that will allow you to remotely control various

parameters of the 220i. The ZC-1 offers remote programmable Volume control to any installation using

the DriveRack 220i. The ZC-2 provides programmable Volume and Mute control. Both the ZC-1 and

ZC-2 can be programmed to outputs of the DriveRack 220i. The ZC-3 allows Program Selection on

the 220i. The ZC-4 also offers Program Selection via Contact Closure inputs for Room Combining

applications. Up to six Zone Controllers can be used with a single DriveRack 220i, and can either be

wired in series or parallel. The ZC-BOB was created to accommodate “home-run” or parallel wiring to

the unit. With a maximum length of 1,000 ft., the Zone Controllers offer a simple way to create a simple

yet elegant solution to many installation applications.

SELECT

A

A

B

C

D

ZC-3

B

C

D

2 3 4 INOUT

1

+V

ZC-4

1 2 3

ZC-BOB

VOLUME

456

3

7

2

8

1

9

0

10

4 5 6

ZC-1

VOLUME

456

3

2

1

0

MUTE

ZC-2

7

8

9

10

0.2 - Service Contact Info

If you require technical support, contact dbx Customer Service. Be prepared to accurately describe the

problem. Know the serial number of your unit - this is printed on a sticker attached to the top panel. If

you have not already taken the time to fill out your warranty registration card and send it in, please do so

now.

Before you return a product to the factory for service, we recommend you refer to the manual. Make

sure you have correctly followed installation steps and operation procedures. If you are still unable to

solve a problem, contact our Customer Service Department at (801) 568-7660 for consultation. If you

need to return a product to the factory for service, you MUST contact Customer Service to obtain a

Return Authorization Number.

No returned products will be accepted at the factory without a Return Authorization Number.

Please refer to the Warranty information on the following page, which extends to the first end-user.

After expiration of the warranty, a reasonable charge will be made for parts, labor, and packing if you

choose to use the factory service facility. In all cases, you are responsible for transportation charges to

the factory. dbx will pay return shipping if the unit is still under warranty.

Use the original packing material if it is available. Mark the package with the name of the shipper and

with these words in red: DELICATE INSTRUMENT, FRAGILE! Insure the package properly. Ship

prepaid, not collect. Do not ship parcel post.

DriveRack® User Manual

3

Page 8

220i

0.3 - Warranty

1. The warranty registration card that accompanies this product must be mailed within 30 days after

purchase date to validate this warranty. You can also register online at www.dbxpro.com. Proofof-purchase is considered to be the responsibility of the consumer. A copy of the original purchase

receipt must be provided for any warranty service.

2. dbx warrants this product, when purchased new from an authorized U.S. dbx dealer and used solely

within the U.S., to be free from defects in materials and workmanship under normal use and service.

This warranty is valid to the original purchaser only and is non-transferable.

3. dbx liability under this warranty is limited to repairing or, at our discretion, replacing defective

materials that show evidence of defect, provided the product is returned to dbx WITH RETURN

AUTHORIZATION from the factory, where all parts and labor will be covered up to a period of two

years. A Return Authorization number must first be obtained from dbx. The company shall not be

liable for any consequential damage as a result of the product’s use in any circuit or assembly.

4. dbx reserves the right to make changes in design or make additions to or improvements upon this

product without incurring any obligation to install the same additions or improvements on products

previously manufactured.

5. The foregoing is in lieu of all other warranties, expressed or implied, and dbx neither assumes nor

authorizes any person to assume on its behalf any obligation or liability in connection with the sale of

this product. In no event shall dbx or its dealers be liable for special or consequential damages or from

any delay in the performance of this warranty due to causes beyond their control.

4

DriveRack® User Manual

Page 9

220i

Section 1

Getting Started

GETTING

STARTED

Page 10

Section 1

Getting Started

220i

1.1 - Rear Panel

IEC Power Cord Receptacle

The DriveRack 220i comes with a power supply that will accept voltages ranging from 100V-120V at

frequencies from 50Hz-60Hz. An IEC cord is included. EU version accepts 220V-240V at frequencies

from 50Hz-60Hz.

PC Connection

This DB-9 type null modem connection is used to send and receive information to and from the GUI

interface.

NOTE: Front and rear PC connections should not be used at the same time as these connections are

wired in parallel.

Zone Control Input (RJ-45 connector type)

This input connection is used to send information and power to the ZC wall controllers.

Inputs 1-2

The input section of the DriveRack 220i offers two electronically balanced XLR connectors mic/line

inputs with Phantom Power.

Outputs 1-2

The output section of the DriveRack 220i offers two electronically balanced XLR connectors. In

addition, the 220i offers Euroblock input connector options.

Signal/Clip LED

This LED is used to indicate microphone signal input or clip.

Mic Gain Control

This knob is used to set the input gain for the microphone input.

Line/Mic Selector

This switch is used to select either a line or microphone input.

6

DriveRack® User Manual

Page 11

220i

Getting Started

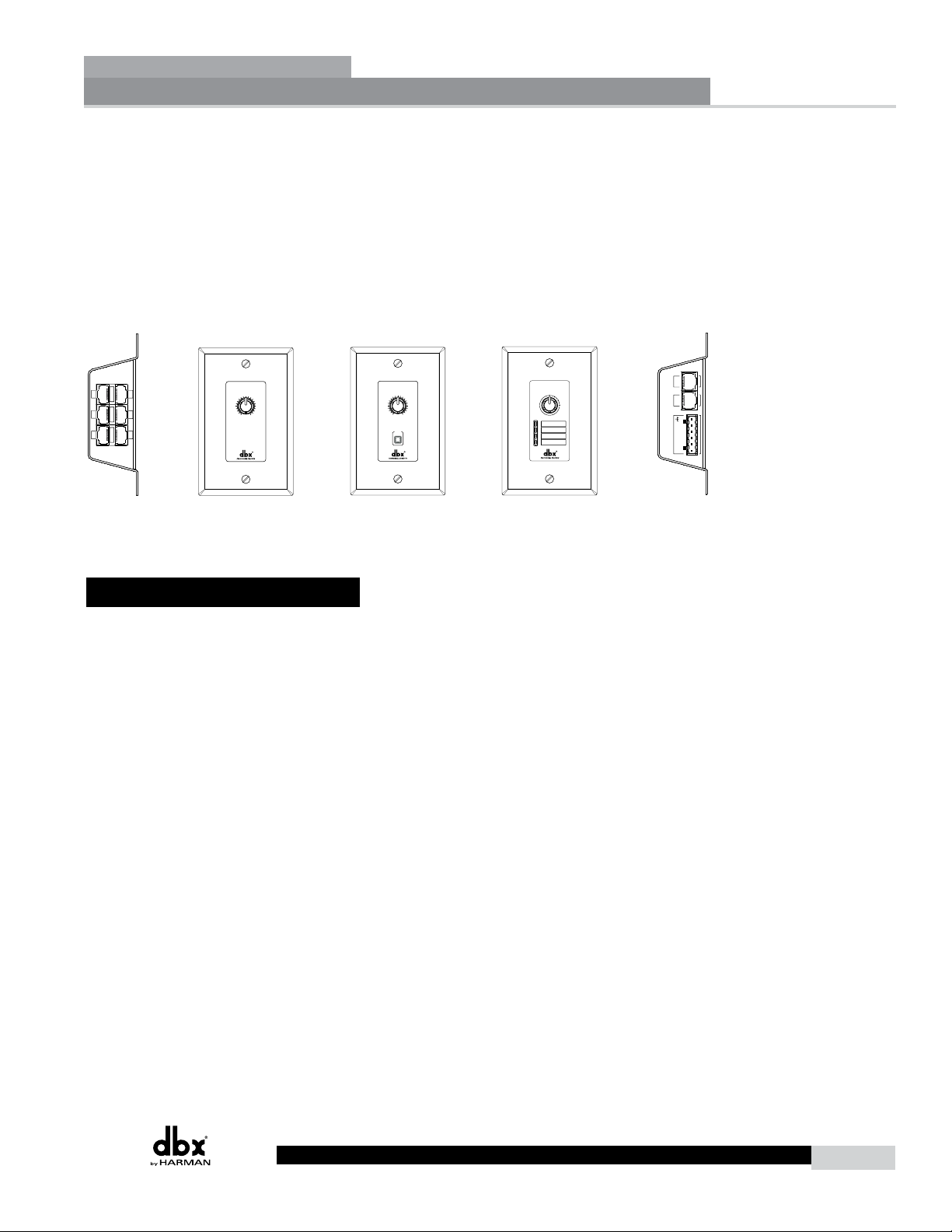

1.2 - Front Panel

PC Connection

This DB-9 type connection is used to send and receive information to and from the computer running

the DriveWare™ software.

NOTE: Front and rear PC connections should not be used at the same time as these connections are

wired in parallel.

Load Button

The load button is used to load the selected program.

Program Display

This program display is used to indicate the currently selected program of the 220i.

Section 1

Program Up and Down (Filter Clear Ch1 and Ch2)

These program up and down buttons are used to scroll through the program menu of the 220i. Pushing

and holding these buttons will clear the live filters on these channels if there are AFS modules in the

signal path.

PC LED

This LED (when lit), indicates that the 220i is connected to the PC. When it is flashing, the 220i is

sending/receiving information from the PC.

CLIP LED

This LED (when lit), .indicates that a signal is clipping, either in the analog input section, or in the DSP.

Input Meters

These meters monitor the signal level at the output of the A/D converter.

Threshold Meters

The threshold meters indicate that the threshold level has been crossed within the output dynamics

section. The tri-color LED will be green when the signal is below the threshold for a Compressor,

Limiter and AGC, and above the threshold for the Gate. Yellow indicates that the signal is in the overeasy region in the Compressor or Limiter and within the Window of the AGC. Red indicates that the

signal has passed over the threshold for the Compressor, Limiter and AGC, or below the threshold for

the Gate.

Output Meters

These meters monitor the signal level at the input of the D/A converter.

DriveRack® User Manual

7

Page 12

Section 1

Getting Started

220i

1.3 - Connections

• When setting up the DriveRack 220i, make connections as follows:

• Always make connections prior to applying power to the unit.

• Connect the output from the sending device (mixer) to either of the two XLR input connectors

shown below.

• Make output connections from any one of the 2 output XLR or Euroblock connectors shown

below to the input of the selected power amps.

• It is recommended that the power amps are turned off prior to cycling power to the DriveRack

220i. Always make sure that your power amps are the last item turned on and the first turned

off.

Once all of the connections have been made and the unit is powered up, you can navigate through the

entire signal path of the DriveRack 220i from the included DriveWare GUI. The display provides you

with a clear and concise overview of each aspect of the signal path from the input to the output section.

1.4 - PC GUI Installation

Minimum System Requirements

• 266MHz processor

• Windows 98 edition 2 or Windows NT 4.0

• 16 bit color

• 64 meg RAM

Installation

• Install DriveWare from the included CD ROM or download DriveWare from the dbx website

at www.dbxpro.com.

• After clicking on the “.exe” install file, follow the instructions in the installer. The application

will proceed to prompt you for the installation location.

• Once the software installation is complete, it is recommended that you restart your computer.

8

DriveRack® User Manual

Page 13

220i

Section 2

Software Operation

SOFTWARE

OPERATION

Page 14

Section 2

Software Operation

For your convenience, all editing functions of the DriveRack 220i are performed via the included

Driveware GUI. This section has been created to act as a tutorial for performing various editing aspects

of the unit.

220i

2.1 - DriveRack 220i Philosophy

The philosophy of the DriveRack 220i is built around the idea of a program.

Programs

A program consists of processing modules configured to form the desired signal path. The processing

modules and all their parameters are saved as part of the program. The quickest way to get up and

running with the DriveRack 220i is to select one of the programs that are already configured. If

modifications are needed then the program can be reconfigured to select the appropriate processing

modules and parameters can be edited to taste. All module parameters are part of the program and

as such they are saved off when the program is stored. These parameters are also saved as part of the

program file when the program is exported to a computer.

Utilities and Mutes

Utilities and Mutes are global functions and are independent of the program. Utilities and Mutes are not

saved as part of the program when it is stored but they can be saved as part of the device file. This can

be helpful as Utilities can be set up just once rather than having to set up the utilities for each program.

The same applies to Mutes; output Mutes can be used regardless of the program that is being recalled. If

the need arises to mute an output as part of a program and have that level remain with the program, the

output level can be set to –inf in the Matrix Mixer. This means that no matter whether the output mute

is engaged or not, that output will have no output level.

2.2 - PC Connection

Once the software has been loaded and the DriveRack unit is connected via the included Null Modem

cable, run the DriveWare Graphic User Interface (GUI) by double clicking on the application icon. You

will see the DriveWare window open with an icon of the DriveRack 220i unit. Double clicking on the

unit will open the unit to the program screen where you will be able to see the processing modules and

the configuration.

2.3 - Views

There are three different views within the DriveWare GUI; Venue view, Unit view, and Module view.

Venue view provides you with an overall system view of the DriveRack network including other

DriveRack units if you are using 480 series DriveRack units that can be networked together. Double

clicking on a unit icon in the Venue view takes you to the Unit view. Unit view (often called program

screen) provides you with a graphic representation of the configuration of the individual DriveRack unit,

including all the processing modules and their positions in the signal path. Unit view offers access to

meters and output muting, program selection and loading, processing configuration, program import and

export, program storing, as well as utility menu control. Double clicking on the processing module takes

you to the Module view. Module view (also called edit screen) provides access to the processing and

utility parameters. Editing of parameters is done in Module view.

10

DriveRack® User Manual

Page 15

220i

Software Operation

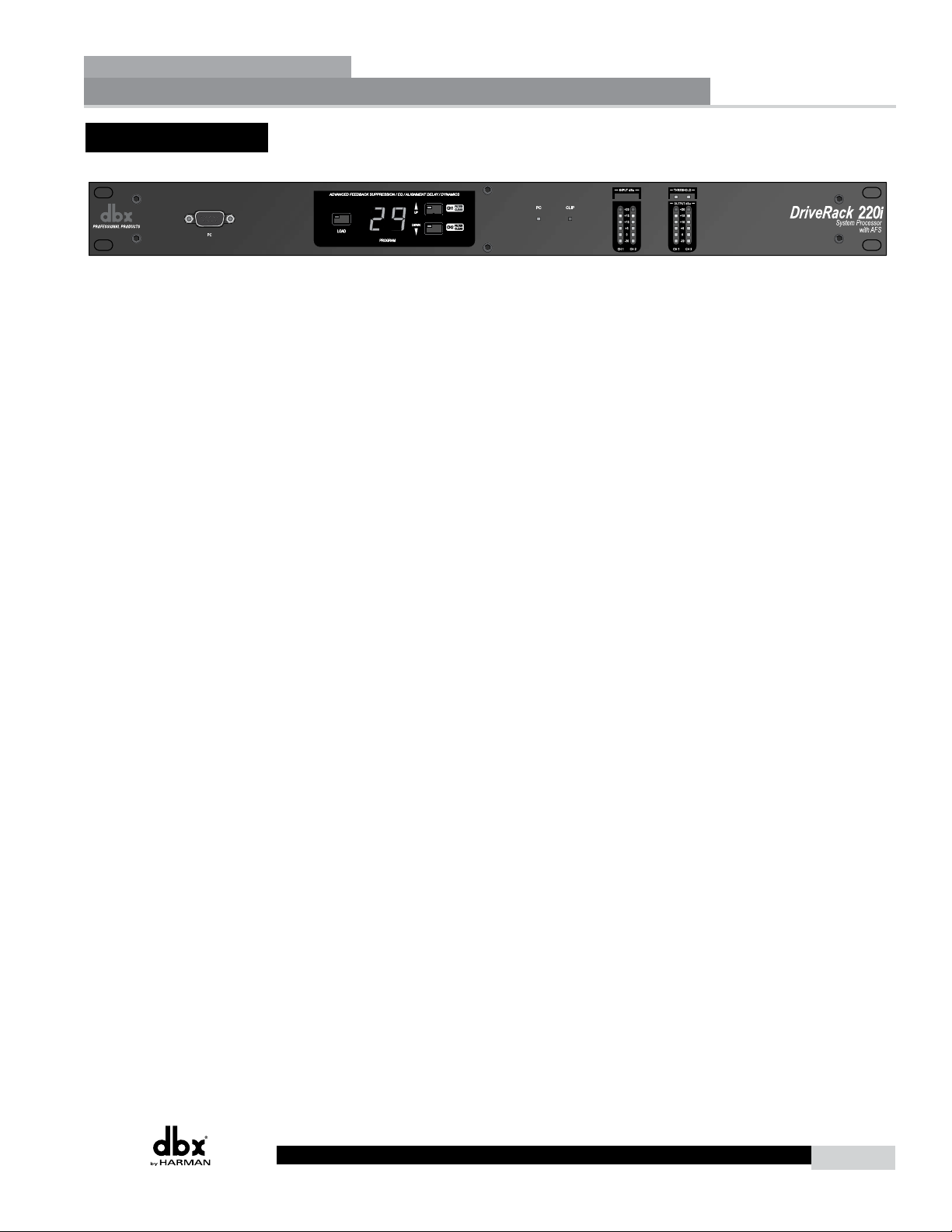

2.4 - Configuration

Configuration of the DriveRack units is done in Unit view. The DriveRack 220i configuration can

be changed by clicking on the CONFIG button. Once the CONFIG button has been clicked, the

modules can be changed by right clicking on the module to be changed. For example, if you want to

change the processing module in one of the inserts, you simply right-click on that module and you will

be able to select another processing block as well as unlink that module (if it is stereo linked). To link

modules in stereo, click on one of the module that you want to link. While holding the Ctrl button click

the other module that you want to link it to; both modules should now be highlighted. By right-clicking

on either module you can now select LINK. Once the desired configuration is created you must click the

CONFIG button once more to load the configuration.

Section 2

2.5 - Editing

To edit a processing module double click on that module. Adjust the module to taste; make sure that

the module is engaged, this is usually indicated by the module on button in the upper left corner of the

parameter section. Although process editing is done in real-time, the changes can either be discarded or

accepted by selecting the OK or CANCEL button.

DriveRack® User Manual

11

Page 16

Section 2

Software Operation

220i

2.6 - Copy and Paste

Parameters can be copied and pasted between channels in the DriveRack devices. From the program

screen right click on the module that you want to copy and select Copy. To paste, right click on a

like module and select Paste. Obviously you cannot copy parameters to and from unlike modules, for

example from a Compressor to a Parametric EQ.

2.7 - Meters and Mutes

The input and output level meters and mute buttons can be seen by clicking on the METER button in

the upper right corner of the program screen. Outputs can be muted by clicking on the mute buttons.

12

2.8 - Loading

The LOAD button is used for loading one of the programs in the program table. Right click on the

program name (directly below the large 220i in the upper left hand corner of the Unit view), to see a list

of programs. Select one of the programs by clicking on it. At this point this new program is not loaded;

to load this program click on the load button.

DriveRack® User Manual

Page 17

220i

Software Operation

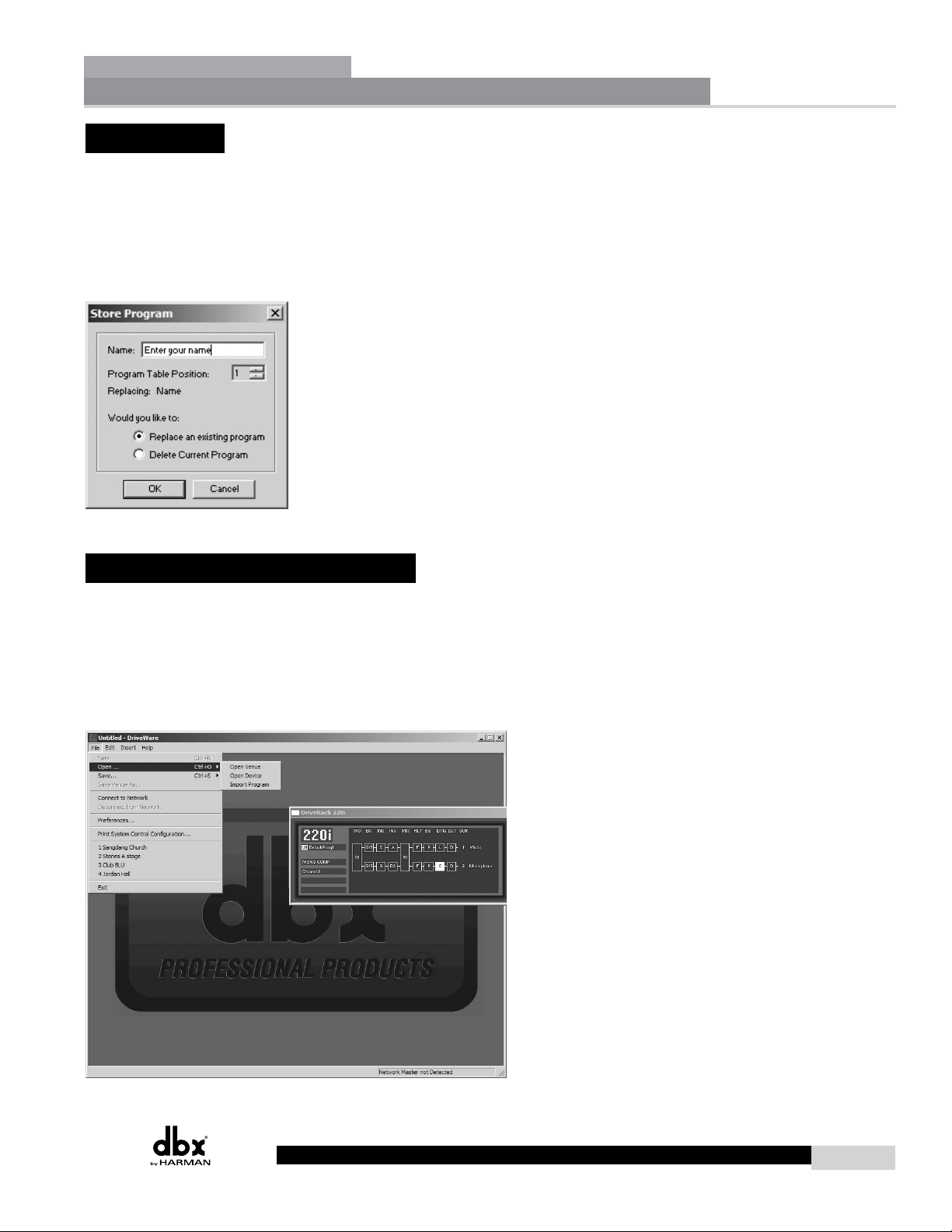

2.9 - Storing

Programs can be stored in the DriveRack unit or saved on the computer. To store a program in the

DriveRack unit the GUI software must be on-line with the unit. The DriveRack 220i allows both

program naming and along with that name you can also select where in the user program table you

would like to store the program. Clicking the STORE button enters the store routine where a name

for the program can be entered. Under the name lies the Program Table position selector for this new

program. To complete the storing process, make sure that the “Replace an Existing Program” button is

selected and click OK.

Section 2

2.10 - Importing and Exporting

To save a program to your computer click on File on the Menu Bar and select Save, then select Export

Program – you are exporting a program from the DriveRack unit to the computer. You will then be

taken to a folder where you can save this DriveWare Program (.dwp). You can also save the DriveRack

device file (.dwd). The difference between the device file and the program file is the device file saves all

the utility information in addition to the program information. To import a program from the computer

select File on the Menu Bar and click on Open, then select the file you would like to import to the

DriveRack unit.

DriveRack® User Manual

13

Page 18

Section 2

Software Operation

2.11 - Utilities

The DriveRack 220i utilities can be entered by clicking on Edit on the Menu Bar and selecting Utilities.

2.12 - Online/Offline

The DriveWare GUI provides a mechanism for creating programs while not physically connected to the

DriveRack unit. The GUI can be opened and a DriveRack unit can be inserted using the Insert menu

from the Menu Bar. The unit can be configured and edited just the way a real unit can. The program can

then be Exported to the computer and saved.

220i

2.13 - Preferences

Preferences can be found by clicking on File on the Menu Bar. Preferences allow you to change your

communication preferences. It is recommended that you not adjust these unless there is a specific

problem that is keeping you from connecting to the DriveWare GUI.

14

DriveRack® User Manual

Page 19

220i

Section 3

Detailed Parameters

DETAILED

PARAMETERS

Page 20

Section 3

Detailed Parameters

The 220i DriveRack offers complete editing flexibility, by offering in-depth control over every parameter

within each effect module. The following section will provide you with a module block representation

for each effect, as well as descriptions and explanations of all parameters within the 220i.

220i

3.1 - Input Routing

The signal routing begins at the INPUT ROUTING block of the 220i. These parameters are user

adjustable on all programs.

Input 1 Level -Inf to 20dB

Adjusts the input level from analog input one.

Input 2 Level -Inf to 20dB

Adjusts the input level from analog input one.

Level Left or Right Inf to 20dB

This parameter is used to adjust the level for the selected channel.

3.2 - Pre-Matrix EQ

The 220i’s Pre-matrix EQ section may be configured as a single or linkable 15-band or 28 band graphic

EQ or 9-Band PEQ.

16

DriveRack® User Manual

Page 21

220i

Detailed Parameters

GEQ

EQ On/Off

Turns the EQ on and off.

Flatten/Restore

This parameter either flattens the GEQ or restores the GEQ to the last setting before flattening. The

DriveRack unit allows you to leave the EQ edit window and return without losing the edited EQ

settings.

Frequency (F) 31.5Hz to 16.0kHz

This parameter allows you to select any one the 28 available frequencies.

Gain (G) -12 to +12 dB

This parameter allows you to adjust the level of any one of the 28 bands of the GEQ in .5 dB

increments.

Section 3

PEQ

EQ On/Off

Turns the PEQ on and off.

Flat Set/Undo

This parameter either flattens (set) or restores (undo) all bands to their original settings.

Band 1 Frequency 20 to 20kHz (Low Shelf)

Selects the frequency of the low pass shelf parametric EQ.

Slope 1 3-12dB/Octave

Sets the slope of the low shelf parametric EQ.

Level 1 -12 to 12 dB

Sets the overall gain of the shelf EQ.

Band (2-8) Frequency 20 to 20k

Selects the frequency of the selected band of the parametric EQ.

DriveRack® User Manual

17

Page 22

Section 3

Detailed Parameters

Q (2-8) 0.105 to 16.0

Q is adjustable from 0.105 to 16.000

Level (2-8) -12 to 12 dB

Sets the overall level of the selected parametric EQ frequency.

Band 9 Frequency 20 to 20k (High Shelf)

Selects the frequency of the high shelf parametric EQ.

Slope 9 3-12dB/Octave

Sets the slope of the high shelf parametric EQ.

Level 9 -12 to 12 dB

Sets the overall gain of the high shelf parametric

220i

3.3 - Advanced Feedback Suppression

The 220i offers the exclusive patent pending AFS (Advanced Feedback Suppression) feedback

elimination module. Feedback is caused when a microphonic signal such as a guitar pickup or

microphone is reproduced by an amplification and is repeatedly picked up in phase. The AFS uses

Precision Frequency Detection and state-of-the-art processing to determine the exact portions of a given

frequency of your feedback that need to be removed (instead of taking out large sections of your sound).

The AFS module of the 220i allows the user to optimize the elimination of feedback. In the past, graphic

equalizers were used to eliminate feedback from a system. This was an acceptable method for eliminating

feedback, but when this method was precision tested, the result clearly showed that a single 1/3 octave

EQ slider was removing approximately half of the signal power. With the AFS, the module removes the

feedback automatically and the proprietary, precision AFS filters remove only a fraction of the frequency

spectrum. The following diagram shows AFS as opposed to competing, competitive feedback eliminators and

conventional graphic EQs:

18

AFS On/Off

Turns the AFS module on and off. If AFS is Off, the filters are bypassed, and the algorithm is halted

(the filters are not updated). If AFS is On, the filters are active, and the they are updated according to

the current selected mode (Fixed or Live).

DriveRack® User Manual

Page 23

220i

Detailed Parameters

Clear Live/All

This parameter clears the filters. If Clear Live is selected, then (if invoked) the live filters are reset. If

Clear All is selected, then (if invoked) all of the filters are reset. When either Clear Live or Clear All is

selected, the third parameter row displays “Start w/ Data Wheel.”

Mode - Live or Fixed

When the mode is Fixed, the algorithm updates only the fixed filters. When the mode is Live, the

algorithm updates only the live filters. In FIXED mode, the filters are automatically assigned to a

frequency creating feedback fixed filters that are stored remain with the program and at that frequency

until cleared by the user. Fixed mode is used before the performance without any input signal. In LIVE

mode, the live filters automatically detect and remove feedback during the performance. When all of

the live filters have been used, they begin to round robin. Essentially this means that the first filter set

is replaced where a new feedback is detected and notched out. This mode is useful because feedback

frequencies may change as the microphone is moved, and/or as the characteristics of the venue change.

Note- Only the fixed filter settings will be stored with the program.

Type - Speech, Low Music, Medium Music and High Music

Type allows the AFS algorithm to be customized for the application. The Values correspond to different

Q and sensitivity settings. Values are; Speech (Q=7.25), Music Medium (Q=29), Music High (Q=128).

NOTE: Because lower frequencies have longer wavelengths, it is sometimes more difficult to find the

exact feedback frequency; as a result the AFS algorithm will sometimes use a slightly wider Q filter to

notch low frequency feedback.

Section 3

Total Number of Filters 1-12

This parameter selects the number of filters being used

Number Fixed - 0-12

This sets the number of fixed filters. This sets the number of Fixed AFS filters and ranges from 0-12.

This also sets the number of Live filters as the Total number of filters - number of Fixed Filters =

number of Live Filters.

Live Filter Lift (On/Off)

This parameter turns the Live Filter Lift on and off.

Lift After - 5 sec to 60 min

This parameter allows the user to setup the box so that the Live filters will automatically be removed

after a set time (as indicated by the “Lift After” parameter). It ranges from 5 seconds to 60 minutes. This

feature is useful if the microphone being used is moved or the characteristics of the venue change over

time. This feature removes unnecessary filters from the spectrum to increase sonic quality.

Virtual Highpass 0.00-410.1Hz

This parameter sets a highpass filter in the path of the AFS detector. There may be occasions where

the AFS algorithm is removing too much low end because it is being triggered by Synthesizer or Bass

notes that are not really feedback. This parameter provides a mechanism to make the AFS algorithm less

sensitive to low frequency thereby setting fewer filters in the bass region.

DriveRack® User Manual

19

Page 24

Section 3

Detailed Parameters

Sensitivity -20-+20dB

The AFS algorithm is very effective when the audio has a nominal level of 0 dBu, however if the audio

is too low in level the AFS algorithm may not catch feedback as quickly as possible. By increasing or

decreasing the sensitivity you can adjust for audio that is either too loud or too soft and help the AFS

function properly.

220i

3.4 - Automatic Gain Control (AGC)

The AGC is used to keep the average level of a signal at a constant level. This is done by selecting

a desired Target output level and Window. The AGC keeps the signal within the Window about the

selected Target by slowly adjusting the gain. The maximum gain that can be applied to the signal is

selected by the Gain parameter. When the input signal falls below the Low Threshold the AGC releases

the gain and returns to unity. This prevents the AGC from adding gain when there is no signal present

and raising the system noise floor. High level signals are reduced by a fast limiter to prevent distortion

by clipping. The AGC Threshold meters show what region of the AGC the input signal is in. The

T (yellow) indicates the signal is within the Window. A + (red) indicates the signal is going into the

Limiter. A – (green) indicates the AGC is adding Gain and is at or below the window. When the

Threshold meter is off the signal is below the Low Threshold.

20

AGC: On/Off

Turns the AGC module On and Off.

Target: -20 to 20 dB

The Target parameter defines where you would like the average level of the AGC output to be. If the

average level of the signal rises above the Target the gain will be reduced. For signals with an average

level below the Target the gain will be increased.

Gain: 1 to 20dB

This adjusts the maximum amount of gain that can be added by the AGC.

Window: 1 to 10dB

This adjusts the amount of variation in the output

DriveRack® User Manual

Page 25

220i

Low Threshold: -60 to -30dB

The Low Threshold sets a lower limit to the AGC. This prevents the AGC from adding gain to low

level signals or noise.

Attack: 0.20 to 5 Seconds

This adjusts how fast the AGC will increase gain.

Release: 30.0 to 1 dB/Second

This adjusts how fast the AGC will reduce gain.

Detailed Parameters

3.5 - De-Esser

The 220i offers a dedicated De-Esser module. This De-esser effect is ideal for removing unwanted vocal

sibilance.. These parameters are user adjustable on all programs and are as follows:

Section 3

De-Esser On/Off

Turns the De-Esser on or off.

Freq. 800 Hz to 8.00 kHz

This is the center frequency the De-Esser uses when in Band Pass mode or the corner frequency used

when in High Pass mode.

Amount 0 to 100%

This controls the amount of De-Essing. The amount control is very much like a combination threshold/

ratio control. A higher amount applies more De-Essing to the signal.

Type HP or BP

Selects the type of filter used by the De-Esser.

Width

Sets the Q of the Band Pass Filter.

DriveRack® User Manual

21

Page 26

Section 3

Detailed Parameters

220i

3.6 - Ducker

The Ducker provides a method for attenuating the signal in one channel when a signal is present in the

other channel.

Ducker On/Off

Turns the Ducker on or off.

Threshold -40 to +20dBu

Threshold is the level from signal path A at which the Ducker will begin attenuating the signal passing

through the Ducker (signal path B).

Amount -0 to 6dB

This parameter sets the amount sets the amount of attenuation.

Attack 0.1 m Sec to 200 m Sec

Attack is how quickly the signal is attenuated in the second channel when a signal is present in the first

channel.

Hold 0 to 500 m Sec

Hold time is the length of time after the signal in the first channel goes below the threshold that the

attenuation is applied to the signal in the second channel.

Release 360 dB / Sec to 5 dB / Sec

Release is how quickly the attenuated signal returns to its nominal level.

3.7 - Compressor

The 220i also offers a dedicated compression module. The Compressor is a full bandwidth Stereo

Compressor inserted prior to the Crossover. The Compressor is the perfect tool for tightening uneven

signal sources such as vocals and guitars. The parameters for the Compressor are as follows.

22

DriveRack® User Manual

Page 27

220i

Compressor On/Off

Turns the Compressor module on and off.

Detailed Parameters

Section 3

OverEasy (O) Off to 10

There are ten levels of OverEasy® that can be used for the limiters. The point when the compressor

starts to compress is the “knee.” When the compressor starts to reduce the level of a signal abruptly

as it passes over the threshold, this is called “hard knee” compression. OverEasy® (soft knee as it is

sometimes called) is when the volume of the sound is compressed gradually. OverEasy® compression

starts to compress before the level of the signal reaches the

threshold and reaches full compression after the level has gone above the threshold. OverEasy®

compression, by its very nature, sounds much smoother and more natural and will be used for most

applications. When it is gentle (natural sounding or light) compression that you are looking for, the

compressor offers VariKnee™. VariKnee™ gives you ten levels of OverEasy® compression to choose

from (1 being almost hard knee and 10 being the most OverEasy®). This lets you choose the exact knee

that is needed for the dynamic effect you are looking for.

Threshold (T) -40 to +20dBu

Threshold is the signal level at which the unit starts to compress the signal. If the level is set to -10 dBu,

than any signal larger than -10 dBu is compressed while any signal that has a level that is lower than

-10dBu is left at the same signal level. Light compression is where only the loudest parts of the signal go

over the threshold. Very heavy compression can be achieved by setting the threshold low enough that

almost the entire signal content is over the threshold. For most signals the most natural compression is

achieved when most of the signal content remains just below the threshold and only the peaks cross the

threshold.

Ratio (R) 1.0 to Inf:1

Ratio is the amount the unit reduces the signal level of the sound that is above the threshold. A 2:1 ratio

means that if the incoming signal is 2dB over the threshold the unit will compress the signal, and outputs

a signal that only goes 1dB over the threshold. For light compression choose a lower ratio, while a heavy

compression requires a higher ratio. A setting of Inf:1 makes the compressor act as a limiter.

DriveRack® User Manual

23

Page 28

Section 3

Detailed Parameters

Gain (G) -20 to +20 dB

This parameter is used to compensate for the gain lost during compression. By using heavy compression

on a signal and then boosting the signal with the output gain, the user can create a signal that sounds

much louder than it actually is.

Auto On/Off

When Auto Mode is on, the220i automatically sets the Attack, Hold, and Release times for the signal.

The auto mode constantly adjusts these parameters in real time for optimum performance from the unit.

You will find that for most applications, not only is using the auto mode faster and easier but by letting

the unit constantly tweak these parameters for you will result in a better end result (try and hit a snare

exactly the same for three minutes).

Attack 0.1 m Sec to 200 m Sec

Attack is how fast the compressor starts to compress the signal after it passes the threshold. Fast attack

is useful when dealing with lots of fast transients. The attack control is not active when in auto mode.

Hold 0 to 500 m Sec

Hold is the time the 220i remains in compression after the signal has dropped below the threshold. A

longer hold time is useful in smoothing out the sound when compressing several fast peaks that are fairly

close together in time. In general some hold time helps to make the compression sound more natural but

too much can over compress your signal making for an unwanted drop in level. The hold control is not

active while in auto mode.

220i

Release 360 dB / Sec to 5 dB / Sec

Release is how fast the 220i comes out of compression. The release is in dB per second. For example, if

release is set to 5 dB /sec, and the signal is at 10dB of gain reduction, the release time is 2 seconds. Too

fast a release time can result in an audible volume jump, while too slow a release time can result in the

compression of signal that is not above the threshold. This can cause volume drops in your signal that

may not be desired. The release control is not active while in auto mode.

3.8 - Noise Gate

24

DriveRack® User Manual

Page 29

220i

Gate On/Off

Turns the Gate on and off.

Threshold -50 to 20 dBu

The threshold is the volume level at which the gate opens. Anything above the threshold passes, while

signal that is lower than the threshold is attenuated. Beware, setting the threshold to high can cut off the

tail end of signals as they fade out (the sustain of a guitar note, a held piano chord, a reverb tail, etc.).

Ratio 1:1.0 to 1:15

This is where you decide how much downward expansion you want. This ratio works opposite from that

of the compressor or limiter. If a ratio of 1:4 is selected, a signal that is 1dB below the threshold will be

reduced in gain so that it becomes 4dB below the threshold.

Attack 0.1 to 200 m Sec

As the signal reaches the threshold area, the Attack control sets the speed at which the gate opens. Use

very fast attack times to catch the fronts of transient signals.

Hold 0 to 500 m Sec

The Hold control sets the amount of time the gate is held open after the signal passes below the

threshold point.

Detailed Parameters

Section 3

Release 360 to 5 dB

Release sets the speed at which the gate “closes” or attenuates when the end of the Hold time is reached.

Max ATT 0 to Inf. dB

This sets the maximum amount of attenuation for the gate.

3.9 - Notch Filters

The notch filter is the perfect tool for dropping out undesirable frequencies that may appear in the input

signal.

Notch On/Off

Turns the notch filters on and off.

Frequency (1 to 6) 20 to 20K

Selects the desired notch filter frequency of the selected notch filter.

DriveRack® User Manual

25

Page 30

Section 3

Detailed Parameters

Gain -36 to 6 dB

Sets the level of the selected notch filter. Set to +6dB to help find unwanted feedback, then set to -3dB

to -36dB to remove.

Q 16 to 128

Selects the Q of the selected notch filter.

220i

3.10 - Matrix Mixer

This adjusts the mix and output levels of the 220i. If there is a Ducker in the signal path this also

provides for bypassing the ducker module to one or both outputs.

26

Input A Level -Inf to 20dB

Adjusts the level from signal path A.

Input B Level -Inf to 20dB

Adjusts the level from signal path B.

Output 1 Level -Inf to 20dB

Adjusts the output level of Output 1.

Output 2 Level -Inf to 20dB

Adjusts the output level of Output 2.

3.11 - Post-Matrix PEQ

In addition to the pre-matrix EQ options within the signal path, the 220i also offers a 4-band parametric

EQ after the matrix section. The parameters for the post-matrix EQ are as follows and are user

adjustable.

DriveRack® User Manual

Page 31

220i

PEQ On/Off

Turns the PEQ band on and off.

The following figure shows the constant Q parametric filter.

Detailed Parameters

Section 3

Flatten/Restore

This parameter either flattens the PEQ or restores the PEQ to its original shape.

Type

This parameter selects the PEQ type. Types include: 1. Bell-All parametrics are bell-shaped 2. HShelf One shelf is High, while all others are bell 3. LShelf - One shelf is Low, while all others are bell and 4.

LHShelf - One shelf is High and one is Low, and the others are bell.

Band (1-4) Frequency 20Hz to 20kHz

Selects the frequency of the selected band of the parametric EQ.

Level (1-4) -12dB to 12dB

Sets the peak level of the selected parametric EQ.

Q (1-4) 0.20 to 16 dB

Sets the Q or Bandwidth of the selected Parametric EQ.

DriveRack® User Manual

27

Page 32

Section 3

Detailed Parameters

3.12 - Bandpass Filter

This Bandpass FIlter module allows the user to adjust the output bandwidth.

Highpass Out to 20kHz

Adjusts the lowest frequency that the output will achieve.

Lowpass Out to 20Hz

Adjusts the highest frequency that the output will achieve.

220i

3.13 - Limiter

The 220i offers a dedicated Limiter module. The Limiters are located on each output channel and have

been strategically placed for speaker and amplifier protection.

Limiter On/Off

Turns the Limiter module on and off.

28

DriveRack® User Manual

Page 33

220i

Detailed Parameters

OverEasy (O) Off to 10

There are ten levels of OverEasy® that can be used for the limiters. The point when the compressor

starts to compress is the “knee.” When the compressor starts to reduce the level of a signal abruptly

as it passes over the threshold this is called “hard knee” compression. OverEasy® (soft knee as it is

sometimes called) is when the volume of the sound is compressed gradually. OverEasy® compression

starts to compress before the level of the signal reaches the threshold and reaches full compression after

the level has gone above the threshold. This OverEasy® compression, by its very nature sounds much

smoother and more natural and will be used for most applications. When it is gentle (natural sounding

or light) compression that you are looking for, the compressor offers VariKnee™. VariKnee™ gives you

ten levels of OverEasy® compression to choose from (1 being almost hard knee and 10 being the most

OverEasy

for.

®

). This lets you choose the exact knee that is needed for the dynamic effect you are looking

Threshold (T) -40 to +20dBu

Threshold is the signal level at which the unit starts to compress the signal. If the level is set to -10 dBu,

any signal larger than -10 dBu is compressed while any signal that has a level that is lower than -10dBu is

left at the same signal level. Light compression is where only the loudest parts of the signal go over the

threshold. Very heavy compression can be achieved by setting

the threshold low enough that almost the entire signal content is over the threshold. For most signals,

the most natural compression is achieved when most of the signal content remains just below the

threshold and only the peaks cross the threshold.

Section 3

Auto On/Off/

When auto is turned on the 220i will continuously set the attack / hold / release controls itself.

Attack .01 to 200 m Sec (per band or global)

This is the speed at which the limiter starts to compress the signal once it has crossed the threshold. Set

the attack time longer for lower frequency bands, and shorter for higher frequency bands.

Hold 0 to 500 m Sec (per band or global)

Hold is the time the limiter stays in gain reduction after the signal level has dropped below threshold.

Hold is useful when you want the limiter to function for a period of time after it has been triggered. Be

careful not to set the hold time too long as it will not release in time.

Release 360 to 5 dB / Sec (per band or global)

Just like the release time on the compressor, the limiter’s release time controls how fast the limiter

releases from gain reduction after the signal drops below the threshold. Set the release times longer for

lower frequency bands and shorter for higher frequency bands.

PeakStop+™ On/Off and 1-6

This parameter turns the PeakStop+ limiting on and off. PeakStop+ involves a two-stage process of

dynamic limiting. The first stage of PeakStop+ is the Instantaneous Transient Clamp™ which clamps the

signal with a soft logarithmic clamp function. This logarithmic function ensures that the signal will not

exceed the level set by the PeakStop+™ OVERSHOOT control by more than the overshoot amount,

and that it will not introduce harsh artifacts. The second stage is a unique program limiter featuring

Intelligent Predictive Limiting™. Its function is to monitor the input signal and intelligently predict the

amount of gain reduction needed to keep the output signal below the ceiling set by the Instantaneous

Transient Clamp™. Note that since the PeakStop+™ limiter is a fail-safe limiter, it must come after the

OUTPUT GAIN control.

DriveRack® User Manual

29

Page 34

Section 3

Detailed Parameters

Overshoot 1-6

This parameter sets the amount of overshoot for the Instantaneous Transient Clamp™.

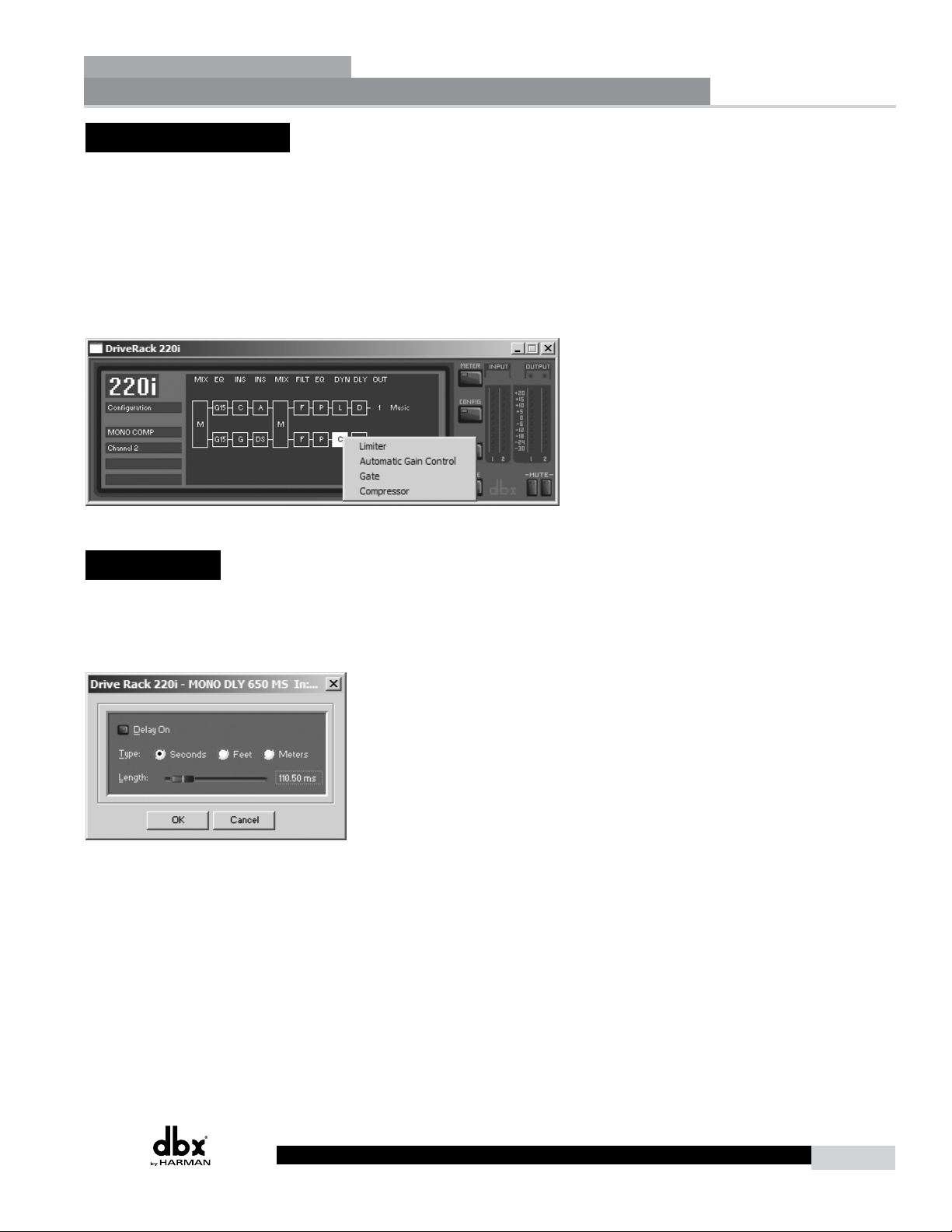

3.14 - Delay

The parameters for the delay are as follows and are user adjustable:

Delay On/Off

Turns the delay on and off.

220i

Length

Sets the amount of delay time.

Units - Seconds, Feet or Meters

Selects the unit of measurement for the delay.

3.15 - Output

The output section 220i DriveRack provide the user with the ability to control output levels of the

unit and adjust phase compensation of loudspeakers within the signal path. The output level control is

located in the signal path before the compressor/limiters; this means that the compressor/limiter directly

affects the output level. The parameters for the Phase Compensation effect are as follows and are user

adjustable.

30

Polarity/Phase On/Off

This parameter is used to turn the selected output phase and polarity on parameters on or off. When off,

the phase is 00 and polarity is positive.

DriveRack® User Manual

Page 35

220i

Polarity Positive or Negative

This section is used to select either the Positive or Negative polarity.

Phase 0 to 180

This parameter sets the amount of phase within the selected output path. The phase is referenced to the

uppermost frequency within the band.

Detailed Parameters

3.16 - Subharmonic Synthesizer

The Subharmonic Synthesizer module has been specifically optimized to enhance Bass audio material for

use in a variety of professional applications, including nightclub and dance DJ mixing, theatre and film

sound, music recording, live music performance and broadcasting.

The Subharmonic Synthesizer module’s two separate bands of subharmonic synthesis provide the best

combination of smoothness and control, and the independent low frequency boost circuit is designed to

get the most out of high-performance low frequency speaker systems.

Section 3

Sub-Harmonic Synth - On/Off

Turns the Subharmonic Synth module on and off.

Sub-Harmonics Synth - 0 to 100%

This parameter sets the overall level of the Subharmonic Synthesizer.

24-36Hz and 36-56Hz (Subharmonic Synthesis) Level - 0 to 100%

These controls individually let you customize the amount of the respective synthesized frequencies to

be added in, tuning the ultimate bass response of your system to taste. For example, if the sound is too

woofy or growly, try turning down the 36Hz-56Hz level. If your woofers are bottoming out (making a

ticking, popping sound), try turning down the 24Hz-36Hz level. You may find that a setting produces

fine results in one room, but produces too much boominess in another. If this occurs, adjust the controls

as needed, (e.g., increase one or the other of the band levels). Experimentation will pay off with smooth,

full, deeply extended bass. Remember, you are not selecting a frequency. You are controlling the overall

level of each band.

DriveRack® User Manual

31

Page 36

Page 37

220i

Section 4

Utilities

Program List

Zone Control

Front Panel Lockout

Page 38

Section 4

Utilities

e Utility section of the DriveRack 220i gives you the ability to perform several key

operational functions including: custom Program List creation, Zone Controller settings, and front panel lockout mode selection. Use this section of the manual to make

yourself familiar with all aspects of the Utility menu of the DriveRack system.

220i

4.1 - Program List/Program Change

The 220i allows you to set the unit to either scroll through programs in a sequential manner, or create

custom program lists from within the Utility menu. This list makes it convenient for restricting access to

a small list of programs. The procedure for setting up the program list is as follows.

Open the Utility menu by clicking on Edit on the Menu Bar, and selecting Utilities.

To create a custom Program list first, select the desired list size by using the up and down arrows to the

right of the Program List Size indicator.

34

Select the programs in the list by clicking on one of the programs then use the up and down arrows at

the bottom of the window to select which program from the user program table you want.

4.2 - ZC Setup

This feature gives you the ability to create a custom interface for the end user and program that interface

for either program selection or output level and mute.

The Zone Controllers offer additional utility to the DriveRack® 220i. They allow real-time adjustment of

output levels, mutes and program changes from simple wall panel interfaces. On the 220i, a maximum

number of six Zone Controllers may be used and they may be nested, in other words, one controller

may be used for a single zone and then another controller may be used for the entire venue or system.

With a maximum distance of up to 1000 ft. on CAT5 cable with RJ-45 connectors, the Zone Controllers

offer an easy to program and use remote control surface.

DriveRack® User Manual

Page 39

220i

Programming

To be programmed, each Zone Controller must have its identification set using the DIP switches on the

rear of the panel. The Zone Controllers are programmed from the Utility menu in the GUI. The Zone

Controllers are programmed from the Utility menu in the GUI. The ZC-3 and ZC-4 allow program

selection from either a wall panel, or contact closures. The diagrams on the following page show screen

shots from the GUI, a ZC-3 being programmed with the selected programs and the panel that is assigned

and a ZC-4 being programmed with up to four contact switches and the program that each of these

combinations of switches will load.

Utilities

Section 4

DriveRack® User Manual

35

Page 40

Section 4

Utilities

4.3 - Front Panel Lockout

The Utility menu of the 220i also offers the option of performing a front panel lockout. This is the

perfect security deterrent for unwanted editing. Open the utility menu by selecting Edit on the Menu Bar

and then clicking on Utilities. Select the tab labeled Misc. and select Front Panel Lockout Mode. You

can then choose between a complete Front Panel Lockout, Front Panel Lockout with Filter Clearing, or

Unlocked.

220i

36

DriveRack® User Manual

Page 41

220i

Section 5

Application Guide

APPLICATION

GUIDE

Page 42

Mic Processing / Mixing

Section 5

Application Guide

This Application guide section is provided to offer suggested installation applications of the DriveRack®

units that will allow you to optimize peak performance of the units. Note that the four included

applications represent the extensive flexibility of the DriveRack® units. These applications can be used

verbatim, or as sample reference guide templates for designing countless audio applications.

220i

5.1 - Mic Processing/Mixing

Hardware

1. Connect the outputs of the microphones to the inputs of the DriveRack.

2. Connect the outputs of the DriveRack to the mixer.

3. Making sure that all outputs are muted, apply power to the mixer and amplifiers.

4. Make connections between the Zone Controllers and the 220i if applicable.

Software

1. Select Program 3 - Mic Mix as a template.

2. Load the program by from the front panel or from the DriveWare GUI.

3. Adjust the individual parameters for the system by selecting the Processing Module from the

GUI interface.

4. Using the Utility Menu, select the ID for the Zone Controller if applicable.

Provides:

Mic Pre

EQ

Feedback Suppression

Mixing

Hignpass Filtering

Compression

Gating

38

DriveRack® User Manual

Page 43

220i

Stereo / Dual Mono System Processing

Application Guide

5.2 - Stereo/Dual Mono System Processing

Hardware

1. Connect the outputs of the mixer to the inputs of the DriveRack.

2. Connect the outputs of the DriveRack to the inputs of the amplifier.

3. Making sure that all outputs are muted, apply power to the mixer and amplifiers.

Software

1. Select Program 1 - Stereo & AFS.

2. Load the program by pressing the Program Up and Down buttons on the front panel, or from

the DriveWare GUI.

3. Adjust the individual parameters for the system by selecting the Processing Modules from the

DriveWare GUI.

Section 5

Provides:

EQ

Feedback Suppression

Bandpass Filtering

Limiting

Delay

Compression

DriveRack® User Manual

39

Page 44

Room Combining

Section 5

Application Guide

220i

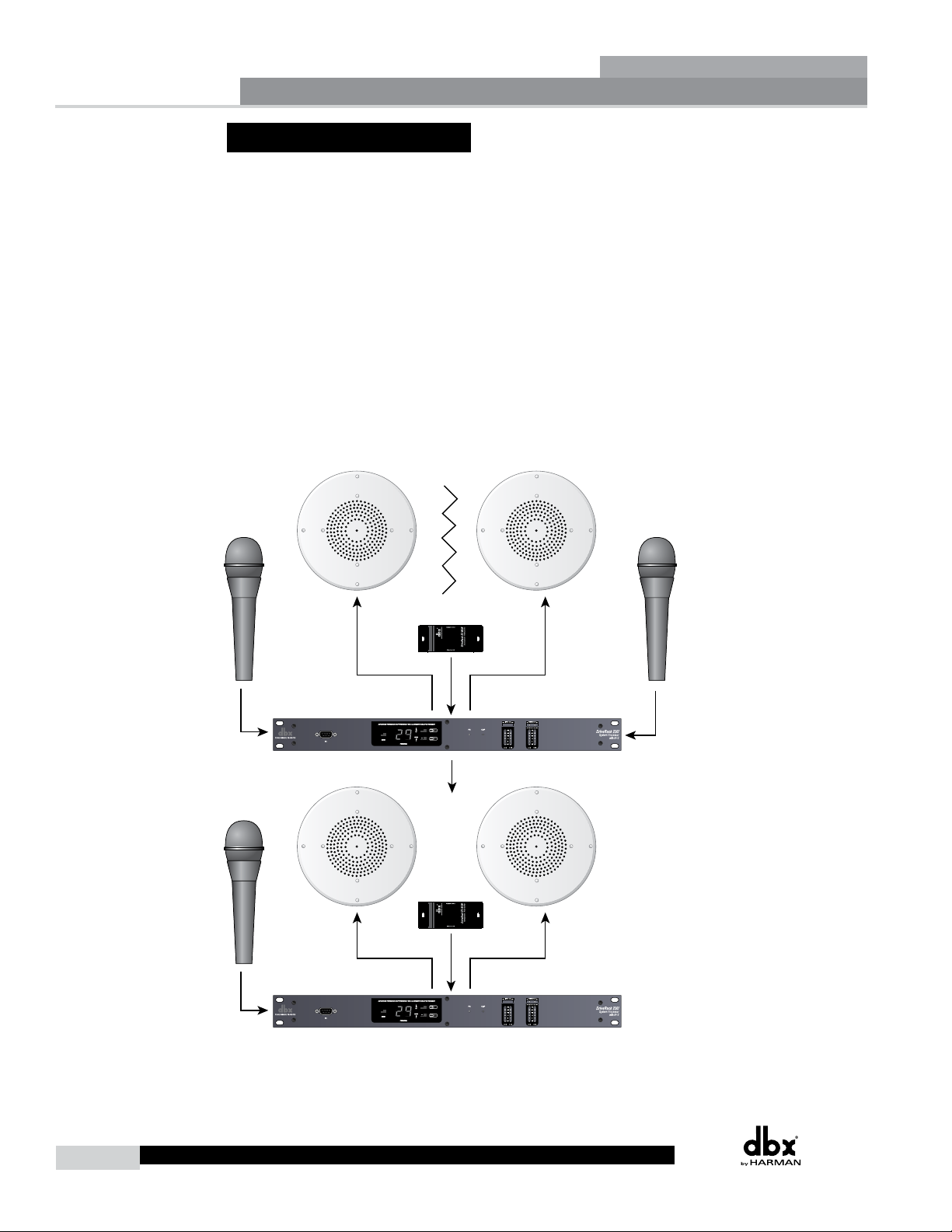

5.3 - Room Combining

Hardware

1. Connect the audio source to the inputs of the DriveRack.

2. Connect the outputs of the DriveRack to the amplifier.

3. Making sure that all outputs are muted, apply power to the mixer and amplifiers.

4. Make connections between the ZC-4 and the DriveRack. Make connections between the

contact closure and the ZC-4.

Software

1. Select Program 7 - Room Combine 1.

2. Load the program from the front panel or from the DriveWare GUI .

3. Using the Utility menu, select the ID for the ZC-4 and program the ZC-4 with switch position

0 being Program 7 and switch position 1 being Program 8.

Retractable Wall

Provides:

Mic Pre

EQ

Feedback Suppression

Auto Gain Control

Bandpass Filtering

Limiting

Delay

40

DriveRack® User Manual

Page 45

220i

Application Guide

5.4 - BGM/Paging

Hardware

1. Connect the audio source to CH 2 of the DriveRack 220i.

2. Connect the outputs of the DriveRack to the amplifier.

3. Making sure that all outputs are muted, apply power to the mixer and amplifiers.

4. Make connections between the Zone Controllers and the 220i if applicable.

Software

1. Select Program 5 - Restaurant.

2. Load the program from either the front panel of the DriveWare GUI.

3. Adjust the individual parameters for the system by selecting and editing the Processing Modules

from the DriveWare GUI.

4. Using the utility menu select the ID for the Zone Controller and program the boost and cut

amounts.

Section 5

DriveRack® User Manual

41

Page 46

Page 47

220i

Appendix

Appendix

Page 48

Appendix

220i

A.1 - Factory Reset/Flash Update

In the event that a reset is required, the DriveRack® 220i offers you the option of performing a “Soft”

or “Hard” reset. The Soft Reset resets all operating parameters except user programs. The Hard Reset

Procedure will reset all programmable information back to the factory defaults.

Factory (“Hard”) Reset

• Press and hold the PROGRAM UP button on power-up until the following message appears

in the 7-Seg Display: HD”

• Pressing the LOAD button will start a Factory Reset (All User Programs will become copies

of the Factory Programs, all Utility settings will be defaulted, and all Security settings will be

defaulted) Pressing any other button will abort the Factory Reset sequence and the unit will

reset normally.

Factory (“Soft”) Reset.

• Press and Hold the PROGRAM DOWN button on power-up until the following message

appears in the 7-Seg Display: ST “

• Pressing the LOAD button will start a System Reset (All Utility settings will be defaulted.)

Pressing any other button will abort the System Reset sequence and the unit will reset normally.

Flash Update

To flash update the firmware version of the DriveRack 220i the unit needs to be put into Flash Update

Receive mode. This is done by holding the LOAD button while connecting power to the unit. Once in

Flash Update Receive mode it is ready to receive the new firmware.

44

DriveRack® User Manual

Page 49

220i

A.2 - Specifications

Analog Inputs:

Number of Inputs: (2) Switchable line or mic inputs

Connectors: Female XLR line inputs and Euroblock

Type: Electronically balanced/RF filtered

Impedance: >50kΩ

Max input line level: +20dBu

CMRR: > 40dB, typically >55db @ 1kHz

Mic Pre gain: 30 to 60dB

MicEIN: <118dB,22Hz-22kHz,150Ω

Mic Phantom Power: 15V

Analog Outputs:

Number of Outputs: (2)

Connectors: Male XLR and Euroblock

Type: Electronically balanced, RF filtered

Impedance: 120Ωbalanced,60Ωunbalanced

Max Output Level: +20dBu

A/D Performance:

Type: dbx Type IV™ conversion system

Dynamic Range line: >113 dB A-weighted, >110 dB unweighted

Type IV dynamic range: >119 dB, A-weighted, 22kHz BW

>117 dB, unweighted, 22kHz BW

Sample Rate: 48kHz

Appendix

D/A Performance:

Dynamic Range: 112 dB A-weighted, 109dB unweighted

System Performance:

Dynamic Range: >110 dB A-weighted, >107dB unweighted,

THD+N: 0.003% typical at +4dBu, 1kHz, 0dB gain

Frequency Response: 20Hz – 20kHz, +/- 0.5dB

Interchannel Crosstalk: >110dB, 120dB typical

Crosstalk input to output: >80dB

Propagation Delay: 0.6 msec

Operating voltage: 100 VAC, 50/60Hz, 120 VAC, 60Hz, 230VAC 50/60Hz

Power Requirements:

Physical:

Weight:

Dimensions:

12 Watts

5.5 lbs.(2.5 kg) Shipping weight 7 lbs. (3.18 kg)

1.75” H x 5.75” D x 19” W

DriveRack® User Manual

45

Page 50

Appendix

220i

A.3 - Program List

Factory Program List

1. Stereo & AFS - Designed for Stereo systems.

2. Two Mics - Processing for two separate microphones.

3. Mic Mix - Processing and mixing two microphones together.

4. Page 2 Zones - With a microphone in ch. 1 and music in ch. 2 this will send both music and

page announcements to both outputs.

5. Restaurant - With a setup similar to #4, the music is sent to both outputs, but the paging only

occurs in output 2 (Lobby).

6. Auto Dealer - Similar to programs #4 and #5, but the music is only sent to the output #2

(Showroom), while paging is sent to both outputs.

7. Room Comb-1 - This program is the first of two that allows room combining. In this program

the rooms are separate.

8. Room Comb-2 - This program is the second of two programs that provide room combining.

This program combines the two rooms with inputs from either room being sent to both rooms.

9. Crossover - This program uses input 1 as the source for a bi-amp crossover at 100 Hz.

10. Mix & XOver - Like program #9, this program provides crossover functions, with the addition

of mixing together inputs 1 and 2.

Programs 11-20 are duplicates of these first 10.

46

DriveRack® User Manual

Page 51

220i

A.4 - Block Diagram

Mic Gain

30-60dB

Appendix

RF Filter

Input

Mic Signal/Clip

TYPE IV™

Clip

Down

Channel 2 threshold

Logic

Channel 1 Threshold

Up

Programmable

Bypass

Load

20

Seven-Segment Display

CLIP Detect

Processor

Micro

Front RS 232

Rear RS 232

A/D

DSP

D/A

Filter

RF

Power Down

Relay Bypass

Input meter

Output meter

DriveRack 220i Block Diagram

OutputsInputs

DriveRack® User Manual

47

Page 52

220i Main Board

Appendix

220i

A.5 - Gain and Relay Jumpers

CAUTION: These servicing instructions are for use by qualified service

personnel only. To reduce the risk of electric shock, do not perform any

servicing other than that contained in the operating instructions unless you

are qualified to do so. Refer all servicing to qualified service personnel.

Disconnect mains power before servicing.

The 220i DriveRack gives you the option of changing the input gain level settings. There are 2 hardware

configurable gain settings. They are: +4 dBu, -10 dBV. For these cases, use the following procedure to

change the gain level settings. Please be advised however, that once the gain level has been changed

from the factory settings, the output meters will no longer be calibrated correctly.

You can configure the unit to pass audio when it is not powered up. Please refer to the information

below. You can also configure the unit to not pass audio when the power is off (Relay Bypass); the

normal mode is Relay bypass.

To change the the gain level or relay jumpers move the jumpers to the desired settings.

1. First, make sure that the unit has been shut off and unplugged prior to opening the unit.

2. Ground yourself prior to opening the 220i chassis to prevent ESD damage.

3. Open the chassis by removing 4 screws on each side of the chassis, as well as the top center

allen screw located on the front panel.

4. Locate the jumper block shown in the illustration below:

+4dBu -10dBv

+4dBu -10dBv

Input/Ouput

Bypass Jumpers

Audio Bypassed

Audio Not Bypassed

Jumpers Levels

Jumper Locations:

• Input and Output jumpers are located at P4, P8, and P6 for Channel 1 and at P5, P9 and P13 for

Channel 2.

• Bypass Jumpers are located at P7 for Channel 1 and P12 for Channel 2.

NOTE: There are two jumper blocks per input and one jumper block per output

48

DriveRack® User Manual

Page 53

220i

A.6 - Tips, Tricks and Troubleshooting

Speaker Tunings

Various “Speaker Tunings” are available for some of the different DriveRack units; on the DriveRack

480 units speaker tunings can be downloaded from the website, whereas on the DriveRack 260 the

speaker tunings are found in the Wizard function. Since they are not all available for the same platforms

there is a mechanism to replicate these tunings from one DriveRack type to the next. Open the platform

that has the speaker tuning. Open a second DriveWare window and insert the DriveRack unit that

will be your final platform; for example if you want to create JBL AE tunings for the DriveRack 480