Davey STERIFLO SF1000S mkII, STERIFLO SF2500S mkII Installation And Operating Instructions Manual

Page 1

Installation and

Operating Instructions

for STERIFLO

®

Ultra Violet

Water Treatment System

Models SF1000S mkII & SF2500S mkII

Please pass these instructions onto the operator

of this equipment.

Distributed in Australia by Davey Water Products Pty Ltd.

DO NOT DISASSEMBLE ANY COMPONENTS UNTIL YOU HAVE FULLY READ

THESE INSTRUCTIONS!

Ultra violet radiation is harmful to skin & eyes.

DO NOT LOOK AT UV LAMP WHILE LAMP IS OPERATING.

WARNING: The UV Chamber operates under pressure. Under no

circumstances should the UV Chamber be disassembled unless the internal

pressure of the unit has been relieved. Failure to observe this warning will

expose persons to the possibility of personal injury and may result in

damage to the UV system or other property.

This unit is designed to treat water at ambient temperatures (5oC to 45oC).

Contact your dealer for details of UV systems suitable for hot water service.

Maximum operating pressure for stainless steel UV chambers is 850kPa (125

psi). If this pressure can be exceeded or if operating close to this pressure

fit a suitable pressure limiting valve in the supply to the UV chamber.

Plastic UV chambers have a maximum operating pressure of 400kPa (60 psi).

Page 2

2

Table of Contents

Introduction Page 3

Preparing your system Page 3

Choosing a Site Page 4

Housing your Steriflo®System Page 4

Power Connection Page 5

Electrical Power Surge Protection Page 5 - 6

Pipe Connections Page 6

Pre-treatment (drinking water) Page 6

Lamp Installation Page 7

Operation Page 7

Maintenance Page 8 - 9

Water Quality Page 9

Lamp Alarm System Page 9

Trouble Shooting Page 9 - 10

Part Numbers Page 10

Warning - UV Radiation Page 11

After Sales Service Page 11

Page 3

3

Congratulations on your purchase of a high quality, New Zealand made Steriflo

®

Ultra Violet water treatment system. All components have been designed and

manufactured to give trouble free, reliable operation.

Your new Steriflo

®

system incorporates a lamp failure system design feature that

enables you to be warned of a lamp failure by :-

1. A lamp failure LED

2. An audible alarm

3. Remote alarm contacts

In addition when the alarm “beeps” on and off, the lamp is due to be changed so

that effective treatment is maintained.

Preparing your system

On removing your Steriflo®system from its carton you should check all

components, especially the lamp, to ensure all are present and have not been

damaged in transportation. You should have:

1. Power supply control box with indicator light(s) and electrical flex.

2. UV lamp (or lamps).

3. Treatment chamber with mounting brackets.

Before installing your new Steriflo®, please read all instructions carefully as failures

caused by incorrect installation or operation are not covered by the guarantee. Your

Ultra Violet water treatment system is designed to handle clean water. The system

should not be used for any other purpose without specific referral to CCL. The use of

the system with flammable, corrosive and other materials of a hazardous nature is

specifically excluded.

Lamp

Quartz Sleeve (pre-installed in chamber)

Drain plug

Lamp Lead

1 metre

OUTLET

or

INLET

INLET

or

OUTLET

Treatment Chamber

Power Lead

1.5 metre

Alarm LED (Red)

Alarm reset

On LED (Amber)

The appliance is not intended

for use by young children or

infirm persons without

supervision. Young children

should be supervised to ensure

they do not play with the

appliance

NOTE: The quartz sleeve has been

factory fitted, and there is no need to

remove these endcaps on first

installation. Before removing endcaps,

please read the Maintenance section of

these instructions completely.

Page 4

4

Choosing a Site

Choose a site with a firm mounting position. Allow room for removal of the lamp

and sleeve during servicing. Leave a chamber lengths space at the lamp

connector end for lamp removal, with 100mm free at the other end for access to

the end nut. The ‘open’ end nut and the blank end nut are interchangeable, so

lamp removal can be from either end.

Housing your Steriflo®System

To protect your Steriflo®system from the weather, make sure the site is water

proof, frost free and has adequate ventilation. The unit should be either

horizontally mounted with the inlet and outlet facing upwards or vertically mounted

with the inlet at the bottom. Allow for drainage, to avoid damage to flooring etc.,

that over time may occur from leaking pipe joints or seals and allow room to

remove the lamp.

WARNING: Some insects, such as small ants, find electrical

devices attractive for various reasons. If your site or enclosure is

susceptible to insect infestation you should implement a suitable

pest control plan.

Page 5

Power Connection

Connect lead to power supply designated on control box label. Earth stainless

steel chambers using bolt provided on the chamber (see illustration below).

5

WARNING: When servicing or attending your Steriflo®, always

ensure power is switched off and lead unplugged. Electrical

connections should be serviced only by qualified persons. If the

electrical supply lead of this system is damaged, it must only be

replaced by a qualified service personnel.

The Steriflo®control box has a red LED alarm indicator light

mounted on its front panel, adjacent to the amber “power on” LED.

This light will be illuminated whenever the Steriflo®control box

senses no lamp current. There is also an audible alarm in the

event of lamp failure. The LED and/or alarm will only work when

unit is connected to the correct electrical supply.

Install the power supply enclosure above the treatment chamber

so that in the event of a leak, water cannot drip down the lamp

lead into the enclosure.

CAUTION: The supply cord is necessary for lamp changing. The

three pin supply plug must remain accessible after installation. If

installed to fixed wiring without the plug a two pole switch must be

fitted and its ON and OFF positions shall be marked.

Page 6

6

Electrical Power Surge Protection

An electrical power surge or spike can travel on the supply lines and cause serious

damage to your electrical equipment. The Steriflo

®

control box has a 2 Amp fuse

to protect the circuit. The fuse is not a lightning arrestor and may not protect the

Steriflo

®

if lightning or a very powerful surge hits the unit.

If the installation is subject to electrical power surges or lightning we strongly

recommend the use of suitable additional surge protection devices on ALL

electrical equipment.

We recommend the use of an RCD or earth leakage circuit breaker on the

power supply to your unit.

Pipe Connections

Never use PVC pipe directly connected to unit. PVC pipe and fittings can be used

after 90obends of a suitable material are connected to the inlet and outlet of the

chamber. Larger diameter pipe may be used to minimise resistance to flow, but

maximum flow rates should not be exceeded, as correct water treatment cannot be

assured at higher flows. If flows may exceed the design maximum, install a flow

restriction device.

Use unions at pipe connections to enable easy removal and servicing. Use

sufficient tape to ensure airtight seal and do not over tighten. To prevent strain on

unit threads always support heavy inlet and outlet pipes.

Do not use pipe thread sealing compounds (especially hemp) on

any part of this unit. ONLY use Teflon sealing tape.

NOTE: Prior to installation remove the transport plugs from the

inlet, outlet and lamp end cap.

DO NOT DISASSEMBLE ANY COMPONENTS UNTIL YOU HAVE

FULLY READ THESE INSTRUCTIONS!

Ultra violet radiation is harmful to skin & eyes.

DO NOT LOOK AT UV LAMP WHILE LAMP IS OPERATING.

Page 7

7

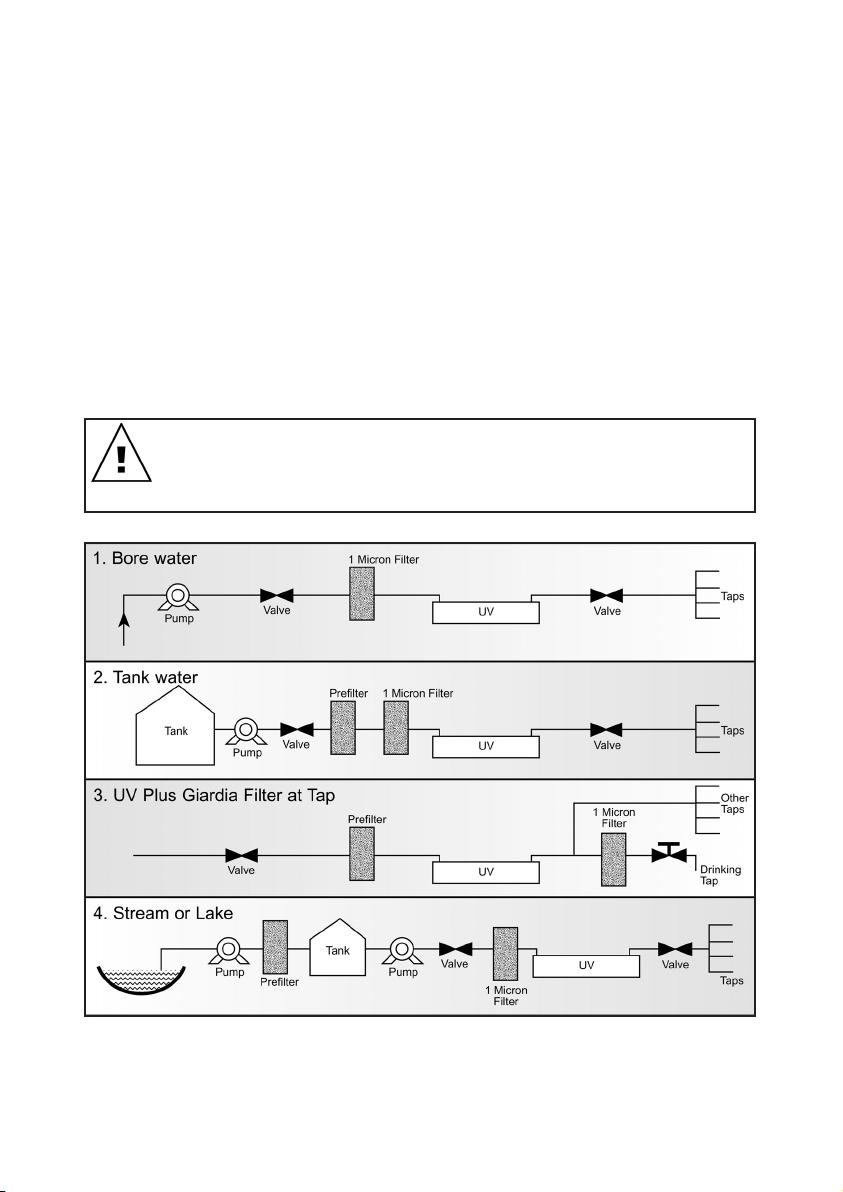

Pre-treatment (drinking water)

Prefiltration is usually required to ensure that particulate matter does not shield

micro-organisms from the UV light. Sand filtration or 20 micron cartridge filtration

is the usual minimum. In some cases, particularly with surface water, finer filtration

may be necessary, or if cysts like Giardia or Cryptosporidium may be present. In

this case 1 micron filtration is required, not necessarily for the whole supply,

filtration for the drinking tap only may be practical.

Lamp Installation

Once the Steriflo®Treatment Chamber has been connected to the pipework, the

installation should be checked for water leaks.

Attach the “DO NOT LOOK AT LAMP” sticker in an obvious position on the

treatment chamber, check that the chamber is clean to ensure the sticker will

adhere correctly.

The Quartz Sleeve is pre-installed in the treatment chamber, and provided the

endcaps have not been disturbed or undone, is able to withstand well in excess of

the maximum operating pressures.

If the chamber test is successful, it is now time to insert the lamp. DO NOT

INSERT THREE PIN POWER PLUG TO POWER OUTLET YET!

Expose the connection end of the lamp from its transport tube and protective

wrapping. The lamp connection socket is “keyed” to ensure correct alignment.

Carefully remove the tube fully from its transport tube, touching the lamp as little as

possible. Handle the lamp by the ends where possible. Wipe with clean cloth and

methylated spirits if fingerprints or dirt need removing.

Slide the lamp into the chamber, fit lamp connection socket and then fasten the

end washer into the endcap, with the screws provided.

Operation

Once all leak testing and lamp fitment has been completed, open valves and allow

water to fill the chamber. Connect three pin plug to outlet and switch on. The

“Mains On” Amber LED will be illuminated and the red alarm light will flash slowly.

Allow two minutes for the UV lamp to reach full intensity before starting water flow.

Full lamp performance for a new installation will be achieved in 24 hours. On a

new installation where no other form of sterilisation has been in constant usage,

we recommend flushing the pipework with a suitable sanitiser such as Steritank HP

at 100mg/L. This solution should be left in the piping for at least an hour and

preferably overnight.

The Steritank solution can be dosed to the water tank or if necessary added as a

shot dose to the bowl of any filter housing installed with the UV system and slowly

flushed into the piping.

If dosed to the water tank the Steritank HP will be left in the water as it is tasteless

and suitable for use in drinking water. If added as a shot dose it should be rinsed

out through a nearby tap.

Davey Water Products Limited can not accept responsibility for loss or

damage resulting from incorrect or unauthorised installations.

Page 8

8

Maintenance

Lamp changing (every year of operation) :

1. Shut valve(s) so that water cannot flow through steriliser.

2. Switch off steriliser by unplugging mains.

3. Undo end cover screws.

4. Unplug lamp connector.

5. Remove lamp.

Reverse procedure when replacing lamp, ensuring that lamp is centrally located in

the chamber. Handle only by the ends.

Quartz Sleeve Cleaning (three monthly) :

If dirt is allowed to build up on the quartz sleeve it will impair the UV output. The

quartz sleeve should be removed after one month and inspected for deposits.

Clean with methylated spirits (5% hydrochloric acid if heavily fouled) and carefully

dry. Handle the sleeve with tissue to keep it clean. The sleeve should be cleaned

every three months or as required.

Sleeve removal (use care-fragile) :

1. Remove lamp as described.

2. Remove drain port cap and empty water from chamber.

3. Undo nut at one end of the chamber and remove o-ring, repeat with nut at

other end and remove o-ring, withdraw sleeve carefully.

4. Inspect o-rings for damage, replace annually.

CAUTION: Handling lamp and quartz sleeve. Keep the quartz

components free of finger marks to avoid loss of output through

dirt or grease shadows - handle the lamps by their ends where

possible. Wipe lamp and sleeve with clean cloth or tissue if

needed. The o-rings should be replaced annually or if damaged –

do not grease the o-rings.

NOTE: When withdrawing sleeve take care not to let the end drop

into the chamber as it could break - a clean dowel inserted right

through the sleeve to support it is useful.

Page 9

9

Maintenance continued...

Reverse procedure when replacing sleeve.

When replacing quartz sleeve after cleaning, the sleeve should stick out about 1cm

at each end. Place o-ring over closed nut end and fit closed nut, fastening it hand

tight. Hold the other end of the sleeve in position during the tightening with the

other hand, then fit open end o-ring and cap.

A tiny amount of silicon spray or CRC in the end of aluminium endcap threads will

aid easy tightening. Do not use excessive force when tightening nuts. Do not reuse quartz sleeve or o-rings if damaged.

Water Quality

Where the water being pumped contains unusually high levels of dissolved solids

(hard water), iron, manganese or biological organisms, a deposit build up on the

quartz sleeve may occur over time. This will compromise the effectiveness of the

UV system and the sleeve should be cleaned as required to maintain it in a clean

condition. Discoloured water will reduce the effectiveness of the UV system and

filtration should be installed.

Lamp Alarm System

If the UV lamp is out due to a failure or bad connection the alarm buzzer will sound

and the red LED will light and the alarm contacts will changeover. These are able

to close a normally open solenoid valve. The alarm function can be checked by

switching the unit off, disconnecting the lamp and then switching the unit back on.

The lamp should be replaced after a year’s running time. The alarm will beep

intermittently after the internal clock has measured this time as a reminder to

change the lamp. Pressing the recessed ‘reset’ button witha ballpoint pen will

silence it for 24 hours at a time to allow time for a new lamp to be obtained. Once

a new lamp is installed press the reset button for 5 seconds to start another year’s

timing. Do this whenever a new lamp is installed. The alarm light flashes slowly

during normal operation to show the timer circuit is running.

Trouble Shooting

Principle. A ballast (choke) provides the correct voltage and current for the

lamp(s). The circuit board monitors the current to the lamp and if it is not present,

illuminates the red alarm light and sounds the alarm buzzer (a “squealing” noise).

An orange light indicates the power is on.

a) UV LAMP OUT, NO ORANGE “ON” LIGHT, NO ALARM

1. No mains voltage.

2. Internal fuse failed.

3. Check mains power connections inside power supply.

b) UV LAMP FLICKERING, ALARM ON

1. Failed lamp.

2. Incorrect lamp or ballast fitted.

Page 10

10

Trouble Shooting continued...

c) UV LAMP OUT, ALARM ON

1. Lamp failed.

2. Poor connection to lamp (check/clean connector/lamp pins).

3. Ballast failed (unlikely).

d) LAMP ON, ALARM ON

1. Faulty circuit board.

e) LAMP OUT, ALARM OFF

1. Loose connection or faulty circuit board, possibly short in lamp circuit.

Part Numbers

a) Lamp (SF2500S has 2 lamps and 2 sleeves)

SF1000/SF2500 GPH840N2/S

b) Sleeve

SF1000/SF2500 QS880

c) O-rings

All models S24x3N70 (2 per sleeve)

d) Lamp Connector

All models S114/2

WARNING: When servicing or attending your Steriflo

®

, always

ensure power is switched off and lead unplugged. Electrical

connections should be serviced only by qualified persons. If the

electrical supply lead of this system is damaged, it must only be

replaced by qualified personnel.

Care should also be taken when servicing or disassembling the

unit and associated pipework to avoid possible injury from

pressurised water. Unplug power, relieve pressure by opening a

tap on the discharge side of the unit and allow any water in the

unit to cool before attempting to dismantle.

Page 11

11

After Sales Service

For professional after sales service or repair, contact your dealer.

For assistance in locating your nearest dealer, contact Davey Water Products

Limited in New Zealand on 0800 654 333, by fax on 0800 654 334 or by email to

sales@daveywaterproducts.co.nz, or in Australia contact Davey Water Products

Pty Ltd, customer service centre on 1300 367 866 or visit davey.com.au.

WARNING

ULTRA-VIOLET RADIATION IS HARMFUL TO SKIN AND EYES.

EYES

Switch off UV system before removing covers. If working within line of sight

of UV light, ensure that a suitable full face plastic facemask is worn.

SKIN

It is recommended that exposed skin is covered to prevent sunburn,

possibly severe, if working within line of sight of operating UV system.

Note: exposure to UV light results in symptoms that develop slowly, the

exposure cannot be felt at the time.

SYMPTOMS

EYES: Mild exposure - irritation developing several hours later.

Severe exposure - sore, red eyes, sensitive to light, painful to keep

eyes open.

SKIN: Mild exposure - slight reddening, tenderness, mild sunburn

symptoms.

Severe exposure - skin sloughing (peeling), weeping area, sever

sunburn symptoms.

FIRST AID

EYES: In mild cases, if in doubt seek medical attention.

Severe cases cover eyes with gauze or clean cloth, seek medical

attention.

SKIN: In mild cases removal from exposure may be sufficient. If in doubt

seek medical attention.

In severe cases, cover affected area loosely with a clean bandage or

cloth. Seek medical attention. Do not apply fat, butter or oil to skin.

The above notes are intended to highlight the dangers of exposure to UV

radiation. With sensible precautions any hazard can be eliminated.

Germicidal UV cannot pass through clothing or other opaque materials or

clear materials such as plastics or even window glass.

During service DO NOT use lubricants or sealants of any type on

the o-rings. Keep the inside of the quartz sleeve dry and clean.

WARNING - Do not use hydrocarbon based or hydrocarbon

propelled sprays around the electrical components of this unit.

Page 12

PRODUCT GUARANTEE (NEW ZEALAND)

Steriflo

®

systems, except for lamps, are guaranteed for a period of one year from the date of original

purchase to be free of material or manufacturing defects. Should any part fail as a result of such defects

within this period, the pressure system will be repaired free of charge. Additionally, a one year pro-rata,

parts only guarantee commencing from the date of original purchase shall apply only to the lamp.

TERMS AND CONDITIONS

1. This guarantee applies to all states and territories of Australia and New Zealand only and is subject to

the provisions of the Trade Practices Act (Aust.), the Goods and Consumer Protection Legislation of

the various Australian states and the Consumers Guarantee Act 1993 (NZ) as applicable.

2. The guarantee period commences on the date of original purchase of the equipment. Evidence of

this date of original purchase must be provided when claiming repairs under guarantee. It is

recommended you retain all receipts in a safe place.

3. This guarantee covers parts and workshop labour only. Goods should be forwarded, with proof of

date of original purchase, to an Authorised Davey Service Centre in Australia or Davey Water Products

Limited in New Zealand, freight paid.

4. The pro-rata lamp guarantee is calculated on a monthly basis, up to 12 months.

5. This guarantee is subject to due compliance by the original purchaser with all directions and

conditions set out in the Installation and Operating Instructions. Failure to comply with these

instructions, damage or breakdown caused by fair wear and tear, negligence, misuse, incorrect

installation, chemical or additives in the water, inadequate protection against freezing, rain or other

adverse weather conditions, corrosive or abrasive water, lightning or high voltage spikes or through

unauthorised persons attempting repairs are not covered under guarantee. The product must only be

connected to the voltage shown on the nameplate.

6. Without limiting the original purchaser’s entitlements under the Trade Practices Act (Aust.), the Goods

& Consumer Protection Legislation of the various Australian states, or the Consumers Guarantee Act

1993 (NZ), Davey shall not be liable for any loss of profits or any consequential, indirect or special

loss, damage or injury of any kind whatsoever arising directly or indirectly from the product or any

defect.

7. Where the Trade Practices Act (Aust.), the Goods and Consumer Protection Legislation of the various

Australian states and the Consumers Guarantee Act 1993 (NZ) does not apply, Davey shall not be

liable for any loss of profits or any consequential, indirect or special loss, damage or injury of any kind

whatsoever suffered by the purchaser arising directly or indirectly from the product or any defect and

the purchaser shall indemnify Davey against any claim by any other person whatsoever in respect of

any such loss, damage or injury.

8. Nothing in this guarantee is intended to have the effect of contracting out of the provisions of the

Trade Practices Act (Aust.), the Goods and Consumer Protection Legislation of the various Australian

states and Consumers Guarantee Act 1993 (NZ) except to the extent permitted by the various Acts

and this guarantee is to be modified to the extent necessary to give effect to that intention.

9. Davey may be collecting personal information from you in order to provide you with a service. Davey

Water Products Pty Ltd promises only to use this information in accordance with the Provisions of the

Privacy Act 1988 (Cth) and the Privacy Policy of Davey Water Products Pty Ltd which is available at

davey.com.au.

® Davey and Steriflo are registered trademarks of Davey Water Products Pty Ltd.

© Davey Water Products Pty Ltd 2005.

P/N 400585-3 CC ver 0508 supersedes P/N 400585-2 CC ver 0807

Australia

Davey Water Products Pty Ltd

Member of the GUD Group

ABN 18 066 327 517

Head Office and Manufacturing Customer Service Centre Interstate Offices

6 Lakeview Drive, Ph: 1300 367 866 Sydney • Brisbane • Adelaide

Scoresby, Australia 3179 Fax: 1300 369 119 Perth • Townsville

Ph: +61 3 9730 9222 E-mail: sales@davey.com.au

Fax: +61 3 9753 4100 International Offices

Website: davey.com.au Germany • New Zealand • USA

New Zealand

Davey Water Products Limited

7 Rockridge Avenue, PO Box 14-641

Penrose, Auckland 1061, New Zealand Panmure, Auckland 1741

Ph: +64 9 570 9135

Fax: +64 9 527 7654

E-mail: sales@dwp.co.nz

Website: microlene.co.nz

Loading...

Loading...