Davey SJ60-08PC Automatic Water Pressure System User Manual

Silver Series Jet Pumps

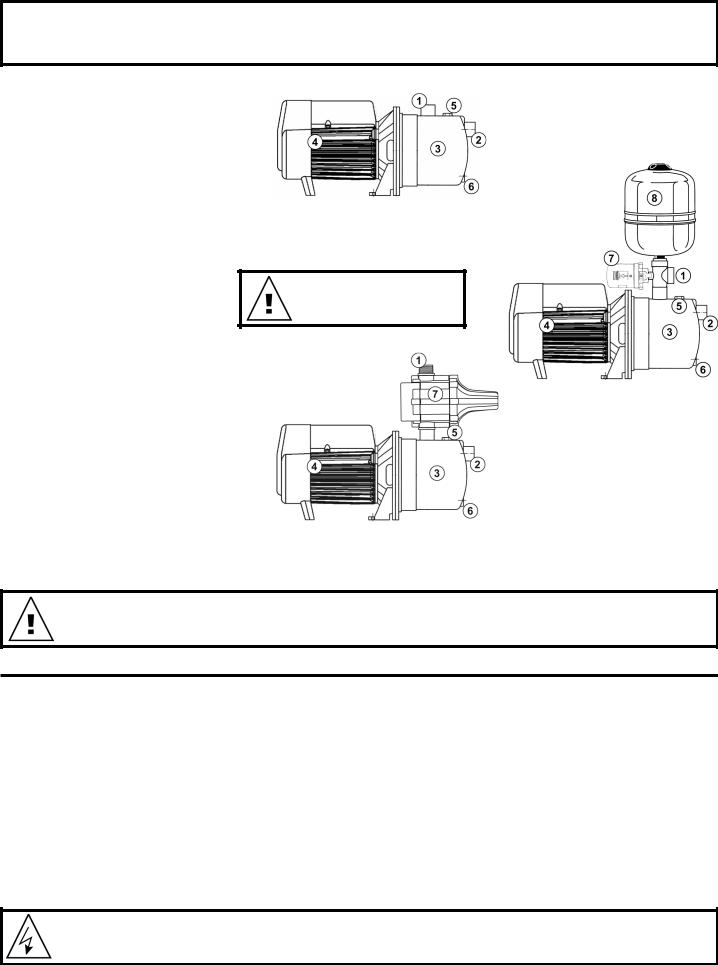

Manual Pressure Pump

Model SJ35-04

Automatic Water Pressure System

Models SJ35-04P2C/LOP, SJ35-04PC

& SJ60-08PC

Installation & Operating

Instructions

Please pass these instructions on to the operator of this equipment.

Congratulations on your purchase of a Silver Series quality pressure pump or water pressure system. All components have been designed and manufactured to give trouble free, reliable operation.

Before installing your new pump, please read all instructions carefully as failures caused by incorrect installation or operation are not covered by the guarantee. Your SJ Silver Series Jet Pump is designed to handle clean water. The pump should not be used for any other purpose without specific referral to Davey. The use of the pump to handle flammable, corrosive and other materials of a hazardous nature is specifically excluded.

Model SJ35-04

1.Delivery outlet - 1” BSP(F)

2.Suction inlet - 1” BSP(F)

3.Pump body

4.Motor

5.Priming port and plug

6.Drain port and plug

Model SJ35-04P2C/LOP

1.Delivery outlet - 1” BSP(F)

2.Suction inlet - 1” BSP(F)

3.Pump body

4.Motor

5.Priming port and plug

6.Drain port and plug

7.Pressure Switch

8.Pressure Tank

Model SJ35-04PC & SJ60-08PC

1.Delivery outlet - 1” BSP(M)

2.Suction inlet

–SJ35-04PC - 1”BSP(F)

–SJ60-08PC - 11/4”BSP(F)

3.Pump body

4.Motor

5.Priming port and plug

6.Drain port and plug

7.Presscontrol

NOTE: 1” FI x FI suction check valve and 1” nipple not illustrated.

Do not use this pump to pump flammable fluids, such as petrol or diesel fuels.

Choosing a Site

Choose a site with a firm base and as close to the water source as possible with correct power supply. Make sure your pump is always connected to an adequate, reliable source of clean water.

Housing your SJ Silver Series Jet Pump

To protect your pump from the weather, make sure the cover provided is water proof, frost free and has adequate ventilation.

The pump should be horizontally mounted on a firm base allowing for drainage, to avoid damage to flooring etc., that over time may occur from leaking pipe joints or pump seals. Do not mount the pump vertically.

WARNING: Some insects, such as small ants, find electrical devices attractive for various reasons. If your pump enclosure is susceptible to insect infestation you should implement a suitable pest control plan.

~ 2 ~

Power Connection

The pump motor is fitted with an earthed three pin plug & lead.

The installer is responsible for the correct connection of the electrical supply to the pump motor.

•Make sure the supply voltage and frequency is the same as the nameplate.

•Make sure that there is a sound earth connection available.

In accordance with AS/NZS 60335.2.41 we are obliged to inform you that this pump is not to be used by children or infirm persons and must not be used as a toy by children.

POWER CONNECTION

Connect lead to power supply designated on pump label. Do not use long extension leads as they cause substantial voltage drop, poor pump performance and may cause motor overload.

EARTH CONNECTION

The pump power lead includes an earth pin on the plug, which MUST be correctly connected to a suitable earth on the electrical supply.

Electrical Power Surge Protection

An electrical power surge or spike can travel on the supply lines and cause serious damage to your electrical equipment.

The Presscontrol fitted to this pump has a metal oxide varistor (MOV) fitted to help protect it’s circuit. This MOV is a “sacrificial” device, meaning that it effectively gradually destroys itself every time it takes a surge. The MOV is not a lightning arrestor and may not protect the Presscontrol if lightning or a very powerful surge hits the pump unit.

If the installation is subject to electrical power surges or lightning we strongly recommend the use of a suitable surge protection device on ALL electrical equipment.

Pipe Connections

For best performance use P.V.C. or polythene pipes at least the same diameter as the pumps inlet and delivery outlet openings. Larger diameter pipe may be used to minimise resistance to flow when pumping longer distances.

Use unions as pipe connections to enable easy removal and servicing. Use sufficient tape to ensure airtight seal and hand tighten only. To prevent strain on pump threads always support heavy inlet and outlet pipes. If there is a likelihood the water supply may contain solid particles such as pieces of plant or vegetable matter, a suction strainer should be installed before the pump to avoid blocking of the pump. Lay suction pipe at a constant gradient to avoid air pockets which reduce pump efficiency.

NOTE - Suction leaks are the largest cause of poor pump performance and are difficult to detect. Ensure all connections are completely sealed USING THREAD TAPE ONLY.

Installations with a Suction Lift

Installations with a suction lift require a good quality foot valve to avoid loss of prime.

For model SJ35-04P2C/LOP the enclosed suction check valve can have a suction strainer fitted and used as a foot valve.

Installations with Flooded Suction

Installations with flooded suction require a gate valve so water supply can be turned off for pump removal and servicing. Model SJ35-04P2C/LOP must have the enclosed suction check valve fitted with the enclosed nipple directly into the pump inlet. Ensure the check valve is installed in the correct direction to allow flow into pump inlet.

WARNING

DO NOT RUN DRY.

DO NOT RUN WITH LOSS OF PRIME.

DO NOT PUMP WATER CONTAINING ABRASIVE MATERIALS.

~ 3 ~

Loading...

Loading...