Davey Speedman Compact Constant Water Pressure Systems User Manual

Installation and Operating Instructions for Davey Speedman Compact Constant Water

Pressure Systems

NOTE: Prior to installation remove the inlet and outlet pipe transport plugs & associated seals from the suction and/or discharge ports.

WARNING : The Speedman Compact system and associated pipework operate under pressure. Under no circumstances should the Speedman Compact System or associated pipework be disassembled unless the internal pressure of the unit has been relieved. Failure to observe this warning will expose persons to the possibility of personal injury and may also result in damage to the pump, pipework or other property.

WARNING: Failure to follow these instructions and comply with all applicable codes may cause serious bodily injury and/or property damage.

Please pass these instructions on to the operator of this equipment.

Prior to using this pump you must ensure that:

•The pump is installed in a safe and dry environment

•The pump enclosure has adequate drainage in the event of leakage

•Any transport plugs are removed

•The pipe-work is correctly sealed and supported

•The pump is primed correctly

•The power supply is correctly connected

•All steps have been taken for safe operation

Appropriate details for all of these items are contained in the following Installation and Operating Instructions. Read these in their entirety before switching on this pump. If you are uncertain as to any of these Installation and Operating Instructions please contact your Davey dealer or the appropriate Davey office as listed on the back of this document.

Congratulations on your purchase of a high quality, Davey constant pressure water pressure system. All components have been designed and manufactured to give trouble free, reliable operation.

Your new pressure system incorporates the Speedman Compact, electronic flow controller – a unit that enables the use of a highly efficient pump design and offers the following benefits:–

1.Enables the pump to deliver a constant pressure of water particularly across a wide range of flow rates – reducing the inconvenience of pressure variation in showers etc.

2.Provides automatic “cut-out” protection should the pump run out of water, should the pump fail to start due to low voltage or a blockage in the pump.

3.Provides warning indications for system faults.

4.Has adjustable pressure setting to allow for various operating conditions.

5.Automatic retry functions in the event of a variety of system faults.

6.Motor overload protection included.

Before installing your new pump system, please read all instructions carefully as failures caused by incorrect installation or operation are not covered by the guarantee. Your Davey pressure system is designed to handle clean water. The system should not be used for any other purpose without specific referral to Davey. The use of the system to pump flammable, corrosive and other materials of a hazardous nature is specifically excluded.

NOTE: Prior to installation remove the inlet and outlet pipe transport plugs from the suction and/or discharge.

2

Technical Features and Usage Conditions

•Operational temperature: 0ºC to +40ºC

•Maximum humidity: 50% at +40ºC (no condensate)

•Temperature of fluid: +1ºC to +40ºC

•Nature of fluid: water with no chemical additives (ph 5 to 9)

•Power Supply: Single phase: 230 Vac 50Hz*

•Set point pressure: preset at 2.5 bar (250kPa) and adjustable between

1.0 to 7.5 Bar (100 to 750kPa), ± 0.2 Bar

•Overpressure Maximum: 12 Bar

•Electric safety and electromagnetic compatibility: EN60730, EN61000-6-3, EN61000-6-4

*For 60Hz operation consult your Davey Water Products dealer for advice.

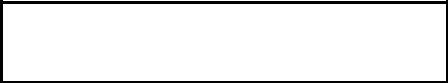

1. |

Pump Priming Plug |

|

175 |

2. |

Speedman Compact |

|

|

|

1 |

|

|

|

1 |

|

|

|

Control Module |

3 |

|

3. |

Discharge Outlet (11/4” |

|

|

|

BSPF) |

2 |

|

4. |

Suction Inlet (11/4” BSPF) |

|

|

5. |

Pump Body |

|

|

6. |

Motor |

|

|

7. |

Rotary Coupling |

|

|

8. |

Motor Mounting Bolts |

|

|

9. |

Controller Mounting |

|

|

|

Screws |

|

|

10. Support Bracket |

7 |

|

|

|

Capscrews |

|

|

|

6 |

5 |

4 |

All measurements |

|

||

|

125 |

||

in mm. |

|

||

8460 |

|

||

|

|

|

|

3

2

9

9

620

1

4

10

256

Preparing Your System

On removing your Speedman Compact system from the carton check that the standard orientation of the pump inlet and controller is suitable. If required, the inlet can be re-orientated 180 degrees.

To rotate the pump inlet to the alternate position, prior to installation, undo the two motor mounting bolts (8), the four controller mounting screws

(9) and the two support bracket capscrews (10). The pump can then be rotated relative to the controller by loosening the rotary coupling slightly

(7). Re-position the support bracket to the holes on the opposite end of the mounting base and re-affix with the support bracket capscrews. Re-position the pump and controller on the base, tightening all items (7, 8, 9 and 10) carefully.

Only connect the discharge pipework to the discharge port. The priming port is not a discharge port.

3

Choosing a Site

Choose a site with a firm base and as close to the water source as possible with correct power supply. Make sure your pressure system is always connected to an adequate, reliable source of clean water.

Housing your Davey Pressure System

To protect your pressure system from the weather, make sure the pump house is both water proof, frost free and has adequate ventilation. The pump should be horizontally mounted on a firm base allowing for drainage, to avoid damage to flooring etc., that over time may occur from leaking pipe joints or pump seals. Do not mount the pump vertically.

WARNING: Some insects, such as small ants, find electrical devices attractive for various reasons. If your pump enclosure is susceptible to insect infestation you should implement a suitable pest control plan.

Power Connection

Connect lead to power supply (220-240V 1phase 50Hz) as designated on controller label. Note that while the pump motor is rated three phase, the single phase supply is inverted to suit in the controller. Do not use long extension leads as they cause substantial voltage drop, poor pump performance and may cause motor overload.

The Davey Speedman Compact fitted to this pump has a status indicator mounted on its front panel. This will be illuminated whenever the Speedman Compact senses that there is electrical power available. It will only work when unit is connected to the correct electrical supply.

The electrical connections and checks must be made by a qualified electrician and comply with applicable local standards.

Electrical Power Surge Protection

An electrical power surge or spike can travel on the supply lines and cause serious damage to your electrical equipment. The Speedman Compact controller fitted to this system has a metal oxide varistor (MOV) fitted to help protect it’s circuit. This MOV is a “sacrificial” device, meaning that it effectively is gradually damaged every time it takes a surge. The MOV is not a lightning arrestor and may not protect the control unit if lightning or a very powerful surge hits the pump unit.

If the installation is subject to electrical power surges or lightning we strongly recommend the use of suitable additional surge protection devices on ALL electrical equipment.

4

In accordance with AS 3350.2.41 we are obliged to inform you that this appliance is not intended for use by young children or infirm persons unless they have been adequately supervised by a responsible person to ensure that they can use the appliance safely.

Young children should be supervised to ensure that they do not play with the appliance.

NOTE: For protection, the Davey Speedman Compact controller is equipped with an automatic reset current sensing overload, constant tripping of this overload indicates a problem e.g. low voltage at pump, excessive temperature (above 50°C) in pump enclosure.

Pipe Connections

For best performance use P.V.C. or polythene pipes at least the same diameter as the pump’s inlet and delivery outlet openings. Larger diameter pipe may be used to minimise resistance to flow when pumping longer distances.

Do not use pipe thread sealing compounds on any part of this pump. ONLY use Teflon sealing tape.

Use unions at pipe connections to enable easy removal and servicing. Use sufficient tape to ensure airtight seal and hand

tighten only. To prevent strain on pump threads always support heavy inlet and outlet pipes. If there is a likelihood the water supply

may contain solid particles such as pieces of plant or vegetable matter, a filter should be installed before the pump to avoid blocking of water ways. Lay suction pipe at a constant gradient to avoid air pockets which may reduce pump efficiency.

NOTE: Suction leaks are the largest cause of poor pump performance and are difficult to detect. Ensure all connections are completely sealed using thread tape only.

Extra Draw-off Capacity

The Speedman Compact has an in-built accumulator which will accommodate small leaks. In some applications it may be appropriate to install additional accumulator

(Supercell pressure tank) capacity. These applications includes:

•Long suction lines (see Suction Lines / Lift)

•Low flow appliances connected to the pump, such as evaporative air conditioners, slow filling toilet cisterns.

Any additional accumulators can be installed downstream of the controller (ie. between the controller and the first outlet).

Where extra draw-off capacity is utilised the additional pressure tank should have a pre-charge 15kPa below the system pressure setting.

DO NOT USE THREAD SEALING COMPOUNDS, HEMP OR PIPE DOPE!

5

Loading...

Loading...