Davey SilensorPRO SP200BT, SilensorPRO SP400BT Installation And Operating Instructions Manual

Page 1

SilensorPRO SP200BT & SP400BT

Swimming Pool Pump

Installation and Operating

Instructions

50/60Hz

SP200BT

SP400BT

UK - Installation and Operating Instructions 1-20

DE - Installations- und Betriebs-anleitung 21-40

IT - Istruzioni di montaggio e di utilizzo 41-60

NL - Installatie- en gebruiksinstructies 61-80

PT - Instruções de Instalação e Funcionamento 81-100

ES- Instalación e instrucciones de funcionamiento 101-120

FR - Instructions d’installation et d’utilisation 121-140

Please refer to the Davey website in your region as per back page of this

document for any product information updates.

Please pass these instructions on to the operator of this equipment.

English

Page 2

Congratulations on your purchase of a high quality, SilensorPRO SP200BT, or SP400BT pump. All

components have been designed and manufactured to give trouble free, reliable operation.

Table of Contents:

1. INSTALLATION OF THE DAVEY VARIABLE SPEED PUMP .....................................................................3

Power connection .......................................................................................................................................3

Pipe connection ..........................................................................................................................................4

2. TYPICAL INSTALLATION DIAGRAM .........................................................................................................5

3. PERFORMANCE SPECIFICATIONS .........................................................................................................5

3.1 SP200BT Hydraulic Performance .........................................................................................................5

3.2 SP200BT Electrical Specifications ........................................................................................................6

3.3 SP400BT Hydraulic Performance .........................................................................................................6

3.4 SP400BT Electrical Specifications ........................................................................................................6

4. OWNERS MANUAL ....................................................................................................................................7

Saving energy with your SilensorPRO ........................................................................................................7

Pre-start up checklist ..................................................................................................................................7

Low energy operation .................................................................................................................................8

Guidelines for recommended pump operating hours ..................................................................................8

Emptying the strainer basket ......................................................................................................................9

Routine maintenance ..................................................................................................................................9

5. FEATURES & FUNCTIONALITY ..............................................................................................................10

Multi-Coloured LED indicator light ............................................................................................................10

Backwash Speed Cycling Technology ......................................................................................................10

Full variable frequency drive with user friendly selectable speed dial ......................................................10

Large 4.5 litre lint pot ................................................................................................................................10

Patented water-cooled design for smooth and super quiet operation ......................................................10

SP400BT constant flow/speed compensation ..........................................................................................10

SP400BT weatherproof RJ45 Communication Port (see section 7 for connection details) ......................10

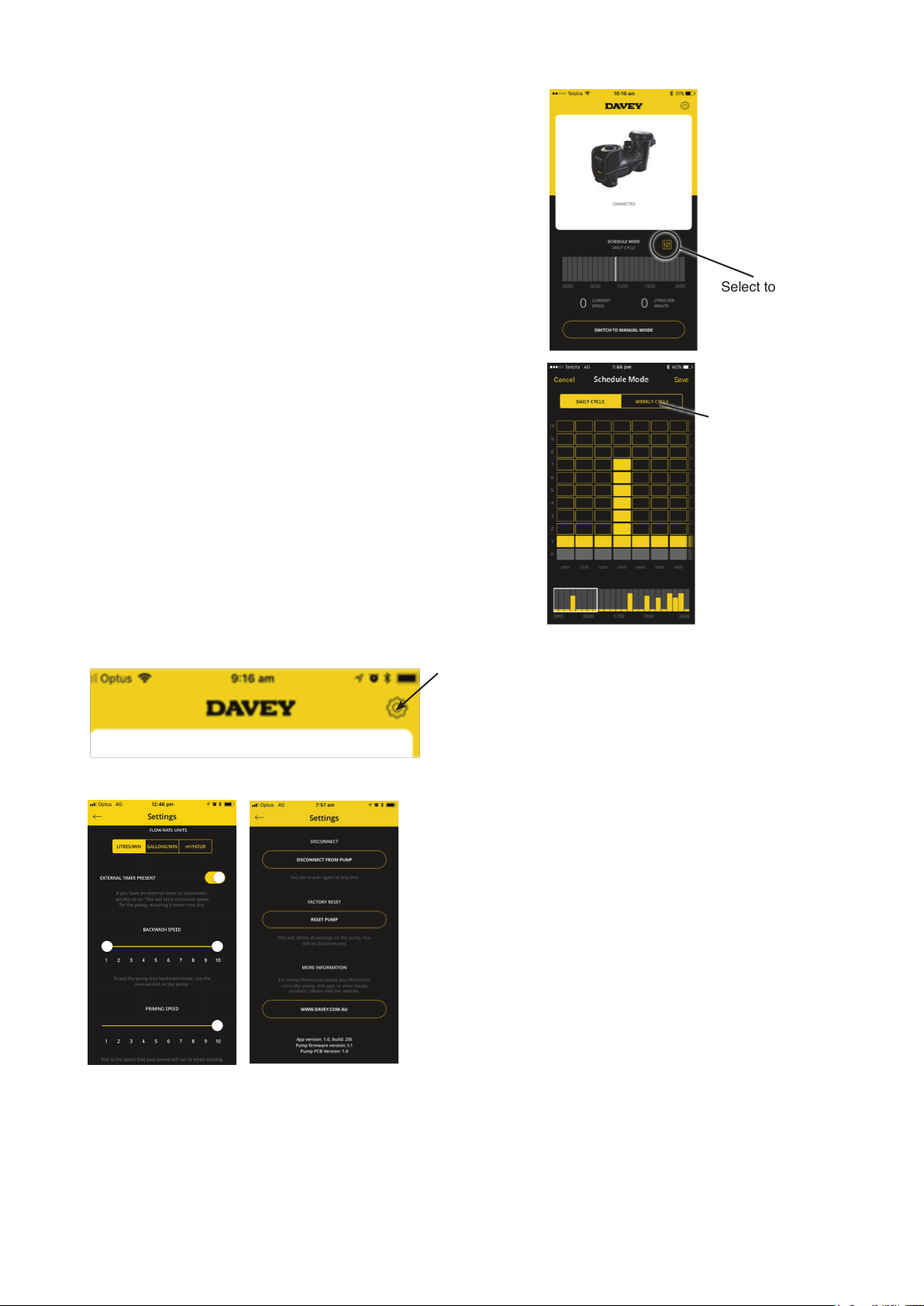

6. BLUETOOTH FUNCTIONALITY ..............................................................................................................11

Bluetooth App Set Up ...............................................................................................................................11

Pairing a device to the pump ....................................................................................................................11

External Timer / Chlorinator ......................................................................................................................11

Schedule mode ......................................................................................................................................... 11

Setting a schedule ....................................................................................................................................12

Settings .....................................................................................................................................................12

Priming speed / Max speed ......................................................................................................................12

Backwash..................................................................................................................................................13

External time present ................................................................................................................................13

Disconnect function ..................................................................................................................................13

Factory reset .............................................................................................................................................13

Pump fault finding .....................................................................................................................................13

7. ADVANCED SETUP OF SP400BT ...........................................................................................................14

External AUX connections overview .........................................................................................................14

Digital control inputs .................................................................................................................................15

Interfacing equipment to the SilensorPRO SP400BT ...............................................................................15

Analogue control inputs ............................................................................................................................16

8. TECHNICAL SPECIFICATIONS ...............................................................................................................16

9. USING YOUR SILENSORPRO WITH A SALT WATER CHLORINATOR .................................................17

10. OPERATING YOUR SUCTION POOL CLEANER ....................................................................................17

11. TROUBLE SHOOTING .............................................................................................................................18

12. REMOVAL OF THE SILENSORPRO FROM PIPEWORK ........................................................................18

13. WATER QUALITY .....................................................................................................................................18

14. DAVEY WARRANTY .................................................................................................................................20

English

2

Page 3

1. INSTALLATION OF THE DAVEY VARIABLE SPEED PUMP

The SilensorPRO should be located as close to the water as practicable and mounted on a firm base in a

well drained position, high enough to prevent any flooding. It is the installer/owner’s responsibility to locate

the pump such that the nameplate can be easily read and the SilensorPRO can be readily accessed for

service. It is recommended that the SilensorPRO is protected from the weather. Enclosures should be

ventilated to prevent condensation build-up.

Failure to follow these instructions and comply with all applicable codes may cause

serious bodily injury and/or property damage.

This pump requires professional expertise for installation and maintenance. The

installation of this product should be carried out by a person knowledgeable in

swimming pool plumbing requirements and who follows the installation instructions

provided in this manual.

Power connection

IMPORTANT INFORMATION Your SilensorPRO is double insulated to water circuit.

If equipotential bonding structure is required, then an Equipotential Bonding Point

is provided. (Please refer to your local statutes and/or regulations for AS/NZ 3000

equivalent wiring standards).

CAUTION! In the interest of safety, we advise that all brands and types of pool pumps

must be installed in accordance with AS/NZS 3000, known as the national wiring

rules, or equivalent local standards. All electrical installations must be carried out by

a qualied electrician. Davey recommends that all installations are tted with earth

leakage, or residual current protection devices. Rated residual operating current not

exceeding 30mA.

WARNING! Ensure that an electrical isolation switch is located with easy access so that

the pump can be switched off in an emergency.

F NFC C 15-100 GB BS7671:1992

D DIN VDE 0100-702 EW EVHS-HD 384-7-702

A OVE 8001-4-702 H MSZ 2364-702:1994/MSZ 10-533 1/1990

E UNE 20460-7-702 1993, REBT ITC-BT-31 2002 M MSA HD 384-7-702.S2

IRL IS HD 384-7-702 PL PN-IEC 60364-7-702: 1999

I CEI 64-8/7 CZ CSN 33 2000 7-702

LUX 384-7.702 S2 SK STN 33 2000-7-702

NL NEN 1010-7.702 SLO SIST HD 384-7-702.S2

The SilensorPRO is suitable for connection to a nominal 220 – 240 volt 50/60Hz power supply and is

equipped with a flex cord. If a power outlet is not available within 3 metres of the pump, a 3-pin power point

in a safe, dry place may need to be provided by an electrician. Extension cords are unsafe around pools and

should be avoided. If the supply cord of the SilensorPRO is damaged it must be replaced by Davey, or an

approved agent with genuine Davey spares.

The SilensorPRO incorporates motor overload detection designed to protect the motor from overheating.

If the motor gets too hot during operation, its operating speed will reduce to bring it within an acceptable

operating temperature and then will speed up to the originally set speed.

To reset the motor, switch the power off for 30 seconds, and then return the power from the mains switch.

English

3

Page 4

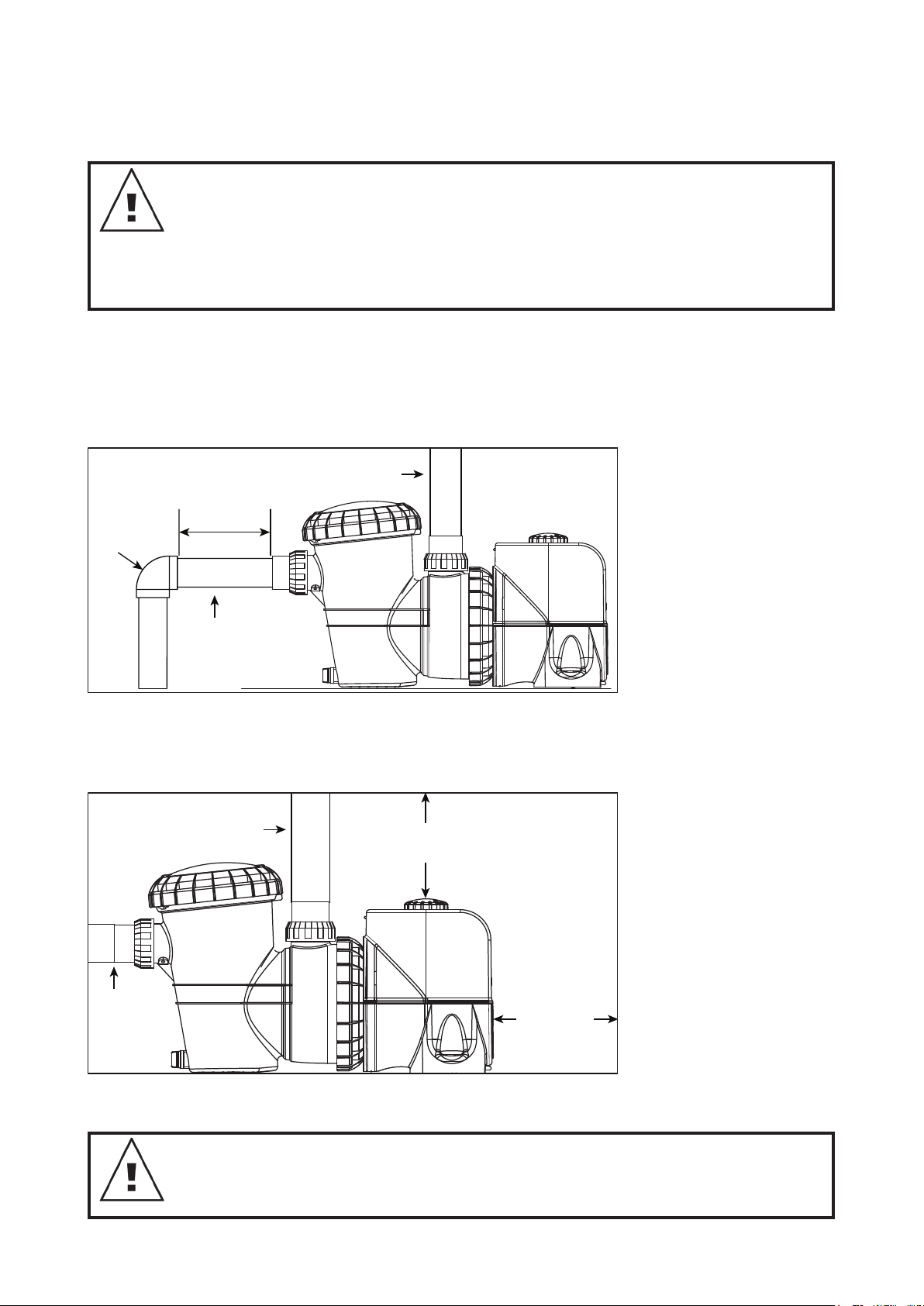

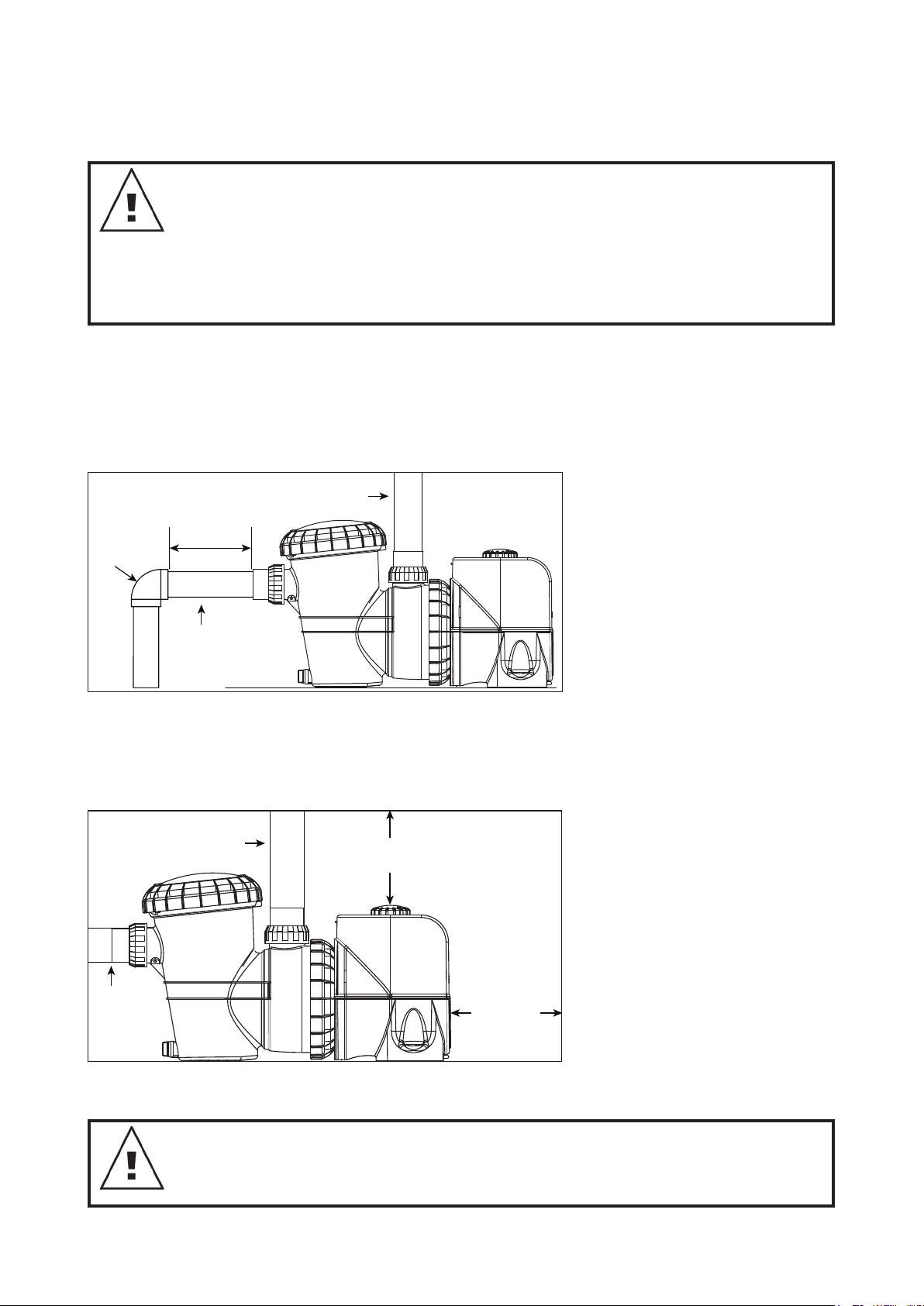

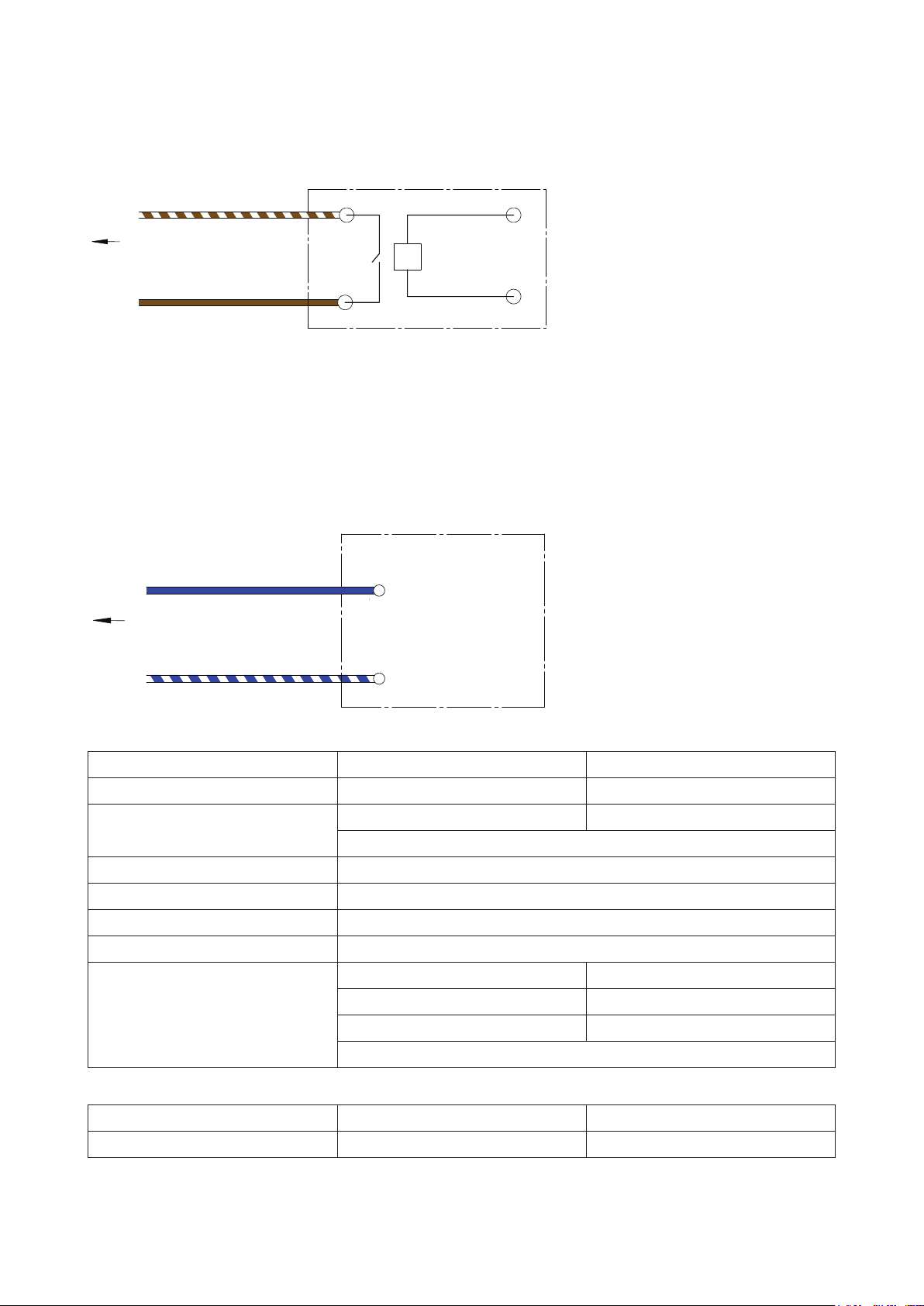

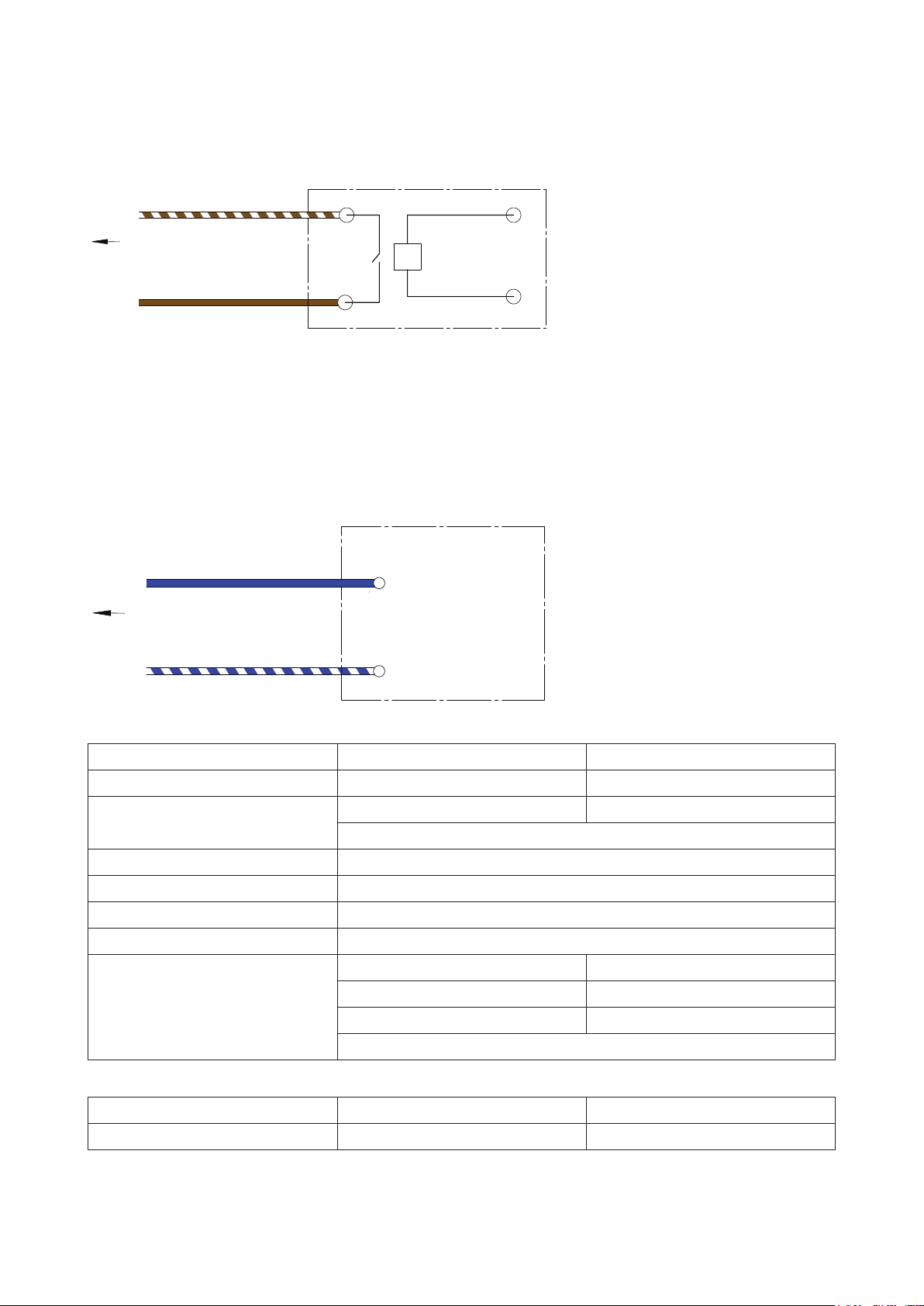

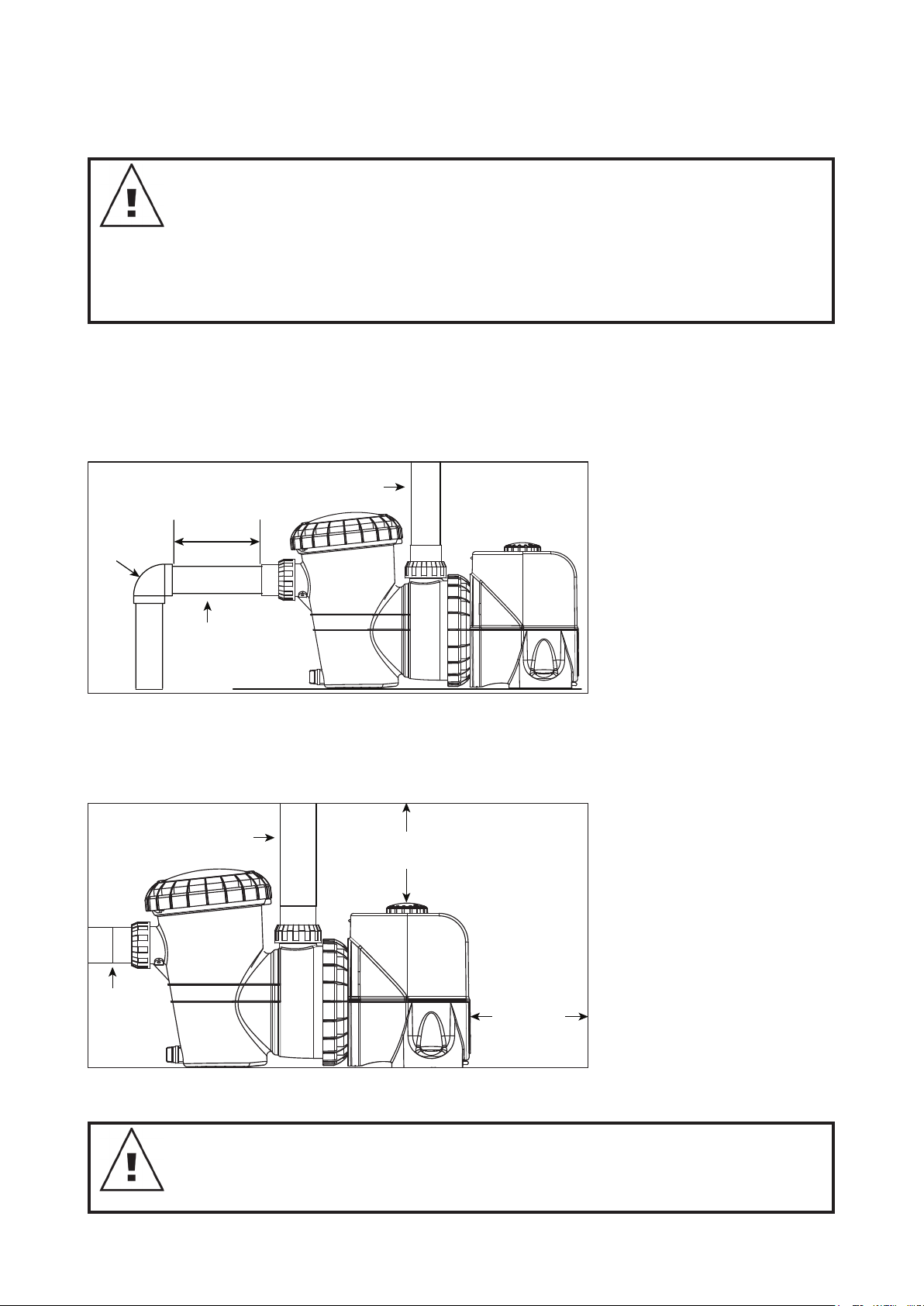

Pipe connection

Figure 1.2

152mm

MINIMUM

76mm

MINIMUM

Suction line

50/63mm

Return to

Pool

50/63mm

Return to

Barrel unions are provided for connecting to the piping from the pool. The pumps are designed to accept

50/63mm PVC fittings.

IMPORTANT INFORMATION If the SilensorPRO and lter are located below pool water

level, it is necessary to t isolating valves in the pipe between the pump and skimmer

box and in return pipe from the lter to the pool. When plumbing the discharge pipe,

ensure that the pipework does not interfere with the pumps speed dial. Barrel unions

need to be hand tightened. No sealant, glues or silicones are required.

The ttings on the SilensorPRO are constructed of ABS. Some PVC jointing compounds

are incompatible with ABS. Check compound suitability before use.

The use of any pipe smaller than those specified above is not recommended. Suction piping should be free

from all air leaks and any humps and hollows which cause suction difficulties. To achieve best efficiency, the

SilensorPRO should be installed such that turbulent water is limited as much as possible. As shown in figure

1.1, do not install a 90° elbow closer that 250mm from the inlet barrel union. Isolation valves used where

equipment is located below pool water level, should also be installed no closer than 250mm from inlet barrel

union. This will assist laminar flow.

ELBOW

The discharge piping from the SilensorPRO outlet should be connected to the inlet connection on the

swimming pool filter (usually at the filter control valve). As shown in figure 1.2, ensure adequate clearance

above the pump to not interfere with the SilensorPRO speed dial. Use a check valve in the discharge line

when using this pump for any application where there is significant height to the plumbing after the pump.

Figure 1.1

Figure 1.2

250mm

Suction line

50/63mm

Return to

Pool

50/63mm

Pool

50/63mm

152mm

MINIMUM

Suction line

50/63mm

76mm

MINIMUM

Be sure to install check valves when plumbing with another pump. This helps prevent reverse rotation of the

impeller and motor.

WARNING! Pump suction is hazardous and can trap and drown, or disembowel bathers.

Do not block suction. Do not operate swimming pools, spas, or spa baths if a suction

cover is broken, missing or loose. Two suction covers, or inlets must be provided into

every pump to avoid suction entrapment.

English

4

Page 5

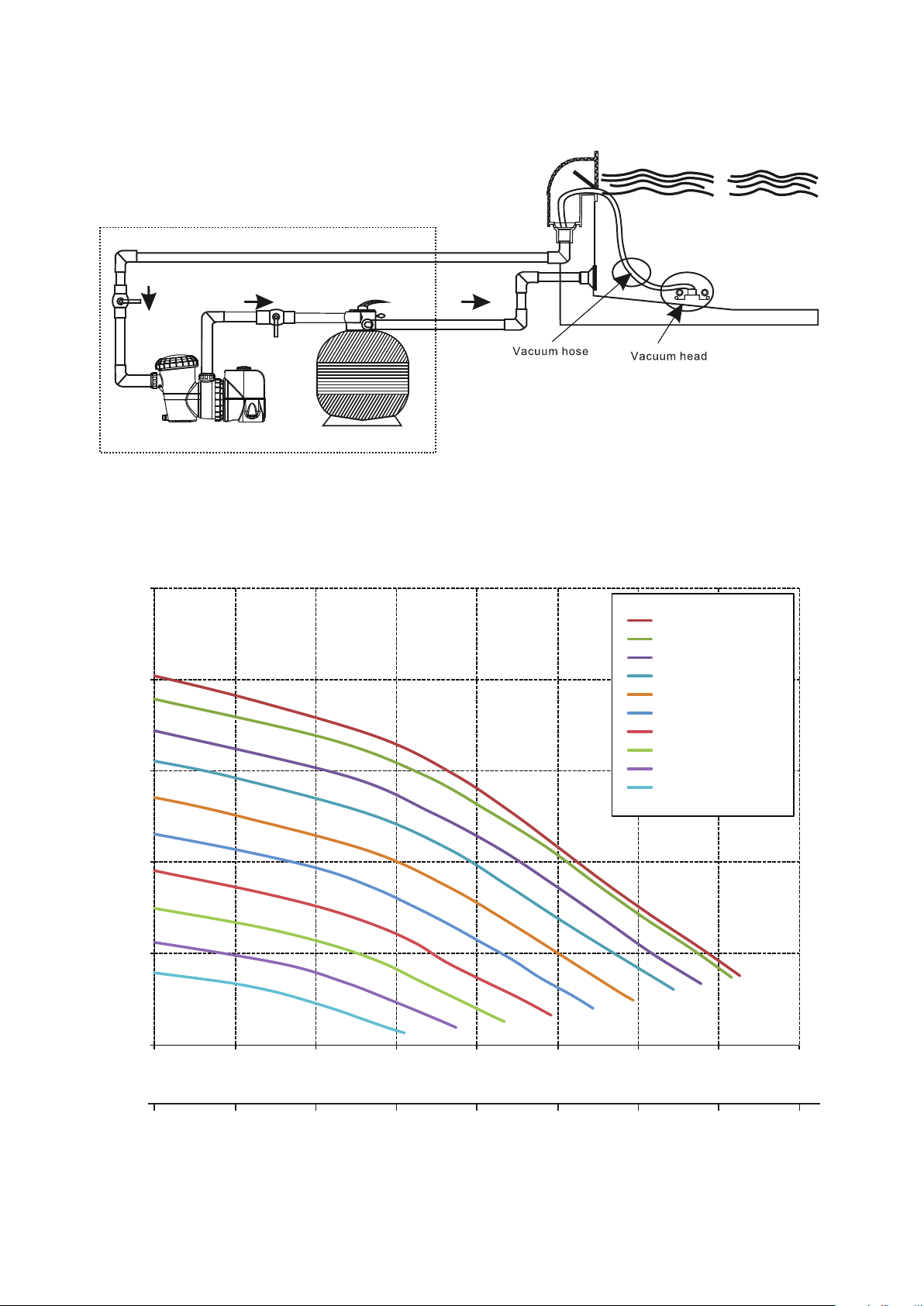

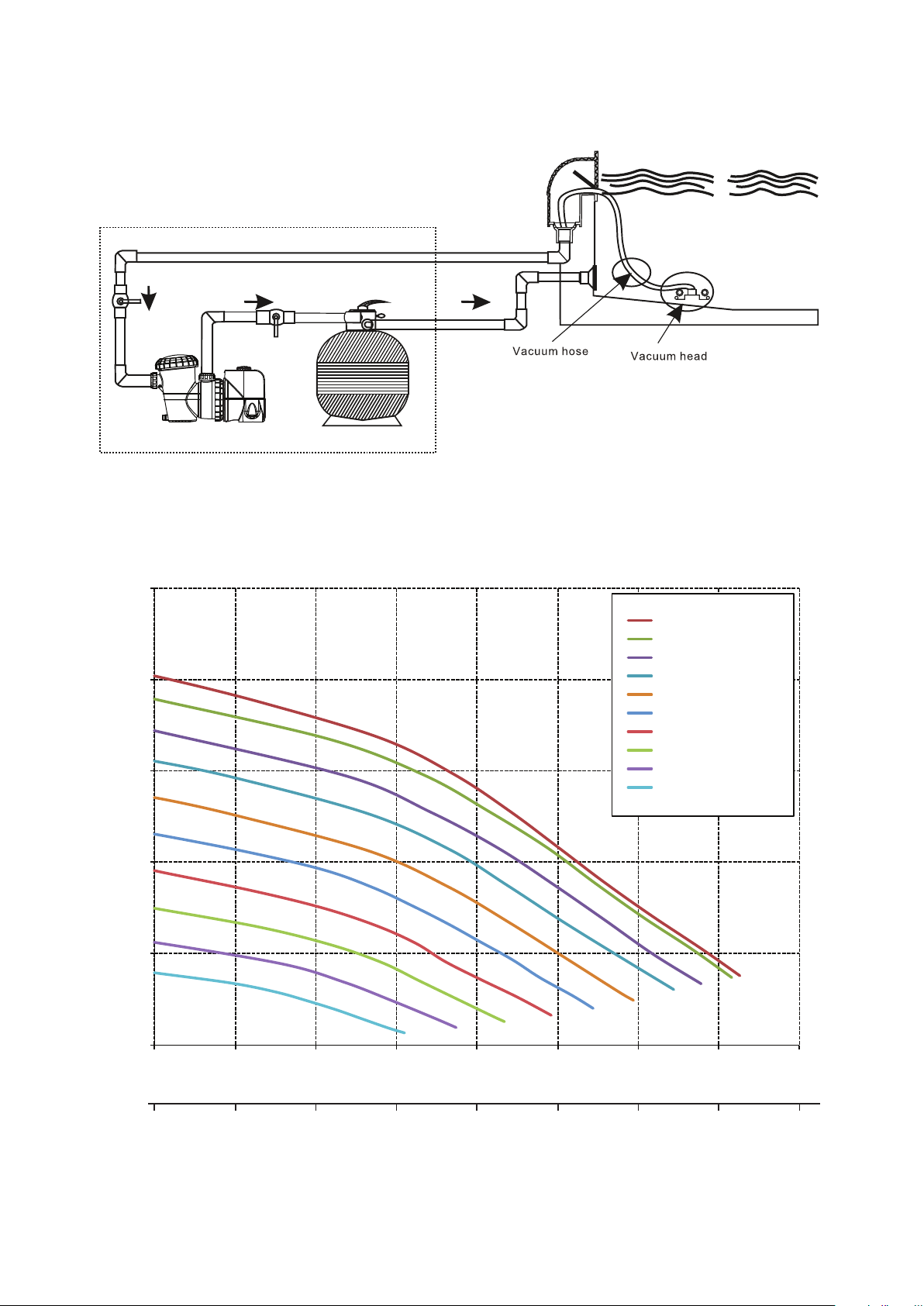

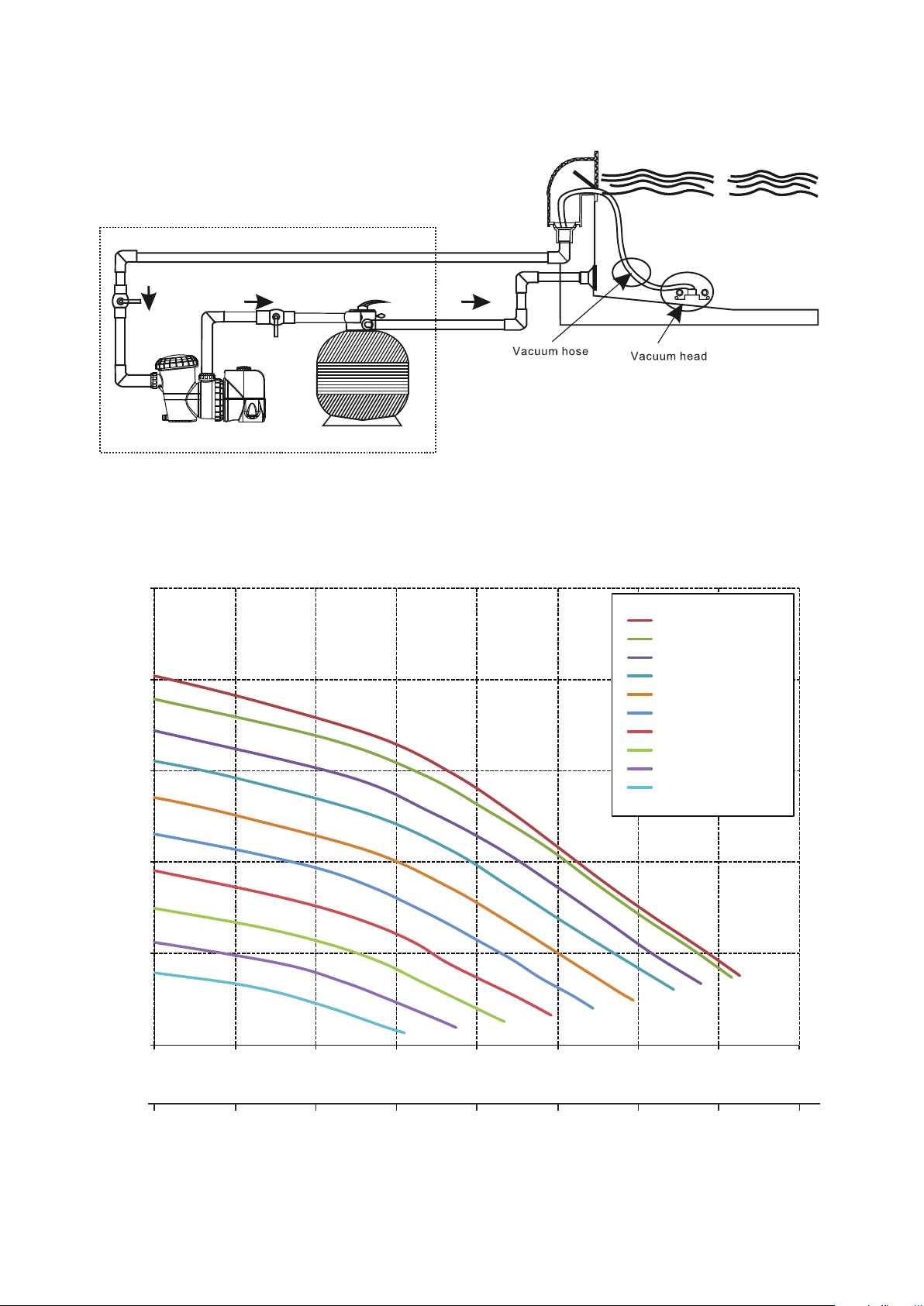

2. TYPICAL INSTALLATION DIAGRAM

ProMaster - PM200SV

Performance

Pool pump Media Filter

3. PERFORMANCE SPECIFICATIONS

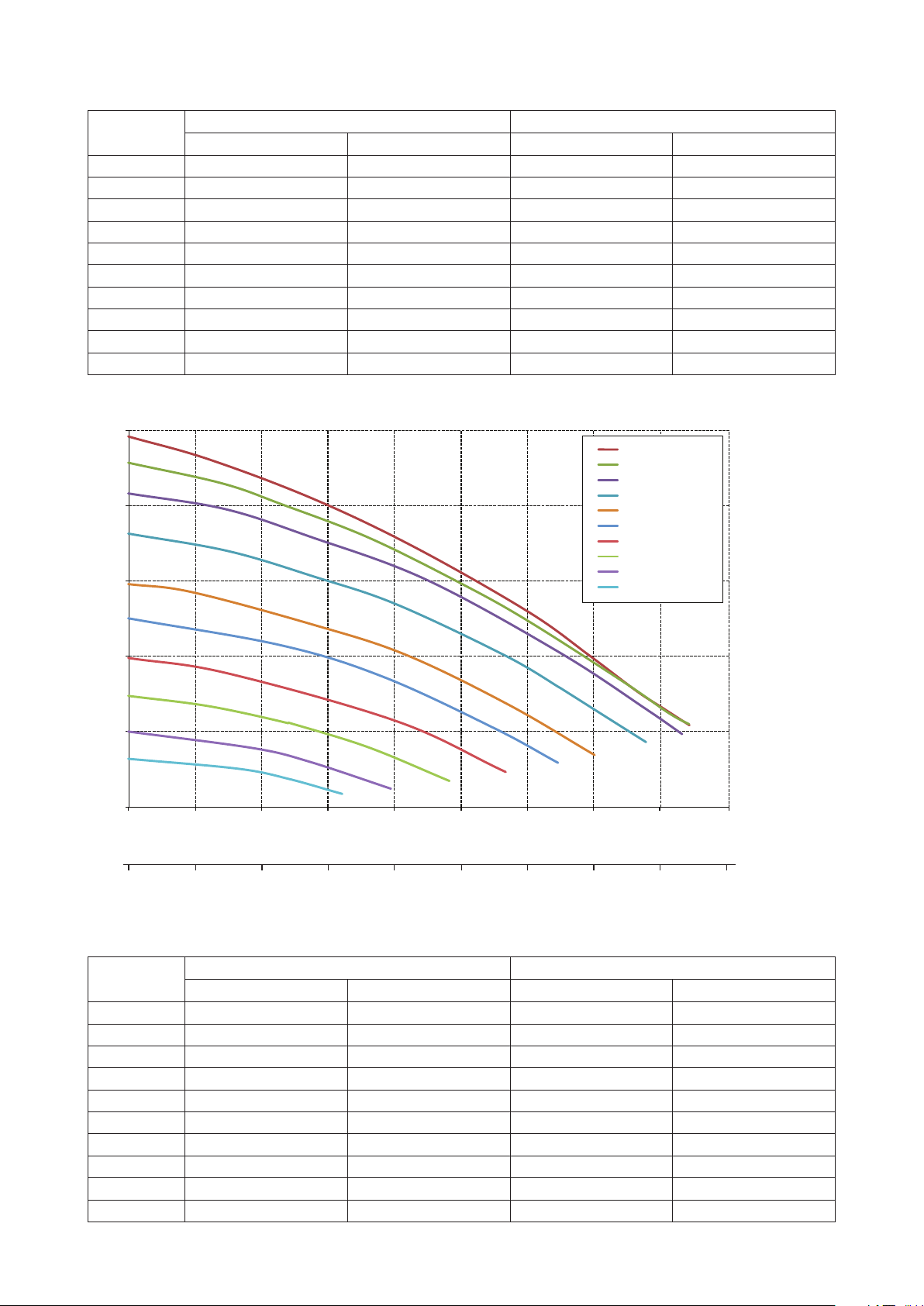

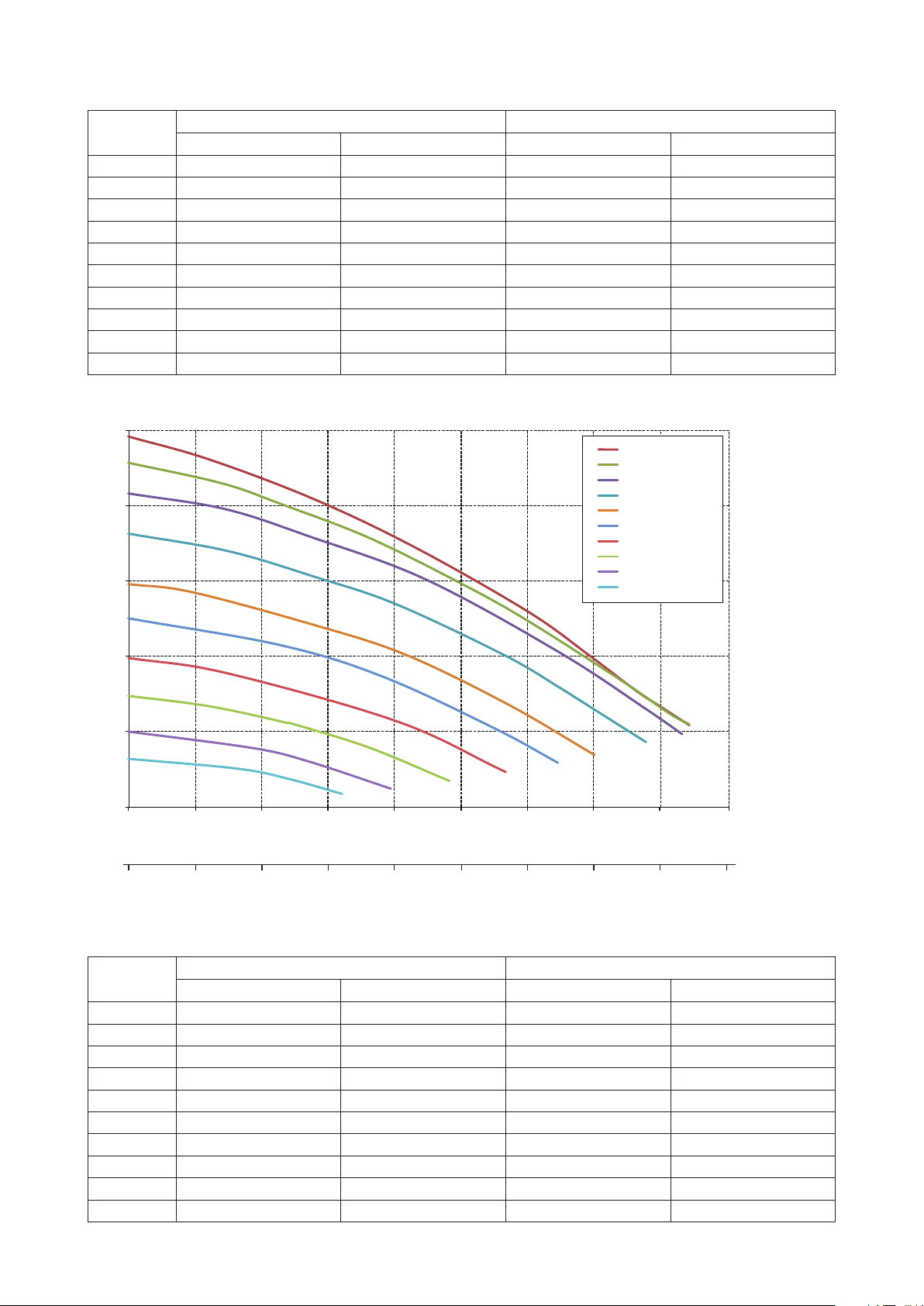

3.1 SP200BT hydraulic performance

25

20

15

Total Head ( m )

10

5

Dial position No. 10

Dial position No. 9

Dial position No. 8

Dial position No. 7

Dial position No. 6

Dial position No. 5

Dial position No. 4

Dial position No. 3

Dial position No. 2

Dial position No. 1

0

0 50 100 150 200 250 300 350 400

Flow ( lpm )

0

036 9 12 15 18 21 24

3

Flow ( m

5

/h )

English

Page 6

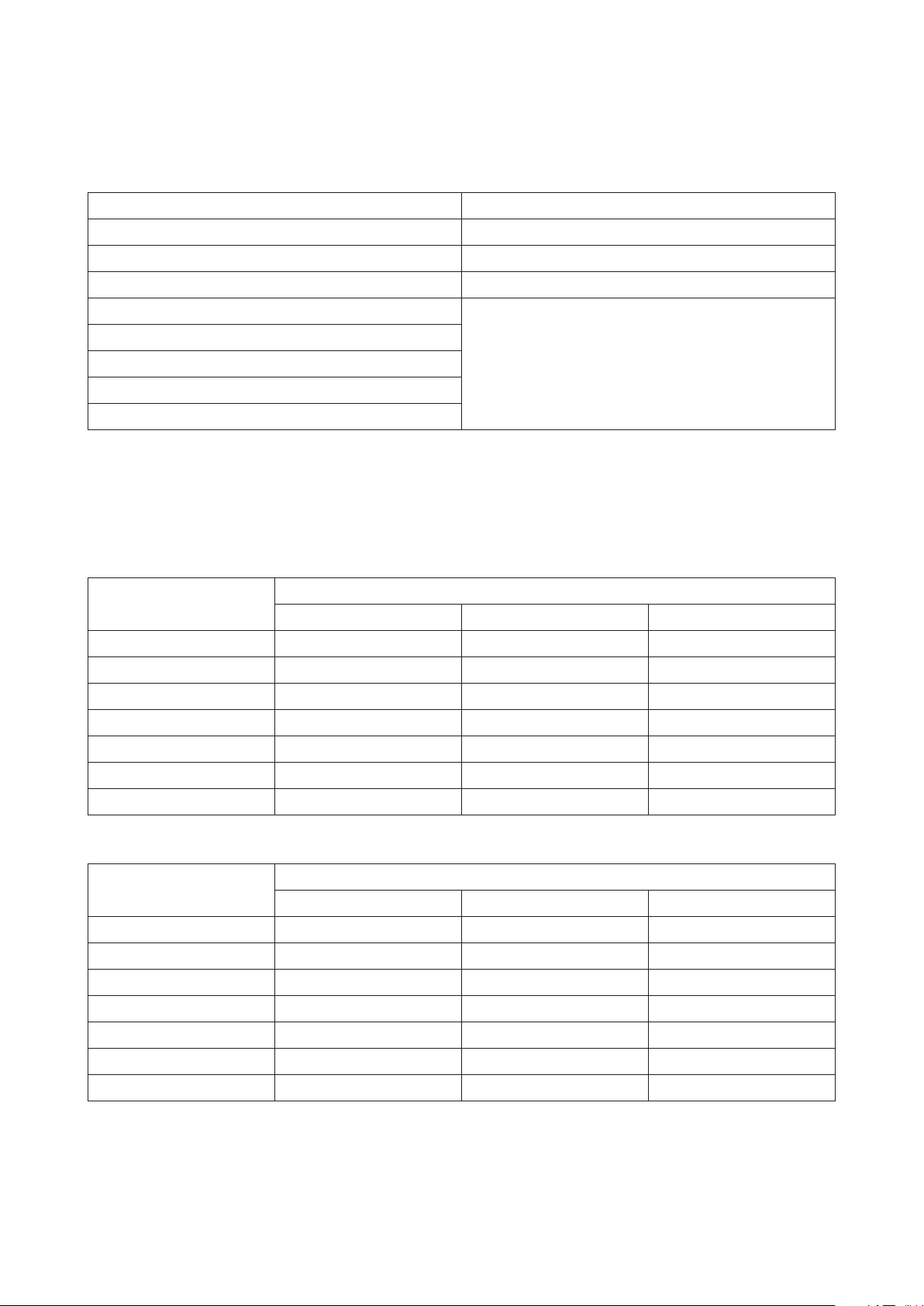

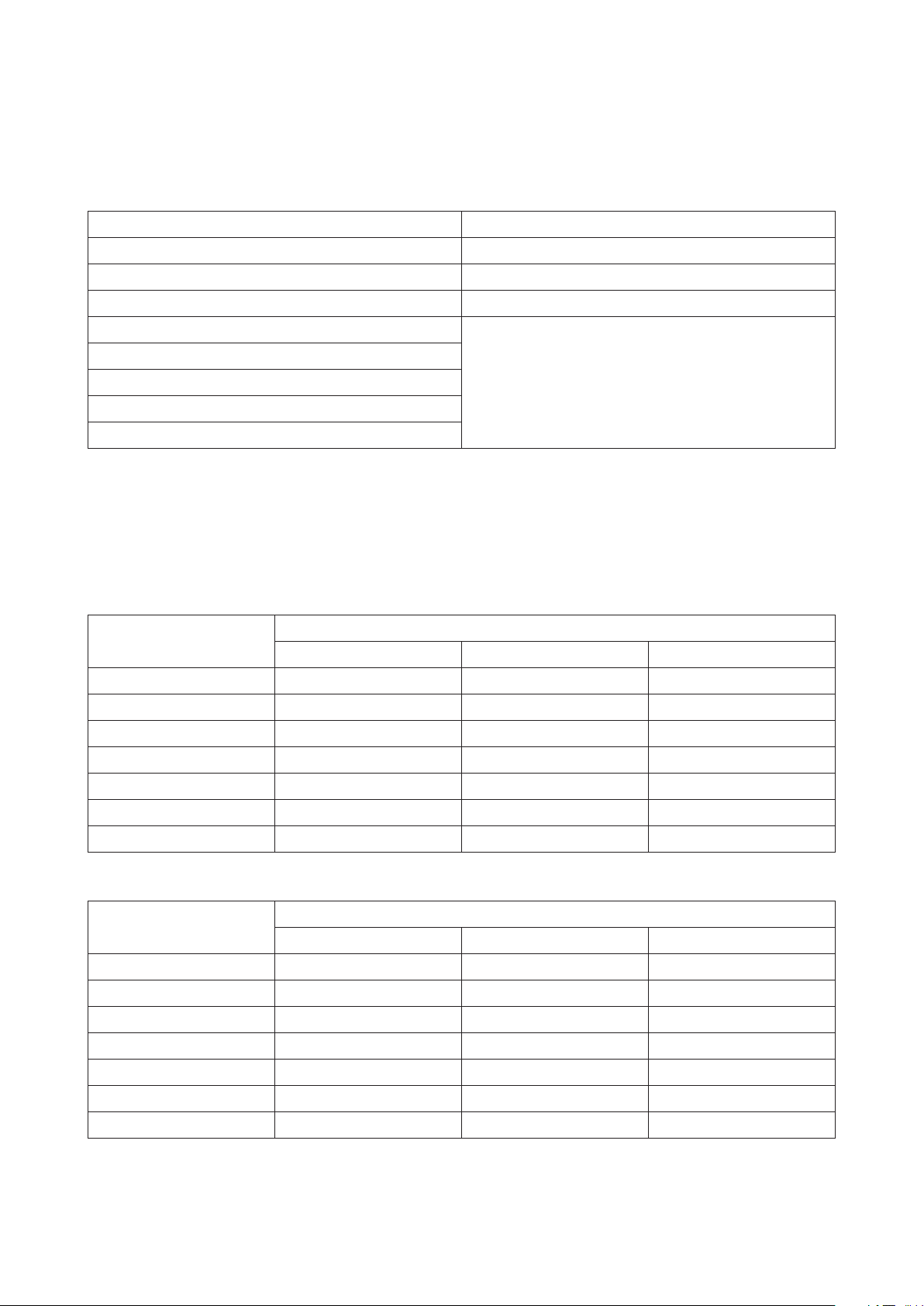

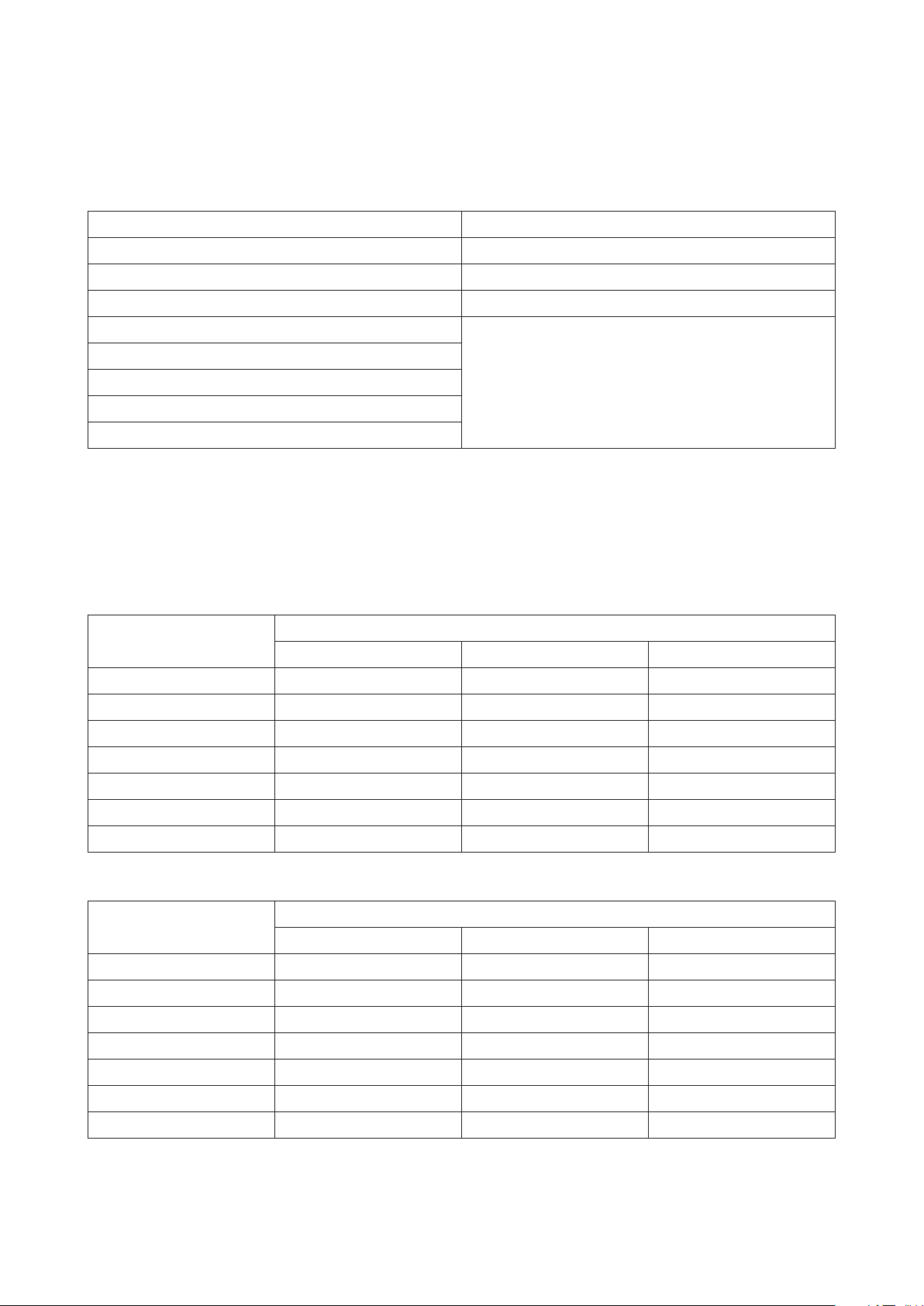

3.2 SP200BT electrical specifications

450

Speed

Setting

Dial 1 0.17 128 0.12 90

Dial 2 0.28 207 0.19 145

Dial 3 0.39 293 0.27 205

Dial 4 0.53 398 0.37 279

Dial 5 0.70 524 0.49 367

Dial 6 0.87 655 0.61 459

Dial 7 1.08 807 0.75 565

Dial 8 1.25 936 0.87 655

Dial 9 1.44 1,078 1.01 755

Dial 10 1.48 1,111 1.04 778

hp W hp W

Input Output

3.3 SP400BT hydraulic performance

25

Dial position No. 10

Dial position No. 9

Dial position No. 8

20

15

Dial position No. 7

Dial position No. 6

Dial position No. 5

Dial position No. 4

Dial position No. 3

Dial position No. 2

Dial position No. 1

Total Head ( m )

10

5

0

0 50 100 150 200 250 300 350 400

Flow ( lpm )

0

036 9 12 15 18 21 24 27

3

Flow ( m

/h )

3.4 SP400BT electrical specifications

Speed

Setting

Dial 1 0.17 126 0 .12 89

Dial 2 0.28 210 0.20 147

Dial 3 0.46 347 0.32 243

Dial 4 0.70 522 0.49 366

Dial 5 0.97 728 0.68 510

Dial 6 1.22 913 0.85 639

Dial 7 1.61 1, 211 1.13 848

Dial 8 1.97 1,478 1.38 1,034

Dial 9 2.18 1,635 1.59 1,191

Dial 10 2.19 1,639 1.62 1,212

hp W hp W

Input Output

English

6

Page 7

4. OWNERS MANUAL

This SilensorPRO is Bluetooth enabled, so you will be able to set and control the pump functions from your

smart device. Bluetooth is a wireless communication protocol that enables communication between devices.

This function is supported by any device that can download an app from IOS or Android App Store.

Read these instructions in their entirety before switching on this pump. If you are uncertain as to any of these

installation and operating instructions, please contact Davey as listed on the back of this document.

Every SilensorPRO is thoroughly water tested against a number of flow, pressure, voltage, current and

mechanical performance parameters. Davey’s advanced pump manufacturing technology provides reliable

and efficient pumping performance that lasts and lasts.

Saving energy with your SilensorPRO

The Davey variable speed pump is a super-efficient pump utilising a very clever, state of the art infinitely

variable AC motor that provides lower levels of noise, lower operating costs and lower greenhouse emissions

than traditional pool pumps.

Due to its ability to run at lower speeds than conventional pumps, your pump will also experience less

mechanical wear and tear due to less stress on the internal mechanical components. To achieve energy

efficient pumping is easy. Simply run the filtration pump at a lower speed but run it for longer than a

conventional fixed speed pump to “turn over” your pool water for adequate filtration and sanitisation. The

result is lower energy use and up to 70% lower operational costs.

The SilensorPRO has adjustable speed settings, so you can vary the speed you circulate your pool or spa

water at. Speeds can be adjusted to power a suction pool cleaner, in-floor cleaning system & pool heaters. A

backwash setting on the pump can be selected to backwash a media filter.

What to expect with the SilensorPRO (energy efficient operation) on your pool:

• If your SilensorPRO pump is replacing a traditional AC motor pump, you may will need to run it longer than

your old fixed speed pump. This is NORMAL and you will save energy when using lower speed settings.

• You may also notice that the pressure gauge on your filter is indicating a much lower pressure than you are

used to. This is also NORMAL. The lower system pressure is simply a result of the lower speed and flow

rate produced by the pump.

• While running at the lower speed settings you will also notice a significant reduction in pump noise. This is

a major benefit for you as it allows you to run your SilensorPRO during off peak electricity tariffs, which will

also assist in the reduction of your operating costs. Plus, you will also have much happier neighbours.

Many pool products rely on minimum flow rates for best operation and/or efficiency. If you are using low flow

settings on the SilensorPRO (e.g. speed 1 to 4) Davey recommends that you check the compatibility of the

speed or minimum flow rate required to run specific pool equipment such as:

• Suction pool cleaners;

• Ozone generators;

• Heating systems;

• Salt water chlorinator cells;

• In-floor pool cleaning systems.

Pre-start up checklist

• Speed setting chosen is a compatible setting with other pool equipment;

• The pump is installed in a safe and dry environment;

• The pump enclosure has adequate drainage in the event of leakage;

• Any transport plugs are removed;

• The pipe-work is correctly sealed and supported;

• The pump is primed correctly;

• The power supply is correctly connected;

• All steps have been taken for safe operation;

• The filter has been plumbed with 50/63mm pipe;

• The (app) schedule settings correspond with any other times in the system.

English

7

Page 8

Low energy operation

Your SilensorPRO SP200BT has speed settings from 1,500 - 3,600rpm. The SilensorPRO SP400BT has

speed settings from 1,050 - 3,100rpm. Speed 1 being the slowest and speed 10 being the fastest.

• Speed 1 provides the lowest speed and therefore the greatest energy efficiency and savings.

Operation

Backwashing your media filter

Pool Filtration

Suction pool cleaner operation

Manually cleaning your pool

Water Feature operation

Spa Jet operation

In-floor cleaning systems

Solar pool heating

Recommended Speed Setting

Backwash Speed

Speed 1 to 4

Speed 5 to 8

Speed 9 to 10

Guidelines for recommended pump operating hours

Typical residential pool turnover rate shall be a single turnover of the full volume of the pool water, within the

daily period that the pump would normally be operating. The table below provides a guide only to the running

times of your pump while in filtration mode in order to achieve the minimum turnover rate:

SilensorPRO SP200BT

Pool size

(Litres)

20,000 3.3 1.7 1.1

Speed 1 Speed 5 Speed 10

Speed Setting (hours)

30,000 5.0 2.5 1.7

40,000 6.7 3.3 2.2

50,000 8.3 4.2 2.8

60,000 10.0 5.0 3.3

80,000 13.3 6.7 4.4

100,000 16.7 8.3 5.6

SilensorPRO SP400BT

Pool size

(Litres)

20,000 2.4 1.3 0.9

30,000 3.7 2.0 1.4

40,000 4.9 2.7 1.9

50,000 6.1 3.3 2.3

60,000 7.4 4.0 2.8

80,000 9.8 5.3 3.8

100,000 12.3 6.7 4.7

Speed Setting (hours)

Speed 1 Speed 5 Speed 10

English

8

Page 9

In accordance with EN60335.1 we are obliged to inform you that this appliance can

be used by children aged from 8 years and above and persons with reduced physical

sensory, or mental capabilities, or lack of experience and knowledge, if they have been

given supervision, or instruction concerning use of the appliance in a safe way and

understand the hazards involved. Children should be supervised to ensure they do not

play with the appliance.

Emptying the strainer basket

The strainer basket should be inspected frequently through the transparent lid and emptied when a build-up

of rubbish is evident. The directions below should be followed.

• Switch off pump;

• Unscrew the strainer basket lid anti-clockwise and remove;

• Remove the strainer basket by lifting upwards from its housing;

• Empty the trapped refuse from the basket. Hose out with water if necessary.

NOTE: NEVER knock the plastic basket on a hard surface as it will cause damage.

• Check the strainer basket for cracks, replace the strainer basket in the pump if damaged;

• Replace the lid and ensure that it seals on the large rubber o-ring. Firm hand tightness only is required.

The o-ring & thread can be lubricated with Hydra Slip or equivalent products.

Failure to undertake regular maintenance may cause damage not covered by warranty.

Routine maintenance

To maximise the life of the SilensorPRO, and for personal safety use this checklist once a week. Ensure

pump is off before starting:

• Make sure that any pressure gauges are in working condition and the operating pressure is within limits as

specified on the product;

• Make sure that each suction inlet and main drain has a cover that is securely attached and in safe working

condition;

• Make sure that all skimmer covers are securely attached and in safe working condition. These should be

replaced every 3 to 4 years;

• Remove any obstructions or debris from the main drain cover;

• Ensure the skimmer and pump baskets are free of leaves and debris at least once a week;

• Remove obstructions and combustibles from around the pump motor;

• Make sure all wiring connections are clean and that all wiring and electrical equipment is in good condition.

Damaged wiring must be repaired or replaced by a qualified electrician as soon as damage is discovered;

• Check water balance and sanitizer levels at your local pool shop.

English

9

Page 10

5. FEATURES & FUNCTIONALITY

The SilensorPRO has several operational features. The following explain each of these.

Multi-coloured LED indicator light

Used for identifying required settings for programming time for full speed (Boost) cycling and warnings:

• Solid green = Normal dial operation

• Slow flashing green = In backwash mode

• Fast Flashing green = AUX external control

• Solid White = Time to Backwash

• Fast Flashing White = Fault detected - reset pump

• Slow Flashing blue = Operated by Bluetooth

• Solid blue = Bluetooth mode

Backwash speed cycling technology

When in backwash mode the SilensorPRO will cycle between a low and high speed to help agitate the filter

media for a more effective clean. This reduces wasted water and chemicals during the backwash cycling

process.

Full variable frequency drive with user friendly selectable speed dial

• Provides for easy selection of desired filtration speed

• No complicated digital push button controls

Large 4.5 litre lint pot

• Provides for longer intervals between cleaning

Patented water-cooled design for smooth and super quiet operation

The SilensorPRO has a water-cooled membrane and jacket around the motor which helps to keep the pump

cool during operation. Waste heat off the motor is transferred into the pool water, helping to reduce pool

heating energy costs.

SP400BT constant flow/speed compensation

As the pool filter becomes dirty, pressure builds up. With a typical pool pump, this would naturally slow the

flow coming through the system. The SilensorPRO has the intelligence to automatically detect the resistance

applied by a filter and slowly compensate the reduction flow, by increasing the speed of the motor. The result

is the flow remains constant between filter cleans.

When the SilensorPRO detects that the speed increase indicates time to backwash your filter, the LED

indicator will show a solid white display (see item above).

SP400BT weatherproof RJ45 communication port

(see section 7 for connection details)

• For communication and connecting to external pool control systems

• For receiving a signal from a heat pump, or gas heater to ramp the SilensorPRO speed to full during the

heating process

• Service diagnostics and software updates (For Davey use only)

10

English

Page 11

6. BLUETOOTH FUNCTIONALITY

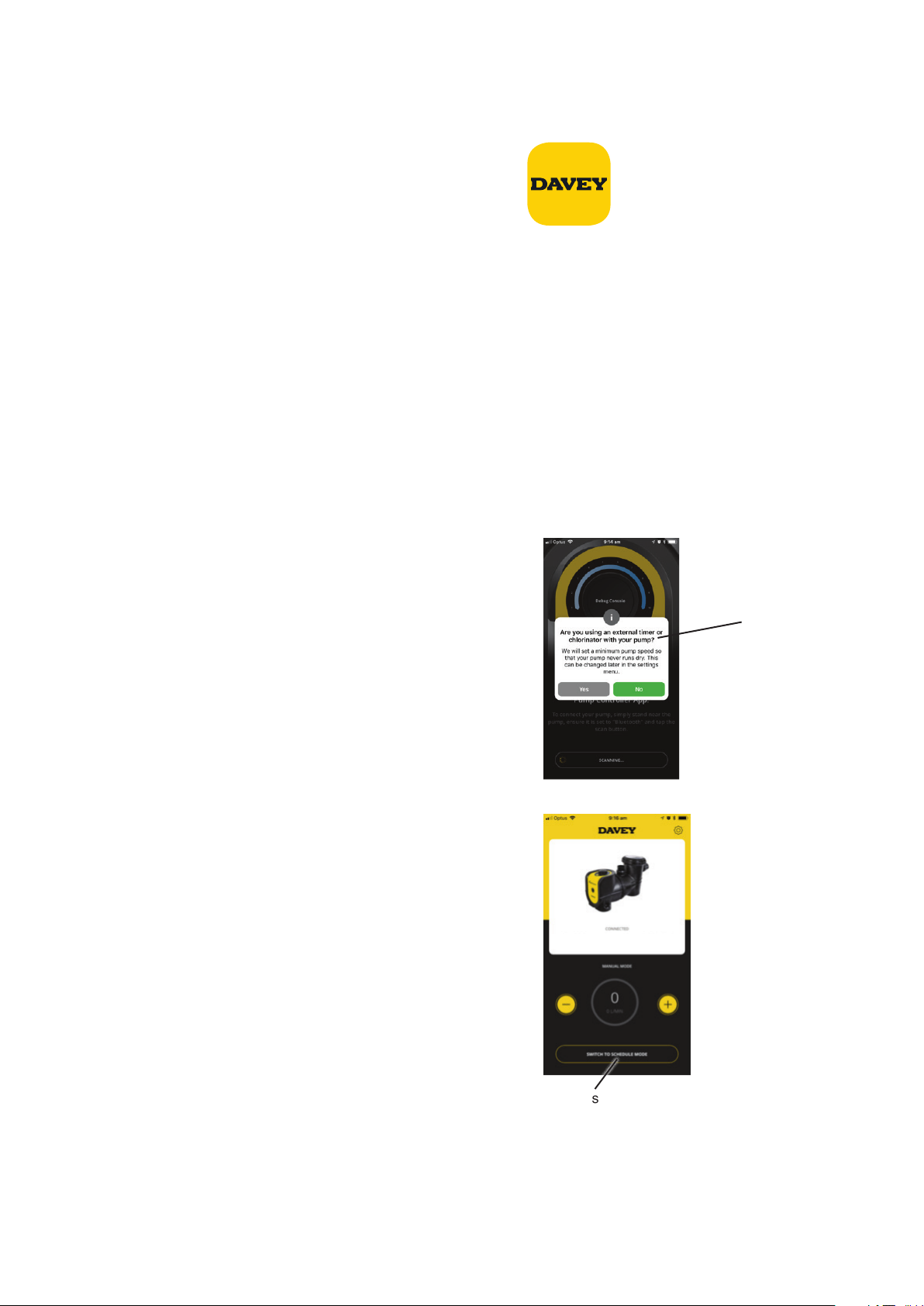

Bluetooth app set up

• Open the “App Store” app that is available on your device.

• Search “Davey Pool Pump”

• Install the app on your device

The app can be installed on to as many devices as desired, however, only one device can control the pump

at any given time. The language and time of the app is the same as your device setting. The measuring units

are automatically defaulted to your device’s region units, however, you can choose between Litres, Gallons

3

/hr.

or m

Pairing a device to the pump

• Open app on your smart device.

• Turn dial on the pump from “off” to “Bluetooth”, you will see the LED flash white for a second.

• On your device, press the connect button.

• When setting up for the first time ONLY, select “YES” to allowing location.

• Please note that the first time the devices are paired, there is a 2-minute time limit to do so before the

procedure will have to be repeated.

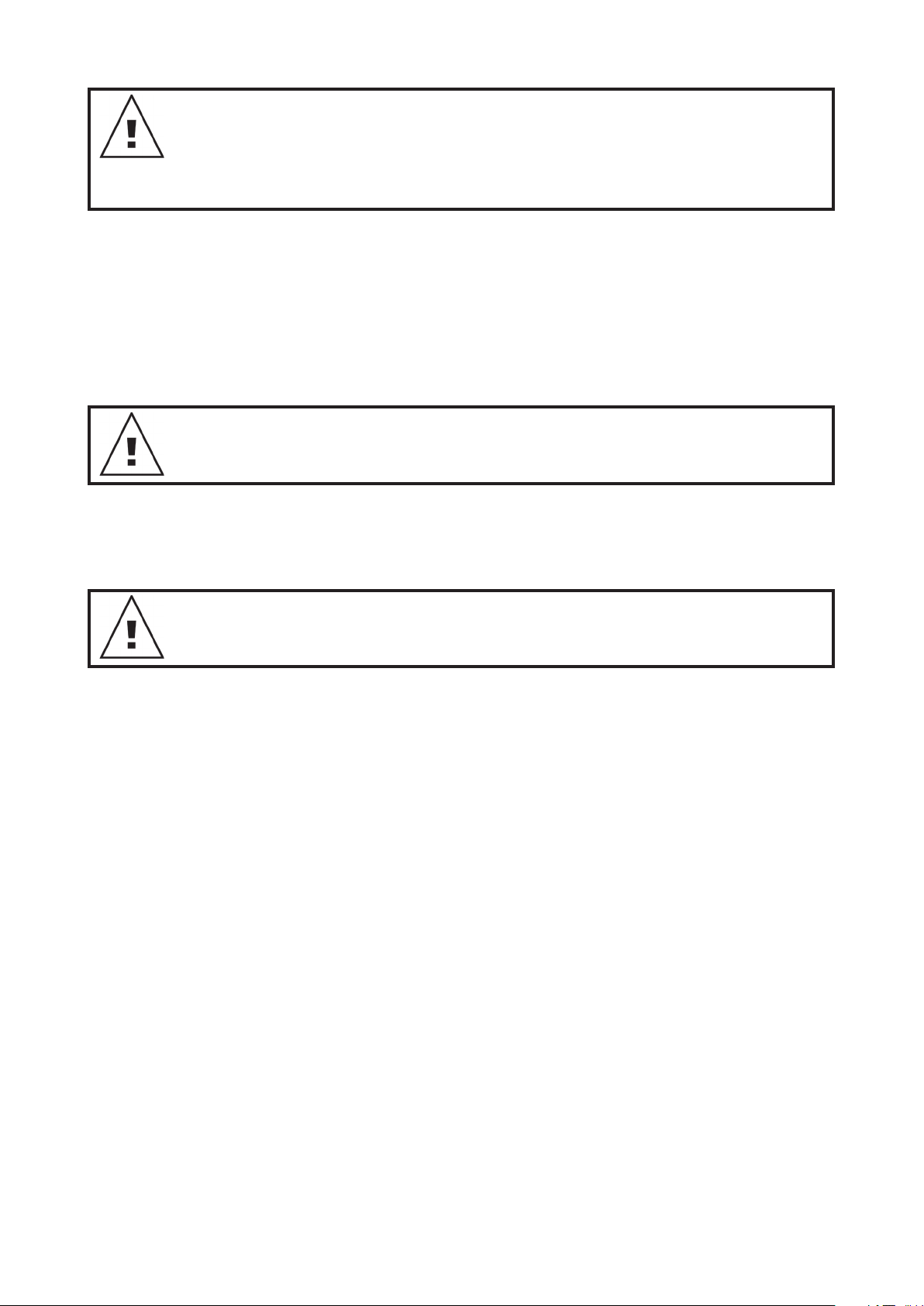

External timer / chlorinator

A pop-up will appear asking if you are using an external timer, or

chlorinator to control the SilensorPRO. Please select “yes”, “no”.

This is a safety function that helps ensure the chlorinator only

runs when the pump is working.

This pop-up

will show

Note: App screenshots are for demonstration purposes only.

Actual screens may vary.

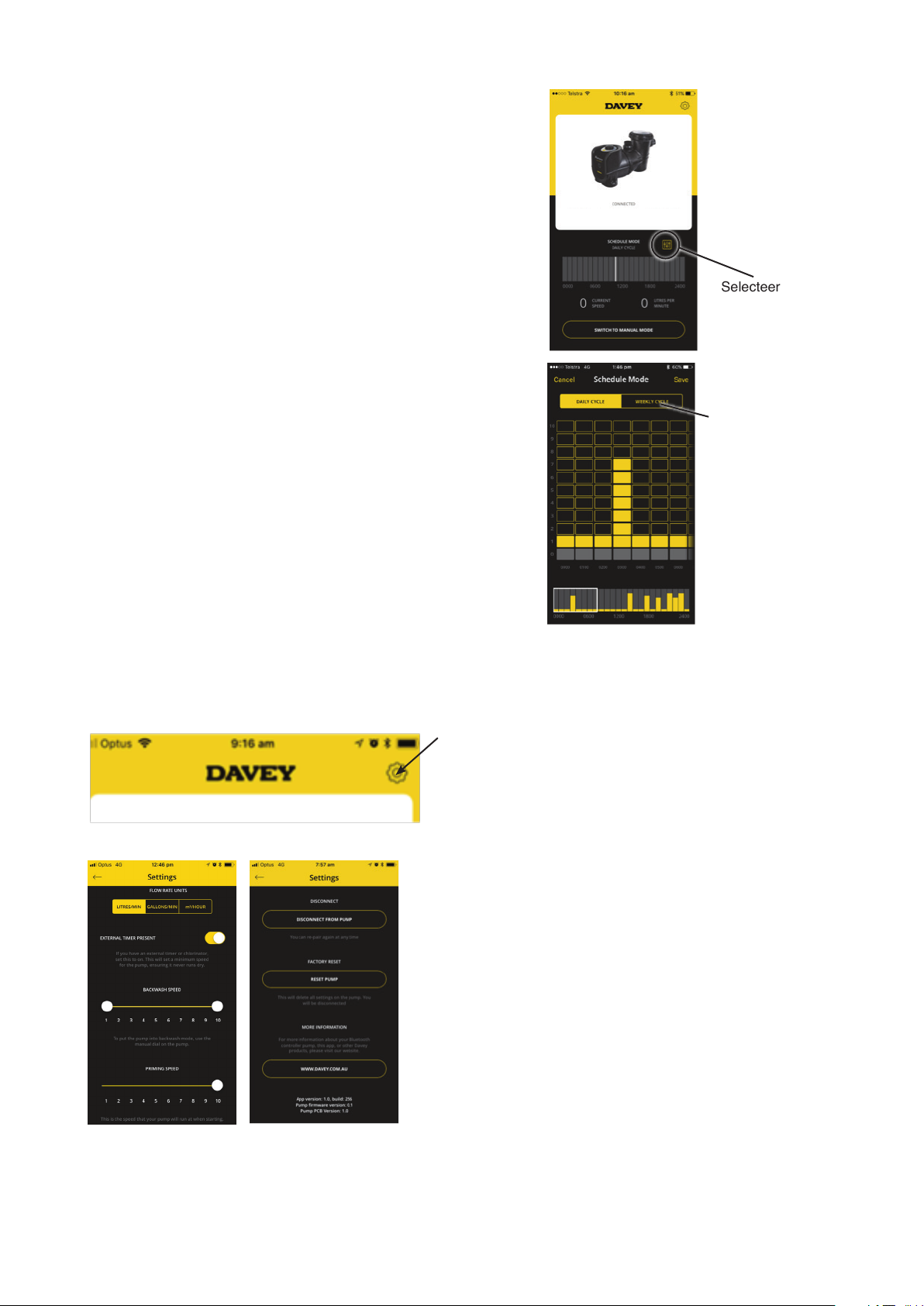

Manual, or scheduled mode

Two modes are available depending on whether you wish to

manually operate the SilensorPRO, or alternatively you can

create a schedule of operation.

Manual mode

• If in schedule mode, press “switch to manual mode”

• The app will now be in manual mode and you can manually

adjust the speed by pressing the (+/ -) buttons.

• In manual mode, the SilensorPRO will run at the set speed,

even if the phone is not in range.

• Anytime the dial is switched to the Bluetooth position, it will

run at the previous set speed after the priming cycle.

Schedule mode

• There are two options (set a daily cycle, or a weekly cycle) by

pressing the desired box.

• This option allows you to either create a standard “daily

schedule” which will consistently operate the set levels every day;

11

SilensorPro BT

To switch between

manual or schedule

mode you can press

this button.

English

Page 12

There are two options (set a daily cycle or a weekly cycle) by

pressing the desired box. This option allows you to either create

a standard “daily schedule” which will consistently operate the set

levels every day

• The “weekly cycle” option can be set for the entire week, giving

you the ability to alter daily pump cycles depending on the

weather, bather load etc.

Setting a schedule

SilensorPro BT

• Select the box which relates to the time that you require the

pump to operate;

• Select the speed setting you would like the pump to run at any

time. Note: Settings of the pump (1-10) refers to slowest to

fastest operating speed of the pump;

• Once you are happy with your schedule, select “Save”.

Communications between the device and the pump can take

up to 20 seconds depending on the schedule selected;

• The row at the bottom of the screen indicates a summary

of where the schedule is by day and by hour. This summary

screen can easily be altered by swiping up or down the

columns above;

• Note: If using a chlorinator, you must ensure that the “on”

times on the pump correspond to the “on” times on the

chlorinator. The pump will remain in the last used mode,

whether that be manual mode or schedule mode.

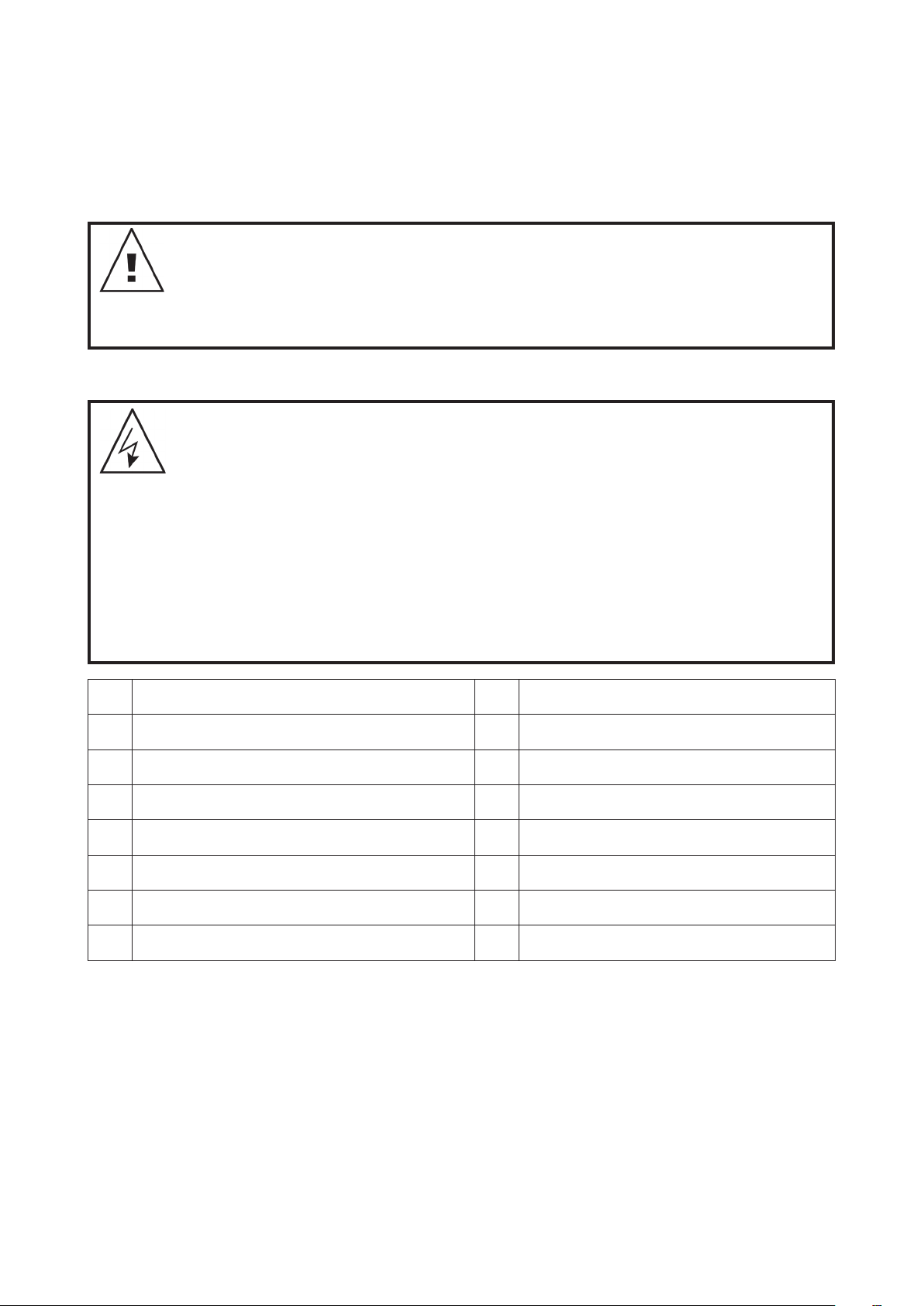

Settings

To alter setup settings, click on the settings icon:

Select to edit the

schedule settings

Select if you

would like the

daily cycle or the

weekly cycle.

This will display the following screens (scroll down screen for full information).

Priming speed / max speed

Each time your pump starts it will go through 2 minutes of priming to ensure there is water in the system. You

can adjust the speed in which it does this between 5 & 10. The speed you set will limit the maximum speed

the pump will run in manual or schedule mode.

12

English

Page 13

Backwash

Can be set as a single speed or alternatively set two speeds and the pump speed will “pulse” between the

two settings. Minimum speed can be set between 1-10, maximum speed can only be set between 5-10.

External time present

Swipe this on or off, depending on whether you are using an external timer/chlorinator.

Disconnect function

The “disconnect from pump” function can be used to:

• Allow another device to control the pump;

• Disconnect so that you will not automatically connect to the pump;

• Please note that the Bluetooth connection will automatically disconnect after a minute of no communication.

Factory reset

This will reset the pump back to factory configurations and allows you to start the setup process again.

• Select “reset pump”;

• Turn dial to “off” position, then turn dial to “Bluetooth”;

• You can then re-pair with your phone. This procedure is in place so that the pump cannot accidentally be reset.

Pump fault finding

In the instance that there is a fault, the following screen will appear, with text description below the fault

indicating how to remedy.

SilensorPro BT

Fault title Fault description

Check that the motor can rotate freely. Unplug for 1

Pump fault – overcurrent

Pump fault – under voltage

minute and plug back in to reset. If problem persists call

Davey, or an authorised repair agent.

Supply voltage issue. When power is back to normal,

unplug for 1 minute and plug back in to reset.

Pump fault – over temperature

Pump fault – motor stalled

Pump fault – underload/loss of prime

Pump is too hot. Check the ambient temperature. Set to

lowest speed possible if ambient temperature is too high.

Check that the motor can rotate freely. Unplug for 1

minute and plug back in to reset.

Check if there’s enough water inside the pump. Unplug for

1 minute and plug back in to reset. If problem persists call

Davey, or an authorised repair agent.

English

13

Page 14

Pump fault – motor over temperature; or

Pump fault – over voltage; or

Pump fault – earth fault; or

Pump fault – system fault; or

Pump fault – output phase fault; or

Pump fault – power overload; or

Pump fault – EEPROM checksum; or

Pump fault – watchdog error; or

Pump fault – back EFM protection; or

Pump fault – thermistor fault; or

Pump fault – safe torque off; or

Pump fault – internal bus communication; or

Pump fault – application error; or

Pump fault – IGBT temperature high; or

Pump fault – 4mA analogue input fault; or

Pump fault – external fault; or

Pump fault – keypad communication error; or

Unplug for 1 minute and plug back in to reset. If problem

persists call Davey, or an authorised repair agent.

Pump fault – fieldbus communication error; or

Pump fault – fieldbus interface error.

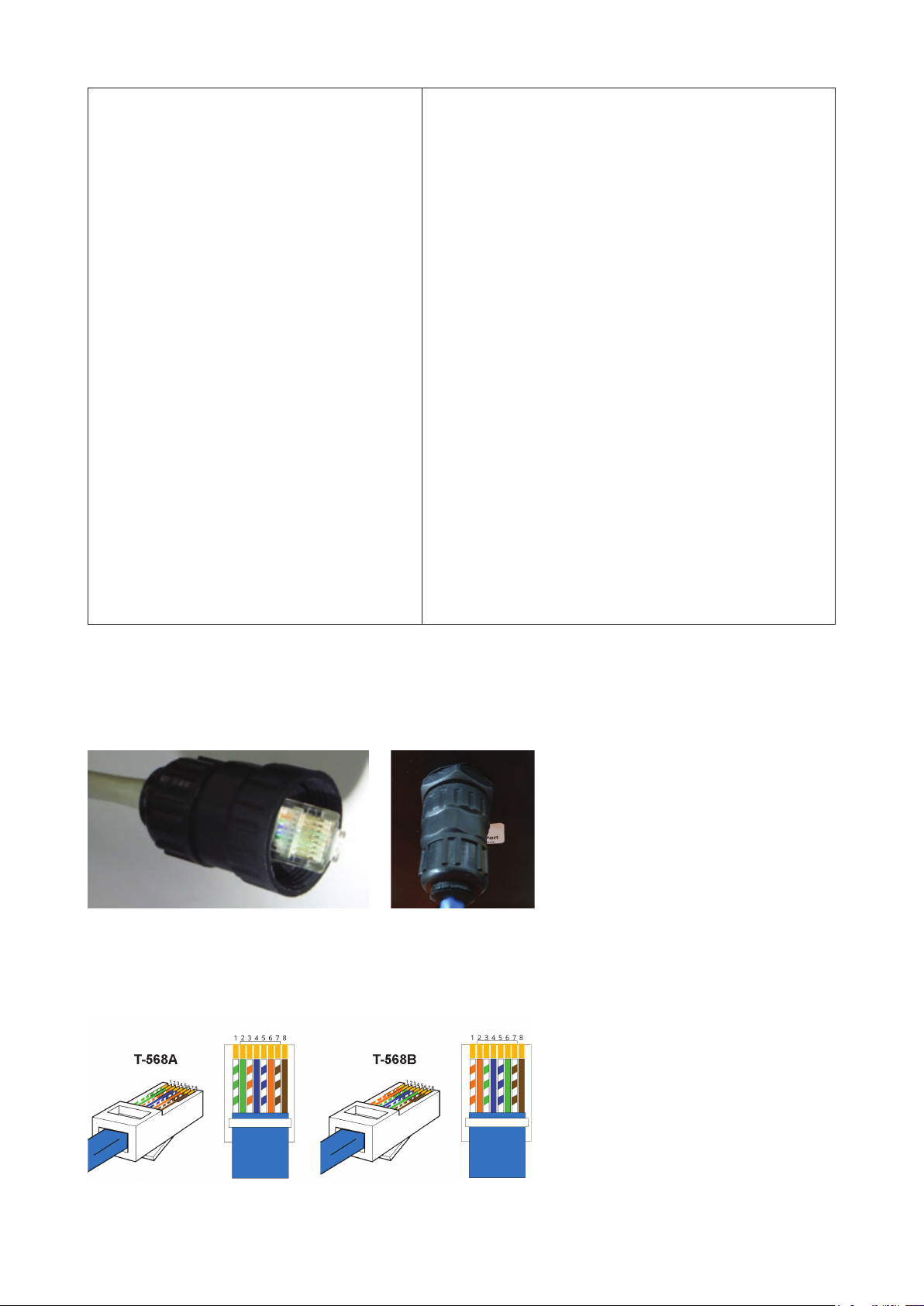

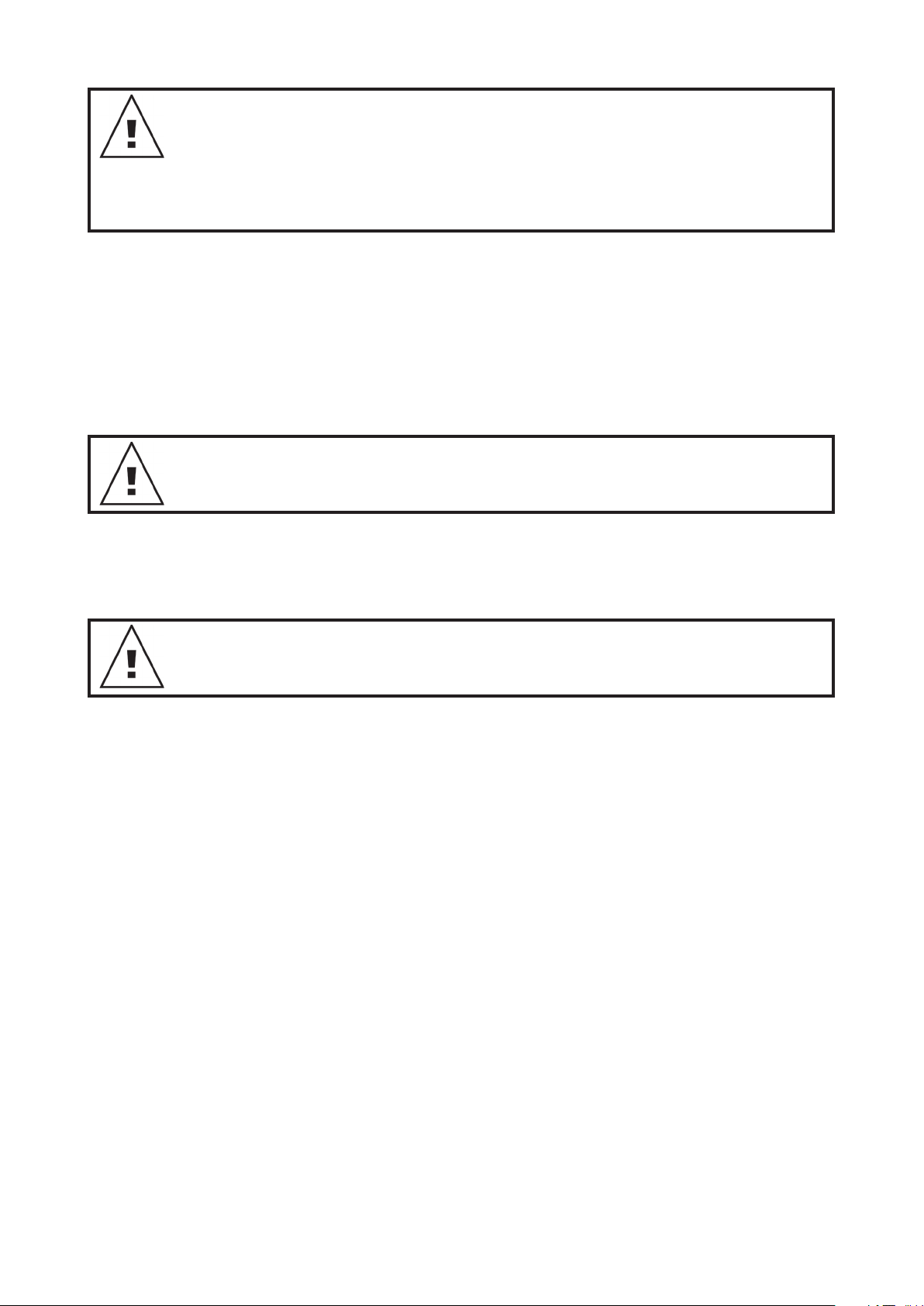

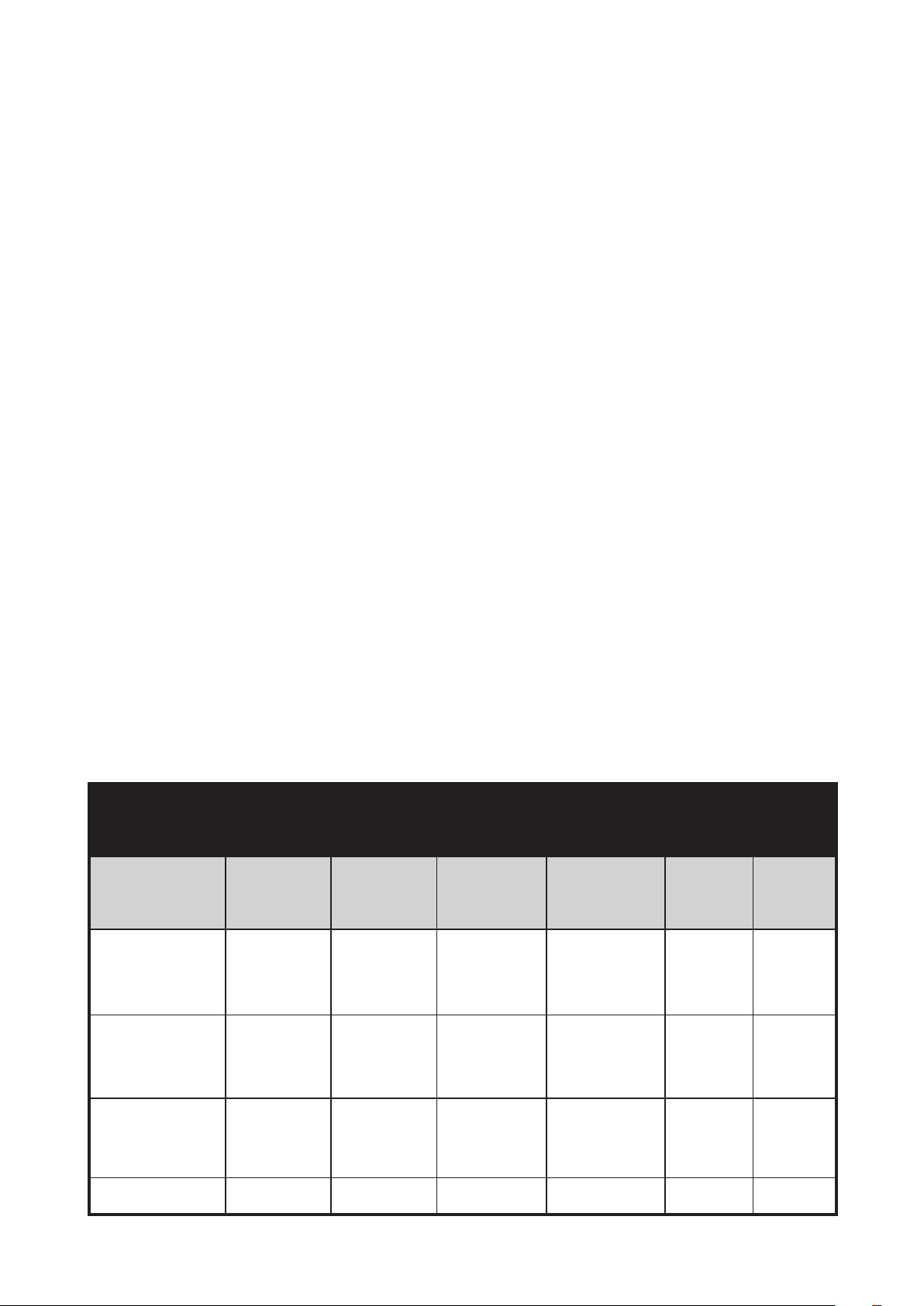

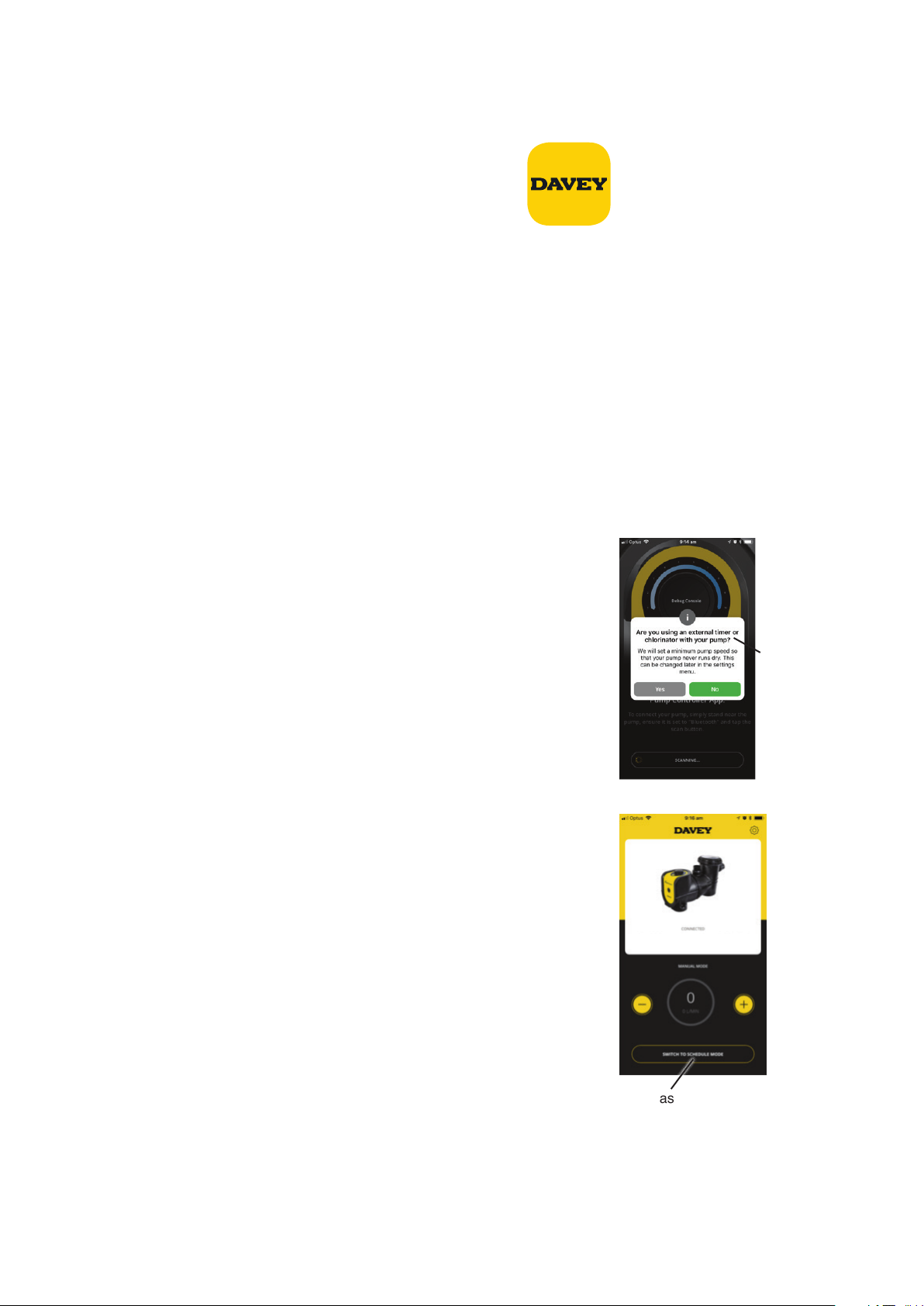

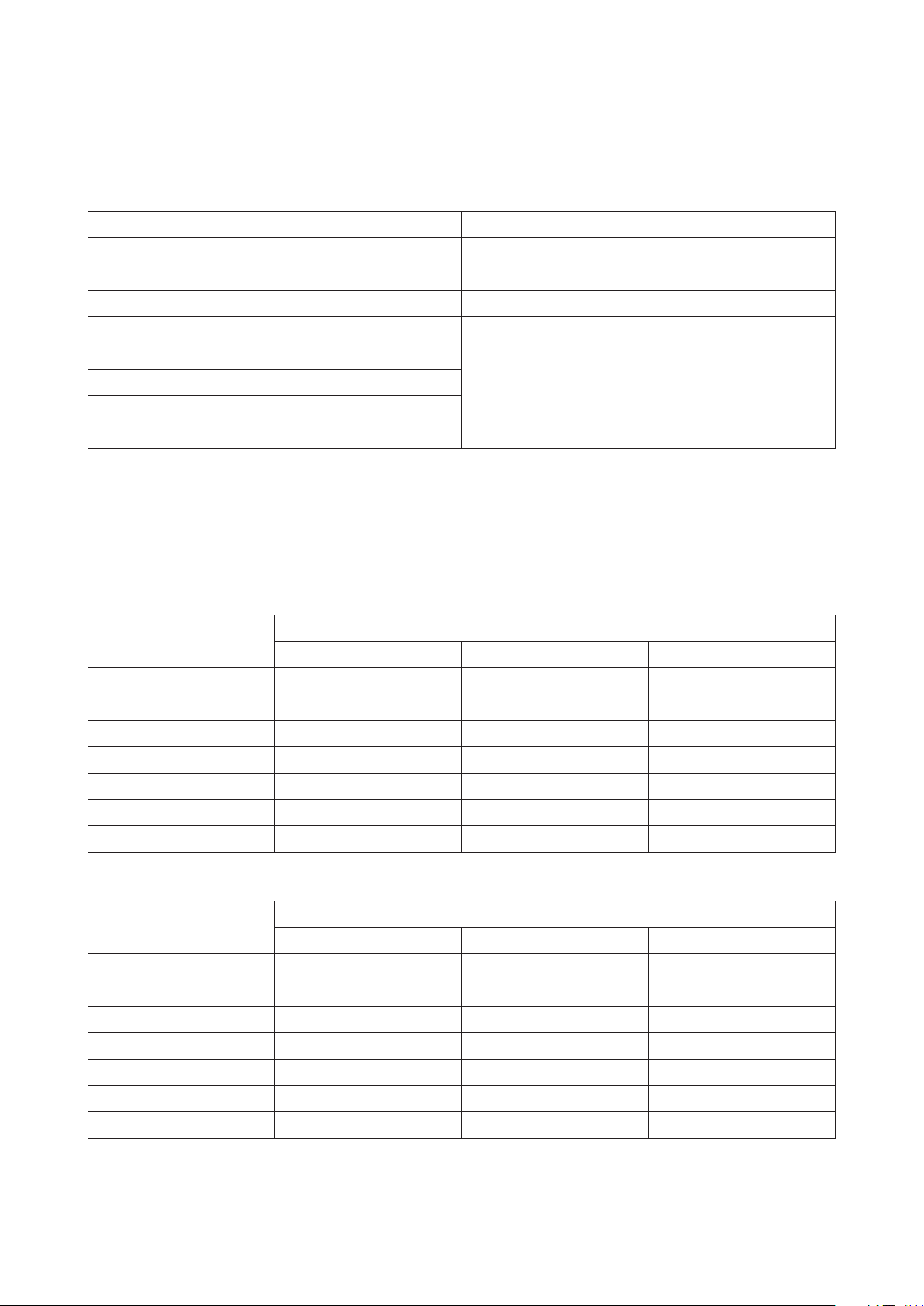

7. ADVANCED SETUP OF SP400BT

External AUX connections overview

Your SilensorPRO SP400BT has an RJ45 style waterproof socket to allow for external control of motor speed

and other functionality. A standard RJ45 network cable (without boot) can be used.

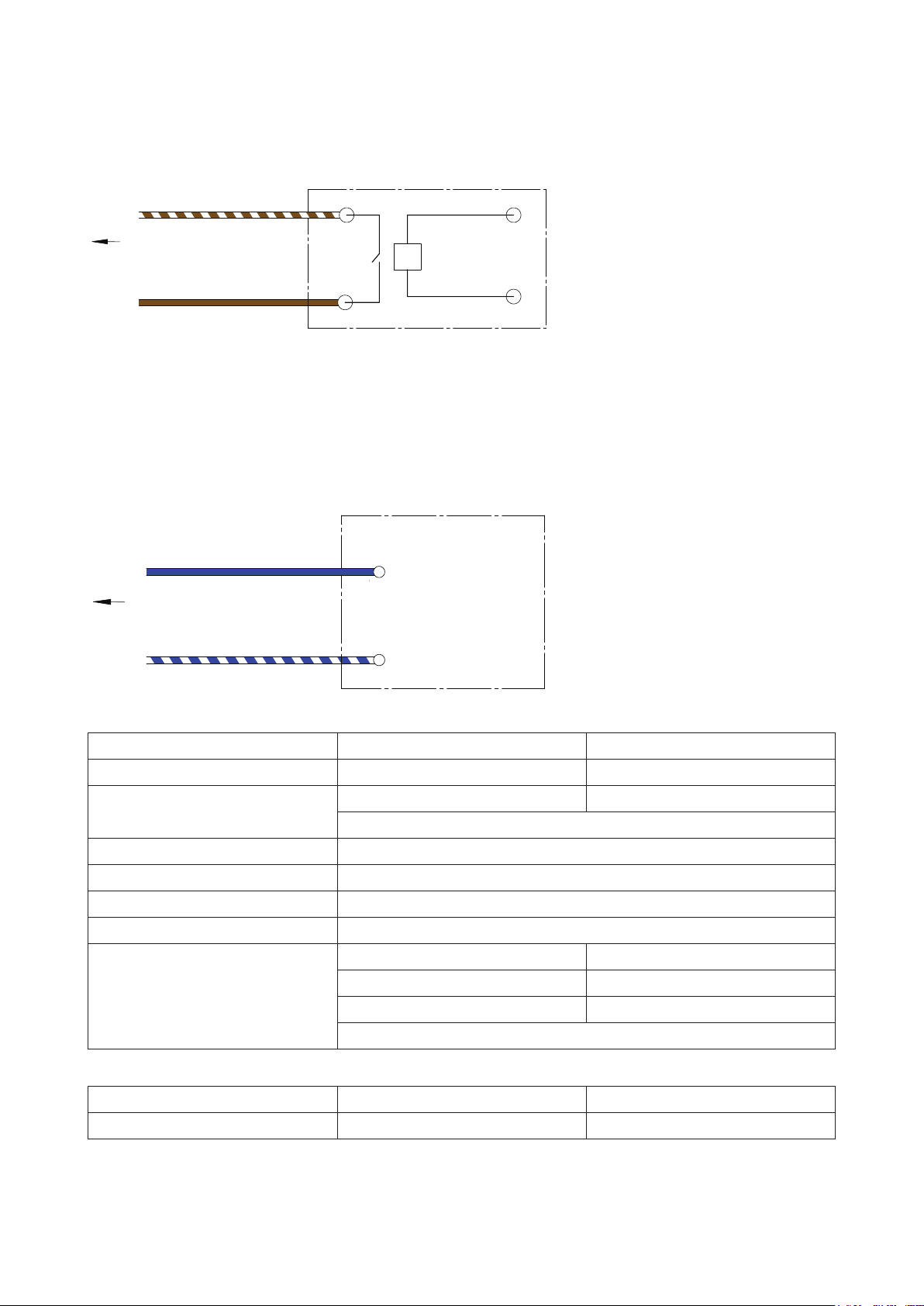

Figure 1: RJ45 Plug installed in housing (from rear)

It is recommended to keep the cable length between the pump and external pool controller or heater as short

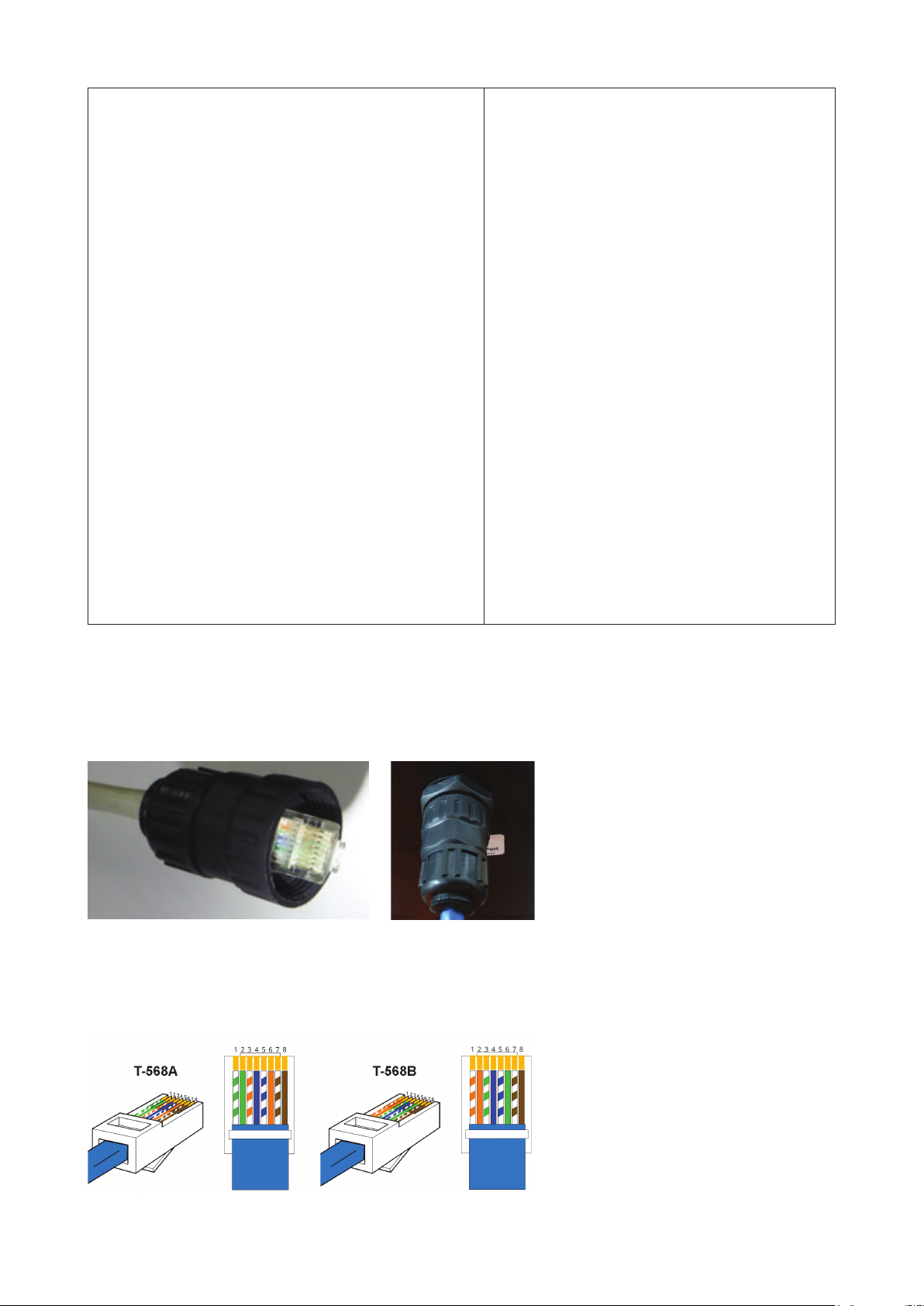

as possible. There are two major pin configurations as shown below:

RJ45 PINOUT

Figure 2: RJ45 pin connections

English

14

Page 15

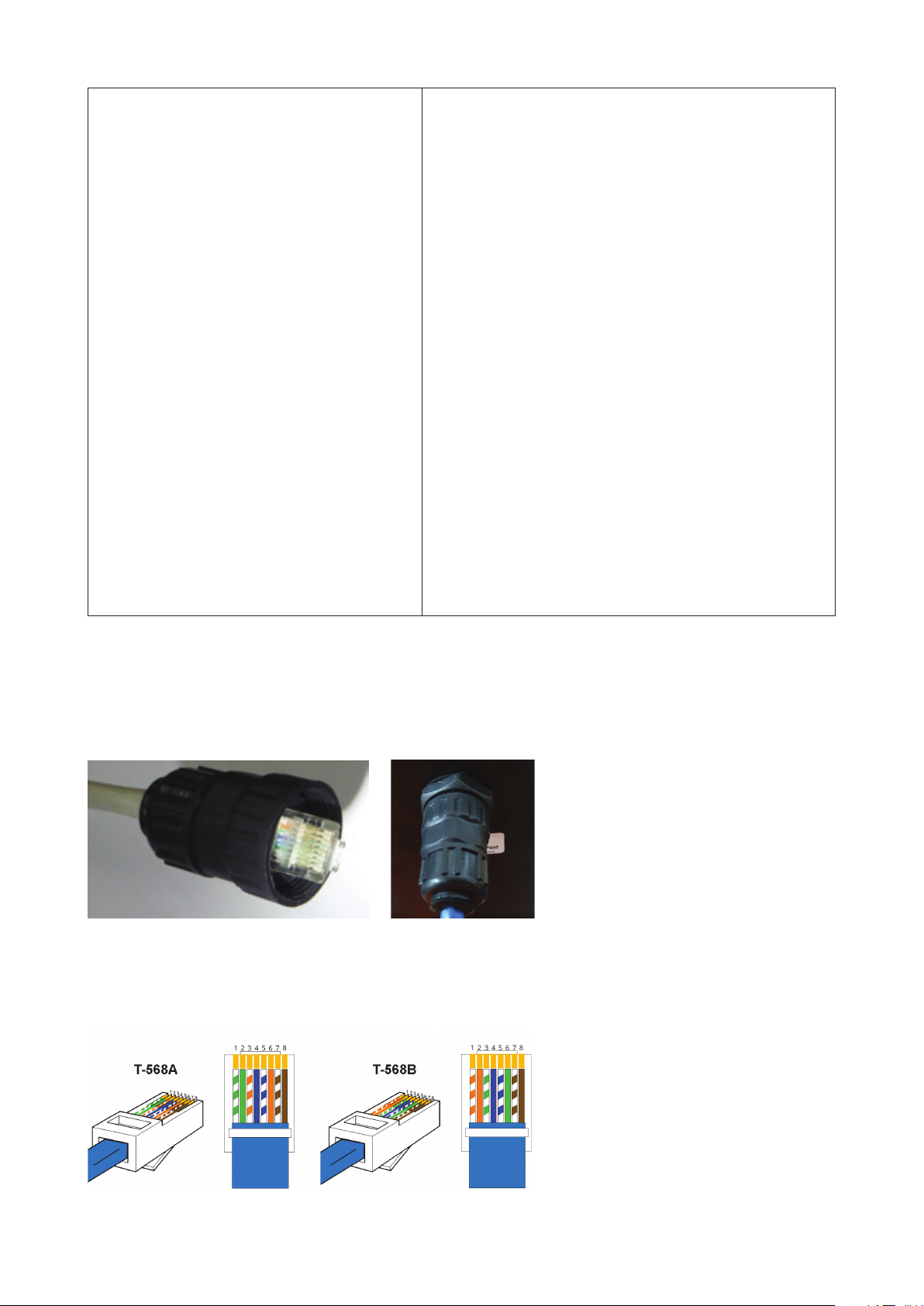

Pin Function T-568A T-568B

1 RS485 +ve Green/white Orange/white

2 RS485 -ve Green Orange

3 Digital input 3 Orange/white Green/white

4 Analogue input Blue Blue

5 0V DC ground Blue/white Blue/White

6 Digital input 2 Orange Green

7 Digital input 1 Brown/white Brown/white

8 24V Brown Brown

Check that the cable you use has the above colour coding pins 1 through to 8. If an alternative colour coding

has been used make sure to record the colour which corresponds to each pin to avoid misconnection at

the pool controller or heater. If an alternative cable is used make sure the analogue input and ground are a

twisted pair.

The 24V connection is only to be used as a reference for the digital inputs – DO NOT power external

equipment from this supply rail.

Digital control inputs

The 3 digital inputs allow for overriding the dial speed setting. To set one of these inputs either:

• Connect an isolated 24V supply between DC ground and the digital input pin

• Connect the switched contacts of a relay between the 24V pin and the digital input

The fixed speeds (as a proportion of full speed) are:

Input 1 (Pin 7) Input 2 (Pin 6) Input 3 (Pin 3) Output Speed

0 0 0 Dial

0 0 24V 33%

0 24V 0 50%

0 24V 24V Backwash

24V 0 0 100%

24V 0 24V 67%

24V 24V 0 83%

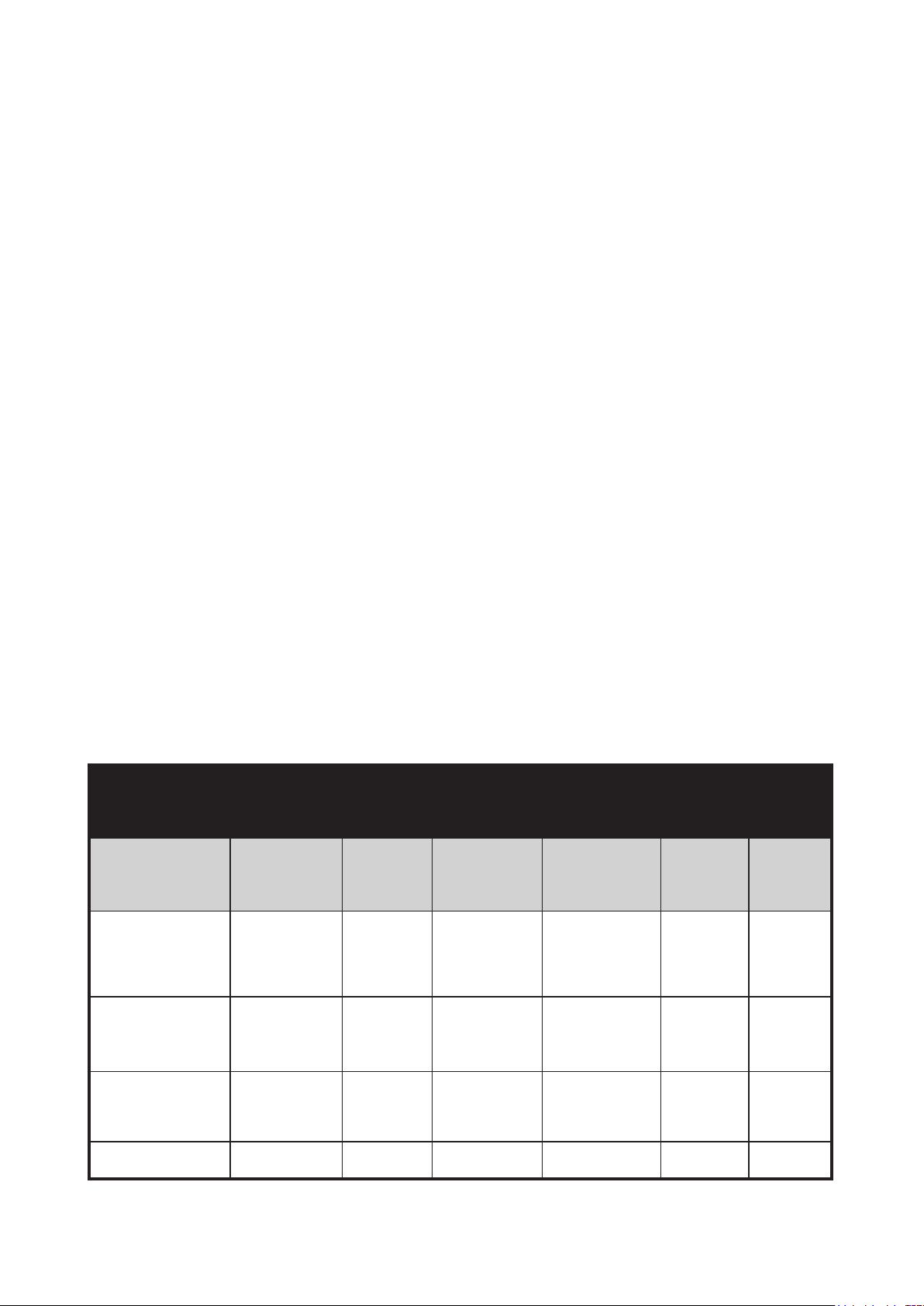

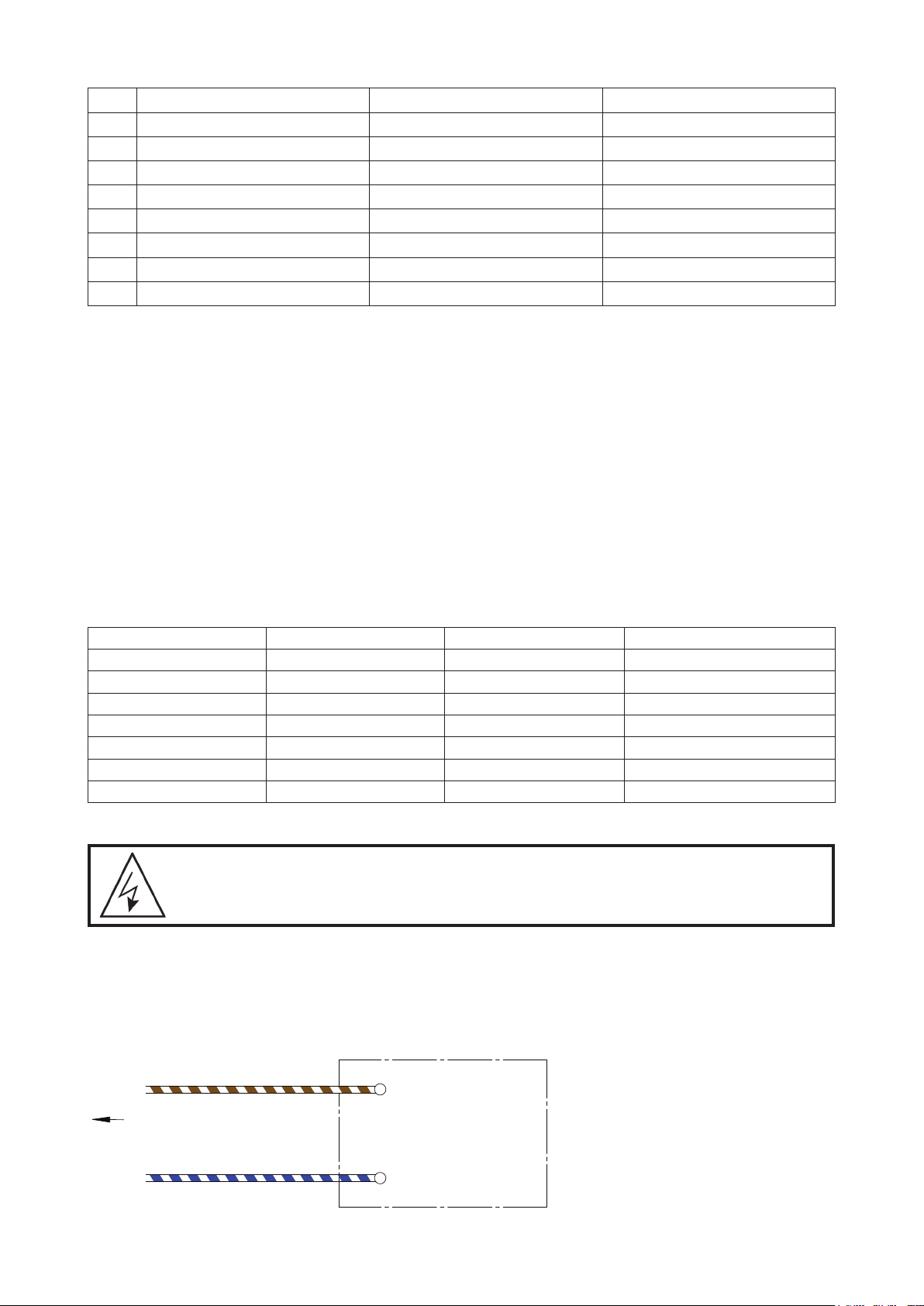

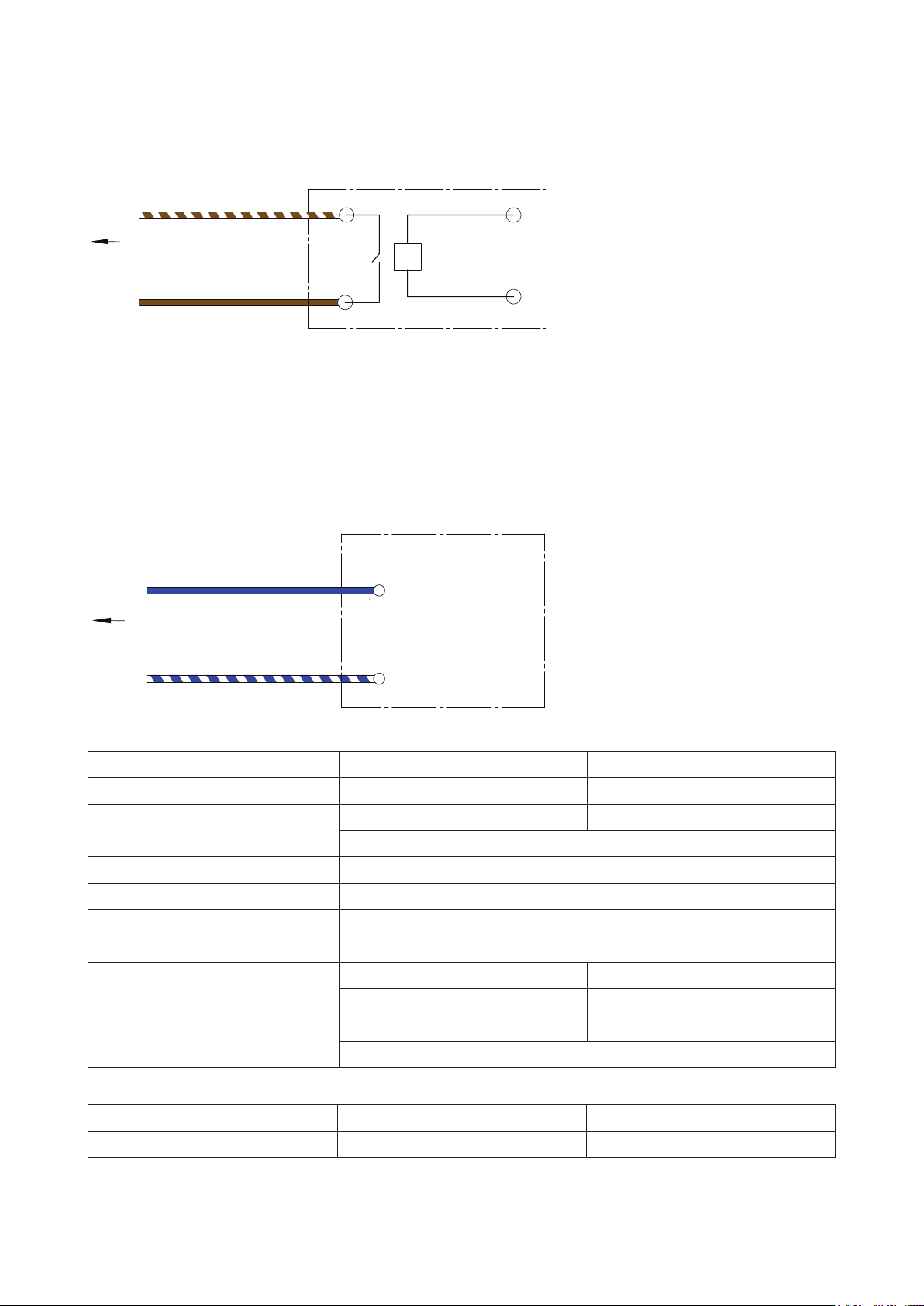

Interfacing equipment to the SilensorPRO SP400BT

WARNING! A qualied electrician is required to carry out the work shown below.

The SilensorPRO SP400BT can be controlled by other equipment to turn it on to high speed (or any other

pre-set speeds, see section 8 for details). This is to achieve maximum efficiency, for example, when using a

gas heater, or a heat pump. If the equipment has an isolated 18- 24V DC signal output, simply connect pin 7

to 24V DC positive and pin 5 to DC ground as shown in the following diagram:

Pin7 (Brown/White)

To RJ45 Socket of VSD Pump

Pin5 (Blue/White)

Controlling Equipment

+ 18 ~ 24V DC

DC Ground

English

15

Page 16

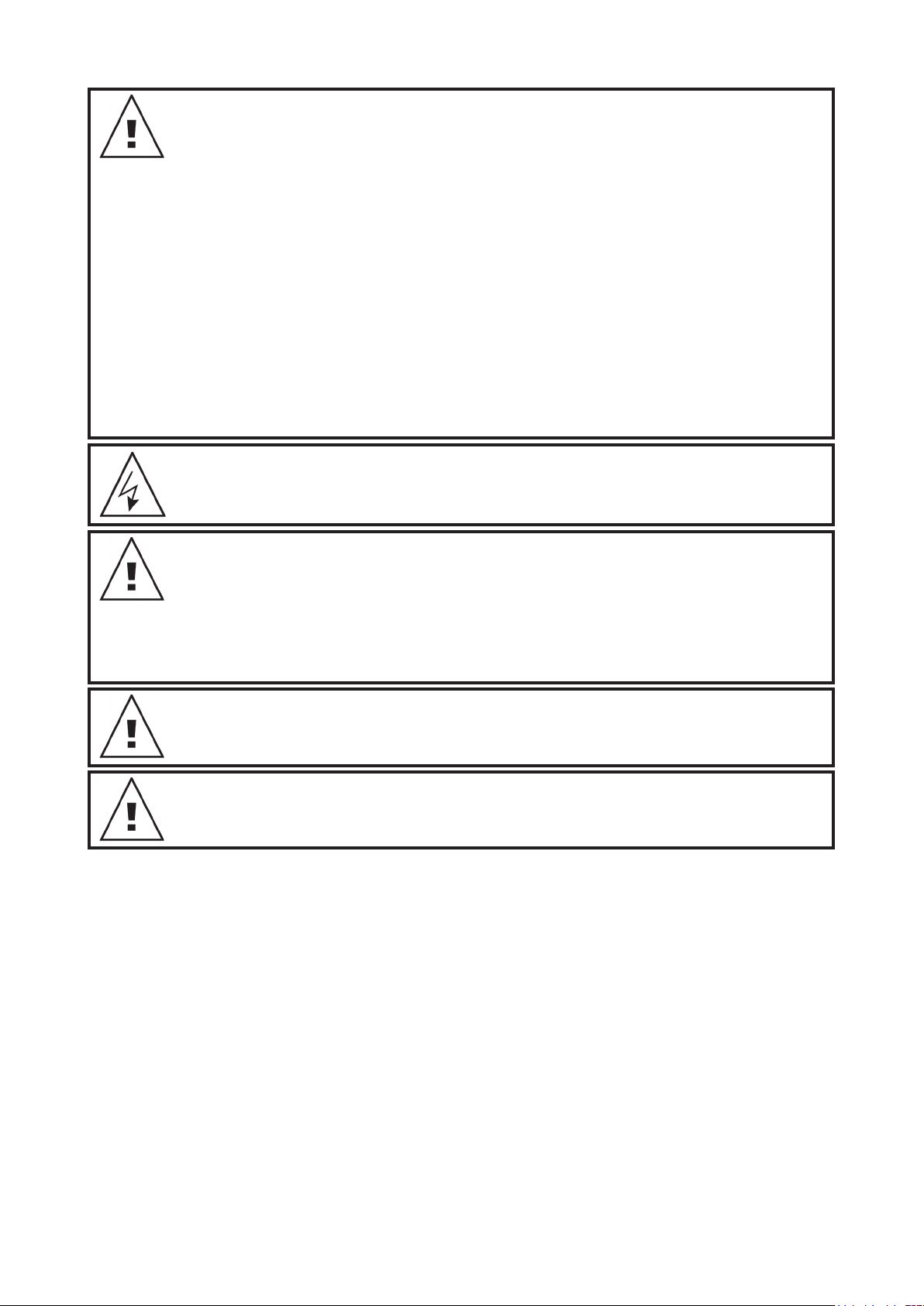

If the controlling equipment does not have 18-24V DC voltage output as above, but has 24V AC, 230V AC,

12V AC, or 12V DC etc. signal output, a suitable relay (the coil voltage must be the same as the signal output

voltage of the controlling equipment) can be used to do this job as mentioned above, and shown in the

following diagram:

Controlling Equipment

Pin7 (Brown/White)

To RJ45 Socket of VSD Pump

Pin8 (Brown)

Relay (Dry)

Contact

Relay Coil, must be

the same voltage

as the equipment

signal output

If the controlling equipment already has the relay output (dry contact) for controlling purpose, an extra relay

is not necessary, simply connect Pin 7 (Brown/White) and Pin 8 (Brown) to the dry contacts as shown in the

left part of the diagram above.

Analogue control inputs

Speed control can also be achieved by connecting a 0-10V DC signal at the input on pin 4 (ground at pin 5).

As soon as a signal above 0V is registered, this input will take priority over dial settings. For example, 10V

DC will change pump speed pump to 100%, 5V DC will change pump speed to 50% etc.

Controlling Equipment

+ 0~ 10 V DC Signal Output

Pin4 (Blue)

To RJ45 Socket of VSD Pump

Pin5 (Blue/White)

of controlling equipment

DC Ground

8. TECHNICAL SPECIFICATIONS

Model

Max head (m)

RPM

Enclosure class (IP)

Insulation class

Voltage (V)

Supply freq (Hz)

Motor input power: (W)

Operating Limits

Max water temperature:

Max ambient temperature:

Speed 1 – 10: 1,500 – 3,600 Speed 1 – 10: 1,050 – 3,100

Speed 10: 1,111 Speed 10: 1,639

SP200BT SP400BT

20 26

Backwash speed: variable

45

F

220 – 240VAC

50/60 Hz

Speed 1: 128 Speed 1: 126

Speed 5: 524 Speed 5: 728

Backwash speed: variable

40°C 40°C

50°C 50°C

16

English

Page 17

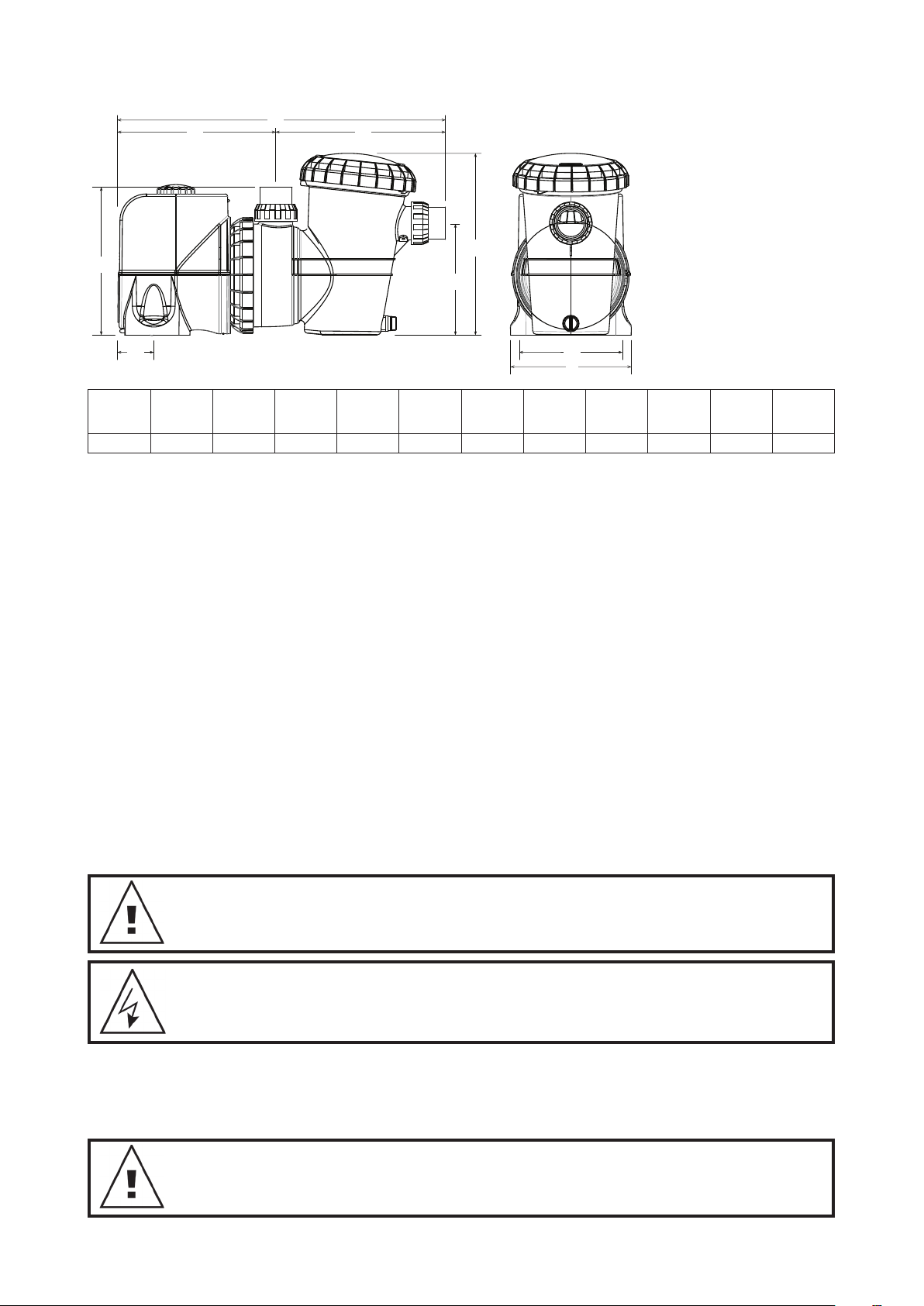

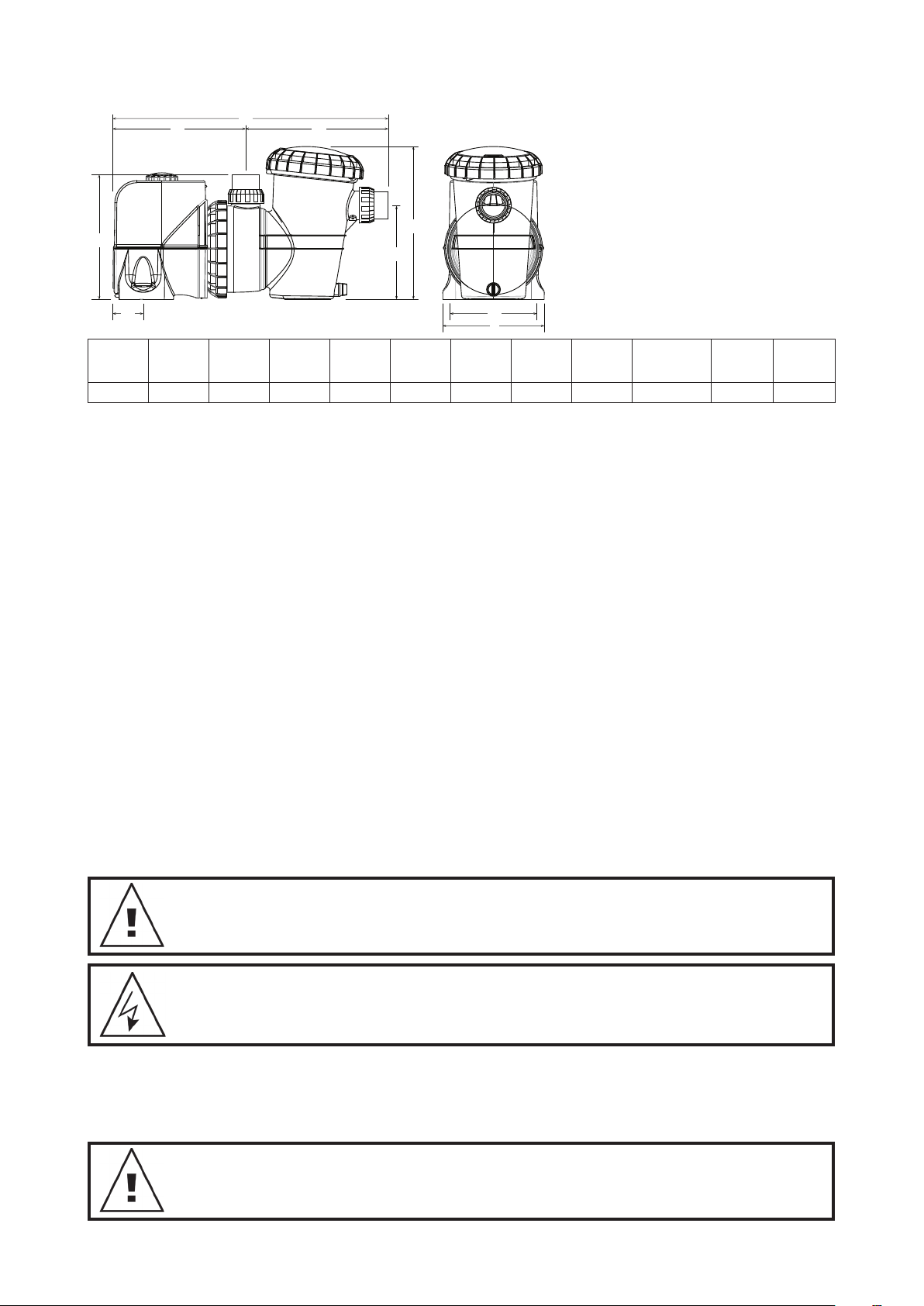

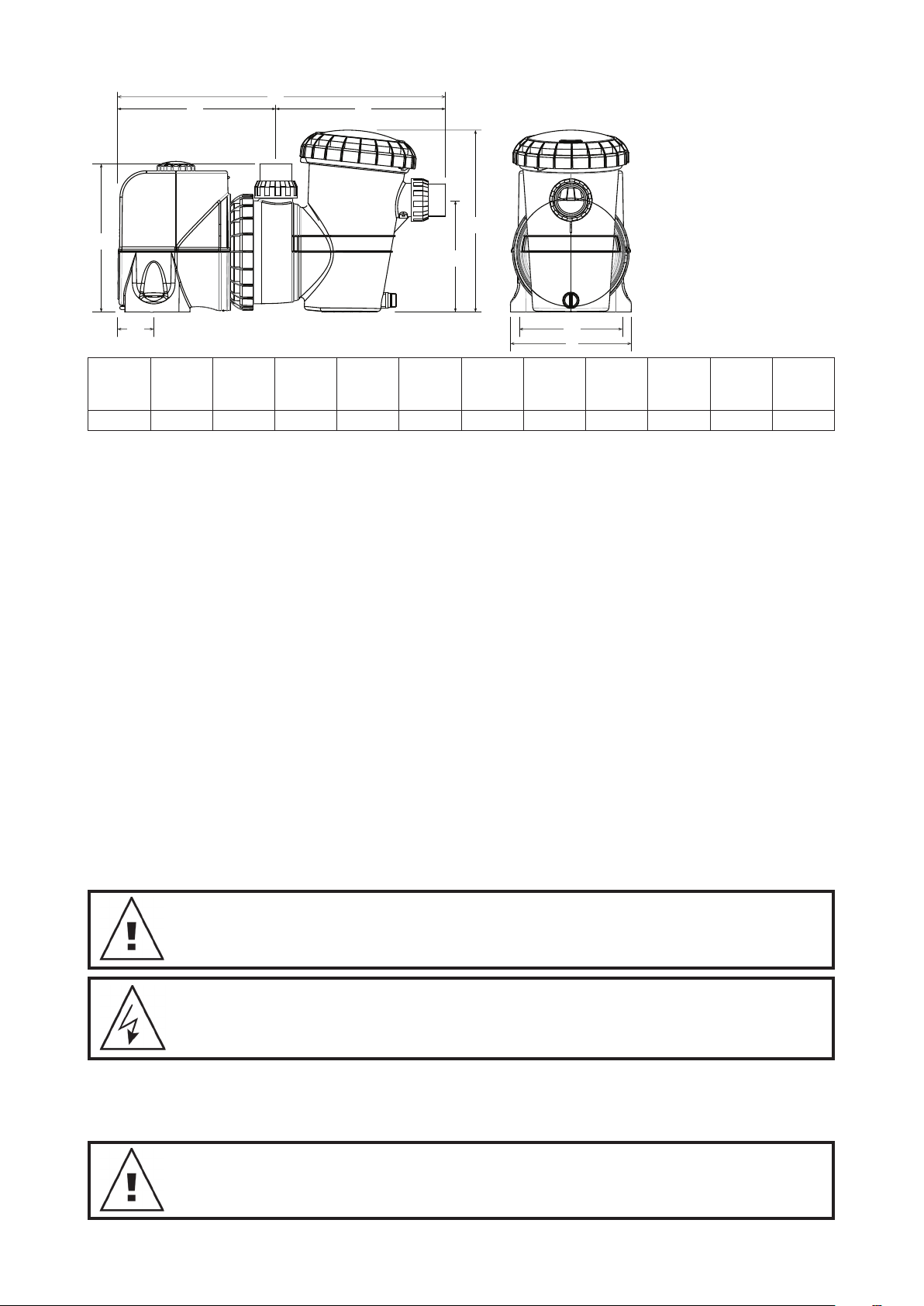

Dimensions

A

C

B

D

G

F

E

A

305mm 670mm 320mm 350mm 65mm 230mm 380mm 200mm 250mm 10mm 50/63 14

B C

D E F G H I

H

I

Mounting

Holes

Diameter

Inlet/Outlet

PVC

Net

Weight

(kg)

9. USING YOUR SILENSORPRO WITH A SALT WATER CHLORINATOR

Chlorinators require a minimum flow rate through the chlorinator cell for best efficiency and cell life. Please

refer to your chlorinator guide as a reference for the flow required by your pool system. Ensure flow rate is

enough to cover your chlorinator cell plates completely at all times of operation.

10. OPERATING YOUR SUCTION POOL CLEANER

Before installing or purchasing a pool cleaner for use with your SilensorPRO, it is important to know the

minimum flow rates required for it to operate effectively.

To operate a suction pool cleaner:

• Activate the High Flow setting (10) and allow the pump to fully prime by running for around 2 minutes. You

will know the pump is primed when you can see a strong flow of water through the clear leaf basket lid.

• When all air is expelled from the leaf basket, connect the pool cleaner hose firmly into the skimmer plate or

dedicated wall suction.

• Select the speed setting that enables best performance from your suction pool cleaner. Speed 3 to 7 should

be ample for most cleaners, however if the cleaner requires better performance, select speeds 7 to 10.

• The cleaner should only be connected for as long as is required to clean the surface of your pool. When

cleaning is complete, disconnect the cleaner and remove the skimmer plate from the skimmer box.

• Reactivate the most efficient speed setting for daily filtration. Speeds 1 to 4 is recommended.

NOTE: To get optimum energy efciency from your SilensorPRO, DO NOT keep the

suction pool cleaner connected when cleaning is not required.

NOTE: If the SilensorPRO is hard-wired into a time clock, or another automatic control,

the wiring should be removed by a qualied technician.

• Close the water valves on the pool return and the SilensorPRO inlet pipework;

• Remove the discharge & suction barrel unions taking care not to lose the o-rings;

• Move the pipework with the barrel unions attached until the SilensorPRO can be pulled clear.

NOTE: When making any enquiries about your SilensorPRO be certain to quote the

model number from the nameplate located on the motor.

English

17

Page 18

11. TROUBLE SHOOTING

If the pump runs but there is no water flow, or water flow is reduced, the following conditions may apply:

• The filter requires backwashing or it is blocked. Refer to the relevant section in the Filter Manual;

• The pump is not primed. Re-prime as per instruction in ‘Starting the pump’;

• There are air leaks in the suction piping. Check all piping and eliminate leaks, also check for a loose

strainer basket lid. Air bubbles in the water flowing back to the pool would indicate a leak in the suction to

the pump allowing air to enter the pipework.

• A leaking pump shaft seal may also prevent operation. Evidence of this would be water on the ground

under the pump.

• The pump is not able to get water from the pool. Check that the valves to the pump are fully open and

that the pool water level is up to the skimmer box. Typically, half way up the face of the skimmer box is

sufficient;

• Blockage in the piping or pump. Remove the strainer basket and check for any blockage to the pump

impeller entry. Check the skimmer box for blockage.

If the pump does not operate, the following conditions may apply:

• The power is not connected. For 220-240 volt only, check the power point by plugging in a portable

appliance to ensure power is available. Also check fuses and the main power supply switch;

• Automatic overload is tripped. The pump has an in-built thermal overload which will reset automatically

after the motor has cooled following an overheating period. Determine the cause of the overload tripping

and rectify. Reset the pump by switching the power OFF for 30 seconds;

• Blockage is preventing the pump from rotating.

12. REMOVAL OF THE SILENSORPRO FROM PIPEWORK

Should it be necessary to remove the SilensorPRO, follow these instructions:

• Switch off the power and remove the plug from the power source;

• Unscrew the barrel union on the front and top of the pump, releasing the pump from the pipework;

• Slide the pump out of position.

13. WATER QUALITY

RECOMMENDED POOL WATER CHEMISTRY

POOL WATER

BALANCING

Ideal Reading / Range 1 – 3

To Increase

Free Chlorine

(ppm)

Increase output of

chlorinator. Add

chlorine. Increase

ltration time.

pH

Concrete &

Tiled Pools:

7.4-7.6

Other Surfaces:

7.2-7.4

Add buffer

or soda ash

(Sodium

Carbonate)

Total Alkalinity TA

(ppm)

Concrete & Tiled

Pools – 80-120.

Other Surfaces –

125-150

Add Sodium

Bicarbonate

Calcium Hardness

(ppm)

Concrete & Tiled

Pools – 200-275.

Other Surfaces –

100-225

Add Calcium

Chloride

Stabiliser –

Cyanuric Acid

(ppm)

25 – 50 4500 – 6000

Add Cyanuric

Acid

Optimum

Salt Level

(ppm)

Add Salt

To Decrease

Frequency of Testing Weekly Weekly Weekly Weekly Regularly Regularly

Add Muriatic

Acid

Add Muriatic Acid

or Dry Acid

Partially drain &

rell pool with lower

hardness water to

dillute

Partially drain

& rell pool to

dillute

Partially drain

& rell pool

to dillute

English

18

Page 19

Routine Maintenance tasks - to maximise the life of your pool equipment & personal

safety, use this checklist once a week. Turn pump off rst.

a. Make sure that any pressure gauges are in working condition and the operating

pressure is within limits as specied on the product.

b. Make sure that each suction inlet and main drain has a cover that is securely

attached and in safe working condition.

c. Make sure that all skimmer covers are securely attached and in safe working

condition. These should be replaced every 3 to 4 years.

d. Remove any obstructions or debris from the main drain cover.

e. Ensure the skimmer baskets and the pump hair and lint pots are free of leaves and

debris at least once a week.

f. Remove obstructions and combustibles from around the pump motor.

g. Make sure all wiring connections are clean and that all wiring and electrical

equipment is in good condition. Damaged wiring must be repaired or replaced by a

qualied electrician as soon as damage is discovered.

h. Check water balance and sanitiser levels at your local pool shop.

POWER CONNECTIONS AND WIRING MUST BE CARRIED OUT BY AN AUTHORISED

ELECTRICIAN.

DANGER Hazardous suction. Do not block water entry into ltration system with any

part of your body as the pressure can trap hair or body parts, causing severe injury or

death. Do not block suction.

Turn off pump immediately if someone becomes trapped.

Do not use or operate swimming pools, spas or spa baths if a suction cover is broken,

missing or loose. Two suction covers and inlets must be provided into every pump to

avoid suction entrapment.

In accordance with AS/NZS60335.2.41 we are obliged to inform you that this device is

not to be used by children or inrm persons and must not be used as a toy by children.

CAUTION! Do not add chemicals directly to the pool skimmer. Adding undiluted

chemicals may damage pump and lter and void warranty.

19

English

Page 20

Davey warranty

Davey Water Products come with guarantees that cannot be excluded under the local country Law. You are

entitled to a replacement, or refund for a major failure and compensation for any other reasonably foreseeable

loss, or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a major failure.

Davey Water Products Pty Ltd (Davey) of 6 Lakeview Drive Scoresby VIC 3179 provides the following warranty in

relation this product. Davey warrants that, subject to the exclusions and limitations below, the product will be free

from defects in material and workmanship for a period of 24 months from the date of purchase (warranty period).

If a defect appears in the product before the end of the warranty period and Davey finds the product to be

defective in materials or workmanship, Davey will, in its sole discretion, either:

1. replace or repair the product or the defective part of the product free of charge; or

2. arrange for the product or the defective part of the product to be repaired or replaced by a qualified repairer

free of charge.

Davey reserves the right to replace defective parts of the product with parts or components of similar quality,

grade and composition where an identical part or component is not available. Goods presented for repair may

be replaced by refurbished goods of the same type rather than being repaired.

Warranty claims:

1. If a fault covered by the warranty occurs, Davey suggests, in the first instance, that you contact the Davey

Dealer from whom you purchased the product. Alternatively, you can: phone the Davey Customer Service line

on 1300 367 866 in Australia, or 0800 654 333 in New Zealand; send a written letter to Davey at the address

listed above; or email sales@davey.com.au.

2. Any warranty claim must be accompanied by proof of purchase and details of the alleged defect.

3. On receipt of your claim, Davey will seek to resolve your difficulties, or if the product is faulty or defective,

advise you on how to have your product repaired, obtain a replacement or a refund.

4. This warranty is limited to defects in the materials or workmanship in the product and does not cover

expendable parts or the replacement of parts due to fair wear and tear.

Exclusions:

The warranty will not apply where:

1.

The Product has been modified, repaired or serviced by someone other than Davey, or an authorised repairer.

2. Davey cannot establish any fault in the product after testing.

3. The product has been used other than for the purpose for which it was designed.

4. The product has been subject to abnormal conditions, whether of temperature, water, humidity, pressure,

stress or similar.

5. The purchaser has used or fitted non-genuine, or non-approved parts and accessories.

6. The Product defect has arisen due to abuse, misuse, neglect or accident.

7. The Product defect has arisen due to the purchaser’s failure to properly maintain or use the product.

8. The damage has been caused by the use of chemicals and detergents not approved by Davey.

Should your Davey product require repair or service after the warranty period, please contact your nearest Davey

Dealer, or phone or email the Davey Customer Service Centre. For a complete list of Davey Dealers please visit

our website.

INTERNATIONAL

Australian Head Offi ce

Ph: +613 9730 9124

Fax: +613 9753 4248

Email: export@davey.com.au

Davey Water Products Pty Ltd

Member of the GUD Group

ABN 18 066 327 517

AUSTRALIA

Head Offi ce

6 Lakeview Drive,

Scoresby, Australia 3179

Ph: 1300 232 839

Fax: 1300 369 119

Email: sales@davey.com.au

Website: davey.com.au

® Davey is a trademark of Davey Water Products Pty Ltd. © Davey Water Products Pty Ltd 2019.

Website: davey.com.au

EUROPE

ZAC des Gaulnes

355 Avenue Henri Schneider

69330 Meyzieu, France

Ph: +33 (0) 4 72 13 95 07

Fax: +33 (0) 4 72 33 64 57

Email: info@daveyeurope.eu

Website: daveyeurope.eu

NEW ZEALAND

7 Rockridge Avenue,

Penrose, Auckland 1061

Ph: 0800 654 333

Fax: 0800 654 334

Email: sales@dwp.co.nz

Website: daveynz.co.nz

NORTH AMERICA

Ph: +1 866 328 7867

Email: export@davey.com.au

Website: daveyusa.com

MIDDLE EAST

Ph: +971 50 6368764

Fax: +971 6 5730472

Email: info@daveyuae.com

Website: daveyuae.com

20

P/N 403308-1

Page 21

SilensorPRO SP200BT und SP400BT

Schwimmbadpumpe

Installations- und Betriebs-anleitung

50/60 Hz

SP200BT

Für Aktualisierungen der Produktinformationen konsultieren Sie bitte die DaveyWebsite Ihrer Region, wie auf der Rückseite dieses Dokuments angegeben.

Bitte geben Sie diese Anweisungen an den Bediener dieser Anlage weiter.

SP400BT

Deutsch

Page 22

Wir beglückwünschen Sie zum Kauf einer hochwertigen SilensorPRO SP200BT bzw. SP400BT Pumpe. Alle

Komponenten wurden so konzipiert und hergestellt, dass sie einen störungsfreien und zuverlässigen Betrieb

gewährleisten.

Inhaltsverzeichnis:

1. INSTALLATION DER DREHZAHLGEREGELTEN PUMPE VON DAVEY ................................................23

Netzanschluss ..........................................................................................................................................23

Rohrleitungsanschluss ..............................................................................................................................24

2. TYPISCHER INSTALLATIONSPLAN .......................................................................................................25

3. LEISTUNGSDATEN ..................................................................................................................................25

3.1 SP200BT Hydraulische Leistung ........................................................................................................25

3.2 SP200BT Elektrische Spezifikationen .................................................................................................26

3.3 SP400BT Hydraulische Leistung ........................................................................................................26

3.4 SP400BT Elektrische Spezifikationen .................................................................................................26

4. BEDIENUNGSANLEITUNG......................................................................................................................27

Mit dem SilensorPRO Energie sparen ......................................................................................................27

Checkliste vor Inbetriebnahme .................................................................................................................27

Niedrigenergiebetrieb ...............................................................................................................................28

Richtlinien für empfohlene Pumpenbetriebszeiten ...................................................................................28

Siebkorb entleeren ....................................................................................................................................29

Routinewartung .........................................................................................................................................29

5. EIGENSCHAFTEN UND FUNKTIONEN ..................................................................................................30

Mehrfarbige LED-Anzeigeleuchte .............................................................................................................30

Rückspül-Speed-Cycling-Technologie ......................................................................................................30

Vollvariabler drehzahlgesteuerter Motor mit benutzerfreundlichem Drehzahlwähler ................................30

Großer 4,5l-Flusentopf ..............................................................................................................................30

Patentiertes wassergekühltes Design für reibungslosen und superleisen Betrieb ...................................30

SP400BT Konstante Durchfluss-/Drehzahlkompensation ........................................................................30

SP400BT wetterfester RJ45 Kommunikationsanschluss (s. Abschnitt 7 für Details) ................................30

6. BLUETOOTH-FUNKTIONALITÄT ............................................................................................................31

Einrichtung der Bluetooth-App ..................................................................................................................31

Gerät mit der Pumpe verbinden ................................................................................................................31

Externer Zeitnehmer / Chlorinator ............................................................................................................31

Zeitplan-Modus .........................................................................................................................................31

Zeitplan festlegen .....................................................................................................................................32

Einstellungen ............................................................................................................................................32

Ansaugdrehzahl/max. Drehzahl ................................................................................................................32

Rückspülung .............................................................................................................................................33

Externer Timer vorhanden ........................................................................................................................33

Funktion Trennen ......................................................................................................................................33

Auf Werkseinstellung zurücksetzen ..........................................................................................................33

Pumpen-Fehlersuche ...............................................................................................................................33

7. ERWEITERTE EINSTELLUNGEN VON SP400BT ..................................................................................34

Übersicht externe AUX-Anschlüsse ..........................................................................................................34

Digitale Steuerungseingänge ....................................................................................................................35

Schnittstellenequipment für die SilensorPro SP400BT .............................................................................35

Analoger Steuereingang ...........................................................................................................................36

8. TECHNISCHE DATEN ..............................................................................................................................36

9. VERWENDUNG DER SILENSOPRO MIT EINEM SALZWASSER-CHLORINATOR...............................37

10. BETRIEB EINES BECKEN-SAUGREINIGERS ........................................................................................37

11. FEHLERSUCHE .......................................................................................................................................38

12. SILENSORPRO VON ROHRLEITUNG ENTFERNEN .............................................................................38

13. WASSERQUALITÄT .................................................................................................................................38

14. DAVEY-GARANTIE ...................................................................................................................................40

22

Deutsch

Page 23

1. INSTALLATION DER DREHZAHLGEREGELTEN PUMPE VON DAVEY

SilensorPRO sollte so nah wie möglich am Wasser stehen und auf einem festen Untergrund in einer gut

entwässerten Position montiert werden, die hoch genug ist, um Überschwemmungen zu vermeiden. Es liegt in der

Verantwortung des Monteurs/Besitzers, die Pumpe so aufzustellen, dass das Typenschild einfach abzulesen ist und

SilensorPRO für Wartungen jederzeit zugänglich ist. Es wird empfohlen, SilensorPRO vor Witterungseinflüssen zu

schützen. Umbauten sollten gelüftet sein, um die Bildung von Kondensation zu vermeiden.

Die Nichtbeachtung dieser Anweisungen und die Nichteinhaltung aller geltenden

Vorschriften können zu schweren Körperverletzungen und/oder Sachschäden führen.

Für die Installation und Wartung dieser Pumpe ist professionelles Fachwissen

erforderlich. Die Installation dieses Produkts sollte von einer Person durchgeführt

werden, die mit den Anforderungen von Poolinstallationen vertraut ist und welche die

Installationsanweisungen in diesem Handbuch befolgt.

Netzanschlüsse

WICHTIGER HINWEIS Ihr SilensorPRO ist gegen den Wasserkreislauf doppelt isoliert.

Wenn eine Potentialausgleichsvorrichtung erforderlich ist, wird ein PotentialausgleichsPunkt mitgeliefert. (Bitte beachten Sie die örtlichen Standards und Vorschriften zur

Verdrahtung, wie beispielsweise AS/NZ 3000).

VORSICHT! Im Interesse Ihrer eigenen Sicherheit empfehlen wir, dass alle

Marken und Typen von Poolpumpen gemäß AS/NZS 3000, den nationalen

Anschlussreglementierungen, oder gleichwertigen lokalen Reglementierungen

installiert werden. Alle elektrischen Installationen müssen von einem qualizierten

Elektriker ausgeführt werden. Davey empehlt, alle Anlagen mit einem Erdschluss

oder Fehlerstrom-Schutzeinrichtungen auszustatten. Nennfehlerbetriebsstrom von

höchstens 30mA.

WARNUNG! Stellen Sie sicher, dass es einen einfach zugänglichen Trennschalter gibt,

mit dem sich die Pumpe im Notfall ausschalten lässt.

F NFC C 15-100 GB BS7671:1992

D DIN VDE 0100-702 EW EVHS-HD 384-7-702

A OVE 8001-4-702 H MSZ 2364-702:1994/MSZ 10-533 1/1990

E UNE 20460-7-702 1993, REBT ITC-BT-31 2002 M MSA HD 384-7-702.S2

IRL IS HD 384-7-702 PL PN-IEC 60364-7-702: 1999

I CEI 64-8/7 CZ CSN 33 2000 7-702

LUX 384-7.702 S2 SK STN 33 2000-7-702

NL NEN 1010-7.702 SLO SIST HD 384-7-702.S2

SilensorPRO ist für den Anschluss an eine Versorgungs-Nennspannung von 220 – 240 Volt 50/60Hz

vorgesehen und mit einem flexiblen Anschlusskabel ausgestattet. Wenn für die Pumpe in einem Umkreis

von 3 Metern kein Spannungsanschluss verfügbar ist, muss der Elektriker an einem sicheren, trockenen

Ort einen 3-poligen Stromanschluss installieren. Verlängerungskabel im Poolbereich sind eine Gefahr und

sollten vermieden werden. Wenn das Netzkabel der SilensorPRO beschädigt ist, muss es von Davey oder

einem autorisierten Händler durch ein echtes Davey-Ersatzteil ausgetauscht werden.

SilensorPRO verfügt über einen Motorüberlastschutz, der den Motor vor Überhitzung schützt. Wenn

der Motor während des Betriebs zu heiß wird, wird die Drehzahl reduziert, um ihn auf eine akzeptable

Betriebstemperatur abzukühlen und ihn dann auf die eingestellte Drehzahl beschleunigen.

Um den Motor zurückzusetzen, schalten Sie das Gerät für 30 Sekunden aus und schalten Sie dann den

Netzschalter wieder ein.

Deutsch

23

Page 24

Rohrleitungsanschluss

Figure 1.2

152mm

MINIMUM

76mm

MINIMUM

Suction line

50/63mm

Return to

Pool

50/63mm

Return to

Für den Anschluss an die Rohrleitung aus dem Becken sind Fassverschraubungen vorgesehen. Die Pumpe

ist so ausgelegt, dass sie mit 50/63 mm PVC-Verschraubungen verbunden werden kann.

WICHTIGER HINWEIS Benden sich Pumpe und Filter unterhalb des

Beckenwasserspiegels, müssen Absperrventile in der Rohrleitung zwischen Pumpe und

Skimmer und in der Rücklaueitung vom Filter zum Becken eingebaut werden. Bei der

Verbindung der Auslassleitung ist darauf zu achten, dass die Verbindung nicht in die

Drehzahlanzeige der Pumpe eingreift. Fassverbindungen müssen per Hand angezogen

werden. Dichtungsmittel, Kleber oder Silikone werden nicht benötigt.

Die Verschraubungen an SilensorPRO bestehen aus ABS. Manche PVC-Dichtungsmassen

sind nicht mit ABS verträglich. Prüfen Sie die Eignung der Dichtmasse vor der Verwendung.

Die Verwendung von Rohren mit geringerem Durchmesser als angegeben wird nicht empfohlen. Die

Ansaugverbindungen sollten frei von Luftlecks, Höckern und Hohlräumen sein, die Probleme beim Ansaugen

verursachen. Für einen optimalen Wirkungsgrad sollte der SilensorPRO so installiert werden, dass

Wasserwirbel so weit wie möglich begrenzt werden. Wie in Abbildung 1.1 dargestellt, keinen 90°-Ellbogen

näher als 250 mm an der Rohrverschraubung am Einlass installieren. Absperrventile unterhalb des

Beckenwasserspiegels sollten ebenfalls nicht näher als 250 mm vor der Rohrverschraubung am Einlass

installiert werden. Diese Maßnahme unterstützt laminare Strömung.

Figure 1.1

250mm

ELBOW

Suction line

50/63mm

Pool

50/63mm

Die Auslassleitung von SilensorPRO sollte an den Eingangsanschluss des Beckenfilters (in der Regel am

Filterregelventil) angeschlossen werden. Wie in Abbildung 1.2 dargestellt, auf ausreichenden Platz über

der Pumpe achten, um die Kurzwahltasten von SilensorPRO nicht zu beeinträchtigen. Verwenden Sie ein

Rückschlagventil in der Druckleitung, wenn Sie diese Pumpe für alle Anwendungen verwenden, bei denen

die Höhe der Rohrleitung nach der Pumpe groß ist.

Figure 1.2

Return to

Pool

50/63mm

152mm

MINIMUM

Suction line

50/63mm

Stellen Sie sicher, Rückschlagventile zu installieren, wenn Sie die Pumpe mit einer anderen Pumpe

betreiben. Dies schützt vor einer umgekehrten Rotation des Impellers und des Motors.

76mm

MINIMUM

WARNUNG! Der Saugdruck der Pumpe ist gefährlich und kann Badegäste erfassen und

ertränken, oder ausweiden. Den Absaugstutzen nicht blockieren. Betreiben Sie keine

Schwimmbäder, Spas oder Spa-Bäder, wenn eine Saugabdeckung gebrochen ist, fehlt

oder lose ist. In jede Pumpe müssen zwei Saugabdeckungen oder -Einlässe eingebaut

werden, um ein Einklemmen des Saugers zu vermeiden.

24

Deutsch

Page 25

2. TYPISCHER INSTALLATIONSPLAN

ProMaster - PM200SV

Performance

Pool pump Media Filter

3. LEISTUNGSDATEN

3.1 SP200BT Hydraulische Leistung

25

20

15

Total Head ( m )

10

5

Dial position No. 10

Dial position No. 9

Dial position No. 8

Dial position No. 7

Dial position No. 6

Dial position No. 5

Dial position No. 4

Dial position No. 3

Dial position No. 2

Dial position No. 1

0

0 50 100 150 200 250 300 350 400

Flow ( lpm )

0

036 9 12 15 18 21 24

3

Flow ( m

25

/h )

Deutsch

Page 26

3.2 SP200BT Elektrische Spezifikationen

450

Drehzahl

Einstellung

Einstellung 1 0,17 128 0,12 90

Einstellung 2 0,28 207 0,19 145

Einstellung 3 0,39 293 0,27 205

Einstellung 4 0,53 398 0,37 279

Einstellung 5 0,70 524 0,49 367

Einstellung 6 0,87 655 0,61 459

Einstellung 7 1,08 807 0,75 565

Einstellung 8 1,25 936 0,87 655

Einstellung 9 1,44 1078 1,01 755

Einstellung 10 1,48 1111 1,04 778

PS W PS W

Eingang Ausgangs

3.3 SP400BT Hydraulische Leistung

25

Dial position No. 10

Dial position No. 9

Dial position No. 8

20

15

Dial position No. 7

Dial position No. 6

Dial position No. 5

Dial position No. 4

Dial position No. 3

Dial position No. 2

Dial position No. 1

Total Head ( m )

10

5

0

0 50 100 150 200 250 300 350 400

Flow ( lpm )

0

036 9 12 15 18 21 24 27

3

Flow ( m

/h )

3.4 SP400BT Elektrische Spezifikationen

Drehzahl

Einstellung

Einstellung 1 0,17 126 0,12 89

Einstellung 2 0,28 210 0,20 147

Einstellung 3 0,46 347 0,32 243

Einstellung 4 0,70 522 0,49 366

Einstellung 5 0,97 728 0,68 510

Einstellung 6 1,22 913 0,85 639

Einstellung 7 1,61 1211 1,13 848

Einstellung 8 1,97 1478 1,38 1034

Einstellung 9 2,18 1635 1,59 1191

Einstellung 10 2,19 1639 1,62 1212

PS W PS W

Eingang Ausgangs

26

Deutsch

Page 27

4. BEDIENUNGSANLEITUNG

Die Pumpe verfügt über einen Bluetooth-Anschluss, sodass Sie die Pumpe mit ihrem Smart-Gerät einrichten

und kontrollieren können. Bluetooth ist ein kabelloses Kommunikationsprotokoll, das die Kommunikation

zwischen Geräten ermöglicht. Diese Funktion wird von allen Geräten unterstützt, die Anwendungen für iOS

oder aus dem Android App Store herunterladen können.

Lesen Sie diese Anweisungen komplett, bevor Sie die Pumpe einschalten. Sollten Sie Teile dieser

Installations- und Bedienungsanweisungen nicht verstanden haben, kontaktieren Sie bitte Davey (siehe Liste

am Ende dieses Dokuments).

Jede SilensorPRO wird gründlich gegen eine Reihe von Durchfluss-, Druck-, Spannungs-, Strom- und

mechanischen Leistungsparametern getestet. Die fortschrittliche Pumpenfertigungstechnik von Davey

ermöglicht eine langanhaltende verlässliche und effiziente Pumpenleistung.

Mit dem SilensorPRO Energie sparen

Die drehzahlgesteuerte Pumpe von Davey ist eine hocheffiziente Pumpe mit einem regelbaren

Wechselstrommotor mit einem niedrigen Schallpegel, niedrigeren Betriebskosten und niedrigeren TreibhausEmissionen als traditionelle Poolpumpen.

Aufgrund ihrer Fähigkeit, mit niedrigeren Drehzahlen als herkömmliche Pumpen zu arbeiten, ist der

mechanische Verschleiß niedriger aufgrund einer geringeren Belastung der mechanischen Komponenten.

Energie-effizientes Pumpen ist einfach zu erreichen. Lassen Sie die Filtrationspumpe auf einer niedrigeren

Drehzahl, aber dafür länger laufen als eine konventionelle Pumpe mit fester Drehzahl, um Ihr PoolWasser für eine angemessene Filtration und Säuberung auszutauschen. Das Ergebnis ist ein geringerer

Energieverbrauch und bis zu 70% niedrigere Betriebskosten.

SilensorPRO verfügt über einstellbare Drehzahleinstellungen, so dass Sie die Drehzahl, mit der Sie

Ihr Pool- oder Spa-Wasser zirkulieren, variieren können. Die Drehzahlen können eingestellt werden,

um einen Becken-Saugreiniger, ein Bodenreinigungssystem und Poolheizungen zu betreiben. Eine

Rückspüleinstellung kann an der Pumpe ausgewählt werden, um den einen Medienfilter zu spülen.

Was Sie von Ihrem SilensorPRO (energieeffizienter Betrieb) am Pool erwarten können:

• Wenn Ihre SilensorPRO-Pumpe eine herkömmliche Wechselstrom-Motorpumpe ersetzt, müssen Sie sie

eventuell länger laufen lassen als Ihre alte Pumpe mit fester Drehzahl. Das ist NORMAL und spart Energie

bei niedrigen Drehzahlen.

• Sie werden bemerken, dass die Druckanzeige an Ihrem Filter einen viel niedrigeren Druck als Sie gewohnt

sind anzeigt. Das ist ebenfalls NORMAL. Der niedrigere Systemdruck ist ein Ergebnis der niedrigeren

Drehzahl und Durchflussrate der Pumpe.

• Wenn die Pumpe bei niedrigeren Drehzahlen läuft, werden Sie eine signifikante Reduzieren des

Pumpen-Schallpegels bemerken. Dies ist ein großer Vorteil für Sie, da Sie SilensorPRO während der

Spitzenstromtarife betreiben können, was auch zur Senkung Ihrer Betriebskosten beiträgt. Außerdem

werden Ihre Nachbarn sehr viel zufriedener sein.

Viele Poolprodukte sind auf Mindestdurchflussmengen angewiesen, um einen optimalen Betrieb

und/oder Wirkungsgrad zu gewährleisten. Wenn Sie an SilensorPRO niedrige Durchflusswerte

verwenden (d.h. Drehzahl 1 bis 4), empfiehlt Davey, dass Sie die Kompatibilität der Drehzahl oder der

Mindestdurchflussmenge prüfen, die für den Betrieb bestimmter Poolausrüstungen erforderlich ist, wie z.B.:

• Becken-Saugreiniger; • Salzwasser-Chlorinatorzellen;

• Ozongeneratoren; • Bodenreinigungssysteme

• Solar-Heizsysteme;

Checkliste vor Inbetriebnahme

• Die gewählte Drehzahleinstellung ist eine kompatible Einstellung mit anderen Poolgeräten;

• Die Pumpe in einer sicheren und trockenen Umgebung installiert ist;

• Der Pumpenraum sollte für den Fall einer Undichtigkeit über ein geeignetes Abflusssystem verfügen;

• Eventuell vorhandene Transportstopfen sind zu entfernen;

• Die Rohrleitungen müssen sachgerecht abgedichtet und abgestützt sein;

• Die Pumpe wurde richtig angesaugt;

• Die Stromversorgung ordnungsgemäß angeschlossen ist;

• Alle Vorkehrungen für einen sicheren Betrieb getroffen wurden;

• Der Filter wurde mit einer 50/63 mm Rohrleitung versehen;

• Die (App)Betriebszeiteneinstellungen korrespondieren mit allen anderen Zeiten im System.

Deutsch

27

Page 28

Niedrigenergiebetrieb

Ihr SilensorPRO SP200BT verfügt über Drehzahleinstellungen von 1500 - 3600 U/min. Der SilensorPRO

SP400BT verfügt über Drehzahleinstellungen von 1050 - 3100 U/min. Die Drehzahl 1 ist die langsamste und

Drehzahl 10 die schnellste.

• Drehzahl 1 bietet die niedrigste Drehzahl und damit die größte Energieeffizienz und Einsparung.

Betrieb

Rückspülung des Medienfilters

Poolfiltration

Betrieb des Becken-Saugreinigers

Reinigen Ihres Pools

Wasserfeature-Betrieb

Spa-Jet-Betrieb

Bodenreinigungssysteme

Solar-Poolheizung

Empfohlene Drehzahleinstellung

Rückspülgeschwindigkeit

Drehzahl 1 bis 4

Drehzahl 5 bis 8

Drehzahl 9 bis 10

Richtlinien für empfohlene Pumpenbetriebszeiten

Die typische Umschlagshäufigkeit in Privatanlagen sollte ein einziger Umsatz des gesamten

Poolwasservolumens innerhalb des Zeitraums sein, in dem die Pumpe normalerweise in Betrieb ist. Die

folgende Tabelle gibt lediglich einen Überblick über die Laufzeiten Ihrer Pumpe im Filtrationsbetrieb, um die

Mindestumschlagsleistung zu erreichen:

SilensorPRO SP200BT

Poolgröße

(Liter)

Drehzahl 1 Drehzahl 5 Drehzahl 10

Drehzahleinstellung (Stunden)

20.000 3,3 1,7 1,1

30.000 5,0 2,5 1,7

40.000 6,7 3,3 2,2

50.000 8,3 4,2 2,8

60.000 10,0 5,0 3,3

80.000 13,3 6,7 4,4

100.000 16,7 8,3 5,6

SilensorPRO SP400BT

Poolgröße

(Liter)

20.000 2,4 1,3 0,9

30.000 3,7 2,0 1,4

40.000 4,9 2,7 1,9

50.000 6,1 3,3 2,3

60.000 7,4 4,0 2,8

80.000 9,8 5,3 3,8

100.000 12,3 6,7 4,7

Drehzahleinstellung (Stunden)

Drehzahl 1 Drehzahl 5 Drehzahl 10

28

Deutsch

Page 29

Nach EN60335.1 sind wir verpichtet, Sie darüber zu informieren, dass dieses Produkt

von Kindern ab 8 Jahren und Personen mit physischen, sensorischen oder geistigen

Einschränkungen oder mangelnder Erfahrung und mangelnden Kenntnissen verwendet

werden kann, sofern sie entsprechend beaufsichtigt oder in der sicheren Verwendung

dieser Anlage angeleitet wurden und mit den damit verbundenen Gefahren vertraut

gemacht wurden. Kinder müssen während der Nutzung beaufsichtigt werden, um

sicherzustellen, dass sie nicht mit dem Produkt spielen.

Siebkorb entleeren

Der Siebkorb sollte regelmäßig durch den Klarsichtdeckel inspiziert und entleert werden, wenn eine

Anhäufung von Abfällen erkennbar ist. Befolgen Sie die Anweisungen unten.

• Schalten Sie die Pumpe aus;

• Schrauben Sie den Siebkorbdeckel gegen den Uhrzeigersinn ab und nehmen Sie ihn ab;

• Entfernen Sie den Siebkorb, indem Sie ihn nach oben aus dem Gehäuse heben;

• Entleeren Sie den eingefangenen Müll aus dem Korb. Spülen Sie ihn bei Bedarf mit Wasser aus.

HINWEIS: Schlagen Sie den Plastikkorb NIEMALS auf eine harte Oberäche, da dies zu

Beschädigungen führen kann.

• Prüfen Sie den Siebkorb auf Risse, tauschen Sie den Siebkorb in der Pumpe ggf. aus;

• Setzen Sie den Deckel wieder auf und vergewissern Sie sich, dass er den großen O-Ring aus Gummi

abdichtet. Es ist nur eine handfeste Abdichtung erforderlich. Der O-Ring und das Gewinde können mit

Schmiermittel der Marke Hydra Slip oder gleichwertigen Produkten geschmiert werden.

Die Nichteinhaltung der regelmäßigen Wartung kann zu Schäden führen, die nicht unter

die Garantie fallen.

Routinewartung

Verwenden Sie diese Checkliste einmal pro Woche, um die Lebensdauer des SilensorPRO zu maximieren

und ihre persönliche Sicherheit zu gewährleisten. Vor dem Beginn sicherstellen, dass die Pumpe

ausgeschaltet ist:

• Stellen Sie sicher, dass sich alle Manometer im Betriebszustand befinden und der Betriebsdruck innerhalb

der auf dem Produkt angegebenen Grenzen liegt;

• Vergewissern Sie sich, dass jeder Ansaug- und Hauptablass mit einer Abdeckung versehen ist, die sicher

befestigt ist und sich in einem sicheren Betriebszustand befindet;

• Stellen Sie sicher, dass alle Abdeckungen des Skimmers sicher befestigt sind und sich in einem sicheren

Betriebszustand befinden. Diese sollten alle 3 bis 4 Jahre ausgetauscht werden;

• Entfernen Sie alle Hindernisse oder Fremdkörper von der Hauptablaufabdeckung;

• Stellen Sie sicher, dass die Skimmer- und Pumpenkörbe mindestens einmal pro Woche von Laub und

Schmutz befreit werden;

• Entfernen Sie Hindernisse und brennbare Stoffe rund um den Pumpenmotor;

• Vergewissern Sie sich, dass alle Kabelverbindungen sauber und alle Kabel und elektrischen Geräte in

gutem Zustand sind. Beschädigte Leitungen müssen von einem qualifizierten Elektriker repariert oder

ersetzt werden, sobald Schäden festgestellt werden;

• Überprüfen Sie den Wasserhaushalt und die Desinfektionsmittelstände in Ihrem örtlichen

Poolzubehörgeschäft.

Deutsch

29

Page 30

5. EIGENSCHAFTEN UND FUNKTIONEN

Der SilensorPRO verfügt über mehrere Betriebsfunktionen. Im Folgenden werden diese einzeln erklärt.

Mehrfarbige LED-Anzeigeleuchte

Wird verwendet, um die erforderlichen Einstellungen für die Programmierzeit für maximale Drehzahl (Boost-)

Zyklen und Warnungen zu identifizieren: