Datasheet USB100N24, USB100N18, USB100M20, USB100AN24, USB100AN18 Datasheet (Fairchild Semiconductor)

Page 1

1

www.fairchildsemi.com

USB100 Programmable Low-Cost USB Machine (PLUM)

USB100 rev.D

USB100

Programmable Low-Cost USB Machine (PLUM)

Single Chip Controller for Mouse, Trackball, Joystick and Gamepad Applications

General Description

The USB100 is a Low cost, fully customizable controller for USB

HID-class pointing devices. It is in full compliance with REV 1.0

of the USB standard and implements the HID class specification

for mice, trackballs, joysticks and gamepads. This device interprets the commands specified in the HID class document and

provides appropriate responses from an On-Chip EEPROM. It

also provides ability to customize the device according to individual needs of the designers. Programming utilities supplied with

this device allow HID manufacturers to easily create the necessary data to be programmed into the device.

The device includes the necessary transceiver for USB operation

and meets all of the active and standby current specifications for

a bus-powered device.

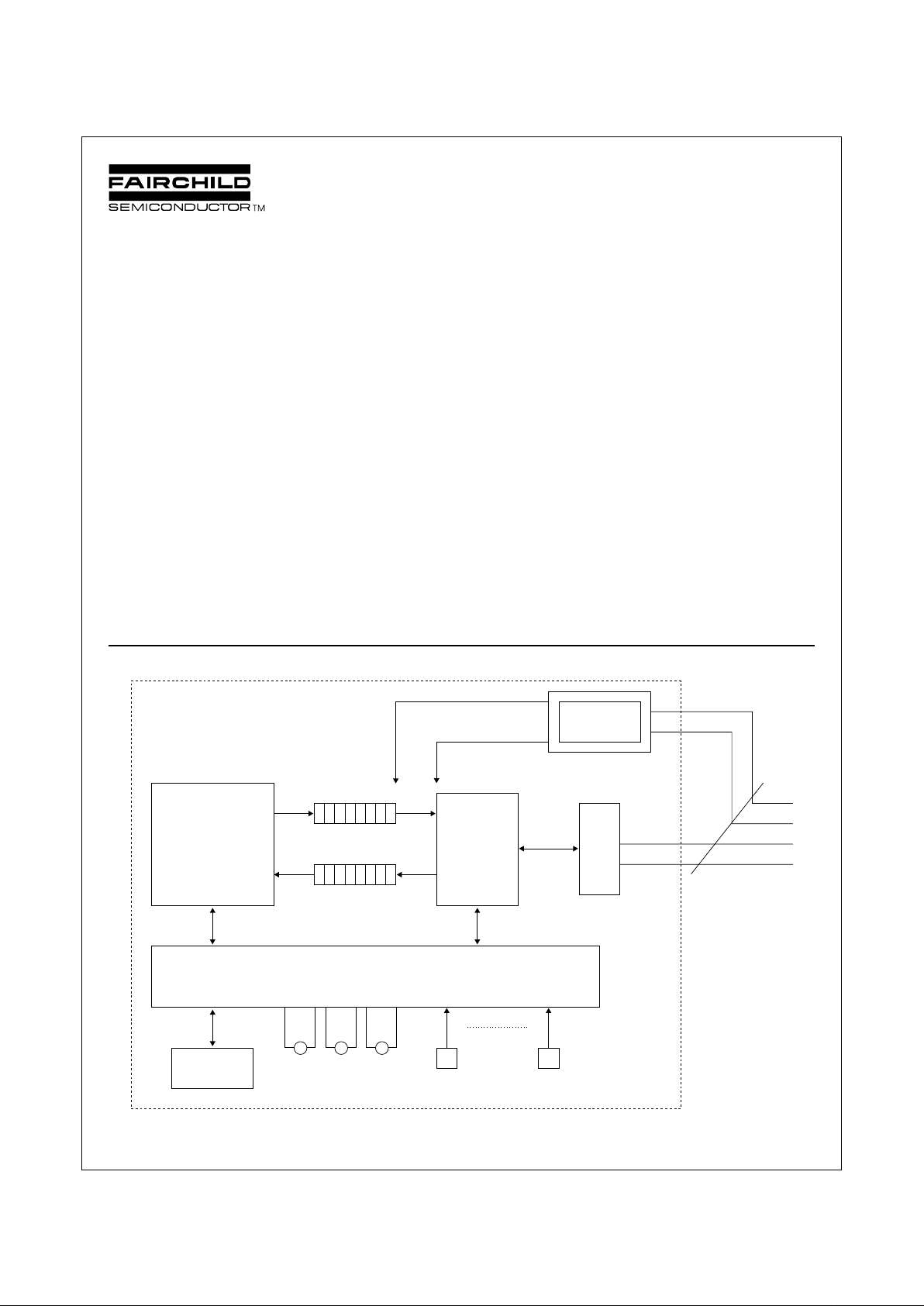

Block Diagram

PRELIMINARY

January 1999

Features

■ USB 1.0 standard compliant

■ Has the necessary on-chip transceivers

■ Support for 2D and 3D mice with 2, 3 or more buttons

■ Supports 3 potentiometer mechanisms for joysticks

■ Up to 16 buttons for digital gamepads

■ Choice of 18-pin and 24-pin packages

■ Choice of 2Kbit and 4Kbit EEPROM densities

Use "A Diagram Number" Style Sheet"

STATE MACHINE

USB

COMMAND

PROCESSOR

(HID)

SERIAL

INTERFACE

ENGINE

X

C

V

R

POWER

EEPROM

TX-FIFO

RX-FIFO

USB CABLE

(D+, D-,

POWER &

GROUND)

UP TO 16 BUTTONS

UP TO 3 ROLLER/

POTENTIOMETER

MECHANISMS

© 1999 Fairchild Semiconductor Corporation

Page 2

2

www.fairchildsemi.com

USB100 Programmable Low-Cost USB Machine (PLUM)

USB100 rev.D

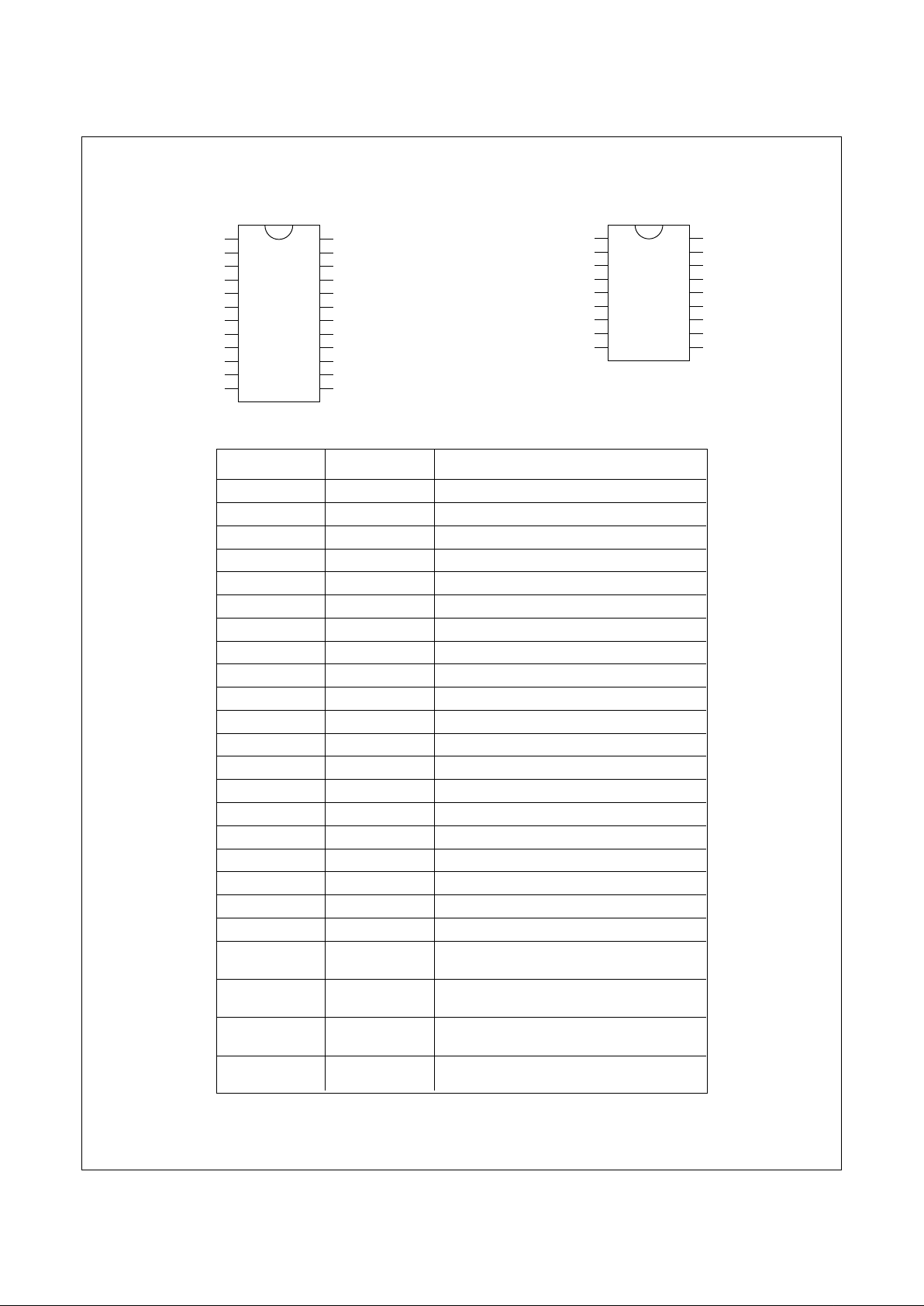

Pin Description

Pin Type Description

H4 I Roller/Button/Joystick input.

H3 I Roller/Button/Joystick input.

O2 I/O Register output pin / Button input.

OSC1 I Crystal input number 1.

OSC2 I Crystal input number 2

B4 I Button input

Reset I Active high reset pin

H1 I Roller/Button/Joystick input.

H2 I Roller/Button/Joystick input.

V1 I Roller/Button/Joystick input.

V2 I Roller/Button/Joystick input.

GND I Ground

B7 I Button input

B6 I Button input

B5 I Button input

VDD I Positive power supply

USBD+ O USB D + line

USBD- O USB D – line

GND I Ground

B8/F I/O Button input / LED driver

B1/CS I Button input and chip select to internal

EEPROM.*

B2/SK I Button input and system clock to internal

EEPROM.*

B3/DI I Button input and data in to internal

EEPROM.*

O1/DO O Button input and data out to read from

internal EEPROM.*

* See Programming internal EEPROM section

Pinout

24 Pin Package 18 Pin 3D Package

OSC1 VDD

OSC2 B6

H4 USBD+

B8/F USBD-

RESET GND

H3 B7

H1 B5

H2 B1

V1 B2

V2 B3

O2 B4

GND O1

OSC2 OSC1

H4 VDD

F USBD+

RESET USBD-

H3 GND

H1 B1

H2 B2

V1 B3

V2 O1

Page 3

3

www.fairchildsemi.com

USB100 Programmable Low-Cost USB Machine (PLUM)

USB100 rev.D

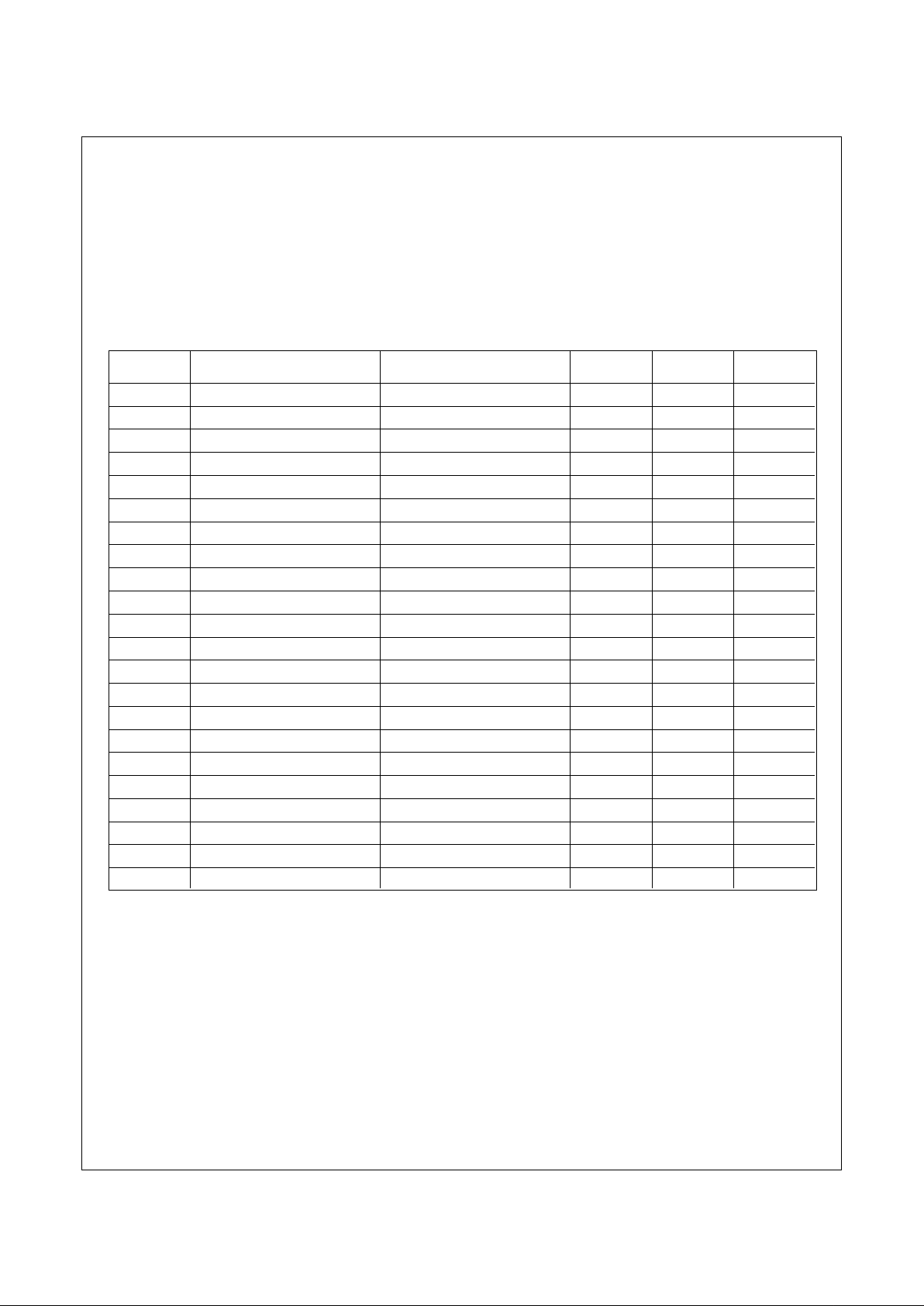

Absolute Maximum Ratings

Ambient Storage Temperatures -65°C to + 150°C

All Input or Output Voltages with VCC + 1 to – 0.3V

respect to ground

Lead Temperature +300%

(Soldering, 10 seconds)

ESD Rating 2000V

Operating Conditions

Ambient Operating Temperature 0°C to +70°C

Power Supply (VCC) Range 4.4V to 5.5V

DC and AC Electrical Characteristics 4.4V ≤ VCC ≤ 5.5V

Symbol Parameter Conditions Min Max Units

I

CCA

Operating Current USB interface in active mode 40 mA

I

CCS

Standby Current USB interface in suspend 500 µA

V

IL

Input Low Voltage 0.8 V

V

IH

Input High Voltage 2 V

V

OL

Output Low Voltage 0.4 V

V

OH

Output High Voltage 2.4 V

I

IL

Input Leakage Current 2.5 µA

I

OL

Output Leakage Current 2.5 µA

F

SK

SK Clock Frequency Note 3 0 1 MHz

T

SKH

SK High Time 250 ns

T

SKL

SK Low Time 250 ns

T

CS

Minimum CS Low Time Note 4 250 ns

T

CSS

CS Setup Time 50 ns

T

DH

DO Hold Time 70 ns

T

DIS

DI Setup Time 100 ns

T

CSH

CS Hold Time 0 ns

T

DIH

DI Hold Time 20 ns

T

PD1

Output Delay to “1” 500 ns

T

PD0

Output Delay to “0” 500 ns

T

SY

CS to Status Valid 500 ns

T

DF

CS to DO in TRI-STATE 100 ns

T

WP

Write Cycle Time 10 ms

AC Test Conditions

Output Load 1 TTL Gate

Input Pulse Levels 0.4V and 2.4V

Timing Measurements Reference Level

Input 1V and 2V

Output 0.8V and 2.0V

Note 1: Stress ratings above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and operation of the

device at these or any other conditions above those indicated in the operational sections of the specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

Note 2: The shortest allowable S clock period = 1/fSK (as shown under the fSK parameter). Maximum SK clock speed (minimum SK period) is determined by the interaction of

several AC parameters stated in the datasheet. Within this SK period, both t

SKH

and t

SKL

limits must be observed. Therefore, it is not allowable to set 1/fSK = t

SKH

(minimum) +

t

SKL

(minimum) for shorter SK cycle time operation.

Note 3: CS (Chip Select) must be brought low (to VIL) for an interval of tCS in order to reset all internal device registers (device reset) prior to beginning another opcode cycle.

(This is shown in the opcode diagrams in the following pages.)

Page 4

4

www.fairchildsemi.com

USB100 Programmable Low-Cost USB Machine (PLUM)

USB100 rev.D

Interface Pin Descriptions

H1, H2, H3, H4, V1, V2 (Roller/Joystick inputs)

When configured as roller inputs these pins function in pairs, H1

and H2, H3 and H4, V1 and V2 to allow photo diodes to be

attached in a mouse or trackball application. See the section

“Roller Movement Reporting” for a more detailed description.

When configured for a joystick only one of the inputs pairs is used.

A potentiometer is attached to track the movements of a joystick

lever. When these inputs are configured as buttons they all act

independently as active low button inputs. All of them have

internal pull-ups and debounce circuitry which can be programmed

using the ICB registers. These inputs also contain current sink

features so no external resistor is needed to sink current from the

photo diode.

B1, B2, B3, B4, B5, B6, B7, B8/F (Button inputs)

The button inputs to the USB100 have internal pull up resistors,

with active low inputs to the chip. These inputs also contain

debounce circuitry which can be programmed by the ICB registers.

Key Debounce Select Table (ICB register3[3:2])

KD[1:0]

00 15 ms

01 30 ms

10 45 ms

11 60 ms

USBD -, USBD +

These inputs are the serial bus lines which USB data is communicated. These bi – directional lines connect to the host, through

a USB type A or type B connector, and are used to communicate

all USB information to and from the host. The two lines must both

be wired through a 27 ohm resistor before being attached to the

USB connector. See Recommended Configuration for a detailed

diagram.

Reset

This pin is used to reset the entire chip. It must be held high for

more than 10ns, to reset the chip and then brought low for the reset

of normal chip operation.

O1, O2

These two pins are wired to internal registers which can be

programmed with either a “1” or a “0” by a USB request. If this

command is sent to the USB100. INSERT COMMAND FROM

INSPECTOR. Then the O1 and O2 pins will be programmed with

the values that are in the second data package. These two pins

can also be configured as standard button inputs by one of the ICB

registers.

O1, O2 Functionality. ICB register 1[3:2]

IOM[1:0] Function

00 Both O1 and O2 function as programmable

outputs.

01 O1 is a programmable output but O2 is a

standard button input.

11 Both O1 and O2 are standard inputs.

In case these are selected as outputs, their state (1 or 0) can be

set using the USB set_report command. These outputs are opencollector. A typical use of these outputs is using them to drive LEDs

(for example, a drag-lock function in a trackball). These pins have

a programmable current sink capability.

B8/F

When this pin is configured as an input it will behave as a standard

button input. But if the pin is disabled in the ICB registers then this

pin can be used to control the roller LEDS in powersave mode.

Using the B8/F pin to control the LEDs

This allows the LEDs to be shut off during powersave mode which

allows the USB100 to draw very little current. The official name for

powersave mode on a USB device is known as suspend mode

which is discussed in the section labeled Suspend Mode Operation.

OSC1, OSC2

These two pins are the clock inputs into the USB100. The speed

at which the chip runs at is 6MHz. The clock sign can be generated

two ways. The first is to use a parallel resonant, fundamental mode

crystal circuit or a ceramic resonator circuit connected to the

OSC1 and OSC2 inputs. The other method is to use a crystal

oscillator connected to the OSC2 input and leaving the OSC1

input unconnected

USB modes of operation

The USB100 loads up its configuration from the EEPROM on

power-on reset, or when a USB reset command is issued. Upon

completion of reset, the device is in a operational mode, and

responds correctly to the various commands described in the USB

spec rev 1.0. The USB100 supports two endpoints – the default

endpoint (endpoint 0) and the interrupt endpoint (endpoint 1). The

supported packet size on both endpoints is 8 bytes. The endpoint

1 is an “IN” endpoint.

USB100

F

VDD

Page 5

5

www.fairchildsemi.com

USB100 Programmable Low-Cost USB Machine (PLUM)

USB100 rev.D

Standard Requests

The USB100 supports all of the required standard requests.

These requests are sent to the device using control transfers to

endpoint 0.

In USB terminology, the data transmitted by the mouse when

movement is detected is called a report. The reports are generated by the USB100 device in accordance to the USB HID spec

1.0 Final.

Programming the EEPROM

The on-chip EEPROM can be programmed in a special mode

which defines some of the button inputs/output as a microwire

port.. In this mode, these inputs behave as a conventional Microwire

serial port. Data can be easily programmed and verified, by

executing simple EEPROM programming commands.

Initial Configuration Bytes (ICB) register

description

The first five bytes in the EEPROM are used to configure the

physical characteristics of the USB100 device, and are called the

Initial configuration Byte registers. Some of the bits in these

registers are reserved, and are referred to as RFU (reserved for

future use) in the following section.

Roller Configuration Byte (Address 0)

D7 D6 D5 D4 D3 D2 D1 D0

IS3 IS2 IS1 IS0 IOM1 IOM0 R1 R0

R[1:0]: No of roller pairs. This pair of bits configure the functionality of the three roller pair inputs – <H1, H2>, <V1,V2> and <H3,

H4>.

00: No rollers on this device, all roller inputs are available as

general purpose inputs

01: H1, H2 are the only roller mechanism active. The other

roller inputs are available as general purpose inputs.

10: H1, H2 and V1 and V2 are defined as roller mechanism

pairs. The other pair is still available as general purpose

inputs.

11: All the three pairs of roller inputs function as roller inputs.

It must be noted that the reassignment of the rollers must be done

only as follows: If the application needs to use only one roller – use

H1 and H2. Two rollers – use H1, H2 and V1, V2, Three rollers –

use H1, H2, V1, V2 and H3, H4. Any other choice for roller use is

illegal and results in unpredictable device behavior.

IOM[1:0]: I/O functionality of the O0 and O1 pins. When IOM0 is

set to ‘0’, the O0 bit functions as an output. When set to ‘1’ it

becomes an input. . When IOM1 is set to ‘0’, the O1 bit functions

as an output. When set to ‘1’ it becomes an input. The only valid

combinations for these bits are 00, 01 and 11 respectively.

IS[3:0]: This 4-bit value is to set the amount of current that an

external device can sink into the H1, H2, V1, V2 and H3 and H4

inputs When these bits are set to 0000 the current sink is set to 0.1

mA on each of the inputs. In can be varied in steps of 0.1mA up

to a max of 1 mA.

IS[3:0] Current

0000 0.1 mA

0001 0.2 mA

0010 0.3 mA

0011 0.4 mA

0100 0.5 mA

0101 0.6 mA

0110 0.7 mA

0111 0.8 mA

1000 0.9mA

1001 1.0mA

Input Pin Configuration Byte 0 (ICB0) (Address 1)

D7 D6 D5 D4 D3 D2 D1 D0

B8 B7 B6 B5 B4 B3 B2 B1

B[7:0]: Input Pin Report Generator. A ‘1’ causes this bit to be

reported in the corresponding report generated when the device

is polled for the status. The device accepts only the following bit

patterns as valid. B[7:0] control the functionality for pin inputs

B[8:1] respectively.

00000000

00000001

00000011

00000111

00001111

00011111

00111111

01111111

11111111

Input Pin Configuration Byte 1 (ICB1) (Address 2)

D7 D6 D5 D4 D3 D2 D1 D0

IO1 IO0 EB5 EB4 EB3 EB2 EB1 EB0

EB[5:0]: Input Pin Report Generator, Extended byte. The functionality of this register is influenced by the roller configuration

byte. A ‘1’ causes this bit to be reported in the corresponding report

generated when the device is polled for the status. EB0 corresponds to H3 and EB1 corresponds to H4. EB2 corresponds to V1

and EB3 corresponds to V2. EB4 corresponds to H1 and EB5

corresponds to H2.

00000000

00000001

00000011

00000111

00001111

00011111

00111111

Page 6

6

www.fairchildsemi.com

USB100 Programmable Low-Cost USB Machine (PLUM)

USB100 rev.D

RFU: Reserved for future use, must be set to 0.

IO[1:0]: When the IO pins are reconfigured as inputs, a ‘1’ in the

corresponding bit position will cause the input to be included in the

report generator.

Application Configuration Byte (Address 3)

D7 D6 D5 D4 D3 D2 D1 D0

FIS3 FIS2 FIS1 FIS0 KD1 KD0 F1 F0

F[1:0]: Function Select. Selects between the following

00 : Mouse operation

01: RFU

10: Joystick Operation.

11: Digital Gamepad operation

KD[1:0]: Key Debounce Select:

00: 15 Ms

01: 30 Ms

10: 45 Ms

11: 60 Ms

FIS[3:0]: These bits select the amount of current that the ‘F’ pin

can sink, in 1 mA increments. When FIS[3:0] = “0000” The current

sink is set at 2 mA. Incrementing this count by 1 will cause the

current to be increased by 1mA The maximum value is 10 mA.

Remote Resume Config Byte (Address 4)

D7 D6 D5 D4 D3 D2 D1 D0

RFU RFU RFU RFU RRES RRES RRES RRES

_EN 2 1 0

RRES_EN: Remote_resume enable. This bit, when set, enables

remote resume operation.

RRES[2:0]: Duration Select. When the device has entered in

suspend mode, these bits select the duration after which an

internal “momentary wakeup” is done to check whether there has

been any movement on the rollers in the mouse mode or the

potentiometers in the joystick mode. The RRES_EN bit must be

set to 1 to enable this feature.

000: 15 ms

001: 30 ms

010: 45 ms

011: 60 ms

100: 75 ms

101: 90 ms

110: 105 ms

111: Reserved for future use (do not use this combination,

unpredictable operation could result)

Descriptor Setup

The EEPROM stores a Descriptor Description Table (DDT) followed by the actual descriptors (DES). The DDT begins at byte

address 8 in the EEPROM. It consists of 14 Words. Each Word

consists of two bytes – The first byte is a byte indicating the type

of descriptor (these byte values are indicated in the USB specification). The second byte is an address. This address indicates the

first byte of this descriptor in the EEPROM. An unimplemented

descriptor table entry begins with a 00. The following table shows

a possible configuration.

Address Map

Memory AddressRange Data type

08-35 Descriptor Description Table

36-53 Device Descriptor

54-62 Config Descriptor

63-71 Interface Descriptor

72-78 Mouse HID Class Descriptor

79-86 Endpoint Descriptor

87-118 String Descriptor

Descriptor Description Table (for above example)

Address Descriptor type Memory Offset

08 Device 36

10 Config 54

12 Interface 63

14 Mouse-HID 72

16 Endpoint 78

18 String 87

20 00 00

22 00 00

24 00 00

26 00 00

28 00 00

30 00 00

32 00 00

34 00 00

Roller Movement Reporting

The roller mechanism built on the USB100 is capable of interfacing either to a LED-chopper wheel-Phototransistor system or a

mechanical system using a commutator with wiper contacts.

Page 7

7

www.fairchildsemi.com

USB100 Programmable Low-Cost USB Machine (PLUM)

USB100 rev.D

Negative Counting

Positive Counting

H1 or V1 or H3

H2 or V2 or H4

H2 or V2 or H4

H1 or V1 or H3

D1

D2

Q1

Q2

H2

H1

F

USB100

v

Schematic 1: Roller Mode of Operation

When the Roller configuration register is used to define an input

pair as roller inputs, the corresponding roller movement reporting

is enabled. In this case, internally, the roller wheel pulses are

counted and registered into an 8 bit register. One register is

available per input pair. A total of three rollers movement registers

(RMRs) are available, corresponding to the three roller mechanisms available. On all the input pairs (H1, H2 or V1, V2 or H3, H4)

the positive counting sequence is defined as (0,0), (0,1), (1,1) and

(0,0) and the same sequence repeating over again. Negative

counting sequence is defined as (0,0), (1,0), (1,1) and (0,1) and

the same sequence repeating again. Each of the above transitions

will result in the counter incrementing or decrementing by one

depending on whether the rollers are moving in the positive or

negative direction. Each time an IN query is sent on endpoint 1, the

counter contents are transferred to a temporary holding register

and queued for transmission on the USB. When an ACK is

received for the current transaction, the counter is cleared.

Hardware Features

Roller / Potentiometer Interface

One of the key differences between the mouse and joystick

hardware implementation is that themouse uses optical encoding

V1

H1

USB100

v

P1

P2

Schematic 2 : Potentiometer Mode of

Operation for Joystick

Page 8

8

www.fairchildsemi.com

USB100 Programmable Low-Cost USB Machine (PLUM)

USB100 rev.D

and a roller wheel to detect mouse movement. In contrast, joystick

uses a potentiometer to detect angular motion. The function select

bits [F1:0] allow the designer

to set the bits. In a mouse mode, the H1, H2, V1,V2 and H3 & H4

inputs are selected for the roller mechanism decode.In the joystick

mode, it selects the potentiometer interface. The state machine

uses a different algorithm for interpreting the inputs to the chip.

This function selection also affects the format of the report that is

generated.The roller mode is shown in schematic 1 and the

potentiometer mode is shown in schematic 2.

In case of the roller mode of operation (mouse/trackball), the

transitions on the Hx and Vx pairs are used in the counting process

to generate a digital estimate of the motion of the ball. In the

joystick mode of operation, the RC timing constant changes the

width of an internal digital pulse whose width is measured and

reported back. All of the buttons feature an internal pullup. The

actual switches used is a push button switch with one terminal

connected to a button input and the second terminal connected to

ground.

Crystal / Crystal Oscillator combination

OSC2

OSC1

The above configuration is the recommended configuration for

use with a crystal or a ceramic resonator. The capacitors are

optional and if used, must be in the 10-30pf range. The resistor is

necessary and its value is 1MΩ. A metal-can oscillator may be

used too. In this case, the output of the oscillator must be

connected to OSC1 and OSC2 must be left unconnected.

Suspend mode operation

When the PLUM device determines that the necessary conditions

(laid down in the USB standard), it goes into the suspend mode.

It wakes up on USB bus activity, or when any of the buttons are

depressed. There exists an internal timer, whose timing operation

could be selected via bits 3 through 0 in ICB register 5. The PLUM

device wakes up on the expiration of the timer. It senses the roller/

potentiometer interface to determine if these inputs have changed

since the last poll. It does a remote wakeup, when such a

movement has occurred.

Remote Wakeup Support

This device supports the remote wakeup feature. This is indicated

to the host via the corresponding descriptor. Internally, the state

machine uses the values of the RRES_EN and RRES[2:0] bits in

the Remote Resume configuration byte to enable this feature, and

the amount of time between the “polls” to the roller/potentiometer

ports to determine whether the necessary conditions for wakeup

have been met.

Fairchild does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and Fairchild reserves the right at any time without notice to change said circuitry and specifications.

Life Support Policy

Fairchild's products are not authorized for use as critical components in life support devices or systems without the express written

approval of the President of Fairchild Semiconductor Corporation. As used herein:

1. Life support devices or systems are devices or systems which,

(a) are intended for surgical implant into the body, or (b) support

or sustain life, and whose failure to perform, when properly

used in accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a significant

injury to the user.

2. A critical component is any component of a life support device

or system whose failure to perform can be reasonably expected to cause the failure of the life support device or system,

or to affect its safety or effectiveness.

Fairchild Semiconductor Fairchild Semiconductor Fairchild Semiconductor Fairchild Semiconductor

Americas Europe Hong Kong Japan Ltd.

Customer Response Center Fax: +44 (0) 1793-856858 8/F, Room 808, Empire Centre 4F, Natsume Bldg.

Tel. 1-888-522-5372 Deutsch Tel: +49 (0) 8141-6102-0 68 Mody Road, Tsimshatsui East 2-18-6, Yushima, Bunkyo-ku

English Tel: +44 (0) 1793-856856 Kowloon. Hong Kong Tokyo, 113-0034 Japan

Français Tel: +33 (0) 1-6930-3696 Tel; +852-2722-8338 Tel: 81-3-3818-8840

Italiano Tel: +39 (0) 2-249111-1 Fax: +852-2722-8383 Fax: 81-3-3818-8841

Loading...

Loading...