Page 1

DATA SHEET

BIPOLAR ANALOG INTEGRATED CIRCUIT

µ

PC339

LOW POWER QUAD COMPARATOR

DESCRIPTION

The µPC339 is a quad comparator which is designed

to operate from a single power supply over a wide range

of voltage. Operation from split power supplies, is also

possible and the power supply current drain is very low.

Further advantage, the input common-mode voltage includes ground, even though operated from a single power

FEATURES

• Common-mode input voltage range includes V

• Wide supply voltage range

2 V to 32 V (Single)

±1 V to ±16 V (Split)

• Low supply current

• Open collector output

supply voltage.

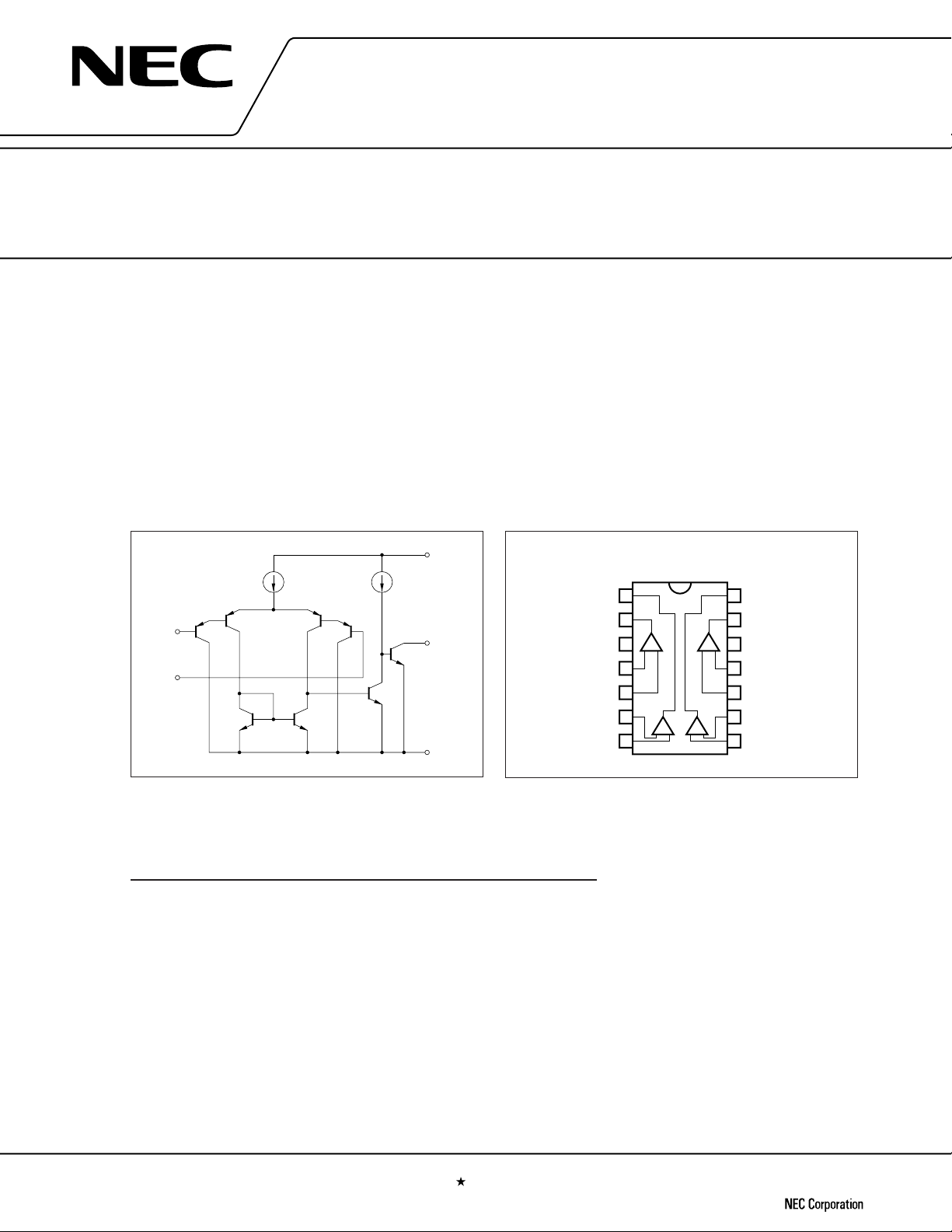

EQUIVALENT CIRCUIT (1/4 Circuit) PIN CONFIGURATION (Top View)

+

V

100 A 100 A

µ

+

I

N

–

I

I

Q

2

Q

1

Q

5

Q

3

Q

4

Q

Q

6

µ

OUT2

OUT

8

Q

7

–

V

OUT1

PC339C, 339G2

µ

1

2

+

3

V

4

I

I1

5

I

N1

6

I

I2

7

I

N2

14

13

14

–+ –+

23

12

11

10

9

–+–+

8

OUT3

OUT4

V

I

N4

I

I4

I

N3

I

I3

–

–

ORDERING INFORAMTION

Part Number Package

µ

PC339C 14-pin plastic DIP (300 mil)

µ

PC339G2 14-pin plastic SOP (225 mil)

Document No. G11764EJ3V0DS00 (3rd edition)

(Previous No. IC-1986)

Date Published February 1997 N

Printed in Japan

The information in this document is subject to change without notice.

The mark shows major revised points.

©

1997

Page 2

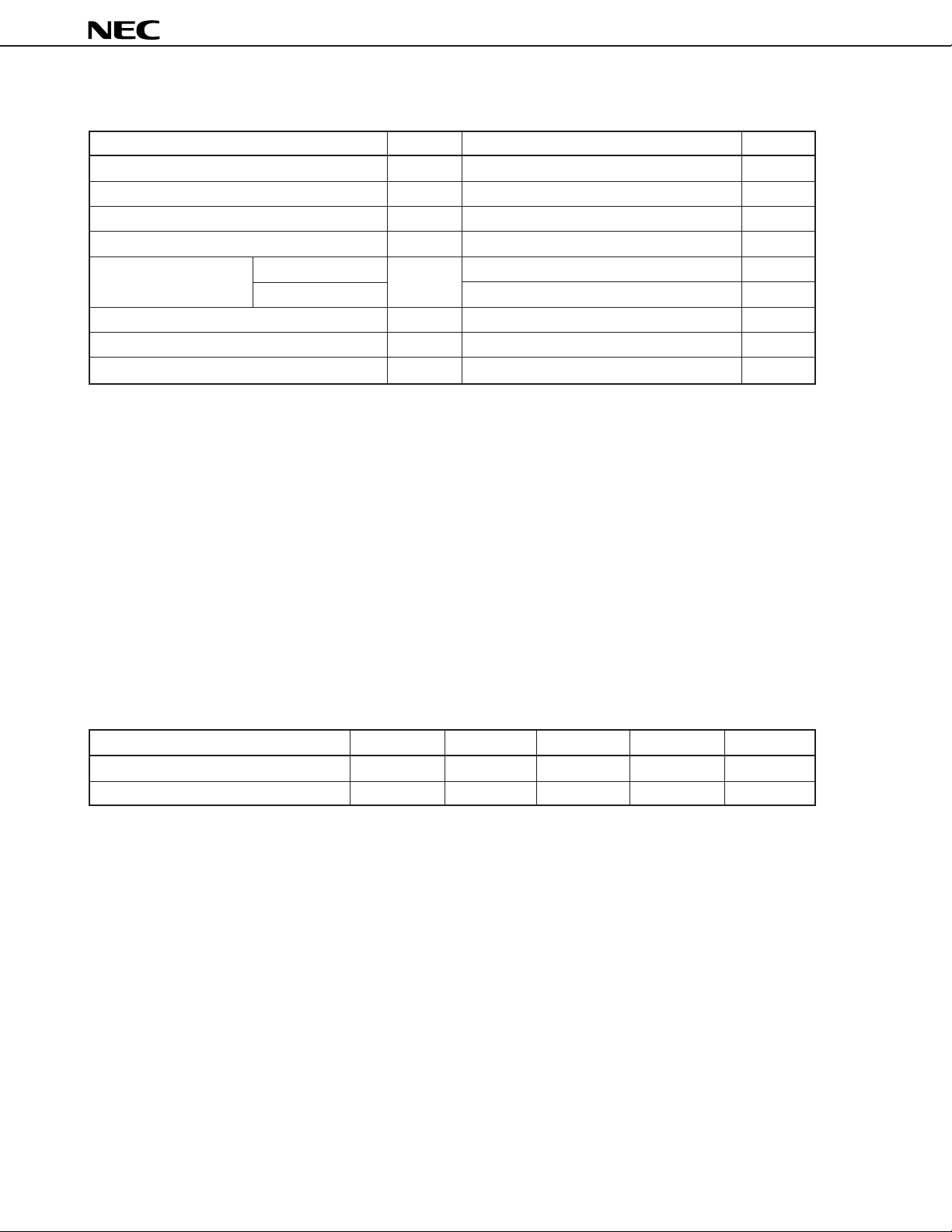

ABSOLUTE MAXIMUM RATINGS (TA = 25 °C)

Parameter Symbol Ratings Unit

Voltage between V+ and V

Differential Input Voltage VID ±36 V

Input Voltage Note 2 VI V– –0.3 to V– +36 V

Output Voltage Note 3 VO V– –0.3 to V– +36 V

Power Dissipation C Package Note 4 PT 570 mW

Output Short Circuit Duration Note 6 Indefinite sec

Operating Ambient Temperature TA –20 to +80 °C

Storage Temperature Tstg –55 to + 125 °C

–

G2 Package Note 5 550 mW

Note 1 V+ –V

Notes 1. Reverse connection of supply voltage can cause destruction.

2. The input voltage should be allowed to input without damage or destruction independent of the

magnitude of V+. Either input signal should not be allowed to go negative by more than 0.3 V. The normal

operation will establish when any input is within the Common Mode Input Voltage Range of electrical

characteristics.

3. This specification is the voltage which should be allowed to supply to the output terminal from external

without damage or destruction independent of the magnitude of V

of supply voltage, power on/off etc., this specification should be kept.

4. Thermal derating factor is –7.6 mW/°C when operating ambient temperature is higher than 55 °C.

5. Thermal derating factor is –5.5 mW/°C when operating ambient temperature is higher than 25 °C.

6. Short circuits from the output to V

dissipation not to exceed the absolute maximum ratings, Note 4 and Note 5.

–

+

can cause destruction. Pay careful attention to the total power

–0.3 to +36 V

+

. Even during the transition period

µ

PC339

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol MIN. TYP. MAX. Unit

Supply Voltage (Split) V

Supply Voltage (V– = GND) V

±

+

±1 ±16 V

+2 +32 V

2

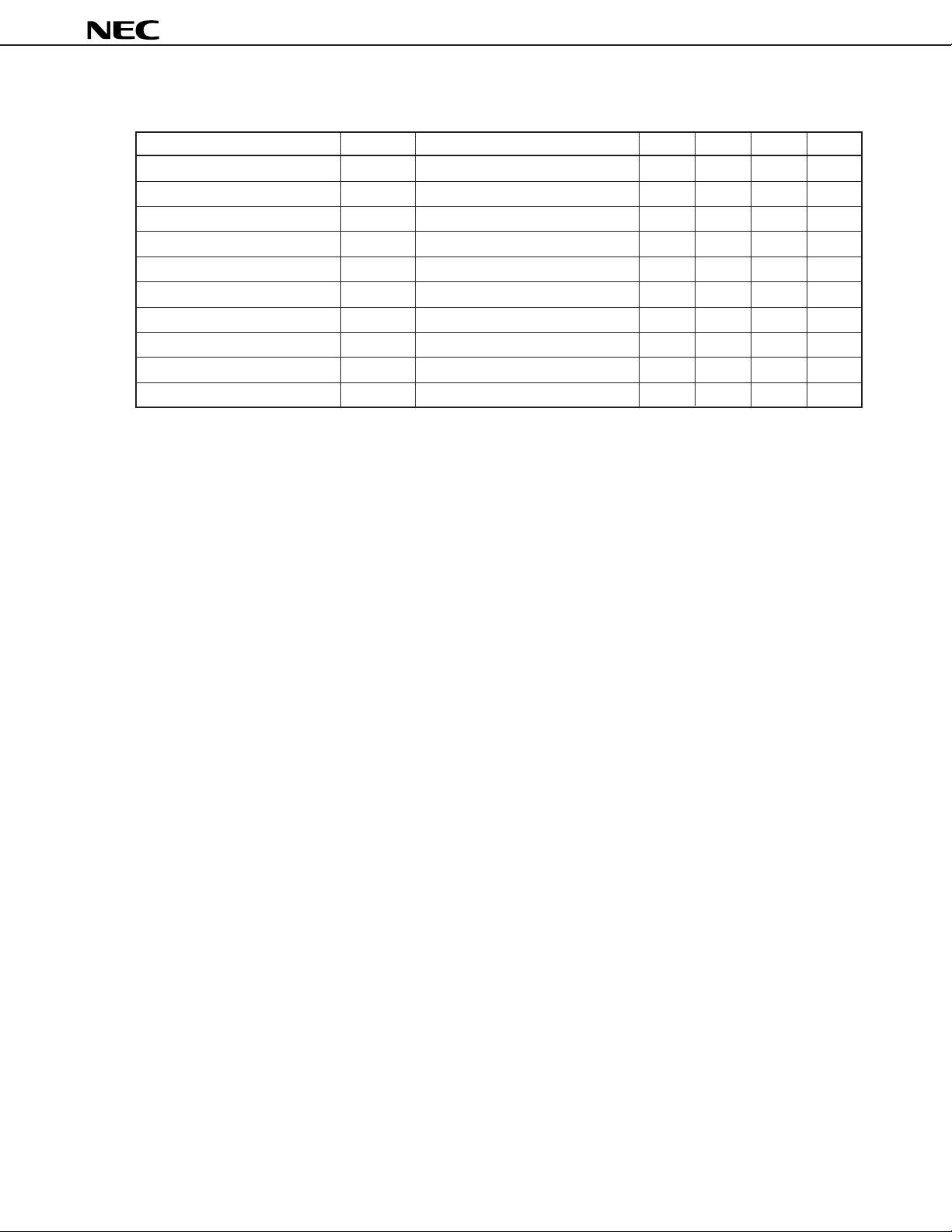

Page 3

µ

PC339

ELECTRICAL CHARACTERISTICS (TA = 25 °C, V+ = 5 V, V– = GND)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Input Offset Voltage VIO VO = 1.4 V, VREF = 1.4 V, RS = 0 Ω±2±5mV

Input Offset Current IIO VO = 1.4 V ±5 ± 50 nA

Input Bias Current IB VO = 1.4 V 25 250 nA

Voltage Gain AV RL = 15 kΩ 200 V/mV

Supply Current ICC RL = ∞, IO = 0 A, All Comparators 0.8 2 mA

Common Mode lnput Voltage Range

Output Saturation Voltage VOL

Output Sink Current IO SINK VIN (–) = 1 V, VIN (+) = 0 V, VO ≤ 1.5 V 6 16 mA

Output Leakage Current IO LEAK VIN (+) = 1 V, VIN (–) = 0 V, VO = 5 V 0.1 nA

Response Time RL = 5.1 kΩ, VRL = 5 V 1.3

VICM 0V

·

·

·

·

VIN (–) = 1 V, VIN (+) = 0 V, IO SINK = 4 mA

+

–1.5 V

0.2 0.4 V

µ

s

3

Page 4

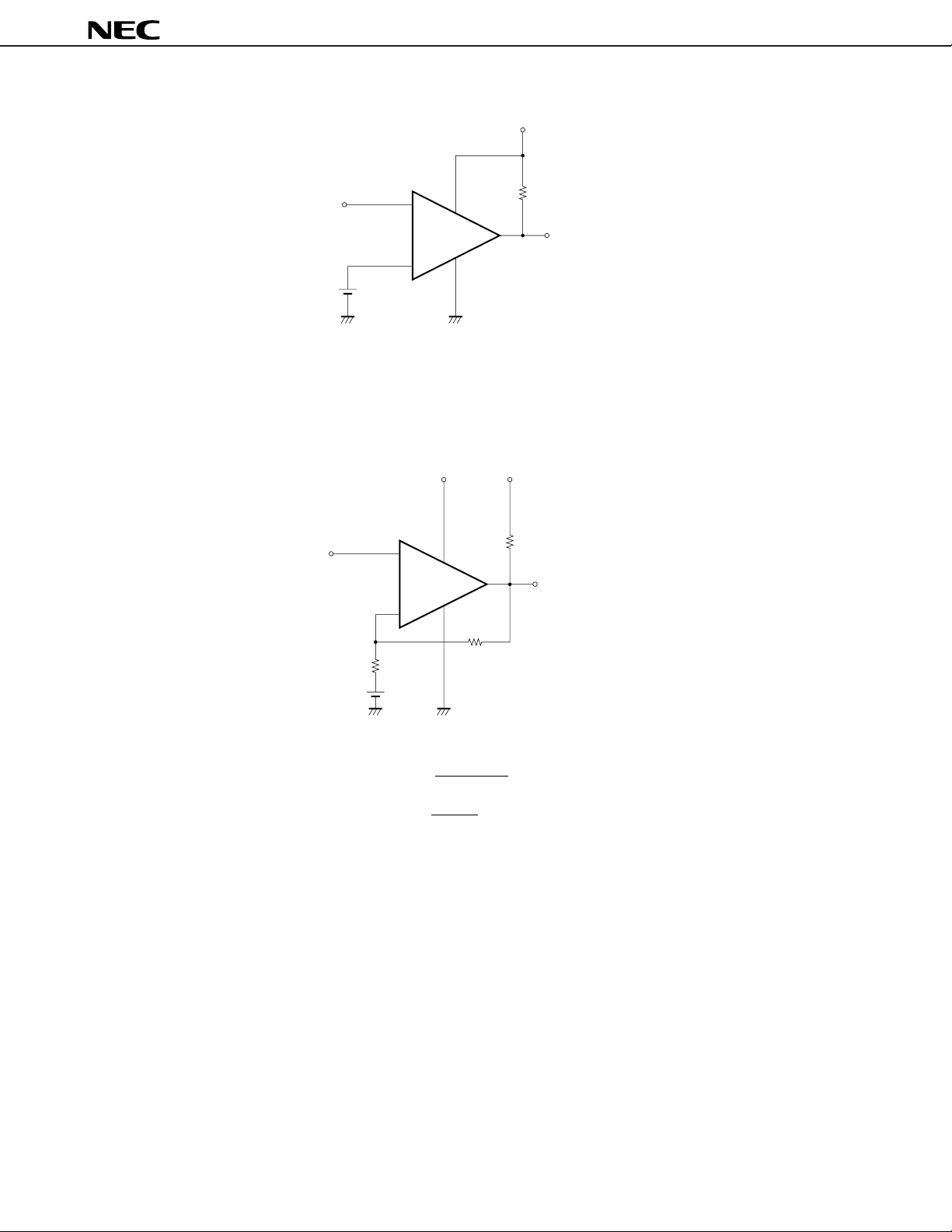

APPLICATION CIRCUIT EXAMPLE

(

)

IN

V

4, 6, 8, 10

5, 7, 9, 11

V

REF

–

+

V

REF

: V– to V+ –1.5 (V)

COMPARATOR with HYSTERESIS CIRCUIT

µ

PC339

+

V

R

L

3

OUT

1, 2

12

+

V

13, 14

V

RL

V

IN

R

1

Threshold voltage

•

TH (High)

V

V

TH (Low)

VRL > V

–

+

R

V

REF

R

·

= V

REF

+ (VRL – V

·

·

= V

REF

– (V

·

REF

> V

OL

1

RL + R2 + R

R

1

R1 + R

2

L

R

OUT

2

REF

1

REF

– VOL)

)

4

Page 5

TYPICAL PERFORMANCE CHARACTERISTICS (TA = 25 °C, TYP.)

µ

PC339

POWER DISSIPATION

1,000

800

339C

600

339G2

400

- Total Power Dissipation - mWV

200

T

P

0 20406080100

A

- Operating Ambient Temperature - °C

T

INPUT OFFSET VOLTAGE

3

V+ = +5 V

–

V

= GND

2

1

SUPPLY CURRENT

R

L

= ∞

1.2

TA = 0 °C

1.0

TA = 25 °C

0.8

- Supply Current - mA

CC

I

A

= 70 °C

T

0.6

0 10203040

+

- Supply Voltage - V (V– = GND)

V

INPUT BIAS CURRENT

50

40

TA = 0 °C

0

–1

- Input Offset Voltage - mVV

IO

–2

–3

A

- Operating Ambient Temperature - °C

T

0

OUTPUT SATURATION VOLTAGE

10

1

0.1

0.01

- Output Saturation Voltage - V

OL

A

= 70 °C

T

T

A

= 25 °C

A

= 0 °C

T

4020–40 –20

60 80

30

A

= 25 °C

T

- Input Bias Current - nA

B

20

I

10

0 10203040

+

- Supply Voltage - V (V– = GND)

V

A

= 70 °C

T

0.001

0.01 0.1 1 10 100

O SINK

- Output Sink Current - mA

I

5

Page 6

µ

PC339

RESPONSE TIME FOR VARIOUS INPUT

OVERDRIVES I

5

4

20 mV

3

2

100 mV

1

0

0

–50

–100

VIN - Input Voltage - mV VO - Output Voltage - V

0 0.5 1.0 1.5 2.0

5.0 mV Input Overdrive

+5 V

VIN

–

+

TA = 25 °C

t - Time - s

µ

5.1 kΩ

O

V

RESPONSE TIME FOR VARIOUS INPUT

OVERDRIVES II

5

4

3

2

1

0

100

50

TA = 25 °C

0

VIN - Input Voltage - mV VO - Output Voltage - V

0 0.5 1.0 1.5 2.0

100 mV Input Overdrive

5 mV

20 mV

VIN

–

+

t - Time - s

µ

+5 V

5.1 kΩ

O

V

6

Page 7

PACKAGE DRAWINGS

14PIN PLASTIC DIP (300 mil)

14 8

17

µ

PC339

A

I

J

H

G

F

DN

NOTES

1) Each lead centerline is located within 0.25 mm (0.01 inch) of

its true position (T.P.) at maximum material condition.

2) ltem "K" to center of leads when formed parallel.

M

C

B

K

L

M

R

ITEM MILLIMETERS INCHES

A 20.32 MAX. 0.800 MAX.

B 2.54 MAX. 0.100 MAX.

C 2.54 (T.P.) 0.100 (T.P.)

0.01

+0.004

–0.005

+0.004

–0.003

D 0.50±0.10 0.020

F 1.2 MIN. 0.047 MIN.

G 3.6±0.3 0.142±0.012

H 0.51 MIN. 0.020 MIN.

I 4.31 MAX. 0.170 MAX.

J 5.08 MAX. 0.200 MAX.

K 7.62 (T.P.) 0.300 (T.P.)

L 6.4 0.252

M 0.25 0.010

N 0.25

R 0~15° 0~15°

+0.10

–0.05

P14C-100-300B1-1

7

Page 8

14 PIN PLASTIC SOP (225 mil)

14 8

17

detail of lead end

P

µ

PC339

A

G

F

E

C

D

M

M

N

NOTE

Each lead centerline is located within 0.12 mm (0.005 inch) of

its true position (T.P.) at maximum material condition.

B

H

I

K

L

ITEM MILLIMETERS INCHES

A

10.46 MAX.

B

1.42 MAX.

C

1.27 (T.P.)

D 0.40

E

F

G

H

I

J

K 0.15

L 0.6±0.2 0.024

M

N

P3° 3°

+0.10

–0.05

0.1±0.1

1.8 MAX.

1.49

6.5±0.3

4.4

1.1

+0.10

–0.05

0.12

0.10

+7°

–3°

J

0.412 MAX.

0.056 MAX.

0.050 (T.P.)

+0.004

0.016

–0.003

0.004±0.004

0.071 MAX.

0.059

0.256±0.012

0.173

0.043

+0.004

0.006

–0.002

+0.008

–0.009

0.005

0.004

+7°

–3°

S14GM-50-225B, C-4

8

Page 9

µ

PC339

RECOMMENDED SOLDERING CONDITIONS

When soldering this product, it is highly recommended to observe the conditions as shown below. If other soldering

processes are used, or if the soldering is performed under different conditions, please make sure to consult with our

sales offices.

For more details, refer to our document “SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL”

(C10535E).

Surface mount device

µ

PC339G2: 14-pin plastic SOP (225 mil)

Process Conditions Symbol

Infrared ray reflow Peak temperature: 230 °C or below (Package surface temperature), IR30-00-1

Reflow time: 30 seconds or less (at 210 °C or higher),

Maximum number of reflow processes: 1 time.

Vapor Phase Soldering Peak temperature: 215 °C or below (Package surface temperature), VP15-00-1

Reflow time: 40 seconds or less (at 200 °C or higher),

Maximum number of reflow processes: 1 time.

Wave Soldering Solder temperature: 260 °C or below, Flow time: 10 seconds or less, WS60-00-1

Maximum number of flow processes: 1 time,

Pre-heating temperature: 120 °C or below (Package surface temperature).

Partial heating method Pin temperature: 300 °C or below, –

Heat time: 3 seconds or less (Per each side of the device).

Caution Apply only one kind of soldering condition to a device, except for “partial heating method”, or

the device will be damaged by heat stress.

Through-hold device

µ

PC339C: 14-pin plastic DIP (300 mil)

Process Conditions

Wave soldering Solder temperature: 260 °C or below,

(only to leads) Flow time: 10 seconds or less.

Partial heating method Pin temperature: 300 °C or below,

Heat time: 3 seconds or less (per each lead.)

Caution For through-hole device, the wave soldering process must be applied only to leads, and make

sure that the package body does not get jet soldered.

9

Page 10

REFERENCE DOCUMENTS

QUALITY GRADES ON NEC SEMICONDUCTOR DEVICES C11531E

SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL C10535E

IC PACKAGE MANUAL C10943X

GUIDE TO QUALITY ASSUARANCE FOR SEMICONDUCTOR DEVICES MEI-1202

SEMICONDUCTORS SELECTION GUIDE X10679E

NEC SEMICONDUCTOR DEVICE RELIABILITY/ IEI-1212

QUALITY CONTROL SYSTEM - STANDARD LINEAR IC

µ

PC339

10

Page 11

[MEMO]

µ

PC339

11

Page 12

µ

[MEMO]

The application circuits and their parameters are for reference only and are not intended for use in actual design-ins.

No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

PC339

M4 96.5

2

Loading...

Loading...