Page 1

INTEGRATED CIRCUITS

DATA SH EET

TZA3005H

SDH/SONET STM1/OC3 and

STM4/OC12 transceiver

Product specification

Supersedes data of 1997 Aug 05

File under Integrated Circuits, IC19

2000 Feb 17

Page 2

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

FEATURES

• Supports STM1/OC3(155.52 Mbits/s) and STM4/OC12

(622.08 Mbits/s)

• Supports reference clock frequencies of 19.44, 38.88,

51.84 and 77.76 MHz

• Meets Bellcore, ANSI and ITU-T specifications

• Meets ITU jitter specification typically to a factor of 2.5

• Integral high-frequency PLL for clock generation

• Interface to TTL logic

• Low jitter PECL (Positive Emitter Coupled Logic)

interface

• 4 or 8-bit STM1/OC3 TTL data path

• 4 or 8-bit STM4/OC12 TTL data path

• No external filter components required

• QFP64 package

• Diagnostic and line loopback modes

• Lock detect

• LOS (Loss of Signal) input

• Low power (0.9 W typical)

• Selectable frame detection and byte realignment

• Loop timing

• Forward and reverse clocking

• Squelched clock operation

• Self-biased PECL inputs to support AC coupling.

TZA3005H

GENERAL DESCRIPTION

The TZA3005H SDH/SONET transceiver chip is a fully

integrated serialization/deserialization STM1/OC3

(155.52 Mbits/s) and STM4/OC12 (622.08 Mbits/s)

interfacedevice. It performsallnecessaryserial-to-parallel

and parallel-to-serial functions in accordance with

SDH/SONET transmission standards. It is suitable for

SONET-based applications and can be used in

conjunction with the data and clock recovery unit

(TZA3004), optical front-end (TZA3023 with TZA3034/44)

anda laser driver(TZA3001). A typicalnetworkapplication

is shown in Fig.10.

A high-frequency phase-locked loop is used for on-chip

clock synthesis, which allows a slower external transmit

reference clock to be used. A reference clock of 19.44,

38.88,51.84 or 77.76 MHzcan be usedtosupportexisting

system clocking schemes. The TZA3005H also performs

SDH/SONET frame detection.

The low jitter PECL interface ensures that Bellcore, ANSI,

and ITU-T bit-error rate requirements are satisfied.

The TZA3005H is supplied in a compact QFP64 package.

APPLICATIONS

• SDH/SONET modules

• SDH/SONET-based transmission systems

• SDH/SONET test equipment

• ATM (Asynchronous Transfer Mode) over SDH/SONET

• Add drop multiplexers

• Broadband cross-connects

• Section repeaters

• Fibre optic test equipment

• Fibre optic terminators.

ORDERING INFORMATION

TYPE

NUMBER

TZA3005H QFP64 plastic quad flat package; 64 leads (lead length 1.6 mm);

2000 Feb 17 2

NAME DESCRIPTION VERSION

body 14 × 14 × 2.7 mm

PACKAGE

SOT393-1

Page 3

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

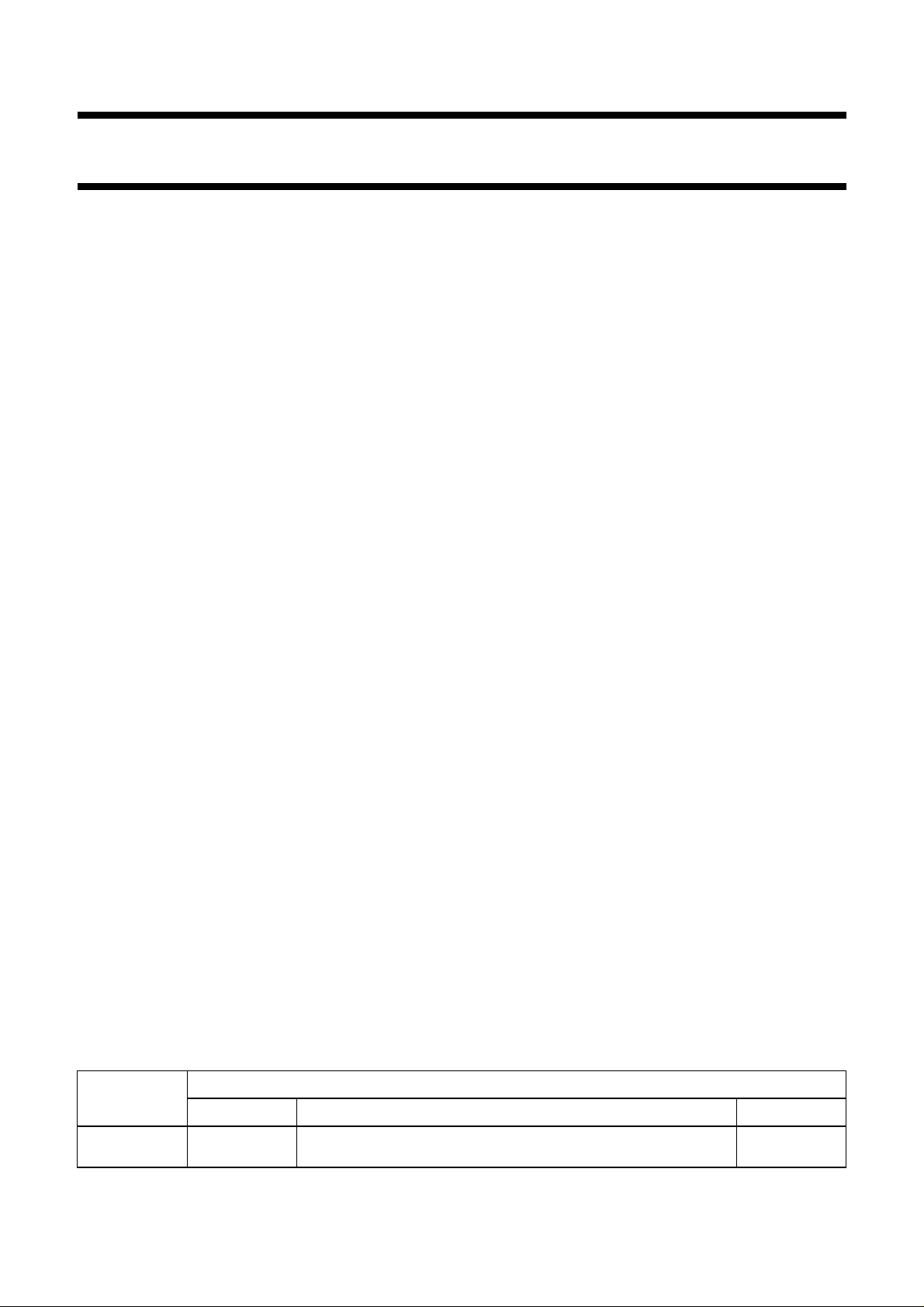

BLOCK DIAGRAM

handbook, full pagewidth

LLEN

TXPD0 to

TXPD7

TXPCLK

MRST

TEST1

TEST2

TEST3

BUSWIDTH

31

53 to 60

61

48

10

11

13

30

8

8:1 OR 4:1

P ARALLEL T O SERIAL

RF

SWITCH

BOX

TRANSMITTER

(1)

D

2

2

TZA3005H

17, 18

21, 20

TZA3005H

TXSD and

TXSDQ

TXSCLK and

TXSCLKQ

REFSEL0 and

REFSEL1

MODE

REFCLK and

REFCLKQ

SDTTL

SDPECL

OOF

DLEN

RXSD and

RXSDQ

RXSCLK and

RXSCLKQ

V

CC(SYNOUT)

3, 4

49

15, 14

22

23

33

32

24, 25

27, 28

GND

2

CLOCK

SYNTHESIZER

2

on-chip capacitor

2

2

2

D

RECEIVER

1

2 5 8, 9 6 7 16 19

V

CCD(SYN)

SYN

V

CCA(SYN)

SYNOUT

DGND

SYN

AGND

12

GND

V

CLOCK

DIVIDER

BY 4 OR BY 8

1:8 OR 1:4

SERIAL TO P ARALLEL

FRAME HEADER DETECT

26

GND

TXOUT

CC(TXOUT)

GND

V

CC(RXCORE)

8

29

V

CC(RXOUT)

RXCORE

36, 37, 39, 40,

41, 43 to 45

34, 42

38, 46

GND

RXOUT

62

63

64

47

35

52

51

SYNCLKDIV

LOCKDET

19MHZO

RXPD0 to

RXPD7

RXPCLK

FP

V

CC(TXCORE)

GND

MGS975

TXCORE

(1) Dashed lines represent normal operation mode.

Fig.1 Block diagram.

2000 Feb 17 3

Page 4

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

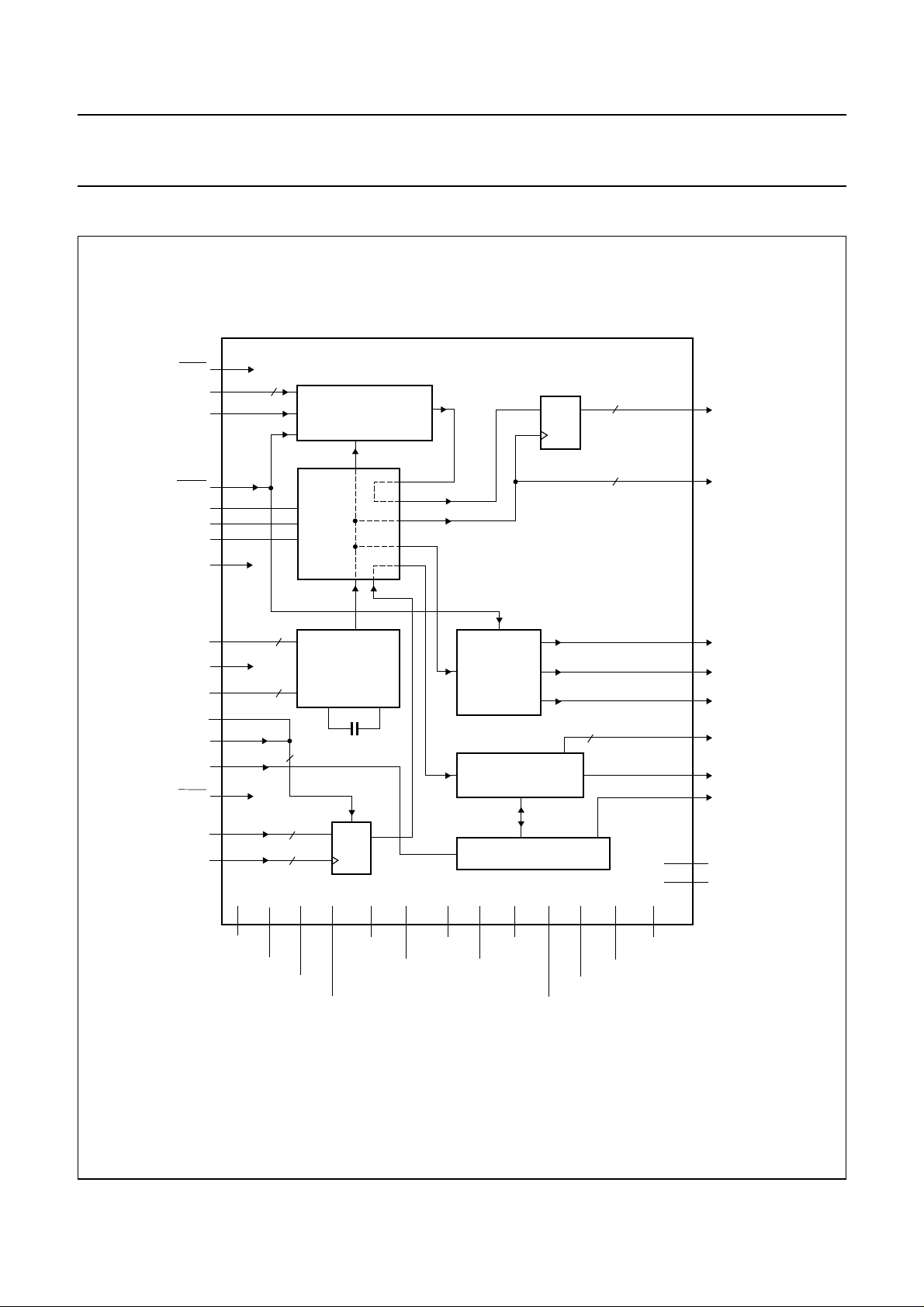

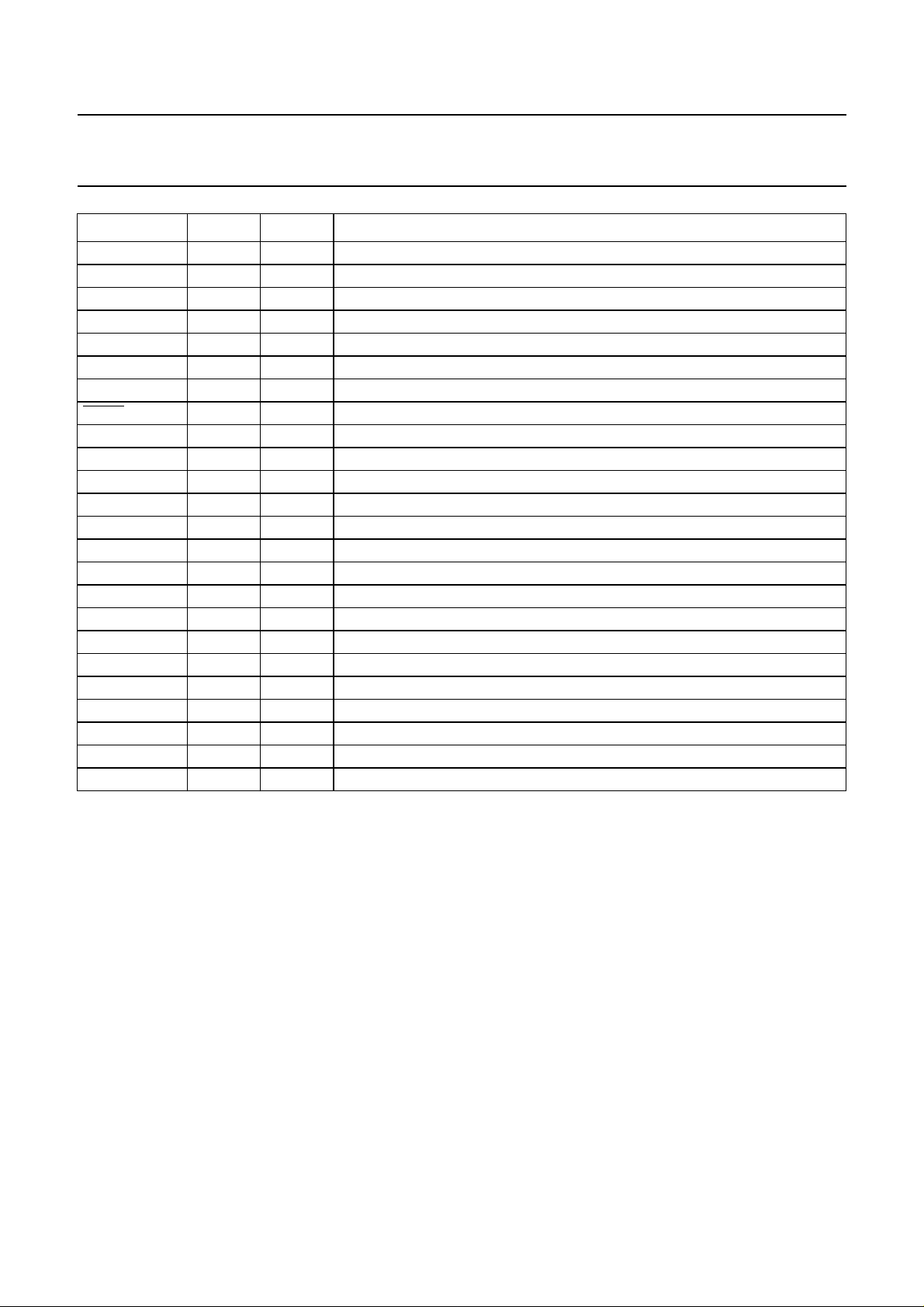

PINNING

SYMBOL PIN TYPE

V

CC(SYNOUT)

GND

SYNOUT

1 S supply voltage (synthesizer output)

2 G ground (synthesizer output)

REFSEL0 3 I reference clock select input 0

REFSEL1 4 I reference clock select input 1

DGND

V

CCD(SYN)

V

CCA(SYN)

AGND

AGND

SYN

SYN

SYN

5 G digital ground (synthesizer)

6 S digital supply voltage (synthesizer)

7 S analog supply voltage (synthesizer)

8 G analog ground (synthesizer)

9 G analog ground (synthesizer)

TEST1 10 I test and control input

TEST2 11 I test and control input

GND 12 G ground

TEST3 13 I test and control input

REFCLKQ 14 I inverted reference clock input

REFCLK 15 I reference clock input

V

CC(TXOUT)

16 S supply voltage (transmitter output)

TXSD 17 O serial data output

TXSDQ 18 O inverted serial data output

GND

TXOUT

19 G ground (transmitter output)

TXSCLKQ 20 O inverted serial clock output

TXSCLK 21 O serial clock output

SDTTL 22 I TTL signal detect input

SDPECL 23 I PECL signal detect input

RXSD 24 I serial data input

RXSDQ 25 I inverted serial data input

V

CC(RXCORE)

26 S supply voltage (receiver core)

RXSCLK 27 I serial clock input

RXSCLKQ 28 I inverted serial clock input

GND

RXCORE

29 G ground (receiver core)

BUSWIDTH 30 I 4/8 bus width select input

LLEN 31 I line loopback enable input (active LOW)

DLEN 32 I diagnostic loopback enable input (active LOW)

OOF 33 I out-of-frame enable input

GND

RXOUT

34 G ground (receiver output)

FP 35 O frame pulse output

RXPD0 36 O parallel data output 0

RXPD1 37 O parallel data output 1

V

CC(RXOUT)

38 S supply voltage (receiver output)

RXPD2 39 O parallel data output 2

RXPD3 40 O parallel data output 3

(1)

DESCRIPTION

TZA3005H

2000 Feb 17 4

Page 5

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

SYMBOL PIN TYPE

RXPD4 41 O parallel data output 4

GND

RXOUT

RXPD5 43 O parallel data output 5

RXPD6 44 O parallel data output 6

RXPD7 45 O parallel data output 7

V

CC(RXOUT)

RXPCLK 47 O receive parallel clock output

MRST 48 I master reset (active LOW)

MODE 49 I serial data rate select STM1/STM4

ALTPIN 50 I test and control input

GND

TXCORE

V

CC(TXCORE)

TXPD0 53 I parallel data input 0

TXPD1 54 I parallel data input 1

TXPD2 55 I parallel data input 2

TXPD3 56 I parallel data input 3

TXPD4 57 I parallel data input 4

TXPD5 58 I parallel data input 5

TXPD6 59 I parallel data input 6

TXPD7 60 I parallel data input 7

TXPCLK 61 I transmit parallel clock input

SYNCLKDIV 62 O transmit byte/nibble clock output (synchronous)

LOCKDET 63 O lock detect output

19MHZO 64 O 19 MHz reference clock output

42 G ground (receiver output)

46 S supply voltage (receiver output)

51 G ground (transmitter core)

52 S supply voltage (transmitter core)

(1)

DESCRIPTION

TZA3005H

Note

1. Pin type abbreviations: O = Output, I = Input, S = Supply, G = Ground.

2000 Feb 17 5

Page 6

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

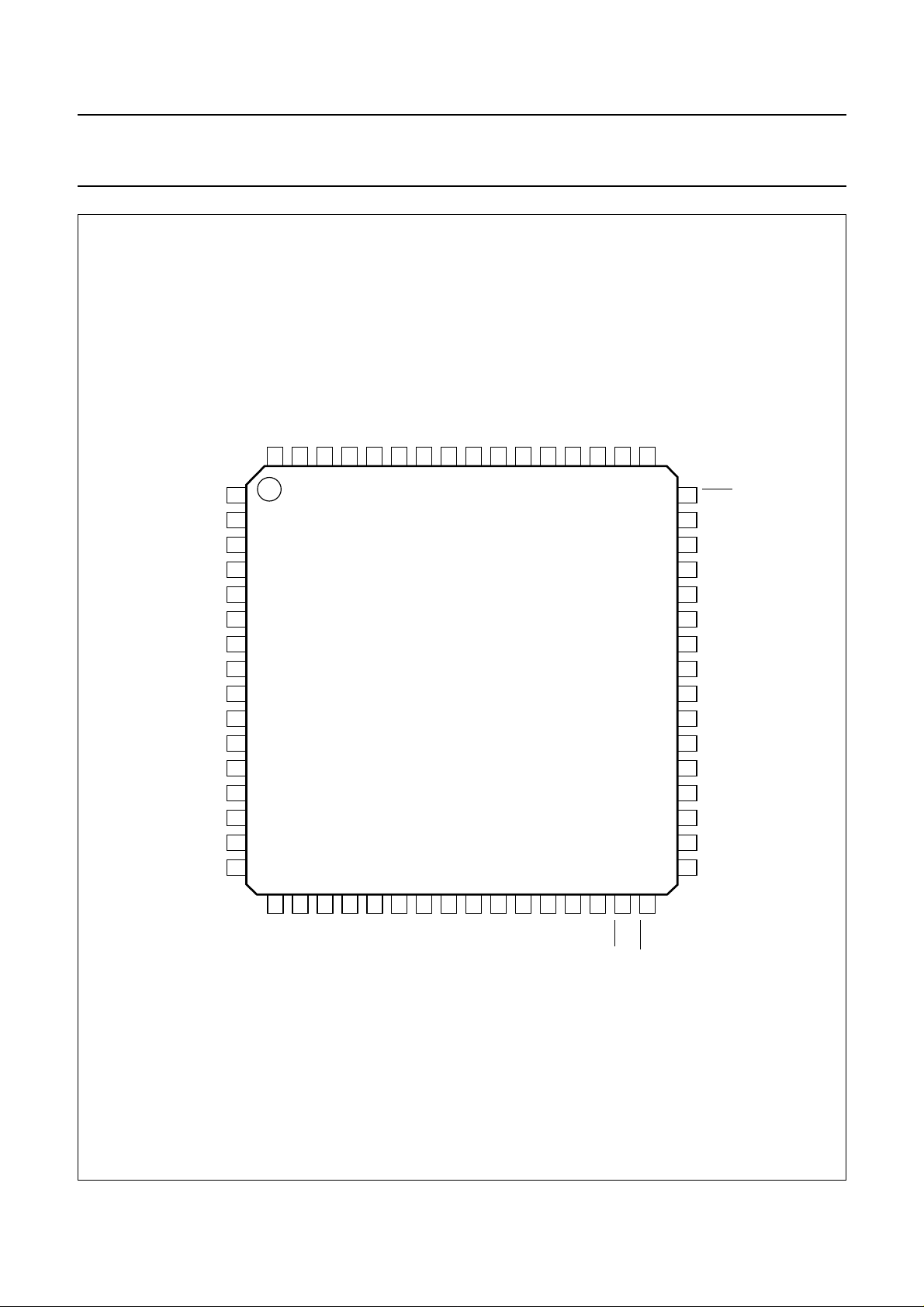

handbook, full pagewidth

19MHZO

LOCKDET

SYNCLKDIV

TXPCLK

TXPD7

TXPD6

TXPD5

TXPD4

64

63

62

61

60

59

58

57

SYN

SYN

SYN

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

TZA3005H

V

CC(SYNOUT)

GND

SYNOUT

REFSEL0

REFSEL1

DGND

V

CCD(SYN)

V

CCA(SYN)

AGND

AGND

TEST1

TEST2

TEST3

REFCLKQ

REFCLK

V

CC(TXOUT)

TXPD3

56

TXPD2

55

TXPD1

54

CC(TXCORE)

TXPD0

V

53

52

TXCORE

GND

ALTPIN

51

50

MODE

TZA3005H

48

MRST

RXPCLK

47

V

46

CC(RXOUT)

RXPD7

45

RXPD6

44

RXPD5

43

GND

42

RXOUT

RXPD4

41

RXPD3

40

RXPD2

39

V

38

CC(RXOUT)

RXPD1

37

RXPD0

36

FP

35

GND

34

RXOUT

33

OOF

17

TXSD

18

19

TXSDQ

GND

20

TXOUT

TXSCLKQ

22

SDTTL

TXSCLK

23

24

RXSD

SDPECL

21

Fig.2 Pin configuration.

2000 Feb 17 6

25

26

RXSDQ

CC(RXCORE)

V

27

28

RXSCLK

RXSCLKQ

29

30

RXCORE

BUSWIDTH

GND

31

LLEN

32

MGK483

DLEN 49

Page 7

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

FUNCTIONAL DESCRIPTION

Introduction

The TZA3005H transceiver implements SDH/SONET

serialization/deserialization, transmission and frame

detection/recovery functions. The TZA3005Hcan beused

as the front-end for SONET equipment. It handles the

serial receive and transmit interface functions including

parallel-to-serial and serial-to-parallel conversion and

clock generation. A block diagram showing the basic

operation of the chip is shown in Fig.1.

The TZA3005H has a transmitter section, a receiver

section, and an RF switch box. The sequence of

operations is as follows:

• Transmitter operations:

– 4 or 8-bit parallel input

– parallel-to-serial conversion

– serial output.

• Receiver operations:

– serial input

– frame detection

– serial-to-parallel conversion

– 4 or 8-bit parallel output.

The RF switch box receives serial clock and data signals

from the transmitter section, the receiver inputbuffers and

from the clock synthesizer. These signals are routed by

multiplexers to the transmitter section, the transmitter

output, the receiver andto the clock divider, dependingon

the status of the control inputs. The switch box also

supports a number of test and loop modes.

TZA3005H

CLOCK SYNTHESIZER

The clock synthesizer generates a serial output clock

(TXSCLK) which is phase synchronised with the input

reference clock (REFCLK). The serial output clock is

synthesized from one of four SDH/SONET input reference

clock frequencies and can have a frequency of either

155.52 MHz for STM1/OC3 or 622.08 MHz for

STM4/OC12 selected by the MODE input (see Table 1).

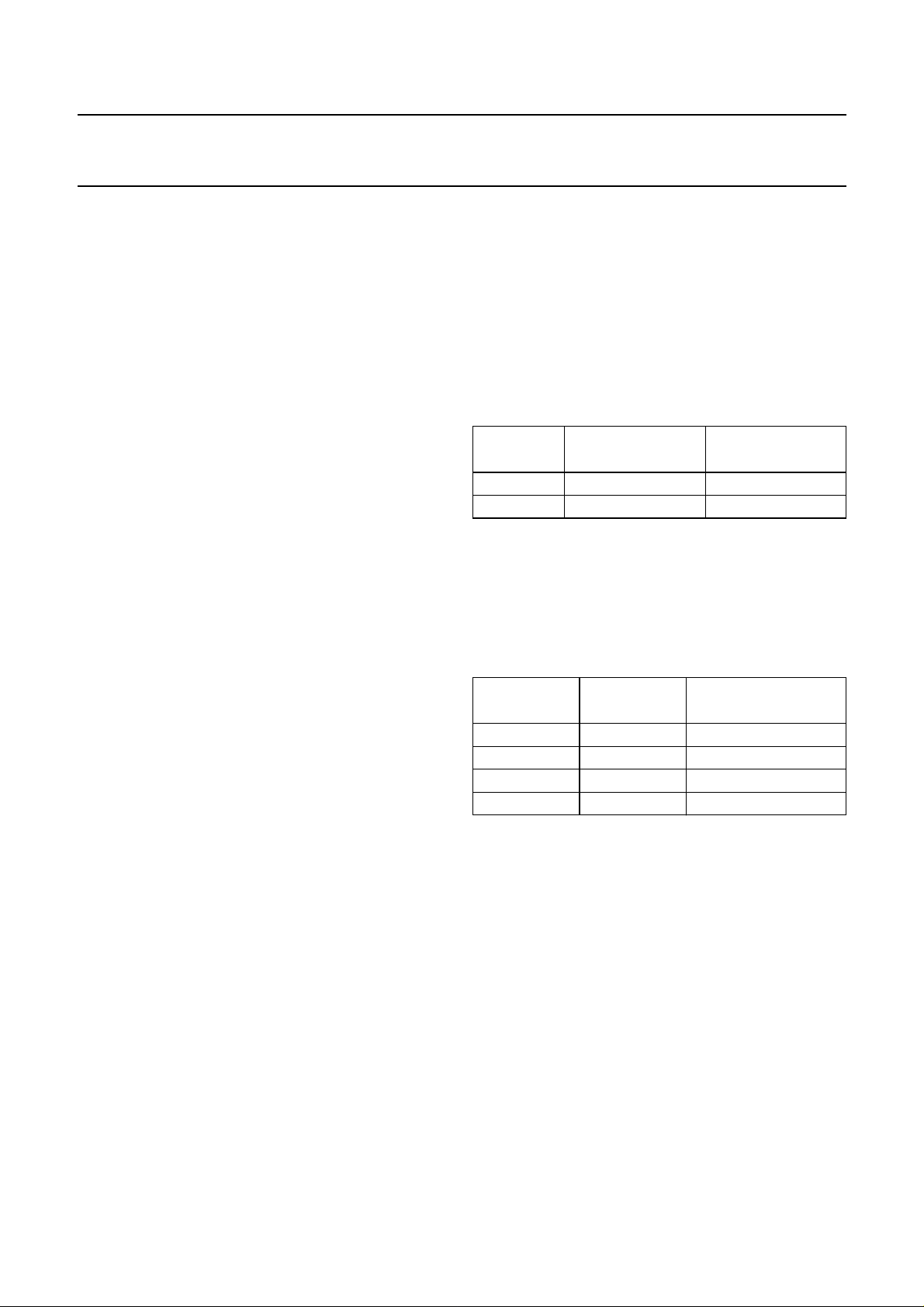

Table 1 Transmitter output clock (TXSCLK)

frequency options

MODE

INPUT

0 155.52 MHz STM1/OC3

1 622.08 MHz STM4/OC12

The frequency of the input reference clock is divided to

obtain a frequency of about 19 MHz which is fed to the

phase detector in the PLL. The appropriate divisor is

selected by control inputs REFSEL0 and REFSEL1 as

shown in Table 2.

Table 2 Reference frequency (REFCLK) options

REFSEL1 REFSEL0

0 0 19.44 MHz

0 1 38.88 MHz

1 0 51.84 MHz

1 1 77.76 MHz

TXSCLK

FREQUENCY

OPERATING

MODE

REFCLK

FREQUENCY

Transmitter operation

The transmitter section of the TZA3005H converts

STM1/OC3 or STM4/OC12 byte-serial input data to a

bit-serial output data format. Input data rates of 19.44,

38.88, 77.76 or 155.52 Mbytes/s are converted to an

output data rate of either 155.52 or 622.08 Mbits/s. It also

provides diagnostic loopback (transmitterto receiver), line

loopback (receiver to transmitter) and also loop timing

(transmitter clocked by the receiver clock).

An integral frequency synthesizer, comprising a

phase-locked loop and a divider, can be used to generate

a high-frequency bit clock from an input reference clock

frequency of 19.44, 38.88, 51.84 or 77.76 MHz.

2000 Feb 17 7

To ensure the TXSCLK frequency is accurate enough to

operate ina SONET system,REFCLK must begenerated

from a differential PECL crystal oscillator having a

frequency accuracy better than 4.6 ppm for compliance

with

“ITU G.813 (option 1)”

(option 2)”

To comply with SONET jitter requirements, the maximum

value specified for reference clock signal jitter must be

guaranteed over the 12 kHz to 1 MHz bandwidth (see

Table 3).

.

, or 20 ppm for

“ITU G.813

Page 8

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

Table 3 ITU reference clock signal (REFCLK) jitter limits

MAXIMUM JITTER OF REFCLK

12 kHz TO 1 MHz

56 ps (RMS) STM1/OC3

14 ps (RMS) STM4/OC12

The on-chip PLL contains a phase detector, a loop filter

and a VCO. The phase detector compares the phases of

the VCO and the divided REFCLK signals. The loop filter

convertsthephase detector outputtoa smooth DCvoltage

which controls the VCO frequency and ensures that it is

always 622.08 MHz. In STM1/OC3 mode, the correct

output frequency at TXSCLK is obtained by dividing the

VCO frequency by 4. The loop filter parameters are

optimized for minimal output jitter.

CLOCK DIVIDER

The clock divider generates either a byte rate or a nibble

rate version of the serial output clock (TXSCLK) which is

output on pin SYNCLKDIV (see Table 4).

Table 4 SYNCLKDIV frequency

MODE

INPUT

SYNCLKDIV is intended for use as a byte speed clock for

upstream multiplexing and overhead processing circuits.

Using SYNCLKDIV for upstream circuits ensures a stable

frequency and phase relationship is maintained between

the data in to and out of the TZA3005H.

For parallel-to-serial data conversion, the parallel input

data is transferred from the TXPCLK byte clock timing

domain to theinternally generatedbit clocktiming domain.

The internally generated bit clock does not have to be

phase aligned to the TXPCLK signal but must be

synchronized by the master reset (MRST) signal.

Receiver operation

The receiver section of the TZA3005H converts

STM1/OC3 or STM4/OC12 bit-serial input data to a

parallel data output format. In byte mode, input data rates

of 155.52 or 622.08 Mbits/s are converted to an output

data rate of either 19.44 or 77.76 Mbytes/s. In nibble

BUSWIDTH

0 0 (nibble) 38.88 MHz STM1/OC3

0 1 (byte) 19.44 MHz STM1/OC3

1 0 (nibble) 155.52 MHz STM4/OC12

1 1 (byte) 77.76 MHz STM4/OC12

SYNCLKDIV

FREQUENCY

OPERATING

MODE

OPERATING

MODE

TZA3005H

mode, a 4-bit parallel data stream is generated having a

clock frequency of either 38.88 or 155.52 MHz. It also

provides diagnostic loopback (transmitterto receiver), line

loopback (receiver to transmitter) and squelched clock

operation (transmitter clock to receiver).

FRAME AND BYTE BOUNDARY DETECTION

The frame and byte boundary detection circuit searches

the incoming data for the correct 48-bit frame pattern

whichis asequenceof threeconsecutive A1 bytes ofF0 H

followed immediately by three consecutive A2 bytes of

28 H. Frame pattern detection is enabled and disabled by

the out-of-frame enable input (OOF). Detection isenabled

by a rising edge on pin OOF, and remains enabled while

the level on pin OOF is HIGH. It is disabled when at least

one frame pattern is detected and the level on pin OOF is

no longer HIGH.When framepattern detectionis enabled,

the frame pattern is used to locate byte and frame

boundaries in the incoming data stream (Received Serial

Data (RXSD) or looped transmitter data). The serial to

parallel converterblock uses thelocated byte boundaryto

divide the incoming data stream into bytes for output on

theparallel output databus(RXPD0 to RXPD7). When the

correct 48-bit frame pattern is detected, the occurrence of

the frame boundary is indicated by the Frame Pulse (FP)

signal. When frame pattern detection is disabled, the byte

boundaryis fixed,and only frame patterns whichalign with

the fixed byte boundary produce an output on pin FP.

It is extremely unlikely that random data in an STM1/OC3

or STM4/OC12 data stream will replicate the 48-bit frame

pattern. Therefore, the time taken to detect the beginning

of the frame should be less than 250 µs (as specified in

“ITU G.783”

Once down-stream overhead circuits verify that frame and

byte synchronization are correct, OOF can be set LOW to

prevent the frame search process synchronizing to a

mimic frame pattern.

SERIAL-TO-PARALLEL CONVERTER

The serial-to-parallel converter causes a delay between

thefirst bitof an incomingserial data byteto thestartof the

parallel output of thatbyte. Thedelay dependson the time

taken for the internal parallel load timing circuit to

synchronizethe databyte boundaries tothe fallingedge of

RXPCLK. The timing of RXPCLK is independent of the

byte boundaries. RXPCLK is neither truncated nor

extended during reframe sequences.

) even at extremely high bit error rates.

2000 Feb 17 8

Page 9

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

Transceiver pin descriptions

TRANSMITTER INPUT SIGNALS

Parallel data inputs (TXPD0 to TXPD7)

These areTTL data word inputs. The input data is aligned

with the TXPCLK parallel input clock. TXPD7 is the most

significant bit (corresponding to bit 1 of each PCM word,

the first bit transmitted). TXPD0 is the least significant bit

(corresponding to bit 8 of each PCM word, the last bit

transmitted). Bits TXPD0 to TXPD7 are sampled on the

rising edge of TXPCLK. If a 4-bit bus width is selected,

TXPD7 is the most significant bit and TXPD4 is the least

significant bit. Inputs TXPD0 to TXPD3 are unused.

Parallel clock input (TXPCLK)

This is a TTL input clock signal having a frequency of

either19.44,38.88, 77.76 or 155.52 MHz andadutyfactor

of nominally 50%, to which input data bits TXPD0 to

TXPD7 are aligned. TXPCLK transfers the input data to a

holding register in the parallel-to-serial converter.

The rising edge of TXPCLK samples bits TXPD0 to

TXPD7. After a master reset, one rising edge of TXPCLK

is required to fully initialize the internal data path.

TZA3005H

Signal detect PECL (SDPECL)

This is a single-ended PECL input with an internal

pull-down resistor. This input is driven by an external

optical receiver module to indicate a loss of received

optical power (LOS). SDPECL is active HIGH when

SDTTL is at logic 0 and active LOW when SDTTL is at

logic 1or unconnected. When there is a loss of signal,

SDPECL is inactive and the bit-serial data on pins RXSD

and RXSDQ is internally forced to a constant zero. When

SDPECL is active, the bit-serial data on pins RXSD and

RXSDQ is processed normally (see Table 5).

Signal detect TTL (SDTTL)

This is a single-ended TTL input with an internal pull-up

resistor. This input isdriven byan external optical receiver

module toindicate a loss of received optical power (LOS).

SDTTL is active HIGH when pin SDPECL is logic 0 or

unconnected, and active LOW when pin SDPECL is at

logic 1. When there is a loss of signal, SDTTL is inactive

and the bit-serial data on pins RXSD and RXSDQ is

internallyforced to aconstantzero. When SDTTLisactive,

thebit-serialdata on pins RXSD and RXSDQ isprocessed

normally (see Table 5).

RECEIVER INPUT SIGNALS

Receive serial data (RXSD and RXSDQ)

These are differential PECL serial data inputs, normally

connectedto an opticalreceiver module orto the TZA3004

dataand clockrecovery unit, and clocked byRXSCLK and

RXSCLKQ. These inputs can be AC coupled without

external biasing.

Receive serial clock (RXSCLK and RXSCLKQ)

These are differential PECL recovered clock signals

synchronized to the input data RXSD and RXSDQ. It is

used by the receiver as the master clock for framing and

deserialization functions. These inputs can be AC coupled

without external biasing.

Out-of-frame (OOF)

This is aTTL signalwhich enablesframe patterndetection

logic in the TZA3005H. The frame pattern detection logic

is enabled by a rising edge on pin OOF, and remains

enabled until a frameboundary isdetected andOOF goes

LOW. OOF is an asynchronous signal with a minimum

pulse width of one RXPCLK period (see Fig.3).

If pin SDTTLinstead of pin SDPECL is to be connected to

the optical receiver module, connect pin SDPECL to a

logic HIGH-level to implement an active-LOW signal

detect, or leave pin SDPECL unconnected to implement

an active-HIGH signal detect.

Table 5 SDPECL/SDTTL truth table

SDPECL SDTTL RXPD OUTPUT DATA

0 or floating 0 0

0 or floating 1 or floating RXSD input data

1 0 RXSD input data

1 1 or floating 0

COMMON INPUT SIGNALS

Bus width selection (BUSWIDTH)

This is a TTL signal which selects 4-bit or 8-bit operation

for the transmit and receive parallel interfaces.

BUSWIDTH LOW selects a 4-bit bus width. BUSWIDTH

HIGH selects an 8-bit bus width.

2000 Feb 17 9

Page 10

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

Reference clock (REFCLK and REFCLKQ)

These are differential PECL reference clock inputs for the

internal bit clock synthesizer.

Diagnostic loopback enable (DLEN)

This is an active-LOW TTL signal which selects diagnostic

loopback. When DLEN is HIGH, the TZA3005H receiver

usesthe primary data(RXSD)andclock (RXSCLK) inputs.

When DLEN is LOW, the receiver uses the diagnostic

loopback clock and the transmitter input data.

Master reset (MRST)

This is an active LOW TTL signal which initializes the

transmitter. SYNCLKDIV is LOW during reset.

Line loopback enable (LLEN)

This is an active LOW TTL signal which selects line

loopback. When LLEN is LOW, the TZA3005H routes the

data and clock from the receiver inputs RXSD and

RXSCLK to the transmitter outputs TXSD and TXSCLK.

Reference select (REFSEL0 and REFSEL1)

These are TTL signals which select the reference clock

frequency (see Table 2).

Mode select (MODE)

This TTL signal selects the transmitter serial data rate.

MODE LOW selects 155.52 Mbits/s. MODE HIGH selects

622.08 Mbits/s.

TZA3005H

Parallel clock (SYNCLKDIV)

This is a TTL reference clock generated by dividing the

internal bit clock by eight, or by four when BUSWIDTH is

LOW. It is normallyused tocoordinate byte-wide transfers

between upstream logic and the TZA3005H.

Lock detect (LOCKDET)

This is an active HIGH CMOS signal. When active, it

indicates that the transmit PLL is locked to the reference

clock input.

19 MHz clock output (19MHZO)

This is a 19 MHz CMOS clock from the clock synthesizer.

It can be connected to the reference clock input of an

external clock recovery unit, such as the TZA3004.

RECEIVER OUTPUT SIGNALS

Parallel data outputs (RXPD0 to RXPD7)

These outputs comprise a parallel TTL data bus.

The parallel output data is aligned with the parallel output

clock (RXPCLK). RXPD7 is the most significant bit

(corresponding to bit 1 of each PCM word, the first bit

received). RXPD0 is the least significant bit

(corresponding to bit 8 of each PCM word, the last bit

received). RXPD0 to RXPD7 are updated on the falling

edge of RXPCLK. When a 4-bit bus width is selected,

RXPD7 is the most significant bit and bit 4 is the least

significant bit.Outputs RXPD0 to RXPD3 are forced LOW.

Frame pulse (FP)

Test inputs (ALTPIN, TEST1, TEST2, TEST3)

These are active HIGH TTL signals which control the

operating mode andtest internalcircuits duringproduction

testing. For normal operation, these inputs are left

unconnected and internal pull-down resistors hold each

pin LOW. See Table 7 for more details.

TRANSMITTER OUTPUT SIGNALS

Transmit clock outputs (TXSCLK and TXSCLKQ)

These are differential PECL serial clock signalswhich can

be used to retime TXSD. The clock frequency is either

155.52 MHz or 622.08 MHz depending on the operating

mode.

Transmit serial data (TXSD and TXSDQ)

These are differential PECL serial data stream outputs

which are normally connected to an optical transmitter

module or to the TZA3001 laser driver.

2000 Feb 17 10

This is a TTL signal which indicates frame boundaries

detected in the incoming data stream onpin RXSD. When

frame pattern detection is enabled (see Section

“Out-of-frame (OOF)”), FP goes HIGH for one cycle of

RXPCLK when a 48-bit sequence matching the frame

pattern is detected on inputs RXSD and RXSDQ. When

frame pattern detection is disabled, FP goes HIGH only

whenthe incoming datamatches the framepattern and fits

exactly within the fixed byte boundary. FP is updated on

the falling edge of RXPCLK.

Parallel output clock (RXPCLK)

This is a TTL byte-rate output clock having a frequency of

either19.44,38.88, 77.76 or 155.52 MHz andadutyfactor

of nominally 50%, to which the byte-serial output data bits

RXPD0 to RXPD7 are aligned. The falling edge of

RXPCLK updatesthe data on pins RXPD0 to RXPD7 and

the FP signal.

Page 11

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

Other operating modes

DIAGNOSTIC LOOPBACK

A transmitter-to-receiver loopback mode is available for

diagnostic purposes. When DLEN is LOW, the differential

serial clock and data from the transmitter parallel-to-serial

block continue to be routed to transmitter outputs, but are

also routed to the receiver serial-to-parallel block instead

of the receiver input signals from pins RXSD/RXSDQ and

RXSCLK/RXSCLKQ.

LINE LOOPBACK

A receiver-to-transmitter loopback mode is available for

line testing purposes. When LLEN is LOW, the receiver

input signals (RXSD/RXSDQ and RXSCLK/RXSCLKQ)

are routed, after retiming,to thetransmitter output buffers.

The receiver clock and data are also routed to the

serial-to-parallel block.

LOOP TIMING

TZA3005H

SQUELCHED CLOCK OPERATION

Some clock recovery devices force their recovered output

clock to zero if a loss of input signal is detected. If this

happens, the SDTTL or SDPECL signals are inactive and

no clock signal ispresent atpins RXSCLK and RXSCLKQ.

If no clock signal is present at pins RXSCLK/RXSCLKQ,

there is no RXPCLK signal. This may not be suitable for

some applications, in which case, the TZA3005H can be

set to squelched clock operation by setting pins ALTPIN,

TEST1, TEST2 and TEST3 as shown in Table 6.

In squelched clock operation, receiver timing isperformed

by a part of the internal clock synthesizer which normally

onlyprovides transmittertiming. This producesa RXPCLK

clock signal when either SDTTL or SDPECL is inactive. If

either SDTTL or SDPECL is inactive in squelched clock

operation, it is equivalent to normal operation. During a

transition from normal operation to squelched clock

operation, the RXPCLK clock cycle exhibits a once-only

random shortening.

In loop timing mode, the transmitter section is clocked by

the receiver input clock (RXSCLK) instead of by the

internal clock synthesizer. SYNCLKDIV is now derived

from RXSCLK so that it can be used to clock upstream

transmitter logic. Loop timing is enabled by setting pins

ALTPIN, TEST1, TEST2 and TEST3 (see Table 6). After

activatingthe looptimingmode, thereceiver clock mustbe

synchronized to the transmitter input data

(TXPD0 to TXPD7) by activating master reset (MRST).

In loop timing mode, the internal clock synthesizer is still

used to generate the 19MHz output clock signal on

pin 19MHZO.

Table 6 shows that the same operating mode can be

selected at different settings of the control inputs.

If ALTPIN = 0, the STM4 nibble mode is not available, but

is used for squelched clock operation. If ALTPIN = 1, all

operating modes are available, including STM4 nibble

mode.

2000 Feb 17 11

Page 12

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

TZA3005H

transceiver

Table 6 Truth table operating modes

ALTPIN

(pin 50)

0 X X 0 X 0 X 1 1 normal operation

0 X X 0 0 1 0 1 1 squelched clock

0 X X 0 0 1 1 1 1 normal operation

0 X X 0 1 1 X 1 1 normal operation

0 X X 1 X X X 1 1 loop timing

1000X XX11normal operation

1001X XX11loop timing

1010X X011squelched clock

1010X X111normal operation

XXXXX XXX0diagnostic loopback

XXXXX XX0Xline loopback

TEST1

(pin 10)

TEST2

(pin 11)

TEST3

(pin 13)

BUSWIDTH

(pin 30)

MODE

(pin 49)

SD

(1)

LLEN

(pin 31)

DLEN

(pin 32)

FUNCTIONAL

OPERATING MODE

(STM1 byte/nibble)

operation

(STM4 byte)

(STM4 byte)

(STM4 byte)

operation

Note

1. SD denotes either pin 22 (SDTTL) or pin 23 (SDPECL) (signal present = active = 1; loss of signal = inactive = 0).

During a loss of signal, the outputs RXPD0 to RXPD7 are forced to zero (see Table 5).

Receiver frame alignment

Figure 3 shows a typical frame and boundary alignment

sequence. Frameand byte boundary detection is enabled

onthe rising edgeofOOF andremainsenabled while OOF

is HIGH. Byteboundaries arerecognized afterthe thirdA2

byte is received. FP goes HIGH for one RXPCLK cycle to

indicate that this is the first data byte with the correct byte

alignment on the output parallel data bus

(RXPD0 to RXPD7).

When interfaced with a section terminating device, OOF

must remain HIGH for a full frame period after the initial

frame pulse (FP). This is to allow the section terminating

device to internally verify that frame and byte alignment

arecorrect (seeFig.4). Because atleast one framepattern

will have been detected since the rising edge of OOF,

boundary detection is disabled when OOF goes LOW.

The frame and byte boundary detection block is activated

onthe rising edgeofOOF, and remainsactiveuntil a frame

pulse (FP) occurs and OOF goes LOW, whichever occurs

last.Figure 4 showsa typical OOFtiming pattern whenthe

TZA3005H is connected to a down stream section

terminating device. OOF stays HIGH for one full frame

after the first frame pulse (FP). The frame and byte

boundary detection block is active until OOF goes LOW.

Figure 5 shows frame and byte boundary detection

activated on the rising edge of OOF, and deactivated by

the first frame pulse (FP) after OOF goes LOW.

2000 Feb 17 12

Page 13

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

handbook, full pagewidth

RXSCLK

OOF

RXSD

A1 A1 A1 A2 A2 A2

RXPD0 to

RXPD7

invalid data

RXPCLK

TZA3005H

A2 (28H)

valid

data

handbook, halfpage

OOF

FP

FP

boundary detection enabled

Fig.3 Frame and byte detection.

handbook, halfpage

OOF

MGK486

FP

MGK485

boundary detection enabled

MGK487

Fig.4 OOF operating time with PM5312 STTX

or PM5355 SUNI-622 (see Table 7).

2000 Feb 17 13

Fig.5 Alternate OOF timing.

Page 14

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

TZA3005H

transceiver

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

V

n

I

I(n)

P

tot

T

stg

T

j(bias)

T

case(bias)

supply voltage −0.5 +6 V

voltage

on any input pin −0.5 V

+ 0.5 V

CC

between two differential PECL input pins −2+2V

on SDPECL input pin V

− 3VCC+ 0.5 V

CC

current

into any TTL output pin −8+8mA

into any PECL output pin −50 +1.5 mA

total power dissipation − 1.5 W

storage temperature −65 +150 °C

junction temperature under bias −55 +125 °C

case temperature under bias −55 +100 °C

HANDLING

Inputs and outputs are protected against electrostatic discharge in normal handling. However it is good practice to take

normal precautions appropriate to handling MOS devices (see

“Handling MOS devices”

).

THERMAL CHARACTERISTICS

SYMBOL PARAMETER VALUE UNIT

T

T

R

amb

j

th(j-a)

ambient temperature; note 1 −40 +85

junction temperature −40 +125

thermal resistance from junction to ambient; note 2 55 K/W

Notes

1. For applications with T

2. R

is determined with the IC soldered on a standard single-sided 57 × 57 × 1.6 mm FR4 epoxy PCB with 35 µm

th(j-a)

>75 °C, it is advised that the board layout is designed to allow optimum heat transer.

amb

thick copper tracks. The measurements are performed in still air. This value will vary depending on the number of

board layers, copper sheet thickness and area, and the proximity of surrounding components.

2000 Feb 17 14

Page 15

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

TZA3005H

transceiver

DC CHARACTERISTICS

For typical values, T

ranges.

SYMBOL PARAMETER CONDITION MIN. TYP. MAX. UNIT

General

V

CC

P

tot

I

CC(tot)

supply voltage 3.0 3.3 5.5 V

total power dissipation outputs open;

total supply current outputs open;

TTL inputs

V

IH

V

IL

I

IH

I

IL

R

pu

R

pd

HIGH-level input voltage 2 − V

LOW-level input voltage 0 − 0.8 V

HIGH-level input current VIH=VCC; note 1 −10 − +10 µA

LOW-level input current VIL= 0; note 1 −10 − +10 µA

pull-up resistor note 2 8 10 12 kΩ

pull-down resistor at

pin SDTTL

TTL outputs

V

OH

V

OL

HIGH-level output voltage IOH= −1 mA; note 3 2.4 −−V

LOW-level output voltage IOL=4mA −−+0.5 V

PECL I/O

V

IH

V

IL

V

OH

V

OL

∆V

o(dif)

∆V

i(dif)(sens)

HIGH-level input voltage note 4 VCC− 1.2 −−V

LOW-level input voltage −−V

HIGH-level output voltage terminated with

LOW-level output voltage VCC− 1.9 − VCC− 1.6 V

differential output voltage ±600 −±900 mV

differential input sensitivity PECL inputs are AC

=25°C and VCC= 3.3 V; minimum and maximum values are valid over entire Tj and V

amb

V

= 3.47 V − 0.9 1.4 W

CC

= 5.5 V −−2.3 W

V

CC

V

= 3.47 V − 272 394 mA

CC

= 5.5 V −−420 mA

V

CC

CC

8 1012kΩ

CC

VCC− 1.1 − VCC− 0.9 V

50 Ω to VCC− 2.0 V

±100 −−mV

coupled

CC

V

− 1.6 V

Notes

1. For input pins REFSEL0, REFSEL1, BUSWIDTH,

LLEN, DLEN, OOF, MRST, MODE, TXPDn, TXPCLK.

2. For input pins SDPECL, ALTPIN, TEST1, TEST2, TEST3.

3. Only applies to pin 19MHZO; guaranteed by simulation.

4. The PECL inputs are high impedance. The transmission lines should be terminated externally using an appropriate

termination.

2000 Feb 17 15

Page 16

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

TZA3005H

transceiver

AC CHARACTERISTICS

For typical values, T

ranges.

SYMBOL PARAMETER CONDITION MIN. TYP. MAX. UNIT

General

f

TXSCLK(nom)

J

o

f

REFCLK(tol)

t

, t

r

f

nominal TXSCLK frequency f

data output jitter in lock; note 1 − 0.004 0.006 UI (RMS)

frequency tolerance of REFCLK meets SONET output

rise/fall time PECL outputs 20% to 80%; 50 Ω load

Receiver timing (see Figs 6 and 7)

C

L

δ

RXPCLK

t

PD

TTL output load capacitance −−15 pF

duty factor of RXPCLK note 2 40 50 60 %

propagation delay; RXPCLK

LOW to RXPDn, FP

t

su

set-up time; RXSD/RXSDQ to

RXSCLK/RXSCLKQ

t

h

hold time; RXSD/RXSDQ to

RXSCLK/RXSCLKQ

Transmitter timing (see Figs 8 and 9)

δ

TXSCLK

t

su

t

h

t

PD

duty factor of TXSCLK 40 50 60 %

set-up time; TXPDn to TXPCLK −0.5 −−ns

hold time; TXPDn to TXPCLK 1.5 −−ns

propagation delay time;

TXSCLK LOW to TXSD

=25°C and VCC= 3.3 V; minimum and maximum values are valid over entire Tj and V

amb

REFCLK

as Table 2;

MODE = 0 155.517 155.52 155.523 MHz

MODE = 1 622.068 622.08 622.092 MHz

−20 − +20 ppm

frequency specification;

note 1

− 220 450 ps

to VCC− 2.0 V

−0.5 +1.5 +2.5 ns

400 −−ps

400 −−ps

−−440 ps

CC

Notes

1. Jitter on pins REFCLK/REFCLKQ complies with Table 3.

2. Minimum value is 35% in STM4 nibble mode.

2000 Feb 17 16

Page 17

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

handbook, halfpage

RXPCLK

t

PD

RXPD0 to

RXPD7, FP

MGK488

handbook, halfpage

RXSCLK

RXSD/RXSDQ

TZA3005H

t

su

t

h

MGK489

For TTL outputs, tPD is the time (ns) from the 50% point of the

reference signal to the 50% point of the output signal.

Fig.6 Receiver output timing.

handbook, halfpage

TXPCLK

TXPD0 to

TXPD7

t

su

t

h

MGK490

Timing is measured from the cross-over point of the referencesignal

to the cross-over point of the input signal.

Fig.7 Receiver input timing.

handbook, halfpage

TXSCLK

t

PD

TXSD

MGK491

For TTL signals, tsu between input data and clock signals is the

time (ps) from the 50% pointofthedatatothe 50% point of the clock.

For TTL signals, t

time (ps) from the 50% pointoftheclocktothe 50% point of the data.

between input data and clock signals is the

h

Fig.8 Transmitter input timing.

2000 Feb 17 17

Timing ismeasuredfromthecross-overpointofthereference

signal to the cross-over point of the output signal.

Fig.9 Transmitter output timing.

Page 18

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

INTERNAL CIRCUITRY

PIN SYMBOL AND DESCRIPTION CHARACTERISTIC EQUIVALENT CIRCUIT

24 RXSD; serial data input PECL inputs

27 RXSCLK; serial clock input

25 RXSDQ; inverted serial data

input

28 RXSCLKQ; inverted serial clock

input

14 REFCLKQ; inverted reference

PECL inputs

clock input

15 REFCLK; reference clock input

andbook, halfpage

10 kΩ 10 kΩ

24, 27

andbook, halfpage

10 kΩ 10 kΩ

2 kΩ 2 kΩ

14 15

V

V

CC

V

CC

600fF600

CC

GND

−1.35 V

−1.35 V

100 µA

V

CC

fF

TZA3005H

25, 28

MGS979

23 SDPECL; PECL signal detect

input

PECL input

andbook, halfpage

23

600 fF

25 kΩ

V

GND

CC

100 µA

100 µA

GND

MGS980

V

CC

−1.35 V

MGS981

2000 Feb 17 18

Page 19

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

PIN SYMBOL AND DESCRIPTION CHARACTERISTIC EQUIVALENT CIRCUIT

3 REFSEL0; reference clock

select input 0

4 REFSEL1; reference clock

select input 1

10 TEST1; test and control input

11 TEST2; test and control input

13 TEST3; test and control input

30 BUSWIDTH; 4/8 bus width

select input

LLEN; line loopback enable

31

input (active LOW)

DLEN; diagnostic loopback

32

enable input (active LOW)

33 OOF; out-of-frame enable input

48

MRST; master reset (active

LOW)

49 MODE; serial data rate select

STM1/STM4

50 ALTPIN; test and control input

22 SDTTL; TTL signal detect input TTL inputs

53 TXPD0; parallel data input 0

54 TXPD1; parallel data input 1

55 TXPD2; parallel data input 2

56 TXPD3; parallel data input 3

57 TXPD4; parallel data input 4

58 TXPD5; parallel data input 5

59 TXPD6; parallel data input 6

60 TXPD7; parallel data input 7

61 TXPCLK; transmit parallel clock

input

36 RXPD0; parallel data output 0 TTL outputs

37 RXPD1; parallel data output 1

39 RXPD2; parallel data output 2

40 RXPD3; parallel data output 3

41 RXPD4; parallel data output 4

43 RXPD5; parallel data output 5

44 RXPD6; parallel data output 6

45 RXPD7; parallel data output 7

47 RXPCLK; receive parallel clock

output

62 SYNCLKDIV; transmit

byte/nibble clock output

(synchronous)

TTL inputs

andbook, halfpage

3, 4, 10, 11, 13,

30 to 33, 48 to 50

andbook, halfpage

andbook, halfpage

22, 53 to 61

15 Ω

15 Ω

MGS984

50 kΩ

1 pF

GND

100 Ω

GND

V

CC

36, 37, 39 to 41, 43 to 45, 47, 62

GND

TZA3005H

MGS982

≈ 50 µA

MGS983

2000 Feb 17 19

Page 20

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

PIN SYMBOL AND DESCRIPTION CHARACTERISTIC EQUIVALENT CIRCUIT

63 LOCKDET; lock detect output;

R=50Ω

64 19MHZO; 19 MHz reference

clock output; R = 20 Ω

17 TXSD; serial data output PECL outputs

18 TXSDQ; inverted serial data

output

20 TXSCLKQ; inverted serial clock

output

21 TXSCLK; serial clock output

CMOS outputs

andbook, halfpage

andbook, halfpage

V

CC

50 Ω

63, 64

R

MGS985

V

CC

500 µA 500 µA

GND

MGS986

17, 21

18, 20

GND

TZA3005H

2000 Feb 17 20

Page 21

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly whenbrowsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2000 Feb 17 21

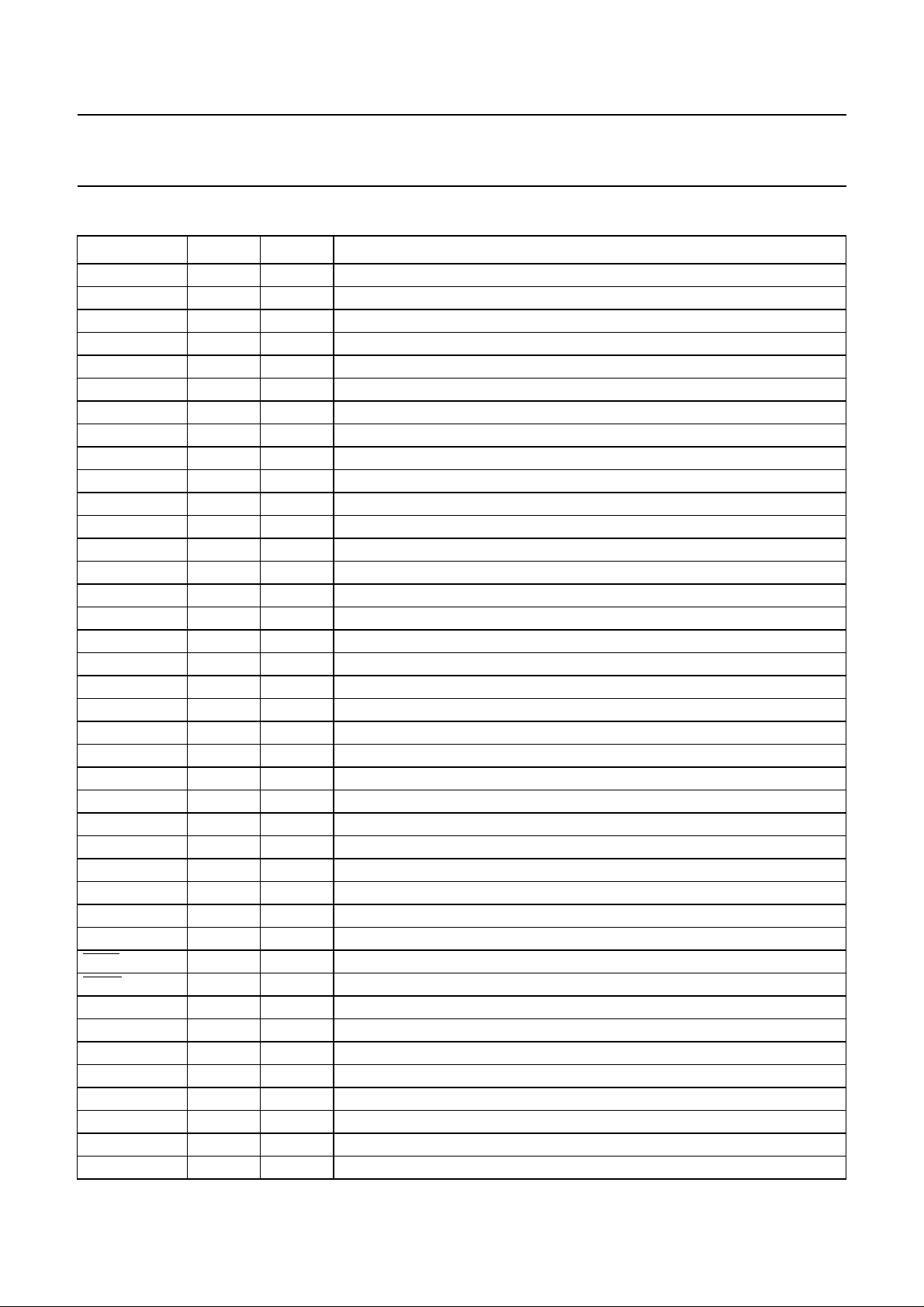

handbook, full pagewidth

APPLICATION INFORMATION

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

8

CONTROLLER

TZA3005

8

TRANSCEIVER

(1) DCR = Data and Clock Recovery unit.

clock

data

TZA3001

LASER

DRIVER

TZA3004

(1)

DCR

TZA3023

AND

TZA3044

OPTICAL

RECEIVER

LASER

DIODE

PHOTO

DIODE

optical

fibre

PHOTO

DIODE

LASER

DIODE

Fig.10 Application diagram.

TZA3023

AND

TZA3044

OPTICAL

RECEIVER

TZA3001

LASER

DRIVER

TZA3004

(1)

DCR

data

clock

TZA3005

TRANSCEIVER

8

8

CONTROLLER

MGK494

TZA3005H

Page 22

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

Forward clocking

It is sometimes necessary to ‘forward clock’ data in an

SDH/SONET system. When this is the case, the input

parallel data clock (TXPCLK) and the reference clock

(REFCLK/REFCLKQ) from which the high speed serial

clockis synthesized willbothoriginate from thesameclock

source. This section explains how to configure the

TZA3005H to operate in this mode.

The connections required for forward clocking are shown

in Fig.13. There are no timing specifications for the phase

relationship between REFCLK and TXPCLK.

The TZA3005H can handle any phase relationship

betweenthese twoinput clocks ifthey are derivedfrom the

same clock source. The TZA3005H internal transmitter

logic must be synchronized by asserting a master reset

(MRST).

TZA3005H

Reverse clocking

In many cases, a reverse clocking scheme is used where

the upstream logic is clocked by the TZA3005H using

SYNCLKDIV (see Fig.14). There is no requirement

specification for the propagation delay from SYNCLKDIV

toTXPCLK becausetheTZA3005H canhandleany phase

relationship between these two signals. The TZA3005H

internal transmitter logic must be synchronized by

asserting a master reset (MRST).

PECL output termination

The PECL outputs have to be terminated with 50 Ω

connected to VCC− 2.0 V. If this voltageis not available, a

Thevenin termination can be used as shown in Figs 11

and 12.

handbook, halfpage

VCC = 5.0 V

R1

83.3 Ω

GND

R3

125 Ω

R2

83.3 Ω

R4

125 Ω

MGK654

Fig.11 PECL output termination scheme

(VCC= 5.0 V).

TXSD/TXSCLK

TXSDQ/TXSCLKQ

handbook, halfpage

GND

VCC = 3.3 V

R1

127 Ω

R3

82.5 Ω

R2

127 Ω

R4

82.5 Ω

MGS978

Fig.12 PECL output termination scheme

(VCC= 3.3 V).

TXSD/TXSCLK

TXSDQ/TXSCLKQ

2000 Feb 17 22

Page 23

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

handbook, full pagewidth

ASIC

8

CLOCK

SOURCE

parallel

data

PECL

REFCLK

TXPCLK

TZA3005

TXPD0 to TXPD7

MGS976

serial

data

TZA3005H

handbook, full pagewidth

Fig.13 TZA3005H in forward clocking scheme.

PECL

REFCLK

TXPCLK

TZA3005

TXPD0 to TXPD7

SYNCLKDIV

MGS977

ASIC

8

CLOCK

SOURCE

parallel

data

serial

data

Fig.14 TZA3005H in reverse clocking scheme.

2000 Feb 17 23

Page 24

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

TZA3005H

transceiver

Table 7 Suggested interface devices

MANUFACTURER TYPE

Philips TZA3004 622 or 155 clock recovery

TZA3031/3001 155/622 laser driver

TZA3034/3044 155/622 post amplifier

TZA3033/3023 155/622 transimpedance amplifier

PMC-Sierra PM5312 155 or 622 transport terminal transceiver

PM5355 622 Saturn user network interface

DATA RATE

(Mbits/s)

FUNCTION

2000 Feb 17 24

Page 25

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

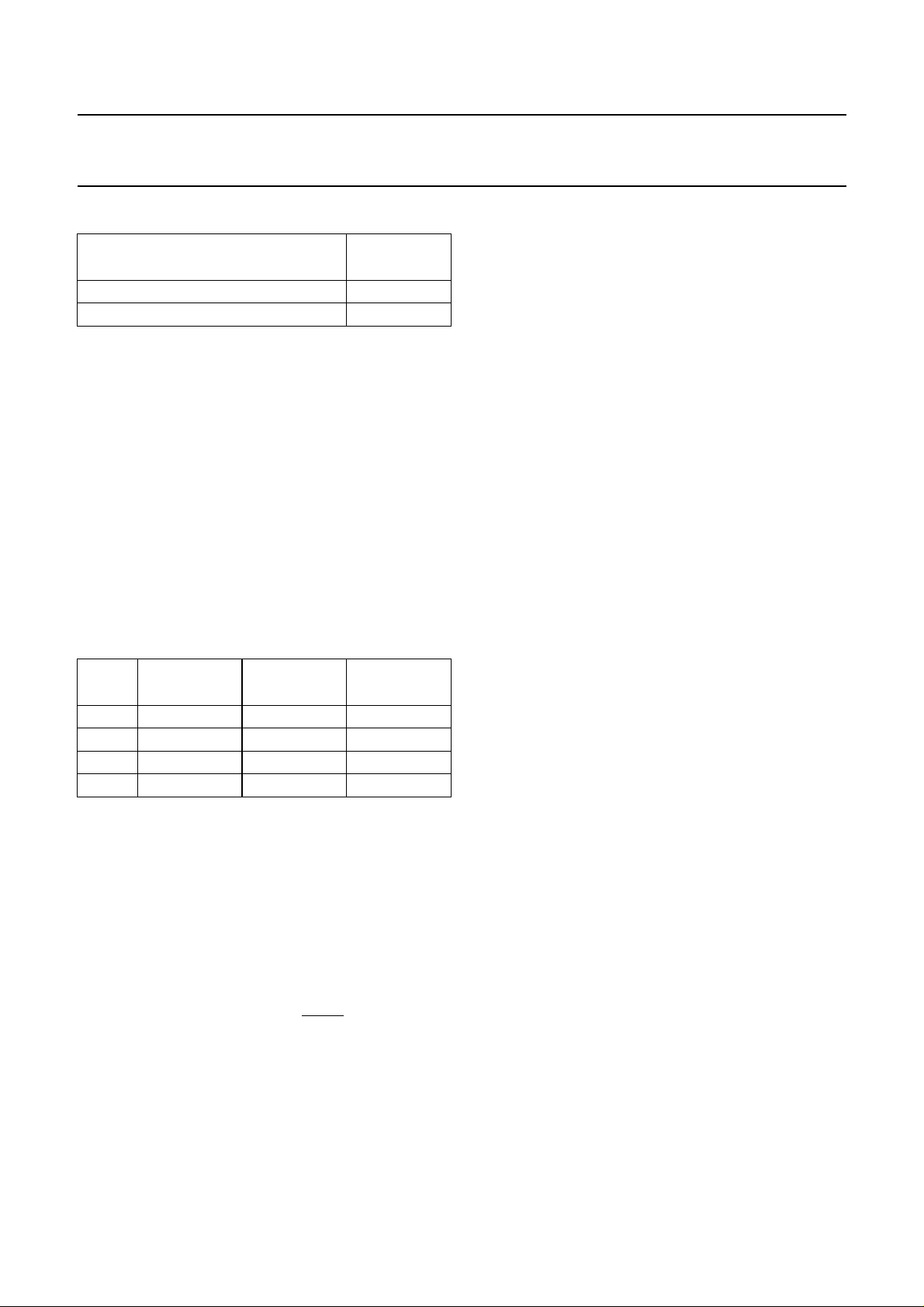

PACKAGE OUTLINE

QFP64: plastic quad flat package; 64 leads (lead length 1.6 mm); body 14 x 14 x 2.7 mm

c

y

X

A

48 33

49

32

Z

E

TZA3005H

SOT393-1

e

w M

b

pin 1 index

64

1

w M

b

0.25

p

D

H

0.45

0.30

D

0.23

14.1

0.13

13.9

e

DIMENSIONS (mm are the original dimensions)

mm

A

max.

3.00

0.25

0.10

2.75

2.55

UNIT A1A2A3bpcE

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

17

16

Z

D

0 5 10 mm

(1)

(1) (1)(1)

D

14.1

13.9

p

B

v M

scale

eH

H

17.45

0.8

16.95

v M

D

E

A

B

E

17.45

16.95

H

E

LL

A

1.03

0.73

p

A

2

A

1

detail X

Z

D

0.16 0.100.161.60

1.2

0.8

(A )

3

L

p

L

Zywv θ

E

1.2

7

0.8

0

θ

o

o

OUTLINE

VERSION

SOT393-1 134E07 MS-022

IEC JEDEC EIAJ

REFERENCES

2000 Feb 17 25

EUROPEAN

PROJECTION

ISSUE DATE

99-12-27

00-01-19

Page 26

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

transceiver

SOLDERING

Introduction to soldering surface mount packages

Thistext gives averybrief insighttoa complex technology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages.Wave solderingis notalways suitable

for surface mount ICs, or for printed-circuit boards with

high population densities. In these situations reflow

soldering is often used.

Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

tothe printed-circuitboardby screenprinting,stencilling or

pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example,

infrared/convection heating in a conveyor type oven.

Throughput times (preheating, soldering and cooling) vary

between 100 and 200 seconds depending on heating

method.

Typical reflow peak temperatures range from

215 to 250 °C. The top-surface temperature of the

packages should preferable be kept below 230 °C.

Wave soldering

Conventional single wave soldering is not recommended

forsurface mount devices(SMDs)or printed-circuit boards

with a high component density, as solder bridging and

non-wetting can present major problems.

TZA3005H

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• Forpackages with leadsonfour sides, thefootprintmust

be placedat a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering is used the following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wavewith high upwardpressure followed bya

smooth laminar wave.

2000 Feb 17 26

Page 27

Philips Semiconductors Product specification

SDH/SONET STM1/OC3 and STM4/OC12

TZA3005H

transceiver

Suitability of surface mount IC packages for wave and reflow soldering methods

PACKAGE

BGA, LFBGA, SQFP, TFBGA not suitable suitable

HBCC, HLQFP, HSQFP, HSOP, HTQFP, HTSSOP, SMS not suitable

(3)

PLCC

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO not recommended

Notes

1. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

2. These packages are not suitable for wave soldering as a solder joint between the printed-circuit board and heatsink

3. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

4. Wave soldering is only suitable for LQFP, TQFP and QFP packages with a pitch (e) equal to or larger than 0.8 mm;

5. Wave soldering is onlysuitable for SSOP and TSSOPpackages with a pitch (e)equal toor larger than 0.65 mm; it is

, SO, SOJ suitable suitable

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporization of the moisture in them (the so called popcorn effect). For details, refer to the

Drypack information in the

(at bottom version) can not be achieved, and as solder may stick to the heatsink (on top version).

The package footprint must incorporate solder thieves downstream and at the side corners.

it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

SOLDERING METHOD

WAVE REFLOW

(2)

(3)(4)

(5)

suitable

suitable

suitable

(1)

.

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philipsfor any damages resulting from such

improper use or sale.

2000 Feb 17 27

Page 28

Philips Semiconductors – a w orldwide compan y

Argentina: see South America

Australia: 3 Figtree Drive, HOMEBUSH, NSW 2140,

Tel. +61 2 9704 8141, Fax. +61 2 9704 8139

Austria: Computerstr. 6, A-1101 WIEN, P.O. Box 213,

Tel. +43 1 60 101 1248, Fax. +43 1 60 101 1210

Belarus: Hotel Minsk Business Center, Bld. 3, r. 1211, Volodarski Str. 6,

220050 MINSK, Tel. +375 172 20 0733, Fax. +375 172 20 0773

Belgium: see The Netherlands

Brazil: see South America

Bulgaria: Philips Bulgaria Ltd., Energoproject, 15th floor,

51 James Bourchier Blvd., 1407 SOFIA,

Tel. +359 2 68 9211, Fax. +359 2 68 9102

Canada: PHILIPS SEMICONDUCTORS/COMPONENTS,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

China/Hong Kong: 501 Hong Kong Industrial Technology Centre,

72 Tat Chee Avenue, Kowloon Tong, HONG KONG,

Tel. +852 2319 7888, Fax. +852 2319 7700

Colombia: see South America

Czech Republic: see Austria

Denmark: Sydhavnsgade 23, 1780 COPENHAGEN V,

Tel. +45 33 29 3333, Fax. +45 33 29 3905

Finland: Sinikalliontie 3, FIN-02630 ESPOO,

Tel. +358 9 615 800, Fax. +358 9 6158 0920

France: 51 Rue Carnot, BP317, 92156 SURESNES Cedex,

Tel. +33 1 4099 6161, Fax. +33 1 4099 6427

Germany: Hammerbrookstraße 69, D-20097 HAMBURG,

Tel. +49 40 2353 60, Fax. +49 40 2353 6300

Hungary: see Austria

India: Philips INDIA Ltd, Band Box Building, 2nd floor,

254-D, Dr. Annie Besant Road, Worli, MUMBAI 400 025,

Tel. +91 22 493 8541, Fax. +91 22 493 0966

Indonesia: PTPhilipsDevelopmentCorporation,SemiconductorsDivision,

Gedung Philips, Jl. Buncit Raya Kav.99-100, JAKARTA 12510,

Tel. +62 21 794 0040 ext. 2501, Fax. +62 21 794 0080

Ireland: Newstead, Clonskeagh, DUBLIN 14,

Tel. +353 1 7640 000, Fax. +353 1 7640 200

Israel: RAPAC Electronics, 7 Kehilat Saloniki St, PO Box 18053,

TEL AVIV 61180, Tel. +972 3 645 0444, Fax. +972 3 649 1007

Italy: PHILIPS SEMICONDUCTORS, Via Casati, 23 - 20052 MONZA(MI),

Tel. +39 039 203 6838, Fax +39 039 203 6800

Japan: Philips Bldg 13-37, Kohnan 2-chome, Minato-ku,

TOKYO 108-8507, Tel. +81 3 3740 5130, Fax. +81 3 3740 5057

Korea: Philips House, 260-199 Itaewon-dong, Yongsan-ku, SEOUL,

Tel. +82 2 709 1412, Fax. +82 2 709 1415

Malaysia: No. 76 Jalan Universiti, 46200 PETALING JAYA, SELANGOR,

Tel. +60 3 750 5214, Fax. +60 3 757 4880

Mexico: 5900 Gateway East, Suite 200, EL PASO, TEXAS 79905,

Tel. +9-5 800 234 7381, Fax +9-5 800 943 0087

Middle East: see Italy

Netherlands: Postbus 90050, 5600 PB EINDHOVEN, Bldg. VB,

Tel. +31 40 27 82785, Fax. +31 40 27 88399

New Zealand: 2 Wagener Place, C.P.O. Box 1041, AUCKLAND,

Tel. +64 9 849 4160, Fax. +64 9 849 7811

Norway: Box 1, Manglerud 0612, OSLO,

Tel. +47 22 74 8000, Fax. +47 22 74 8341

Pakistan: see Singapore

Philippines: Philips Semiconductors Philippines Inc.,

106 Valero St. Salcedo Village, P.O. Box 2108 MCC, MAKATI,

Metro MANILA, Tel. +63 2 816 6380, Fax. +63 2 817 3474

Poland: Al.Jerozolimskie 195 B, 02-222 WARSAW,

Tel. +48 22 5710 000, Fax. +48 22 5710 001

Portugal: see Spain

Romania: see Italy

Russia: Philips Russia, Ul. Usatcheva 35A, 119048 MOSCOW,

Tel. +7 095 755 6918, Fax. +7 095 755 6919

Singapore: Lorong 1, Toa Payoh, SINGAPORE 319762,

Tel. +65 350 2538, Fax. +65 251 6500

Slovakia: see Austria

Slovenia: see Italy

South Africa: S.A. PHILIPS Pty Ltd., 195-215 Main Road Martindale,

2092 JOHANNESBURG, P.O. Box 58088 Newville 2114,

Tel. +27 11 471 5401, Fax. +27 11 471 5398

South America: Al. Vicente Pinzon, 173, 6th floor,

04547-130 SÃO PAULO, SP, Brazil,

Tel. +55 11 821 2333, Fax. +55 11 821 2382

Spain: Balmes 22, 08007 BARCELONA,

Tel. +34 93 301 6312, Fax. +34 93 301 4107

Sweden: Kottbygatan 7, Akalla, S-16485 STOCKHOLM,

Tel. +46 8 5985 2000, Fax. +46 8 5985 2745

Switzerland: Allmendstrasse 140, CH-8027 ZÜRICH,

Tel. +41 1 488 2741 Fax. +41 1 488 3263

Taiwan: Philips Semiconductors, 6F, No. 96, Chien Kuo N. Rd., Sec. 1,

TAIPEI, Taiwan Tel. +886 2 2134 2886, Fax. +886 2 2134 2874

Thailand: PHILIPS ELECTRONICS (THAILAND) Ltd.,

209/2 Sanpavuth-Bangna Road Prakanong, BANGKOK 10260,

Tel. +66 2 745 4090, Fax. +66 2 398 0793

Turkey: Yukari Dudullu, Org. San. Blg., 2.Cad. Nr. 28 81260 Umraniye,

ISTANBUL, Tel. +90 216 522 1500, Fax. +90 216 522 1813

Ukraine: PHILIPS UKRAINE, 4 Patrice Lumumba str., Building B, Floor 7,

252042 KIEV, Tel. +380 44 264 2776, Fax. +380 44 268 0461

United Kingdom: Philips Semiconductors Ltd., 276 Bath Road, Hayes,

MIDDLESEX UB3 5BX, Tel. +44 208 730 5000, Fax. +44 208 754 8421

United States: 811 East Arques Avenue, SUNNYVALE, CA 94088-3409,

Tel. +1 800 234 7381, Fax. +1 800 943 0087

Uruguay: see South America

Vietnam: see Singapore

Yugoslavia: PHILIPS, Trg N. Pasica 5/v, 11000 BEOGRAD,

Tel. +381 11 3341 299, Fax.+381 11 3342 553

For all other countries apply to: Philips Semiconductors,

International Marketing & Sales Communications, Building BE-p, P.O. Box 218,

5600 MD EINDHOVEN, The Netherlands, Fax. +31 40 27 24825

© Philips Electronics N.V. SCA

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

2000

Internet: http://www.semiconductors.philips.com

69

Printed in The Netherlands 403510/150/02/pp28 Date of release: 2000 Feb 17 Document order number: 9397 750 06573

Loading...

Loading...