Page 1

现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

Data Sheet TLE6284G

H-Bridge Driver IC

Features

•

Compatible to very low ohmic normal

level input N-Channel MOSFETs

•

PWM – DIR - Interface

•

PWM frequency up to 50kHz

•

Operates down to 7.5 V

supply voltage

•

Low EMC sensitivity and emission

•

Adjustable dead time with shoot through protection

• Deactivation of dead time and shoot through protection possible

•

Short circuit protection for each Mosfet can be disabled and adjusted

•

Driver undervoltage shut down

•

Reverse polarity protection for the driver IC

•

Fast disable function / Inhibit for low quiescent current

•

Input with TTL characteristics

•

2 bit diagnosis

•

Thermal overload warning for driver IC

•

Shoot through protection

•

Integrated bootstrap diodes

Product Summary

Turn on current I

Turn off current I

Supply voltage range V

Gxx(on)

Gxx(off)

Vs

850 mA

580 mA

7.5 … 60 V

Gate Voltage VGS 10 V

Temperature range T

J

-40...+150 °C

P-DSO-20

Application

•

Dedicated for DC-brush high current motor bridges in PWM control mode for 12, 24 and 42V powernet applica-

tions.

•

The input structure allows an easy control of a DC-brush motor

General Description

H-bridge driver IC for MOSFET power stages with multiple protection functions.

The TLE6184G is very similar to the TLE6281G. The major difference is that the Short Circuit protection level of

the TLE6284G can be adjusted by external resistors or even disabled. The pin outs are different as well.

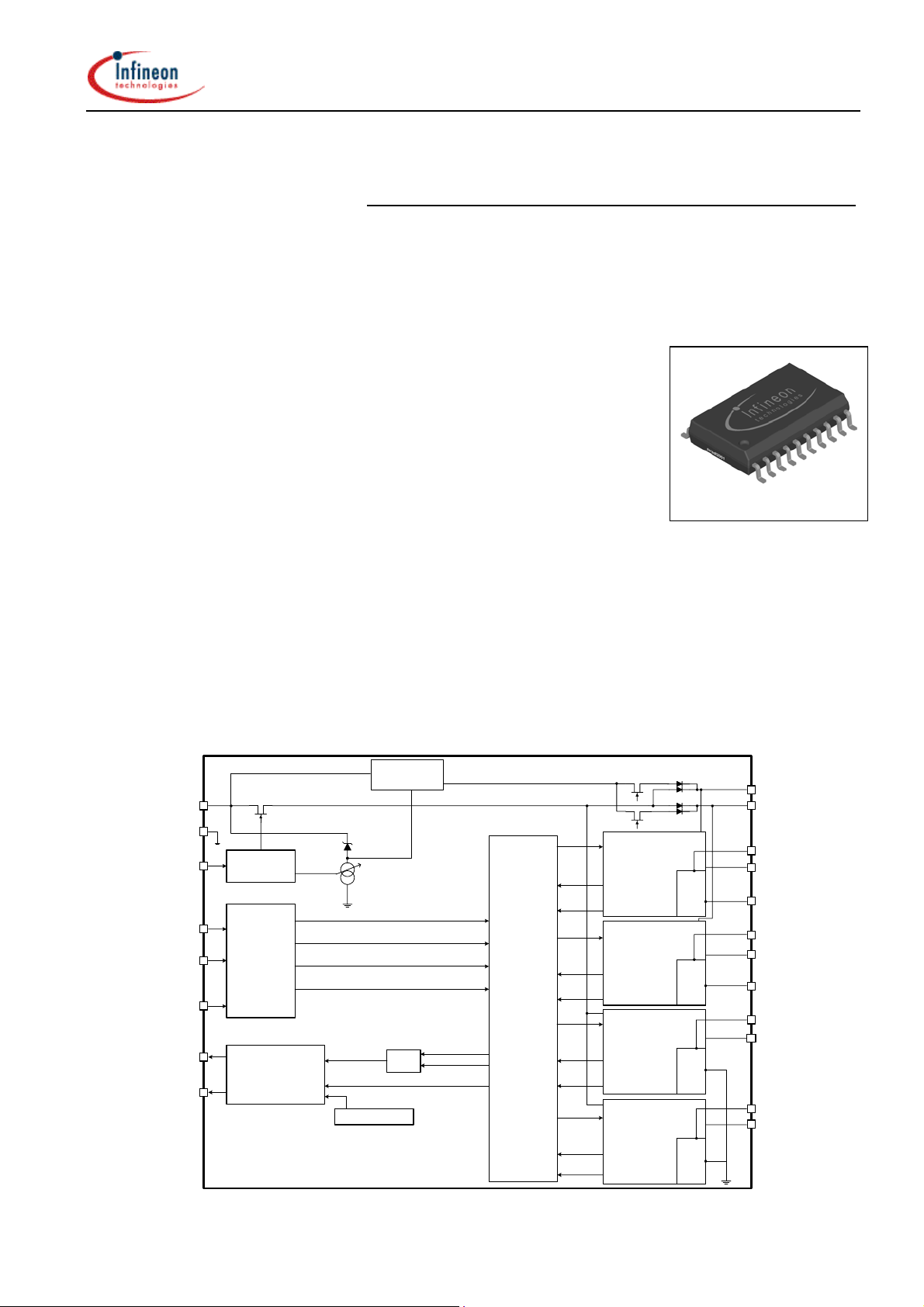

Block Diagram

Charge Pump

OR

Short Cir cuit Detection

Tj > 170oC typ.

Undervoltage HSx

Undervoltage LSx

Level

Shift

Floating HS Dr iver 1

+

limitation HS1

V

GS

+

Short circu it

detect.

+

Undervoltage

Floating HS Dr iver 2

+

V

limitation HS2

GS

+

Short circu it

detect.

+

Undervoltage

Floating LS Dri ver 1

+

V

limitation LS1

GS

+

Short circu it

detect.

+

Undervoltage

Floating LS Dri ver 2

+

V

limitation LS2

GS

+

Short circu it

detect.

+

Undervoltage

BH1

BH2

DH1

GH1

SCD

SH1

DH2

GH2

SCD

SH2

DL1

GL1

SCD

DL2

GL2

SCD

V

S

GND

INH

PWM

DIR

DT/DIS

ER1

ER2

Linear

Regulator

INH

HS1

Input control

Dead time

Undervoltage

Short circuit Detect.

Overtemp. warning

LS1

HS2

LS2

1 2006-01-30

Page 2

Data Sheet TLE6284G

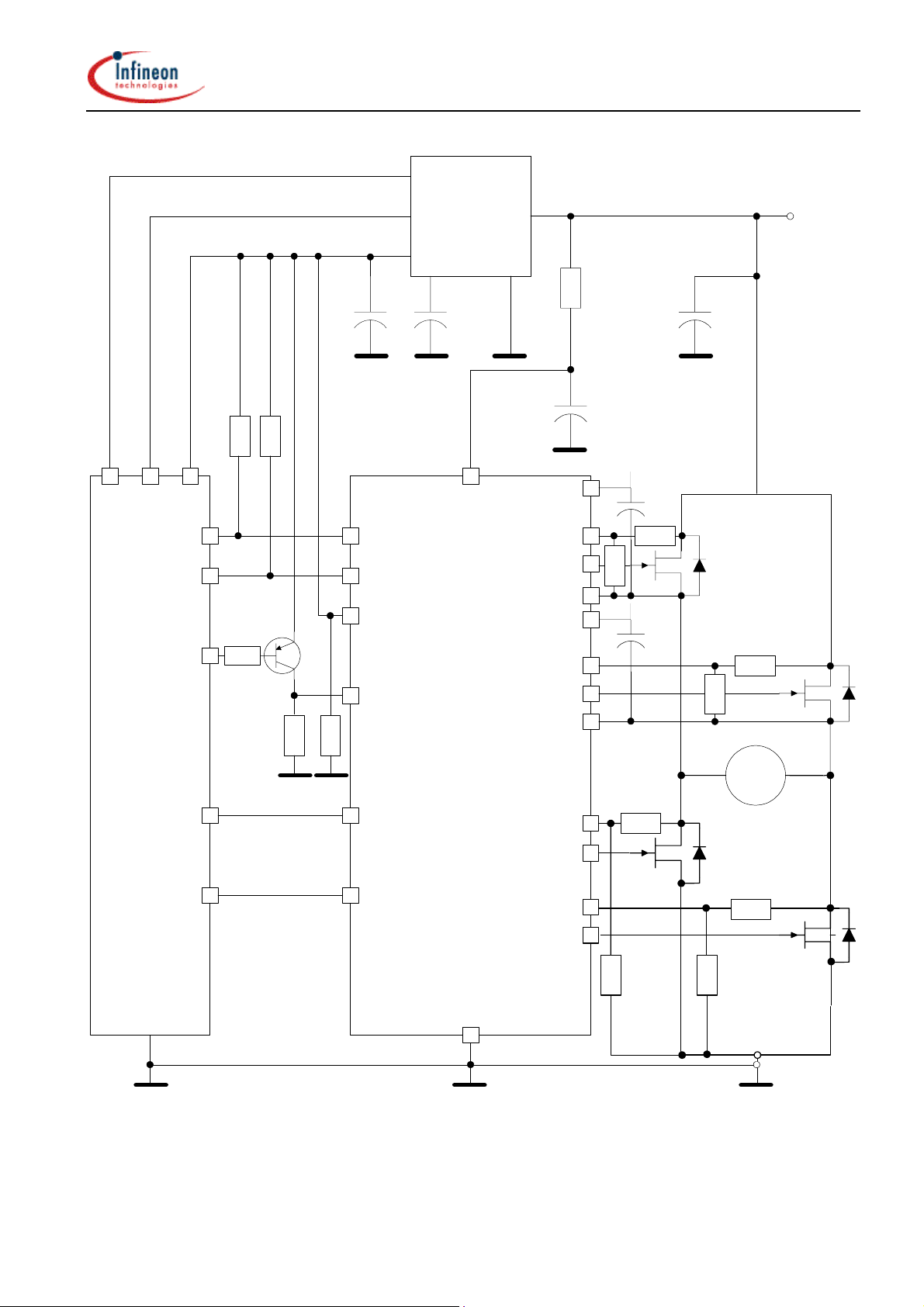

Application Block Diagram

Watchdog

WD R V

µC

R

Q

47kOhm

cc

68 kOhm

10kOhm

R

Q

= 47µF

C

s

R

Q

47kOhm

BCR192W

C

47µF

Q

DT / DIS

R

220k

Reset

Q

ER1

ER2

INH

INH

TLE

4278G

D

= 47nF

C

D

Vs

I

BH1

DH1

GH1

SH1

BH2

DH2

GH2

SH2

R = 10 Ohm

C

s

= 1µF

C

s

R

SCD

= 47µF

C

B

220nF

R

SCD

C

220nF

Vs = 12V

B

R

SCD

R

SCD

M

R

PWM

DL1

GL1

DIR

DL2

GL2

GND

This application block diagram shows one of the possibilities to use this Driver IC. The voltage devider networks accross the 4 MOSFETs (resistors R

limit threshold for Short Circuit protection. The R

the bootstrap capacitors. If R

resistors are not used in the application, a 12k Ohm resistor

SCD

resistors also provide a charge path for

SCD

SCD

should be introduced between SH1 to GND and SH2 to GND.

SCD1

R

SCD3

R

SCD2

R

SCD4

) allow to increas the current

2 2006-01-30

Page 3

Data Sheet TLE6284G

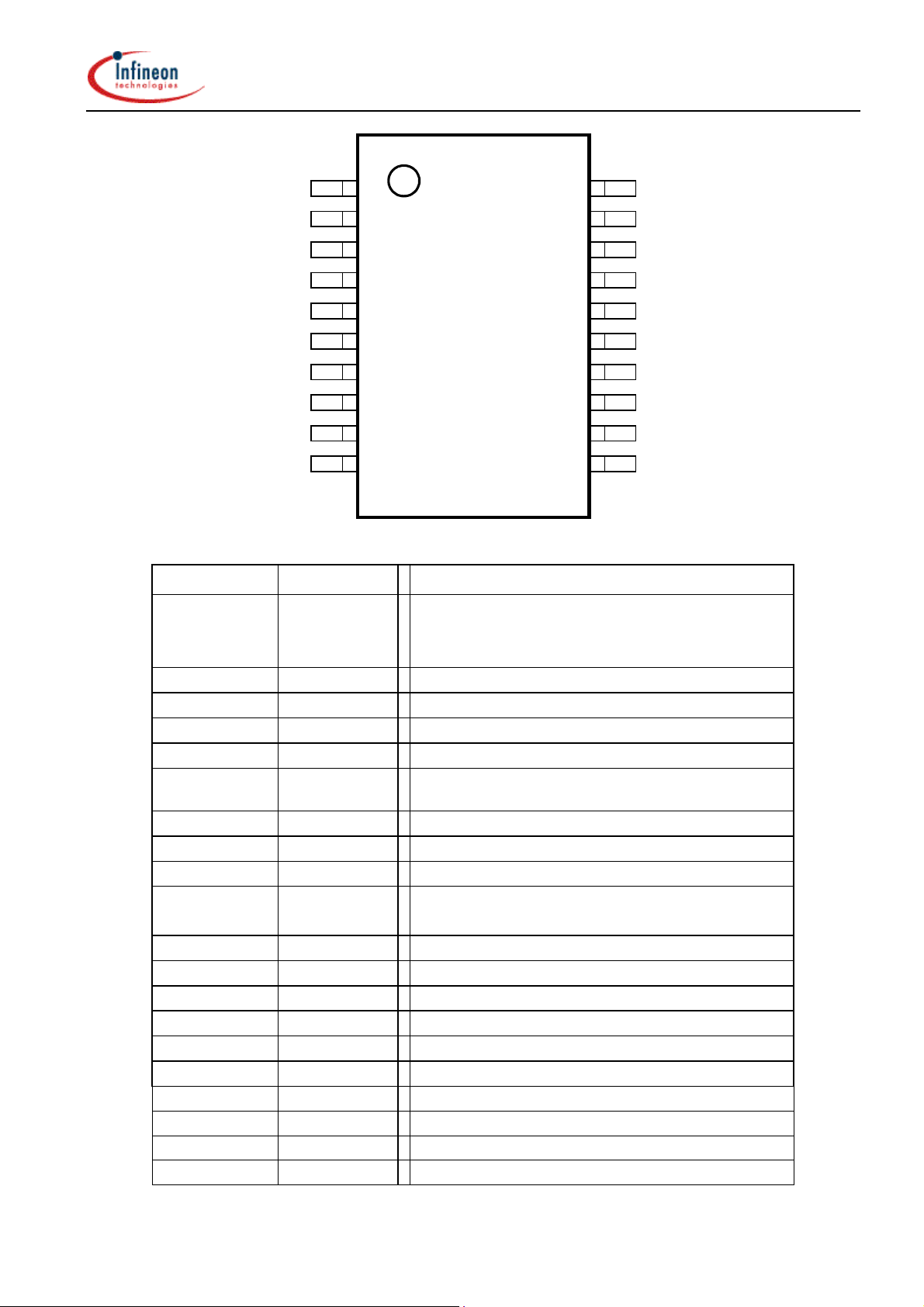

DT/DIS

ER1

DIR

PWM

DL2

VS

DL1

INH

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

TLE6284G

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

GL2

SH2

GH2

BH2

DH2

DH1 ER2

BH1 GND

GH1

SH1

GL1

Pin Symbol Function

1 DT / DIS a) Set adjustable dead time by external resistor

b) Reset ERx register

c) Disable output stages

2 ER1 Error flag for driver shut down

3 DIR Control input for spinning direction of the motor

4 PWM Control input for PWM frequency and duty cycle

5 DL2 Sense contact for short circuit detection low side 2

6 ER2 Warning flag Temperature / distinguish if short cir-

cuit or undervoltage lock out occured

7 GND Logic Ground

8 VS Voltage supply

9 DL1 Sense contact for short circuit detection low side 1

10

11 GL1 Output to gate low side switch 1

12 SH1 Connection to source high side switch 1

13 GH1 Output to gate high side switch 1

14 BH1 Bootstrap supply high side switch 1

15 DH1 Sense contact for short circuit detection high side 1

16 DH2 Sense contact for short circuit detection high side 2

17 BH2 Bootstrap supply high side switch 2

18 GH2 Output to gate high side switch 2

19 SH2 Connection to source high side switch 2

20 GL2 Output to gate low side switch 2

INH Sets complete device to sleep mode to achieve low

quiescent currents

3 2006-01-30

Page 4

Data Sheet TLE6284G

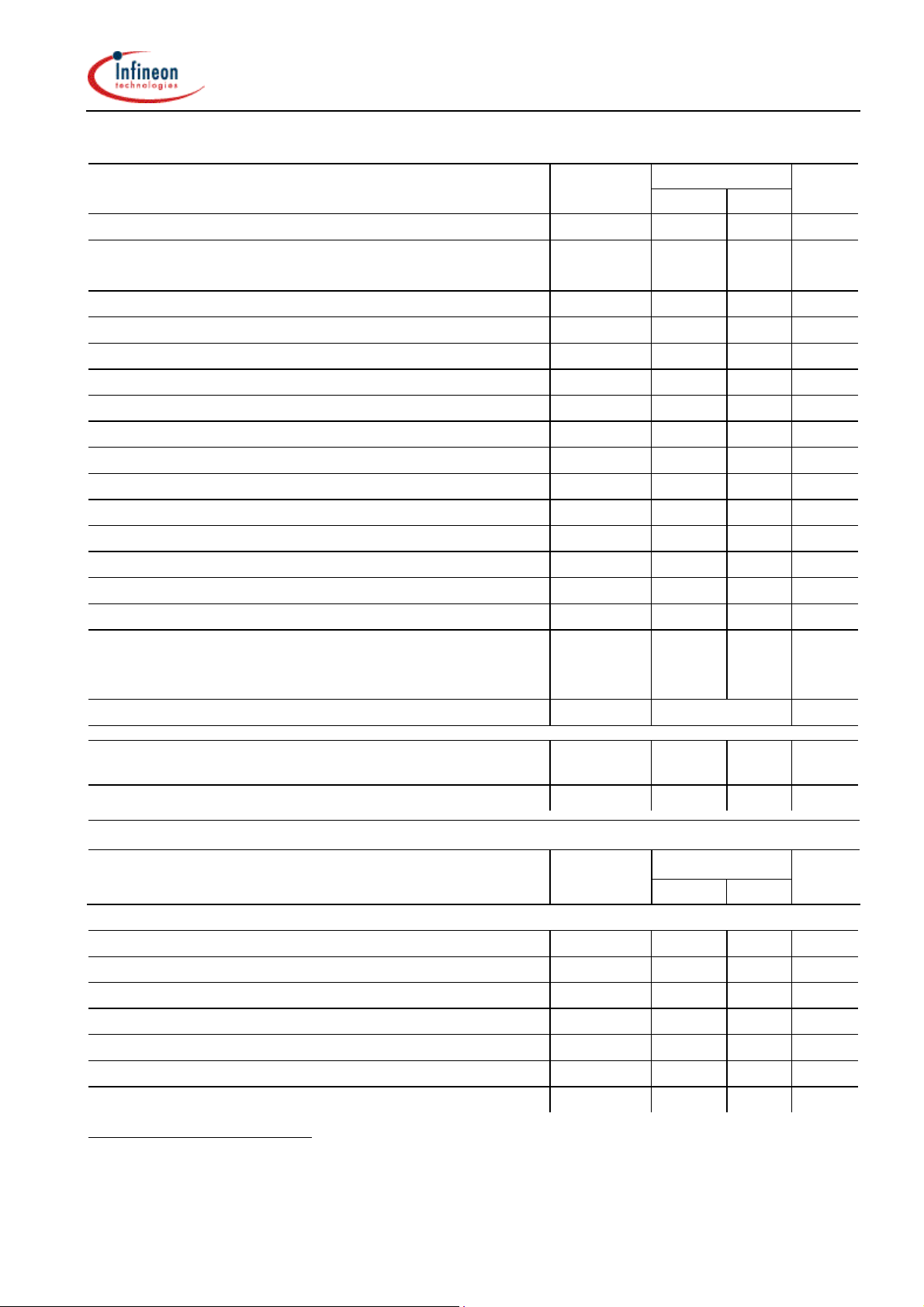

Maximum Ratings at Tj=-40…+150°C unless specified otherwise

Limits ValuesParameter Symbol

Unit

Min. Max.

Supply voltage 1 VS -4 60 V

Operating temperature range

Storage temperature range

Tj

T

stg

-40

-55

150

150

°C

Max. voltage range at PWM, DIR, DT/DIS -1 6V

Max. voltage range at ERx -0.3 6V

Max. voltage range at INH VINH -0.6 60 V

Max. voltage range at BHx VBHx -0.3 90 V

Max. voltage range at DHx

Max. voltage range at GHx

Max. voltage range at SHx

2

VDHx -4 75 V

3

VGHx -6.8 86 V

3

VSHx -6.8 75 V

Max. voltage range at GLx VGLx -2 12 V

Max. voltage range at DLx VDLx -2 75 V

Max. voltage difference BHx – SHx VBHx-VSHx -0.3 17 V

Max. voltage difference Gxx – Sxx VGxx-VSxx -0.3 11 V

Power dissipation (DC) @ TA=125°C / min.footprint P

Power dissipation (DC) @ TA=85°C / min.footprint P

Electrostatic discharge voltage (Human Body Model)

0.33 W

tot

0.85 W

tot

4

V

ESD

2kV

according to MIL STD 883D, method 3015.7 and

EOS/ESD assn. standard S5.1 – 1993

Jedec Level 3

Thermal resistance junction - ambient (minimal foot-

R

75 K/W

thJA

print with thermal vias)

Thermal resistance junction - ambient (6 cm2) R

75 K/W

thJA

Functional range

Parameter and Conditions Symbol Values Unit

at Tj = -40…+150°C, unless otherwise specified

min max

Supply voltage VS 7.5 60 V

Operating temperature range Tj -40 150 °C

Max. voltage range at PWM, DIR, DT/DIS -0.3 5.5 V

Max. voltage range at ERx -0.3 5.5 V

Max. voltage range at INH VINH -0.6 60 V

Max. voltage range at BHx VBHx -0.3 90 V

Max. voltage range at DHx2 VDHx -4 75 V

1

With external resistor (≥10 Ω ) and capacitor

2

The min value -4V is reduced to –( V

3

The min value -7V is reduced to –(V

4

All test involving Gxx pins V

ESD

=1 kV!

BHx

BHx

- V

) in case of bootstrap voltages V

SHx

- V

- 1V) in case of bootstrap voltages V

SHx

BHx-VSHx

BHx-VSHx

<4V

<8V

4 2006-01-30

Page 5

Data Sheet TLE6284G

Max. voltage range at GHx3 VGHx -6.8 86 V

Max. voltage range at SHx3 VSHx -6.8 75 V

Max. voltage range at GLx VGLx -2 12 V

Max. voltage range at DLx VDLx -2 75 V

Max. voltage difference BHx – SHx VBHx-VSHx -0.3 12 V

Max. voltage difference Gxx – Sxx VGxx-VSxx -0.3 11 V

PWM frequency FPW M 0 50 kHz

Minimum on time external lowside switch – static con-

dition @ 20 kHz; Q

= 200nC

Gate

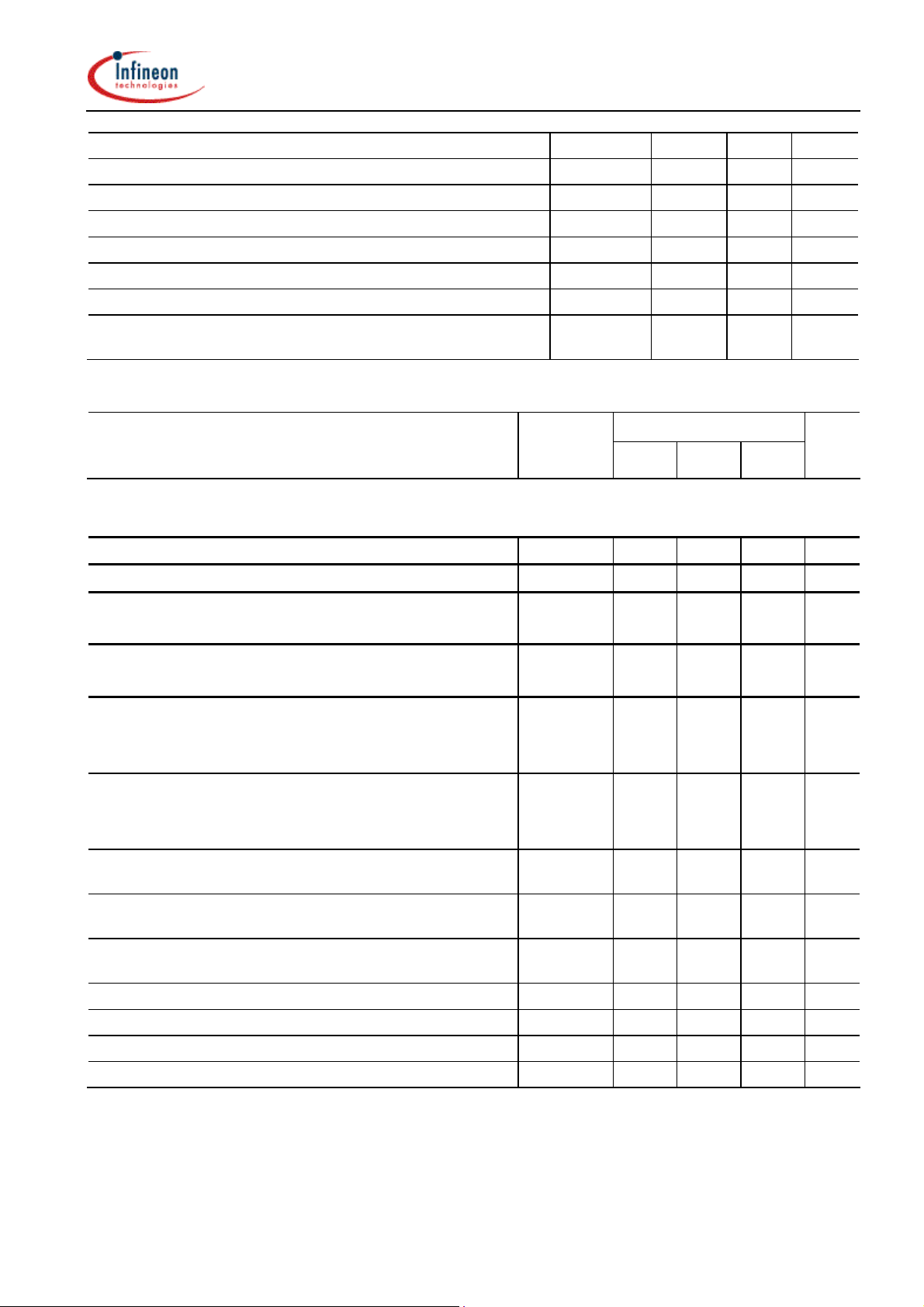

Electrical Characteristics

Parameter and Conditions Symbol Values Unit

at Tj = -40…150°C, unless otherwise specified

and supply voltage range V

Static Characteristics

S = 7.5 … 60V; f

= 20kHz

PWM

tp(min) 2µs

min typ max

Low level output voltage (VGSxx) @ I=10mA

High level output voltage (VGSxx) @ I=-10mA

Supply current at VS (device disabled)

@ V

= VS =14V R

bat

=400kΩ

DT

Supply current at VS (device disabled)

@ V

= VS =42V R

bat

=400kΩ

DT

Quiescent current at VS (device inhibited)

@ V

R

= VS =14V R

bat

SCD1+RSCD2

DT

= R

SCD3+RSCD4

=400kΩ

=12kΩ

Quiescent current at VS (device inhibited)

@ V

R

Supply current at VS @ V

f

PWM

Supply current at VS @ V

f

PWM

Supply current at VS @ V

f

PWM

= VS =42V R

bat

SCD1+RSCD2

= R

=400kΩ

DT

SCD3+RSCD4

= VS =14V,

bat

= 20kHz (Outputs open)

= VS =14V,

bat

= 50kHz (Outputs open)

= VS =42V,

bat

= 20kHz (Outputs open)

=12kΩ

∆

VLL -- 60 150 mV

∆

VHL 8 10 11 V

IVS(dis)14V -- 4 8 mA

IVS(dis)42V -- 4 8 mA

IVS(inh)14V -- 0.6 1.5 mA

IVS(inh)42V -- 0.6 1.5 mA

I

VS(open)14V

I

VS(open)14V

I

VS(open)42V

-- 7 15 mA

-- 7 15 mA

-- 7 15 mA

Low level input voltage VIN(LL) -- -- 1.0 V

High level input voltage VIN(HL) 2.0 -- -- V

Input hysteresis

Inhibit trip level V

∆

VIN 100 170 mV

1.3 2 3 V

INH

5 2006-01-30

Page 6

Data Sheet TLE6284G

Dynamic characteristics (pls. see test circuit and timing diagram)

Turn on current @ VGxx –VSxx = 0V; Tj=25°C

@ VGxx –VSxx = 4V; Tj=125°C

@ C

=22nF ; R

Load

load

= 0Ω

Turn off current @ VGxx –VSxx = 10V; Tj=25°C

@ VGxx –VSxx = 4V; Tj=125°C

@ C

= 22nF ; R

Load

load

=0Ω

Dead time (adjustable) @ RDT = 1 kΩ

@ RDT = 10 kΩ

@ R

@ R

@ C

Rise time @ C

Fall time @ C

=10nF ; R

Load

load

=10nF ; R

Load

=10nF ; R

Load

=1Ω

DT = 50 kΩ

DT = 200 kΩ

=1Ω (20% to 80%) t

load

=1Ω (80% to 20%) tfall -- 150 440 ns

load

Disable propagation time

@ C

=10nF ; R

Load

load

=1Ω

Reset time of diagnosis

@ C

=10nF ; R

Load

load

=1Ω

Input propagation time

(low side turns on, 0% to 10%)

Input propagation time

(low side turns off, 100% to 90%)

Input propagation time

(high side turns on, 0% to 10%)

Input propagation time

(high side turns off, 100% to 90%)

Input propagation time difference

(all channels turn on)

Input propagation time difference

(all channels turn off)

Input propagation time difference

(one channel; low on – high off)

Input propagation time difference

(one channel; high on – low off)

Input propagation time difference

(all channels; low on – high off)

Input propagation time difference

(all channels; high on – low off)

IGxx(on) --

IGxx(off) --

tDT --

0.05

0.40

--

--

--

850

700

580

300

0.01

0.20

1.0

3.1

--

--

----mA

--

0.38

2.50

--

mA

µs

-- 100 300 ns

rise

tP(DIS) 3.6 5 7 µs

tP(CL) 1 2 3.1 µs

tP(ILN) -- 250 500 ns

tP(ILF) -- 110 500 ns

tP(IHN) -- 200 500 ns

tP(IHF) -- 130 500 ns

tP(Diff) 20 50 70 ns

tP(Diff) -- 25 50 ns

tP(Diff) -- 120 180 ns

tP(Diff) -- 100 180 ns

tP(Diff) -- 120 180 ns

tP(Diff) -- 100 180 ns

6 2006-01-30

Page 7

Data Sheet TLE6284G

Test Circuit and Timing Diagram

x2

PWM

GHx

SHx

GLx

SLx

R

C

R

C

= 1 Ohm

load

= 10 nF

load

= 1 Ohm

load

= 10 nF

load

V

V

GHX_C

GLX_C

PWM

V

GHX_C

50%

t

t

t

P(IHN)

rise

80%

20%

10%

t

P(IHF)

t

fall

90%

t

t

t

P(ILF)

fall

t

t

P(ILN)

rise

V

Test Conditions :

GLX_C

Junction temperature Tj = -40 … 150oC

Supply voltage range Vs = 7.5 … 60V

PWM frequency f

= 20 kHz

PWM

Diagnosis and Protection Functions

Overtemperature warning T

Hysteresis for overtemperature warning ∆T

Short circuit protection filter time t

Short circuit criteria (VDS of Mosfets)

SCP(off)

V

For Low sides

For High sides

Disable input level V

Disable input hysteresis ∆V

Error level @ 1.6mA I

Under voltage lock out for highside output – boot-

V

ERx

V

strap voltage

Under voltage lock out for lowside output –

V

supply voltage

90%

80%

20%

150 170 190 °C

J(OV)

20 °C

J(OV)

6 9 12 µs

DS(SCP)

0.5

0.45

3.3 3.7 4.0 V

DIS

180 mV

DIS

-- -- 1.0 V

ERx

BHx (uvlo)

Vs (uvlo)

3.7 4.6 V

4.8

0.75

0.75

1.0

1.05

5.9 V

10%

t

V

7 2006-01-30

Page 8

Data Sheet TLE6284G

Remarks:

Default status of input pins:

To assure a defined status of the logic input pins in case of disconnection, these pins are

internally secured by pull up / pull down current sources with approx. 20µA. The high voltage

proof input INH should be secured by an external pull down resistor close to the device. The

following table shows the default status of the logic input pins.

Input pin Default status

PWM and DIR Low (= break in high side)

DT/DIS (active high) High

Definition:

In this datasheet a duty cycle of 98% means that the GLx pin is 2% of the PWM period in

high condition.

Remark: Please consider the influence of the dead time and the propagation time differences for the input duty cycle

Functional description

Description of Dead Time Pin / Disable Pin / Reset

This pin allows to adjust the internal generated dead time. The dead time protects the external highside and lowside Mosfets in the same halfbridge against a lowohmic connection between battery and GND and the resulting cross current through these Mosfets. The adjustable dead time allows to minimize the power dissipation caused by the current flowing

through the body diode during switching the halfbridge.

In addition this pin allows to reset the diagnosis registers without shut down of any output

stage as well as the possibility to shut down all outputs simultaneously.

Condition of DT/DIS pin Function

0 - 3.5V Adjust dead time between 10ns and 3.1µs

> 4V

Description of Inhibit functionality

In automotive applications which are permanently connected to the battery line, it is very important to reduce the current consumption of the single devices. Therefore the TLE6284G

offers a inhibit mode to put the device to sleep and asure very low quiescent currents. To

deactivate the inhibit mode the INH pin has to be set to high. This can be done by connecting this pin to voltages between 3.3 and 60V without external protection. An inhibit mode

means a complete reinitialisation of the device.

Description of Diagnosis

The two ERx pins are open collector outputs and have to be pulled up with external pull up

resitors to 5V. In normal conditions both ERx signals are high. In case of shutdown of any

output stage the ER1 is pulled down. This shut down can be caused by undervoltage or

short circuit. In this condition ER2 indicates the reason for the shut down.

a) Reset of diagnosis register if DT/DIS voltage is higher than

4V for a time between 3.1µs and 3.6µs

b) Shut down of output stages if DT/DIS voltage is higher

than 4V for a time above 7µs (Active pull down of gate voltage)

8 2006-01-30

Page 9

Data Sheet TLE6284G

Condition of

ER1 pin

5V 5V no errors

5V 0V overtemperature warning of driver IC

0V 5V Shut down of any output stage caused by short circuit

0V 0V Shut down of any output stage caused by undervoltage

Recommended Start-up procedure

The following procedure is recommended whenever the Driver IC is powered up:

• Disable the Driver IC via DT/DIS pin

• Wait until the bootstrap capacitors of High Side MOSFET C

time depends on application conditions, e.g. CBx and RBx)

• Enable the Driver IC via DT/DIS pin

• Start the operation by applying the desired pulse patterns. Do not apply any pulse pat-

terns to the PWM or DIR pin, before the CBx capacitors are charged up.

Short Circuit protection

The current threshold limit to activate the Short Circuit protection function can be adjusted to

larger values, it can not be adjusted to lower values. This can be done by external resistors

to form voltage deviders across the “sense element” (pls. see Application block diagram on

pg. 2), consisting of the Drain-Source-Terminals, a fraction of the PCB trace and – in some

cases – current sense resistors (used by the µC not by the Driver IC).

The Short Circuit protection can be disabled for the High Side MOSFETs by shorting DH1

with SH1 and DH2 with SH2 on the PCB; in this case the DHx pins may not be connected to

the Drains of the associated MOSFETs. To disable Short Circuit protection for the Low Side

MOSFETs the DL1 and DL2 pin should be connected to the Driver IC´s Ground.

Shut down of the driver

A shut down can be caused by undervoltage or short circuit.

A short circuit will shut down only the affected Mosfet until a reset of the error register by a

disable of the driver occurs. A shut down due to short circuit will occur only when the Short

Circuit criteria V

t

SCP(off)

. Yet, the exposure to or above V

tive Short Circuit conditions shorter than t

MOSFET.

An undervoltage shut down shuts only the affected output down. The affected output will

auto restart after the undervoltage situation is over.

Operation at Vs<12V

If Vs<11.5V the gate voltage will not reach 10V. It will reach approx Vs-1.5V, dependant on

duty cyle, bootstrap capacitor, total gate charge of the external Mosfet and switching frequency.

Operation at different voltages for Vs, DH1 and DH2

If DH1 and DH2 are used with a voltage higher than Vs, a duty cycle of 100% can not be

guaranteed. In this case the driver is acting like a normal driver IC based on the bootstrap

principle. This means that after a maximum “On” time of the highside switch of more than

1ms a refresh pulse to charge the bootstrap capacitor of about 1µs is needed to avoid undervoltage lock out of this output stage.

Condition of

ER2 pin

DS(SCP)

is met for a duration equal to or longer than the Short Circuit filter time

Function

DS(SCP)

scp(off)

are charged (the waiting

Bx

is not counted or accumulated. Hence, repeti-

will not result in a shut down of the affected

9 2006-01-30

Page 10

Data Sheet TLE6284G

Operation at extreme duty cycle:

The integrated charge pump allows an operation at 100% duty cycle. The charge pump is

strong enough to replace leakage currents during “on”-phase of the highside switch. The

gate charge for fast switching of the highside switches is supplied by the bootstrap capacitors. This means, that the bootstrap capacitor needs a minimum charging time of about 1ms,

if the highside switch is operated in PWM mode (e.g. with 20kHz a maximum duty cycle of

96% can be reached). The exact value for the upper limit is given by the RC time formed by

the impedance of the internal bootstrap diode and the capacitor formed by the external Mosfet (C

Mosfet=QGate

MOSFET the driver IC has to drive. Usually the bootstrap capacitor is about 10-20 times bigger then C

Mosfet

The charge pump is active when the highside switch is “ON” and the voltage level at the SHx

is higher than 4V. Only under these conditions the bootstrap capacitor is charged by the

charge pump.

Estimation of power loss within the Driver IC

The power loss within the Driver IC is strongly dependent on the use of the driver and the

external components. Nevertheless a rough estimation of the worst case power loss is possible. Worst case calculation is:

P

= (Q

Loss

gate

With:

P

= Power loss within the Driver IC

Loss

f

= Switching freqency

PWM

Q

= Total gate charge of used MOSFETs at 10V VGS

gate

n = Number of switched MOSFETs

const = Constant considering some leakage current in the driver (about 1.2)

I

VS(open)

= Current consumption of driver without connected Mosfets during switching

VVS = Voltage at Vs

P

= Power dissipation in the external gate resistors

RGate

This value can be reduced dramatically by usage of external gate resistors.

/ VGS). The size of the bootstrap capacitor has to be adapted to the external

. External components at the Vs Pin have to be considered, too.

*n*const* f

PWM

+ I

VS(open)

/20kHz)* VVs - P

RGate

Estimated Power Lo ss P

0,8

0,7

0,6

0,5

(W)

0,4

LOSS

0,3

P

0,2

0,1

0

0 102030405060

Conditions

Junction temperature Tj = 25oC

Number of switched MOSFET n = 2

Power dissipation in the external gate resistors P

for different supply voltages V

LOSS

at QG = 100nC @ VGS = 10V

Vs = 8V

Vs = 14V

Vs = 18V

PWM Frequency (kHz)

:

with in the Driv er IC

s

Estimated Power Loss P

for different gate charges Q

at sup ply voltage Vs = 14V

0,8

0,7

0,6

0,5

(W)

0,4

LOSS

0,3

P

0,2

0,1

0

0 102030405060

RGate

QG = 50nC

= 100nC

Q

G

= 200nC

Q

G

PWM Frequency (kHz)

= 0,2*P

within the Driver IC

LOSS

Loss

G

10 2006-01-30

Page 11

Data Sheet TLE6284G

Gate Drive characteristics

Logic

+

V

PWM_HS

Level

Shift

+

V

GS

limit

+

Under

voltage

SCD

i

Gxx(on)

i

Gxx(off)

BHx

DHx

GHx

SHx

C

i

GHx

V

PWM_HS

V

s

i

Gxx(on)

850 mA Peak

B

i

Gxx(off)

580 mA Peak

Motor

TLE6284G

High Side Driver

- Turn Off : V

Test Conditions :

- Turn On : V

= 0V, Tj = 25oC

GS

= 10V, Tj = 25oC

GS

This figure represents the simplified internal

circuit of one high side gate drive. The drive

circuit of the low sides look similar.

i

GHx

This figure illustrates typical voltage and

current waveforms of the high side gate drive;

the associated waveforms of the low side

drives look similar.

11 2006-01-30

Page 12

Data Sheet TLE6284G

Truth Table

Input Conditions Output driver IC Output

Bridge

DIR PWM DT / DIS UV OT SC GH1 GL1 GH2 GL2 ER1 ER2 Out1 Out2

0

1

<3.5V 0 0 0 1 0 0 1

0 0 <3.5V 0 0 0 1 0 1 0

1 1 <3.5V 0 0 0 0 1 1 0

1 0 <3.5V 0 0 0 1 0 1 0

0

1

<3.5V 1 0 0 B 0 0 B

0 0 <3.5V 1 0 0 B 0 B 0

1 1 <3.5V 1 0 0 0 B B 0

1 0 <3.5V 1 0 0 B 0 B 0

0

1

<3.5V 0 1 0 1 0 0 1

0 0 <3.5V 0 1 0 1 0 1 0

1 1 <3.5V 0 1 0 0 1 1 0

1 0 <3.5V 0 1 0 1 0 1 0

0

1

<3.5V 0 0 1 E 0 0 E

0 0 <3.5V 0 0 1 E 0 E 0

1 1 <3.5V 0 0 1 0 E E 0

5V 5V 1 0

5V 5V 1 1

5V 5V 0 1

5V 5V 1 1

C D 1

C D 1

A

0 A

A

1 A

C D 0 A 1 A

C D 1 A 1 A

5V 0V 1 0

5V 0V 1 1

5V 0V 0 1

5V 0V 1 1

F 5V 1

A

0 A

F 5V 1 A 1 A

F 5V 0 A 1 A

1 0 <3.5V 0 0 1 E 0 E 0

X

X

X X X X 0 0 0 0

X X >4V X X X 0 0 0 0

F 5V 1 A 1 A

5V 5V T T

5V 5V T T

A) Tristate when affected by undervoltage shut down or short circuit

B) 0 when affected; 1 when not affected; self recovery

C) 0V when output does not correspond to input patterns; 5V when output corresponds to

input patterns

D) Is an output affected by undervoltage ER2 is 0V

E) 0 when affected– the outputs of the affected halfbridge are shut down and stay latched

until reset; 1 when not affected

F) 0V when output does not correspond to input patterns – the outputs of the affected half-

bridge are shut down and stay latched until reset; 5V when output corresponds to input

patterns.

T) Tristate

X) Condition has no influence

Remark: To generate fast decay control mode, set PWM to 1 and send pwm-pattern to DIR

input.

12 2006-01-30

Page 13

Data Sheet TLE6284G

Driving Sequence and current flow in the MOSFETs and the motor

t

PWM

t

GL1

V

GH2

V

t

t

DIR

V

t

GH1

t

GL2

V

t

Vs

Vs

Vs

Vs

Vs

Vs

Acceleration Motor turns right Motor stops Motor turns left Motor stops

motor

I

M

M

M

M

M

M

13 2006-01-30

Page 14

Data Sheet TLE6284G

Package and Ordering Code

(all dimensions in mm)5

Package Code

P-DSO 20

5

For detailed information about packages please contact

http://www.infineon.com/cgi/ecrm.dll/ecrm/scripts/pack_cat.jsp?oid=-8781

14 2006-01-30

Page 15

Data Sheet TLE6284G

Published by

Infineon Technologies AG,

Bereich Kommunikation

St.-Martin-Strasse 53,

D-81541 München

© Infineon Technologies AG 1999

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as warranted characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding

circuits, descriptions and charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest Infineon Technologies Office in Germany or our Infineon Technologies Representatives worldwide (see address

list).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life

support devices or systems are intended to be implanted in the human body, or to support and/or maintain and

sustain and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may be endangered.

15 2006-01-30

Loading...

Loading...