Page 1

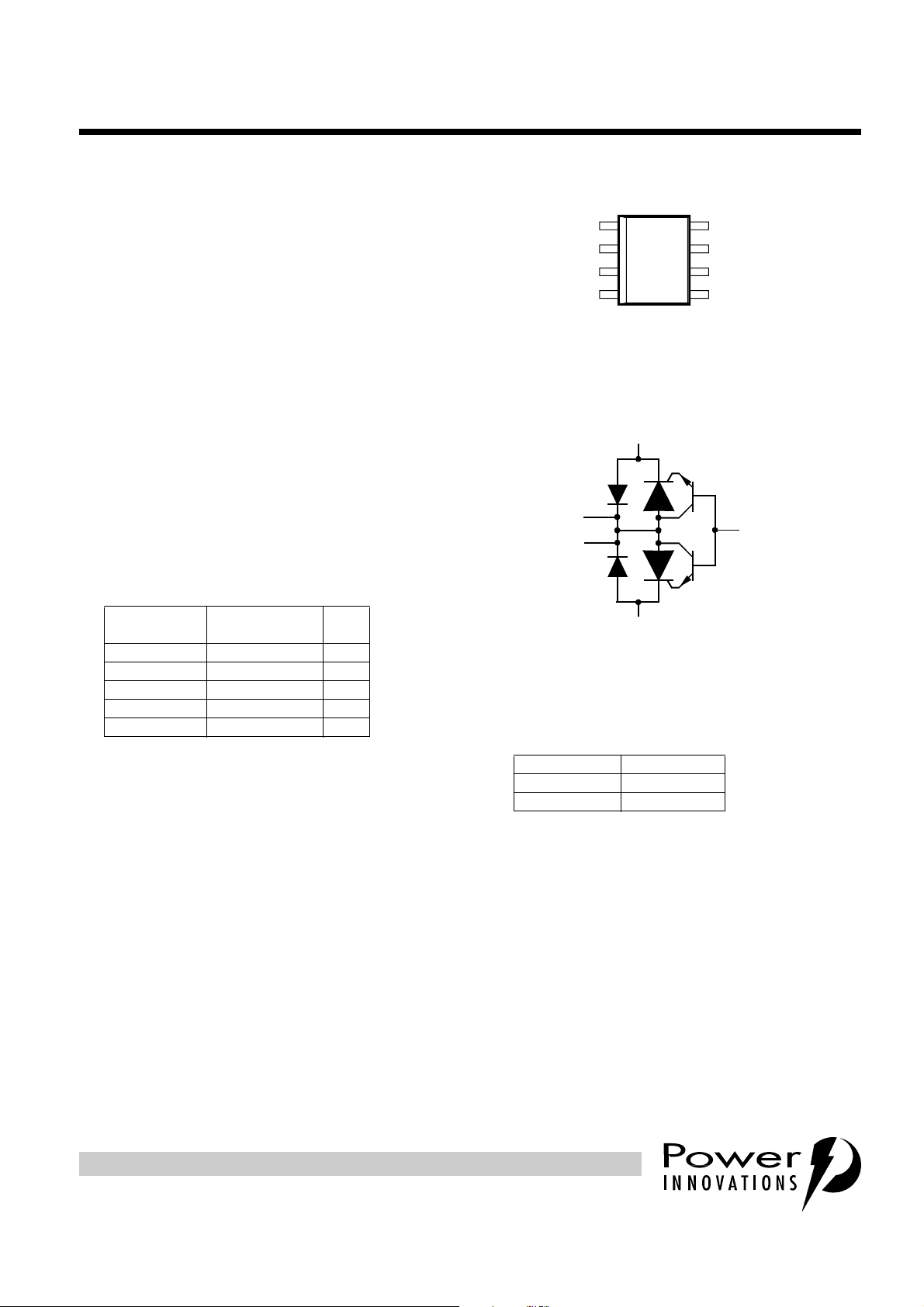

TISPPBL2SD

‡ C

SLIC inf

K1

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999Copyright © 1999, Power Innovations Limited, UK

OVERVOLTAGE PROTECTION FOR ERICSSON COMPONENTS LINE INTERFACE CIRCUITS

Overvoltage Protector‡ for:-

●

PBL 3762A

PBL 3764A/4, PBL 3764A/6

PBL 3766, PBL 3766/6

PBL 3767, PBL 3767/6

PBL 3796, PBL 3796/2

PBL 3798, PBL 3798/2

PBL 3798/5

PBL 3798/6

PBL 3799

PBL 3860A/1, PBL 3860A/6

PBL 386 10/2

PBL 386 11/2

PBL 386 20/1

PBL 386 21/1

PBL 386 30/1

PBL 386 40/1

PBL 386 50/1

PBL 3898/M

(Tip)

(Gate)

(Ring)

Terminal typical application names shown in

device symbol

A

A

D PACKAGE

(TOP VIEW)

K1

G

NC

K2

NC - No internal connection

1

2

3

4

parenthesis

8

7

6

5

NC

A

A

NC

(Ground)

(Ground)

MD6XBA

G1,G2

Rated for International Surge Wave Shapes

●

I

WAVE SHAPE STANDARD

2/10 µs GR-1089-CORE 100

1.2/50 µs ITU-T K22 100

0.5/700 µs I3124 40

10/700 µs ITU-T K20, K21 40

10/1000 µs GR-1089-CORE 30

Single-Lead Line Connection Version of

●

Feed-Through TISPPBL2D

- Ground Lead Creepage Distance . . > 3 mm

TSP

A

K2

Termin als K1, K2 and A cor respond to t he alternative

line designators of T, R and G or A, B and C. The

negative protection voltage is controlled by the

voltage, V

Small Outline Surface Mount Package

●

applied to the G terminal.

GG,

- Available Ordering Options

CARRIER ORDER #

Tube TISPPBL2SD

Taped and reeled TISPPBL2SDR

description

The TISPPBL2S is a dual forward-conducting buffered p-gate overvoltage protector. It is designed to p rotect

the Ericsson Components PBL 3xxx family of SLICs (Subscriber Line Interface Circuits) against overvoltages

on the telephone line cause d by lightning, a.c. power contact and indu ction. The TISPPB L2S limits voltages

that exceed the SLIC supply rail levels.

The SLIC line driver section is typically powered from 0 V (ground) and a negative voltage in the region of

-10 V to -85 V. The protector gate is connected to this negative supply. This references the protection

(clipping) voltage to the negative supply voltage. As the protection voltage will track the negative supply

voltage the overvoltage stress on the SLIC is minimised.

SD6XAP

Positive overvoltage s are clipped to grou nd by diode forward conduction. Negative overvoltage s are initially

clipped close to the SLIC negative supply rail value. If sufficient current is available from the overvoltage, then

the protector will crowbar into a low voltage ground referenced on-state condition. As the overvoltage

ustomers are advised to obtain the latest version of the relevant Ericsson Components

the information being relied on is current.

ormation to verify, before placing orders, that

PRODUCT INFORMATION

Information is current as of publication date. Products conform to specifications in accordance

with the terms of Power Innovations standard warranty. Production processing does not

necessarily include testing of all parameters.

1

Page 2

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

subsides the high holdin g c ur rent of th e cr owbar prevents d.c. latchup. The TISPPBL2S buffered gate design

reduces the loading on the SLIC supply during overvoltages caused by power cross and induction.

These monolithic prote ction devices are fabricated in ion-implanted planar vertical power str uctures for high

reliability and in nor mal system operatio n they are virtual ly transparent. The TISPPBL2 S is the TISPPBL2D

with a different pinout. The feed-through Ring ( leads 4 — 5) and Tip (lead s 1 — 8) connections have been

replaced by single Ring (lea d 4) and Tip ( lead 1) connec tions. This in creases pa ckage creepag e distance of

the biased to ground connections from about 0.7 mm to over 3 mm.

absolute maximum ratings

RATING SYMBOL VALUE UNIT

≤

Repetitive peak off-state voltage, I

Repetitive peak gate-cathode voltage, V

Non-repetitive peak on-state pulse current (see Notes 1 and 2)

10/1000 µs (Bellcore GR-1089-CORE, Issue 1, November 1994, Section 4) 30

0.2/310 µs (I3124, open-circuit voltage wave shape 0.5/700µs)

5/310 µs (ITU-T K20 & K21, open-circuit voltage wave shape 10/700 µs)

1/20 µs (ITU-T K22, open-circuit voltage wave shape 1.2/50 µs)

2/10 µs (Bellcore GR-1089-CORE, Issue 1, November 1994, Section 4) 100

Non-repetitive peak on-state current, 50/60 Hz (see Notes 1 and 2)

100 ms 11

1s

5s

300 s

900 s

Non-repetitive peak gate current, 1/2 µs pulse, cathodes commoned (see Note 1) I

Operating free-air temperature range T

Junction temperature T

Storage temperature range T

= 0, -40°C≤T

G

= 0, -40°C≤T

KA

85°C V

J

≤

85°C V

J

DRM

GKRM

I

TSP

I

TSM

GSM

A

J

stg

-100 V

-90 V

40

40

100

4.5

2.4

0.95

0.93

40 A

-40 to +85 °C

-40 to +150 °C

-40 to +150 °C

A

A

NOTES: 1. Initially the protector must be in thermal equilibrium with -40 °C≤T

its initial conditions.

2. These non-repetitive rated currents are peak values for either polarirty. The rated current values may be applied either to the Ring

to Ground or to the Tip to Ground terminal pairs. Additionally, both terminal pairs may have their rated current values applied

simultaneously (in this case the Ground terminal current will be twice the rated current value of an individual terminal pair). Above

85 °C, derate linearly to zero at 150 °C lead temperature.

recommended operating conditions

C

G

R

1

electrical characteristics, T

I

D

Gate decoupling capacitor 100 220 nF

TISPPBL2S series resistor for GR-1089-CORE first-level and second-level surge survival

TISPPBL2S series resistor for GR-1089-CORE first-level surge sur vival

TISPPBL2S series resistor for ITU-T recommendation K20/21

= 25 °C (unless otherwise noted)

amb

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Off-state current VD=V

DRM

, VGK=0

PRODUCT INFORMATION

≤

85 °C. The surge may be repeated after the device returns to

J

MIN TYP MAX UNIT

40

25

10

T

= -40 °C -5 µA

J

= 85 °C -50 µA

T

J

Ω

2

Page 3

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

electrical characterist ics, T

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

V

t

(BR)

V

V

t

FR

I

H

I

GAS

I

GAT

I

GAF

I

GT

V

C

(BO)

F

FRM

GT

AK

Breakover voltage

Breakdown time

Forward voltage IF= 5 A, tw= 500 µs 3V

Peak forward recovery

voltage

Forward recovery time

Holding current IT= -1 A, di/dt = 1A/ms, VGG=-50V, -40°C≤T

Gate reverse current VGG=V

Gate reverse current,

on state

Gate reverse current,

forward conducting

state

Gate trigger current IT=-5A, t

Gate trigger voltage IT=-5A, t

Anode-cathode offstate capacitance

T

Figure 2)

I

T

cuit (See Note 3 and Figure 2)

IF= 20 A, 0.5/700 generator, Fi gure 3 test circuit (See Note 4 and Figure 2)

I

F

cuit (See Note 4 and Figure 2)

I

T

I

F

f=1MHz, V

= 25 °C (unless otherwise noted) (continued)

amb

= -20 A, 0.5/700 generator, Figure 3 test circuit (See Note 3 and

= -20 A, 0.5/700 generator, Figure 3 test cir-

< -50 V 1 µs

V

(BR)

-70 V

8V

10000

1

µs

= 20 A, 0.5/700 generator, Figure 3 test cir-

, VAK=0

GKRM

VF > 5 V

> 1 V

V

F

≤

85 °C -150 mA

J

T

= -40 °C -5 µA

J

T

= 85 °C -50 µA

J

=-0.5A, tw= 500 µs, VGG=-50V -1 mA

= 1 A, tw= 500 µs, VGG= -50 V -10 mA

≥

20 µs, V

p(g)

≥

20 µs, V

p(g)

=1V, IG= 0, (see Note 5)

d

=-50V 5 mA

GG

=-50V 2.5 V

GG

V

= -3 V 110 pF

D

V

=-50V 60 pF

D

NOTES: 3. For the required TIPX and RINGX terminal negative pulse performance refer to the respective Ericsson Components SLIC data

sheet. The PBL 379x family of SLICs has ratings of -120 V for 0.25 µs, -90 V for 1 µs, -70 V for 10 ms and -70 V for d.c. The PBL

376x family together with the PBL 3860A SLIC have the same maximum ratings when the applied battery voltage is -50V. As the

FLEXI-SLIC™ PBL 386 xx family is specified in terms of current pulses, a minimum value of 2Ω for R

Compliance to these conditions is guaranteed by the maximum breakover voltage and the breakdown times of the TISPPBL2S.

should be used.

P

4. For the required TIPX and RINGX terminal positive pulse performance refer to the respective Ericsson Components SLIC data

sheet. The PBL 379x family of SLICs has ratings of 15 V for 0.25 µs, 10 V for 1µs, 5 V for 10 ms and 1 V for d.c. The PBL 376x

family together with the PBL 3860A SLIC have similar ratings. As the FLEXI-SLIC™ PBL 386 xx family is specified in terms of

current pulses, a minimum value of 2Ω for R

should be used. Compliance to these conditions is guaranteed by the peak forward

P

recovery voltage and the forward recov ery times of the TISPPBL2S

5. These capacitance measurements employ a three terminal capacitance bridge incorporating a guard circuit. The unmeasured

device terminals are a.c. connected to the guard terminal of the bridge.

thermal characteristics

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

P

=0.8W, TA=25°C

R

Junction to free air thermal resistance

θ

JA

tot

5cm

2

, FR4 PCB

D Package 160 °C/W

PRODUCT INFORMATION

3

Page 4

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

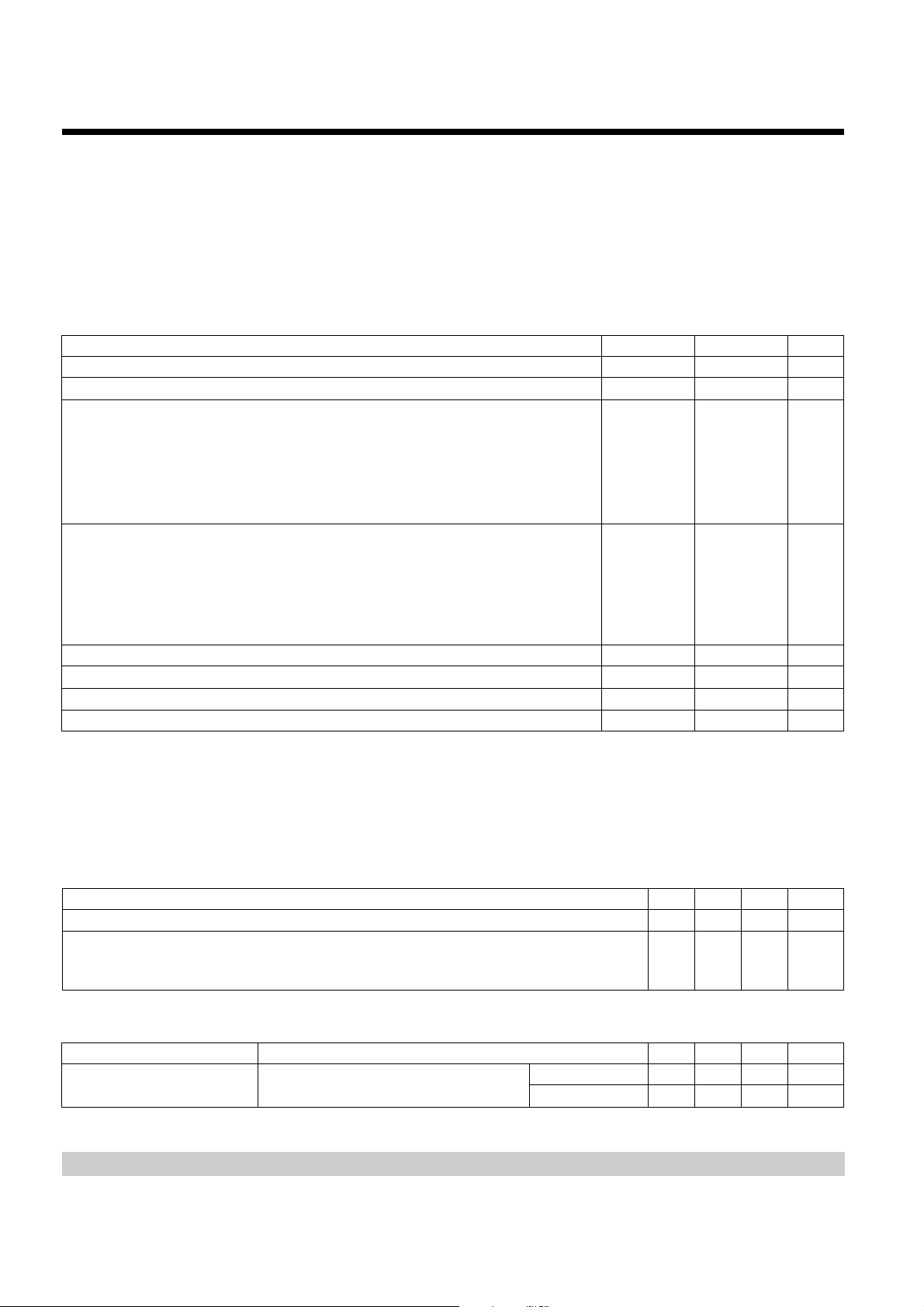

PARAMETER MEASUREMENT INFORMATION

V

GK(BO)

-v

I

(BO )

V

V

(BO)

Quad r a nt III

Switchin g

Characteristic

Figure 1. PRINCIPAL TERMINAL AND GATE TRANSFER CHARACTERISTICS

PRINCIPAL TERMINAL V-I CHARACTERISTIC

(= |I

I

FSP

I

(= |I

FSM

TSM

GG

I

S

V

S

V

D

V

T

TSP

GATE TRANSFER

CHARACTERISTIC

+i

|)

Quadrant I

Forward

Conduction

Characteristic

+i

K

|)

I

F

V

F

+v

-i

PM6XAIA

G

I

GAF

I

GAT

I

K

I

D

I

H

I

T

I

TSM

I

TSP

-i

I

F

I

GT

+i

G

I

T

I

G

-i

K

PROTECTOR MAXIMUM LIMIT ING VOLTAGE

vs

TIME

-50

VOLTAGE - V

-60

-70

-80

10

5

1 µs

10 ms

0

1 µs

MAX V

MAX V

FRM

(BO)

= 8 V

= -70 V

Figure 2. TRANSIENT LIMITS FOR TISPPBL2S LIMITING VOLTAGE

V

BAT

Time

= -50 V

PM6XAL

PRODUCT INFORMATION

4

Page 5

TISPPBL2SD

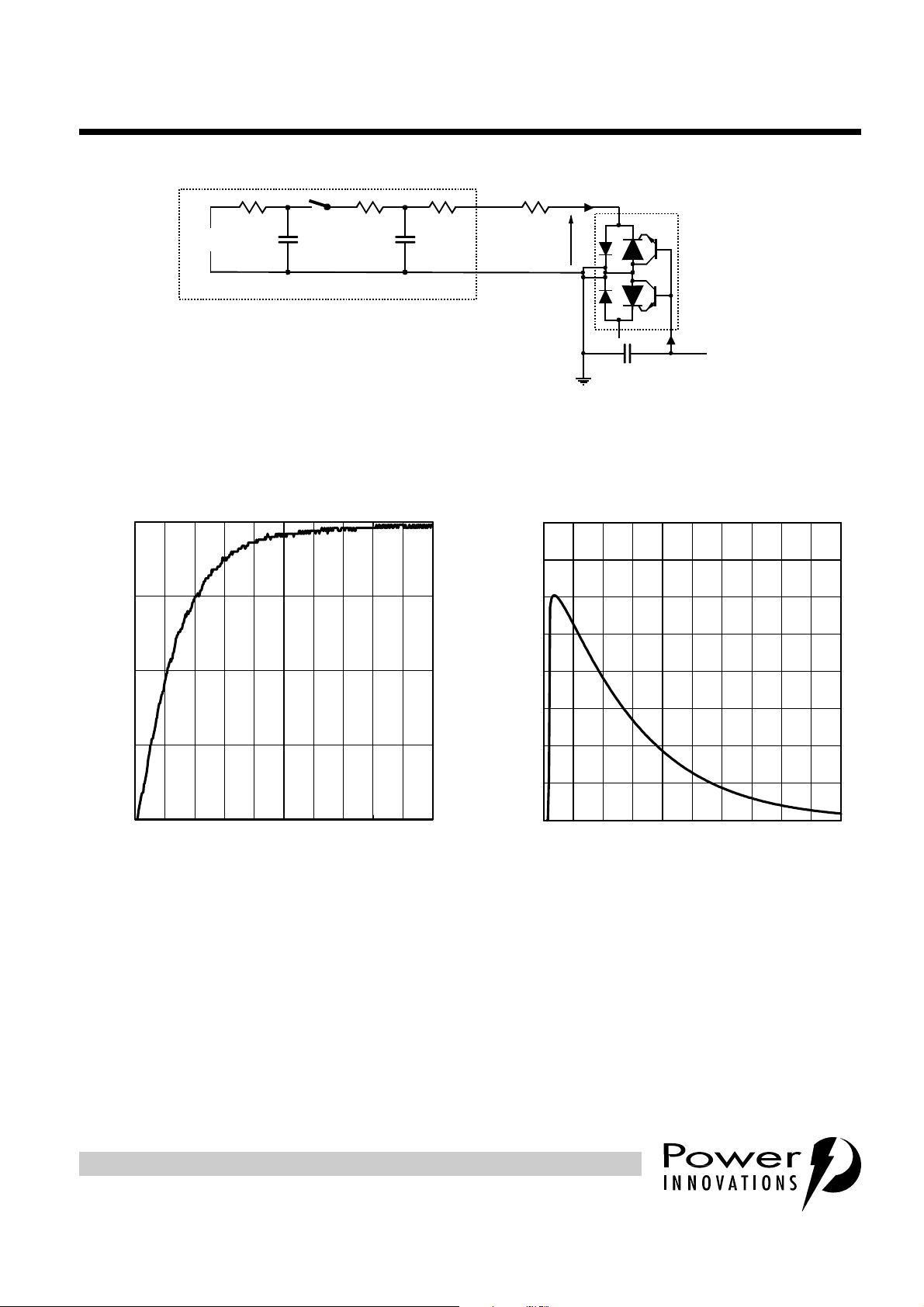

E502 0.5/700 WAVEFRONT di/dt

vs

TIME

Time - µs

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

di/dt - Rate of Rise of Wavefront Current - A/µs

0

10

20

30

40

50

60

70

80

AI6XAZ

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

IMPULSE

R1

CURRENT

ΩΩΩΩ

50

Hi

I

, I

T

F

S1

±1960 V

ECAT WITH E502 0.5/700 SURGE NETWORK

R1 = ONE SECTION OF A PBR 530 01/1 LPC LINE

RESISTOR NETWORK

Figure 3. TEST CIRCUIT FOR MEASUREMENT OF LIMITING VOLTAGE

E502 0.5/700 WAVEFRONT CURRENT

vs

TIME

20

15

10

15

25

ΩΩΩΩ

20 nF20 µF

AI6XAY

ΩΩΩΩ

VOLTAGE

Lo

LIMITING

, V

V

K

F

220 nF

Th4

Th5

DUT

(TISPPBL2S)

V

I

GG

G

-50 V

(V

)

BAT

AI6XBAS

i - Wavefront Current - A

5

0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

Time - µs

Figure 4. CURRENT WAVEFRONT Figure 5. CURRENT WAVEFRONT di/dt

PRODUCT INFORMATION

5

Page 6

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

THERMAL INFORMATION

PEAK NON-RECURRING A.C.

vs

CURRENT DURATION

10

RING AND TIP CONNECTIONS Equal I

GROUND CONNECTION Curren t is twice I

values were applied to both

TSM

TSM

V

GEN

R

GEN

VG = -48 V, T

value

= 600 Vrms

= 70 to 950

AMB

TI6LACA

Ω

Ω

Ω Ω

= 85°C

- Peak Non-Recurrent 50 Hz Current - A

TSM

1

I

0·1 1 10 100 1000

t - Current Duration - s

Figure 6.

PRODUCT INFORMATION

6

Page 7

0

DISTRIBUTION LIMITS OF

DIODE FORWARD VOLTAGE

vs

TIME

Time - µs

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

V

F

- Forward Voltage - V

0

1

2

3

4

5

6

AI6XAX

50 devices tested from 10 wafer lots

0.5/700 Waveform

I

F

= 20 A

T

A

= 25°C

V

GG

= -50 V

TC61AD

DIODE FORWARD CURRENT

vs

FORWARD VOLTA G E

VF - Forward Voltage - V

0.5 0.6 0.7 0. 8 0.9 1.0 1.1 1.2

I

F

- Forward Current - A

0.02

0.04

0.07

0.2

0.4

0.7

0.01

0.1

1

-40°C25°C

85°C

-10

-20

-30

-40

- Cathode Voltage - V

K

-50

V

TYPICAL CHARACTERISTICS

DISTRIBUTION LIMITS OF

THYRISTOR LIMITING VOLTAGE

vs

TIME

50 devices tested from 10 wafer lots

0.5/700 Waveform

= -20 A

I

T

= 25°C

T

A

= -50 V

V

GG

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

AI6XAW

-60

-70

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

CUMULATIVE POPULATION %

PEAK LIMITING VOLTAGE

99·999

99·99

0·001

50 devices tested from 10 wafer lots

I

= 20 A, IT = -20 A, 0.5/700 Waveform

F

99·9

Cumulative Populati on - %

0·01

= 25°C, VGG = -50 V

T

A

99

90

70

50

30

10

1

0·1

456789 1510

DIODE

V

FRM

Time - µs

Figure 7. Figure 8.

vs

TC6XAB

THYRISTOR

- V

V

GG

(BO)

Peak Limiting Voltage - V

Figure 9. Figure 10.

PRODUCT INFORMATION

7

Page 8

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

CUMULATIVE POPULATION %

vs

LIMITING TIME

99·999

50 devices tested from 10 wafer lots

99·99

I

= 20 A, IT = -20 A, 0.5/700 Waveform

F

99·9

= 25°C, VGG = -50 V

T

A

99

90

70

50

30

10

1

DIODE t

FR

for VF > 5 V

Outliers

(2) @ 0 µs

THYRISTOR t

for V

(BR)

Cumulative Population - %

0·1

0·01

0·001

0.001 0.01 0.1 1

t

(BR)

0.004 0.04 0.4

, tFR - Breakdown and Forward Recovery Times - µs

Figure 11. Figure 12.

< V

TC6XAC

(BR)

GG

NORMALISED PEAK LIMITING VOLTAGES

vs

JUNCTION TEMPERATURE

1.10

Normalised to 25°C values

and V

of V

(BO)

IF = 20 A, IT = -20 A

0.5/700 Waveform

1.05

V

GG

= -50 V

THYRISTOR

1.00

0.95

DIODE

0.90

-40-30-20-100 1020304050607080

FRM

V

(BO)

V

FRM

TJ - Junction Temperature - °C

TC6XAA

APPLICATIONS INFORMATION

operation of gated protectors

Figure 13 and Figure 14 show how the TISPPB L2S limits overvoltages. The TISPPBL2S thyristor section s

limit negative overvoltages and the diode sections limit positive overvoltages.

SLIC

PROTECTOR

SLIC

I

K

AI6XANS

V

PBL2S

GG

TISP

Th5

C1

I

G

V

Bat

D1

C2

I

F

AI6XAOS

Figure 13. NEGATIVE OVERVOLTAGE CONDITION Figure 14. POSITIVE OVERVOLTAGE CONDITION

Negative overvoltages (Figure 13) are initially cl ipped close to the SLIC ne gative supply rail value (V

the conduction of t he transistor base-emi tter and the thyristor g ate-cathode junctio ns. If sufficient curren t is

SLIC

PROTECTOR

Th5

TISP

PBL2S

V

C1

GG

D1

SLIC

V

C2

Bat

) by

BAT

PRODUCT INFORMATION

8

Page 9

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

available from the overvoltage, then the thyristor will crowbar into a low voltage ground referenced on-state

condition. As the overvoltage subsides the high holding current of the crowbar thyristor prevents d.c. latchup.

The negative protection voltage will be the sum of the gate supply (V

voltage (V

). Under a.c. overvoltage conditions V

GK(BO)

will be less than 3 V. The integrated transistor

GK(BO)

) and the peak gate(terminal)-cathode

BAT

buffer in the TISPPBL2S greatly reduces protectors source and sink current loading on the V

Without the transistor, the thyristor gate current would charge the V

supply. An electronic power supply is

BAT

not usually designed to b e charged like a batter y. As a result , the electronic supp ly would switch off and the

thyristor gate current would provide the SL IC supply current. Nor mally the SLIC current wou ld be less than

the gate current, which would cause the supply voltage to increase and destroy the SLIC by a supply

overvoltage. The integrated transistor buffer removes this problem.

Fast rising impulses will cause short term overshoots in gate-cathode voltage. The negative protection

voltage under impulse conditions will also be increased if there is a long connection between the gate

decoupling capacitor, C1, and the gate terminal. During the initial rise of a fast impulse, the gate current (I

the same as the cathode current (I

). Rates of 60 A/µs can cause inductive voltages of 0.6 V in 2.5 cm o f

K

printed wiring track. To minimise this inductive voltage increase of protection voltage, the length of the

capacitor to gate ter minal tracking should be minimised. Inductive voltages in the protec tor cathode wiring

can increase the protection voltage. These voltages can be minimised by routing the SLIC connection via the

protector as shown in Figure 13 and Figure 14.

Positive overvoltages (Figure 14) are clipped to ground by forward conduction of the diode section in the

TISPPBL2S. Fast rising impulses will cause short term overshoots in forward voltage (V

FRM

).

TISPPBL2S limiting voltages

This clause details the TISPPBL2S voltage limiting levels under impulse conditions.

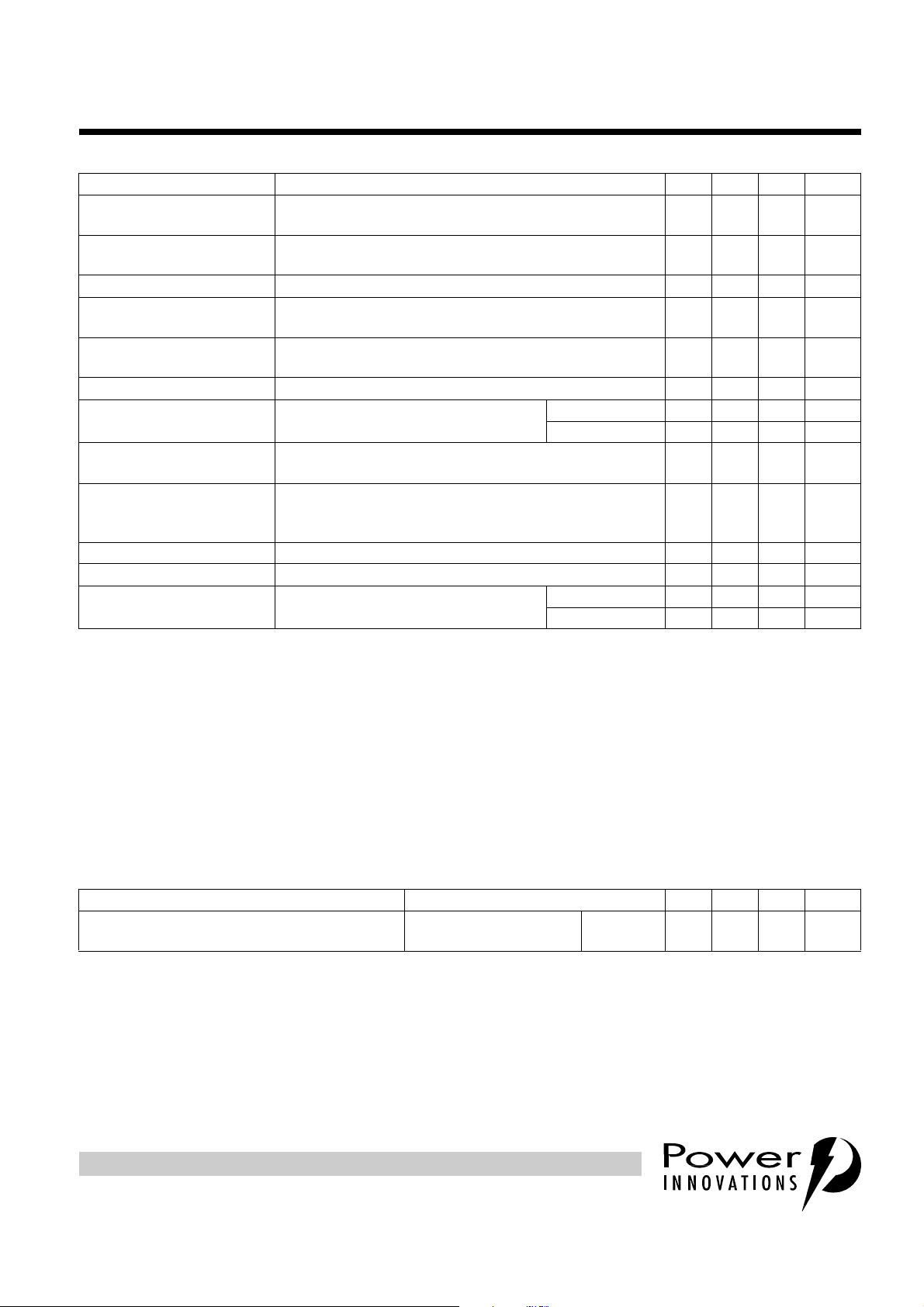

test circuit

Figure 3 shows the basic test circuit used for the measurement of impulse limiting voltage. During the

impulse, the high levels of electrical en er gy and rapid rates of change cause electrical noise to be i ndu ce d or

conducted into the me asurement system. It i s possible for the electrical nois e voltage to be many times the

wanted signal voltage. Elaborate wiring and measurement techniques where used to reduce the noise

voltage to less than 2 V peak to peak.

BAT

supply.

) is

G

impulse generator

A Keytek ECAT E-Class series 100 wi th an E 502 surge networ k was used for testing. The E 502 pro duces a

0.5/700 voltage impulse. This particular waveform was used as it ha s the fastest rate of curren t r ise (di/dt) o f

the commonly used lightning surge waveforms. This maximises the measured limiting voltage. Figure 4

shows the current wavefront through the DUT. To produce a peak test current level of ±20 A, the E502

charging voltage was set to ±1960 V. Figure 5 shows the DUT current di/dt. Initially the wavefront current rises

at 60 A/µs, this rate then reduces as the peak current is approached. At the TISPPBL2S V

condition the

(BO)

di/dt is about 50 A/µs.

limiting voltage levels

Fifty devices were measured in the test circ uit of Figure 3. The 50 devices were made up from groups of 5

devices taken from 10 separately processed device lots. Figure 7 shows the total waveform variation of the

thyristor limiting voltage acr oss the 50 devices. This shows t hat the largest peak limiting voltage (Bre akover

volt a ge, V

exceeds the gate reference supply voltage level for a period (t

) is -62 V, a 12 V overshoot beyond the -50 V gate reference supply, VGG. The limiting voltage

(BO)

) of about 0.4 µs.

(BR)

PRODUCT INFORMATION

9

Page 10

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

Figure 9 and Figure 11 s how these two waveform parameters in ter ms of device pop ulation. In Fig ure 9, the

limiting voltage is shown in terms of the overshoot bey ond the gate reference supply (V

the gate reference voltage level magnifies the thyristor limiting voltage variation and shows the data

stratification caused by the osci ll os co pe di git isati on. Ex trapolating the data tren d ind ic ate s that th e overshoot

is less than 14 V at the 99.9 97% level (equal to 30 ppm of the populatio n exceeding 14 V, equivalent to +4

sigma point of a nor mal distr ibution). In Figure 11, extrapolating the thyristor data trend to the 99.997 % level

indicates a maximum breakdown time, t

, of 0.5 µs. Figure 12 shows that inc reasing the temperature up to

(BR)

85°C increase s the thyristor p eak limiting voltage by 2.4%, giving a maximum 85° C peak limiting voltage of

1.024x(-50-14) = -65.5 . Over the -40°C to 85°C temperature range the TISPPBL2S is sp ecified to have a

maximum V

value of -70 V and a breakdown time, t

(BO)

(BR)

, of 1 µs.

Figure 8 shows the total waveform variation of the d iode limiting voltage across the 50 devices. The peak

limiting voltage (Peak Forward Recovery Voltage V

) is less than 6 V, and this value includes the 2 V of

FRM

magnetically indu ced noise in the probe. Figure 9 shows that extrapolated 99.997% level is about 5.5 V. In

Figure 11, extrapolating the diode da ta trend to the 99.997% level indicates a maximum forward recovery

time, t

, of 0.1 µs. Figure 12 indicates that there is about a 10% uplift by increasing the temperature to 85°C.

FR

This gives a maximum 85°C peak limitin g voltage of 1.1x(5.5) = 6.1 V. Over the -40°C to 85°C temperature

range, the TISPPBL2S is specified to have a maximum V

value of 8 V and a maximum forward recovery

FRM

time of 1 µs.

GG

- V

(BO)

). Removing

Diodes do not switch to a much lower voltage like thyristors, so the diode limiting voltage applies for the whole

impulse duration. Forward voltages of 1 V or less are nor mally considered safe. Figure 10 shows that the

lowest current 1 V condition occurs a t -40°C with a c urrent of 0.3 A. Wh en the TIS PPBL 2S is tes ted w ith the

rated 10/1000 impulse it would take about 8 ms for the current to decay from 30 A to 0.3 A. Over the -40°C to

85°C temperature range, the TISPPBL2S is specified to have a V

below 1 V within 10 ms.

F

SLIC protection requirements

This clause discusses the various requirements of the Ericsson Components SLICs detailed on the first page

of this data sheet and co mpares these to the TISPPBL2 S protector parameters. Some SLICs are rated for

0°C to 70°C operation, others for -40°C to 85°C operation. The TISPPBL2S protector is specified for -40°C to

85°C operation and so covers both temperature ranges.

normal operation

Depending on the SLIC type, the maximum SLIC supply voltage rating (V

-85V rating of the TISPPBL2S gate-cathode (V

) matches the highest SLIC voltage rating.

GKRM

To restore normal op eration after the TISP PBL2S has switched on, the minimum switch-off curr ent (holding

current I

) needed is equal to the maximum SL IC short circuit current to ground (d.c. line current together

H

with the maximum longitudinal current). For the SLICs listed on the first page of this data sheet, the

TISPPBL2S minimum holding current of 140 mA will ensure switch-off after an overvoltage.

overvoltage protection

Ericsson Com ponents specify SL IC withstand capabi lity as a serie s of stress-tim e values. Figure 15 shows

the voltage withstand limits of the PBL 3762A SLIC.

) will be -70 V, -80 V or -85 V. The

Bat

In the positive polar ity, the PBL 3762A RING or TIP voltage must not exceed +1 5 V. For 250 ns, the PBL

3762A will be able to w ithstand a voltage between +1 0 V and +15 V. For 1 µs, the PBL 379 6 will be able to

withstand a voltage between +5 V and +10 V. For 10 ms, the PBL 3796 will be able to withstand a voltage

between +2 V and +5 V. To protect against positive overvoltage, the TISPPBL2S positive limiting voltage must

be equal to or less than these voltage values during the specified time periods.

PRODUCT INFORMATION

10

Page 11

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

PBL 3762A SLIC RING AND TIP VOLTAGE WITHSTAND

vs

- 70 V

V

BAT

TIME

- 40 V

Time

V

BAT

V

- 20 V

BAT

D.C. and 10 ms pulse rating increased

to -70 V (independent of V

by use of series battery feed diode

value)

BAT

AI6XBC

15

10

5

0

set to -50 V) - V

-50

BAT

-60

-70

-80

-90

Voltages (with V

-100

-110

-120

0.25 µs

1 µs

10 ms

10 ms

1 µs

0.25 µs

V

BAT

Figure 15. TRANSIENT LIMITS FOR PBL 3762A WITHSTAND VOLTAGE

In the negative polarity, the PBL 3762 A RING or TIP voltage must not exceed V

PBL 3762A can withstand a V

drawn for a V

of -50 V and so that the peak voltage becomes -120 V.

BAT

For 250 ns, the PBL 3762A will be able to withst and a voltage between V

of -70 V and this implies a maximum peak voltage of -140 V. Figure 15 is

BAT

-40V and V

BAT

and -120 V in this case. For 1 µs, the PBL 3796 will be a ble to withstand a voltage between V

V

-40 V or -70 V and -90 V in this case. For 10 ms, the PBL 379 6 will be able to withstand a voltage

BAT

between V

BAT

and V

-20 V o r -50 V and -70 V in this case. By adding a ser ies feed diode in the battery

BAT

feed the d.c. and 10 ms voltage withstands increase to -70 V, independent of the actual V

- 70. Continuously the

BAT

-70V or -90V

BAT

BAT

-20V and

BAT

valu e.To protect

against negative overvoltage, the TISP PBL2S negative limitin g voltage must be equal t o or less than thes e

voltage values during the specified time periods.

The following table lists the protection requiremen ts of three sel ections from different SLIC families. Two, the

PBL 3796 and the PBL 3762A, specify voltage withstand. The PBL 3796 specifies the negative voltages in

absolute term s and the P BL 3762A s pecifies th e negative voltages in ter ms of voltage rel ative to the batter y

supply voltage, V

BAT

.

Tertiary protection is incorporated in the PBL 386 20/1 SLIC and the withstand is specified in terms of current

into this protection. This type of SLIC al so has more ti me periods specified for the curre nt withstand values.

To co-ordinate the SLIC external secondar y protection (TISPPBL2S) and the inter nal tertiar y protection, a

series resistor, R

withstand current through resistor R

required limiting voltage level of the TISPPBL2S. A suitable value for R

, is required between the two. The tertiary protection will develop about 1 V and the

P

will also develop a voltage. The sum of these voltages will determine the

P

is 2Ω.

P

The negative limiting voltage of the TISPPBL2S is def ined as a 1 µs, -20 V pulse below the batter y voltage

(Figure 2). This value does not exceed any of the voltage withstand levels listed in the SLIC withstand table. In

the positive polarity the TIS PBL2S limits the maximum voltage to 8 V in a 1 µs per iod and between 1 V an d

5 V for a 10 ms period. These values do not exceed the values listed in the SLIC withstand table.

PRODUCT INFORMATION

11

Page 12

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

SLIC withstand comparison

SLIC PBL 3796 PBL 3762A PBL 386 20/1

CONDITION V V V V A A

continuous

pulse < 10 ms

pulse < 1 ms

pulse < 10 µs

pulse < 1 µs

pulse < 250 ns

Notes: 1. These voltage rating require a diode to be installed in series with the V

, RF2 ≥ 20Ω is also required. Pulse supplied to TIP and RING outside RF1, R

2. R

F1

3. A diode in series with the V

A pulse ≤ 1 µs is increased to the greater of |-70 V| or |V

, RF2 ≥ 20Ω is also required. Pulse supplied to TIP and RING outside RF1, R

4. R

F1

5. Pulse is applied to TIP and RING outside RP1 and R

6. Permitted continuous voltage for V

-70

Note 1

-70

Note 1

-90

Note 1

-120

Note 1, 2

+1

Note 1

+5

Note 1

+10

Note 1

+15

Note 1, 2

input increases the permitted continuous voltage and pulse < 10 ms to -70 V.

Bat

is -75 V

Bat

V

(-70 V)

Bat

Note 3

- 20

V

Bat

Note 3

- 40

V

Bat

Note 3

V

- 70

Bat

Note 4

P2

Bat

+2

+5

+10

+15

- 40 V|

Bat

pin.

-0.1

Note 6

-2

Note 5

-5

Note 5

-15

Note 5

-20

Note 5

-20

Note 5

F2

F2

+0.1

+2

Note 5

+5

Note 5

+15

Note 5

+20

Note 5

+20

Note 5

A graphical representation is shown in Figure 16. In the positive polarity, the three line types correspond to the

three SLIC types discussed (R

is 2Ω for the PBL 386 20/1). The two shaded areas represent th e positive

P

and negative maximum limiting voltage levels of the TISPPBL2S as per Figure 2. The negative voltage

withstand capability of the three SLICs is shown relative to their maximum rated battery supply voltage,

V

. Figure 16 shows that the TISPPBL2S maximum limiting voltage levels do not exceed the SLIC voltage

BATM

withstand ratings.

application circuit

Figure 17 shows a typical TISPPB L2S SLIC card protection ci rcuit. The incoming line conduc tors, R and T,

connect to the relay matrix via the series over-current protection. Fusible resistors, fuses and positive

temperature coefficient (PTC) resistors can be used for over-current protection. Resistors will reduce the

prospective current from the surge generator for both the TISPPBL2S and the ring/test protector. The

TISP7xxxF3 protector has the sam e pr otection voltage for any ter mina l pair. This protector i s used when t he

ring generator configuration may be ground or battery-backed. For dedicated ground-backed ringing

generators, the TISP3xxxF3 gives better protection as its inter-conductor protection voltage is twice the

conductor to ground value.

Relay contacts 3a and 3b conn ect the line conductors to the SLIC via the TISPPBL2S protector. Closing

contacts 3a and 3b connects the TISP PBL2 S protector in parallel wi th the r ing/test protec tor. As the ring/test

protector requires much higher voltages than the TISPPBL2S to operate, it will only operate when the

contacts 3a and 3b are open. Both protectors will divert the same levels of peak surge current and their

PRODUCT INFORMATION

12

Page 13

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

TIP

WIRE

PBL 3xxx SLIC VOLTAGE WITHSTAND

AND TISPPBL2S VOLTAGE LIMITING

vs

TIME

PBL 386 20/1

PBL 386 20/1

V

V

V

V

V

V

V

Voltage - V

BATM

BATM

BATM

BATM

BATM

BATM

BATM

V

40

30

20

10

BATM

- 10

- 20

- 30

- 40

- 50

- 60

- 70

PBL 3762A

PBL 3796

TISPPBL2S

0

1 ms

10 µs

1 µs

0.25 µs

TISPPBL2S

PBL 3796

PBL 3762A

Figure 16. SLIC VOLTAGE WITHSTAND AND TISPPBL2S PROTECTION LEVELS

OVER-

CURRENT

PROTECTION

R1a

RING/TEST

PROTECTION

Th3

Th1

TEST

RELAY

S1a

RING

RELAY

S2a

SLIC

RELAY

S3a

PROTECTION

SLIC

AI6XBDS

R

P

Th4

Time10 ms

PBL

3xxx

SLIC

RING

WIRE

R1b

TISP

3xxxF3

OR

7xxxF3

Th2

S1b

TEST

EQUIP-

MENT

S2b

RING

GENERATOR

S3b

TISP

PBL2S

RP IS USED WHEN THE SLIC

HAS TERTIARY PROTECTION

Th5

R

C1

220 nF

P

V

AI6XAPS

Figure 17. TYPICAL APPLICATION CIRCUIT

required current ratings should be simila r. The TISPPBL2S protector gate reference voltage comes fr om the

SLIC negative supply (V

). A 220 nF gate capacitor sources the high gate current puls es caused by fast

BAT

rising impulses. When the SLIC has internal tertiary protection (e.g. PBL 386 21/1), then the two R

need to be added for protection co-ordination.

PRODUCT INFORMATION

BAT

resistors

P

13

Page 14

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

MECHANICAL DATA

D008

plastic small-outline package

This small-outline pa ckage consists of a circuit mo unted on a lead frame an d encapsulated with in a plastic

compound. The compound will withstand soldering temperature with no deformation, and circuit performance

characteristics will remain stable when operated in high humidity conditions. Leads require no additional

cleaning or processing when used in soldered assembly.

D008

6,20 (0.244)

5,80 (0.228)

1,75 (0.069)

1,35 (0.053)

4,00 (0.157)

3,81 (0.150)

8

1

7° NOM

3 Places

5,00 (0.197)

4,80 (0.189)

765

432

0,50 (0.020)

0,25 (0.010)

x 45°NOM

Designation per JEDEC Std 30:

PDSO-G8

5,21 (0.205)

4,60 (0.181)

0,203 (0.008)

0,102 (0.004)

0,79 (0.031)

0,28 (0.011)

ALL LINEAR DIMENSIONS ARE IN MILLIMETERS AND PARENTHETICALLY IN INCHES

NOTES: A. Leads are within 0,25 (0.010) radius of true position at maximum material condition.

B. Body dimensions do not include mold flash or protrusion.

C. Mold flash or protrusion shall not exceed 0,15 (0.006).

D. Lead tips to be planar within ±0,051 (0.002).

Pin Spacing

1,27 (0.050)

(see Note A)

6 Places

0,51 (0.020)

0,36 (0.014)

8 Places

0,229 (0.0090)

0,190 (0.0075)

PRODUCT INFORMATION

14

7° NOM

4 Places

1,12 (0.044)

0,51 (0.020)

4° ± 4°

MDXXAA

Page 15

TISPPBL2SD

PROGRAMMABLE OVERVOLTAGE PROTECTORS

FOR ERICSSON COMPONENTS PBL 3xxx SLICS

AUGUST 1999

IMPORTANT NOTICE

Power Innovations Limited (PI) reserves the right to make changes to its products or to discontinue any semiconductor product

or service without notice, and advises its customers to verify, before placing orders, that the information being relied on is

current.

PI warrants performance of its semiconductor products to the specifications applicable at the time of sale in accordance with

PI's standard wa rrant y. Testing and o t he r qu al ity c ontrol techniques are utilis ed to the extent PI deems necessary to support this

warranty. Specific testing of all parameters of each device is not necessarily performed, except those mandated by government

requirements.

PI assumes no liability for applications assistance, customer product design, software performance, or infringement of patents

or services described herein. Nor is any license, either express or implied, granted under any patent right, copyright, design

right, or other intellectual property right of PI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used.

PI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, INTENDED, AUTHORISED, OR WARRANTED TO BE SUITABLE

FOR USE IN LIFE-SUPPORT APPLICATIONS, DEVICES OR SYSTEMS.

Copyright © 1999, Power Innovations Limited

PRODUCT INFORMATION

15

Loading...

Loading...