Page 1

PROGRAMMABLE SLIC OVER VOLTAGE PROTECTION FOR LSSGR ‘1089

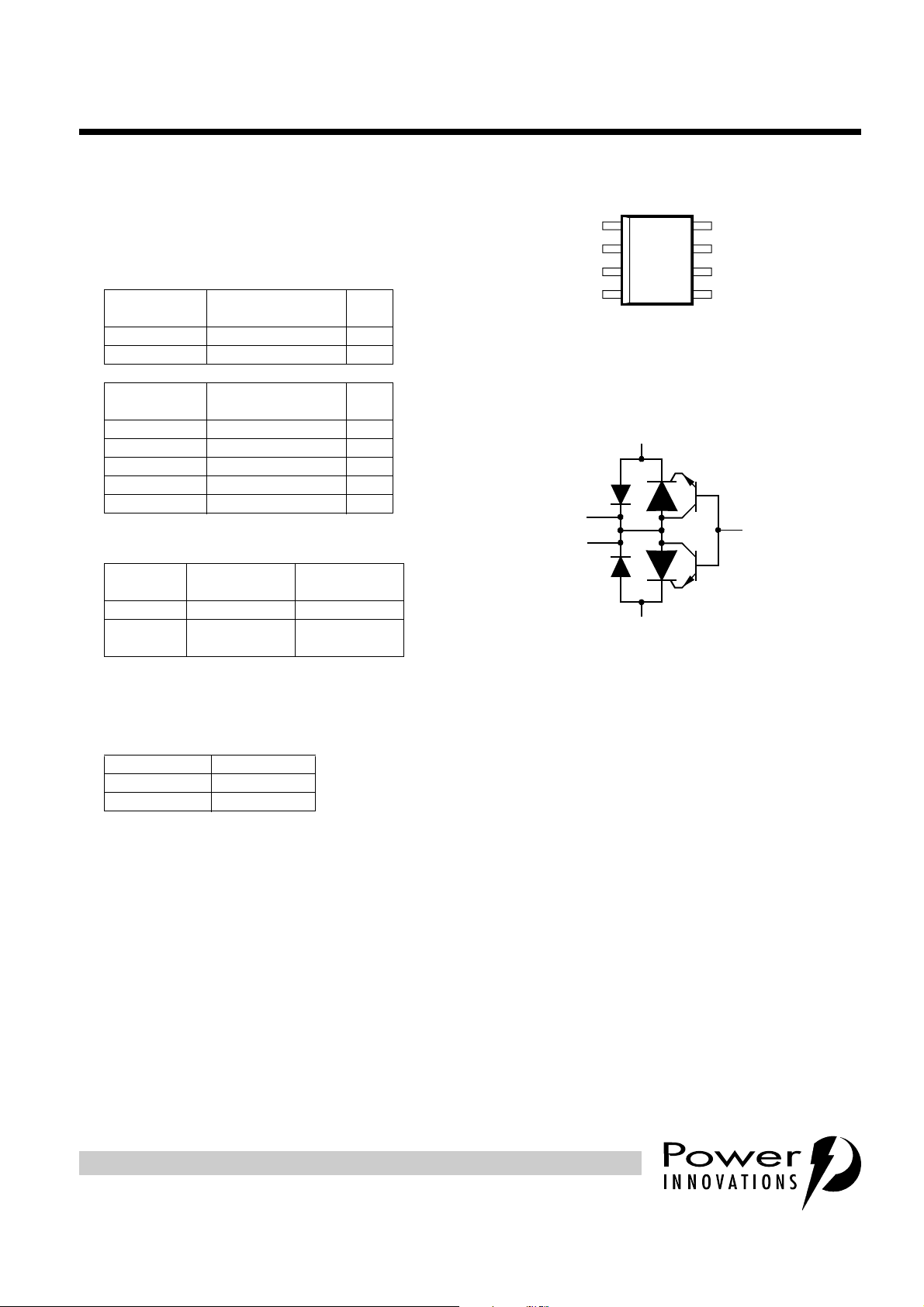

device symbol

●

Dual Voltage-Programmable Protectors

- Wide 0 to -85 V Programming Range

- Low 5 mA max. Gate Triggering Current

- High 150 mA min. Holding Current

●

Rated for LSSGR ‘1089 Conditions

WAVE SHAPE

2/10 µs 4.5.8 Second-Level 1 120

10/1000 µs 4.5.7 First-Level 3 30

‘1089 TEST CLAUSE

AND TEST #

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

D PACKAGE

(TOP VIEW)

I

TSP

(Tip)

(Gate)

K1

G

NC

(Ring)

A

K2

NC - No internal connection

Terminal typical application names shown in

1

2

3

4

parenthesis

8

NC

7

A

(Ground)

6

A

(Ground)

5

NC

MD6XBA

JULY 1999Copyright © 1999, Power Innovations Limited, UK

60 Hz POWER

FAULT TIME

100 ms 4.5.13 Second-Level 2 11

1 s 4.5.13 Second-Level 2 4.5

5 s 4.5.13 Second-Level 2 2.4

300 s 4.5.13 Second-Level 1 0.95

900 s 4.5.13 Second-Level 1 0.93

●

2/10 Protection Voltage Specified

ELEMENT

Diode 6 8

Crowbar

= -48 V

V

GG

●

Also Rated for ITU-T 10/700 impulses

●

Small Outline Surface Mount Package

- Available Ordering Options

CARRIER ORDER #

Tube TISP61089SD

Taped and reeled TISP61089SDR

‘1089 TEST CLAUSE

AND TEST #

FIRST-LEVEL

V @ 56 A

-57 -60

I

TSM

A

SECOND-LEVEL

V @ 100 A

K1

A

A

K2

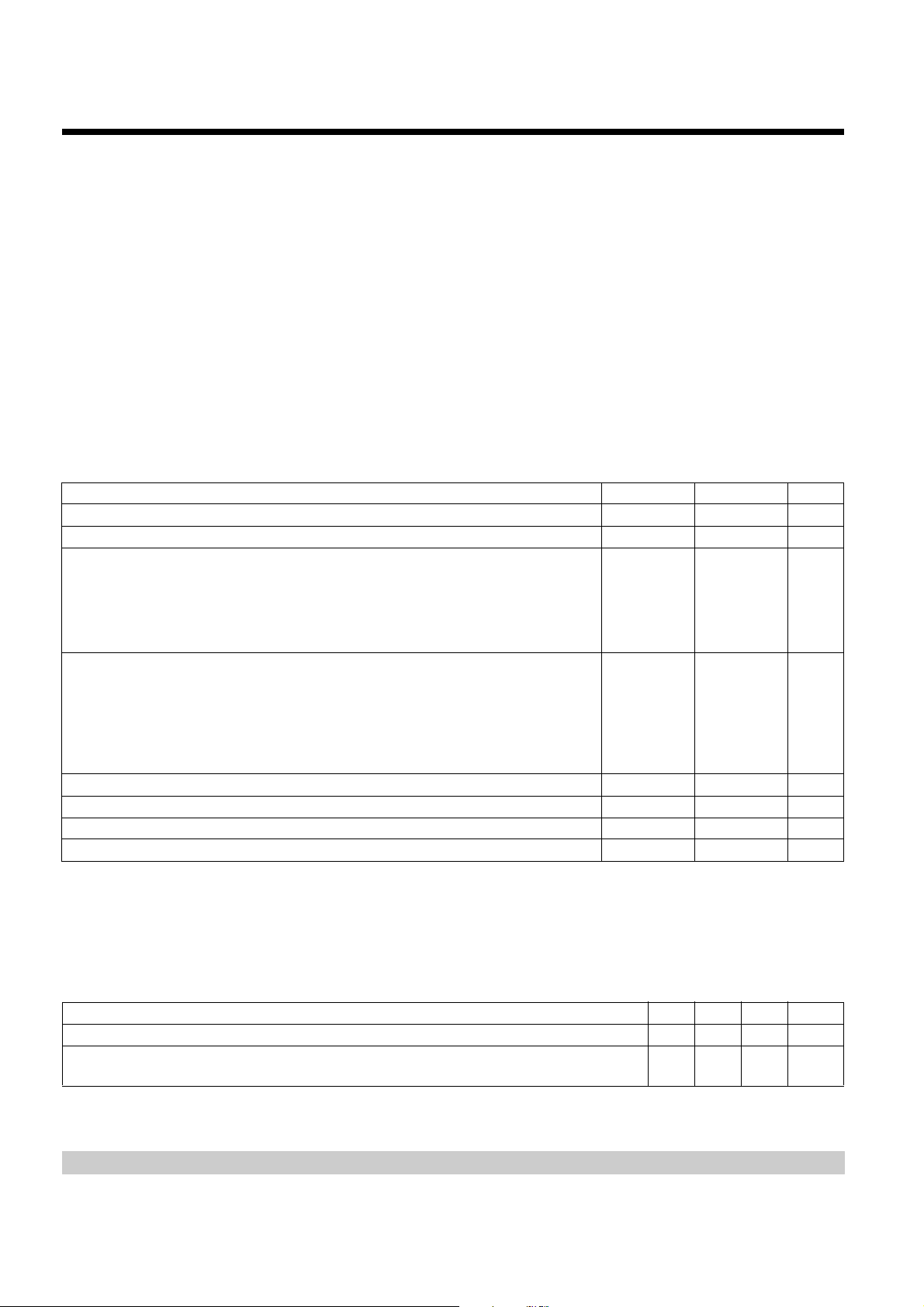

Termin als K1, K2 and A correspond to the alternative

line designators of T, R and G or A, B and C. The

negative protection voltage is controlled by the

voltage, V

●

Single-Lead Line Connection Version of

applied to the G terminal.

GG,

G1,G2

Feed-Through TISP61089D

- Ground Lead Creepage Distance . . > 3 mm

description

The TISP61089S is a dual forward-conduct ing buffered p-gate overvoltage protec tor. It is designed to p rotec t

monolithic SLICs (Sub scriber Line Interface Circui ts) against overvoltages on the telepho ne line caused by

lightning, a.c. power contact a nd indu ction. The TISP6 1089S l imits voltages tha t exceed the SLIC s upply rail

voltage. The TISP61089S parameters are specifi ed to allow equipment compliance wi th Bellcore GR-1089CORE, Issue 1.

SD6XAP

PRODUCT INFORMATION

Information is current as of publication date. Products conform to specifications in accordance

with the terms of Power Innovations standard warranty. Production processing does not

necessarily include testing of all parameters.

The SLIC line driver section is typically powered from 0 V (ground) and a negative voltage in the region of

-10 V to -75 V. The protector gate is connected to this negative supply. This references the protection

(clipping) voltage to the negat ive supply voltage. As the p rotecti on voltage will th en track the negati ve supply

voltage the overvoltage stress on the SLIC is minimised.

Positive overvoltages are cli pped to ground by diode forward conducti on. Negative overvoltages are init ially

clipped close to the SLIC negative supply rail value. If sufficient current is available from the overvoltage, then

1

Page 2

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

the protector will c rowbar in to a l ow voltage on-state cond ition. As the overvoltage sub side s the hi gh hol ding

current of the crowbar prevents d.c. latchup.

The TISP61089S is intended to be used with a ser ies combination of a 25Ω or higher resistance and a

suitable overcurrent protector. Power fault compliance requires the serie s overcurrent element to open- cir cuit

or become high impedance (see Applications Information). For equipment compliant to ITU-T

recommendations K20 or K21 only, the series resistor value is set by the power cross requirements. For K20

and K21, a minimum series resistor value of 10Ω is recommended.

These monolithic prote ction devices are fabricated in ion-implanted planar vertic al power structures for high

reliability and in normal system operation they are virtually transparent. The TISP61089S buffered gate

design reduces the loading on the SLIC supply dur ing overvoltages caused by power cross and induction.

The TISP61089S is the TISP61089D with a different pinout . The feed-through Ring (leads 4 — 5) and Tip

(leads 1 — 8) connection s have been replaced by single Ring (lead 4) and Tip (lead 1) connections. This

increases package creepage distance of the biased to ground connections from about 0.7 mm to over

3 mm.

absolute maximum ratings

RATING SYMBOL VALUE UNIT

≤

Repetitive peak off-state voltage, I

Repetitive peak gate-cathode voltage, V

Non-repetitive peak on-state pulse current (see Notes 1 and 2)

10/1000 µs (Bellcore GR-1089-CORE, Issue 1, November 1994, Section 4)

5/320 µs (ITU-T recommendation K20 & K21, open-circuit voltage wave shape 10/700)

1.2/50 µs (Bellcore GR-1089-CORE, Issue 1, November 1994, Section 4, Alternative) 100

2/10 µs (Bellcore GR-1089-CORE, Issue 1, November 1994, Section 4) 120

Non-repetitive peak on-state current, 60 Hz (see Notes 1 and 2)

0.1 s 11

1s

5s

300 s

900 s

Non-repetitive peak gate current, 1/2 µs pulse, cathodes commoned (see Notes 1 and 2) I

Operating free-air temperature range T

Junction temperature T

Storage temperature range T

= 0, -40°C≤T

G

= 0, -40°C≤T

KA

85°C V

J

≤

85°C V

J

DRM

GKRM

I

TSP

I

TSM

GSM

A

J

stg

-100 V

-85 V

30

40

4.5

2.4

0.95

0.93

40 A

-40 to +85 °C

-40 to +150 °C

-40 to +150 °C

A

A

NOTES: 1. Initially the protector must be in thermal equilibrium with -40°C≤T

its initial conditions.

2. The rated current values may be applied either to the Ring to Ground or to the Tip to Ground ter minal pairs. Additionally, both

terminal pairs may have their rated current values applied simultaneously (in this case the Ground terminal current will be twice the

rated current value of an individual terminal pair). Above 85°C, derate linearly to zero at 150°C lead temperature.

recommended operating conditions

C

Gate decoupling capacitor 100 220 nF

G

TISP61089S series resistor for first-level and second-level surge survival

R

S

TISP61089S series resistor for first-level surge survival

PRODUCT INFORMATION

2

≤

85°C. The surge may be repeated after the device returns to

J

MIN TYP MAX UNIT

40

25

Ω

Page 3

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

electrical characterist ics, TJ = 25°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

D

V

V

V

I

H

I

GKS

I

GT

V

Q

C

(BO)

F

FRM

GT

GS

AK

Off-state current VD=V

2/10 µs, I

Breakover voltage

2/10 µs, I

1.2/50 µs, I

1.2/50 µs, I

, IG=0

DRM

=-56A, RS=45

T

= -100 A, RS=50

T

= -53 A, RS=47

T

= -96 A, RS=52

T

Ω,

VGG=-48V, CG= 220 nF

Ω,

VGG=-48V, CG= 220 nF

Ω,

VGG=-48V, CG= 220 nF

Ω,

VGG=-48V, CG= 220 nF

Forward voltage IF= 5 A, tw= 200 µs 3V

Ω,

VGG=-48V, CG= 220 nF

Ω,

VGG=-48V, CG= 220 nF

Ω,

VGG=-48V, CG= 220 nF

Ω,

VGG=-48V, CG= 220 nF

Peak forward recovery

voltage

2/10 µs, I

2/10 µs, I

1.2/50 µs, I

1.2/50 µs, I

=56A, RS=45

F

= 100 A, RS=50

F

=53A, RS=47

F

=96A, RS=52

F

Holding current IT= -1 A, di/dt = 1A/ms, VGG= -48 V -150 mA

Gate reverse current VGG=VGK=V

Gate trigger current IT= 3 A, t

Gate trigger voltage IT= 3 A, t

p(g)

p(g)

GKRM

≥

20 µs, V

≥

20 µs, V

, VKA=0

=-48V 5 mA

GG

=-48V 2.5 V

GG

Gate switching charge 1.2/50 µs, IT=53A, RS=47Ω, VGG= -48 V CG= 220 nF 0.1 µC

Anode-cathode off-

state capacitance

f=1MHz, V

=1V, IG= 0, (see Note 3)

d

T

T

T

T

V

V

TISP61089S

JULY 1999

= 25°C -5 µA

J

= 85°C -50 µA

J

-57

-60

-60

-64

6

8

8

12

= 25°C -5 µA

J

= 85°C -50 µA

J

= -3 V 100 pF

D

=-48V 50 pF

D

V

V

NOTE 3: These capacitance measurements employ a three terminal capacitance bridge incorporating a guard circuit. The unmeasured

device terminals are a.c. connected to the guard terminal of the bridge.

thermal characteristics

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

= 25 °C, EIA/JESD51-3 PCB,

T

R

Junction to free air thermal resistance

θ

JA

A

EIA/JESD51-2 environment, I

= I

T

TSM(900)

105 °C/W

PRODUCT INFORMATION

3

Page 4

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

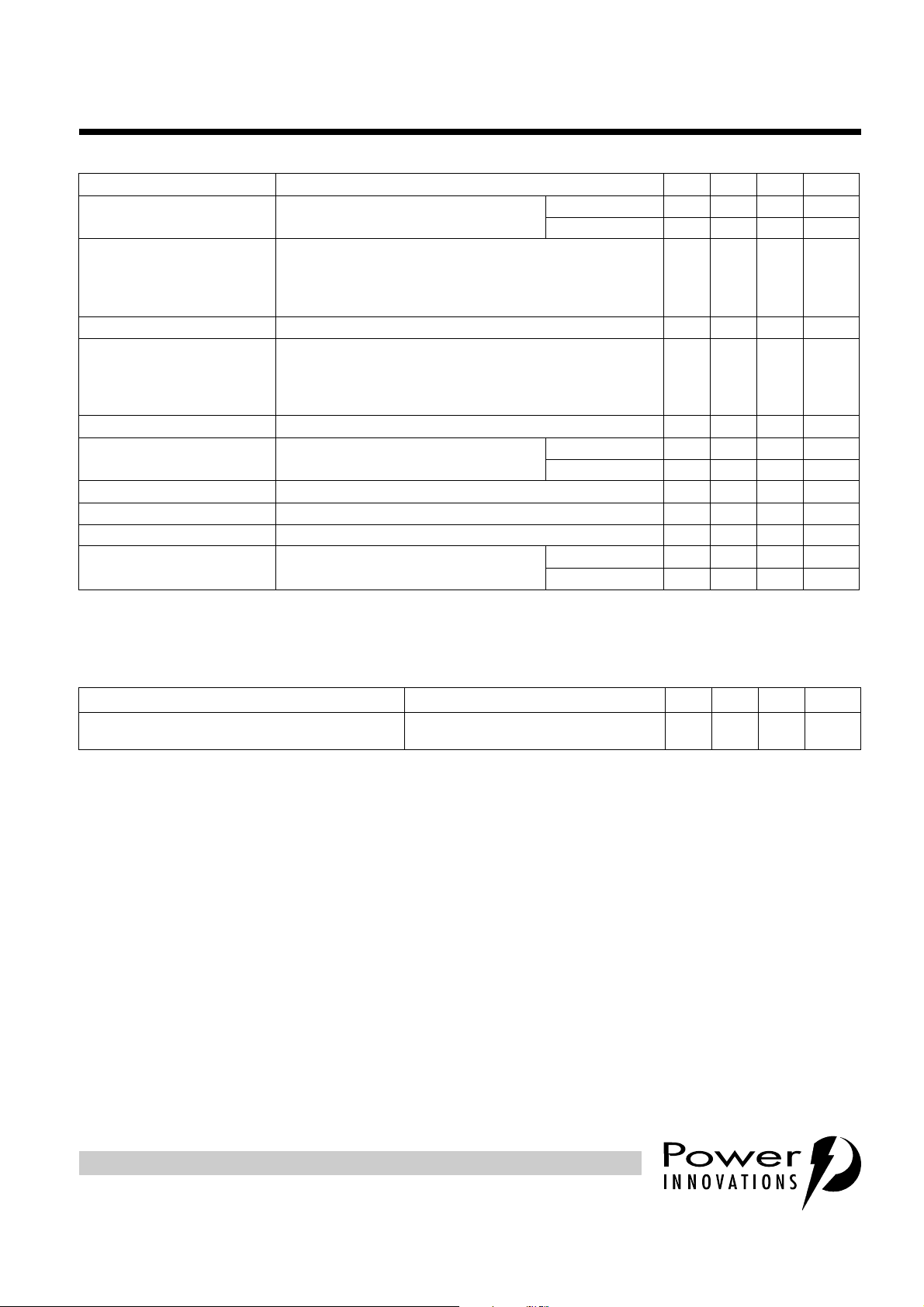

PARAMETER MEASUREMENT INFORMATION

-v

I

(BO)

V

Quadrant III

Switching

Characteristic

V

(BO)

GK(BO)

V

+i

I

(= |I

TSP

|)

FSP

Characteristic

I

(= |I

FSM

GG

I

S

V

S

V

D

|)

TSM

I

F

V

F

I

D

I

H

V

T

I

T

I

TSM

I

TSP

-i

Quadrant I

Forward

Conduction

+v

PM6XAAA

Figure 1. VOLTAGE-CURRENT CHARACTERISTIC

PRODUCT INFORMATION

4

Page 5

10

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

THERMAL INFORMATION

PEAK NON-RECURRING A.C.

vs

CURRENT DURATION

RING AND TIP CONNECTIONS -

applied simultaneously to both

I

TSM

GROUND CONNECTION Return current is twice I

V

GEN

R

GEN

VG = -48 V, T

TSM

= 600 Vrms

= 70 to 950

AMB

TI6LACA

Ω

Ω

Ω Ω

= 85°C

JULY 1999

- Peak Non-Recurrent 60 Hz Current - A

TSM

1

I

0·1 1 10 100 1000

t - Current Duration - s

Figure 2. NON-REPETITIVE PEAK ON-STATE CURRENT AGAINST DURATION

APPLICATIONS INFORMATION

gated protectors

This section covers three topics. Firstly, it is explained why gated protectors ar e n eed ed. S econd, the voltage

limiting action of the protector is described. Third, an example application circuit is described.

purpose of gated protectors

Fixed voltage thyristor overvoltage protectors have been used since the early 1980s to protect monol ithic

SLICs (Subscriber Line Interface Circuits) against overvoltages on the telephone line caused by lightning, a.c.

power contact and induction. As the SLIC was usually powered from a fixed voltage negative supply rail, the

limiting voltage of the protector could als o be a fixed value. The TISP1072F3 is a typical example of a fixed

voltage SLIC protector.

SLICs have become more sophisticated. To minimise power consumption, some designs automatically adjust

the supply voltage, V

supply voltage would be set low, but for long lines, a higher supply voltage would be generated to drive

sufficient line curre nt. The optimum protection for this type of SLIC would be given by a protection voltage

which tracks the SLIC supply voltage. This can be achieved by connecting the protection thyristor ga te to th e

SLIC supply, Figure 3. This gated (programmable) protection arrangement mi nimises the voltage stress on

the SLIC, no matter what value of supply voltage.

, to a value that is just sufficient to drive the requir ed line curre nt. For shor t lines th e

BAT

PRODUCT INFORMATION

5

Page 6

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

TIP

WIRE

ΩΩΩΩ

600

GENERATOR

SOURCE

RESISTANCE

ΩΩΩΩ

600

RING

WIRE

A.C.

GENERATOR

0 - 600 Vrms

50

50

R1

R2

TISP61089S

ΩΩΩΩ

ΩΩΩΩ

Th4

Th5

C1

220 nF

SLIC

SWITCHING MODE

POWER SUPPLY

Tx

I

I

SLIC

G

I

BAT

C2

V

BAT

D1

AI6XAZ

Figure 3. TISP61089S BUFFERED GATE PROTECTOR (SECTION 4.5.12 TESTING CONDITION)

operation of gated protectors

Figures 4. and 5. show how the TISP61089S limit s negati ve and positive overvoltages. Positive overvoltages

(Figure 5) are clipped by the antiparallel di odes in the TISP61089S and the resulti ng current is diverted to

ground. Negative overvoltages (Figure 4.) are initially c lipped close to the SLIC negative supply rail value

(V

). If sufficient current i s available from the overvoltage, then the protector (Th5) wil l crowbar into a low

BAT

voltage on-state conditio n. As the overvoltage subsi des th e high holding curren t of the crowbar prevents d.c.

latchup. The protection voltage will be th e sum of the gate s upply (V

(V

). The protection voltage wi ll be increased if the re i s a l ong c on nec tio n bet ween th e gate d ec oup li ng

GK(BO)

capacitor, C1, and the gate terminal. During the in iti al rise of a fast impulse, the gate cur rent ( I

as the cathode current (I

). Rates of 70 A/µs can cause inductive voltages of 0.7 V in 2.5 cm of printed wiring

K

) and the peak gate-cathode voltage

BAT

) is the same

G

track. To minimise this inductive voltage increase of protection voltage, the length of the capacit or to gate

terminal tracking should be minimised. Inductive voltages in the protector cathode wiring will also increase the

protection voltage. These voltages can be minimised by routing the line to SLIC connection via the protector.

I

K

AI6XBZ

SLIC

PROTECTOR

Th5

TISP

61089S

C1

220 nF

SLIC

I

F

I

G

V

BAT

AI6XCA

SLIC

PROTECTOR

Th5

TISP

61089S

C1

220 nF

SLIC

V

BAT

Figure 4. NEGATIVE OVERVOLTAGE CONDITION Figure 5. POSITIVE OVERVOLTAGE CONDITION

PRODUCT INFORMATION

6

Page 7

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

In Figure 6, the positive gate char ge (QGS) is about 0.1 µC which, with the 0.1 µF gate de couplin g capaci tor

used, increased the gate supply by about 1 V (= Q

volt age, V

. This increas e does not directly add to the protection voltage as the supply vo ltage change

BAT

reaches a maximum at 0.4 µs wh en the gat e curre nt reverses polarity; wher eas t he prot ection voltage peaks

at 0.3 µs. In Figure 6, the peak clamping voltage (V

supply voltage. This 5.5 V increase is the sum of the supply rail increase at that time, (0.5 V), and the

protection circuits cath ode diode to supp ly rail breakover voltage (5 V). In practice, use of the recommende d

220 nF gate decoupling capacitor would give a supply rail increase of 0.25 V and a V

-77.25 V.

0

-20

/C1). This change is just visible on the -72 V gate

GS

) is -77.5 V, an increase of 5.5 V on the nom inal gate

(BO)

value of about

(BO)

V

-40

Voltage - V

-60

-80

0.0 0.5 1.0 1.5

1

Q

GS

0

-1

-2

Current - A

-3

-4

-5

0.0 0.5 1.0 1.5

K

Time - µs

Time - µs

I

G

V

BAT

I

K

Figure 6. PROTECTOR FAST IMPULSE CLAMPING AND SWITCHING WAVEFORMS

application circuit

Figure 7 shows a typical TIS P61089S SLIC card prote ction circuit. The incoming line conductors, Ring (R)

and Tip (T), connect to the relay matrix via the series overcurrent protection. Fusible resistors, fuses and

positive temperature coefficient (PTC) r esistors can be used for overcurrent protection. Resisto rs will reduc e

the prospective current from the surge generator for both the TISP61089S and the ring/test protec tor. The

TISP7xxxF3 protector ha s the same pro tectio n voltage for any ter minal pair. This protector is use d when the

ring generator configuration may be ground or battery-backed. For dedicated ground-backed ringing

generators, the TISP3xxxF3 gives better protection as its inter-conductor protection voltage is twice the

conductor to ground value.

PRODUCT INFORMATION

7

Page 8

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

TIP

WIRE

RING

WIRE

OVER-

CURRENT

PROTECTION

R1a

R1b

RING/TEST

PROTECTION

Th1

Th3

Th2

TISP

3xxxF3

OR

7xxxF3

TEST

RELAY

S1a

S1b

TEST

EQUIP-

MENT

RING

RELAY

S2a

S2b

RING

GENERATOR

SLIC

RELAY

S3a

S3b

SLIC

PROTECTOR

Th4

Th5

TISP

61089S

C1

220 nF

SLIC

V

BAT

AI6XCB

Figure 7. TYPICAL APPLICATION CIRCUIT

Relay contacts 3a and 3b connect the line conductors to the SLIC via the TISP61089S protector. The

protector gate reference voltage comes from the SLIC negative supply (V

). A 220 nF gate capacitor

BAT

sources the high gate current pulses caused by fast rising impulses.

LSSGR 1089

GR-1089-CORE, “1089”, covers electromagnetic compatibility and electrical safety generic criteria for US

network telecommunica tion equipment. It is a module in Volume 3 of LSSGR (LATA (Local Ac cess Transport

Area) Switching Sy stems G ener ic Requ irements, FR- NWT-000064 ). In 1 089 s urge and power fault immunity

tests are done at two levels. After first-level testing the equipment shall not be damaged and shall continue to

operate correctly. Under second level testing the equipment shall not become a safety hazard. The equipment

is permitted to fail as a result of second-level testing. When the equipment is to be located on customer

premises, second-level testing incl udes a wiri ng simulator test, whic h requires the equ ipment to reduce t he

power fault current below certain values.

The following clauses reference the 1089 section a nd calculate the protector stress levels. The TISP61089S

is specified for use with a 4 0Ω series resistor. This resistor value will ensure that the TISP61089S sur vives

second level surge testing. Values down to 25Ω may be used if some second level surge failure is

acceptable. All the tabulated values are for a ser i es r esis tan ce of 40Ω. Peak current values for a 25Ω series

resistor are covered in the clause text.

The values of protector current are calculated fr om the open circuit generator voltage divide d by the sum of

the total circuit resistance. The total circuit resistance is the sum of the generator fictive source resistance and

the TISP61089S series resistor value. Most generators have multiple outputs and each output connects to an

individual line conductor. For those generators that have a single output, each conductor will have an effective

generator fictive source resistance of n times the generator fictive source resistance, where n is the number of

conductors simultaneou sl y tes ted.

PRODUCT INFORMATION

8

Page 9

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

section 4.5.7 - first-level surge testing

The two most significant test wave shapes in this section are the high energy 10/1000 and the high current

2/10. As shown in table 1, the peak currents for these surges are 2x20 A and 2x56 A respectively. The

protector must sur vive the 2x20 A 10/1000 surge an d the TISP61089S will do this as its rating is 2x30 A.

When both conductors are surged simultaneously the return (anode) current will be 40 A, again the

TISP61089S will survive this as its rating for this condition will be 60 A. Similarly the TISP61089S will survive

the 2x56 A 2/10 as its rating is 2x120 A.

table 1. first-level surge currents

GENERATOR

WAVE SHAPE

2/10 2500 500 5 45 2x56

OPEN-CIRCUIT

VOLTAGE

V

SHORT-CIRCUIT

CURRENT

A

FICTIVE

SOURCE

RESISTANCE

Ω

TOTAL CIRCUIT

RESISTANCE

Ω

JULY 1999

I

T

A

1.2/50, 8/20

(See Text)

10/360 1000 100 10 50 2x20

10/1000 600 100 6 46 2x13

10/1000 1000 100 10 50 2x20

The highest protectio n voltage will b e for the 56 A 2/10 wave shape. Under this condit ion the average rate of

current rise will be 56/2 = 28 A/µs. The value of diode and thyristor voltage under this condition is specified in

the electrical characteristics.

Compared to TR-NWT-0010 89, Issue 1, October 1 991, GR- 1089-CORE, Issue 1, November 1994, adds th e

alternative of using the IEEE C62.41 1.2/50-8/20 combination wave generator for the 2/10 test. This generator

usually has a sin gle ou tput and a fic tive resista nce of 2Ω. The 2/10 generator has a fictive output res ista nce

5Ω, (2500/500), and GR-1089-CORE compensates for this by adding an extra 3Ω in the output of the 1.2/508/20 generator. In practice, the extra 3Ω causes the prospective short-circuit current wave shape to be similar

to the 1.2/50 open-cir cuit voltage wave shape. The TISP61089S w ill s urvive the 2x53 A 1.2/50 as i ts rating is

2x100 A.

Using a 25Ω series resistor will result in table 1. I

TISP61089S will survive these peak current values as they are lower than the TISP61089S ratings.

section 4.5.8 - second-level surge testing

This is a 2/10 wave shape test. As shown in table 2, the peak current for this surge is 2x100 A. The

TISP61089S will survive the 2x100 A 2/10 surge as its rating is 2x120 A.

2500 360 4 + 3 47 2x53

column values of 2x83, 2x78 , 2x 29, 2x 19 a nd 2x 29. Th e

T

Under this condition the average rate of current r is e will be 1 00/2 = 50 A/µs. The value of dio de and thyr istor

voltage under this condition is specified in the electrical characteristics.

Compared to TR-NWT-0010 89, Issue 1, October 1 991, GR- 1089-CORE, Issue 1, November 1994, adds th e

alternative of using the IEEE C62.41 1.2/50-8/20 combination wave generator for the 2/10 test. The 2/10

generator has a fictive output resistance 10Ω, (5000/500), and GR-1089-CORE compensates for this by

adding an extra 8Ω in the output of the 1.2/50-8/20 generator. In practice, the extra 8Ω causes the

PRODUCT INFORMATION

9

Page 10

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

table 2. second-level surge current

WAVE SHAPE

2/10 5000 500 10 50 2x100

1.2/50, 8/20

(See Text)

prospective shor t-cir cuit curr ent wave shape to be similar to the 1.2/ 50 open- circuit voltage wave shape. The

TISP61089S will survive the 2x96 A 1.2/50 as its rating is 2x100 A.

Using a 25Ω series resistor will result in table 2. I

fail at these peak current values as they are higher than the TISP61089S ratings.

section 4.5.9 - Intra-building surge testing

These tests use a 2/10 wave shape. As shown in table 3, the peak currents for this test are 2x27 A and 17 A.

The TISP61089S can survive both these levels as its rating is 2x120 A.

OPEN-CIRCUIT

VOLTAGE

V

5000 420 4 + 8/conductor 52 2x96

SHORT-CIRCUIT

CURRENT

A

column values of 2x143 and 2x135. The TISP61089S may

T

GENERATOR

FICTIVE

SOURCE

RESISTANCE

Ω

TOT AL

CIRCUIT

RESISTANCE

Ω

table 3. intra-building surge currents

GENERATOR

WAVE SHAPE

OPEN-CIRCUIT

VOLTAGE

V

SHORT-CIRCUIT

CURRENT

A

FICTIVE

SOURCE

RESISTANCE

Ω

TOTAL CIRCUIT

RESISTANCE

Ω

I

T

A

I

T

A

2/10 1500 100 15 55 2x27

800 100 8 48 17

1.2/50, 8/20

(See Text)

Compared to TR-NWT-001089, Issue 1, October 1991, GR-1089-CORE , Issue 1, November 1994, the 2/10

alternative of using a CCITT Recommendation K.22 1.2/50-8/20 combination wave generator has been

changed to an IEEE C 62.41 1.2/50-8/20 gen erator. This generator usually has a singl e output and a fictive

resistance of 2Ω. The 2/10 generator has fictive output resistances of 15Ω and 8Ω. GR-1089-CORE

compensates for this by adding an extra resistances of 12Ω and 6Ω in the output of the 1.2/50-8/20

generator. In practice, this extra resistance causes the pros pective shor t-circuit current wave shape to be

similar to the 1.2/50 o pen-circui t voltage wave shape. The TISP61089S will sur vive the 2x27 A 1.2 /50 as its

rating is 2x100 A.

Using a 25Ω series resistor will result in table 3. I

will survive these peak current values as they are lower than the TISP61089S ratings.

1500 94 4 + 12/conduc-

tor

800 100 2 + 6 48 17

column values of 2x38, 24, 2x37 and 24. The TISP61089S

T

56 2x27

PRODUCT INFORMATION

10

Page 11

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

section 4.5.12 - first-level power fault testing

The most significant tests are a long duration (900 s) medium current test and a higher current tests of 60 one

second power applications. As shown in table 4, the peak current s for these tests are 2x0. 37 A and 2x1.3 A

respectively. The TISP6 1089S will sur vive both these conditions as its ratings are 2x0.9 3 A and 2x4.5 A for

these time periods

table 4. first-level power fault currents

JULY 1999

A.C.

DURATION

s

1 200 0.33 600 640 2x0.31 2x0.44

1 400 0.67 600 640 2x0.63 2x0.88

1 600 1 600 640 2x0.94 2x1.3

1 1000 1 1000 1040 2x0.96 2x1.3

900 50 0.33 150 190 2x0.26 2x0.37

900 100 0.17 590 630 2x0.16 2x0.22

Using a 25Ω series resistor will result in table 4. I

2x0.23. The TISP61089S will survive these peak current values as they are lower than the TISP61089S

ratings.

section 4.5.13 - second-level power fault testing

The two most significant test s are a long duration (900 s) medium cu rrent test and a hi gher current 5 s tes t.

As shown in table 5, the peak currents for these tests are 2x17 A and 2x7.7 A respectively. For the

TISP61089S to survive this test, the series current limiting element must operate within 0.1 s and 0.5 s

respectively.

OPEN-CIRCUIT

RMS VOLTAGE

V

SHORT-CIRCUIT

RMS CURRENT

A

SOURCE

RESISTANCE

Ω

column values of 2x0.45, 2x0.9, 2x1.4, 2x1.4, 2x0.4 and

TM

TOTAL CIRCUIT

RESISTANCE

Ω

I

TRMS

A

I

TM

A

table 5. second-level power fault currents

A.C.

DURATION

s

5 600 60 10 50 2x12 2x17

5 600 7 86 126 2x4.8 2x6.8

900 120 25 5 45 2x2.7 2x3.8

900 277 25 11 51 2x5.4 2x7.7

900 100 0.37 273 313 2x0.32 2x0.45

900 300 1.1 273 313 2x0.96 2x1.4

900 600 2.2 273 313 2x1.9 2x2.7

OPEN-CIRCUIT

RMS VOLTAGE

V

SHORT-CIRCUIT

CURRENT

A

SOURCE

RESISTANCE

Ω

TOTAL

CIRCUIT

RESISTANCE

Ω

I

TRMS

A

PRODUCT INFORMATION

I

TM

A

11

Page 12

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

Using a 25Ω series resistor will result in table 5. ITM column values of 2x24, 2x7.7, 2x5.7, 2x11, 2x0.47, 2x1.4

and 2x2.9. The TISP61089S will probably fail for a peak current level of 2x24 A and the series current limiting

element must operate in under 0 .1 s to p revent exceeding the TISP61089S package li mit. For 2x7.7 A, t he

series current limiting element must operate within 0.4 s for TISP61089S survival.

section 4.5.15 - second-level power fault testing with wiring simulator

The purpose of this test is to en sure that the telep hone cable does not become a hazard due to excessive

current. A seri es fuse, typ e MDQ 1-6/10A, si mulates the safe current levels of a telepho ne cable. If this fuse

opens the equipment fails the test. For the equipment to pass, the equipment series overcurrent element must

reduce the curren t to below the MDQ 1-6 /10A fusing level to prevent the simulator operating. The a .c. test

voltage can range from zero to 60 0 V, whic h gives a maximum co nductor current of 10 A. Table 6 shows the

simulator fusing times for three current levels.

table 6. second-level power fault currents with MDQ 1-6/10A fuse

A.C.

DURATION

s

1000 100 5 20 60 1.7 2.4

1000 300 15 20 60 5.0 7.1 30

1000 600 30 20 60 10 14 0.7

Using a 25Ω series resis tor will result in table 6. I

operating times will be ∞, 12 s and 0.4 s respectively

For the equipment to pass thi s test, t he TISP 61089S ser ies current l imiti ng eleme nt must o perate be fore the

MDQ 1-6/10A fusing times shown in table 7.

OPEN-CIRCUIT

RMS VOLTAGE

V

SHORT-

CIRCUIT

CURRENT

A

SOURCE

RESISTANCE

Ω

column values of 2x3.1, 2x 9.4 and 2x19. Simulator

TM

TOTAL

CIRCUIT

RESISTANCE

Ω

I

TRMS

A

I

TM

A

table 7. operating times of MDQ 1-6/10A fuse

TIME TO

OPERATE

s

0.2 17

0.5 12

I

RMS

A

TIME

TO

OPEN

s

∞

19

57

10 6.8

1000 2.5

overcurrent protection

To meet ‘1089, the overcurrent protectio n must be c oordi nate d wit h the r equ irements of sections 4.5.7, 4.5 .8,

4.5.9, 4.5.12, 4.5.13, 4.5 .15 and the TISP61089S. The overcurrent protection must no t fail in the first level

tests of sections 4.5.7, 4.5.9 and 4.5.12. Recoverable overcurrent protectors (e.g. Positive Temperature

Coefficient Resisto rs) may operate dur ing first level testing, but norm al equipm ent wor king must be restor ed

PRODUCT INFORMATION

12

Page 13

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

after the test has ended. The test current levels and their duration are shown in Figure 8. First level tests have

a high source resistance and the current levels are not strongly dependent on the TISP61089S series resistor

value.

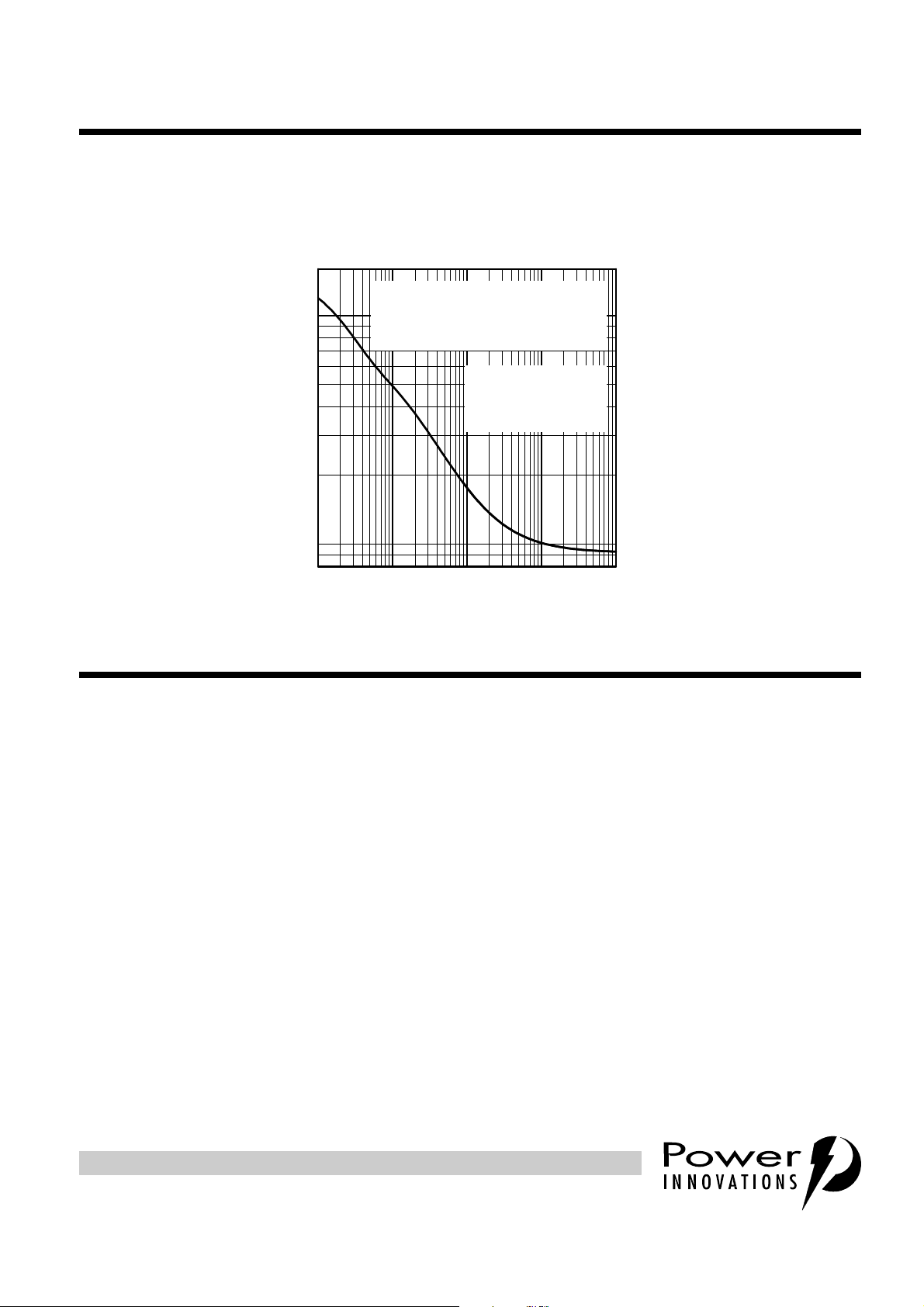

Second level tests have a low source resistan ce and the current levels are dependent on the TISP61089S

series resis tor value. The two stepped lines at the top of Fig ure 8 are for the 25Ω and 40Ω series resistor

cases. If the full current-time duration s occur the equipment will fail the wiring simulator test. The MDQ 1-6/

10A fusing characteristic is also shown in Figure 8. The TISP61089S series overcurrent protection must

operate before the MDQ 1-6/10 A fus es, so th is r ep rese nts a noth er bo und ary condi tio n in the s el ect ion o f th e

overcurrent protector.

MAXIMUM RMS CURRENT

vs

30

20

10

TIME

Second Level Tests - 25

7

5

3

2

Second Level Tests - 40

MDQ 1-6/10A Fuse

AI6XAK

ΩΩΩΩ

ΩΩΩΩ

1

0.7

0.5

Maximum RMS Current - A

0.3

0.2

0.1

0.01 0.1 1 10 100 1000

Time - s

First Level Tests - 25 & 40

ΩΩΩΩ

Figure 8. ‘1089 MAXIMUM TEST CURRENT LEVEL

Figure 9 summaris es these boundar y condition s. The highest current levels that can flow are influe nced by

the TISP61089S seri es resistance. After one second the maximum curren t-time boundary bec omes set by

the MDQ 1-6/10A fusing characteristic. Fusible overcurrent protectors cannot operate at first level current

levels.

Figure 9 shows two other curves. The lower one is the TIS P61089S rated c urrent. The overcurrent p rotector

should not allow current-time d urations greater than thi s otherwise the TIS P61089S may fail. If second level

failure is acceptable then the overcurrent protector

must

operate before the TISP61089S package limit is

reached.

The TISP61089S a.c. ratings are wo rse case values when the device is mounted on the mi nimal sized PCB

used for measuring ther mal resistance. Typical PCBs would give a 25% increase in the rated currents for

periods above 0.1 s.

PRODUCT INFORMATION

13

Page 14

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

OVERCURRENT PROTECTOR OPERATION LIMITS

vs

TIME

Maximum RMS Current - A

30

Second Level Tests - 25

20

10

7

5

3

2

1

0.7

0.5

0.3

0.2

Second Level Tests - 40

ΩΩΩΩ

ΩΩΩΩ

AI6XAL

MDQ 1-6/10A Fuse

TISP61089 Package Limit

TISP61089 Survival

First Level Tests - 25 & 40

ΩΩΩΩ

0.1

0.01 0.1 1 10 100 1000

Time - s

Figure 9. OVERCURRENT PROTECTOR REQUIREMENTS

PRODUCT INFORMATION

14

Page 15

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

MECHANICAL DATA

D008

plastic small-outline package

This small-outline package c onsists of a circuit mounted on a lead frame and encapsulated withi n a plastic

compound. The compound will withstand soldering temperature with no deformation, and circuit performance

characteristics will remain stable when operated in high humidity conditions. Leads require no additional

cleaning or processing when used in soldered assembly.

JULY 1999

D008

6,20 (0.244)

5,80 (0.228)

1,75 (0.069)

1,35 (0.053)

4,00 (0.157)

3,81 (0.150)

8

1

7° NOM

3 Places

5,00 (0.197)

4,80 (0.189)

765

432

0,50 (0.020)

0,25 (0.010)

x 45°NOM

Designation per JEDEC Std 30:

PDSO-G8

5,21 (0.205)

4,60 (0.181)

0,203 (0.008)

0,102 (0.004)

0,79 (0.031)

0,28 (0.011)

ALL LINEAR DIMENSIONS ARE IN MILLIMETERS AND PARENTHETICALLY IN INCHES

NOTES: A. Leads are within 0,25 (0.010) radius of true position at maximum material condition.

B. Body dimensions do not include mold flash or protrusion.

C. Mold flash or protrusion shall not exceed 0,15 (0.006).

D. Lead tips to be planar within ±0,051 (0.002).

Pin Spacing

1,27 (0.050)

(see Note A)

6 Places

0,51 (0.020)

0,36 (0.014)

8 Places

0,229 (0.0090)

0,190 (0.0075)

PRODUCT INFORMATION

7° NOM

4 Places

1,12 (0.044)

0,51 (0.020)

4° ± 4°

MDXXAA

15

Page 16

TISP61089S

DUAL FORWARD-CONDUCTING P-GATE THYRISTORS

PROGRAMMABLE OVERVOLTAGE PROTECTORS

JULY 1999

IMPORTANT NOTICE

Power Innovations Limited (PI) re se rves the r ig ht t o make chan g es t o it s pr od uc ts o r t o di sc ont inu e any s em ic o nduc t or p r o duct

or service without notice, and advises its customers to verify, before placing orders, that the information being relied on is

current.

PI warrants perfor mance of its semiconductor products to the specifications applicable at the time of sale in accordance with

PI's standard w arr anty. Testing and other quality control tec hn iqu es are utilized to th e extent PI deems necessary to support this

warranty. Specific testing of all parameters of each device is not necessarily performed, except those mandated by government

requirements.

PI assumes no liability for applications assistance, customer product design, software performance, or infringement of patents

or services described herein. Nor is any license, either express or implied, granted under any patent right, copyright, design

right, or other intellectual property right of PI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used.

PI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, INTENDED, AUTHORISED, OR WARRANTED TO BE SUITABLE

FOR USE IN LIFE-SUPPORT APPLICATIONS, DEVICES OR SYSTEMS.

Copyright © 1999, Power Innovations Limited

PRODUCT INFORMATION

16

Loading...

Loading...