Page 1

INTEGRATED CIRCUITS

TDF5140A

Brushless DC motor drive circuit

Product specification 1999 March 15

Page 2

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

FEATURES

• Full-wave commutation (using push/pull drivers at the

output stages) without position sensors

• Built-in start-up circuitry

• Three push-pull outputs:

– 0.8 A output current (typ.)

APPLICATIONS

• VCR

• Laser beam printer

• Fax machine

• Blower

• Automotive.

– low saturation voltage

– built-in current limiter

• Thermal protection

• Flyback diodes

• Tacho output without extra sensor

• Position pulse stage for phase-locked-loop control

GENERAL DESCRIPTION

The TDF5140A is a bipolar integrated circuit used to drive

3-phase brushless DC motors in full-wave mode. The

device is sensorless (saving of 3 hall-sensors) using the

back-EMF sensing technique to sense the rotor position.

• Transconductance amplifier for an external control

transistor.

QUICK REFERENCE DATA Measured over full voltage and temperature range.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

V

P

VMOT

supply voltage note 1 4 − 18 V

input voltage to the output

note 2 1.7 − 20 V

driver stages

V

I

DO

LIM

drop-out output voltage IO = 100 mA − 0.93 1.05 V

current limiting V

= 10 V; RO= 3.9 Ω 0.7 0.8 1 A

VMOT

Notes

1. An unstabilized supply can be used.

2. V

= VP; +AMP IN = −AMP IN = 0 V; all outputs IO = 0 mA.

VMOT

ORDERING INFORMATION

PACKAGE

EXTENDED TYPE NUMBER

PINS PIN POSITION MATERIAL CODE

TDF5140A 18 DIL plastic SOT102

1999 March 15 2

Page 3

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

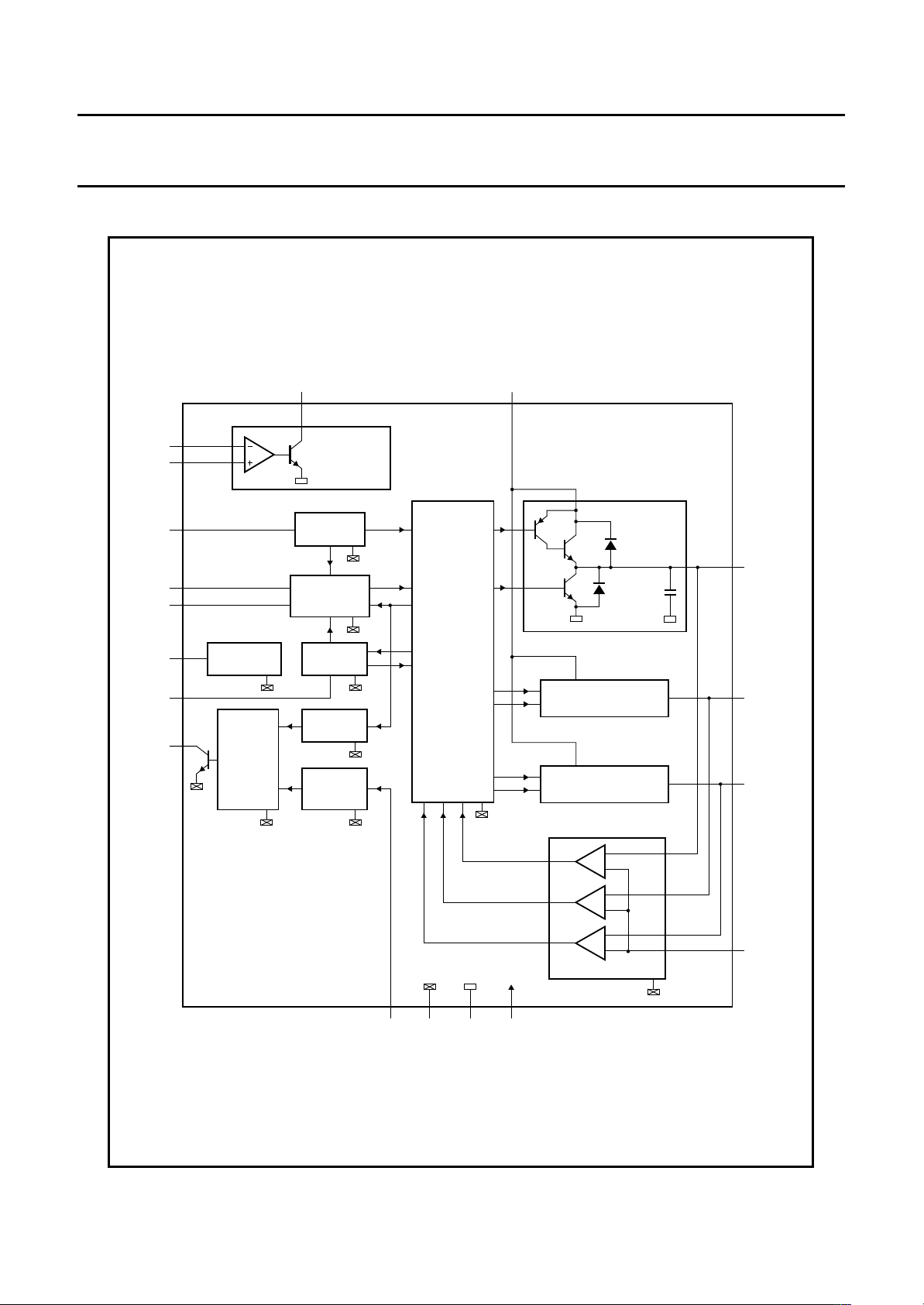

BLOCK DIAGRAM

−AMP IN

+AMP IN

CAP-ST

CAP-DC

CAP-CD

TEST

CAP-TI

PG/FG

13

14

11

10

9

2

PROTECTION

12

6

THERMAL

ROTATION

POSITION

SPEED

&

DETECTOR

OUTPUT

STAGE

AMP OUT

15

CONDUCTANCE

AMPLIFIER

START-UP

OSCILLATOR

ADAPTIVE

COMMUTATION

DELAY

TIMING

DIVIDE

POSITION

DETECTOR

STAGE

TRANS-

BY 2

COMMUTATION

LOGIC

VMOT

4

PUSH/PULL

FLYBACK

D

H

OUTPUT

D

L

DRIVER

STAGE 1

OUTPUT DRIVER

STAGE 2

OUTPUT DRIVER

STAGE 3

1

MOT1

3

MOT2

16

MOT3

TDF5140A

57 8

PGIN GND218GND1 V

Fig.1 Block diagram

1999 March 15 3

P

EMF COMPARATORS

17

MGH313

MOT0

Page 4

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

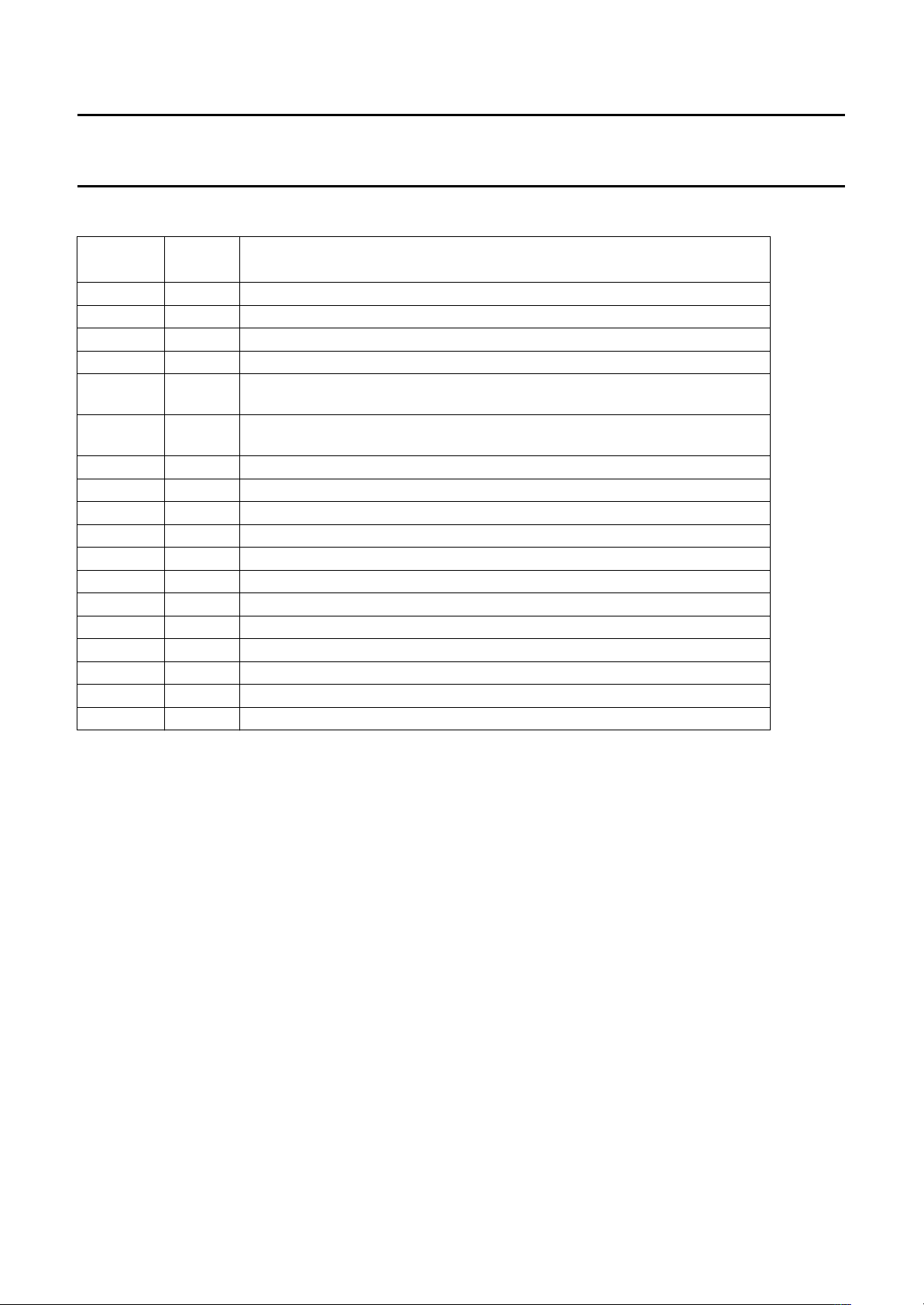

PINNING

SYMBOL

MOT1 1 driver output 1

TEST 2 test input/output

MOT2 3 driver output 2

VMOT 4 input voltage for the output driver stages

PG IN 5 position generator: input from the position detector sensor to the position

PG/FG 6 position generator/frequency generator: output of the rotation speed and position

GND2 7 ground supply return for control circuits

V

P

CAP-CD 9 external capacitor connection for adaptive communication delay timing

CAP-DC 10 external capacitor connection for adaptive communication delay timing copy

CAP-ST 11 external capacitor connection for start-up oscillator

CAP-TI 12 external capacitor connection for timing

+AMP IN 13 non-inverting input of the transconductance amplifier

−AMP IN 14 inverting input of the transconductance amplifier

AMP OUT 15 transconductance amplifier output (open collector)

MOT3 16 driver output 3

MOT0 17 input from the star point of the motor coils

GND1 18 ground (0 V) motor supply return for output stages

PIN

DIL18

detector stage (optional); only if an external position coil is used

detector stages (open collector digital output, negative-going edge is valid)

8 positive supply voltage

DESCRIPTION

1999 March 15 4

Page 5

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

MOT1

TEST

MOT2

VMOT

PG IN

PG/FG

GND2

Vp

CAP-CD

1

2

3

4

5

TDF5140A

6

7

8

9

MGH311

Fig.2 Pin configuration

18

17

16

15

14

13

12

11

10

+AMP IN

CAP-TI

GND1

MOT0

MOT3

AMP OUT

-AMP IN

CAP-ST

CAP-DC

FUNCTIONAL DESCRIPTION

The TDF5140A offers a sensorless three phase motor drive function. It is unique in its combination of sensorless motor

drive and full-wave drive. The TDF5140A offers protected outputs capable of handling high currents and can be used

with star or delta connected motors. It can easily be adapted for different motors and applications. The TDF5140A offers

the following features:

• Sensorless commutation by using the motor EMF.

• Built-in start-up circuit.

• Optimum commutation, independent of motor type or motor loading.

• Built-in flyback diodes.

• Three phase full-wave drive.

• High output current (0.8 A).

• Outputs protected by current limiting and thermal protection of each output transistor.

• Low current consumption by adaptive base-drive.

• Accurate frequency generator (FG) by using the motor EMF.

• Amplifier for external position generator (PG) signal.

• Suitable for use with a wide tolerance, external PG sensor.

• Built-in multiplexer that combines the internal FG and external PG signals on one pin for easy use with a controlling

microprocessor.

• Uncommitted operational transconductance amplifier (OTA), with a high output current, for use as a control amplifier.

1999 March 15 5

Page 6

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

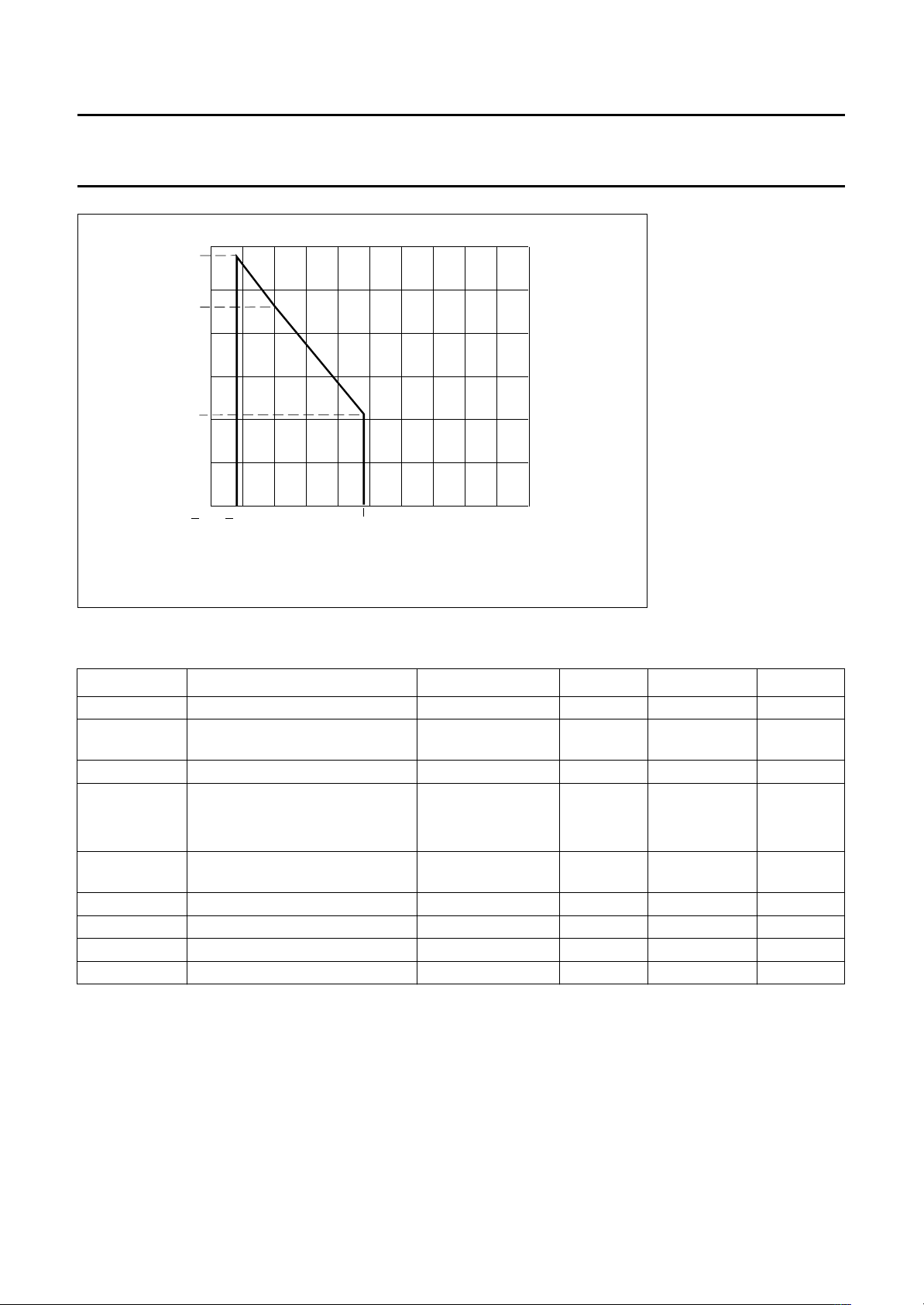

amb

MBD535

o

2.80

P

(W)

tot

2.28

1.05

3

2

0

50

0 200

30

50 100 150

70

T ( C)

Fig.3 Power derating curve (SOT102; DIL18).

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

P

V

I

supply voltage − 18 V

input voltage; all pins except

VI< 18 V −0.3 VP + 0.5 V

VMOT

V

V

V

VMOT

O

I

VMOT input voltage −0.5 20 V

output voltage

AMP OUT and PG/FG GND V

MOT1, MOT2 and MOT3 −1V

input voltage CAP-ST, CAP-TI,

− 2.5 V

P

VMOT

+ V

DHF

CAP-CD and CAP-DC

T

stg

T

amb

P

tot

V

es

storage temperature −55 +150 °C

operating ambient temperature −30 +70 °C

total power dissipation see Fig. 3 −− W

electrostatic handling see “Handling” − 500 V

V

V

HANDLING

Every pin withstands the ESD test in accordance with

“MIL-STD-883C class 2”

3 pulses + and 3 pulses − on each pin referenced to ground.

1999 March 15 6

. Method 3015 (HBM 1500 Ω, 100 pF)

Page 7

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

CHARACTERISTICS

= 14.5 V; T

V

P

=25°C; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

V

I

P

V

P

VMOT

supply voltage note 1 4 − 18 V

supply current note 2 − 3.7 5 mA

input voltage to the output driver

see Fig.1 1.7 − 20 V

stages

Thermal protection

T

SD

local temperature at

130 140 150 °C

temperature sensor causing

shut-down

∆T reduction in temperature before

after shut-down − T

− 30 − K

SD

switch-on

MOT0; centre tap

V

I

I

V

∆V

I

CSW

CSW

input voltage −0.5 − V

input bias current 0.5 V < VI< V

− 1.5 V −10 − 0 µA

VMOT

VMOT

comparator switching level note 3 ±20 ±30 ±40 mV

variation in comparator

−3 0 +3 mV

switching levels

V

hys

comparator input hysteresis − 75 −µV

MOT1, MOT2 and MOT3

V

∆V

DO

OL

drop-out output voltage IO = 100 mA − 0.93 1.05 V

= 500 mA − 1.65 1.80 V

I

O

variation in saturation voltage

IO = 100 mA −− 180 mV

between lower transistors

∆V

OH

variation in saturation voltage

IO = −100 mA −− 180 mV

between upper transistors

I

V

LIM

DHF

current limiting V

diode forward voltage (diode DH)IO = −500 mA; notes 4

= 10 V; RO= 6.8 Ω 0.7 0.8 1 A

VMOT

−− 1.5 V

and 5; see Fig.1

V

DLF

diode forward voltage (diode DL)IO = 500 mA; notes 4 and

−1.5 −−V

5; see Fig.1

I

DM

peak diode current note 5 −− 1A

+AMP IN and −AMP IN

V

I

input voltage −0.3 − VP− 1.7 V

differential mode voltage without

−− ±V

P

'latch-up'

I

b

C

I

V

offset

input bias current −− 650 nA

input capacitance − 4 − pF

input offset voltage −− 10 mV

V

V

1999 March 15 7

Page 8

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

AMP OUT (open collector)

I

I

V

sat

V

O

SR slew rate R

G

tr

PG IN

V

I

I

b

R

I

V

CWS

V

hys

PG/FG (open collector)

V

OL

V

OH(max)

t

THL

δ duty factor − 50 − %

t

PL

CAP-ST

I

sink

I

source

V

SWL

V

SWH

CAP-TI

I

sink

I

source

V

SWL

V

SWM

V

SWH

output sink current 40 −−mA

saturation voltage II = 40 mA − 1.5 2.1 V

output voltage −0.5 − +18 V

= 330 Ω; CL = 50 pF − 60 − mA/µs

L

transfer gain 0.3 −−S

input voltage −0.3 − +5 V

input bias current −− 650 nA

input resistance 5 − 30 kΩ

comparator switching level 86 − 107 mV

comparator input hysteresis −±8− mV

LOW level output voltage IO = 1.6 mA −− 0.4 V

maximum HIGH level output

V

P

−−V

voltage

HIGH-to-LOW transition time CL = 50 pF; RL = 10 kΩ− 0.5 −µs

ratio of PG/FG frequency and

− 1 : 2 −

commutation frequency

pulse width LOW after a PG IN pulse 5 7 18 µs

output sink current 1.5 2.0 2.5 µA

output source current −2.5 −2.0 −1.5 µA

LOW level switching voltage − 0.20 − V

HIGH level switching voltage − 2.20 − V

output sink current − 28 −µA

output source current 0.05 V < V

0.3 V < V

CAP-TI

< 0.3 V −−57 −µA

CAP-TI

< 2.2 V −−5−µA

LOW level switching voltage − 50 − mV

MIDDLE level switching voltage − 0.30 − V

HIGH level switching voltage − 2.20 − V

1999 March 15 8

Page 9

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

CAP-CD

I

sink

I

source

I

sink/Isource

V

IL

V

IH

CAP-DC

I

sink

I

source

I

sink/Isource

V

IL

V

IH

Notes

1. An unstabilized supply can be used.

2. V

VMOT

3. Switching levels with respect to MOT1, MOT2 and MOT3.

4. Drivers are in the high-impedance OFF-state.

5. The outputs are short-circuit protected by limiting the current and the IC temperature.

output sink current 10.6 16.2 22 µA

output source current −5.3 −8.1 −11 µA

ratio of sink to source current 1.85 2.05 2.25

LOW level input voltage 850 875 900 mV

HIGH level input voltage 2.3 2.4 2.55 V

output sink current 10.1 15.5 20.9 µA

output source current −20.9 −15.5 −10.1 µA

ratio of sink to source current 0.9 1.025 1.15

LOW level input voltage 850 875 900 mV

HIGH level input voltage 2.3 2.4 2.55 V

= VP, all other inputs at 0 V; all outputs at VP; IO = 0 mA.

APPLICATION INFORMATION

full pagewidth

GND1

(1) Value selected for 3 Hz

start-up oscillator frequency

(1) Value selected for 3 Hz start-up oscillator frequency.

Fig.4 Application diagram without use of the operational transconductance amplifier (OTA).

(1)

220

10

nF

nF

18 17 16 15 14 13 12 1011

TDF5140A

1234567 98

PGIN

VMOT

10 µF

PG/FG

18 nF

18 nF

V

P

MBK985

1999 March 15 9

Page 10

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

Introduction (see Fig.5)

Full-wave driving of a three phase motor requires three

push-pull output stages. In each of the six possible states

two outputs are active, one sourcing (H) and one sinking

(L). The third output presents a high impedance (Z) to the

motor which enables measurement of the motor

back-EMF in the corresponding motor coil by the EMF

comparator at each output. The commutation logic is

responsible for control of the output transistors and

selection of the correct EMF comparator. In Table 1 the

sequence of the six possible states of the outputs has

been depicted.

Table 1 Output states.

STATE MOT1

(1)

MOT2

(1)

MOT3

(1)

1ZLH

2HLZ

3HZL

4ZHL

5LHZ

6LZH

Note

1. H = HIGH state;

L = LOW state;

Z = high impedance OFF-state.

Because of high inductive loading the output stages

contain flyback diodes. The output stages are also

protected by a current limiting circuit and by thermal

protection of the six output transistors.

The detected zero-crossings are used to provide speed

information. The information has been made available on

the PG/FG output pin. This is an open collector output and

provides an output signal with a frequency that is half the

commutation frequency. A VCR scanner also requires a

PG phase sensor. This circuit has an interface for a simple

pick-up coil. A multiplexer circuit is also provided to

combine the FG and PG signals in time.

The system will only function when the EMF voltage from

the motor is present. Therefore, a start oscillator is

provided that will generate commutation pulses when no

zero-crossings in the motor voltage are available.

A timing function is incorporated into the device for internal

timing and for timing of the reverse rotation detection.

The TDF5140A also contains an uncommitted

transconductance amplifier (OTA) that can be used as a

control amplifier. The output is capable of directly driving

an external power transistor.

The TDF5140A is designed for systems with low current

consumption: use of I2L logic, adaptive base drive for the

output transistors (patented), possibility of using a pick-up

coil without bias current.

The zero-crossing in the motor EMF (detected by the

comparator selected by the commutation logic) is used to

calculate the correct moment for the next commutation,

that is, the change to the next output state. The delay is

calculated (depending on the motor loading) by the

adaptive commutation delay block.

1999 March 15 10

Page 11

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

handbook, full pagewidth

47 kΩ

from

DAC

220 nF

18 nF

18 nF

TEST

10 nF

FG to

micro-

processor

+5 V

4.7

39 kΩ

BY 2

10 kΩ

47 nF

13

1 µF

COMMUTATION

LOGIC

TP

D

TN

D

TN

TP

D

TN

D

TN

TP

D

TN

D

TN

1

3

16

SCANNER

MOTOR

POSITION

COIL

BD434

+14 V

14

11

10

9

2

12

6

kΩ

680 Ω

47 nF

THERMAL

PROTECTION

ROTATION

SPEED/

DETECTOR

OUTPUT

STAGE

470 Ω

120 Ω

15 4 18

START-UP

OSCILLATOR

ADAPTIVE

COMMUTATION

DELAY

TIMING

DIVIDE

POSITION

DETECTOR

STAGE

8

V

P

GND2

GND1

TDF5140A

75

Fig.5 Typical application of the TDF5140A as a scanner driver, with use of OTA.

1999 March 15 11

17

EMF COMPARATORS

MBK986

Page 12

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

Adjustments

The system has been designed in such a way that the

tolerances of the application components are not critical.

However, the approximate values of the following

components must still be determined:

• The start capacitor; this determines the frequency of the

start oscillator.

• The two capacitors in the adaptive commutation delay

circuit; these are important in determining the optimum

moment for commutation, depending on the type and

loading of the motor.

• The timing capacitor; this provides the system with its

timing signals.

HE START CAPACITOR (CAP-ST)

T

This capacitor determines the frequency of the start

oscillator. It is charged and discharged, with a current of

2 µA, from 0.05 to 2.2 V and back to 0.05 V. The time

taken to complete one cycle is given by:

t

= (2.15 × C) s (with C in µF)

start

The start oscillator is reset by a commutation pulse and so

is only active when the system is in the start-up mode. A

pulse from the start oscillator will cause the outputs to

change to the next state (torque in the motor). If the

movement of the motor generates enough EMF the

TDF5140A will run the motor. If the amount of EMF

generated is insufficient, then the motor will move one step

only and will oscillate in its new position. The amplitude of

the oscillation must decrease sufficiently before the arrival

of the next start pulse, to prevent the pulse arriving during

the wrong phase of the oscillation. The oscillation of the

motor is given by:

f

osc

=

1

---------------------------------- K

I× p×

t

2π

---------------------- -

J

where:

= torque constant (N.m/A)

K

t

I = current (A)

p = number of magnetic pole-pairs

J = inertia J (kg.m2)

Example: J = 72 × 10-6kg.m2, K = 25 × 10-3N.m/A, p = 6

and I = 0.5 A; this gives f

= 5 Hz. If the damping is high

osc

then a start frequency of 2 Hz can be chosen or t = 500 ms,

thus C = 0.5/2 = 0.25 µF, (choose 220 nF).

HE ADAPTIVE COMMUTATION DELAY (CAP-CD AND

T

CAP-DC)

In this circuit capacitor CAP-CD is charged during one

commutation period, with an interruption of the charging

current during the diode pulse. During the next

commutation period this capacitor (CAP-CD) is discharged

at twice the charging current. The charging current is

8.1 µA and the discharging current 16.2 µA; the voltage

range is from 0.9 to 2.2 V. The voltage must stay within this

range at the lowest commutation frequency of interest, f

6–

×

8.1 10

==

C

-------------------------f1.3×

6231

------------ f

c1

(C in nF)

C1

If the frequency is lower, then a constant commutation

delay after the zero-crossing is generated by the discharge

from 2.2 to 0.9 V at 16.2 µA.

maximum delay = (0.076 × C) ms (with C in nF)

Example: nominal commutation frequency = 900 Hz and

the lowest usable frequency = 400 Hz, so:

CAP-CD

6231

------------ 400

15.6==

(choose 18 nF)

The other capacitor, CAP-DC, is used to repeat the same

delay by charging and discharging with 15.5 µA. The same

value can be chosen as for CAP-CD. Fig.6 illustrates

typical voltage waveforms.

:

1999 March 15 12

Page 13

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

handbook, full pagewidth

voltage

on CAP-CD

voltage

on CAP-DC

Fig.6 CAP-CD and CAP-DC typical voltage waveforms in normal running mode.

THE TIMING CAPACITOR (CAP-TI)

Capacitor CAP-TI is used for timing the successive steps

within one commutation period; these steps include some

internal delays.

The most important function is the watchdog time in which

the motor EMF has to recover from a negative diode-pulse

back to a positive EMF voltage (or vice versa). A watchdog

timer is a guarding function that only becomes active when

the expected event does not occur within a predetermined

time.

The EMF usually recovers within a short time if the motor

is running normally (<<ms). However, if the motor is

motionless or rotating in the reverse direction, then the

time can be longer (>>ms).

A watchdog time must be chosen so that it is long enough

for a motor without EMF (still) and eddy currents that may

stretch the voltage in a motor winding; however, it must be

short enough to detect reverse rotation. If the watchdog

t

MGH317

time is made too long, then the motor may run in the wrong

direction (with little torque).

The capacitor is charged, with a current of 57 µA, from

0.2 to 0.3 V. Above this level it is charged, with a current of

5 µA, up to 2.2 V only if the selected motor EMF remains

in the wrong polarity (watchdog function). At the end, or, if

the motor voltage becomes positive, the capacitor is

discharged with a current of 28 µA. The watchdog time is

the time taken to charge the capacitor, with a current of

5 µA, from 0.3 to 2.2 V.

To ensure that the internal delays are covered CAP-TI

must have a minimum value of 2 nF. For the watchdog

function a value for CAP-TI of 10 nF is recommended.

To ensure a good start-up and commutation, care must be

taken that no oscillations occur at the trailing edge of the

flyback pulse. Snubber networks at the outputs should be

critically damped.

Typical voltage waveforms are illustrated by Fig.7.

1999 March 15 13

Page 14

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

k, full pagewidth

V

MOT 1

voltage

on CAP-TI

MGH318

If the chosen value of CAP-TI is too small oscillations can occur in certain positions of a blocked rotor. If the chosen value is too large, then it

is possible that the motor may run in the reverse direction (synchronously with little torque).

Fig.7 Typical CAP-TI and V

voltage waveforms in normal running mode.

MOT1

Other design aspects

There are other design aspects concerning the application

of the TDF5140A besides the commutation function. They

are:

• Generation of the tacho signal FG

• A built-in interface for a PG sensor

• General purpose operational transconductance

amplifier (OTA)

• Possibilities of motor control

• Reliability.

SIGNAL

FG

The FG signal is generated in the TDF5140A by using the

zero-crossing of the motor EMF from the three motor

windings. Every zero-crossing in a (star connected) motor

winding is used to toggle the FG output signal. The FG

frequency is therefore half the commutation frequency.

All transitions indicate the detection of a zero-crossing

(except for PG). The negative-going edges are called FG

pulses because they generate an interrupt in a controlling

microprocessor.

The accuracy of the FG output signal (jitter) is very good.

This accuracy depends on the symmetry of the motor's

electromagnetic construction, which also effects the

satisfactory functioning of the motor itself.

Example: A 3-phase motor with 6 magnetic pole-pairs at

1500 rpm and with a full-wave drive has a commutation

frequency of 25 × 6 × 6 = 900 Hz, and generates a tacho

signal of 450 Hz.

PG

SIGNAL

The accuracy of the PG signal in applications such as VCR

must be high (phase information). This accuracy is

obtained by combining the accurate FG signal with the PG

signal by using a wide tolerance external PG sensor. The

external PG signal (PG IN) is only used as an indicator to

select a particular FG pulse. This pulse differs from the

other FG pulses in that it has a short LOW-time of 18 µs

after a HIGH-to-LOW transition. All other FG pulses have

a 50% duty factor (see Fig.8).

For more information also see

EIE/AN 93014”

.

“application note

1999 March 15 14

Page 15

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

dbook, full pagewidth

PG IN

MOT3

PG/FG

tolerance on PG IN

Fig.8 Timing and the FG and PG IN signals.

The special PG pulse is derived from the negative-going

zero-crossing from the MOT3 output (pin 16). The external

PG signal (PG IN on pin 5) must sense a positive-going

voltage (>80 mV) within 1.5 to 7.5 commutation periods

before the negative-going zero-crossing in MOT3

(see Fig.8).

The voltage requirements of the PG IN input are such that

an inexpensive pick-up coil can be used as a sensor

(see Fig.9).

Example: If p = 6, then one revolution contains 6 × 6=36

commutations. The tolerance is 6 periods, that is 60

degrees (mechanically) or 6.67 ms at 1500 rpm.

2.2 kΩ

22 nF

MBD696

MGH319

PG IN

GND2

If a PG sensor is not used, the PG IN input must be

grounded, this will result in a 50% duty factor FG signal.

1999 March 15 15

Fig.9 Pick-up coil as PG sensor.

Page 16

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

THE OPERATIONAL TRANSCONDUCTANCE AMPLIFIER (OTA)

The OTA is an uncommitted amplifier with a high output

current (40 mA) that can be used as a control amplifier.

The common mode input range includes ground (GND)

and rises to VP− 1.7 V. The high sink current enables the

OTA to drive a power transistor directly in an analog

control amplifier.

Although the gain is not extremely high (0.3 S), care must

be taken with the stability of the circuit if the OTA is used

as a linear amplifier as no frequency compensation has

been provided.

The convention for the inputs (inverting or not) is the same

as for a normal operational amplifier: with a resistor (as

load) connected from the output (AMP OUT) to the positive

supply, a positive-going voltage is found when the

non-inverting input (+AMP IN) is positive with respect to

the inverting input (−AMP IN). Confusion is possible

because a 'plus' input causes less current, and so a

positive voltage.

M

OTOR CONTROL

DC motors can be controlled in an analog manner using

the OTA.

R

ELIABILITY

It is necessary to protect high current circuits and the

output stages are protected in two ways:

• Current limiting of the 'lower' output transistors. The

'upper' output transistors use the same base current as

the conducting 'lower' transistor (+15%). This means

that the current to and from the output stages is limited.

• Thermal protection of the six output transistors is

achieved by each transistor having a thermal sensor

that is active when the transistor is switched on. The

transistors are switched off when the local temperature

becomes too high.

It is possible, that when braking, the motor voltage (via the

flyback diodes and the impedance on VMOT) may cause

higher currents than allowed (>0.6 A). These currents

must be limited externally.

For the control an external transistor is required. The OTA

can supply the base current for this transistor and act as a

control amplifier.

1999 March 15 16

Page 17

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

PACKAGE OUTLINES

seating plane

3.9

3.4

0.85

max

22.00

21.35

3.7

4.7

max

max

0.51

min

2.54

(8x)

1.4 max

18

1

0.53

max

10

9

0.254 M

6.48

6.14

0.32 max

8.25

7.80

7.62

9.5

8.3

MSA259

Dimensions in mm.

Fig.10 18-pin dual in-line; plastic (SOT102).

1999 March 15 17

Page 18

Philips Semiconductors Product specification

Brushless DC motor drive circuit TDF5140A

SOLDERING

Plastic dual in-line packages

Y DIP OR WAVE

B

The maximum permissible temperature of the solder is 260 °C; this temperature must not be in contact with the joint for

more than 5 s. The total contact time of successive solder waves must not exceed 5 s.

The device may be mounted up to the seating plane, but the temperature of the plastic body must not exceed the

specified storage maximum. If the printed-circuit board has been pre-heated, forced cooling may be necessary

immediately after soldering to keep the temperature within the permissible limit.

EPAIRING SOLDERED JOINTS

R

Apply the soldering iron below the seating plane (or not more than 2 mm above it). If its temperature is below 300 °C, it

must not be in contact for more than 10 s; if between 300 and 400 °C, for not more than 5 s.

1999 March 15 18

Page 19

Philips Semiconductors Product specification

TDF5140ABrushless DC motor drive circuit

Data sheet status

Product

Data sheet status

Objective

specification

Preliminary

specification

Product

specification

[1] Please consult the most recently issued data sheet before initiating or completing a design.

[2] The product status of the device(s) described in this data sheet may have changed since this data sheet was published. The latest information is available on the Internet at URL

http://www.semiconductors.philips.com.

[1]

status

Development

Qualification

Production

[2]

Definitions

Short-form specification — The data in a short-form specification is extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 60134). Stress above one

or more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or

at any other conditions above those given in the Characteristics sections of the specification is not implied. Exposure to limiting values for extended

periods may affect device reliability.

Application information — Applications that are described herein for any of these products are for illustrative purposes only. Philips

Semiconductors make no representation or warranty that such applications will be suitable for the specified use without further testing or

modification.

Disclaimers

Life support — These products are not designed for use in life support appliances, devices or systems where malfunction of these products can

reasonably be expected to result in personal injury . Philips Semiconductors customers using or selling these products for use in such applications

do so at their own risk and agree to fully indemnify Philips Semiconductors for any damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to make changes, without notice, in the products, including circuits, standard

cells, and/or software, described or contained herein in order to improve design and/or performance. Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no license or title under any patent, copyright, or mask work right to these

products, and makes no representations or warranties that these products are free from patent, copyright, or mask work right infringement, unless

otherwise specified.

Contact information

For additional information please visit

http://www.semiconductors.philips.com . Fax: +31 40 27 24825

For sales offices addresses send e-mail to:

sales.addresses@www.semiconductors.philips.com.

Definitions

This data sheet contains data from the objective specification for product development.

Philips Semiconductors reserves the right to change the specification in any manner without notice.

This data sheet contains data from the preliminary specification. Supplementary data will be

published at a later date. Philips Semiconductors reserves the right to change the specification

without notice, in order to improve the design and supply the best possible product.

This data sheet contains data from the product specification. Philips Semiconductors reserves the

right to make changes at any time in order to improve the design, manufacturing and supply.

Changes will be communicated according to the Customer Product/Process Change Notification

(CPCN) procedure SNW-SQ-650A.

Koninklijke Philips Electronics N.V. 1999

All rights reserved. Printed in U.S.A.

Date of release: 03-99

Document order number: 9397 750 08754

yyyy mmm dd

1

Loading...

Loading...