Page 1

INTEGRATED CIRCUITS

DATA SH EET

TDA7040T

Low voltage PLL stereo decoder

Product specification

File under Integrated Circuits, IC01

September 1986

Page 2

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

GENERAL DESCRIPTION

The TDA7040T is a monolithic integrated circuit for low cost FM stereo radios with an absolute minimum of peripheral

components and a simple lay-out.

Features

• Built-in four pole low pass filter with a 70 kHz corner frequency suppressing unwanted out-of-band input signals

• Fully integrated 228 kHz oscillator

• Pilot presence detector and soft mono/stereo blend

• Built-in interference suppression

• External stereo lamp driver applicable

• Adjustable gain.

QUICK REFERENCE DATA

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

Supply voltage (pin 4) V

Supply current V

= 3 V I

P

P

P

Total harmonic distortion THD − 0,3 − %

Signal to noise ratio S/(S + N) − 70 − dB

Channel separation α−40 − dB

1,8 − 6V

− 3 − mA

PACKAGE OUTLINE

8-lead mini-pack; plastic (S08; SOT96A); SOT96-1; 1996 July 24.

September 1986 2

Page 3

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

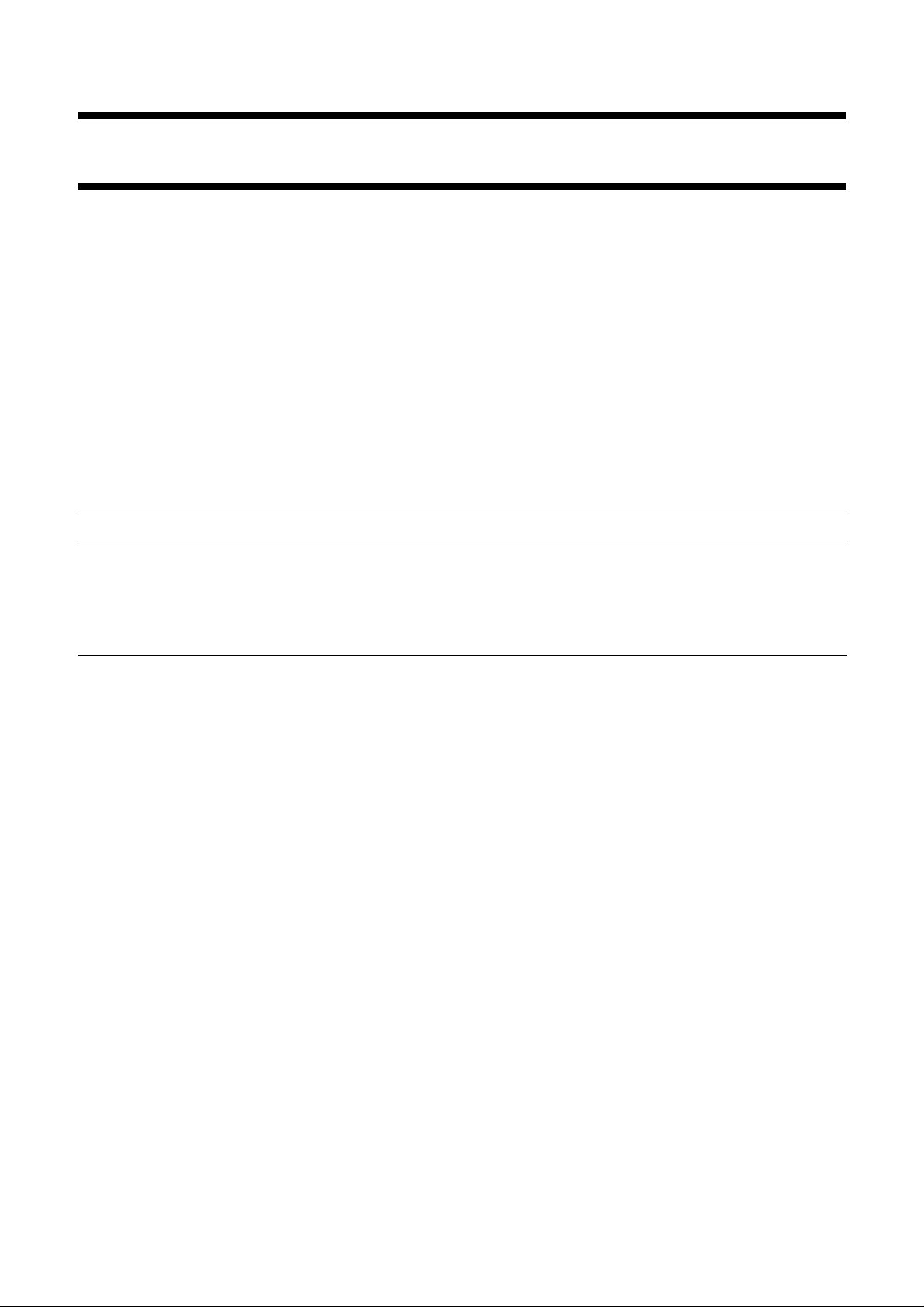

Fig.1 Block diagram.

RATINGS

Limiting values in accordance with the Absolute Maximum System (IEC 134)

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

Supply voltage range V

Operating ambient temperature T

Storage temperature range T

P

amb

stg

September 1986 3

−−7V

−10 −+ 70 °C

−55 −+ 150 °C

Page 4

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

CHARACTERISTICS

V

= 3 V; T

P

Supply voltage (pin 4) V

Supply current I

Output voltage (r.m.s. value)

V

i(rms)

f = 1 kHz V

Channel balance

V

i(rms)

f = 1 kHz ∆G

Output resistance R

Total harmonic distortion

V

i(rms)

f = 1 kHz THD − 0,1 − %

Total harmonic distortion

V

i(rms)

f = 1 kHz; V

Signal-to-noise ratio

V

i(rms)

Signal-to-noise ratio

V

i(rms)

V

p(rms)

Channel separation

V

i(rms)

f = 1 kHz; V

Capture range

V

p(rms)

centre frequency ∆f −± 3 − %

Carrier leak

V

i(rms)

V

p(rms)

f = 19 kHz − 30 − dB

f = 38 kHz − 50 − dB

SCA (Subsidiary Communications

Authorization) rejection

V

i(rms)

V

p(rms)

V

SCA(RMS)

= 25 °C; test circuit Fig.2; unless otherwise specified

amb

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

P

P

1,8 3,0 6,0 V

− 34mA

L and R 120 mV;

5, 6-1

− 240 − mV

L and R 40mV;

v

O

− 01dB

− 5 − kΩ

L and R 40 mV;

L and R 40 mV;

= 12 mV THD − 0,3 − %

p(rms)

= 120 mV; f = 1 kHz S/(S + N) − 70 − dB

= 120 mV; f = 1 kHz

= 12 mV S/(S + N) − 70 − dB

L and R 40 mV;

= 12 mV α−40 − dB

p(rms)

= 12 mV; deviation from

L and R 120 mV;

= 12 mV; f = 1 kHz;

L and R 120 mV;

= 12 mV; f = 1 kHz;

= 12 mV; f = 67 kHz α

67

− 70 − dB

September 1986 4

Page 5

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

ACI (Adjacent channel interference)

V

L and R 120 mV;

i(rms)

V

V

V

Traffic radio (V.W.F.) suppression α

α

57 VWF()

measured with: 91% stereo signal; fm = 1 kHz;

9% pilot signal; 5% traffic subcarrier

(f = 57 kHz, f

= 12 mV; f = 1 kHz;

p(rms)

ACI(RMS)

ACI(RMS)

= 1,3 mV; f = 114 kHz α

= 1,3 mV; f = 190 kHz α

=

------------------------------------------------------------------------------------V

o spurious()

= 23 Hz AM, m = 60%)

m

V

o signal()

at1kHz( 23 Hz )±

at1kHz()

114

119

57(VWF)

− 90 − dB

− 85 − dB

− 75 − dB

Fig.2 Test circuit.

September 1986 5

Page 6

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

Fig.3 Application diagram in combination with TDA7021T and TDA7050T.

September 1986 6

Page 7

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

CHARACTERISTICS

Of the combination TDA7021T, TDA7040T and TDA7050T (Fig.3).

Conditions unless otherwise specified: V

= 1 mV; fhf = 97 MHz; f

vhf(rms)

measured unweighted in a range from 400 Hz to 15 kHz.

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

Total harmonic distortion (pilot on)

= (L + R) signal; f

V

i

V

= L signal; f

i

mod

= 1 kHz THD − 0,5 − %

mod

= 1 kHz THD − 1,0 − %

Signal to noise ratio

V

= (L + R) signal; f

i

mod

= 1 kHz

pilot off S/(S + N) − 56 − dB

pilot on S/(S + N) − 50 − dB

Channel separation

V

= L-signal, f

i

f

= 97 MHz α

RF

V

= L-signal, f

i

= 87,5 MHz and 108 MHz α−14 − dB

f

RF

= 1 kHz; pilot on; − 26 − dB

mod

= 1 kHz; pilot on;

mod

Output voltage (pilot off)

Vi = (L + R) signal, f

= 1 kHz V

mod

o(rms)

= 22,5 kHz; f

dev

= 6,75 kHz; noise

dev pilot

− 80 − mV

a = measured in test circuit (Fig.2)

b = measured in application diagram (Fig.3)

Fig.4 Channel separation as a function of audio frequency.

September 1986 7

Page 8

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

Fig.5 Signal/noise and channel separation behaviour in Fig.3. at R1 = 270 kΩ and R2 = 13 kΩ;

without diode BAW62.

Fig.6 Signal/noise and channel separation behaviour in Fig.3.

at R1 = 200 kΩ, R2 = 30 kΩ; with diode BAW62.

September 1986 8

Page 9

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

PACKAGE OUTLINE

SO8: plastic small outline package; 8 leads; body width 3.9 mm

D

c

y

Z

8

pin 1 index

1

e

5

A

2

A

4

w M

b

p

SOT96-1

E

H

E

1

L

detail X

A

X

v M

A

Q

(A )

L

p

A

3

θ

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

UNIT

mm

inches

Notes

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

2. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

A

max.

1.75

0.069

OUTLINE

VERSION

SOT96-1

A

1

0.25

0.10

0.010

0.004

A2A

1.45

1.25

0.057

0.049

IEC JEDEC EIAJ

076E03S MS-012AA

0.25

0.01

b

3

p

0.49

0.25

0.36

0.19

0.019

0.0100

0.014

0.0075

(1)E(2)

cD

5.0

4.8

0.20

0.19

REFERENCES

4.0

3.8

0.16

0.15

0.050

September 1986 9

eHELLpQZywv θ

1.27

6.2

5.8

0.244

0.228

1.05

1.0

0.4

0.039

0.016

0.7

0.6

0.028

0.024

0.25 0.10.25

0.010.010.041 0.004

EUROPEAN

PROJECTION

(1)

0.7

0.3

0.028

0.012

ISSUE DATE

95-02-04

97-05-22

o

8

o

0

Page 10

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook”

Reflow soldering

Reflow soldering techniques are suitable for all SO

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

(order code 9398 652 90011).

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Repairing soldered joints

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

Wave soldering

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

September 1986 10

Page 11

Philips Semiconductors Product specification

Low voltage PLL stereo decoder TDA7040T

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

September 1986 11

Loading...

Loading...