Page 1

■ FULLY MONOLITHIC FIXED FREQUENCY

SMPS

■ THREE LOW SIDE DRIVERS FOR STOP

TAIL AND TURN LED LAMPS ARRAYS

DRIVING

■ PROGRAMMABLE LOW SIDE DRIVER

OVER CURRENT LIMIT PROTECTION

■ UNDER CURRENT DIAGNOSTIC

■ INPUT OVERVOLTAGE PROTECTION

■ VERY LOW STAND-BY CURRENT

■ THERMALPROTECTION WITH

HYSTERESIS

DESCRIPTION

The STLC1, a device realized with the well

established BCD technology, is a fixed f re quenc y

fully monolithic SMPS, with three independent

smart low side driver, p rima rily intended for

automotive rear led lamps driving.

STLC1

LED LAMPS CLUSTER DRIVER

PowerSO-20

The output voltage is set using a simple resistor

divider. Thermal shutdown with hysteresis, input

over-voltage and overcurrent protections give

robust des ign solutions.

TM

SCHEMATIC DIAGRAM

TURN

STOP

TAIL

CNTL

TS -PWM

GND

LMP -OU T

OSCILLATOR

PULSE WIDTH

CONTROLLER

OSC

LAMP

OUTAGE

DETECT

B+

THERMAL

PROTECTION

I

N

P

U

T

CONTOLLER

PWM

COMP

PWM

SWITCH

COMP1

M3

-

+

-

ERRAMP

+

REF

M2

ST - LTL-L

R

s

1.24V

TR -L

P-OUT

FDBK

REF

TR -DRV

M1

ST -DRV

TL - DRV

1/16September 2002

Page 2

STLC1

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

V

V

TURN,

V

STOP,

V

TAIL

I

TURN,

I

STOP,

I

TAIL

I

TR-DRV,

I

TL-DRV,

I

ST-DRV

I

LMP-OUT

V

P-OUT

I

P-OUT

T

T

Transient Supply Voltage (load dump)

B+

Operating Supply Voltage

B+

60 V

24 V

TURN, STOP and TAIL input pins voltage VB++ 0.3 V

TURN, STOP and TAIL pins current ± 10 mA

TR-DRV, TL-DRV and ST-DRV pins sink current 1.5 A

LMP-OUT pin sink current

P-OUT DC Voltage

P-OUT pin sink current

Storage Temperature Range

stg

Operating Junction Temperature Range

J

120 mA

60 V

Internally Limited A

-55 to +150 °C

-40 to +125 °C

THERMAL DATA

Symbol Parameter

R

thj-case

R

thj-amb

Thermal Resistance Junction-case

Thermal Resistance Junction-Ambient

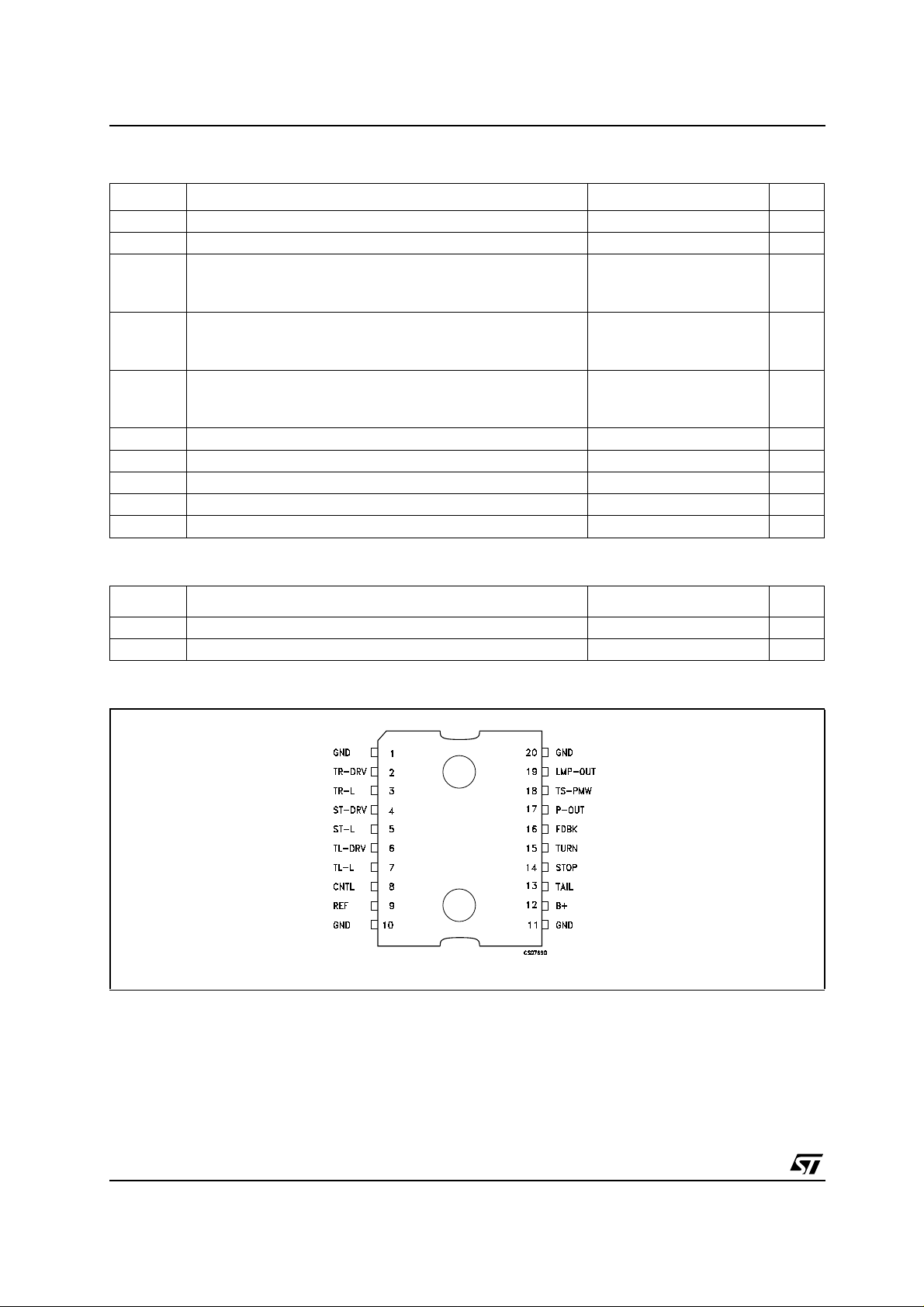

CONNECTION DIAGRAM (t op view)

PowerSO-20

TM

PowerSO-20

TM

2 °C/W

50 °C/W

Unit

2/16

Page 3

PIN DESCRIPTION

Pin N° Symbol Name and Function

1 GND Ground

2 TR-DRV The Low Side Driver drain pin for the TURN LED array

3 TR-L The Low Side Driver source pin, used to detect either a lamp outage or an

over-current condition for the TURN LED array

4 ST-DRV The Low Side Driver drain pin for the STOP LED array

5 ST-L The Low Side Driver source pin, used to detect either a lamp outage or an

over-current condition for the STOP LED array

6 TL-DRV The Low Side Driver drain pin for the TAIL LED array

7 TL-L The Low Side Driver source pin, used to detect either a lamp outage or an

over-current condition for the TAIL LED array

8 CNTL Determines, according to a percentange of VREF,the Pulse Width Controller

internal oscillator duty cycle

9 REF Stable Reference Voltage

10 GND Ground

11 GND Ground

12 B+ Power Supply

13 TAIL TAIL input pin. When brought high, TAIL activates the IC anddrivestheTAIL led

array.

14 STOP STOP input pin. When brought high, STOP activates the IC and drives the

STOP led array.

15 TURN TURN input pin. When brought high, TURN activates the IC and drives the

TURN led array.

16 FDBK Internal Error Amplifier Inverting Pin

17 P-OUT Power MOSFET drain pin

18 TS-PWM A Three State Input. It determine the control logic for TAIL and STOP Low Side

Drivers.

19 LMP-OUT A weak pulled up signal during lamps No Fault condition and an active pulldown

when a Fault condition is detected.

20 GND Ground

STLC1

ORDERING INFORMATION

TYPE

STLC1 STLC1PD

PowerSO-20

TM

3/16

Page 4

STLC1

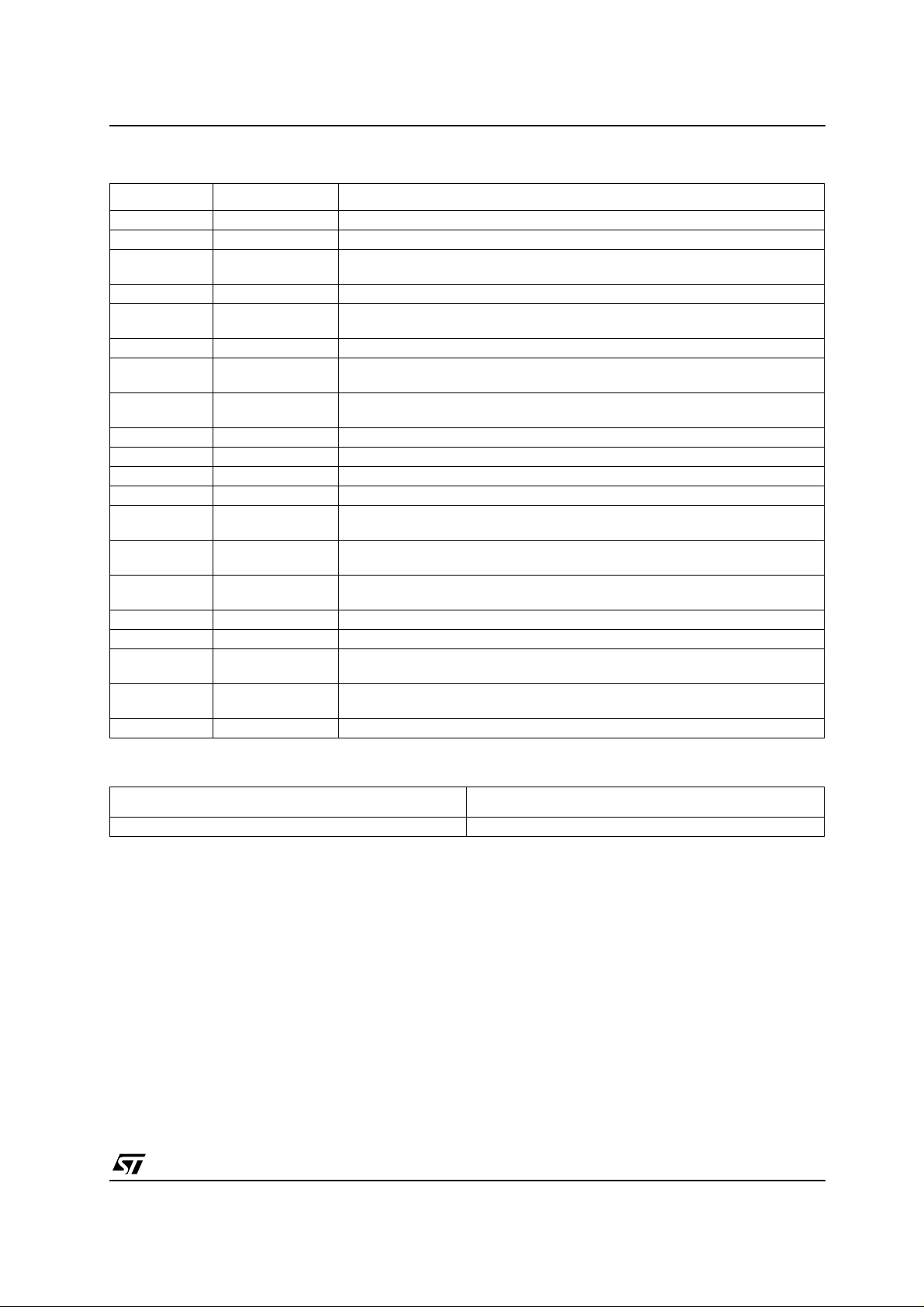

TYPICAL APPLICATION CIRCUIT

TURNTAIL

STOP

RC1

RLR

RLS

RLT

RC2

Iout

OUT

C

OUT

RF1

GND

TR-DRV

TR-L

R

TR

ST-DRV

ST-L

R

TS

TL-DRV

TL-L

R

TT

CNTL

REF

C

GND

REF

GND

LMP-OUT

TS-PWM

P-OUT

FDBK

TURN

STOP

TAIL

GND

IP-OUT

B+

RF2

C

SEPIC

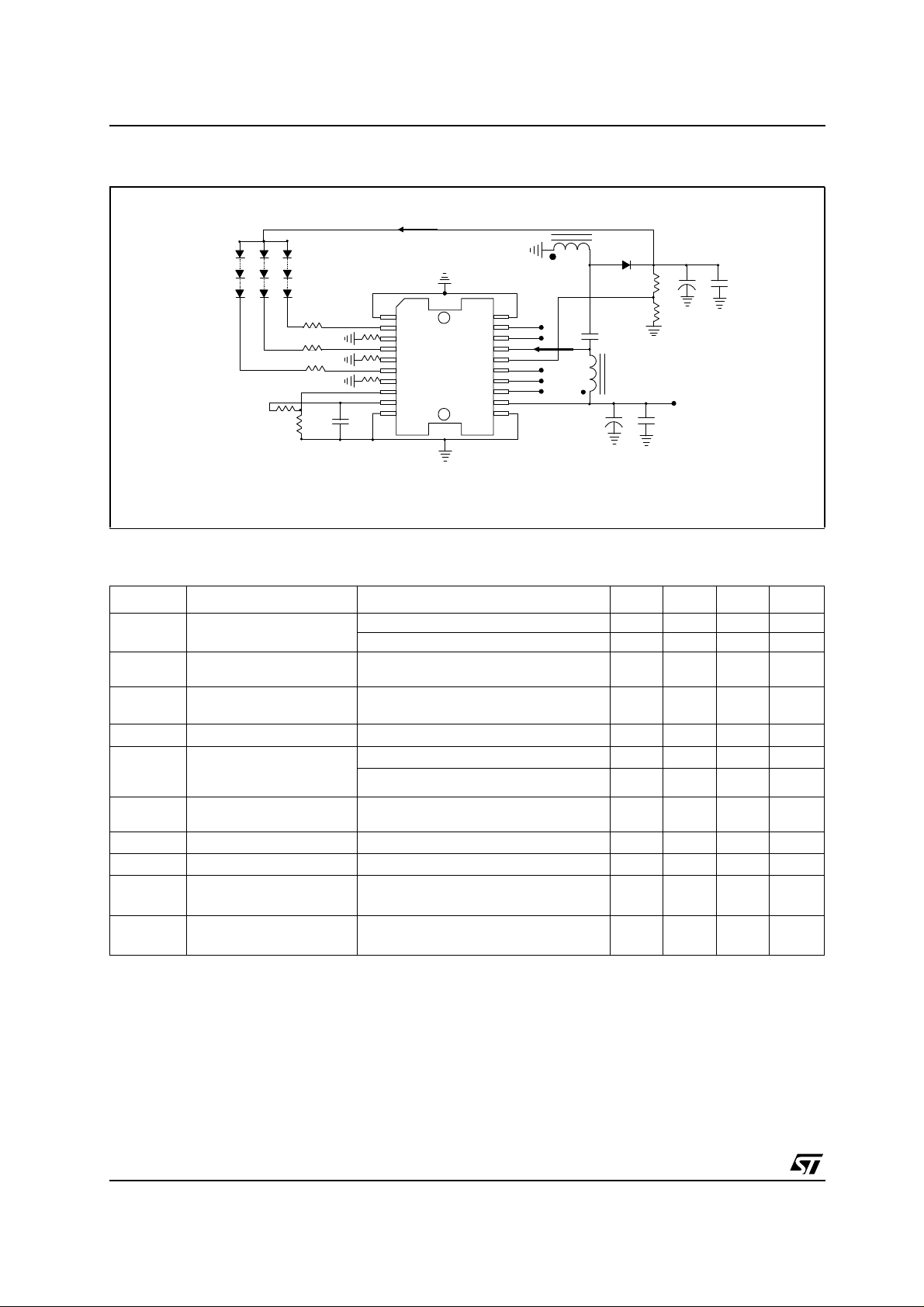

ELECTRICAL CHARACTERISTICS FORSMPD SECTION(T

Typical values are referred at T

=25°C, VB+=14V)

J

=-40 to125°C unless otherwise specified.

J

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

Supply Operating Voltage Normal Operating Range 9 24 V

B+

Normal Operating Range - TAIL only 6 24

V

I

SQ

f

osc

R

P(on)

I

D(off)

I

LIMITIP-OUT

t

SMPS-ON

V

LOAD

V

LINE

B+ Input Overvoltage

SD

Shutdown

Total Off State Quiescent

Current

VB+=14V, V

=0V

TURN=VSTOP=VTAIL

28 30 32 V

120 180 µA

PWM Oscillator Frequency VB+= 14V 140 180 240 kHz

Static drain to ground

SMPS N-channel switch

on resistance

P-OUT Off State leakage

=9V, I

V

B+

=14V, I

V

B+

=4A 180 mΩ

P-OUT

=4A 170 mΩ

P-OUT

VB+= 16V, 20 µA

Current

Current Limit VB+=14V, V

SMPS Turn On Delay C

=1µF (see note 1,4 and Fig 1, 2) 1.6 ms

REF

Load Regulation VB+=14V, I

V

=10V

OUT

Line Regulation VB+= 9 to 16V, I

V

=10V

OUT

= 1V 8 12 16 A

FDBK

= 0.6 to 3A

OUT

OUT

= 1.5A

60 mV

15 mV

4/16

Page 5

STLC1

ELECTRICAL CHARACTERISTICS F OR LOW SIDE DRIVER SECTION (TJ=-40 to 125°C unless

otherwise specified. Typical v alues are referred at T

Symbol Parameter Test Conditions Min. Typ. Max. Unit

R

(on)

I

LSD(off)

t

LSD-ON

V

LS-ON

V

LS-OFF

f

LSD

V

IN(ON)

V

IN(OFF)

Static drain to source LSD

N-channel switch on

resistance

OFF State LSD’S leakage

current

LSD Turn On Delay C

FDBK Voltage over which

LSD’s are enabled

FDBK Voltage over which

LSD’s are disabled

Pulse Width Controller

Internal Oscillator

Frequency

Input Threshold voltage to

enable LSD

Input Threshold voltage to

disable LSD

VB+=9V, V

V

TURN=VSTOP=VTAIL

V

TR-DRV=VST-DRV=VTL-DRV=VB+

=1µFC

REF

(see note 2,4 and Fig 1, 2)

V

TAIL=VB+VTS-PWM=VREF

VB+= 9 to 16V

VB+= 9 to 16V

=25°C, VB+=14V)

J

TURN=VB+VTR-L

I

=1A

TR-DRV

V

STOP=VB+VST-L

I

=1A

ST-DRV

V

TAIL=VB+VTL-L

I

=1A

TL-DRV

=0V

= 220µF

OUT

=0V

=0V

=0V

500 mΩ

500 mΩ

500 mΩ

10 µA

2ms

0.95V

FB

0.5V

FB

/2 200 380 500 Hz

0.6V

B+

0.4V

B+

V

V

V

V

5/16

Page 6

STLC1

ELECTRICAL CHARACTERISTICS F OR FEEDBACK AND CONTROL (TJ=-40 to 125°C unless

otherwise specified. Typical v alues are referred at T

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

LOUT

V

H-SHORT

V

REF

V

V

LH(en)

V

LH(dis)

V

R

(IN)

T

SHDN

T

HYST

t

F(on)

t

F(off)

V

TS-PWM(L)

V

TS-PWM(M)

V

TS-PWM(H)

Note 1: The device is powered. If only one of the three inputs is enabled (the remaining inputs are shorted to ground), t

required for theOUT voltageto reach the10%of its own steady statevalue

Note 2: The device is powered. If only one of the three inputs is brought high (the remaining inputs are shorted to ground), T

time required for the current to flow in the enabled LSD

Note 3: The device is powered and at least one input is enabled. If this input is disabled, T

come zero in the previously enabled LSD.

Note 4: Guaranteed by design, not tested in production.

Lamp Outage Detect

Threshold Voltage

Output Overcurrent

Threshold Voltage

External Voltage

Reference

Internal Band-gap Voltage

FB

Reference (see schematic

diagram)

Device Enabled Lamp

Outage no fault High

Voltage

Device Disabled Lamp

Outage no fault High

Voltage

Lamp Outage fault Low

LL

Voltage

TURN, STOP and TAIL

Input Resistance

Thermal Shutdown

Threshold

Thermal Shutdown

Hysteresis

Time to Fault Indication

ON

Time to Fault Indication

OFF

TS-PWM Low State

Voltage (see table 1)

TS-PWM Mid State

Voltage (see table 1)

TS-PWM High State

Voltage (see table 1)

TJ=25°C 150 200 250 mV

TJ=25°C 1.2 1.3 1.6 V

V

TURN=VSTOP=VTAIL=VB+

I

=500µA

REF

V

TURN=VSTOP=VTAIL=VB+

VB+= 9 to 16V, I

least one input enabled. No fault

condition.

VB+= 9 to 16V, I

V

TURN=VSTOP=VTAIL

VB+= 9 to 16V I

least one input enabled. Fault condition.

VB+= 12V, 18.5 kΩ

(see Note 4) 150 °C

(see Note 4) 10 °C

=25°C, VB+=14V)

J

LMP-OUT

LMP-OUT

<-4mA At

<-2mA

=0V

LMP-OUT

< 100mA At

3.6 3.8 4 V

1.15 1.24 1.3 V

VB+-2 V

VB+-2 V

1.5 V

60 µs

8ms

0.1V

0.21V

REF

0.98V

REF

is the time required for the current to be-

LSD-OFF

0.79V

SMPS-ON

B+

B+

REF

REF

is the time

LSD-ON

V

V

V

V

V

is the

FUNCTIONAL DESCRIPTION

SMPS

The N-channel Power MOSFET is source

grounded, thus it is possible to use any converter

configuration with the power switch connected to

ground. A SEPIC topology (Single Ended Primary

Inductor Current) is shown in the typical

application schematic.

INPUTS PINS

The IC’s inputs are TURN, STOP and T AIL. If all

inputs are disabled, SMPS and most of the

6/16

internal control and diagnostic circuitry are not

active. This is done in order to maintain the

stand-by quiescent cu rren t at v ery low values.

When only one of these inputs is put high (e.g

connected to V

begins. First the C

), a device start-up phase

B+

capacitor is charged and,

REF

once the voltage on it has reached about 95% of

its steady state value (V

), the SM PS is

REF

enabled. In order to allow the output to reach the

regulated voltage value faster, the LSD

corresponding to the input enabled will conduct

Page 7

STLC1

only when the OUT voltage is about 95% of its

final value. Such a start-up phase takes place

when only one input is enabled.

LOW SIDE DRIVER:

The purpose of the l ow side drivers is to connect

the LED cluste r to ground, creating a path for the

current. U s ing external resistors, current flowing

into the LED cluster is set according to the

following formula:

V

–

OUTVARRAY

I

ARRAY

--------------------------------------------- -=

R

++

TRL

R

on()

where (see typical application schem at ic):

R

L=RLT,RLS

RT=RTT,RTS,orR

R

= Static drain to source LSD on resistance

(on)

= Output Voltage

V

OUT

V

ARRAY

,orR

LR

TR

= Expected LED array voltage drop.

LSD over-current protection and under-current

diagnostic (see LAMP OUTAGE DETECTION

section) is performed by sensing the voltage on

resistors, when the corresponding LSD are

enabled.

If the voltage on exceeds V

H-SHORT

,the

over-current protection acts by reducing the LSD

average current by switching ON and OFF t he

LSD itself.

LAMP OUTAGE DETECTION

Resistors are used to sense the LED array

current. In case one or more LEDs fail (open

circuit) the current on the corresponding resistor

will drop due to the increas ed LED array

resistance. As soon as the voltage drop on is

lower than V

, a LED lamp fault condition is

LOUT

detected and the LMP-OUT pin becomes active

(low). The LAMP-OUT AG E functionality is

AND-ed with each input, that is a fault condition

can be detected only when the LE D arrays are

enabled.

DIMMING

The dimming of the LED lamps can be obt ained by

using the internal PULSE WIDTH controller (it

drives t he LSD TAIL and STOP gates). The duty

cycle of this internal oscillator (whose frequency is

380Hz typical) can be set, forcing the vol tag e of

theCNTLpintobeafractionofV

,byusinga

REF

simple res ist or divider (as shown in the typica l

application scheme).

In this case the duty cycle percentage can be

calculated with the following approximated

formula:

R

3.8 if

≅

DC%

R

C1

---------------------------- 100 E l s ewhere•

R

+

C1RC2

C1

---------------------------R

+

C1RC2

≤

0.2

-------------V

REF

The TS-PWM pin voltage, according to the

TABLE1 determines which LSD is PULSE WIDTH

CONTROLLER driven. Internal dimming c an only

be performed on the T A IL a nd STOP arrays. The

TURN arra y can b e externally dim med (as well as

TAIL and STOP) by driving the corresponding

input witha a square pulse signal whose maximum

frequency must be 200Hz.

7/16

Page 8

STLC1

TS-PWM ENCODING TABLE

TYPE INPUTS ACTIVATED

DRIVE TYPE

TAIL ARRAY STOP ARRY

TAIL PWM PWM

STOP OFF ON

TAIL AND STOP PWM ON

TAIL PWM OFF

STOP OFF ON

TAIL AND STOP PWM ON

TAIL PWM PWM

STOP ON ON

TAIL AND STOP ON ON

(V

TS-PWM

(V

(V

TS-PWM

LOW

TS-PWM

<0.1V

HIGH

<0.1V

MID

/2 or floating)

REF

>0.98V

REF

REF

)

)

Figure1 : S t art-up phase and in put signal t im ing diagram (with TS-PWM floating)

8/16

Page 9

Figure2 : Magnified start-up phase tim ing diagram

STLC1

Figure3 : Fault indication on and off timing diagram

9/16

Page 10

STLC1

TYPICAL CHARACTERISTICS (See PCB BOM)

Figure4 : Output Voltage vs Output Current

Figure5 : Output Voltage vs Output Current

Figure7 : Output Voltage vs Output Current

Figure8 : Duty Cycle Oscillator Frequency vs

CNTL Voltage

Figure6 : Output Voltage vs Output Current

10/16

Figure9 : LMP-OUT Voltage (Fault Condition) vs

LMP-OUT SinkedCurrent

Page 11

STLC1

Figure10 : Total OFF State Quies ce nt Current vs

Temperature

Figure11 : Time to Fault Indication ON vs

Temperature

Figure13 : External Reference Voltage vs

Temperature

Figure14 : V

Voltage vs Temperature

FB

Figure12 : Time to Fault Indication OFF vs

Temperature

11/16

Page 12

STLC1

Figure15 : Demoboard Schematic

Figure16 : PCB Components outline

12/16

Page 13

Figure17 : PBC Top Layer

STLC1

Figure18 : PBC Bottom Layer

13/16

Page 14

STLC1

PCB BOM

REFERENCE DESCRIPTION

L1, L2 VK200

C4, C5, C6 22µF-35V Electrolytic Capacitor Low ESR

C16 220nF-35V Ceramic Capacitor X7R Dielectric

C7 47µF-35V Electrolytic Capacitor

C1, C2 4.7nF-35V Ceramic Capacitor X7R Dielectric

C8, C9 220µF-35V Electrolytic Capacitor Low ESR

C14 560pF

C18 560pF-50V

C11 1µF-35V Tantalium Capacitor

C12 220pF Ceramic Capacitor

R10 9.1kΩ Resistor 125mW 0.1%

R11 1.3kΩ Resistor 125mW 0.1%

R15 4.7kΩ Resistor 125mW 5%

R16 56Ω Resistor 125mW 5%

R18 10Ω Resistor 250mW 5%

R12, R13, R14 1.2kΩ Resistor 125mW 5%

R4, R6, R8 2.2Ω Resistor 1W 5%

R5, R7, R9 1Ω Resistor 1W 5%

TR1 10kΩ Trimmer

RLP 1.5kΩ Resistor 125mW 5%

D1 Schottky Diode STPS3L40S

DLP Led Diode

T1 SEPIC inductor, Toroid Horizontal THT 20µH@10ADC, 200-250KHz

JP1, JP2, JP3 Jumper

14/16

Page 15

PowerSO-20 MECHANICAL DATA

STLC1

DIM.

MIN. TYP MAX. MIN. TYP. MAX.

mm. inch

A 3.60 0.1417

a1 0.10 0.30 0.0039 0.0118

a2 3.30 0.1299

a3 0 0.10 0 0.0039

b 0.40 0.53 0.0157 0.0209

c 0.23 0.32 0.0090 0.0013

D (1) 15.80

16.00

0.6220 0.630

E 13.90 14.50 0.5472 0.5710

e 1.27 0.0500

e3 11.43 0.4500

E1 (1) 10.90 11.10 0.4291 0.4370

E2 2.90 0.1141

G 0 0.10 0.0000 0.0039

h 1.10 0.0433

L 0.80 1.10 0.0314 0.0433

N0˚10˚

1

S0˚ 8˚0˚ 8˚

T 10.0 0.3937

(1) “D and E1” do not include mold flash or protusions - Mold flash or protusions shall not exceed 0.15mm (0.006”)

E2

h x 45˚

NN

a2

b

DETAIL A

110

e3

D

T

e

1120

A

E1

DETAIL B

PSO20MEC

R

Gage Plane

a3

lead

E

DETAIL B

0.35

S

a1

L

c

DETAIL A

slug

-C-

SEATING PLANE

GC

(COPLANARITY)

0056635

15/16

Page 16

STLC1

Information furnished is believed to be accurate and reliable. However, STMicroelect ronics assumes no responsibility for t he

consequences of use of such informatio n nor for any infringement of paten ts or o ther rig hts of t hird part ies which ma y result from

its use. No license is granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information

previousl y suppl ied. STM icroel ectronics produc ts are not auth orized for use as c ritica l compone nts in l ife s upport dev ices or

systems without express written approval of STMicroelectronics.

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco

© The ST logo is a registered trademark of STMicroelectronics

© 2002 STMicroelectronics - Printed in Italy - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

© http://www.st.com

16/16

Loading...

Loading...