Page 1

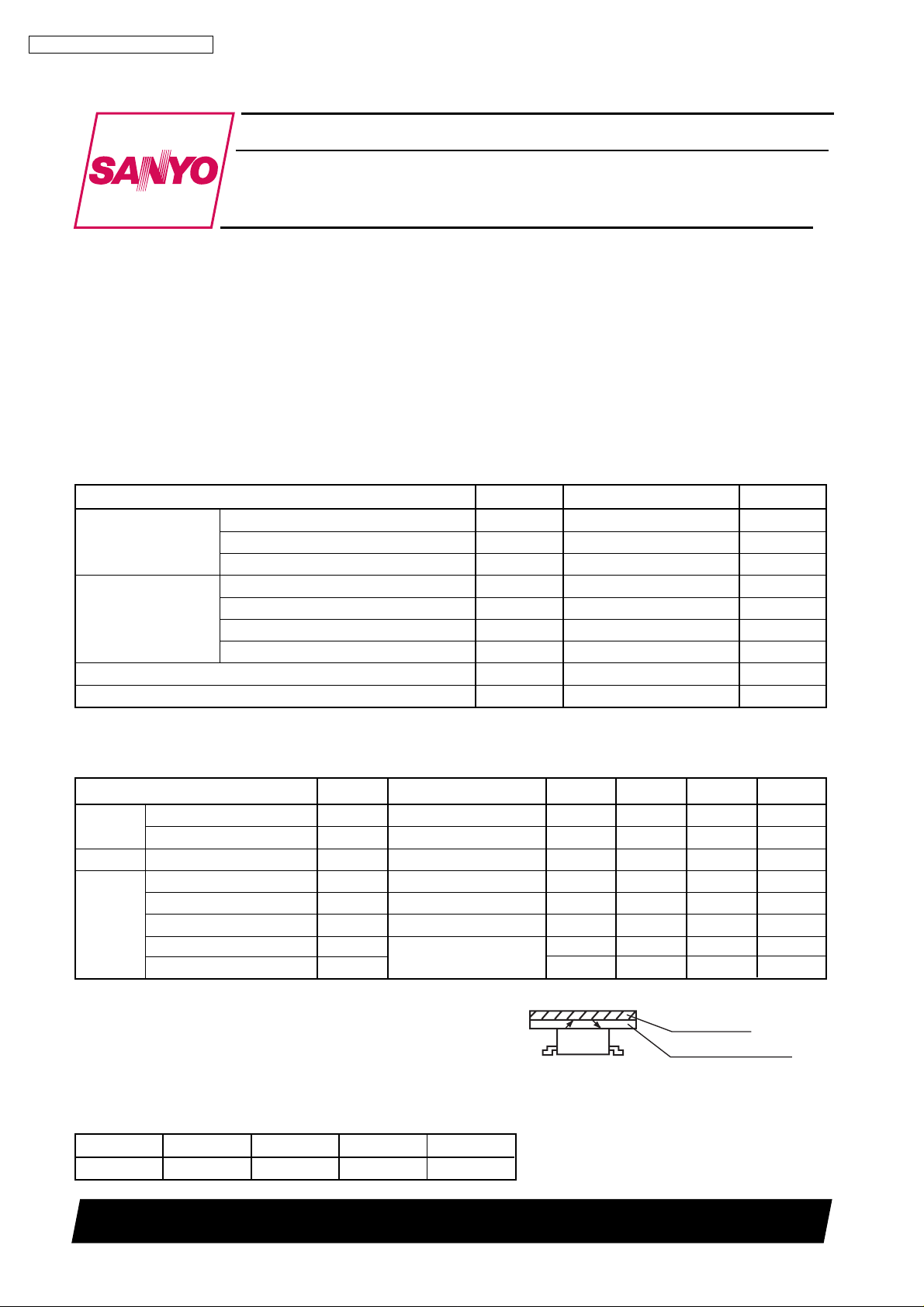

Ordering number : EN6030

SPI-336-99-T1

Ultraminiature photoreflector supporting reflow soldering

(Single transistor type)

Features

• Infrared LED plus Phototransistor (single)

• DIP type

• Compact type : 3.4 (L) ✕ 2.7 (W) ✕ 1.5 (H) mm

• Visible light cut type

• Taping type

Absolute Maximum Ratings at Ta=25°C, 65%RH (as per JIS C7032)

Parameter Symbol Rating Unit

Input LED

Output

Phototransistor

Forward Current I

Reverse Voltage V

Power Dissipation P

Collector-Emitter Voltage V

Emitter-Collector Voltage V

Collector Curren I

Power Dissipation P

Operating Temperature Topr --20 to +80 °C

Storage Temperature Tstg --30 to +100 °C

F

R

D

CEO

ECO

C

C

Infrared LED

SPI-336-99-T1

50 mA

5V

70 mW

20 V

5V

20 mA

70 mW

Electro-Optical Characteristics at Ta=25°C, 65%RH

Parameter Symbol Condition Min. Typ. Max. Unit

Input

Output Dark Current I

Forward Voltage V

Reverse Current I

CEO

Collector Output I

Coupled

Leakage Current I

Collector Emitter VCE(sat) IF=10mA, IC=50µA -- -- 0.5 V

LEAKIF

Rise Time tr

Fall Time tf

1

*

Location of reflector is shown in Fig. 1.

2

*

No reflector

3

*

Table of Classification of Collector Output

Class A B C D

Ic (µA) 1100 to 450 600 to 260 350 to 150 200 to 80

IF=10mA 1.0 1.2 1.6 V

F

VR= 5 V -- -- 1 0 µ A

R

IF=0mA, VCE=10V -- -- 200 nA

IF=10mA, VCE=5V

C

=10mA, VCE=5V

VCC=5V, RL=100Ω

IC=1mA

1

*

2

*

80 - - 1100 µA

-- -- 1 µA

-- 5 -- µs

-- 5 -- µs

Fig. 1 Location of Reflector

AL V .E. film

Glass plate (t=1mm)

SANYO Electric Co.,Ltd. Semiconductor Company

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110-8534 JAPAN

72199 GI, (MI

)

No.6030 1/6

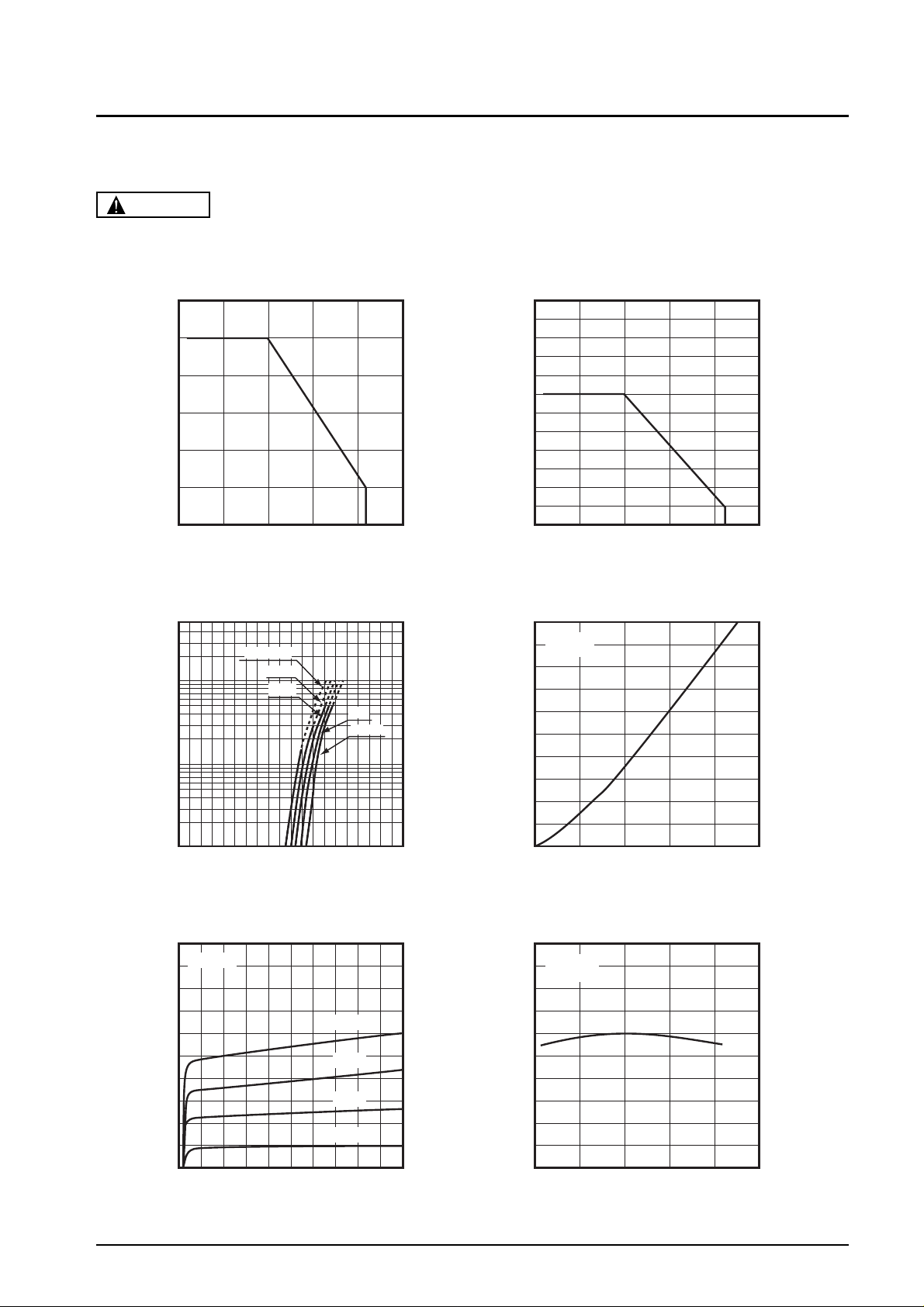

Page 2

SPI-336-99-T1

Typical Characteristics

CAUTION

These numerical value show the electrical and optical characteristics of this product, and not assure this contents.

Forward Current vs. Ambient Temperature

60

50

(mA)Collector Current I

40

F

30

20

Forward Current I

10

0

--25 0 25 50 75 100

Ambient Temperature Ta (°C)

Forward Current vs. Forward Voltage

500

Ta=75°C

50°C

25°C

0°C

--25°C

(mA)

F

100

50

Power Dissipation vs. Ambient Temperature

(Rating) (Rating)

120

100

80

60

40

Power Dissipation P (mW)Relative Collector Current (%)

20

0

--25 0 25 50 75 100

Ambient Temperature Ta (°C)

Collector vs. Forward Current

500

V

=5V

CE

Ta=25°C

400

(µA)

C

300

10

Forward Current I

5

1

0 0.5 1 1.5 2

Forward Voltage VF (V)

Collector Current vs. Collector-emitter Voltage

1000

Ta=25°C

800

(µA)

C

600

400

200

0

0510

Collector-emitter Voltage VCE (V)

IF=20mA

15mA

10mA

5mA

200

Collector Current I

100

0

048121620

Forward Current IF (mA)

Relative Collector Current vs. Ambient Temperature

140

IF=10mA

VCE=5V

120

100

80

60

40

--25 0 25 50 75 100

Ambient Temperature Ta (°C)

No.6030 2/6

Page 3

SPI-336-99-T1

Typical Characteristics

CAUTION

These numerical value show the electrical and optical characteristics of this product, and not assure this contents.

Collector-emitter Saturation Voltage vs.

Ambient Temperature

0.24

(V)

CE (sat)

Collector-emitter Saturation V oltage V

IF=10mA

IC=50µA

0.22

0.20

0.18

0.16

0.14

--25 0 25 50 75 100

Ambient Temperature Ta (°C)

Collector Dark Current vs. Ambient Temperature

-6

10

5

VCE=10V

(A)

-7

10

5

CEO

-8

10

5

-9

10

5

Collector Dark Current I

-10

10

--25 0 25 50 75 100

Ambient Temperature Ta (°C)

Response Time vs. Load Resistance Test Circuit for Response Time

1000

IFP=20mA

500

VCC=5V

Ta=25°C

100

)

S

50

Response (µ

10

5

tf

I

V

FP

tr

R

D

CC

I

FP

V

out

R

L

tr

V

out

tf

90%

10%

1

0.1 0.5 1 5 10 50 100

Load Resistance RL (kΩ)

Relative Collector Current vs. Distance

120

100

80

60

40

Relative Collector Current (%)

20

0

012345

Distance between sensor and Al evaporation d (mm)

IF=10mA

VCE=5V

Ta=25°C

Relative Collector Current vs.

PPC paper Moving Distance

120

100

d

80

60

40

Relative Collector Current (%)

20

0

--4 --2 0 2 4 6

1

PPC paper Moving Distance (mm)

IF=10mA,VCE=5V

Ta=25°C,d=1mm

2

–

0

+

0

–

+

1

2

No.6030 3/6

Page 4

2

1.6

14

C0.6

SPI-336-99-T1

Pin No.

0.4

Pin connection

1. LED Anode

2. LED Cathode

3 .Ph. Tr Collector

4. Ph. Tr Emitter

0.6

2

3.4

3

0.4

4.3 ± 0.5

(3.47)

2.7

10.5

0.2

+ 0.1

-- 0.05

0.05

Tolerance : ±0.2

Unit : mm

No.6030 4/6

Page 5

SPI-336-99-T1

0.5mm

0.5mm

Package dimensions and Pin connection

As stated in the sttached paper. (No.6030 4/6)

Soldering conditions

(1) Reflow soldering

The temperature of the reflow furnace is to be set in accordance with the following temperature profile.

Soldering must be done only two time.

Temperature : On the topsurface of product

Reflow type : Hot air

Max 240°C

200°C

Max 165°C

Max 10sec

Max 120sec

Max 60sec

(2) Manusl soldering

Temperature : Max. 290°C (Soldering iron tip temperature)

Time : Max. 3 sec

Clearance : Min. 0.5mm from package

PRECAUTIONS

(1) Bending a lead should avoid. However, when bending is necessary, take care the next items.

q Bending a lead must be done before soldering.

w Bending a lead must be done in the states of fixing leads and no stress for the regin part. Because it is possible that

stress for the regin part cause troubles such as gold wire breaking and so on.

e A lead must be bend at intervals of 0.5mm from the case edge.

r Do not bend the same position of leads more than twice.

(2) The hole pitch of a circuit board must fit to the lead pitch.

(3) Take core the following when soldering.

q Do not heat a product under any stress (a twist and so on) to leads.

w Do not heat a product in the states of operating force to the regin part.

(4) Use the flux which contain no chlorine, have no corrosion and do not need washing.

(5) Be careful that flux or other chemicals do not attach to the luminous surface and passive surface.

(6) Precautions of the product after the open dry packing

q The product after the open dry packing should be stored in the dry packing again.

The product should be kept under the conditions below, if the product is not stored in the dry paking.

Temperature : 5 to 30°C

Humidity : Max 70%RH

Term : Max 7days

w The product to be out the term without dry packing must be practiced baking.

Baking conditions : +60±5°C, 10 to 20Hr

(7) The reflow conditions must be confirmed that no problem by your reflow furnace.

No.6030 5/6

Page 6

SPI-336-99-T1

CAUTION

1. No products described or contained herein are intended for use in surgical implants, life-support systems,

aerospace equipment, nuclear power control systems, vehicles, disaster / crime-prevention equipment or

the like, and the failure of which may directly or indirectly cause injury, death or property loss.

2. Anyone purchasing any products described or contained herein for an above-mentioned use shall:

1) Accept full responsibility and indemnify and defend SANYO ELECTRIC CO.,LTD., it’s affiliates,

subsidiaries and distributors or any of their officers and employees, jointly and severally, against any

and all claims and litigation and all damages, costs and expenses associated with such use.

2) Not impose any responsibility for any fault or negligence which may be cited in any such claim or

litigation on SANYO ELECTRIC CO., LTD., it’s affiliates, subsidiaries and distributors or any of

their officers and employees jointly or severally.

3. Information (including circuit diagrams and circuit parameters) disclosed herein is for example only; it is not

guaranteed for mass production, SANYO believes the information disclosed herein is accurate and reliable,

but no guarantees are made or implied regarding it’s use or any infringements of intellectual property rights

or other rights of third parties.

Precautionary instructions in handling gallium arsenic products

Special precautions must be taken in handling this product because it contains, gallium arsenic, which is

designated as a toxic substance by law. Be sure to adhere strictly to all applicable laws and regulations

enacted for this substance, particularly when it comes to disposal.

Manufactured by ; Tottori SANYO Electric Co., Ltd.

LED Division

5-318, Tachikawa-cho, Tottori City, 680-8634 Japan

TEL: +81-857-21-2137 FAX: +81-857-21-2161

No.6030 6/6

PS

Loading...

Loading...