Datasheet Si3012-KS, Si3012-KT, Si3014-KS, Si3014-KT, Si3015-BS Datasheet (Silicon Laboratories)

...Page 1

Si3035

3.3 V FCC/JATE D

IRECT

A

CCESS

A

Features

Complete DAA includes the following:

!

3.3 V to 5 V Digital/Analog

Power Supplies

!

JATE Filter Option

!

86 dB Dynamic Range TX/RX

Paths

!

Daisy-Chaining for Up to Eight

Devices

!

Integrated Ring Detec t or

!

3000 V Isolation

!

Support for Caller ID

!

Low Profile SOIC Packages

!

Direct Interface to DSPs

!

Integrated Modem Codec

!

Compliant with FCC Part 68

!

Low-Power Standb y Mode

!

Proprietary ISOcap™ Technology

!

Pin Compatible with Si3034, Si3032

!

Optional IIR Digital Filter

Applications

!

V.90 Modems

!

Voice Mail Systems

!

Fax Machines

!

Set Top Boxes

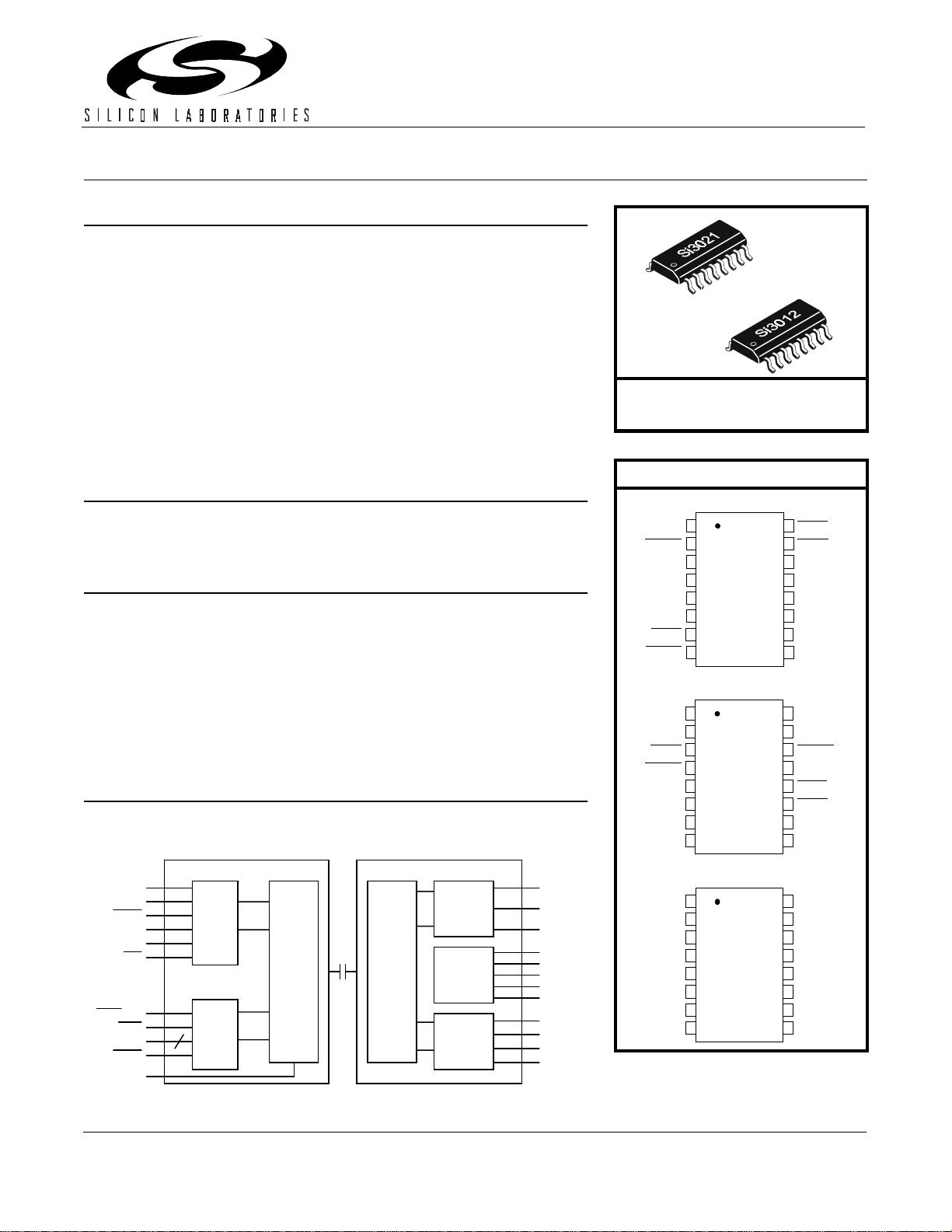

Description

The Si3035 is an integrat ed direct ac cess arrange ment (DAA) c hipset that

provides a digital, low-cost, solid-state interface to a telephone line.

Available in two 16-pin small outline packages, it eliminates the need for an

analog front end (AFE), a n is olation transformer, relays, opto-isolators, and

a 2- to 4-wire hybrid. The Si3035 dramatically reduces the number of

discrete components and cost require d to achieve compliance with FCC

Part 68. The Si3035 interfaces directly to standard modem DSPs and

supports all FCC and J ATE out-of-band noise require ments. International

support is provided by the pin compatible Si3034.

Functional Block Diagram

Si3021 Si3012

RRANGEMENT

Ordering Information

See page 50.

Pin Assignments

Si3021 (SOIC)

MCLK

FSYNC

SCLK

FC/RGDT

RESET

FC/RGDT

RESET

AOUT

1

2

3

V

4

D

SDO

5

SDI

6

7

8

Si3021 (TSSOP)

1

SDO

SDI

2

3

4

5

M1

6

C1A

7

GND

8

16

15

14

13

12

11

10

9

16

15

14

13

12

11

10

9

OFHK

RGDT/FSD

M0

V

A

GND

C1A

M1

AOUT

V

D

SCLK

FSYNC

MCLK

OFHK

RGDT/FSD

M0

V

A

MCLK

SCLK

FSYNC

SDI

SDO

FC/RGT

RGDT/FSD

OFHK

MODE

RESET

AOUT

Digital

Interfa ce

Control

Interfa ce

Isolation

Interfa ce

Isolation

Interfa ce

Hybrid

DC

Termination

Ring Detect

Off-H o o k

Out

TX

In

RX

HYBD

VREG2

VREG

DCT

REXT

IGND

RNG1

RNG2

QB

QE

Si3012 (SOIC or TSSOP)

TSTA

TSTB

IGND

RNG1

RNG2

C1B

QB

QE

1

2

3

4

5

6

7

8

US Patent # 5,870,046

TX

16

NC

15

RX

14

REXT

13

DCT

12

HYBD

11

VREG2

10

VREG

9

US Patent # 6,061,009

Other Patents Pending

Rev. 1.2 12/00 Copyright © 2000 by Silicon Laboratories Si3035-DS12

Page 2

Si3035

2 Rev. 1.2

Page 3

Si3035

T

ABLE OF

C

ONTENTS

Section Page

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Typical Application Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Isolation Barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Off-Hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ring Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Improved JATE Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Digital Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Clock Generation Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

On-Hook Line Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Loop Current Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Multiple Device Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Gain Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Filter Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Revision Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

In-Circuit Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Exception Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Control Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Appendix—UL1950 3rd Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Pin Descriptions: Si3021 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Pin Descriptions: Si3012 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Ordering Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

SOIC Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

TSSOP Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Rev. 1.2 3

Page 4

Si3035

Electrical Specifications

Table 1. Recommended Operating Conditions

Parameter

1

Ambient Temperature T

Si3021 Supply Voltage, Analog V

Si3021 Supply Voltage, Digital

Notes:

1.

The Si3035 specifications are guaranteed when the typical application circuit (including component

3

Symbol Test Condition

A

A

V

D

K-Grade 0 25 70 °C

Min

2

Typ

Max

2

Unit

4.75 5.0 5.25 V

3.0 3.3/5.0 5.25 V

tolerances) and any Si3021 and any Si3012 are used. See Figure 16 on page 15 for typical application

circuit.

2.

All minimum and maximum specifications are guaranteed and apply across the recommended operating conditions.

Typical values apply at nominal supply voltages and an operating temperature of 25 °C unless otherwise stated.

3. The digital supply, V

operating from 3.3 V. The 3.3 V operation applies to both the serial port and the digital signals

RGDT, OFHK, RESET, M0, and M1.

, can operate from either 3.3 V or 5.0 V. The Si3021 supports interface to 3.3 V logic when

D

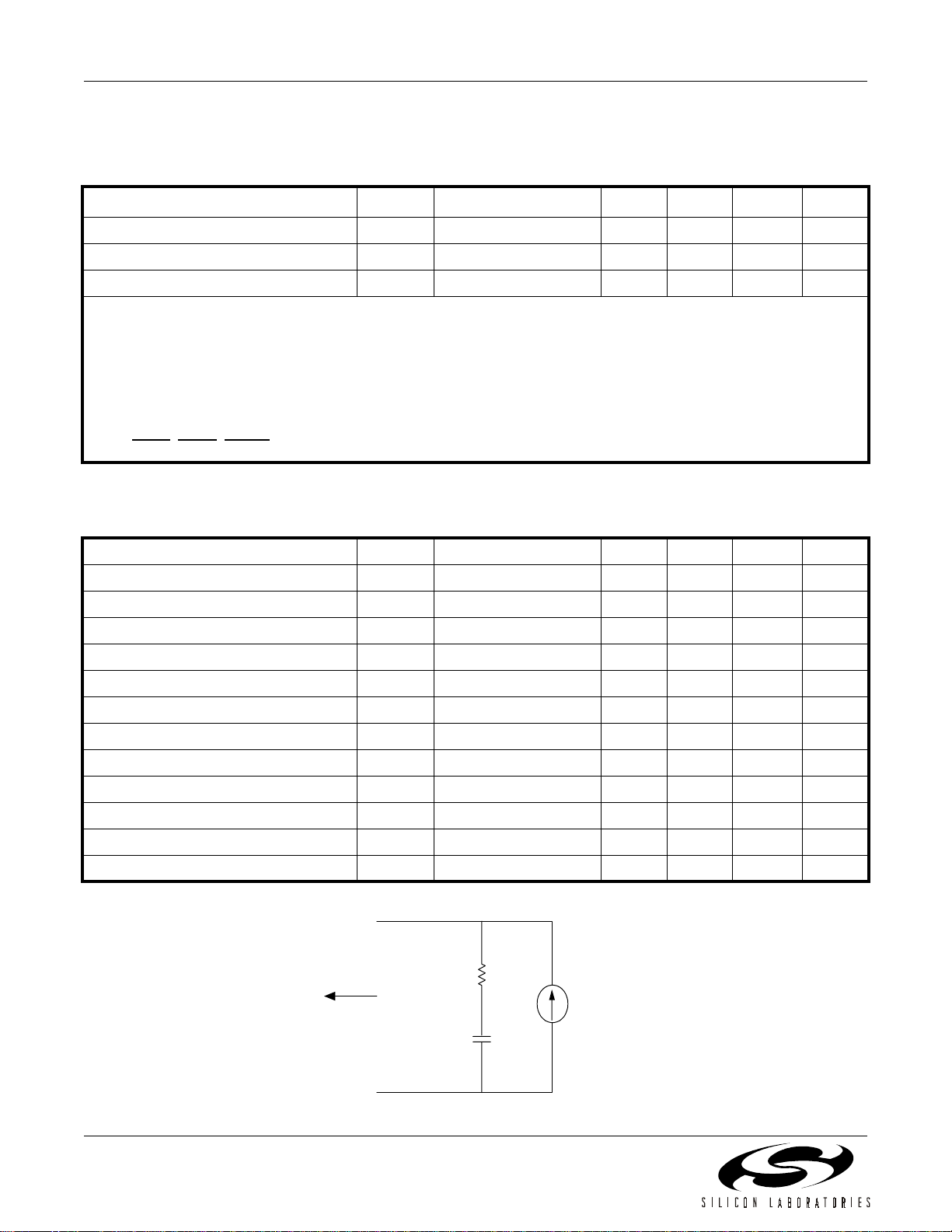

Table 2. Loop Characteristics

(VA = Charge Pump, VD = +3.3 V ± 0. 3 V, TA = 0 to 70°C for K-Grade, Refer to Figure 1)

Parameter Symbol Test Condition Min Typ Max Unit

DC Termination Voltage V

DC Termination Voltage V

DC Ring Current (

DC Ring Current

with caller ID)

(w/o caller ID)

AC Termination Impedance Z

Operating Loop Current I

I

RDC

I

RDC

ACT

LP

TR

TR

Loop Current Sense Bits LCS LCS = Fh 180 155 — mA

IL = 20 mA — — 7.7 V

IL = 105 mA 12 — — V

—— 1 mA

—— 20µA

—600— Ω

20 — 120 mA

Ring Voltage Detect V

Ring Frequency F

On-Hook Leakage Current I

Ringer Equivalence Num. (

Ringer Equivalence Num.

with caller ID)

(w/o caller ID)

Si3012

RING

RD

R

LK

V

BAT

REN — 1.0 1.67 —

REN — 0.2 — —

TIP

+

600

Ω

V

TR

10 µF

–

Figure 1. Test Circuit for Loop Characteristics

4 Rev. 1.2

13 18 26 V

RMS

15 — 68 Hz

= –48 V — — 1 µA

I

L

Page 5

Si3035

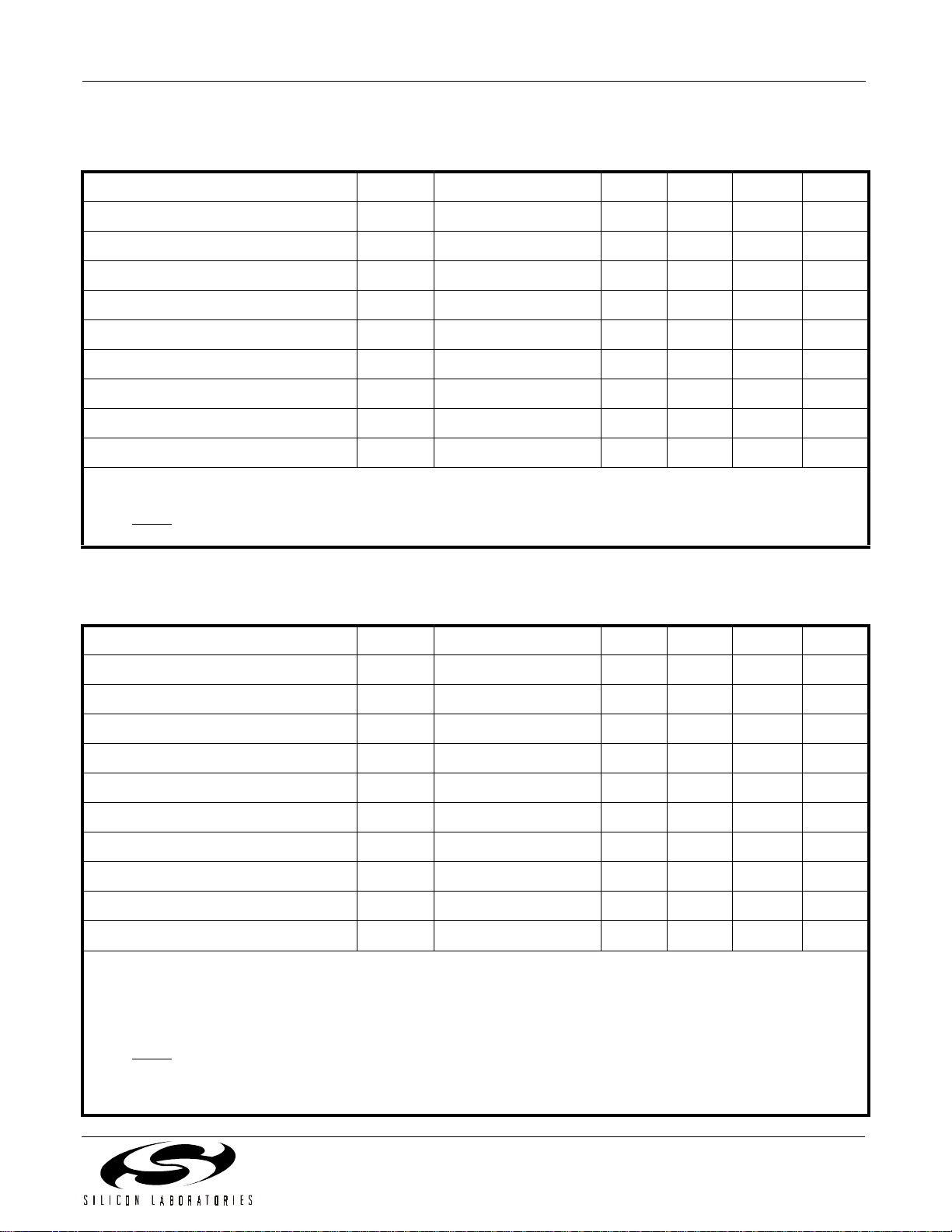

Table 3. DC Characteristics, VD = +5 V

(VA = +5 V ±5%, VD = +5 V ±5%, TA = 0 to 70°C for K-Grade)

Parameter Symbol Test Condition Min Typ Max Unit

High Level Input Voltage V

Low Level Input Voltage V

High Level Output Voltage V

Low Level Output Voltage V

Input Leakage Current I

Power Supply Current, Analog I

Power Supply Current, Digital

Total Supply Current, Sleep Mode

Total Supply Current, Deep Sleep

Notes:

1. All inputs at 0.4 or V

= 0 mA).

OUT

is not functional in this state.

2.

(Static I

RGDT

1

1

1,2

– 0.4 (CMOS levels). All inputs held static except clock and all outputs unloaded

D

IA + I

IA + I

OH

OL

I

D

IH

IL

IO = –2 mA 3.5 — — V

IO = 2 mA — — 0.4 V

L

A

VA pin — 0.3 1 mA

VD pin — 14 18 mA

D

D

PDN = 1, PDL = 0 — 1.3 2.5 mA

PDN = 1, PDL = 1 — 0.04 0.5 mA

3.5 — — V

——0.8V

–10 — 10 µA

Table 4. DC Characteristics, VD = +3.3 V

(VA = Charge Pump, VD = +3.3 V ± 0.3 V, TA = 0 to 70°C for K-Grade)

Parameter Symbol Test Condition Min Typ Max Unit

High Level Input Voltage V

Low Level Input Voltage V

High Level Output Voltage V

Low Level Output Voltage V

Input Leakage Current I

Power Supply Current, Analog

Power Supply Current, Digital

Total Supply Current, Sleep Mode

Total Supply Current, Deep Sleep

Power Supply Voltage, Analog

Notes:

1. Only a decoupling capacitor should be connected to V

2. There is no I

to the V

3. All inputs at 0.4 or V

(Static I

4. RGDT

5. The charge pump is rec om m end ed to be used only when V

applied to the device before V

current consumption when the internal charge pump is enabled and only a decoupling cap is connected

A

pin.

A

= 0 mA).

OUT

is not functional in this state.

1,2

3

3

3,4

1,5

– 0.4 (CMOS levels). All inputs held static except clock and all outputs unloaded

D

is applied on power up if driven from separate supplies.

D

IH

IL

OH

OL

L

I

A

I

D

IA + I

IA + I

V

D

D

A

2.0 — — V

——0.8V

IO = –2 mA 2.4 — — V

IO = 2 mA — — 0.35 V

–10 — 10 µA

VA pin — 0.3 1 mA

VD pin — 9 12 mA

PDN = 1, PDL = 0 — 1.2 2.5 mA

PDN = 1, PDL = 1 — 0.04 0.5

Charge Pump On 4.3 4.6 5.00 V

when the charge pump is on.

A

< 4.5 V. When the charge pum p is not use d, VA should be

D

Rev. 1.2 5

Page 6

Si3035

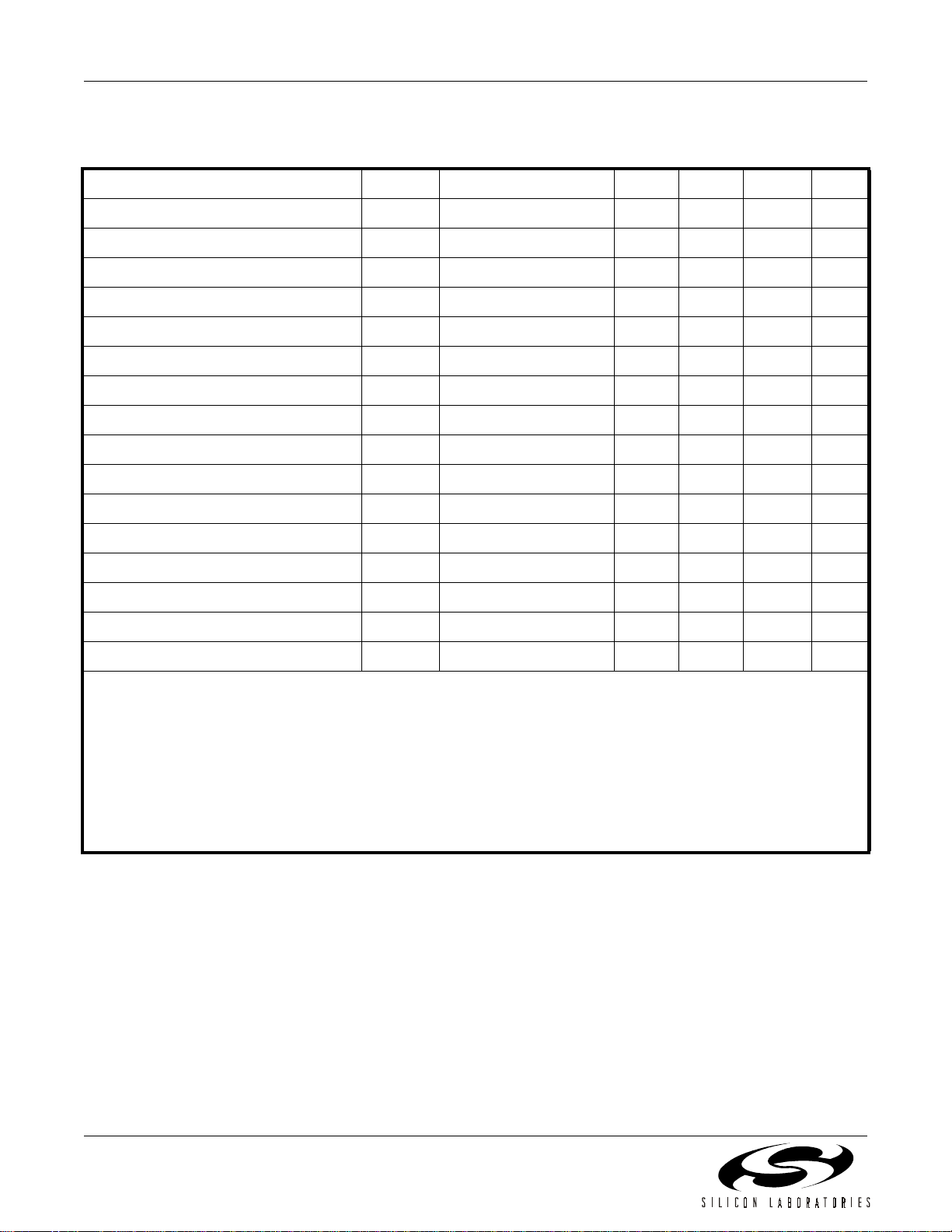

Table 5. AC Characteristics

(VA = Charge Pump, VD = +3.3 V ± 0.3 V, TA = 0 to 70°C for K-Grade)

Parameter Symbol Test Condition Min Typ Max Unit

Sample Rate

1

PLL1 Output Clock Frequency F

Transmit Frequency Response Low –3 dB corner — 16 — Hz

Receive Frequency Response Low –3 dB corner — 16 — Hz

2

Transmit Full Scale Level

Receive Full Scale Level

Dynamic Range

Dynamic Range

4

5

Total Harmonic Distortion

(0 dB gain) V

2,3

(0 dB gain) V

6

Fs Fs = F

PLL1

FPLL1 = F

TX

RX

/5120 7.2 — 11.025 kHz

PLL2

"

MCLK

M1/N1 36 — 58 MHz

—0.98—V

—0.98—V

PEAK

PEAK

DR VIN = 1 kHz, –3 dBFS 80 86 — dB

DR VIN = 1 kHz, –3 dBFS — 84 — dB

THD VIN = 1 kHz, –3 dBFS — –84 — dB

Dynamic Range (call progress AOUT) DR

THD (call progress AOUT) THD

AO

AO

AOUT Full Scale Level — 0.75 V

VIN = 1 kHz 60 — — dB

VIN = 1 kHz — 1.0 — %

—V

D

PP

AOUT Output Impedance — 10 — kΩ

Mute Level (call progress AOUT) –90 — — dB

Dynamic Range (caller ID mode) DR

Caller ID Full Scale Level (0 dB gain)

Notes:

1. See Figure 23 on page 22.

2. Parameter measured at TIP and RING of Figure16 on page 15.

3. Receive Full Scale Level will produce – 0.9 dBFS at SDO.

4.

DR = 3 dB + 20 log (RMS signal/RMS noise). Applies to both the transmit and receive paths. Measurement bandwidth

is 300 to 3400 Hz. Sample Rate = 9.6 kHz, Loop Current = 40 mA.

5.

DR = 3 dB + 20 log (RMS signal/RMS noise). Applies to both the transmit and receive paths. Measurement bandwidth

is 15 to 3400 Hz. Sample Rate = 9.6 kHz, Loop Current = 40 mA.

6. THD = 20 log (RMS distortion/RMS signal). Applies to both the transmit and receive paths.

Sample Rate = 9.6 kHz, Loop Current = 40 mA.

2

V

CID

VIN = 1 kHz, –13 dBFS — 60 — dB

CID

—0.8—V

PEAK

6 Rev. 1.2

Page 7

Si3035

Table 6. Absolute Maximum Ratings

Parameter Symbol Value Unit

DC Supply Voltage V

Input Current, Si3021 Digital Input Pins I

Digital Input Voltage V

Operating Temperature Range T

Storage Temperature Range T

Note: Permanent device damage may occur if the above Absolute Maximum Ratings are exceeded. Functional operation

should be restricted to the conditions as specified in the operational sections of this data sheet. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

, V

D

IN

IND

STG

A

–0.5 to 6.0 V

±10 mA

–0.3 to (VD + 0.3) V

A

–40 to 100 °C

–65 to 150 °C

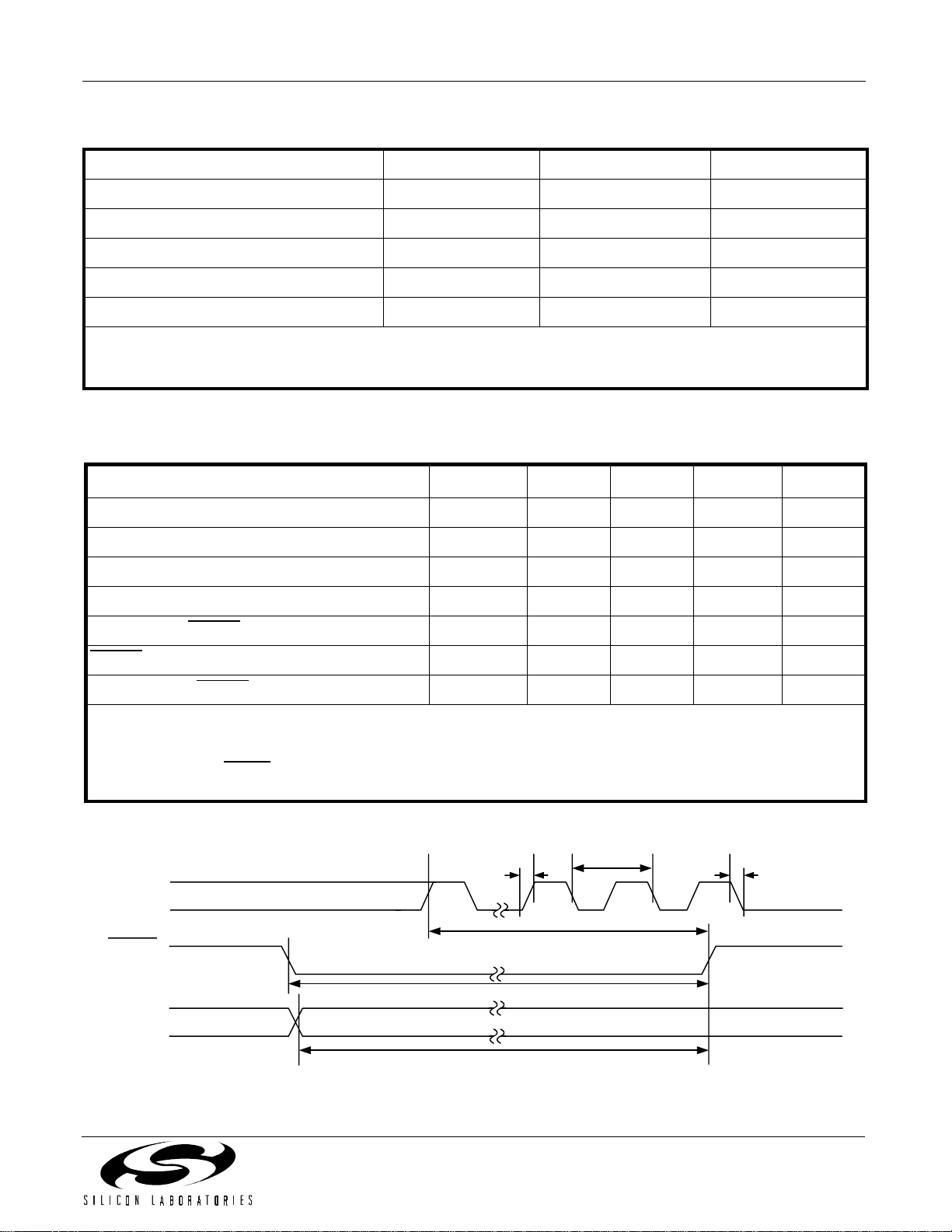

Table 7. Switching Characteristics—General Inputs

(VA = Charge Pump, VD = 3.0 to 5.25 V, TA = 0 to 70°C for K-Grade, CL = 20 pF)

Parameter

1

Cycle Time, MCLK t

MCLK Duty Cycle t

Rise Time, MCLK t

Fall Time, MCLK t

MCLK Before RESET

RESET

Pulse Width

M0, M1 Before RESET

Notes:

1.

All timing (except Rise and Fall time) is referenced to the 50% level of the waveform. Input test levels are

VIH = VD – 0.4 V, VIL = 0.4 V. Rise and Fall times are referenced to the 20% and 80% levels of the waveform.

2. The minimum RESET

3. M0 and M1 are typically connected to V

↑ t

2

3

↑

pulse width is the greater of 250 ns or 10 MCLK cycle times.

or GND and should not be changed during normal operation.

D

Symbol Min Typ Max Unit

16.67 — 1000 ns

40 50 60 %

—— 5 ns

—— 5 ns

10 — — cycles

250 — — ns

150 — — ns

t

mc

dty

mr

t

rl

mxr

r

f

MCLK

RESET

M0, M1

t

t

r

t

rl

t

mxr

mc

t

mr

Figure 2. General Inputs Timing Diagram

Rev. 1.2 7

t

f

V

IH

V

IL

Page 8

Si3035

Table 8. Switching Characteristics—Serial Int erface (DCE = 0)

(VA = Charge Pump, VD = 3.0 to 5.25 V, TA = 0 to 70°C for K-Grade, CL = 20 pF)

Parameter Symbol Min Typ Max Unit

Cycle time, SCLK t

SCLK duty cy cle t

Delay time, SCLK ↑ to FSYNC

↓ t

Delay time, SCLK ↑ to SDO valid t

Delay time, SCLK ↑ to FSYNC

↑ t

Setup time, SDI before SCLK ↓ t

Hold time, SDI after SCLK ↓ t

Setup time, FC ↑ before SCLK ↑ t

Hold time, FC ↑ after SCLK ↑ t

c

dty

d1

d2

d3

su

h

sfc

hfc

354 1/256 Fs — ns

—50—%

——10ns

——20ns

——10ns

25 — — ns

20 — — ns

40 — — ns

40 — — ns

Note: All timing is referenced to the 50% level of the waveform. Input test levels are V

t

c

SCLK

t

d1

FSYNC

(mode 0)

= VD – 0.4 V, VIL = 0.4 V

IH

t

d3

V

OH

V

OL

FSYNC

(mode 1)

16 Bit

SDO

16 Bit

SDI

FC

t

d3

t

d2

D15 D14 D1 D0

t

su

t

h

Figure 3. Serial Interface Timing Diagr am

D0D1D14D15

t

sfc

t

hfc

8 Rev. 1.2

Page 9

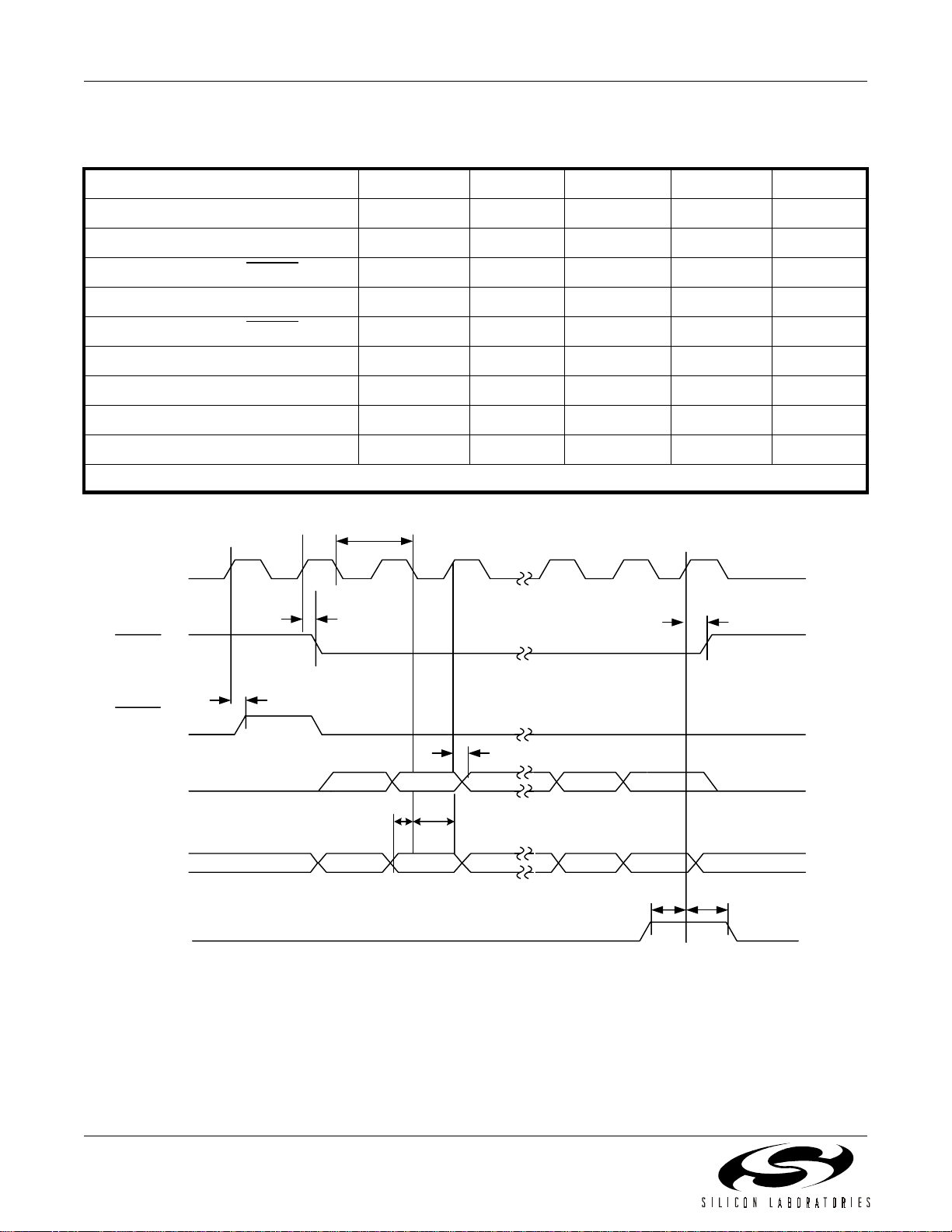

Table 9. Switching Characteristics—Serial Int erface (DCE = 1, FSD = 0)

(VA = Charge Pump, VD = 3.0 to 5.25 V, TA = 0 to 70°C for K-Grade, CL = 20 pF)

Si3035

Parameter

1,2

Cycle Time, SCLK t

SCLK Duty Cycle t

Delay Time, SCLK ↑ to FSYNC

Delay Time, SCLK ↑ to FSYNC

↑ t

↓ t

Delay Time, SCLK ↑ to SDO valid t

Delay Time, SCLK ↑ to SDO Hi-Z t

Delay Time, SCLK ↑ to RGDT

Delay Time, SCLK ↑ to RGDT

↓ t

↑ t

Setup Time, SDO Before SCLK ↓ t

Hold Time, SDO After SCLK ↓ t

Setup Time, SDI Before SCLK t

Hold Time, SDI After SCLK t

Symbol Min Typ Max Unit

c

dty

d1

d2

d3

d4

d5

d6

su

h

su2

h2

354 1/256 Fs — ns

—50 —%

— — 10 ns

— — 10 ns

0.25tc – 20 — 0.25tc + 20 ns

— — 20 ns

— — 20 ns

— — 20 ns

25 — — ns

20 — — ns

25 — — ns

20 — — ns

Notes:

1. All timing is referenced to the 50% level of the waveform. Input test levels are V

2. Refer to the section "Multiple Device Support" on page 25 for functional details.

32 SCLKs

t

c

16 SCLKs 16 SCLKs

= VD – 0.4 V, VIL = 0.4 V.

IH

SCLK

t

d1

FSYNC

(mode 1)

FSYNC

(mode 0)

t

SDO

(ma ster)

SDO

(slave 1)

FSD

(Mode 0)

FSD

(Mode 1)

SDI D15 D0

t

d2

t

d5

d3

t

su

D15 D14 D13 D0

t

su2

D14

t

h

t

h2

D13

t

d2

t

d6

t

d4

t

d5

t

d3

D15

t

d5

t

d2

Figure 4. Serial Interface Timing Diagram (DCE = 1, FSD = 0)

Rev. 1.2 9

Page 10

Si3035

Table 10. Switching Characteristics—Serial Interface (DCE = 1, FSD = 1)

(VA = Charge Pump, VD = 3.0 to 5.25 V, TA = 0 to 70°C for K-Grade, CL = 20 pF)

Parameter

1,2

Cycle Time, SCLK t

SCLK Duty Cycle t

Delay Time, SCLK ↑ to FSYNC

Delay Time, SCLK ↑ to FSYNC

↑ t

↓ t

Delay Time, SCLK ↑ to SDO valid t

Delay Time, SCLK ↑ to SDO Hi-Z t

Delay Time, SCLK ↑ to RGDT

↓ t

Setup Time, SDO Before SCLK ↓ t

Hold Time, SDO After SCLK ↓ t

Setup Time, SDI Before SCLK t

Hold Time, SDI After SCLK t

Symbol Min Typ Max Unit

c

dty

d1

d2

d3

d4

d5

su

h

su2

h2

354 1/256 Fs — ns

—50 —%

— — 10 ns

— — 10 ns

0.25tc – 20 — 0.25tc + 20 ns

— — 20 ns

— — 20 ns

25 — — ns

20 — — ns

25 — — ns

20 — — ns

Notes:

1. All timing is referenced to the 50% level of the waveform. Input test levels are V

2. Refer to the section "Multiple Device Support" on page 25 for functional details.

= VD – 0.4 V, VIL = 0.4 V.

IH

SCLK

FSYNC

(mode 1)

SDO

(ma ste r)

SDO

(slave 1)

FSD

SDI

t

c

t

d1

t

d3

t

d2

D15

t

su

t

h

D14 D13 D0

t

d4

t

d3

D15

t

d5

D14

t

h2

t

su2

D15 D1 D0

Figure 5. Serial Interface Timing Diagram (DCE = 1, FSD = 1)

10 Rev. 1.2

Page 11

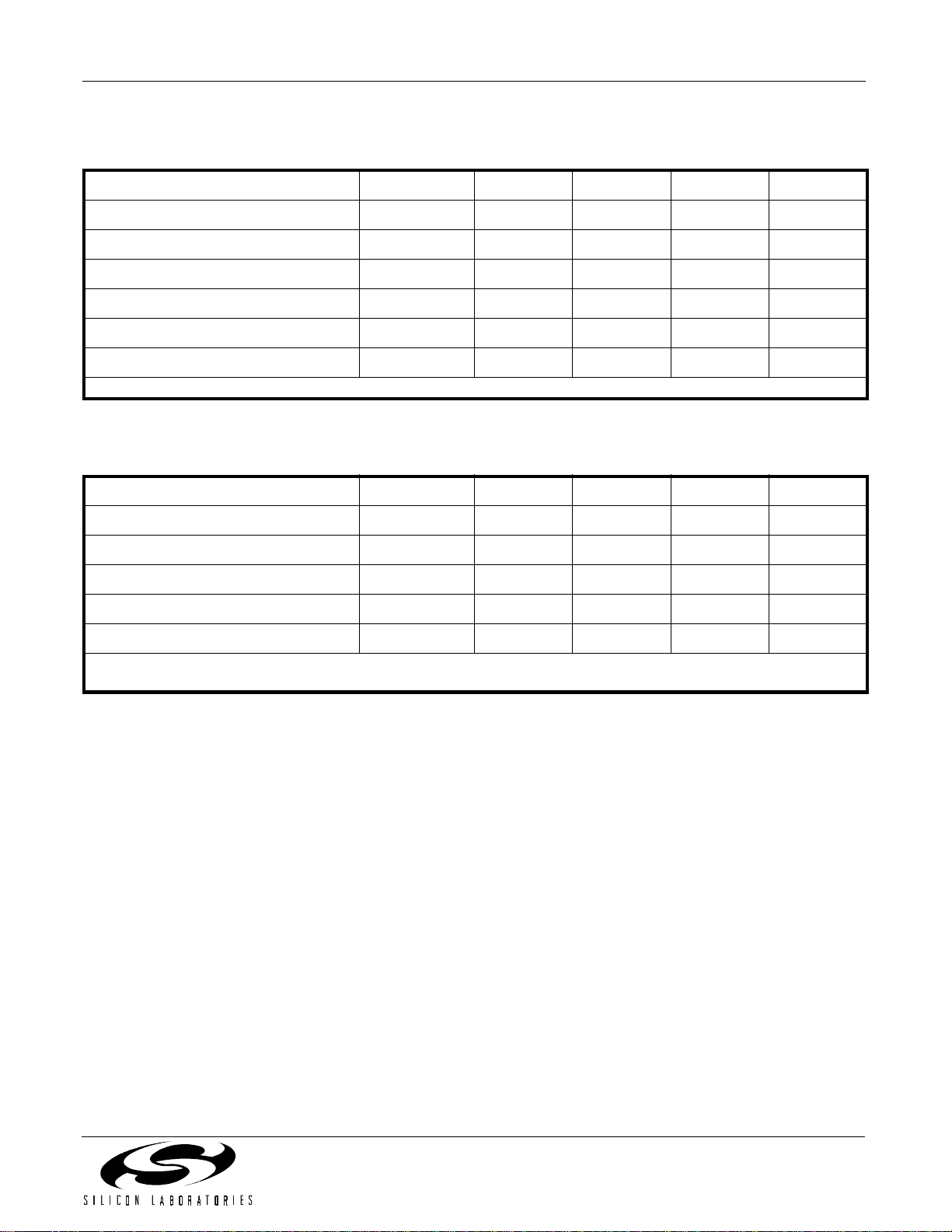

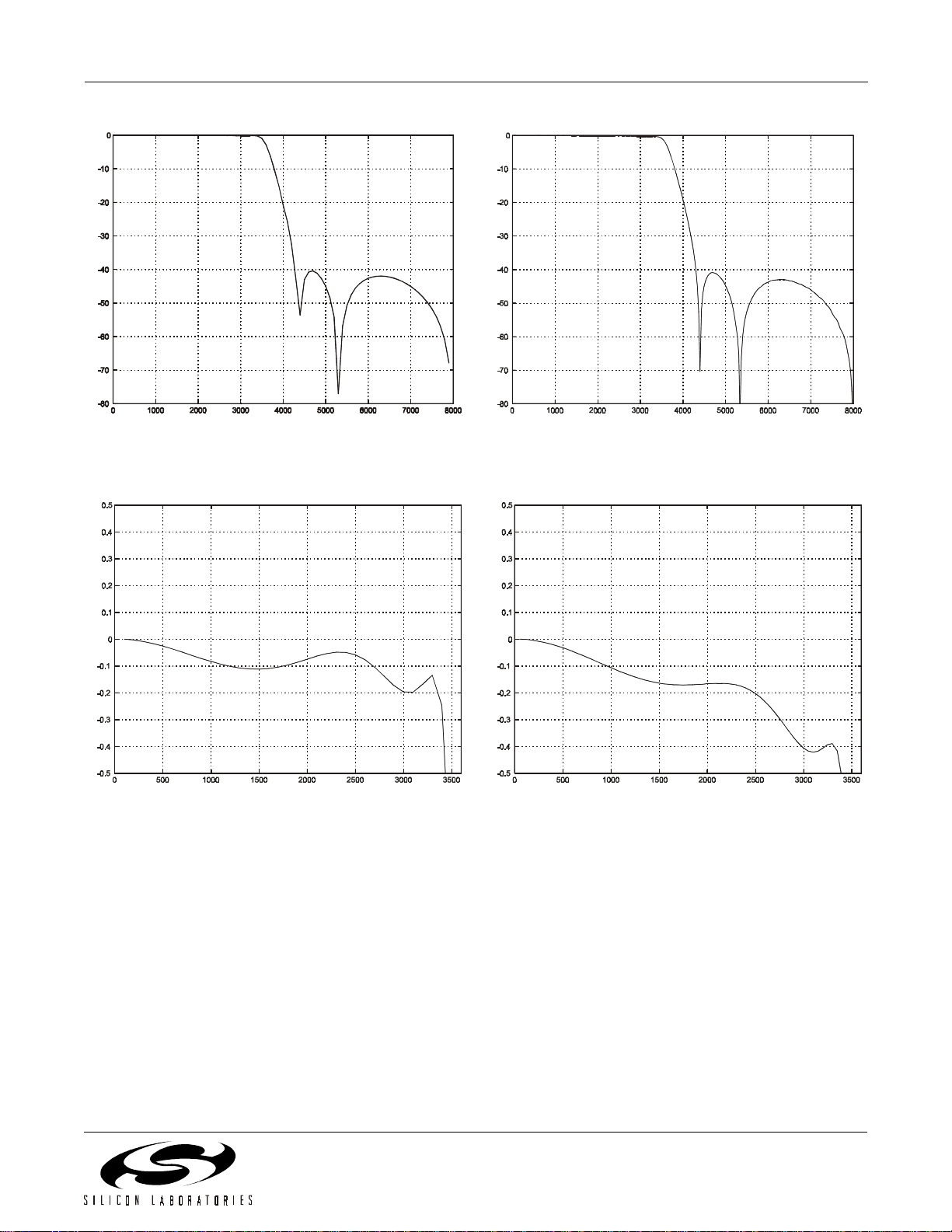

Table 11. Digital FIR Filter Characteristics—Transmit and Receive

(VA = Charge Pump, VD = +5 V ±5%, Sample Rate = 8kHz, TA = 0 to 70°C for K-Grade)

Parameter Symbol Min Typ Max Unit

Si3035

Passband (0.1 dB)

Passband (3 dB)

F

(0.1 dB)

F

(3 dB)

0—3.3kHz

0—3.6kHz

Passband Ripple Peak-to-Peak –0.1 — 0.1 dB

Stopband — 4.4 — kHz

Stopband Attenuation –74 — — dB

Group Delay

Note: Typical FIR filter characteristics for Fs = 8000 Hz are shown in Figures 6, 7, 8, and 9.

t

gd

— 12/Fs — sec

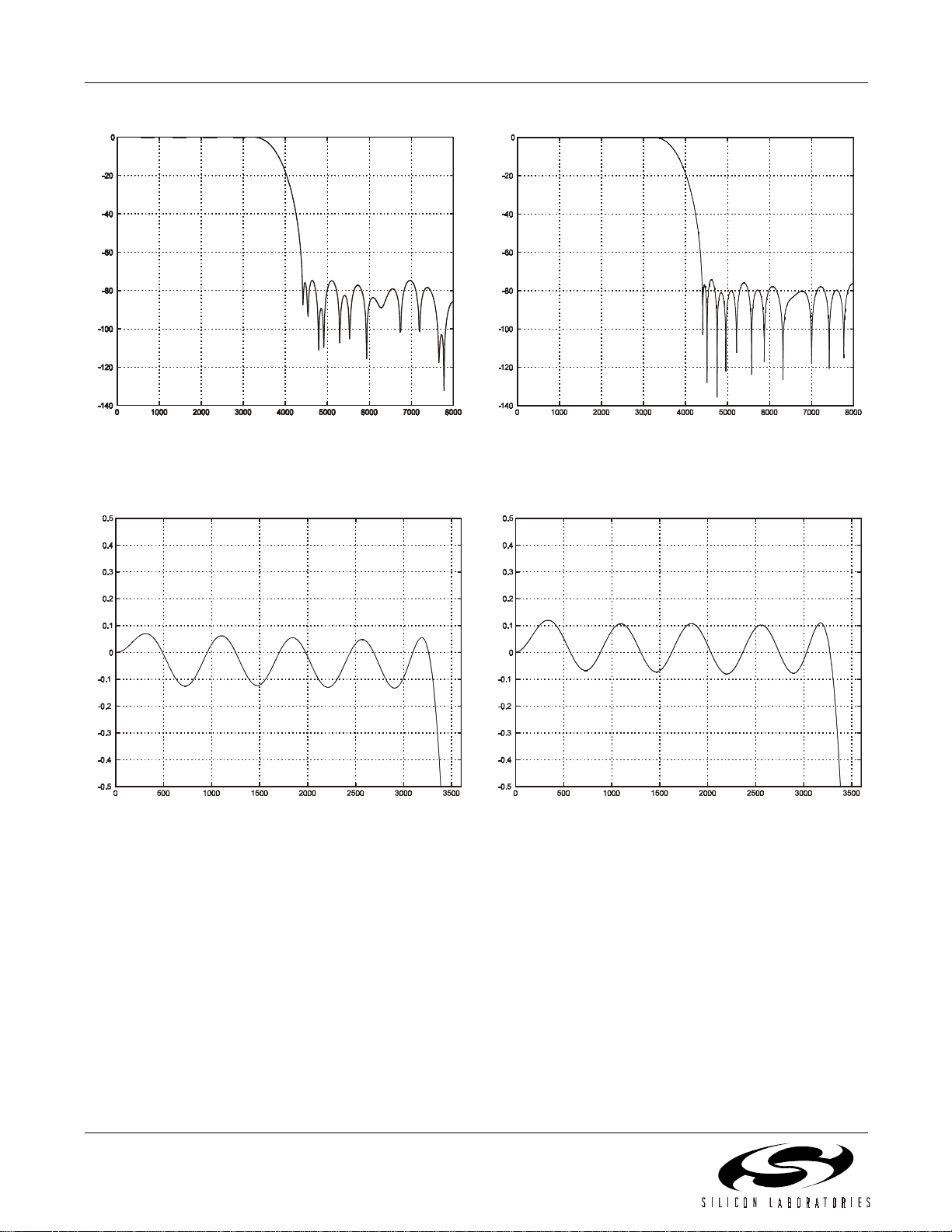

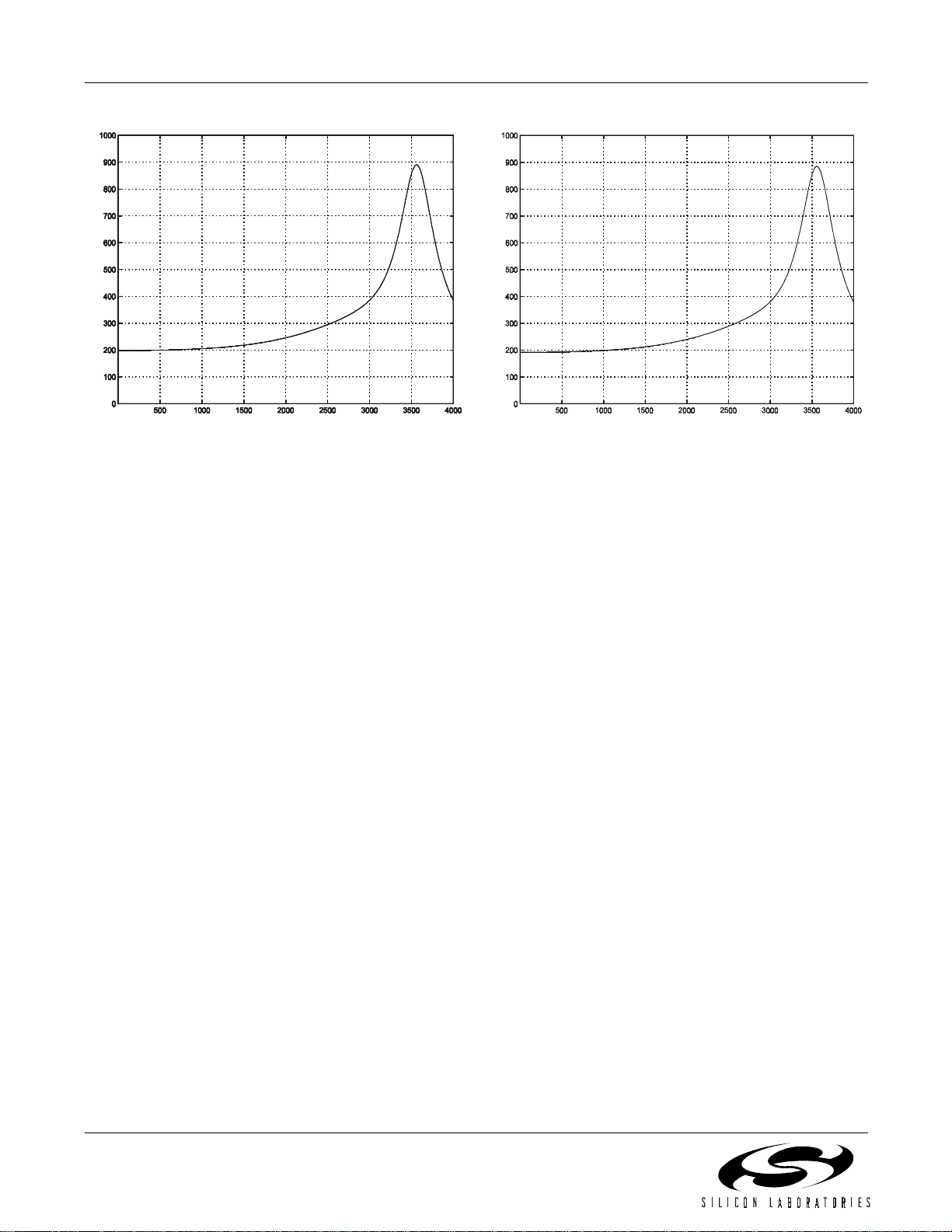

Table 12. Digital IIR Filter Characteri stics—Transmit and Receive

(VA = Charge Pump, VD = +5 V ±5%, Sample Rate = 8 kHz, TA = 0 to 70°C for K-Grade)

Parameter Symbol Min Typ Max Unit

Passband (3 dB)

F

(3 dB)

Passband Ripple Peak-to-Peak –0.2 — 0.2 dB

Stopband — 4.4 — kHz

Stopband Attenuation –40 — — dB

Group Delay

Note: Typical IIR filter characteristics for Fs = 8000 Hz are shown in Figures 10, 11, 12, and 13. Figures 14 and 15 show

group delay versus input frequency.

t

gd

0—3.6kHz

— 1.6/Fs — sec

Rev. 1.2 11

Page 12

Si3035

Attenuation—dB

Input Frequency—Hz

Figure 6. FIR Receive Filter Response

Attenuation—dB

Attenuation—dB

Input Frequency—Hz

Figure 8. FIR Transmit Filter Response

Attenuation—dB

Input Frequency—Hz

Figure 7. FIR Receive Filter Passband Ripple

For Figures 6–9, all filter plots apply to a sample rate of

Fs = 8 kHz. The filters scale with the sample rate as follows:

F

where Fs is the sample frequency.

12 Rev. 1.2

(0.1 dB)

F

(– 3 dB)

= 0.4125 Fs

= 0.45 Fs

Input Frequency—Hz

Figure 9. FIR T ransmi t Filter Passband Ripple

Page 13

Si3035

Attenuation—dB

Input Frequency—Hz

Figure 10. IIR Receive Filter Response

Attenuation—dB

Attenuation—dB

Input Frequency—Hz

Figure 12. IIR T ransmit Filter Response

Attenuation—dB

Input Frequency—Hz

Figure 11. IIR Receive Filter Passband Ripple

For Figures 10–13, all filter plots apply to a sample rate of

Fs = 8 kHz. The filters scale with the sample rate as follows:

F

(–3 dB)

where Fs is the sample frequency.

Input Frequency—Hz

Figure 13. IIR Transmit Filter Passband Ripple

= 0.45 Fs

Rev. 1.2 13

Page 14

Si3035

Delay—µs

Input Frequency—Hz

Figure 14. IIR Receive Group Delay Figure 15. IIR Transmit Group Delay

Delay—µs

Input Frequency—Hz

14 Rev. 1.2

Page 15

Typical Application Circuit

p

Decoupling cap for U1 VD

VCC

C10

RGDTb

OFHKb

MCLK

FSYNCb

SCLK

SDO

RESETb

AOUT

M0

SDI

FC

M1

R3

Decoupling cap for U1 VA

10

C3

Z4

U1

1

MCLK

2

FSYNC

3

SCLK

4

VD

5

SDO

6

SDI

7

FC

89

RESET AOUT

SOIC Pinout

Si3021

OFHK

RGDT

GND

16

15

14

M0

13

VA

12

11

C1A

10

M1

D3

BAV99

R27

C30

Rev. 1.2 15

No Ground Plane In DAA Section

R28

C1

D4

BAV99

C2

Z5

U2

Si3012

1

2

3

4

5

6

7

89

TSTA

TSTB

NC2

IGND

C1B

REXT

RNG1

DCT

RNG2

HYBD

QB

VREG2

QE VREG

16

TX

15

14

RX

13

12

11

10

C6

C16

R23

R1

R4

C12

R2

C8

R21

+

C5

C23

+

R18

Z1

R10

Q1

R5

Q2

R6

C20

Q3

FB2

RING

Note 1: R3 is not required when Vcc=3.3 V and the charge pump is

enabled (CPE = 1).

Note 2: If JATE support is not required, R21, C12 and C23

may be removed (R21 is effectively 0 ohms) and R4 should

be changed to a 604 ohm, 1/4 W, +- 1%.

Note 3: See Appendix for applications requiring UL 1950

3rd Edition com

liance.

D2

C9

C11

R22

C4

C7

R9

RV2

D1

C25

RV1

C24

FB1

C32

C31

TIP

Si3035

Figure 16. Typical Application Schematic

Page 16

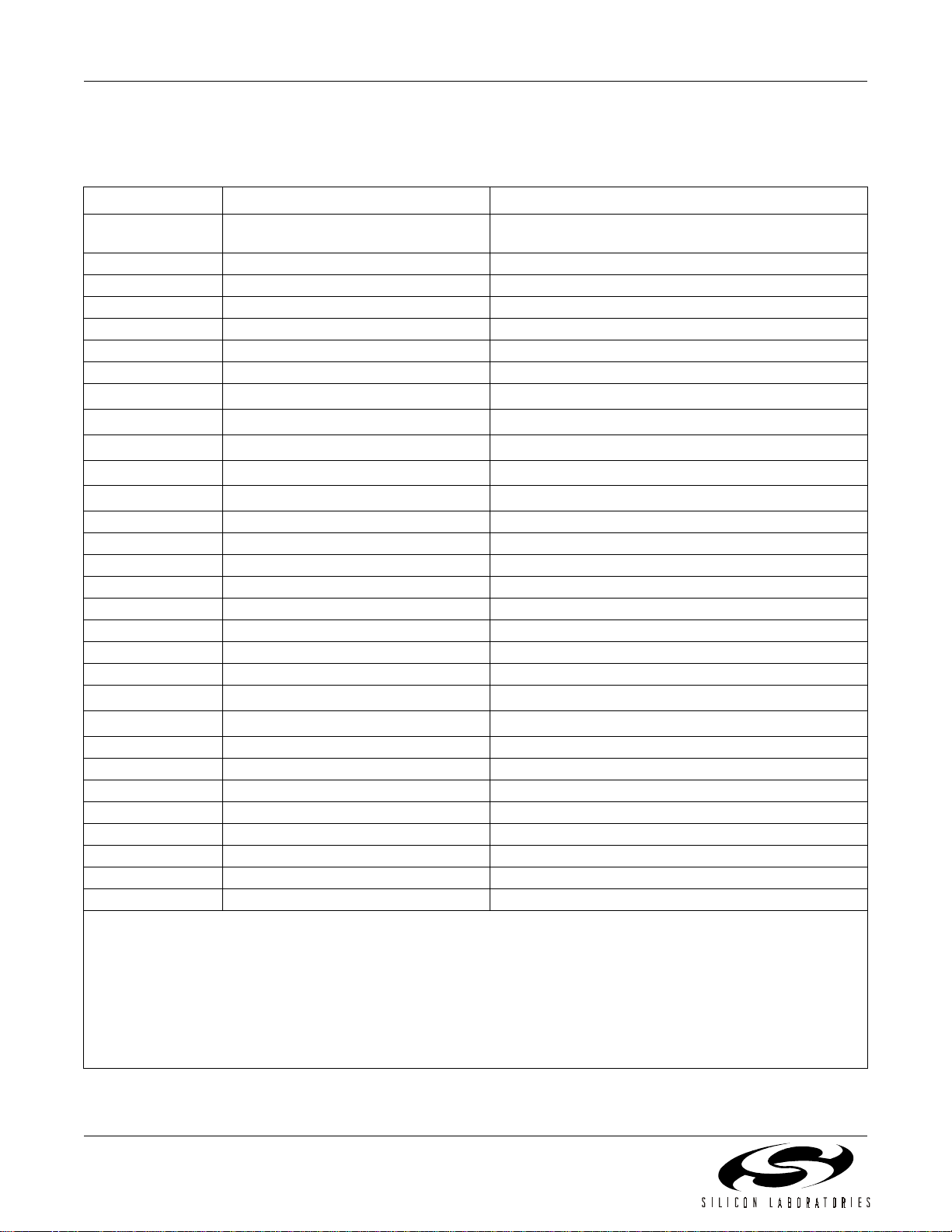

Si3035

Bill of Materials

Table 13. Component Values—Typical Application

Component

1

Value Supplier(s)

C1,C4 150 pF, 3 kV, X7R, ±20% Novacap, Venkel, Johanson, Murata,

Panasonic, SMEC

C2 Not Installed

C3 0.22 µF, 16 V, X7R, ±20%

C5 1 µF, 16 V, Tant/Elec, ±20%

C6,C10,C16 0.1 µF, 16 V, X7R, ±20%

C7,C8,C9 15 nF, 250 V, X7R, ±20% Novacap, Johanson, Murata, Panasonic, SMEC

C11 39 nF, 16 V, X7R, ±20%

2

C12

2

C23

C24, C25, C31,C32

4

C30

5

D1,D2

3

2.7 nF, 16 V, X7R, ±20%

0.1 µF, 16 V, Tant/Elec/X7R, ±20%

1000 pF, 3 kV, X7R, ±10% Novacap, Venkel, Johanson, Murata, Panasonic, SMEC

Not Installed

Dual Diode, 300 V, 225 mA Central Semiconductor

D3,D4 BAV99 Dual Diode, 70 V, 350 mW Diodes, Inc., OnSemiconductor, Fairchild

FB1,FB2 Ferrite B ead Murata

Q1,Q3 A42, NPN, 300 V OnSemiconductor, Fairchild

Q2 A92, NPN, 300 V OnSemiconductor, Fairchild

RV1 Sidactor, 275 V, 100 A Teccor, ST Microelectronics, Microsemi, TI

RV2 MOV, 240 V Panasonic

R1 51 Ω, 1/2 W ±5%

R2 15 Ω, 1/4 W ±5%

R4

2

6

R3

,R18,R21

2

Not Installed

301 Ω, 1/10 W, ±1%

R5,R6 36 kΩ, 1/10 W ±5%

R9,R10 2 kΩ, 1/10 W ±5%

R22,R23 20 kΩ, 1/10 W ±5%

R27,R28 10 Ω, 1/10 W ±5%

U1 Si3021 Silicon Labs

U2 Si3012 Silicon Labs

Z1 Zener diode , 18 V Vishay, Rohm, OnSemiconductor

Z4,Z5 Zener diode, 5.6 V, 1/2 W Diodes, Inc., OnSemiconductor, Fairchild

Notes:

1. The following reference designators were intentionally omitted: C13–C15, C17–C22, C26–C29, R7, R8, R11–R17,

R19, and R20.

2. If JATE support is not required, C12, and C23 may be removed.

3.

Alternate population option is C24, C25 (2200 pF, 3 kV, X7R, ±10% and C31, C32 not installed).

4. Install only if needed for improved radiated emissions performance (10 pF, 16 V, NPO, ±10%).

5. Several diode bridge configurations are acc ep tab le (sup pl iers incl ude General Semi, Diodes Inc.)

6. If the charge pump is not enabl ed (with th e CPE bit in Register 6), V

a 10 Ω, 1/10 W, ±5% if V

is also 4.75 to 5.25 V.

D

must be 4.75 to 5.25 V. R3 can be installed with

A

16 Rev. 1.2

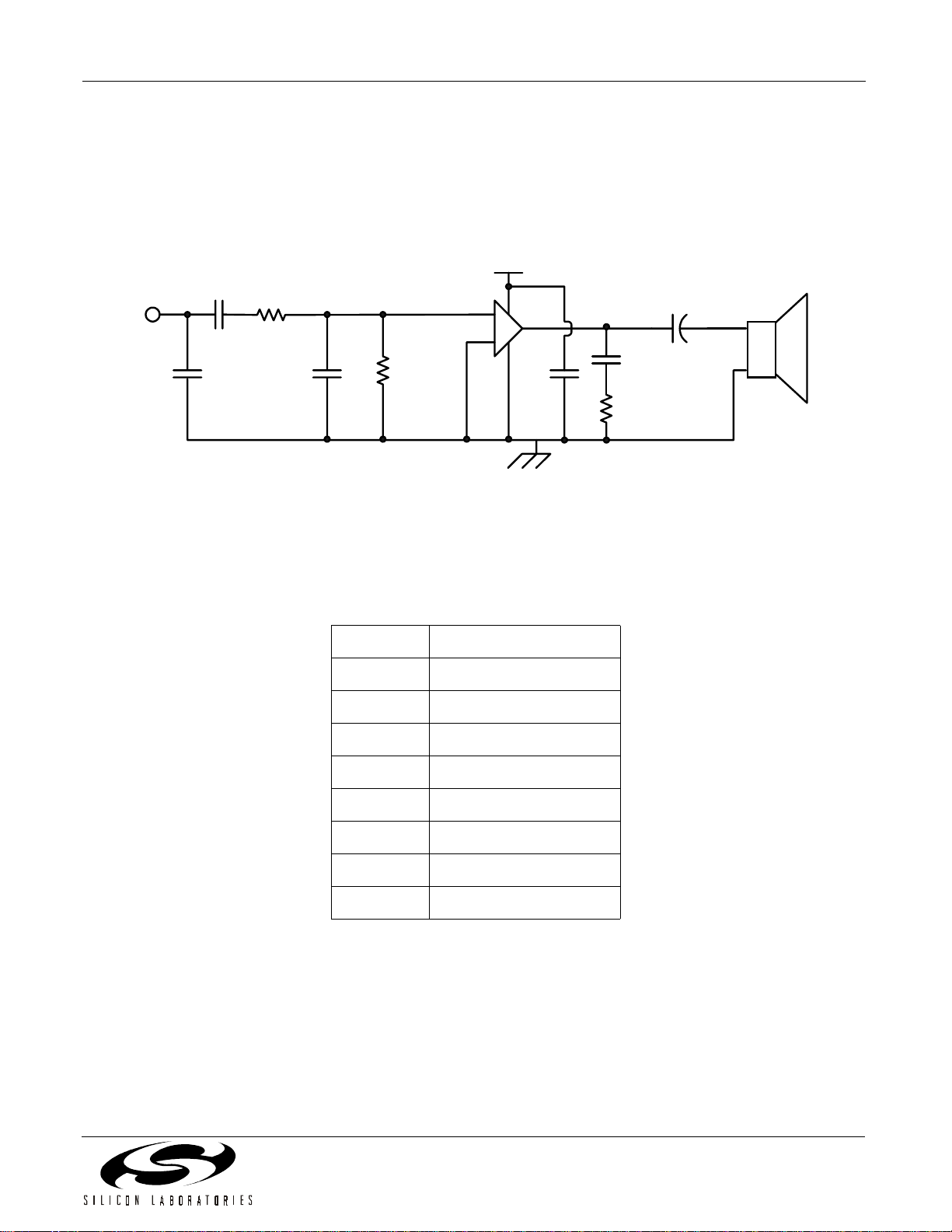

Page 17

Si3035

Analog Output

Figure 17 illustrates an optional application circuit to support the analo g output capability of the Si3035 for call

progress monitoring purp oses . T he AR M bi ts in Regi s ter 6 allow the receive path to be atte nua ted by 0 dB, –6 dB,

or –12 dB. The ATM bits, which are also in Register 6, allow the transmit path to be attenuated by –20 dB, –26 dB,

or –32 dB. Both the transmit and receive paths can also be independently muted.

+5 V

AOUT

C2

C1

R3

C6 R1

6

3

+

5

2

–

4

C3

R2

C4

+

C5

Speaker

Figure 17. Optional Connection to AOUT for a Call Progress Speaker

‘

Table 14. Component Values—Optional Connection to AOUT

Symbol Value

C1 2200 pF, 16 V, ±20%

C2, C3, C5 0.1 µF, 16 V, ±20%

C4 100 µF, 16 V, Elec. ±20%

C6 820 pF, 16 V, ±20%

R1 3 kΩ, 1/10 W, ±5%

R2 10 Ω, 1/10 W, ±5%

R3 47 kΩ, 1/10 W, ±5%

U1 LM386

Rev. 1.2 17

Page 18

Si3035

Functional Description

The Si3035 is an integrated chipset that provides a

low-cost, isolated, silicon-based interface to the

telephone line. The Si303 5 saves cost and board area

by eliminating the need for a modem AFE or serial

codec. It also eliminates the need for an isolation

transformer, relays, opto-isolators, and a 2- to 4-wire

hybrid. The Si3035 solution requires only a few

low-cost, discrete components to achieve full

compliance with FCC Part 68 and JATE out-of-band

noise requirements. See Figure 16 on page 15 for a

typical application circuit. See the pin-compatible

Si3034 or Si3044 data sheets for designs requiring

global support.

The Si3035 North America /Japan DAA offers a number

of new features not supported by the Si3032 device.

These include operation from a single 3.3 V power

supply, JATE (Japan) filter option, finer resolution for

both transmit and receive levels on AOUT (call progress

output), daisy-cha ining for up to eight devices, and an

optional IIR filter. Table 15 summarizes the new Si3035

features.

Table 15. New Si3035 Features

Category Si3032 Si3035

Daisy-Chaining — Up to 8 Devices

Optional IIR Filter — Yes

procedure:

1. Program the PLLs with registers 7 to 9 (N1[7:0], M1[7:0],

N2[3:0] and M2[3:0]) to the appropriate divider ratios for

the supplied MCLK freque ncy and desired sample rate , as

defined in "Clock Generati on Subs ys te m" on page 20.

2. Wait until the PLLs are locked. This time is between

100 µS and 1 ms.

3. Write an 0x80 into Register 6. This enables the charge

pump for the V

and enables the AOUT for call progress monitoring.

pin, powers up the line-sid e chip (Si3012) ,

A

After this procedure is comp lete, the Si3035 is ready for

ring detection and off-hook.

Isolation Barrier

The Si3035 achieves an isolation barrier through a

low-cost, high-voltage capacitor in conjunction with

Silicon Laboratories’ proprietary ISOcap signal

processing technique s. Th ese techn iques eliminate any

signal degradation due to capacitor mismatches,

common mode interference, or noise coupling. As

shown in Figure 16 on page 15, the C1, C2, and C4

capacitors isolate the Si3021 (DSP-side) from the

Si3012 (line-side). All transmit, receive, control, and

caller ID data are communicated through this barrier.

The ISOcap inter-chip communication is disabled by

default. To enable it, the PDL bit in Regis ter 6 must be

cleared. No communication between the Si3021 and

Si3012 can occur until this bit is cleared. The clock

generator must be programmed to an acceptable

sample rate prior to clearing the PDL bit.

Receive Gain 0, 6 dB 0, 3, 6, 9, 12 dB

Transmit Attenuation 0, –3 dB 0, –3, –6 –9,

–12 dB

V

A

V

D

5 V 3.3 V* or 5 V

3.3 V or 5 V 3.3 V or 5 V

JATE Support — Yes

AOUT Levels (dB) 0, mute 0, –6, –12, mute

*Note:

The VA supply is internally generated by an on-chip

charge pump.

Initialization

When the Si3035 is initially powe re d up, the R ES ET pin

should be asserted. When the RESET

deasserted, the regi sters will have default values. This

reset condition gua ra nte es th e li ne- s id e ch ip ( Si3012) is

powered down with no possibility of loading the line (i.e.,

off-hook). The following is an example initialization

pin is

Off-Hook

The communication system generates an off-hook

command by applying logic 0 to the OFHK

a logic 1 to bit 0 of control Register 5. The OF HK

must be enabled by setting bit 1 (OHE) of Register 5 .

With OFHK

at logic 0, the sys t em is in an off-hook sta t e.

This state is used to seize the line for incoming/outgoing

calls and can also be used for pulse dialing. With OFHK

at logic 1, negligible DC current flows through the

hookswitch. When a log ic 0 is appli ed to the O FHK

the hookswitch transi stor pair, Q1 and Q2, turn on. The

net effect of the off-hook s ignal is the application of a

termination impedance across TIP and RING and the

flow of DC loop current. The termination impedance has

both an AC and a DC component.

The AC termination impedance is a 604-Ω resistor,

which is connected to the TX pin. The DC termination is

a 51-Ω resistor, which is connected to the DCT pin.

When executing an off-hook sequence, the Si3035

requires 1548/Fs sec onds to comp lete the off-hook and

provide phone line data on the serial link . This includes

the 12/Fs filter group delay. If necessary, for the shortest

pin or writing

pin

pin,

18 Rev. 1.2

Page 19

Si3035

delay, a higher Fs may be established prior to executing

the off-hook, such as an Fs of 10.286 kHz. The del ay

allows line transients to settle prior to normal use.

Ring Detect

The ring signal enters the Si3035 through low value

capacitors connected to TIP and RING. RGDT

clipped, half-wave rectified version of the ringing

waveform. See Figure 18 for a timing diagram of the

RGDT

pin.

The integrated ring detect of the Si3035 allows the

device to present the ring signal to the DSP, through the

serial port, with no additional signaling required. The

signal sent to the DSP is a clipped version of the original

ring signal. In addition, the S i3035 passes through the

caller ID data unaltered.

The system can also detect an occurring ring by the

status of the RDT bit of Register 5. This bit is a

read-only bit that is set when the line-side device

detects a ring signal at RNG1 an d RNG2. The RDT bit

clears when the system either go es off-hook or 4.5 to 9

seconds after the last ring is detected.

If caller ID is supported in th e system , the designer can

enable the Si3035 to pass th is information to the SDO

output. Following the completion of the first ring, the

system should set the ONHM bit (Register 5, bit 3). This

bit must be cleared at the co nclusion of the receipt of

the caller ID data and prior to the next ring burst.

The Si3021 can support a wake-up-on-ring function

using the RGDT

on page 24 for more details

.

signal. Refer to "Power M anagement"

is a

Improved JATE Support

The HYBD pin connects to a node on the internal hybrid

cancellation circuit providing a pin for a balancing

capacitor, C12. C23 adds the necessary transmit

out-of-band filter ing required to m eet JATE out-of-band

noise specifications. The addition of C23 alters the

transmit path frequency response which must be

balanced with capacito r C12 to obtain maximum hybr id

cancellation.

Products using th e Si3035 which have b een submitted

for JATE approval should document a waiver for the

JATE DC Termination s pecific ation. Thi s sp ecifi catio n is

met in the Si3034 global DAA device.

Digital Interface

The Si3035 has two seria l int erface m ode s tha t supp ort

most standard modem DSPs. The M0 and M1 mode

pins select the interface mode. The key difference

between these two serial modes is the operation of the

FSYNC

definitions.

signal. Table 16 summarizes the serial mode

Table 16. Serial Modes

Mode M1 M0 Description

0 0 0 FSYNC

1 0 1 FSYNC

2 1 0 Slave mode

3 1 1 Reserved

frames data

pulse starts data frame

RNG1/

RNG2

RGDT

SDO

First Ring

0.2–3.0 seconds

0.5–1.5 Sec.

DIGITIZED LINE SIGNAL

Figure 18. Ring Detect Timing

Rev. 1.2 19

> 0.2 Sec.

DATA

Page 20

Si3035

The digital interface consists of a single, synchronous

serial link which communicates both telephony and

control data.

In Serial mode 0 or 1, the Si3021 operates as a master,

where the master clock (MCLK) is an input, the serial

data clock (SCLK) is an output, and the frame sync

signal (FSYNC

) is an output. The MCLK frequency an d

the value of the sample rate control registers 7, 8, 9,

and 10 determine the sampl e rate (Fs). The serial port

clock, SCLK, runs at 256 bits per frame, where the

frame rate is equivalent to the sample rate. Refer to

"Clock Generation Subsystem" on page 20 for more

details on programming sample rates.

The Si3035 transfers 16 -bit or 15-bit telephony data in

the primary timeslot and 16-bit control data in the

secondary timeslot. Figure 19 and Figure 20 show the

relative timing of the serial frames. Primary frames

occur at the frame rate and are always present. To

minimize overhead in the external DSP, secondary

frames are present only when requested.

Two methods exist for transferring control info rm ati on in

the secondary frame. The default power-up mode uses

the LSB of the 16-bit transmit (TX) data word as a flag

to request a secondary transfer. In this mode, only

15-bit TX data is tr ansferred, re sulting in a loss of S NR

but allowing softw are control of the secondar y frames.

As an alternative method, the FC pin can serve as a

hardware flag for requesting a secondary frame. The

external DSP can tu rn on th e 1 6- bit T X m ode by setting

the SB bit of Register 1. In the 16-bit TX mode, the

hardware FC pin must be used to request secondary

transfers.

Communications Frame 1 (CF1) (CF2)

Figure 21 and Figure 22 illustrate the secondary frame

read cycle and writ e cycle, respectively. During a read

cycle, the R/W

bit is high and the 5-bit address field

contains the address of the register to be read. The

contents of the 8-bi t control register are place d on the

SDO signal. During a wri te cy cle, th e R/W

bit is low and

the 5-bit address field contains the address of the

register to be written. The 8-bit data to be written

immediately follows the address on SDI. Only one

register can be read or writte n during each secondary

frame. See "Control Registers" on page 34 for the

register addresses and functions.

In serial mode 2, the Si3021 operates as a slave device,

where the MCLK is a n input, the S CLK is a no c onnect

(except for the master device for which it is an output),

and the FSYNC

is an input. In addi tion, the RGDT/FSD

pin operates as a delayed frame sync (FSD) and the

FC/RGDT

pin operates as ring detect (RGDT). In this

mode, FC operation is not supp or ted. For fur the r detai ls

on operating the Si3021 as a slave device, refer to

"Multiple Device Support" on page 25.

Clock Generation Subsystem

The Si3035 contai ns an on-chip cl ock generator. Using

a single MCLK input frequency, the Si3035 can

generate all the desi red stan dard m odem s ample rates,

as well as the common 11.025 kHz rate for audio

playback.

The clock generator consists of two PLLs (PLL1 and

PLL2) that achieve the desired sample frequencies.

Figure 23 on page 22 illustrates the clock generator.

FSYNC

FC 0

SDI

SDO

Primary

D15 – D1 D0 = 1 (Software FC Bit)

XMT Data

RCV Data

16 SCLKS

128 SCLKS

Secondary Primary

Secondary

Data

Secondary

Data

256 SCLKS

Figure 19. Software FC Secondary Request

20 Rev. 1.2

D15 – D1 D0 = 0 (Software FC Bit)

XMT Data

RCV Data

Page 21

Comm unications Frame 1 (CF1) (CF2)

Si3035

FSYNC

FC 0

SDI

SDO

FSYNC

(mode 0)

Primary

D15–D0

XMT Data

RCV Data

16 SCLKS

128 SCLKS

Secondary Primary

Secondary

Data

Secondary

Data

256 SCLKS

XMT Data

RCV Data

Figure 20. Hardware FC Secondary Request

FSYNC

(mode 1)

D15 D14 D13 D12 D11 D10 D 9 D8 D7 D0

SDI

SDO

0 0 1 A A A A A

R/W

D7 D 6 D 5 D4 D3 D 2 D 1 D 0

D

D D D D D D D

Figure 21. Secondary Communication Data Format—Read Cycle

Rev. 1.2 21

Page 22

Si3035

FSYNC

(mode 0)

FSYNC

(mode 1)

D15 D 1 4 D 1 3 D12 D 1 1 D10 D 9 D 8 D7 D 6 D5 D 4 D 3 D2 D 1 D 0

SDI

SDO

0 0 0 A A A A A

R/W

D D D D D D D D

Figure 22. Secondary Communication Data Format—Write Cycle

UP1 FUP2FPLL1 FPLL2

F

MCLK

DIV N1

8 bits

DIV

25

PLL1 PLL2

DIV M1

8 bits

1

0

CGM

Bit

Figure 23. Clock Generation Subsystem

The architecture of the dual PLL scheme allows for fast

lock time on initial start-up, fast lock time when

changing modem sample rates, high noise immunity,

and the ability to change modem sample rates with a

single register write. A large number of MCLK

frequencies between 1 MHz and 60 MHz are supported.

MCLK should be from a clean source, preferably

directly from a crystal wit h a constant fr equency and no

dropped pulses.

In serial mode 2, the Si3021 operates as a slave device.

The clock generator is con fig ured (by d efau lt) to se t the

SCLK output equal to the MCL K input. The net effect is

the clock generator multiplies the MCLK input by 20. For

further details of slave mode operation, refer to "Multiple

Device Support" on page 25.

DIV N2

4 bits

DIV

5

1024·Fs

0

DIV M2

4 bits

DIV

1

16

Programming the Clock Generator

As noted in Figure 23, the clock generator must output a

clock equal to 1024

sample rate. The 1024

"

Fs, where Fs is the desired

"

Fs clock is d eterm ine d thr ough

programming of the following registers:

Register 7—N1 divider, 8 bits.

Register 8—M1 divider, 8 bits.

Register 9—N2/M2 dividers, 4 bits/4 bits.

Register 10—CGM, 1 bit.

When using the Si3035 for modem applications, the

clock generator can be programmed to allow for a single

register write to change the modem sampling rate.

These standard sample rates are shown in Table 17.

The programming method is described below.

22 Rev. 1.2

Page 23

Si3035

Table 17. N2, M2 Values (CGM = 0, 1)

Fs (Hz) N2 M2

7200 2 2

8000 9 10

8229 7 8

8400 6 7

9000 4 5

9600 3 4

10286 7 10

The main design consideration is the generation of a

base frequency, defined as the following:

F

MCLK

---------------------------------- 36.8 64 M H z C G M,0== =

F

MCLK

--------------------------------------------- -36.864MHzCGM,1== =

F

Base

F

Base

N1 (Register 7) a nd M1 (Register 8 ) are 8-bit unsigned

values. F

is the clock provided to the MCLK pin.

MCLK

Table 18 lists several standard crystal oscillator rates

that could be supplied to MCLK. This list simply

represents a sam pl e o f M CLK fr eq uen cy c ho ices . M any

more are possible.

After the first PLL has be en setup, the secon d PLL can

be programmed easily. The values for N2 and M2

(Register 9) are sho wn in Table 17. N2 an d M2 ar e 4- bit

unsigned values.

When programming the registers of the clock generator,

the order of register writes is important. For PLL1

updates, N1 (Register 7) must always be written first,

immediately foll owed by a write t o M1 (Register 8). For

PLL2, the CGM bit must be set as desired prior to

writing N2/M2 (Register 9). Changes to the CGM bit

only take effect when N2/M2 are written.

Note: The values shown in Table 17 and Table 18 satisfy the

equations above. However, when programming the

registers for N1, M1, N2, and M2, the value placed in

these registers must be one less than the value calculated from t he equations. For ex ample, for CGM = 0

with a MCLK of 48.0MHz, the values placed in the N1

and M1 registers would be 0x7C and 0x5F, respectively. If CGM = 1, a non-zero value must be programmed to Register9 in order for the 16/25 ratio to

take effect.

N1 25⋅

N1

M1⋅16

M1⋅

⋅

Table 18. MCLK Examples

MCLK (MHz) N1 M1 CGM

1.8432 1 20 0

4.0000 5 72 1

4.0960 1 9 0

5.0688 11 80 0

6.0000 5 48 1

6.1440 1 6 0

8.1920 32 225 1

9.2160 1 4 0

10.0000 25 144 1

10.3680 9 32 0

11.0592 3 10 0

12.288 1 3 0

14.7456 2 5 0

16.0000 5 18 1

18.4320 1 2 0

24.5760 32 75 1

25.8048 7 10 0

33.8688 147 160 0

44.2368 96 125 1

46.0800 5 4 0

47.9232 13 10 0

48.0000 125 96 0

56.0000 35 36 1

60.0000 25 24 1

PLL Lock Times

The Si3035 changes sample rates very quickly.

However, lock time will vary based on th e pro gramm ing

of the clock gen erator. The major factor contribu ting to

PLL lock time is the CGM bit. When the CGM bit is used

(set to 1), PLL2 will lock slower than when CGM is 0.

The following relations hips describe the boundaries on

PLL locking time:

PLL1 lock time < 1 ms (CGM = 0,1)

PLL2 lock time: 100 us to 1 ms (CGM = 0)

PLL2 lock time <1 ms (CGM = 1)

For modem designs, it is recommended that PLL1 be

programmed during initialization. No further

programming of PLL1 is necessary. The CGM bit and

PLL2 can be program med for the d esired initi al sample

Rev. 1.2 23

Page 24

Si3035

rate, typically 7200 Hz. All further sample rate changes

are then made by simpl y writin g to Reg ister 9 to update

PLL2.

The final design consid eration fo r the cl ock gene rator is

the update rate of PLL1. The following criteria must be

satisfied in order for the PLLs to remain stable:

F

MCLK

---------------------=144kHz≥

N1

Where F

F

UP1

is shown in Figure 23 on page 22.

UP1

Setting Generic Sample Rates

The above clock gener ation description focu ses on the

common modem sample rates. An application may

require a sample rate not listed in Table 17, such as the

common audio rate o f 11.025 kHz. The restrictio ns and

equations above still apply; however, a more generic

relationship betwe en MC LK a nd F s (the des ir ed sam ple

rate) is needed. The following eq uation describes this

relationship:

M1 M2⋅

--------------------- r a t i o

N1 N2⋅

51024Fs⋅⋅

--------------------------------

⋅=

MCLK

where Fs is the sample frequency, ratio is 1 for

CGM = 0 and 25/16 fo r CGM = 1, and all other symbols

are shown in Figure 23 on page 22.

By knowing the MCLK frequency and desired sample

rate, the values for the M1, N1, M2, N2 registers can be

determined. When determining these values, remember

to consider the range for each register as well as the

minimum update rate for the first PLL.

The values determined for M1, N1, M2, and N2 must be

adjusted by minus one when determining the value

written to the respective registers. This is due to internal

logic, which adds one to the val ue st ored in the register.

This addition allows the user to write a zero value in any

of the registers and the effective divide by is one. A

special case oc curs when both M1 and N1 and /or M2

and N2 are programmed with a zero value. Wh en Mx

and Nx are both zero, the corresponding PLLx is

bypassed. Note that if M 2 and N2 are set to zero, th e

ratio of 25/16 is el iminated and cannot be used in the

above equation. In this condition the CGM bit has no

effect.

Power Management

The Si3035 supports four basic power management

operation modes: normal operation, reset operation,

sleep, and full power down. The power management

modes are controlled by the PDN and PDL bits of

Register 6.

On power up, or followi ng a re se t, the Si 303 5 is in re se t

operation. In this mode, the PDL bit is set, while the

PDN bit is cleared. The Si3021 is fully operational,

except for the ISOcap l ink. No comm unication betwee n

the Si3021 and Si3012 can occur during reset

operation. Any bits asso ciated with the Si3012 are not

valid in this mode.

The most common mode of operation is the normal

operation. In this mode, the PDL and PDN bits are

cleared. The Si3021 is ful ly oper ationa l and the IS Ocap

link is passing in formation betwee n the Si3021 an d the

Si3012. The clock gener ator must be programmed to a

valid sample rate prior to entering this mode.

The Si3035 supports a low-power sleep mode. This

mode supports the popul ar wake-up-on-ring feature of

many modems. The clock g enerator register s 7, 8, and

9 must be programm ed with va lid non- zero va lues prior

to enabling sleep m ode. The n, the PDN bit must be set

and the PDL bit cleared. Whe n the Si3035 is in sleep

mode, the MCLK signal may be stopped or remain

active, but it must be active before waking up the

Si3035. The Si3021 is non-functional except for the

ISOcap and RGDT

sleep mode, pulse the reset pin (RESET

signal. To take the Si3035 out of

) low .

In summary, the power down/up sequence for sleep

mode is as follows:

1. Registers 7, 8, and 9 must have valid non-zero values.

2. Set the PDN bit (Register6, bit 3) and clear the PDL bit

(Register 6, bit 4).

3. MCLK may stay active or stop.

4. Restore MCLK before initiating the power-up sequence.

5. Reset the Si3035 using RESET pin (after MCLK is

present).

6. Program registers to desired settings.

The Si3035 also supports an additional power-down

mode. When both the PDN (Register 6, bit 3) and PDL

(Register 6, bit 4) are set, the chipset ent ers a c omp let e

power-down mode and draws negligible current (dee p

sleep mode). PLL2 should be turned off prior to entering

deep sleep mode (i.e., set Register 9 to 0 and then

Register 6 to 0x18). In this mode , the RGDT

pin does

not function. Normal operation may be restored using

the same process for taking the chipset out of sleep

mode.

Analog Output

The Si3035 supports an analog output (AOUT) for

driving the call progress speaker found with most of

today’s modems. AOUT is an analog signal that is

comprised of a mix of the tran smit and receiv e signals.

The receive portion of this mixed signal has a 0 dB gain,

while the transmit signal has a gain of –20 dB.

The AOUT level can be adj usted via th e ATM and ARM

bits in control Register 6. The transmit portion of the

24 Rev. 1.2

Page 25

Si3035

AOUT signal can be set to –20 dB, –2 6 dB, –32 dB, or

mute. The receive portion of the AOUT signal can be

set to 0 dB, –6 dB, –12 dB, or mu te. Figure 17 on page

17 illustrates a recomme nded application circui t. In the

configuration shown, the LM386 provides a gain of

26 dB. Additional gain adjustments may be made by

varying the voltage divider created by R1 and R3 of

Figure 17.

On-Hook Line Monitor

The Si3035 allows the user to detect line activity when

the device is in an on-hoo k state. When the system is

on-hook, the line data can be passed to the DSP across

the serial port while drawing a small amount of DC

current from the line. This feature is similar to the

passing of line information (such as caller ID), while

on-hook, following a ring signal detection. To activate

this feature, set the ONHM bit in Register 5.

The on-hook line monitor can also be used to detect

whether a phone line is physically connected to the

Si3012 and associ ated circuitry. When the on-hook l ine

monitor is activated (if no line is connect ed), the output

of SDO will move towards a negative full scale value

(–32768). The value is guaranteed to be at least 89% of

negative full scale.

If a line is present whil e in on-hook line monito r mode,

SDO will have a near zero value. The designer must

allow for the group delay of the receive filter (12/Fs)

before making a decision.

Loop Current Monitor

When the system is in an off-hook state, the LCS bits of

Register 12 indicate the approximate amount of DC

loop current that is flowing in the loop. The LCS is a

4-bit value ranging from zero to fifteen. Each unit

represents approximately 6 mA of loop current from

LCS codes 1–14. The typical LCS transfer function is

shown in Figure 24.

15

10

LCS

BIT

5

0

0 6 1218 24 30 36 42 48 54 60 66

Figure 24. Typical LCS Transfer Function

72

78 84 90 96

Loop Current (mA)

155

An LCS value of zero means the loop current is less

than required for normal operation and the system

should be on-hook. Typically, an LCS value of 15 means

the loop current is greater than 155 mA.

The LCS detector has a built-in hysteresis of 2 mA of

current. This allows for a stable LCS value when the

loop current is near a tr ansition level . The LCS valu e is

a rough approximation of the loop current, and the

designer is advised to use this value in a relative means

rather than an absolute value.

This feature enables the ho st processor to detect if an

additional line has “picked up” while the modem is

transferring informat ion. In the case of a second phon e

going off-hook, the loop current falls approximately 50%

and is reflected in the value of the LCS bits.

Multiple Device Support

The Si3035 supports the operation of up to seven

additional devices on a single serial interface.

on page 27

shows the typical connection of the Si3035

and one additional serial voice codec (Si3000).

The Si3035 must be the master in this configuration. The

secondary codec should be configure d as a sl ave de vice

with SCLK and FSYNC

as inputs. On power up, the

Si3035 master will be unaware of the additional codec

on the serial bus. The FC/RGDT

pin is an input,

operating as the hardware control for secondary frames.

The RGDT

/FSD pin is an output, operating as the active

low ring detection signal. It is recommended that the

master device be programmed for master/slave mode

prior to enabling the ISOcap, because a ring signal

would cause a false transition to the slave device’s

FSYNC

.

Register 14 provides the necessary control bits to

configure the Si3035 for master/slave operation. Bit 0

(DCE) sets the Si3035 in master/slave mode, also

referred to as daisy-chain mode. When the DCE bit is

set, the FC/RGDT

and the RGDT

pin becomes the ring detect output

/FSD pin becomes the frame sync delay

output.

Bits 7:5 (NSLV2:NSLV0) set the number of slaves to be

supported on the serial bus. For each slave, the Si3035

will generate a FSYNC

to the DSP. In daisy-chain mode,

the polarity of the ring signal can be controlled by bit 1

(RPOL). When RPOL = 1, the ring detect signal (now

output on the FC/RGDT

pin) is active high.

The Si3035 supports a variety of codecs (e.g., Si3000)

as well as additional Si3035s. The type of slave codec( s)

used is set by bits 4:3 (SSEL1:SSEL0). These bits

determine the type of signalling used i n the LSB of SDO.

This assists the DSP in isolating which data stream is

the master and which is the slave. If the LSB is used for

Figure 25

Rev. 1.2 25

Page 26

Si3035

signalling, the master device will have a unique setting

relative to the slave devices. The DSP can use this

information to determine which FSYNC

beginning of a sequence of data transfers.

The delayed frame sync (FSD) of each device is

supplied as the FSYNC

device in the daisy chain. The master Si3035 will

generate an FSYNC

32 SCLK periods. The dela y perio d is set by R egister 14,

bit 2 (FSD). Figures 26–29 show the relative timing for

daisy chaining operation. Primary communication

frames occur in sequence, followed by secondary

communication frames, if requested. When

writing/reading the master device via a secondary frame,

all secondary frames of the slave devices must be

written as well. When writing/reading a slave device via

a secondary frame, the secondary frames of the master

and all other slaves must be written as well. "No

operation" writes/reads to secondary frames are

accomplished by writing/reading a zero value to address

zero.

If FSD is set for 16 SCLK periods between FSYNC

only serial mode 1 can be used. In addition, the slave

devices must delay the tri-state to active transition of

their SDO sufficiently from the rising edge of SCLK to

avoid bus contention.

The Si3035 supports the operation of up to eight Si3035

devices on a single serial bus. The master Si3035 must

be configured in serial mode 1. The slave(s) Si3035 is

configured in serial mode 2. Figure 30 shows a typical

master/slave connection using three Si3035 devices.

When in serial mode 2, FSYNC

RGDT

/FSD becomes the delay frame sync output, and

FC/RGDT

addition, the internal PLLs are fixed to a multiply by 20.

This provides the desired sample rate when the ma ste r’s

SCLK is provided to the slave’s MCLK. The SCLK of the

slave is a no connect in this configuration. The delay

between FSYNC

(RGDT

output has a waveform identical to the FSYNC

serial mode 0. In addition, the LSB of SDO is set to zero

by default for all devices in serial mode 2.

becomes the ring detection output. In

input and delayed frame sync output

/FSD) will be 16 SCLK periods. The RGDT/FSD

of each subsequent slave

signal for each device every 16 or

becomes an input,

marks the

signal in

Register 13 must be 0.

The receive path can support gains of 0, 3, 6 , 9, and

12 dB. The gain is selected by bits 2:0 (ARX2:ARX0).

The receive path can also be muted by setting bit 3

(RXM). The transmit path can support attenuations of 0,

3, 6, 9, and 12 dB. The attenuation is selec ted by bits

6:4 (ATX2:ATX0). The transmit path can also be muted

by setting bit 7 (TXM).

Filter Selection

The Si3035 supports addi tional filter selections for the

receive and transmit s ignals. When set, the IIRE bit of

Register 16 enables the IIR filters defined in T able 12 on

page 11. This filter provides a much lower, however

non-linear, group delay than the default FIR filters.

s,

Gain Control

The Si3035 supports multiple gain and attenuation

settings for the rece iv e an d tr an sm it p aths , r espec ti ve ly,

via Register 13. When the ARX bit is set, 6 dB of gain is

applied to the receive path. When the ATX bit is set,

–3 dB of gain is applied to the transmit path.

Register 15 can be used to provide additional gain

control. For Register 15 to have an effect on the receive

and transmit paths, the ATX and ARX bits of

26 Rev. 1.2

Page 27

MCLK

DSP Si3021

MCLK

SCLK

SDO

SDI

FSYNC

SCLK

SDI

SDO

FSYNC

Si3035

INT 0

FC/RGDT

VCC

RGDT/FSD

M0

M1

47 k

Ω

47 k

Ω

+5 V

47 kΩ

Si3000

SCLK

MCLK

FSYNC

SDI

SDO

Voice

Codec

Figure 25. Typical Connection for Master/Slave Operation (e.g., Data/Fax/Voice Modem)

Rev. 1.2 27

Page 28

Si3035

Master

Slave 1

Master FSYNC

Master FSD/

Slave1 FSYNC

SDI [0 ]

SDI [1 5 ..1 ]

SDO [0]

SDO[15..1 ]

Comments

Master

Slave 1

Serial Mode 1

Reg 14: NSLV = 1, SSEL = 2, FSD = 0, DCE = 1

Serial Mode 2

Reg 14 Reset values: NSLV = 1, SSEL = 3, FSD = 1, DCE = 1

Primary Frame (Data) Secondary Frame (Control)

128 SCLKs 128 SCLKs

32 SCLKs 32 SCLKs

1

Master

1

Master

Primary frames with secondary frame requested via SDI[0] = 1

1

Slave1

0

Slave1

Figure 26. Daisy Chaining of a Single Slave (Pulse FSD)

Serial Mode 1

Reg 14: NSLV = 1, SSEL = 2, FSD = 1, DCE = 1

Serial Mode 2

Reg 14 Reset values: NSLV = 1, SSEL = 3, FSD = 1, DCE = 1

Primary Frame (Data) Secondary Frame (Control)

128 SCLKs 128 SCLKs

Master

Master

Master

Master

Slave1

Slave1

Slave1

Slave1

Master FSYNC

Master FSD/

Slave1 FSYNC

SDI [0 ]

SDI [1 5 ..1 ]

SDO [0]

SDO[15..1 ]

Comments

16 SCLKs

1

Master

1

Master

Primary frames with secondary frame requested via SDI[0] = 1

16 SCLKs 16 SCLKs 16 SCLKs

1

Slave1

0

Slave1

Master

Master

Master

Master

Figure 27. Daisy Chaining of a Single Slave (Frame FSD)

Slave1

Slave1

Slave1

Slave1

28 Rev. 1.2

Page 29

Master

Slave 1

Master

FSYNC

Master FSD/

Slave1 FSYNC

Slave1 FSD/

Slave2 FSYNC

Slave2 FSD/

Slave3 FSYNC

Serial Mode 1

Reg 14: NSLV = 7, SSEL = 2, FSD = 1, DCE = 1

Serial Mode 2

Reg 14 Reset values: NSLV = 1, SSEL = 3, FSD = 1, DCE = 1

Primary Frame (Data)

128 SCLKs

16 SCLKs

Secondary Frame (Control)

128 SCLKs

Rev. 1.2 29

Slave3 FSD/

Slave4 FSYNC

Slave4 FSD/

Slave5 FSYNC

Slave5 FSD/

Slave6 FSYNC

Slave6 FSD/

Slave7 FSYNC

SDI [0]

SDI [15..1]

SDO [0]

SDO[15..1]

Comments

1

Master

1

Master

Primary frames with secondary frame requested via SDI[0] = 1

1

Slave1

0

Slave1

1

Slave2

0

Slave2

1

Slave3

0

Slave3

1

Slave4

0

Slave4

1

Slave5

0

Slave5

1

Slave6

0

Slave6

1

Slave7

0

Slave7

Master

Master

Master

Master

Slave1

Slave1

Slave1

Slave1

Slave2

Slave2

Slave2

Slave2

Slave3

Slave3

Slave3

Slave3

Slave4

Slave4

Slave4

Slave4

Slave5

Slave5

Slave5

Slave5

Slave6

Slave6

Slave6

Slave6

Slave7

Slave7

Slave7

Slave7

Si3035

Figure 28. Daisy Chaining of Eight DAAs

Page 30

Si3035

Master

Slave 1

Master FSYNC

Master FSD/

Slave1 FSYNC

SDI [0 ]

SDI [1 5 ..1 ]

SDO [0]

SDO [15..1 ]

Comments Primary frames with secondary frame requested via SDI[0] = 1

Serial Mode 0

Reg 14: NSLV = 1, SSEL = 2, FSD = 0, DCE = 1

Serial Mode 2

Reg 14 Reset values: NSLV = 1, SSEL = 3, FSD = 1, DCE = 1

Primary Frame (Data) Secondary Frame (Control)

128 SCLKs 128 SCLKs

16 SCLKs

1

Master

1

Master

1

Slave1

0

Slave1

Figure 29. Daisy Chaining with Framed FSYNC and Framed FSD

Master

Master

Master

Master

Slave1

Slave1

Slave1

Slave1

30 Rev. 1.2

Page 31

MCLK

DSP Si3021–Master

MCLK

SCLK

SDO

SDI

FSYNC

SCLK

SDI

SDO

FSYNC

Si3035

INT 0

47 k

FC/RGDT

RGDT/FSD

VCC

M1

M0

Ω

47 k

Ω

Si3021–Slave 1

MCLK

SCLK

FSYNC

SDI

SDO

RGDT/FSD

VCC

M1

M0

Si3021–Slave 2

MCLK

SCLK

FSYNC

SDI

SDO

RGDT/FSD

VCC

M1

M0

Figure 30. Typical Connection for Multiple Si3035s

Rev. 1.2 31

Page 32

Si3035

Revision Identi fication

The Si3035 provides t he system designer the a bility to

determine the revi sion of the Si30 21 and /or the S i3012 .

Register 11 identifies the revision of the Si3021 with 4

bits named REVA. Register 13 identifies the re vision of

the Si3012 with 4 bits named REVB. Table 19 shows

the values for the various revisions.

Table 19. Revision Values

Revision Si3021 Si3012

A 1000 —

B 1001 —

C 1010 —

D — 0100

E — 0101

G — 0111

Calibration

The Si3035 initiates an auto-calibration by default

whenever the device goes off-hook or experiences a

loss in line power. Calibration is used to remove any

offsets that may be present in the on-chip A/D converter

which could affect the A/D dynamic range.

Auto-calibration is typically initiated after the DAA DC

termination stabilizes and takes 512/Fs seconds to

complete. Due to the large variation in line conditions

and line card behavior that may be presented to the

DAA, it can be beneficial to use manual calibration in

lieu of auto-calibration. Manual calibration should be

executed as close as possible to 512/Fs seconds before

valid transmit/receive data is expected.

The following steps should be taken to implement

manual calibration:

1. The CALD (auto-calib ration dis able—Regis ter 17) bit must

be set to 1.

2. The MCAL (manual calibration) bit must be toggled to 1

and then 0 to begin and complete the calibration.

3. The calibration will be completed in 512/Fs seconds.

In-Circuit Testing

The Si3035’s advanced design provides the modem

manufacturer with an increased ability to determine

system functionali ty d ur ing pr od uction line tests, as well

as support for end-user diagnostics. Four loopback

modes exist allowing increased coverage of system

components. For three of the test modes, a line-side

power source is needed. While a standard phone line

can be used, the test circuit in Figure 1 on page 4 is

adequate. In addition, an off-hook sequence must be

performed to connect the power sour ce to the line-side

chip.

For the start-up test mode, no line-side power is

necessary and no off-hook sequence is required. The

start-up test mode i s enabled by default. Whe n the PD L

bit (Register 6, bit 4) is set (the default case), the line

side is in a power-down mode and the DSP -side is in a

digital loop-back mod e. In this mode, data received on

SDI is passed through the internal filters and

transmitted on SDO. This path will introduce

approximately 0.9 dB of attenuation on the SDI signal

received. The grou p delay of both transmit and re ceive

filters will exist between SDI and SDO. Clearing the

PDL bit disables this mode and the SDO data is

switched to the receiv e data from the line side. When

the PDL bit is cleared the FDT bit (Register 12, bit 6) will

become active, indicating the successful

communication between the line-side and DSP-side.

This can be used to verify that the ISOcap link is

operational.

The remaining test modes require an off-hook sequence

to operate. The following s equ enc e d efi nes the off-hook

requirement:

1. Power up or reset.

2. Program clock generator to desired sample rate.

3. Enable line-side by clearing PDL bit.

4. Issue off-hook

5. Delay 1548/Fs to allow calibration to occur.

6. Set desired test mode.

The ISOcap digital loopback mode allows the data

pump to provide a digital input tes t pattern on SDI and

receive that dig ital te st patt ern ba ck o n SDO. To enable

this mode, set the DL bit of Register 1. In this mode, the

isolation barrier is actually being tested. The digital

stream is delivered acro ss the isolati on capacit or, C1 of

Figure 16 on page 15, to the line-side device and

returned across the same barrier. In this mode, the

0.9 dB attenuation and filter group delays also exist.

The analog loopback mod e al low s an ex te rnal device to

drive the RX pin of the line-side chip and receive the

signal from the TX pin. This mode allows testing of

external components connecting the RJ-11 jack (TIP

and RING) to the line side of the Si3 035. To enable this

mode, set the AL bit of Register 2.

The final testing mode, internal analog loo pback , allows

the system to test the basic operation of the

transmit/receive path of the line side and the external

components R4, R18, R21, and C5 of Figure 16 on

page 15. In this test m ode, the data pump provides a

32 Rev. 1.2

Page 33

Si3035

digital test waveform on SDI. This data is passed across

the isolation barrier, looped from the T X to the RX pin,

passed back across the isol ation ba rrier, and presente d

to the data pump on SDO. To enable this mode, clear

the HBE bit of Register 2.

Clearing the HBE bit will cause a DC offset which

affects the signal swing of the transmit signal. In this test

mode, it is recommended that the transmit signal be

12 dB lower than normal transmit levels. This lower

level will eliminate clipping caused by the DC offset

which results fro m disabl ing the hybrid . It is ass umed i n

this test that the line AC impedance is nominally 600 Ω.

Note:

All test modes are mutually exclusive. If more than one

test mode is enabled concurrently, the results are

unpredictable.

Exception Handling

The Si3035 provides s everal mechanis ms to determ ine

if an error occurs during operation. Through the

secondary frames of the serial link, the contr olling DSP

can read several status bits. The bit of highest

importance is the frame detect bit (FDT, Register 12,

bit 6). This bit indi cates that the DSP-s ide (Si3021) an d

line-side (Si3012) devices are communicating. During

normal operation, the FDT bit can be checked before

reading any bits that indica te information abo ut the line

side. If FDT is not set, the following bits related to the

line-side are invalid: RDT, LCS, CBID, and REVB. The

RGDT

operation will also be non-functional.

Following power-up and reset, the FDT bit is not set

because the PDL bit (Re gister 6, bit 4) defaults to 1. In

this state, the ISOcap link is not operating and no

information about the line-side can be determined . The

user must program the clock generator to a valid

configuration for the system and clear the PDL bit to

activate the ISOcap link. W hile the Si3021 and Si3012

are establishing communication, the Si3035 will not

generate FSYNC

will take less than 10 ms. Therefore, if the controlling

DSP serial interface is interrupt driven, based on the

FSYNC

special delay loop to wait for this event to complete.

The FDT bit can also ind icate if the line-side executes

an off-hook request successfu lly. If the line -side is not

connected to a p hon e l in e (i .e., the us er fai ls to connect

a phone line to the modem), the FDT bit remains

cleared. The contr olling DSP must allow suffici ent time

for the line-side to execute the off-hook request. The

maximum time for FDT to be valid following an off-hook

request is 10 ms. At this time, the LCS bits ind icate the

amount of loop current flowing. For more information,

see “Loop Current Monitor ” on page 25. If the FDT bit

fails to be set following an off-hook request, the line-side

signal, the controllin g DSP does not require a

signals. Establishing communication

chip must be reset. This is accomplished by setting the

PDL bit for at least 1 ms.

Another useful bit is t he comm unica tion li nk err or (CLE)

bit (Register 12, bit 7). The CLE bit indicat es a time-out

error for the ISOcap link following a change to either

PLL1 or PLL2. For more information, see “Clock

Generation Subsys tem” on page 20. Whe n the CLE bit

is set, the DSP-side chip has failed to receive

verification from the lin e side that the clock change has

been accepted in an expec ted period of time (l ess than

10 ms). This condition indicates a severe error in

programming the clock generator or possibly a defective

line-side chip.

Rev. 1.2 33

Page 34

Si3035

Control Registers

Any regist er not listed here is reserved and s hould not be written.

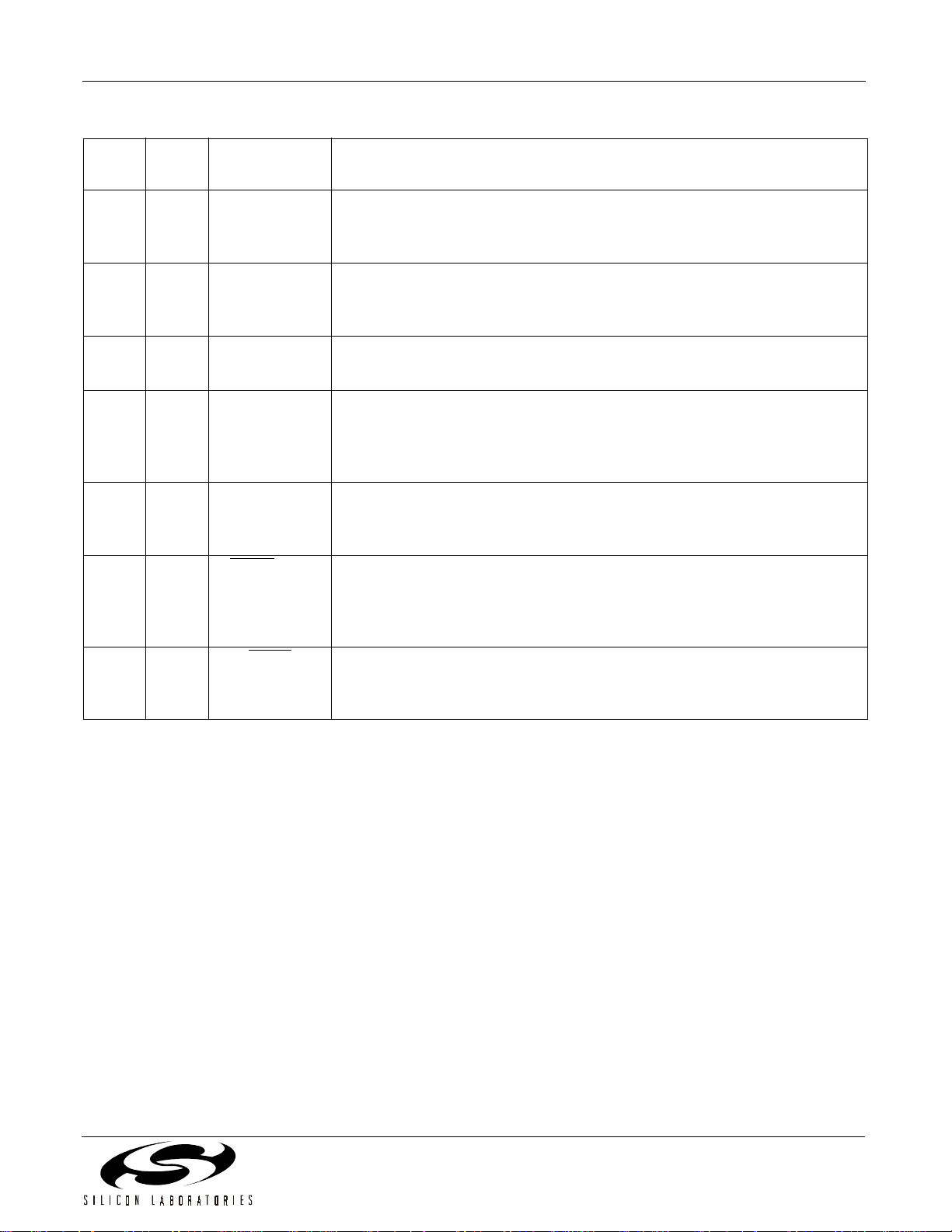

T able 20. Register Summary

Register Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 Control 1 SR DL SB

2 Control 2 AL HBE RXE

3 Control 3

4 Control 4

5 DAA Control 1 OPOL ONHM RDT OHE OH

6 DAA Control 2 CPE ATM1 A RM1 PDL PDN ATM0 ARM0

7 PLL1 Divide N1 N1[7:0]

8 PLL1 Multiply

M1

9 PLL2 Div./Mult.

N2/M2

10 PLL Control CGM

11 Chip Revision REVA[3:0]

12 Line Side Status CLE FDT LCS[3:0]

13 Transmit and

Receive Gain

14 Daisy-Chain

Control

15 TX/RX Gain

Control

16IIR Filter Control000IIRE1000

17 Calibration 0 MCAL CALD

NSLV2 NSLV1 NSLV0 SSEL1 SSEL0 FSD RPOL DCE

TXM ATX2 ATX1 ATX0 RXM ARX2 ARX1 ARX0

N2[3:0] M2[3:0]

CBID REVB[3:0] ARX ATX

M1[7:0]

34 Rev. 1.2

Page 35

Register 1. Control 1

Bit D7D6D5D4D3D2D1D0

Name SR DL SB

Type R/W R/W R/W

Reset settings = 0000_0000

Bit Name Function

7SRSoftware Reset.

0 = Enables chip for normal operation.

1 = Sets all registers to their reset value.

6:2 Reserved Read returns zero.

1DLIsolation Digital Loopback.

0 = Disables digital loopback mode across the isolation barrier.

1 = Enables digital loopback mode across the isolation barrier.

0SBSerial Digital Interface Mode.

0 = Operation is in 15-bit mode and the LSB of the data field indicates whether a secondary

frame is required.

1 = The serial port is operating in 16-bit mode and requires use of the secondary frame sync

signal, FC/RGDT

, to initiate control data reads/writes.

Si3035

Register 2. Control 2