Page 1

50 Ω 50 Ω 50 Ω

R

LightChargerTM155 Mb/s Transimpedance Amplifier

Applications

§ SONET/SDH-based transmission systems, test

equipment and modules

§ OC-3 fibre optic modules and line termination

§ ATM and FDDI optical receivers

Features

§ Single +5 V power supply

§ Input noise current = 12 nA rms when used with a

0.5 pF detector

§ Transimpedance gain = 15 kΩ into a 50 Ω load

(single-ended)

§ On-chip automatic gain control gives input

current overload of 2.6 mA pk and max output

voltage swing of 300 mV pk-pk

§ 50 Ω single-ended or 100 Ω differential wire bond

selectable outputs

§ Bandwidth (-3 dB) = 150 MHz (min)

§ Wide data rate range = 10 Mb/s to 155 Mb/s

§ High input bias level = 2 V

§ Minimal external components, supply decoupling

only

§ Operating junction temperature range = -40°C to

+95°C

§ Equivalent to Nortel Networks AB52

Ordering Information

SE1000W

Final

Product Description

SiGe Semiconductor offers a portfolio of optical

networking ICs for use in high-performance optical

transmitter and receiver functions, from 155 Mb/s up

to 12.5 Gb/s.

SiGe Semiconductor’s SE1000W is a fully integrated,

silicon bipolar transimpedance amplifier; providing

wideband, low noise preamplification of signal current

from a photodetector. It features single-ended or

differential outputs, selectable by wire bond options,

and incorporates an automatic gain control

mechanism to increase dynamic range, allowing input

signals up to 2.6 mA peak. For differential outputs, a

decoupling capacitor on the supply is the only

external circuitry required.

Noise performance is optimized for 155 Mb/s

operation, with a calculated rms noise based

sensitivity of –41 dBm for 10

using a detector with 0.5 pF capacitance and a

responsivity of 0.95 A/W, with an infinite extinction

ratio source.

-10

bit error rate, achieved

Type Package Remark

SE1000W Bare Die Shipped in

Waffle Pack

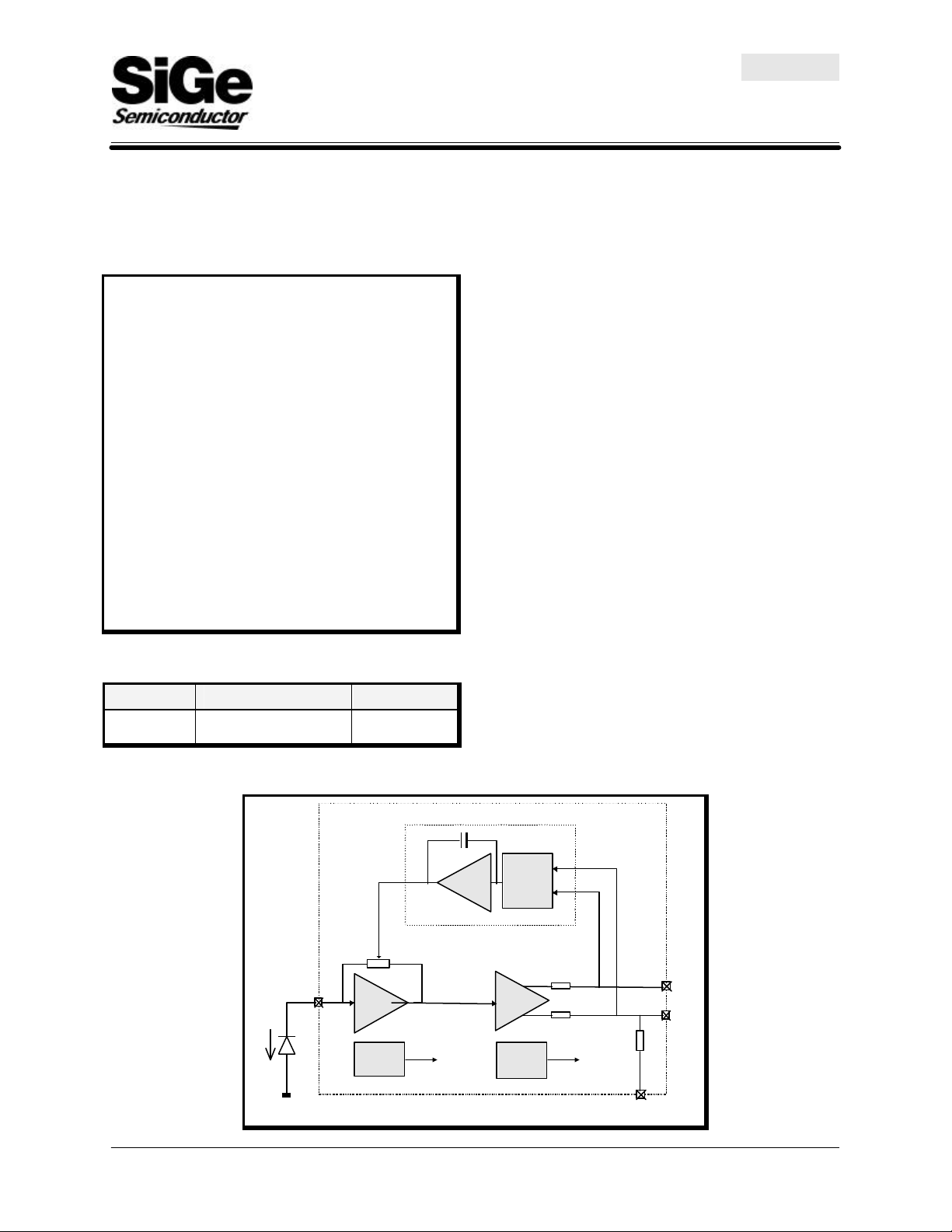

Functional Block Diagram

Input

Current

GND or –ve supply

TZ_IN

SE1000

TzAmp

155 Mb/s

Bandgap

Reference

f

Tz Amp

Automatic Gain Control

Integrator Rectifier

Output

Driver

Power

Supply

Rejection

Wire bond option for single -ended operation

OUTP

OUTN

ACGND

40-DST-01 § Rev 1.5 § May 24/02 1 of 9

Page 2

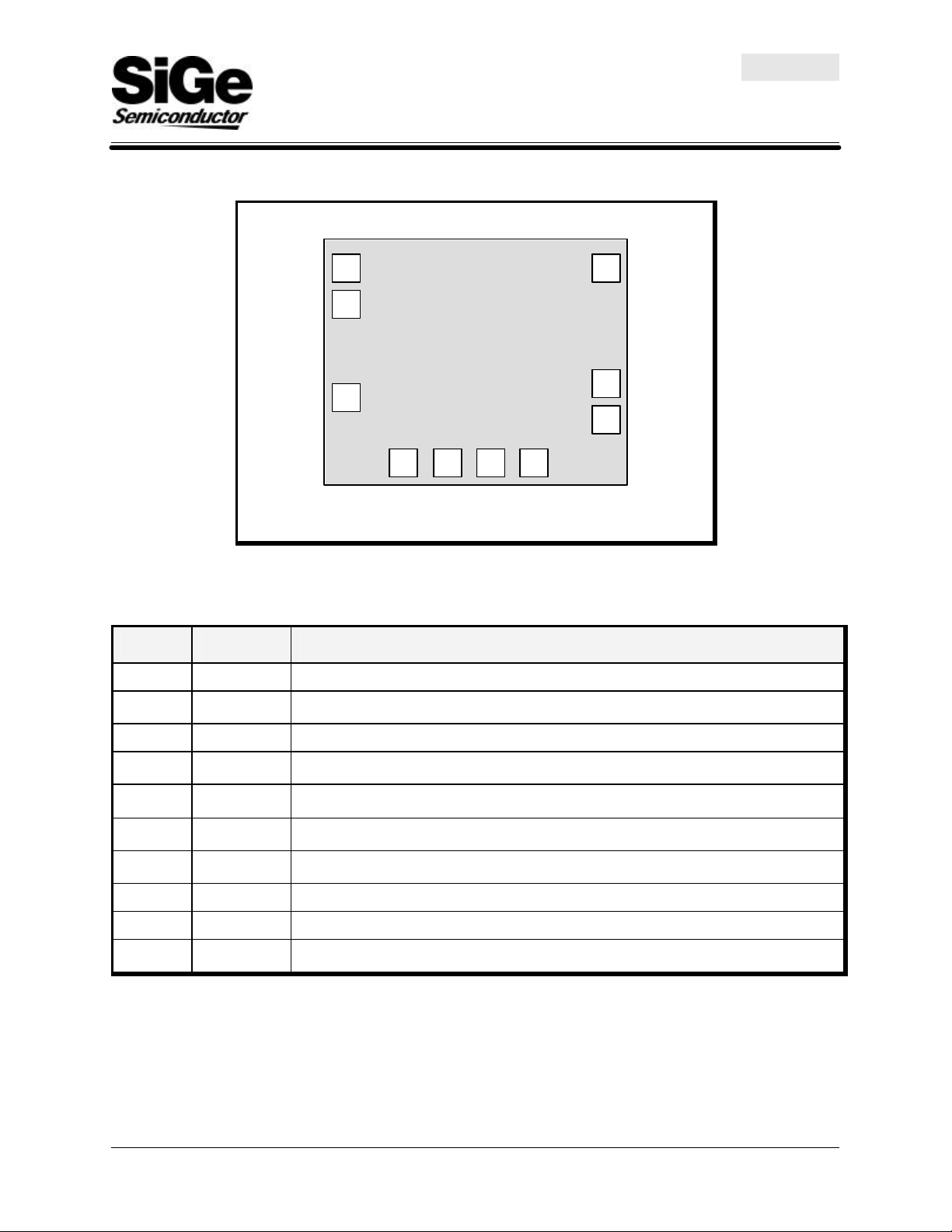

Bondpad Diagram

SE1000W

LightChargerTM155 Mb/s Transimpedance Amplifier

Final

VCC2

VCC1

TZ_IN

1

2

Top

View

3

7 6 5 4

VEE2 VEE1 VEE1 ACGND

10

VCC1

9

OUTP

8

OUTN

Bondpad Description

Pad No. Name Description

1 VCC2 Positive supply (+5.0 V), front end circuitry only.

2 VCC1

3 TZ_IN Input pad (connect to photodetector cathode).

4 VEE2

5 ACGND

6 VEE1

7 VEE1

8 OUTN Negative differential voltage output; leave unconnected for single-ended operation.

Positive supply (+5.0 V), pads 2 & 10 are connected on chip. Only one pad needs to

be bonded.

Negative supply (0V) – Note this is separate ground for the input stage, which is AC

coupled on chip. There is no DC current through this pad.

Bond option: Connected to external capacitor to ground for single-ended operation

(recommended 1 nF); unconnected for differential operation.

Negative supply (0V), pads 6 & 7are connected on chip. Only one pad needs to be

bonded.

Negative supply (0V), pads 6 & 7 are connected on chip. Only one pad needs to be

bonded.

9 OUTP Positive differential or single-ended voltage output.

10 VCC1

Positive supply (+5.0 V), pads 2 & 10 are connected on chip. Only one pad needs to

be bonded.

40-DST-01 § Rev 1.5 § May 24/02 2 of 9

Page 3

LightChargerTM155 Mb/s Transimpedance Amplifier

Functional Description

Amplifier Front-End

The transimpedance front-end amplifies an input

current from a photodetector, at pin TZ_IN, to produce

an output voltage with the feedback resistor Rf

determining the level of amplification (see the

functional block diagram on page 1). An automatic

gain control loop varies this resistor, to ensure that

the output from the front-end does not saturate the

output driver stage that follows. This gain control

allows input signals of up to 2.6 mA peak.

The input pin TZ_IN is biased at 3 V below the supply

voltage VCC, allowing a photodetector to easily be

reverse biased by connecting the anode to ground,

and hence enabling single rail operation.

The front-end stage has its own supply pins, VCC2

(+5 V) and VEE2 (0 V), to achieve optimum noise

performance and maintain integrity of the high-speed

signal path. The remainder of the circuitry uses the

supply pins VCC1 (+5 V) and VEE1 (0 V).

Output driver stage

The output driver acts as a buffer stage, capable of

swinging up to 150 mVpk-pk into a 50 Ω load (or

300 mVpk-pk differential into a 100 Ω load). The

small output swings allow ease of use with low

voltage post amplifiers (e.g. 3.3 V parts).

The output can be configured in a differential or

single-ended mode. For differential operation, the pad

ACGND is not wire bonded and the circuit provides a

fully balanced 100 Ω output, on the pins OUTP and

OUTN. For single-ended operation, the ACGND pad

is required to be wire bonded to an external capacitor

SE1000W

Final

to ground (recommend 1 nF). Under these

circumstances, OUTP operates as a single-ended

50 Ω output. In both cases, increasing optical input

level gives a positive-going output signal on the

OUTP pin.

Automatic Gain Control (AGC)

The AGC circuit monitors the voltages from the output

driver and compares them to an internal reference

level produced via the on-chip bandgap reference

circuit. When this level is exceeded, the gain of the

front-end is reduced by controlling the feedback

resistor Rf.

A long time-constant integrator is used within the

control loop of the AGC with a typical low frequency

cut-off of 5 kHz.

Power Supply Rejection

An on-chip power supply rejection circuit is used to

achieve both single-ended and differential rejection

from the +5 V VCC rail.

This stable DC reference minimizes the variation in

the noise and bandwidth performance of the circuit

due to power supply variation of +4.7 V to +5.3 V.

The AC rejection ensures that performance is not

degraded by noise on the power supply. The circuit

achieves a power supply rejection on the outputs of

40 dB for both single-ended and differential operation,

up to 100 kHz. The use of external decoupling will

help to remove any unwanted signals at higher

frequencies.

40-DST-01 § Rev 1.5 § May 24/02 3 of 9

Page 4

SE1000W

LightChargerTM155 Mb/s Transimpedance Amplifier

Final

Absolute Maximum Ratings

These are stress ratings only. Exposure to stresses beyond these maximum ratings may cause permanent damage

to, or affect the reliability of the device. Avoid operating the device outside the recommended operating conditions

defined below.

Symbol Parameter Min Max Unit

VCC Supply Voltage –0.7 6.0 V

VIO Voltage at any input or output –0.5 VCC+0.5 V

I

IO

IIO Current sourced into pin TZ_IN –5 5 mA

Current sourced into any input or output except

TZ_IN

–20 20 mA

V

ESD

V

ESD

Tstg Storage Temperature –65 150

Electrostatic Discharge (100 pF, 1.5 kΩ) except

TZ_IN

Electrostatic Discharge (100 pF, 1.5 kΩ) pin

TZ_IN

–2 2 kV

–0.25 0.25 kV

Recommended Operating Conditions

Symbol Parameter Min Typ Max Unit

VCC Supply Voltage 4.7 5.0 5.3 V

Tj Operating Junction Temperature –40 95

DC Electrical Characteristics

Symbol Parameter Min Typ Max Unit

ICC Supply Current 39 58 mA

lagc AGC Threshold 4

Vin Input Bias Voltage VCC–3.2 VCC–3.0 VCC–2.7 V

Vout Output Bias Voltage 2.9 3.5 V

µA pk-pk

°C

°C

Rout Output Resistance 35 50 65

Ω

40-DST-01 § Rev 1.5 § May 24/02 4 of 9

Page 5

SE1000W

LightChargerTM155 Mb/s Transimpedance Amplifier

AC Electrical Characteristics

Symbol Parameter Min Typ Max Unit

BW (3dB) Small Signal Bandwidth at –3dB point 150 MHz

Final

Tz

Dri Input Data Rate 10 155 Mb/s

Voutmax Maximum Differential Output Voltage 300 mV pk-pk

Flf Low Frequency Cut -off 5 kHz

PSRR

lOL

Pol Optical Overload +1.4 dBm

Nrms Input Noise Current (in 100 MHz) 12 15 nA rms

DC and AC electrical characteristics are specified under the following conditions:

Supply Voltage (VCC).........................................4.7 V to 5.3 V

Junction Temperature (Tj) ..................................–40°C to 95°C

Load Resistor (RL)...............................................50 Ω AC coupled via 220 nF (single-ended)

Photodetector Capacitance (Cd) .......................0.5 pF

Input bond wire inductance................................1 nH

Photodetector responsivity.................................0.95 A/W

Transimpedance (Tz) measured with 1 µA mean photocurrent

Single-ended Tra nsimpedance (50 Ω on output,

f = 50 MHz)

Power Supply Rejection Ratio (single-ended or

differential) up to 100 kHz

Input Current before overload (155 Mb/s NRZ

data)

11 15 20 kΩ

40 dB

2600

µA pk-pk

40-DST-01 § Rev 1.5 § May 24/02 5 of 9

Page 6

SE1000W

LightChargerTM155 Mb/s Transimpedance Amplifier

Bondpad Configuration

The bondpad center coordinates are referenced to the center of the lower left pad (pad 4). All dimensions are in

microns (µm).

Final

Pad No. Name

1 VCC2 -307.3 679.0

2 VCC1 -307.3 549.0

3 TZ_IN -307.3 315.0

4 VEE2 0 0

5 ACGND 130.0 0

6 VEE1 260.0 0

7 VEE1 390.0 0

8 OUTN 690.7 155.0

9 OUTP 690.7 285.0

10 VCC1 690.7 679.0

X

Coordinate

(µm)

Y

Coordinate

(µm)

40-DST-01 § Rev 1.5 § May 24/02 6 of 9

Page 7

SE1000W

LightChargerTM155 Mb/s Transimpedance Amplifier

Final

The diagram below shows the bondpad configuration of the SE1000W Transimpedance Amplifier. Note that the

diagram is not to scale. All bondpads are 92 µm x 92 µm with a passivation opening of 82 µm x 82 µm. There are two

VCC1 and two VEE1 pads for ease of wire bonding; these pad pairs are connected on-chip and only one pad of each

type is required to be bonded out.

Mechanical die visual inspection criteria per MIL-STD-883 Method 2010.10 Condition B Class Level B.

998.0

998.0

998.0

998.0

130.0

130.0

130.0

130.0

394.0

394.0

394.0

394.0

234.0315.0

234.0315.0

234.0315.0

925.0

925.0

925.0

925.0

234.0315.0

Top

Top

View

View

126.0

126.0

126.0

126.0

130.0 130.0 130.0

130.0 130.0 130.0

130.0 130.0 130.0

130.0 130.0 130.0

307.3

307.3

307.3

307.3

123.0

123.0

123.0

123.0

1250.0

1250.0

1250.0

1250.0

Side View

Side View

All Dimensions in Microns ( µm)

All Dimensions in Microns ( µm)

All Dimensions in Microns ( µm)

All Dimensions in Microns ( µm)

130.0

130.0

130.0

130.0

155.0

155.0

300.7

300.7

400.0

400.0

400.0

400.0

40-DST-01 § Rev 1.5 § May 24/02 7 of 9

Page 8

1 2 10 3 4 6 7 9 8

NC

5

–

ve bias

1 2 10 3 4 6 7 9 8

NC

5

–

ve bias

SE1000W

LightChargerTM155 Mb/s Transimpedance Amplifier

Final

Applications Information

For optimum performance it is recommended that the device be used in differential mod e with the circuit shown in the

first diagram below.

Note that the two VCC1 pads (2, 10) are connected on-chip, as are the VEE1 pads (6, 7), and only one pad of each

type is required to be bonded out. However, in order to minimize inductance for optimum high speed performance, it

is recommended that all power pads are wire bonded. The VEE2 and VCC2 pads are not connected on chip to VEE1

and VCC1 respectively, and must be bonded out separately.

Connections for differential operation:

+5 V

1 nF min

TZ_IN

PIN

0 V or

Connections for single-ended operation:

+5 V

PIN

0 V

TZ_IN

VCC2

TZ Amplifier

VEE2

VCC2

TZ Amplifier

SE1000W

VEE2

VCC1

SE1000W

VEE1

VCC1

VEE1

OUTP

OUTN

ACGND

OUTP

OUTN

ACGND

To 50 O loads,

AC coupled

1 nF min

To 50 O load,

AC coupled

1 nF

0 V or

0 V

40-DST-01 § Rev 1.5 § May 24/02 8 of 9

Page 9

SE1000W

LightChargerTM155 Mb/s Transimpedance Amplifier

Final

http://www.sige.com

Headquarters: Canada

Phone: +1 613 820 9244

Fax: +1 613 820 4933

2680 Queensview Drive

Ottawa ON K2B 8J9 Canada

sales@sige.com

U.S.A. United Kingdom

1150 North First Street 1010 Cambourne Business Park

San Jose, CA Cambourne

USA 95112 Cambridge CB3 6DP

Phone: +1 408 998 5060 Phone: +44 1223 598 444

Fax: +1 408 998 5062 Fax: +44 1223 598 035

Product Preview

The datasheet contains information from the product concept specification. SiGe Semiconductor reserves the right to change

information at any time without notification.

Preliminary

The datasheet contains information from the design target specification. SiGe Semiconductor reserves the right to change

information at any time without notification.

Final

The datasheet contains information from the final product specification. SiGe Semiconductor reserves the right to change

information at any time without notification. Production testing may not include testing of all parameters.

Information furnished is believed to be accurate and reliable and is provided on an “as is” basis. SiGe Semiconductor Inc. assumes

no responsibility or liability for the direct or indirect consequences of use of such information nor for any infringement of patents or

other rights of third parties, which may result from its use. No license or indemnity is granted by implication or otherwise under any

patent or other intellectual property rights of SiGe Semiconductor Inc. or third parties. Specifications mentioned in this publication

are subject to change without notice. This publication supersedes and replaces all information previously supplied. SiGe

Semiconductor Inc. products are NOT authorized for use in implantation or life support applications or systems without express

written approval from SiGe Semiconductor Inc.

LightCharger™ is a trademark owned by SiGe Semiconductor.

Copyright 2002 SiGe Semiconductor

All Rights Reserved

40-DST-01 § Rev 1.5 § May 24/02 9 of 9

Loading...

Loading...