Page 1

H-BRIDGE MOTOR DRIVER/AMPLIFIER

12345678910

ANALOG

GND

CF

NC

Vcc

+Vs

ANALOG

INPUT

POWER

GND

11

12

DISABLE

ISENSE A

A OUT

B OUT

ISENSE B

PWM

INPUT

*

*

*

*

*

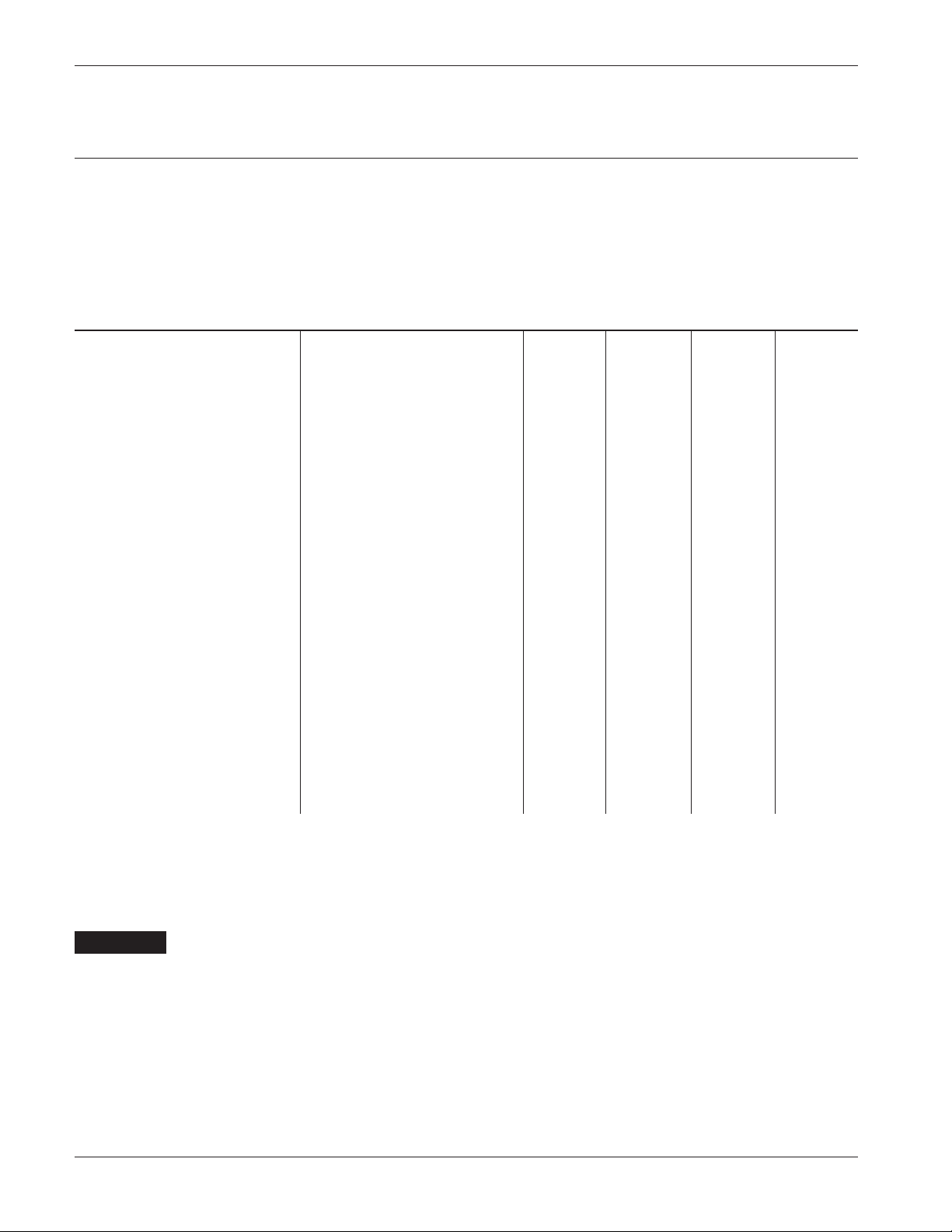

Protection diodes are recommended for

applications where +Vs exceeds 50V.

Required RC network. See paragraph on

transient supression.

‡

‡

‡

MICROTECHNOLOGY

HTTP://WWW.APEXMICROTECH.COM (800) 546-APEX (800) 546-2739

FEATURES

• LOW COST COMPLETE H-BRIDGE

• SELF-CONTAINED SMART LOWSIDE/HIGHSIDE DRIVE

CIRCUITRY

• WIDE SUPPLY RANGE: UP TO 80V

• 10A CONTINUOUS OUTPUT

• ISOLATED CASE ALLOWS DIRECT HEATSINKING

• HIGH EFFICIENCY: UP TO 97%

• FOUR QUADRANT OPERATION, TORQUE

CONTROL CAPABILITY

• INTERNAL/PROGRAMMABLE PWM FREQUENCY

GENERATION

SA60

APPLICATIONS

• BRUSH TYPE MOTOR CONTROL

• CLASS D SWITCHMODE AMPLIFIER

• REACTIVE LOADS

• MAGNETIC COILS (MRI)

• ACTIVE MAGNETIC BEARING

• VIBRATION CANCELLING

DESCRIPTION

The SA60 is a pulse width modulation amplifier that can

supply 10A continuous current to the load. The full bridge

amplifier can be operated over a wide range of supply voltages. All of the drive/control circuitry for the lowside and

highside switches are internal to the hybrid. The PWM circuitry

is internal as well, leaving the user to only provide an analog

signal for the motor speed/direction, or audio signal for

switchmode audio amplification. The internal PWM frequency

can be programmed by an external integrator capacitor. Alternatively, the user may provide an external TTL-compatible

PWM signal for simultaneous amplitude and direction control

for four quadrant mode.

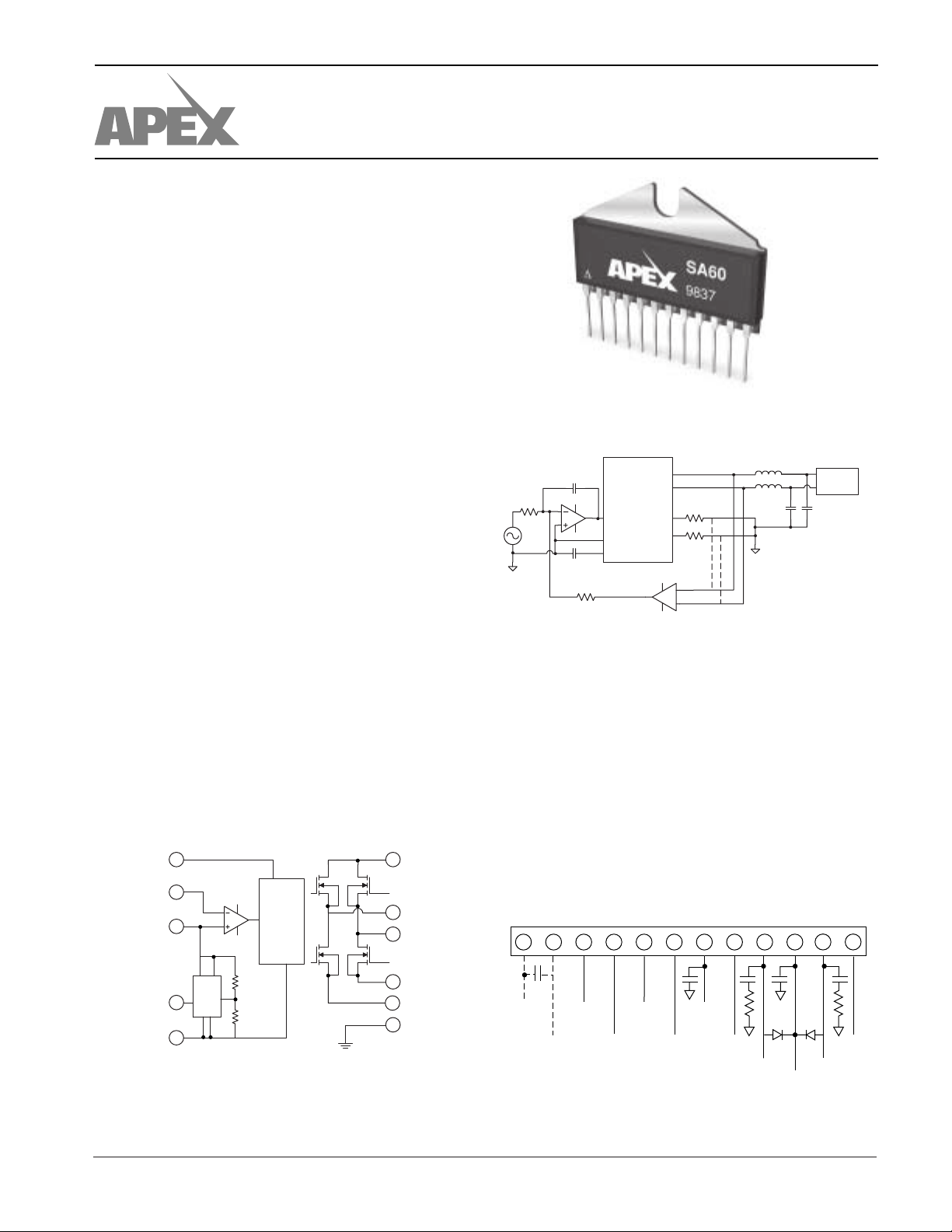

BLOCK DIAGRAM

DISABLE

ANALOG IN

Cf/PWM IN

3

4

2

H-Bridge

Drive

10

11

9

+V

s

B OUT

A OUT

TYPICAL APPLICATION

11

9

SA60

4

3

2

8

12

A wide variety of loads can be driven in either the voltage

mode or the current mode. The most common applications use

three external blocks: a low pass filter converting pulse width

data to an analog output, a difference amplifier to monitor

voltage or current and an error amplifier. Filter inductors must

be suitable for square waves at the switching frequency

(laminated steel is generally not acceptable). Filter capacitors

must be low ESR and rated for the expected ripple current. A

difference amplifier with gain of less than one translates the

differential output voltage to a single feedback voltage. Dashed

line connections and a higher gain difference amplifier would

be used for current control. The error amplifier integrates the

difference between the input and feedback voltages to close

the loop.

LOAD

EXTERNAL CONNECTIONS Package: SIP03

2

6

555

8

4

7

49K

2.58K

1

1

7

V

cc

ANALOG GND

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

8

12

6

A

I

sense

I

B

sense

POWER

GND

Page 2

SA60

ABSOLUTE MAXIMUM RATINGS

SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

SPECIFICATIONS

PARAMETER TEST CONDITIONS

INPUT

ANALOG INPUT VOLTAGES Vcc = 12V

A, B OUT = 50% Duty Cycle 1/2VCC Vdc

A OUT = 100% Duty Cycle High 1/3VCC Vdc

B OUT = 100% Duty Cycle High 2/3VCC Vdc

PWM INPUT

PWM PULSE LOW VOLTAGE 0 0.8 Vdc

PWM PULSE HIGH VOLTAGE 2.7 5.0 Vdc

PWM FREQUENCY 45 250 KHz

DISABLE ON 2.7 Vcc Vdc

DISABLE OFF 0 0.8 Vdc

OUTPUT

Vds (ON) VOLTAGE, each MOSFET Ids = 10A 1.7 2.5 Vdc

TOTAL Ron, both MOSFETs .45 Ω

EFFICIENCY, 10A OUTPUT +VS = 80V 91 %

CURRENT, continuous 10 A

CURRENT, peak t = 100 msec 15 A

SWITCHING FREQUENCY Cf = 270 pf 45 KHz

DEAD TIME 90 nS

SUPPLY VOLTAGE, +V

OUTPUT CURRENT, peak 15A

LOGIC SUPPLY VOLTAGE, Vcc 16V

POWER DISSIPATION, internal 156W

TEMPERATURE, pin solder - 10s 300°C

TEMPERATURE, junction

TEMPERATURE, storage –65 to +150°C

OPERATING TEMPERATURE RANGE, case –25 to +85°C

2

S

3

MIN TYP MAX UNITS

80V

1

150°C

POWER SUPPLY

+VS VOLTAGE +VS Current = Load Current 80 Vdc

Vcc VOLTAGE 9.5 12 16 Vdc

Vcc CURRENT Vcc = 12Vdc 28 36 mA

+VS CURRENT Switching, no load, VS = 50V 5 mA

THERMAL

RESISTANCE, junction to case Full temp range, for each transistor 1.6 °C/W

RESISTANCE, junction to air Full temperature range 30 °C/W

TEMPERATURE RANGE, case –25 +85 °C

NOTES: 1. Each of the two active output transistors can dissipate 78W.

CAUTION

3

2. Unless otherwise noted: TC = 25°C, Vcc = 12Vdc.

3. Long term operation at the maximum junction temperature will result in reduced product life. Derate internal power dissipation to

achieve high MTTF. For guidance, refer to the heatsink data sheet.

The SA60 is constructed from MOSFET transistors. ESD handling procedures must be observed.

The exposed substrate contains beryllia (BeO). Do not crush, machine, or subject to temperatures in excess of 850°C to

avoid generating toxic fumes.

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

Page 3

TYPICAL PERFORMANCE

GRAPHS

SA60

80

POWER DERATING

60

40

20

EACH OUTPUT

TRANSISTOR

0

INTERNAL POWER DISSIPATION, (W)

CASE TEMPERATURE, T (°C)

Vs QUIESCENT VS VOLTAGE

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

NORMALIZED QUIES CURRENT (X)

10 7020 30 40 50 60

85°C

Vs, (V)

75

1000 25 50 125

C

25°C

80

TOTAL VOLTAGE DROP

35

30

25

20

15

10

VOLTAGE DROP, V

100

80

60

40

DUTY CYCLE (%)

20

ANALOG INPUT AS PROPORTION OF Vcc

Tc = 110°C

Tc = 85°C

Tc = 60°C

5

0

369

01215

OUTPUT CURRENT, A

Tc = 35°C

DUTY CYCLE VS ANALOG INPUT

A OUT B OUT

0

1/6 5/6

1/3

1/2 2/3

1000

100

CLOCK FREQUENCY, Fsw (KHz)

10

10 100 1000

EXTERNAL INTEGRATION CAP, C (pF)

10

1

FLYBACK CURRENT ISD(A)

0.1

0.6 0.8 1.4

PWM FREQ VS EXT INT CAP

Cf (pF) = (1.44E7/Fsw)–50

REVERSE DIODES

1.2 1.81.6

1

SOURCE TO DRAIN VOLTAGE

Vs QUIESCENT VS SWITCH FREQ

160

140

120

100

80

60

40

20

Vs QUIES CURRENT Iq (mA)

0

0 50 100 150 200 250

SWITCHING FREQUENCY, Fsw (KHz)

Vcc IQ VS SWITCH FREQ

1.6

1.5

1.4

1.3

1.2

1.1

1

0.9

NORMALIZED QUIESCENT, 1q(X)

0.8

25 50 75 100 125

SWITCHING FREQUENCY, Fsw (KHz)

Vcc QUIESCENT VS VOLTAGE

1.4

1.3

1.2

1.1

1

0.9

0.8

0.7

0.6

NORMALIZED QUIES CURRENT, (X)

91610 11 12 13 14 15

Vcc VOLTAGE (V)

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

Page 4

SA60

OPERATING

CONSIDERATIONS

GENERAL

Please read Application Note 30 on "PWM Basics". Refer to

Application Note 1 "General Operating Considerations" for

helpful information regarding power supplies, heat sinking and

mounting. Visit www.apexmicrotech.com for design tools that

help automate pwm filter design; heat sink selection; Apex’s

complete Application Notes library; Technical Seminar Workbook; and Evaluation Kits.

PWM OSCILLATOR – INTERNAL OR EXTERNAL

The SA60 contains an internal PWM oscillator whose frequency is determined by an external capacitor connected

between pin 1 and pin 2. Maximum frequency is 125 kHz. The

user may also disregard the internal PWM oscillator and

supply the SA60 with an external TTL pulse generator up to

250KHZ.

PIN DESCRIPTION

VCC - is the low voltage supply for powering internal logic

and drivers for the lowside and highside MOSFETS. The

supplies for the highside drivers are derived from this voltage.

V

- is the higher voltage H-bridge supply. The MOSFETS

S

obtain the output current from this supply pin. The voltage on

this pin is limited to +80V by the drive IC. The MOSFETS are

rated at 100 volts.

ISENSE A AND B - These are tied to power gnd directly or

through sense resistors.

ANALOG GND -is the reference for the internal PWM

oscillator. Connect this pin to pin 6. Connect low side of Vcc

supply and any other supply used to generate analog input

signals to ANALOG GND.

ANALOG INPUT - is an analog input for controlling the PWM

pulse width of the bridge. A voltage higher than Vcc/2 will

produce greater than 50% duty cycle pulses out of B OUT. A

voltage lower than Vcc/2 will produce greater than 50% duty

cycle pulses out of A OUT. If using in the digital mode, bias this

point at 1/2 the logic high level.

DISABLE - Is the connection for disabling all 4 output

switches. DISABLE high overrides all other inputs. When

taken low, everything functions normally. An internal pullup to

Vcc will keep DISABLE high if pin left open.

PWM INPUT - Is the TTL compatible digital input for

controlling the PWM pulse width of the bridge. A duty cycle

greater than 50% will produce greater than 50% duty cycle

pulses out of the A out. A duty cycle less than 50% will produce

greater than 50% duty cycle from the B out. For analog inputs,

the integration capacitor for the internal clock must be connected between this pin and analog ground. The internal

switching frequency is programmable up to 125 kHz by selection of the integration capacitor. The formula is:

C

(pF) =

F

1.44 x10

(

Fsw

7

)

– 50

BYPASSING

Adequate bypassing of the power supplies is required for

proper operation. Failure to do so can cause erratic and low

efficiency operation as well as excessive ringing at the outputs.

The Vs supply should be bypassed with at least a 1µF ceramic

capacitor in parallel with another low ESR capacitor of at least

10µF per amp of output current. Capacitor types rated for

switching applications are the only types that should be considered. The 1µF ceramic capacitor must be physically connected

directly to the Vs and POWER GND pins. Even one inch of lead

length will cause excessive ringing at the outputs. This is due

to the very fast switching times and the inductance of the lead

connection. The bypassing requirements of the Vcc supply are

less stringent, but still necessary. A .1µF to .47µF ceramic

capacitor connected directly to the Vcc and ANALOG GND

pins will suffice.

PCB LAYOUT

The designer needs to appreciate that the SA60 combines

in one circuit both high speed high power switching and low

level analog signals. Certain layout rules of thumb must be

considered when a circuit board layout is designed using the

SA60:

1. Bypassing of the power supplies is critical. Capacitors must

be connected directly to the power supply pins with very

short lead lengths (well under 1 inch). Ceramic chip capacitors are best.

2. Connect ANALOG GND to POWER GND with a conductor

having no intermediate connections. Connect all Vs power

supply, filter and load related ground connections to POWER

GND keeping these conductors separate until reaching pin

6. Connect all Vcc power supply and input signal related

ground connections to ANALOG GND keeping conductors

separate until reaching pin 1. Do not allow ground loops to

form by making additional ground connections at the low

side of the physical power supplies. If ground plane is used

do not allow more than 1mA to flow through it.

3. Beware of capacitive coupling between output connections

and signal inputs through the parasitic capacitance between layers in multilayer PCB designs.

4. Do not run small signal traces between the pins of the output

section (pins 8-12).

CURRENT SENSE

There are two load current sensing pins, I SENSE A and I

SENSE B. The two pins can be shorted to POWER GND in the

voltage mode connection but both must be used in the current

mode connection. It is recommended that R SENSE resistors be

non-inductive. Load current flows in the I SENSE pins. The SA60

has no internal current limit.

TRANSIENT SUPPRESSION

An RC Network of A 100 PF Capacitor and a one ohm resistor

is required as shown in the external connection diagram on page

1. This network assures proper operation under various loads.

Minimal power is dissipated in the resistor.

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice.

APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739

SA60U REV. E FEBRUARY 2000 © 2000 Apex Microtechnology Corp.

Loading...

Loading...