Page 1

Programmable Single Phase Energy Metering

IC with Tamper Detection

SA2007P

FEATURES

+ Provides direct interface to mechanical counters

+ Calibration and setup stored on external EEPROM - no

trimpots required

+ Monitors both Live and Neutral for tamper detection

+ Flexible programmable features

+ Meets the IEC 521/1036 Specification for Class 1 AC Watt

hour meters

DESCRIPTION

The SAMES SA2007P is a single phase bi-directional energy

metering integrated circuit. It provides a cost effective solution

for energy meters with electro-mechanical displays, such as

stepper motors and impulse counters. A precision oscillator,

that replaces an external crystal is integrated on chip.

Two current sensor inputs allow the measurement of energy

consumption on both the live and neutral lines.

Direction detection of energy flow as well as other common

tamper conditions are flagged.

The power consumption on both the live and neutral are

samessames

+ Total power consumption rating below 50mW

+ Adaptable to different types of sensors

+ Operates over a wide temperature range

+ Precision voltage reference on-chip

+ Precision oscillator on chip

continuously measured and the larger of the two is selected for

energy metering.

The SA2007P drives the calibration LED, the indicator LEDs

and the electro-mechanical counter directly.

The SA2007P does not require any external trim-pots. All

required calibration and configuration data is read from a small

external EEPROM.

The SA2007P integrated circuit is available in 20 pin dual-inline plastic (DIP-20) and small outline (SOIC-20) package

types.

SPEC-0074 (REV. 2)

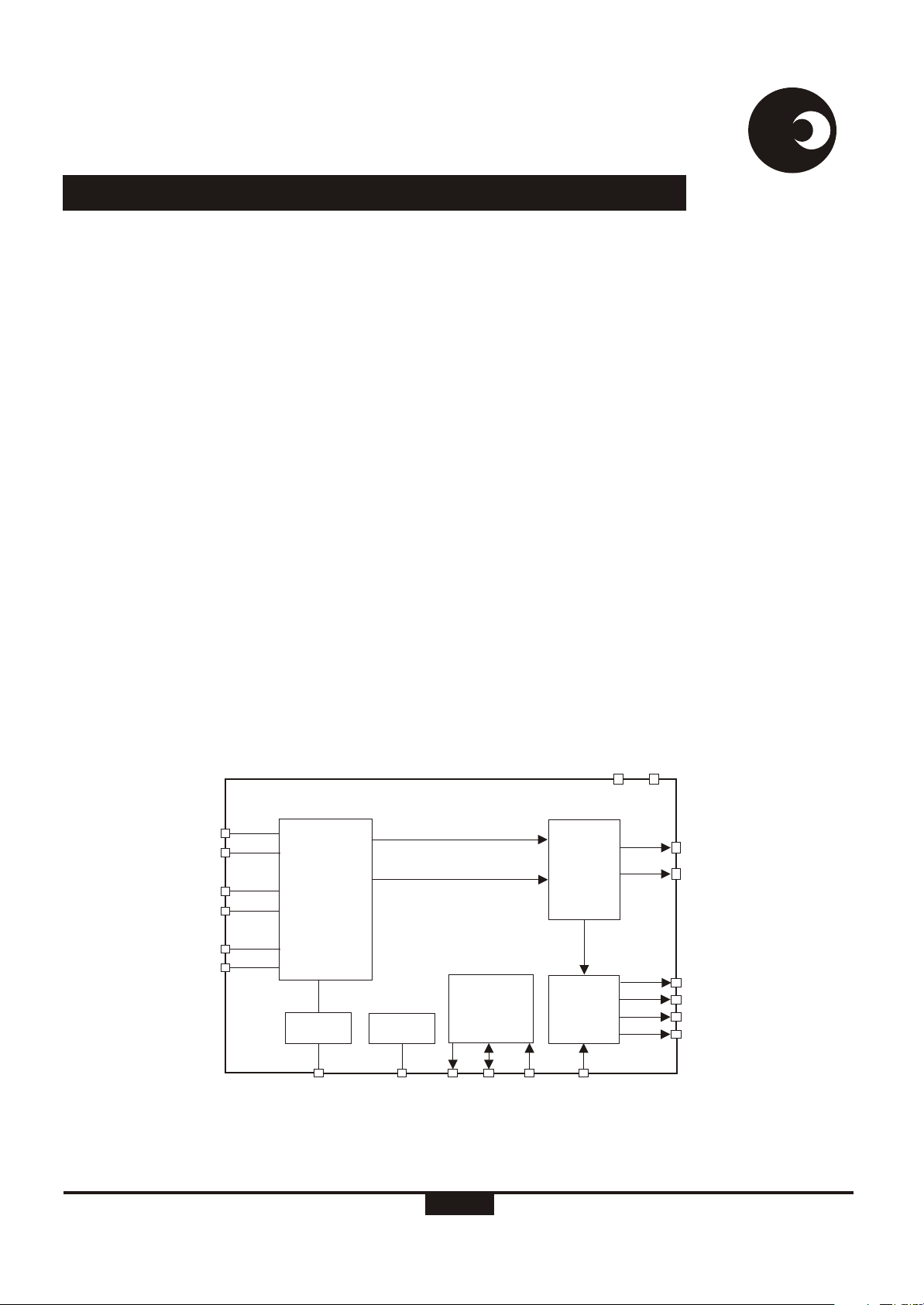

IIN1

IIP1

IIN2

IIP2

IVP

GND

Dr-01594

ANALOG

SIGNAL

PROCESSING

AND

POWER

CALCULATION

VOLTAGE

REF.

VREF

POWER 1 (DIGITAL)

POWER 2 (DIGITAL)

IIC

BUS

OSC

TCLK SDASCL

Figure 1: Block diagram

INTERFACE

RLOAD

1/12

VSSVDD

COM-

PARATOR

POWER

TO

PULSE

RATE

TEST

PRELIMINARY

ELT

SEL1

DIRO

LED

MOP

MON

16-01-01

Page 2

SA2007P

samessames

ELECTRICAL CHARACTERISTICS

(V = 2.5V, V = -2.5V, over the temperature range -10°C to +70°C , unless otherwise specified.)

DD SS

Parameter

Operating temp. Range

Supply Voltage: Positive

Supply Voltage: Negative

Supply Current: Positive

Supply Current: Negative

Symbol

T

O

V

DD

V

SS

I

DD

I

SS

Min

-25

2.25

-2.75 -2.25

4.7

4.7

#

Typ

Max

+85

2.75

6.6

6.6

9.4

9.4

Current Sensor Inputs (Differential)

Input Current Range

I

II

-25

+25

Voltage Sensor Input (Asymmetrical)

Input Current Range

Pin VREF

Ref. Current

Ref. Voltage

I

IV

-I

R

V

R

-25

45

1.1

50

1.2

+25

55

1.3

Digital I/O

Pins RLOAD, TCLK, TEST, SEL1,

ELT, SDA

Input High Voltage

Input Low Voltage

V

IH

V

IL

V-1

DD

V+1

SS

Pins MOP, MON, LED, SCL, DIRO

V

Output High Voltage

Output Low Voltage

Pin SDA

Pull up current

OH

V

OL

-I

IL

V-1

DD

V+1

24 54

SS

Unit

°C

V

V

mA

mA

µA

µA

µA

V

V

V

V

V

µA

Condition

Peak value

Peak value

With R = 24kW

connected to V

Reference to V

I = -2mA

OH

I = 5mA

OL

V = V

I

SS

SS

SS

Pins TEST, RLOAD, TCLK

Pull down current

I

IH

48 110

µA

V = V

I

DD

# Extended Operating Temperature Range available on request.

ABSOLUTE MAXIMUM RATINGS*

Parameter Symbol Min Max Unit

Supply Voltage V -V -0.3 6.0 V

Current on any pin I -150 +150 mA

Storage Temperature T -40 +125 °C

Operating Temperature T -40 +85 °C

*Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress

rating only. Functional operation of the device at these or any other condition above those indicated in the operational sections of

this specification, is not implied. Exposure to Absolute Maximum Ratings for extended periods may affect device reliability.

http://www.sames.co.za

DD SS

PIN

STG

O

2/12

PRELIMINARY

Page 3

SA2007P

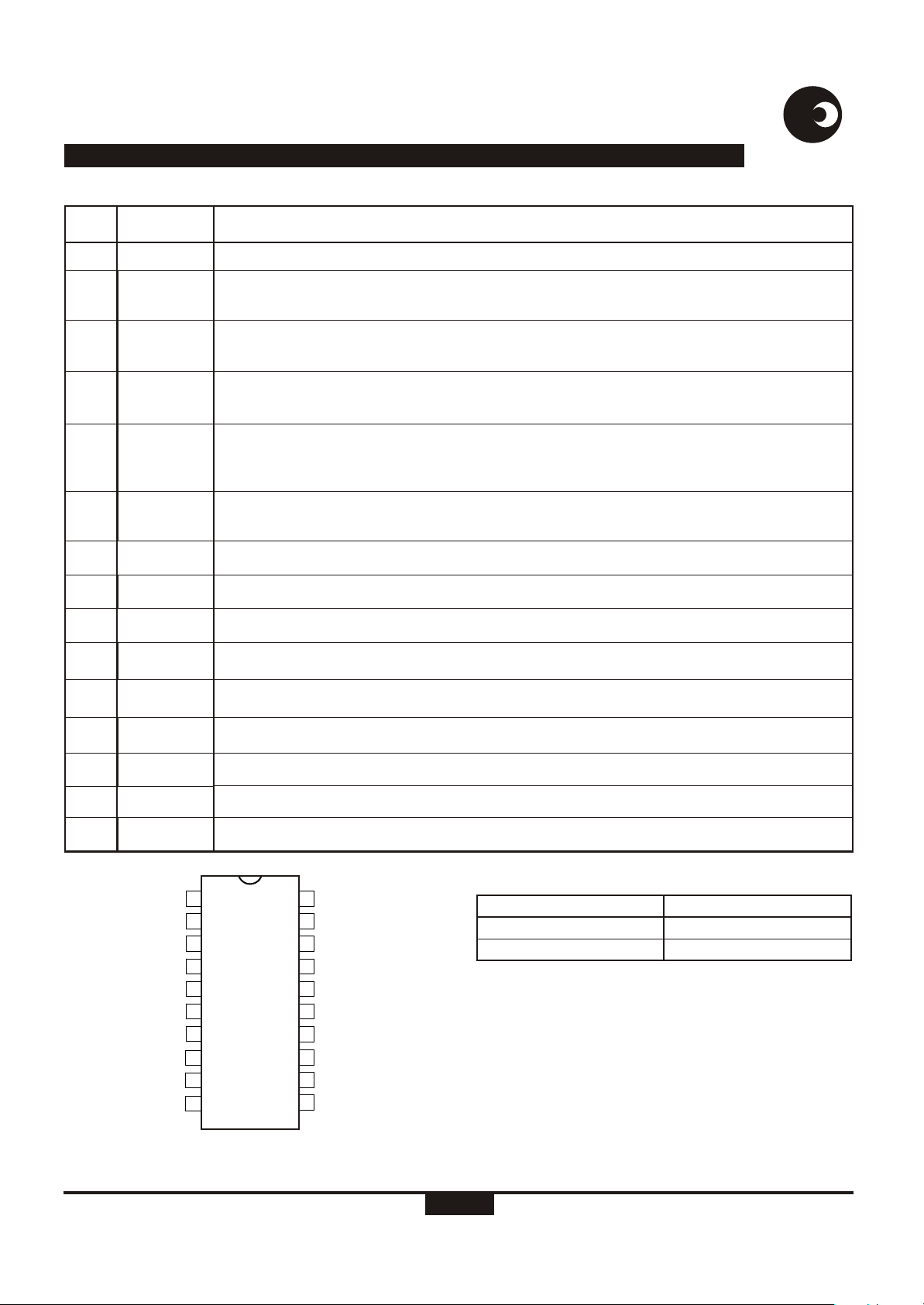

PIN DESCRIPTION

Designation Description

PIN

samessames

20

8

14

19

1, 2,

3, 4

5

6

7

9, 12

13

15

GND

V

DD

V

SS

IVP

IIN1, IIP1

IIN2, IIP2

VREF

SCL

SDA

MON, MOP

LED

RLOAD

Analog Ground. The voltage to this pin should be mid-way between V and V .

DD SS

Positive supply voltage. The voltage to this pin is typically +2.5V if a shunt resistor is used for

current sensing or in the case of a current transformer a +5V supply can be applied.

Negative supply voltage. The voltage to this pin is typically -2.5V if a shunt resistor is used for

current sensing or in the case of a current transformer a 0V supply can be applied.

The current into the A/D converter should be set at 14µA at nominal mains voltage. The voltage

RMS

sense input saturates at an input current of ±25µA peak.

Inputs for current sensor - channel 1 and channel 2. The shunt resistor voltage from each channel

is converted to a current of 16µA at rated conditions. The current sense input saturates at an

RMS

input current of ±25µA peak.

This pin provides the connection for the reference current setting resistor. A 24kW resistor

connected to V sets the optimum operating condition.

SS

Serial clock output. This output is used to strobe data from the external EEPROM.

Serial data. Send and receive data from an external EEPROM.

Motor pulse outputs. These outputs can be used to drive an impulse counter or stepper motor directly.

Calibration LED output. Refer to section Led Output (LED) for the pulse rate output options.

Configuration reload input. A falling edge will trigger a register reload from the external EEPROM.

16

17

18

10, 11

SEL1

ELT

DIRO

TEST, TCLK

IIP1 IVP

IIN2 DIRO

IIP2

VREF

SCL

SDA

VDD

MON

Current channel select output. This output indicates which channel is been used for kWh metering.

Earth loop tamper output. This output indicates an earth loop tamper condition.

Direction output. This output indicates the energy flow direction

Test input. Connect to V for normal operation.

1IIN1 GND

2

3

4

5

6 15

7

8

9

10

DR-01595

20

19

18

ELT

17

SEL1

16

RLOAD

VSS

14

LED

13

MOP

12

11

TCLKTEST

SS

Figure 2: Pin connections: Package: DIP-20, SOIC-20

ORDERING INFORMATION

Part Number

SA2007PPA

SA2007PSA

Package

DIP-20

SOIC-20

http://www.sames.co.za

3/12

PRELIMINARY

Page 4

SA2007P

samessames

FUNCTIONAL DESCRIPTION

The SA2007P is a CMOS mixed signal Analog/Digital

integrated circuit, which performs power/energy calculations

across a power range of 1000:1, to an overall accuracy of

better than Class 1.

The integrated circuit includes all the required functions for

single phase power and energy measurement such as

oversampling A/D converters for the voltage and current sense

inputs, power calculation and energy integration. Internal

offsets are eliminated through the use of cancellation

procedures. The SA2007P incorporates an anti-tamper

scheme by continuously measuring the power consumption on

both LIVE and NEUTRAL lines. A fault is indicated when these

measurements differ by more than 12.5%. The SA2007P

generates pulses with a frequency proportional to the larger of

the two current measurements. The source (LIVE or

NEUTRAL) for these pulses is indicated on the SEL1 pin. The

metering of energy consumption is taken from the source,

which shows the higher consumption.

Various pulse outputs (MOP, MON and LED) are available.

The pulse rate on these pins follows the active power

consumption measured.

A low voltage stepper may be driven directly from the device by

connecting it between the MOP and MON pins, alternatively an

impulse counter may be driven directly by connecting it

between MOP and V .

The SA2007P configures itself from an external low cost

EEPROM that contain all meter configurations and calibration

data. No external trimming is required for this device.

Calibration of the meter may be fully automated.

POWER CALCULATION

In Figure 7, the voltage drops across the current transformers

terminating resistors are converted to currents for each

current sense input, by means of resistors R and R (channel

1) as well as R and R (channel 2). The current sense input

saturates at an input current of ±25µA peak.

SS

10 11

12 13.

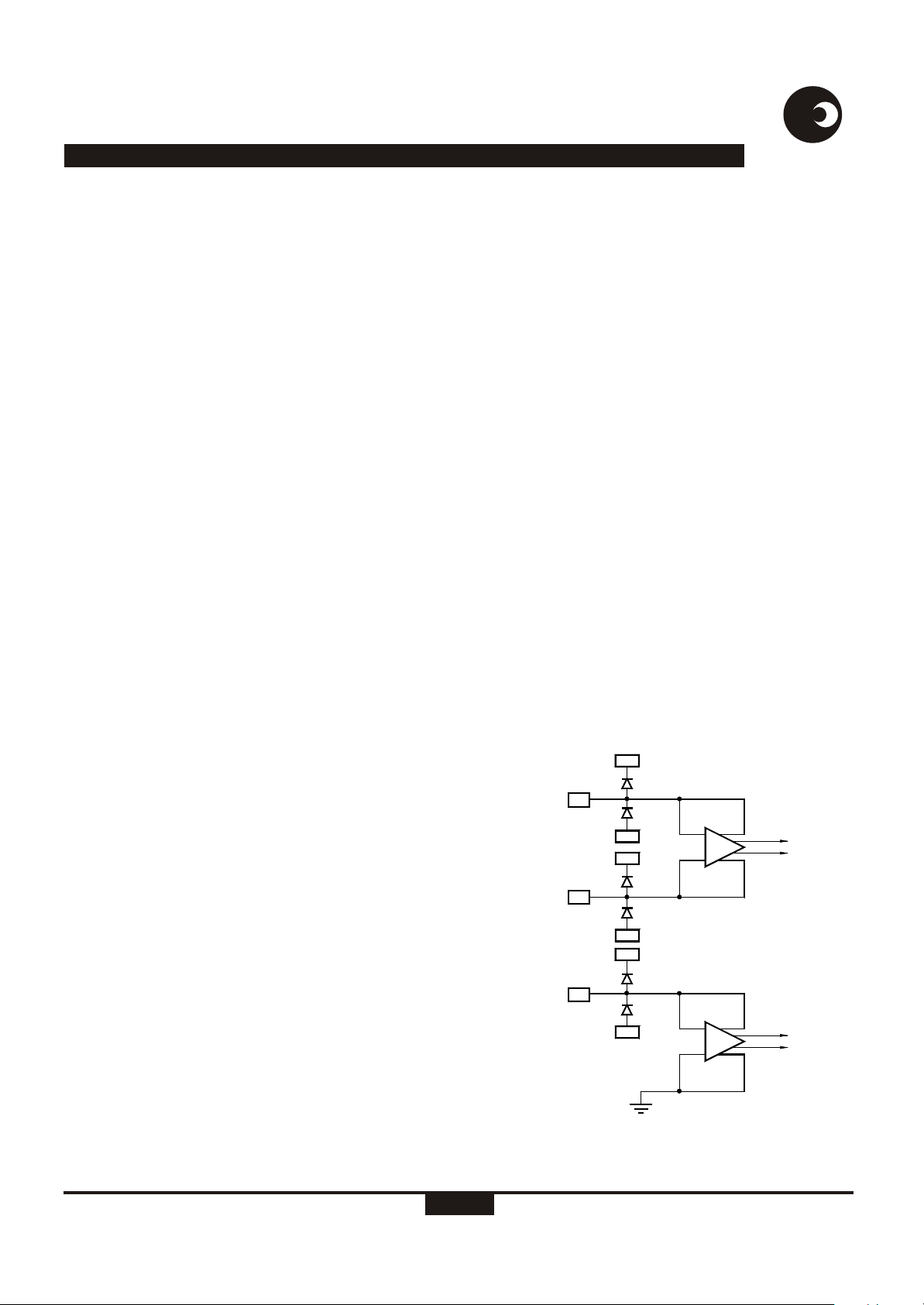

ANALOG INPUT CONFIGURATION

The input circuitry of the current and voltage sensor inputs are

illustrated in figure 3. These inputs are protected against

electrostatic discharge through clamping diodes.

The feedback loops from the outputs of the amplifiers A and A

IV

generate virtual shorts on the signal inputs. Exact duplications

of the input currents are generated for the analog signal

processing circuitry.

AUTOMATIC DEVICE CONFIGURATION (BOOT UP)

During power up, registers containing configuration and

calibration information are updated from an external

EEPROM. The device itself never writes to the EEPROM so

any write protect features offered by manufacturer of

EEPROM's may be used to protect the configuration and

calibration data of the meter. The device reloads its

configuration every 1193 seconds from the external EEPROM

in order to ensure correct operation of the meter. Every data

byte stored in the EEPROM is protected with a checksum byte

to ensure data integrity.

ELECTROSTATIC DISCHARGE (ESD)

PROTECTION

The SA2007P integrated circuit's input's/outputs are protected

against ESD.

POWER CONSUMPTION

The power consumption rating of the SA2007P integrated

circuit is less than 30mW.

V

DD

IIP

V

CURRENT

SENSOR

INPUTS

IIN

SS

V

DD

V

SS

V

DD

A

I

The mains voltage (230VAC) is divided down through a divider

to 14V . The current into the A/D converter input is set at

RMS

14µA at nominal mains voltage, via resistor R (1MW).

RMS 7

See Device Configuration for more details on the processing of

measured energy to frequency outputs.

http://www.sames.co.za

4/12

IVP

VOLTAGE

SENSOR

INPUT

DR-01288

V

SS

GND

A

V

Figure 3: Analog input internal configuration

PRELIMINARY

Page 5

SA2007P

INPUT SIGNALS

VREF

A bias resistor of 24kW set optimum bias and reference

conditions on chip. Calibration of the SA2007P should be done

as described in the Device Configuration section.

Serial Data (SDA)

The SDA pin connects directly to the SDA pin of an external

EEPROM. The pin is used to transfer data between the

EEPROM to the SA2007P. An external pull up resistor in not

needed.

Serial Clock (SCL)

The SCL pin connects directly to the SCL pin of an external

EEPROM. The SCL output is used to strobe data at a rate of

50kHz out of the EEPROM. An external pull up resistor in not

needed.

Configuration Reload (RLOAD)

A falling edge on the RLOAD pin, will trigger a register update

from the external EEPROM. This feature may be used during

calibration to load updated register data in the SA2007P. For

normal operation of the SA2007P the RLOAD pin may be left

floating.

OUTPUT SIGNALS

Motor output (MOP, MON)

The motor pulse width is programmable for 71ms and 142ms.

The MON pulse will follow the MOP pulse within the selected

pulse width time. This prevents that the motor armature is in

the wrong position after a power failure. Both MOP and MON

outputs are active high. One energy pulse is represented by a

MOP pulse followed by a MON pulse. The motor drive wave

forms are shown in figure 4.

LED output (LED)

Three options for the LED output pulse rate are available, 6400

and 3200 pulses per kWh, as well as a pulse rate of 1252

pulses per second at rated conditions. At 1252 pulse per

second t is 71µs, for the other options t is 10ms. The LED

output is active low as in figure 5.

An integrated anti-creep function prevents any output pulses if

the measured power is less than 0.02% of the meters rated

current.

MOP

LED LED

VDD

VSS

samessames

Selected Input Indicator (SEL1)

The SA2007P continuously compares the power

consumptions on current channel 1 inputs and current channel

2 inputs. The larger of the two measurements is used for

metering. The SEL1 output pin indicates which channel is

currently being used for the pulse output.

Signal

Output

SEL 1

Value

0

1

Channel 1 selected (IIN1/IIP1)

Channel 2 selected (IIN2/IIP2)

Switching between channels will not be faster than once per

second in case both channels are balanced.

Earth Loop Tamper Indication (ELT)

In case the power measurements from both current channels

differ by more than 12.5%, (indicating a earth loop tamper

condition), the ELT output is set to zero. The SA2007P

continues to generate output pulses from the larger of the two

measured powers in this condition. The ELT output is active low.

Direction Indication (DIRO)

The SA2007P provides information about the energy flow

direction of both current channels on pin DIRO .

A logic 1 on pin DIRO indicates reverse energy flow of both

current channels. Reverse energy flow is defined as the

condition where the voltage sense input and current sense

input are out of phase (greater than 90 degrees). Positive

energy flow, when voltage sense and both current sense input

are in phase, is indicated on pin DIRO as a logic 0.

The DIRO output will toggle between 1 and 0 a rate of 1Hz in

case one of the current channels measure positive energy and

the other negative energy. The condition may accure with a

improper installed or tampered meter.

The DIRO pin may be used to drive a LED in order to indicate

reverse energy.

Signal

Output

DIRO

Value

1

0

1Hz

Reverse energy flow

Forward energy flow

Out of phase current channels

Description

Description

VDD

MON

VSS

DR-01559

t

m

Figure 4: Motor drive on MON and MOP pins

http://www.sames.co.za

VDD

LED

t

t

m

m

VSS

DR-01332

t

LED

Figure 5: LED pulse output

5/12

PRELIMINARY

Page 6

SA2007P

Channel 1

Balance

÷Kc1

Channel 2

Balance

÷Kc2

Earth Leakage

Compensation

Ne

Channel Select (1, 2, auto) Cs

Rated Condition

÷Kr

Counter

Resolution

Cres

Counter

Pulse width

CPW

LED-Constant

Cled

MOP MON

LED

Normally 6400p/kWh

Normally 1253p/s

Channel 1 Power

641454p/s

Channel 2 Power

641454p/s

DEVICE CONFIGURATION

SIGNAL FLOW DESCRIPTION

The following is an overview of the SA2007P's registers. For a

detailed description of each parameter please refer to

parameter description section.

Figure 6 shows the various registers in the SA2007P's power

to pulse rate block. The inputs to this block are two single bit

pulse density modulated signals, each having a pulse rate of

641454 pulses per second at rated conditions. The

parameters Kc1, Kc2, Ne, Cs, Kr, Cres, and Cled contain

values which are read from the external EEPROM during

power up.

The divider registers, Channel 1 Balance and Channel 2

samessames

Balance, are used for calibration and to balance the gain of

each channel. The Earth Leakage Compensation register is

used to compensate for any permissible earth leakage that

may cause the SA2007P to indicate a tamper condition at low

current. The Channel Select register selects the source

(channel 1 or channel 2) which will be used for the pulse output.

Register Rated Condition is used to program the rated

condition of the meter and feeds the registers LED-constant

and Counter Resolution with the applicable pulse rate. These

two registers are programmed to select the LED output rate

and the counter resolution (pulses per kWh) respectively. The

Counter Pulse Width register is used to program the pulse

width for the mechanical counter driver output MOP and MON.

http://www.sames.co.za

Figure 6: Signal flow block diagram

6/12

PRELIMINARY

Page 7

SA2007P

PARAMETER DESCRIPTION

Refer to the EEPROM memory allocation map as well as the

Signal flow diagram figure 6, for a description of the registers

used in this section.

EEPROM Memory Allocation

The following table shows the EEPROM memory allocation as

well as the corresponding name. The uneven byte always

contains the XORed byte of the previous even byte. This is the

checksum byte used by the SA2007P to ensure data integrity.

samessames

Kc is made up of 2 bytes, D12 and D14 or D16 or D18 which

forms a 10 bit value.

Rated Condition (KR)

Kr is used to program the rated condition of the meter. This

feature is required for a correct counter increment of meters

designed for different rated conditions using the same

integrated circuit. Rated conditions from less than 10A to

several 100A are possible.

Channel Balance (KC)

Kc defines the dividing factor, which is applied to the incoming

pulse rate. This value is typically 511. This factor is used for

calibration and gain balancing of the 2 current channels. The

value for Kc is usually between 400 and 640.

Description

Channel 1 Balance LSB

Channel 1 Balance MSB

Channel 2 Balance LSB

Channel 2 Balance MSB

Rated Condition

Led Pulse-rate

Counter Pulse-width

Counter Resolution

Earth leak Compensation

Channel Select Mode

2

E Address

12

13

14

15

16

17

18

19

20

21

22

23

24

24

25

26

26

27

The channel balance values should be used to compensate for

rounding errors in Kr. Kr is calculated as follows:

Kr =(1252 x 1000 x 3600)/(Rated volt x Rated current x 6400)-1

Kr is made up of 1 byte (D20)

Contents

Kc1

XOR of ADDR 12

Kc1

XOR of ADDR 14

Kc2

XOR of ADDR 16

Kc2

XOR of ADDR 18

Kr

XOR of ADDR 22

Cled

XOR of ADDR 22

Cpw

Cres

XOR of ADDR 24

Ne

Cs

XOR of ADDR 24

Bit [7:0]

vvvvvvvv

xxxxxxxx

------vv

xxxxxxxx

vvvvvvvv

xxxxxxxx

------vv

xxxxxxxx

vvvvvvvv

xxxxxxxx

------vv

xxxxxxxx

0v------

------vv

1xxxxxxx

------vv

----vv--

xxxxxxxx

Name

D12

D14

D16

D18

D20

D22

D24

D26

KEY: (- = DON’T CARE); (V = VALUE/PARAMETER); (0,1 = LOGICAL VALUE); (X = BIT-XOR)

http://www.sames.co.za

7/12

PRELIMINARY

Page 8

SA2007P

samessames

LED Pulse-rate (CLED)

Two bits of byte D22 allow for the selection of 3 different LED

Pulse-rate as follows.

D22[1] D22[0]

0

0

1

Refer to LED output section for details on the LED pulse width.

Counter Pulse-Width (CPW)

The pulse with for the mechanical counter driver output is

selectable to accommodate various step-motor and impulsecounter requirements. Bit 6 from byte D24 selects the pulse

rate as follows:

D24[6]

0

1

Counter Resolution (CRES)

Bit 1 and 0 from byte D24 allow for the selection of 3 different

counter resolutions. Note that one energy pulse is represented

by a MOP pulse followed by a MON pulse.

D24[1] D24[0]

0

1

-

0

1

-

Counter Pulse-Width

71ms

142ms

0

0

1

Calibrated LED - Output

6400 p/KWh

3200 p/KWh

1252 pulses/second @rated for

fast calibration

Counter Resolution

1 p/KWh

10 p/KWh

100 p/KWh

Channel Select Mode (CS)

For calibration purposes, the source for the energy metering

may be selected from a specific channel. The ELT-indication is

not influenced, but the metering is taken from the selected

channel only. For normal operation, the channel select mode is

set to automatic mode so that the larger of the two channels is

used for energy measurement. Bits 3 and 2 of byte D26 sets

the channel select mode as follows:

D26[3] D26[2]

-

1

0

Earth Leak Compensation (NE)

Earth leakage in domestic wiring systems could result in

tamper detection at low current levels. The SA2007P caters for

these conditions, by taking possible earth leakage into account

when comparing the power consumption in live and neutral.

The value for the permissible earth leakage is usually around

30mA. It has to be adjusted according to the rated meter

condition and allows for derivations from the 30mA value. The

actual value of the leak current can be calculated from the

following formula:

Ileak = Rated current x Ne

Ileak is the earth leakage current in mA used for correction. this

value is subtracted from the difference measured between live

and neutral power.

Ne is made up of bits 1 and 2 of byte D26 and can be set as

follows:

0

1

1

Metering Source

Automatic, channel 1 or 2 whichever

shows higher consumption

Channel 1

Channel 2

http://www.sames.co.za

8/12

D26[1]

0

0

1

D26[0]

0

1

-

Ne factor

0.15

0.076

0.038

PRELIMINARY

Page 9

SA2007P

TYPICAL APPLICATION

The analog (metering) interface described in this section is

designed for measuring 230V/60A with precision better than

Class 1.

The most important external components for the SA2007P

integrated circuit are the current sense resistors, the voltage

sense resistors and the bias setting resistor. The resistors

used in the metering section should be of the same type so

temperature effects are minimized.

Current Input IIN1, IIP1, IIN2, IIP2

Two current transformers are used to measure the current in

the live and neutral phases. The output of the current

transformer is terminated with a low impedance resistor. The

voltage drop across the termination resistor is converted to a

current that is fed to the differential current inputs of the

SA2007P.

CT Termination Resistor

The voltage drop across the CT termination resistor at rated

current should be at least 20mV. The CTs have low phase shift

and a ratio of 1:2500. The CT is terminated with a 3.6W resistor

giving a voltage drop of 86.4mV across the termination resistor

at rated conditions (I for the meter).

Current Sensor Input Resistors

The resistors R10, R11 and R12, R13 define the current level

into the current sense inputs of the SA2007P. The resistor

values are selected for an input current of 16µA on the current

inputs of the SA2007P at rated conditions. For a 60A meter at

2500:1 CT the resistor values are calculated as follows:

R10 = R11 = ( I / 16µA ) x R / 2

= 60A / 2500 / 16µA x 3.6W / 2

= 2.7kW

I =Line current

L

RSH = CT Termination resistor

2500 = CT ratio

The two current channels are identical so R10 = R11 = R12 =

R13.

Voltage Input IVP

The voltage input of the SA2007P (IVP) is driven with a current

of 14µA at nominal mains voltage. The voltage input saturates

max

LSH

samessames

at approximately 17µA. At a nominal voltage current of 14µA

allows for 20% overdriving. The mains voltage is divided with a

voltage divider to 14V that is fed to the voltage input pins via a

1MW resistor.

Voltage Divider

The voltage divider is calculated for a voltage drop of 14V.

Equations for the voltage divider in figure 4 are:

RA = R1 + R2 + R3

RB = R7 || R5

Combining the two equations gives:

( RA + RB ) / 230V = RB / 14V

Values for resistors R5 = 24kW and R7 = 1MW is chosen.

Substituting the values result in:

RB = 23.437kW

RA = RB x ( 230V / 14V – 1 )

RA = 362kW.

Standard resistor values for R1, R2 and R3 are chosen to be

120kW each.

The capacitor C1 is used to compensate for phase shift

between the voltage sense inputs and the current sense inputs

of the device, in cases where CTs with phase errors are used.

The phase shift caused by the CT may be corrected by

inserting a capacitor in the voltage divider circuit. To

compensate for a phase shift of 0.18 degrees the capacitor

value is calculated as follows:

C = 1 / (2 x p x Mains frequency x R5 x tan (Phase shift angle))

C = 1 / ( 2 x p x 50 x 1MW tan (0.18 degrees ))

C = 1.013µF

Reference Voltage Bias resistor

R6 defines all on chip and reference currents. With R6 = 24kW

optimum conditions are set. Device calibration is done with

calibration data.

http://www.sames.co.za

9/10

PRELIMINARY

Page 10

http://www.sames.co.za

SA2007P

NEUTRAL

LIVE

Figure 7: Typical application circuit

10/12

PRELIMINARY

LIVE

NEUTRAL

GND

IVP

DIRO

ELT

SEL1

VSS

LED

MOP

TCLK

R18

R19

14V

VDD

20

19

18

17

16

15

14

13

12

11

VSS

C2

GND

C3

R5

R15

LED3

VDD

R16

LED1

LED4

R17

VSS

CNT1

VSS

C1

R7

LED2

R14

.1123456

U1

1

R4

L

TZ1

T1

D1

D3

p s

GND

CT2

CT1

D2

R8

GND

R9

GND

U2

1

A0

A1

A2

VSS

24C01A

VCC

TEST

SCL

SDA

VSS

2

3

4

D4

R1 R2 R3

R10

R11

R12

R13

VSS

C4

8

7

6

5

Vin

GND

2

+C5

VSS

R6

10

VSS

Vout

1

2

3

4

5

6

7

8

9

3

U3

IIN1

IIP1

IIN2

IIP2

VREF

SCL

SDA

VDD

MON

TEST

DR-01596

+

C6

RLOAD

samessames

Page 11

SA2007P

Parts List for Application Circuit: Figure 7

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Symbol

U1

U2

D1

D2

D3

D4

LED1

LED2

LED3

LED4

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

C1

C2

C3

C4

C5

C6

CT1

CT2

T1

U1

CNT1

TZ1

Description

SA2007P

AT24C01, or equivalent device

Diode, Silicon 1N4148

Diode, Silicon 1N4148

Diode, Silicon 1N4148

Diode, Silicon 1N4148

Light emitting diode, Green

Light emitting diode, Amber

Light emitting diode, Red

Light emitting diode, Green

Resistor, 120k, 1/4W, 1%, metal

Resistor, 120k, 1/4W, 1%, metal

Resistor, 120k, 1/4W, 1%, metal

Resistor, 10W, 2W, Wire wound

Resistor, 24k, 1/4W, 1%, metal

Resistor, 24k, 1/4W, 1%, metal

Resistor, 1M, 1/4W, 1%, metal

Resistor, 1/4W, 1%, metal

Resistor, 1/4W, 1%, metal

Resistor, 1/4W, 1%, metal

Resistor, 1/4W, 1%, metal

Resistor, 1/4W, 1%, metal

Resistor, 1/4W, 1%, metal

Resistor, 1k, 1/4W

Resistor, 1k, 1/4W

Resistor, 1k, 1/4W

Resistor, 1k, 1/4W

Resistor, 1k, 1/4W, 1%, metal

Resistor, 1k, 1/4W, 1%, metal

Capacitor

Capacitor, 220nF

Capacitor, 220nF

Capacitor, 820nF

Capacitor, 2200µF, 25V, electrolytic

Capacitor, 100µF, 16V, electrolytic

Current Transformer

Current Transformer

Transformer, 230V/9V

78LC05, Voltage regulator

Bipolar step motor

400V, Metal oxide varistor

samessames

Detail

DIP-20/SOIC-20

or Similar

or Similar

or Similar

or Similar

Note 2

Note 2

Note 1

Note 1

Note 1

Note 1

Note 4

Note 3

Note 1: Resistor (R10, R11, R12 and R13) values are dependent upon the selected value of R8 and R9

Note 2: See TYPICAL APPLICATION when selected the value of R8 and R9.

Note 3: Capacitor (C4) to be positioned as closed to Supply Pins (V & V ) of U-1, as possible.

Note 4: Capacitor (C1) selected to minimize phase error introduced by current transformer (typically 1.5µF for normal CTs)

http://www.sames.co.za

11/12

DD SS

PRELIMINARY

Page 12

PM9607AP

SA2007P

samessames

samessames

DISCLAIMER:

The information contained in this document is confidential and proprietary to South African Micro-Electronic Systems (Pty) Ltd

("SAMES") and may not be copied or disclosed to a third party, in whole or in part, without the express written consent of SAMES.

The information contained herein is current as of the date of publication; however, delivery of this document shall not under any

circumstances create any implication that the information contained herein is correct as of any time subsequent to such date.

SAMES does not undertake to inform any recipient of this document of any changes in the information contained herein, and

SAMES expressly reserves the right to make changes in such information, without notification, even if such changes would render

information contained herein inaccurate or incomplete. SAMES makes no representation or warranty that any circuit designed by

reference to the information contained herein, will function without errors and as intended by the designer.

Any sales or technical questions may be posted to our e-mail address below:

For the latest updates on datasheets, please visit our web site:

SOUTH AFRICAN MICRO-ELECTRONIC SYSTEMS

DIVISION OF LABAT TECHNOLOGIES (PTY) LTD

P O BOX 15888

33 ELAND STREET

LYNN EAST 0039

REPUBLIC OF SOUTH AFRICA

energy@sames.co.za

http://www.sames.co.za.

Tel: (012) 333-6021

Tel: Int +27 12 333-6021

Fax: (012) 333-8071

Fax: Int +27 12 333-8071

33 ELAND STREET

KOEDOESPOORT INDUSTRIAL AREA

PRETORIA

REPUBLIC OF SOUTH AFRICA

http://www.sames.co.za

12/12

Loading...

Loading...